Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

150results about How to "Reduce cost burden" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

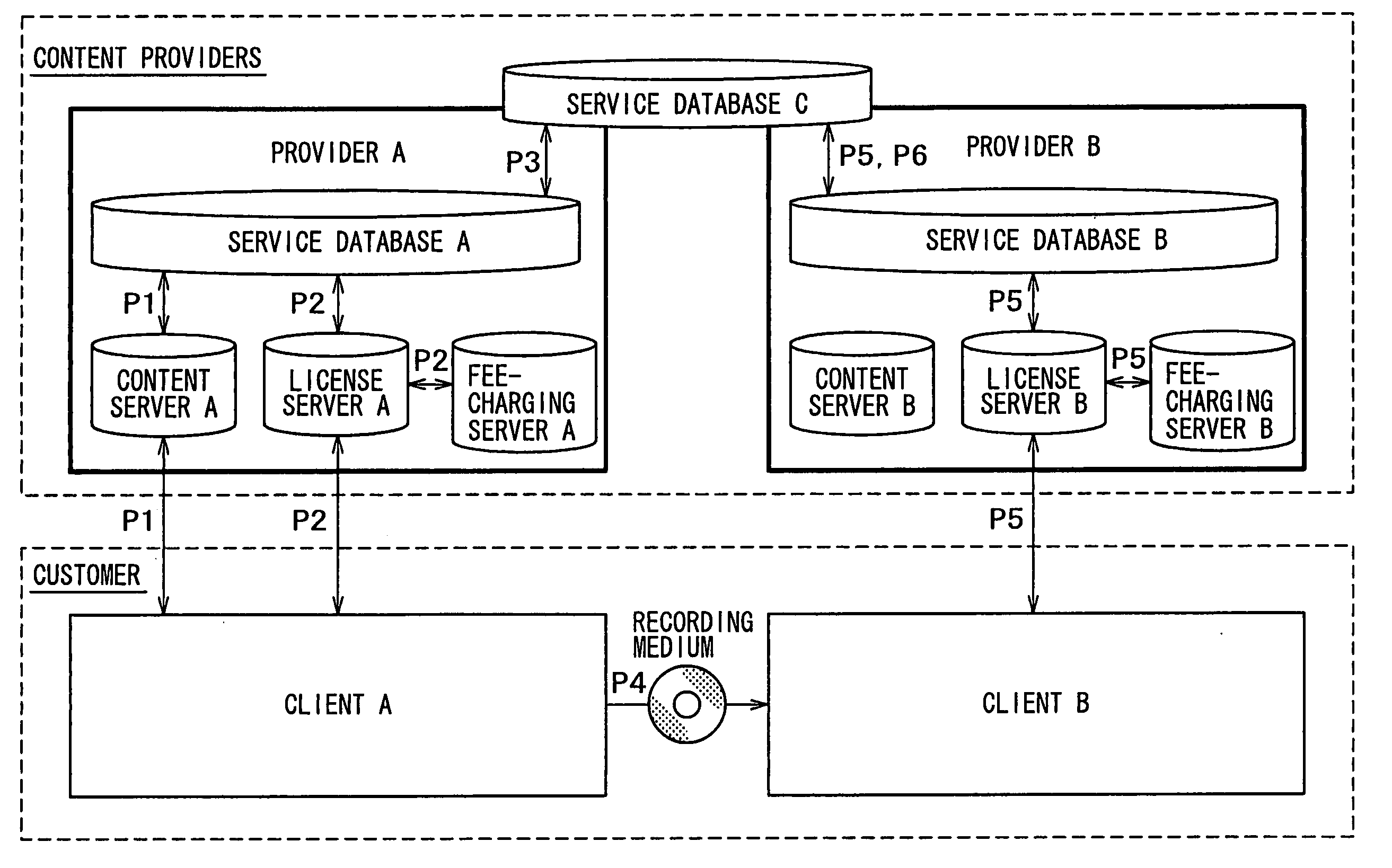

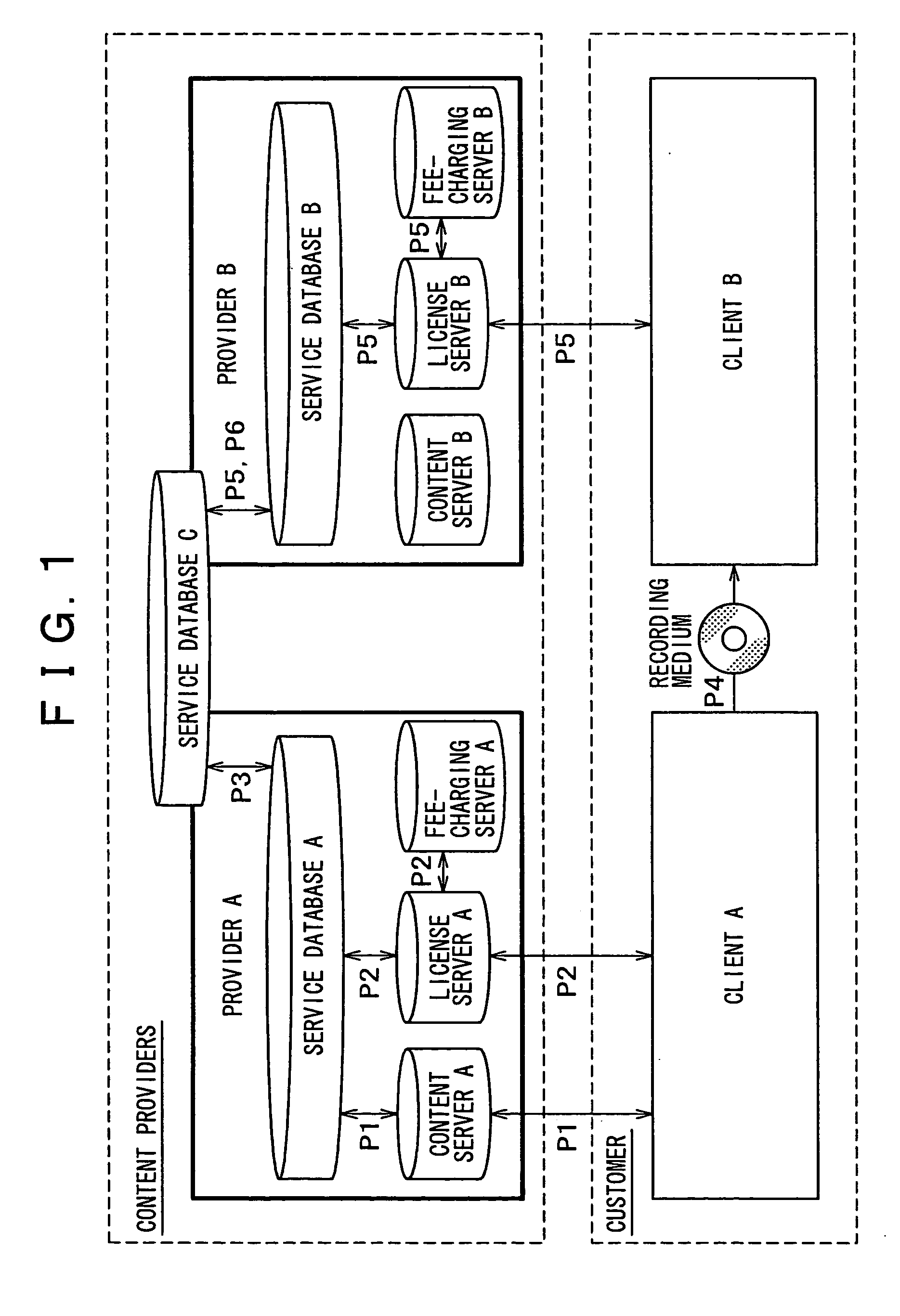

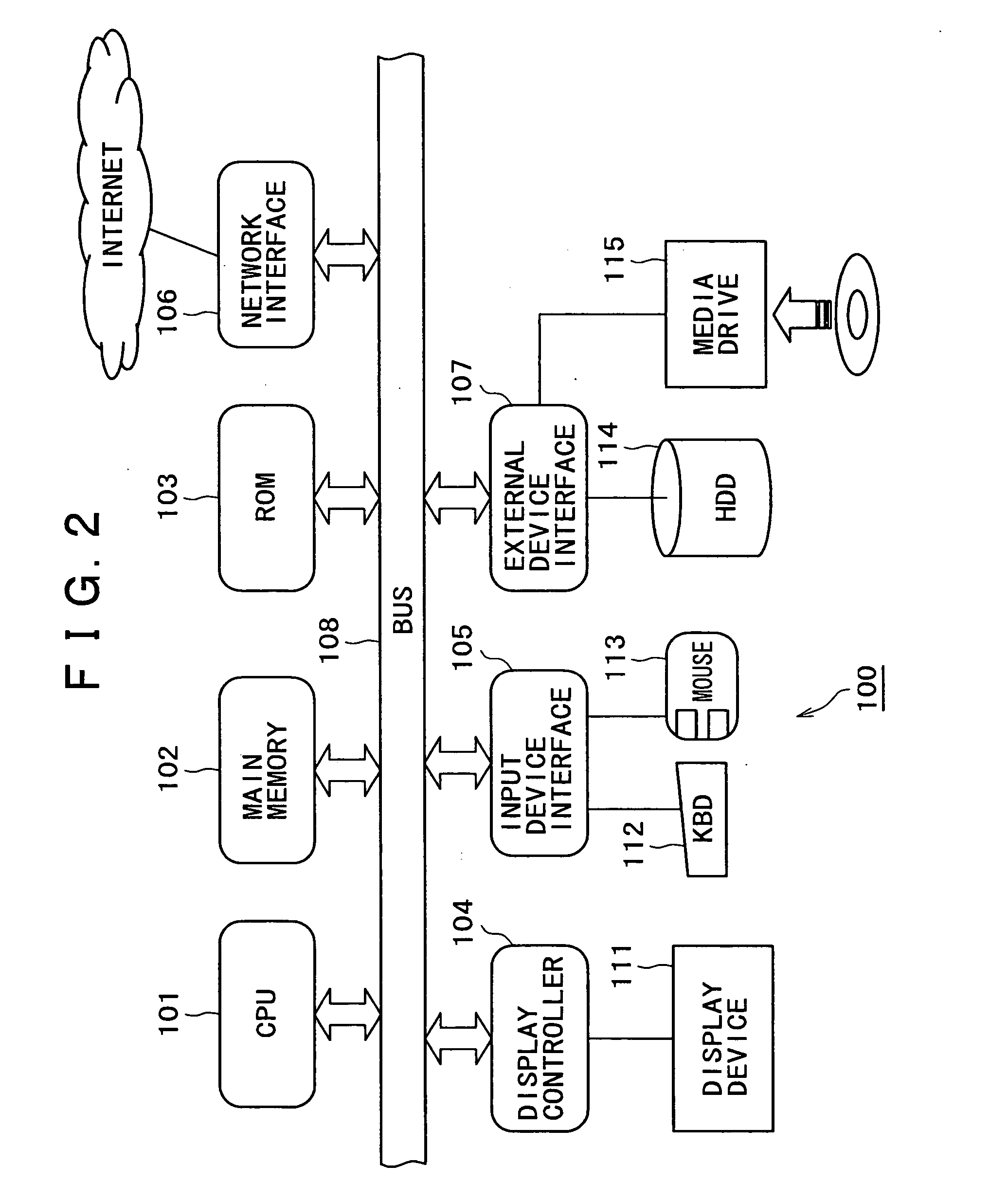

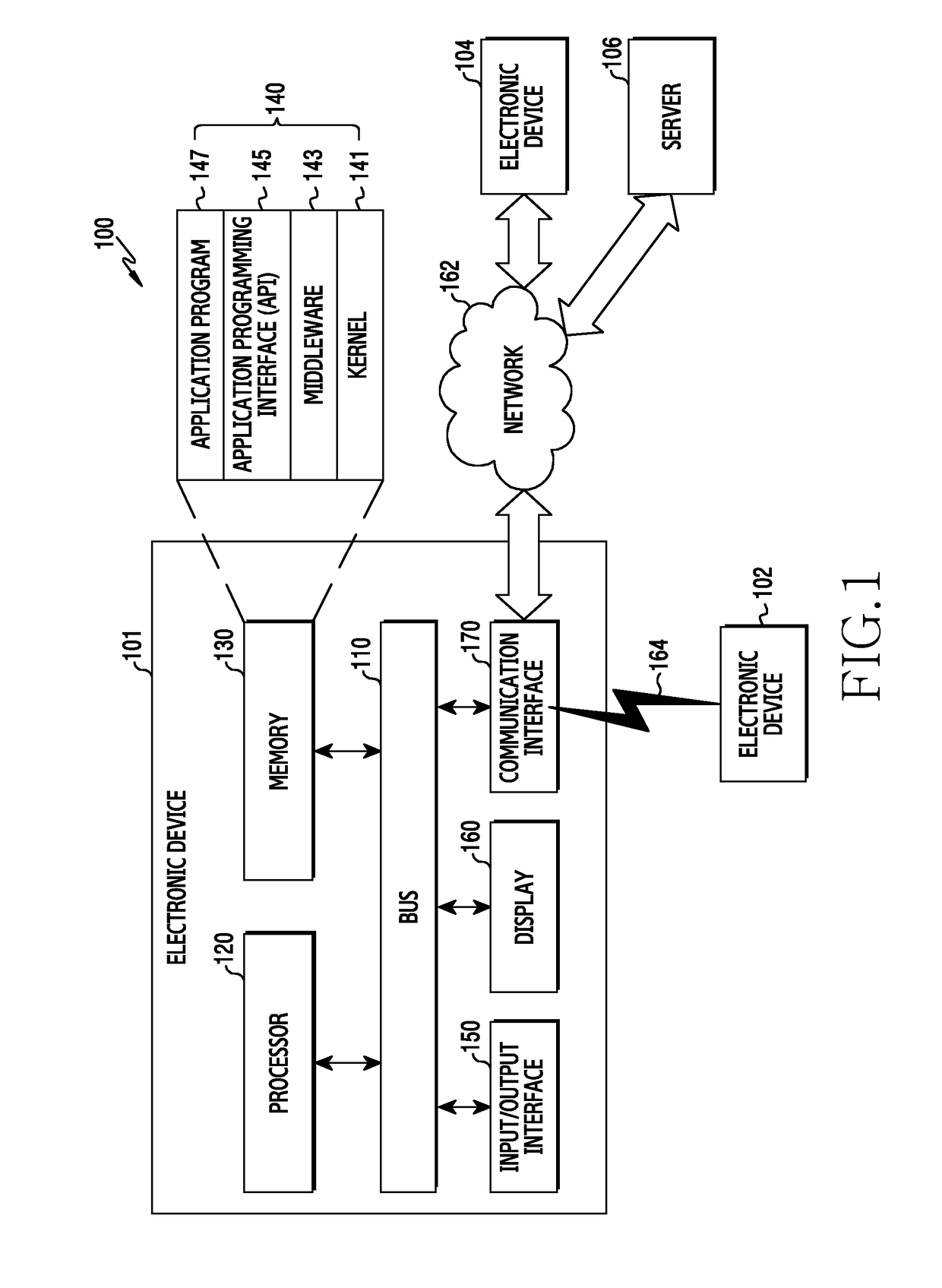

Content delivery system, information processing apparatus or information processing method, and computer program

InactiveUS20050149340A1Alleviate cost burdenInhibitory contentUnauthorized memory use protectionDigital data protectionClient-sideComputer security

A copyright-managed environment is provided in which encrypted content and a license for decrypting the content are handled separately. Each client registered in the environment uses content legitimately. After the content acquired by a client A of a user is stored into a client B of the same user, the client B may receive a new license for the same content from a license server. This allows the content to be shared between the clients A and B while the copyright of the content is protected. The inventive environment allows the user having acquired a license to use the corresponding content on a plurality of apparatuses in his or her possession while illegal content uses are forestalled.

Owner:SONY CORP

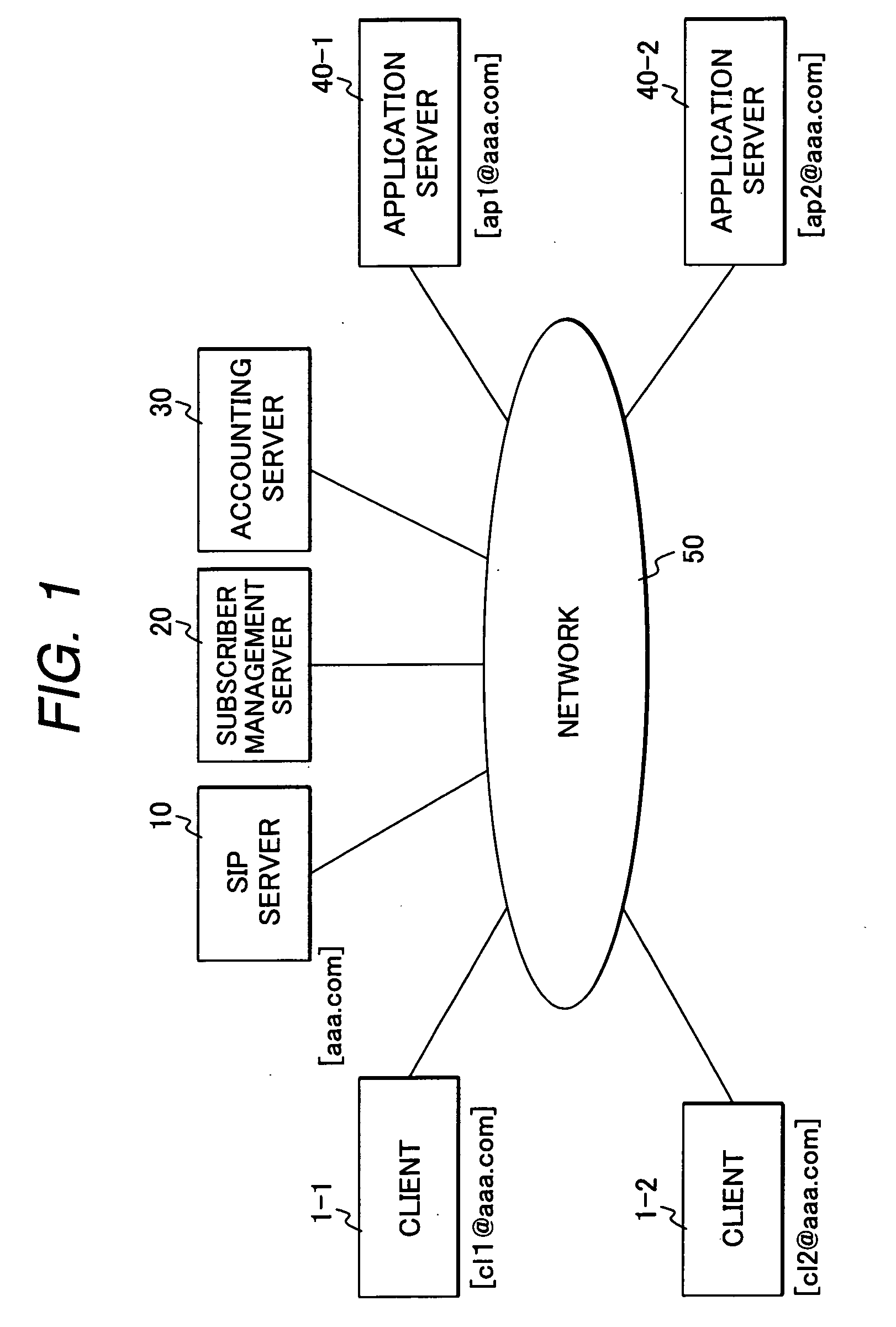

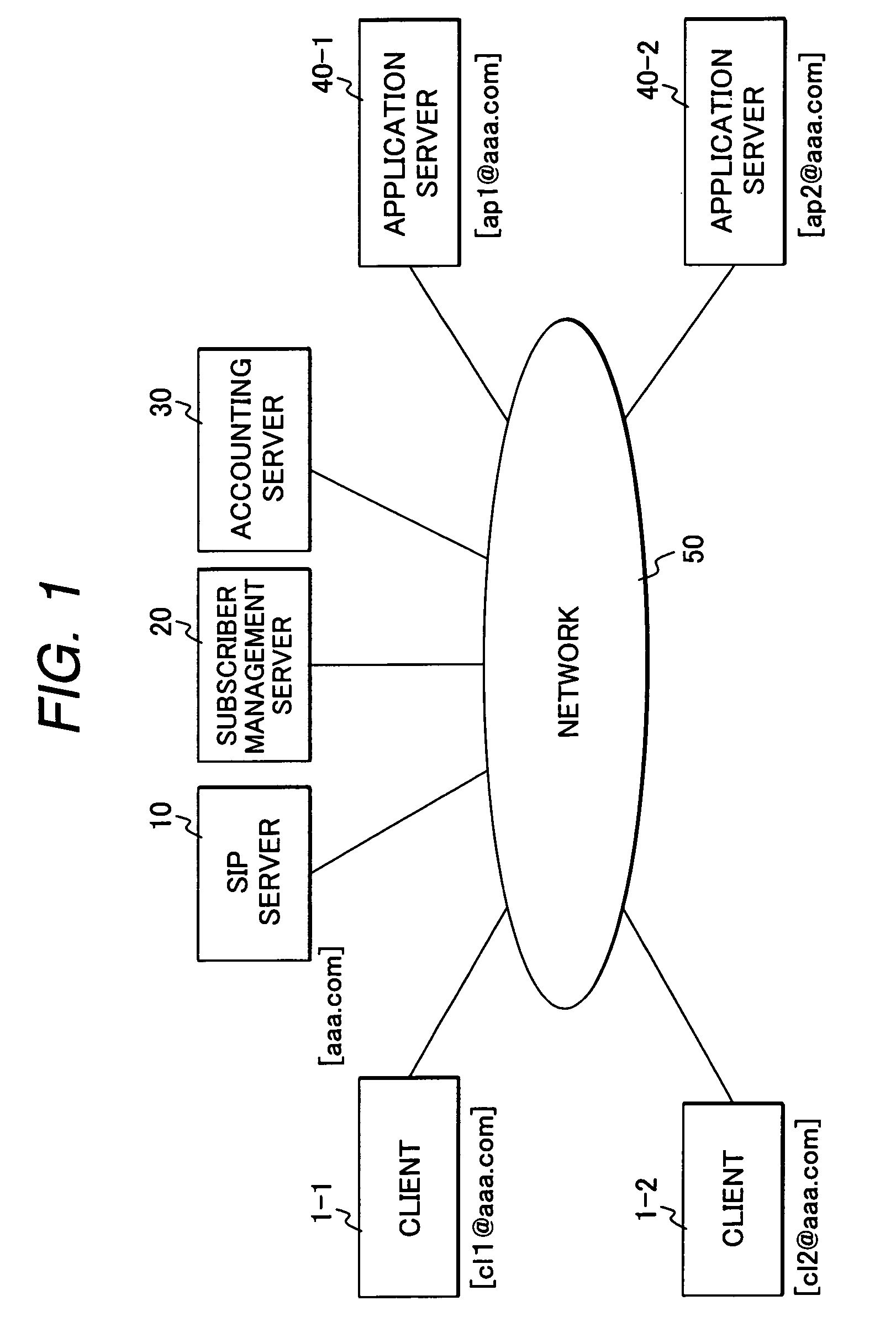

Information service communication network system and session management server

InactiveUS20050220039A1Reduce loadEasy to manageSpecial service provision for substationMultiplex system selection arrangementsClient-sideApplication server

A session management server, which is provided with a service determination table having a plurality of entries each indicating a service identifier in association with possible particular items of information which may be extracted from a session setup request packet, receives a session setup request packet issued from a client to a particular application server and determines whether the client terminal is authorized to receive an information service by referring to the determination table, in place of the particular application server. When the determination results in success, the session setup request packet is forwarded to the particular application server.

Owner:HITACHI LTD

Medicinal compositions for concomitant use as anticancer agent

InactiveUS20030215523A1Good synergyEliminate side effectsHeavy metal active ingredientsBiocideCarboplatinAnticarcinogen

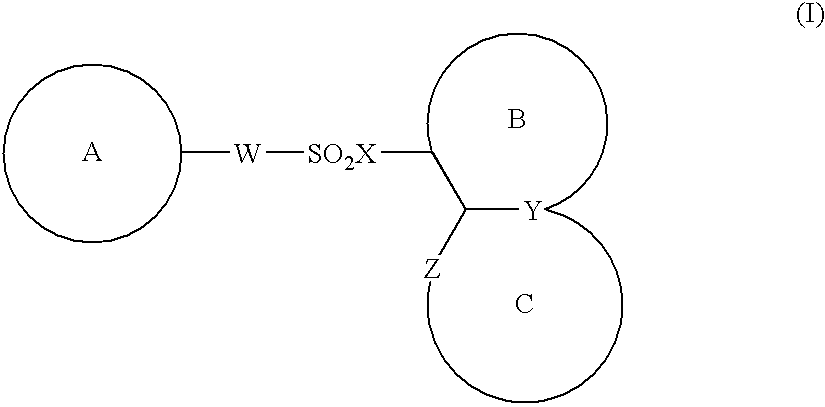

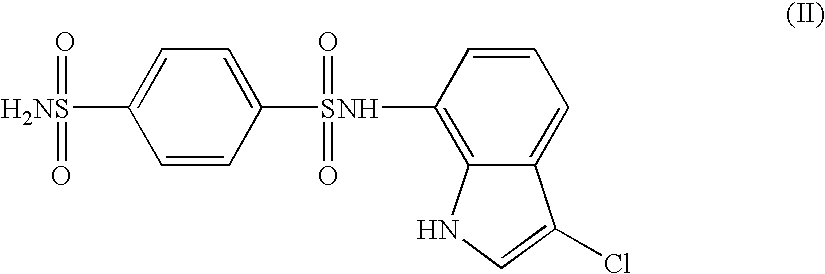

The present invention provides a medicinal composition having an excellent antitumor activity. That is, it provides a medicinal composition comprising a sulfonamide compound, a sulfonate compound or a salt of them, which is represented by the following formula: (wherein ring A represents an aromatic ring which may have a substituent group; ring B represents a 6-membered unsaturated hydrocarbon ring which may have a substituent group etc.; ring C represents a 5-membered hetero-ring containing one or two nitrogen atoms, and the ring C may have a substituent group; W represents a single bond or -CH=CH-; X represents -NH- etc.; and Y represents a carbon atom or a nitrogen atom; and Z represents -NH- etc.), particularly N-(3-chloro-1H-indol-7-yl)-4-sulfamoylbenzenesulfonamide or a salt thereof, combined with at least one substance selected from (1) irinotecan hydrochloride trihydrate; (2) mitomycin C; (3) 5-fluorouracil; (4) cisplatin; (5) gemcitabine hydrochloride; (6) doxorubicin; (7) taxol; (8) carboplatin; (9) oxaliplatin; (10) capecitabine; and (11) a salt of the above-mentioned (1) to (10).

Owner:EISIA R&D MANAGEMENT CO LTD

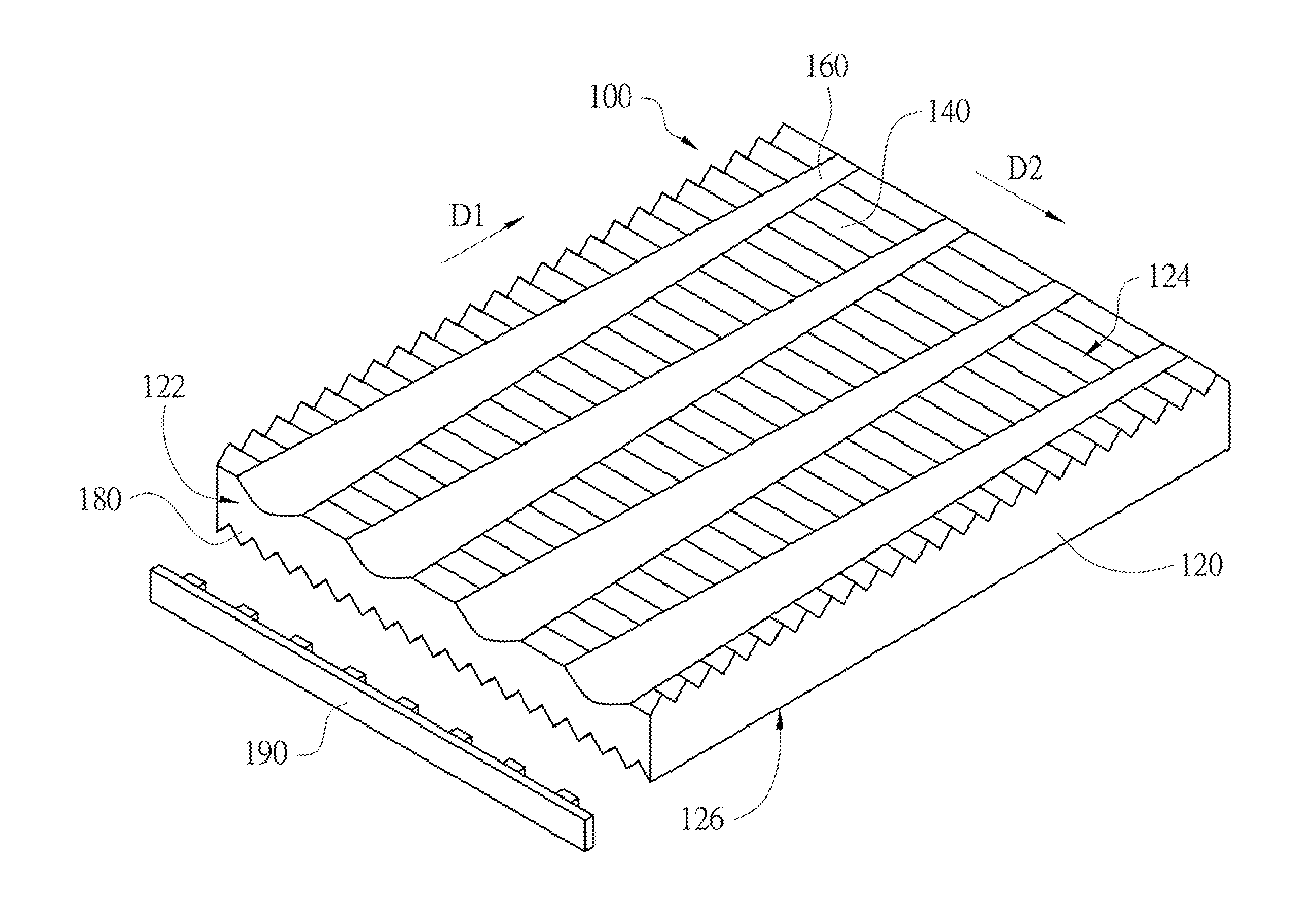

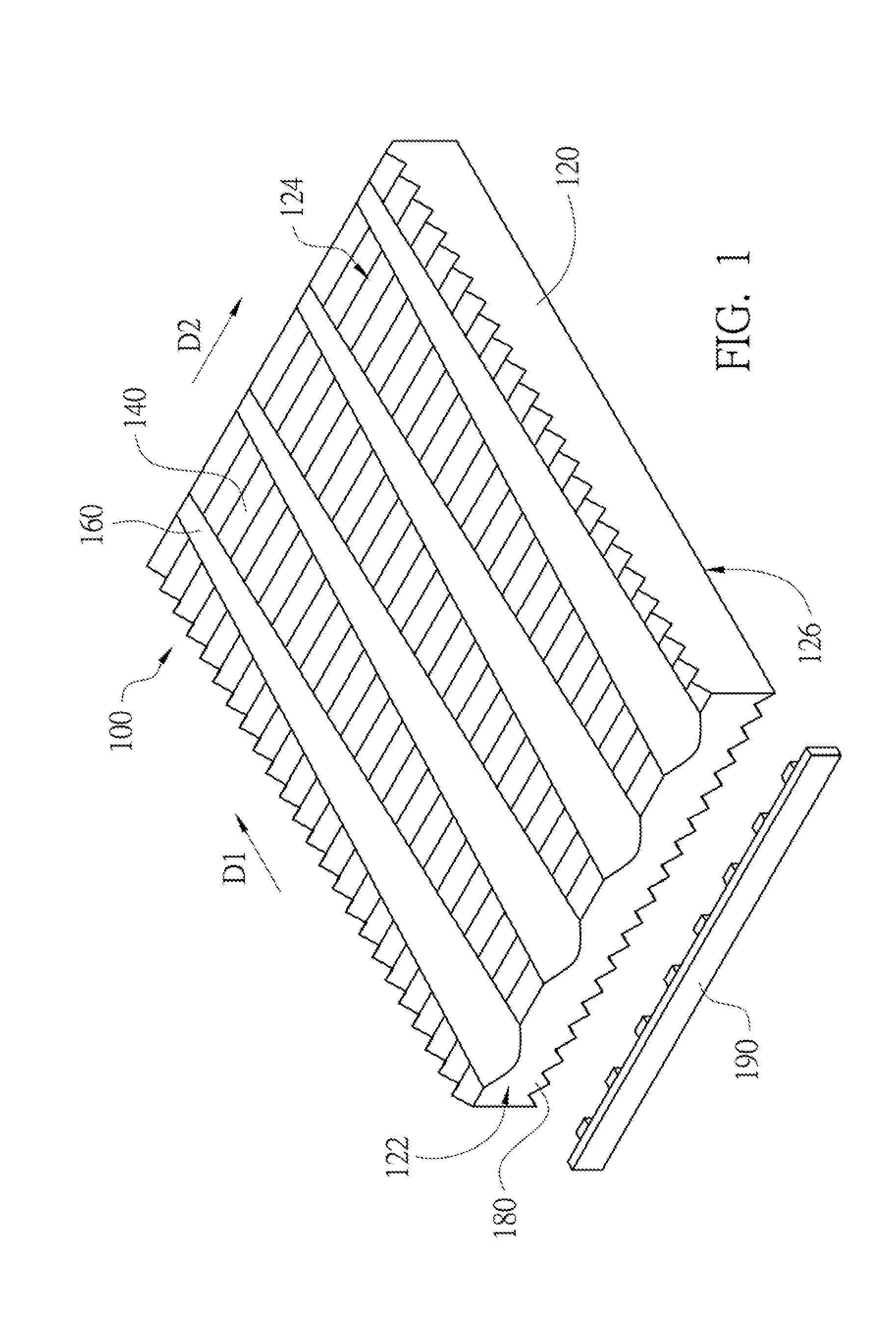

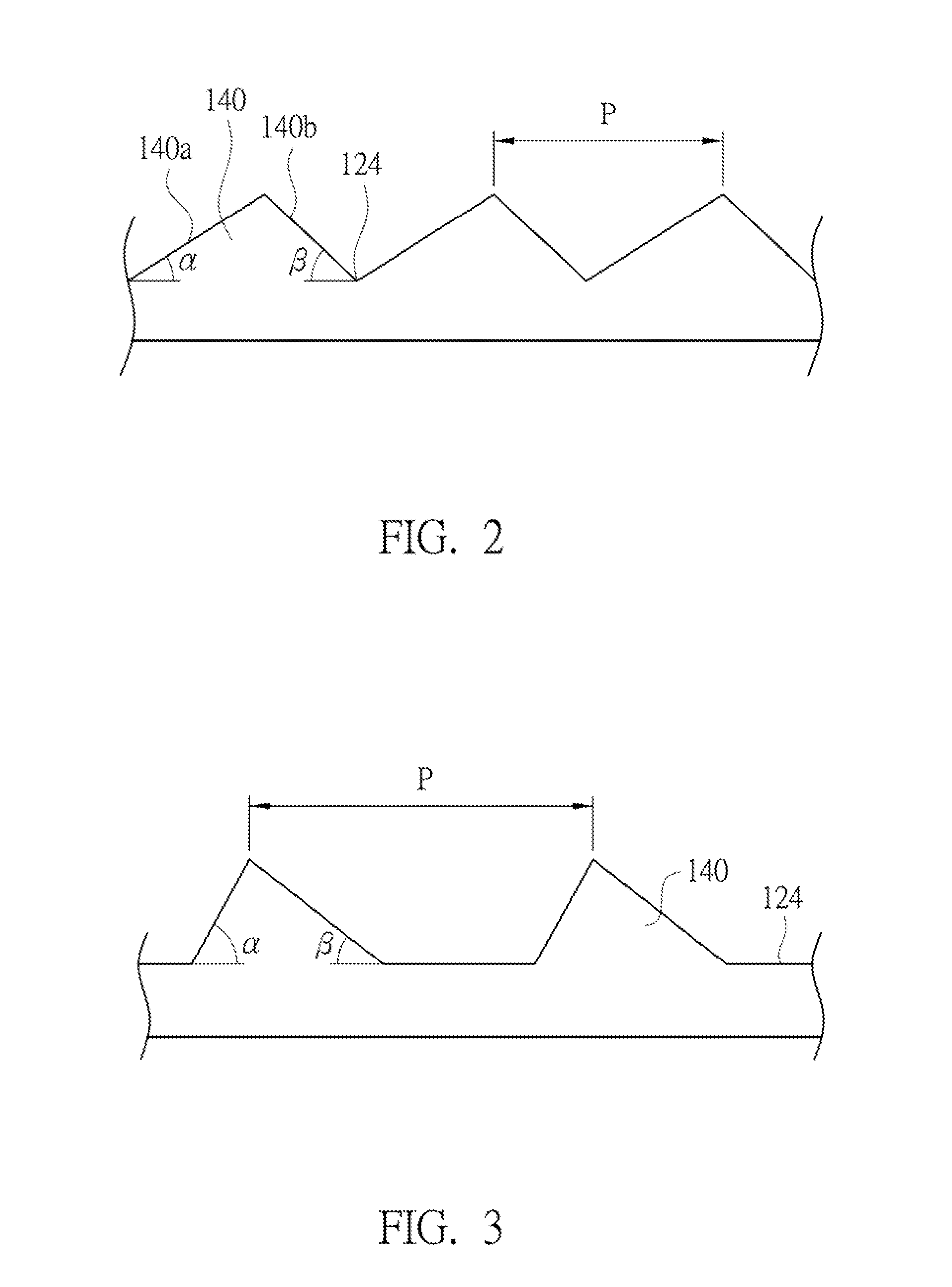

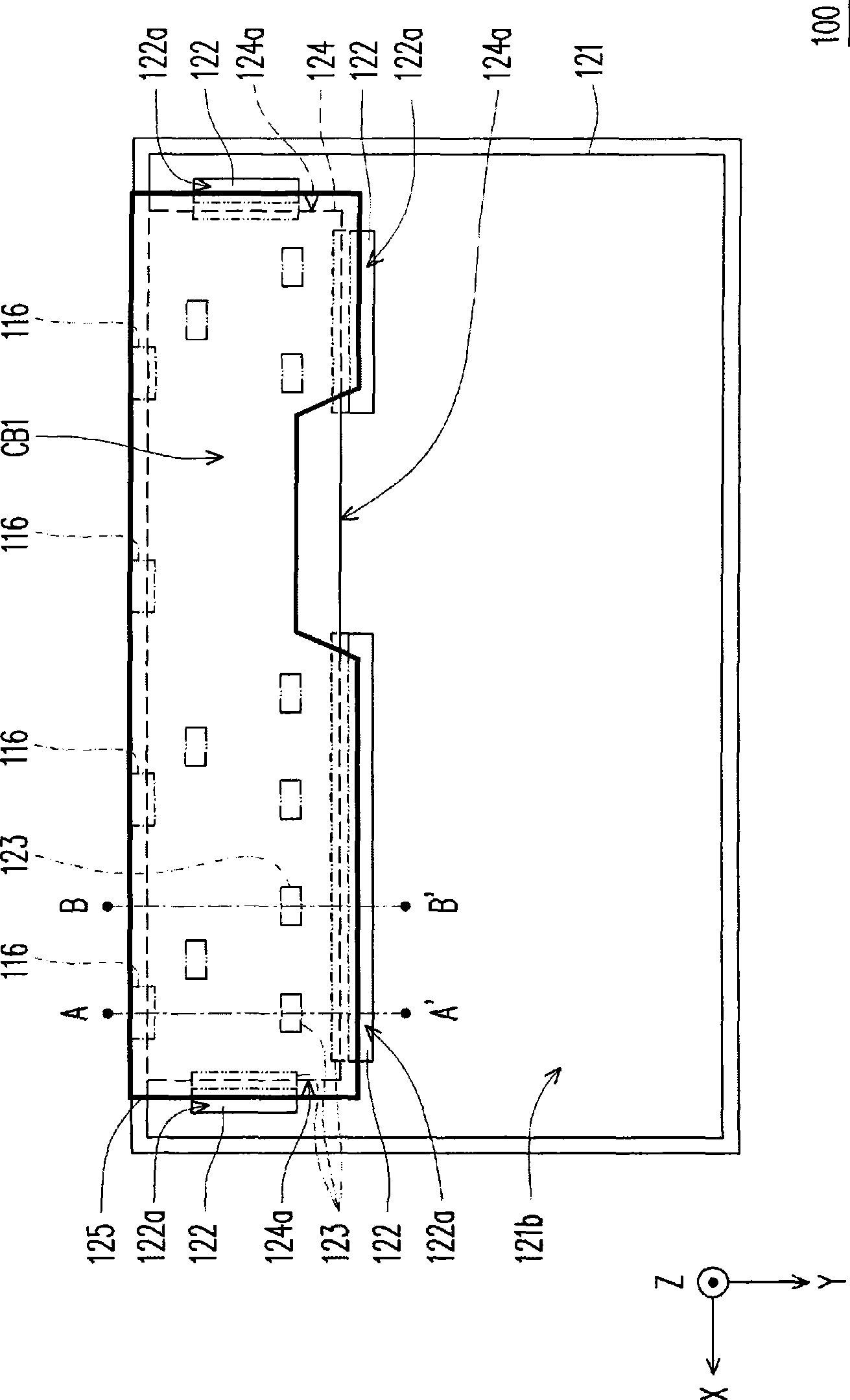

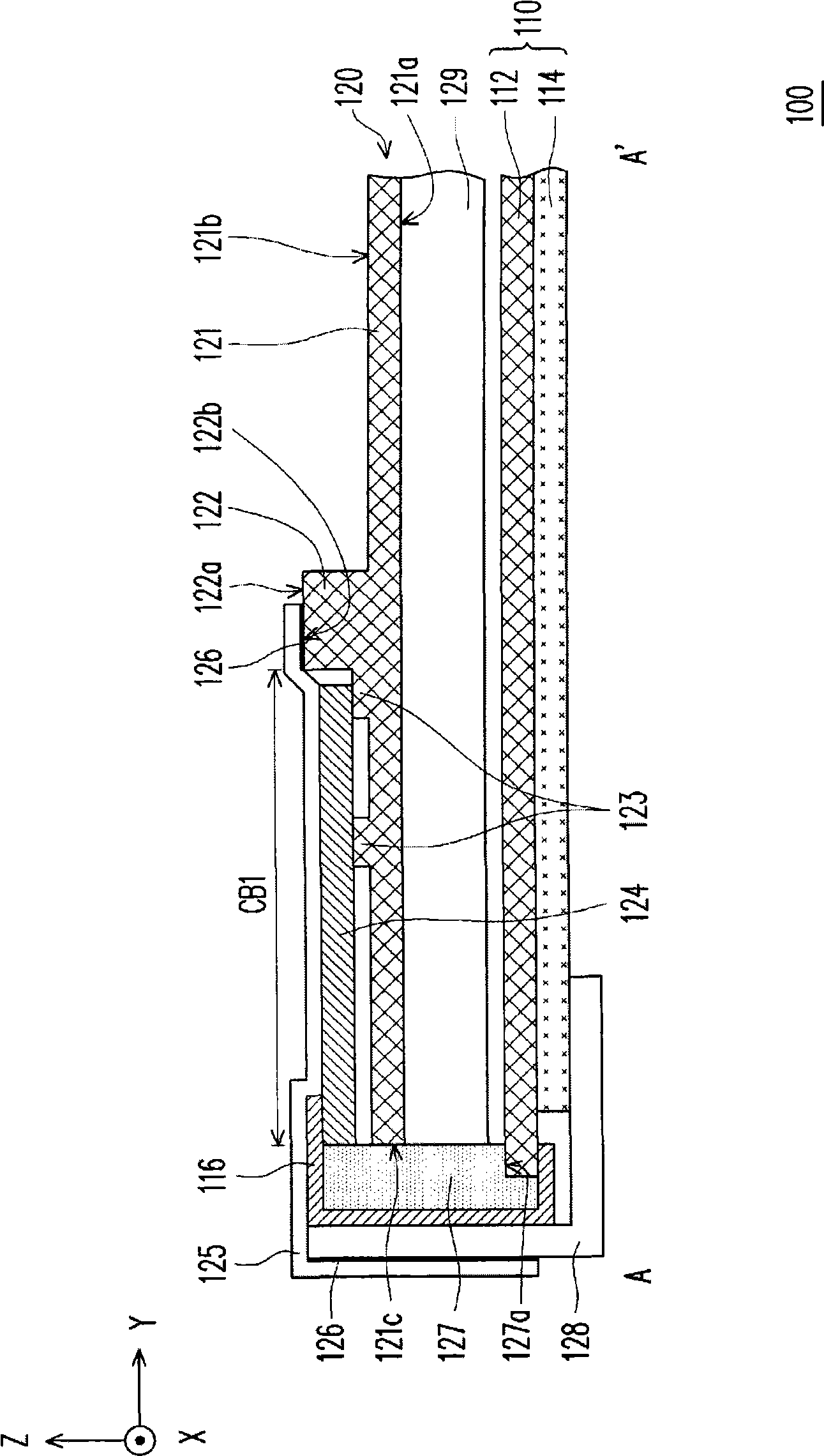

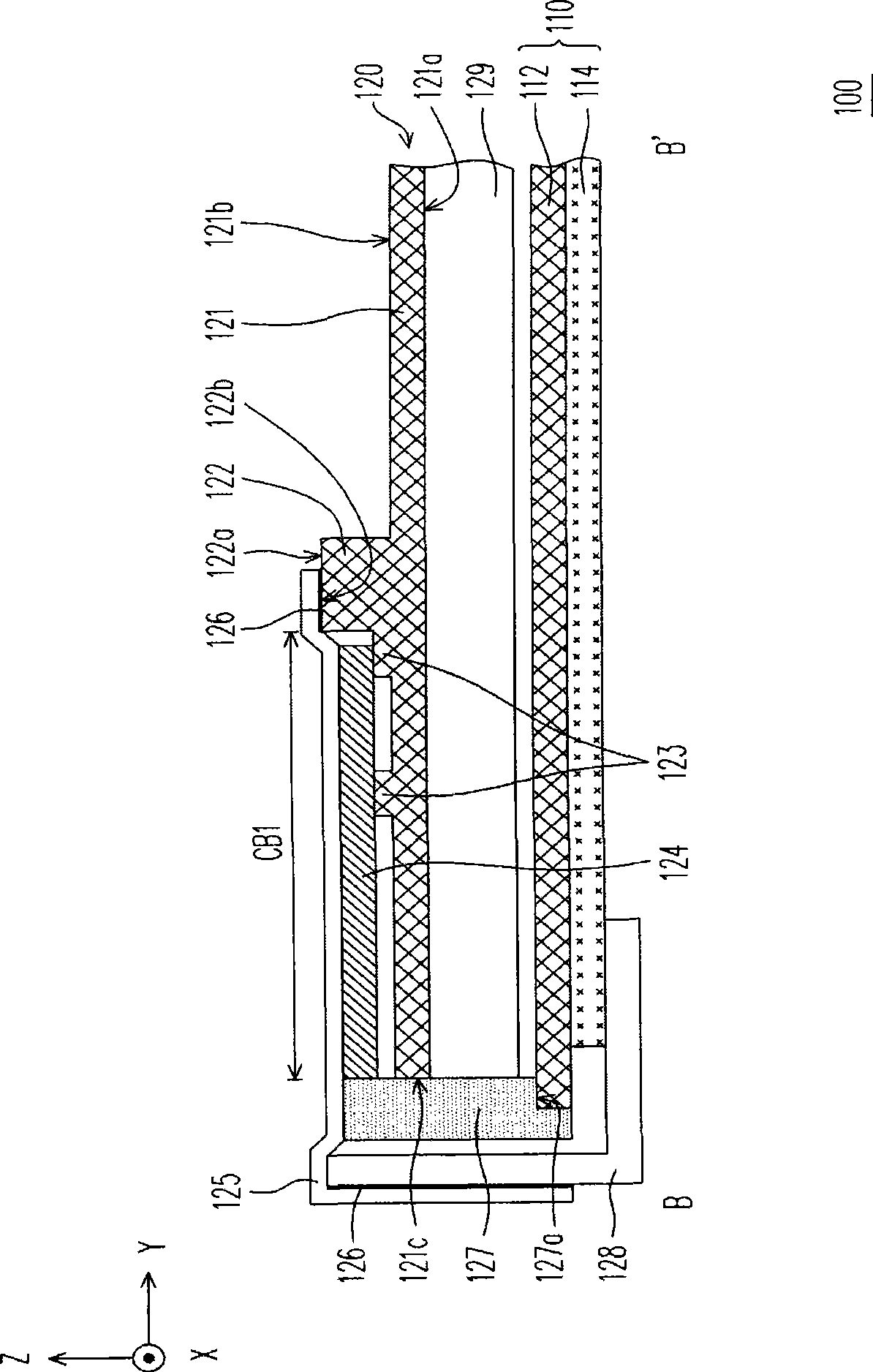

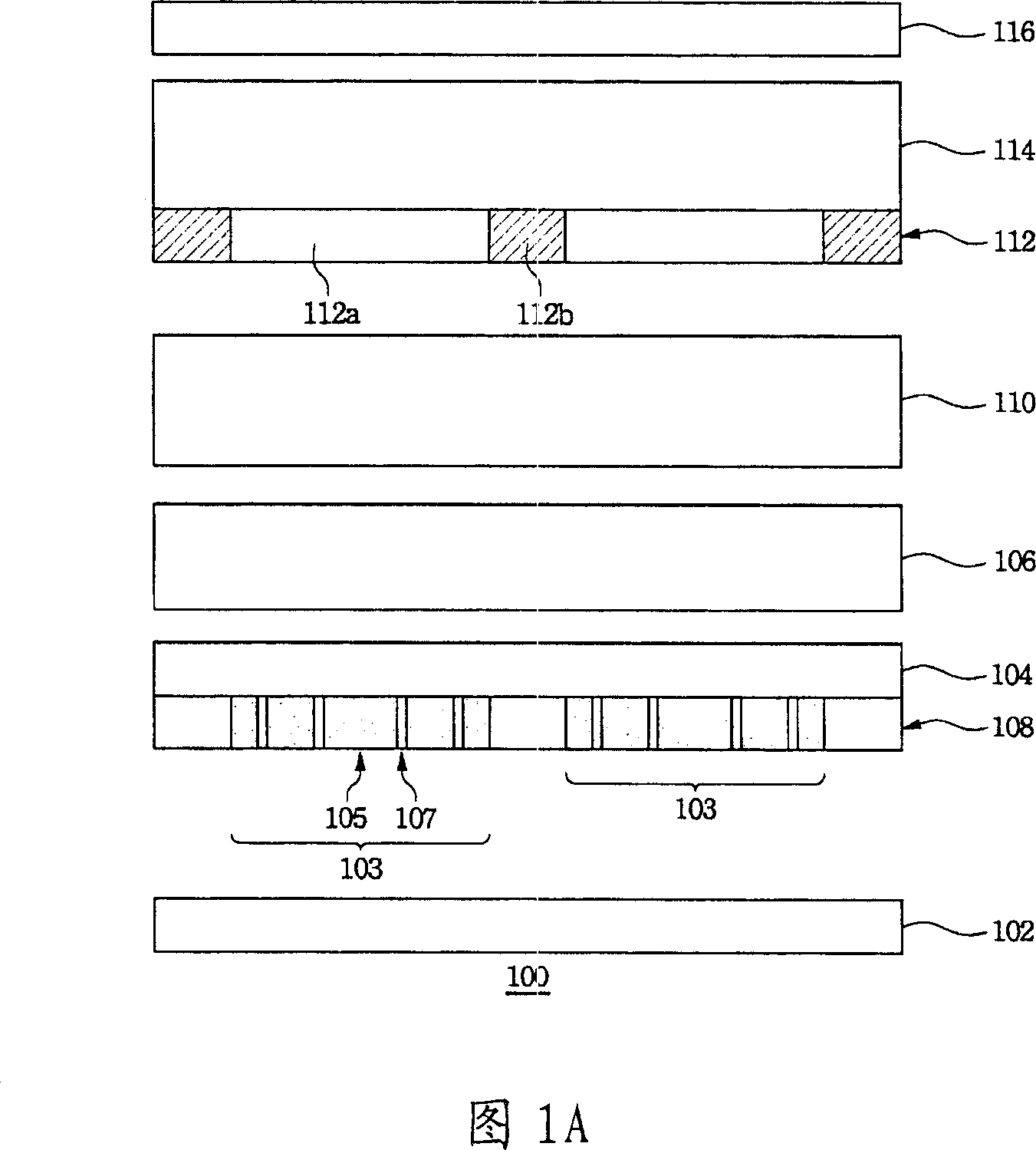

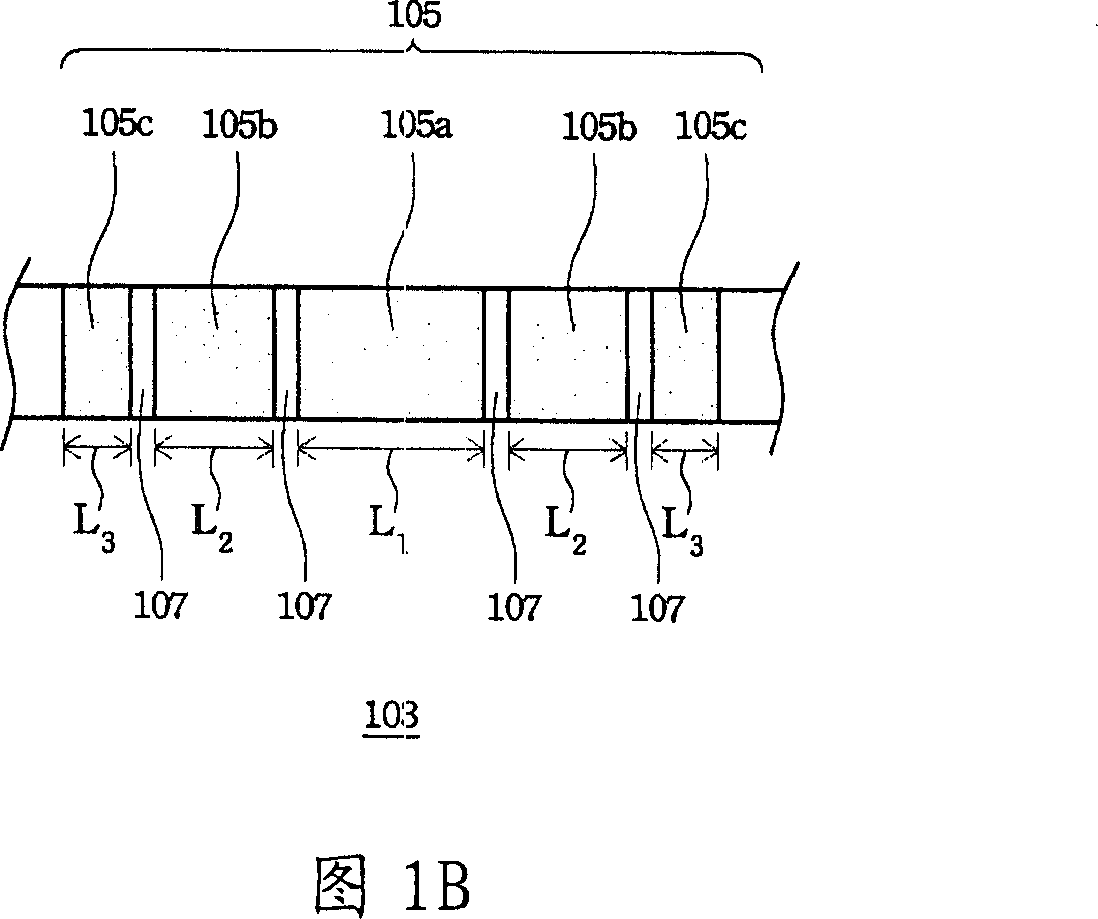

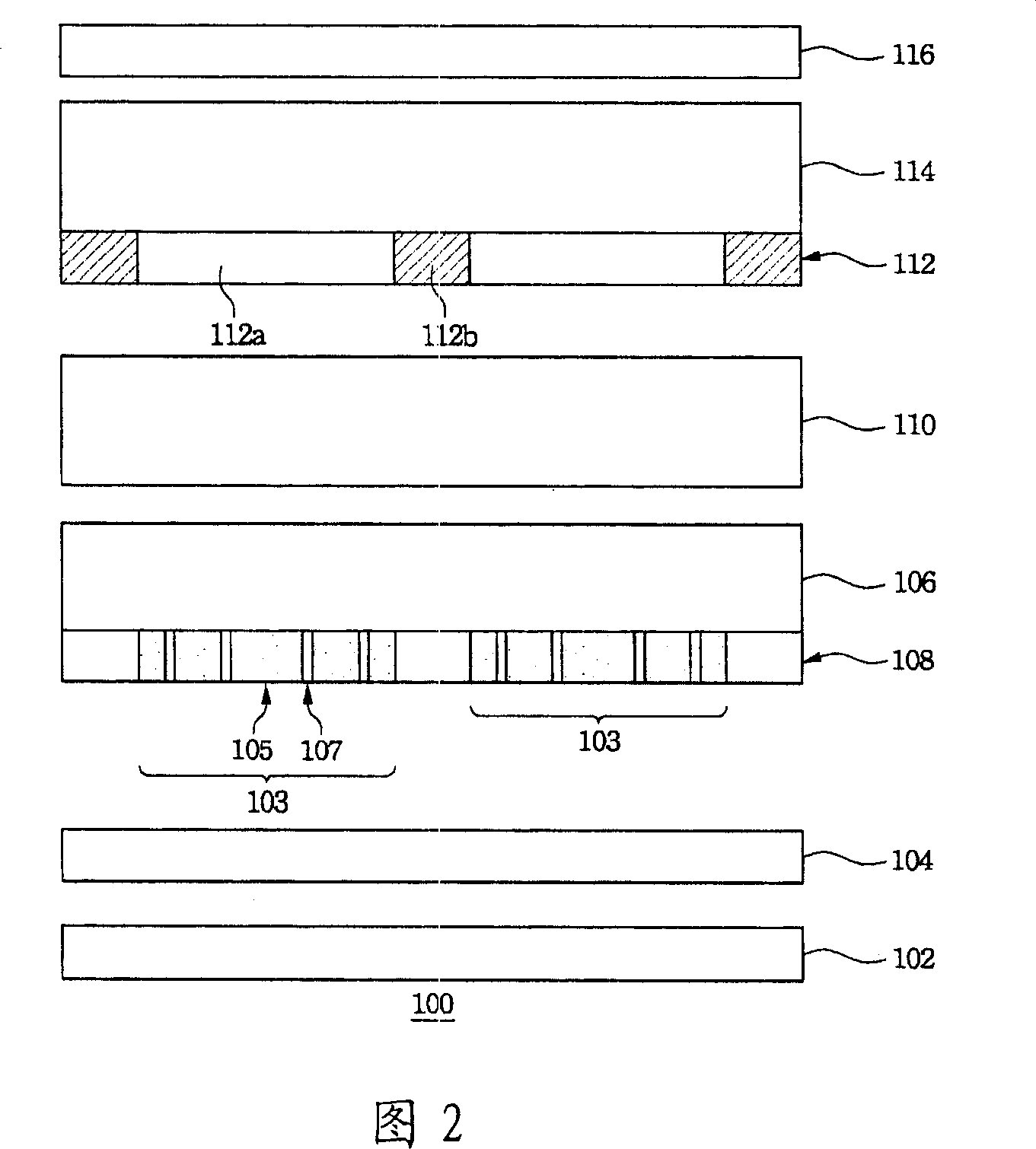

Light guide plate with multi-directional structures

ActiveUS20150055366A1Uniform effectReduce cost burdenMechanical apparatusPlanar/plate-like light guidesLight guideMulti directional

A light guide plate with multi-directional structures includes a main body, a plurality of first microstructures and a plurality of second microstructures. The main body includes a light-incident surface, a light-emitting surface and a reflecting surface. The light-incident surface connects the light-emitting surface and the reflecting surface. The first microstructures are disposed on the light-emitting surface or the reflecting surface and arranged along a first extending direction. The second microstructures are disposed on the light-emitting surface or the reflecting surface and arranged along a second extending direction. The second microstructures and the first microstructures are disposed on the same plane and intersect with each other. Each of the second microstructures is a single stripe pattern, and has a width which becomes gradually smaller from one end of the second microstructure near the light-incident surface to the other end of the second microstructure away from the light-incident surface.

Owner:RADIANT OPTO ELECTRONICS

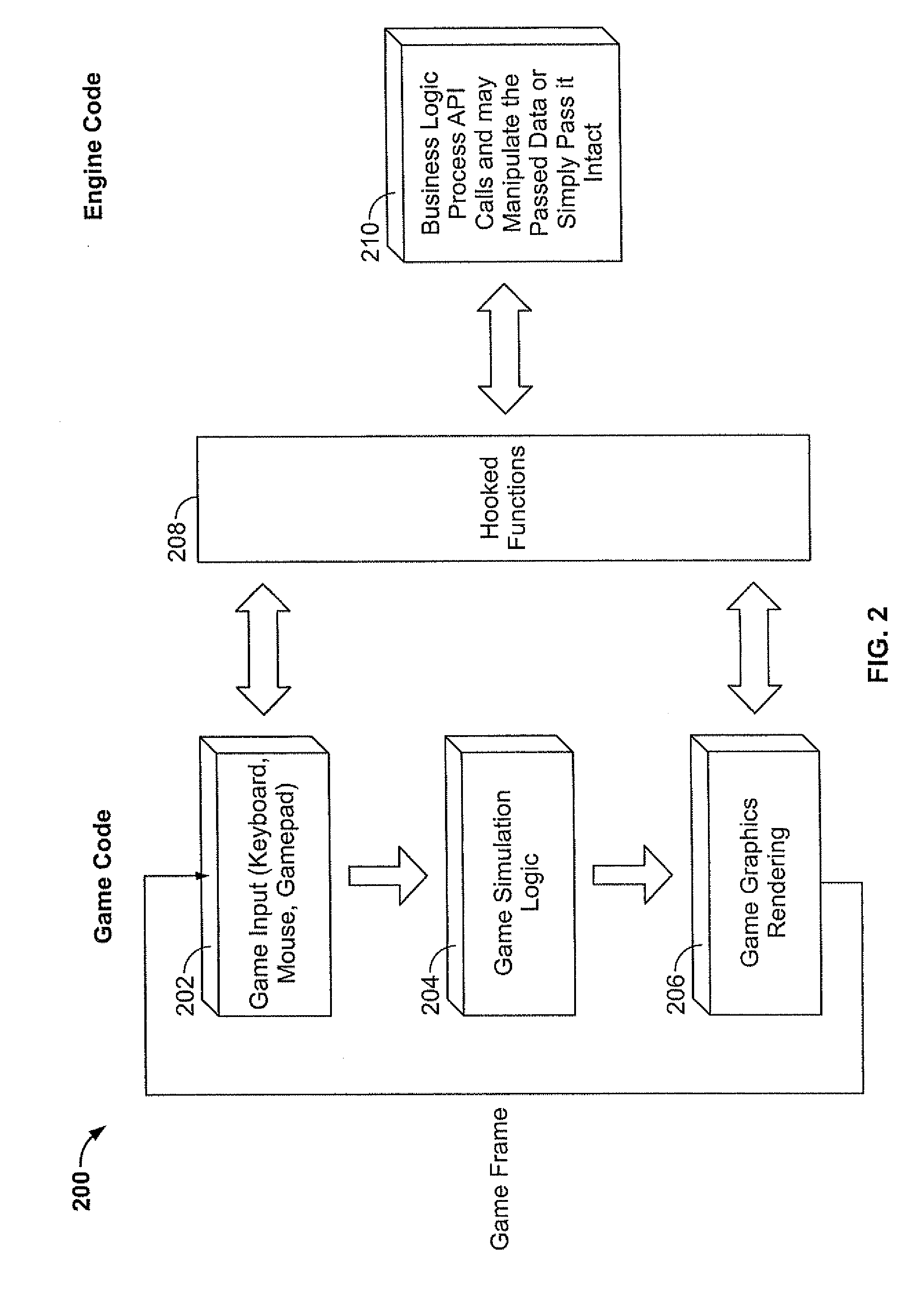

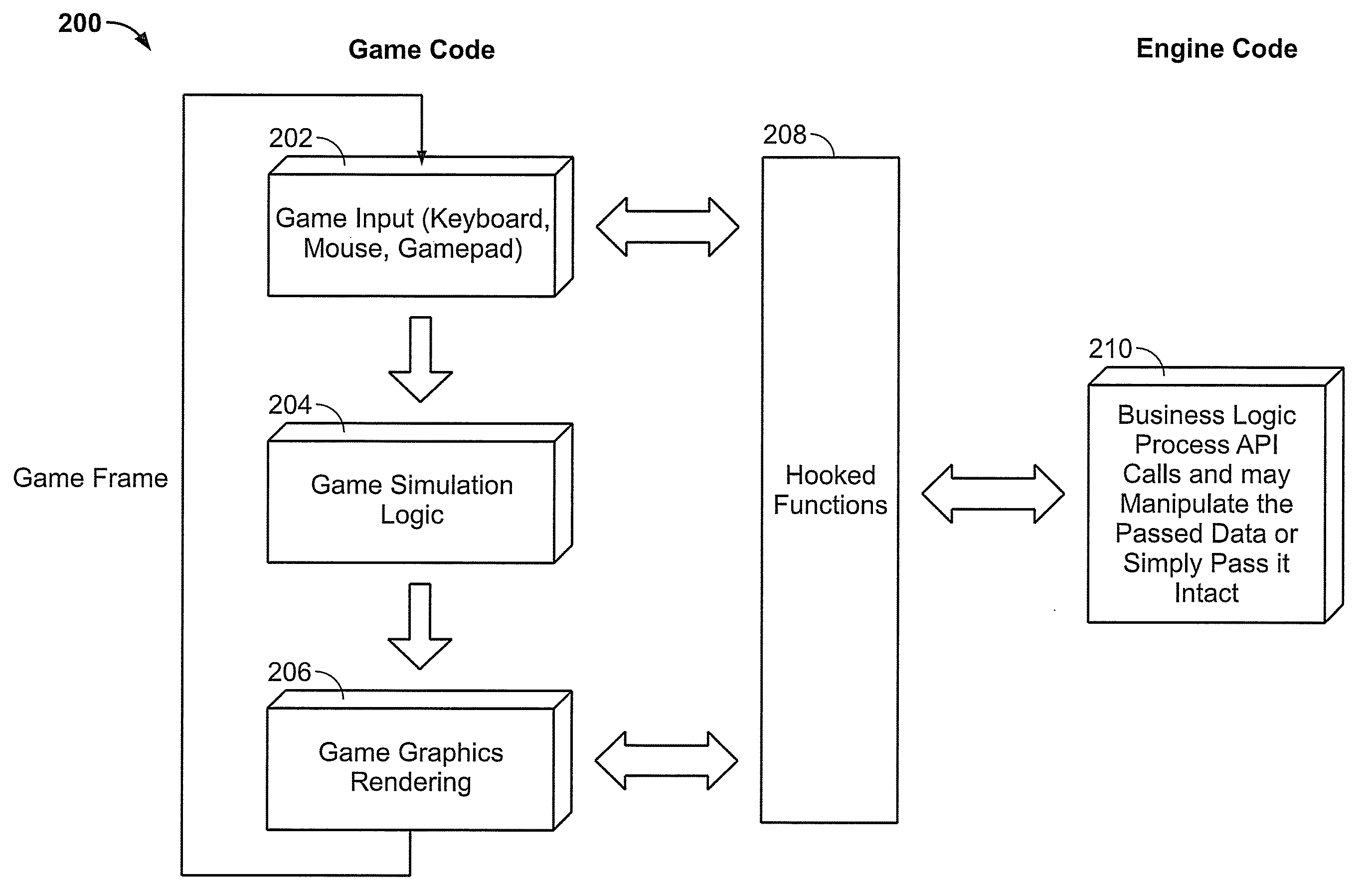

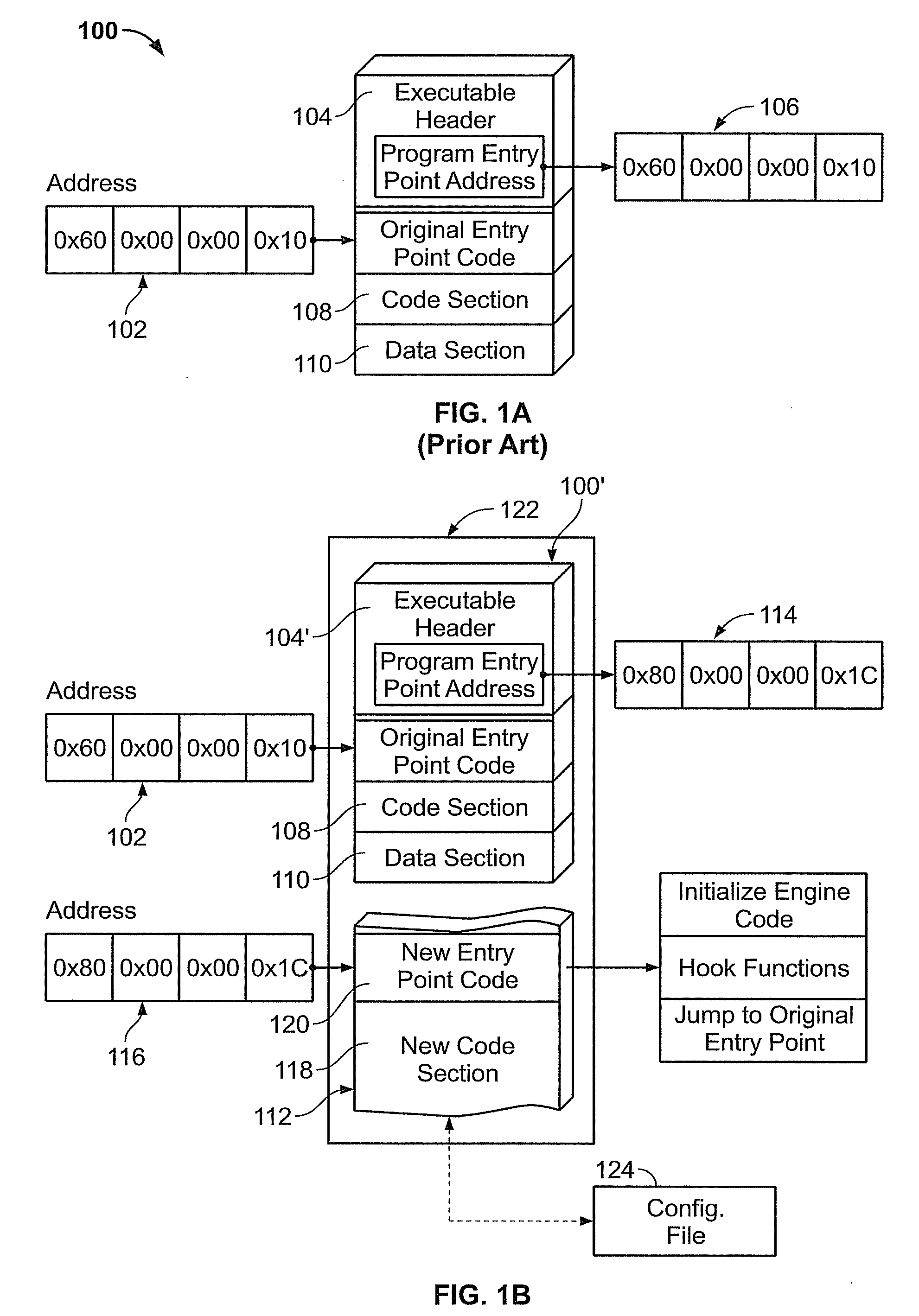

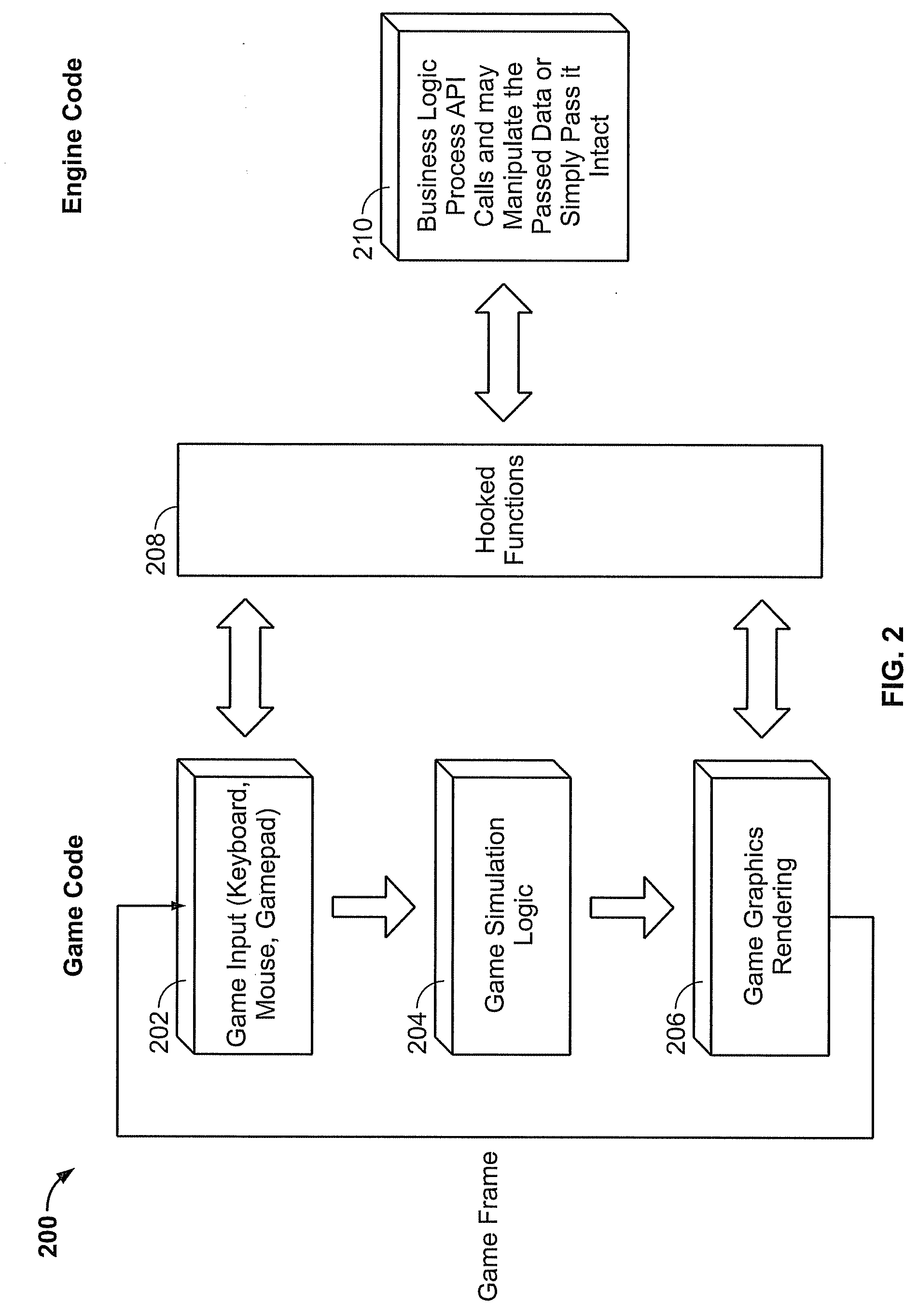

Independently-defined alteration of output from software executable using distributed alteration engine

InactiveUS20090054140A1Add featureReduce cost burdenVideo gamesSpecial data processing applicationsClient-sideBusiness logic

A first executable, such as a computer game, operates co-extensively with a second independently operating executable that monitors events on a client operating the first executable. The second executable determines actions to be performed in response to monitored events, as defined by a business logic table. The second executable traps API calls to perform actions altering apparent output of the first executable. The business logic table may be distributed to the client separately. The second executable and the first executable may be configured to execute during the same times on the client node. The second executable may be used to provide additional content, including advertising, in the context of an existing game or other software executable.

Owner:PLENUS MANAGEMENT 2007 III

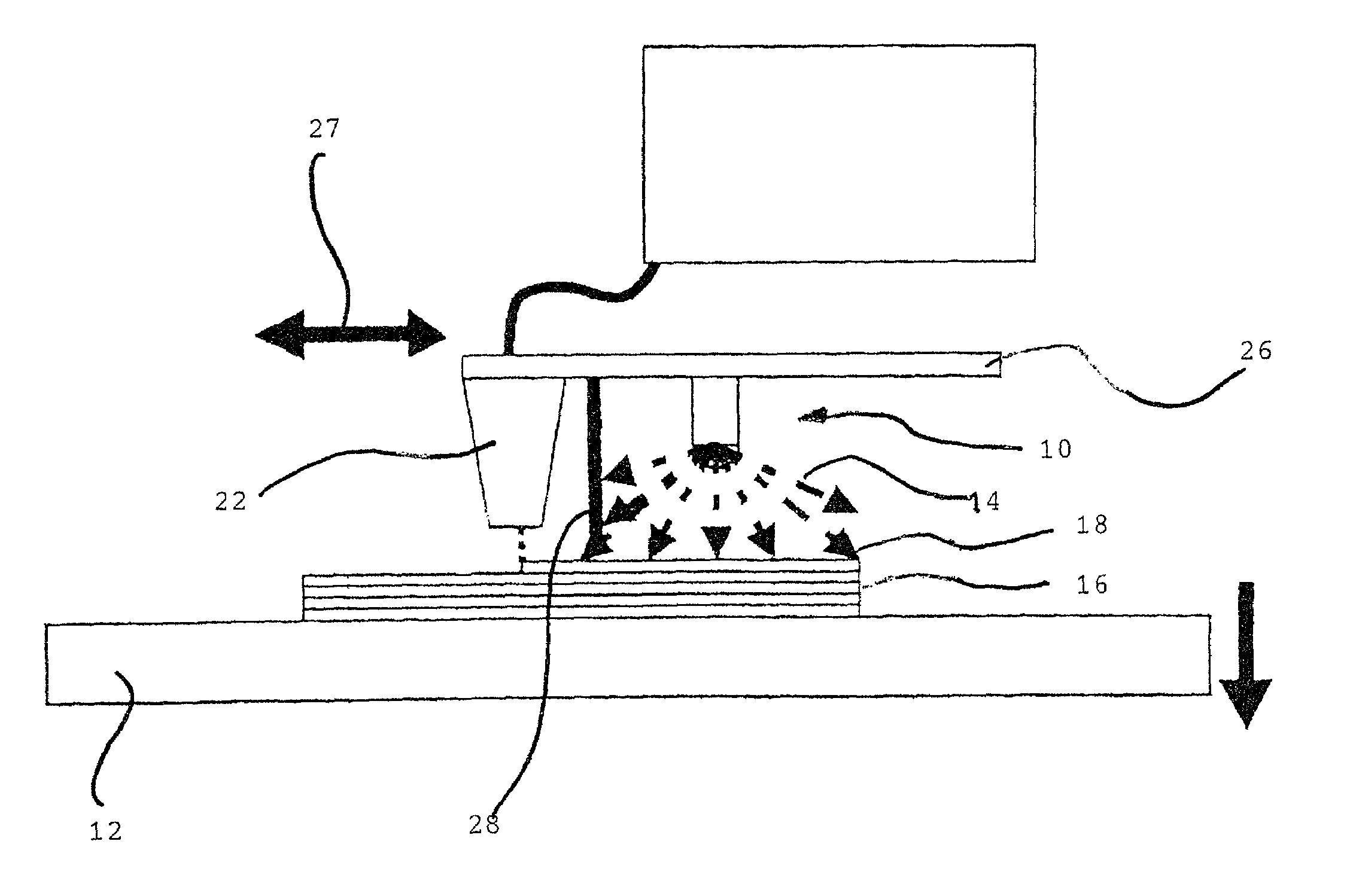

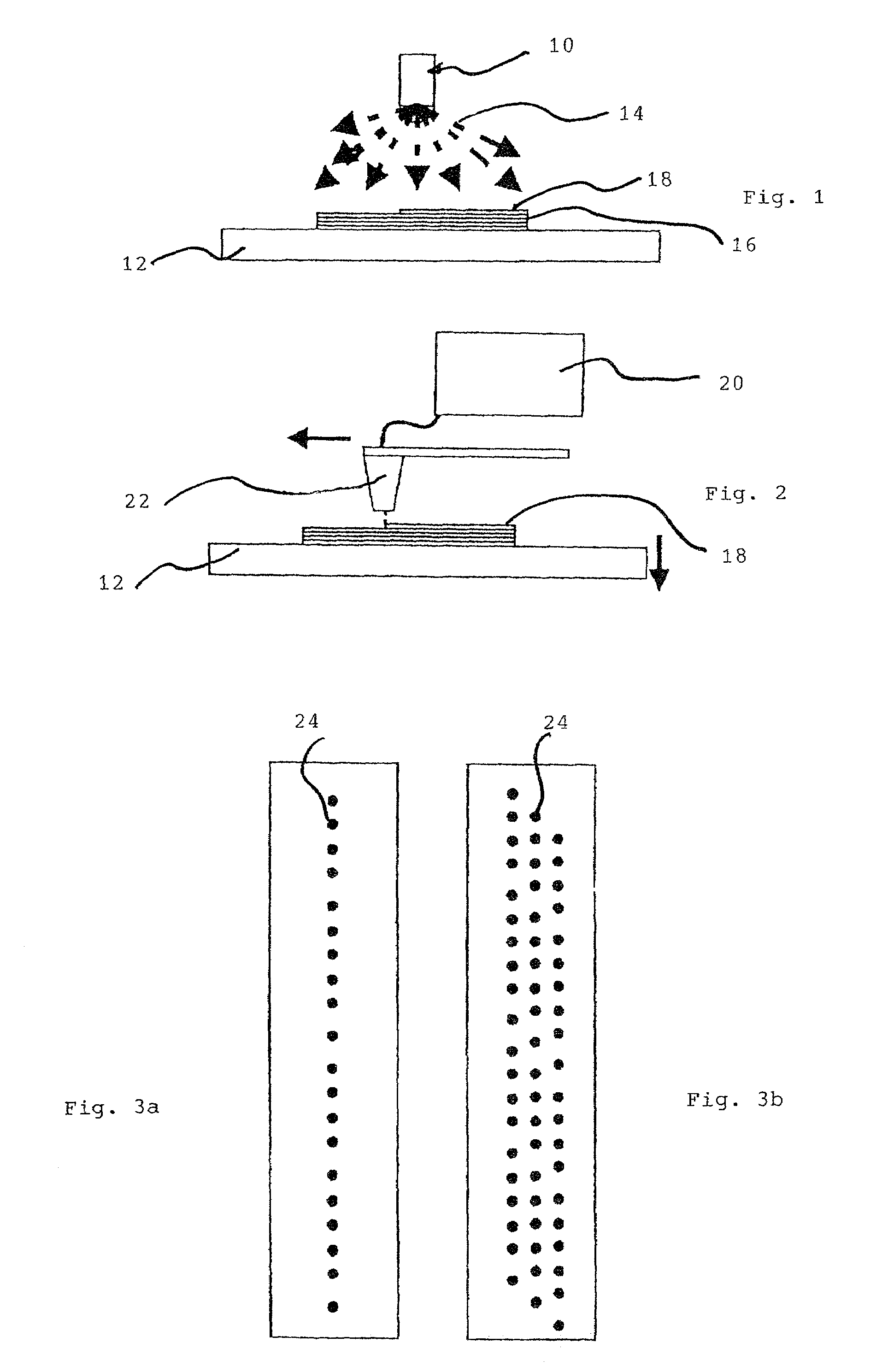

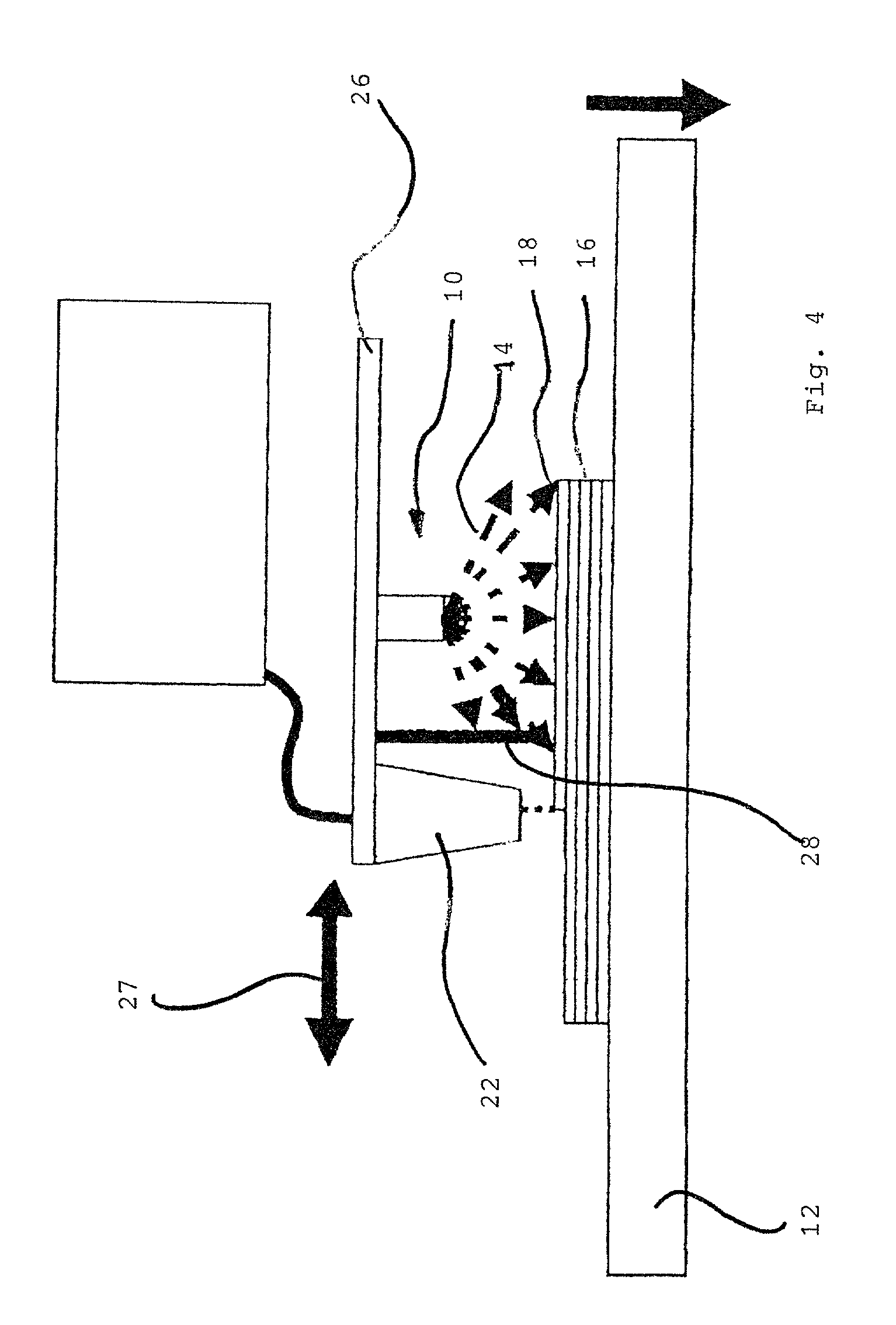

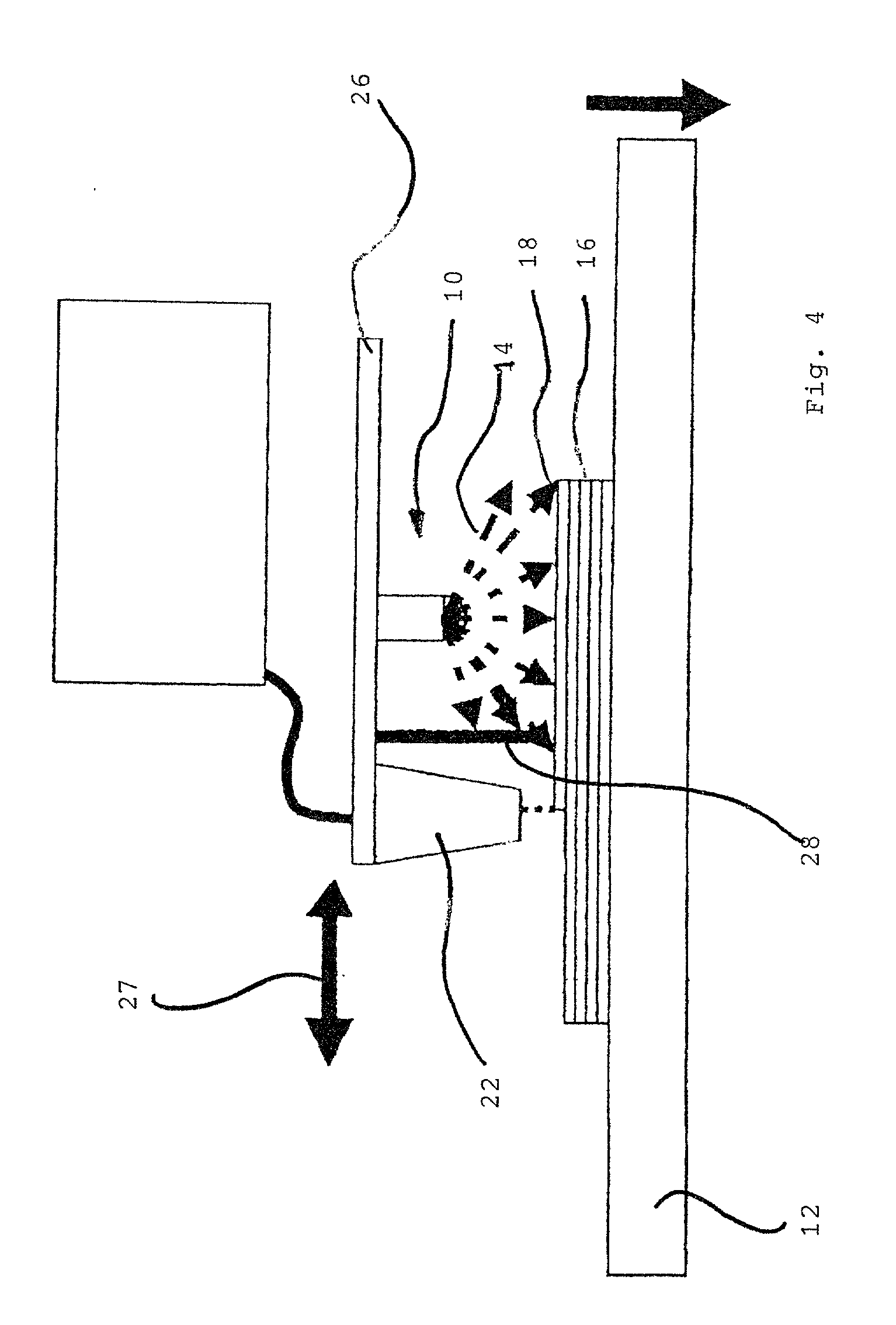

Method for producing a synthetic material part

InactiveUS7189344B2Rapid productionReduce capital investment costsImpression capsGum massageSynthetic materialsViscosity

A method for producing a synthetic material part such as, for example, a dental restorative part, is provided and includes spray applying with a spray device a material having at least a polymerizable synthetic material onto a base in succeeding layers. Each layer of the spray applied material is substantially continuously polymerized by the spray device and has a viscosity which permits working of the applied material in an unpolymerized condition thereof with the spray device. The method also includes hardening the one or more of the already applied layers prior to the application of subsequent layers.

Owner:IVOCLAR VIVADENT AG

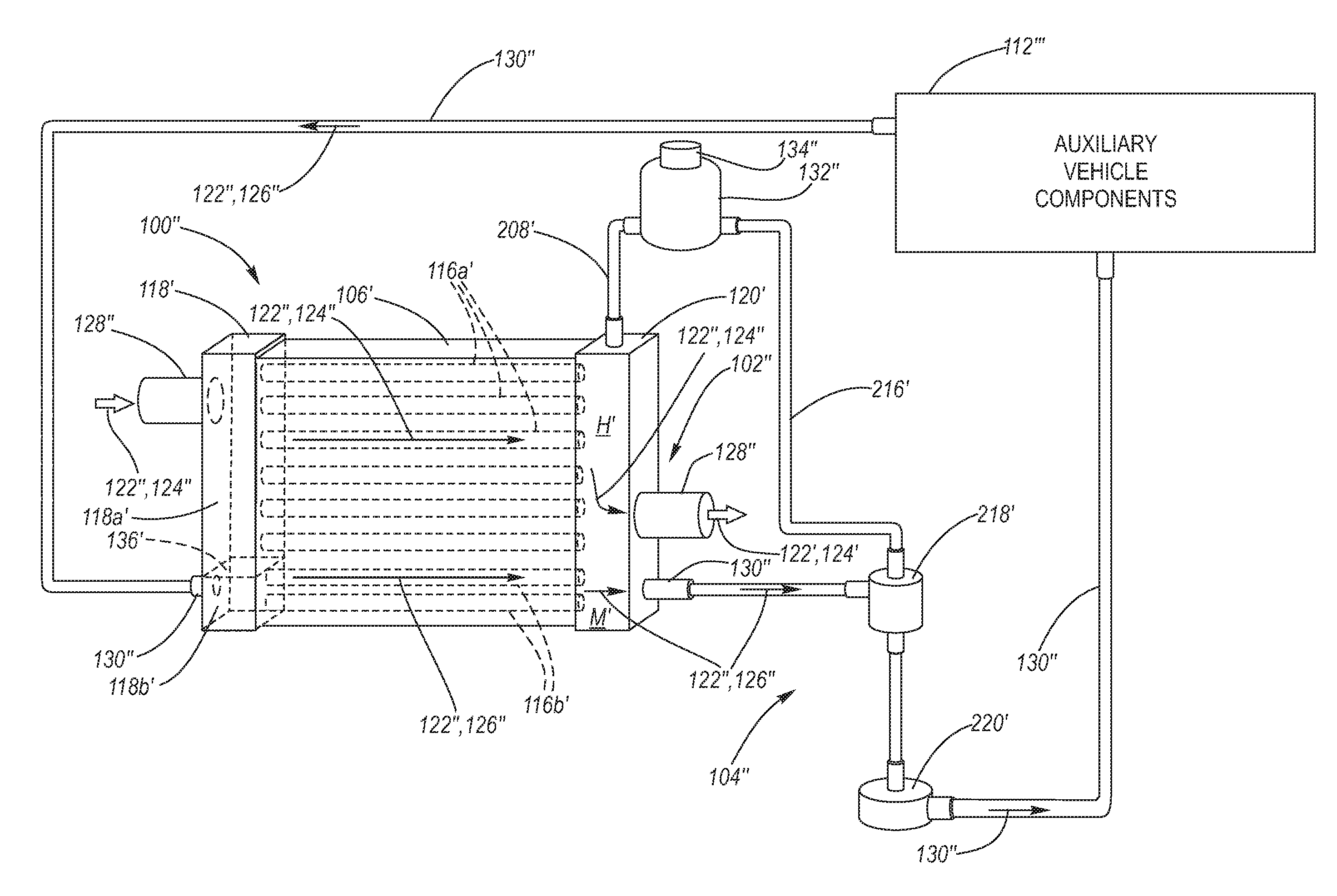

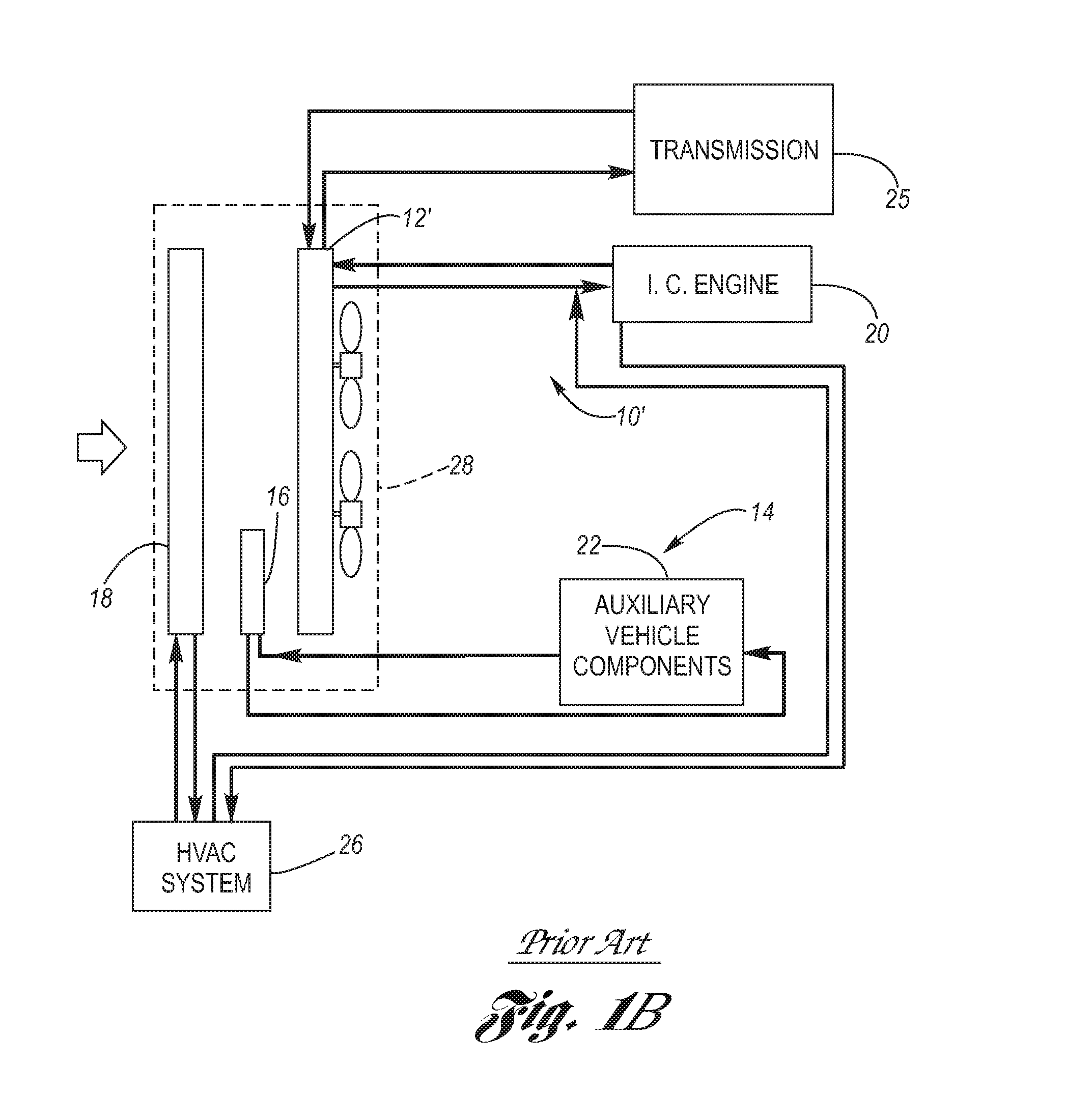

Integrated Vehicle Cooling System

ActiveUS20090020081A1Reduces vehicle cost burdenReduce packageLiquid coolingCoolant flow controlInternal combustion engineCoolant pump

An integrated high and moderate temperature cooling system both for an internal combustion engine and for auxiliary vehicle components requiring cooling. The integrated cooling system shares a coolant, yet the shared coolant is stratified to retain thermal identity between the portion of the coolant used for engine cooling and the portion of the coolant used for auxiliary vehicle components cooling. A shared coolant reservoir is used; preferably a shared heat exchanger, and optionally a common coolant pump may also be used.

Owner:GM GLOBAL TECH OPERATIONS LLC

Integrated vehicle cooling system

ActiveUS7669558B2Reduce cost burdenLevel of cooling performanceLiquid coolingCoolant flow controlInternal combustion engineCoolant pump

An integrated high and moderate temperature cooling system both for an internal combustion engine and for auxiliary vehicle components requiring cooling. The integrated cooling system shares a coolant, yet the shared coolant is stratified to retain thermal identity between the portion of the coolant used for engine cooling and the portion of the coolant used for auxiliary vehicle components cooling. A shared coolant reservoir is used; preferably a shared heat exchanger, and optionally a common coolant pump may also be used.

Owner:GM GLOBAL TECH OPERATIONS LLC

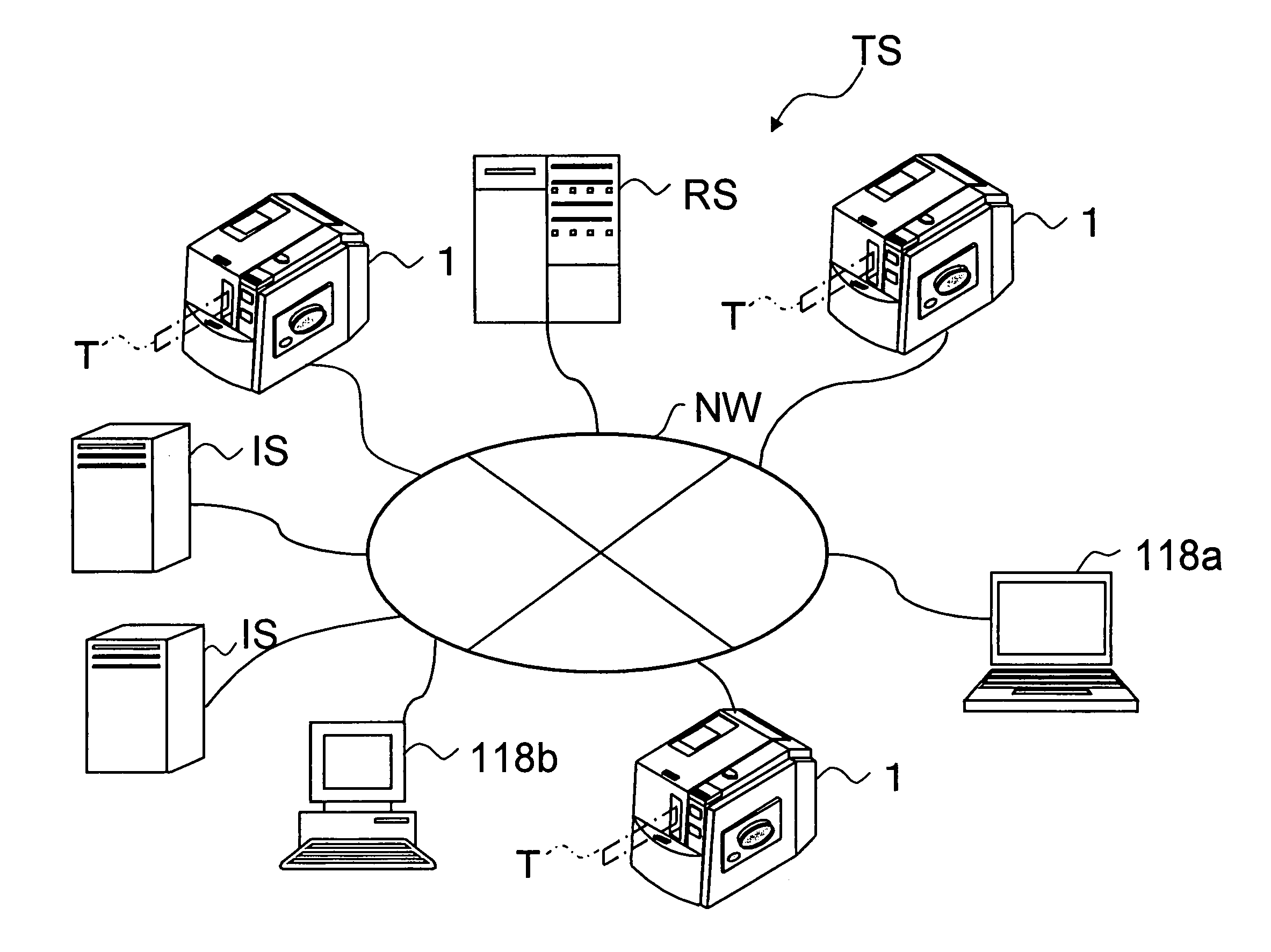

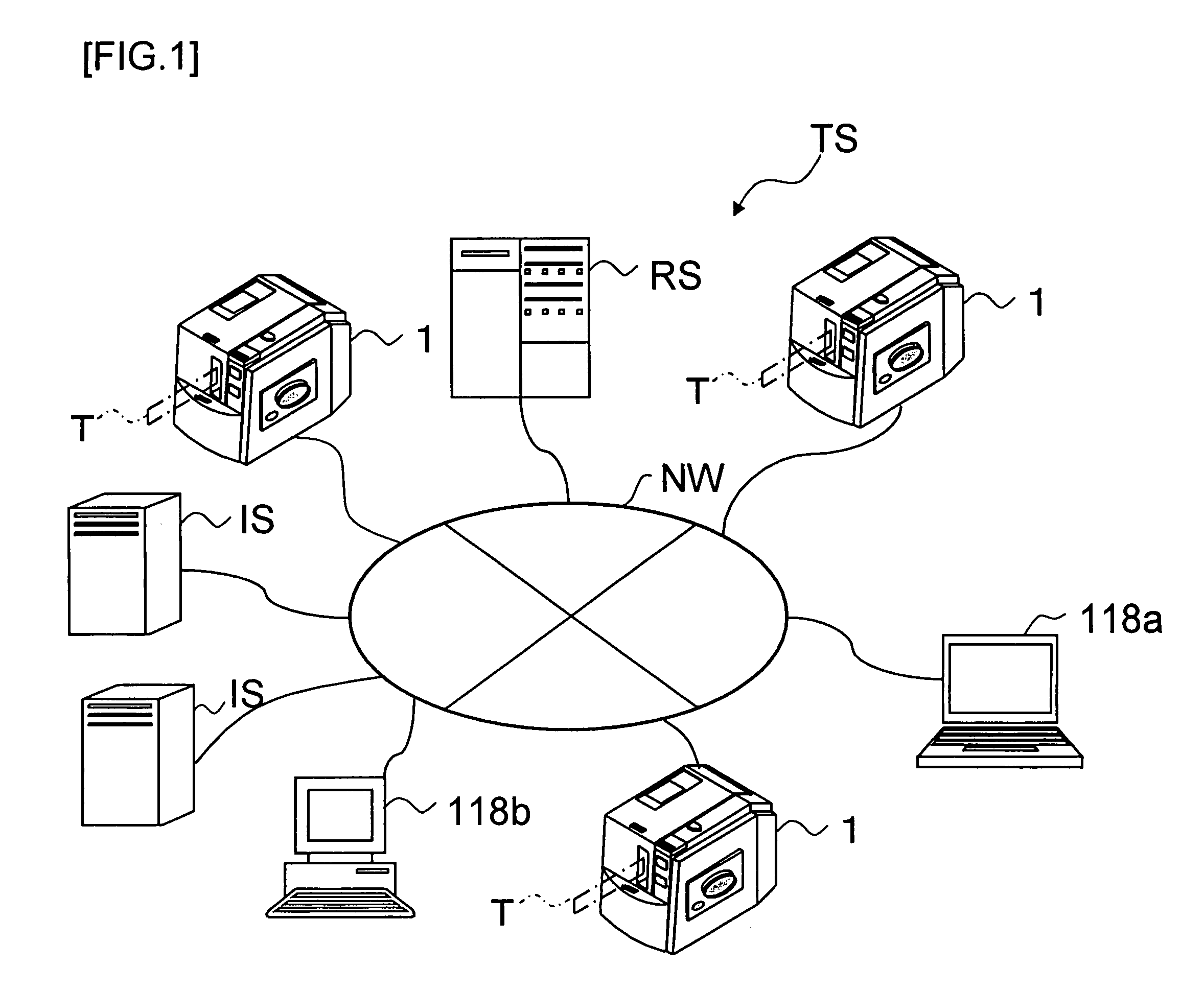

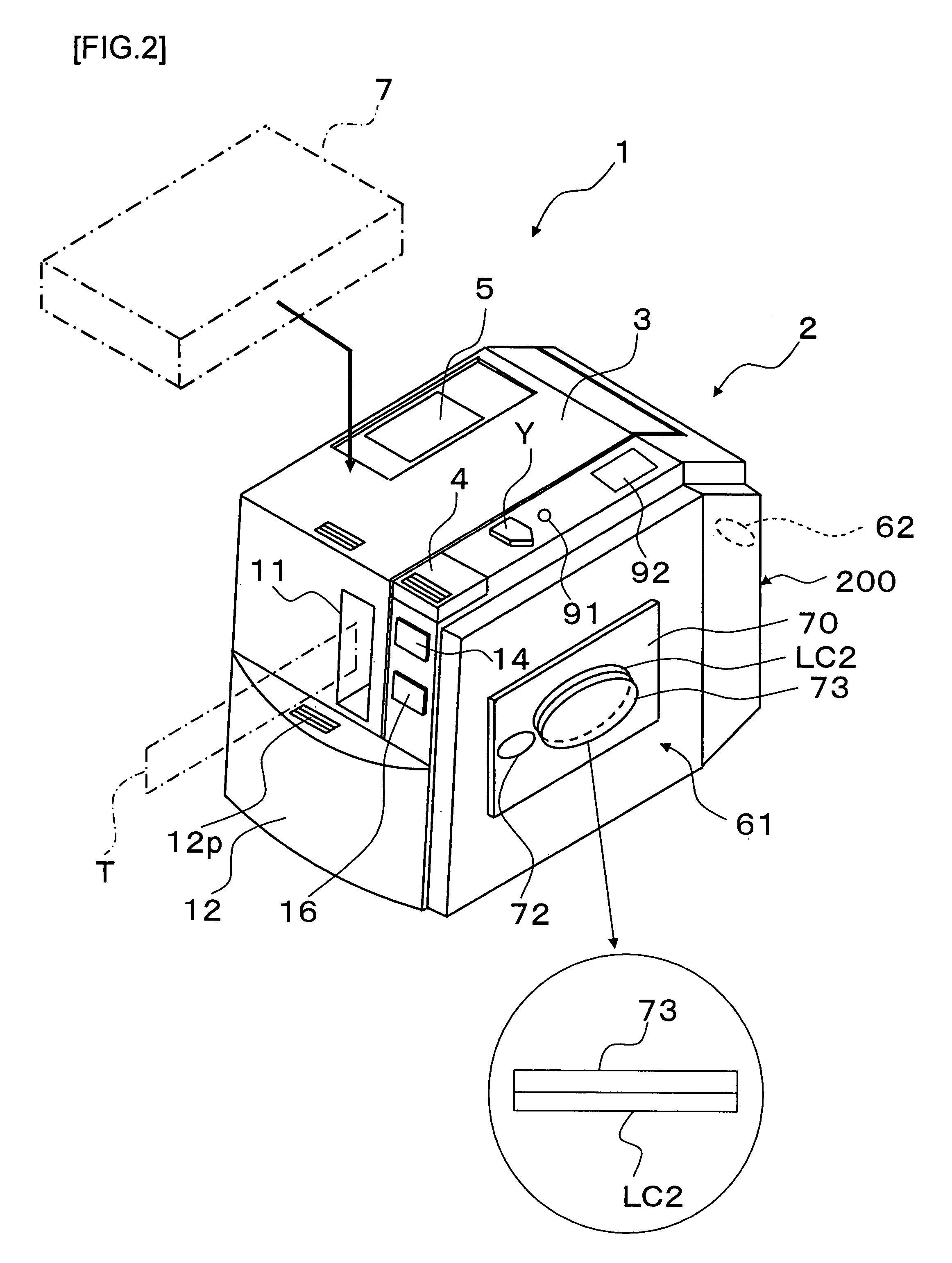

RFID tag information communicating apparatus

ActiveUS7876223B2Simple configurationReduce cost burdenConveying record carriersCo-operative working arrangementsInformation transmissionEngineering

An RFID tag information communicating apparatus includes a feeding roller driving shaft that is provided within a housing constituting a shell of an apparatus main body and feeds a base tape, and an antenna for label production and an antenna for information transmission and reception, which are capable of transmitting and receiving information with an RFID circuit element for label production included in a base tape and an RFID circuit element for information transmission and reception located outside the housing. Each of the RFID circuit elements has an IC circuit part that stores information and an antenna that transmits and receives information. The apparatus is configured capable of performing both of the information reading and information writing with the RFID circuit element for label production and the RFID circuit element for information transmission and reception via the antennas.

Owner:BROTHER KOGYO KK

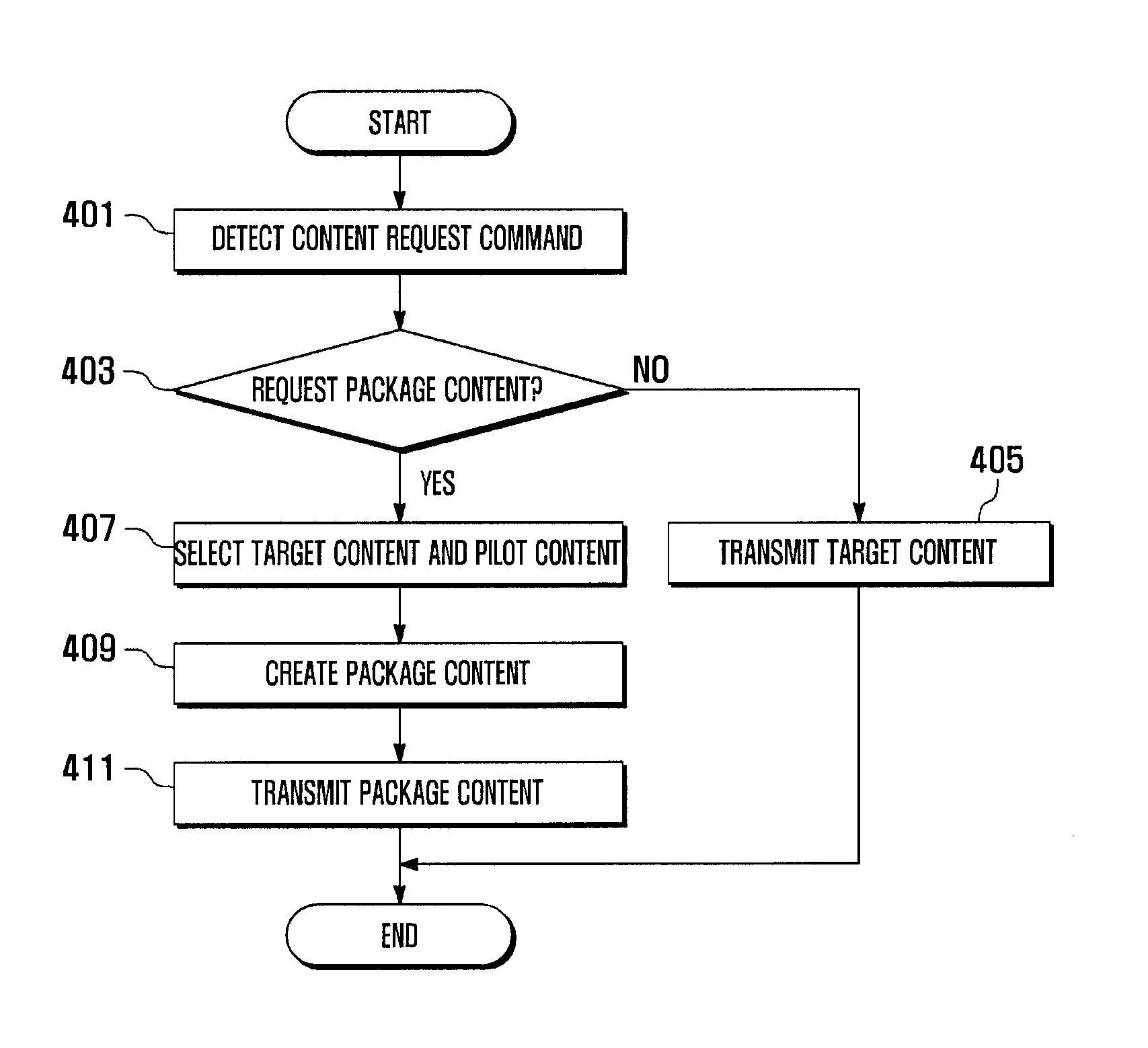

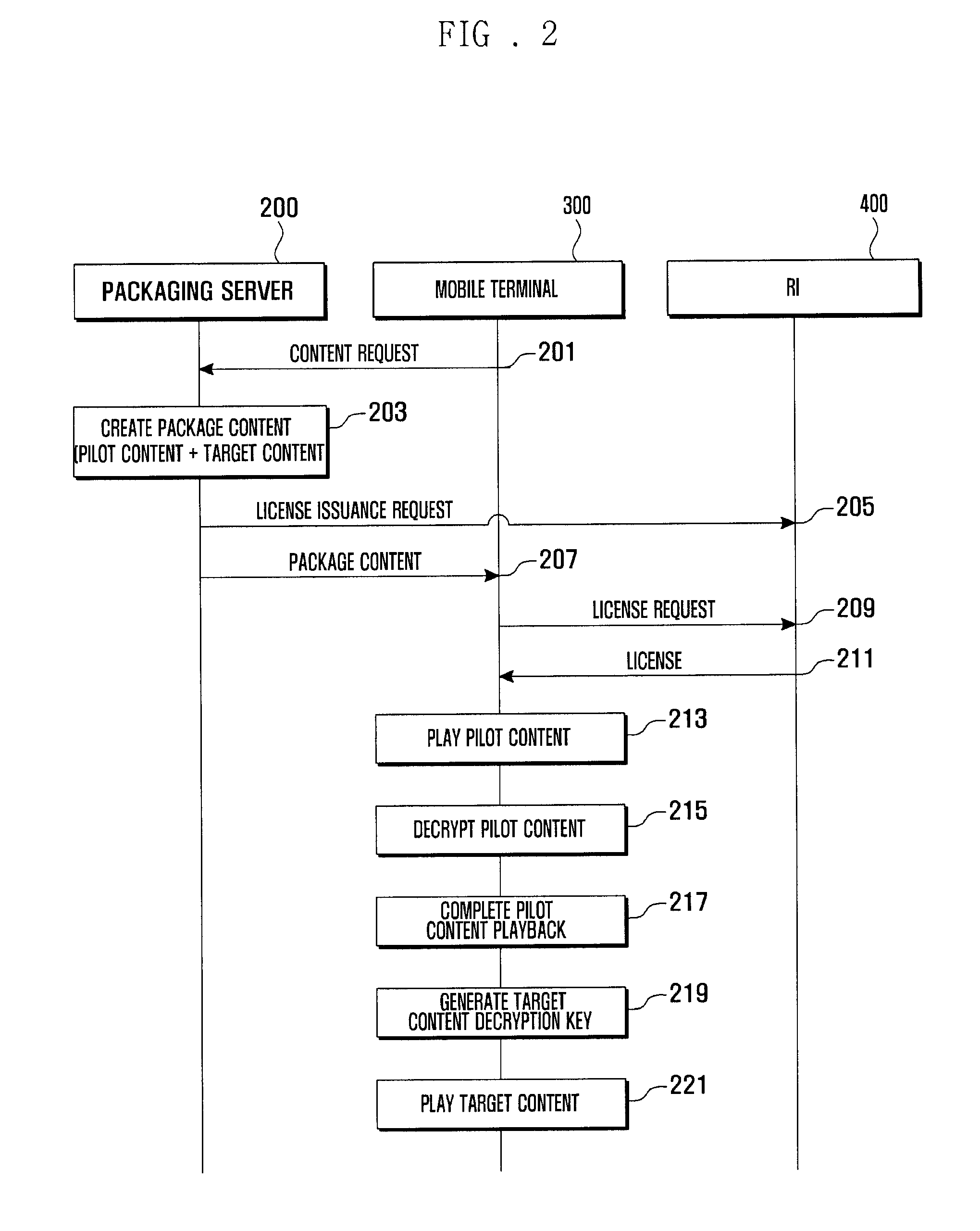

System and method for configuring content object

InactiveUS20100198687A1Improved content object formatEasy to useTelevision systemsTransmissionDigital contentDistribution method

A digital content distribution method and system for delivering a content package including a Digital Rights Management (DRM) content and an advertisement content which is played to generate a license for playing the DRM content is disclosed. The content object format of the present invention includes a target content object; a pilot content object containing specific advertisement data; and a header indicating locations of the target content object and the pilot content object.

Owner:SAMSUNG ELECTRONICS CO LTD

Information service communication network system and session management server

InactiveUS8271667B2Reduce loadEasy to manageSpecial service provision for substationMultiplex system selection arrangementsSession managementApplication server

A session management server, which is provided with a service determination table having a plurality of entries each indicating a service identifier in association with possible particular items of information which may be extracted from a session setup request packet, receives a session setup request packet issued from a client to a particular application server and determines whether the client terminal is authorized to receive an information service by referring to the determination table, in place of the particular application server. When the determination results in success, the session setup request packet is forwarded to the particular application server.

Owner:HITACHI LTD

Method for producing a synthetic material part

ActiveUS20020127345A1High transparencyRapid productionImpression capsGum massageSynthetic materialsViscosity

A method for producing a synthetic material part such as, for example, a dental restorative part, is provided and includes spray applying with a spray device a material having at least a polymerizable synthetic material onto a base in succeeding layers. Each layer of the spray applied material is substantially continuously polymerized by the spray device and has a viscosity which permits working of the applied material in an unpolymerized condition thereof with the spray device. The method also includes hardening the one or more of the already applied layers prior to the application of subsequent layers.

Owner:IVOCLAR VIVADENT AG

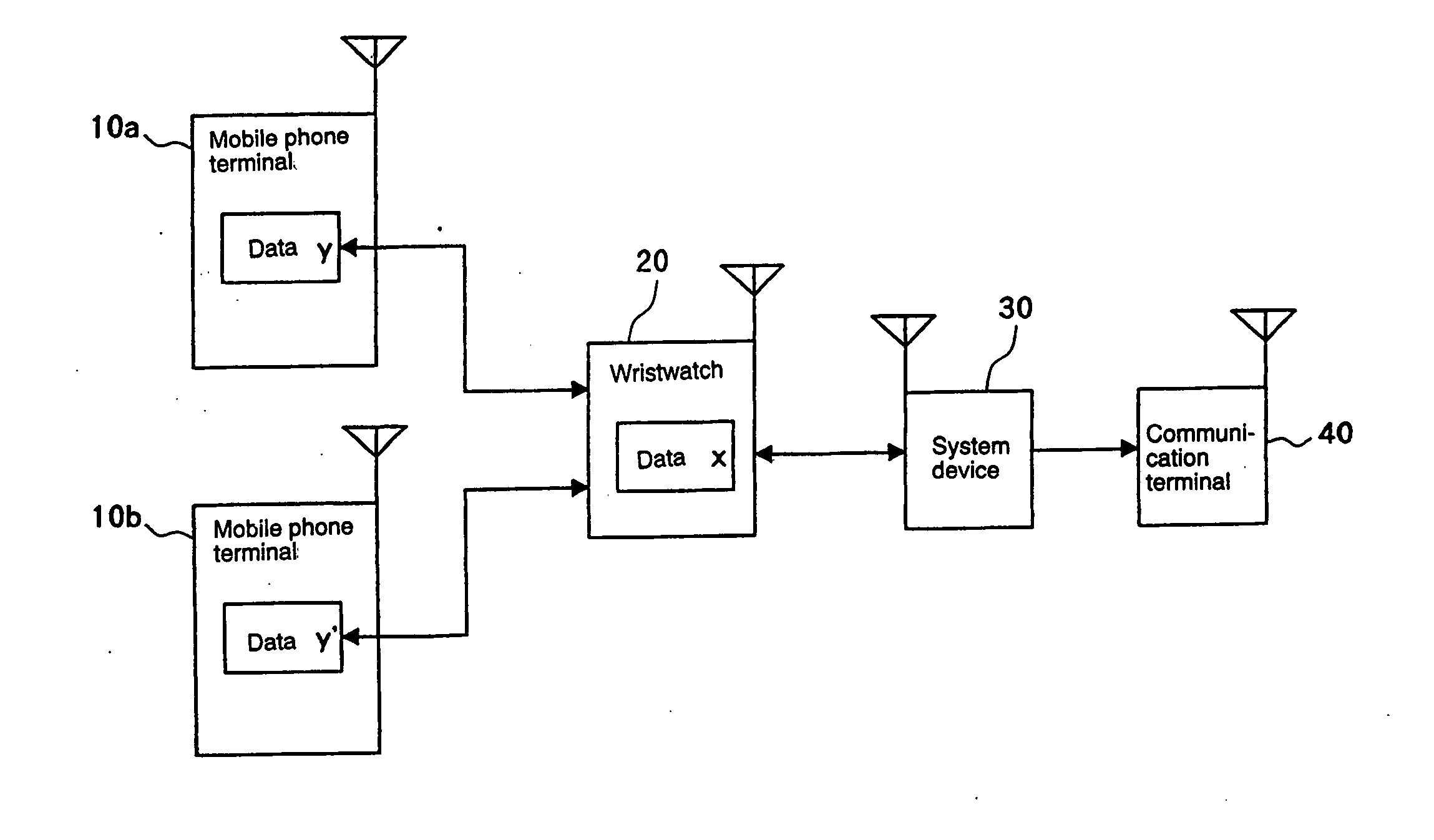

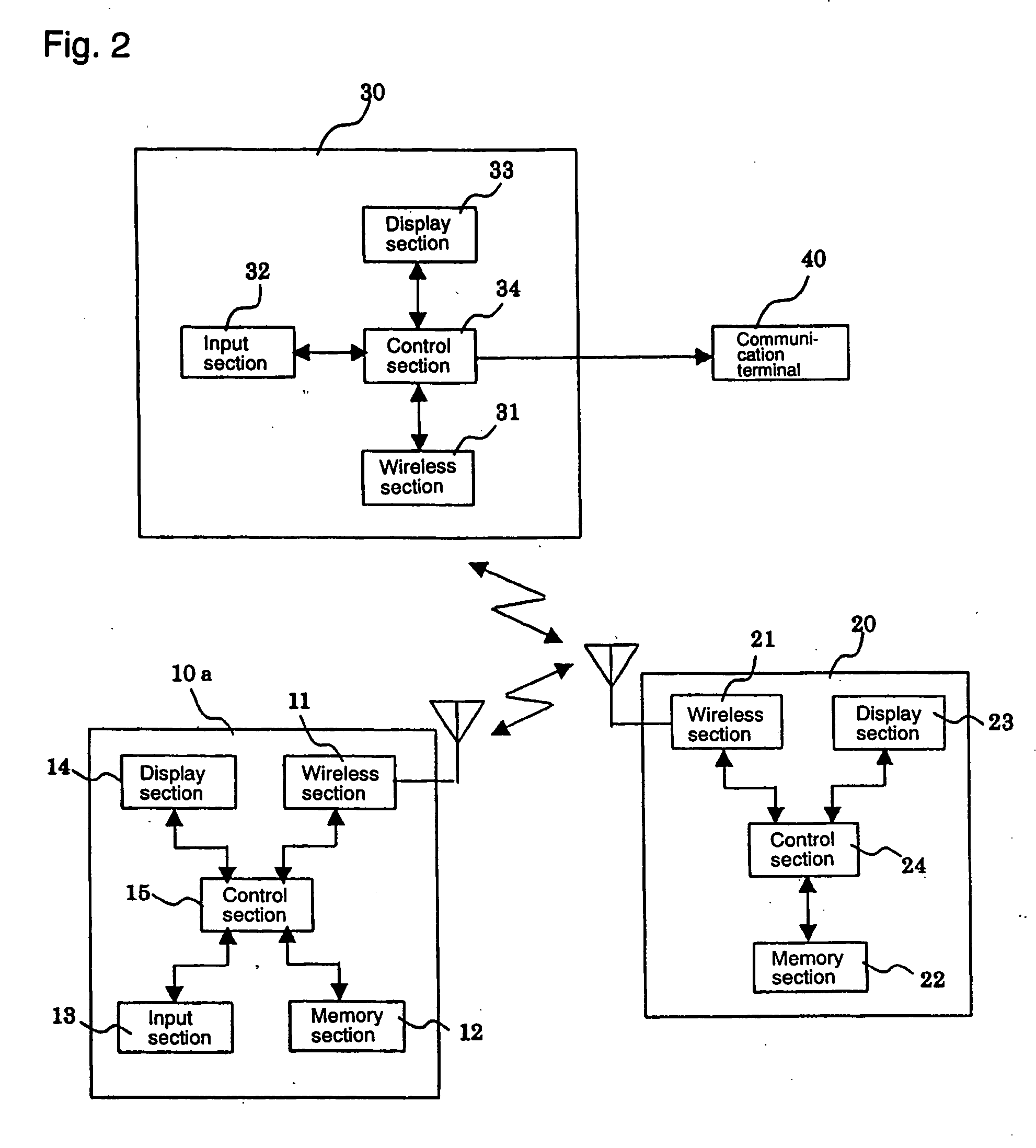

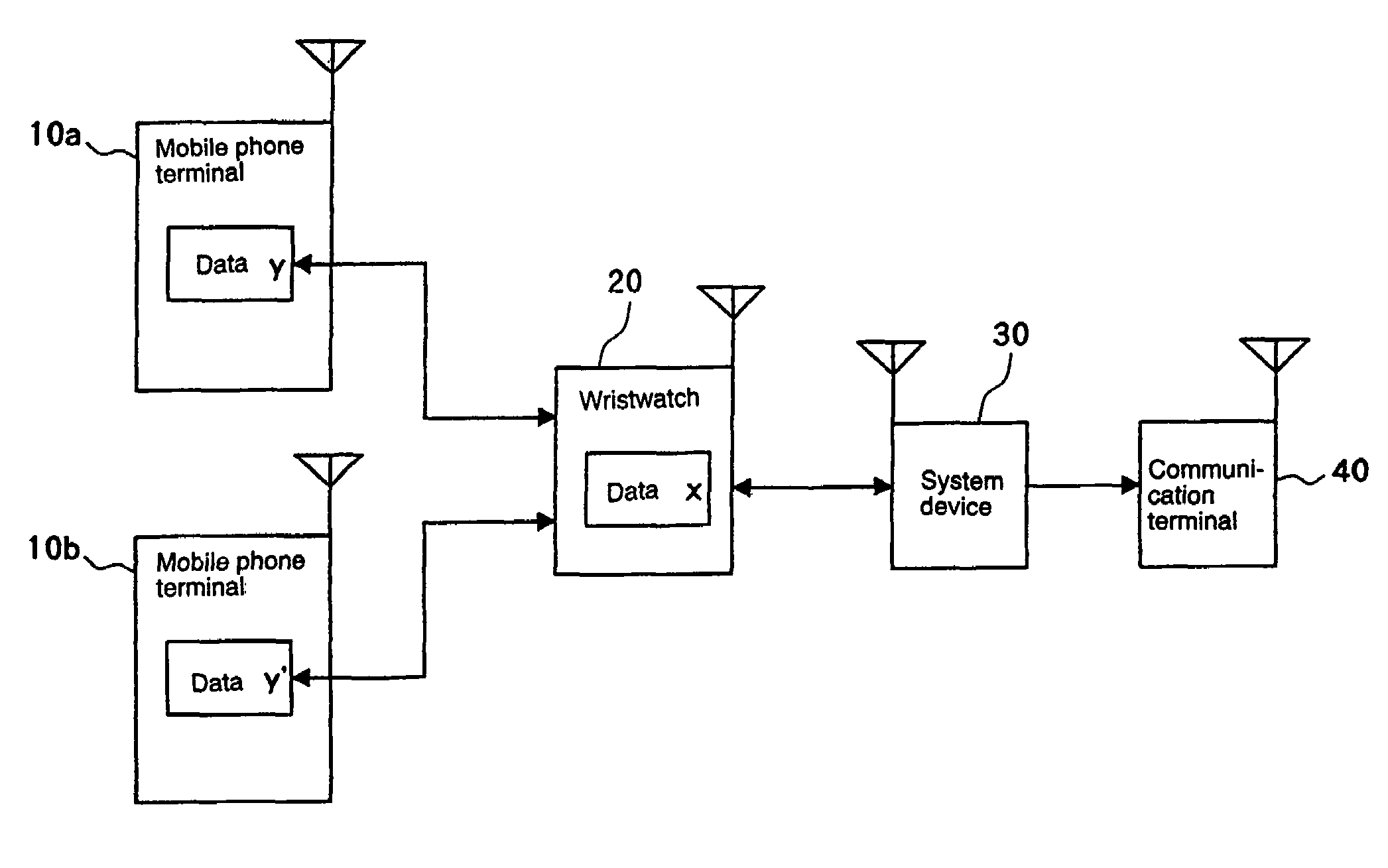

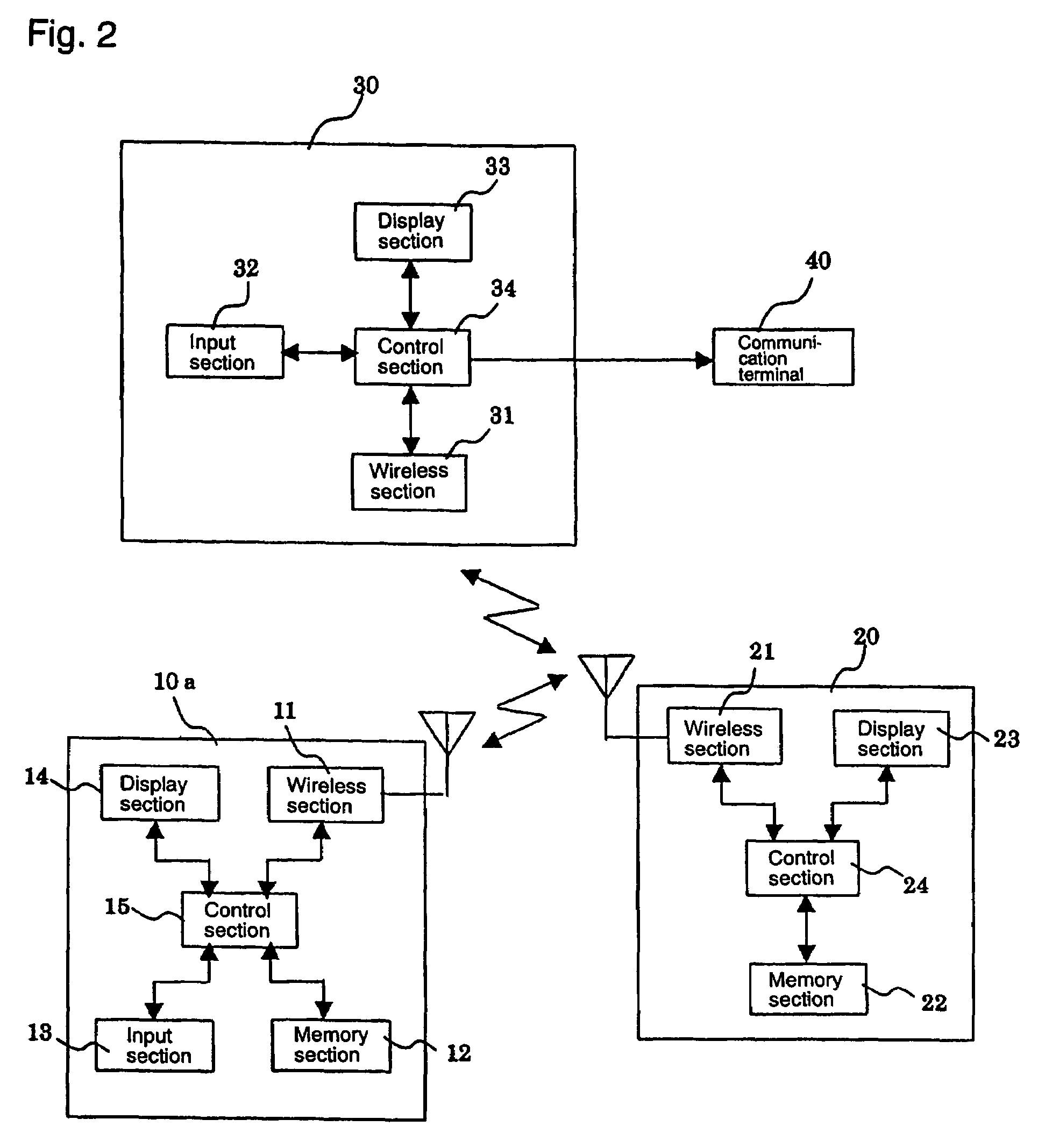

System and method for storing and managing personal information

ActiveUS20050059380A1Reduce cost burdenPromotes its utilizationUnauthorised/fraudulent call preventionEavesdropping prevention circuitsComputer hardwareShort range wireless

A system for storing and managing personal information comprising at least one mobile communication terminal, and a wristwatch capable of making mutual communication with the mobile communication terminal through short-range wireless communication. The wristwatch is provided with: a memory section that stores in advance user's personal information and also registered authentication information for deciding validity of the mobile communication terminal; and a control section that permits the mobile communication terminal to access the personal information stored in the memory section only when the information for authentication received from the mobile communication terminal matches said registered authentication information stored in the memory section.

Owner:LENOVO INNOVATIONS LTD HONG KONG

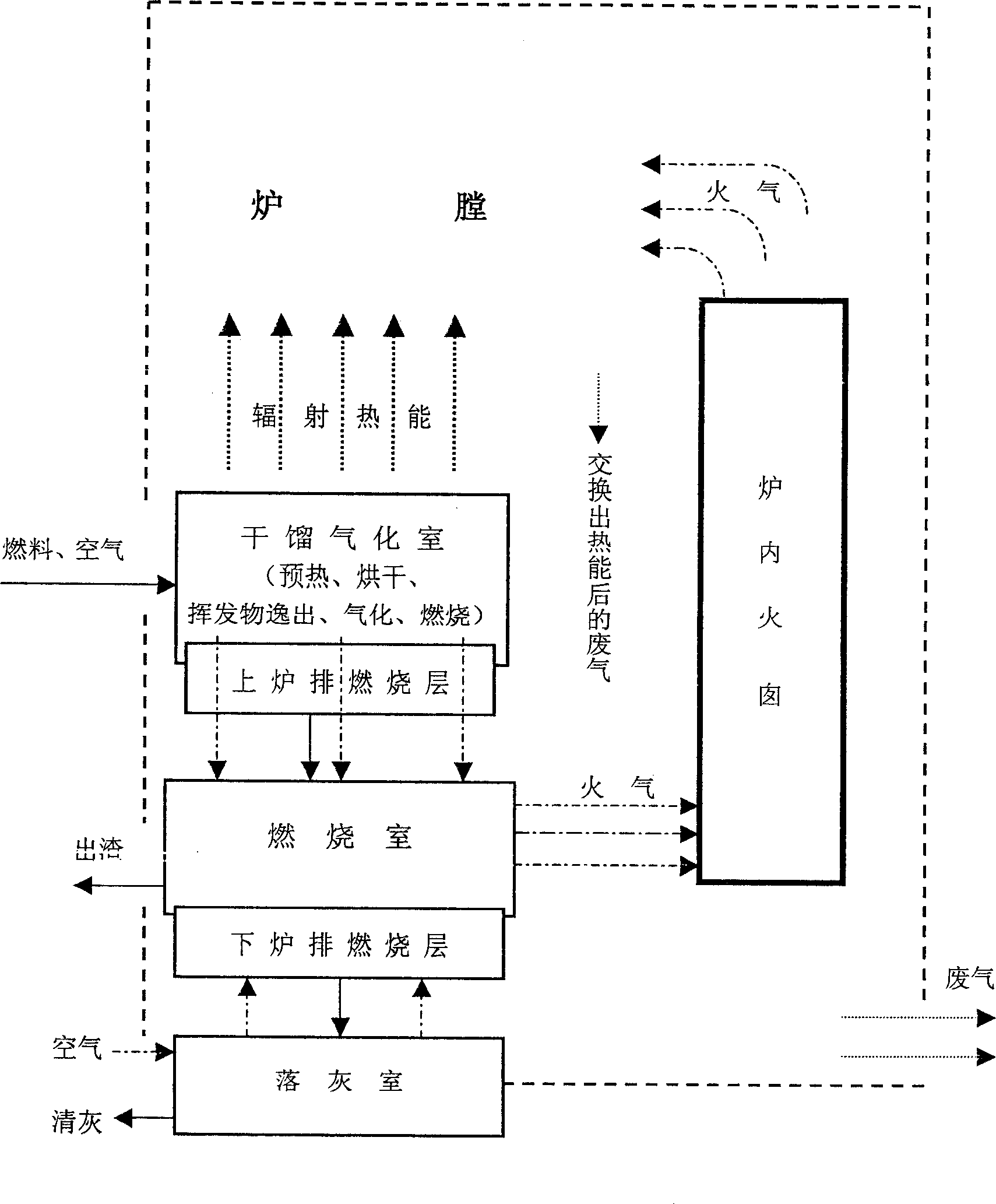

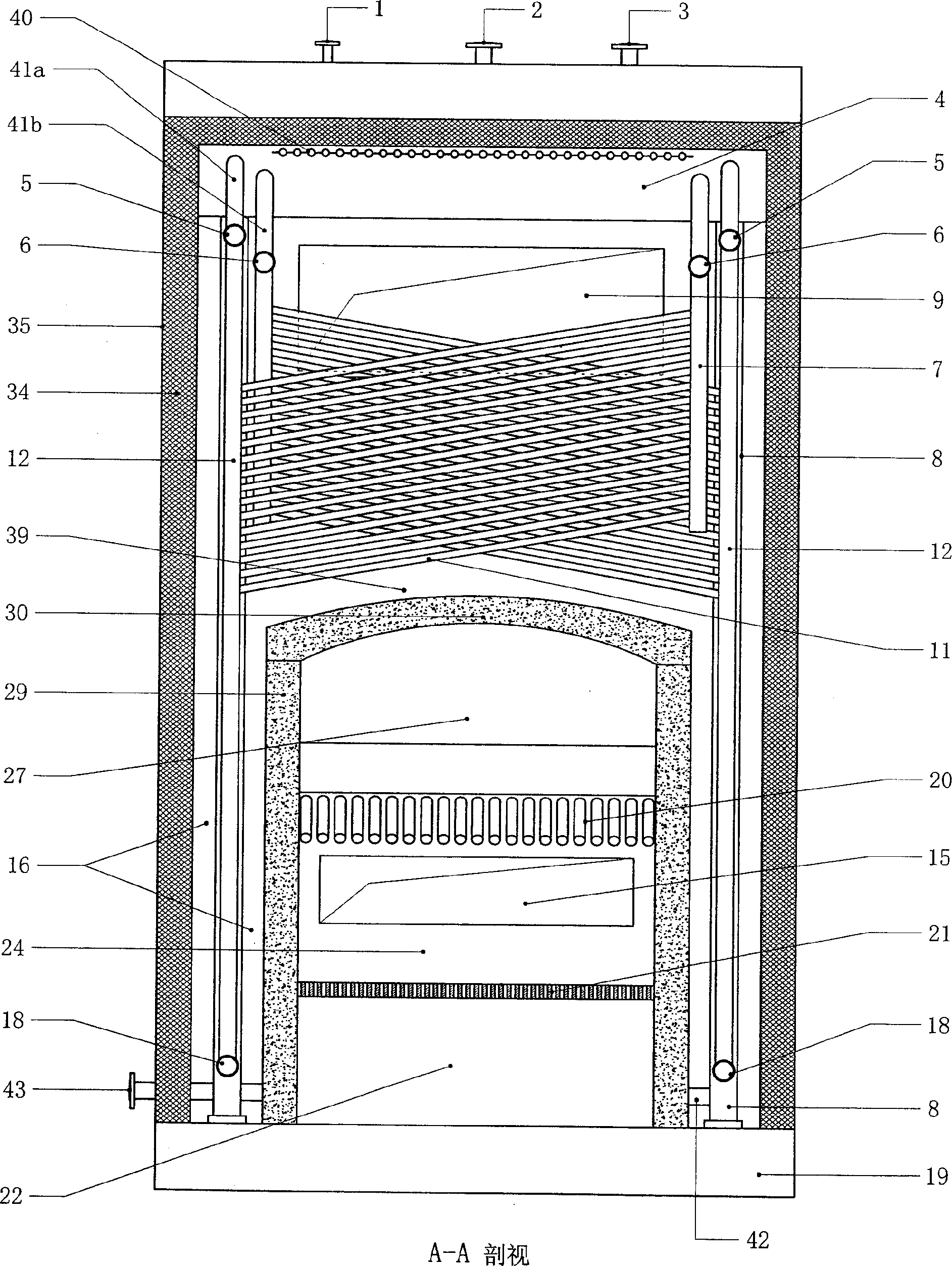

Smokeless burning technique and equipment with fire fontanel being setup inside furnace

InactiveCN1916490AAchieve clean combustionImprove combustion efficiencySolid fuel combustionCombustion apparatusCombustion chamberEngineering

A smokeless combustion device with fire stack in furnace consists of destructive distillation gasification combustion chamber, the second combustion chamber, top fire grate, bottom fire grate, fire stack in furnace, firepot, heated surface and fender. The extensive fuel materials such as raw coal, bulk coal, section coal, wood, straw and agricultural wastes can be used as fuel material of said device.

Owner:周开根

Process and its device for clean burning and value gaining burning of solid fuel

InactiveCN1900590AAchieve clean combustionRealize value-added burningSolid fuel combustionNon-combustible gases/liquids supplyAir preheaterThermal energy

The invention related to heat energy device by using coal, garbage, and biomass as fuel. The firing system is composed of fuel supply system, water vapor input unit, gasification firebox, hearth, water-cooling type or wind-cooling type fire grate in up layer, fixed grate or moving grate in low layer, primary and secondary air supply arrangement etc. Gasification firebox is in quasi-closed position. Water vapor input unit includes water vapor nozzle or plasma generator. In gasification firebox, solid fuel carries out following procedures: preheating, drying, gasifying, desulfurizing, dechloridizing, burning by exsilient volatile, and burning from fuel bed. Passing through full hot fuel bed on fire grate in up layer, flue gas in high temperature enters into hearth to carry out second time of burning so as to eliminating coal smoke. Being fed to gasification firebox, water vapor is in use for restraining generation of coal smoke to implement clean burning and value added burning.

Owner:周开根

System and method for storing and managing personal information

ActiveUS7324806B2Promotes its utilizationReduce cost burdenUnauthorised/fraudulent call preventionEavesdropping prevention circuitsComputer hardwareShort distance

A system for storing and managing personal information comprising at least one mobile communication terminal, and a wristwatch capable of making mutual communication with the mobile communication terminal through short-range wireless communication. The wristwatch is provided with: a memory section that stores in advance user's personal information and also registered authentication information for deciding validity of the mobile communication terminal; and a control section that permits the mobile communication terminal to access the personal information stored in the memory section only when the information for authentication received from the mobile communication terminal matches said registered authentication information stored in the memory section.

Owner:LENOVO INNOVATIONS LTD HONG KONG

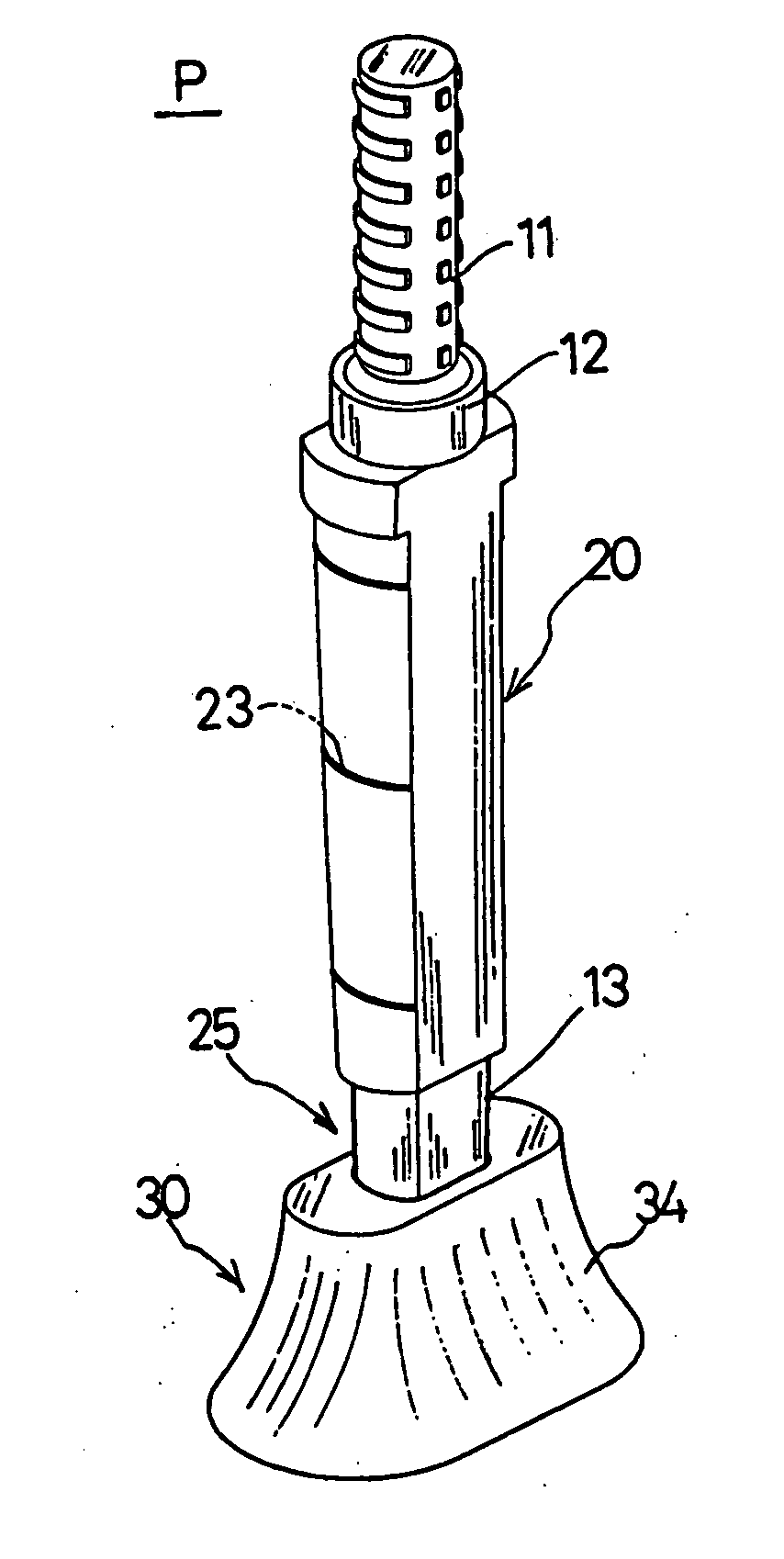

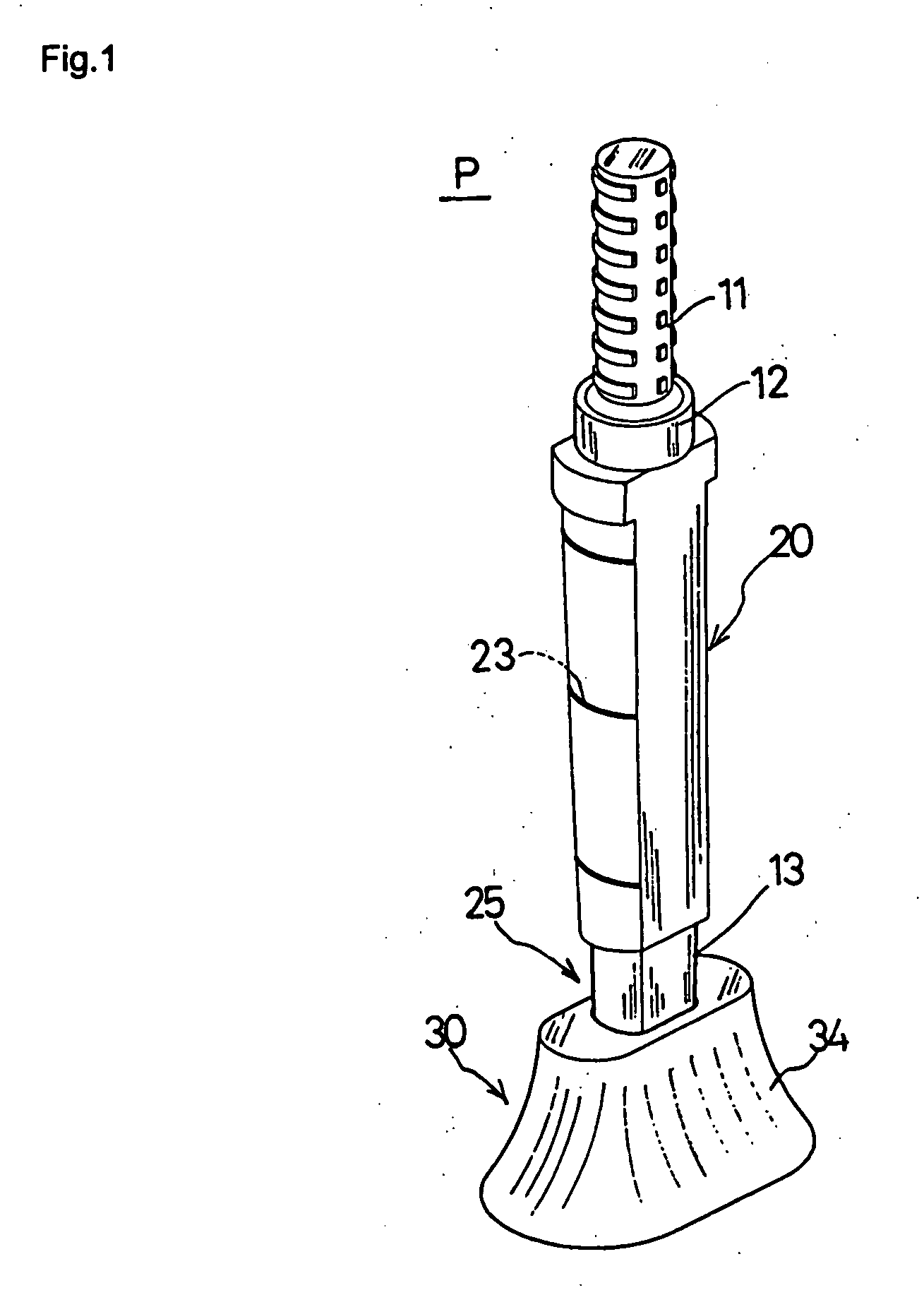

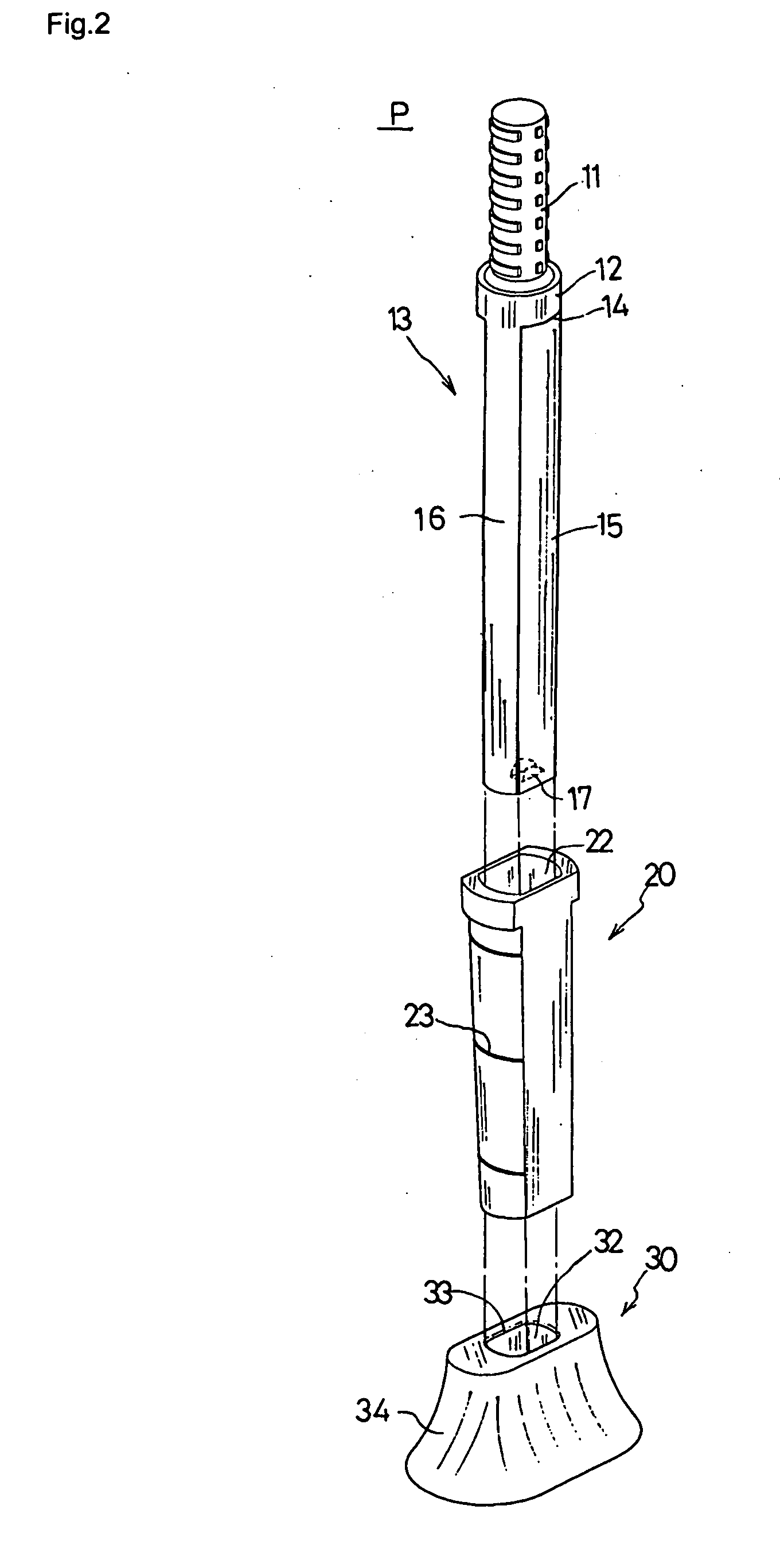

Pin for fixing dental model

InactiveUS20050233278A1Increase workflowIncrease productivityImpression capsDental ArticulatorsAdhesive

Provided is a dowel pin for fixing a dental model with a cap to be used to connect a dental model die with the dental model during the formation of a model of patient's teeth in a dental hospital or a dental laboratory. The dowel pin for fixing a dental model includes a top fixing portion having a knurling formed along an outer circumference such that it is inserted into the bottom of the dental model to a predetermined depth and firmly fixed by an adhesive, and a body formed at a lower portion of the top fixing portion by a predetermined length so that it is inserted or fitted into a pin hole of an articulator or a die on which the dental model is seated, the body having a stopper at its top portion, the stopper having a sectional area larger than that of the top fixing portion and contacting the bottom of the dental model, wherein a body cap having a plurality of separation barriers formed on an outer surface is fitted into the lower portion of the body having the stopper formed thereat, so that the body cap is firmly attached to a hardened dental model die after being embedded therein, and an end cap spaced a predetermined distance apart from the body cap is fitted to a distal end of the body in such a way as to expose a portion of the body.

Owner:KIM YUNSOON

Preparation method of swine pseudorabies vaccine

The invention relates to a preparation method of a swine pseudorabies vaccine, which comprises the following steps of: culturing a virus by using a swine testicle cell, and when one layer of cells grows, inoculating a swine pseudorabies virus; then adding into a cell maintenance medium, statically or rotatably culturing, when the cell suffers from more than 80 percent of pathological changes, harvesting a cell culture, repeatedly freeze-thawing to obtain a cell venom containing supernate, and mixing the cell venom qualified in toxic valence detection with formaldehyde for inactivating; and mixing with an emulsifying agent for emulsifying to obtain the swine pseudorabies vaccine. Compared with the prior art, a strain used for preparing the vaccine has the advantages of stronger toxicity and high virus valence; the swine pseudorabies vaccine has good immunogenicity and long immunization period; and the preparation method has the advantages of reasonable process and lower cost, thereby greatly lowering the cost load of the fish breeding and poultry raising industry.

Owner:SHANGHAI ELITE AGRI SCI TECH GROUP +1

Backlight module and display equipment

The invention relates to a backlight module and a display device. The backlight module comprises a backplate, a convex rib structure, a supporting lug boss, a circuit board, a covering film, an adhesive layer, an adhesive frame and a frame. The backplate is provided with a front surface and a rear surface. The rear surface is provided with a circuit board placing area. The convex rib structure is positioned on the periphery of the circuit board placing area; and the surface of the top part of the convex rib structure is provided with an adhesion area. The supporting lug boss is positioned inside the circuit board placing area. The circuit board is positioned inside the circuit board placing area, is supported by the supporting lug boss and is limited to move in the X direction and the Y direction by the convex rib structure positioned on the periphery of the circuit board placing area. The covering film covers the circuit board and the convex rib structure so as to limit the movement of the circuit board in the Z direction. The adhesive layer is positioned between the covering film and the adhesion area of the convex rib structure. The adhesive frame is positioned on the side of the backplate. The frame is positioned on the outer side of the adhesive frame. The invention also provides a display device with the backlight module.

Owner:AU OPTRONICS CORP

Treatment method of heavy metal wastewater

ActiveCN103265151AExpand pool capacityIncrease project costMultistage water/sewage treatmentChemistryHeavy metals

The invention discloses a treatment method of heavy metal wastewater. The treatment method of heavy metal wastewater comprises the following steps of: delivering heavy metal wastewater supernatant liquor subjected to pretreatment into an A3O biochemical reaction system comprising a hydrolytic acidification reaction tank, an oxygen-poor denitrification reaction tank, an oxygen-poor dephosphorization reaction tank and an activated sludge tank; delivering effluent into a heavy metal membrane reactor, adding obligate bacteria for degrading organic matters in the reactor; and refluxing the wastewater in the heavy metal membrane reactor at intervals into the oxygen-poor dephosphorization reaction tank. According to the treatment method, the A2O biochemical treatment process is replaced by the A3O biochemical treatment process, the reflux ratio is adjusted, and the effects of reducing chemical oxygen demand (COD) of the biochemical system, adsorbing heavy metal, denitrifying and dephosphorizing without increasing the hydraulic retention time, the tank volume and the project cost are strengthened; and besides, a secondary sedimentation tank is replaced by M-MBR, the concentration of activated sludge and the biochemical reaction rate are improved, the COD and BOD are further reduced, and the equipment and process are simple. The treatment method can be popularized and applied on a large scale.

Owner:GUANGDONG XINDAYU ENVIRONMENTAL PROTECTION TECH CO LTD +1

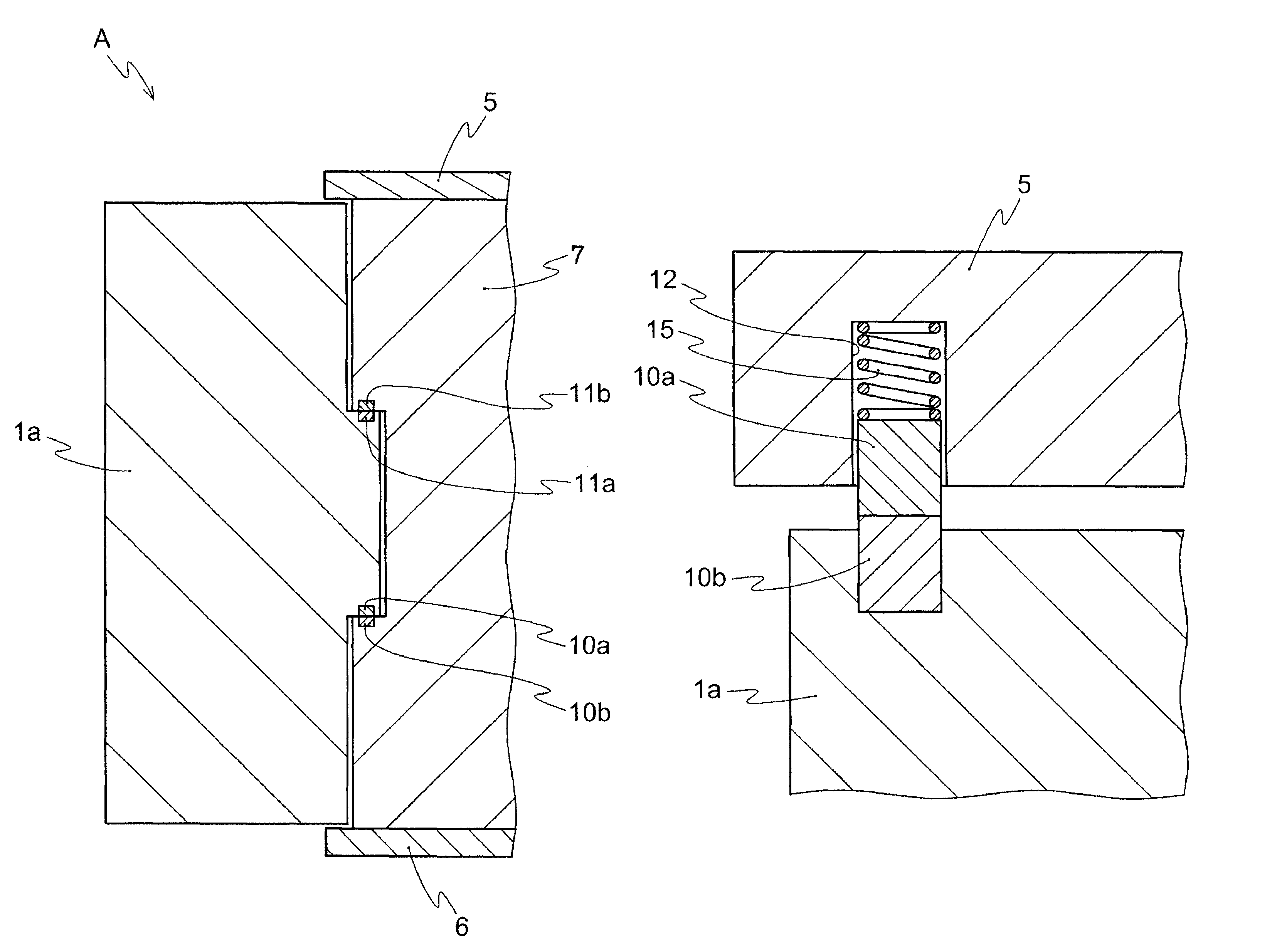

Door opening/closing structure

InactiveUS8839561B2Simple designReduce stocking quantityPinless hingesWing arrangementsEngineeringMagnet

Provided is a door opening / closing structure in which the attachment / detachment of the door is easy in the rotatably opening / closing door. In the door opening / closing structure, an axial member attached to a door and an axial member attached to an object to which the door is attached are arranged to oppose each other in at least one position of the rotatably fixed door, wherein one of the two axial members comprises a magnet and the other comprises a magnetic body or a magnet which attracts each other with the magnet.

Owner:YAGIKEN

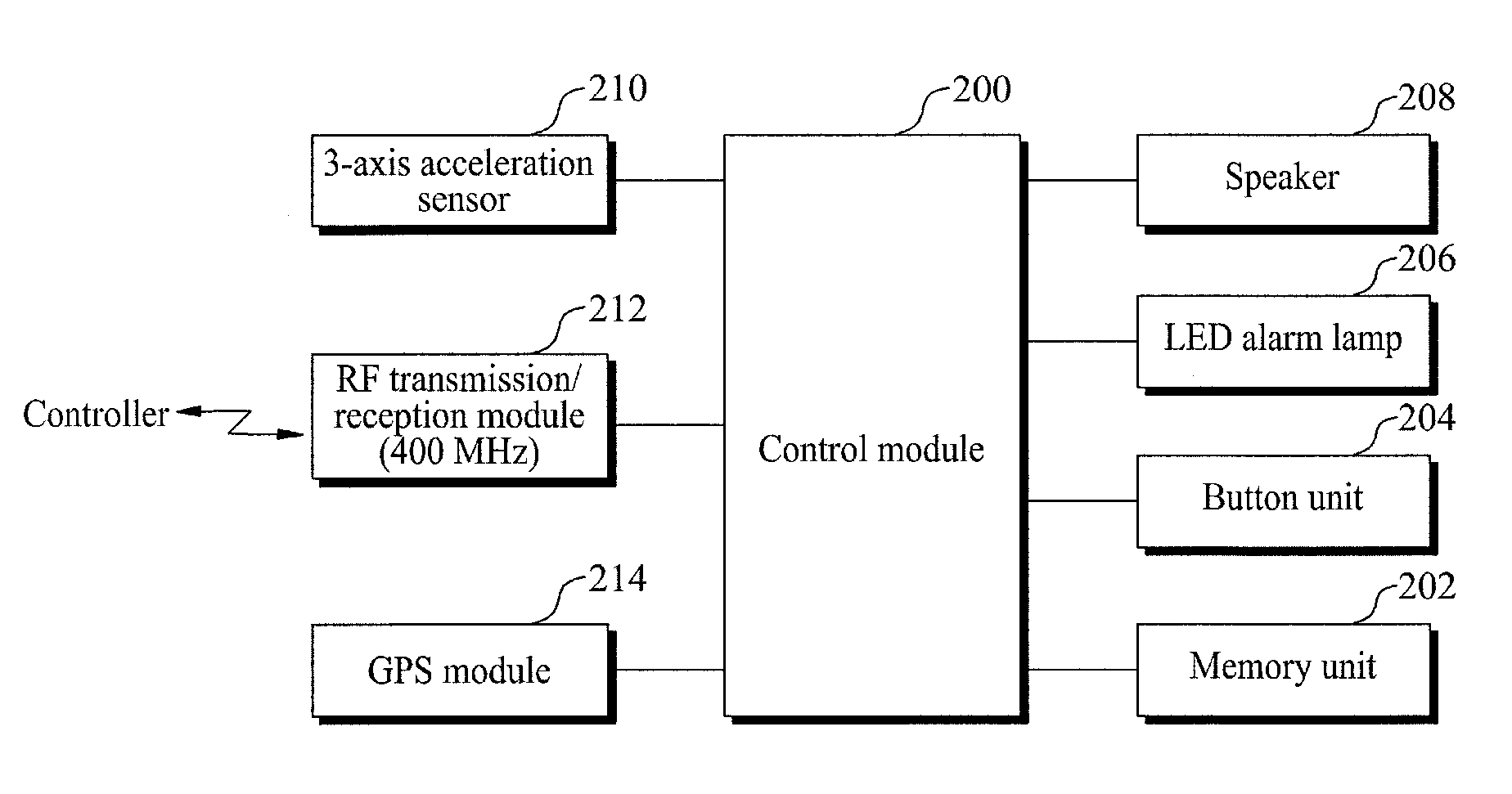

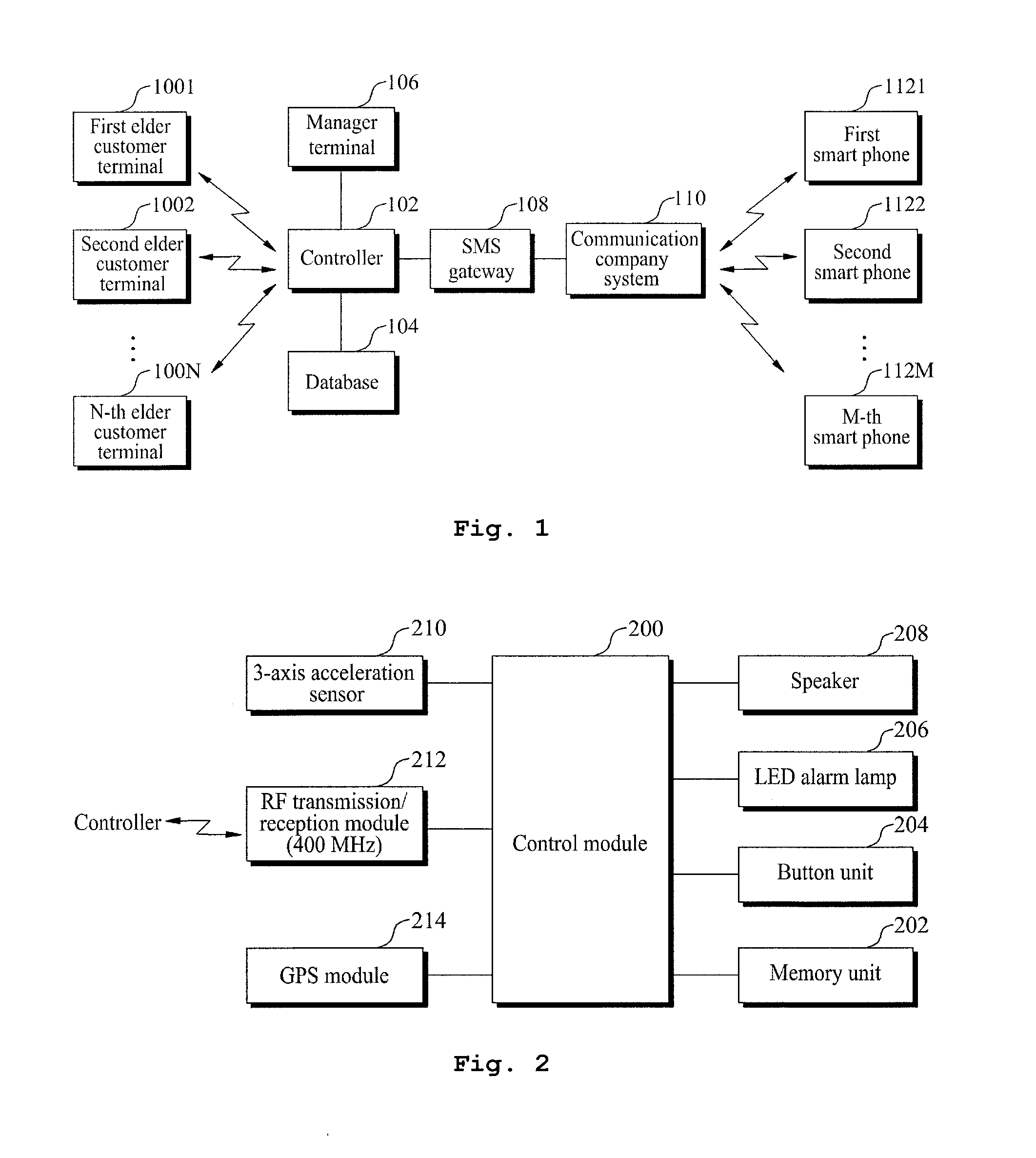

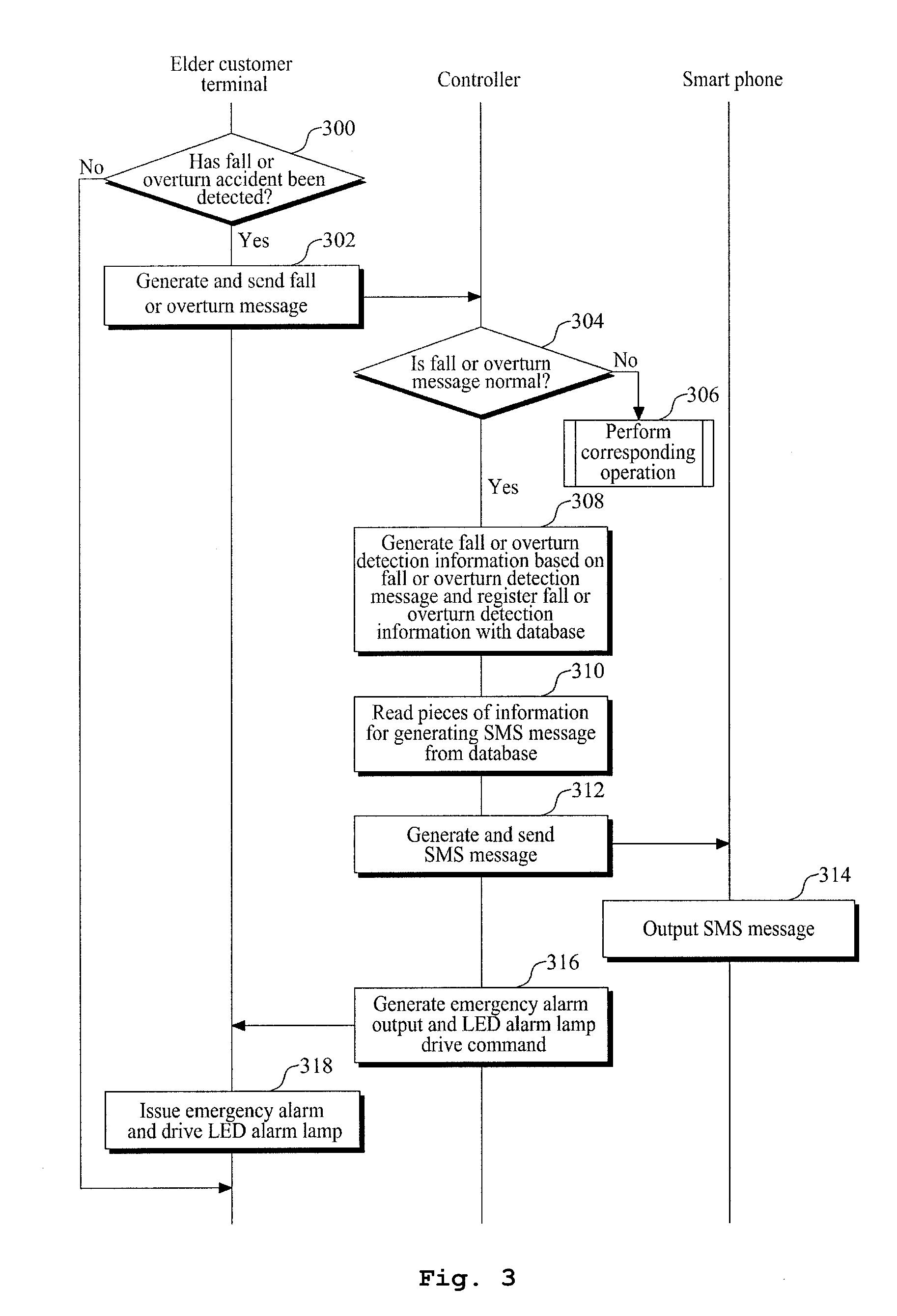

Method, terminal, and system for automatically transferring information about fall or overturn accident using smart phone

InactiveUS20120258682A1Reduce burdenSimplify configurationEmergency connection handlingTelephonic communicationSmart phoneTelephony

A method, a terminal, and a system for automatically transferring information about a fall or overturn accident using a smart phone are provided. The method includes, by an elder customer terminal assigned to an elder customer, detecting a fall or overturn accident via a 3-axis acceleration sensor, and sending a fall or overturn detection message, including its own ID information and a fall or overturn state, to a controller based on the detection, by the controller, receiving the fall or overturn detection message, generating fall or overturn detection information based on the received fall or overturn detection message, and registering the fall or overturn detection information with a database, and, by the controller, configuring a message based on the fall or overturn detection information, and notifying the smart phone of the message based on the fall or overturn detection information.

Owner:IND ACADEMIC COOPERATION FOUND KEIMYUNG UNIV

Independently-defined alteration of output from software executable using later-integrated code

A first executable, such as a computer game, is configured with a second independently operating executable that monitors events on a client operating the first executable. The second executable determines actions to be performed in response to monitored events, as defined by a business logic table. The second executable traps API calls to perform actions altering apparent output of the first executable. The business logic table may be distributed to the client separately. The second executable and the first executable may be combined in a single file. The second executable may be used to provide additional content, including advertising, in the context of an existing game or other software executable.

Owner:PLENUS MANAGEMENT 2007 III

Method for integrated management of messages and electronic device implementing same

ActiveUS20170201485A1Easy to useReduce cost burdenSubstation equipmentMessaging/mailboxes/announcementsMessage passingComputer science

Various embodiments provide an electronic device and method therefor, the electronic device including: a display; at least one communication circuit configured to perform wireless communication with an external electronic device using one of a plurality of communication protocols; a processor electrically connected to the display and the communication circuit; and a memory electrically connected to the processor, wherein the memory stores a plurality of messaging applications for providing one of a plurality of messaging services, and the memory stores instructions which, when executed by a processor, cause the processor to perform operations comprising: displaying a user interface on the display, in which the user interface is configured to provide, to one message thread, the plurality of messaging applications or outgoing and incoming messages associated with the plurality of messaging services; storing, in the memory, a plurality of first identifications (IDs) identifying communication with the external electronic device and / or an account associated with the external electronic device, using one of each of the plurality of messaging applications and the plurality of messaging services; storing, in the memory, at least one second ID identifying a message thread associated with communication with the external electronic device and / or an account associated with the external electronic device; receiving a new incoming message using the at least one communication circuit; and selecting a message thread for the new incoming message at least partially based on at least one of the first IDs and the second ID.

Owner:SAMSUNG ELECTRONICS CO LTD

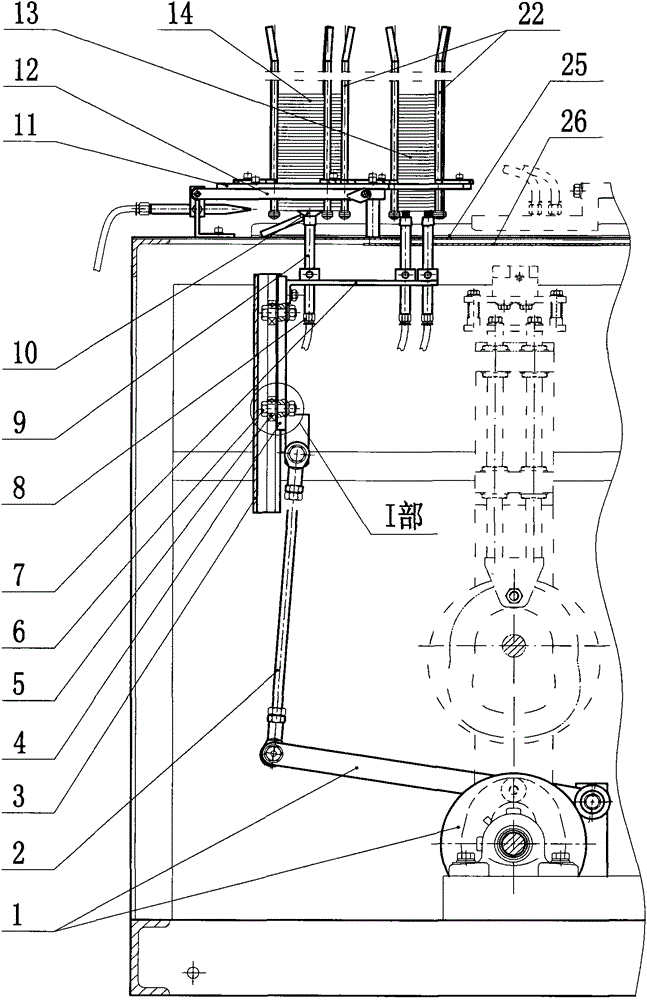

Suction and release double paper mechanism of sticky handle paper cup forming machine

ActiveCN103317776BSolve the problem of hot handsReduce cost burdenPaper/cardboard articlesCost burdenPulp and paper industry

A double paper piece absorbing and releasing mechanism for a pasted handle type paper cup forming machine comprises an absorbing and releasing structure and a stacking structure. A cam rocker drive mechanism is connected with a connecting rod to form the absorbing and releasing structure, the connecting rod is movably connected upwards with a sliding plate, rollers and pins, the sliding plate is sequentially connected upwards with a pipe seat, suction pipes and suction nozzles, and a paper frame plate is arranged above the suction nozzles. The stacking structure mainly comprises the paper frame plate, a paper frame strip, a support leg, a blowing seat, a blowing pipe, a horizontal shaft, a support rod, a frame leg, paper stoppers, paper blocking rods and the like. The paper blocking rods are arranged on the peripheries of a front opening and a rear opening of the paper frame plate, and each paper blocking rod is used for blocking double paper pieces. The double paper piece absorbing and releasing mechanism has the advantages that the double paper pieces are stacked by the aid of a single paper frame, a single cam rocker drives two groups of suction nozzles to move, a paper cup with a handle can be produced once, the problem that the paper cup is too hot to handle is solved, and the cost burden of secondary manufacture is relieved.

Owner:瑞安市胜利机械有限公司

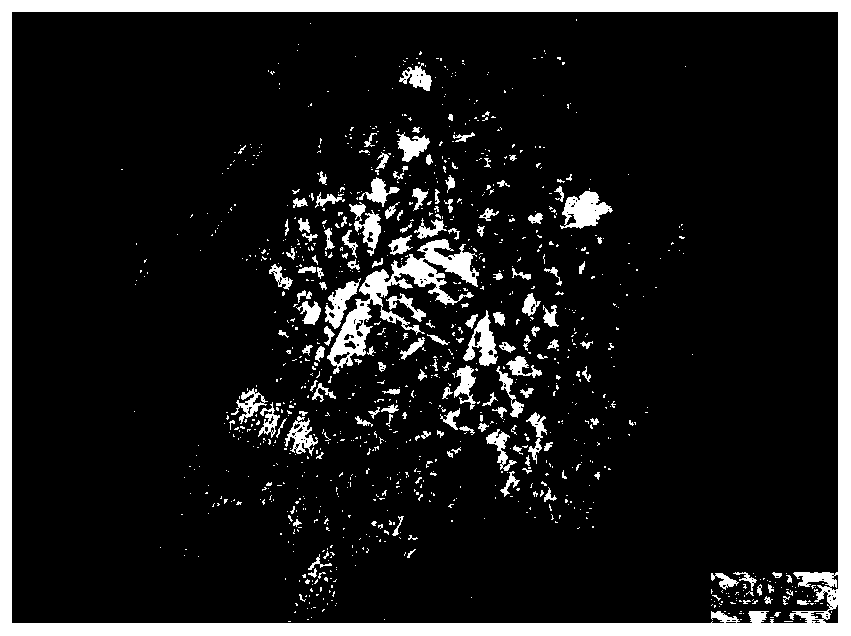

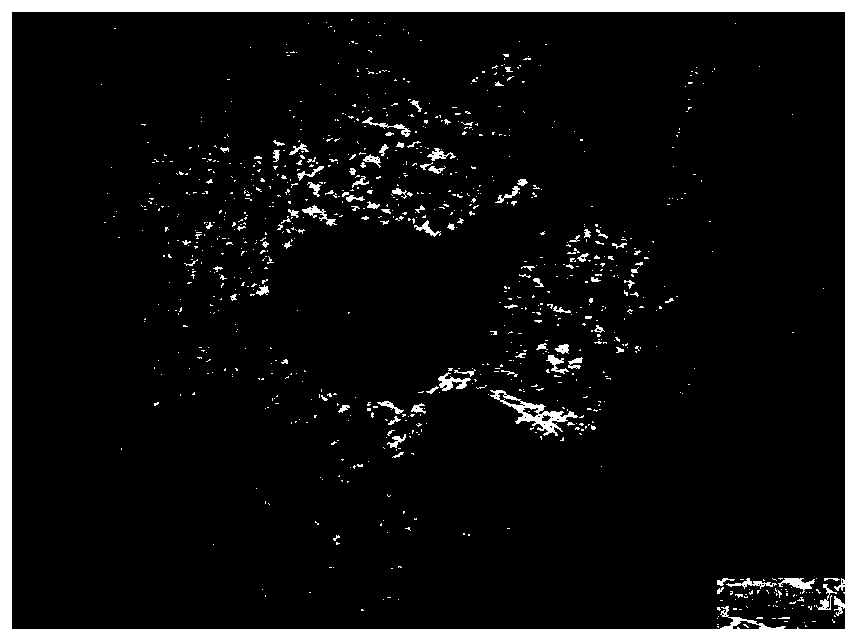

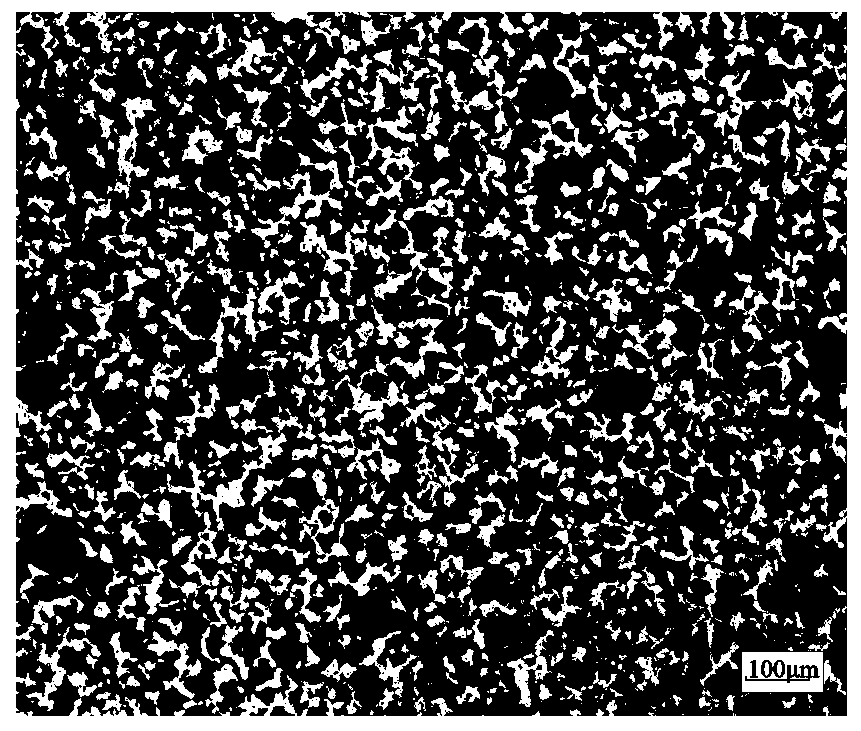

Rolling process of improving 38CrMoAl steel rolling state structure

InactiveCN110180893AImprove uniformityRefined grain sizeTemperature control deviceMetal rolling arrangementsMetallurgyNucleation

The invention discloses a rolling process of improving a 38CrMoAl steel rolling state structure. The rolling process is characterized by comprising the following steps of 38CrMoAl steel blank selection, steel blank heating, steel blank rough rolling, steel blank medium rolling, steel blank finish rolling and steel cooling. The rolling process of improving the 38CrMoAl steel rolling state structurehas the following advantages that a relatively low final rolling temperature is controlled, so that the surface temperature of a rolled piece is lower than a temperature of a core portion in the process, the steel core portion obtains a relatively large compressive stress in the rolling process, the structure uniformity is greatly improved, and crystal grains are further refined; the final rolling temperature is lowered to be close to the actual critical phase change point Ar3, a phase change from gamma to alpha is promoted, and a nucleation site of ferrite is increased, so that a structure morphology of a product is ferrite and pearlite structures in a balanced state; and the rolling process is green and environmentally friendly, does not pollute the environment, is capable of lowering the cost and increasing the benefit and particularly has important significance of controlling the online structure and the performance of medium-low carbon alloy structural steel.

Owner:XINING SPECIAL STEEL +1

Liquid crystal display

ActiveCN1945402AReduce lossIncrease usageNon-linear opticsLiquid-crystal displayArray data structure

An LCD display includes: backlight, the first polarizer that is installed at the top backlight, the first transparent substrate that is installed at the top of the first polarizer, collector array that is installed at the surface of the first transparent substrate polarizer and adjacent to the first polarizer, and each collector array includes: a first refractive block and a number of second high refractive blocks that is located on two sides of the first block, and the two second blocks in the symmetry position have the same width. There is a low refractive block between one first and one second high refractive block, and the width of the first is greater than the second. The second transparent substrate is installed on the top of the first one and has the transparent area that is allocated corresponding to collector array. The LCD layer is located between the first and second transparent substrate. A second polarizer is installed at the top of the second transparent substrate. The invention can effectively lower the leaky light phenomenon when dark.

Owner:AU OPTRONICS CORP

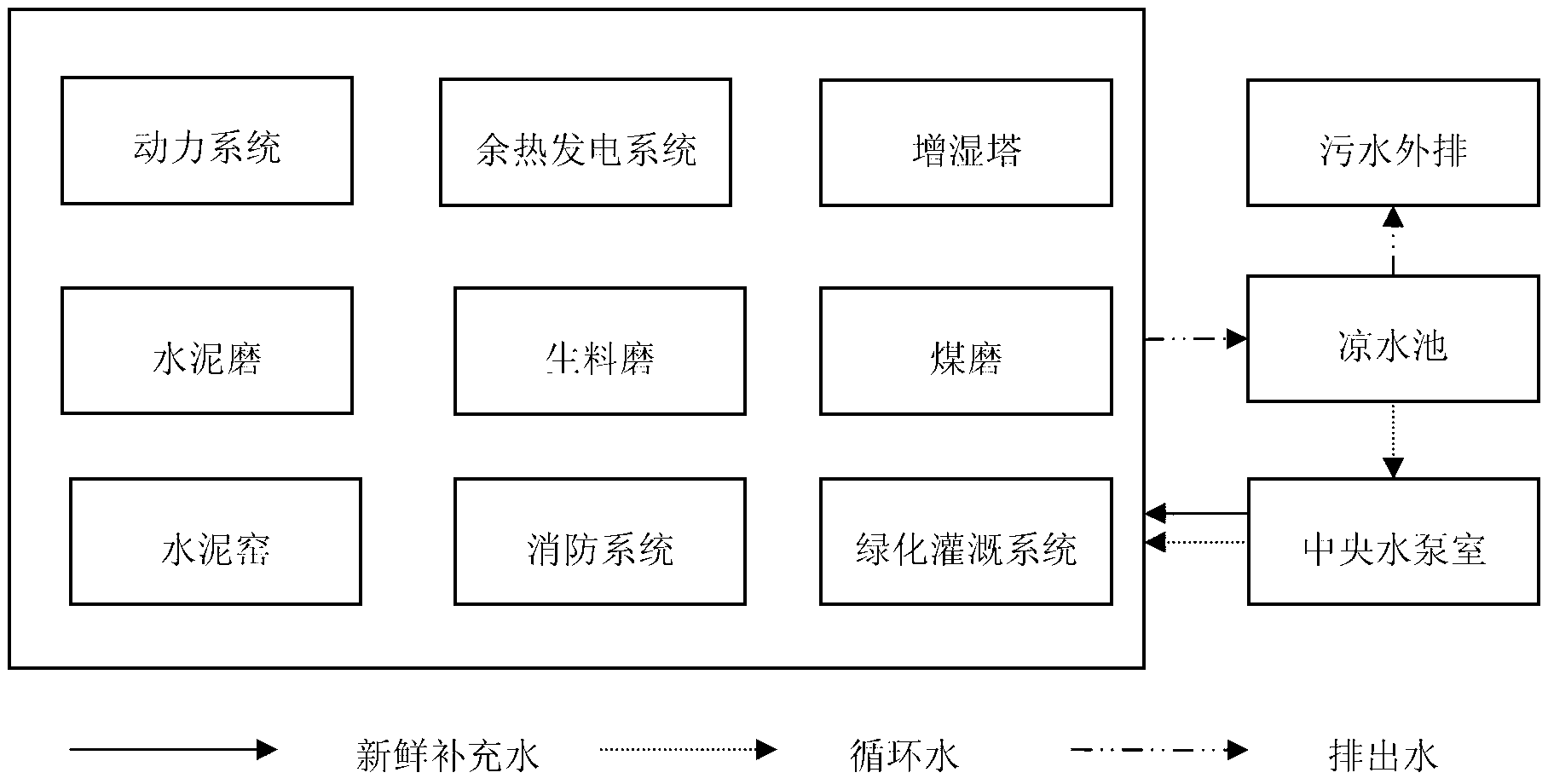

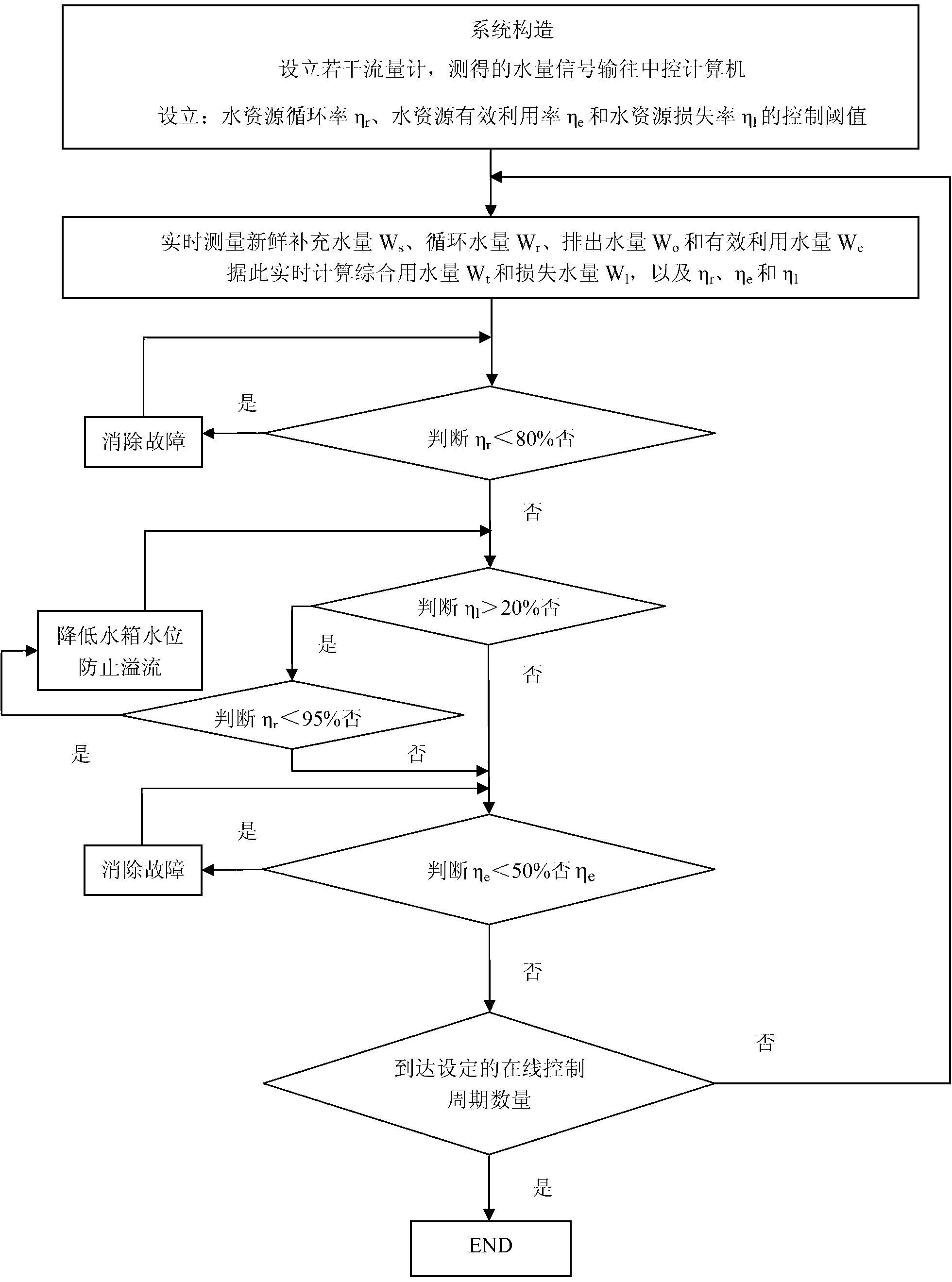

Metering and on-line control method of cement production water footprint

ActiveCN103226350AImprove recycling rateSave resourcesTotal factory controlProgramme total factory controlWater useEngineering

The invention relates to a metering and on-line control method of a cement production water footprint and belongs to the field of water resource management of cement production. The metering and on-line control method is characterized in that the method is accomplished in a cement production water footprint metering and on-line control system controlled by a central control computer, and comprises the steps of measuring fresh water supplement quantity, circulating water quantity, discharged water quantity and effective water utilization quantity in real time under the control of the central control computer, accordingly working out comprehensive water consumption, water loss, and a circulating rate, an effective utilization rate and a loss rate of a water resource, sequentially judging whether the circulating rate of the water resource reaches a standard, whether the loss rate and the circulating rate of the water resource meet a set threshold simultaneously, and whether the effective utilization rate of the water resource is higher than 50%, and adopting failure removal measures corresponding to different stages till meeting a set object. The method facilitates boosting the green progress of the cement industry under the condition of saving the water resource, and facilitates saving the initial investment and operating cost.

Owner:BEIJING UNIV OF TECH

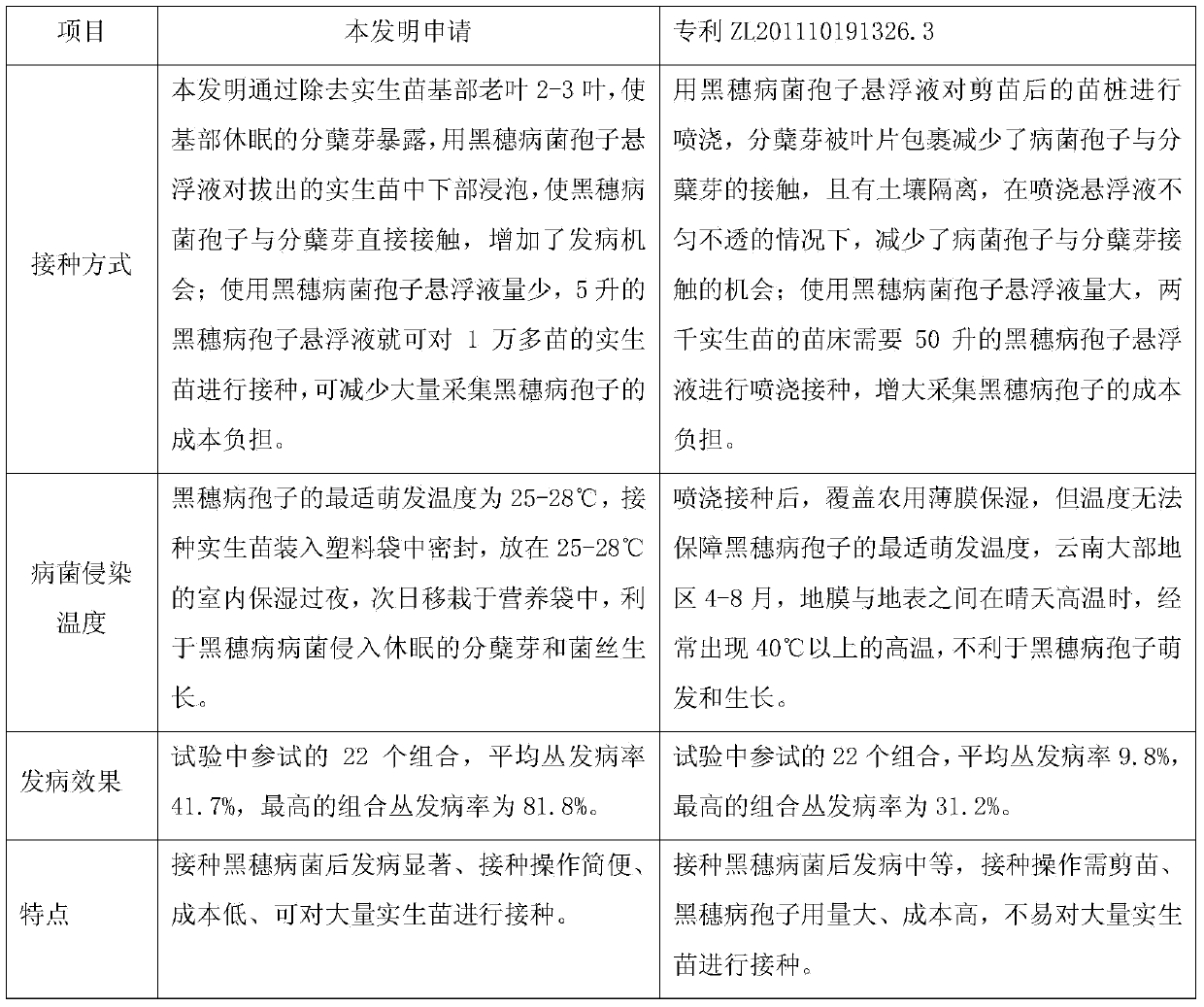

Efficient smut inoculation method for sugarcane seedlings

InactiveCN104170668AEasy to operateLow costMicrobiological testing/measurementHorticulture methodsSporePhacus

A smut inoculation method for sugarcane seedlings comprises the steps as follows: after seven true leaves of each seedling are grown out, the seedling is pulled out from an incubator, the middle-upper parts of the leaves are cut off, 2-3 old leaves at the base part are removed, a spore suspension with the ustilago scitaminea syd concentration of 1*10<7> spores / ml is adopted for soaking the middle-lower part of the pulled seedling for 10 min, and the seedling is sealed, placed in a room at the temperature of 25-28 DEG C overnight in a moisture preserving manner, transplanted in a nutrient bag next day and planted in the field after survived; and combination morbidity is researched during final selection, combination with the combination morbidity higher than 25% is eliminated, and seedlings with good and healthy characters are screened out to enter a next stage for observation. According to the invention, morbidity of the seedlings inoculated with ustilago scitaminea syd are remarkable, the reproducibility is good, the test cycle is short, the operability is high, the cost is low, and a large quantity of seedlings can be inoculated; and the method can be applied to a sugarcane variety breeding institution for new sugarcane variety breeding resistant to sugarcane smut.

Owner:SUGARCANE RES INST OF YUNNAN ACADEMY OF AGRI SCI

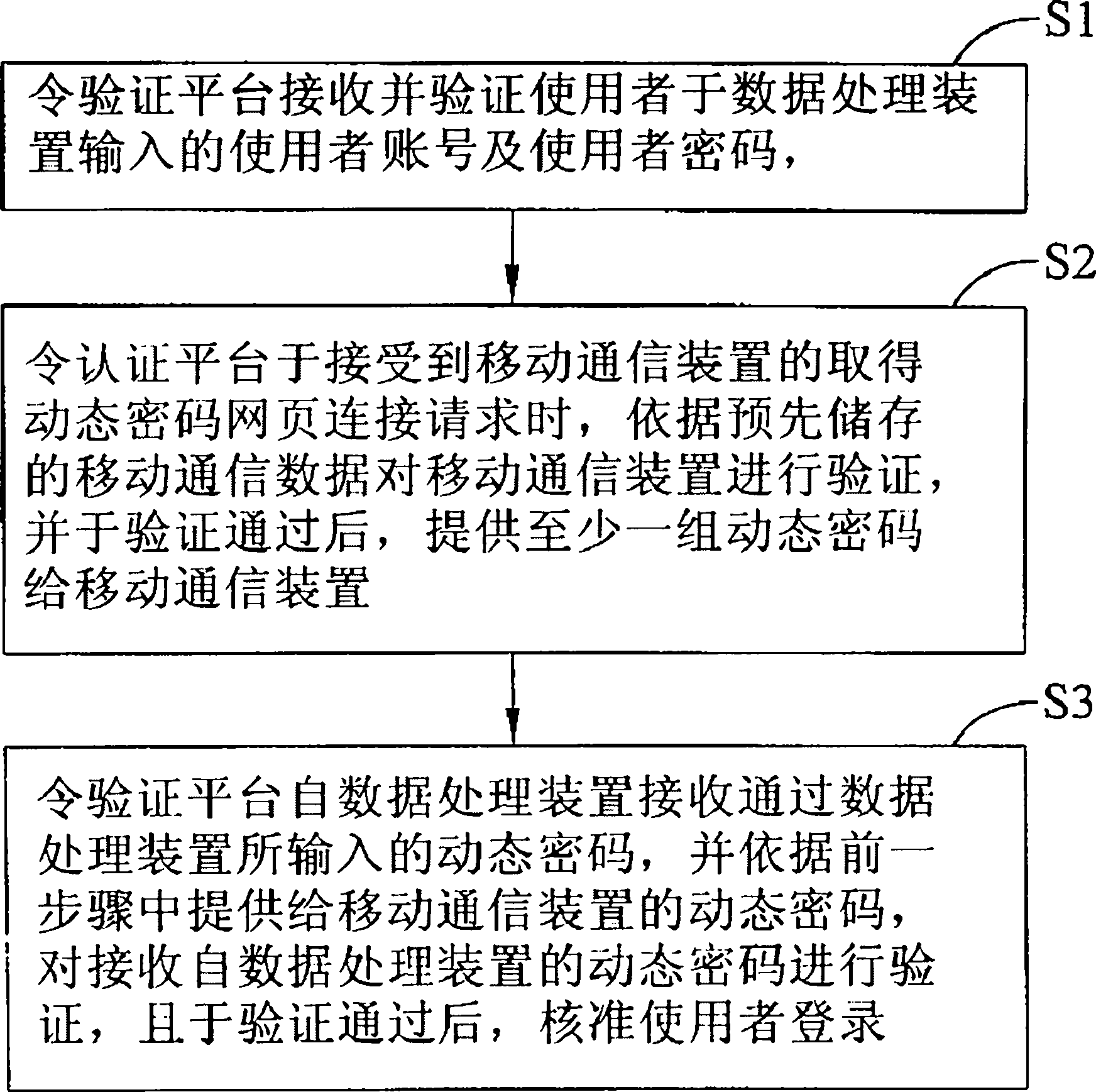

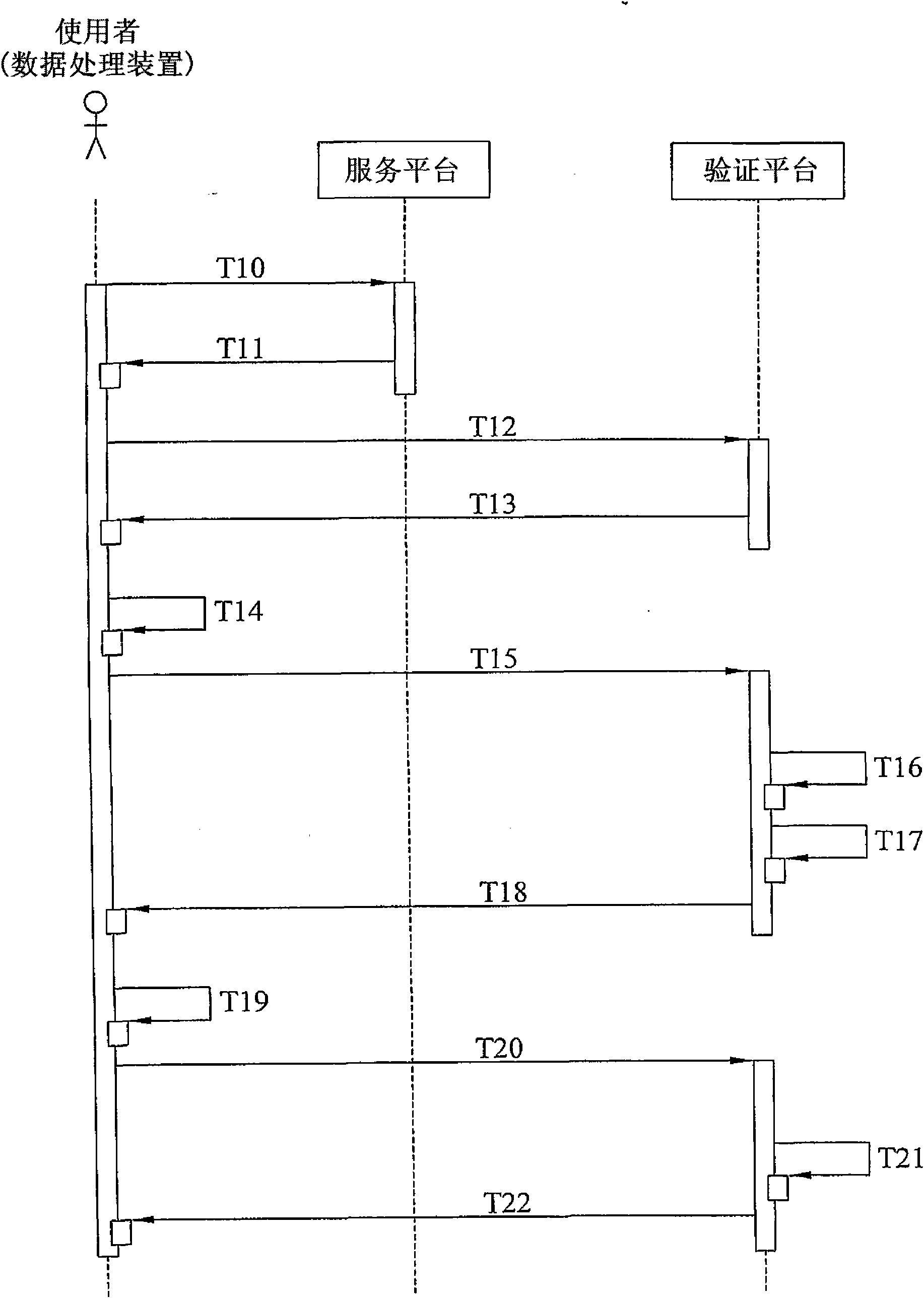

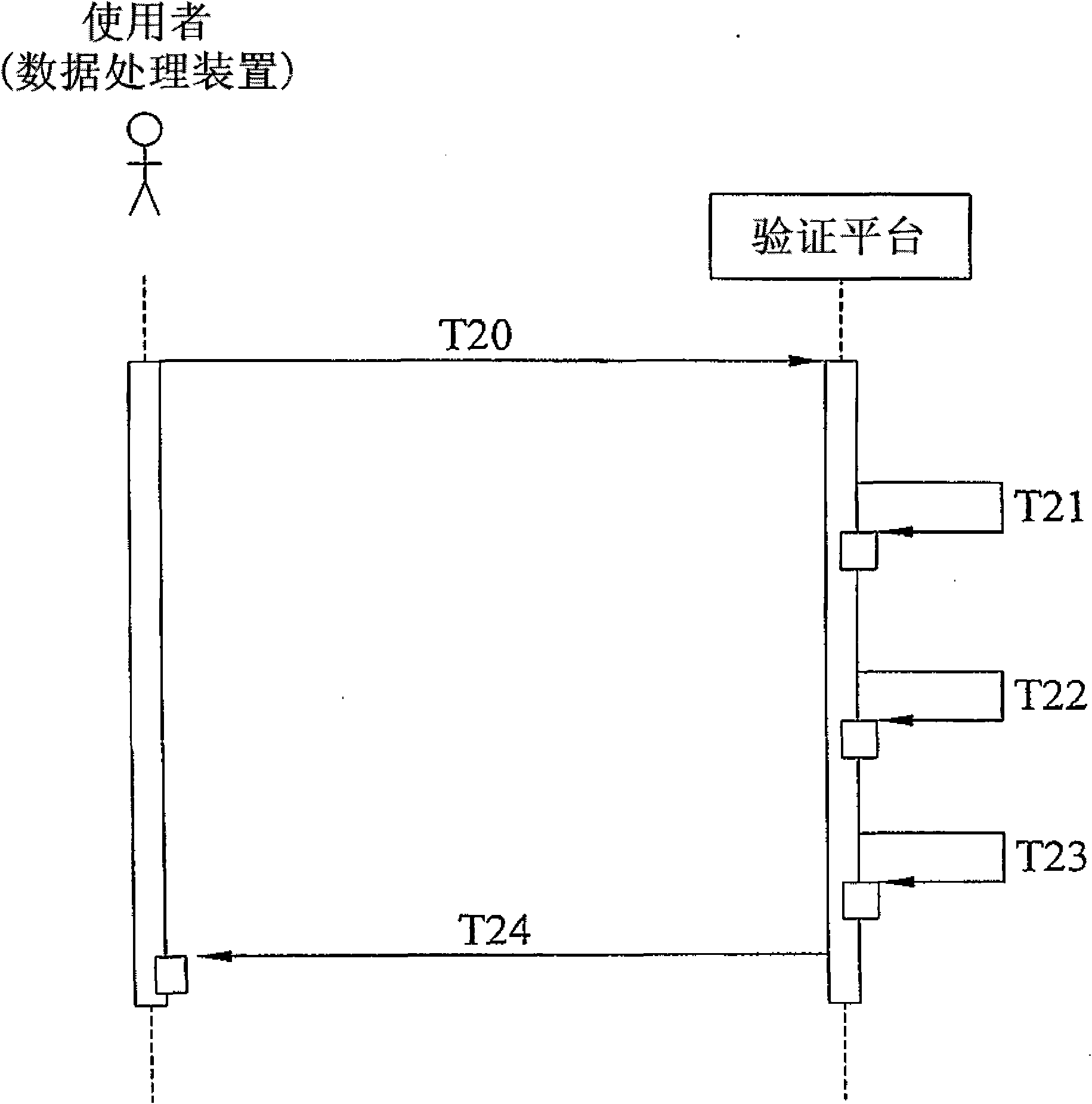

Method for identity authentication of Internet user

InactiveCN102404305AReduce cost burdenImprove the safety of useUser identity/authority verificationInternet usersPassword

A method for the identity authentication of an Internet user is disclosed, for performing identity authentication on a user via a data processing device connected with a service platform and a mobile communication device connected with a verification platform. The method for the identity authentication of an Internet user comprises the following steps of: firstly ordering the service platform to receive and verify a user account and a user password input in the data processing device by a user; after the verification is passed, ordering the verification platform to verify the mobile communication device according to the pre-stored mobile communication data, and providing a dynamic password for the verified mobile communication device; then ordering the verification platform to receive the dynamic password input by the user from the data processing device, and verifying the received dynamic password according to the dynamic password provided for the mobile communication device; and after the verification is passed, approving user login operation performed by the user. Via the method for the identity authentication of an Internet user, the security of user login operation and Internet use is further improved.

Owner:CHUNGHWA TELECOM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com