Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Realize elastic scaling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A service uninterrupted load balancing method and system

ActiveCN109842651AJudgment does not affectNo human intervention requiredTransmissionDistributed computingShared memory

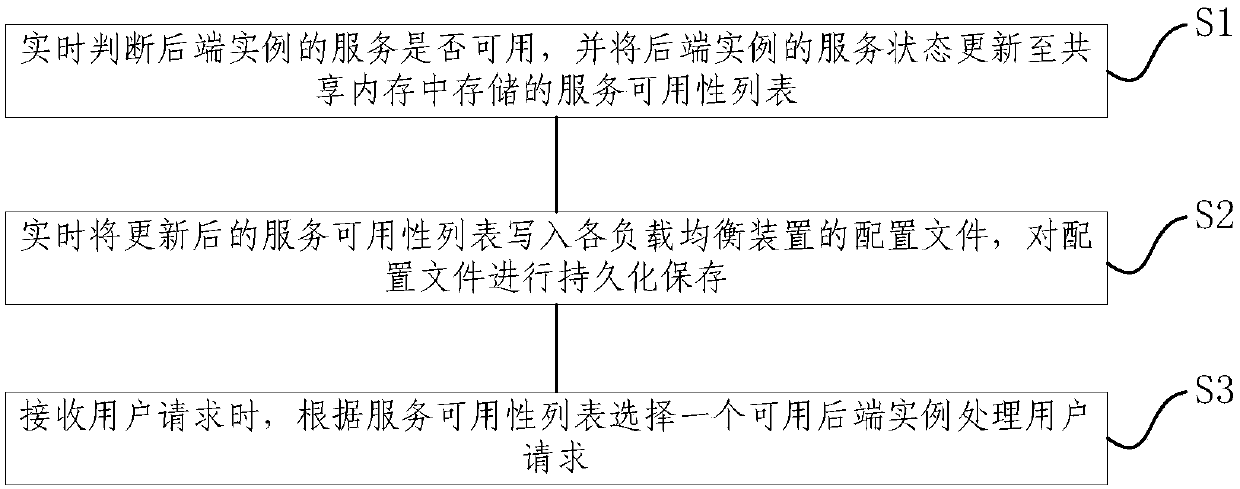

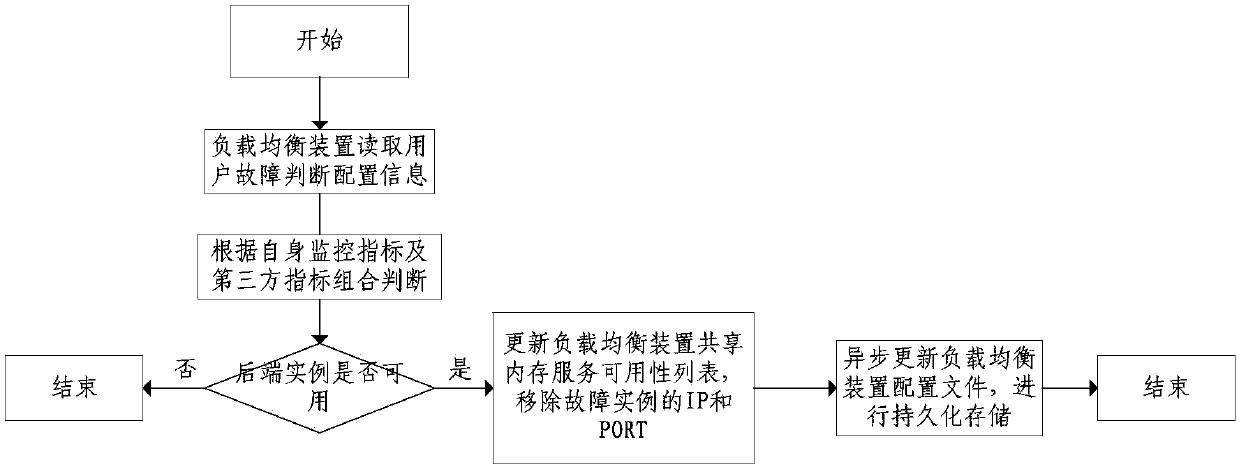

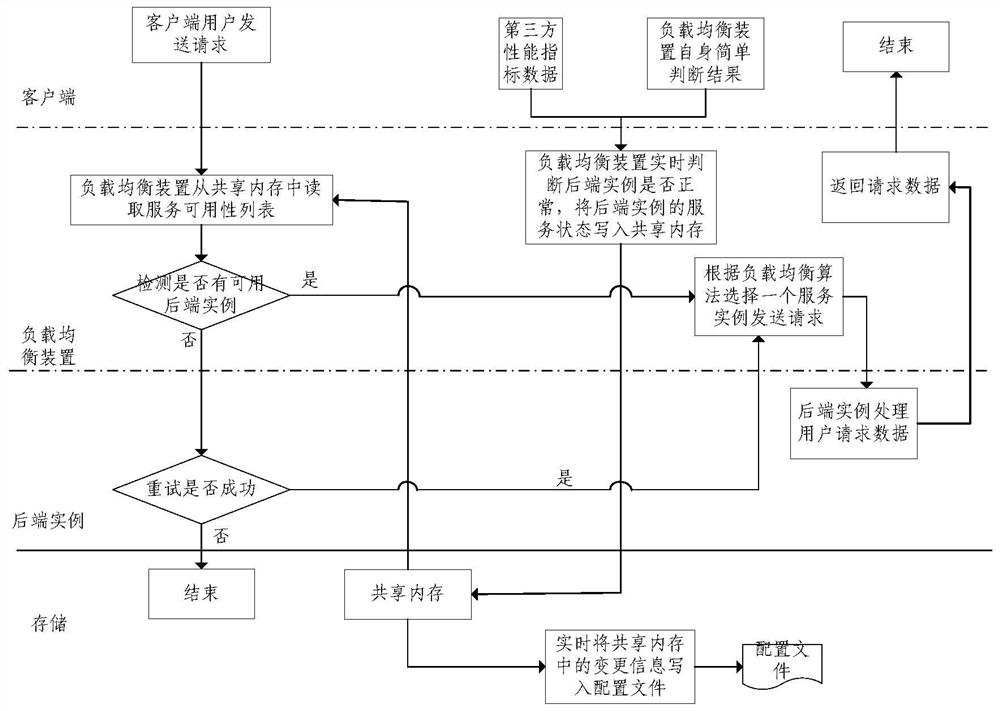

The invention provides a service-uninterrupted load balancing method and system, and the method comprises the steps: S1, enabling a load balancing device to judge whether the service of a rear-end instance is available or not in real time, and updating the service state of the rear-end instance to a service availability list stored in a shared memory; S2, the shared memory writes the updated service availability list into a configuration file of each load balancing device in real time, and persistently stores the configuration file; And S3, when the load balancing device receives the user request, selecting an available back-end instance to process the user request according to the service availability list. Updating the service state of the rear-end instance to a service availability liststored in a shared memory in real time; The shared memory writes the service availability list change information into a configuration file in an asynchronous manner, and notifies other load balancing devices to update related configuration files; The load may be dynamically requested to a backend instance absent in the configuration file without restarting the load balancing device.

Owner:CHINA MOBILE GROUP SHAIHAI +1

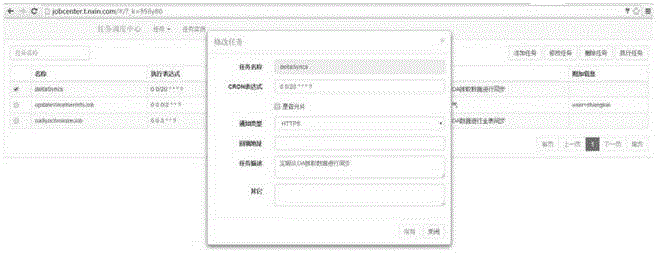

Configuration method and system for executing timed task under distributed system

ActiveCN106201694ARealize elastic scalingSolving Task Scheduling ProblemsProgram initiation/switchingDistributed object oriented systemsClient-sideAuthorization

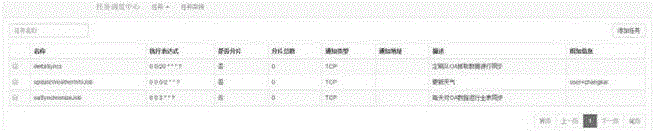

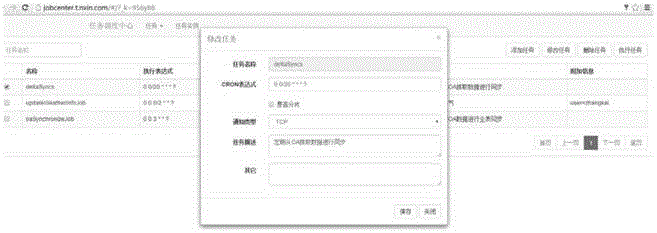

The invention discloses a configuration method for executing a timed task under a distributed system. A server side is of a distributed architecture, view display is achieved at the front end of the server side by means of react, a rest data interface is provided for the front end by the rear end of the server side by means of spring mvc, data operation authorization is guaranteed by means of spring security, access to data and modification of data by unauthorized users are avoided, configured tasks are triggered by means of quartz, a service discovery tool is used for dynamically finding and coordinating different machines to work, and redis is used as arbitration of resource competition; a client side registers a node as a task node and processes task logic. The invention further provides a configuration system for executing a timed task under a distributed system.

Owner:北京农信数智科技有限公司

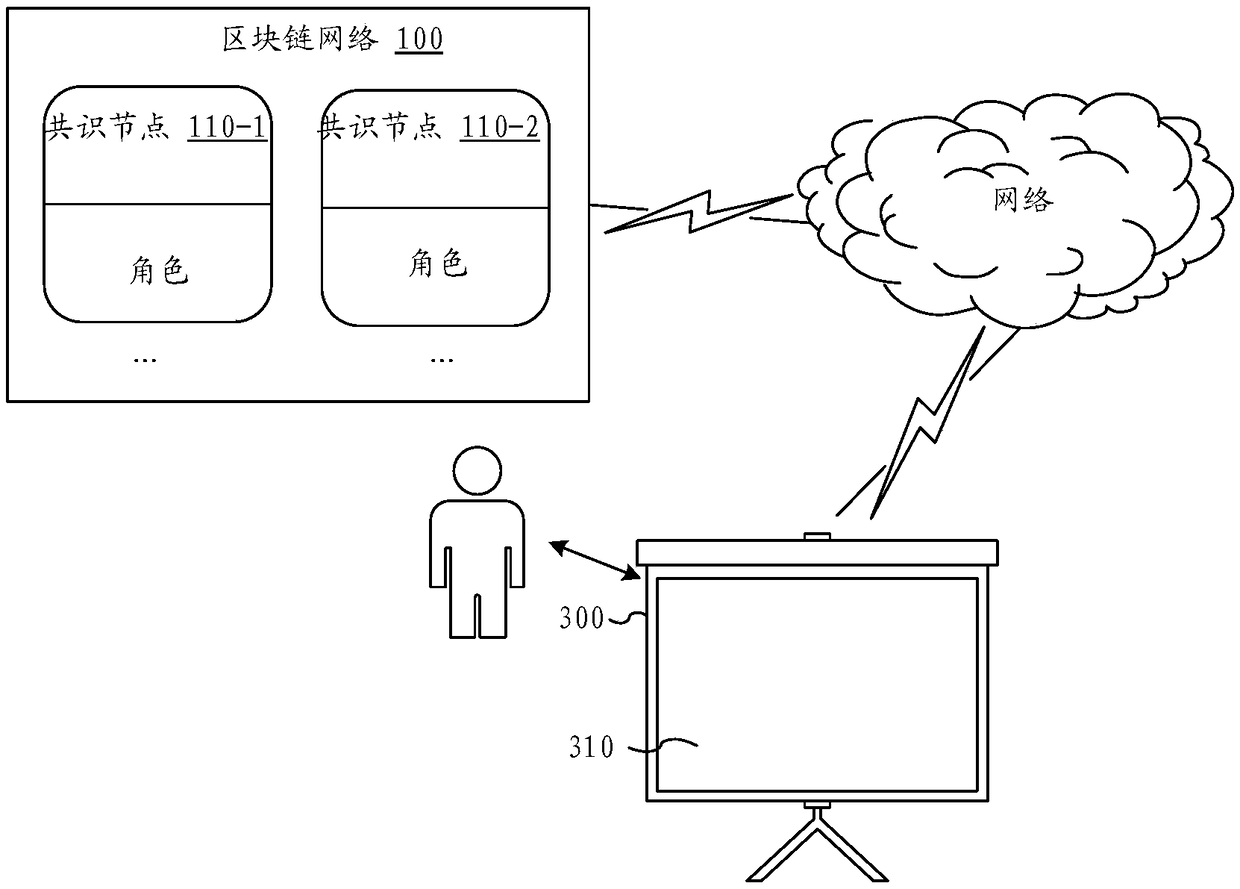

Account-book database component, operation method and storage medium

ActiveCN109241032ARealize elastic scalingVersatilityDatabase design/maintainanceChain networkBlockchain

The invention provides an account book database component, an operation method and a storage medium. The account book database component comprises an account book data protocol component, which is used for deconstructing an account book of a block chain network from a plurality of dimensions to form a data set in the form of a key-value pair; and an account book storage component for storing the formed data set in the form of the key-value pair.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

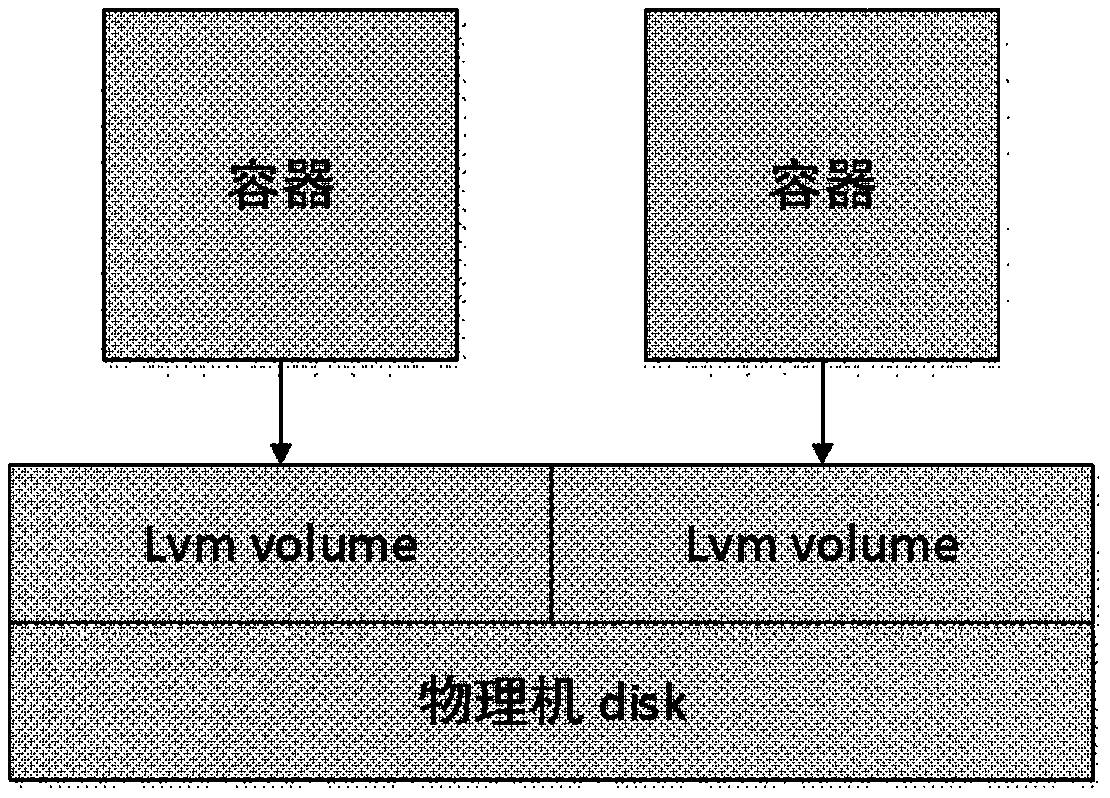

Distributed file system, computer system, and medium

PendingCN111290826AImprove reliabilityRealize elastic scalingDigital data information retrievalSoftware simulation/interpretation/emulationDistributed File SystemUser group

The invention provides a distributed file system. The distributed file system comprises a client, a metadata node, a data node and a volume management node, wherein the client corresponds to one or more containers. The metadata node is used for storing a first corresponding relationship, the first corresponding relationship is a corresponding relationship between file system attributes and a storage position of data, and the data is actual data in a file. The data node is used for storing data. The volume management node is used for responding to a received volume creation request of the client, and creating one or more volumes, wherein each volume is an instance of a file system which can be mounted by at least one container, each file system attribute comprises an index node and corresponding index node identification information, and the index node identification information comprises a file name and any one or more of the following information: a file size, creation time, modification time, a link number, a user, a user group and a file permission. The invention further provides a computer system and a computer readable storage medium.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

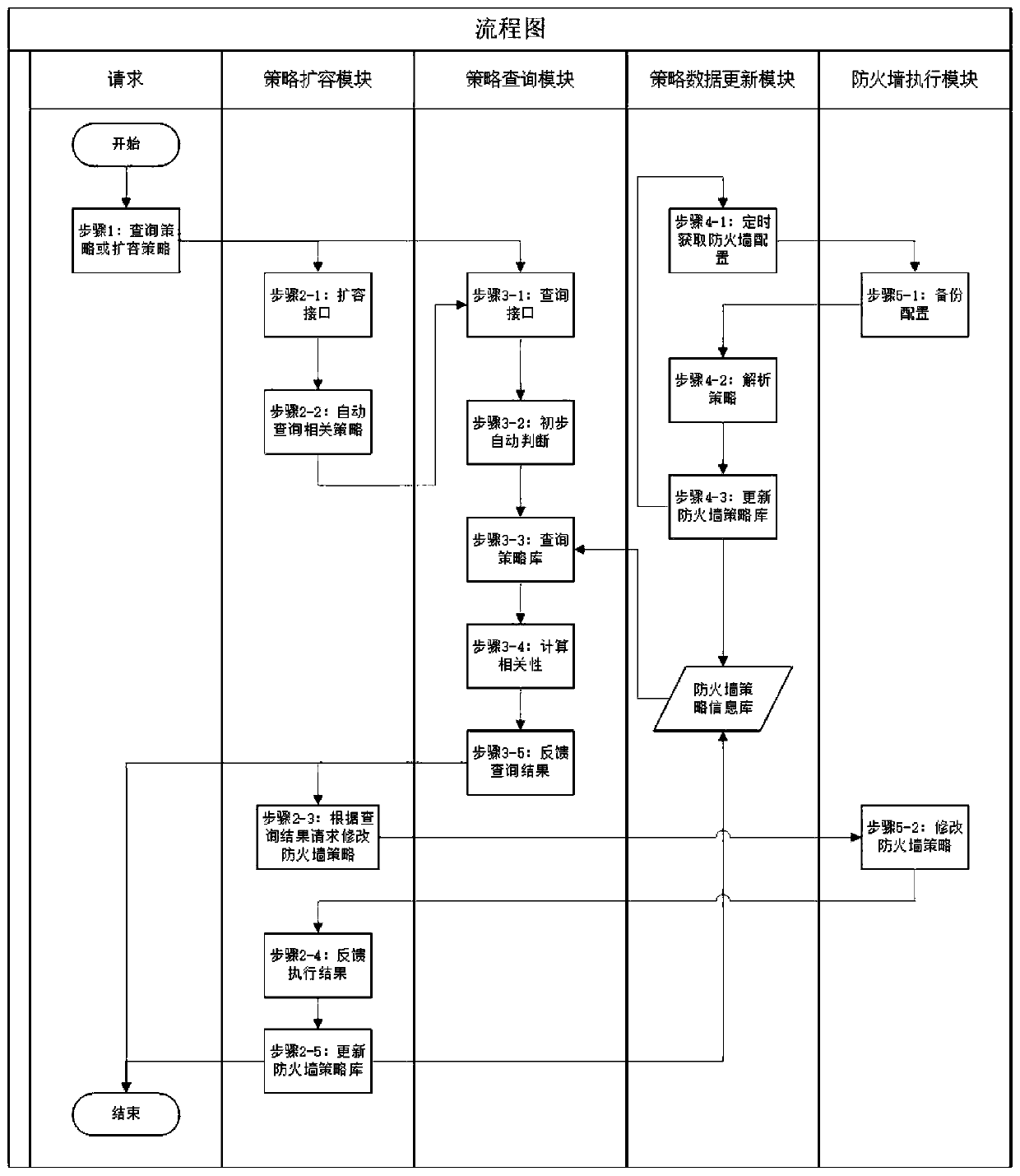

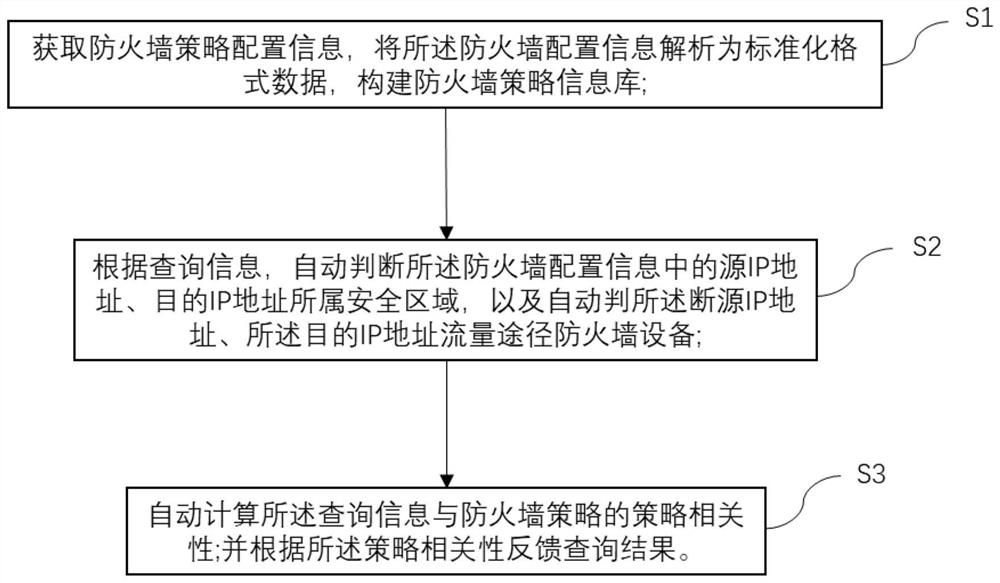

Firewall policy query method and system, firewall policy elastic scaling method and system, equipment and storage medium

ActiveCN111193744AImprove adjustment efficiencyRealize elastic scalingTransmissionIp addressEngineering

The invention relates to a firewall policy query method and system, an elastic scaling method and system, equipment, a storage medium. The firewall policy query method comprises the steps: S1, obtaining firewall policy configuration information, analyzing the firewall policy configuration information into standardized format data, and constructing a firewall policy information base; S2, automatically judging a safe area to which a source IP address and a destination IP address in the firewall configuration information belong according to the query information, and automatically judging that the source IP address and the destination IP address flow pass through firewall equipment; S3, automatically calculating strategy correlation between the query information and a firewall strategy; and feeding back a query result according to the strategy correlation.

Owner:CITIC AIBANK CORPORATION LIMITED

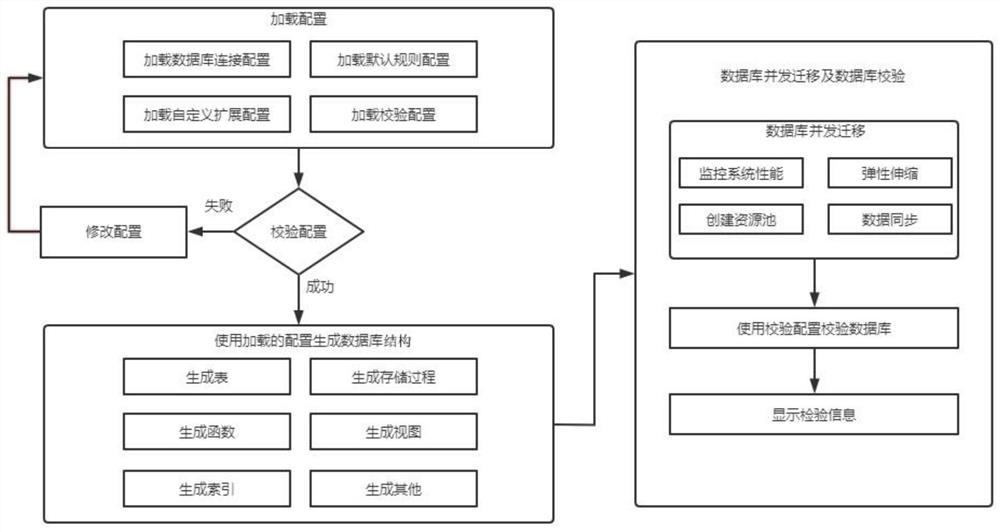

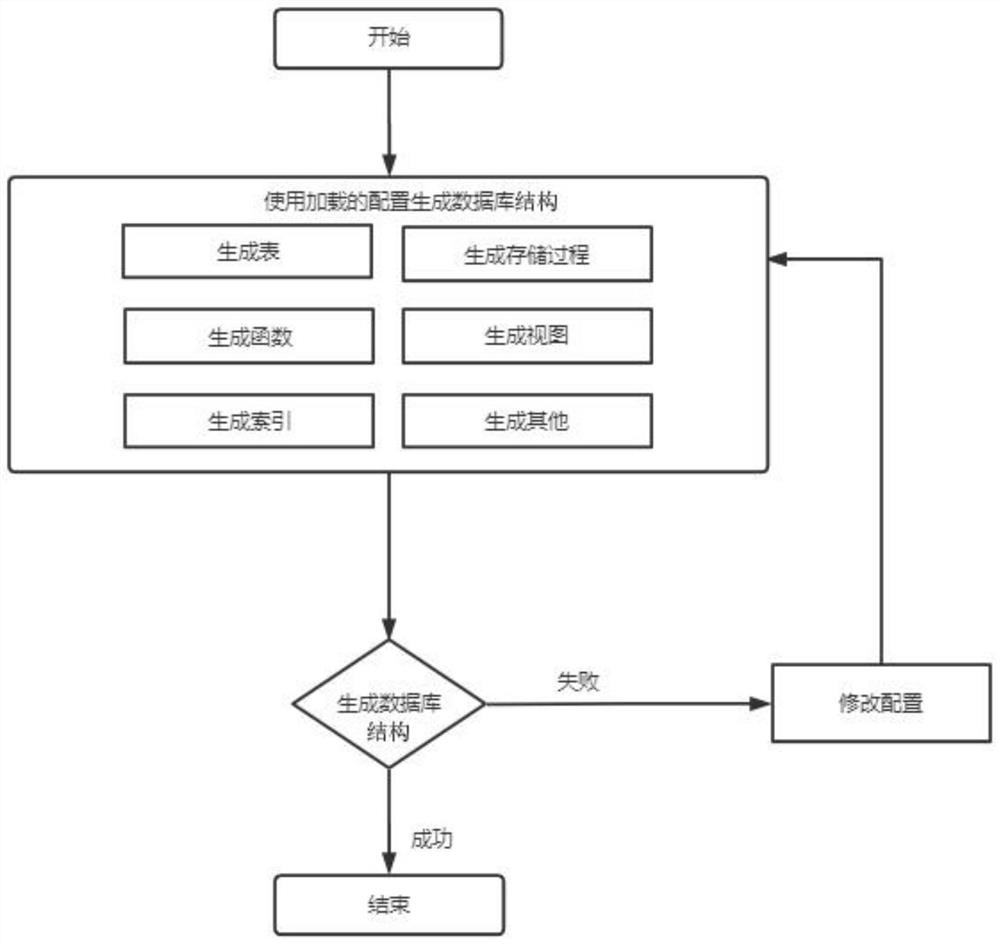

Lightweight concurrent migration method of database

ActiveCN112783859AQuick migrationGuaranteed uptimeDatabase distribution/replicationEnergy efficient computingTable (database)Operational system

The invention discloses a lightweight concurrent migration method of a database, and relates to the technical field of data migration. Aiming at problems and existing defects in the existing database migration process, the technical scheme adopted by the invention comprises the following steps: loading configurations of an original database and a target database, loading a corresponding grammar dialect according to the type of the target database, and performing grammar verification on the configurations; generating a table, a storage process, a function, a view, an index and others of the target database based on the loaded configuration; according to resources of an operating system, dynamically controlling the number of started threads, and carrying out concurrent migration on data of an original database through the started threads; and after migration is completed, performing default verification and configuration verification on the original database and the target database. Third-party middleware is not adopted, the method has the advantages of being efficient in operation, low in use cost, easy to expand, configurable and capable of achieving elastic expansion and contraction, and lightweight fast migration of data can be achieved.

Owner:HEBEI ZHISHENG INFORMATION TECH CO LTD

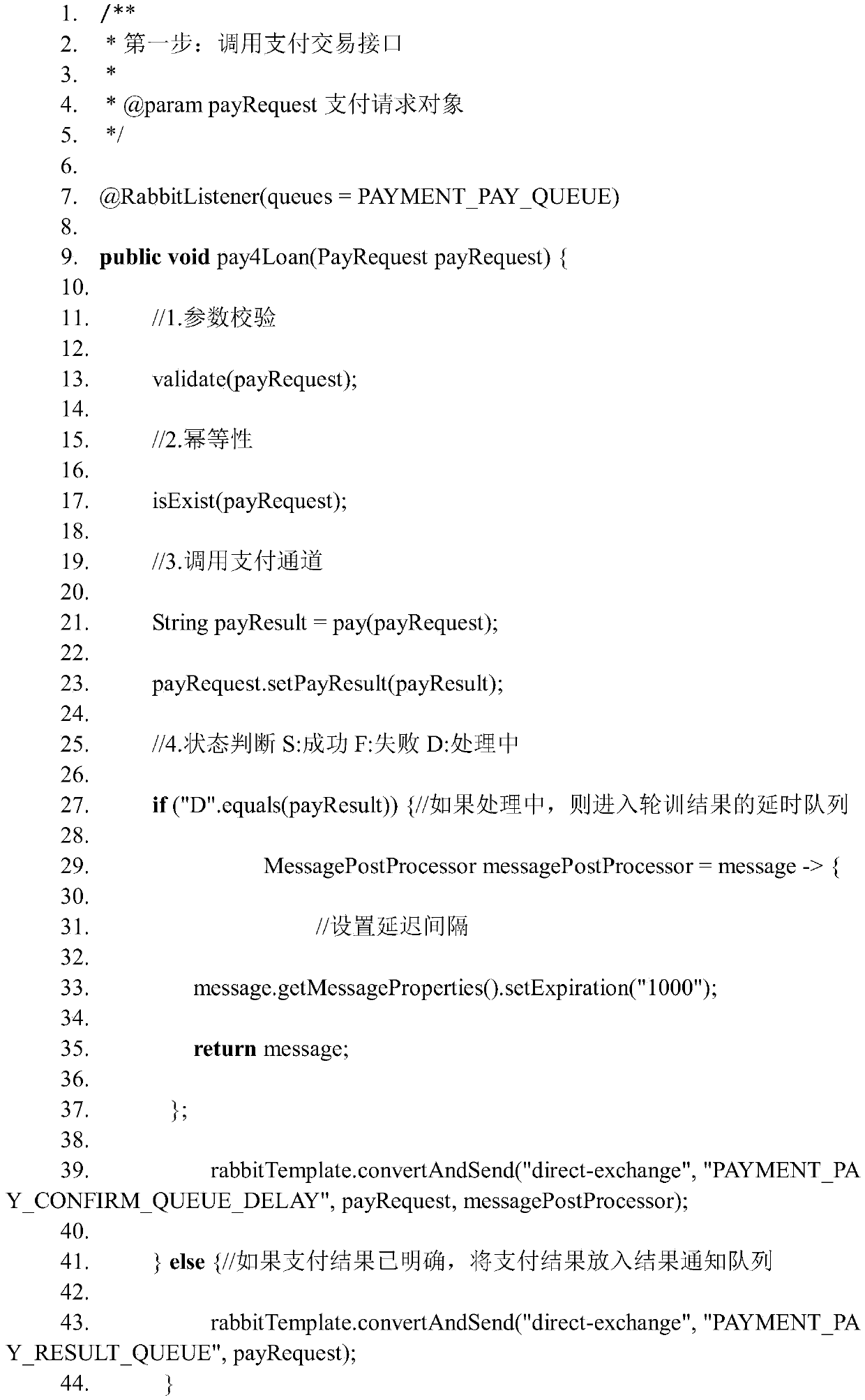

Distributed task polling method based on delay queue

InactiveCN110262910AReduce complexityReduce load pressureInterprogram communicationMessage queueMessage delivery

The invention relates to a distributed task polling method based on a delay queue, which comprises the following steps of A, establishing a service delay queue according to a message expiration and dead message delivery mechanism of a message queue; B, establishing a task polling queue for receiving the task polling request in the micro-service; C, converting the service data needing to be polled into a queue message, putting the queue message into the service delay queue, and automatically putting the service data needing to be polled into the task polling queue after the appointed delay time is over; and D, processing the service data in the task polling queue by the system, and judging whether the service data exits the task polling queue according to a processing result. According to the method, the execution intervals of the tasks can be equal, the processing time of the tasks is relatively fair, the problem of the repeated data reading is solved under the condition that a data grouping mode is not adopted, the complexity of a distributed scheduling program is reduced, and meanwhile the good expansibility is achieved.

Owner:SICHUAN XW BANK CO LTD

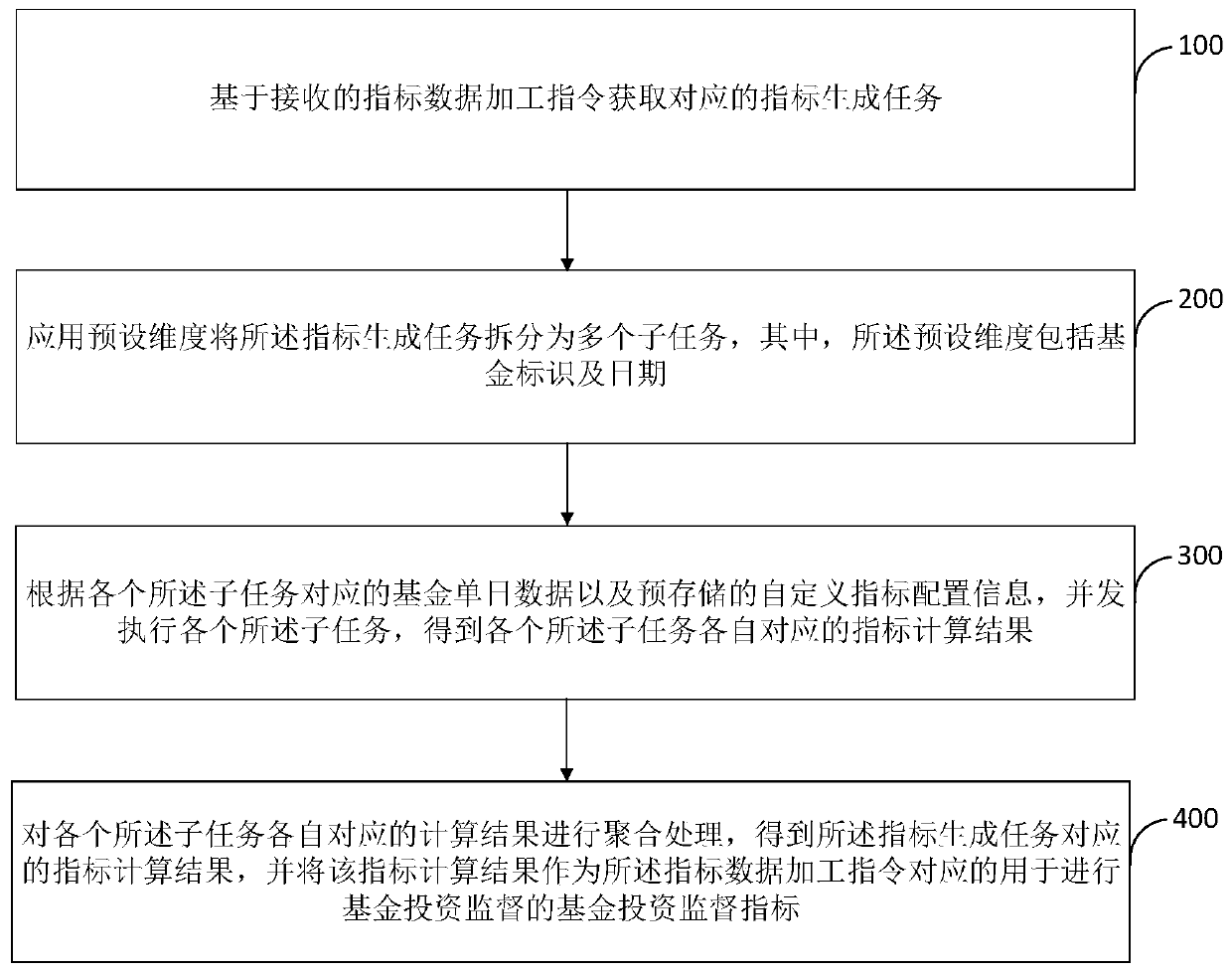

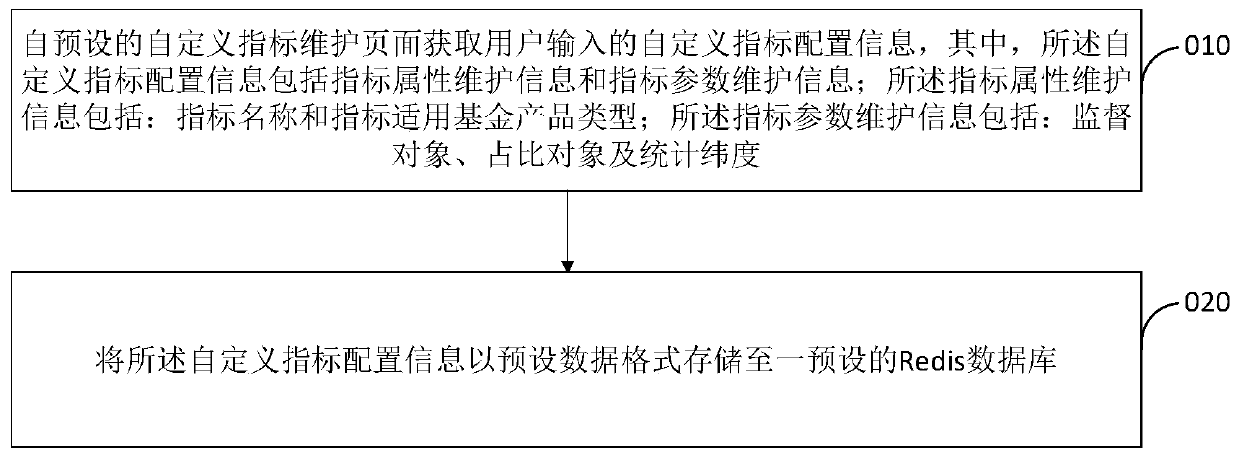

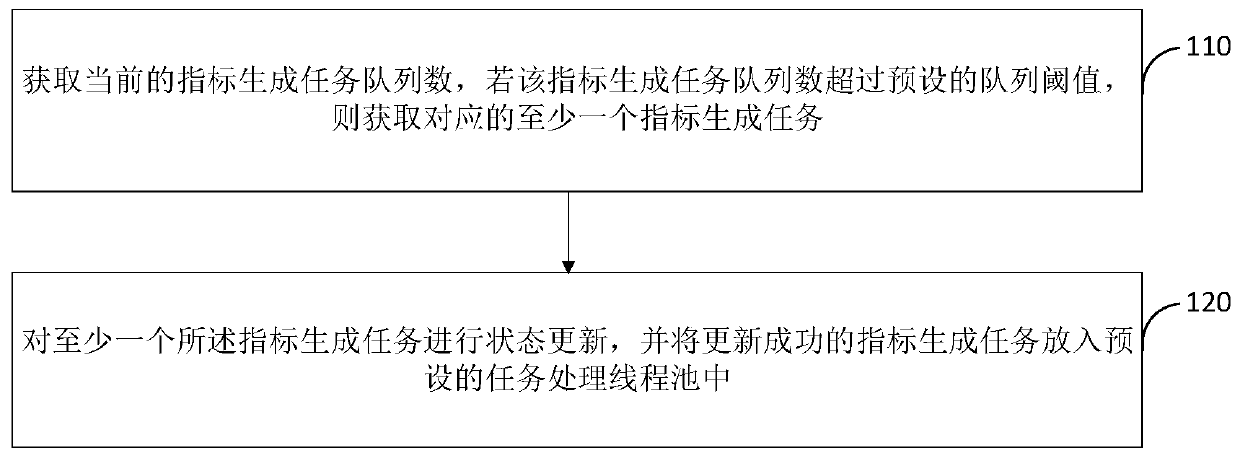

Fund investment supervision index obtaining method and device

PendingCN111383104AAchieve horizontal expansionImprove reliabilityFinanceComputer scienceOperations research

Embodiments of the invention provide a fund investment supervision index obtaining method and device. The method comprises the steps of obtaining a corresponding index generation task based on a received index data processing instruction; splitting the index generation task into a plurality of sub-tasks by applying a preset dimension; according to the fund single-day data corresponding to each sub-task and pre-stored self-defined index configuration information, concurrently executing each sub-task to obtain an index calculation result corresponding to each sub-task; aggregating the calculation results corresponding to the sub-tasks to obtain an index calculation result corresponding to the index generation task, and taking the index calculation result as a fund investment supervision index corresponding to the index data processing instruction and used for fund investment supervision. The method can effectively improve the obtaining accuracy, flexibility and efficiency of the fund investment supervision index, can effectively reduce the development period of the fund investment supervision index, and can effectively improve the reliability and accuracy of fund investment supervision.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

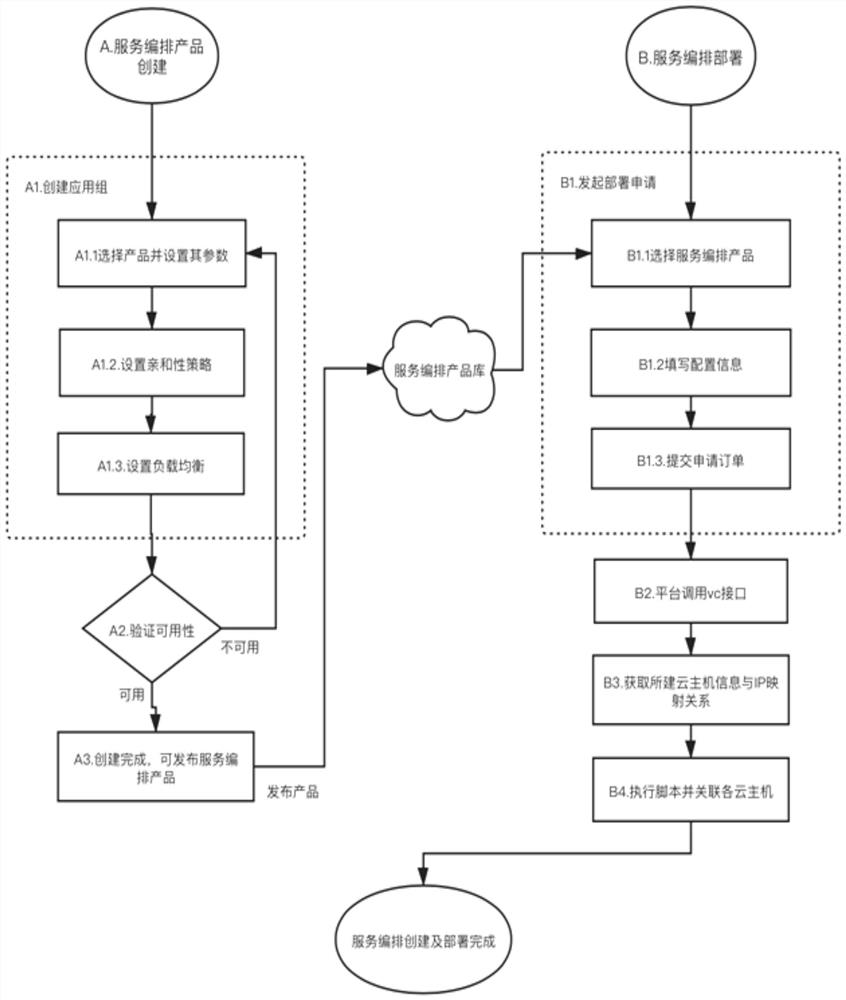

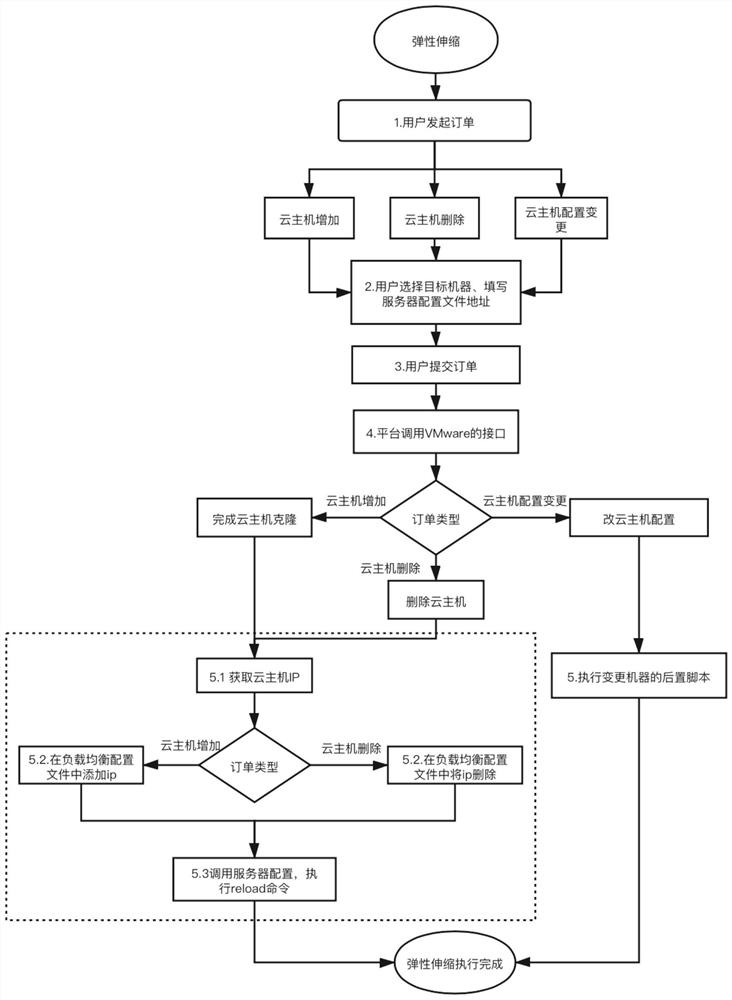

Cloud service system, method and server

PendingCN111884855ARealize elastic scalingElastic scaling balanceData switching networksService systemEngineering

The invention discloses a cloud service system. Service orchestration of the cloud service system comprises the following steps: creating a service orchestration product, and performing service orchestration application deployment, wherein the creation process of the service orchestration product comprises the following steps: A1, creating an application group in the cloud platform; A2, verifyingthe availability of the created application group, and if the verification result is unavailable, returning to the step A1 for reconfiguration; A3, if the verification result is that the service orchestration product is available, publishing the service orchestration product to a service orchestration product library. The process of service orchestration application deployment comprises the following steps: B1, initiating a deployment order application in a cloud platform; B2, after the order application is passed, enabling the cloud platform to create a cloud host according to the cloud hostcreation sequence of the service orchestration; B3, after the cloud hosts are created, reading the information of the cloud hosts and the mapping relationship of the IPs among the cloud hosts; B4, according to the read information of the cloud hosts and the mapping relationship of the IPs among the cloud hosts, establishing the relationship among the cloud hosts and VIP setting.

Owner:CHINA SHIPPING NETWORK TECH

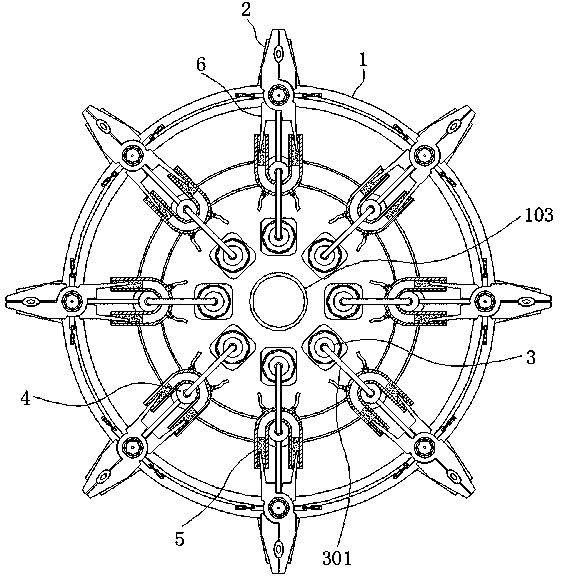

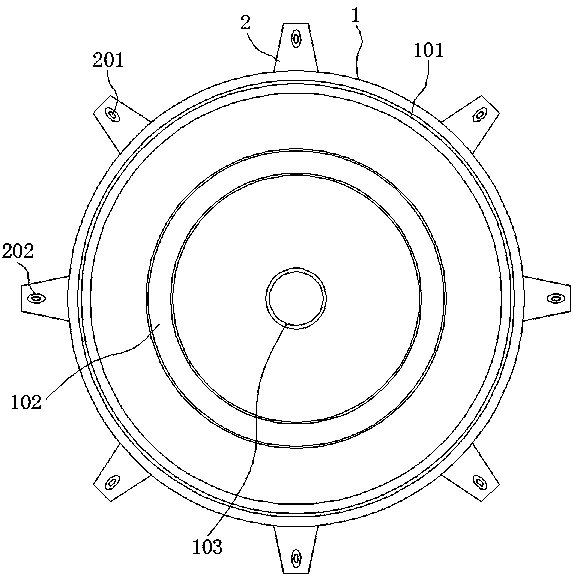

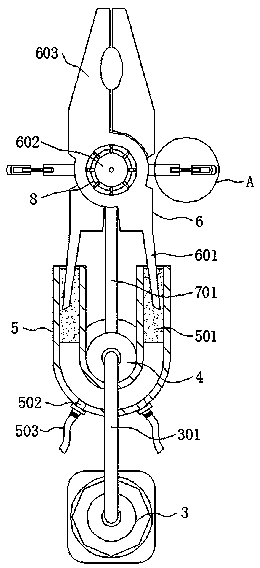

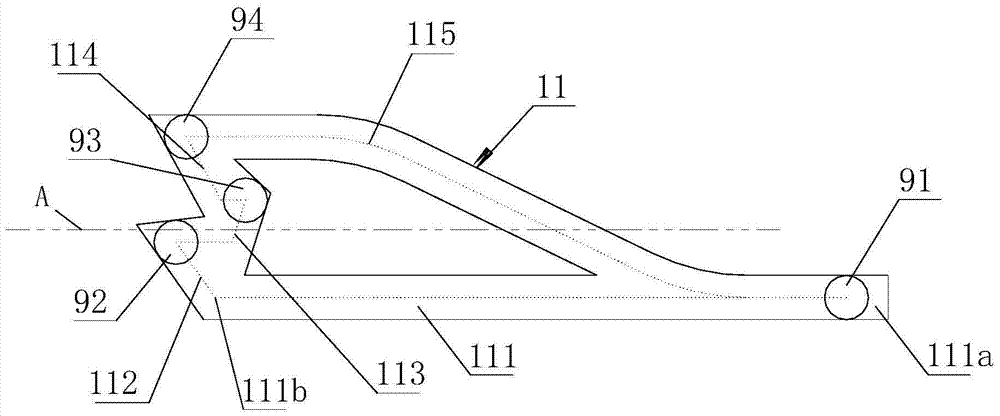

Anti-wear adjustable clamping platform for forceps processing

The invention discloses an anti-wear adjustable clamping platform for forceps processing and relates to the technical field of forceps processing. The anti-wear adjustable clamping platform for forceps processing specifically comprises a horizontal table, a locking pipe and a binding clip. An outer ring chute and an inner ring chute are concentrically formed in the upper surface of the horizontaltable, a swing air cylinder is also fixed to the upper surface of the horizontal table, the moving end of the end part of the swing air cylinder is connected to a swing connecting rod, the locking pipe is fixed to the outer wall of a moving plate core, and the binding clip is clamped to the outer port of the locking pipe. According to the anti-wear adjustable clamping platform for forceps processing, a tray is connected to the moving plate core through the connecting rod, the moving plate core swings back and forth along with the swing air cylinder through the swing connecting rod, a forceps jaw and the tray are bonded and fixed, so that after the swing connecting rod swings, the binding clip swings back and forth therealong under the action of the connecting rod and the tray, and therefore, the multi-angle and multi-position processing demands of auxiliary processing equipment on binding clip are met, and the moving pressure of the auxiliary processing equipment is alleviated.

Owner:DONGGUAN XIANGFEI INTELLIGENT EQUIP TECH CO LTD

Mixing drum inner wall cleaning brush mechanism

PendingCN107752338AEasy to foldRealize elastic scalingBrush bodiesTransportation and packagingEngineeringHinge angle

The invention discloses a mixing drum inner wall cleaning brush mechanism which comprises brush mounting blocks, brush fixing blocks and connecting rods. Two ends of each connecting rod are connectedwith the corresponding brush mounting block and the corresponding brush fixing block, each connecting rod extends into the corresponding brush mounting block and the corresponding brush fixing block and fixed to the same through retractable springs, each brush mounting block is provided with a connection portion for mounting, and a brush is fixed to each brush fixing block. By spring connection ofthe connecting rods with the brush mounting blocks and the brush fixing blocks, elastic extension and retraction of the connecting rods on the brush mounting blocks and the brush fixing blocks can berealized to make it convenient for the brushes to tightly cling to the inner wall of a drum when the brush mechanism is mounted in the mixing drum, so that cleaning effects are improved; each brush is provided with two handles connected through a hinge and a spring, so that the brushes can be folded conveniently in mounting and is convenient to mount from a cover door position and capable of automatically expanding after mounting, and convenience in mounting and demounting is achieved.

Owner:NANJING GAOZHENG AGROCHEM

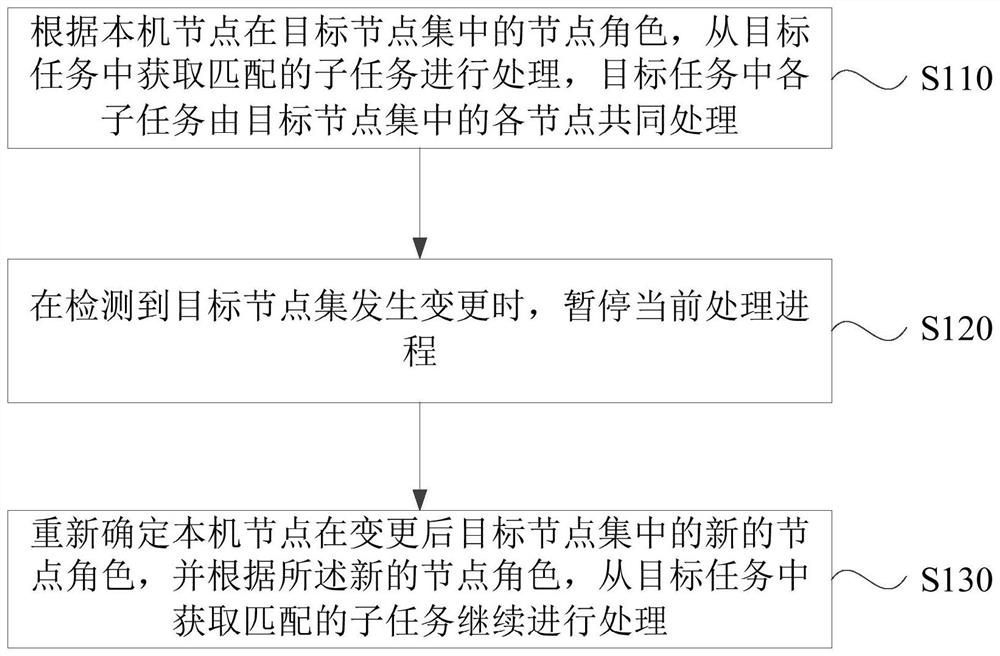

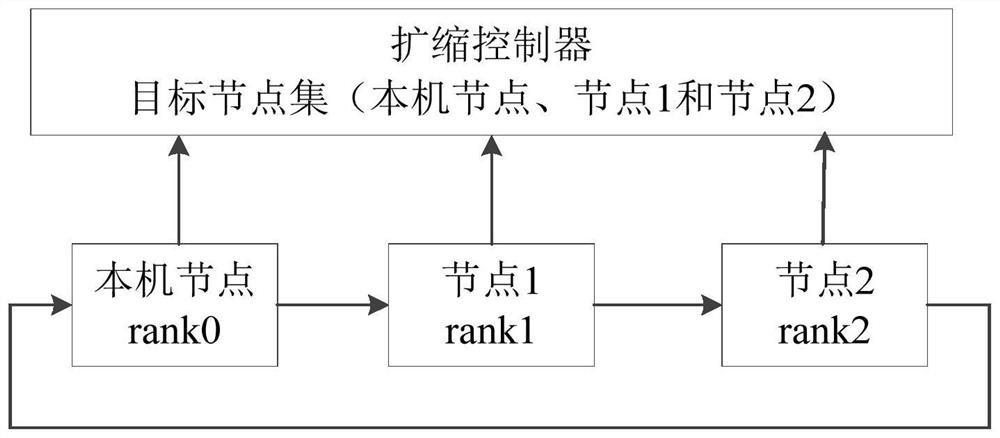

Distributed task processing method, device, equipment, storage medium and system

PendingCN112416591ARealize elastic scalingImprove task processing efficiencyResource allocationGoal nodeDistributed computing

The embodiment of the invention discloses a distributed task processing method, device and equipment, a storage medium and a system. The method comprises: according to the node role of a local node ina target node set, obtaining matched sub-tasks from a target task to be processed, and jointly processing all the sub-tasks in the target task by all nodes in the target node set; when it is detectedthat the target node set is changed, suspending the current processing process; and re-determining a new node role of the local node in the changed target node set, and according to the new node role, obtaining a matched sub-task from the target task to continue processing. By using the technical scheme of the invention, the elastic expansion and contraction of the nodes during task processing can be realized, and the task processing efficiency is improved.

Owner:GUANGZHOU HUYA TECH CO LTD

Flexible damping earphone wire controller without direction press

The invention relates to the field of electronics, in particular to a flexible damping earphone wire controller without direction press. The flexible damping earphone wire controller comprises a fixedplate, outer rings, a connecting ring, inner rings, a connecting spring, a positioning strip, a chip and a wire core, wherein the fixed plate is used for connecting and supporting each part; the outer rings are matched with the inner rings to convey a finger pressing signal to the chip; the connecting ring is used for achieving a purpose of flexibly connecting the three outer rings; and the connecting spring is used for achieving a purpose of flexibly connecting the three inner rings and enabling the connecting ring to be in a tensioned state by means of elasticity. According to the device, an earphone can be controlled, two specific pressing surfaces do not need to be found during operation, the device can be pressed from any direction and the operation is easy; the device is made of a flexible material, and can be flexibly wound into a tool such as a storage box, and the storage is convenient; due to the adoption of the device, the axial elastic expansion can be realized, so that the stretching of an earphone wire can be buffered, and a certain buffering effect can be achieved for a mobile phone when the mobile phone falls accidentally.

Owner:抚州华冠电子科技有限公司

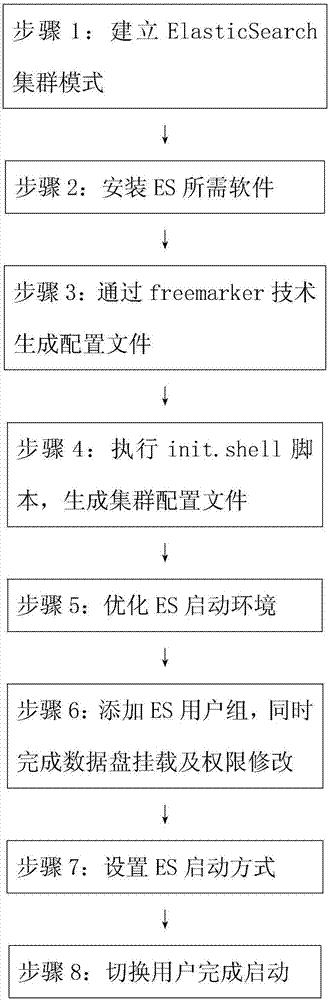

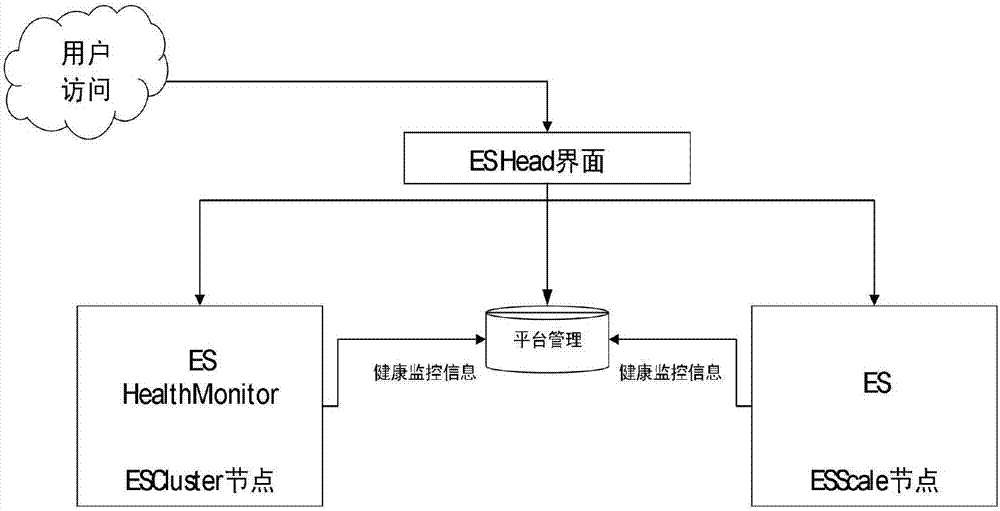

Automatic deployment method of ElasticSearch cluster

InactiveCN107544829ALower deployment costsEasy to deployProgram loading/initiatingInitSearch engine indexing

The invention provides an automatic deployment method of an ElasticSearch cluster. The method comprises the following steps that 1, an ElasticSearch cluster mode is established; 2, software needed bya system is installed; 3, a configuration file is generated through a freemarker technology; 4, an init.shell script is executed, and a cluster configuration file is generated; 5, an ES start-up environment is optimized; 6, an ES user group is added, and data disk mounting and permission changing are completed simultaneously; 7, an ES start-up mode is set; 8, user switching is conducted to complete start-up. One-click setup of the ElasticSearch cluster is achieved, various kinds of search engine design in the market can be accessed and matched while the deployment cost is greatly reduced, andcomplex ElasticSearch cluster deployment is simplified, systematized and normalized.

Owner:SHANDONG LANGCHAO YUNTOU INFORMATION TECH CO LTD

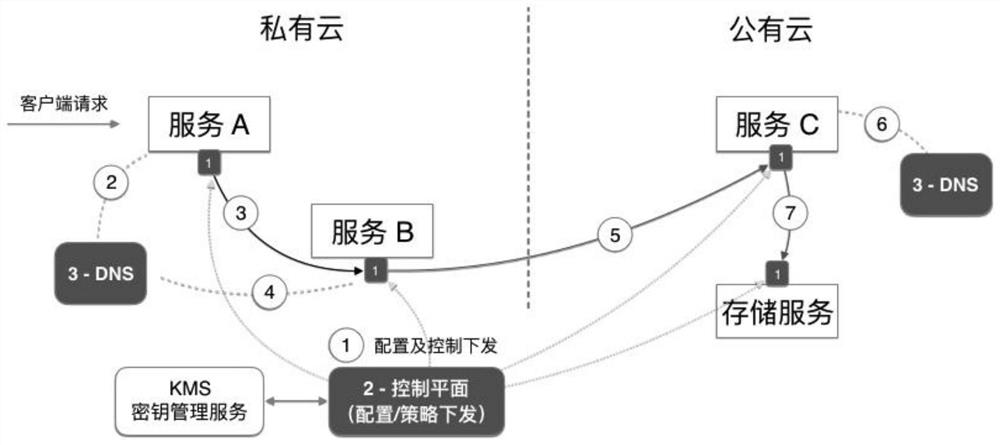

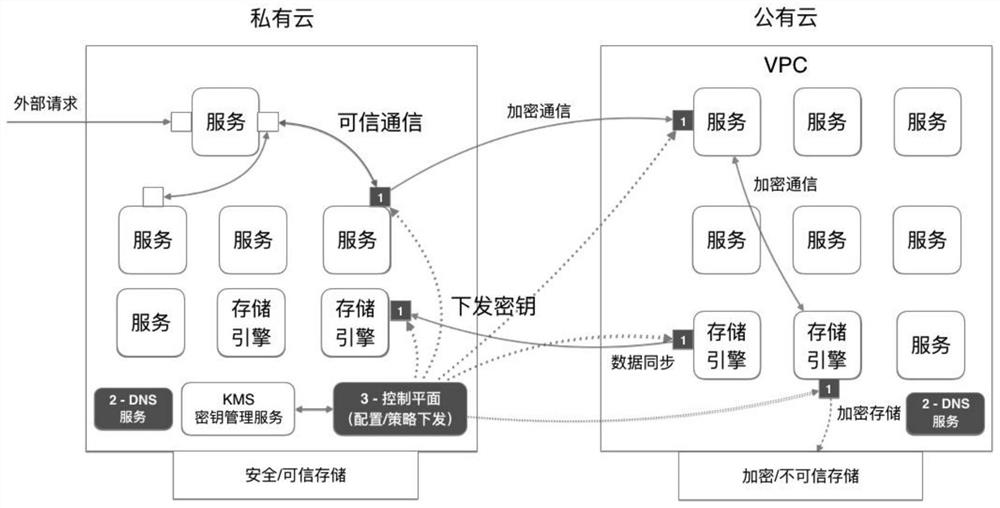

Data security assurance method in hybrid cloud environment based on service grid

ActiveCN112511560AImplement cryptographic operationsImprove application development efficiencyDigital data protectionTransmissionCommunications securityStorage security

A data security assurance method in a hybrid cloud environment based on a service grid relates to the technical field of computers, and comprises the following steps: an administrator configures access security between services, defines security policies between services A, B and C and storage services, determines encrypted communication and non-encrypted communication, and issues the informationto the intelligent agent side by the control plane in a unified manner; after an external entry request arrives at the service A, the service A analyzes the address of the service B through the DNS and initiates calling; the request of the service A for calling the service B is intercepted by the sidecar, and traffic transparent transmission is performed; and the service B calls the service C, andthe DNS analyzes the address of the service C as a public cloud address to configure a security policy. According to the method, the limitation of public cloud manufacturers can be removed, and the network transmission layer security among multiple clouds, the application communication security in the public cloud and the data storage security can be ensured; secure transmission can be flexibly customized, and cross-cloud services are defined to enable secure access.

Owner:北京云思畅想科技有限公司

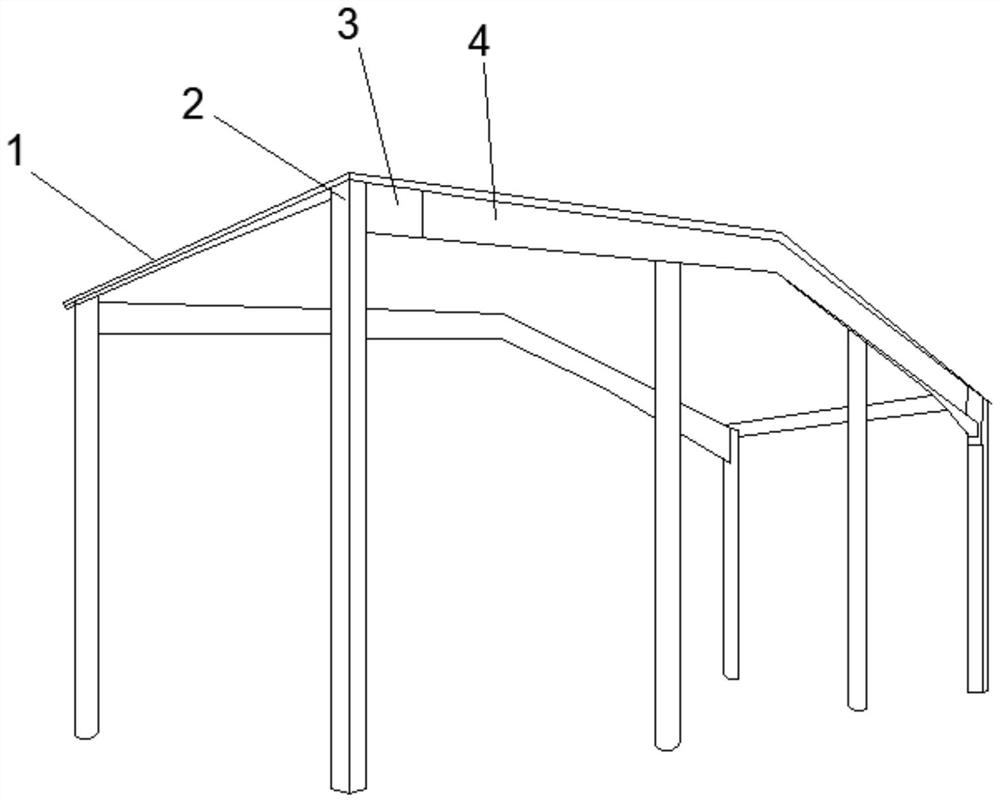

A steel structure building with shock-absorbing and anti-seismic functions

ActiveCN111877553BIt has the function of shock absorption and shock resistanceRealize elastic scalingProtective buildings/sheltersShock proofingArchitectural engineeringSteel frame

The invention belongs to the field of building materials, and specifically discloses a steel structure building with shock-absorbing and anti-seismic functions, including a steel frame; the steel frame is composed of support columns and beams, and the support columns and beams are connected and fixed through connector structures; Wherein, the connector structure includes a connecting column I and a connecting column II, and the connecting column I is hinged and fixed by a hinged plate, and is limitedly locked by a safety lock structure provided on the hinge plate; the safety lock structure There is a fixed pipe on the top, and the fixed pipe is connected to the hinged plate through a plurality of safety locks; and, the connecting column II is equipped with a plurality of elastic legs on the side close to the connecting column I; after violent shaking, the beam The hinge point fixed on the support column through the hinged plate vibrates and rotates, and drives the fixed pipe to squeeze the safety lock. When the vibration is too large, the safety lock is unlocked and the safety lock is released, forming multiple elastic legs against the support. On the column, elastic expansion and contraction are realized, and tough connection is completed, which is used to improve stability.

Owner:山东东珠新型房屋科技有限公司

Bendable headset drive-by-wire device

ActiveCN108810694AEasy to controlEasy to operateEarpiece/earphone cablesEarpiece/earphone mechanical/electrical switchesDrive by wireHeadphones

The invention relates to the electronic field, specifically a bendable headset drive-by-wire device. The device comprises pressing modules, a closing plate, a chip, a connecting spring and a wire core; wherein three groups of pressing modules are provided, each pressing module comprises an inner ring, an outer ring and a connecting ring for producing a pressing signal and transmitting the signal to the chip through the wire core; three groups of pressing modules are connected through the connecting spring; the wire core for transmitting the pressing module signal is spirally wound on the connecting spring; the closing plate is used for closing the upper end and the lower end of the pressing module. The device disclosed by the invention van realize the control on the headset and the pressing can be performed from any direction without finding two specific pressing surfaces in the operation, so that the operation is convenient; the device is made of flexible material and can be flexiblyinto a storage box and like took in the winding way, so that the storage is convenient; the device can realize axial elastic stretching and buffer the tension of the headset wire, and can play a certain buffer effect on the mobile phone when the mobile phone drops in accident.

Owner:广西都安祥云电子科技有限公司

A production line ceramic shock absorber when making ceramics

ActiveCN113232147BRealize auxiliary coolingRealize automatic airflow coolingNon-rotating vibration suppressionAuxillary shaping apparatusProduction lineCeramic

The invention provides a ceramic shock absorber for a production line when making ceramics, relates to the technical field of shock absorbers, and solves the problem that multiple buffers cannot be realized through structural improvements, and its auxiliary buffer structure cannot be organically combined with the disassembly and assembly of buffer parts. ; Can not realize the problem of auxiliary airflow heat dissipation of ceramic parts while buffering. A production line ceramic shock absorber for making ceramics, comprising a shock absorbing main body; Composed of elastic parts. Because the connecting pipe is connected to the sleeve, and the nozzle seat is connected to the connecting pipe; the nozzle seat is an annular structure, and the nozzle seat is sleeved on the outside of the ceramic cylinder; the nozzle seat is provided with nozzle holes A in an annular array, and the nozzle The hole A is a tapered hole structure, so that when the sleeve and the ceramic cylinder stretch, the airflow generated by the sliding of the baffle can be sprayed out through the nozzle hole A, thereby realizing the automatic airflow cooling at the ceramic cylinder.

Owner:江苏海泰新材料科技有限公司

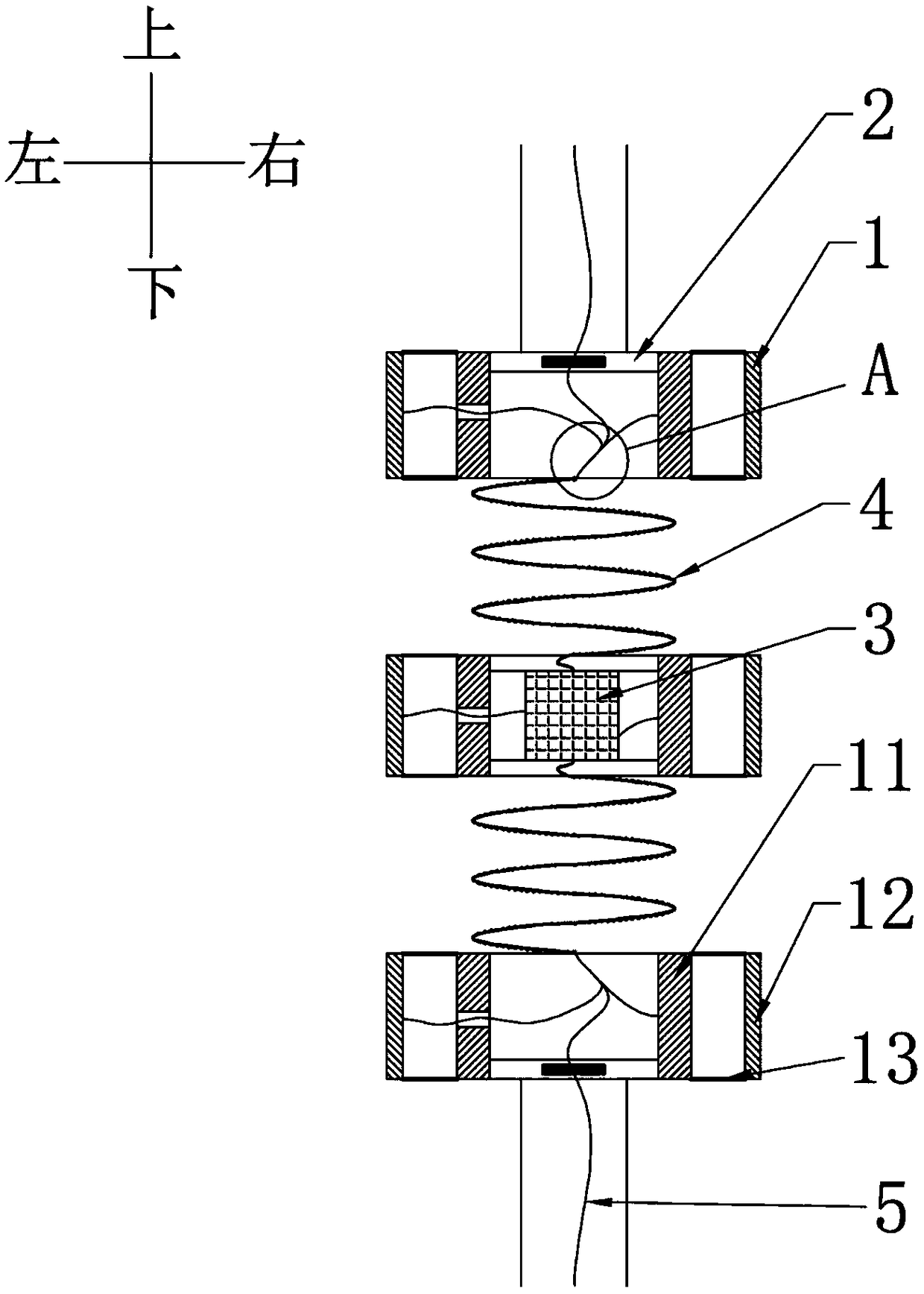

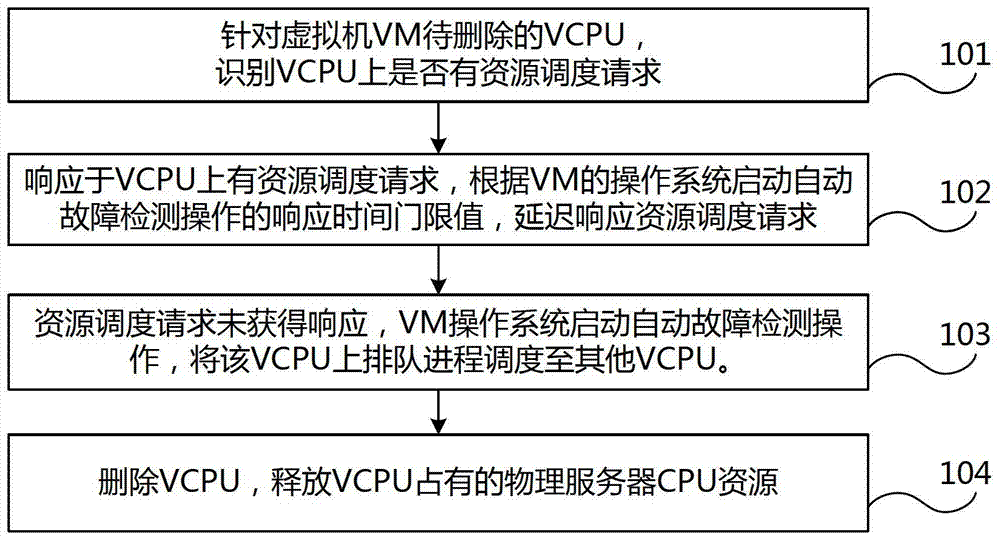

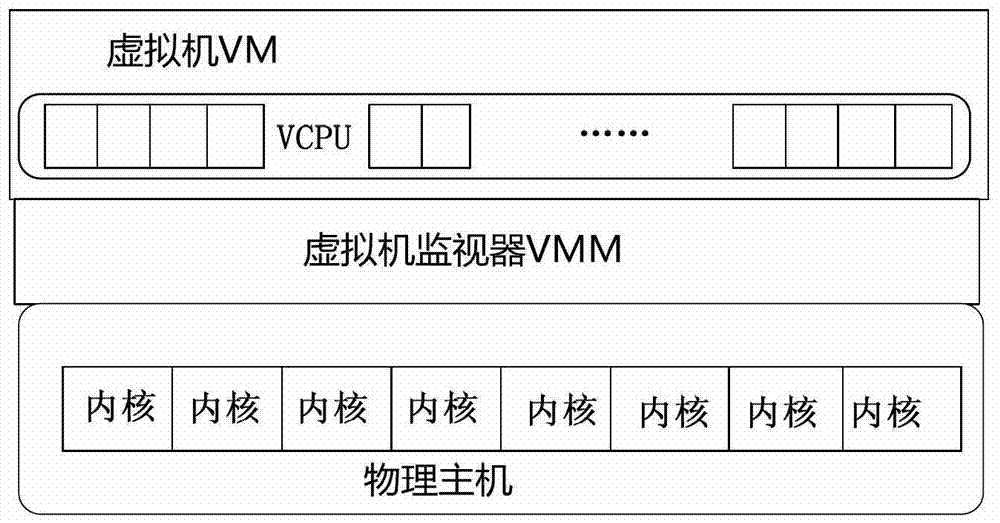

Virtual machine processor resource adjustment method, device and virtual machine system

ActiveCN103870332BSave resourcesRealize elastic scalingResource allocationSoftware simulation/interpretation/emulationDelayed responseOperational system

The invention discloses a virtual machine processor resource adjustment method, device and virtual machine system. The method includes: identifying whether there is a resource scheduling request on the VCPU for the VCPU to be deleted in the virtual machine VM; responding to the resource scheduling request on the VCPU, starting the response time threshold value of the automatic fault detection operation according to the operating system of the VM, and delaying the response Resource scheduling request, so that the resource scheduling request does not get a response within the response time threshold; in response to the resource scheduling request not getting a response within the response time threshold, the VM's operating system starts an automatic fault detection operation, and queues the VCPU The process is scheduled to other VCPUs of the VM; the VCPU is deleted to release the physical server CPU resources occupied by the VCPU. Through the technical solution provided by the invention, the VCPU resource can be reduced in the running state, and the elastic expansion and contraction of the virtual machine resource is realized.

Owner:CHINA TELECOM CORP LTD

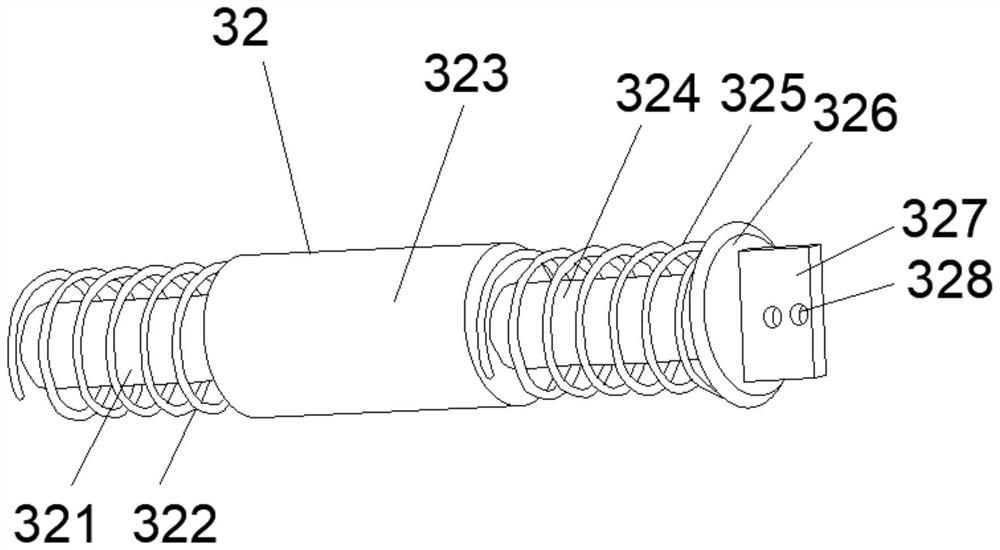

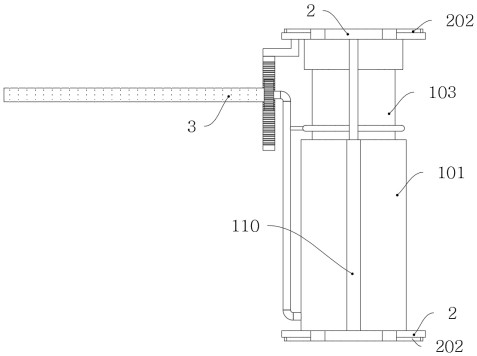

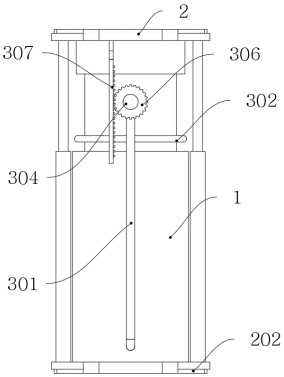

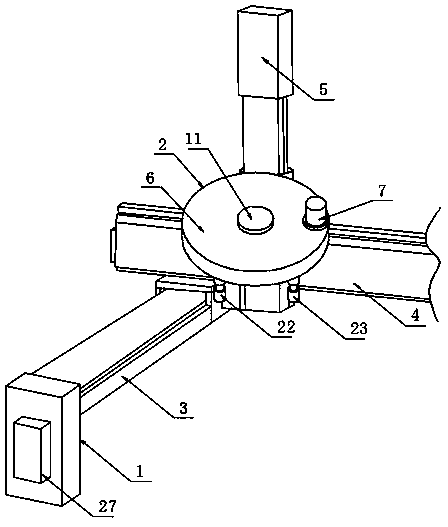

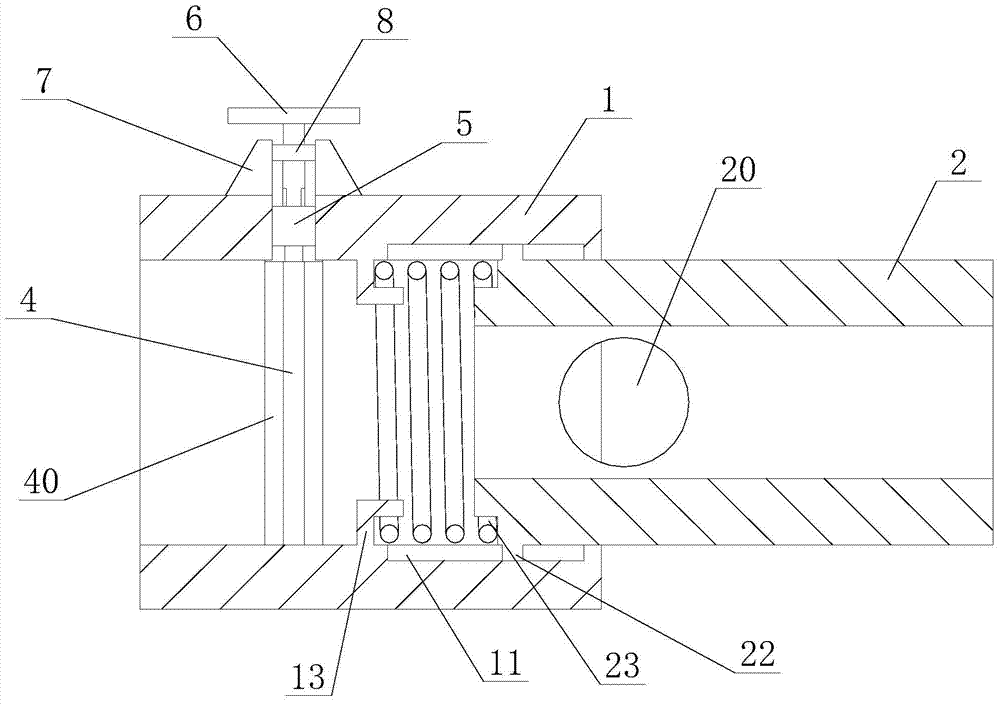

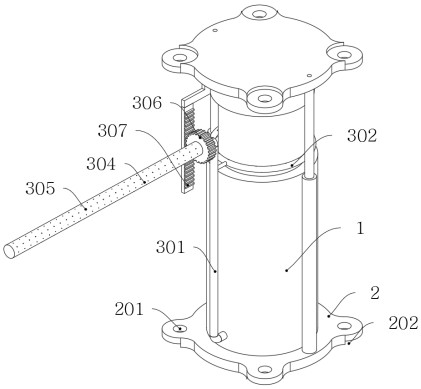

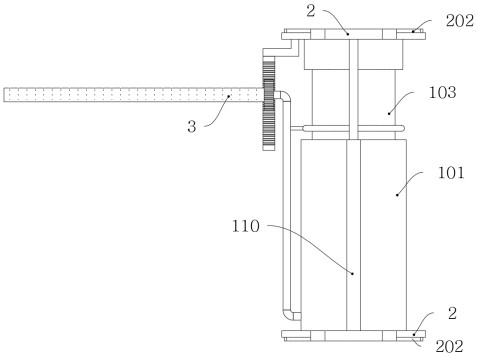

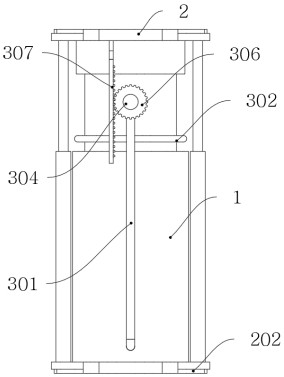

Filter tuning system

PendingCN110429360AEasy to moveSqueeze Tuning SecurityWaveguide type devicesFilter tuningPower equipment

Provided is a filter tuning system, and relates to the technical field of filter tuning; the system comprises a transfer robot and a tuning head, the transfer robot comprises an X conveying shaft, a Yconveying shaft and a Z conveying shaft, and the tuning head comprises a fixed disc, a mounting disc, a servo motor, a first gear, a rotating shaft, a limiting disc, a mounting hole, a second gear, afastener, a clamper, an extrusion tool, an extrusion head, a fastening head, a clamping head, a connecting rod, a connecting sleeve and a spring. According to the invention, the measuring equipment can measure electrical data of the filter, the depth needing to be extruded can be calculated, and movement of the extrusion tool in the X, Y and Z directions can be realized; the filter can be automatically and accurately extruded and tuned, the three parts are driven to move through one moving part, power equipment of the device can be reduced, and the size of the device can be reduced; elastic stretching and retracting of the fastener, the clamper and the extrusion tool can be achieved, and adverse effects caused by simultaneous lifting of the three parts can be avoided.

Owner:湖北广益通讯设备有限公司

A pressing reciprocating valve

The invention discloses a press reciprocating valve. The press reciprocating valve comprises a first pipeline, a sealing element, a handle and a fixed block, wherein a shell is arranged on the outer wall of the first pipeline; a central rod penetrating to the lower inner wall of the first pipeline is arranged in the shell; a valve clack is arranged on the central rod; the central rod further penetrates to the fixed block and the sealing element in the shell; and the top of the central rod is connected with the handle outside the shell. The press reciprocating valve further comprises a second pipeline, wherein an elastically-stretching self-locking structure used for enabling the second pipeline to elastically stretch relative to the first pipeline is arranged between the second pipeline and the first pipeline; the second pipeline is slidably connected to the first pipeline in a sleeving manner; and first water outlet holes are formed in the second pipeline. The valve is reasonable in design; moreover, the water outlet holes are formed in the pipelines, and are capable of dividing water into a plurality of different branches, thereby meeting the needs of people for the branches; and meanwhile, the valve has the advantage of being convenient to control.

Owner:江苏苏爱尔电力设备有限公司

Firewall policy query, elastic scaling method and system, device, storage medium

ActiveCN111193744BRealize elastic scalingImprove regulation efficiencySecuring communicationInformation repositoryAutoscaling

The present invention relates to a firewall policy query, elastic scaling method, system, equipment, storage medium, and firewall policy query method, including: S1. Acquiring firewall policy configuration information, parsing the firewall configuration information into standardized format data, and constructing a firewall policy Information base; S2. According to the query information, automatically determine the source IP address in the firewall configuration information, the security zone to which the destination IP address belongs, and automatically judge the source IP address and the destination IP address flow path firewall device; S3 . Automatically calculating the policy correlation between the query information and the firewall policy; and feeding back the query result according to the policy correlation.

Owner:CITIC AIBANK CORPORATION LIMITED

Cluster scheduling model construction method, scheduling model, scheduling method and system

PendingCN114443254ARealize elastic scalingEnsure stable and efficient operationProgram initiation/switchingResource allocationDeep neural networksResource scheduling

The invention discloses a scheduling model construction method, a scheduling model, a scheduling method and a scheduling system of a cluster, belongs to the technical field of big data processing, and aims to solve the technical problems that the cluster lacks scheduling decisions and the scheduling basis is single. Comprising the following steps: collecting sample data of an optimal adjustment point number through actual set resource scheduling; performing normalization processing on the sample data to obtain preprocessed sample data; a prediction model is constructed based on the deep neural network of back propagation, and the prediction model takes the big data cluster specification, the cluster load and the expected cluster adjustment load input, and takes the optimal adjustment node number as the output; and training a prediction model based on the preprocessed sample data, and adjusting the weight of each layer of neurons of the prediction model based on a back propagation method according to an error between a predicted value output by the prediction model and an actual value of the sample data to obtain a trained prediction model.

Owner:SHANDONG LANGCHAO YUNTOU INFORMATION TECH CO LTD

A load balancing method and system for uninterrupted business

ActiveCN109842651BJudgment does not affectNo human intervention requiredTransmissionComputer networkEngineering

The present invention provides a method and system for uninterrupted service load balancing. The method includes: S1. The load balancing device judges in real time whether the service of the backend instance is available, and updates the service status of the backend instance to the data stored in the shared memory. Service availability list; S2, the shared memory writes the updated service availability list to the configuration file of each load balancing device in real time, and saves the configuration file persistently; S3, when the load balancing device receives a user request, select one according to the service availability list A backend instance can be used to handle user requests. Update the service status of the backend instance to the service availability list stored in the shared memory in real time; the shared memory uses an asynchronous method to write the change information of the service availability list into the configuration file, and notify other load balancing devices to update the relevant configuration files; Dynamically load requests to backend instances that do not exist in the configuration file when the load balancer is restarted.

Owner:CHINA MOBILE GROUP SHAIHAI +1

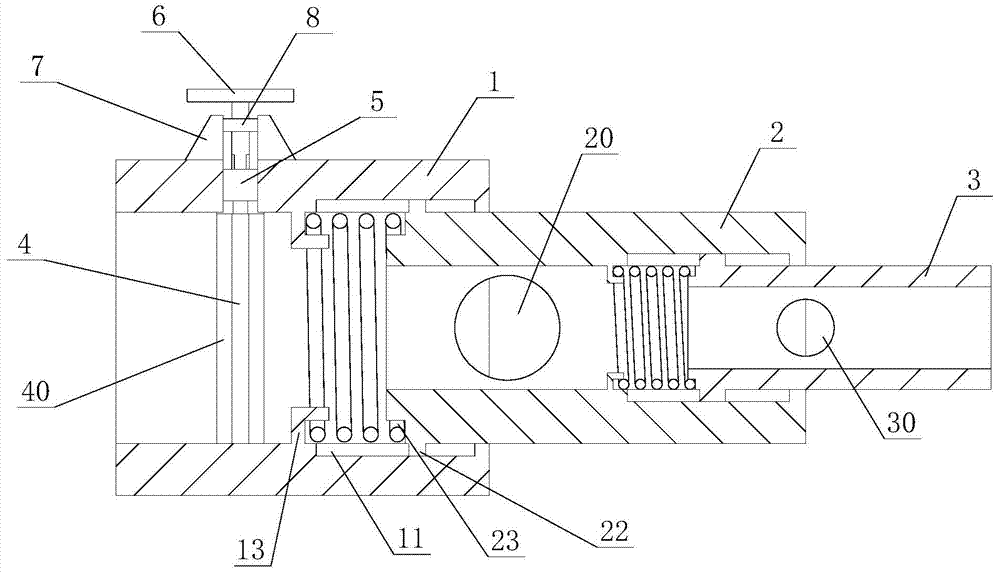

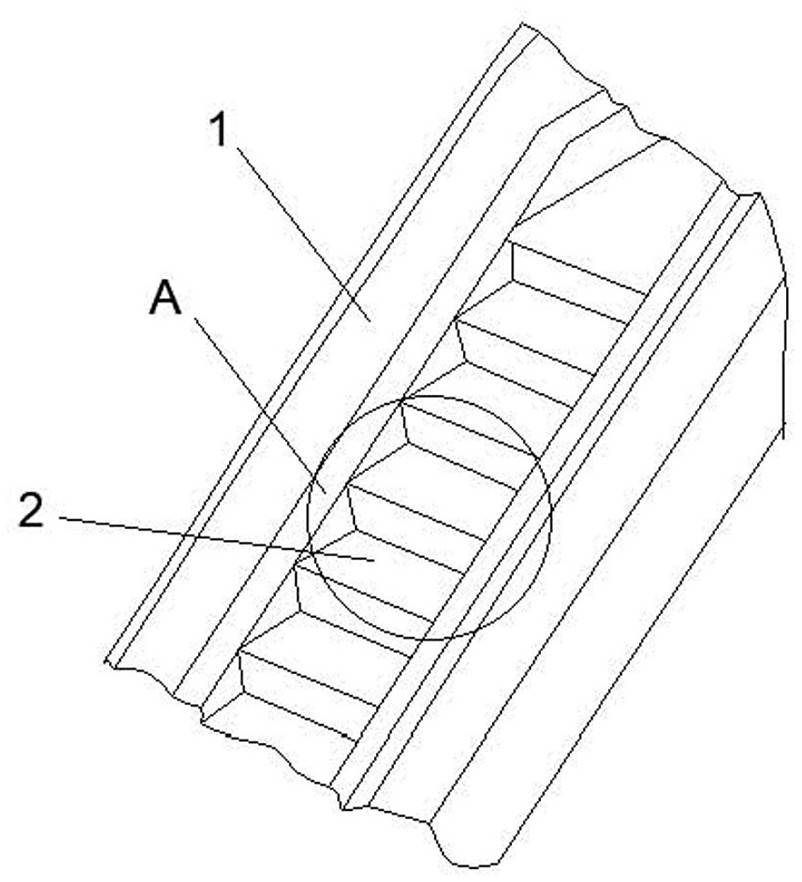

Movable centre structure

The invention discloses a movable centre structure. The movable centre structure comprises a centre base, a centre sleeve and a spring, wherein the centre sleeve is arranged on the centre base in a sleeving mode and is matched with the centre base in a sliding mode, and the spring is arranged between the centre sleeve and the centre base. According to the movable centre structure, a fixed mode of the centre structure of a machine tool headstock can be changed into an axially-telescopic and adjustable mode, and therefore the clamping mode and the driving mode between a machine tool and parts are enriched.

Owner:南京路博利尔精密机械有限公司

A push-and-reciprocate multi-hole valve

ActiveCN105202224BReasonable designMeet needsMultiple way valvesValve housingsSelf lockingEngineering

The invention discloses a pressing reciprocating multi-connection hole valve, comprising a first pipeline, a second pipeline, a third pipeline, a sealing element, a handle and a fixing block, wherein a shell is arranged at the outer wall of the first pipeline; a center rod penetrating the inner wall under the first pipeline is arranged in the shell and is provided with a valve clack; the center rod also penetrates through the fixing block and the sealing element in the shell; the top of the center rod is connected with the handle outside the shell; an elastic telescopic self-locking structure for elastically extending and retracting the second pipeline relative to the first pipeline is arranged between the first pipeline and the second pipeline; the second pipeline slidably sleeves the first pipeline and is provided with first water outlets; the structure between the third pipeline and the second pipeline is identical with that between the second pipeline and the first pipeline. The valve is reasonable in design, and is provided with multiple water outlets which can divide water into multiple different branches, so that the pressing reciprocating multi-connection hole valve meets the requirements of people on the multiple branches and has the advantage of convenience in control.

Owner:JIANGSU TENGLONG PETROCHEM MACHINERY

Production line ceramic shock absorber used during ceramic manufacturing

ActiveCN113232147ARealize auxiliary coolingRealize automatic airflow coolingNon-rotating vibration suppressionAuxillary shaping apparatusProduction lineAnnular array

The invention provides a production line ceramic shock absorber used during ceramic manufacturing, relates to the technical field of shock absorbers, and solves the problems that multiple buffering cannot be realized through structural improvement, an auxiliary buffering structure cannot be organically combined with disassembly and assembly of a buffering piece, and auxiliary airflow heat dissipation of a ceramic piece cannot be realized while buffering is carried out. The production line ceramic shock absorber used during ceramic manufacturing comprises a shock absorption body, and the shock absorption body is composed of a sleeve, a blocking base, a ceramic cylinder, a cylindrical rod, a baffle, a locking nut, a limiting base, an elastic block and an elastic piece. A connecting pipe is connected to the sleeve, and a nozzle seat is connected to the connecting pipe. The nozzle seat is of an annular structure, and the nozzle seat is connected to the outer side of the ceramic cylinder in a sleeving manner; and spray holes A are formed in the nozzle seat in an annular array shape, and the spray holes A are of a conical hole-shaped structure, so that when the sleeve and the ceramic cylinder stretch out and draw back, airflow generated by downward sliding of the baffle can be sprayed out through the spray holes A, and then automatic airflow cooling at the ceramic cylinder is achieved.

Owner:江苏海泰新材料科技有限公司

A data security guarantee method in hybrid cloud environment based on service grid

ActiveCN112511560BImplement cryptographic operationsImprove application development efficiencyDigital data protectionTransmissionCommunications securityTraffic capacity

Owner:北京云思畅想科技有限公司

An expandable escalator pedal

ActiveCN111747278BRealize elastic scalingBig spaceEscalatorsStructural engineeringMechanical engineering

The invention belongs to the field of escalators, and specifically discloses an expandable escalator pedal, which includes an outer expansion plate structure that is movably interspersed on the platform; the outer expansion plate structure is provided with a support plate, and the support plate is movably inserted in the on the platform, and is elastically connected on the platform by using an elastic structure, and the platform is provided with an anti-falling structure acting on the support plate; The other end of the support plate is hinged on the platform; when passengers are riding, the elastic structure can support the support plate by its own elastic restoring force, so that the support plate is extended to the outside of the platform to complete the outreach, and the fixed-width stairway can be With expansion, large luggage can be stably placed on the ladder with a fixed width, the space of the ladder platform can be widened, and the space for adjustable use can be improved, with high safety.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

A configuration method and system for executing scheduled tasks in a distributed system

ActiveCN106201694BRealize elastic scalingSolving Task Scheduling ProblemsProgram initiation/switchingDistributed object oriented systemsData operationsClient-side

Owner:北京农信数智科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com