Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Real-time monitoring speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

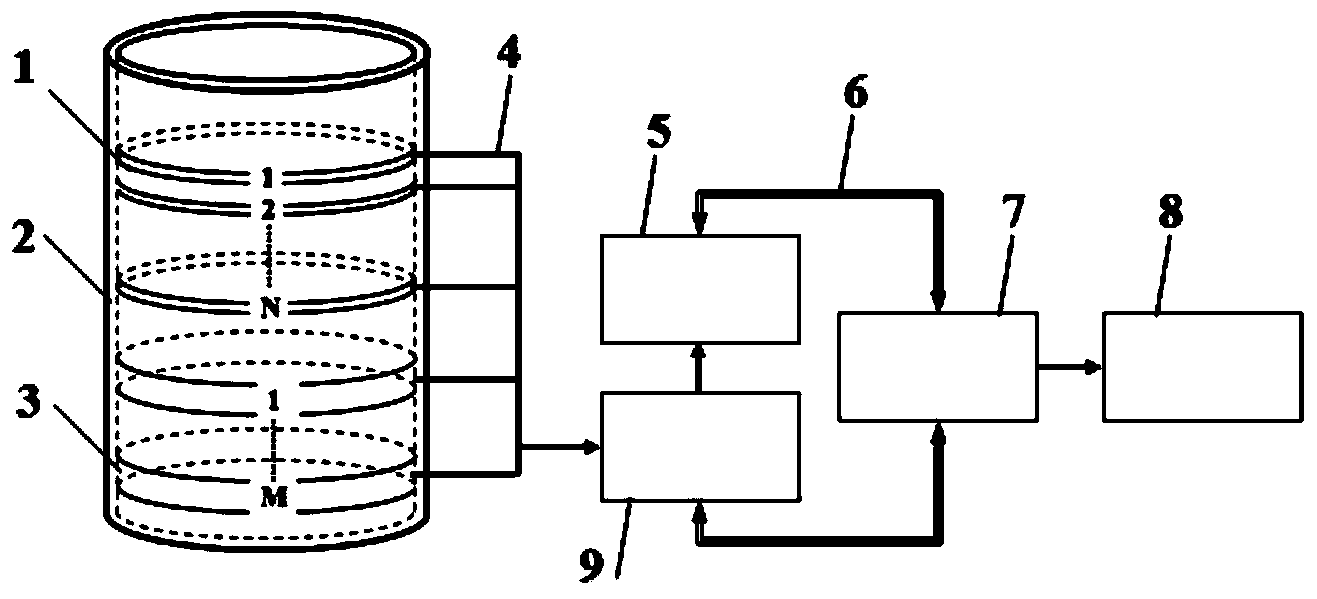

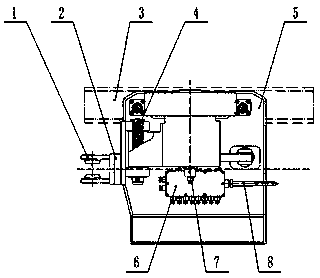

Tool state monitoring and life predicting system based on multi-source information fusion

PendingCN109724785AMonitoring forceThe monitoring device monitors the force in real timeMachine part testingProject managementInformation acquisition

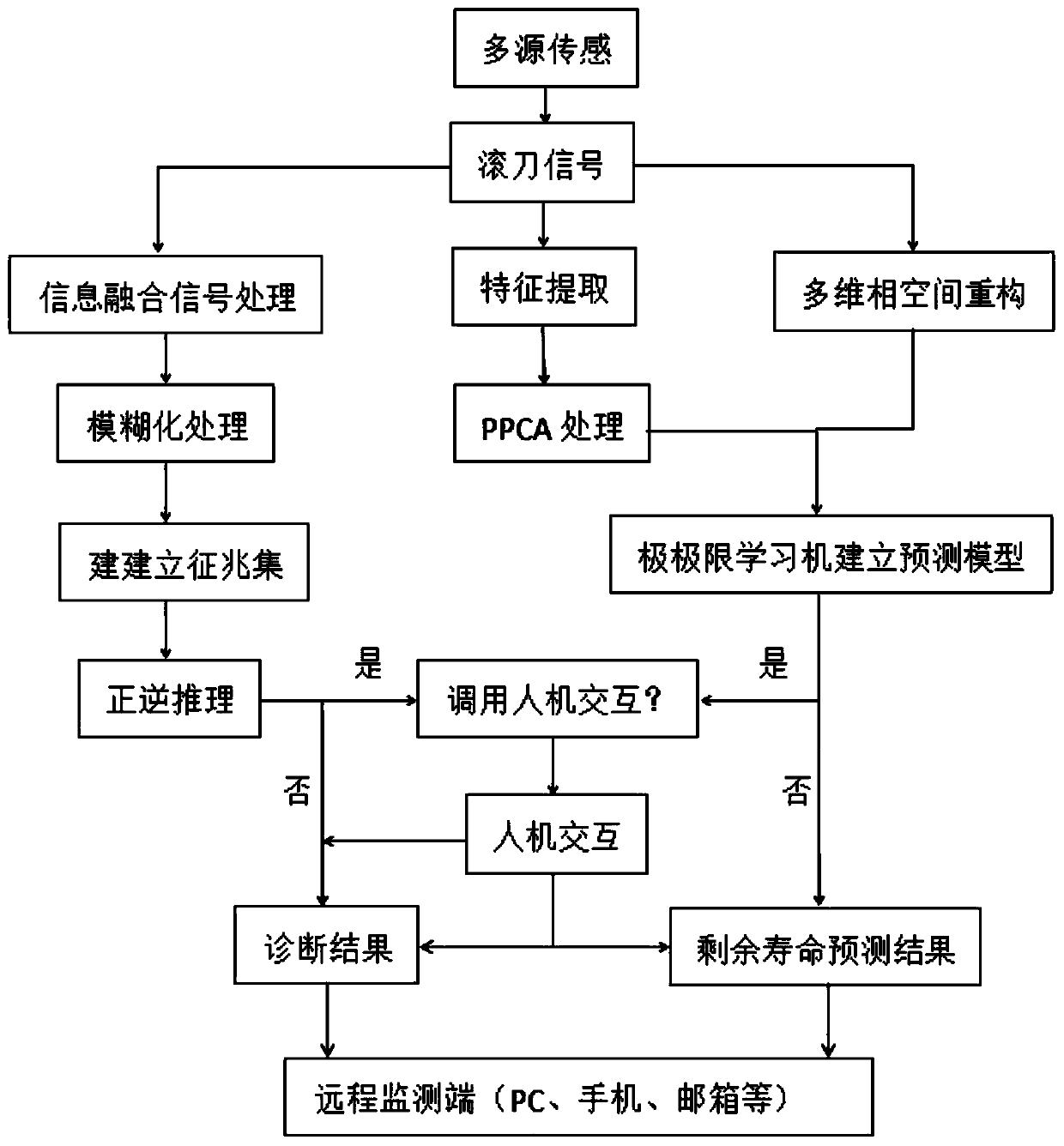

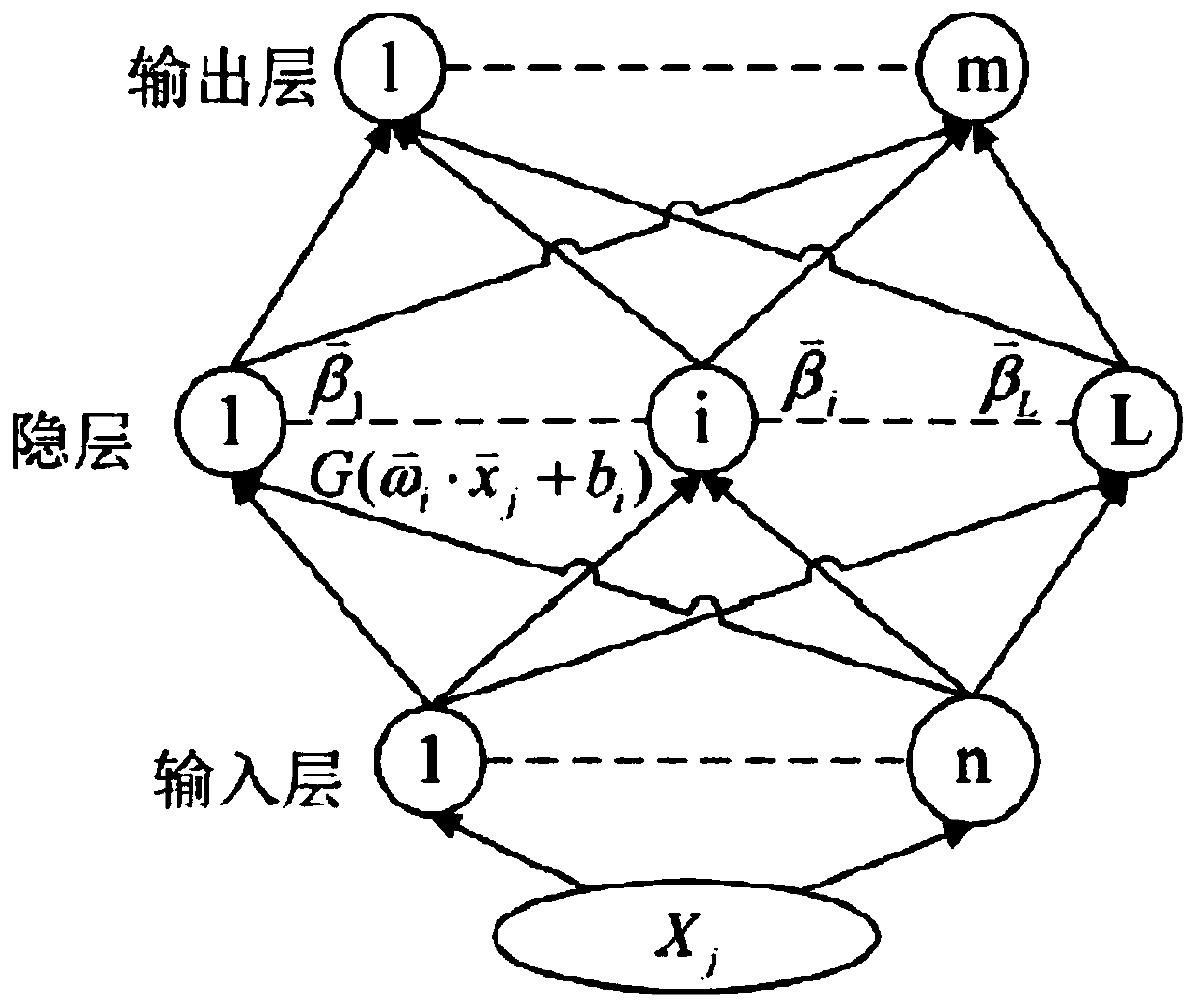

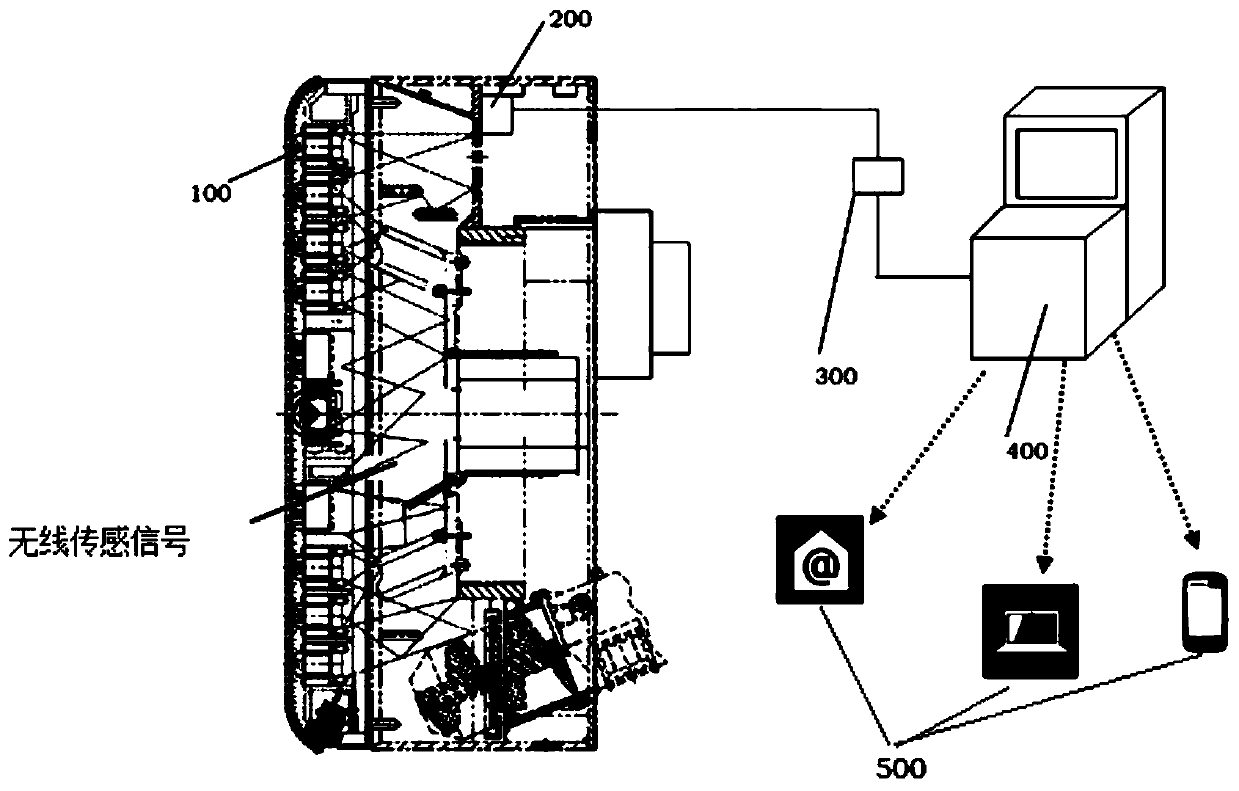

The invention discloses a tool state monitoring and life predicting system based on multi-source information fusion, comprising: an information acquisition module, a signal preprocessing module, a state monitoring module, a life predicting module, and a remote monitoring module. The information acquisition module collects the parameter information of the hob, and sending them to the condition monitoring module and / or the life predicting module after preprocessing by the signal preprocessing module; outputting the hob status by the condition monitoring module; outputting the remaining life of the hob by the life prediction module. The output of the status monitoring module and the life predicting module can be directly viewed on the spot and can be viewed remotely. The tool state monitoringand life predicting system based on multi-source information fusion realizes visual management by real-time monitoring the key parameters such as the force, wear amount, rotation speed, and shape ofthe hob by the hob monitoring device, and monitors the state of the hob in real time and predicts the remaining life of the hob by analyzing and processing the relevant signals of the hob. Further, the communication-related project management staff of the remote monitoring module can view through mobile phones, remote PCs, etc, helping humanely determine if the tool is replaced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

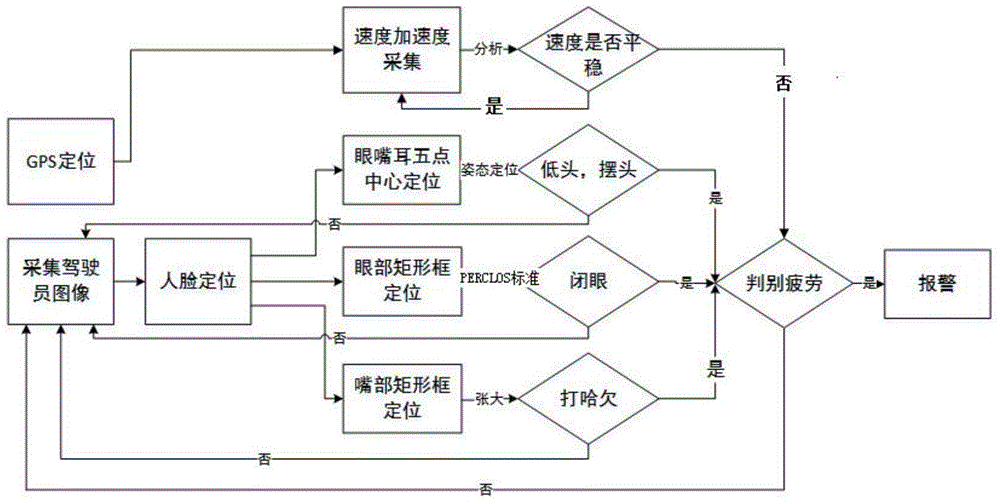

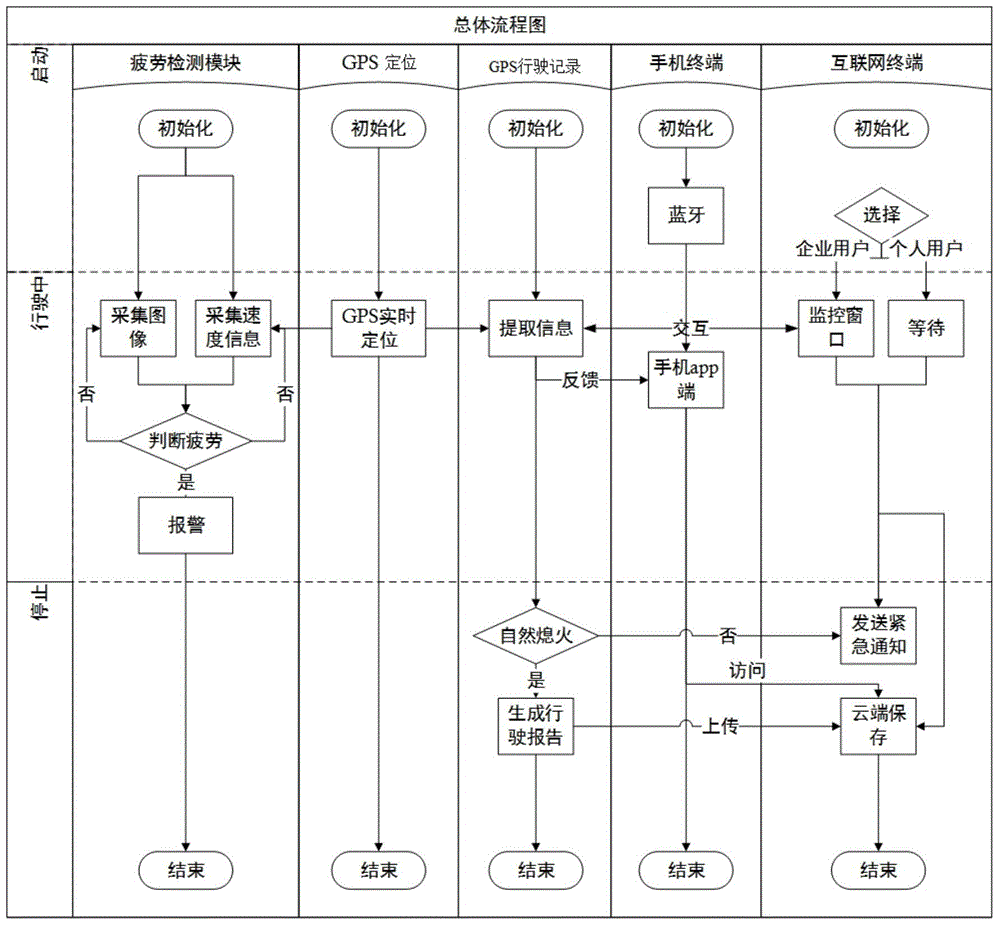

Integrated fatigue detection and driving record system and fatigue detection method

ActiveCN105069976AAdapt to physiological characteristicsImprove accuracyAlarmsDriver/operatorThe Internet

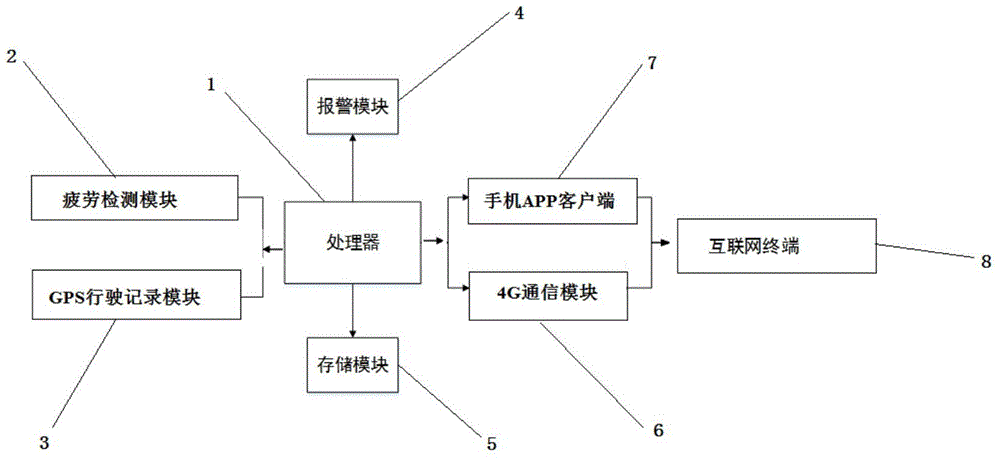

The invention discloses an integrated fatigue detection and driving record system and a fatigue detection method. The integrated fatigue detection and driving record system is characterized by comprising a processor, a fatigue detection module, an alarm module, a GPS driving record module, a communication module and a storage module, wherein the processor is connected with the fatigue detection module, the alarm module, the GPS driving record module, the communication module and the storage module. According to the integrated fatigue detection and driving record system and the fatigue detection method of the invention, through the arrangement of the fatigue detection module, the system well adapts to the physical characteristics of different drivers, the accuracy of judgment is improved, and a driver is reminded through an alarm system or a vehicle is stopped in a forced manner if that the driver is fatigued is judged; and through the arrangement of the GPS driving record module, if an accident happens to a vehicle and the vehicle is stopped abnormally, a program uploads information to the cloud, and the family of the owner, an insurance company or a car service provider is reminded in time via the Internet according to the setting.

Owner:淮安市清江浦区市场监管综合服务中心

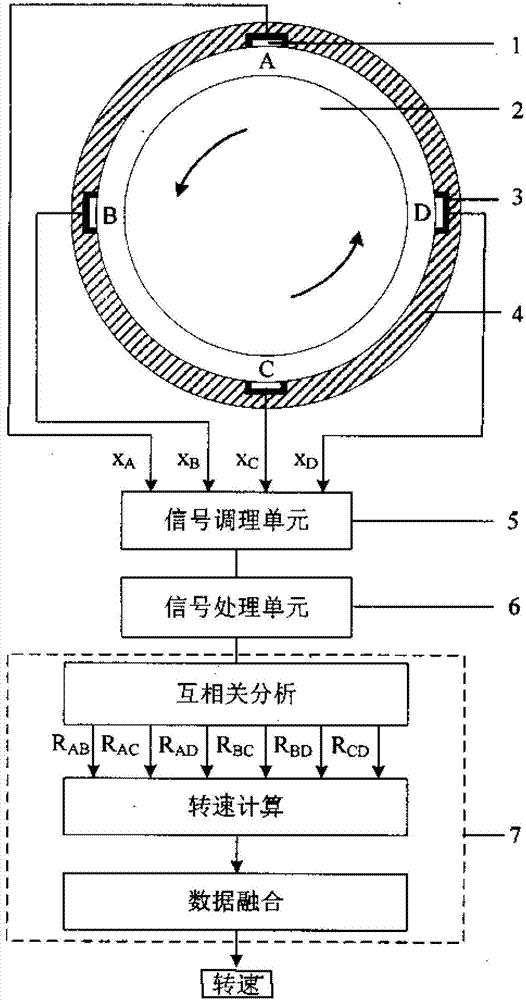

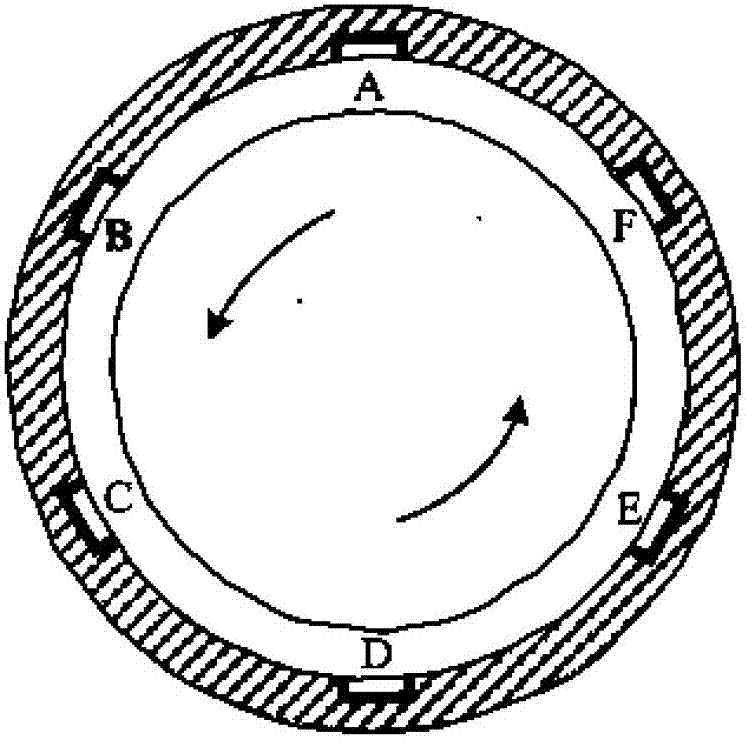

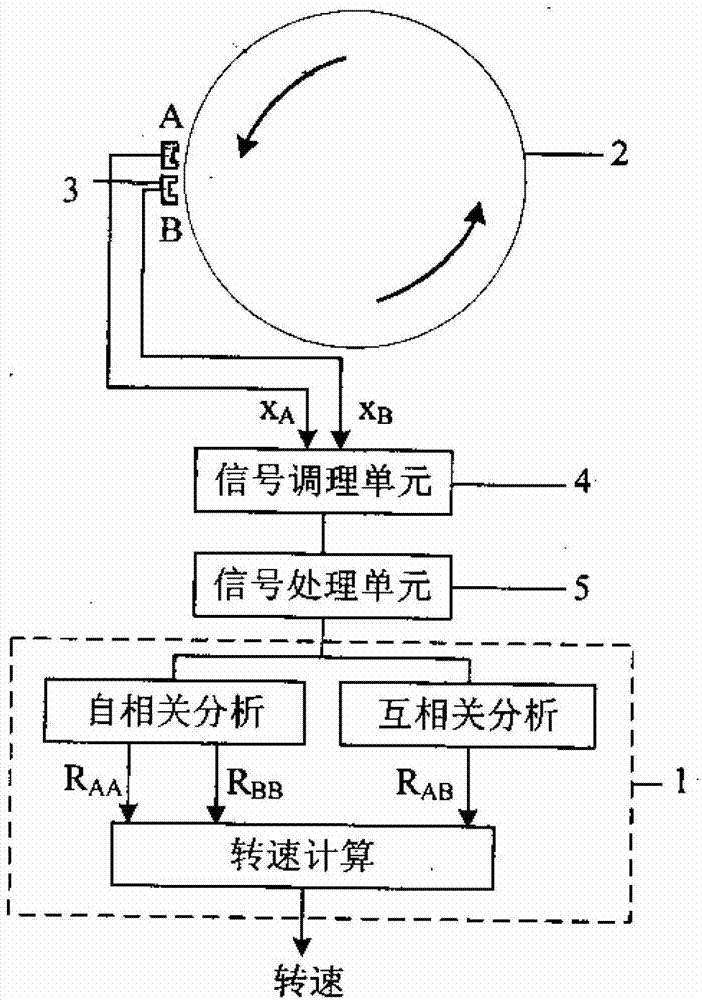

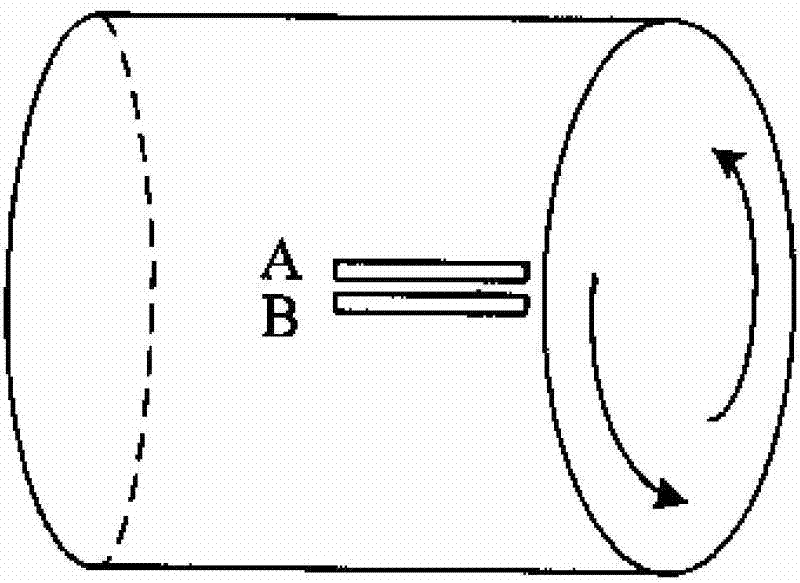

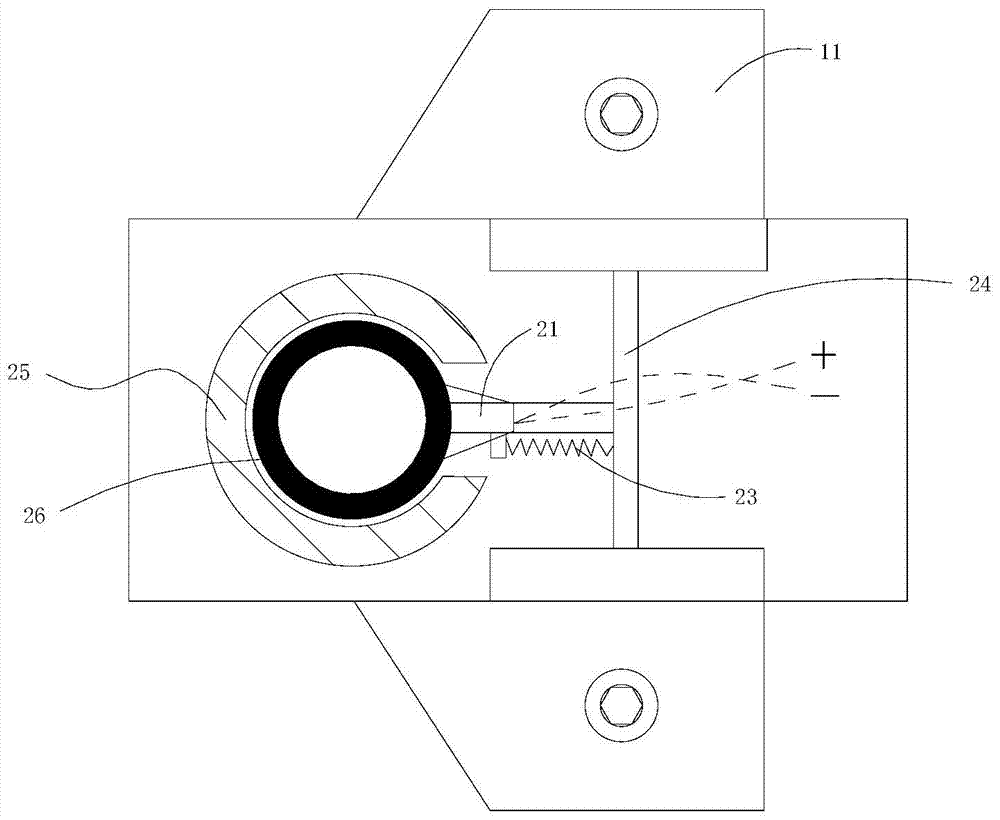

Device and method for measuring rotational speed on basis of electrostatic sensor array and data fusion

InactiveCN102854332ASimple structureReduce volumeIndication/recording movementDevices using electric/magnetic meansSensor arrayMeasurement device

The invention discloses a device and a method for measuring rotational speed on the basis of an electrostatic sensor array and data fusion, and belongs to the technical scope of measurement of rotational speed. The device for measuring the rotational speed on the basis of the electrostatic sensor array comprises a group of electrostatic sensors, the electrostatic sensors are equidistantly mounted on the periphery of the edge of a measured rotating component to form the electrostatic sensor array, an electrostatic signal reflecting rotational information of the component is generated by the electrostatic sensor array via electrostatic induction, is amplified and filtered by a conditioning unit, and is fed into a microprocessor system via a signal processing unit, and all electrostatic signals are subjected to multi-channel correlation analysis, rotational speed computation and the data fusion in a microprocessor, so that the rotational speed of the measured rotating component is acquired. Compared with existing methods for measuring rotational speed, such as an analog method, a stroboscopic method and a counting method, the method for measuring the rotational speed on the basis of the electrostatic sensor array has the advantages that the structure of the device is simple, cost is low, influence of environmental factors is avoided, the method is a non-contact measurement method, and accuracy is high.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

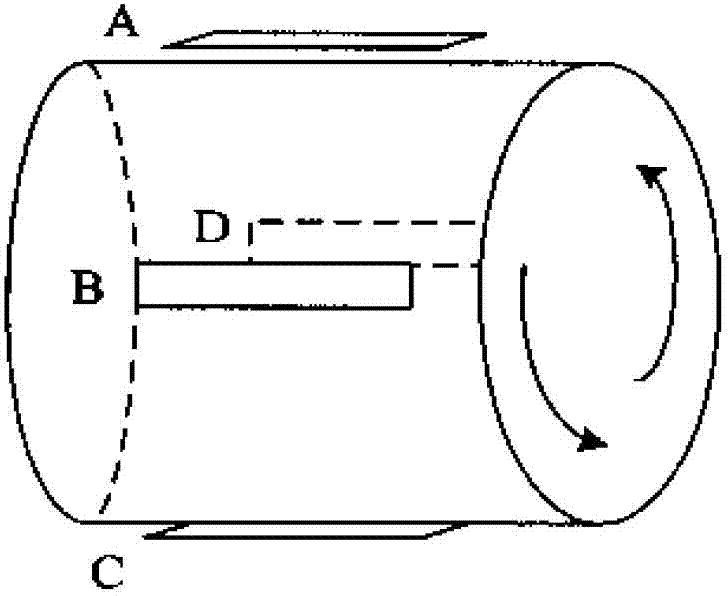

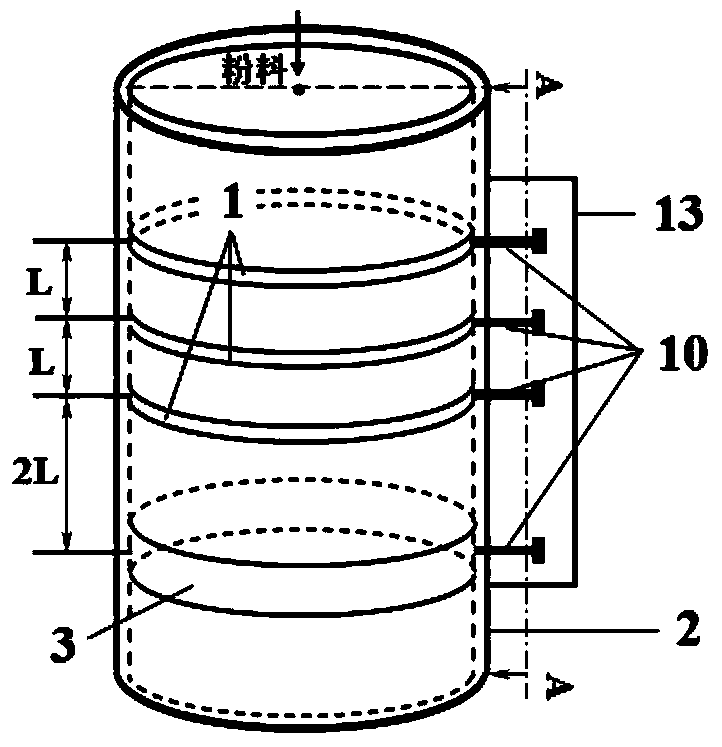

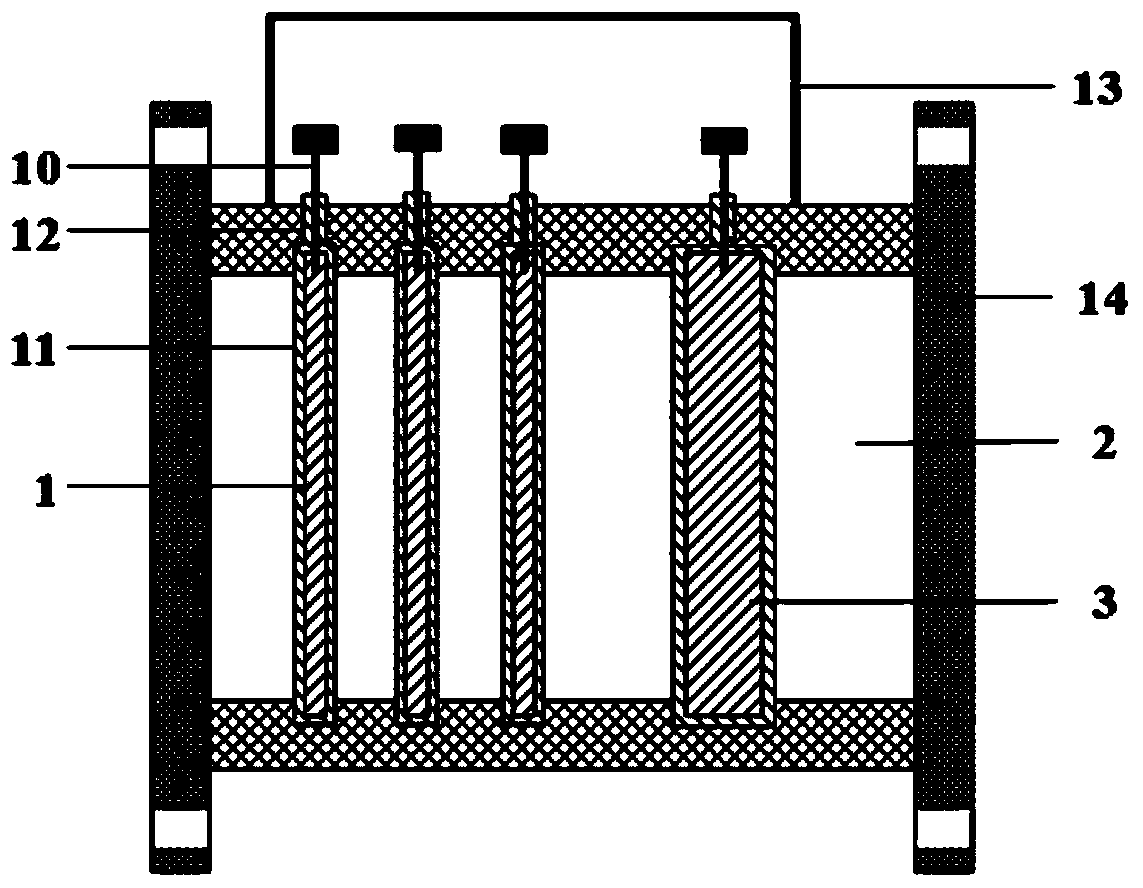

Array type annular electrostatic sensor and pneumatic transmission powder measurement device and method

InactiveCN104316779AReal-time monitoring speedReal-time monitoring of traffic informationBulk conveyorsElectrostatic field measurementsMeasurement deviceMotion parameter

The invention relates to an array type annular electrostatic sensor and a pneumatic transmission powder measurement device and method. The array type annular electrostatic sensor comprises a tubular metal body, at least one set of first metal electrodes and at least one set of second metal electrodes are sequentially arranged on the inner circumferential face of the tubular metal body in a winding mode side by side, the first metal electrodes and the second metal electrodes are annular, and the axial width of the first metal electrodes is smaller than the axial width of the second metal electrodes. The invention further relates to the pneumatic transmission powder measurement device and method based on the sensor. By means of the method, main motion parameters of powder are monitored in real time under the condition that flowing of the powder is not interfered, the measurable range is large, the service life of the sensor is long, installation and maintenance are convenient, and the sensor can be widely used in industrial processes with the pneumatic transmission powder.

Owner:BEIJING ENLANDAR TECH

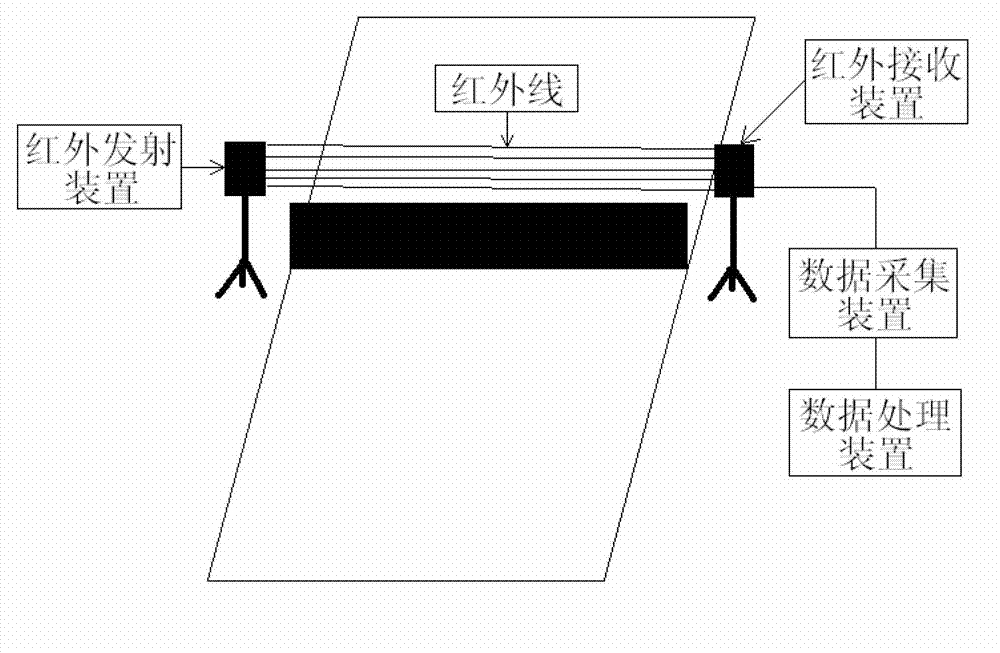

Over-net ball speed tester for net separating competitive items

InactiveCN102784471AReal-time monitoring of motion trajectoryEasy to masterDevices using time traversedSport apparatusInfraredTime information

The invention discloses an over-net ball speed tester for net separating competitive items. The tester comprises an infrared emission device, an infrared receiving device, a data collecting device and a data processing device; the infrared emission device emits infrared rays through an infrared emission end; the infrared receiving device receives the infrared rays emitted by the infrared emission red through an infrared receiving end; the infrared rays in the same vertical plane form an infrared net surface; the infrared net surfaces are two or more in number and are parallel to a separating net; the data collecting device collects breakpoint position information and breakpoint time information received by the infrared receiving device and transmits the collected information to the data processing device; and the data processing device computes and analyzes the received information so as to obtain the speed information of an over-net ball. The over-net ball speed tester for net separating competitive items, provided by the invention, can monitor parameters including over-net speed and motion trail of the ball, and is an extensive, effective and scientific auxiliary device designed for various net separating competitive items.

Owner:宋雅伟

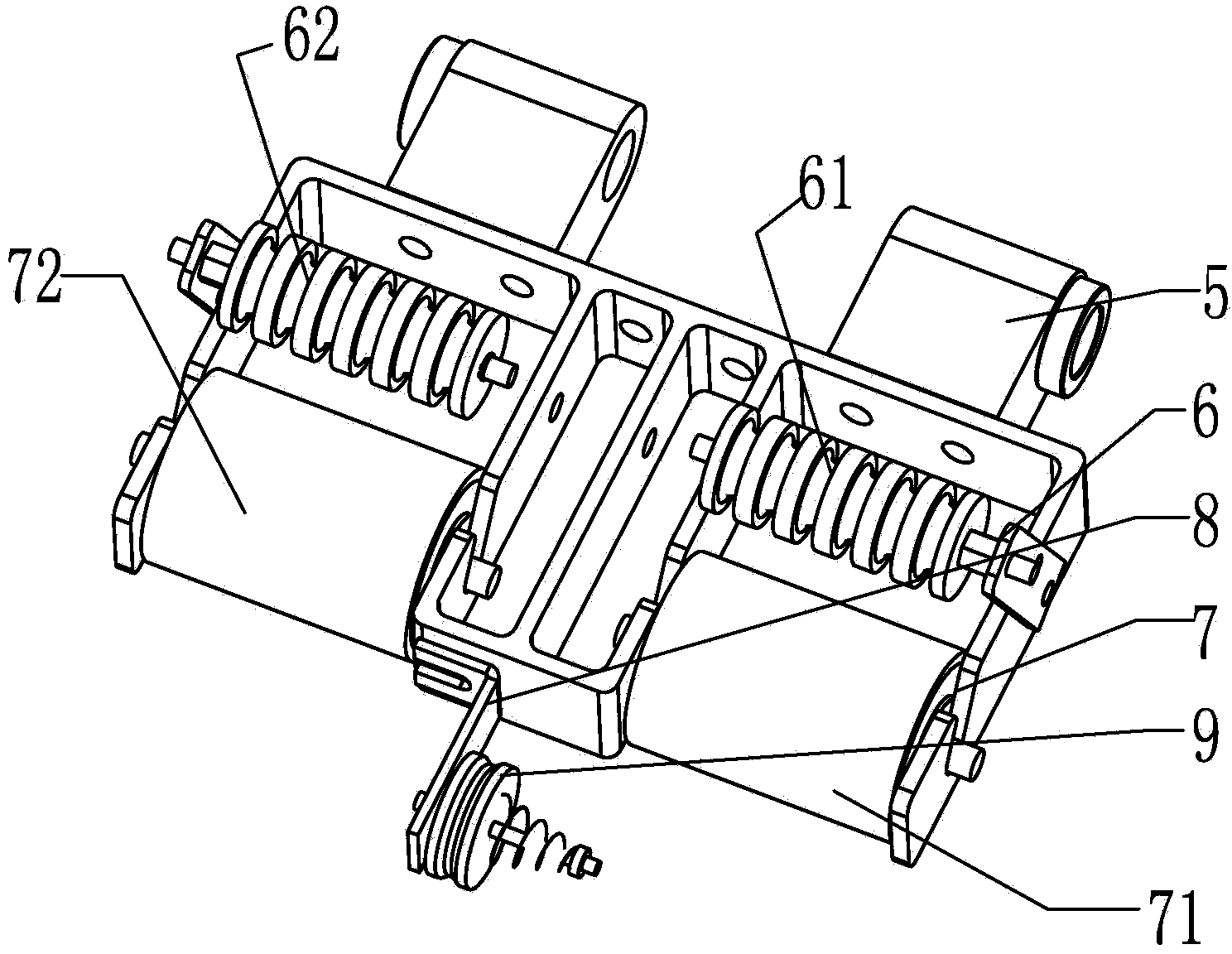

Chenille spinning machine

The invention discloses a chenille spinning machine for spinning chenille yarns. Firstly, knitting wools for spinning the chenille yarns wind an inverted triangle distance cutting sheet through a high-speed swiveling head, and the width of the neck portion of the distance cutting sheet depends on the length of pile yarns. Subsequently, a pressure roller is fed into a grey yarn rack, two core yarns are discharged, one of the core yarns forms a surface layer core yarn of the chenille yarns, and the other one of the core yarns forms a base layer core yarn of the chenille yarns. The knitting wools on the distance cutting sheet are pushed to blades through roller pieces, the blades move in the middle of the neck portion of the distance cutting sheet, and the knitting wools are cut by means of the blades. The cut knitting wools are sideward clamped between the surface layer core yarn and the base layer core yarn, and flaky knitting wools between the two core yarns are scattered towards all sides to form the chenille yarns through downward use of swiveling of reeling spindles. The chenille spinning machine has the advantages of being convenient to operate, high in production efficiency, large in reeling volume, safe, and reliable.

Owner:ZHEJIANG DONGXING TEXTILE MACHINERY

Device and method for measuring rotating speed of rotating object by adopting electrostatic sensor

InactiveCN102854336AReal-time speedReal-time monitoring speedDevices using time traversedPhysicsSignal processing

The invention discloses a device and a method for measuring the rotating speed of a rotating object by adopting an electrostatic sensor. The method is as follows: a single electrostatic sensor electrode or double electrostatic sensor electrodes is / are arranged near a detected rotating part, and is / are used for sensing the rotation information of the rotating object at the position where the electrodes are positioned, the electrode of the electrostatic sensor is connected to a microprocessor in series via a single signal conditioning unit and a signal processing unit, electrostatic signals are amplified and filtered through the conditioning unit and are sent to the microprocessor through the signal processing unit, and relevant analytical calculation is carried out on the electrostatic signals through the microprocessor so as to obtain the rotating speed of the detected rotating object finally. Compared with the conventional rotating speed measuring device, the device is simple in structure, extremely low in cost and convenient to install, is not limited by the size dimension of a detected part and not easy to influence by environmental factors, belongs to noncontact measurement and has relatively high accuracy.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

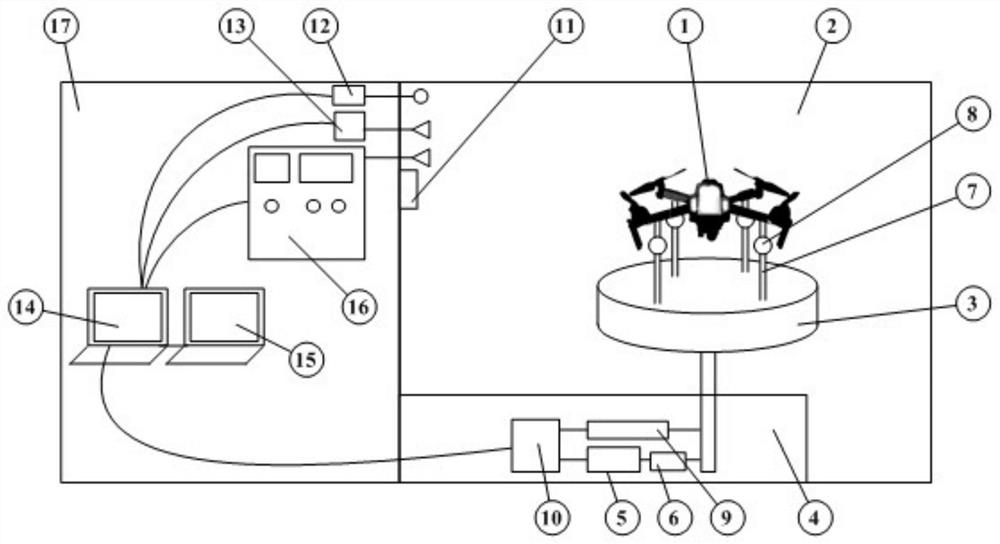

High-power microwave effect test device for micro multi-rotor unmanned aerial vehicle

ActiveCN112009721ARealize dynamic high power microwave effect testMeet the needs of high power microwave effect test simulationAircraft components testingVideo monitoringControl system

The invention discloses a high-power microwave effect test device for a micro multi-rotor unmanned aerial vehicle. The test device at least comprises a simulation flight platform, a video monitoring module, a global positioning signal generation module, an HPM irradiation environment generation module and a device control system. The simulation flight platform at least comprises a mechanical rotating platform, a driving unit, a supporting rod and a supporting induction control unit. The video monitoring module is configured to monitor a to-be-tested unmanned aerial vehicle, and the global positioning signal generation module is configured to generate a positioning signal with a set position and a set height for the to-be-tested unmanned aerial vehicle; the HPM irradiation environment generation module is configured to apply an HPM radiation field with set parameters to the to-be-tested unmanned aerial vehicle. With the structural design of the test device, the problems that the flightstate of the unmanned aerial vehicle cannot be simulated, the effect of the unmanned aerial vehicle cannot be monitored in multiple directions and the power density of the environment field where theunmanned aerial vehicle is located cannot be accurately controlled in the existing micro multi-rotor unmanned aerial vehicle high-power microwave effect test are solved.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

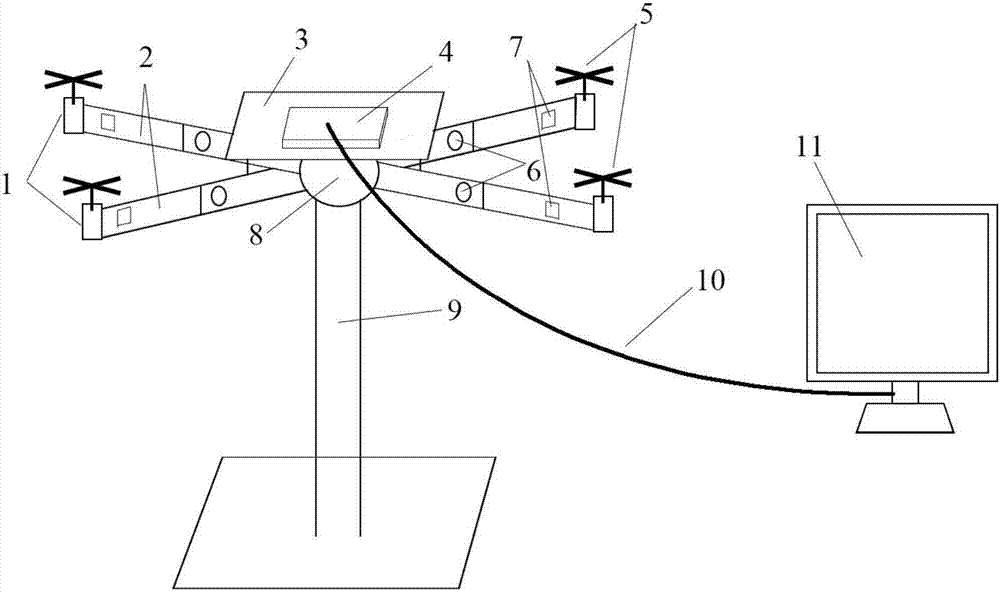

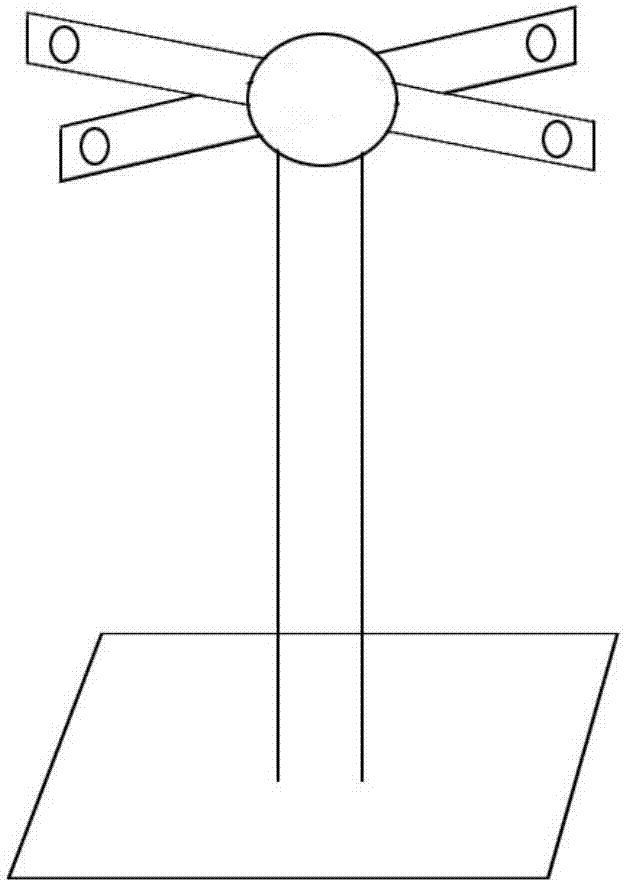

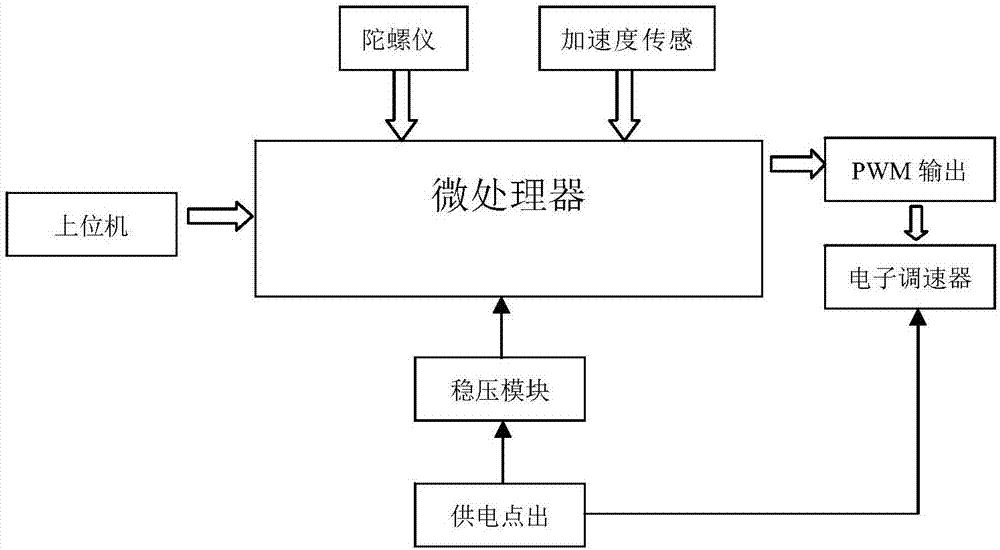

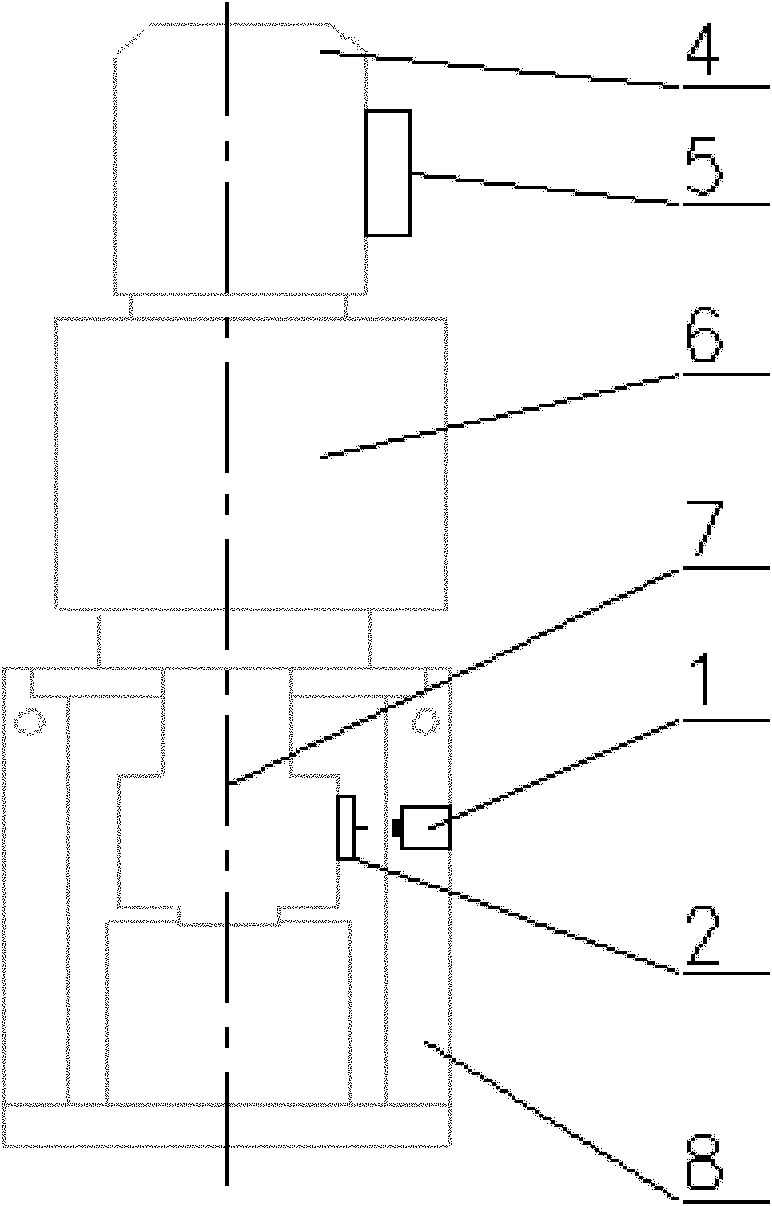

Multi-dimensional four-rotor aircraft attitude control simulation experiment platform

InactiveCN106896738AFlexible and convenient designEasy to understandSimulator controlBrushless motorsAttitude control

The invention relates to a multi-dimensional four-rotor aircraft attitude control simulation experiment platform. The experiment platform includes an aircraft, a flight controller and an upper computer, the upper computer, the flight controller and the aircraft are connected in sequence, the aircraft includes a three-degree-freedom rotating component and a plurality of aerofoils detachably connected with the rotation component, one ends of the aerofoils away from the rotating component are equipped with brushless motors and propellers, the aerofoils are provided with electronic speed regulators, the brushless motors are connected with the electronic speed regulators and the propellers, and the flight controller is connected with the electronic speed regulators. Compared with the prior art, the multi-dimensional four-rotor aircraft attitude control simulation experiment platform provided by the invention has the advantages that the detachable aerofoil design is flexible and convenient, an algorithm is updated in real time, a simulation effect is good, the aircraft state is monitored in real time and research and development cost is reduced.

Owner:SHANGHAI UNIV OF ENG SCI

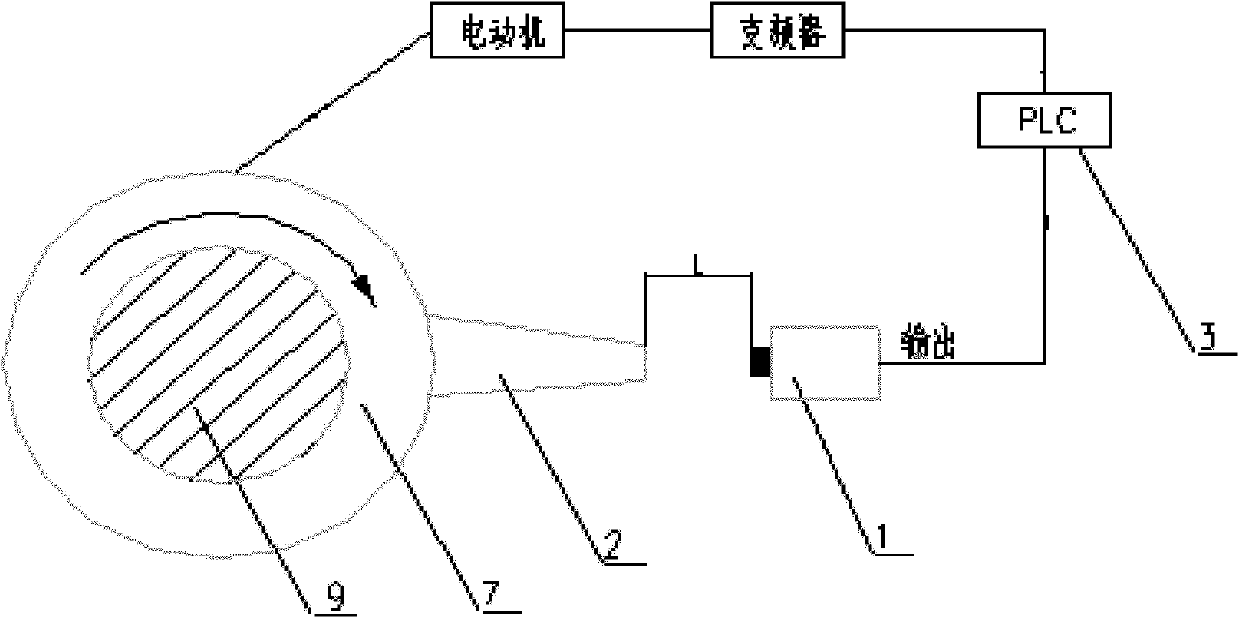

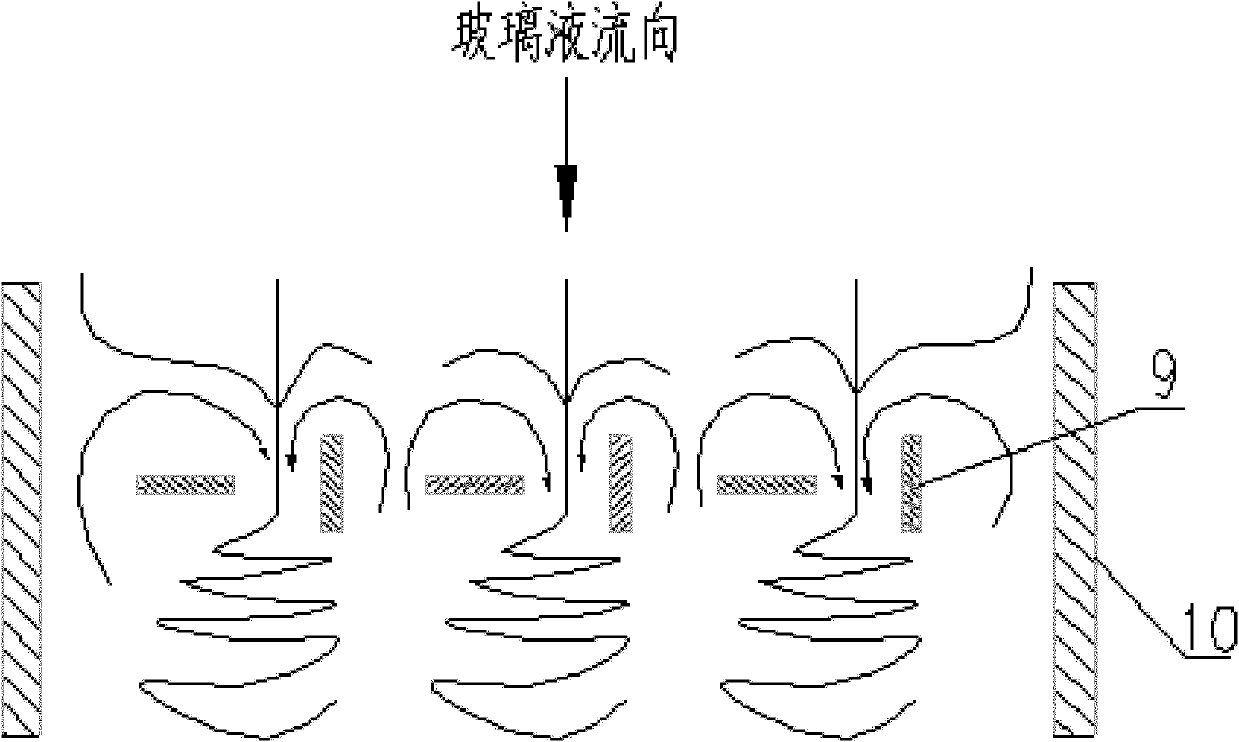

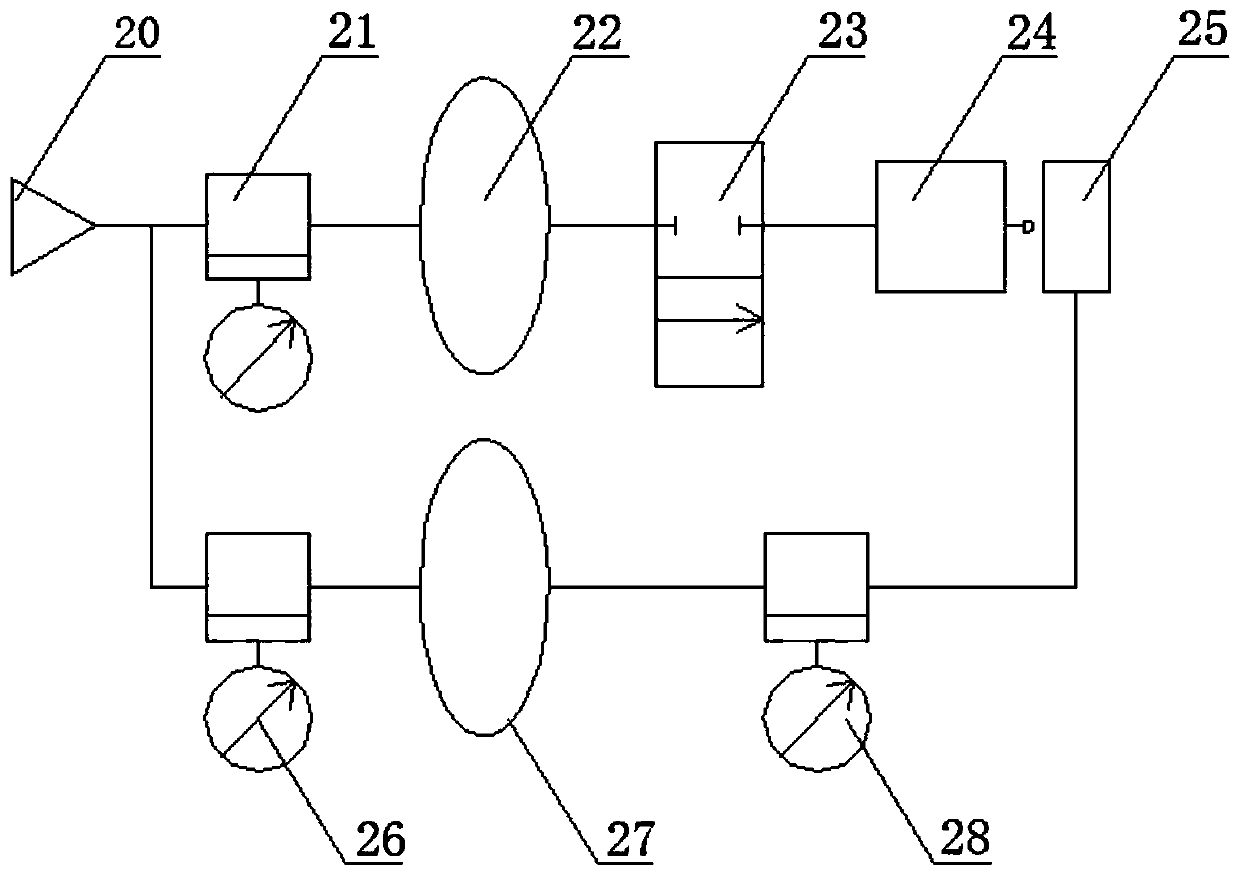

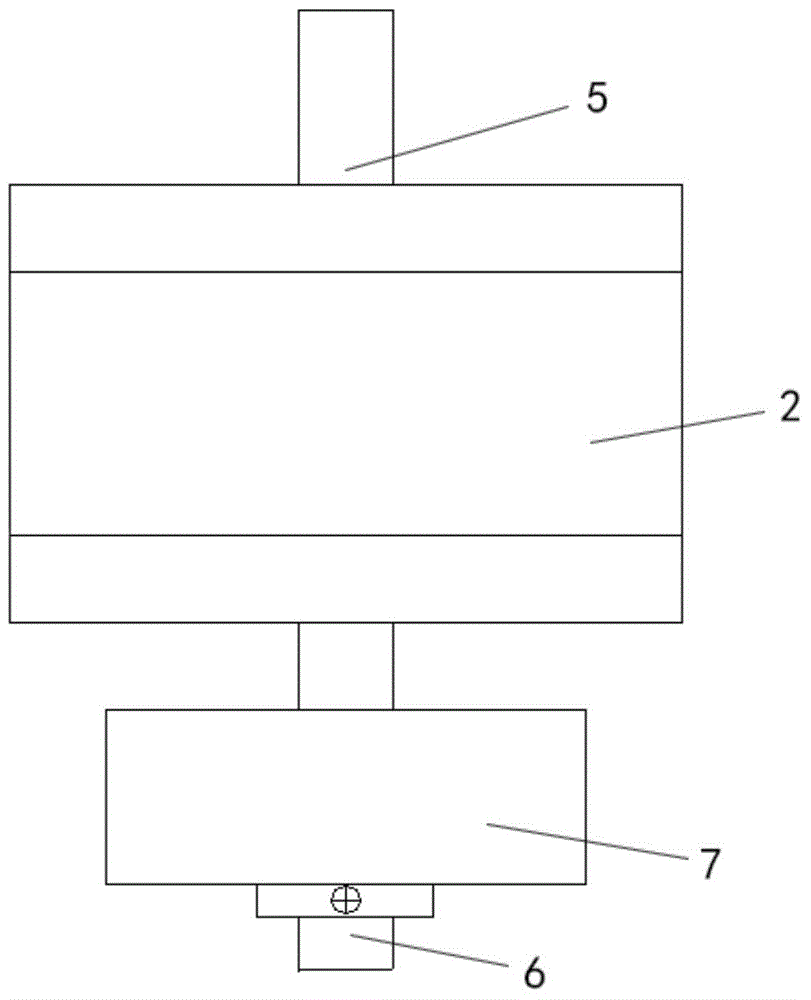

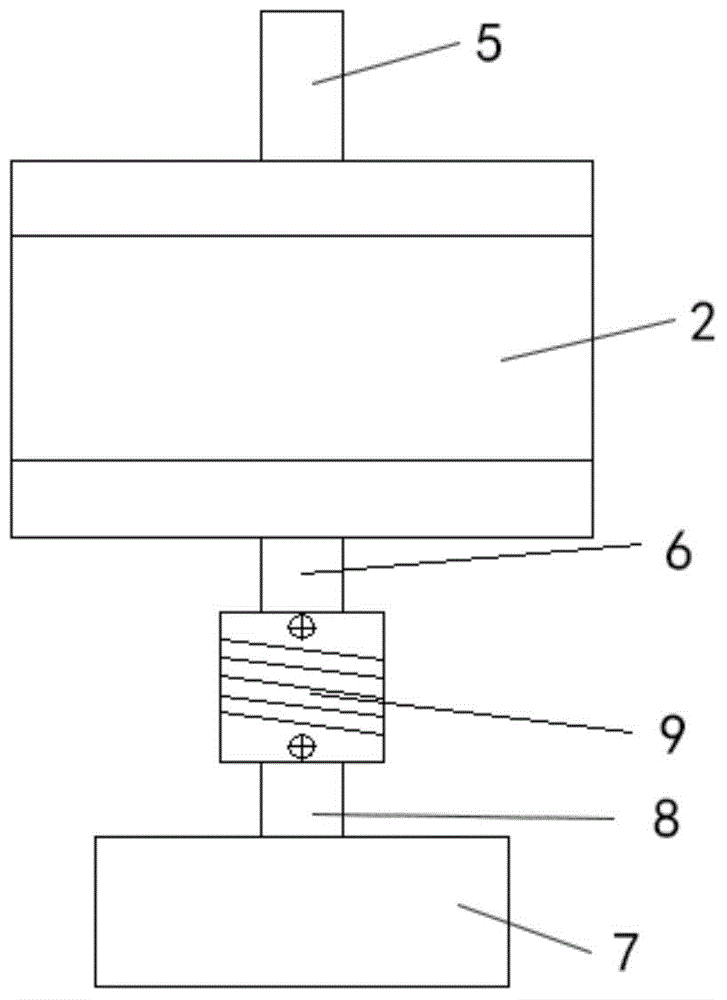

Transmission control mechanism of stirring system

ActiveCN102004493AReal-time monitoring speedReal-time monitoring of steeringAC motor controlPosition/direction controlClutchProgrammable logic controller

The invention relates to the field of glass production machinery, in particular to a transmission control mechanism of a stirring system. The transmission control mechanism is characterized in that: the signal input end of a programmable logic controller (PLC) controlled by a computer is connected with the signal input end of a variable frequency speed regulator set, the signal input end of the variable frequency speed regulator set is connected with the signal input end of a motor, the signal output end of the motor is connected with the signal input end of a clutch, the signal output end of the clutch is connected with the signal input end of a trigger, the signal output end of the trigger is connected with the signal input end of a proximity sensor, and the signal output end of the proximity sensor is connected with the other signal input end of the PLC. The transmission control mechanism has the advantages that: 1, the proximity sensor is matched with the trigger rather than a cheaper coder to monitor the rotational speed and the steering of a stirring blade in real time; 2, the trigger is arranged in the same plane as the stirring blade to simply monitor the phase angle of the stirring blade; and 3, by adopting the PLC for measurement, display and control operation, the transmission control mechanism has high reliability and strong adaptability.

Owner:CHINA TRIUMPH INT ENG

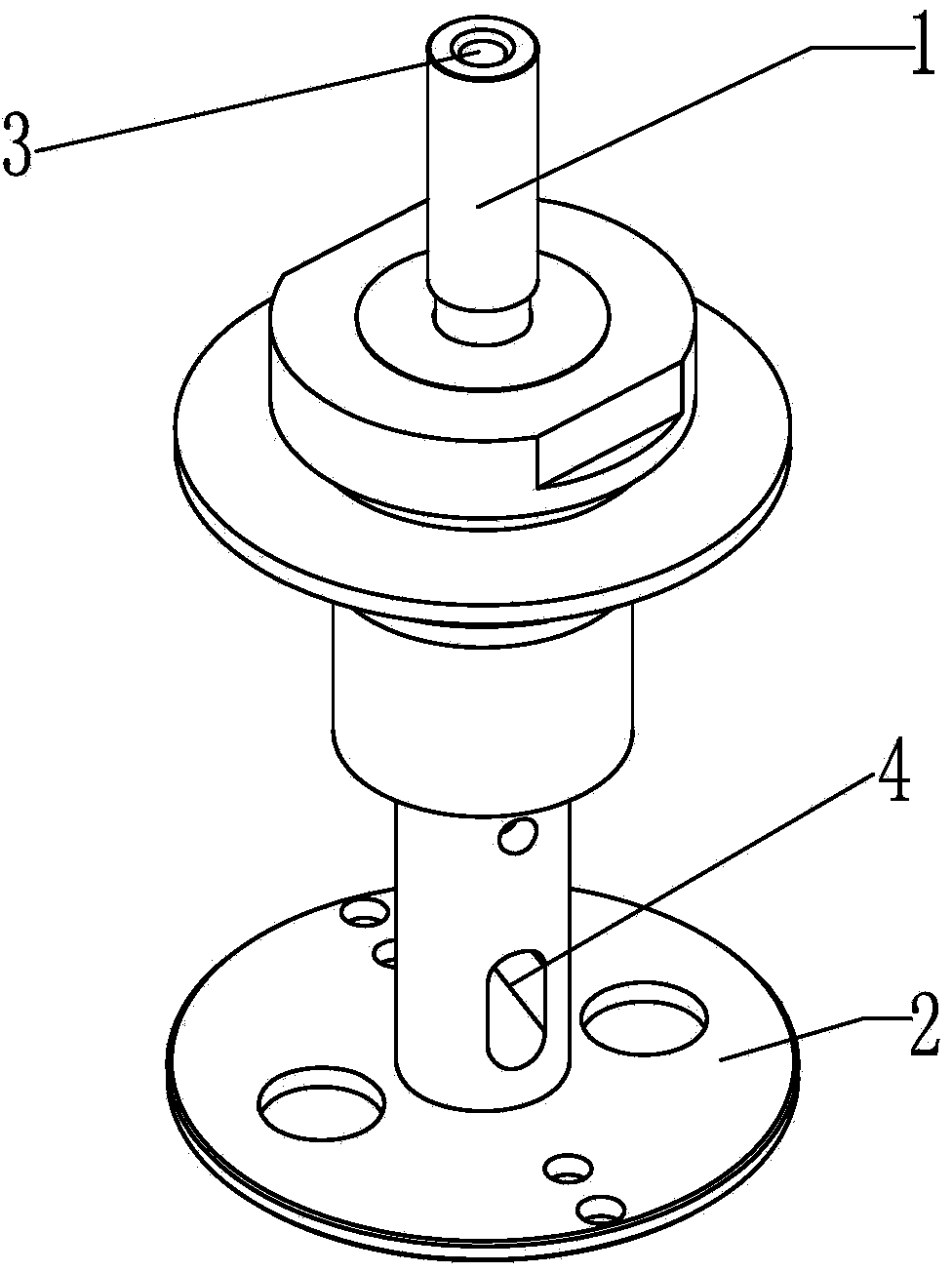

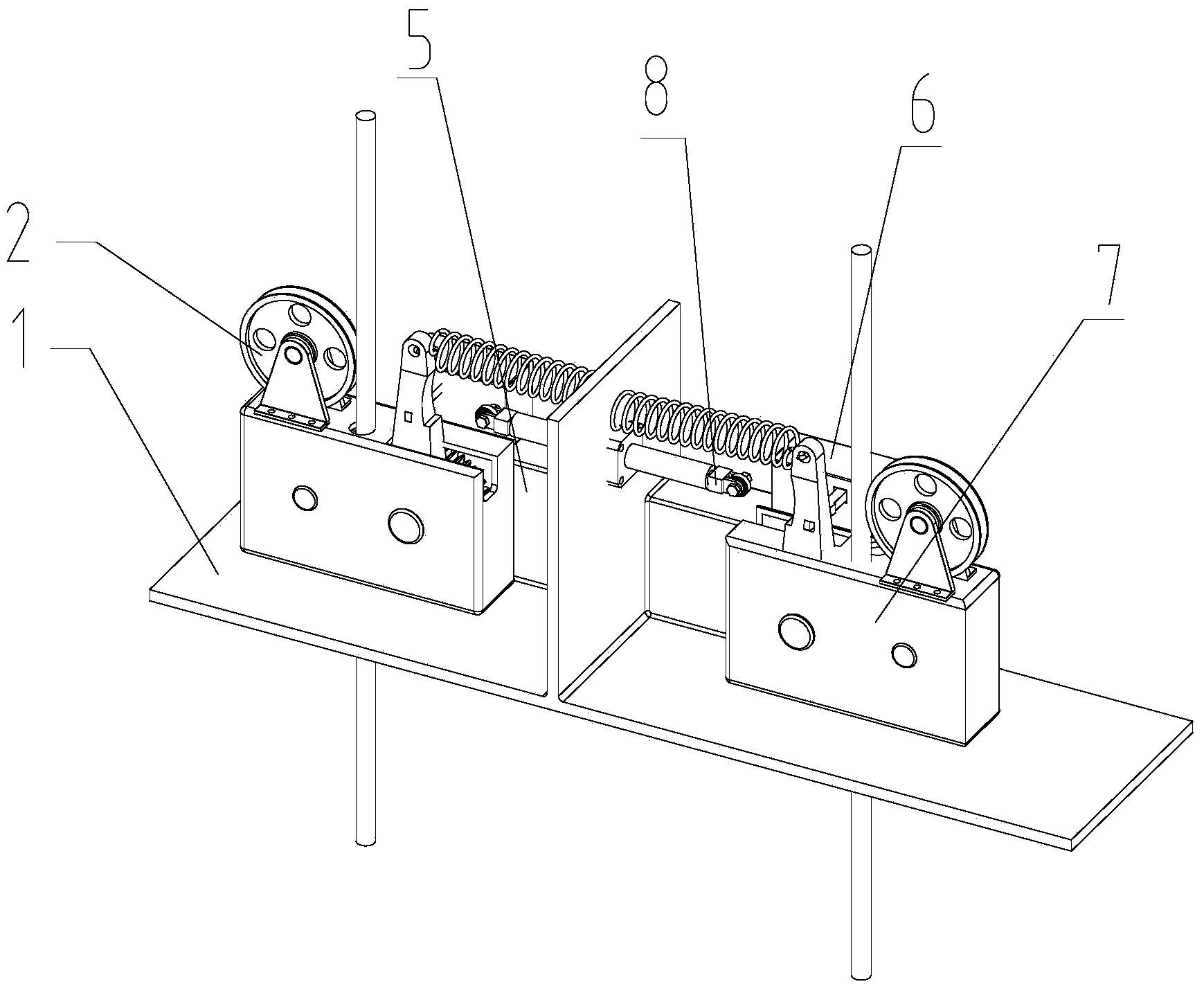

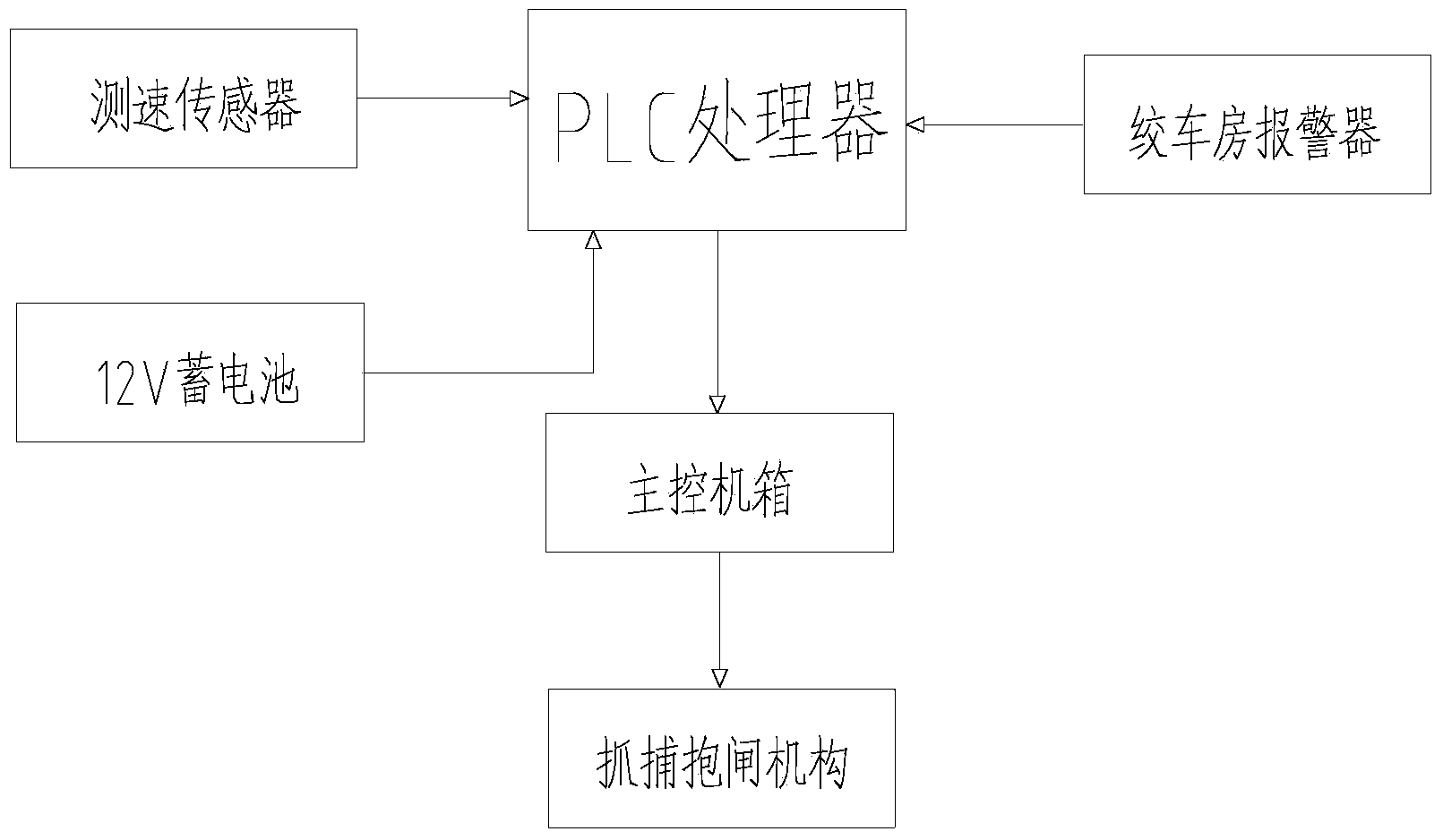

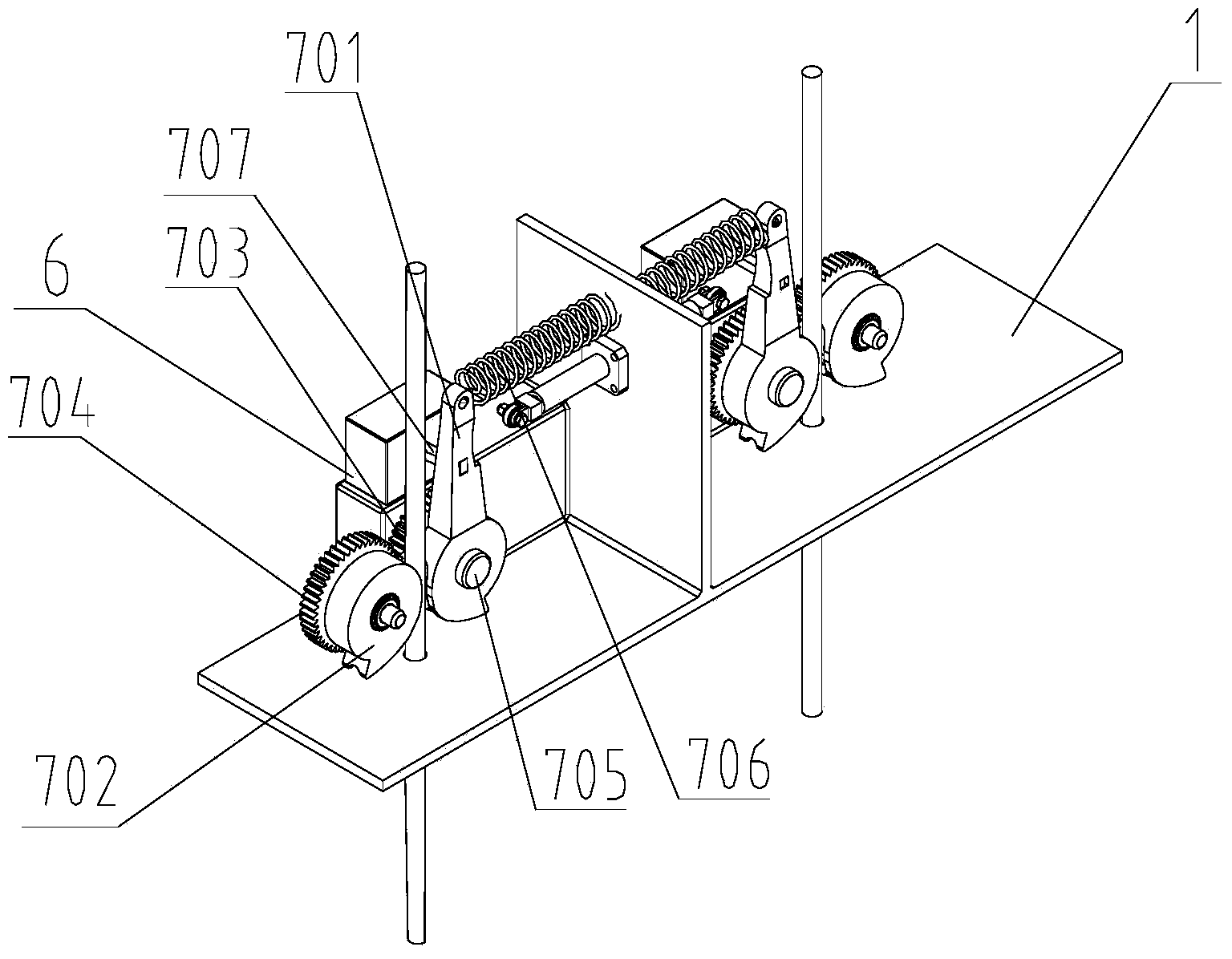

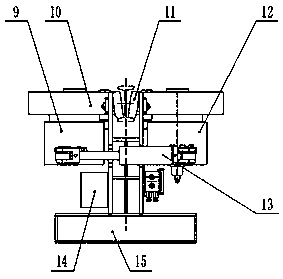

Full-automatic velocity-limiting anti-falling device

InactiveCN104291178AReal-time monitoring speedMonitor location in real timeElevatorsGear transmissionCam

The invention relates to a full-automatic velocity-limiting anti-falling device. The full-automatic velocity-limiting anti-falling device is composed of a position velocity measuring device, an electric control device, a capturing braking device and a resetting device, a position velocity measuring sensor measures a position velocity signal and sends to a PLC controller, the PLC controller controls the electric device, a wedge-shaped slide block is shrank, a crank arm cam is driven to rotate by the shrinkage force of an extension spring, a cam rotates along with the crank arm cam to brake and rub a steel wire rope through gear transmission, and then the cage brake is realized. The full-automatic velocity-limiting anti-falling device is featured with convenience in mounting, high automatic degree, sensitive and reliable control and good brake performance.

Owner:ANHUI UNIV OF SCI & TECH

Pressurizing test method for computing performance of GTX-series graphic cards

InactiveCN107423183APressure test implementationReal-time monitoring speedFunctional testingCUDAPower consumption

The invention discloses a pressurizing test method for computing performance of GTX-series graphic cards and relates to the field of computer big data. The method is used for performing a pressurizing test on the computing performance of the GTX-series graphic cards. The operating system on a test machine is a Linux system, and a CUDA operation platform of NVIDIA is utilized. The method comprises the specific implementation steps that a graphic card driver and a CUDA program are installed, and the pressurizing test and a PCIE bandwidth test are computed. The method is suitable for testing performance, compatibility and heat dissipation of the graphic cards. By aid of the method, the pressurizing test of the computing performance of the GTX-series graphic cards is realized, and meanwhile fan speed, temperature and power consumption in the pressurizing process of the graphic cards can be monitored in real time.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

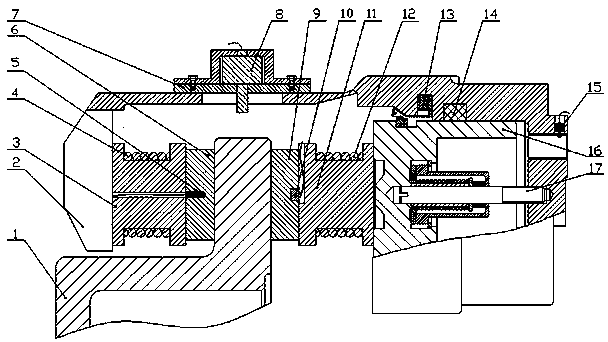

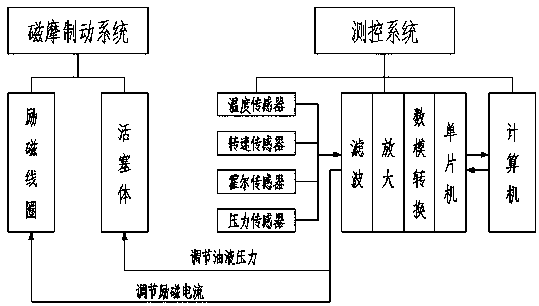

Automobile magnetic and frictional compound brake based on magnetic and frictional coupling effect

ActiveCN105545987AReduce wearImprove braking effectAxially engaging brakesActuatorsState parameterEngineering

The invention discloses an automobile magnetic and frictional compound brake based on a magnetic and frictional coupling effect. Excitation coils wind the surfaces of both a left backboard and a right backboard, through holes are formed in the surface of the left backboard, deep holes are formed in one side surface of a left friction plate, sensors are arranged in the deep holes of the left friction plate, the left backboard is fixed onto a brake caliper body, and the left friction plate is connected with the left backboard and clung to the surface of the left side of a brake disc; deep holes are also formed in the surface of a right friction plate, a through groove is formed in one side surface of the right backboard, sensors are placed in the deep holes of the right friction plate, the right friction plate is connected with the right backboard, the right backboard is fixed onto a piston body, and the piston body is fixed to the brake caliper body via a bolt; a sensor bearing body is welded on the upper surface of the brake caliper body, and a sensor is arranged in the sensor bearing body; all the sensors are electrically connected with a computer. By virtue of the positive effect on friction behavior from a magnetic field, the automobile magnetic and frictional compound brake improves the frictional braking performance, monitors the important state parameters in real time, timely feeds back and adjusts abnormal situations in the braking process, and improves the stability and reliability of a braking system.

Owner:CHINA UNIV OF MINING & TECH

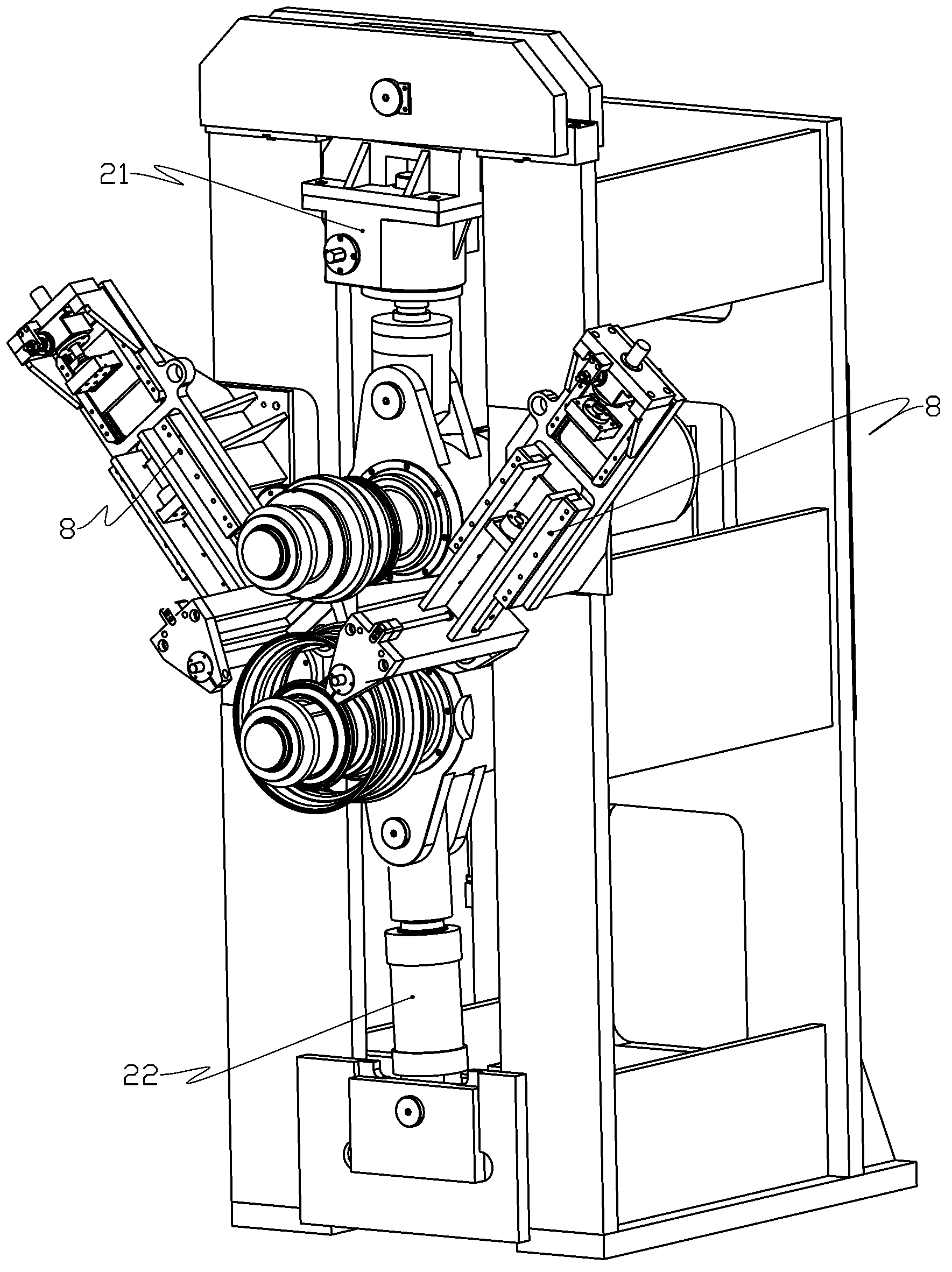

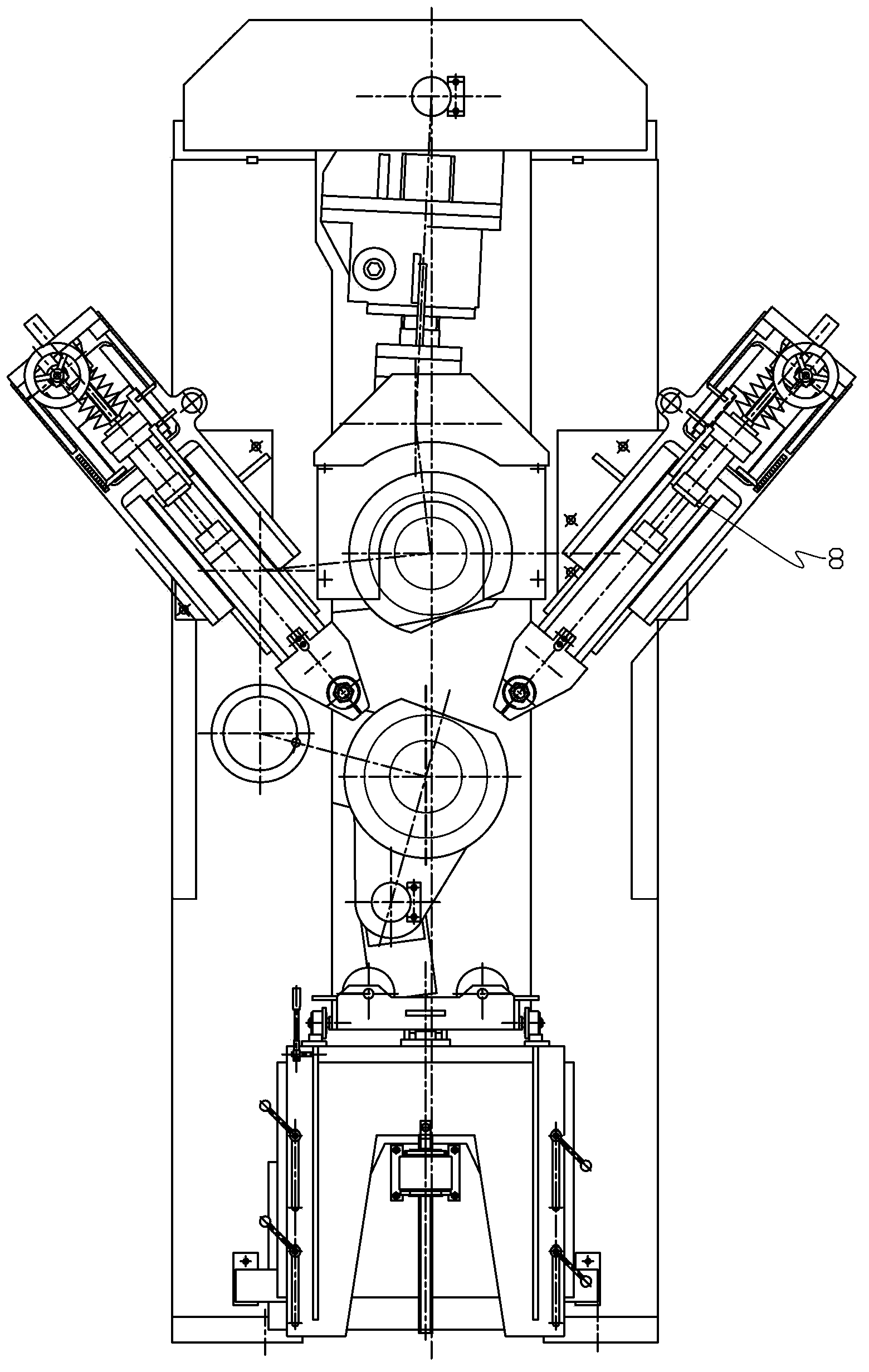

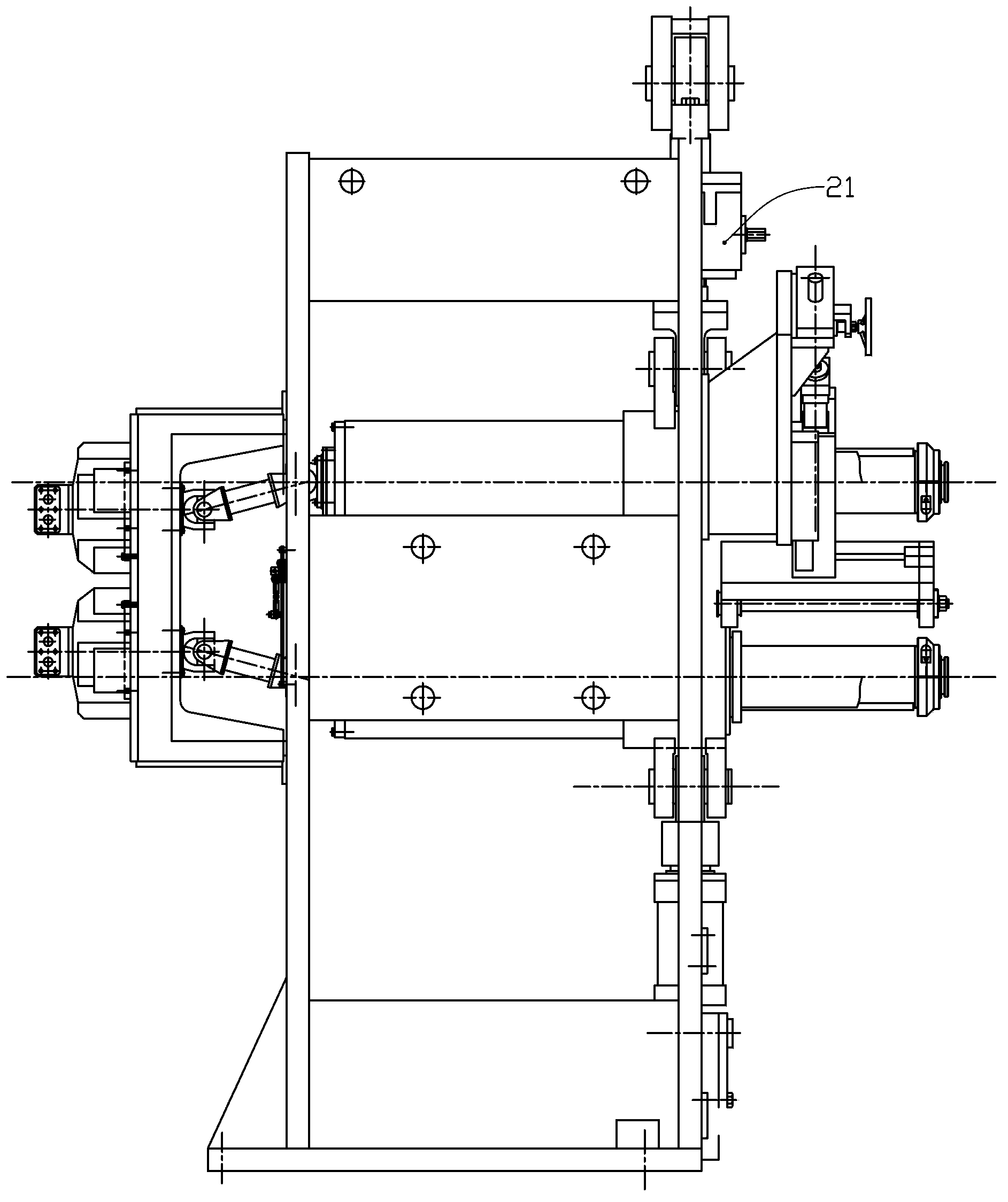

Rim roll forming machine with three-dimensional adjusting function

InactiveCN103350168AAdjust tilt angleLarge adjustment rangeMetal rollingThree-dimensional spaceEngineering

The invention discloses a rim roll forming machine with a three-dimensional adjusting function. The rim roll forming machine with the three-dimensional adjusting function comprises a machine body, an upper main shaft module, a lower main shaft module and a side wheel guiding device. The upper main shaft module comprises a first eccentric block, a first hinged shaft, a first main shaft and a first incomplete gear. The front end of the first hinged shaft is provided with a first oscillating bearing which is arranged on the machine body through a first cylinder sliding sleeve. The rear end of the first hinged shaft is arranged on the machine body in a slipknot mode through the first eccentric shaft sleeve, in addition, a self-aligning bearing is arranged between the first eccentric shaft sleeve and the first hinged shaft. The rear end of the first main shaft is provided with a first driving element, and a first lifting device driving the first eccentric block to lift is arranged between the front middle portion of the first eccentric block and the machine body. The lower main shaft module is basically the same with the upper main shaft module, and a set of annular bodies and a driving device are added. A second lifting device is arranged between the front end of a second eccentric block and the machine body. The rim roll forming machine with the three-dimensional adjusting function can achieve dynamic control and achieve conversion from adjustment in one direction to all-dimensional adjustment in the three-dimensional space.

Owner:SHANDONG XIAOYA PRECISE MACHINERY

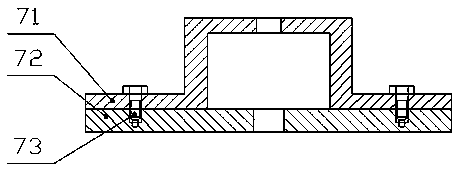

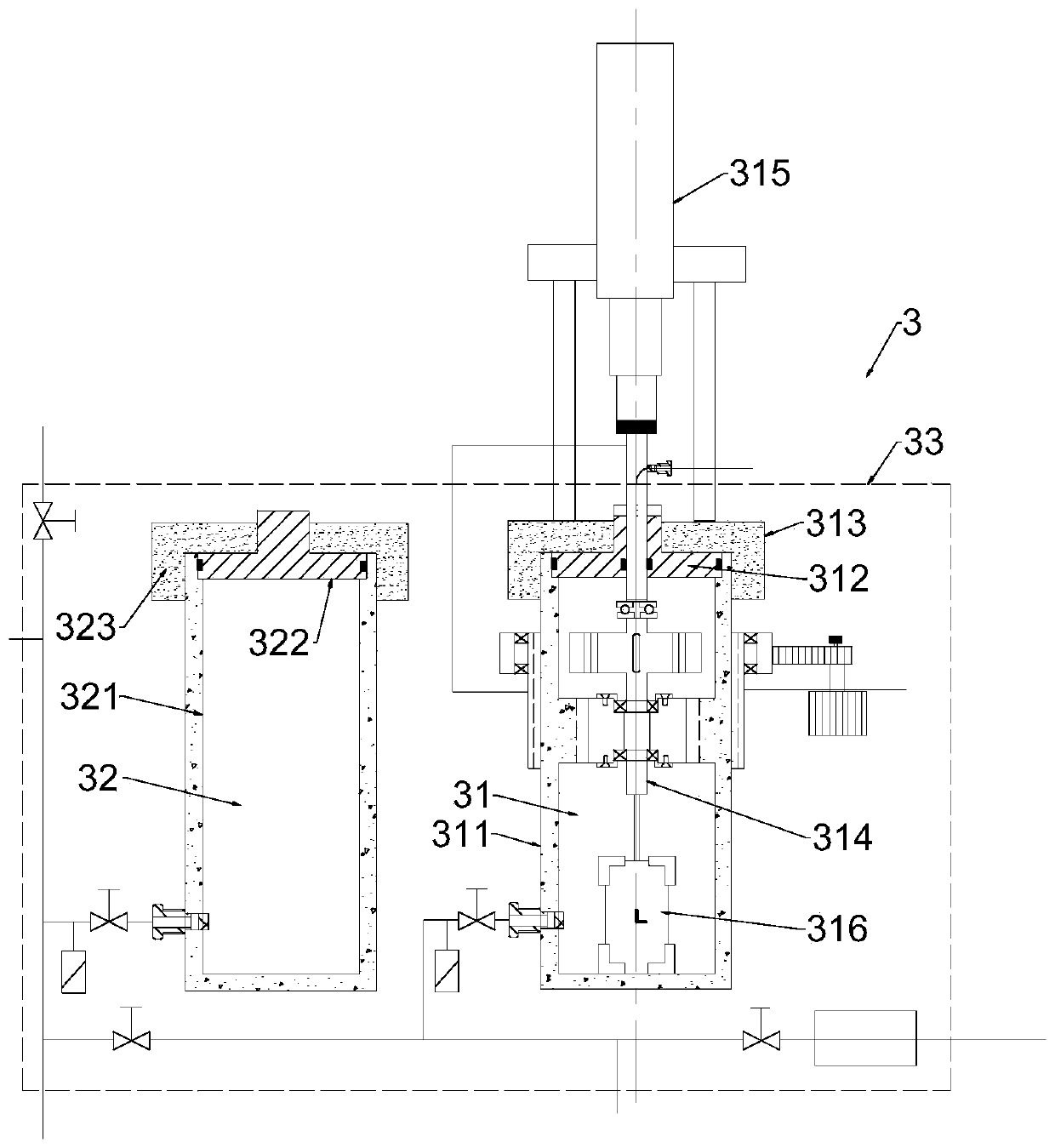

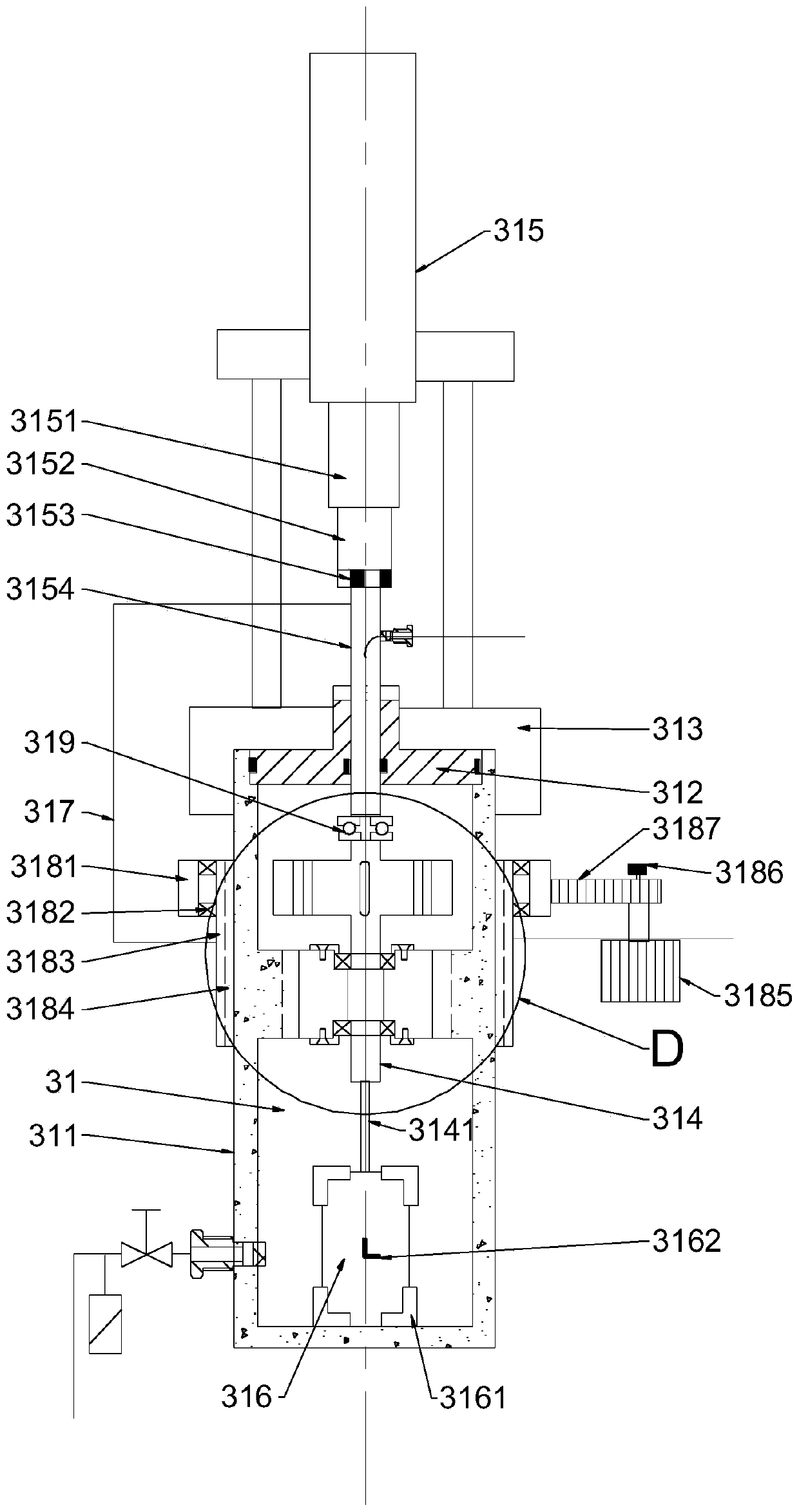

Pneumatic high-speed cupping test device and system

PendingCN111537367AOvercome the disadvantage of insufficient release air pressureIncreased punch speedDevices using time traversedElectromagnetic wave reradiationPhysicsEngineering

The invention discloses a pneumatic high-speed cupping test device and system. The pneumatic high-speed cupping test device comprises a stamping device and a pressing device, wherein the stamping device comprises a cylinder barrel, a piston is arranged in the cylinder barrel, and an electromagnet capable of adsorbing the piston is fixed in the cylinder barrel; the piston is connected with one endof the piston rod, the other end of the piston rod is fixedly provided with a punch; the pressing device and the stamping device are arranged in a spaced mode, the pressing device comprises a female die frame used for placing a test piece, a pressing air cylinder is installed on the side, which is away from the stamping device, of the female die frame, and the pressing air cylinder is connected with a pressing sleeve used for applying blank holder force to the test piece. According to the invention, a stable impact speed can be provided, the blank holder force of the test piece is controllable, and the impact force and the impact speed can be monitored in real time.

Owner:SHANDONG JIANZHU UNIV

Vehicle following safety distance intelligent alarm system

PendingCN112562410ASafe lane changeSafe mergeDetection of traffic movementAnti-collision systemsDriver/operatorVoice data

The invention discloses a vehicle following safety distance intelligent alarm system, which not only can give an alarm to a driver through a voice alarm module according to the speed of the vehicle and the distance between a front vehicle and a rear vehicle, but also can monitor the speed of the front vehicle and the distance between the front vehicle and the rear vehicle and the speed of the rearvehicle and the distance between the front vehicle and the rear vehicle in real time to further give an alarm to the driver. A driver can conveniently adjust the driving speed or change lanes; a warning vehicle distance threshold value corresponding to the vehicle speed parameter is stored and updated through a vehicle distance threshold value database, and a voice warning content corresponding to the dangerous vehicle and the vehicle distance threshold value is stored and updated through the warning voice database, so that the warning diversity is improved, and real-time updating is facilitated; and a millimeter wave radar set can achieve large-area coverage of monitoring of the side area of a vehicle running at a high speed to guarantee that the side of the vehicle and the front and rear portions of the vehicle side can still be monitored when the vehicle runs at the high speed, and a driver is safer during lane changing and doubling.

Owner:QILU UNIV OF TECH

Turbine cooling and natural gas heating integrated gas turbine system

ActiveCN114687805AAvoid wastingLow costBlade accessoriesSafety/regulatory devicesTemperature controlSteam drum

The embodiment of the invention provides a turbine cooling and natural gas heating integrated gas turbine system which comprises a gas turbine system, a turbine cooling and natural gas heating integrated system and a natural gas heat value adjusting system. The other end is communicated with the water inlet end of the TCA system; the TCA system is used for cooling air exhaust of a gas compressor of the gas turbine 2; the water outlet end of the TCA system is communicated with the water inlet end of the FGH system; one end of the low-pressure return water conveying pipeline is connected to the water outlet end of the FGH system, and the other end is communicated with the low-pressure steam pocket; the gas inlet end of the automatic three-way temperature control valve is communicated with a natural gas supply pipeline, and two gas outlet ends are respectively connected with a first conveying pipeline and a second conveying pipeline; the first conveying pipeline is communicated with the air inlet end of the FGH system; the gas outlet end of the FGH system is connected with a third conveying pipeline; and the second conveying pipeline and the third conveying pipeline are converged and then are communicated with a natural gas inlet pipeline.

Owner:HUANENG BEIJING CO GENERATION

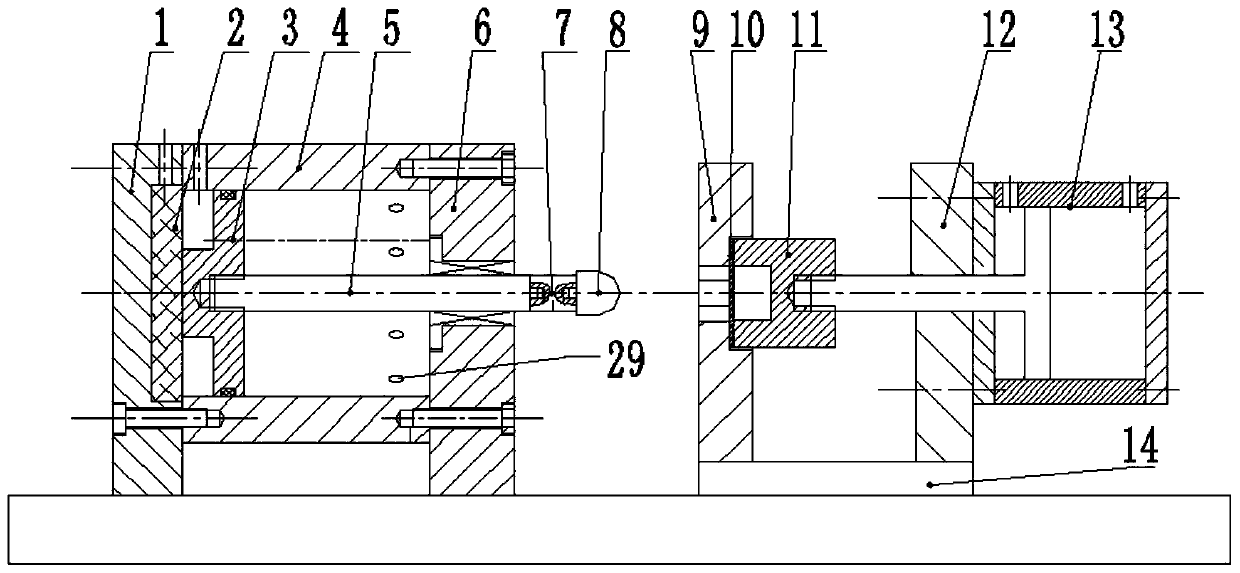

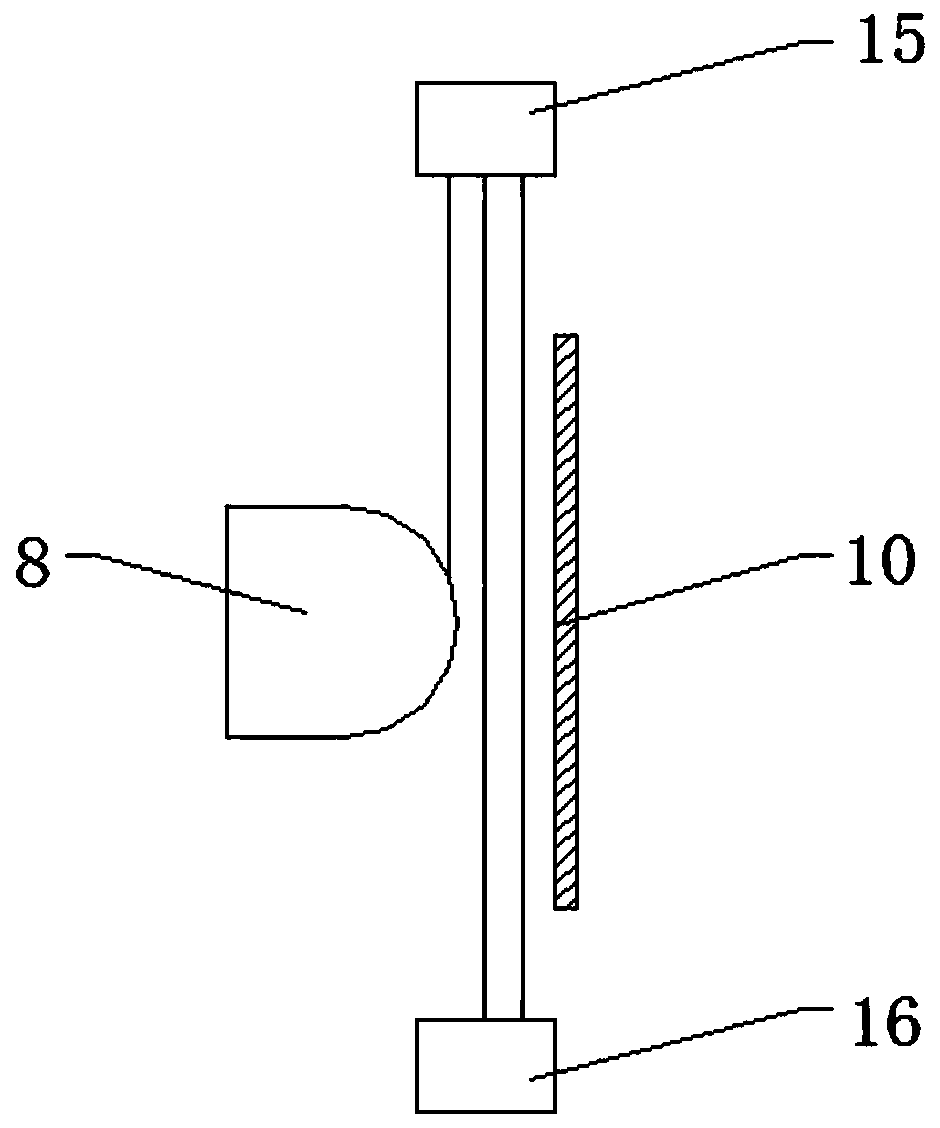

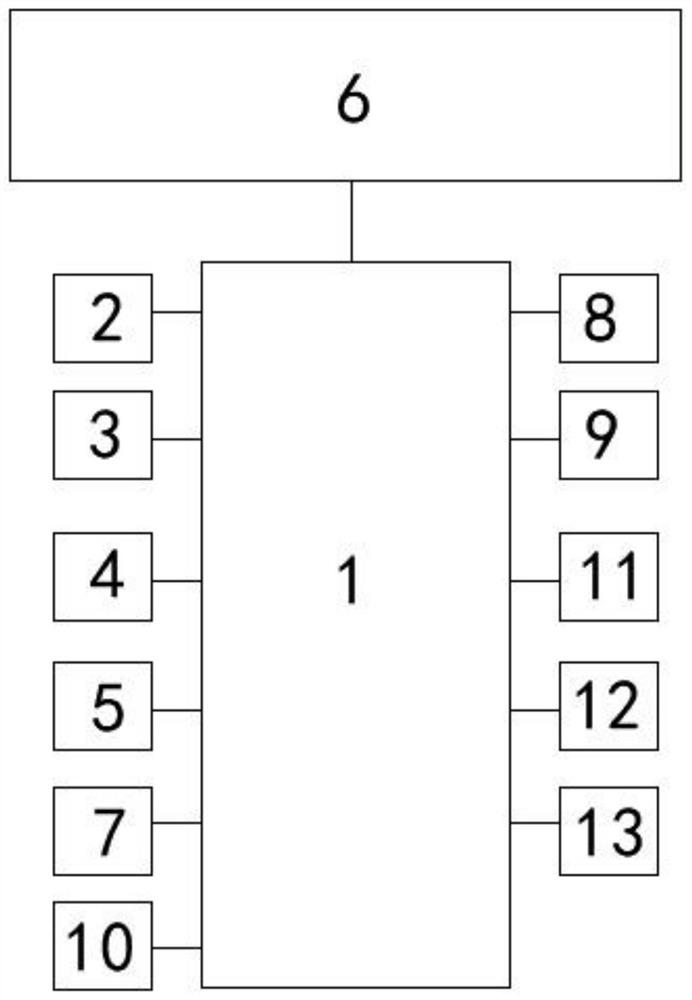

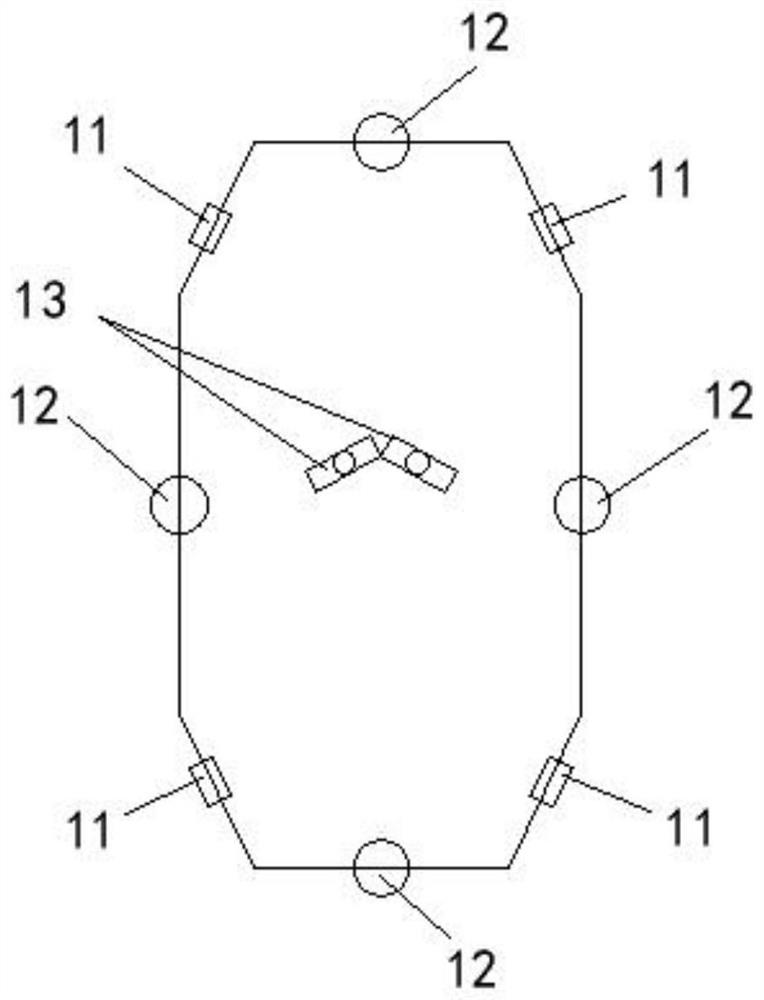

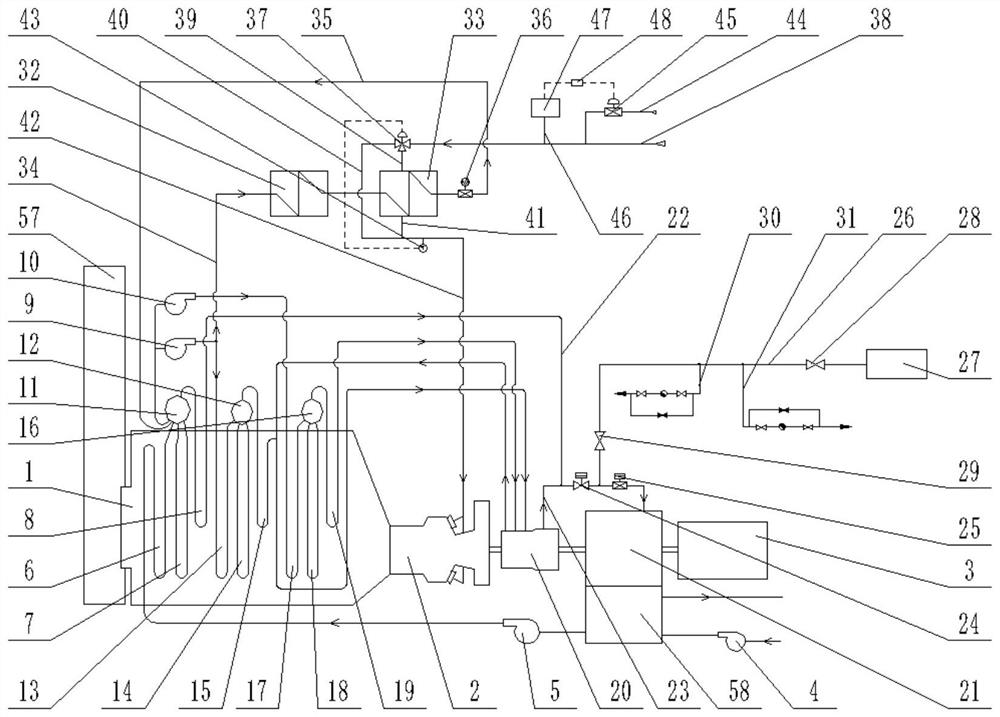

Multi-dimensional data measuring device for lump coal drilling process

ActiveCN111521537AReal-time monitoring of temperature changesGuaranteed air tightness requirementsPermeability/surface area analysisDrive motorTest chamber

The invention discloses a multi-dimensional data measuring device for a lump coal drilling process. The multi-dimensional data measuring device comprises an adsorption tank for adsorbing and desorbinglump coal, a reference tank which has the same size as the adsorption tank and is used for balancing pressure, and a high-low temperature test box for accommodating the adsorption tank and the reference tank, a temperature measuring drill rod is arranged in the adsorption tank, a non-contact magnetic coupling matching mode is adopted, the adsorption tank is driven by a driving motor to rotate, and the temperature measuring drill rod moves up and down through a propelling device; and the reference tank and the adsorption tank are respectively communicated with a gas source system for supplyinggas, a vacuum pumping system for pumping gas and a gas collecting device through a branch gas path and a main gas path. According to the method, various dimension data in the lump coal drilling process of the drill bit can be measured in different temperature environments,wherein the parameters comprise drill bit temperature change, while-drilling parameter change, lump coal gas content data, drill bit drilling process gas real-time analysis quantity and gas adsorption expansion deformation real-time monitoring data.

Owner:TAIYUAN UNIV OF TECH

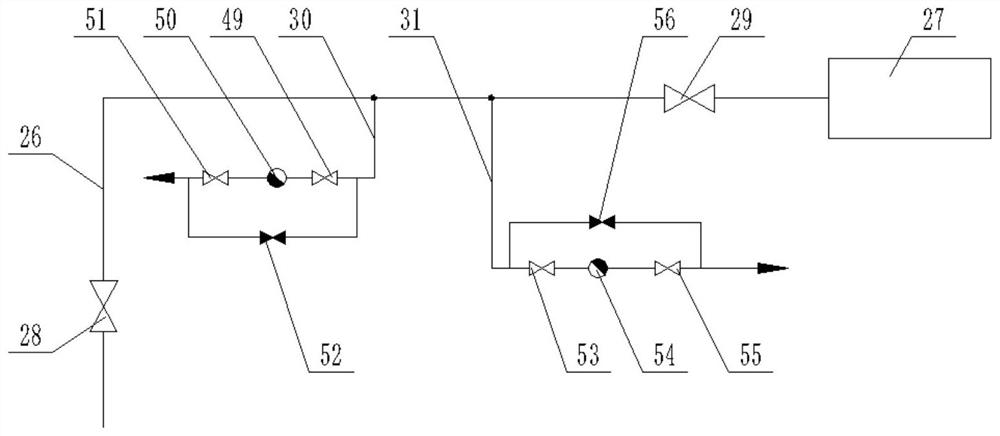

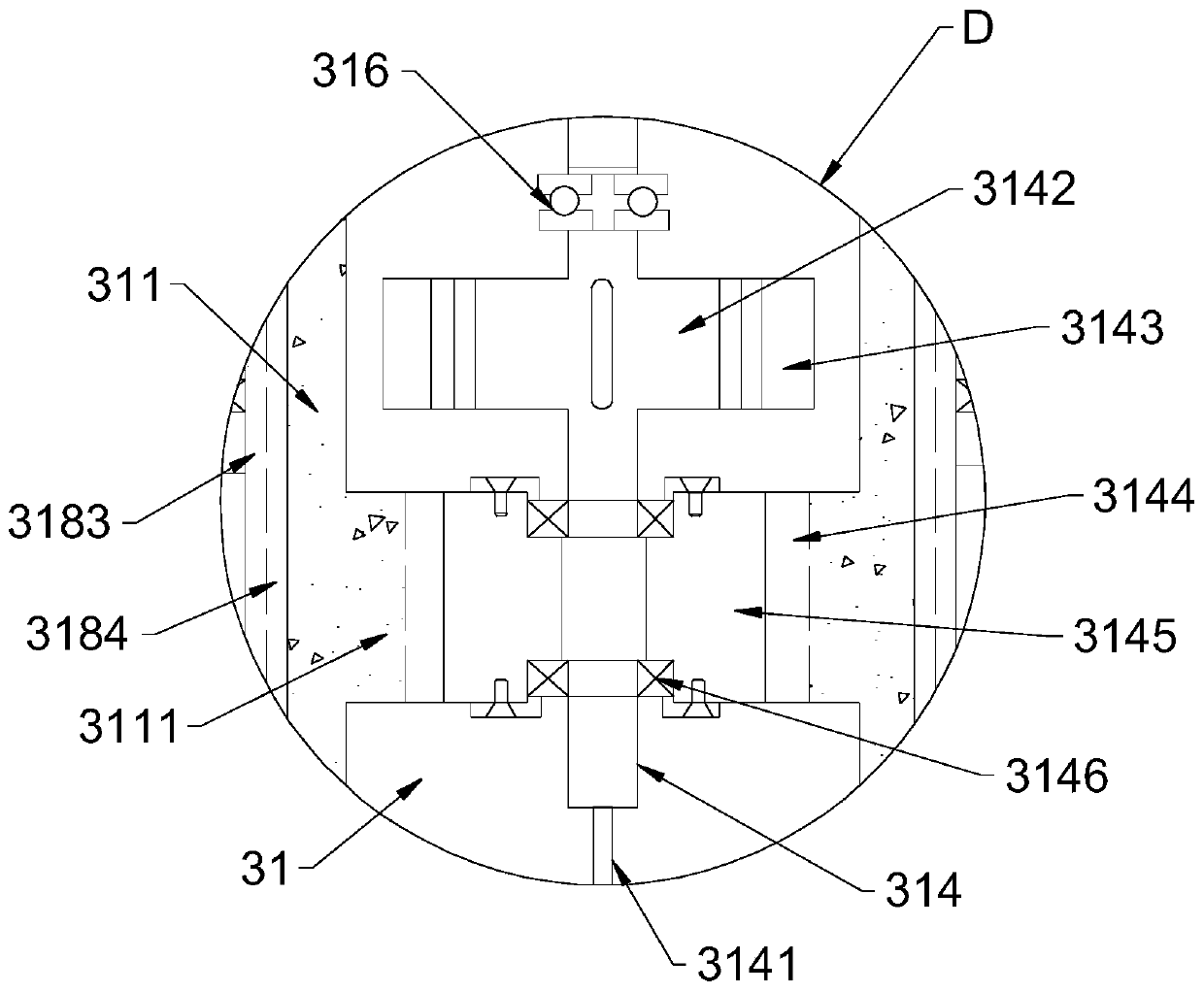

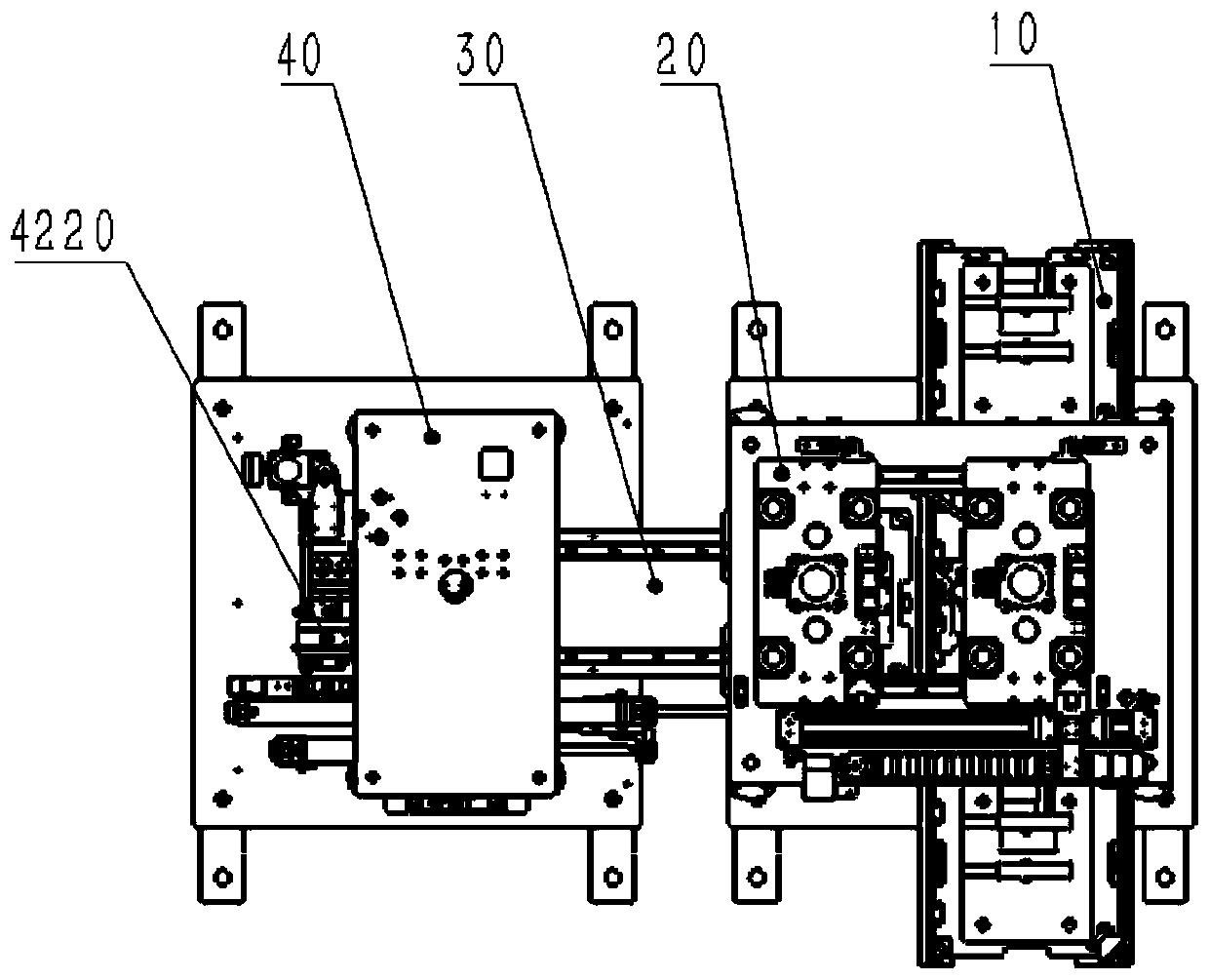

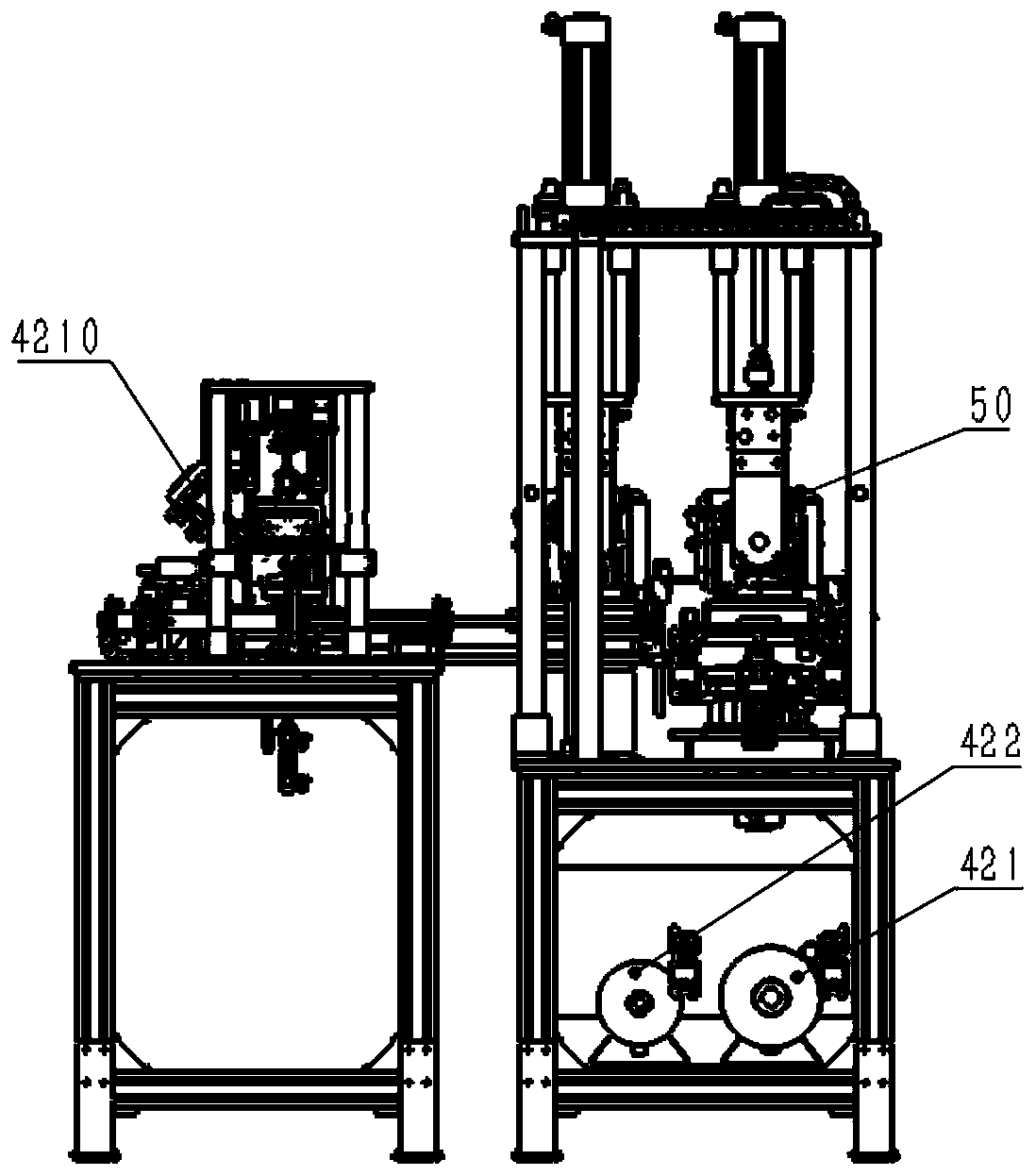

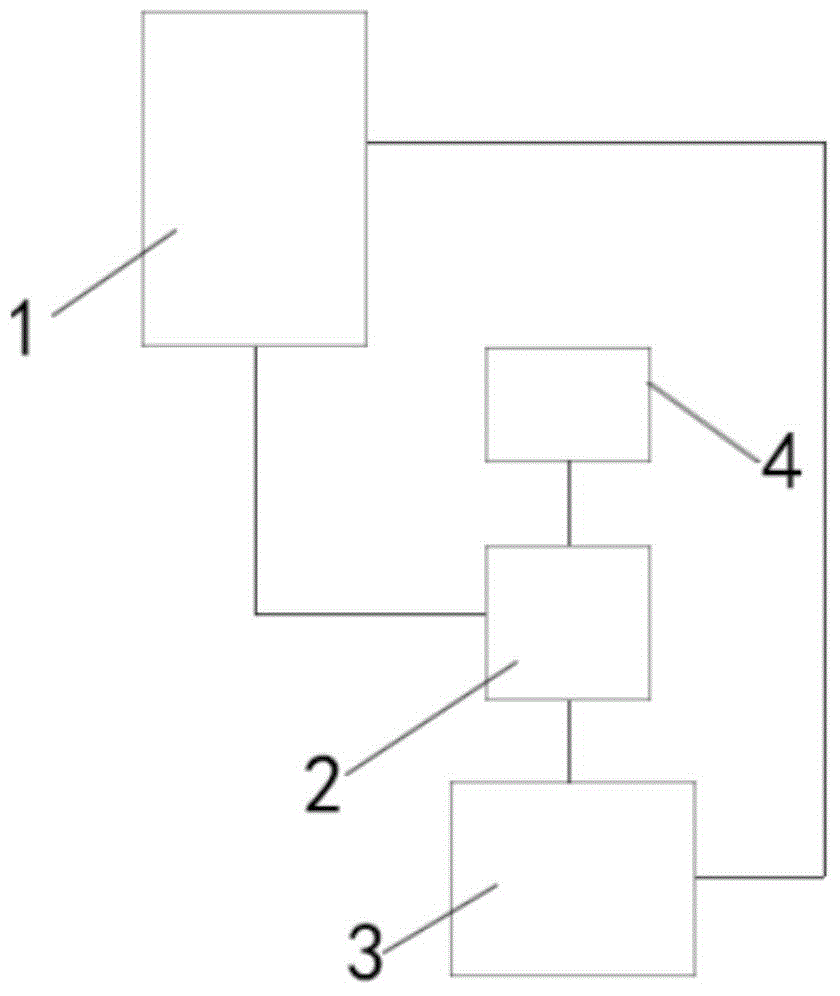

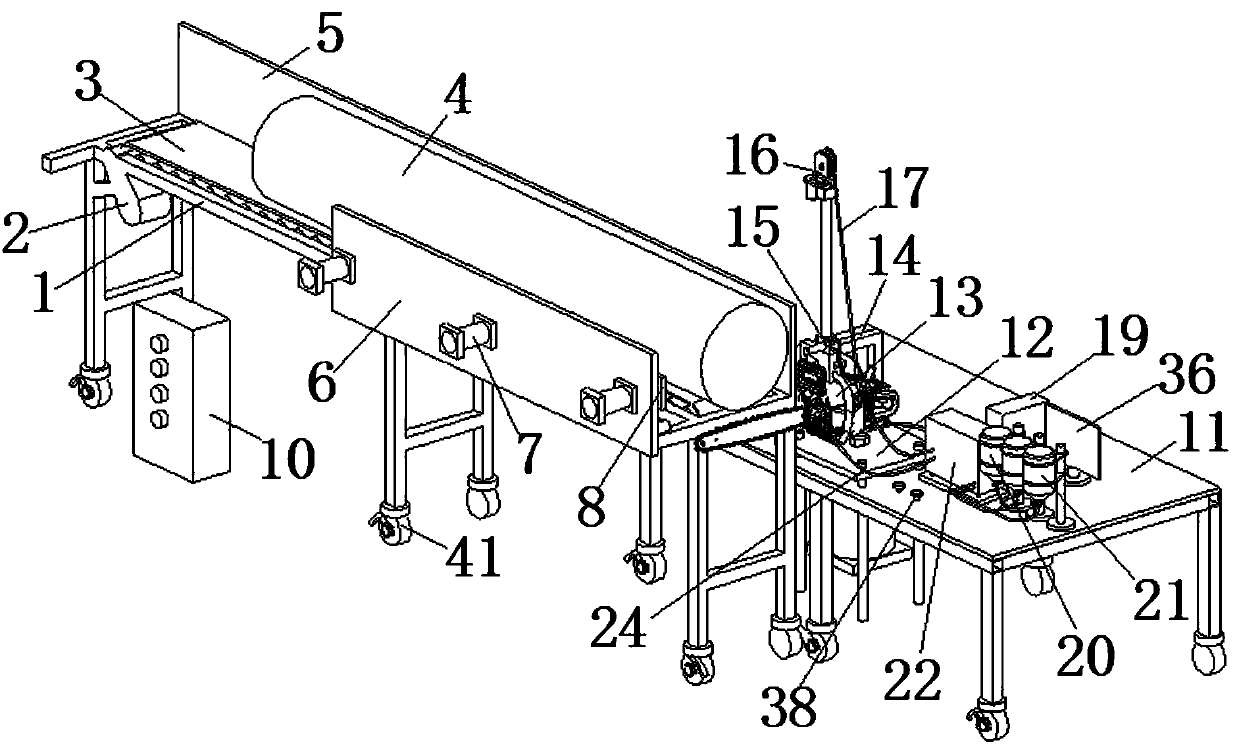

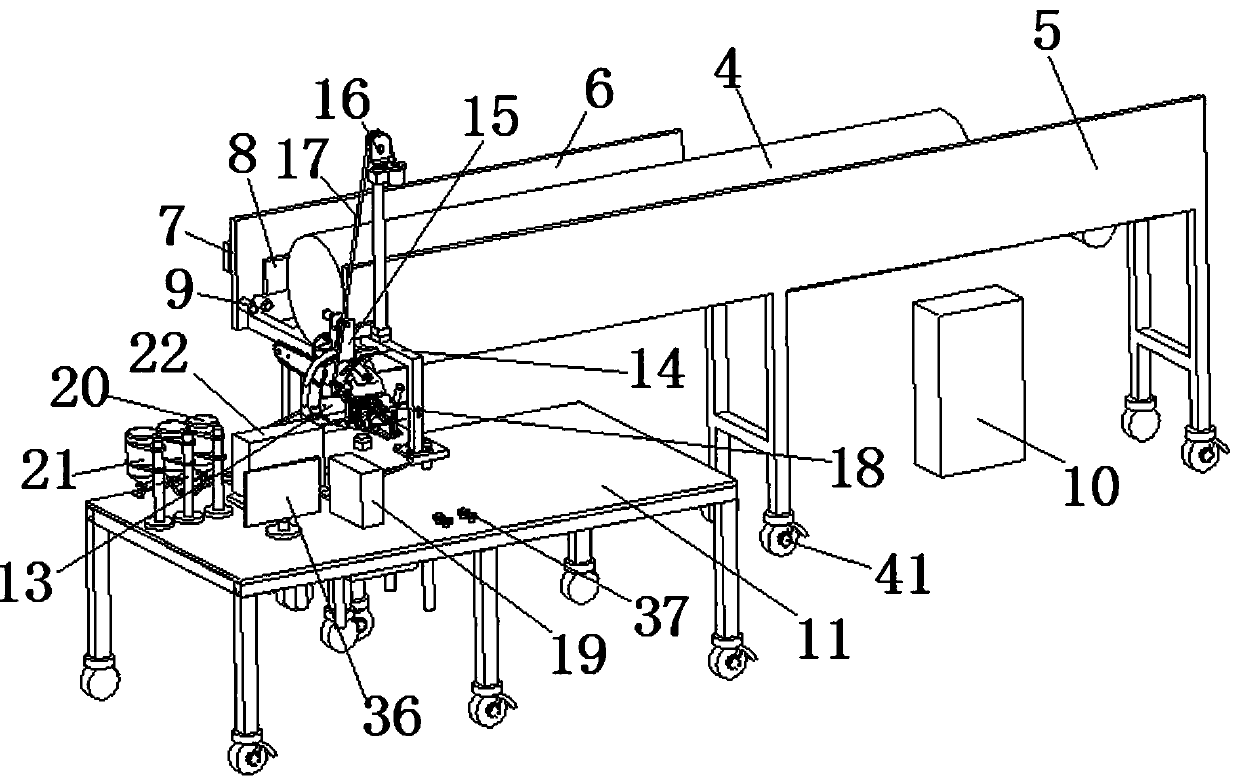

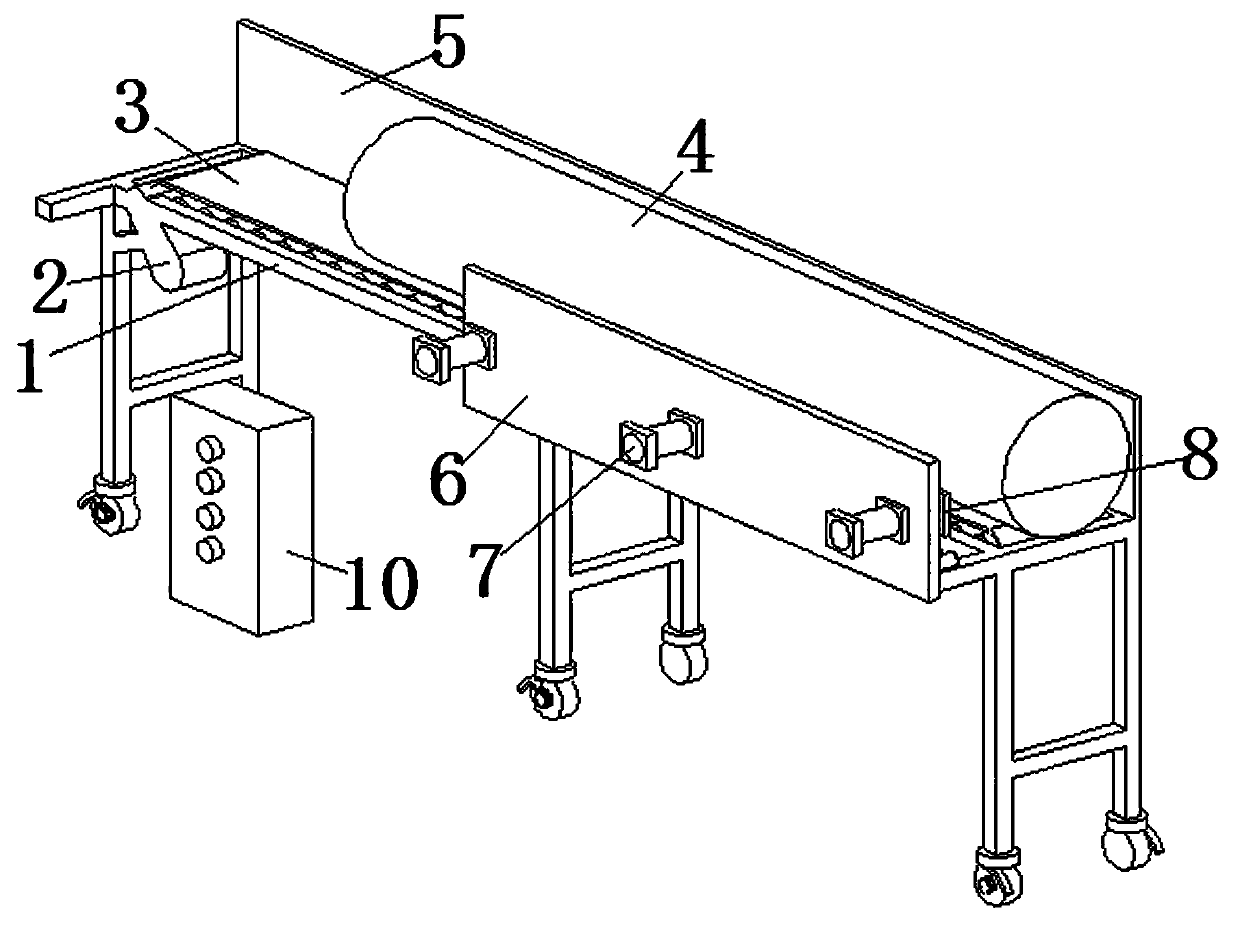

Vehicle air conditioner compressor comprehensive performance testing equipment

ActiveCN110725791AReal-time monitoring speedAvoid manual interventionPump testingPositive-displacement liquid enginesAutomobile air conditioningControl theory

The invention discloses vehicle air conditioner compressor comprehensive performance testing equipment, and belongs to the technical field of vehicle air conditioner compressor assembly. The equipmentcomprises a loading and conveying mechanism, a loading and shifting mechanism, a testing and feeding mechanism and a function testing mechanism connected in sequence; a spiral electric eddy compressor is arranged between the loading and conveying mechanism and the function testing mechanism; the function testing mechanism and the corresponding spiral electric eddy compressor are closed for soundinsulation through a silencing room; and in the simulated operation process of the spiral electric eddy compressor, noise parameters of the spiral electric eddy compressor are tested. The equipment prevents manual intervention, improves the testing efficiency and the testing precision, and comprehensively guarantees the detecting effectiveness and precision; the insulation, the pressure resistance, the vibration and the noise are integrated in one equipment, so that the equipment is high in integrity, light and small; and dual quality indexes of vibration and noise of the compressor can be synchronously detected through vibration change returned by a vibration sensor.

Owner:CSIC PRIDENANJINGINTELLIGENT EQUIP SYST CO LTD

Roller control system of rotor spinning machine

InactiveCN104878482AReal-time monitoring speedImprove operational efficiencyContinuous wound-up machinesOpen-end spinning machinesYarnMotor drive

The invention relates to a roller control system of a rotor spinning machine and belongs to the technical field of textile machinery. The roller control system comprises a controller and a stepping motor. The stepping motor drives a roller to rotate. The controller controls the stepping motor to operate. The front end of the shaft of the stepping motor is in transmission connection with a roller shaft and drives the roller shaft to rotate. The rear end of the shaft of the stepping motor axially extends out of the shell of the stepping motor to form an extension shaft. A speed measuring device is mounted on the extension shaft. The speed measuring device is in signal connection with the controller. The control program of the controller is provided with a speed comparison module and a speed regulating module. By the roller control system, the problem that yarn quality and machine operation efficiency are affected due to the fact that the rotation speed of the stepping motor and the roller of an existing rotor spinning machine cannot be fed back timely is solved, spindle position roller speed deviation change is reduced, and rotor spinning machine operation efficiency is increased.

Owner:ZHEJIANG RIFA TEXTILE MASCH CO LTD

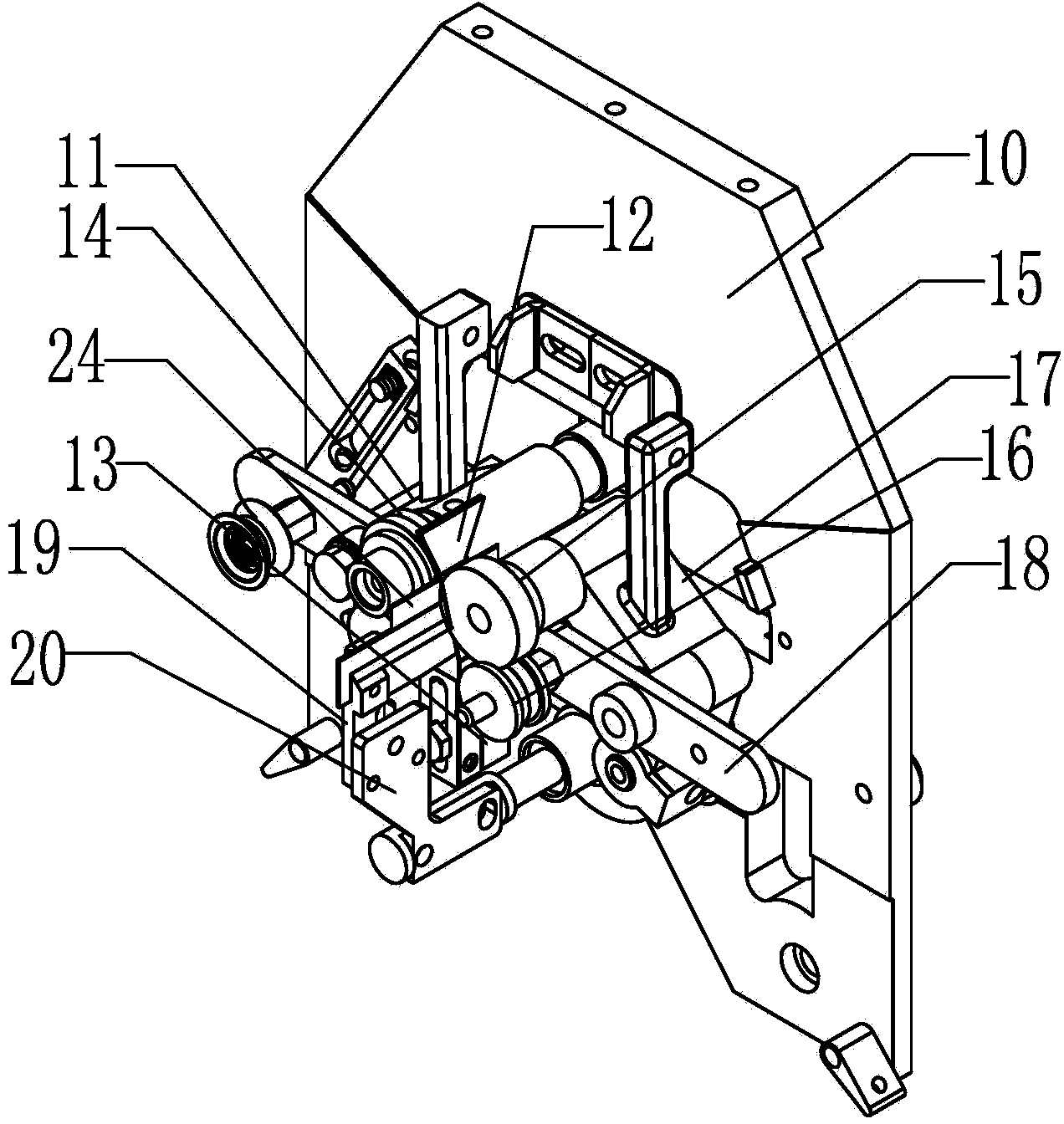

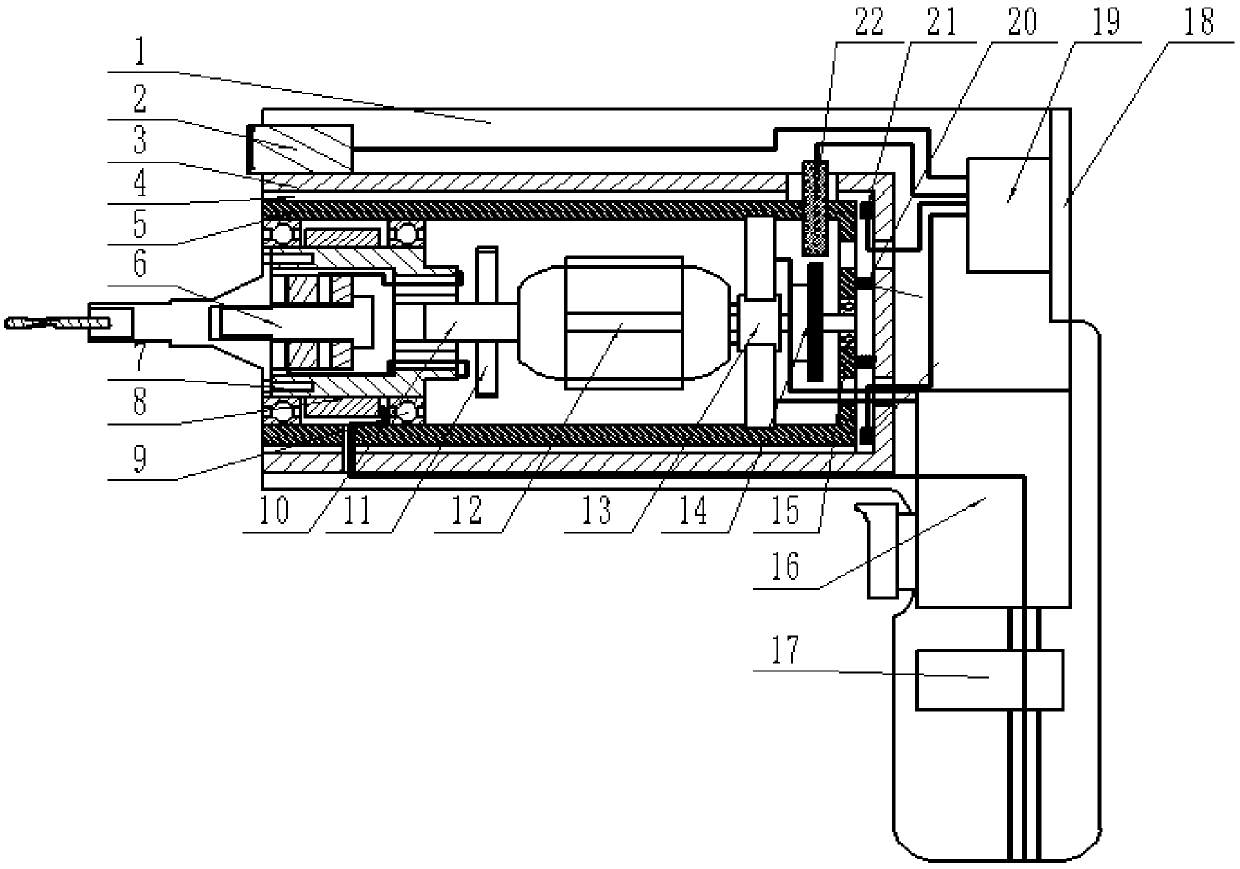

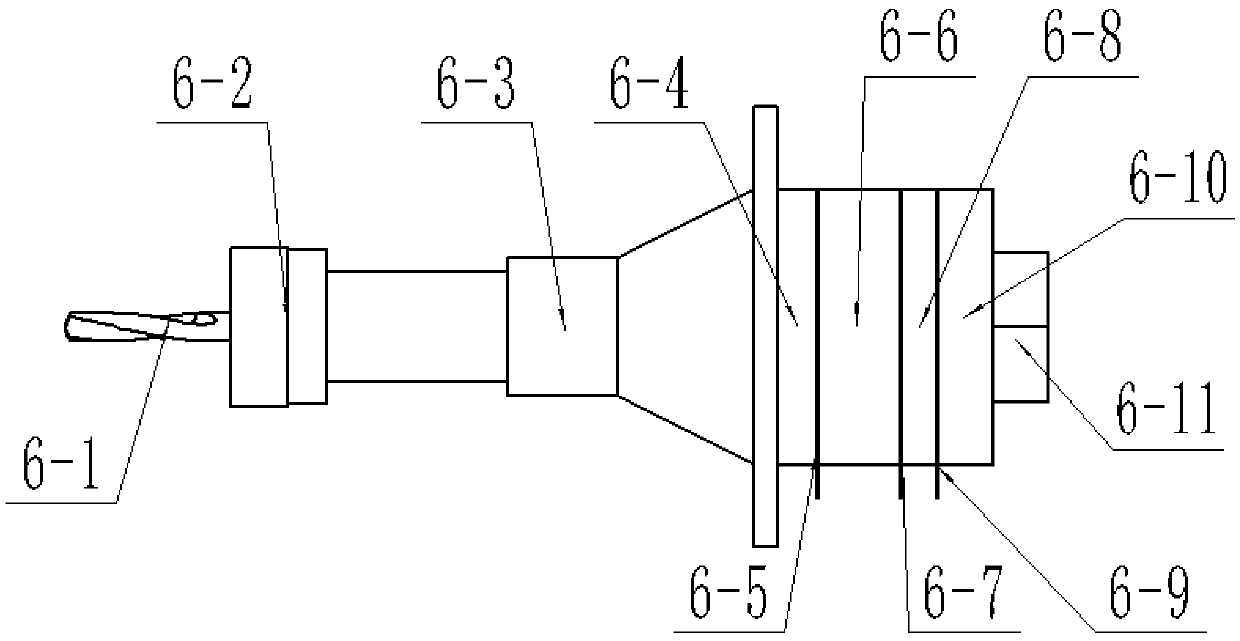

Portable vibration auxiliary drilling device, hole making method and processing signal detecting method

InactiveCN108672766AReduce adverse effectsImprove drilling performancePortable drilling machinesElectricityMachining process

The invention discloses a portable vibration auxiliary drilling device, a hole making method and a processing signal detecting method, which belongs to the field of vibration auxiliary drilling processing. The device comprises a shell (1), a fixed inner shell (3), a movable inner shell (5), a conductive ring (8), a vibration unit (6), and a motor (12). The portable vibration auxiliary drilling device, a hole making method and a processing signal detecting method has advantages that: (1) adjusting the pre-tightening force, the size of the rear cover plate and the intermediate block to adjust the vibration frequency of the device, by using the piezoelectric ceramic driving mode, thereby obtaining excellent drilling performance; (2) real-time monitoring the speed, feed and the number of holesin the drilling process, to achieve intelligent processing, and reducing the adverse effects of human factors on the processing quality; (3) the mobile inner shell structure eliminates the interference signal during non-processing, and the signal detection is more accurate; (4) using a universal tool mounting structure to realize rapid tool change, which is simple and easy to implement in practical applications.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

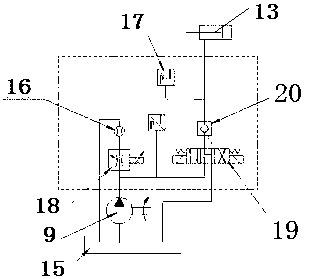

Movement detection device and detection method for monorail crane

PendingCN111458067AQuick disassemblyIncrease output hydraulic dampingServomotor componentsServomotorsPull forceControl engineering

A movement detection device and a detection method for a monorail crane belong to the electrical field, the detection device comprises a hydraulic valve group and a tension sensor, a pull rod seat isconnected with one end of the tension sensor, and the other end of the tension sensor is connected with a frame body; four bearing wheels are arranged on the frame body and slide back and forth alonga monorail track; a hydraulic oil pump and a generator are arranged on the two sides of the frame body respectively and connected with the frame body and a clamping oil cylinder. Driven rubber wheelsare installed at the input wheel ends of the hydraulic oil pump and the generator and can clamp the monorail track through contraction of the clamping oil cylinders. A hydraulic valve group and an electric control box are arranged on the lower sides of the hydraulic oil pump and the generator, and are respectively fixed on two sides of the frame body; and a generator shaft is connected with a rotary encoder, and a hydraulic oil tank is integrated below the frame body. According to the invention, the relation between the speed and the tension of the locomotive in the moving process is analyzed,and the traction force of the locomotive is detected more accurately.

Owner:TAIYUAN KUANGJI ELECTRIC

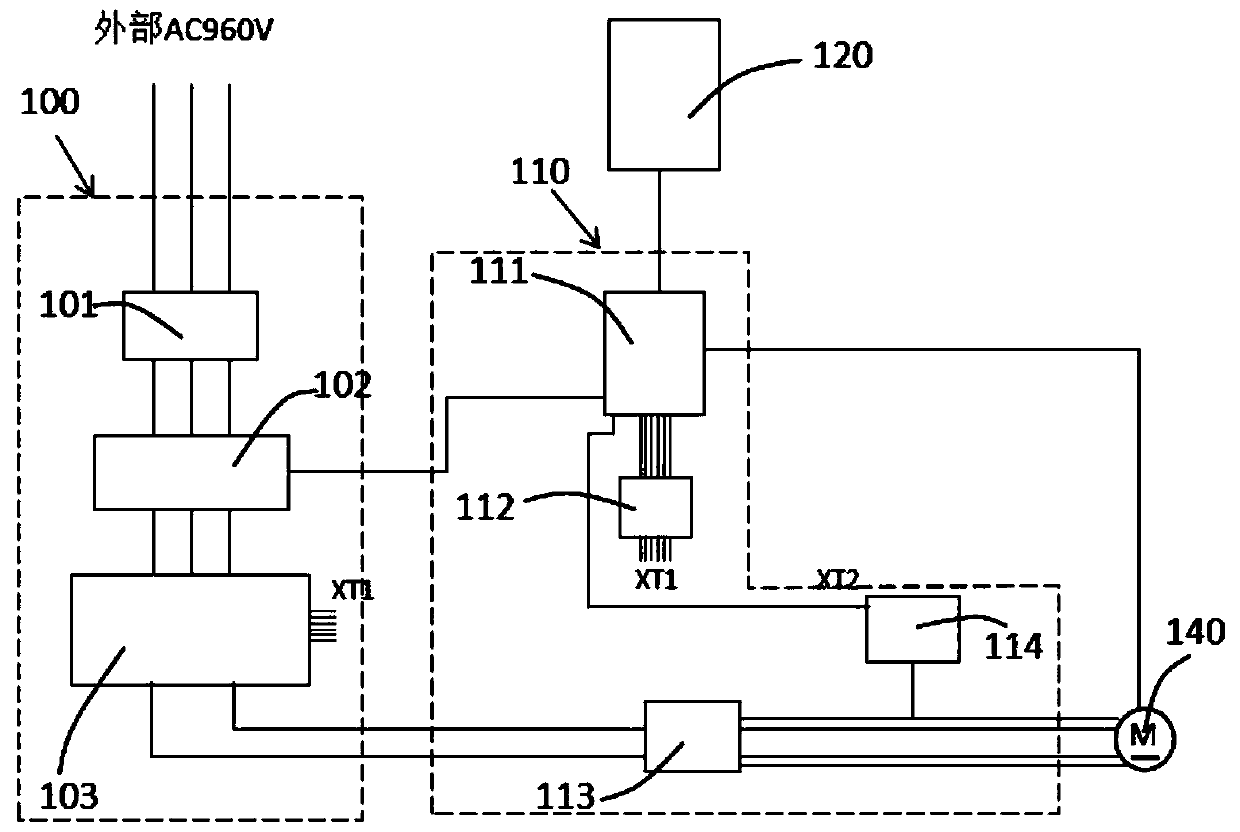

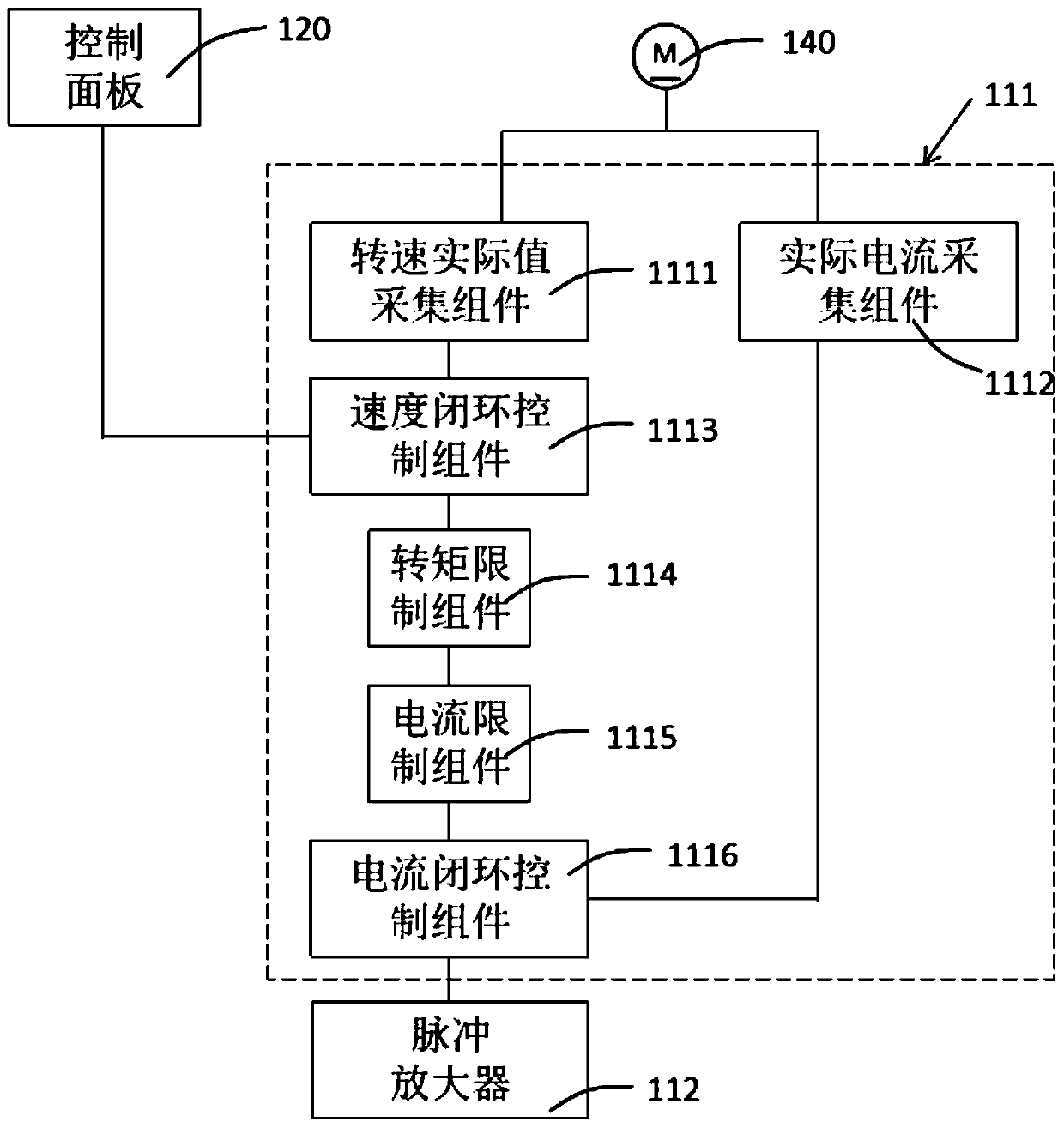

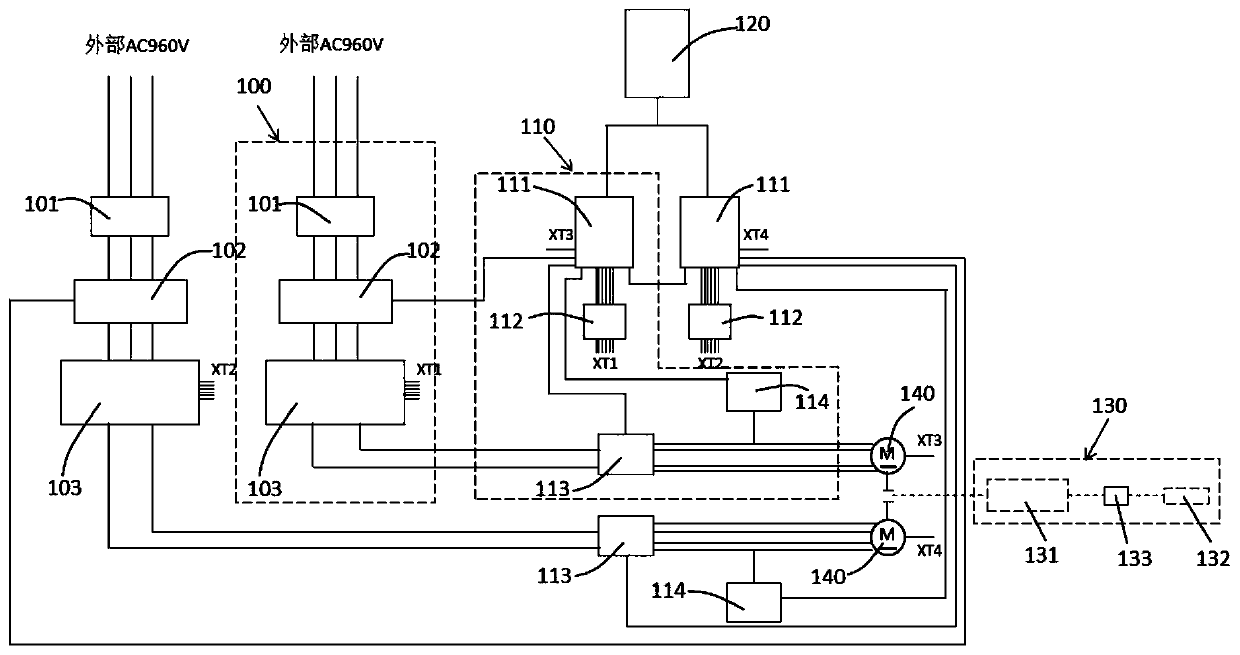

DC motor speed-regulation device and method

InactiveCN109787519ALow costMeet driving needsField or armature current controlMultiple dynamo-electric motors speed regulationLoop controlCurrent limiting

The invention discloses a DC motor speed-regulation device for a drilling platform. The device comprises a rectifier module including a thyristor; a control module including a DC speed regulator and apulse amplifier, wherein one end of the pulse amplifier is connected with the DC speed regulator, and the other end is connected to the thyristor; the DC speed regulator comprises a rotating speed actual value collecting module, a speed closed loop control module, a torque limiting component, a current limiting component and a current closed loop control component connected in order; and an actual collection component connected with the current closed loop control component, wherein the DC speed regulator is connected with the DC motor. The invention further discloses a DC motor speed-regulation method. The DC motor is controlled by adopting a way of combining the DC speed regulator and the pulse amplifier;, the rotating speed of the DC motor is monitored in real time, and a torque sensoris increased between the drilling motor and a drilling rig to collect the torque data in real time, thereby reaching the aims of outputting different torques of different geological conditions, reducing the loss of a transmission system, lowering a well drilling cost, and saving energy.

Owner:湖南鼎创装备有限公司

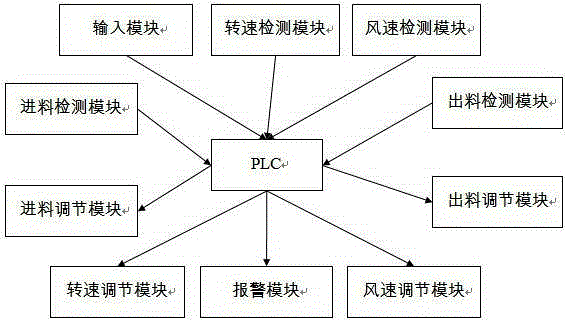

Automatic control system and method of powder concentrator

ActiveCN105234014AIncrease productivityImprove efficiencyVortex flow apparatusAutomatic controlControl system

The invention discloses an automatic control system and method of a powder concentrator. The automatic control system comprises a feeding detection module, a rotation speed detection module, an air speed detection module, a discharge detection module, a PLC, a feeding adjusting module, a rotation speed adjusting module, an air speed adjusting module and a discharge adjusting module. The automatic control system is used for detecting the collection flow rate of fine powder, detecting and adjusting the material feeding speed, the rotation speed of a transmission part, and the intake speed and exhaust speed of recirculating air in real time. By the adoption of the automatic control system and method of the powder concentrator, jamming and unsmooth feeding of a feed inlet can be effectively prevented; the powder concentrator is monitored in real time, so that the system safety and reliability are improved; and possible faults are predicted, and meanwhile emergency operations are realized in case of faults.

Owner:宁夏西墨新材料科技有限公司

Full-automatic chain saw timber-sawing equipment

PendingCN111185969AReal-time monitoring of consumptionReal-time monitoring speedGuide fencesFeeding devicesTransmission beltControl engineering

The invention discloses full-automatic chain saw timber-sawing equipment. The full-automatic chain saw timber-sawing equipment comprises a timber feeding device and an automatic oil saw timber-sawingdevice. A transmission belt is arranged on a transmission machine frame of the timber feeding device, a clamping air cylinder is fixed to a transmission machine mounting plate, a piston rod of the clamping air cylinder is connected with a clamping plate, an infrared sensor is arranged in the transmission machine frame, and a controller is arranged in a control cabinet of the timber feeding device;and the automatic oil saw timber-sawing device comprises a fixed supporting platform, a lifting chain saw working platform is arranged on the fixed supporting platform, an chain saw is placed on thechain saw working platform, a temperature sensor and a speed sensor are installed on the chain saw, a chain saw grip clamping tool, an automatic chain saw starting tool and a chain saw accelerator loading tool are arranged on the chain saw working platform, an industrial personal computer, a fuel oil storage tank, a chain plate oil storage tank and a fuel consumption meter are arranged on the fixed supporting platform. According to the full-automatic chain saw timber-sawing equipment, labor intensity can be effectively reduced, and automatic timber-sawing operation can be realized, and meanwhile, parameters of a chain saw engine can be monitored in real time during the operation.

Owner:ZHEJIANG PIONEER MACHINERY & ELECTRON

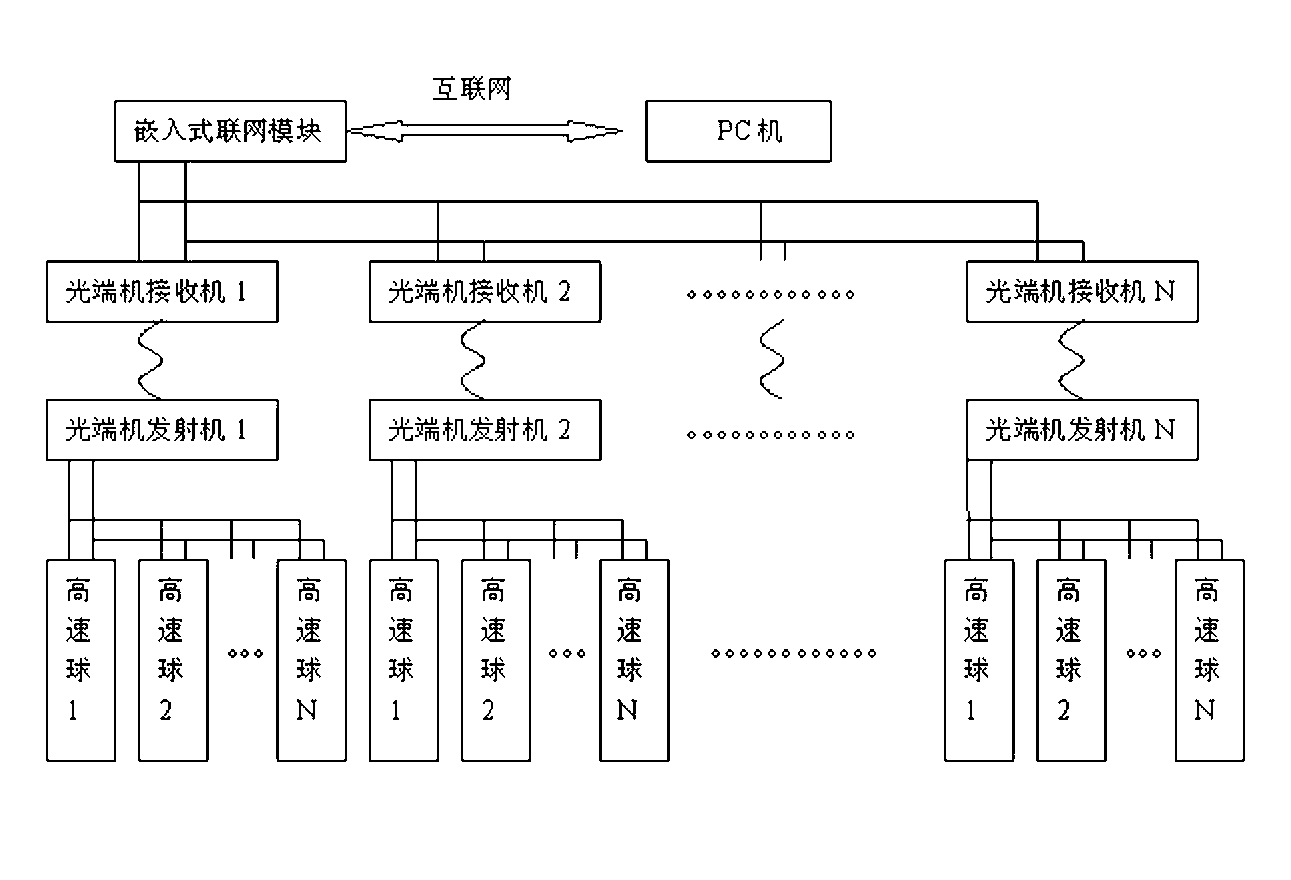

Intelligent fault alarming high-speed ball and network management client side system thereof

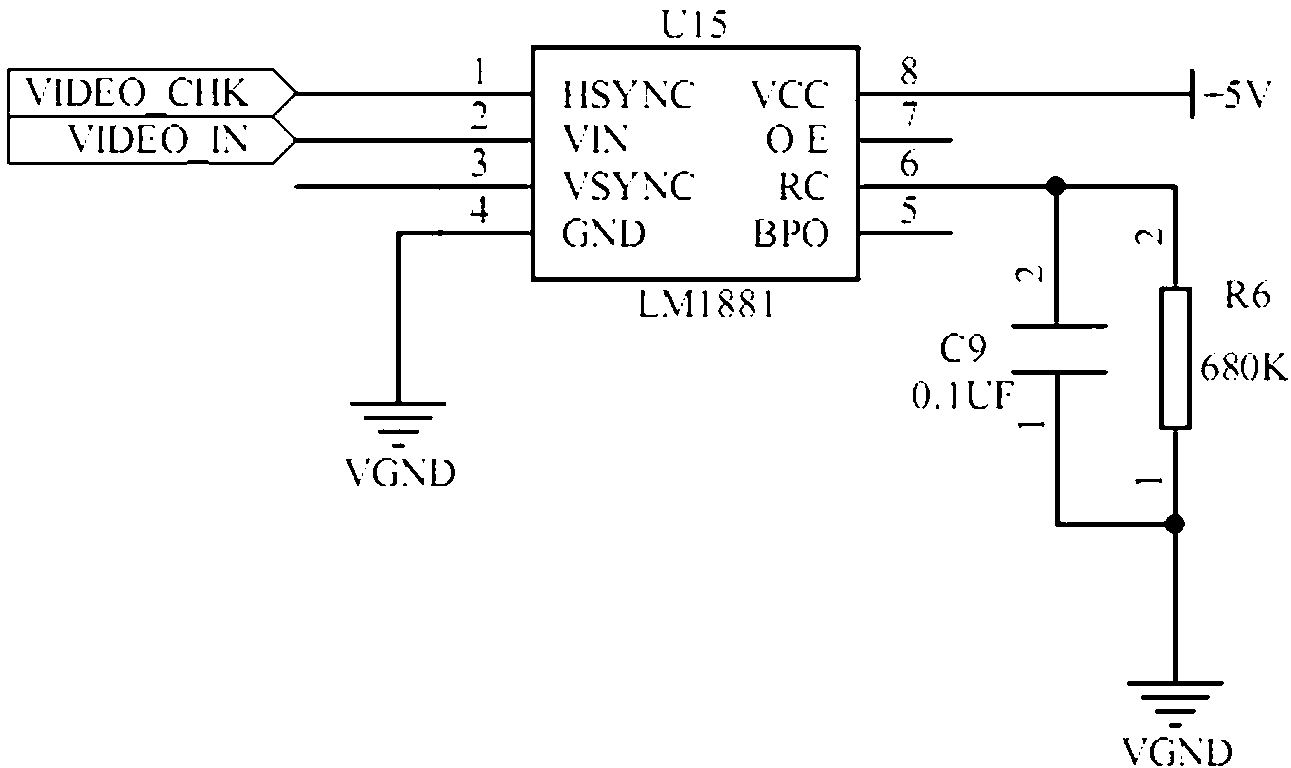

InactiveCN103237196AMonitor video status in real timeReal-time monitoring temperature informationClosed circuit television systemsData switching networksVideo monitoringControl signal

The invention relates to an intelligent fault alarming high-speed ball and a network management client side system thereof, particularly aims to providing a perfect solution to 24-hour real-time monitoring and fault processing for the working state of a high-speed ball in a conventional video monitoring system. An integrate-core video signal monitoring circuit, a temperature acquiring circuit, a voltage detecting circuit, a fan monitoring circuit and an STC12LE5A08S2 as a master-control MCU (microprogrammed control unit) are arranged in the high-speed ball. The network management client side system thereof is formed by three parts including a distributing model of address of the internet of things, realization of high-speed ball control signals (pan / tilt / zoom) and network management signal multiplexing, and data acquisition. The high-speed ball with network management function is realized, and video state, temperature information, voltage value and rotating fan speed of the high-speed ball can be monitored in real time. Operating state can be uploaded to a management center in real time, and via the management center, all the front-end high-speed balls can be switched on / off and reset remotely.

Owner:广州澳视互动传媒有限公司

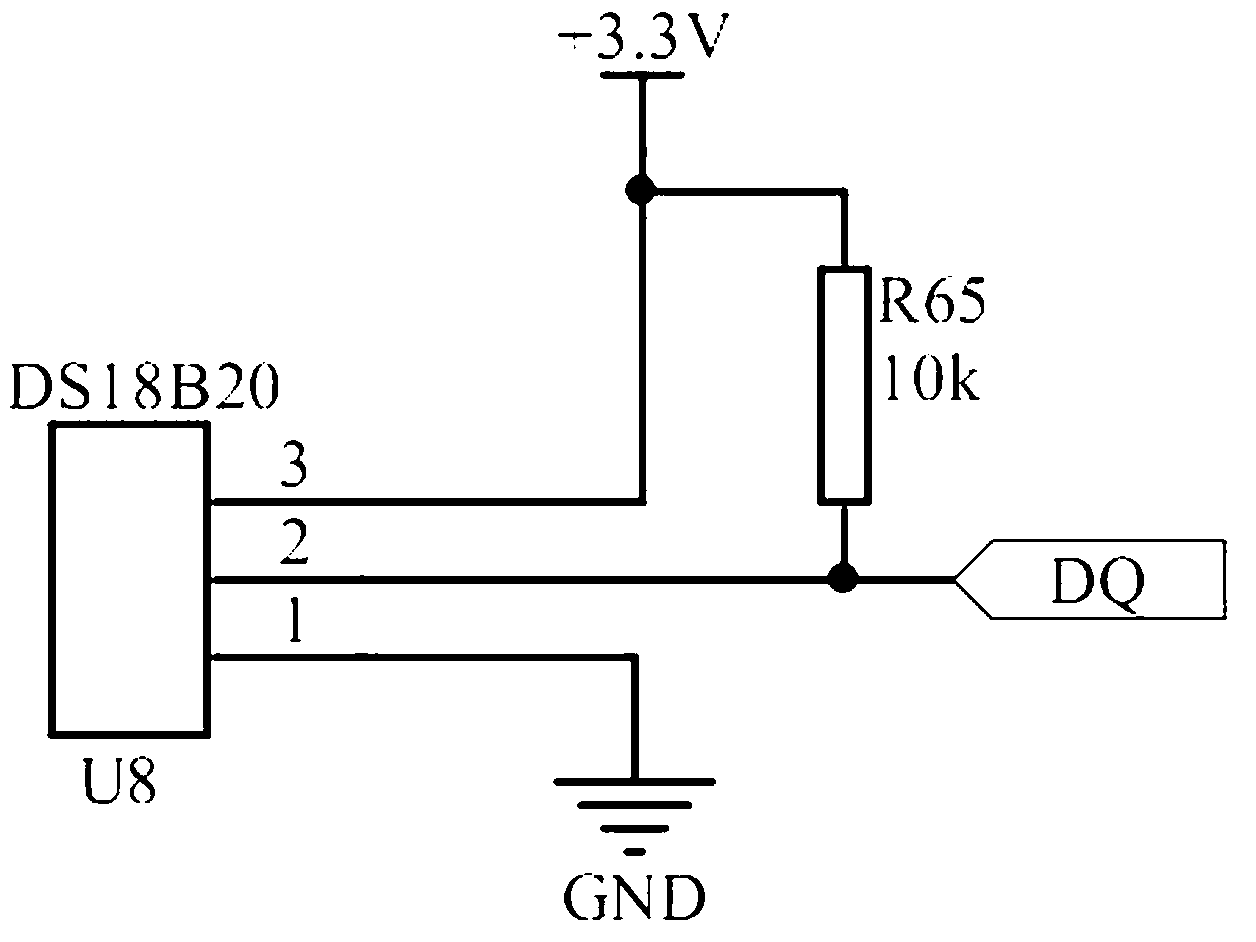

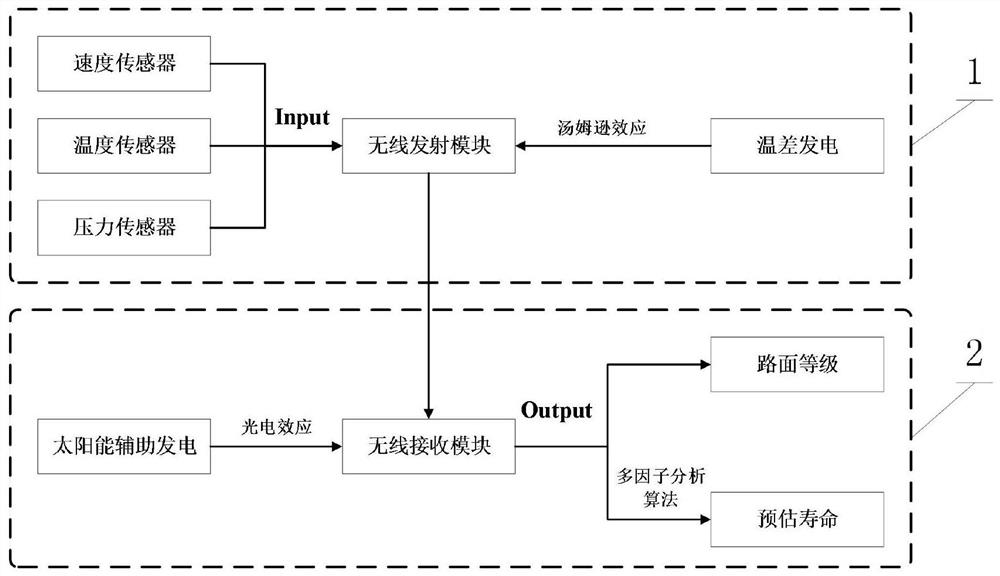

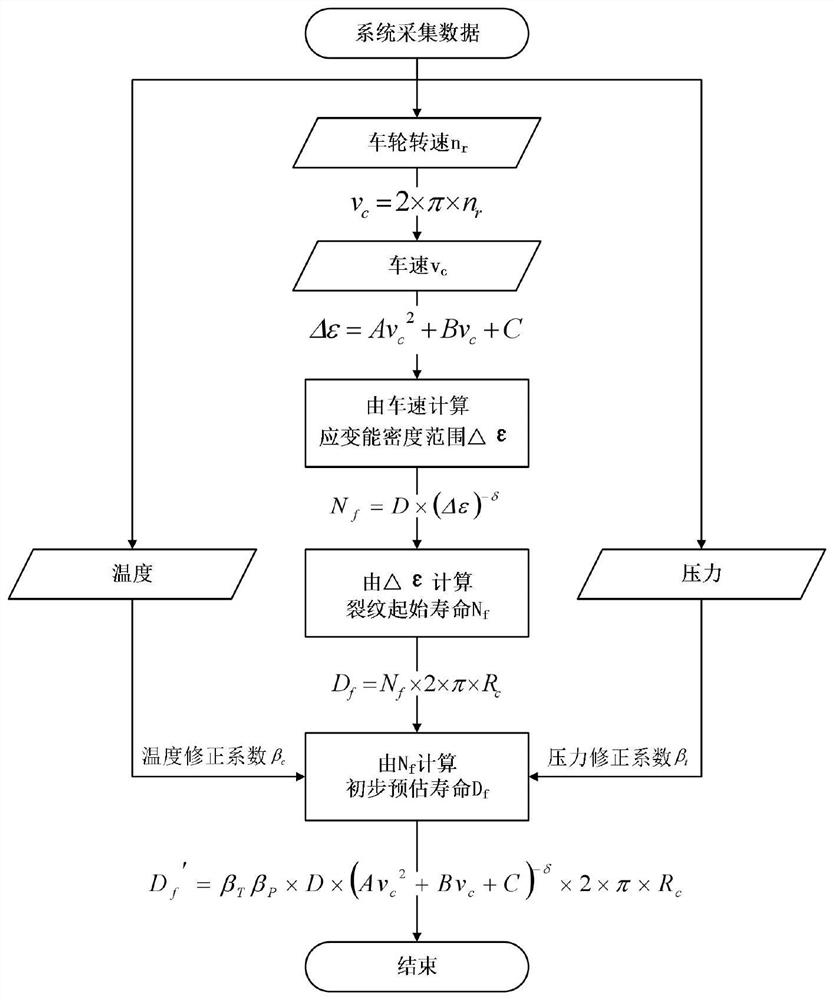

Self-energized tire road monitoring integrated intelligent tire system

ActiveCN112976963ASolve the problem that additional power supply needs to be configuredAvoid replacement maintenance problemsTyre measurementsDriver/operatorMonitoring system

The invention discloses a self-energized tire road monitoring integrated intelligent tire system which is composed of a tire road information monitoring system and an energy self-supplying system. The tire road information monitoring system is composed of a tire transmitting end and an indoor receiving end, information collection modules such as a speed sensor, a temperature sensor and a pressure sensor are combined with a tire life and road unevenness grade algorithm to jointly complete collection and recalculation of tire road information, and a driver is reminded through display; according to the energy self-supply system, power generation and energy supply are carried out on the monitoring system and the transmission system according to different environmental requirements, energy supply of a traditional battery is omitted, and the requirement of green energy is better met. According to the invention, tire road information monitoring and processing in a vehicle driving process can be realized, and self-supply of energy is realized.

Owner:HEFEI UNIV OF TECH

Automatic carrying system based on AGVs and multi-AGV cooperation method

InactiveCN112591663AImprove stabilityImprove batching efficiencyLifting devicesVibration suppression adjustmentsHydraulic cylinderDrive wheel

The invention discloses an automatic carrying system based on AGVs and a multi-AGV cooperation method, and belongs to the technical field of carrying trolleys. The automatic carrying system comprisesan AGV carrier main body, driving wheels are arranged on a lower chassis of the AGV carrier main body, a carrying platform is arranged on the side, in the advancing direction, of the AGV carrier mainbody, and suspension wheels are arranged at the positions, corresponding to the driving wheels, of the lower portion of the AGV carrier main body. According to the arrangement, through mutual cooperation of designed structures such as a first buffer spring, a second buffer spring, a first hydraulic cylinder, a sliding block, a sliding groove, a second hydraulic cylinder, and a buffer device, the distance complementary effect is achieved, so that the stability of a carrying goods table in the pushing advancing process of the AGV carrier main body can be improved, therefore, materials or finished products on a buffer table are prevented from toppling forwards under the action of inertia, smooth operation of the AGV carrier main body is guaranteed, the material distribution efficiency of semi-finished products is improved, and meanwhile idle waste of equipment is avoided.

Owner:DESIGN INST NO 9 MINISTRY OF MECHINE BUILDING

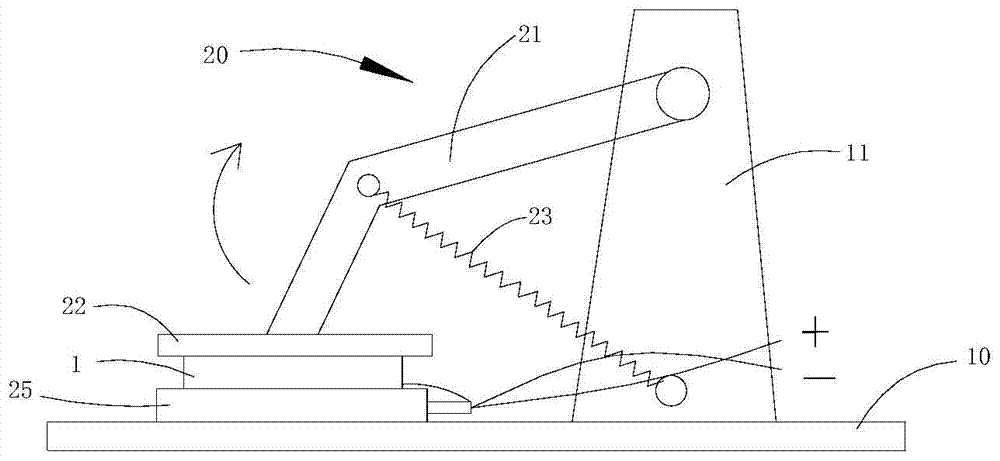

Motor service life testing tool

ActiveCN104749522AEasy to fixReal-time monitoring speedDynamo-electric machine testingWork performanceEngineering

The invention discloses a motor service life testing tool. The motor service life testing tool comprises a base for positioning a motor, a pressing mechanism which consists of a connecting rod and a tension spring and is used for pressing the motor on the upper surface of the base, and a detecting circuit is connected to the input and the input end of the motor and used for monitoring the rotating speed and working current of the motor on real time; the fixing end of the connecting rod can be rotatably fixed on the base; one end of the tension spring is fixed and while the other end of the tension spring is fixed on the connecting rod; the free end of the connecting rod faces the base to press the motor. According to the motor service life testing tool, the motor can be reliably fixed, and the rotating speed and the working current of the motor can be monitored on real time; the working performance of the motor can be accurately analyzed according to the detection data, so that the service life of the motor can be determined; in addition, the inaccurate test caused by noise interface or falling of a welding wire due to the vibration of a motor body during testing the service life of the motor can be effectively avoided.

Owner:东营市东凯空港产业园有限公司

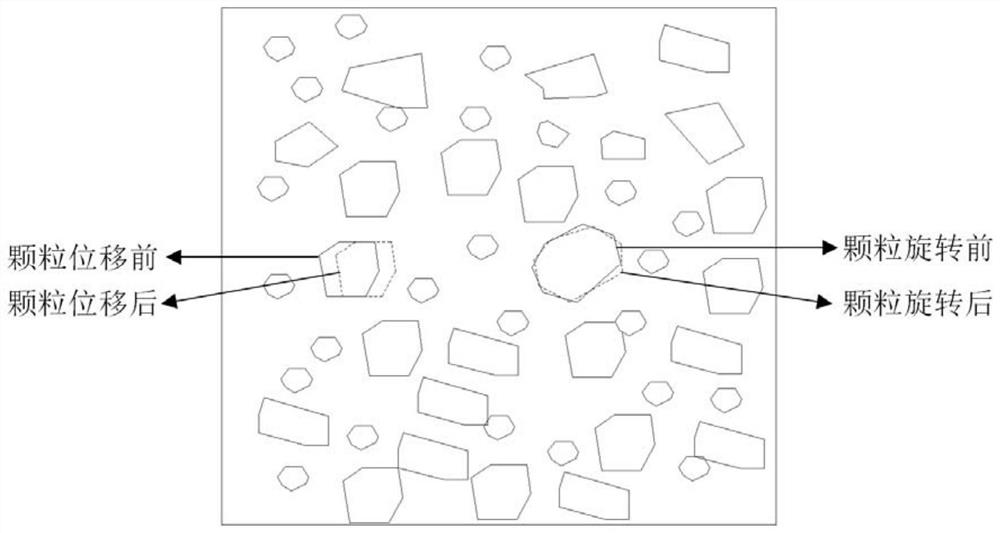

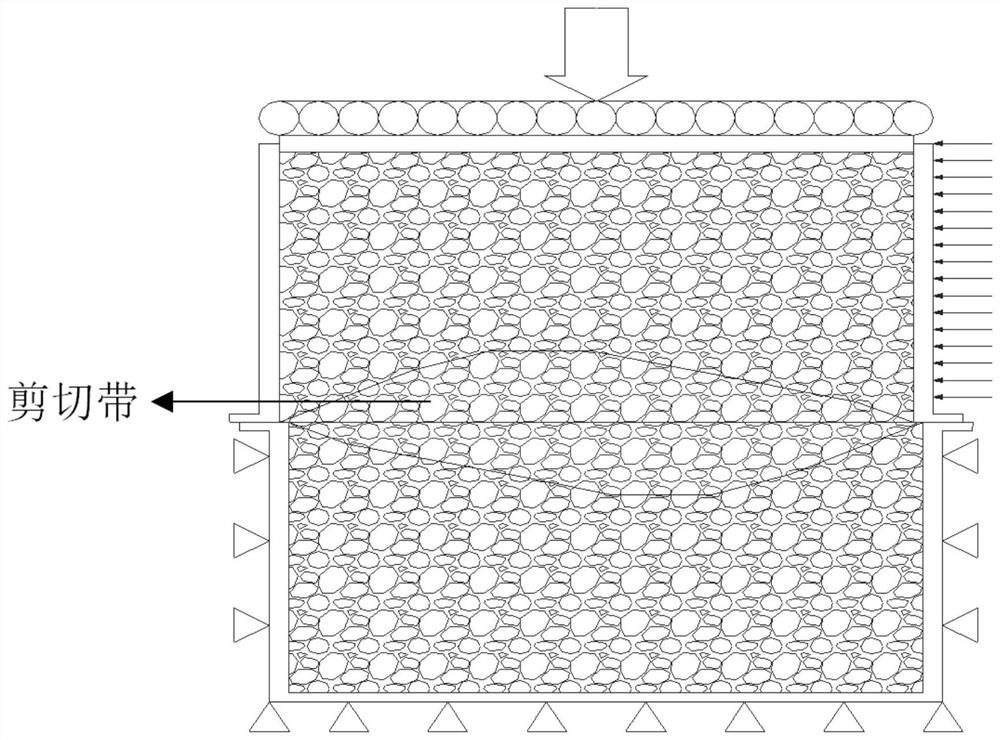

Bulk solid shear characteristic evolution law research method based on image recognition

InactiveCN112924302AReal-time monitoring speedUsing mechanical meansMaterial strength using steady shearing forcesStructural engineeringImage pair

The invention discloses a bulk solid shear characteristic evolution law research method based on image recognition, which comprises the following steps: determining the size of a shear box according to the particle size grading of a bulk solid material to be researched, and modifying a front panel of the shear box into a transparent panel; filling the modified shear box with the to-be-studied discrete material, covering the modified shear box with an upper pressing plate and a sliding pressurizing device, and performing a discrete shear test on the to-be-studied discrete material; performing image acquisition and recording on the shearing process of the to-be-studied discrete material filled in the shear box in real time in the discrete material shear test process through a front panel of the modified shear box by adopting image recognition equipment; and based on the recorded image of the shearing process, carrying out quantitative characterization on the shearing characteristic of the to-be-studied discrete material. According to the method, a new method is developed for research in the field of discrete solids, and theoretical support is provided for safety research of various discrete solids.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com