Portable vibration auxiliary drilling device, hole making method and processing signal detecting method

A portable and signal technology, applied in portable drilling rigs, drilling/drilling equipment, manufacturing tools, etc., to achieve rapid tool change, reduce adverse effects, and accurate signal detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

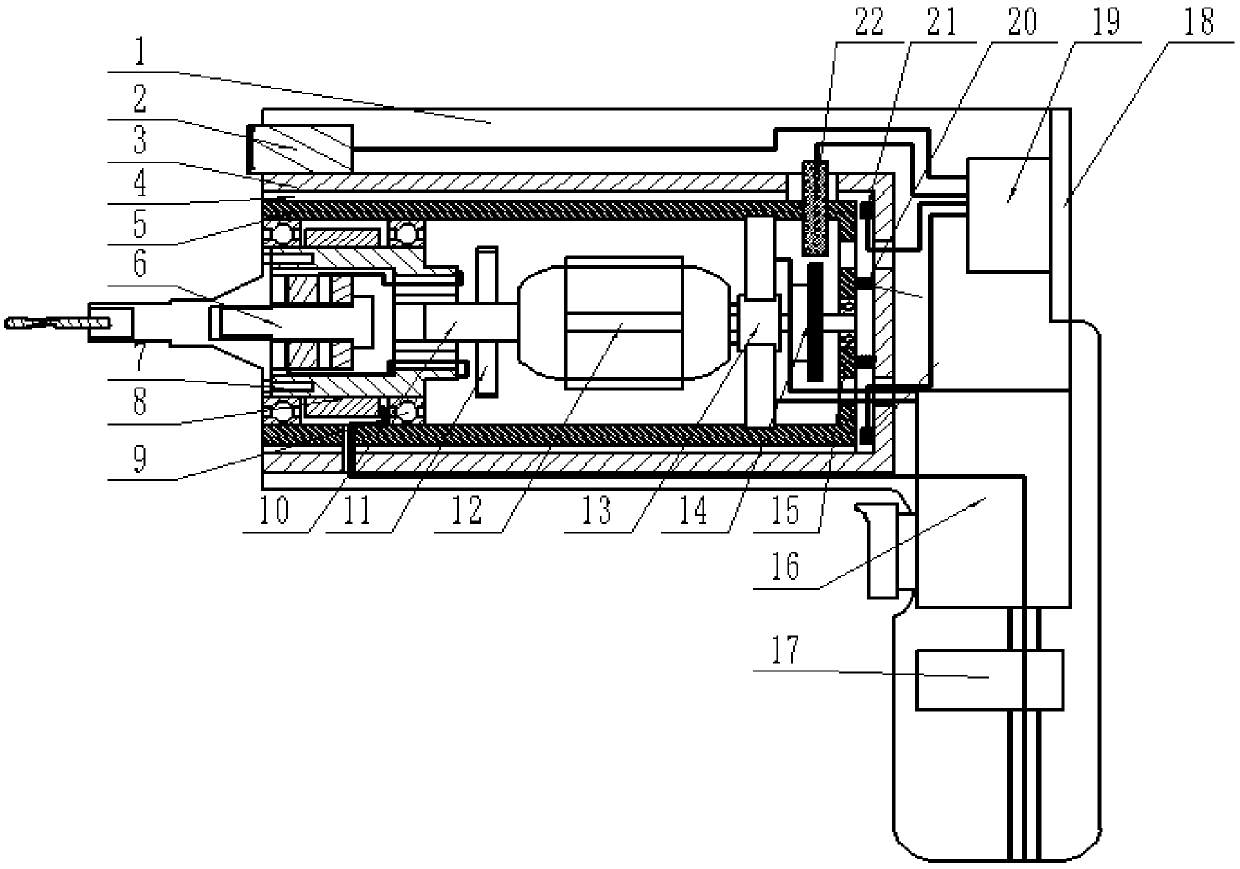

[0031] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] A portable vibration-assisted drilling device, characterized in that:

[0033] The device consists of an outer shell 1, a displacement sensor 2, an inner shell 3-5, a vibration unit 6, a conductive slip ring 8, a motor 12, a detection gear 14, a PLC 19, a piezoelectric ceramic counter 21, and a speed sensor 22;

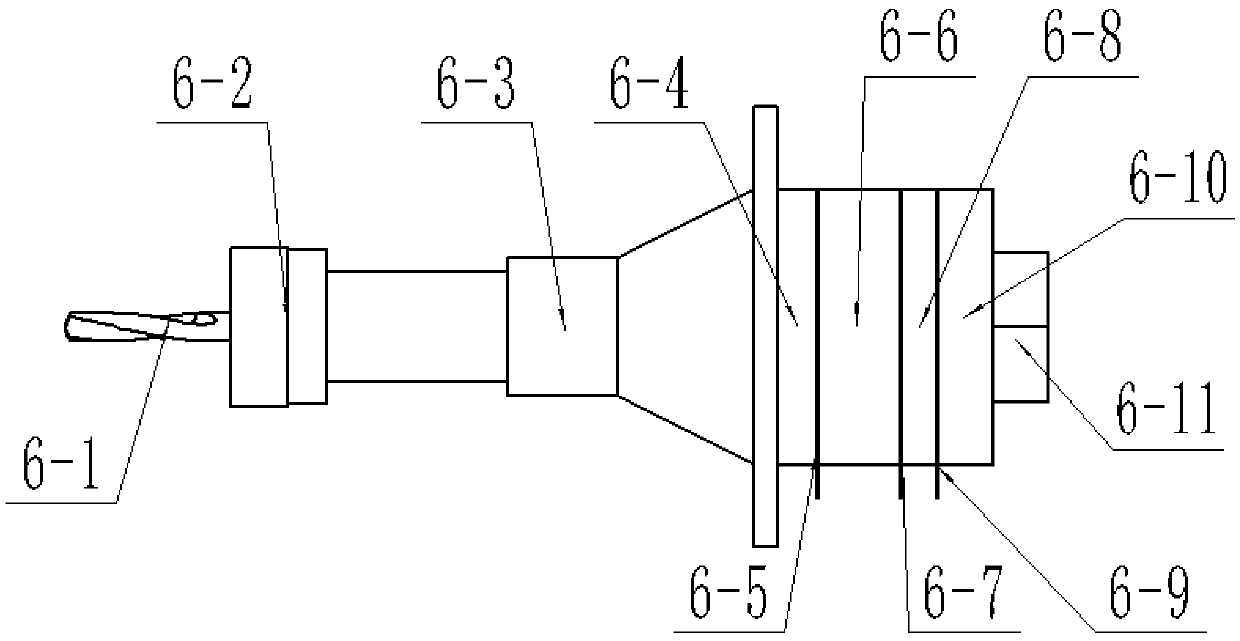

[0034] The above-mentioned vibration unit is composed of cutters, horns and piezoelectric transducers, and piezoelectric ceramics, electrode sheets, intermediate pads, and rear covers are arranged on the piezoelectric transducers, and the pre-tightening bolts are fixed on the On the rod, through the inverse piezoelectric effect of piezoelectric ceramics, electrical energy can be converted into mechanical energy, thereby realizing vibration-assisted drilling.

[0035] The above-mentioned inner shell is composed of a fixed par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com