Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

168results about How to "Quick changeover" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mobile phone screen MURA defect detection method based on convolution neural network pruning algorithm

ActiveCN106875373AGuaranteed accuracyDealing with Moiré InterferenceImage enhancementImage analysisPattern recognitionAlgorithm

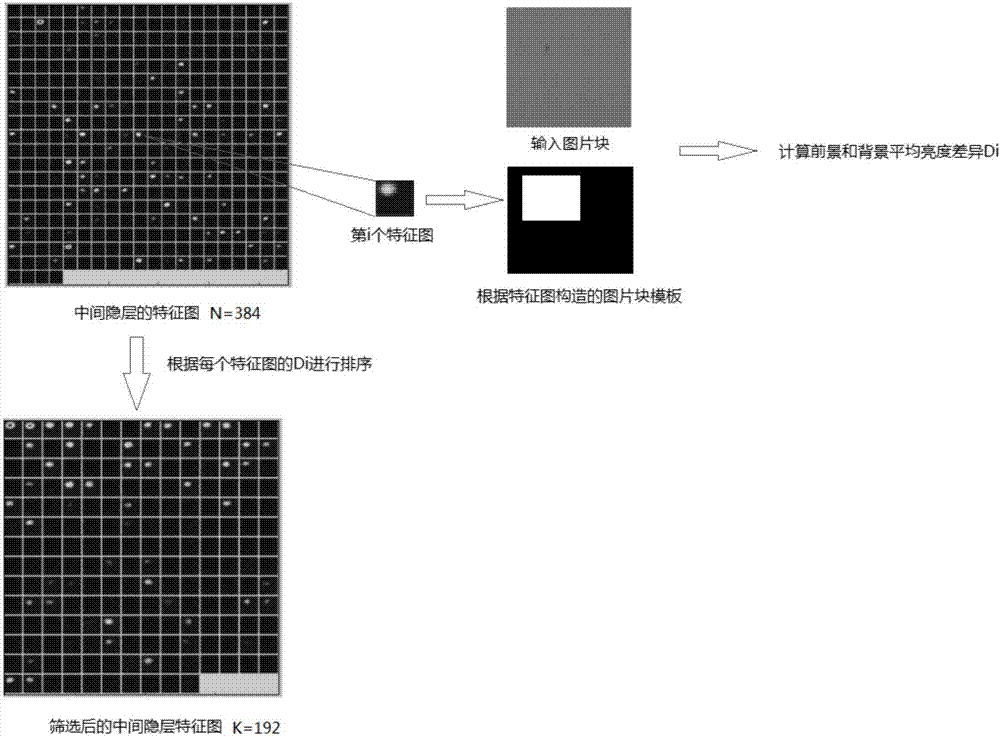

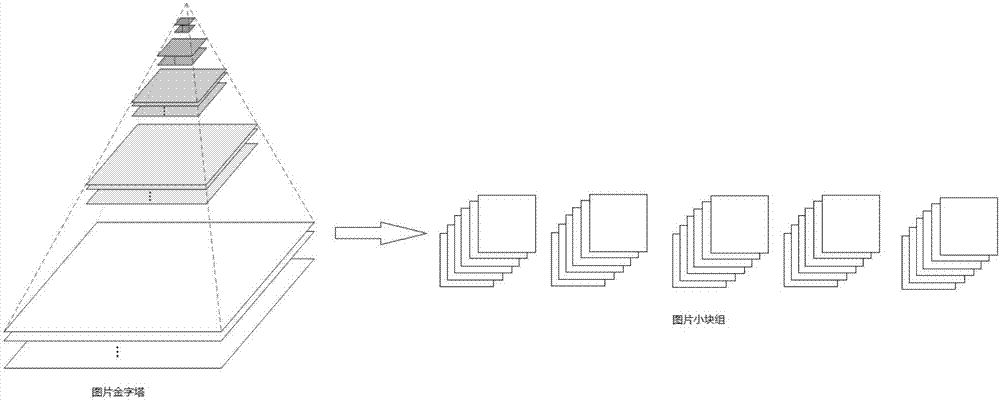

The invention relates to a mobile phone screen MURA defect detection method based on a convolution neural network pruning algorithm. The mobile phone screen MURA defect detection method based on a convolution neural network pruning algorithm includes the steps: 1) customizing a depth convolution neural network, and utilizing the existing training data to train a neural network of detecting a mobile phone screen MURA defect; 2) utilizing an adaptive template coupling method to perform pruning operation on the convolution neural network, reducing the network scale, and reducing the algorithm running time; 3) zooming the mobile phone screen images shot by a high resolution camera, forming an image pyramid, for the image of each scale, utilizing a sliding window method to segment the images into small blocks, and taking all the small blocks of images as one group and sending the group to the convolution neural network; and 4) selecting all the characteristic images of the intermediate layer as the response images for the defect, and utilizing a threshold segmentation method to finally obtain the area position of the mobile phone screen MURA defect.

Owner:HUIZHOU XUXIN PRECISION ELECTRONICS EQUIP

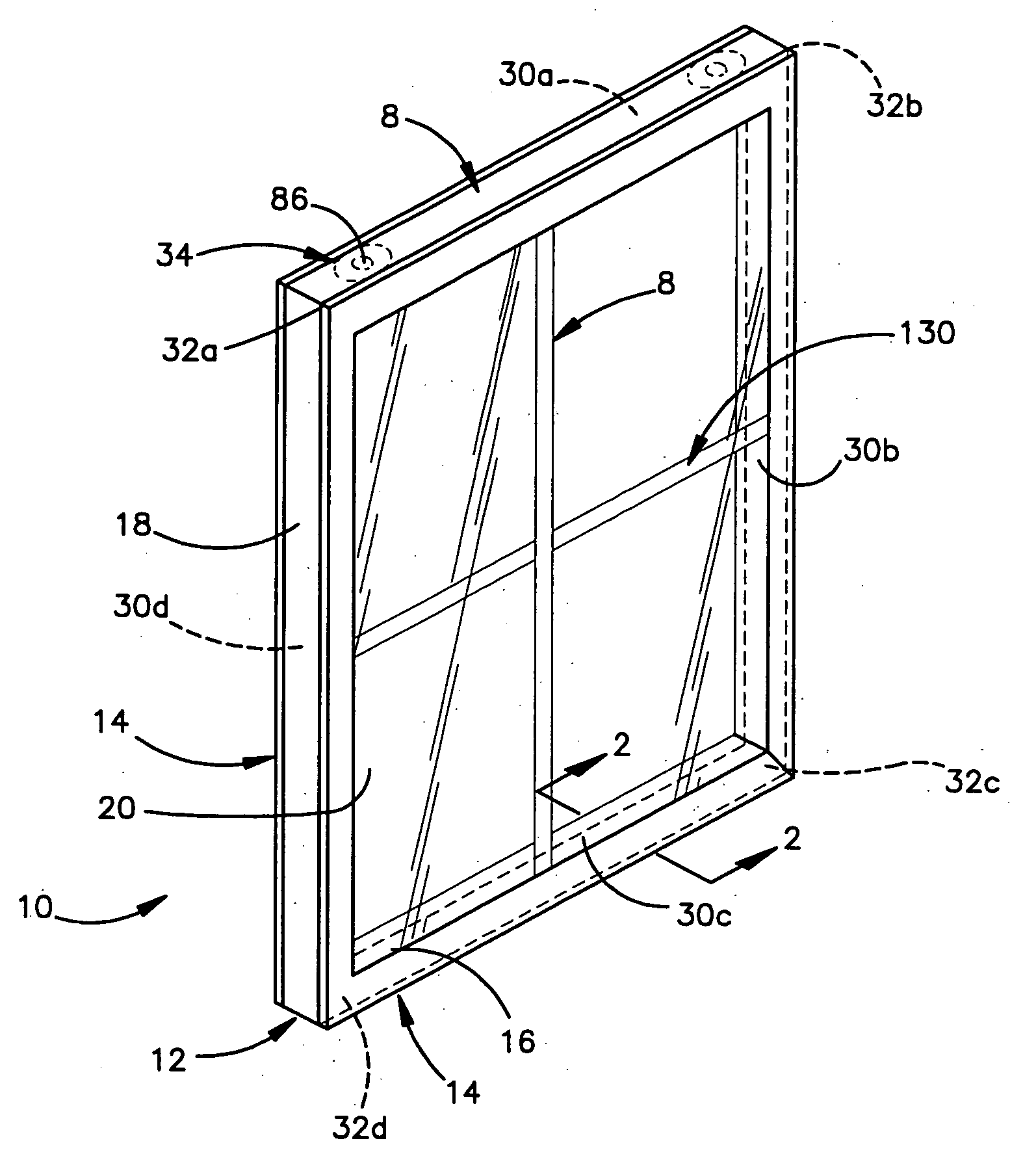

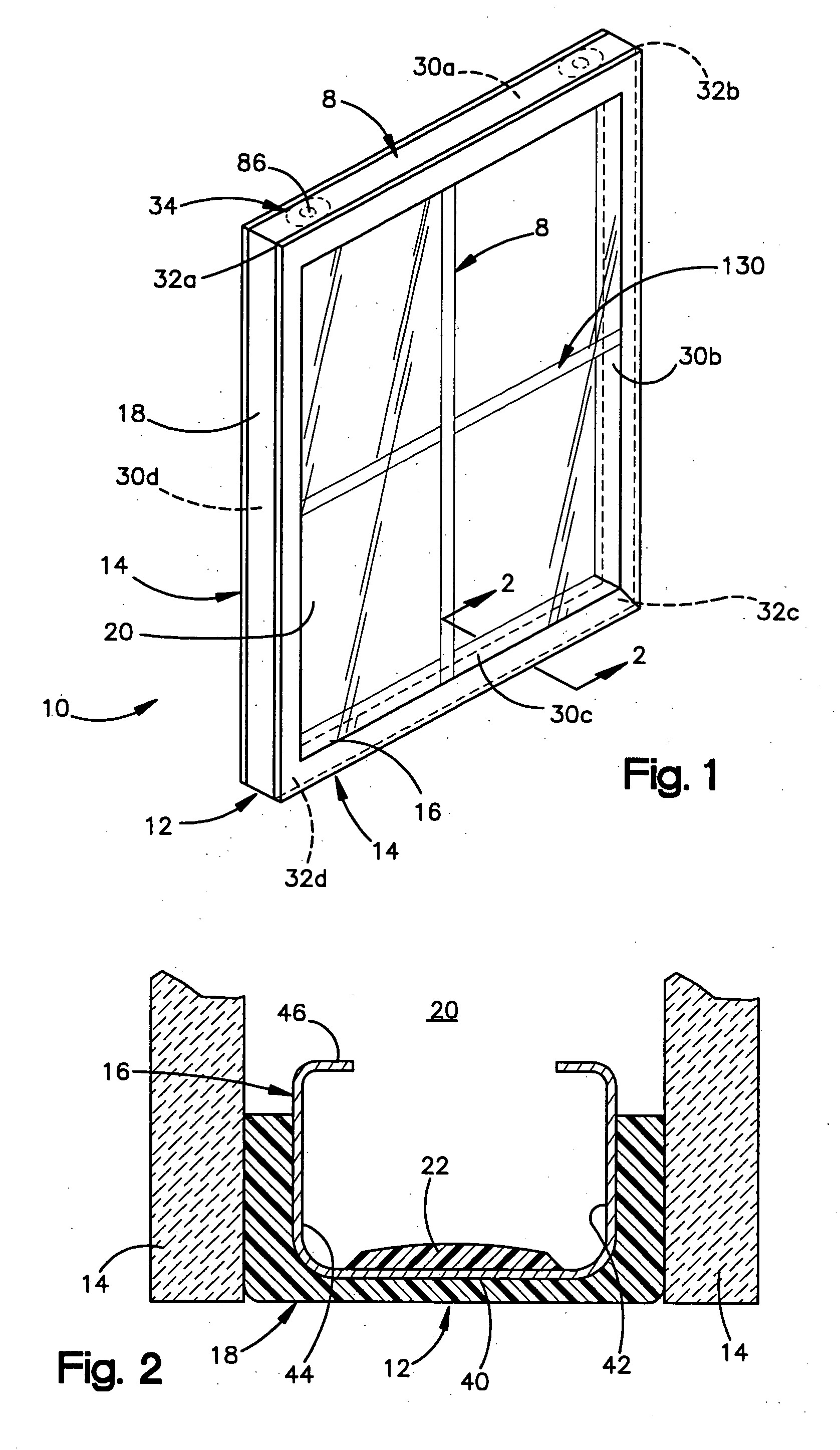

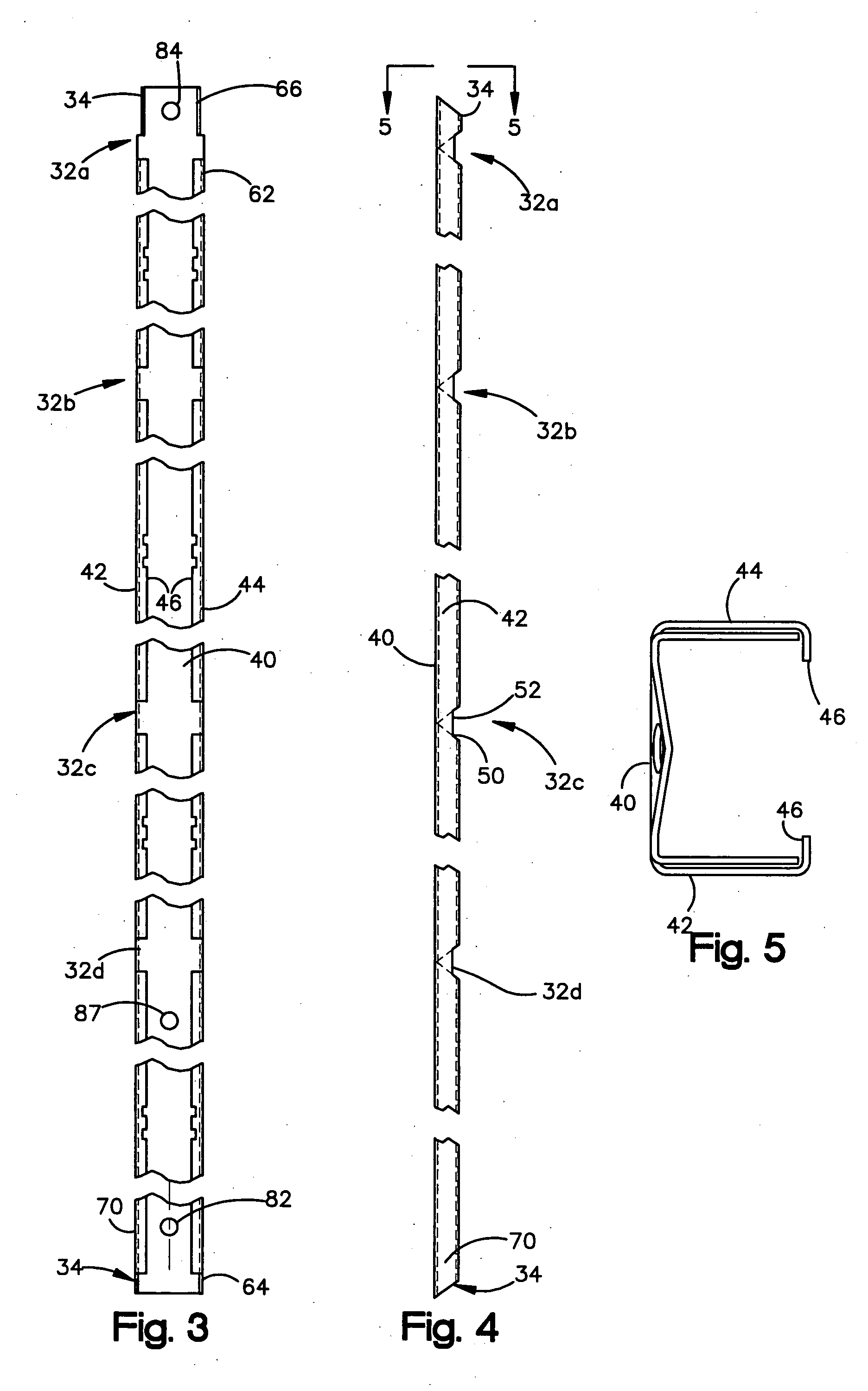

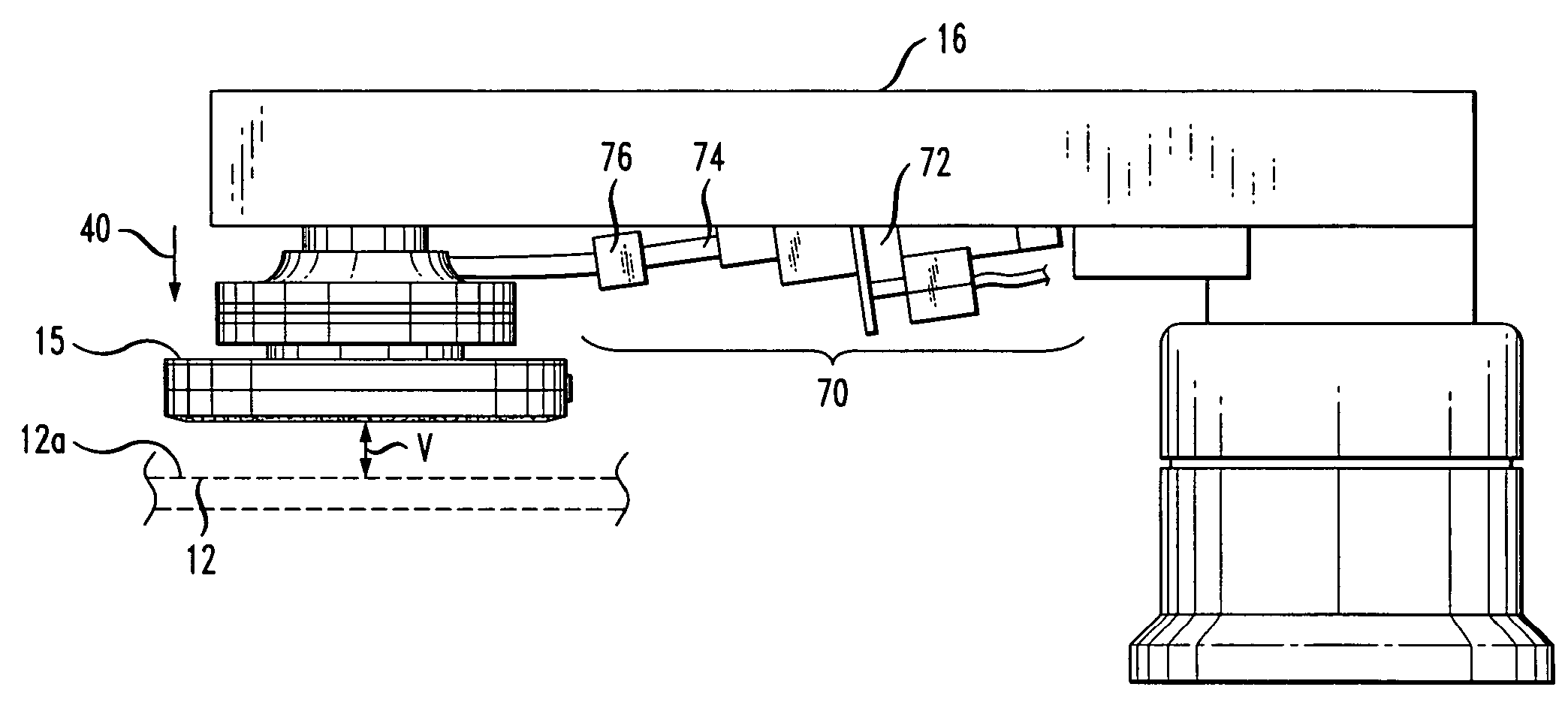

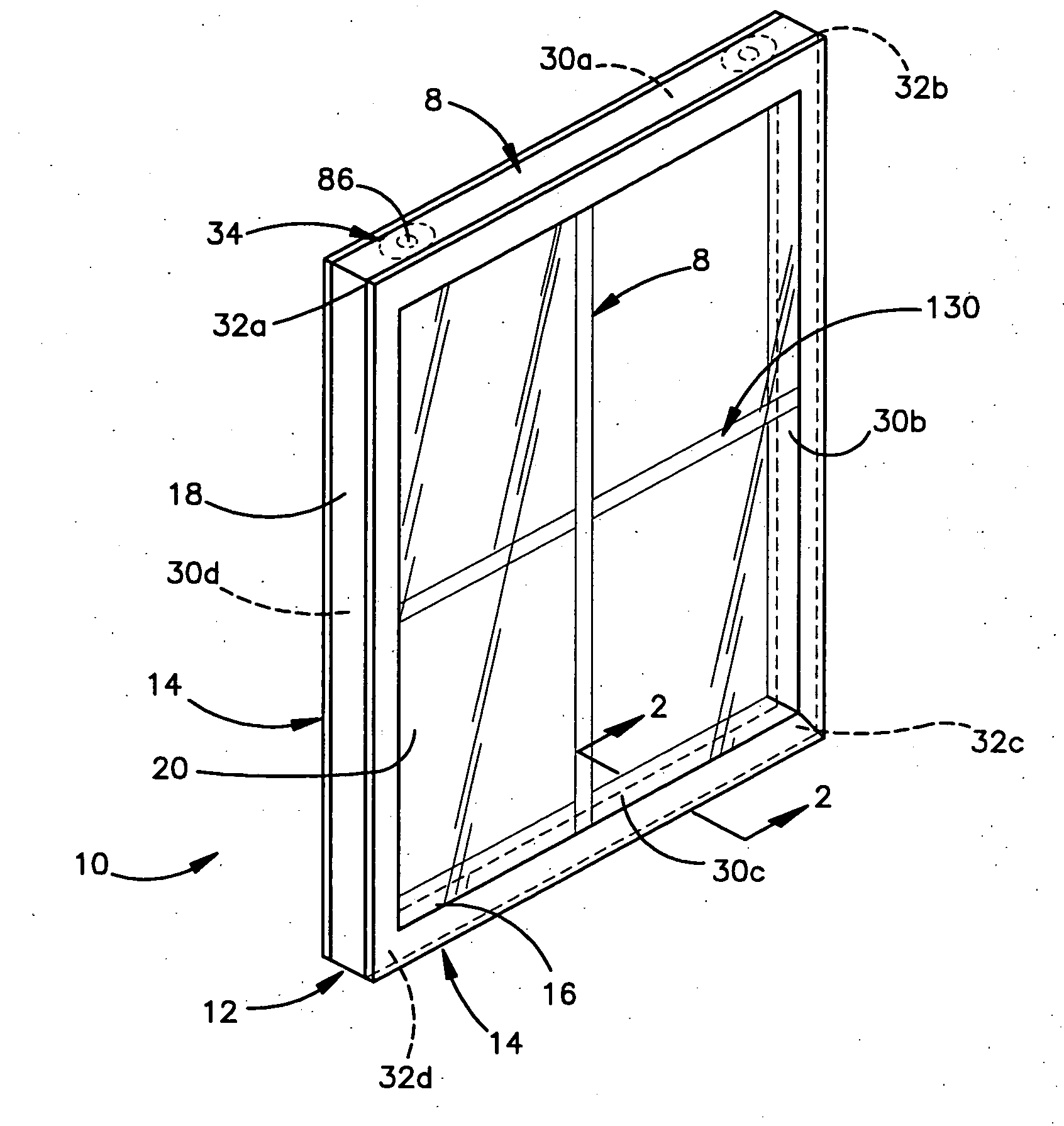

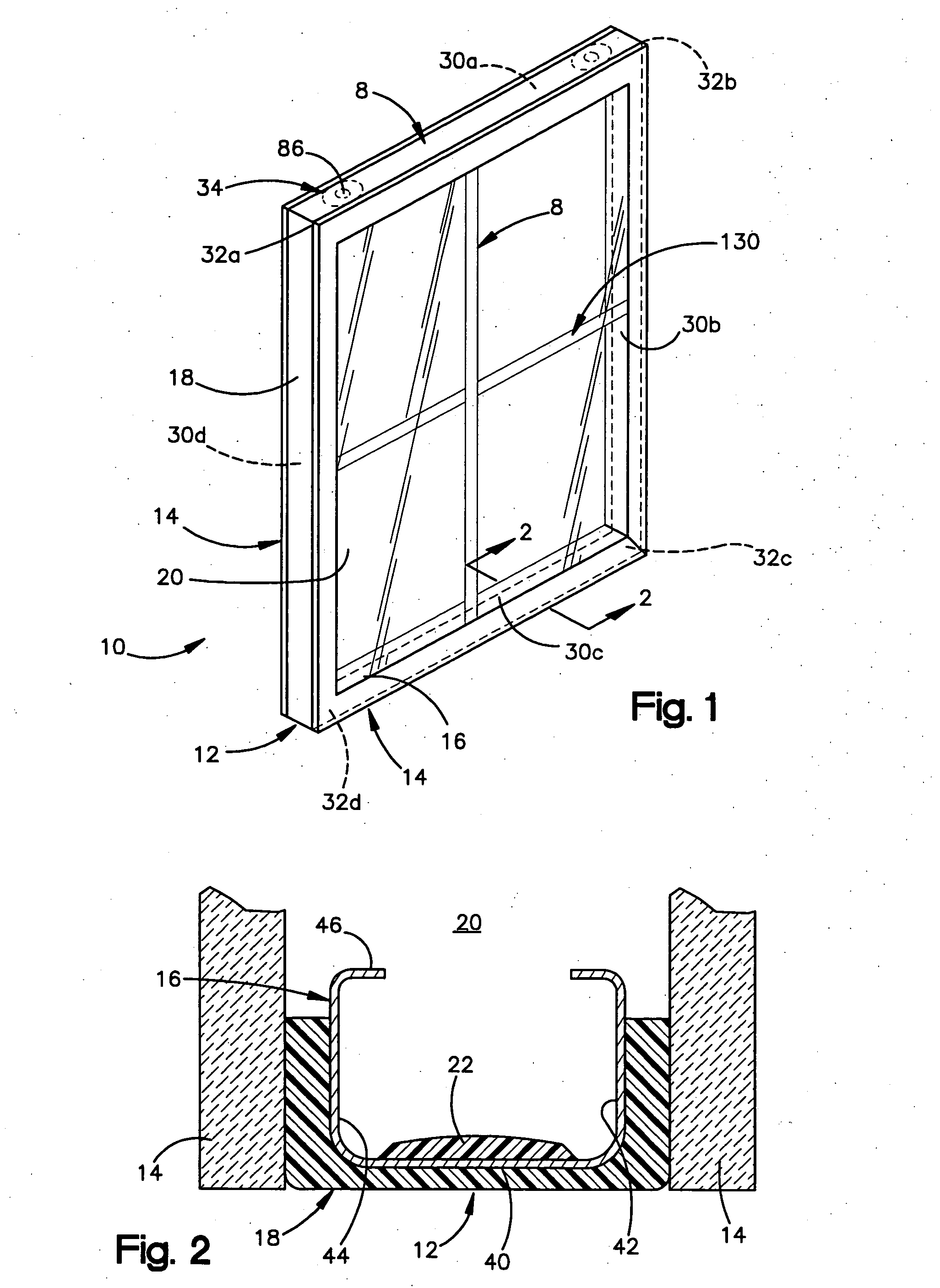

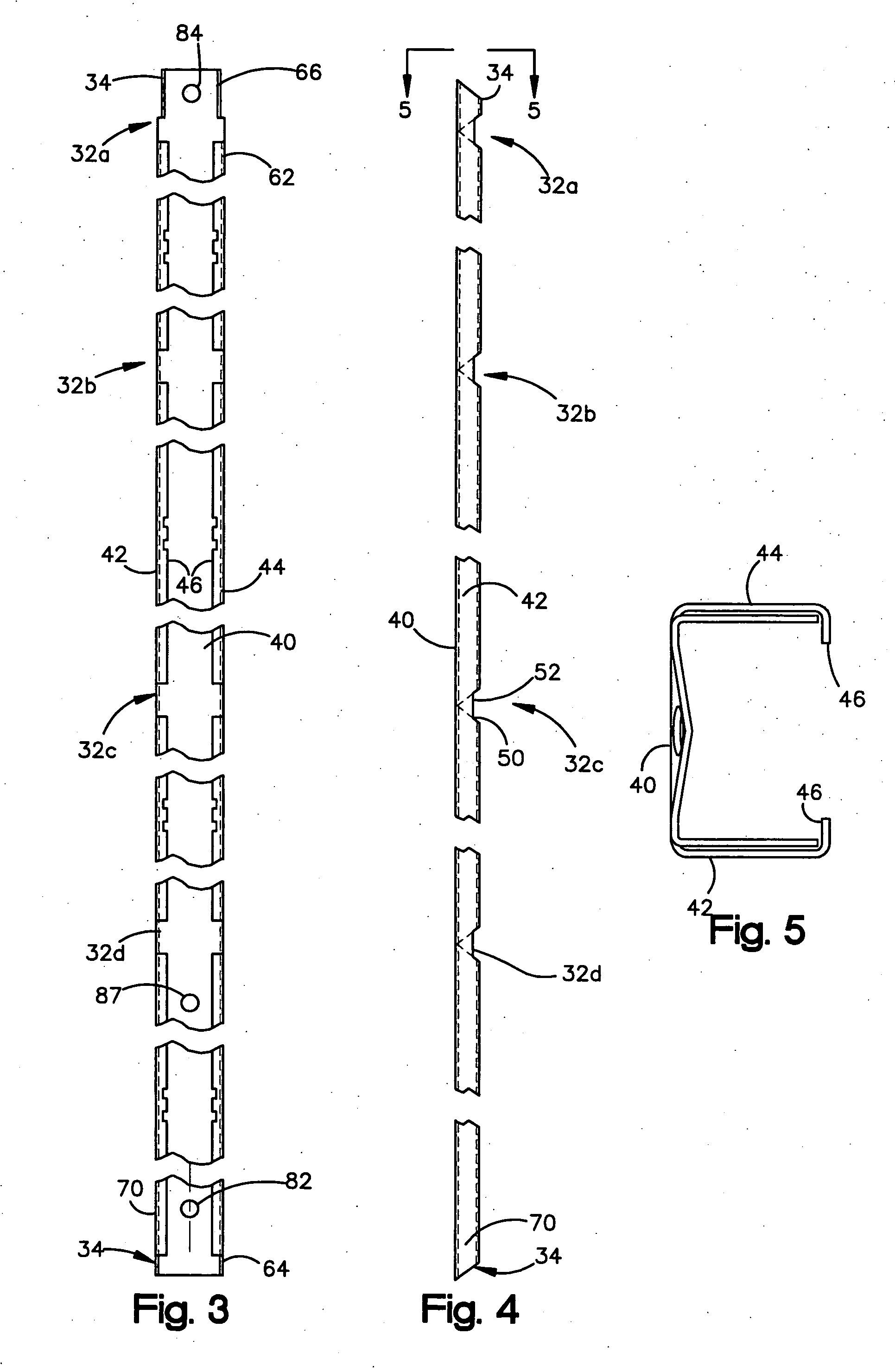

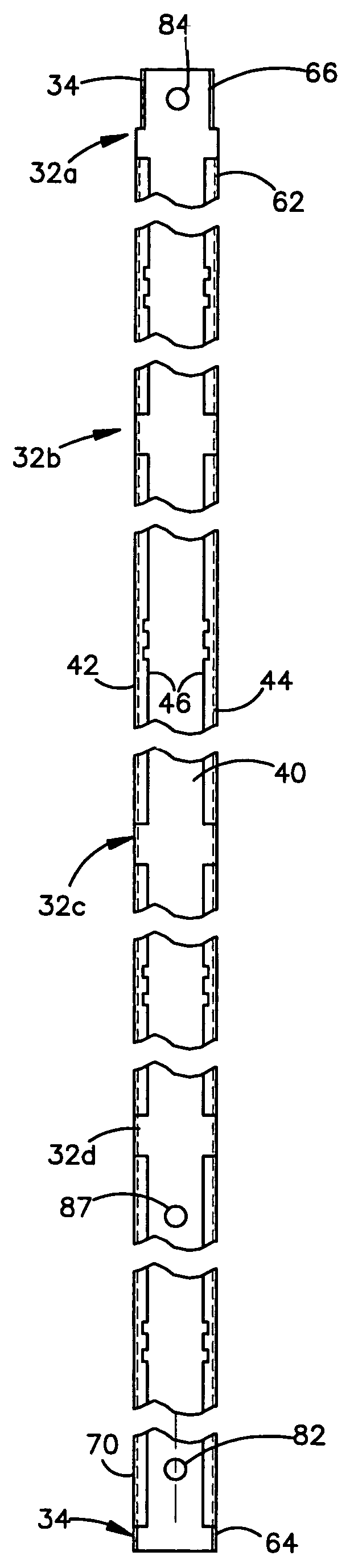

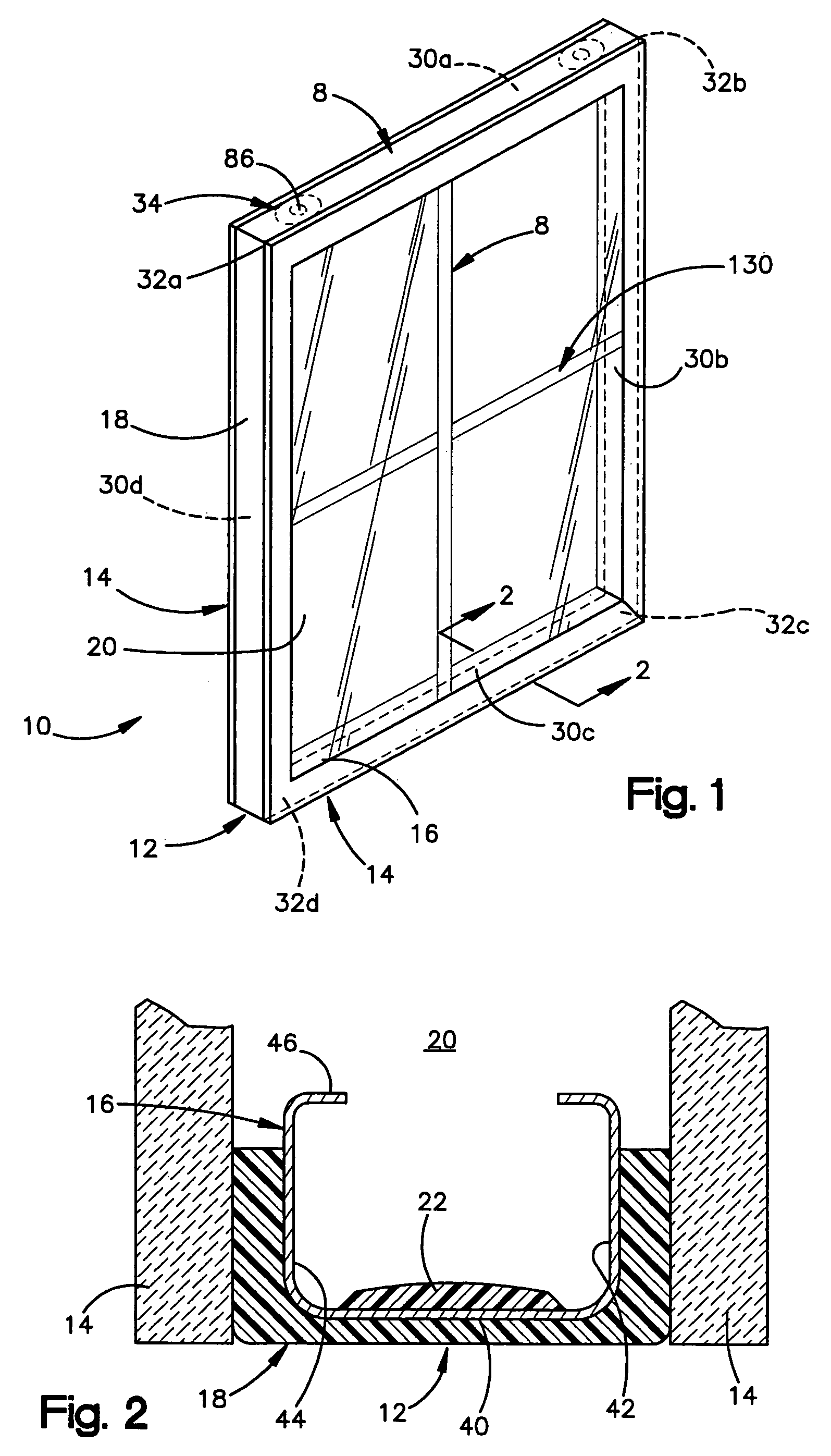

Window component stock transferring

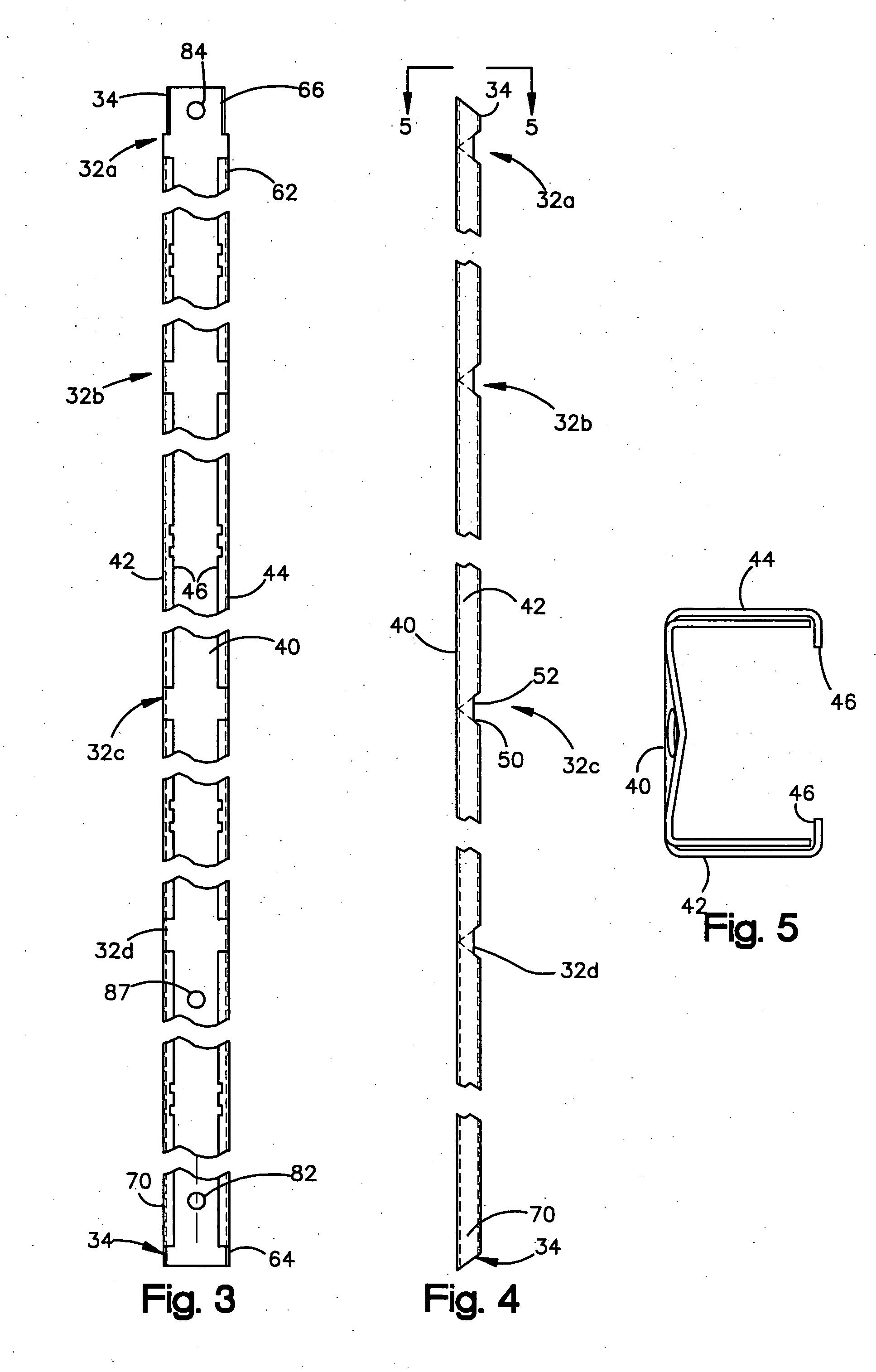

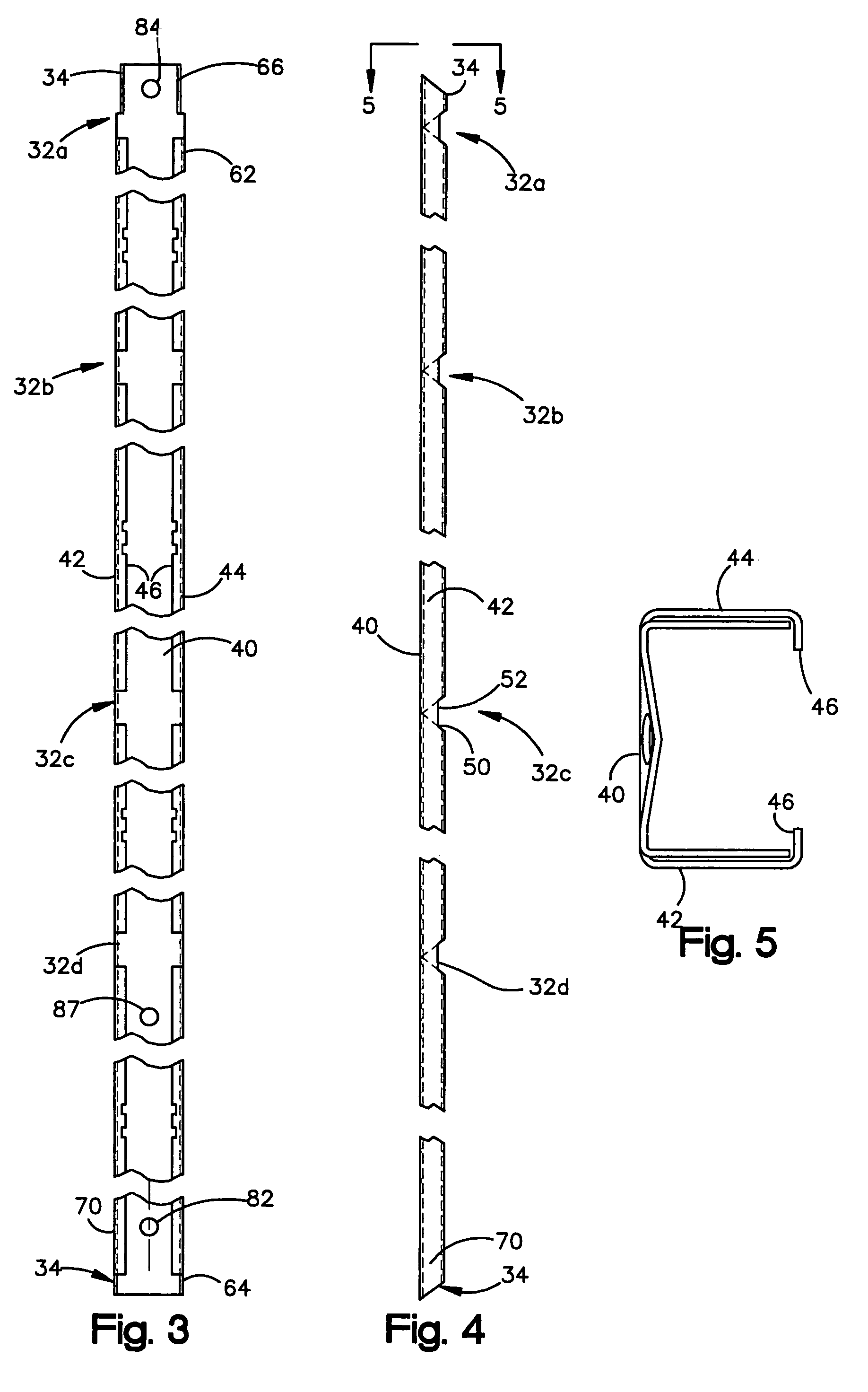

ActiveUS20060065345A1Avoid excessive wasteWasted materialLamination ancillary operationsDoors/windowsProduction lineRoll forming

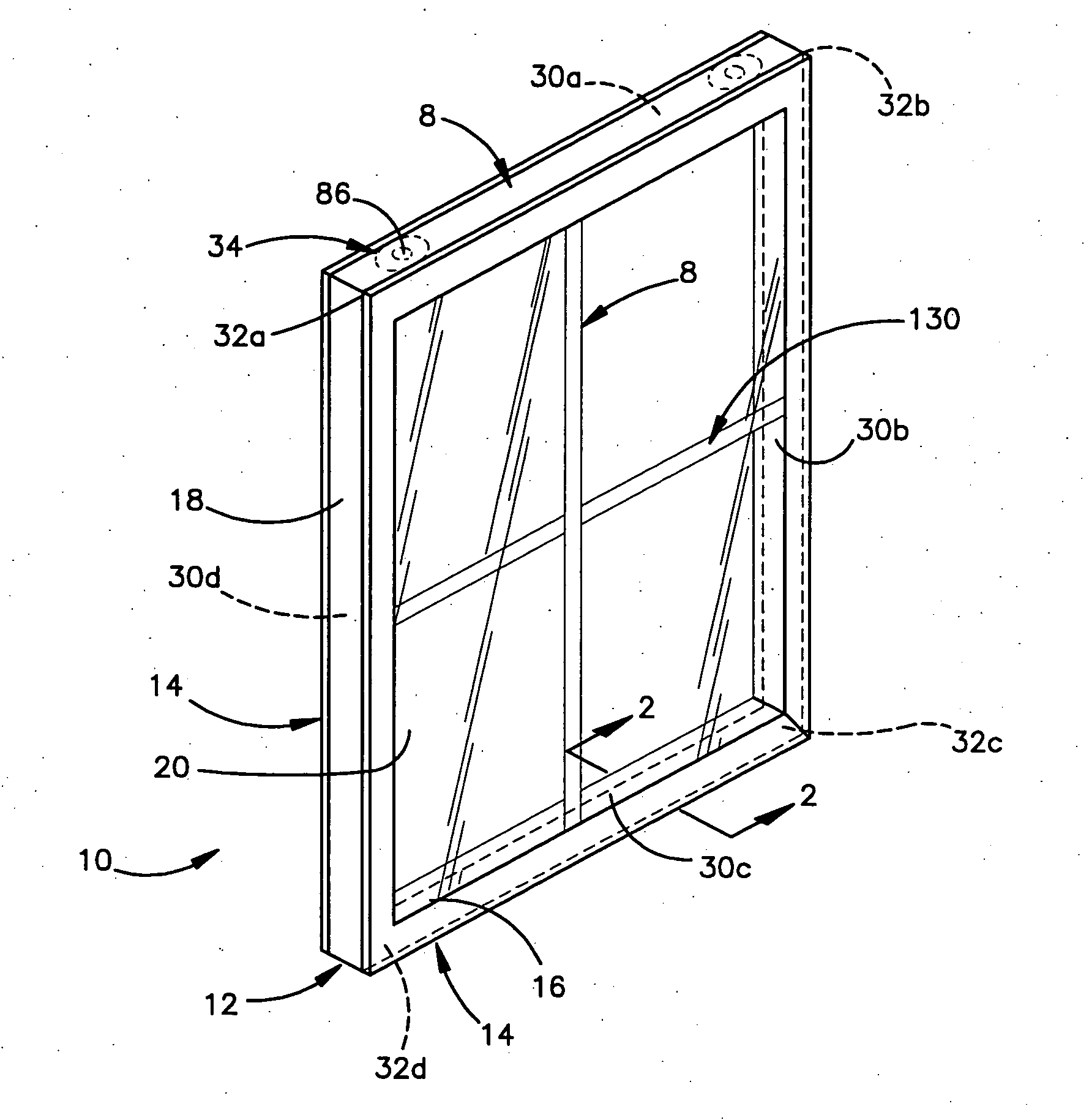

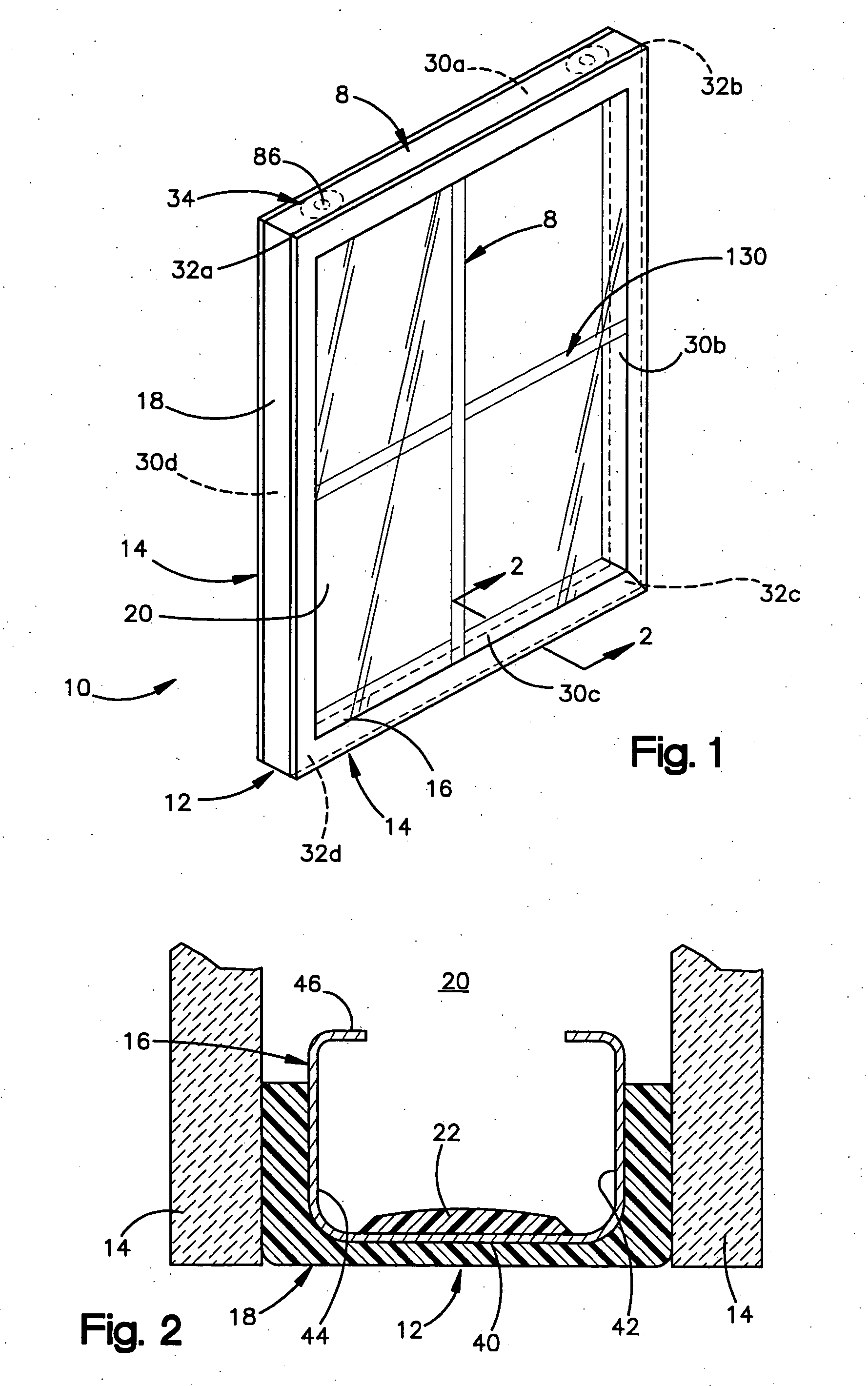

An apparatus for automatic feeding of elongated sheet stock from a stamping station into a roll forming station in a window component production line includes a transfer mechanism, a feed mechanism and a controller. The transfer mechanism is between the stamping station and the roll forming station. The feed mechanism is positioned at an entrance to the roll forming station. The controller is in communication with the stamping station, the transfer mechanism and the feed mechanism. The controller is programmed to engage stock material that extends from the stamping station with the transfer mechanism, transfer the stock material paid out by the stamping station to the feed mechanism, and drive the feed mechanism to feed the elongated sheet stock into the roll forming station.

Owner:GED INTEGRATED SOLUTIONS

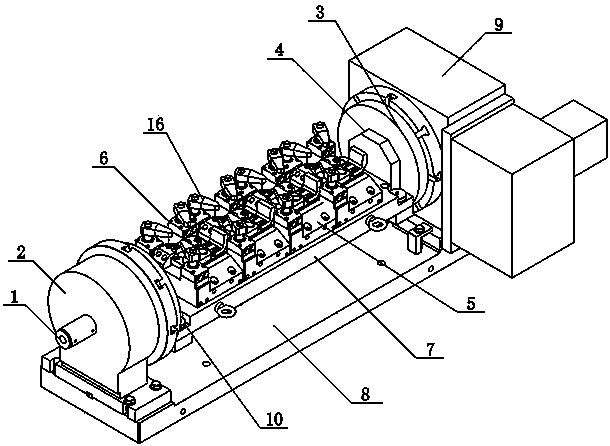

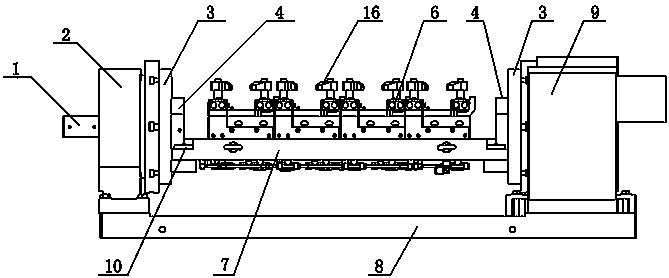

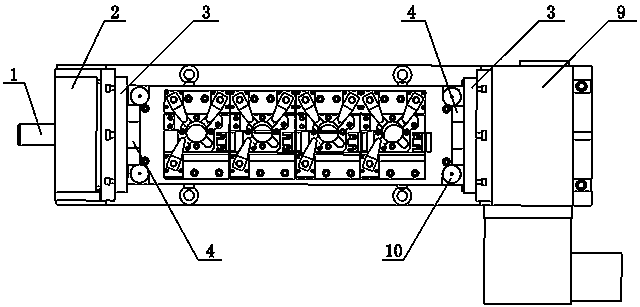

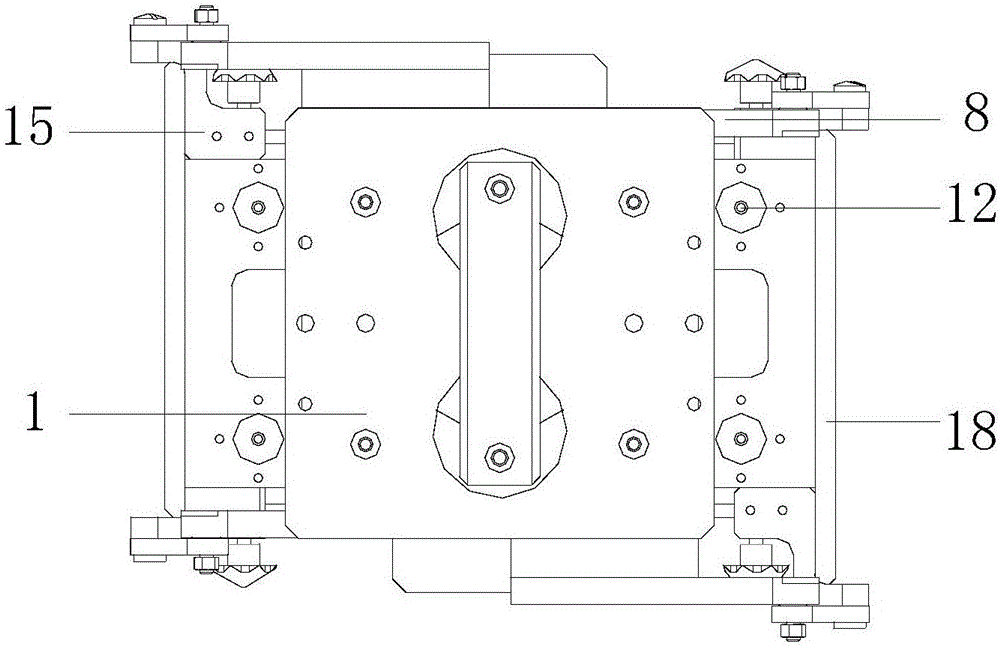

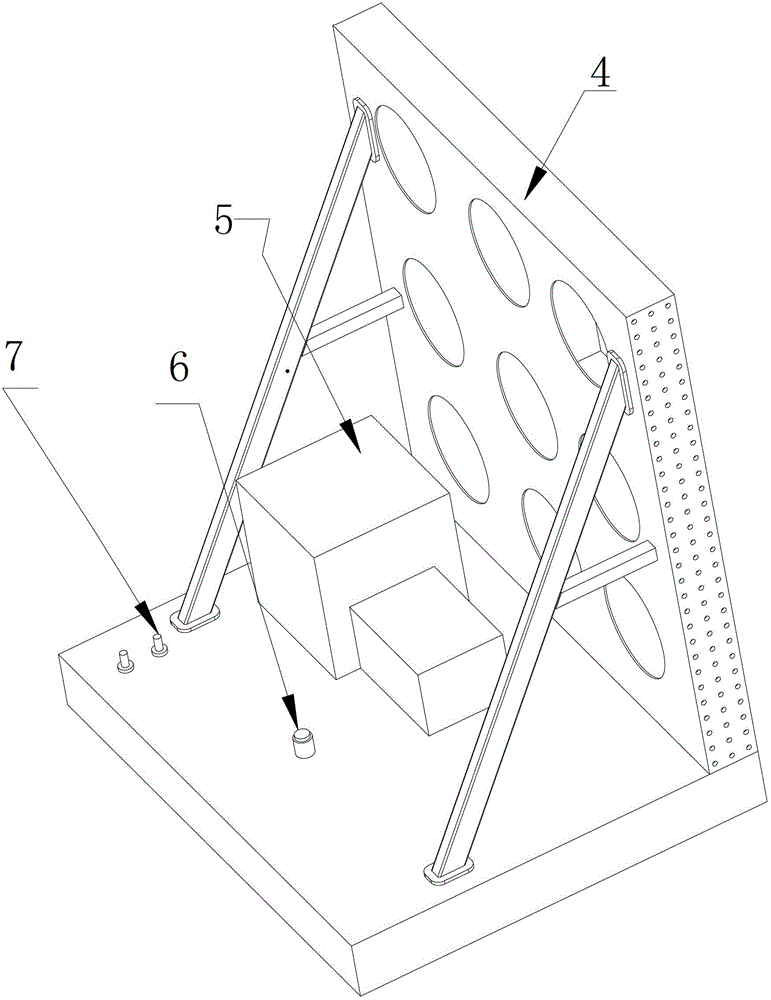

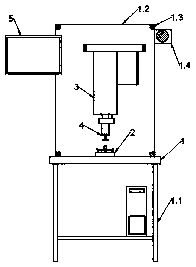

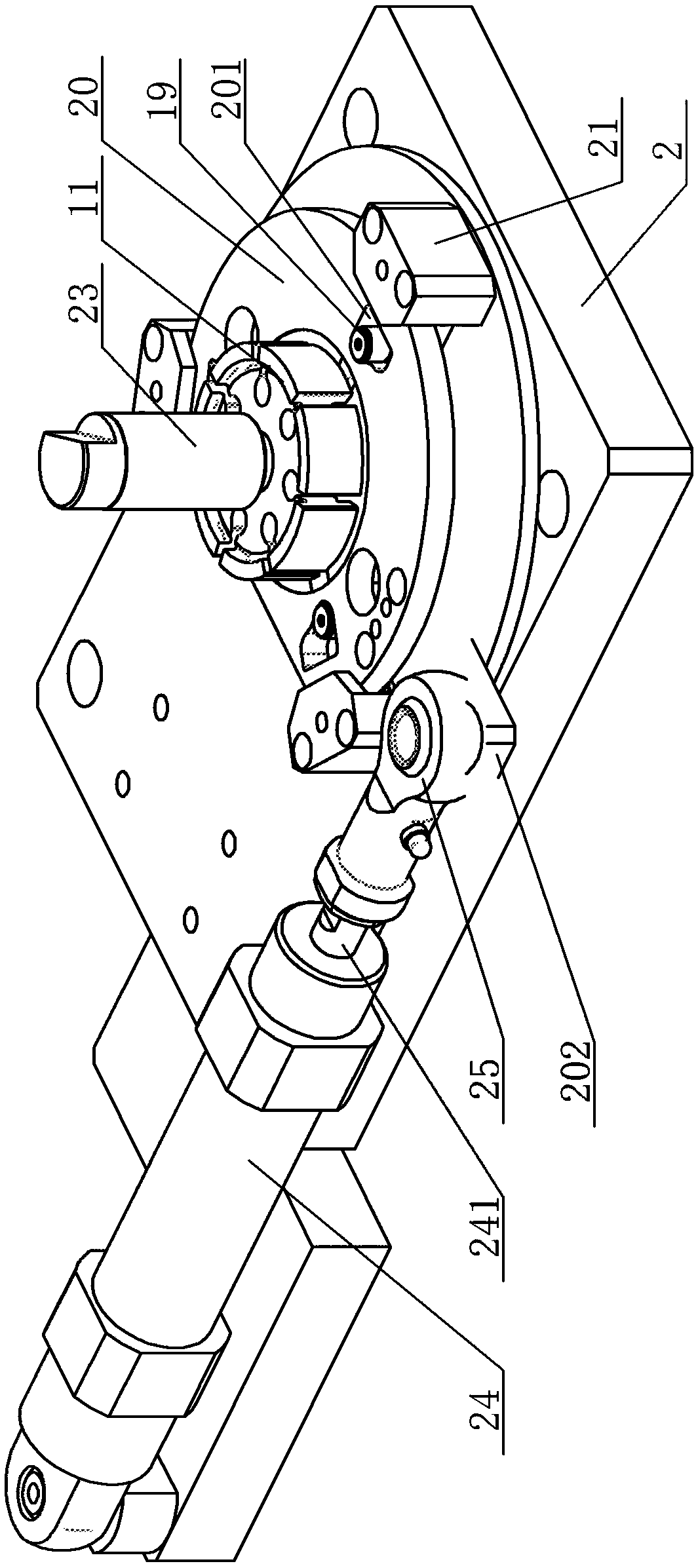

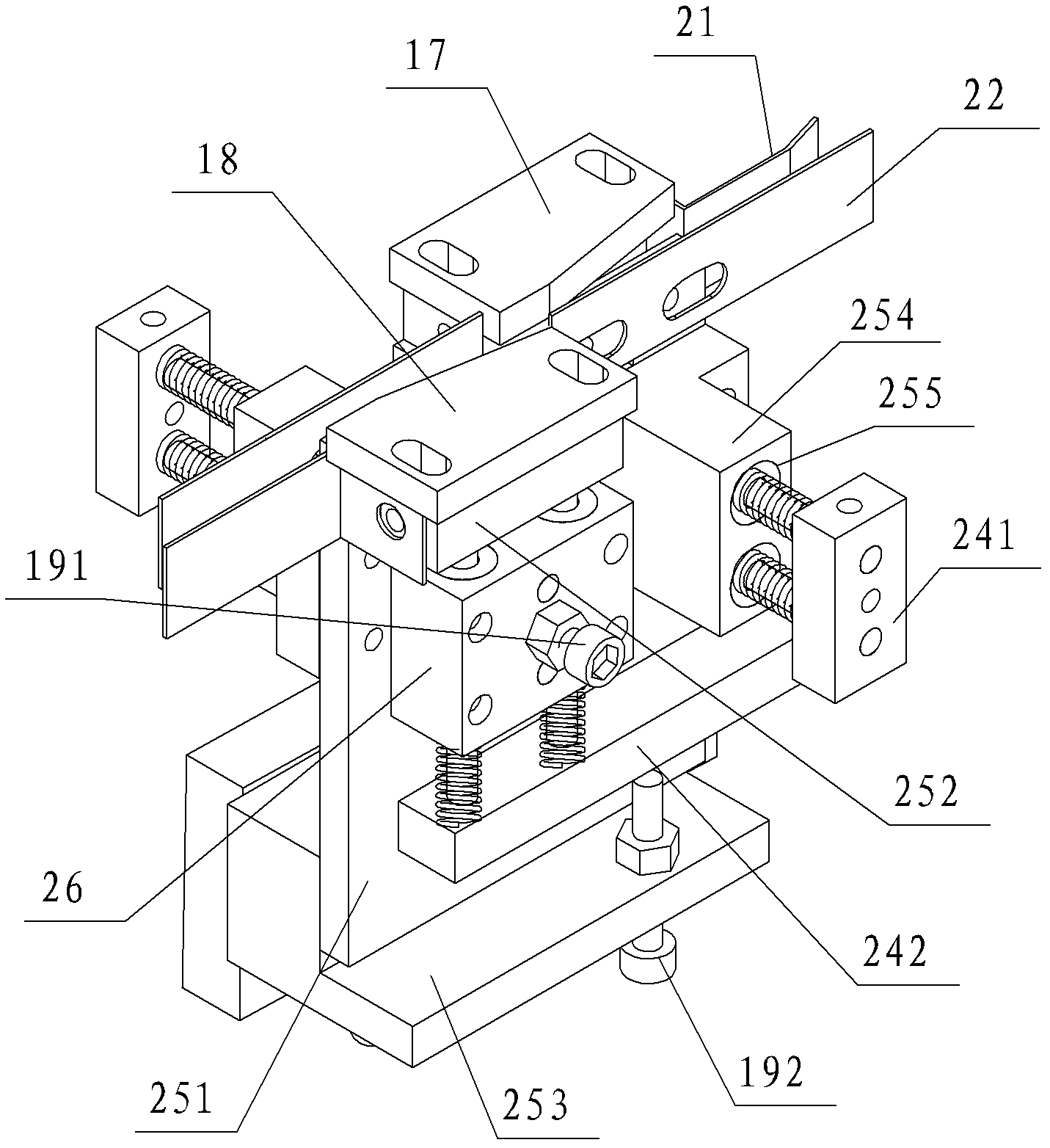

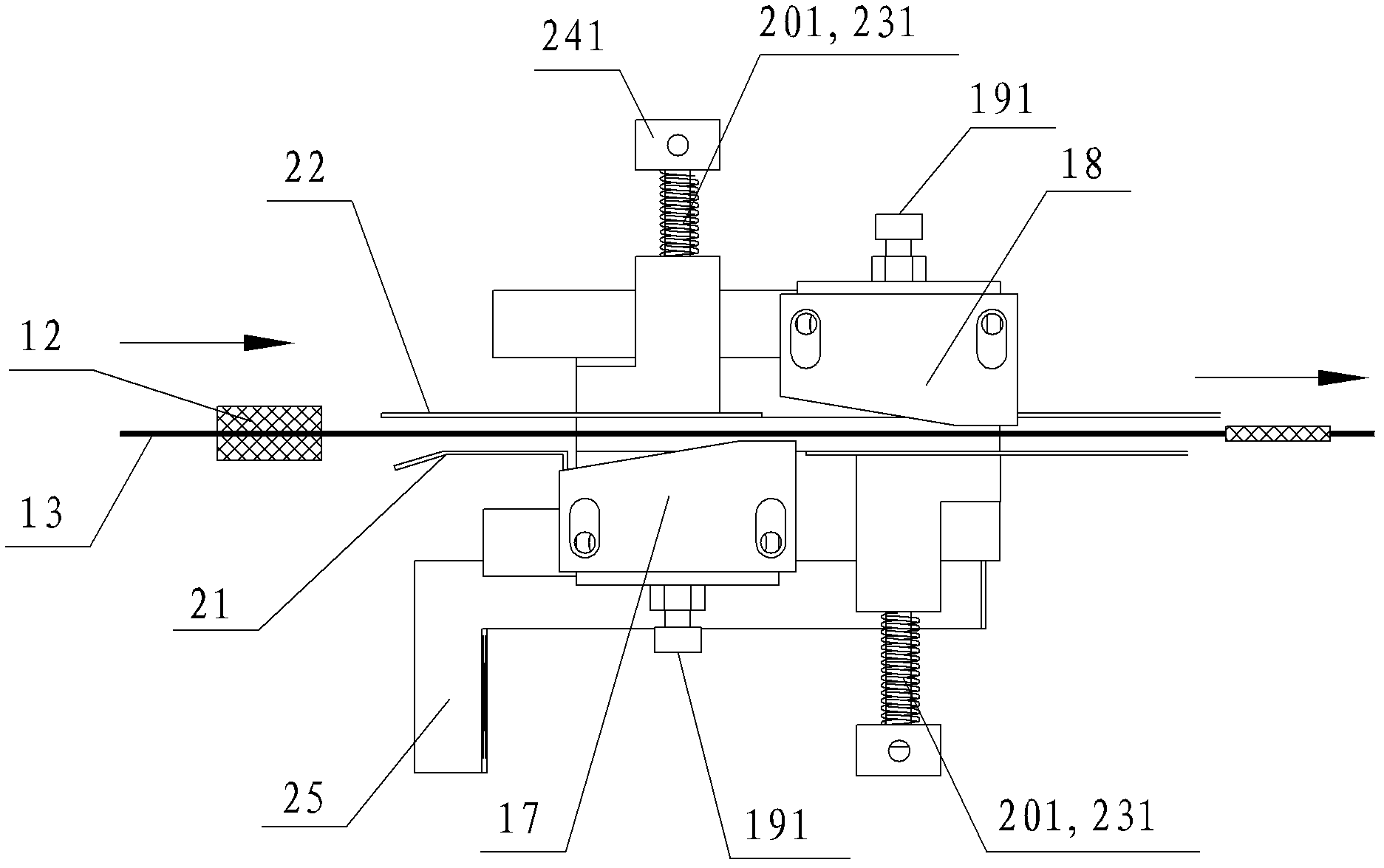

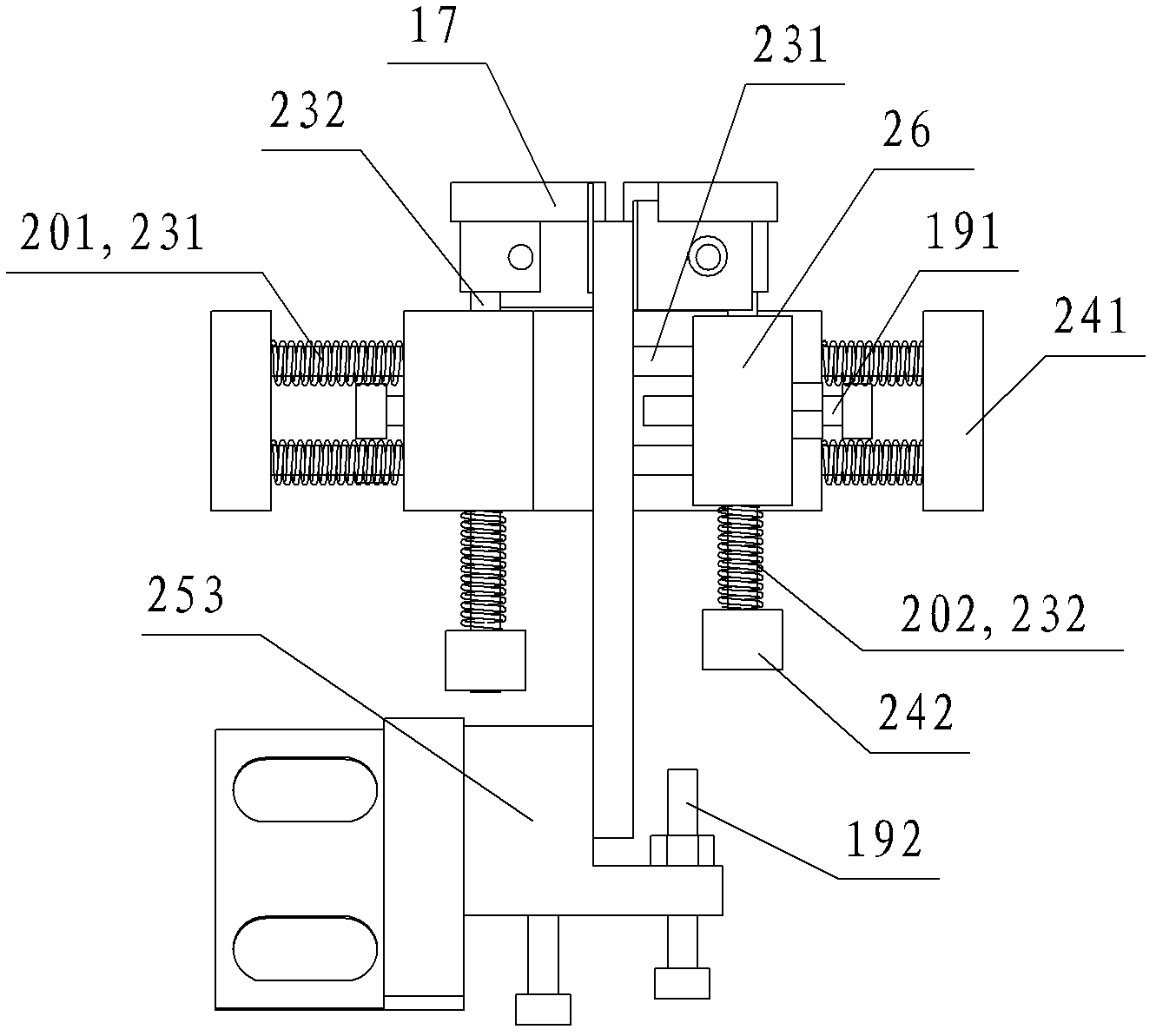

Machine and turntable clamp for four-axis processing center

InactiveCN104325324ASimple changeover operationQuick changeoverMeasurement/indication equipmentsPositioning apparatusProduction lineModular design

The invention relates to a machine and turntable clamp for a four-axis processing center. The clamp comprises a clamp bottom plate (8), a tail seat (2), a dividing head (9), an oil / gas path distributor component (1), L-shaped plates (4), a bridge plate (7) and clamp location clamping units, wherein the tail seat (2) and the dividing head (9) are fixedly arranged on the clamp bottom plate (8); the oil / gas path distributor component (1) is arranged on the outer side face of the tail seat (2); two L-shaped plates (4) are oppositely arranged and are respectively connected with the tail seat (2) and the dividing head (9) by a transition plate (3); two ends of the bridge plate (7) are respectively connected with the L-shaped plates (4); a plurality of clamp location units are provided and are uniformly spaced and fixed on the bridge plate (7) in sequence. The machine and turntable clamp has the advantages that a modular design and a ball lock location system are used for realizing fast changing the clamp when the type of a production line is changed; hydraulic clamping is used, so that a reliable clamping force is provided; an airtight detection technology and a fast assembling / disassembling limit block are used, so that an error proofing function is available.

Owner:SICHUAN HONGGUANG AUTO MACHINERY ELECTRONICS

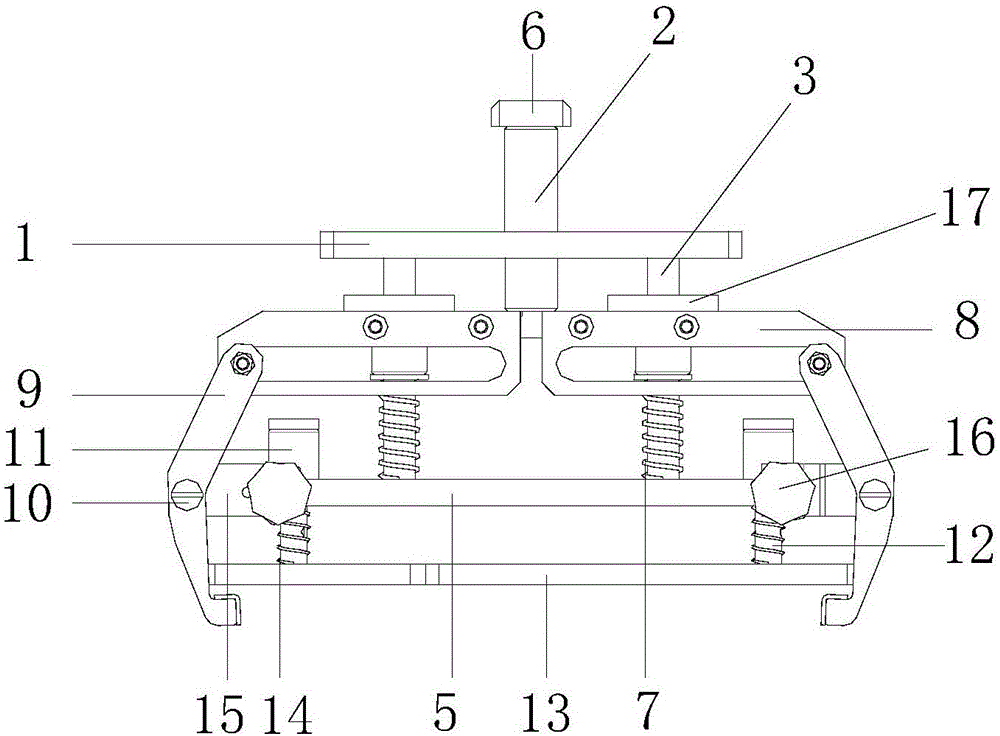

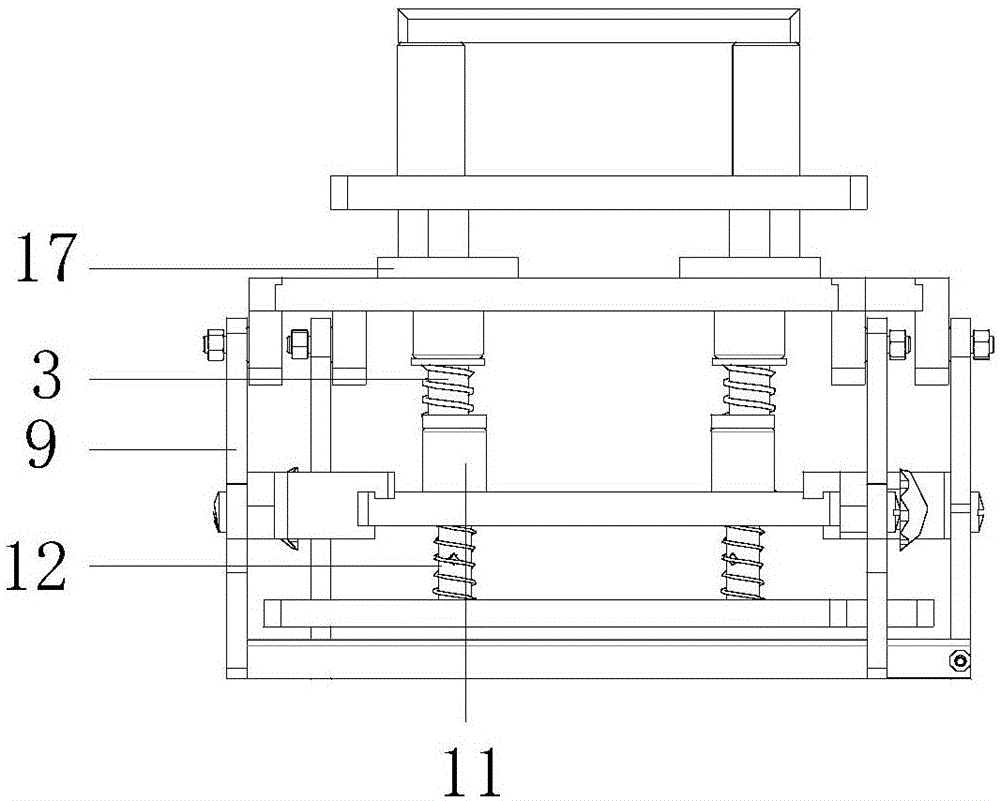

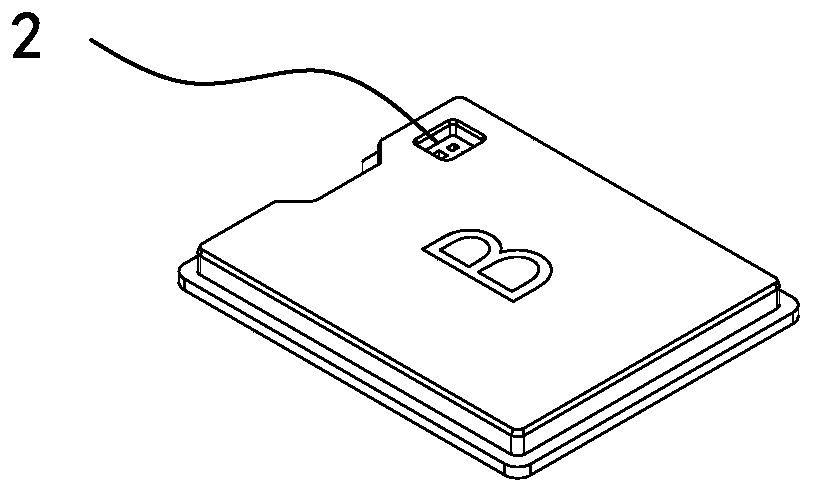

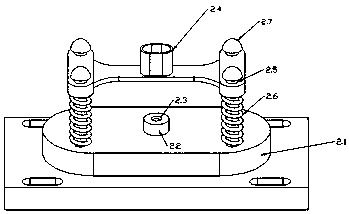

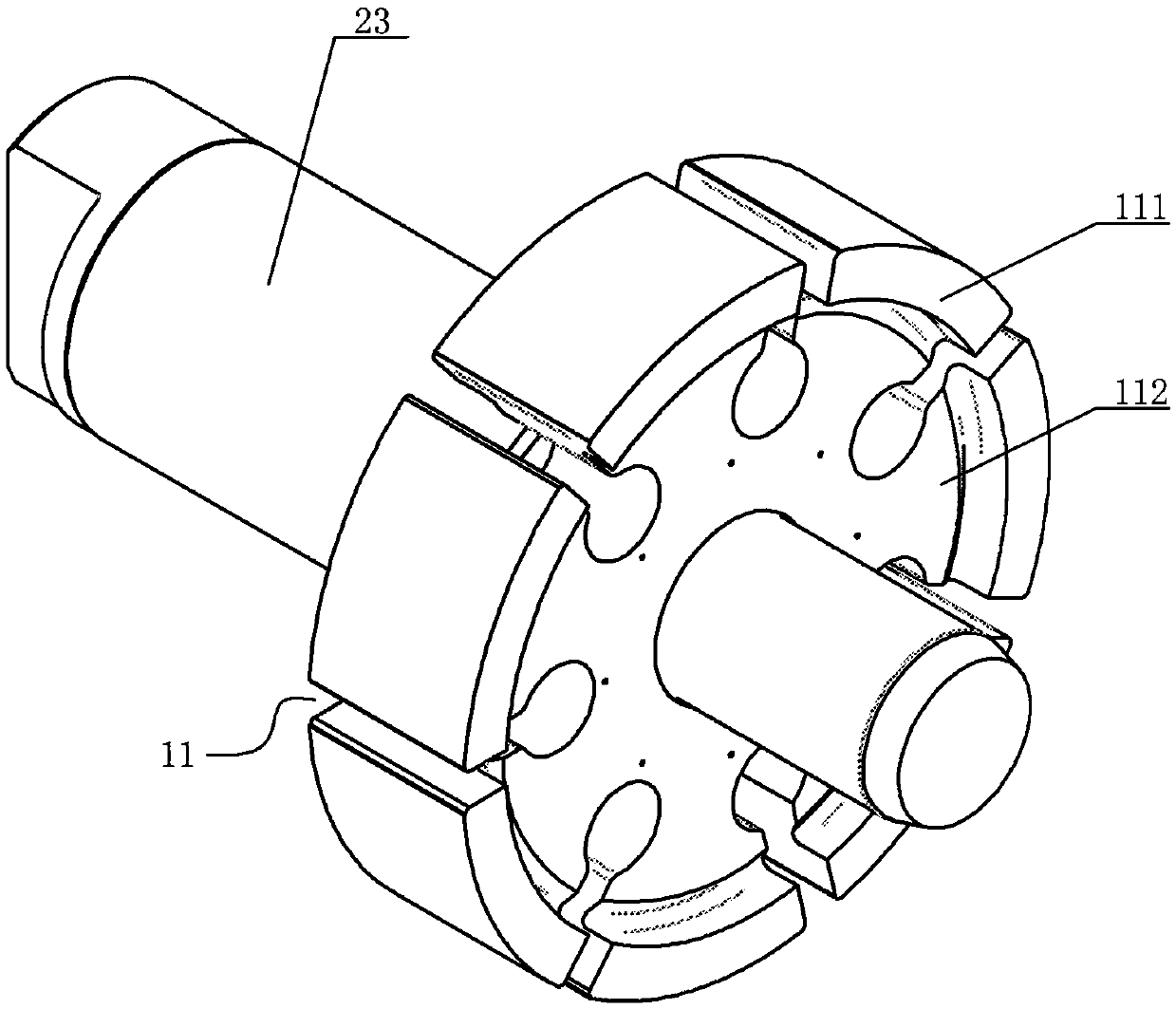

Power battery high-applicability nondestructive automatic clamping apparatus

ActiveCN106078786AWon't hurtPrevent looseningProgramme-controlled manipulatorGripping headsPower batteryMechanical engineering

The invention discloses a power battery high-applicability nondestructive automatic clamping apparatus which comprises a fixed plate, movable guide posts, a press guide post, a movable plate, a supporting plate, a connecting rod and a clamping jaw guide frame, wherein the upper part of the movable plate is provided with the at least two movable guide posts; the movable guide posts respectively penetrate through holes arranged in the fixed plate, and the upper ends are connected through the connecting rod; the press guide post penetrates through the movable plate, the upper end is connected with the fixed plate, and the lower end is connected with the supporting plate; a press guide post spring is sheathed on the press guide post; the press guide post spring is positioned between the movable plate and the supporting plate; the clamping jaw guide frame is installed on the movable plate; the clamping jaw guide frame is connected with a clamping jaw; and the clamping jaw comprises two sections, and is movably connected to the supporting plate through a shaft position screw. The apparatus can be used for quickly and flexibly clamping the batteries without destructing the batteries, can reshape the batteries, and is suitable for different battery models.

Owner:镇江科信动力系统设计研究有限公司

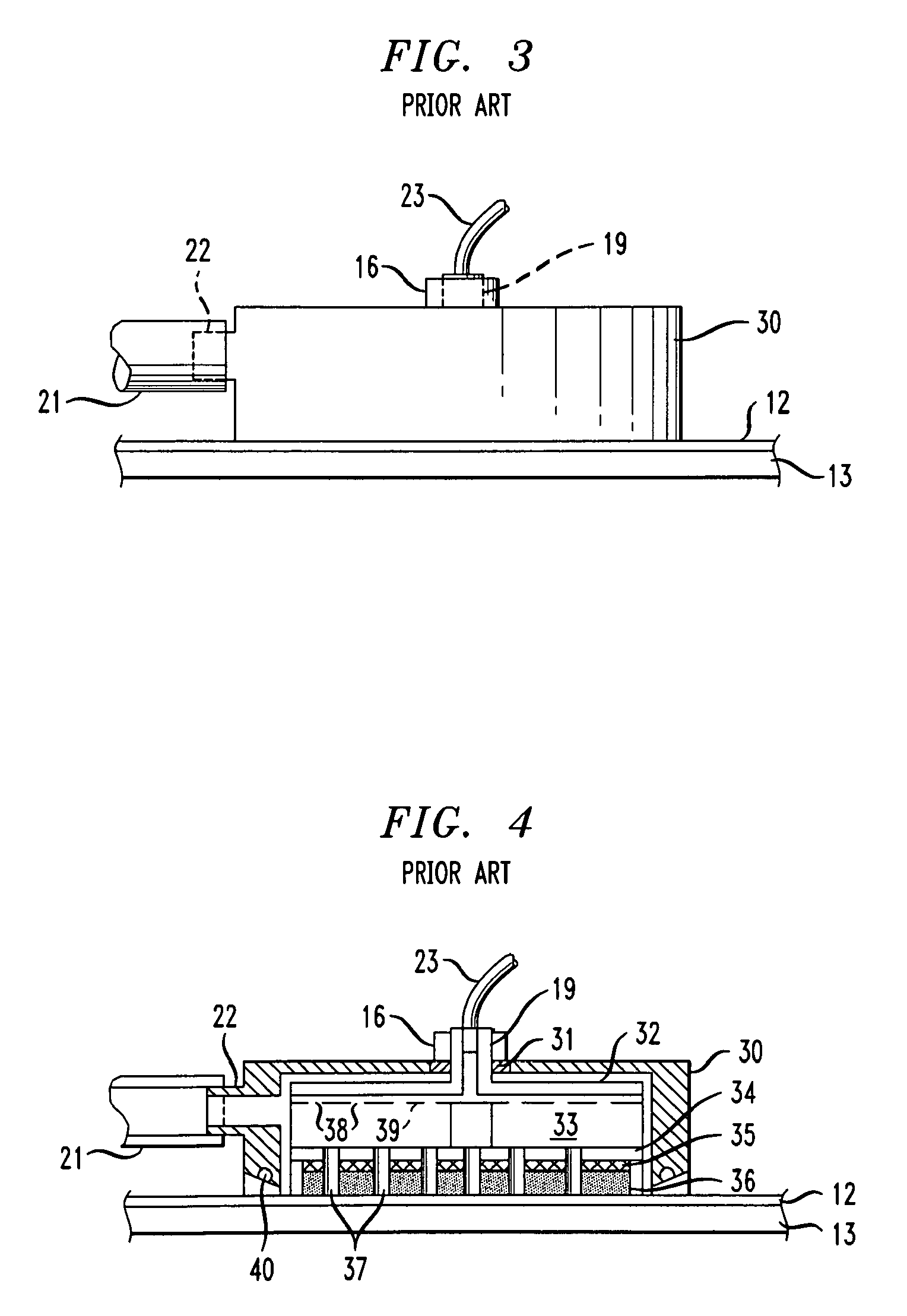

Window component system including pusher for scrap removal

ActiveUS20060075719A1Avoid excessive wasteWasted materialAutomatic control devicesDoors/windowsEngineeringScrap

An apparatus for automatic removal of scrap elongated window component stock from a conveyor includes a path of travel altering mechanism, a translating mechanism, and a controller. The path of travel altering mechanism is positioned along the path of travel that selectively facilitates movement of scrap elongated window component stock off the path of travel. The translating mechanism is in communication with the path of travel altering mechanism for moving the scrap elongated window component stock off of the path of travel.

Owner:GED INTEGRATED SOLUTIONS

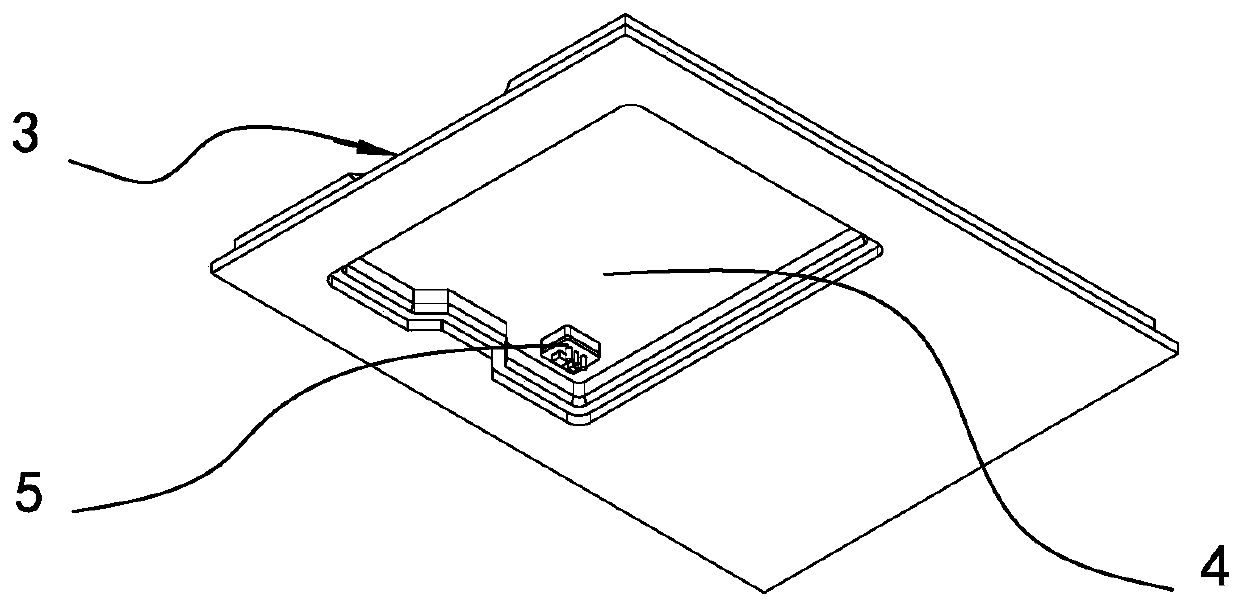

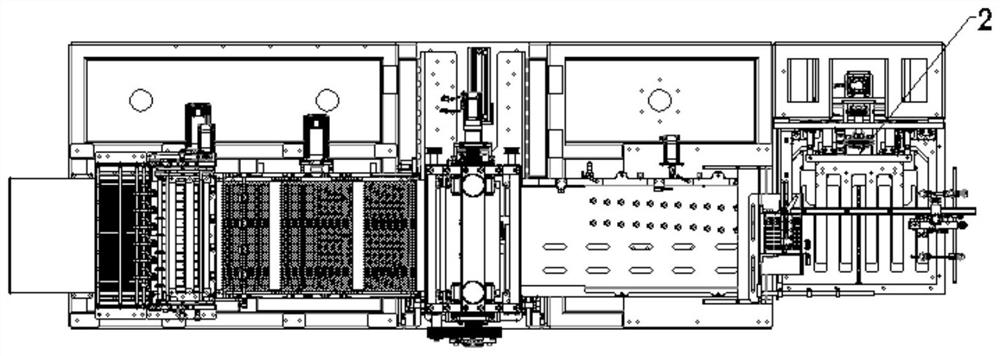

Full-automatic test device

ActiveCN104133173AImprove versatilityTake advantage ofElectronic circuit testingAutomatic test equipmentElectrical and Electronics engineering

The invention discloses a full-automatic test device. The full-automatic test device comprises a first rack, a second rack and a third rack, wherein the first rack, the second rack and the third rack are arranged along the X axis, the first rack is provided with a first conveying mechanism used for conveying tested components and a transfer positioning platform used for positioning the tested components, the first rack is provided with a first carrying mechanism used for carrying the tested components to the transfer positioning platform, the second rack is provided with a plurality of test mechanisms used for detecting whether the tested components are qualified or not in a rectangular array mode, all the test mechanisms are connected with a detection unit, the third rack is provided with a material receiving unit used for colleting qualified products and unqualified products respectively, and a second carrying mechanism is arranged on the side face of the first rack, the side face of the second rack and the side face of the third rack, and is used for carrying the tested components on the transfer positioning platform to the test mechanisms to be detected and then placing the tested components on the material receiving unit after detection is carried out. Automatic line circulating operation is achieved, no personnel are needed for watching over, operation efficiency and detection efficiency are improved, and the full-automatic test device is stable in detection and good in detection effect.

Owner:WEIFANG LOKOMO PRECISION IND

Method for forming hollow front shaft

The invention relates to a method for forming a hollow front shaft, which is characterized in that the specific process is as follows: (1) firstly blanking a pipe section, adopting a band sawing machine and the like to cut a circular pipe material into a fixed-scale pipe blank in a required size, (2) utilizing a medium frequency induction heating furnace to heat pipe ends and a transition region of the cut pipe blank; (3) utilizing a special diameter-reducing machine to perform extrusion and diameter reduction or utilizing a rotary forging device to perform diameter reduction forming on the pipe ends and the transition region through a rotary extrusion and diameter reduction process; (4) carrying out upset forging and forming on the pipe ends; (5) heating the whole; (5) forming the whole; and (7) machining main pin holes at two ends of a pipe. The method for manufacturing a hollow front shaft through the forming process of a pipe blank is simple in manufacturing process, easy to realize the standardization of a mold, fast to remodel, few in production steps, light in weight of a front beam, low in remodeling cost, short in production preparation time and low in cost.

Owner:FAW GROUP

Apparatus for controlling the forces applied to a vacuum-assisted pad conditioning system

InactiveUS7544113B1Quick changeoverControl flatnessEdge grinding machinesGrinding drivesVacuum assistedEngineering

An apparatus for conditioning polishing pads that utilizes an apertured conditioning disk for introducing operation-specific slurries, without the need for additional tooling, platens, and materials handling. The apparatus utilizes a vacuum capability to pull waste material out of the polishing pad and through the apertured conditioning disk to evacuate the apparatus through an outlet port. The apparatus also includes a force adjustment system for providing measurement and control of the force applied by the conditioning disk to the polishing pad.

Owner:TBW IND INC

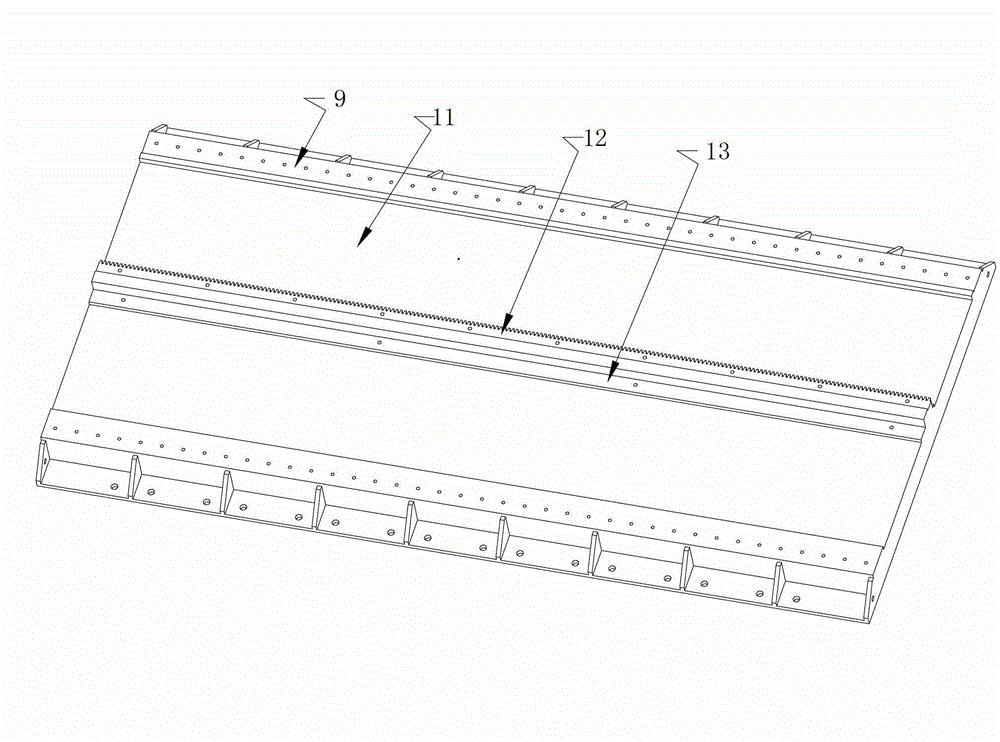

Window component scrap reduction

InactiveUS20060075720A1Avoid excessive wasteWasted materialDoors/windowsBasic electric elementsDefining lengthRoll forming

A method of making elongated spacer frame members prevents a first spacer frame member in a series of spacer frame members from being scrapped. A supply of thin relatively narrow sheet metal stock is provided. The stock is fed endwise to a stamping station. The stock is passed through the stamping station that stamps the stock to define a scrap length of stock followed by a connected first spacer frame defining length of stock. The scrap length of stock and the connected first spacer frame defining length of stock are fed to a roll forming station. The scrap length of stock and the connected first spacer frame defining length of stock are formed into a rigid linearly extending scrap element having opposite side walls and a base wall and a connected rigid linearly extending first spacer frame element having opposite side walls and a base wall. A connection between the scrap element and the first spacer frame element is then severed.

Owner:GED INTEGRATED SOLUTIONS

Combined tooling

InactiveCN102717353AImprove versatilityRealize disassemblyWelding/cutting auxillary devicesWork holdersEngineeringSupport plane

Owner:SANY HEAVY IND CO LTD (CN)

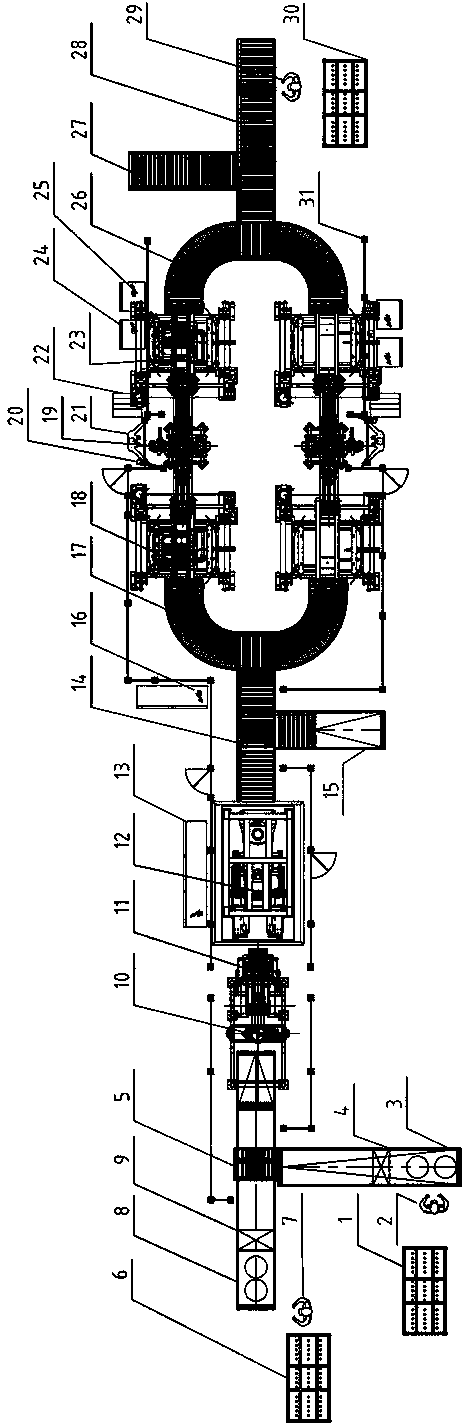

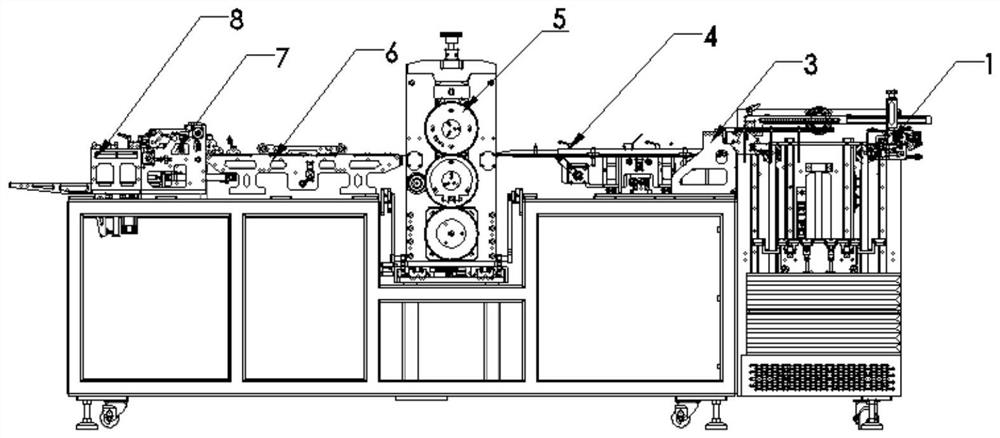

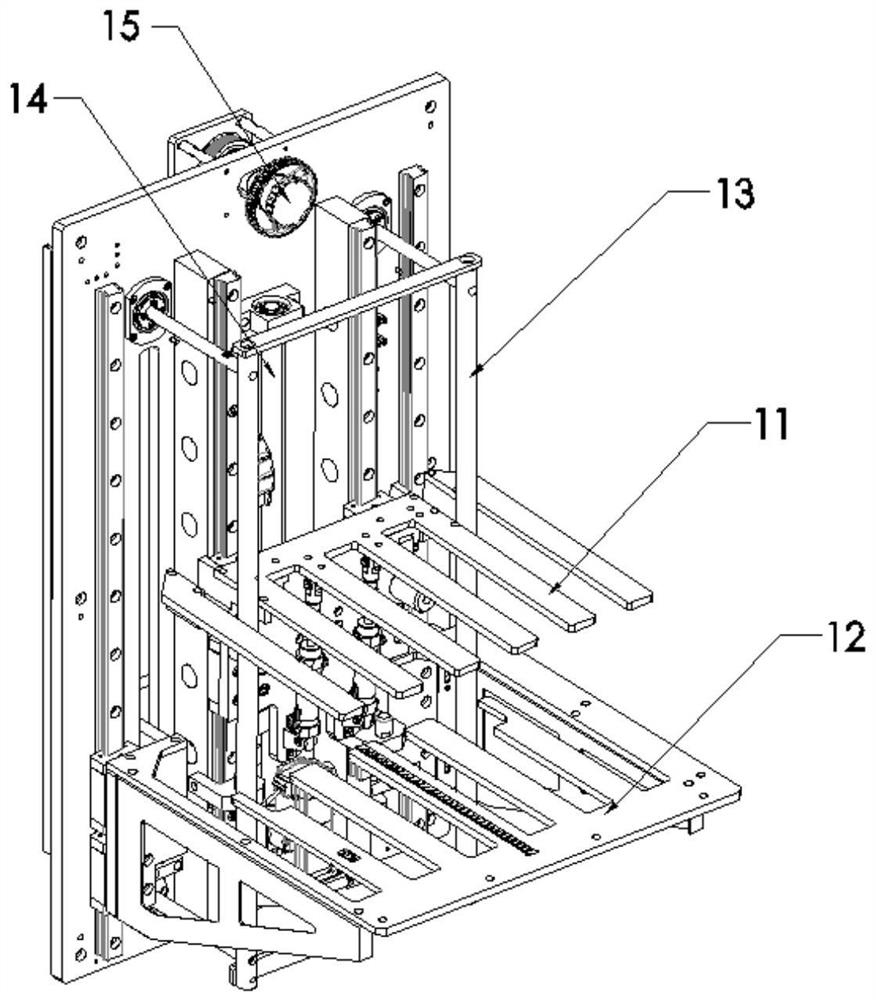

Automatic tube insertion machine and process for condenser and evaporator fins of air conditioner

The invention relates to an automatic tube insertion machine and an automatic tube insertion process for condenser and evaporator fins of an air conditioner. The automatic tube insertion machine comprises a machine frame, a U-shaped tube feeding and positioning device, a fin group feeding and positioning device and an automatic guide pin alignment and circulation feeding device, wherein the U-shaped tube feeding and positioning device, the fin group feeding and positioning device and the automatic guide pin alignment and circulation feeding device are arranged on the machine frame in sequence from left to right. According to the principle of the tube insertion machine, U-shaped tubes are positioned and stacked by using the U-shaped tube feeding and positioning device; a fin group is positioned by using elongated conical guide needles and a positioning baffle, and moves to a first station through a movement platform; the U-shaped tubes are inserted through profiling tube pushing mechanisms and guide pins; after tube insertion is completed, the guide pins are pulled out by using the automatic guide pin alignment and circulation feeding device and are aligned on an alignment baffle; after tube insertion is completed at the first station, the movement platform operates the fin group to a second station, and motions at the first station are repeated until the tube insertion operation of the fin group is completed.

Owner:SHANDONG UNIV

Window component scrap reduction

A method of making elongated spacer frame members prevents a first spacer frame member in a series of spacer frame members from being scrapped. A supply of thin relatively narrow sheet metal stock is provided. The stock is fed endwise to a stamping station. The stock is passed through the stamping station that stamps the stock to define a scrap length of stock followed by a connected first spacer frame defining length of stock. The scrap length of stock and the connected first spacer frame defining length of stock are fed to a roll forming station. The scrap length of stock and the connected first spacer frame defining length of stock are formed into a rigid linearly extending scrap element having opposite side walls and a base wall and a connected rigid linearly extending first spacer frame element having opposite side walls and a base wall. A connection between the scrap element and the first spacer frame element is then severed.

Owner:GED INTEGRATED SOLUTIONS

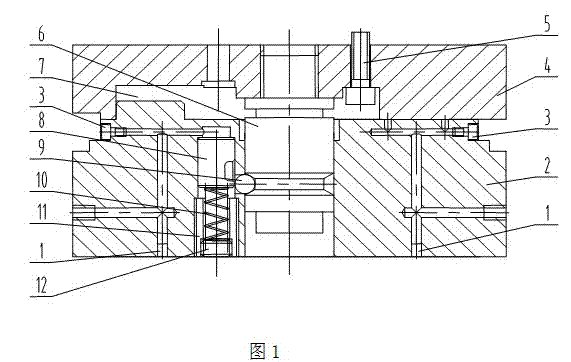

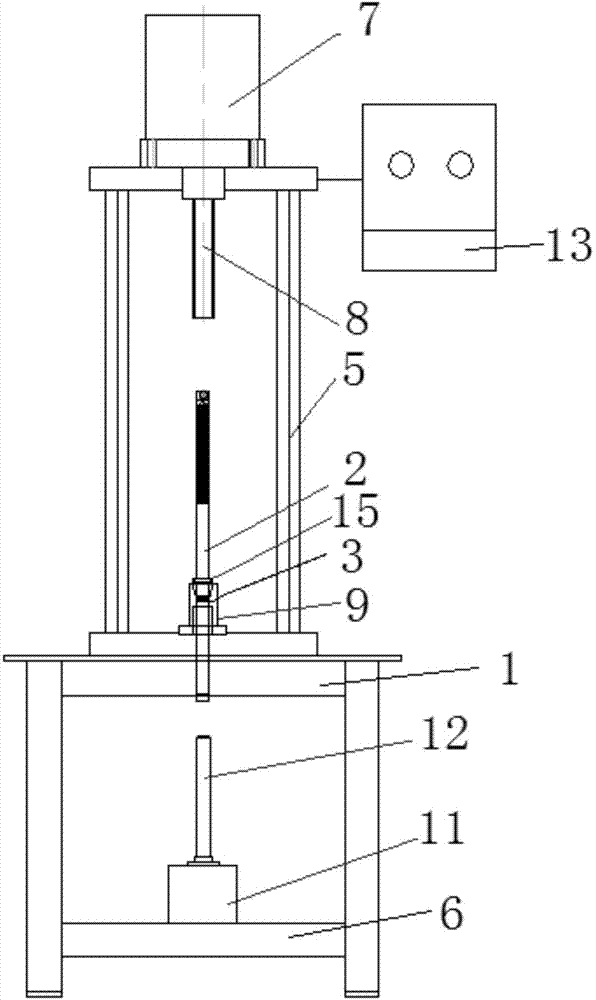

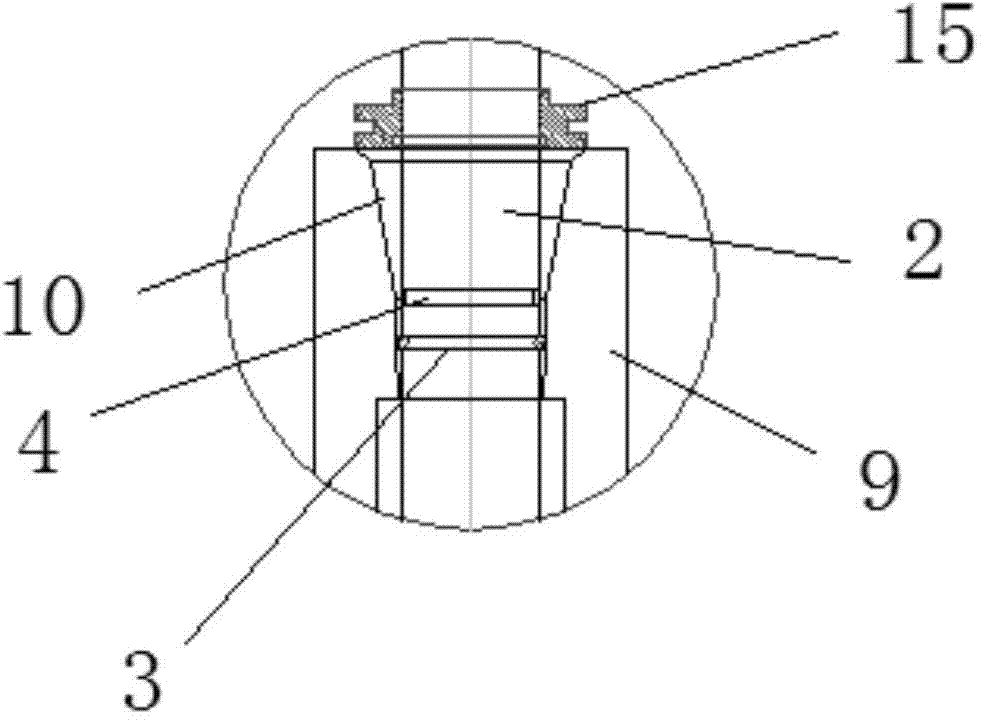

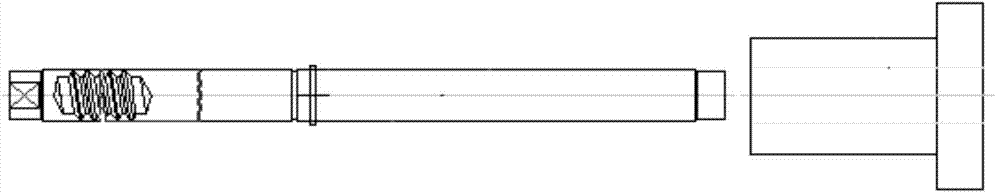

Quick repeated positioning device for machining

ActiveCN102501112AQuick switchEliminate adjustment timePositioning apparatusMetal-working holdersMetal machiningSteel ball

The invention discloses a quick repeated positioning device for machining, which comprises a chuck base seat provided with a center hole and installed on a machine tool spindle or a working table and a tray support seat positioned and installed above the chuck base seat through a blind rivet, wherein an oil cylinder or air cylinder and an oil duct or air duct are arranged inside the chuck base seat; the structure of the oil cylinder or air cylinder comprises a piston and a pressure spring connected below the piston, and the cavity of the oil cylinder or air cylinder is communicated with the center hole of the chuck base seat; and a spherical groove is arranged on the piston, a circular groove is arranged on the blind rivet, and a locking steel ball is arranged between the communication holes of the spherical groove and the circular groove communicated with the center hole of the chuck base seat through the cavity of the oil cylinder or air cylinder. The quick repeated positioning device is used for quickly switching special tooling of metal machining machine tools in various machining centers, turning centers and the like, and the tooling adjustment time is eliminated. The defect of low repeated positioning accuracy of the traditional fixture is overcome, and the effects of improving machining efficiency and lowering cost are achieved.

Owner:SHANDONG CHANGLIN MACHINERY GRP

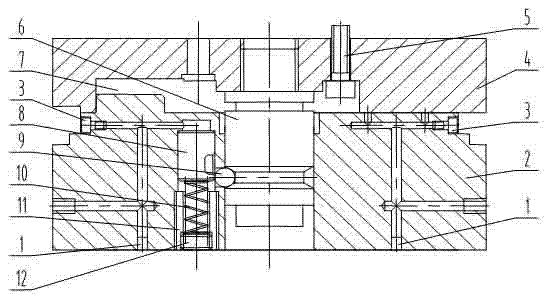

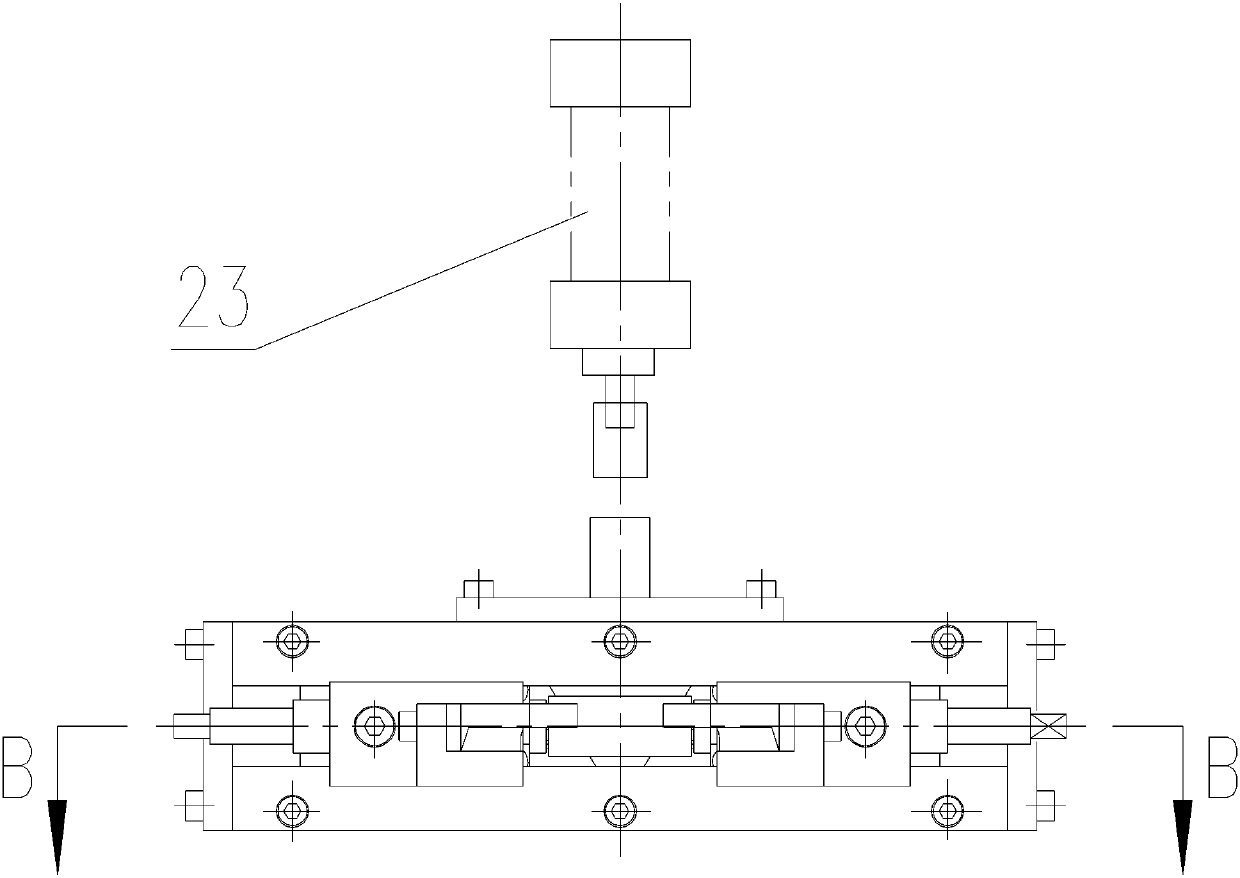

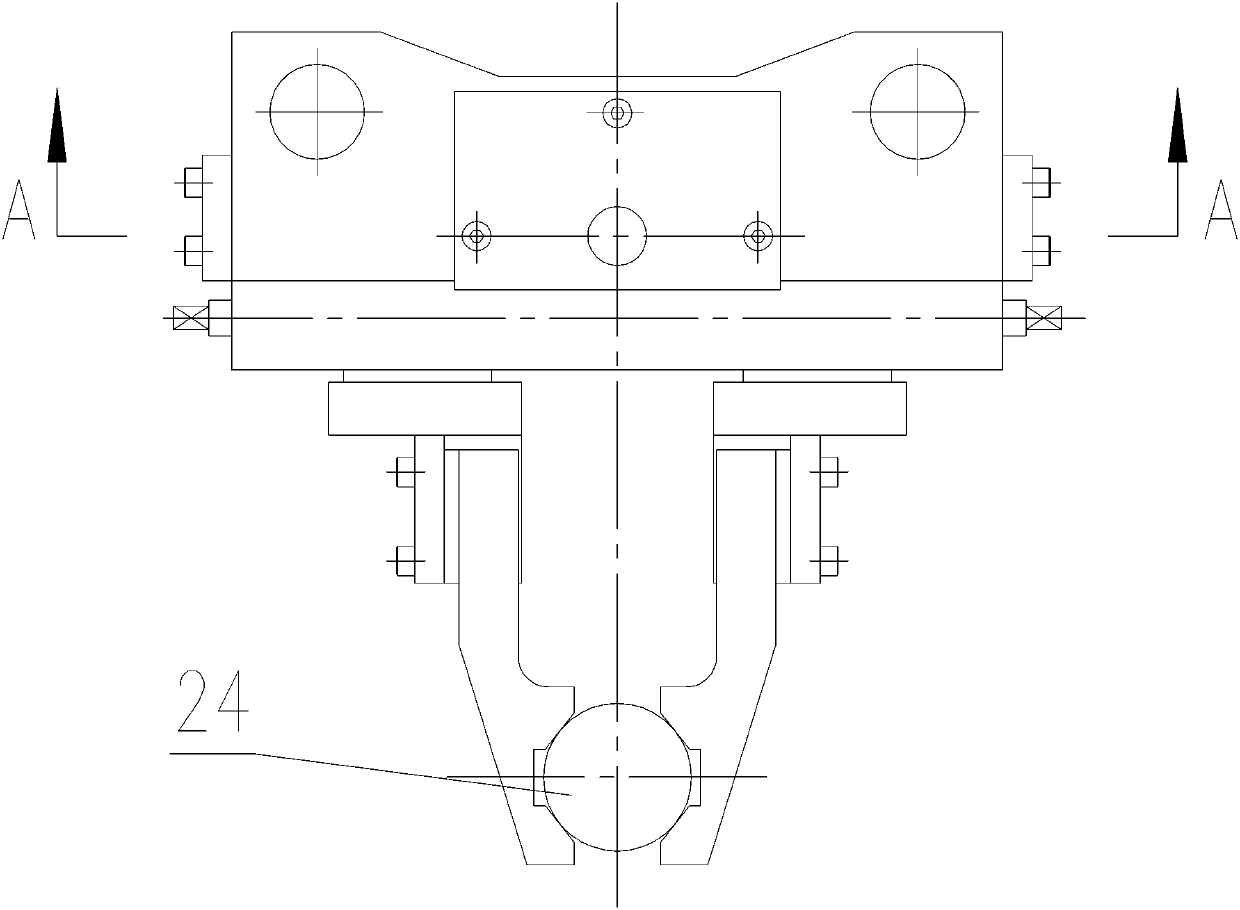

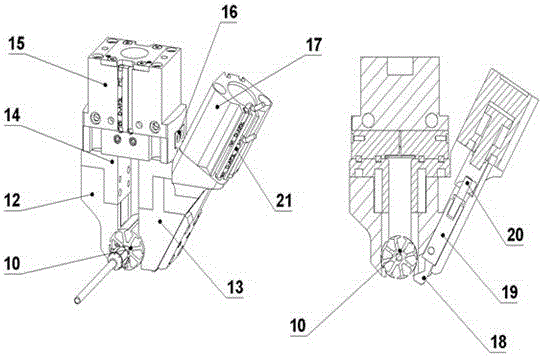

Grabbing mechanism capable of quickly adjusting positions of clamping jaws and using method thereof

The invention relates to a grabbing mechanism capable of quickly adjusting the positions of clamping jaws and a using method thereof. A chute penetrates through a base body; a first sliding inclined block and a second sliding inclined block are symmetrically and reversely arranged and are arranged on the chute in a sliding fit mode; the end face of the first sliding inclined block is in fit connection with a first adjusting screw; the end face of the second sliding inclined block is in fit connection with a second adjusting screw; a first sliding block is arranged on the first adjusting screwin a transmission fit mode through a right-hand thread; a second sliding block is arranged on the second adjusting screw in a transmission fit mode through a left-hand thread; a first clamping jaw isfixedly arranged on the first sliding block through a first clamping jaw mounting seat; a second clamping jaw is fixedly arranged on the second sliding block through a second clamping jaw mounting seat; and the first adjusting screw rod and the second adjusting screw rod match and are connected through an internal spline sleeve. According to the grabbing mechanism, the manipulator claws are rapidly adjustable clamping claws, so that the shape changing efficiency of the claws is greatly improved, and the repeated positioning precision is guaranteed.

Owner:宜昌长机科技有限责任公司

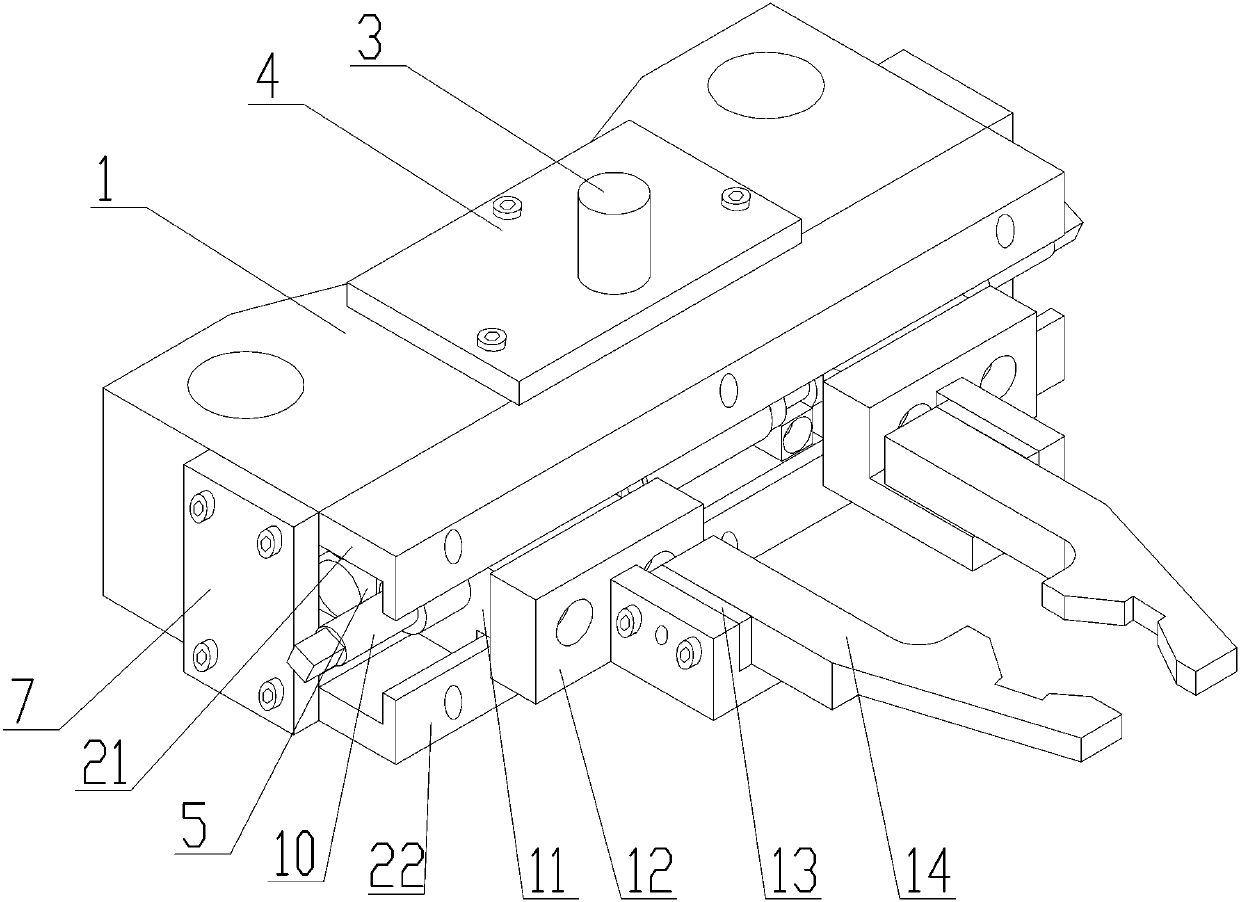

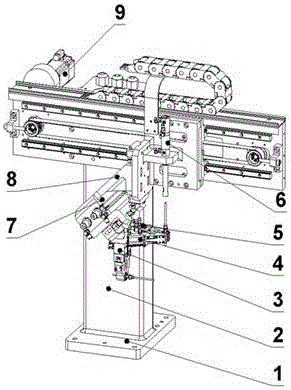

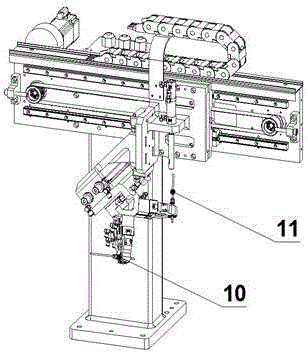

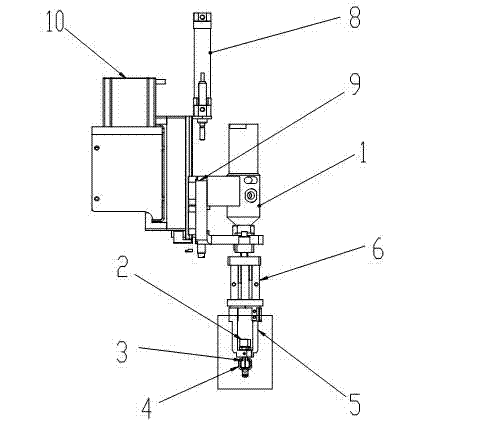

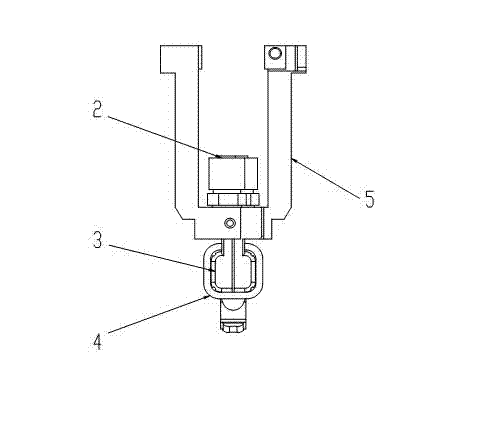

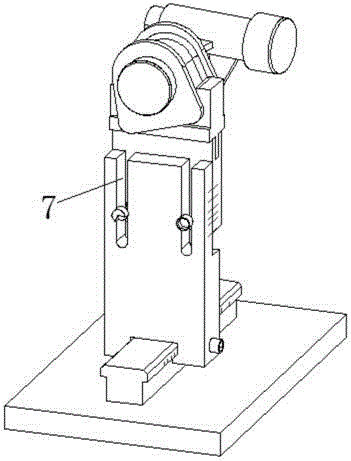

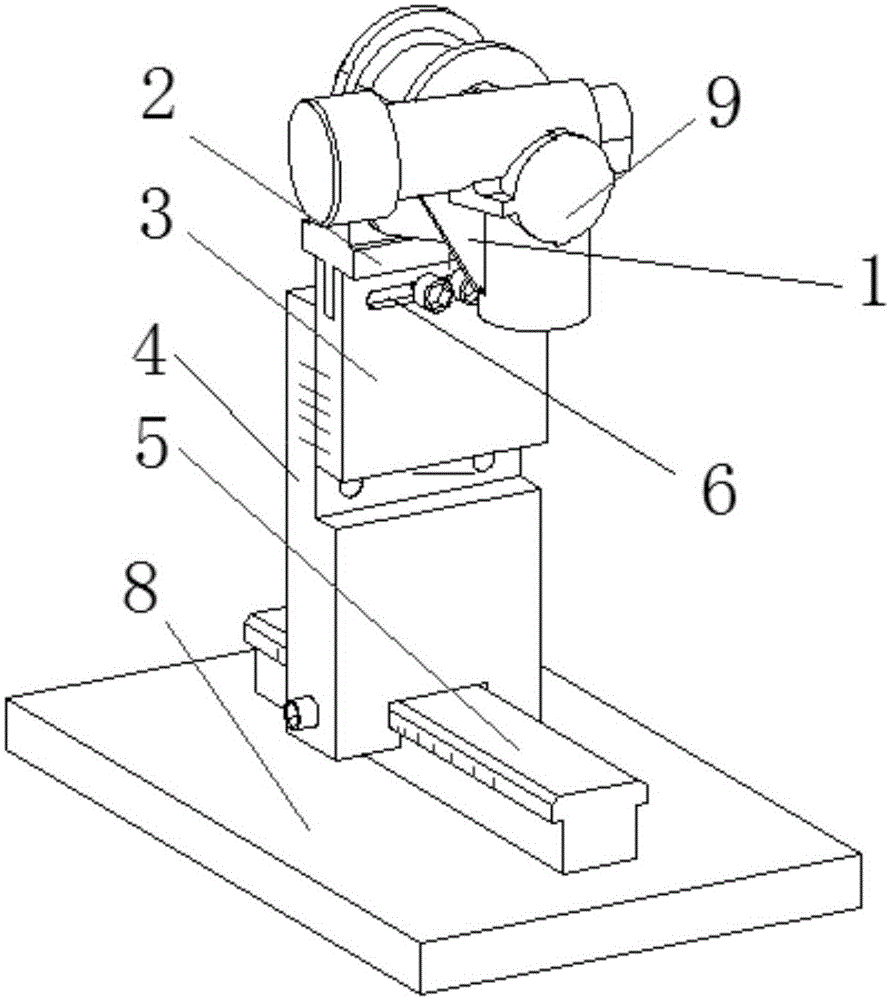

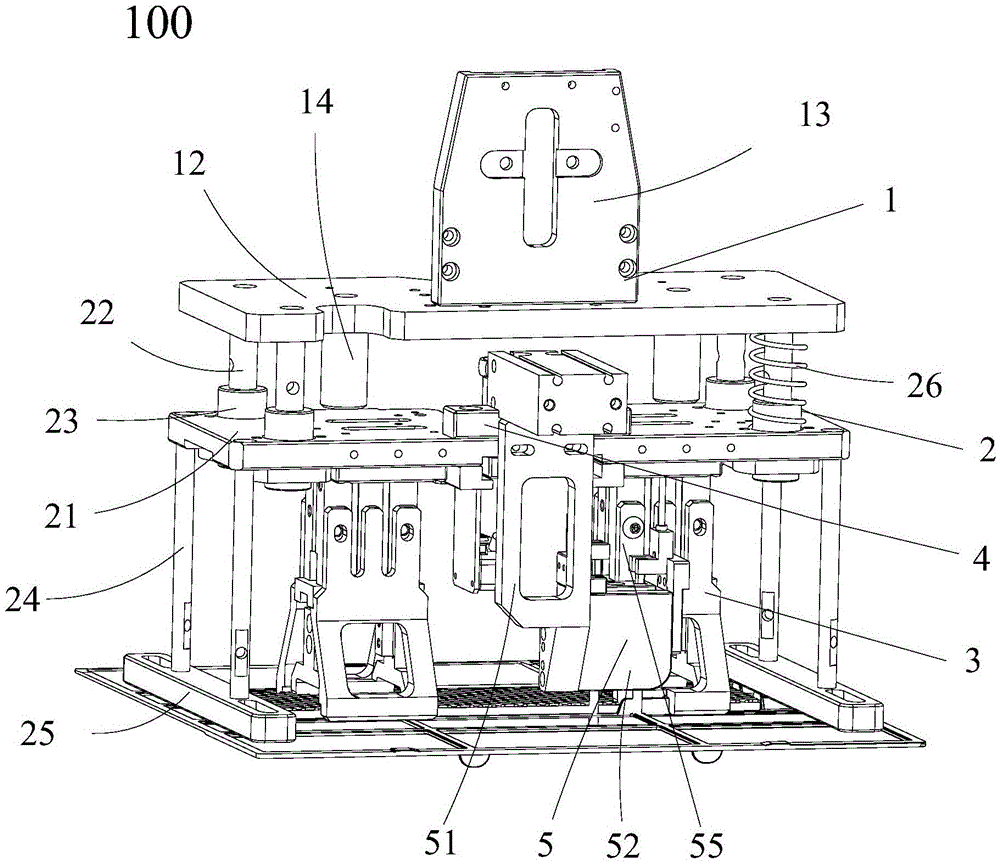

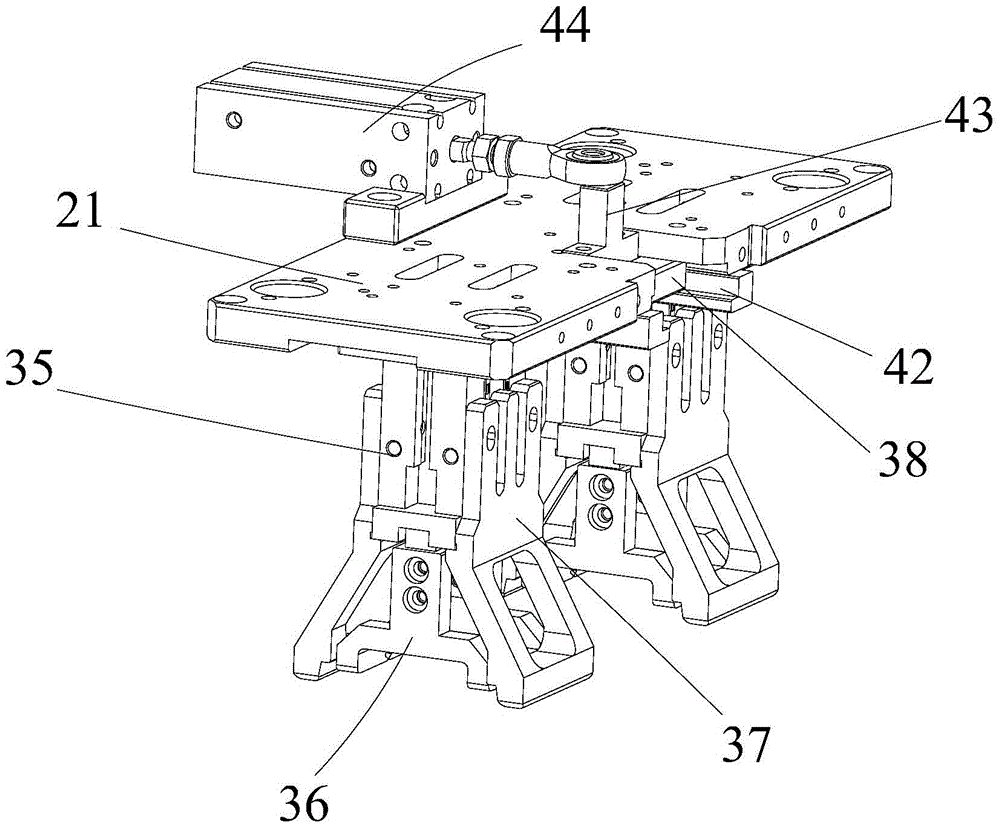

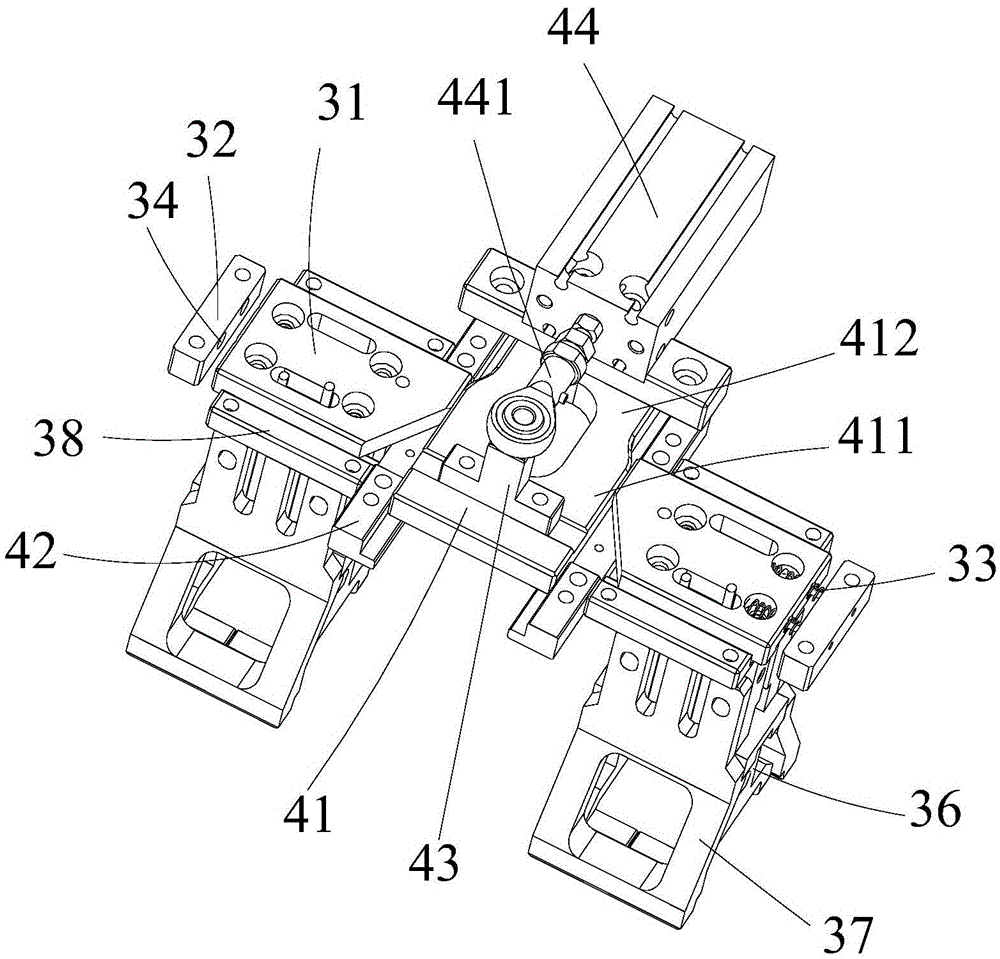

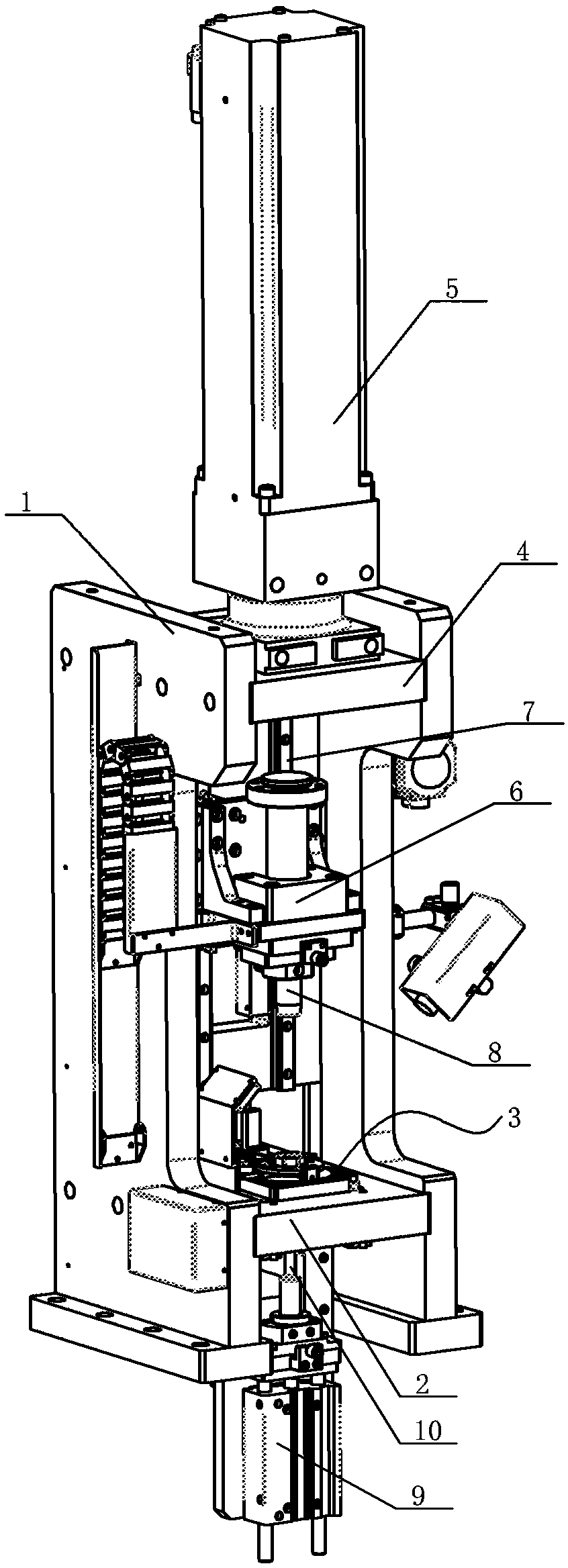

Multifunctional automatic taking and placing manipulator

PendingCN106113000AQuick changeoverMeet the requirements of quick changeoverProgramme-controlled manipulatorGripping headsWinding machineModular design

The invention discloses a multifunctional automatic taking and placing manipulator and particularly relates to a winding machine in the motor industry and an automatic taking and placing manipulator relevant to equipment in the motor manufacture industry. The manipulator comprises a fixed base (1), a supporting main body (2), a finished product material clamping jaw (3), an initial material locating structure (4), a semi-finished product material clamping jaw (5), an axial material locating structure (6), a clamping jaw rotating structure (7), a clamping jaw rotating structure fixing angle block (8) and a clamping jaw horizontal movement servo module (9). According to the multifunctional automatic taking and placing manipulator, the modular design is adopted, and each functional module can be rapidly remodeled, so that the rapid remodeling requirements of customers are met, meanwhile, the maintenance cost of equipment and the stock of spare parts are reduced, and the multifunctional automatic taking and placing manipulator helps the customers increase the production efficiency and ensure the product quality.

Owner:SHENZHEN KAISHENG TECH

Automatic assembly mechanism for steel ball

ActiveCN103084837ASolve assembly difficultiesResolve detectionAssembly machinesButt jointEngineering

The invention relates to an automatic assembly mechanism for a steel ball. The automatic assembly mechanism for the steel ball comprises a steel ball retainer, ball feeding mechanisms and ball pushing mechanisms. Notch grooves for containing the steel balls are arranged at four corners of the steel ball retainer. The steel ball retainer is placed in a sliding groove of a channel jig. A material pushing block is arranged at the back end of the steel ball retainer. The material pushing block is connected with a material pushing mechanism. The front end of the channel jig is in a butt joint with a ball channel jig, wherein a sliding groove which the steel ball retainer can slide in is arranged in the ball channel jig. Two ball channels are arranged at the left side and the right side of the sliding groove of the ball channel jig, wherein the four ball channels are respectively matched with the notch grooves of the steel ball retainer. The ball feeding mechanisms are respectively installed on the left portion and the right portion of the ball channel jig. Two ball feeding channels of the left ball feeding mechanism are communicated with the left ball channels of the ball channel jig, and the two ball feeding channels of the right ball feeding mechanism are communicated with the right ball channels of the ball channel jig. The ball pushing mechanisms are respectively arranged on the left side and the right side of the ball channel jig. Pushing rods of the ball pushing mechanisms stretch into the ball channels of the ball channel jig. The problems that the four rows of ball sliding rails are difficult to assemble and the ball loss can not be detected are resolved.

Owner:KERUI AUTOMATION TECH SUZHOU

Automatic grease injection mechanism for outer frame of slide track

The invention relates to an automatic grease injection mechanism for an outer frame of a slide track. The automatic grease injection mechanism comprises a cylinder, an air claw and nozzles, wherein the cylinder is in driving connection with a moving rack; the air claw is arranged on the moving rack; two nozzles which are symmetrically distributed are arranged on the air claw through a nozzle bracket; the appearances of the two nozzles accord with the internal shape of the outer frame of the slide track; four oil jet holes which are distributed in angles of 90 degree are arranged at corner parts on the two nozzles; and a grease pipeline of an oil feeding system is communicated with the nozzles through oil valves. According to the automatic grease injection mechanism, grease is uniformly injected into four corners of the almost sealed outer frame of the slide track in an extremely small space, and the grease injection precision is ensured; and when the air claw is opened, the two nozzles are adhered to the inner wall of the outer frame of the slide track, thereby ensuring that the grease can be well injected into the four corners of the frame body.

Owner:KERUI AUTOMATION TECH SUZHOU

New energy vehicle quick-replacement type general power battery

PendingCN109768196AEasy to solve temperature controlImprove general performanceParallel/serial switchingPower to auxillary motorsElectricityPower battery

The invention discloses a new energy vehicle quick-replacement type general power battery. A battery body is provided with one or more of quick-replacement interfaces, an interface concave structure,an independent liquid temperature control loop and multi-group interface structures, the battery body is provided with a concave field, and the quick-replacement interfaces are located in the concavefield to leave space for arranging a corresponding connection structure on a vehicle; the independent liquid temperature control loop is arranged on the battery body to meet needs of power battery temperature control, and at the same time the problem that the power battery is not suitable for building a liquid temperature control system with the vehicle under the condition of exchanging is solved;the quick-replacement interfaces are arranged at least two surfaces of the battery body, the vehicle can be loaded in different directions, and the battery body combined with battery form can be usedfor new energy vehicles with different installation space conditions; and so battery generality is strong, a system is composed of no more than 8 main types of quick-replacement general power batteries, the purpose of most of new energy vehicle models selecting and electric changing can be achieved, and the combination of the battery and charging meets the convenience requirement of the new energy vehicles to electric energy supplement.

Owner:王宁豪

Automatic production system for tire set assembly

InactiveCN103722981AImprove efficiencyIncrease usageWheel assembling toolsTyre repairingProduction lineControl system

The invention discloses an automatic production system for tire set assembly. The automatic production system for tire set assembly comprises a charging assembly, an assembly production line, a balance detection assembly as well as a discharging assembly which are connected sequentially; the assembly production line comprises an assembly control system as well as an automatic lubricating machine, a combining and assembling auxiliary machine, a tire assembling air inflating machine and a tire pressure detection line, wherein the automatic lubricating machine, the combining and assembling auxiliary machine, the tire assembling air inflating machine and the tire pressure detection line are sequentially connected; the automatic lubricating machine is connected with an output end of the charging assembly; after lubrication by the automatic lubricating machine, a tire and a hub are respectively conveyed to the combining and assembling auxiliary machine, and are conveyed to the tire assembling air inflating machine; the tire assembling air inflating machine performs assembly according to the assembly data of the assembly control system, and conveys completed finished products to the balance detection assembly; qualified products detected by the balance detection assembly are output from the discharging assembly. The automatic production system for tire set assembly, which is disclosed by the invention, has the advantages of simple and compact structure, reasonable layout, high automation degree, capability of reducing the labor intensity, improving the efficiency and the like.

Owner:湖南伍扬工业科技有限公司

Drill rod welding robot production line

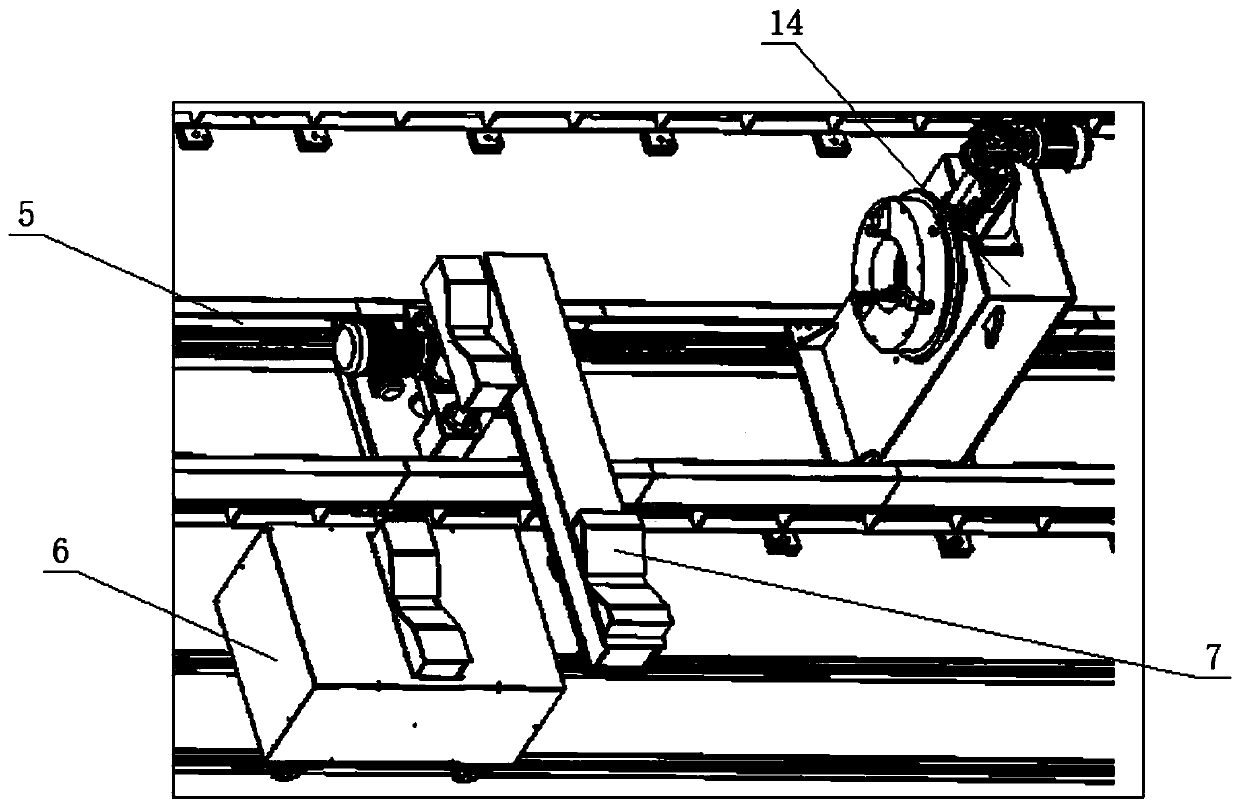

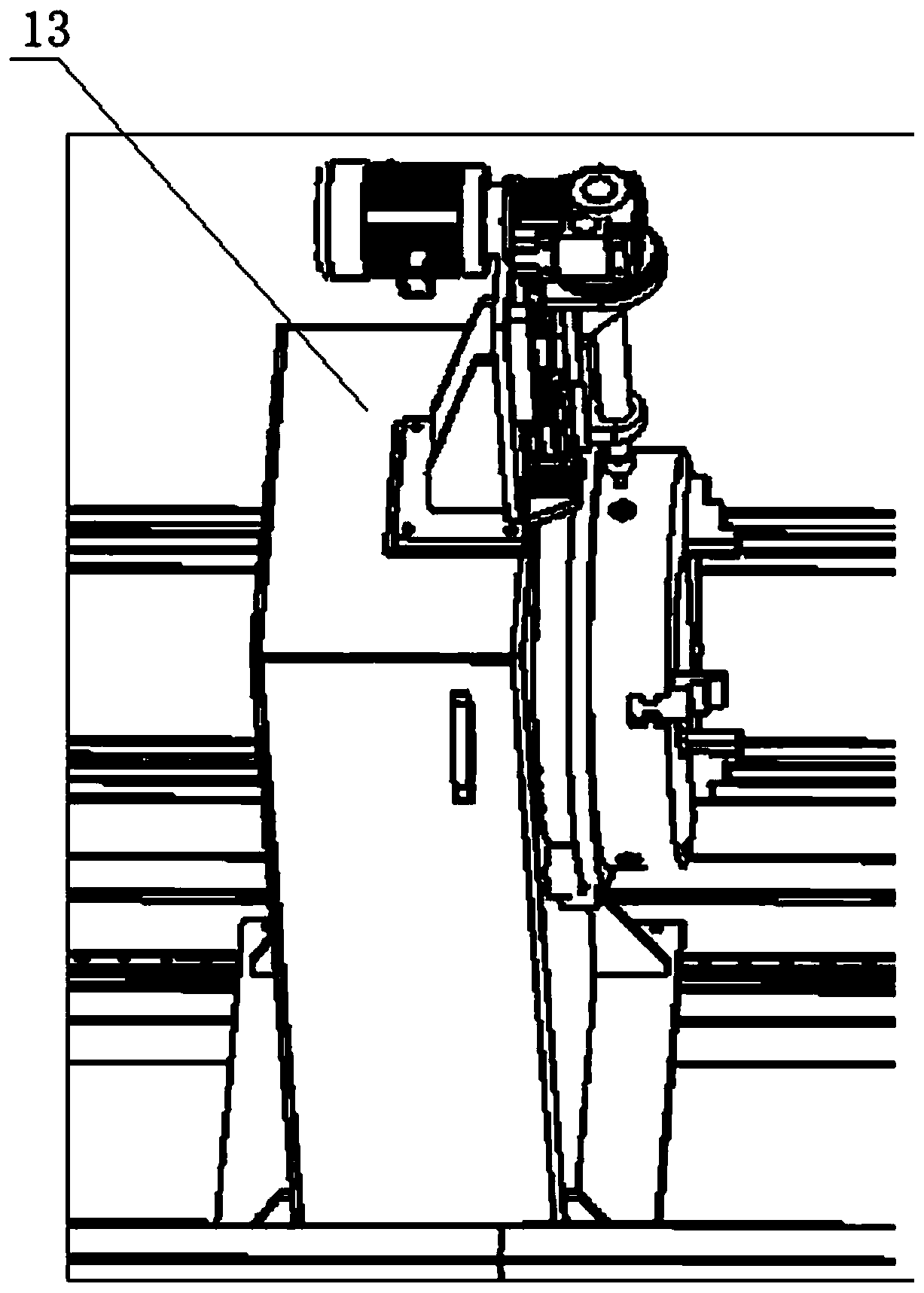

ActiveCN109926772AReduce movement distanceQuick changeoverWelding/cutting auxillary devicesAuxillary welding devicesProduction lineCantilever

The invention discloses a drill rod welding robot production line comprising a positioner movement rail, a positioner and a robot movement rail. Cantilevers are installed on the robot movement rail. Robots are arranged on the cantilevers in an upside-down hanging manner. The drill rod welding robot production line further comprises movement trolleys, material receiving and sending devices and an auxiliary supporting device. The movable positioner comprises a positioner head base and a positioner tail base. The invention further discloses an automatic welding method. The automatic welding method includes the steps that the movement trolleys convey a drill rod workpiece to the material receiving and sending devices, and the material receiving and sending devices place the drill rod workpieceon an auxiliary supporting part; the auxiliary supporting part automatically regulates the height, and therefore the drill rod workpiece can be fixed through electric chucks conveniently; the robotsautomatically complete the welding work; and the auxiliary supporting part places the drill rod workpiece on the upper faces of the material receiving and sending devices, the drill rod workpiece is conveyed away through the movement trolleys, and discharging is completed. The robots in the drill rod welding robot production line can weld different positions of the same workpiece at the same time,the production efficiency is greatly improved, and rapid type change of the workpiece can be achieved; and automatic material receiving and sending are completed, the previous working procedure and the next working procedure are connected, and the automation degree is improved.

Owner:成都焊研威达科技股份有限公司

Method for adjusting adjustable workpiece clamp used for marking machine

The invention discloses a method for adjusting an adjustable workpiece clamp used for a marking machine. The method comprises the following steps of (1) sliding a third sliding block to the required position on a third guide rail horizontally when the marking position of a workpiece needs to be adjusted, and locking the third sliding block through a screw; (2) sliding a second sliding block to the required position on a second guide rail vertically, and locking the second sliding block through a screw in a strip-shaped groove; (3) sliding a first sliding block to the required position on a first guide rail in the horizontal direction perpendicular to the sliding direction of the third sliding block, and locking the first sliding block through a screw in a kidney-shaped hole. The method has the advantages that the position of the workpiece to be marked can be adjusted conveniently, the type of the workpiece can be changed rapidly, and the calibration work of a machine tool does not need to be conducted after the adjustment is finished; the time is saved, and the workload is relieved; the workpiece clamp is simple in structure, short in manufacturing period, low in manufacturing cost and high in working efficiency, the problems that the assembly process is tedious, the control is difficult, the production takt is low, and the quality risk is high are eliminated, and therefore the problems in the producing and type changing process can be solved.

Owner:WUHU HENGLONG AUTO STEERING SYST

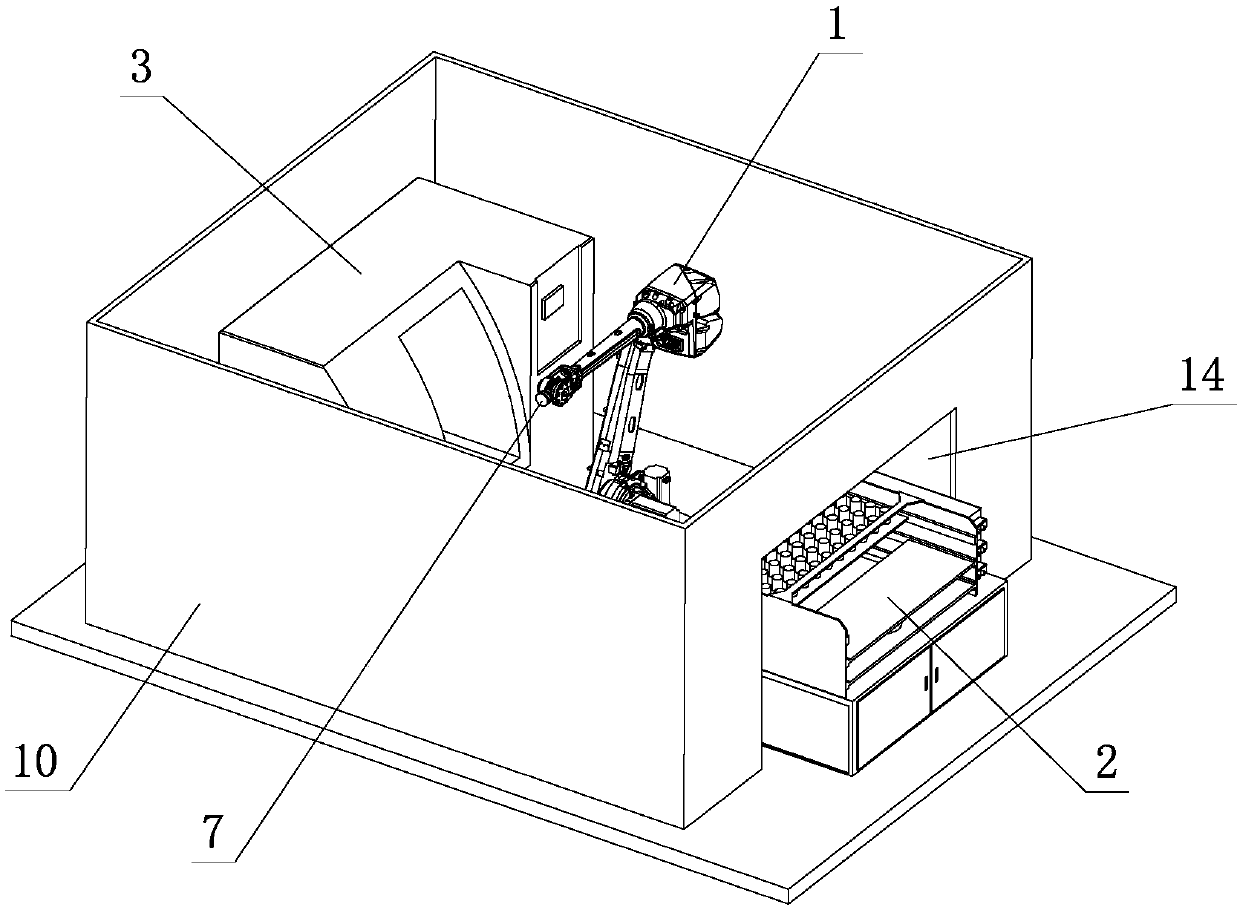

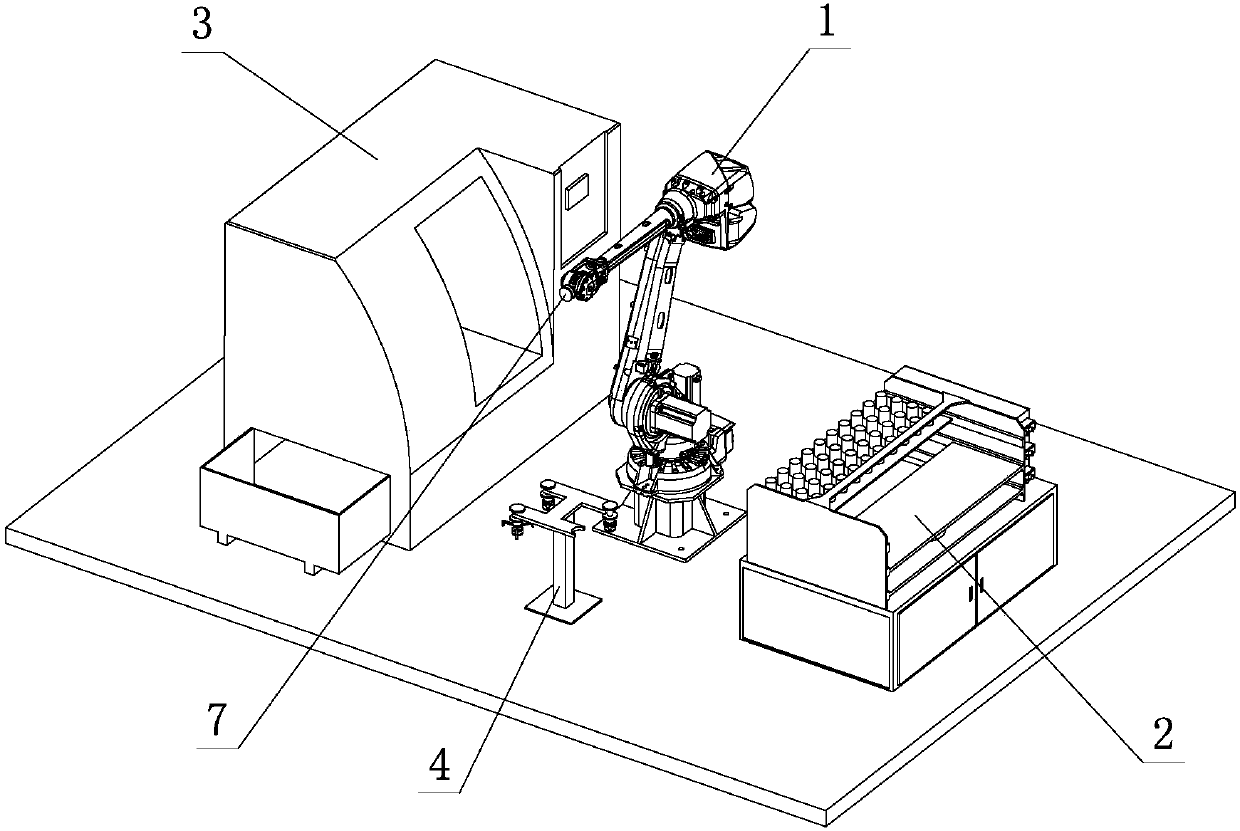

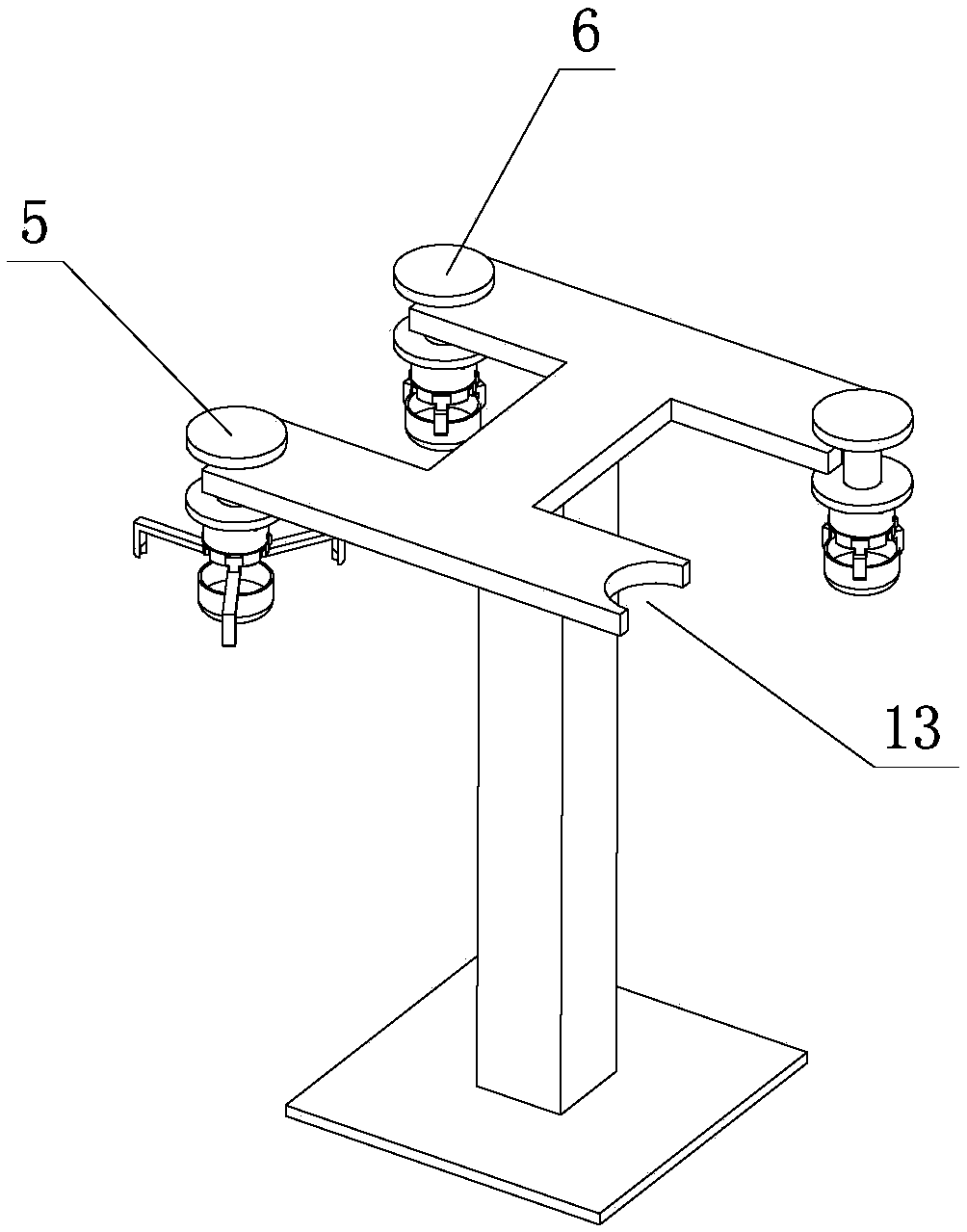

Mother-son fixture feeding and discharging equipment with robot and using method of mother-son fixture feeding and discharging equipment

InactiveCN107900765AReduce security risksIncrease productivityMetal working apparatusEngineeringMachine tool

Disclosed is mother-son fixture feeding and discharging equipment with a robot and a using method of the mother-son fixture feeding and discharging equipment. The mother-son fixture feeding and discharging equipment comprises the robot, a feeding and discharging table and a machine tool. A chuck and a workpiece are placed on the feeding and discharging table. The robot moves back and forth betweenthe feeding and discharging table and the machine tool and is provided with a mother fixture. The side part of the robot is further provided with a fast fixture switching frame. A chuck son fixture and a workpiece son fixture are placed on the fast fixture switching frame. The machine tool is provided with the chuck son fixture. The robot conveys and switches the chuck son fixture on the feedingand discharging table and the machine tool back and forth through the mother fixture. The robot reloads the workpiece son fixture on the fast fixture switching frame through the mother fixture, conveys the workpiece on the feeding and discharging table through the workpiece son fixture to the machine tool to complete feeding operation, and conveys the workpiece machined on the machine tool to thefeeding and discharging table to complete discharging operation. The mother-son fixture feeding and discharging equipment with the robot has the characteristics of being simple and reasonable in structure, excellent in performance, convenient to operate, low in manufacturing cost, easy to produce, easy to realize, full-automated, intelligent, high in production efficiency, safe, reliable and the like.

Owner:GUANGDONG LXD ROBOTICS CO LTD

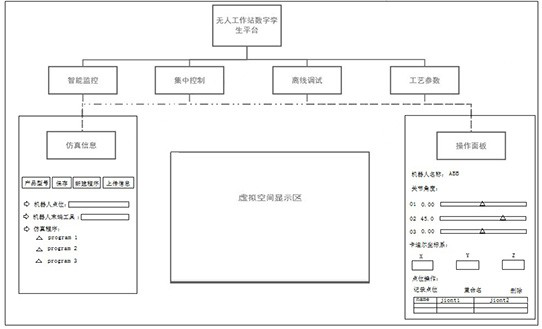

Simulation debugging system based on digital twin platform

ActiveCN113759753AQuick changeoverSimulator controlTotal factory controlFriction weldingControl system

Provided is a simulation debugging system based on a digital twin platform. A robot off-line simulation module is additionally arranged on the digital twin platform, in a remodeling production process of friction welding, robot program point location re-alignment and virtual robot model simulation verification are carried out through the system, a robot motion track is re-planned on a robot off-line debugging interface in a digital twin system, simulation verification is carried out, workpiece parameter setting information in a feeding PLC control system is integrated, an original program is replaced by a simulated robot program on the digital twin platform, and rapid remodeling is achieved.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

Gripping device

Owner:BOZHON PRECISION IND TECH CO LTD

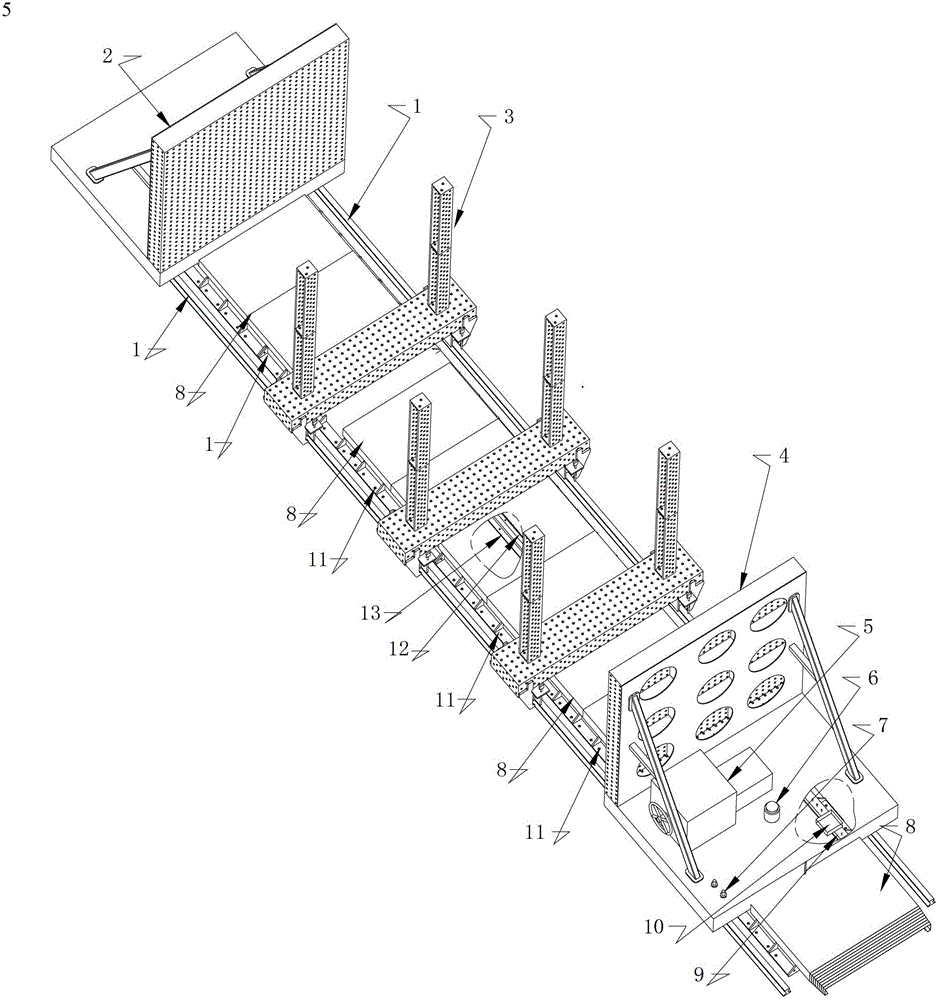

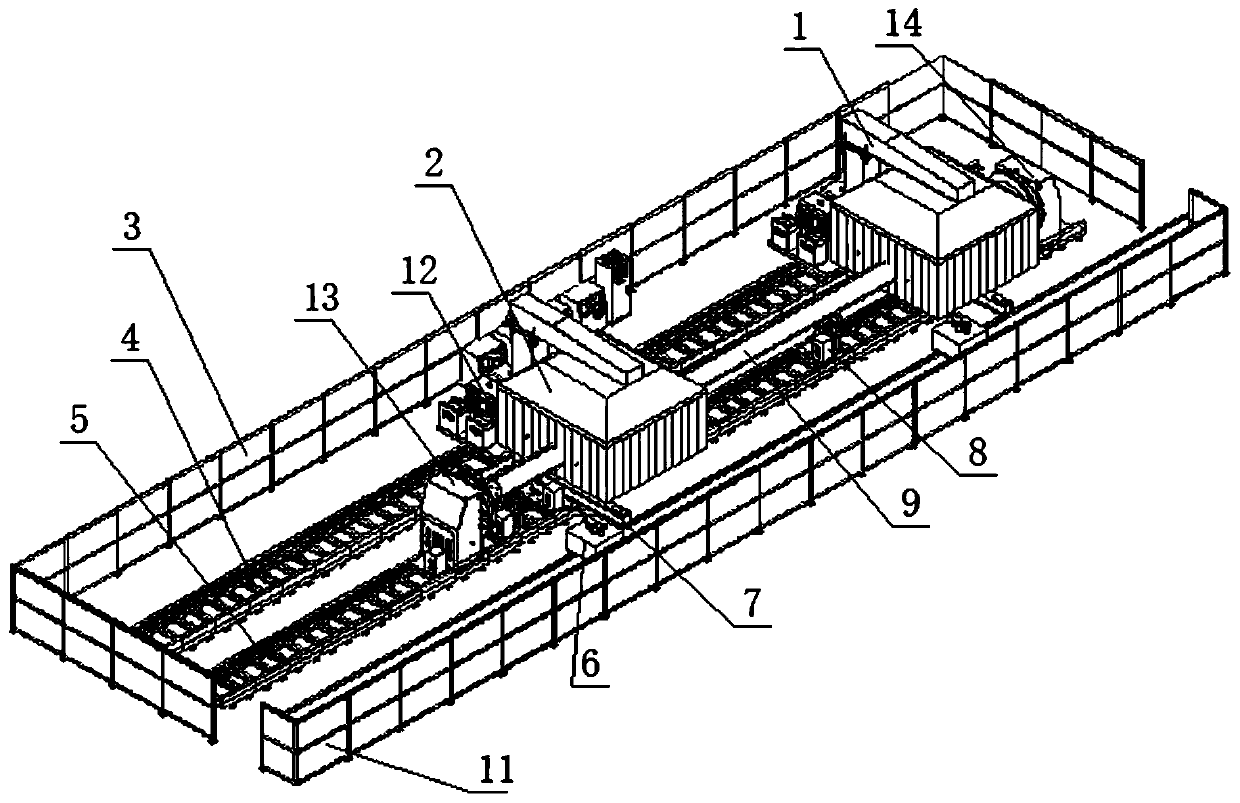

Automatic feeding and blanking production line and control method thereof

The invention discloses an automatic feeding and blanking production line and a control method thereof. The automatic feeding and blanking production line contains two structure modes, namely, a U-shaped line layout and a line type line layout. A production line body is formed by basic units and meets the requirement of a modular assembly technology; each basic unit is divided into an upper layerand a lower layer, so that modular splicing can be realized, and multiple layout forms are realized; and in addition, a tray backflow function can be realized. The production line is further providedwith a tray and tool conveying mechanism for supporting quick changeover, a tray conveying control system, a single-station manual / automatic real-time switching control system, a production line conveyor line body transfer real-time control mechanism, a production line work-in-process temporary storage station design, and flexible and changeable production line arrangement forms. On the basis of the idea of lean production, the problems of high stock level, circulation difficulty, high manufacturing cost, low product quality, waste in space, time, manpower and tool, and the like existing actually are solved.

Owner:西安精雕精密机械工程有限公司

Intelligent assembly device of motor worm

InactiveCN107900644AGuarantee the safety of useQuality assuranceWork holdersMetal working apparatusLower limitGrating

The invention discloses an intelligent assembly device of a motor worm. The intelligent assembly device is mainly utilized in automobile rearview mirror folding assembly equipment. The intelligent assembly device of the motor worm comprises a bracket, a press fit base, a servo motor system, a PLC communication control system and a human-computer interaction interface, wherein safety optical gratings and warning lights are arranged on the four box surfaces of a device box body; the servo motor system comprises a servo electric cylinder and preset setup parameters; the human-computer interactioninterface comprises a system starting and stopping key, a speed parameter adjusting key, a pressure parameter adjusting key, a numeric key region and a press fit real-time position display screen; the press fit real-time position display screen comprises a total displacement display screen and a press fit displacement display screen; and the servo motor system is provided with an upper limit anda lower limit of an axial motion position. According to the intelligent assembly device of the motor worm, the speed, pressure and real-time positions during the motor worm press fit assembly processcan be numerically displayed, geometrical errors and comprehensive errors of parts are decreased, processing precision is improved, model changing efficiency during worm assembly is improved, and safety of the worm assembly process is improved.

Owner:美视伊汽车镜控(苏州)有限公司

Single sheet die cutting process device

PendingCN111975865AEasy to change the type and replace the knife skinQuick changeoverMetal working apparatusArticle feedersStructural engineeringManufacturing engineering

The embodiment of the invention discloses a single sheet die cutting process device. The single sheet die cutting process device comprises an uninterrupted feeding mechanism, a feeder feeding mechanism, a triangular belt paper feeding mechanism, a deviation rectifying mechanism, a circular knife die cutting mechanism, an adsorption belt conveying mechanism, a waste discharging mechanism and a finished product collecting and stacking mechanism which are sequentially arranged according to the machining sequence; the circular knife die cutting mechanism comprises a die cutting assembly and a telescopic assembly; the telescopic assembly comprises a fixed bottom plate and a telescopic plate; the fixed bottom plate is in sliding connection with the telescopic plate; a driving air cylinder used for driving the telescopic plate to do front-back telescopic motion along the fixed bottom plate is arranged on the fixed bottom plate; and the die cutting assembly is fixed to the telescopic plate. According to the single sheet die cutting process device, a knife skin can be quickly changed, and use is convenient.

Owner:SHENZHEN HADESHENG PRECISION TECH

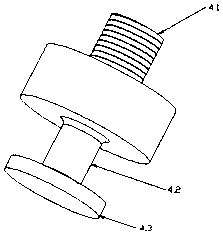

Servo press-fitting floating self-locking supporting mechanism

The invention provides a servo press-fitting floating self-locking supporting mechanism, and has the technical effects that the precision and the yield of press fitting are improved, thus product quality is improved; meanwhile, the mechanism can be compatible with multiple products, thus the flexibility is improved; a tool can be quickly replaced, thus the production efficiency is improved; and the mechanism can be applied to press fitting of multiply products with weak strength. The mechanism comprises a vertical mounting base, the floating self-locking supporting mechanism is arranged on a middle horizontal positioning plate of the vertical mounting base, a top support of the vertical mounting base is fixedly provided with a servo press, the driving end of the lower part of the servo press is fixedly connected with a pressure head mounting seat, the back side guide rail pair of the pressure head mounting base is embedded into the corresponding vertical guide rail, a pressure head isfixedly arranged at the bottom of the pressure head mounting base, the pressure head is arranged at the upper end of the floating self-locking supporting mechanism, a vertical positioning cylinder isfurther arranged at the bottom of the vertical mounting base, and an upper piston of the vertical positioning air cylinder is sleeved with a rotor center positioning die sleeve.

Owner:TZTEK TECH

Adhesive paper package device for pelleter pole lug and pelleter

ActiveCN102623750AVersatileEasy to adjustFinal product manufactureCell component detailsEngineeringMechanical engineering

The invention discloses a pelleter and an adhesive paper package device for a pole lug of the pelleter. The adhesive paper package device for a pole lug comprises guiding plates, a left rubberizing plat and a right rubberizing plate, wherein the guiding plates are arranged along the transmission direction of the pole lug, and are used for enabling adhesive paper protruding out of the pole lug to be folded to be perpendicular to the pole lug, the left rubberizing plat and the right rubberizing plate are used for pressing the adhesive paper on the left side of the pole lug and the adhesive paper on the right side of the pole lug on the upper surface of the pole lug, and the guiding plates, the left rubberizing plat and a right rubberizing plate are all borne on a rubberizing fixation base; the adhesive paper package device for the pole lug further comprises a horizontal adjusting mechanism and a height adjusting mechanism; the longitudinal shape transformation can be generated on a horizontal plane by the horizontal adjusting mechanism, and is perpendicular to the transmission direction of the pole lug, and the longitudinal shape transformation can be caused by the height adjusting mechanism in a vertical direction; and the left rubberizing plat and the right rubberizing plate are all connected with the height adjusting mechanism, and the height adjusting mechanism is fixed on the horizontal adjusting mechanism. The adhesive paper package device disclosed by the invention can meet the rubberizing requirements of different specifications of pole lugs by arranging the adjusting mechanism, and has the advantages of strong generality, convenience in adjustment, and higher production efficiency.

Owner:SHENZHEN HAONENG TECH

Retainer ring press-fitting device and retainer ring press-fitting method for rack shaft of pinion-and-rack type hydraulic steering gear

InactiveCN104259826AAvoid deformationReduce investmentMetal working apparatusEngineeringMechanical engineering

The invention discloses a retainer ring press-fitting device for a rack shaft of a pinion-and-rack type hydraulic steering gear. The device comprises a workbench, a shaft retainer ring clamp, a steering gear rack, a piston, a press-fitting mechanism and a reset mechanism, the shaft retainer ring clamp is arranged on the workbench, the piston is arranged on the steering gear rack, the press-fitting mechanism is used for downwardly pressing the steering gear rack until a shaft retainer ring in the shaft retainer ring clamp is clamped into a retainer ring groove of the steering gear rack, and the reset mechanism is used for upwardly pressing the steering gear rack after press fitting of the shaft retainer ring is finished. By adoption of the structure, the device has the advantages that deformation of the shaft retainer ring is avoided, and whether press fitting is completed or not is completely guaranteed by equipment which alarms if press fitting is unqualified; the special positioning clamp is designed with an inner conical face to effectively limit the retainer ring, and a lower pressing head jacks the rack end face upwards after press fitting is finished so as to pop a rack piston assembly out of the clamp.

Owner:WUHU HENGLONG AUTO STEERING SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com