Multifunctional automatic taking and placing manipulator

An automatic pick-and-place and manipulator technology, applied in the field of manipulators, can solve problems such as difficulty in ensuring product consistency, high labor intensity, and low production efficiency, and achieve high flexibility and intelligence, reduce production tact, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the description of the present invention, it should be noted that, unless otherwise specified and limited, the term "fixed" should be understood in a broad sense, referring to the fixed connection of two parts, or the integration of two parts.

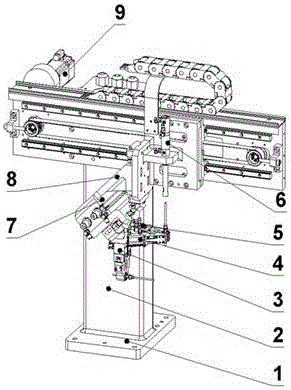

[0024] Such as figure 1 As shown, the present invention includes a base (1) for installation and a supporting body (2) welded on the installation base, and the manipulator also includes a finished material gripper (3), a material initial positioning structure (4), and a semi-finished material clamp Claw (5), material axial positioning structure (6), gripper rotation structure (7), gripper rotation structure fixed angle block (8), gripper horizontal motion servo module (9);

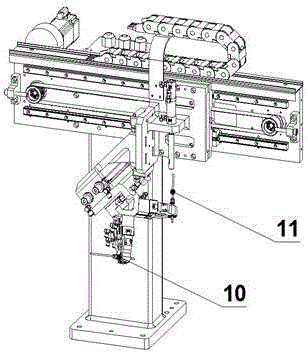

[0025] Such as figure 2 As shown, rotor (10) and rotor (11) change from vertical (horizontal) orientation to horizontal (vertical) orientation at the same time

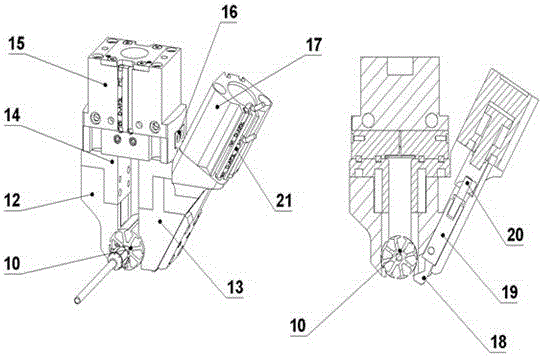

[0026] Such as image 3 As shown, the material initial positioning structure includes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com