Quick repeated positioning device for machining

A technology of repeated positioning and machining, which is applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of low repeated positioning accuracy, overcome the low repeated positioning accuracy, eliminate tooling adjustment time, and improve processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

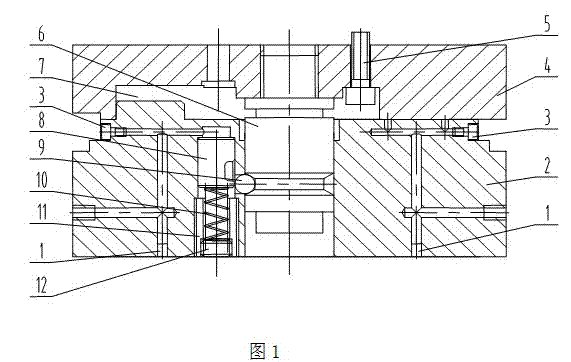

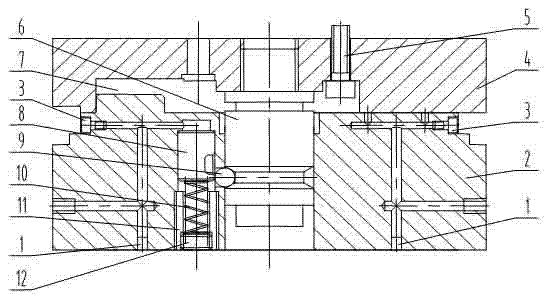

[0015] Next, a quick-change repeat positioning device for machining according to the present invention will be described in detail below with reference to the accompanying drawings.

[0016] A quick-change repeat positioning device for machining, the structure of which includes a chuck base provided with a central hole and installed on the main shaft of a machine tool or a work table, and a tray support positioned above the chuck base by pulling nails; The inside of the chuck base is provided with an oil cylinder or a cylinder and an oil passage or an air passage communicated with the oil cylinder or the cylinder; the structure of the oil cylinder or the cylinder includes a piston and a compression spring connected under the piston, and the inner chamber of the oil cylinder or the cylinder is connected to the chuck The central hole of the base is connected, a spherical groove is provided on the piston, and an annular groove is provided on the pull nail. A lock is arranged betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com