Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Prevent warping and deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

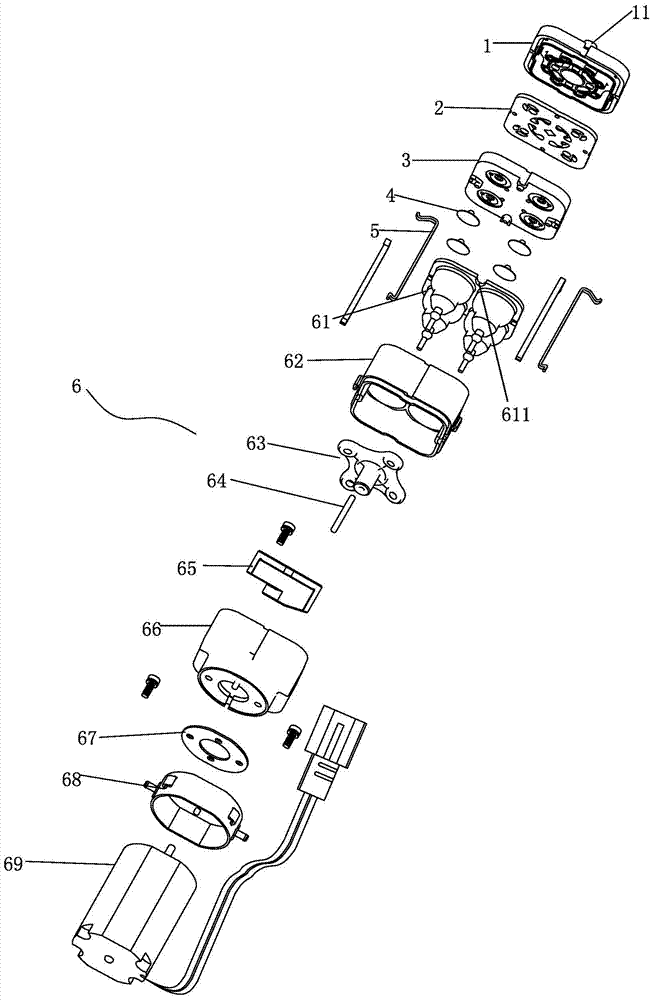

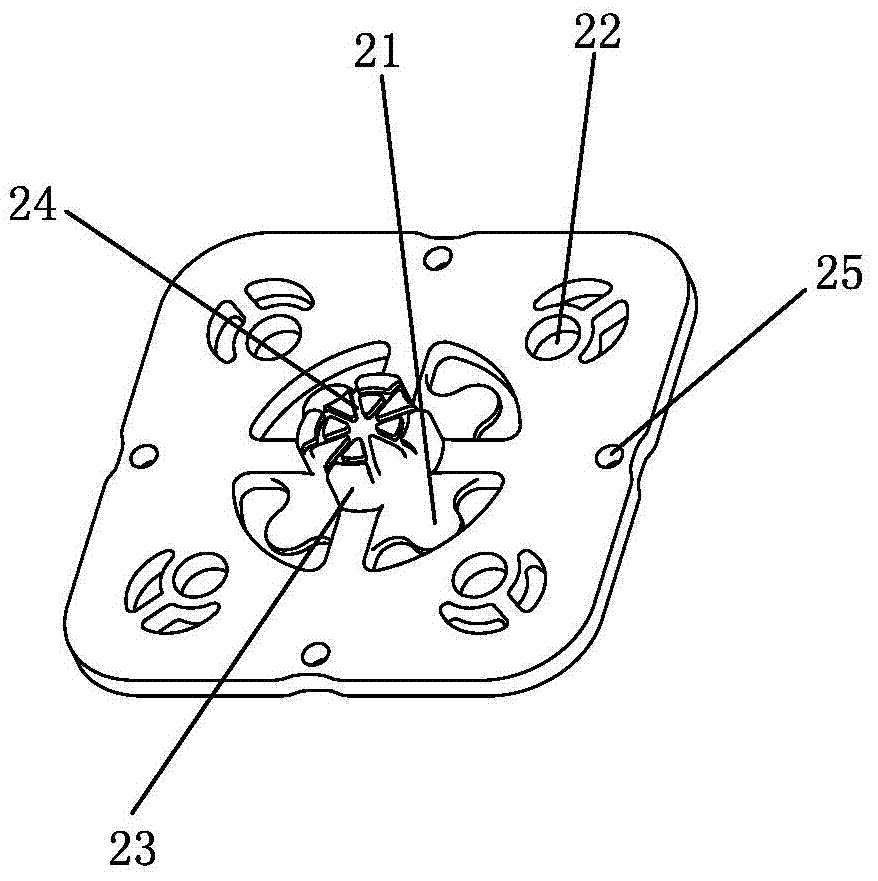

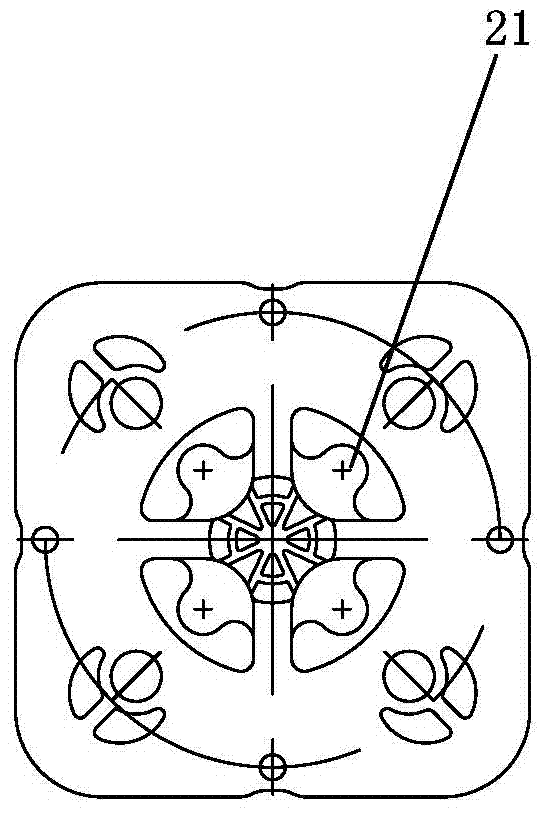

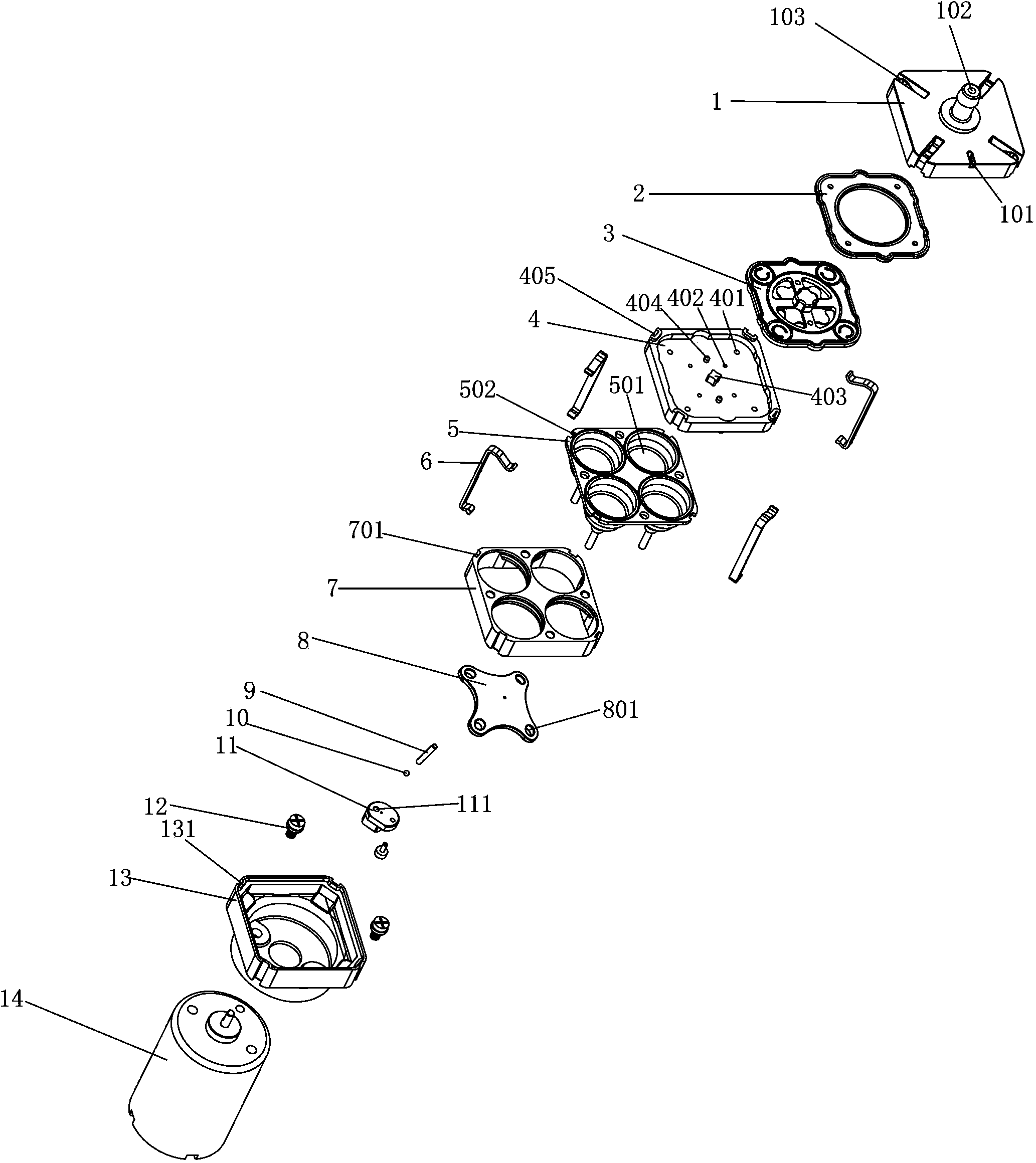

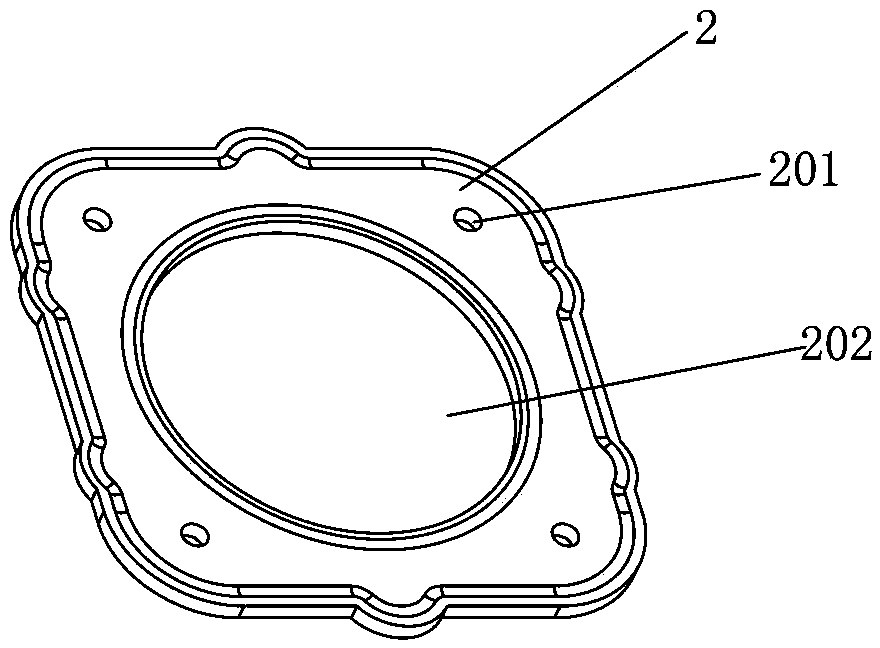

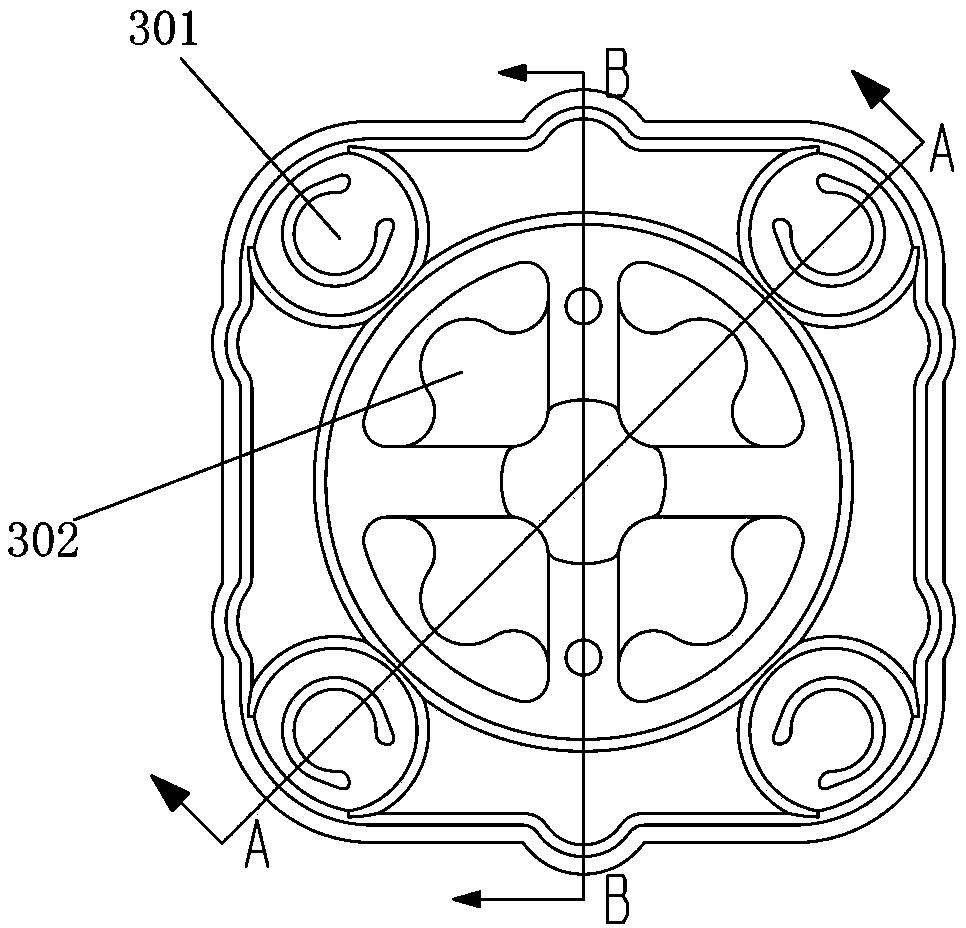

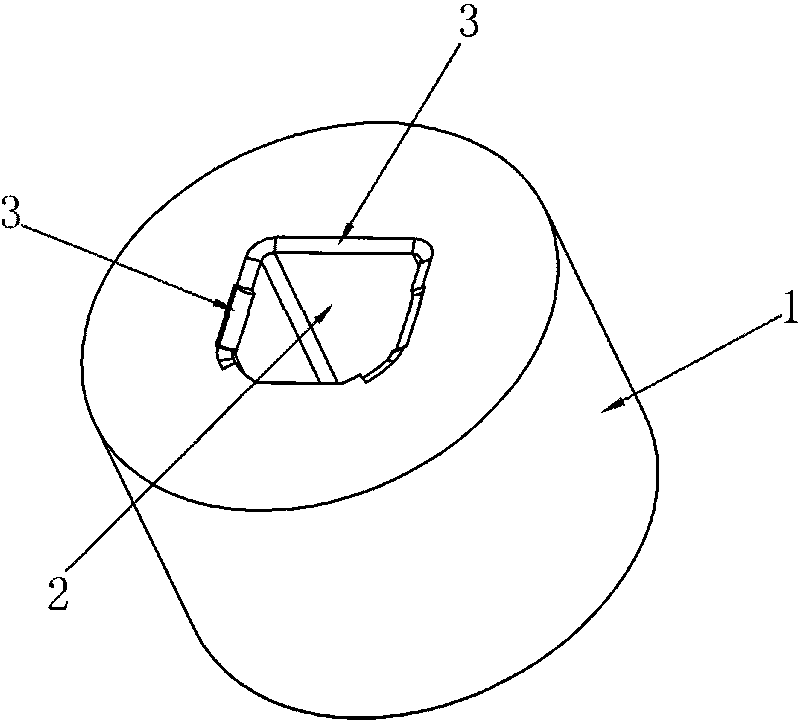

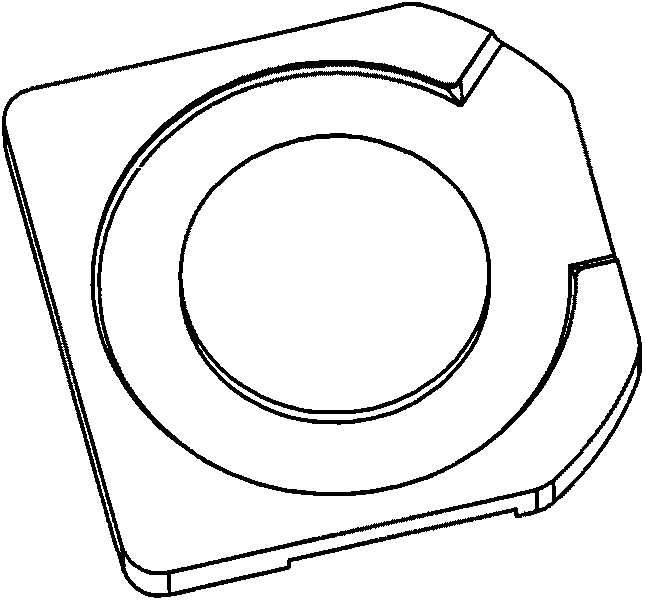

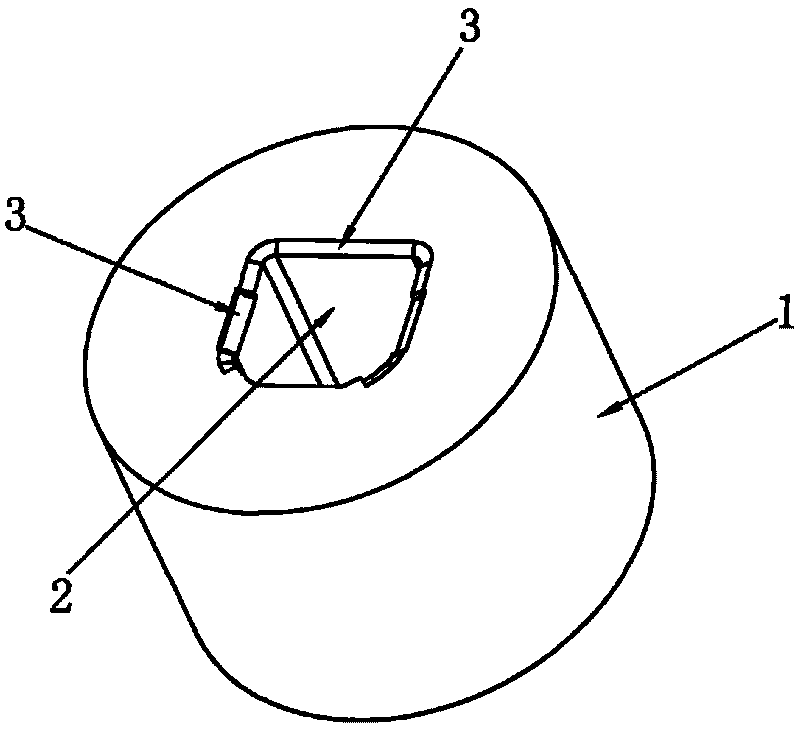

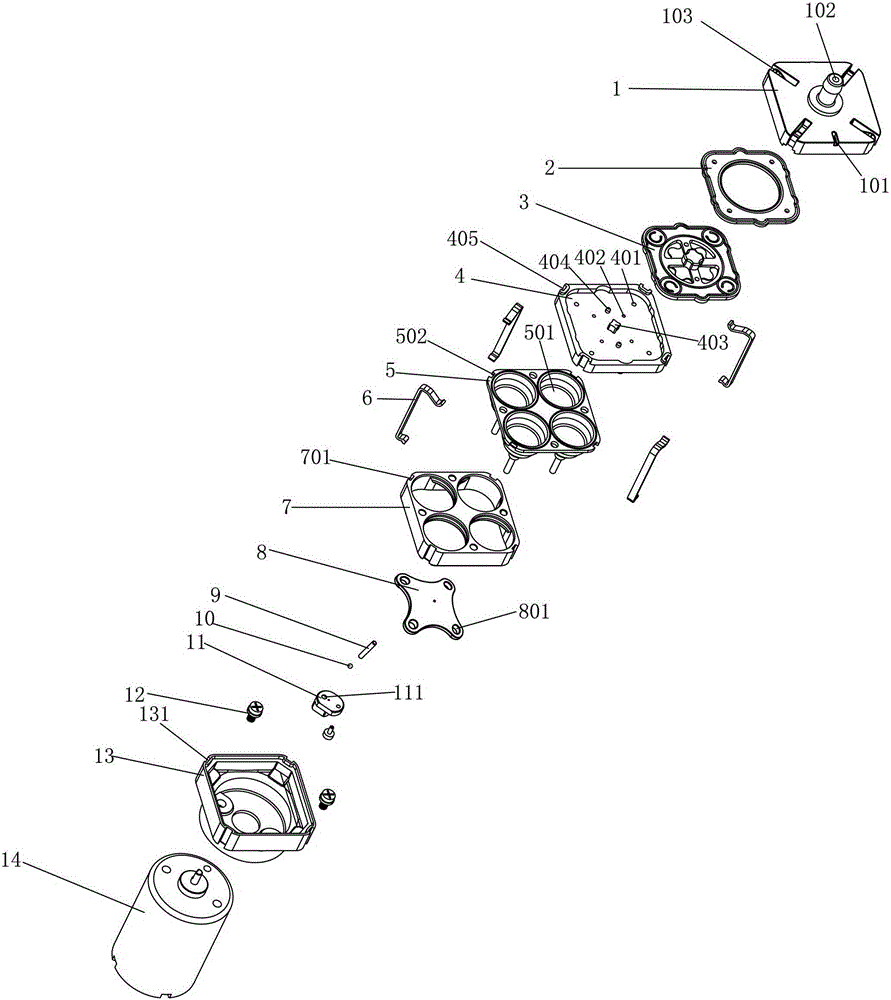

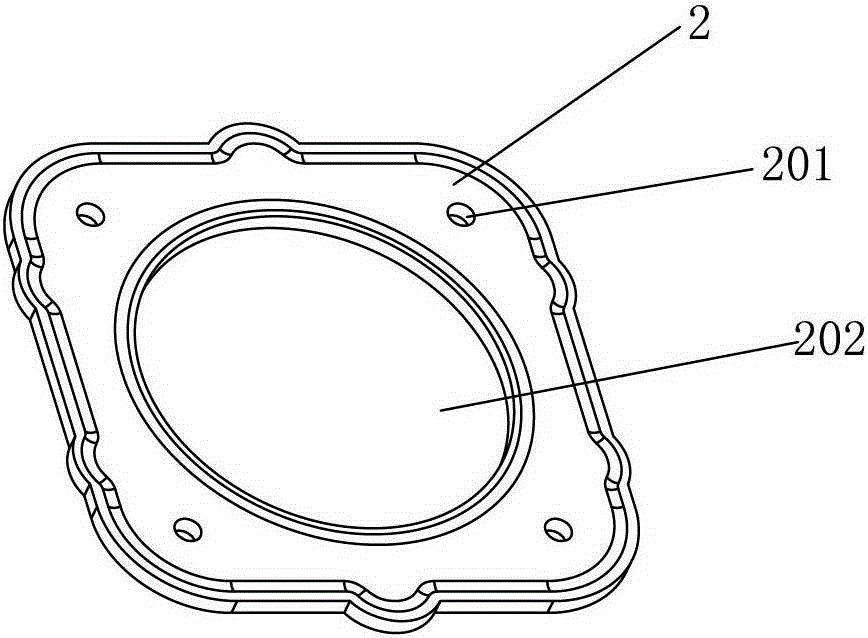

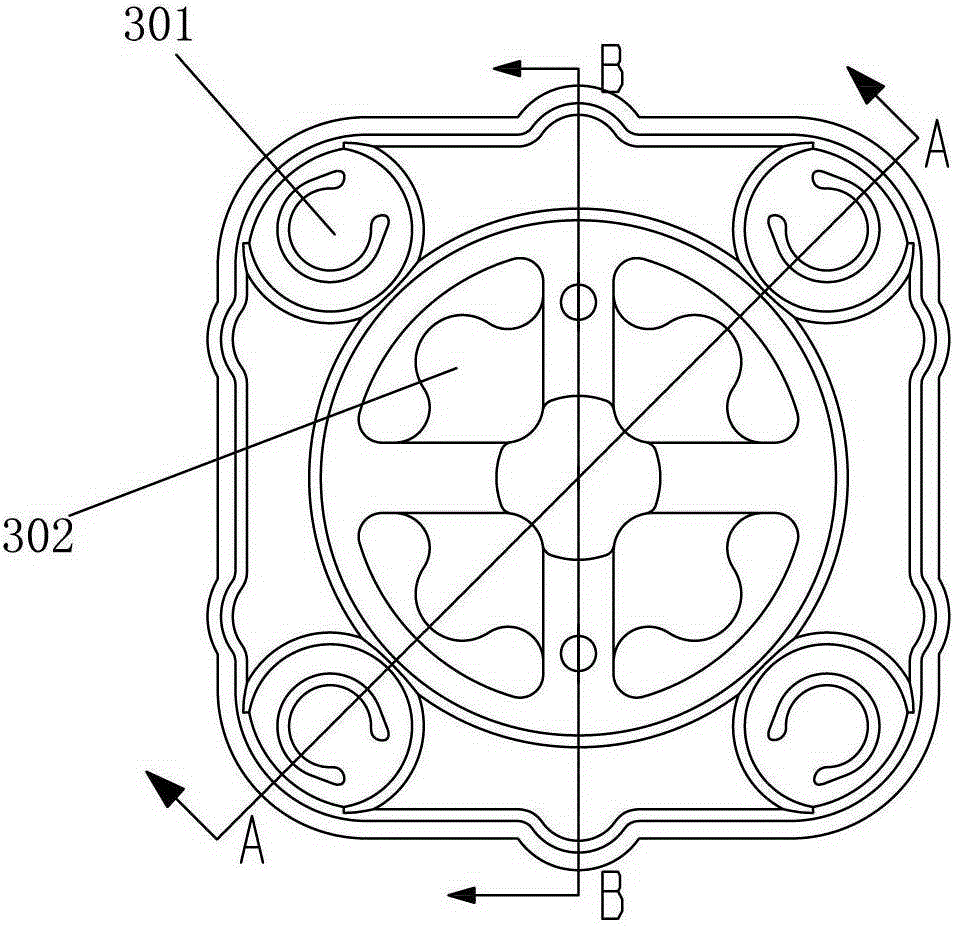

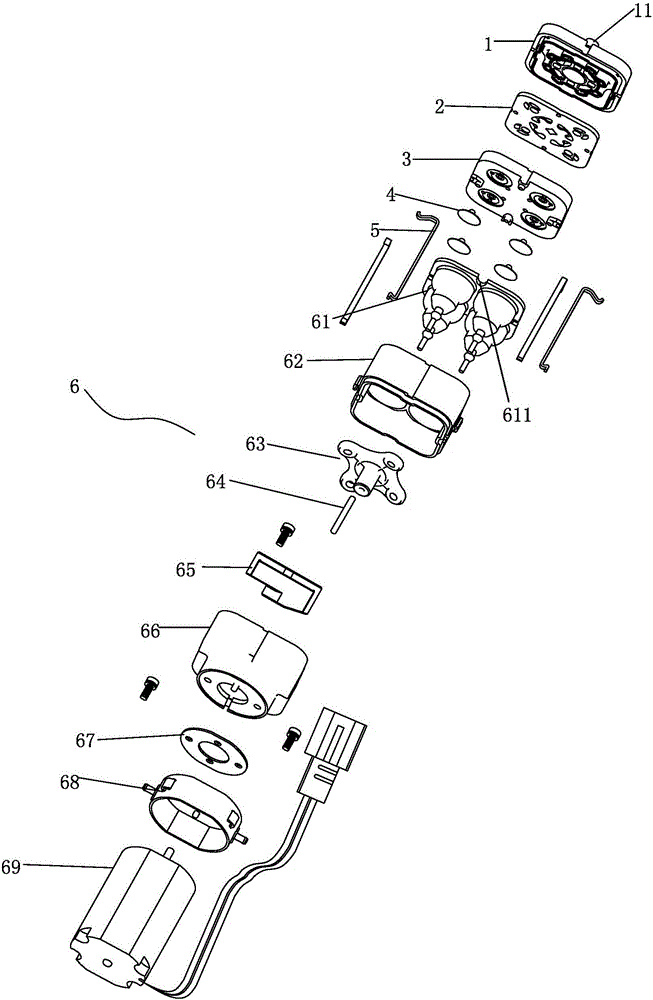

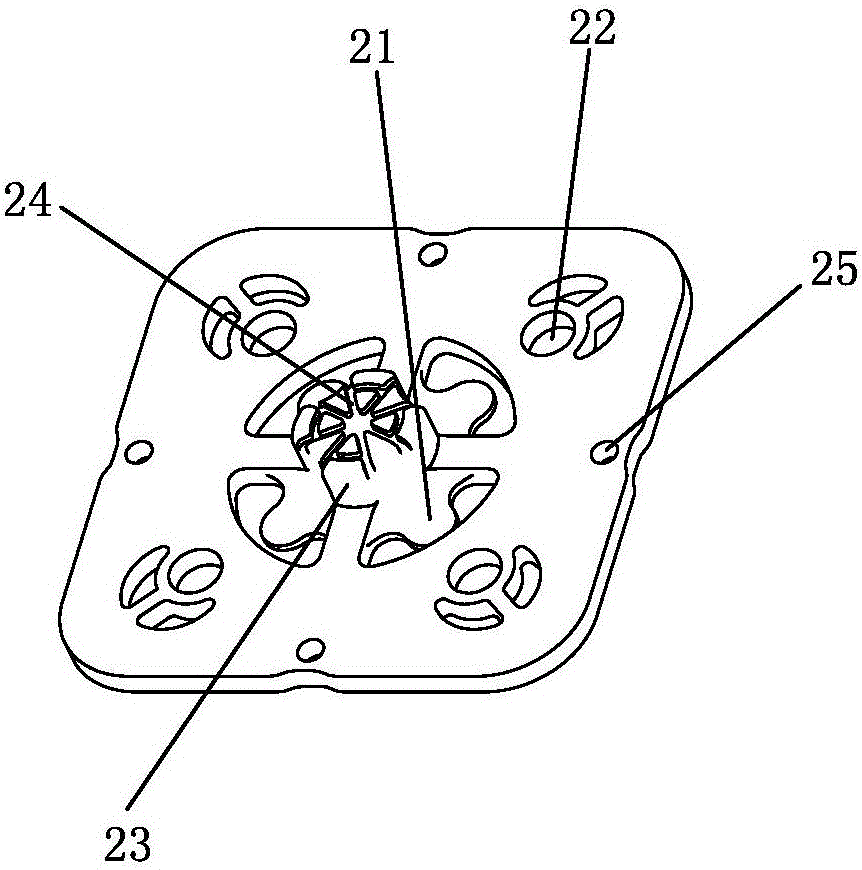

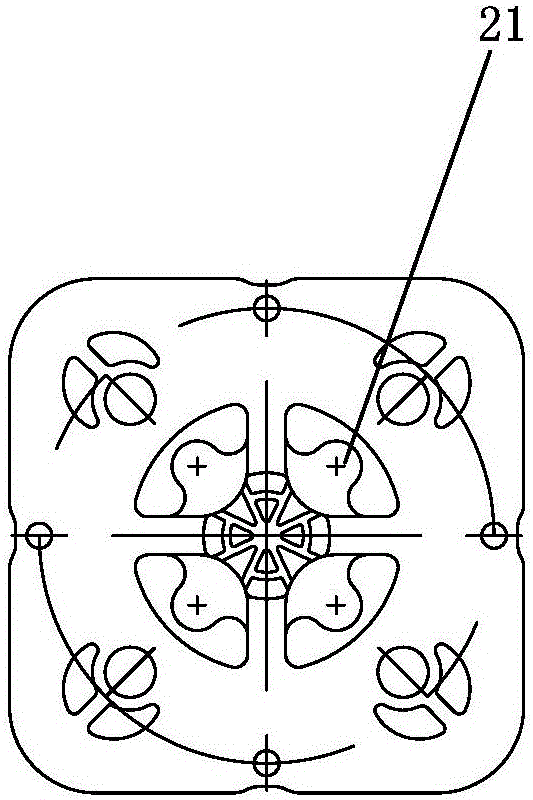

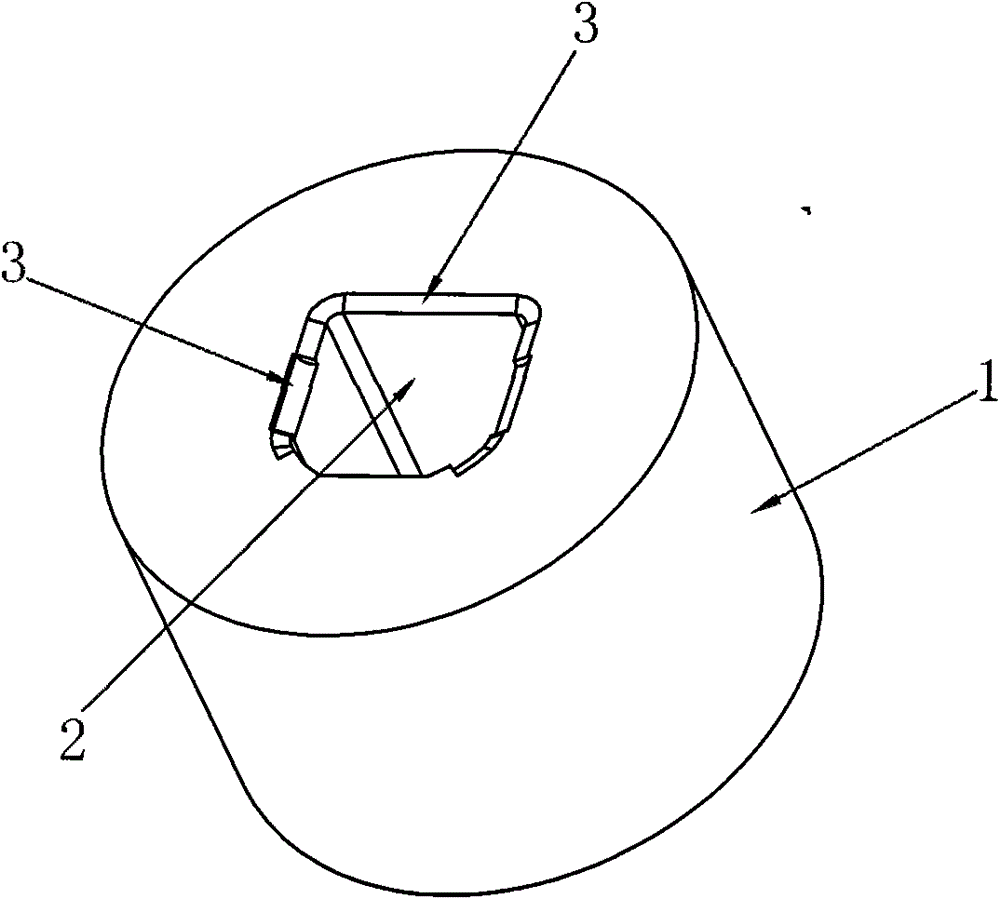

Air pump with improved air tightness

ActiveCN103671079APrevent warping and deformationAvoid warping and deformationPositive displacement pump componentsLiquid fuel engine componentsInlet channelAir pump

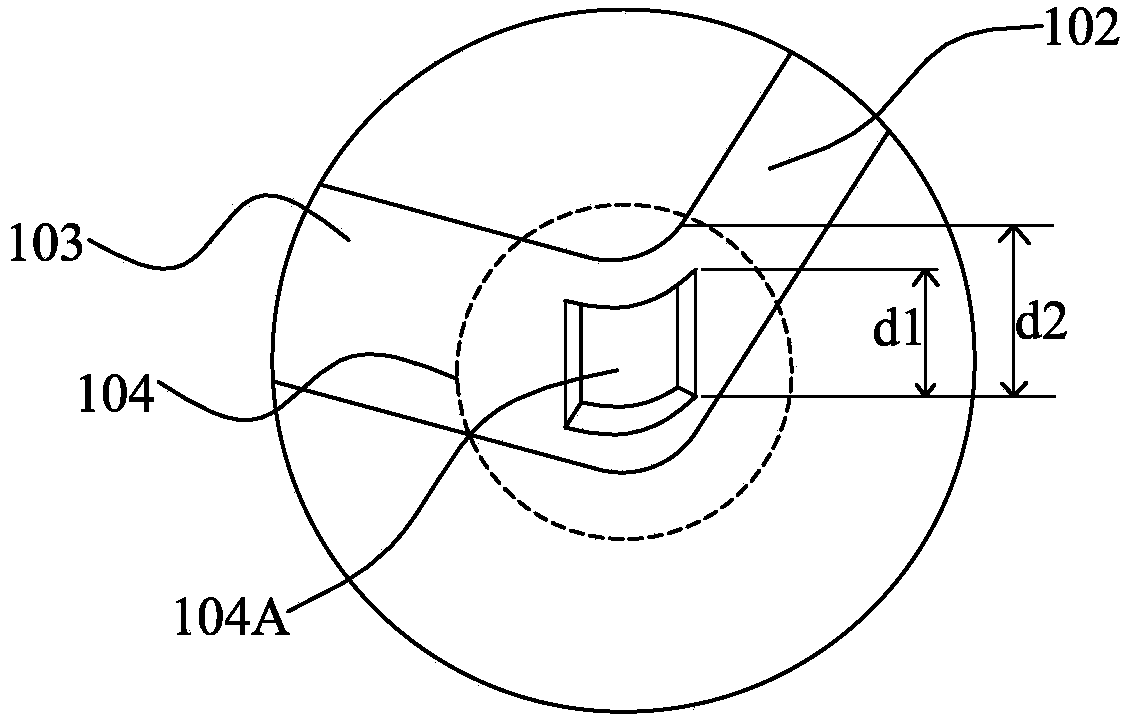

The invention discloses an air pump with improved air tightness. The air pump comprises an upper cover provided with an exhaust nozzle, a gasket, human-head-shaped exhaust one-way valves, a flow distribution device and a piston assembly, wherein the gasket is provided with a first air inlet channel and a first air outlet channel, the gasket is matched with the bottom end of the upper cover in a sealed mode, an air inlet cavity and an air outlet cavity are formed between the gasket and the upper cover, the air inlet cavity and the air outlet cavity are spaced, the first air inlet channel corresponds to the air inlet cavity, the first air outlet channel corresponds to the air outlet cavity, the air outlet cavity is communicated with the exhaust nozzle of the upper cover, the human-head-shaped exhaust one-way valves are integrally connected with the lower surface of the first air outlet channel of the gasket, and the heights of top faces of the human-head-shaped exhaust one-way valves gradually reduce from inside to outside. By the adoption of the structure, the situation that the human head portions of the human-head-shaped exhaust one-way valves tilt and deform due to the fact that compression amounts of edges of the gasket are not uniform or are exceedingly large is avoided, the situation that the human head portions of the human-head-shaped exhaust one-way valves tilt and deform due to elastic fatigue after the human-head-shaped exhaust one-way valves move many times, and accordingly the air tightness of the air pump is greatly improved.

Owner:XIAMEN KOGE MICRO TECH

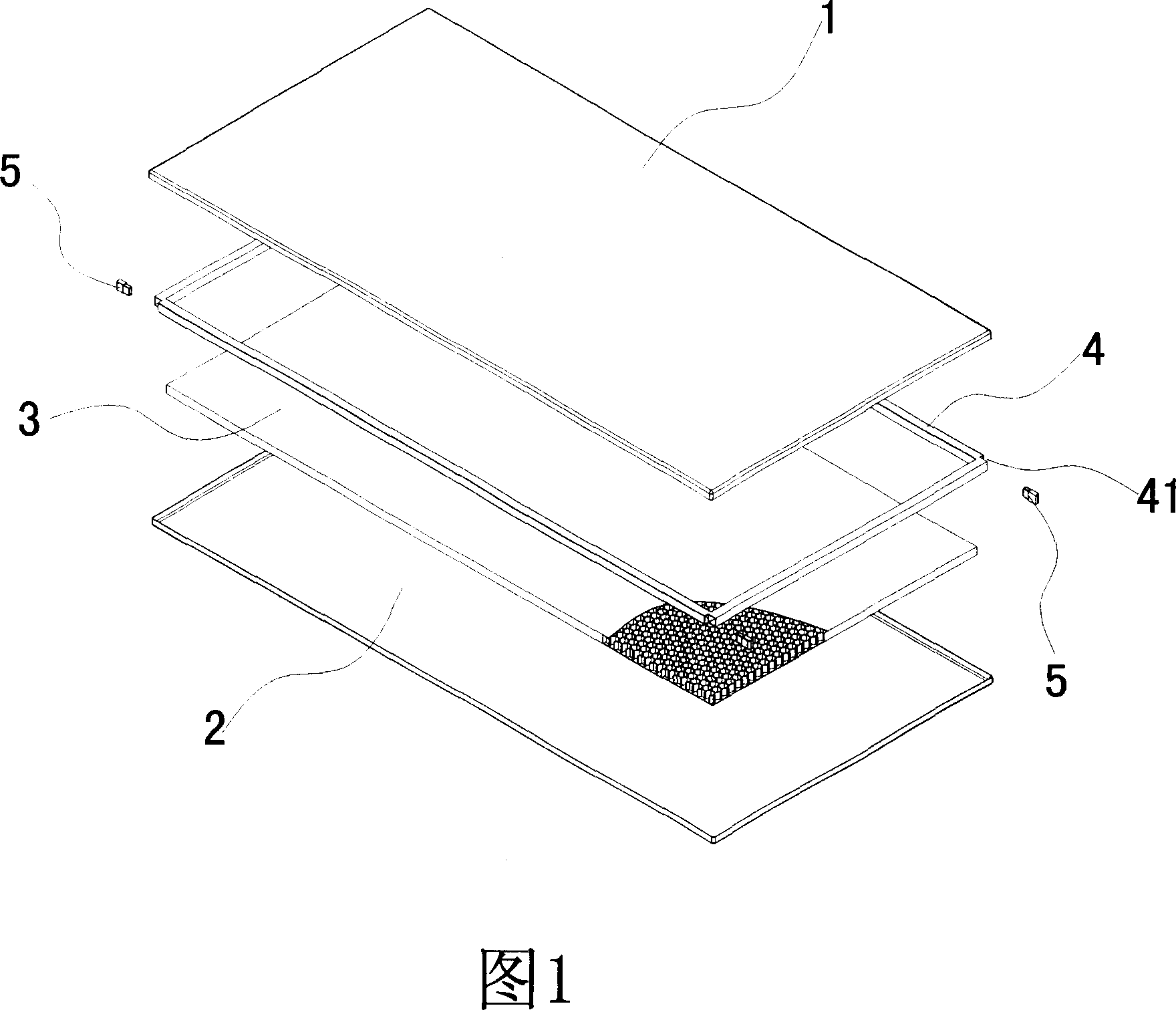

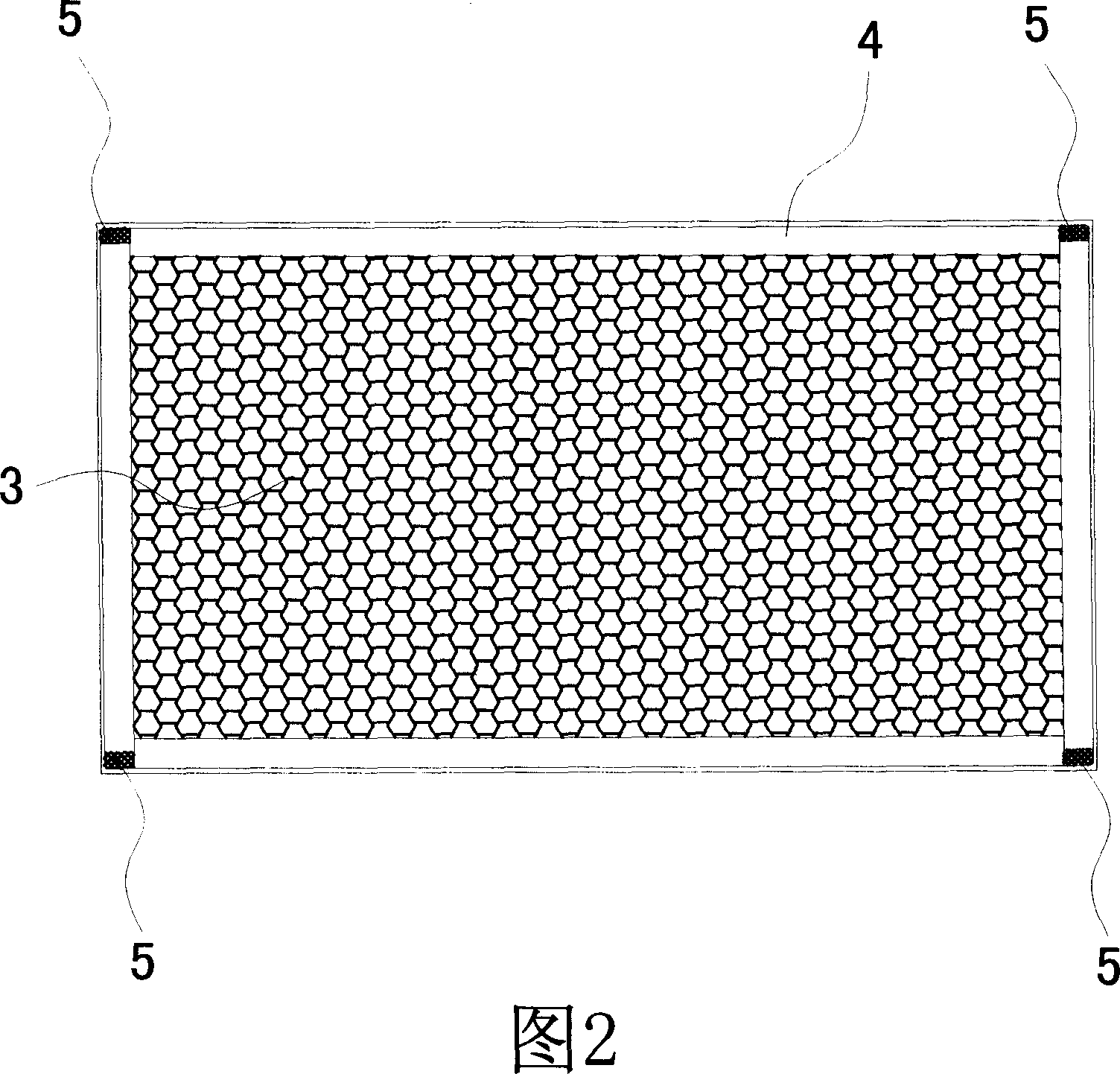

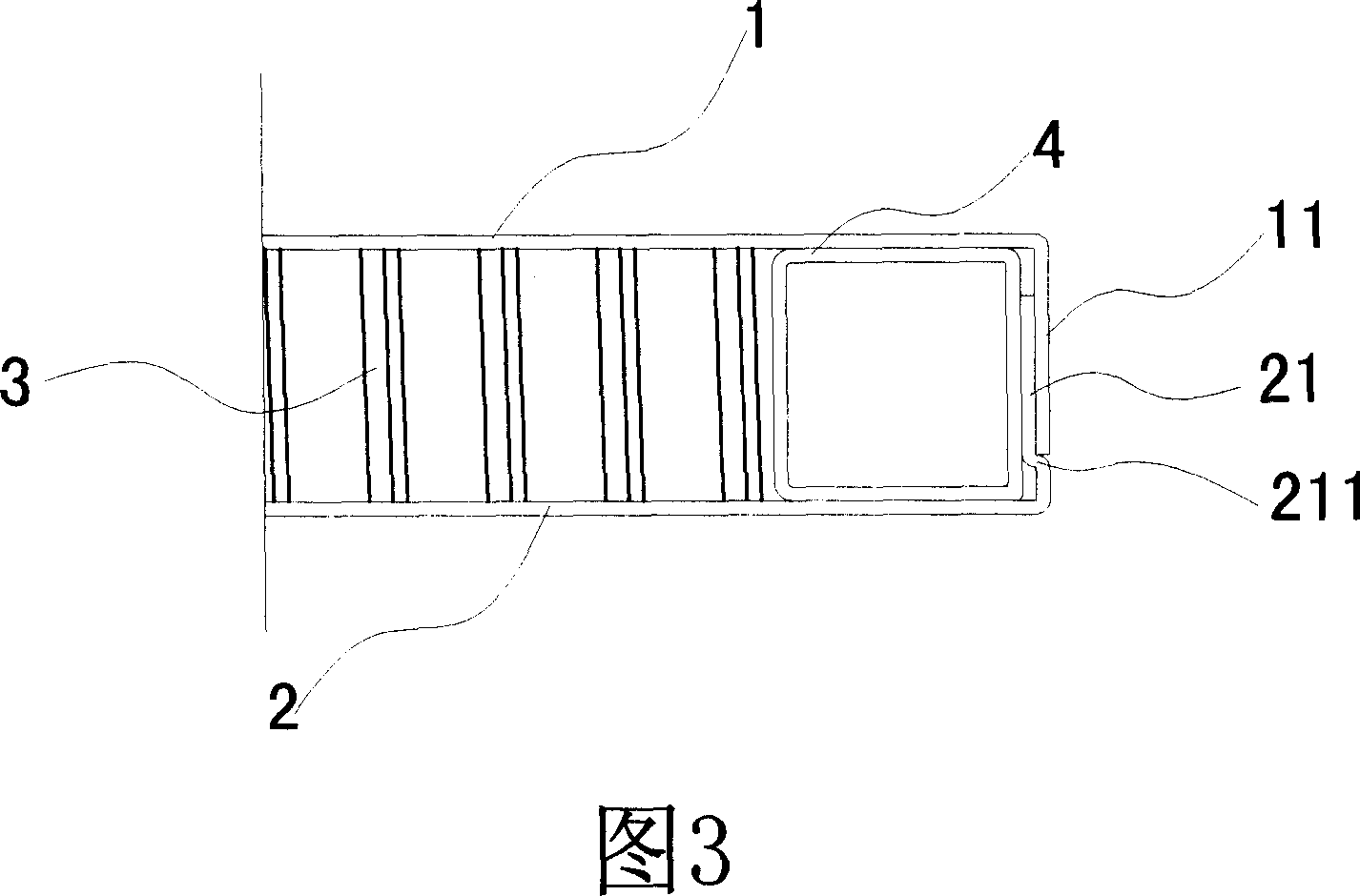

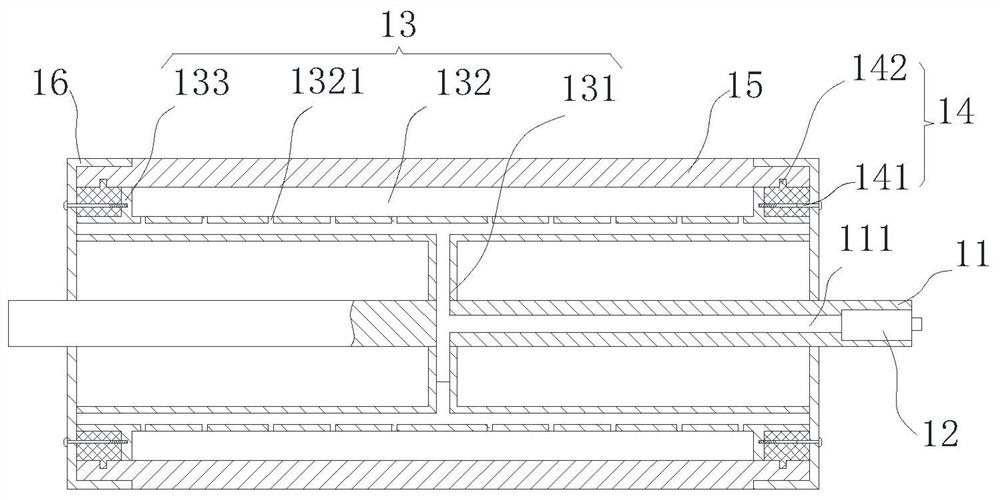

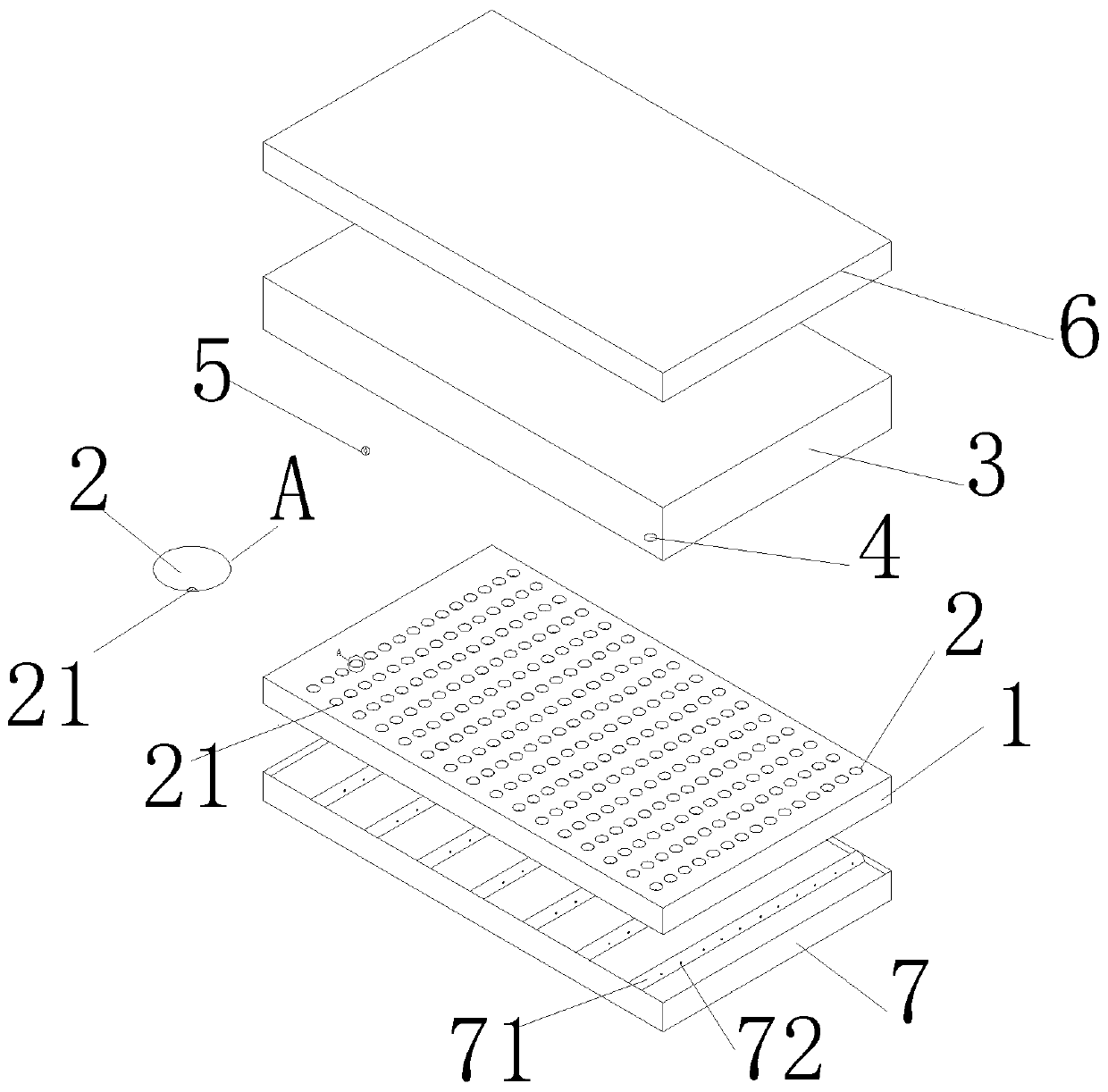

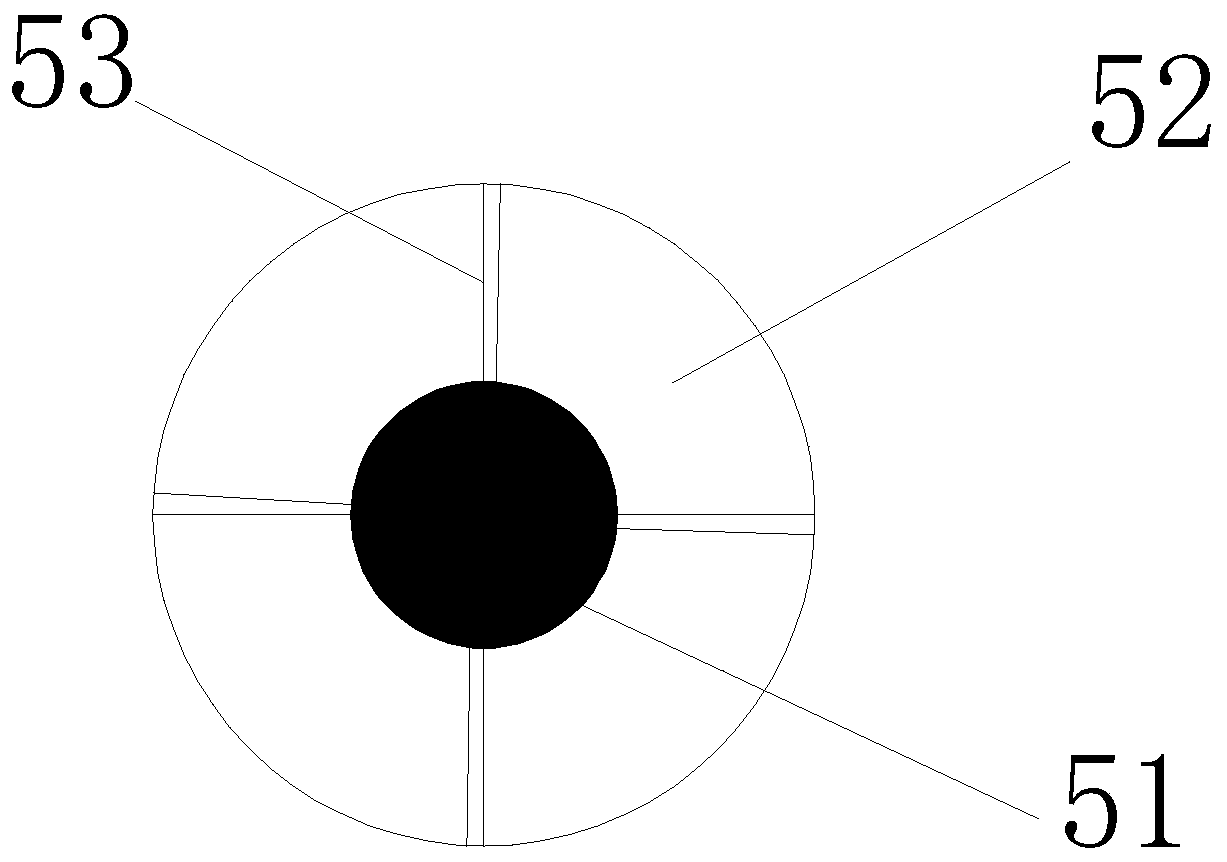

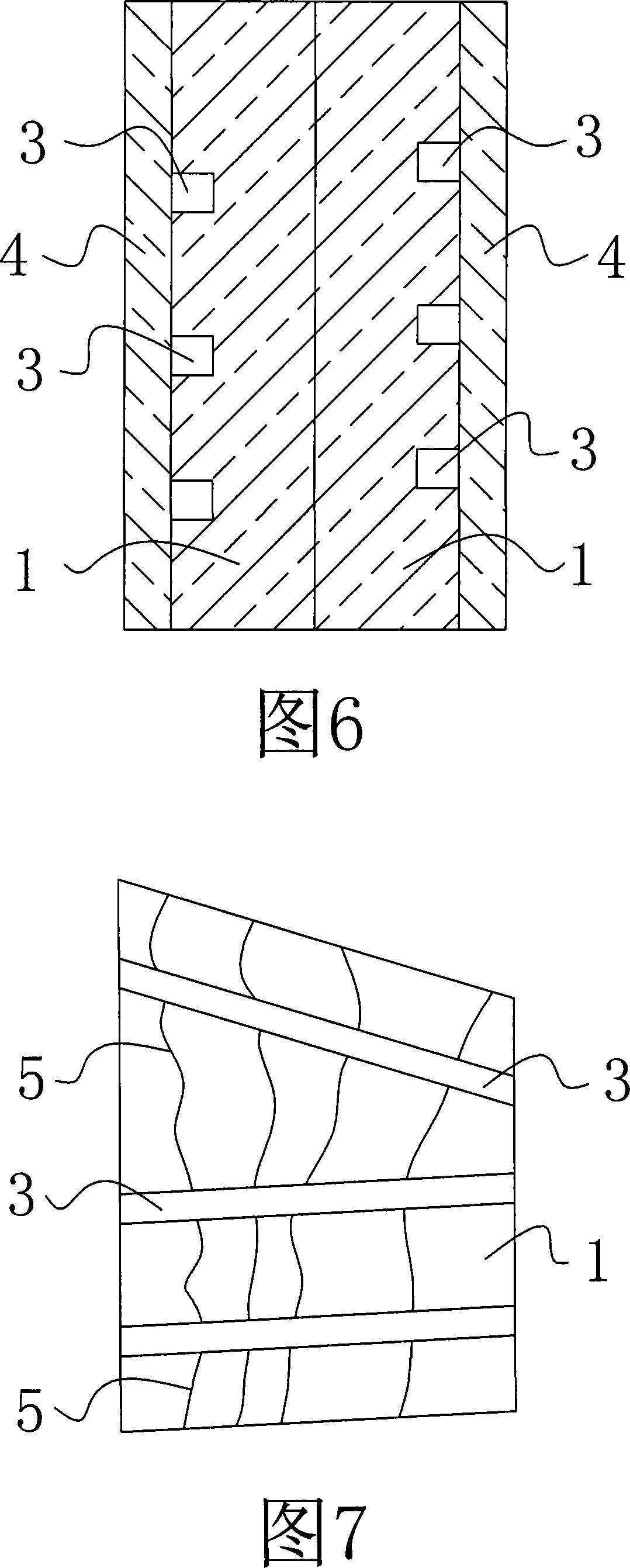

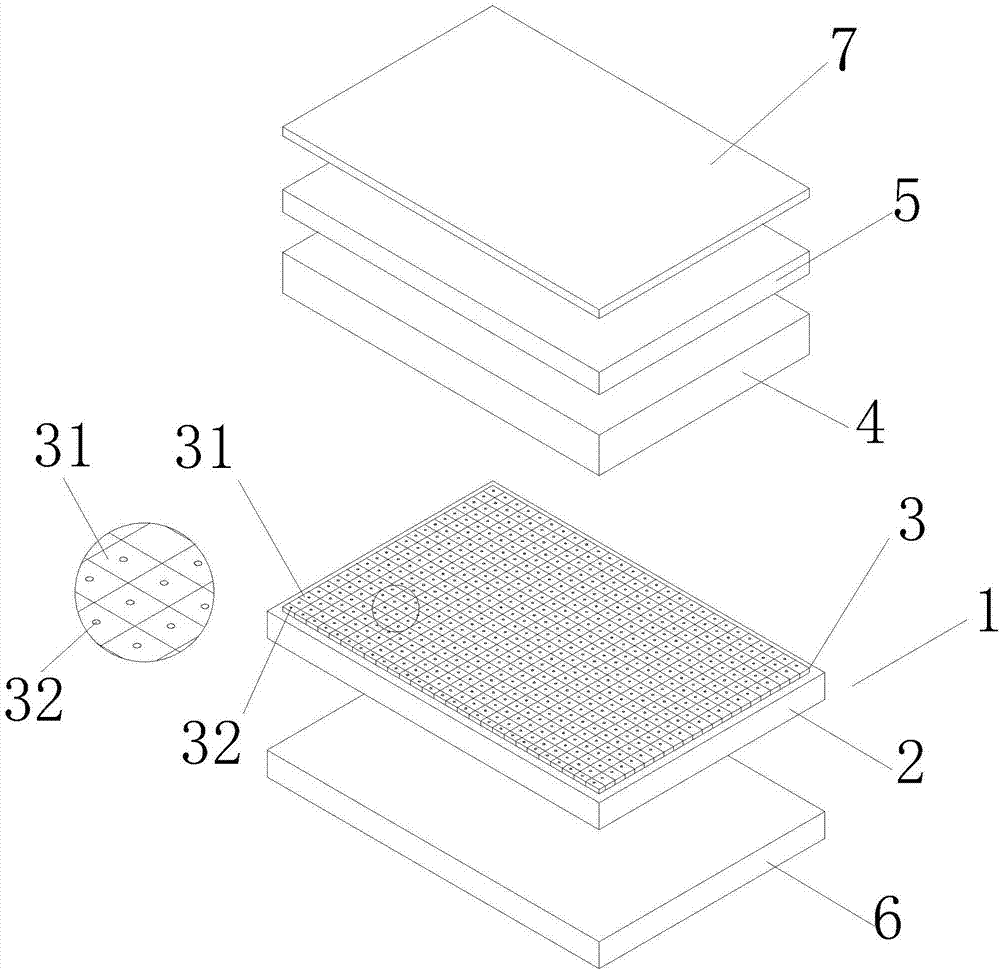

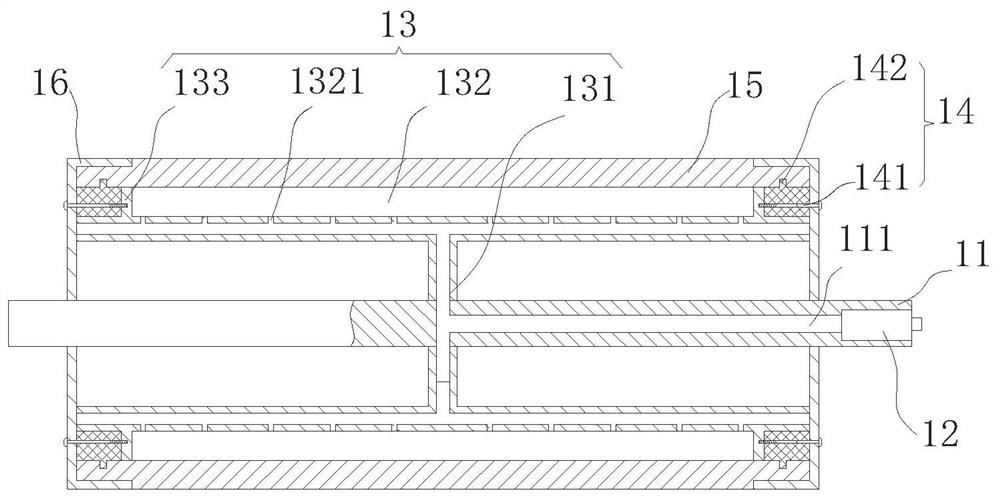

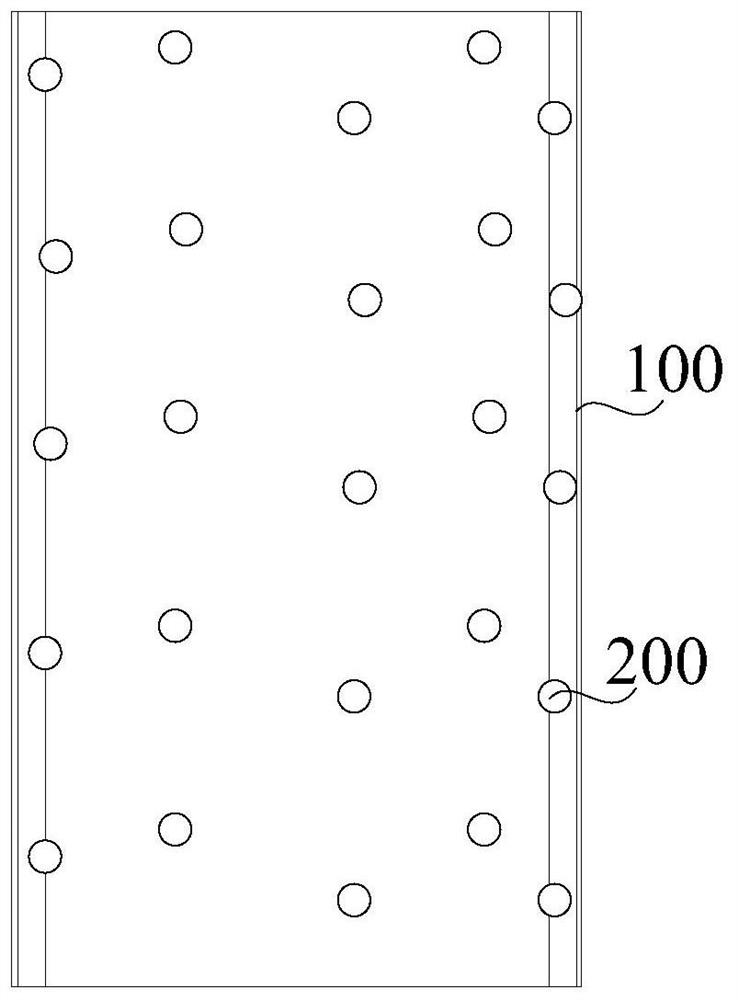

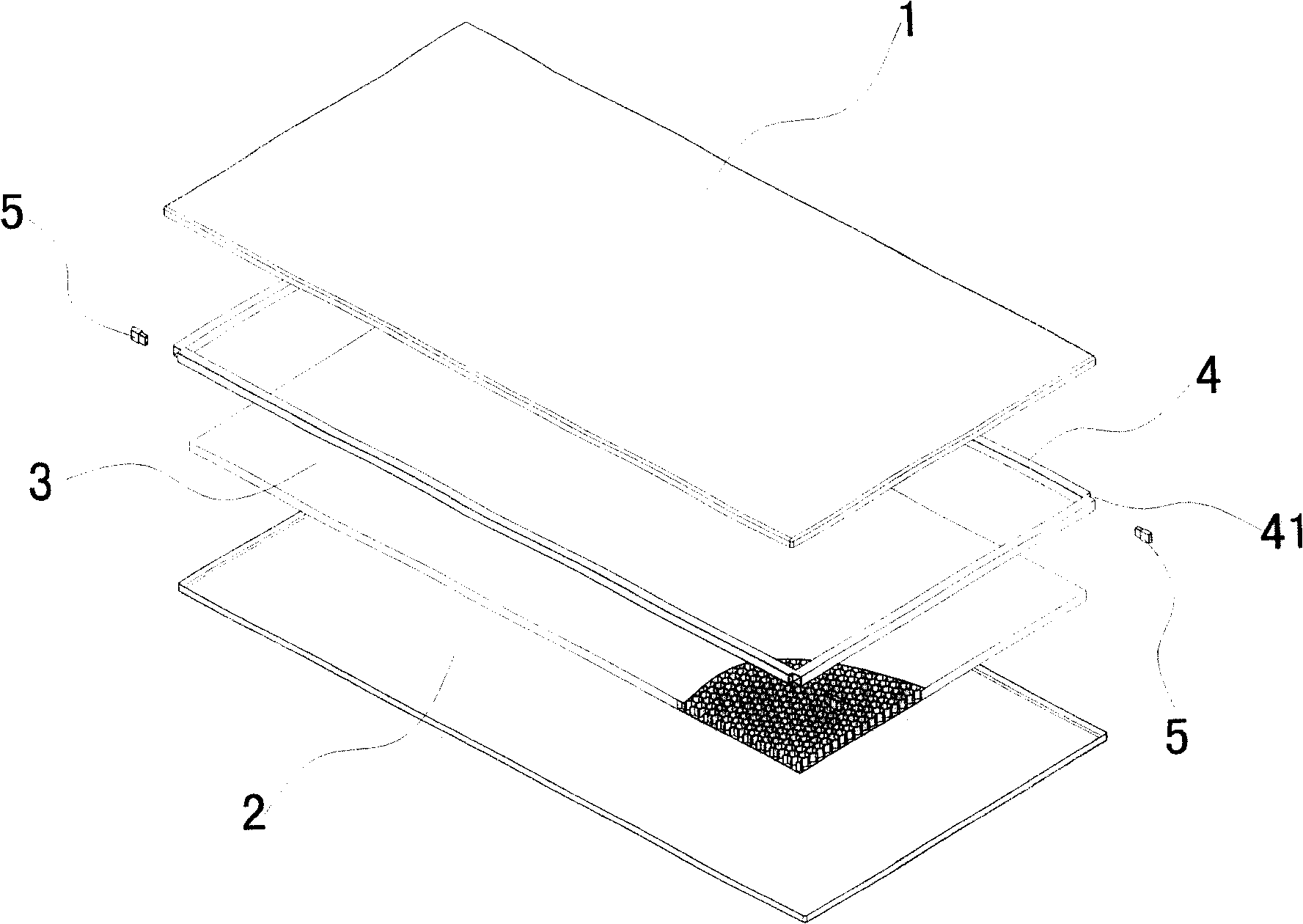

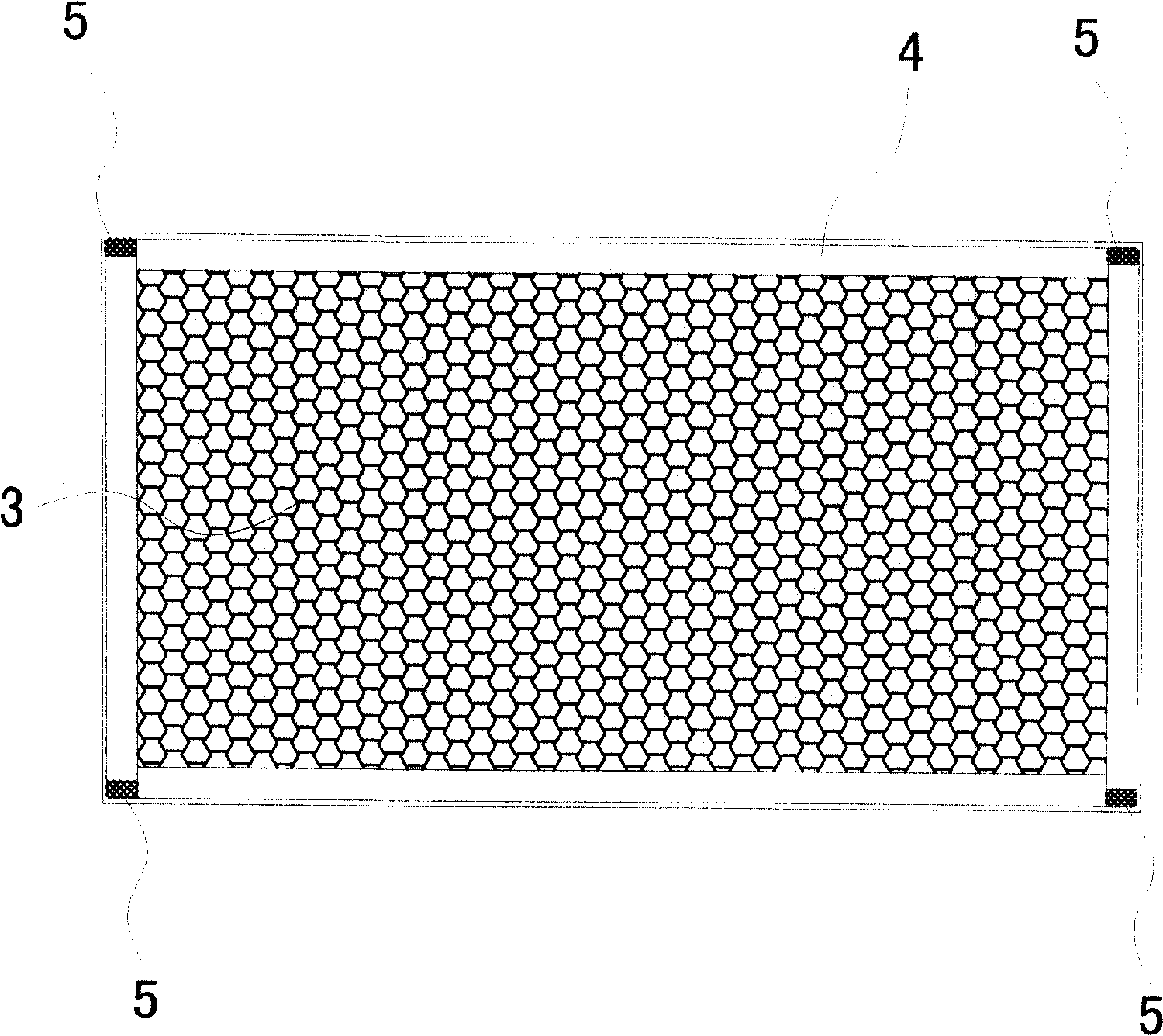

Screen and composite screen board

The invention discloses a screen and composite screen billboard, and the screen is connected by several pieces of composite screen billboard folding. The screen billboard is clad plate and includes: panel and floor; honeycomb panel filled between panel and floor; inner parts playing a connect function between screen billboard and extraneous elements or reinforcement function at the same time, and it is clipped between panel and floor and needs reinforcement and connection. The screen billboard of the invention includes panel, floor, honeycomb panel and inner parts, among them the inner parts plays a connect function between screen billboard and extraneous elements or reinforcement function at the same time, so the connection and assemblage between screen billboard and extraneous elements is convenient, the intensity is high; further more, because of the high intensity of the screen billboard, it can be installed bookshelves, hanging filing cabnet, multipurpose rail and other appurtenances.

Owner:冷鹭浩

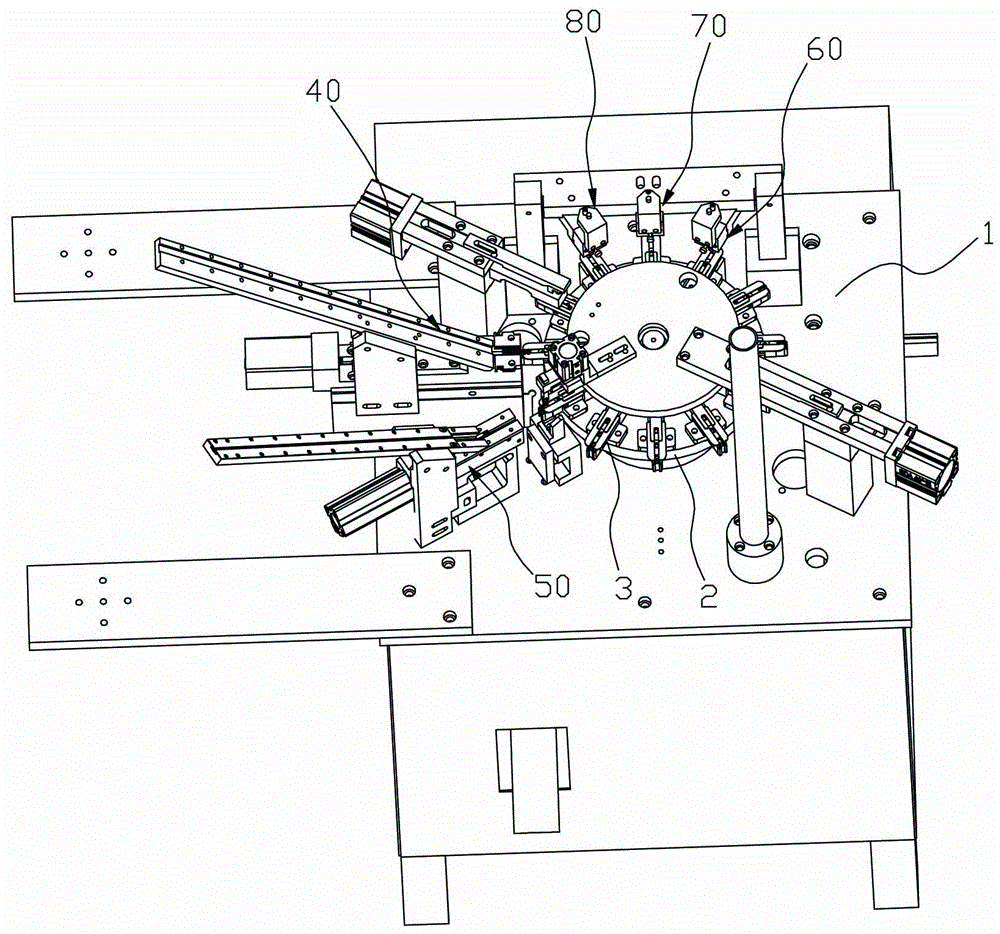

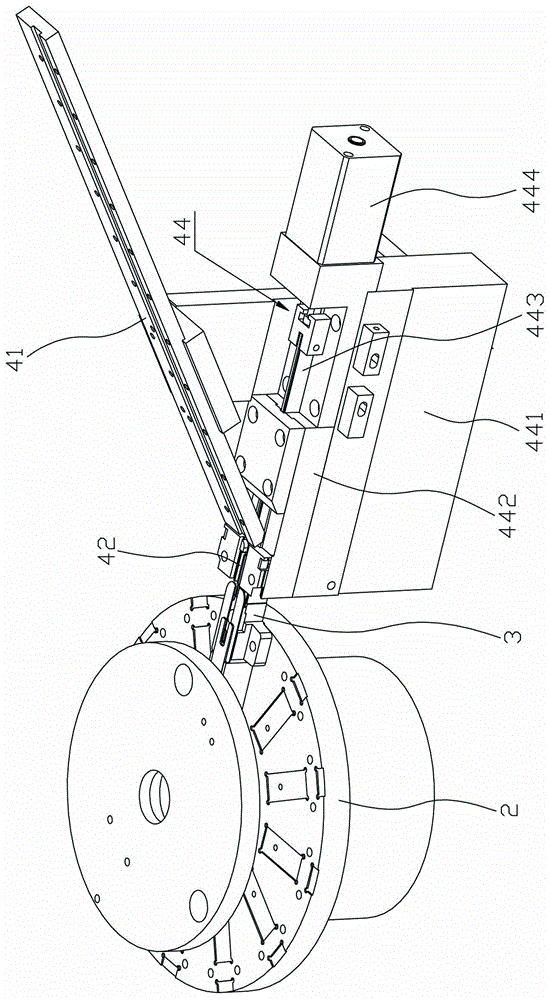

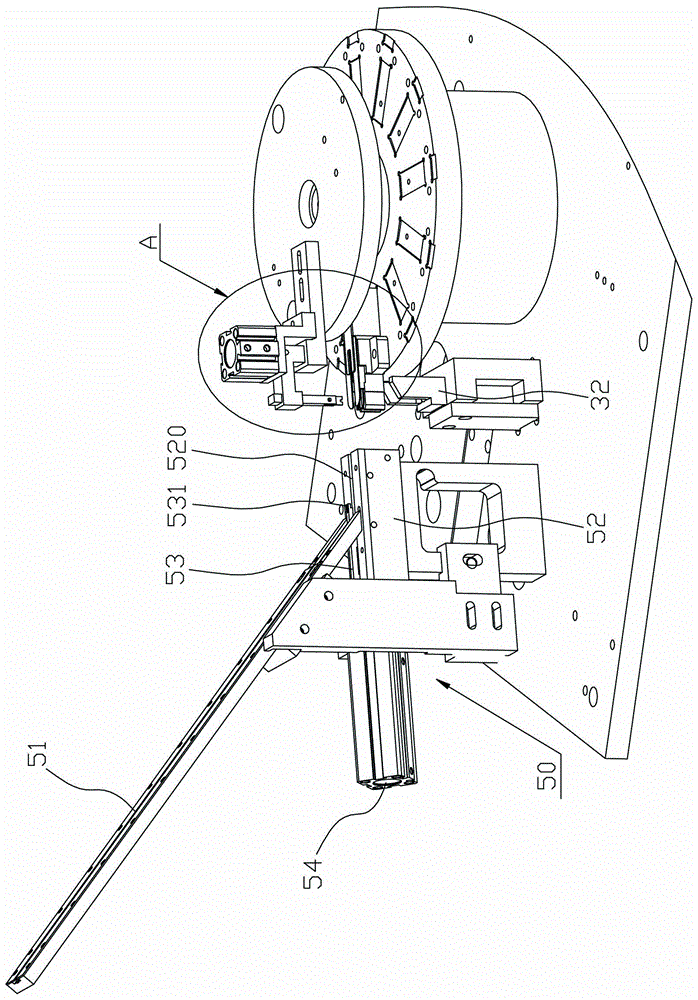

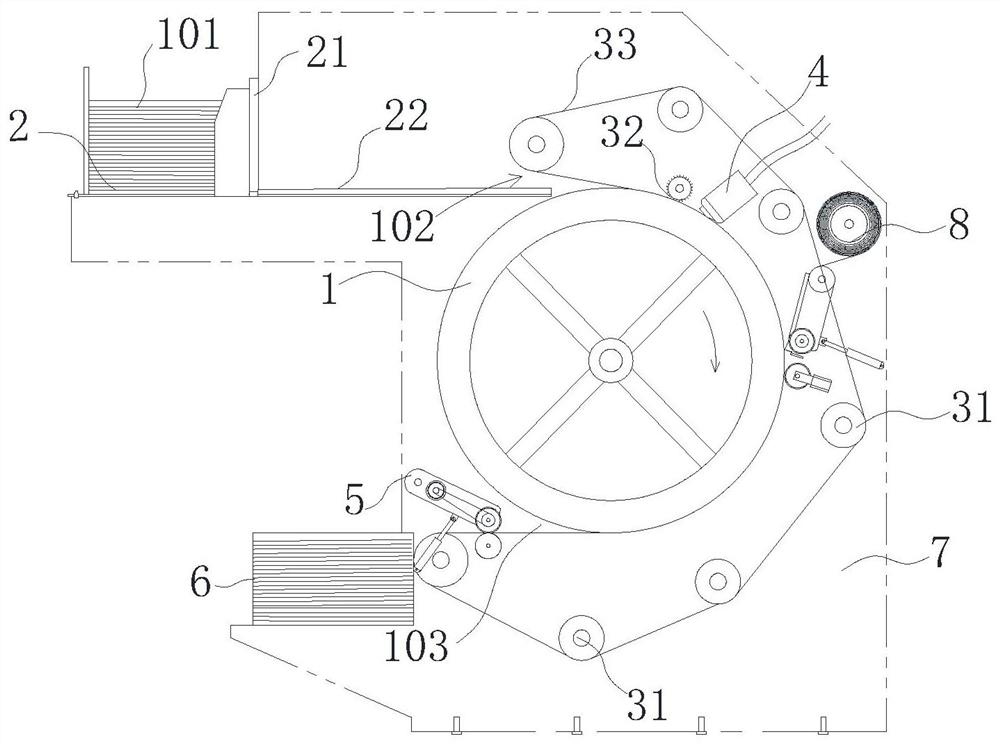

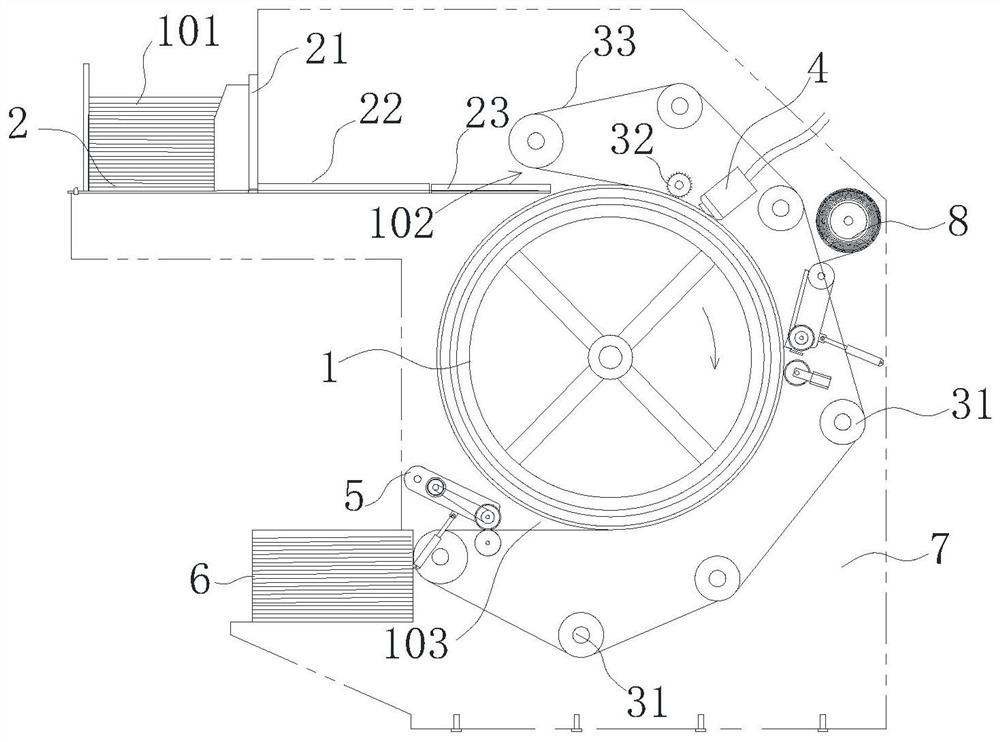

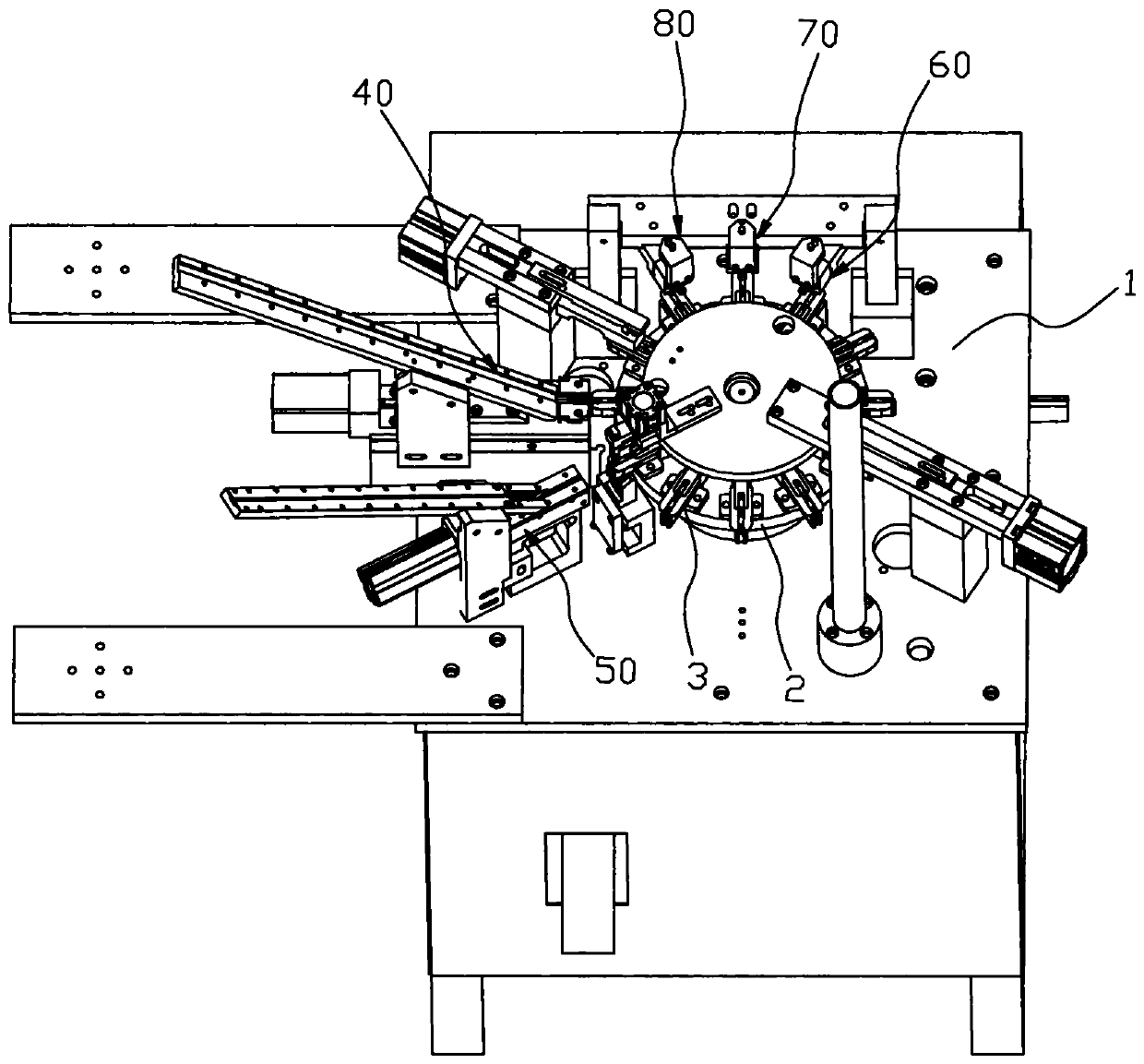

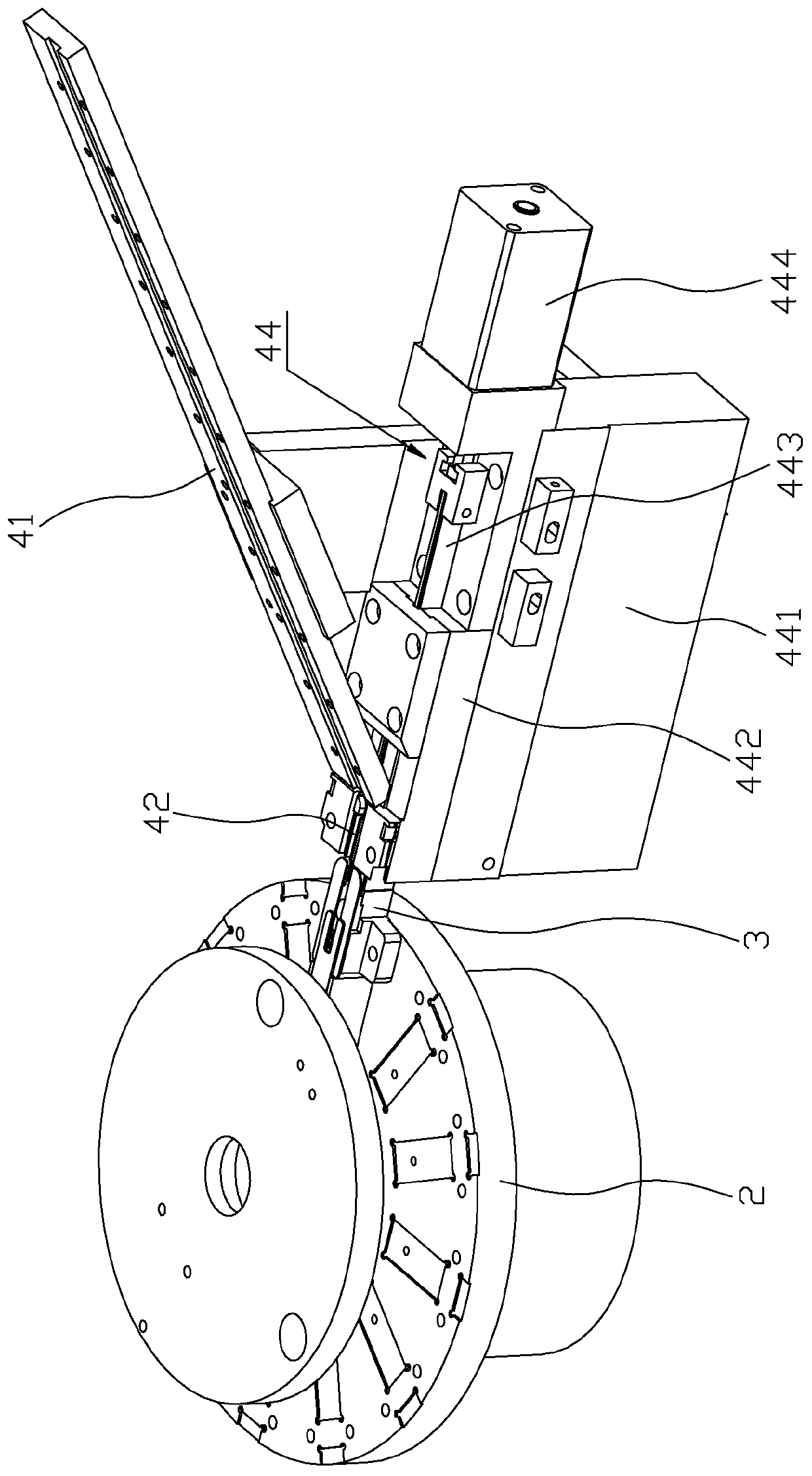

Alloy YG head assembly machine with zipper pulls automatically fed

ActiveCN106141026AImprove product qualification rateImprove riveting efficiency and qualitySlide fastenersMetal-working feeding devicesEngineeringAlloy

The invention discloses an alloy YG head assembly machine with zipper pulls automatically fed. The alloy YG head assembly machine comprises a machine frame and a round rotary plate, the round rotary plate is provided with a plurality of puller mold cores, and a puller conveying device, a zipper pull conveying device and a riveting device are arranged on the machine frame and around the circumferential surface of the round rotary plate; the riveting device comprises a first riveting mechanism, a second riveting mechanism and a third riveting mechanism, each riveting mechanism comprises a guide block, a fixed plate, a riveting cutter and a pressing rod, the fixed plates are arranged above the guide blocks, the riveting cutters are fixed to the lower ends of the fixed plates, the riveting cutter and the pressing rods penetrate through the guide blocks and are located above the puller mold cores, and reset springs are arranged between the pressing rods and the fixed plates; and the three guide blocks are connected to one cross beam, and two lifting rods are arranged at the two ends of the cross beam respectively and are driven by a power driving mechanism to be synchronously lifted. According to the riveting device, riveting convex points of pullers are riveted in three steps, and therefore the riveting force can be conveniently controlled, riveting deformation of the pullers is prevented, and the riveting quality of the pullers is improved.

Owner:QUANZHOU LICHENG DISTRICT ZHAN AUTOMATION EQUIP

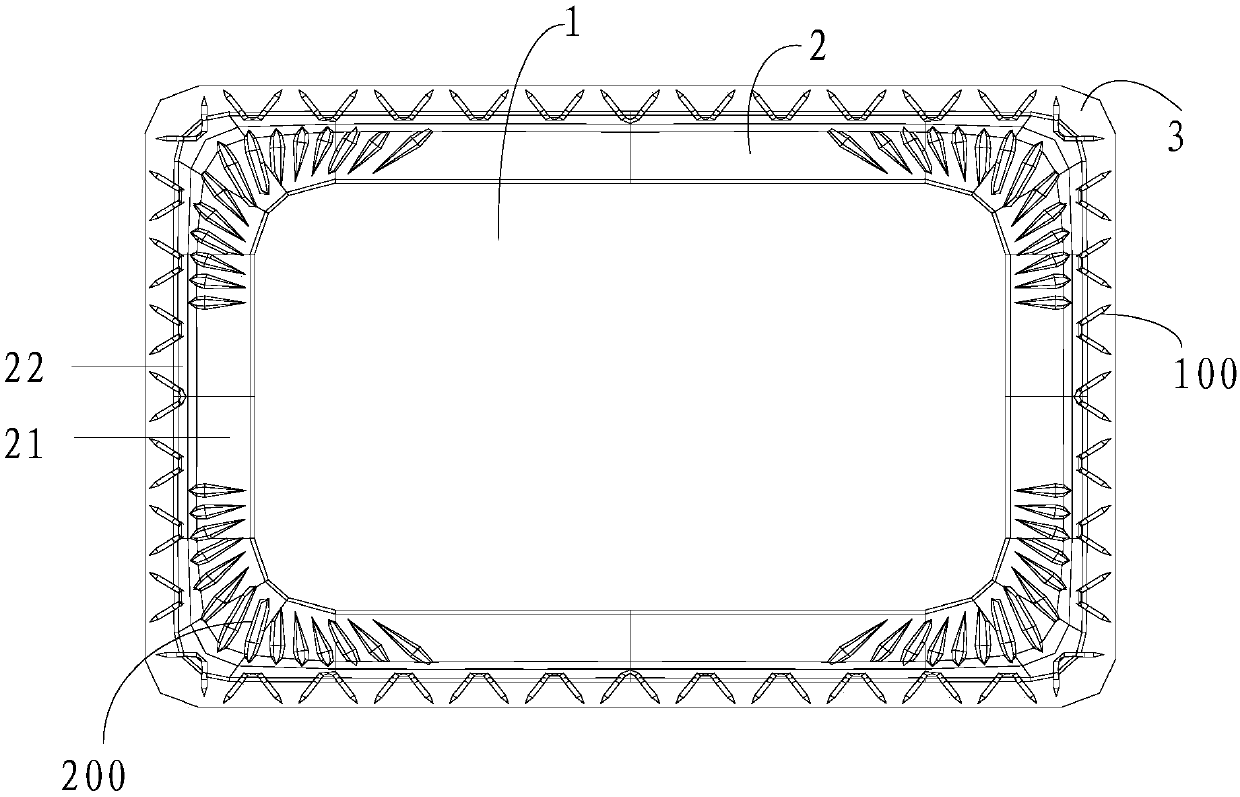

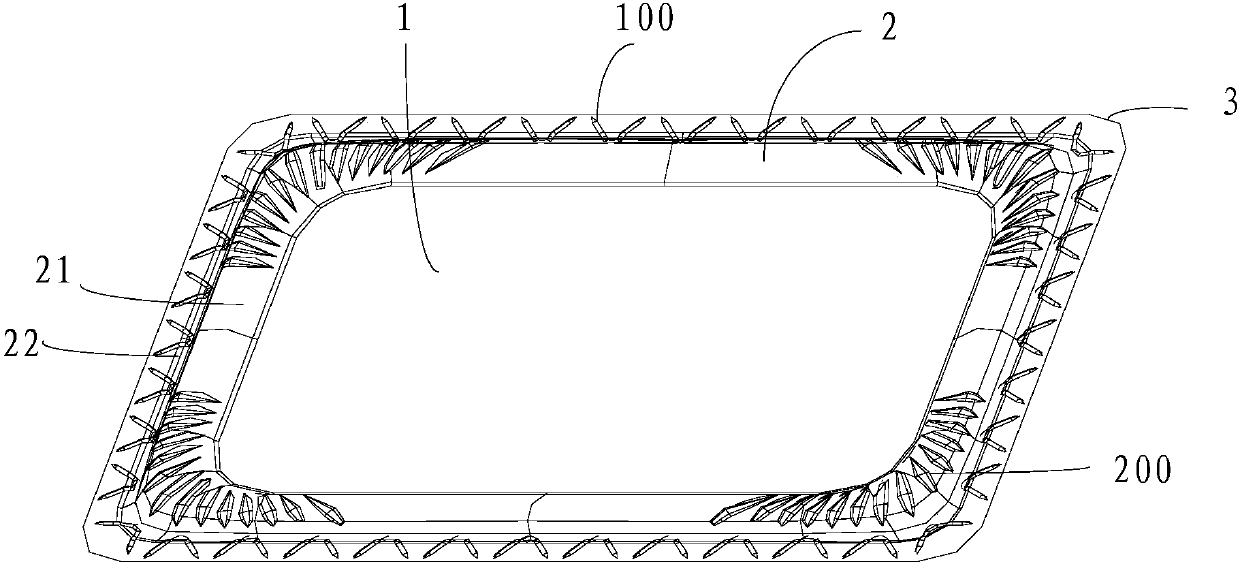

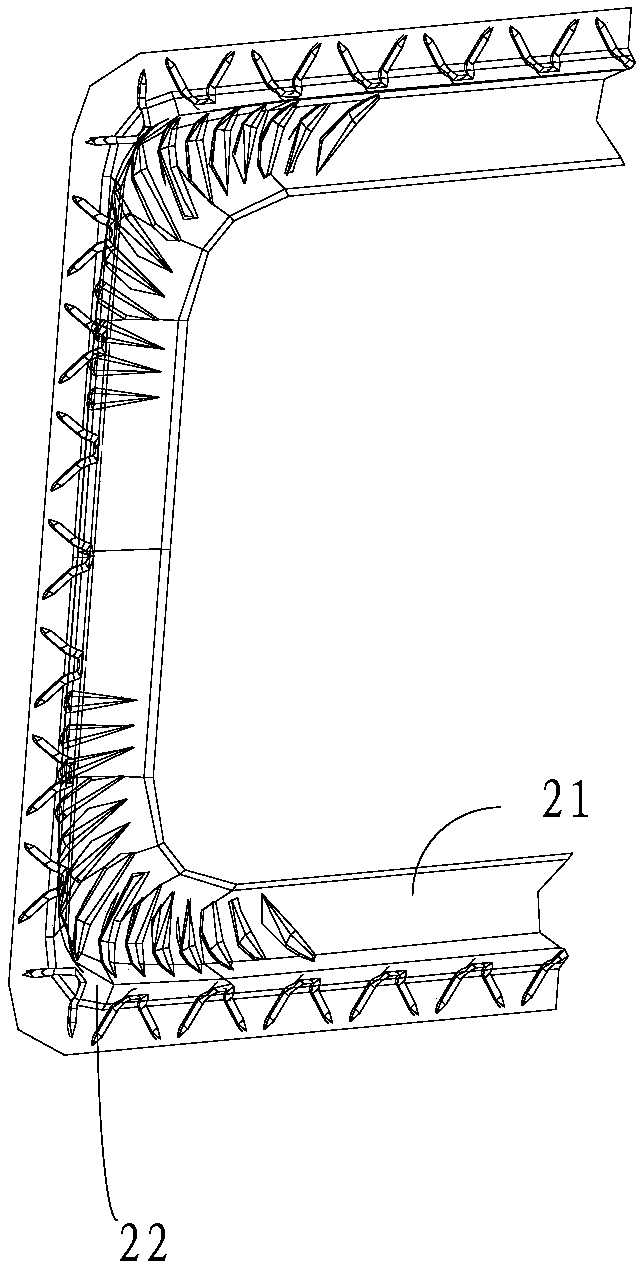

Loudspeaker diaphragm and loudspeaker

ActiveCN107948893AImprove yieldHigh strengthLoudspeakersLoudspeaker diaphragm shapeStress concentrationEngineering

The embodiment of the invention provides a loudspeaker diaphragm and a loudspeaker. The loudspeaker diaphragm comprises a central portion, a folding ring portion and a fixing portion, which are sequentially connected from the inside to the outside; and a plurality of patterns across the folding ring portion and the fixing portion are arranged on the diaphragm; and the first end of each pattern extends toward the peripheral edge of the fixing portion, and the second end of the pattern extends out from the peripheral edge of the folding ring portion to extend onto the folding ring portion. The technical scheme provided by the invention can not only effectively divide the stress of a stress concentration region of the fixing portion but also can increase the strength of the fixing portion, thereby effectively avoiding the problem of warpage and deformation after the diaphragm is formed, and improving the diaphragm yield.

Owner:GOERTEK INC

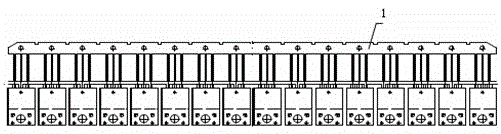

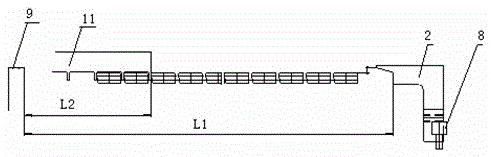

Low-noise air pump

ActiveCN103452806AReduce running noisePrevent warping and deformationPositive displacement pump componentsPositive-displacement liquid enginesLow noiseAir pump

The invention discloses a low-noise air pump which comprises an upper cover, a cylinder, a piston, a base, a unidirectional inlet and outlet air distributing device, a motor, a linkage mechanism and a partition plate. The upper cover is provided with an exhaust port and an air inlet, and the piston is integrally provided with at least two air bags; the partition plate is provided with a first air outlet hole and first air inlet holes; the partition plate is fixed to a position between the upper cover and the unidirectional inlet and outlet air distributing device, the partition plate and the upper cover are hermetically matched with each other to form a sealed cavity, the air inlet of the upper cover and the first air inlet holes of the partition plate are respectively communicated with the sealed cavity, the first air outlet hole of the partition plate is communicated with the exhaust port of the upper cover, and the first air outlet hole and the first air inlet holes are respectively correspondingly matched with the unidirectional inlet and outlet air distributing device to realize a unidirectional outlet air distributing effect and a unidirectional inlet air distributing effect. The low-noise air pump has the advantages that owing to the partition plate, an airflow passage is prolonged, inlet air can be buffered, impact force is reduced, accordingly, running noise of the air pump is greatly reduced, and tilting deformation of an air inlet check valve of the unidirectional inlet and outlet air distributing device due to long-term direct stress can be prevented.

Owner:XIAMEN KOGE MICRO TECH

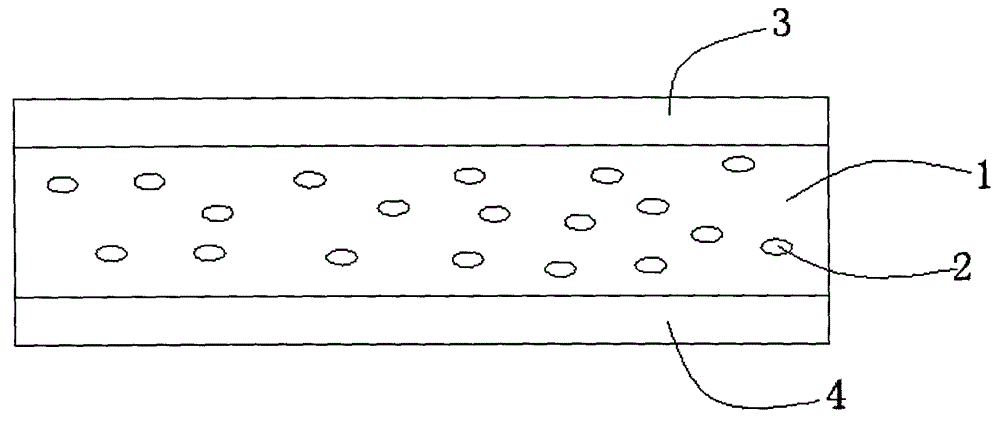

Low-warpage UV-resistant reflective film and its preparation method

ActiveCN103552328AAchieve aging effectInsulationLamination ancillary operationsMirrorsGlycidyl methacrylateMicrobubbles

A low-warpage UV-resistant reflective film comprises a core layer. microbubbles are distributed inside the core layer. The core layer is composed of PET, TOPAS6013 produced by Polyplastics Co., Ltd., an ethene-ethyl acrylate-glycidyl methacrylate triblock copolymer and titanium dioxide particles. The low-warpage UV-resistant reflective film also comprises an upper surface layer and a lower surface layer. The upper and lower surface layers are composed of poly2,6-ethylene naphthalate, titanium dioxide and silicon dioxide. The preparation method comprises the following steps: the mixed upper surface layer material, the mixed lower surface layer material and the mixed core layer material are dried respectively, and then are extruded by a single screw extruder respectively, and after coextrusion of the extruded upper surface layer material, the extruded lower surface layer material and the extruded core layer material, the coextrusion materials are drawn longitudinally and then are drawn horizontally. The Low-warpage UV-resistant reflective film can be protected from ultraviolet irradiation, thus avoiding warpage phenomenon. In addition, the aging problem caused by ultraviolet irradiation is avoided.

Owner:NINGBO DXC NEW MATERIAL TECH

Mould for molding super-thin soft ferrite magnetic core

ActiveCN101700673AUniform densityAvoid warping and deformationCeramic extrusion diesHigh densityHigh volume manufacturing

The invention discloses a mould for molding a super-thin soft ferrite magnetic core, comprising a case mould which is provided with a nib. The mould is characterized in that the edge of the nib is provided with a material spraying slot; by adopting the invention, powder at a higher density part in molding process can be sprayed out by the material spraying slot, thereby ensuring uniform density of each part when molding above products, avoiding or maximally reducing poor buckling deformation generated by density difference, thus reaching the purpose of massively producing super-thin soft ferrite magnetic core with the height less than 0.5mm. The mould has simple design, does not change original operation mode, has no need of specifically training operating personnel and does not increase manufacturing cost.

Owner:中山市华佑磁芯材料有限公司

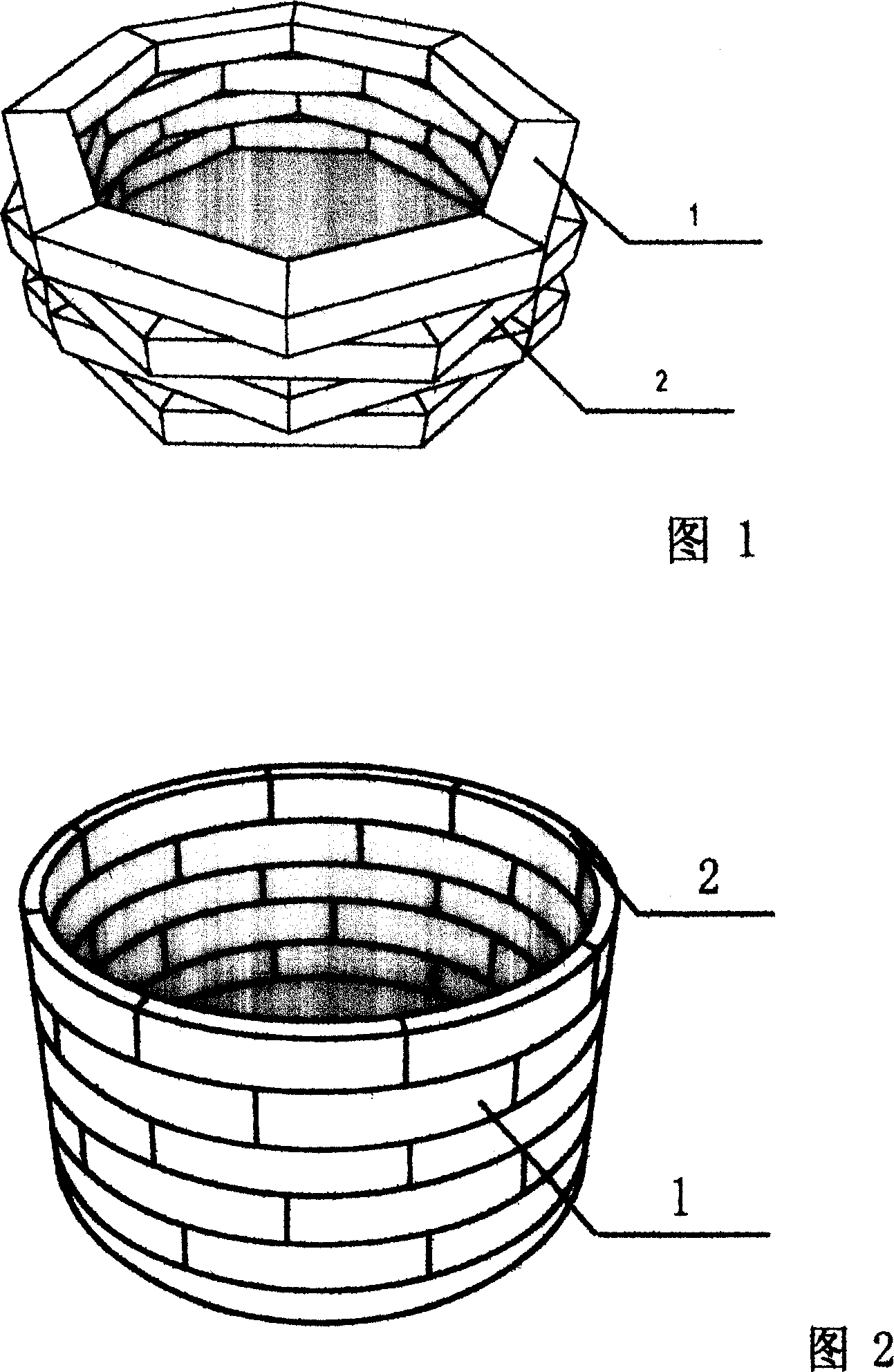

Wooden container making process

InactiveCN101088726AAvoid crackingPrevent deformation and warpingWood working apparatusMechanical engineeringEngineering

The wooden container is made of several layers of wooden loops through offset superposing and adhering, and each of the wooden loops is formed with spliced and adhered wooden sheets and has regular shape.

Owner:松阳县宝森制刷厂(普通合伙)

A low-noise air pump

ActiveCN103452806BReduce running noisePrevent warping and deformationPositive displacement pump componentsPositive-displacement liquid enginesLow noiseAir pump

Owner:XIAMEN KOGE MICRO TECH

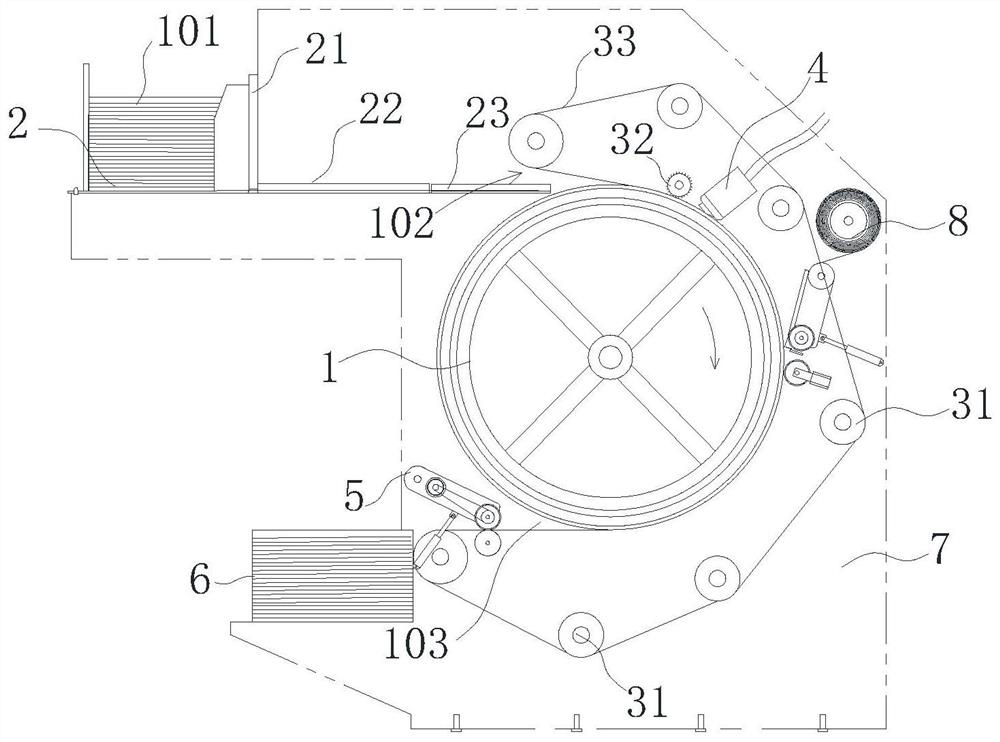

Creasing method and equipment for corrugated boards

PendingCN113306197ARapid indentation processingNo need for frequent handlingPaper-makingBox making operationsCardboardEngineering

The invention provides a creasing method and equipment for corrugated boards. The creasing method comprises the following steps that the corrugated boards are conveyed one by one at a constant speed; the corrugated boards are turned over from top to bottom, glue spreading and film covering are sequentially carried out on the film covering surfaces of the corrugated boards in the turning-over process, the corrugated boards are finally turned over by 180 degrees, and the mode that the film covering surfaces face upwards is changed into the mode that the creasing surfaces face upwards; continuous creasing lines are processed on the creasing surfaces of the corrugated boards; and the paperboards subjected to creasing processing are stacked. According to the creasing method, the compressive strength of the creasing parts of the corrugated boards is improved, rapid creasing processing of the corrugated boards is achieved, the degree of automation of the creasing equipment is high, frequent carrying of the corrugated boards is not needed, the labor intensity is reduced, and the processing efficiency is improved.

Owner:朱梁帅

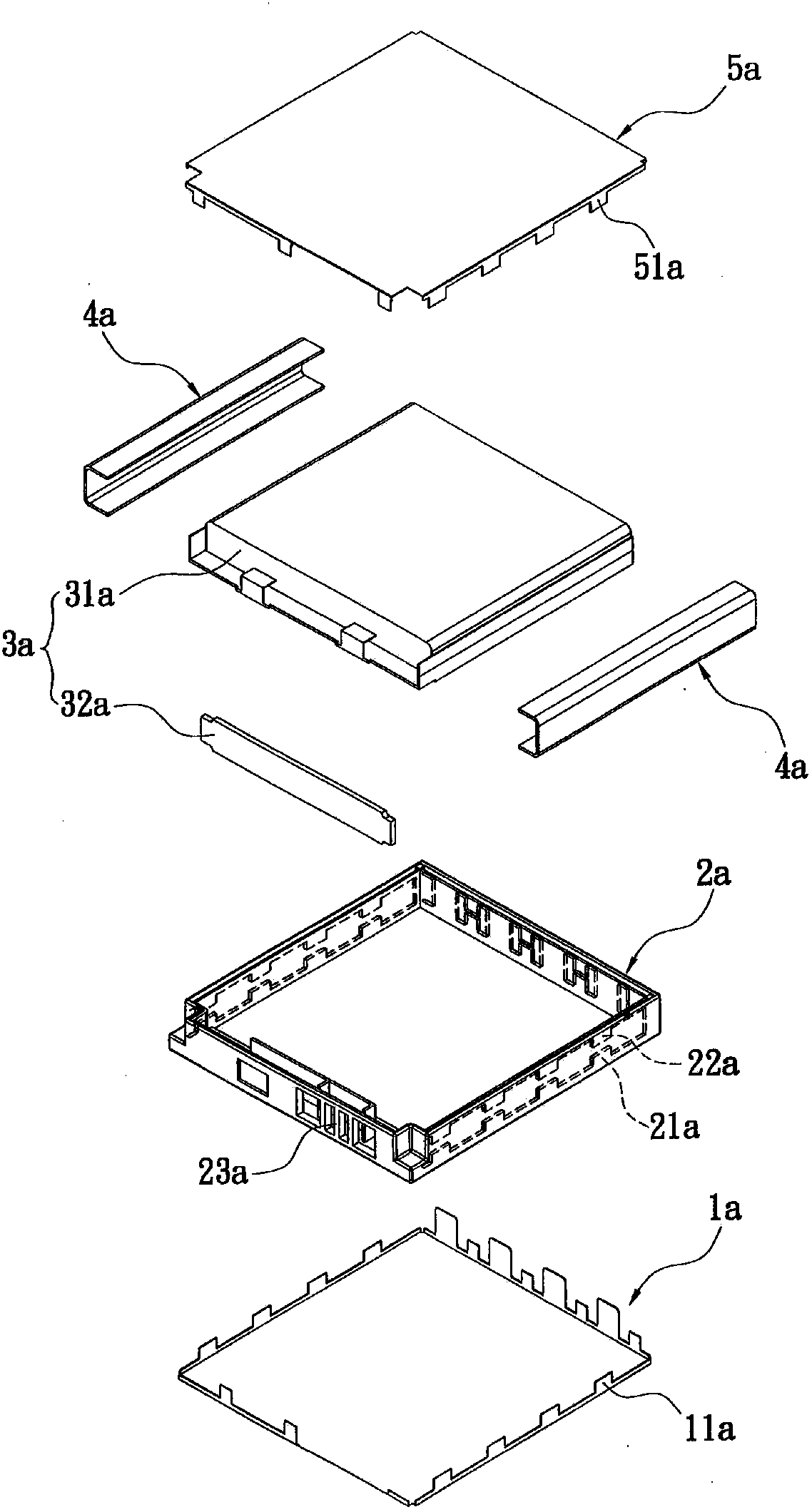

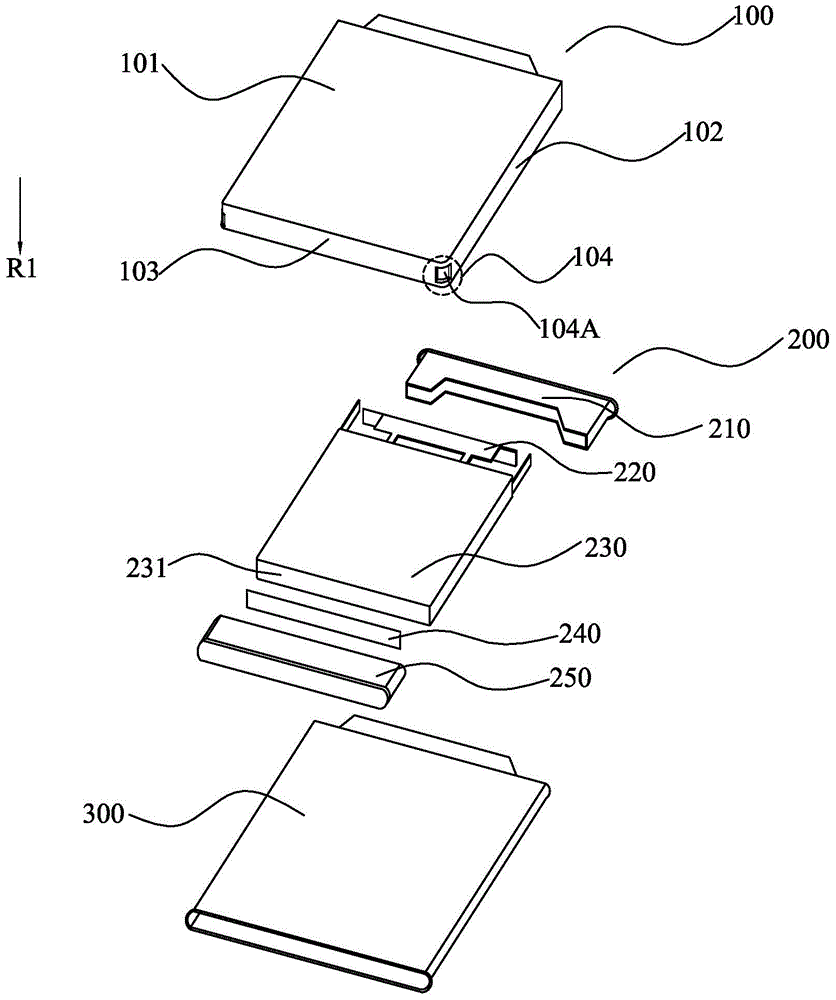

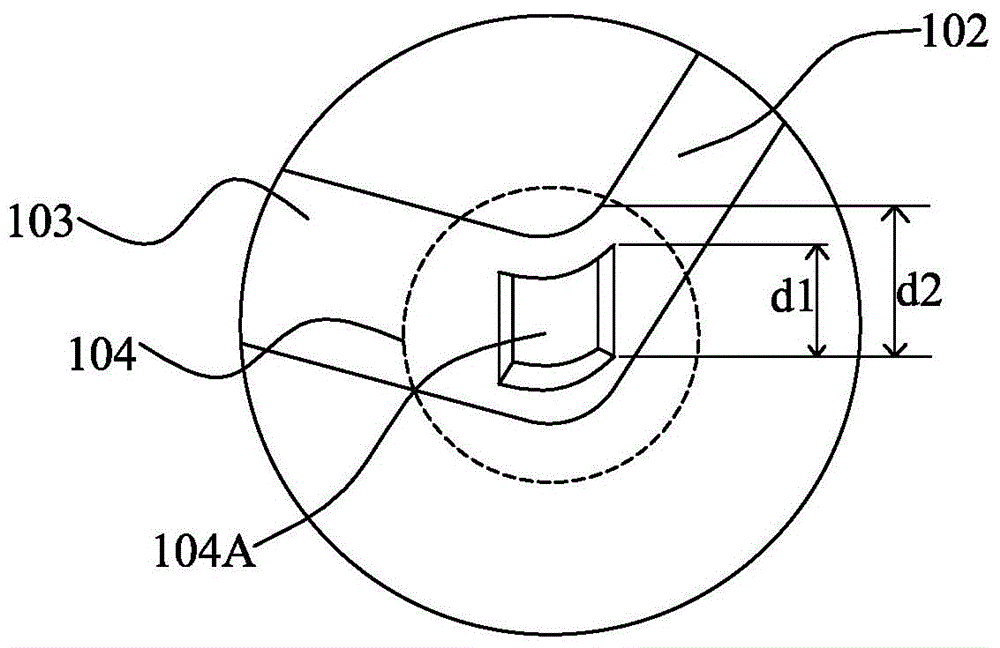

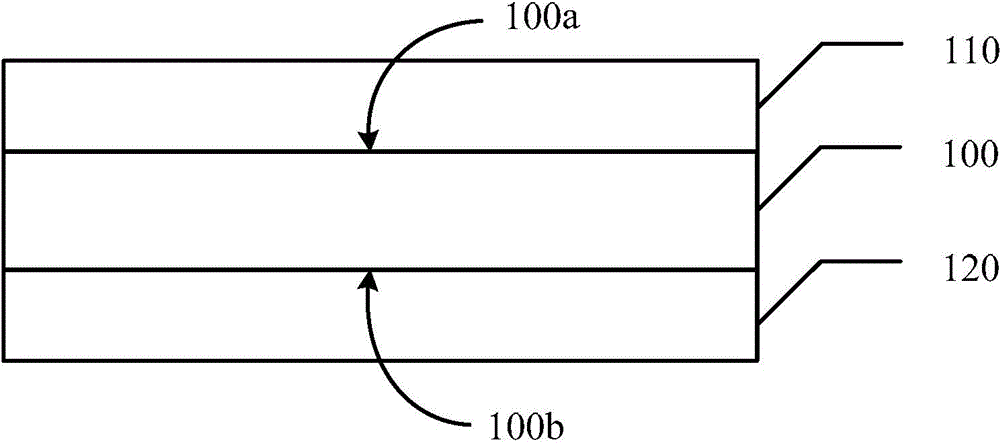

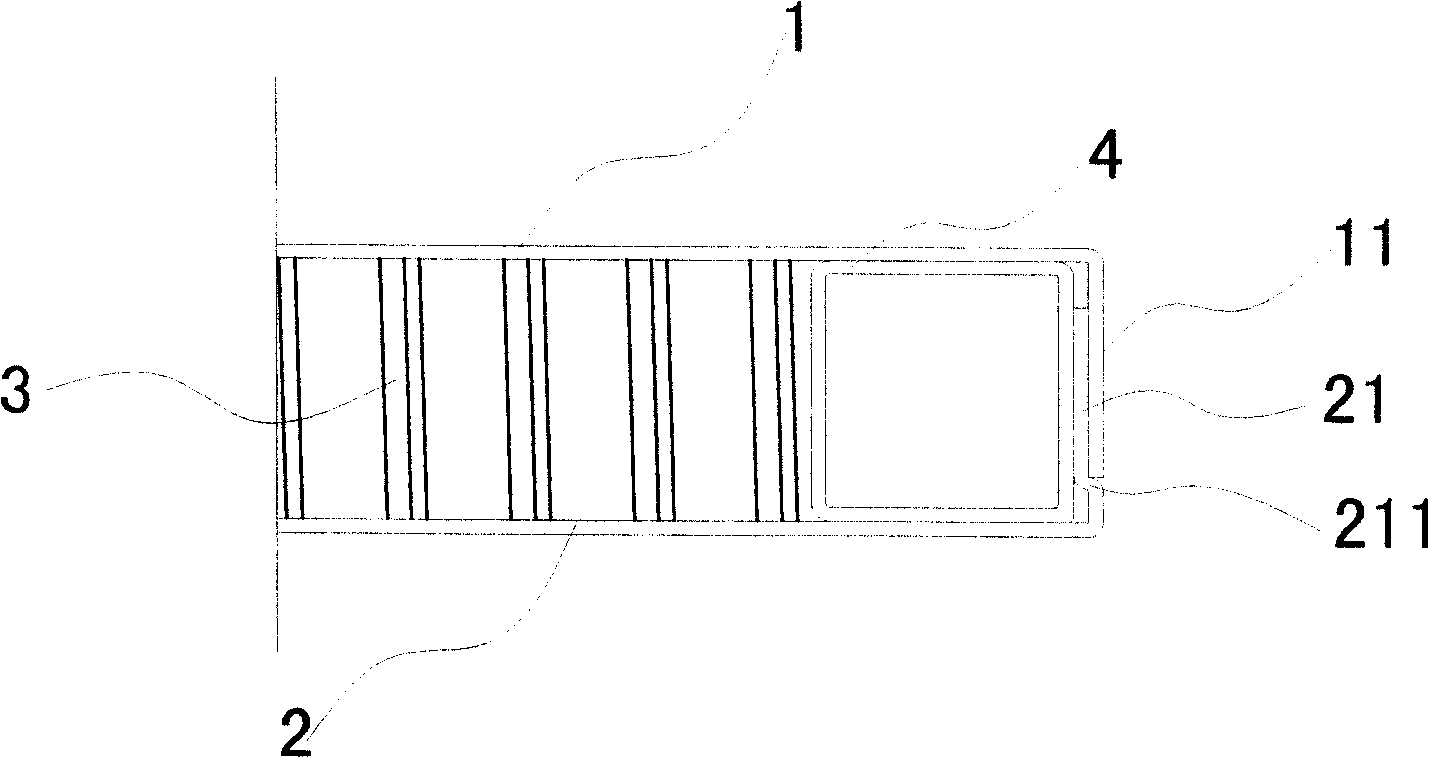

Combinational battery

InactiveCN103441226AImprove packaging securityPackaging Safety GuaranteeCell component detailsEngineeringCell assembly

The invention relates to a combinational battery. The combinational battery comprises a cell assembly and a first shell, wherein the first shell covers the outer surface of the cell assembly and comprises a first substrate, a first side wall and a second side wall; the first side wall extends from a first edge of the first substrate along a first direction, and the first direction is vertical to the direction of the first substrate; the second side wall extends from a second edge of the first substrate along the first direction, the first edge and the second edge are arranged on different sides of the first substrate and adjacent to each other, the first side wall is adjacent to the second side wall and connected with the second side wall, the first side wall is provided with a first connecting part, the first connecting part is provided with a first through hole which runs through from the outer side of the first connecting part to the inner side of the first connecting part, so that the first side wall is partially connected with the second side wall. The connecting part is arranged between the side walls of the shell, so that the side walls are partially connected with each other, the upwarp and deformation of the side walls of the shell when the battery is impacted by an external force can be avoided, and the packaging safety of the battery can be improved.

Owner:QISDA SUZHOU +1

Barrier plate assembly of folding machine

InactiveCN102616604AFolding accuracy guaranteePrevent warping and deformationFolding thin materialsArticle deliveryEngineeringMechanical engineering

The invention discloses a barrier plate assembly of a folding machine, which comprises a short barrier plate, at least one long barrier plate and a pair of support plate, wherein each support plate is provided with a long barrier plate support face and a short barrier plate support face which are arranged in parallel, two sides of the long barrier plate are supported by a pair of long barrier plate support faces, two sides of the short barrier plate are supported by a pair of short barrier plate support faces, and each long barrier plate support face is provided with an extending section which extends upwards and is capable of reducing the overhanging quantity of the long barrier plate. Through adoption of the barrier plate assembly of the folding machine, the barrier plates can be positioned accurately and can be prevented from tilting and deforming, the overhanging vibration is reduced and the folding accuracy can be improved.

Owner:长沙奥托机械股份有限公司

An insect-proof wood-plastic floor

ActiveCN107386585BImprove comfortGuaranteed service lifeCovering/liningsAnimal repellantsMicroorganismEngineering

The invention discloses a novel insect-proof wood-plastic flooring. The novel insect-proof wood-plastic floor comprises a base material layer. A plurality of sets of hemispheric filled holes in are formed in the upper surface of the base material layer. A corresponding layer is arranged on the upper portion of the base material layer. A plurality of sets of hemispheric filled grooves are formed in the lower surface of the corresponding layer. The multiple sets of filled holes and the filled grooves are in one to one correspondence. Elastic traditional Chinese medicine pills are arranged between the multiple sets of filled holes and the filled grooves. A tough layer is arranged on the corresponding layer. An abrasion resistant layer is arranged on the upper portion of the tough layer. A supporting layer is arranged at the bottom of the base material layer. According to the novel insect-proof wood-plastic flooring, a product is simple in structure and soft and comfort in texture, breeding of germs and microorganisms can be inhibited effectively, the family environment is protected effectively, and the impact resistance is achieved.

Owner:舒城欧舍丽新材料科技有限公司

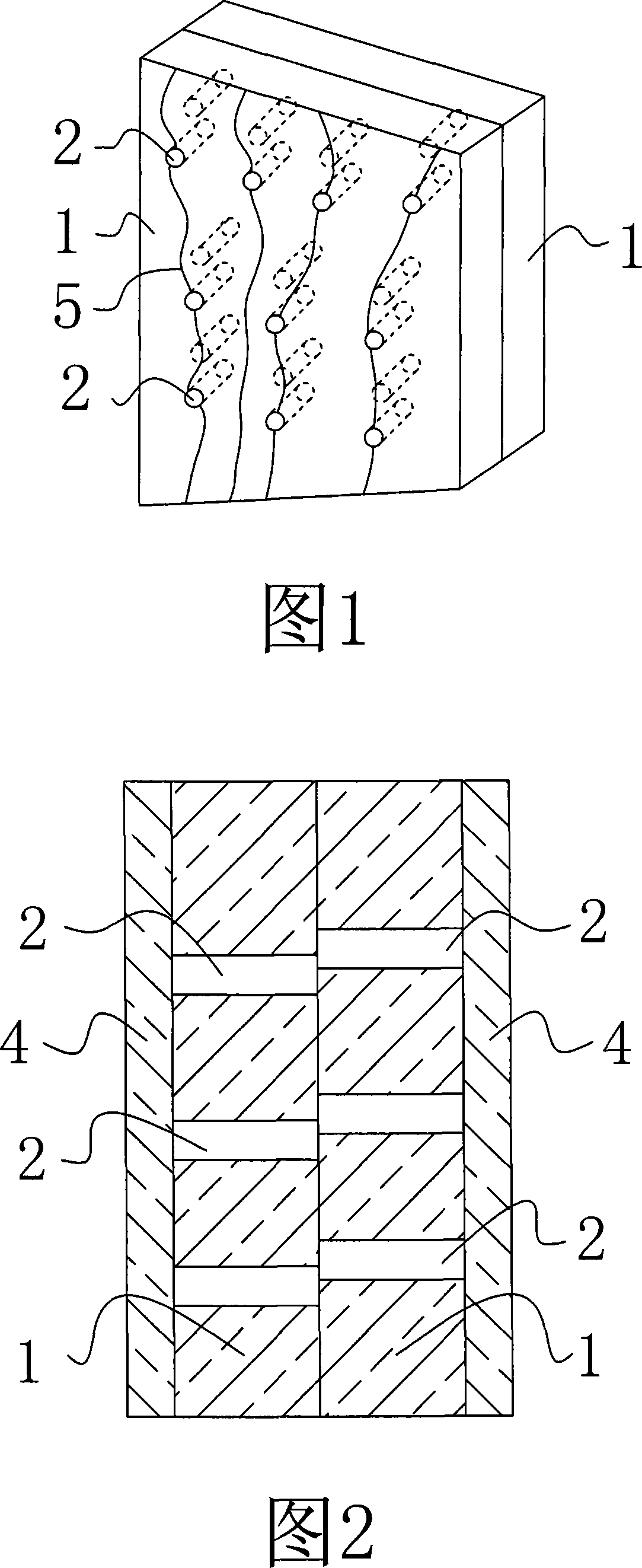

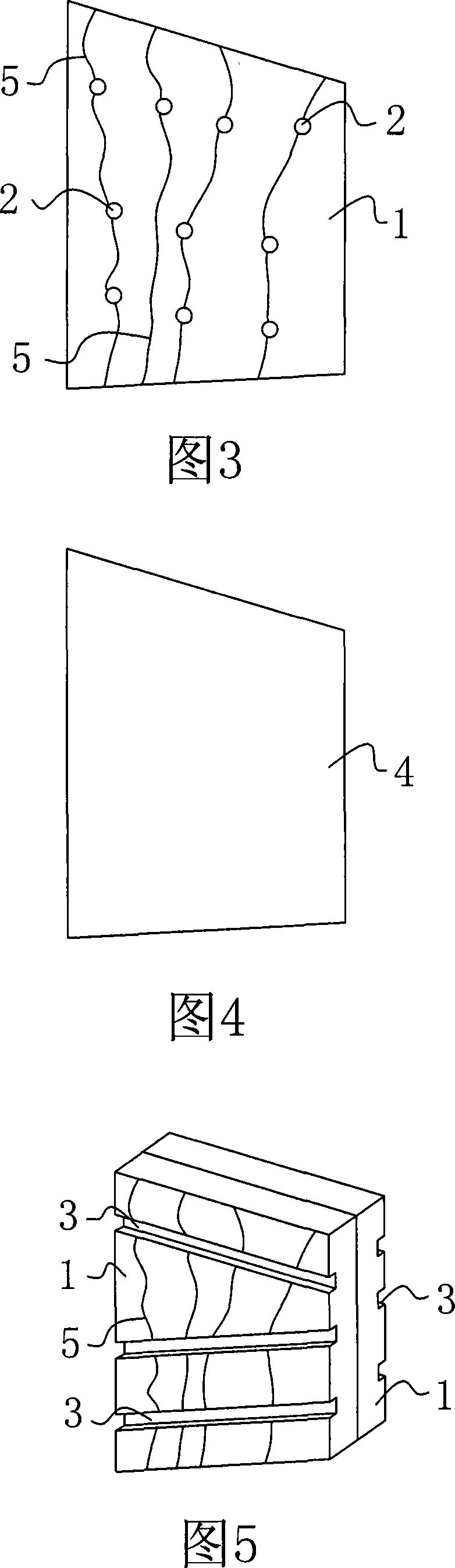

Assemble timber

InactiveCN101239476AReduce internal stressPrevent warping and deformationWood veneer joiningEngineeringUltimate tensile strength

Disclosed is a sectional wood including wood board, characterized in that at least two wood boards with each one having at least one hole or recess which is arranged in a crossing manner with respect to the direction of textures in the wood board are provided, and two adjacent boards are adhered to each other tightly. Owing to the structure, the invention has properties in avoiding natural cracking and warping tendency of the wood and improving adhesive strength between wood boards.

Owner:周有济

Novel insect-proof wood-plastic floor

ActiveCN107386585AImprove comfort performanceGuaranteed service lifeCovering/liningsAnimal repellantsEngineeringTraditional Chinese medicine

The invention discloses a novel insect-proof wood-plastic flooring. The novel insect-proof wood-plastic floor comprises a base material layer. A plurality of sets of hemispheric filled holes in are formed in the upper surface of the base material layer. A corresponding layer is arranged on the upper portion of the base material layer. A plurality of sets of hemispheric filled grooves are formed in the lower surface of the corresponding layer. The multiple sets of filled holes and the filled grooves are in one to one correspondence. Elastic traditional Chinese medicine pills are arranged between the multiple sets of filled holes and the filled grooves. A tough layer is arranged on the corresponding layer. An abrasion resistant layer is arranged on the upper portion of the tough layer. A supporting layer is arranged at the bottom of the base material layer. According to the novel insect-proof wood-plastic flooring, a product is simple in structure and soft and comfort in texture, breeding of germs and microorganisms can be inhibited effectively, the family environment is protected effectively, and the impact resistance is achieved.

Owner:舒城欧舍丽新材料科技有限公司

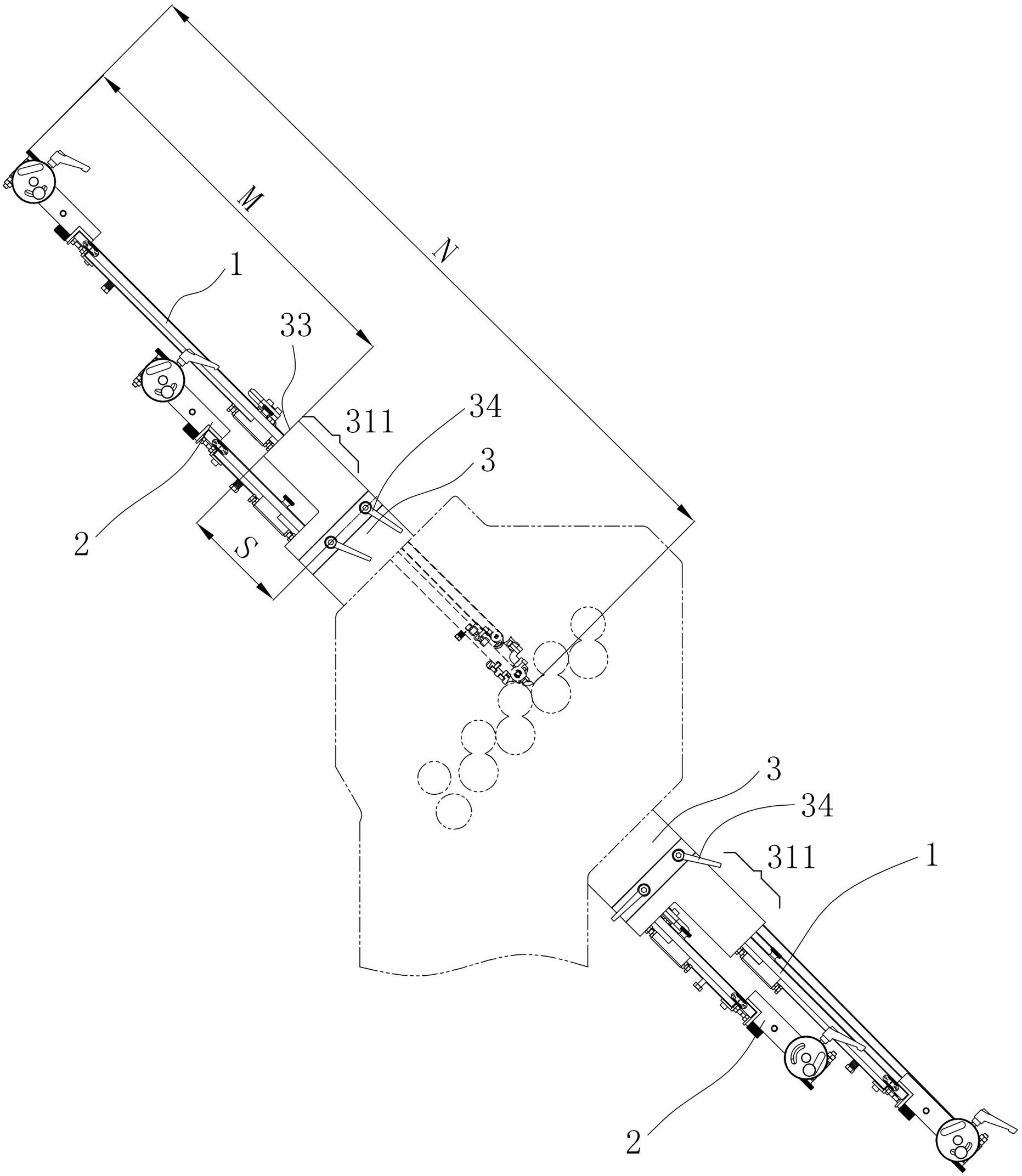

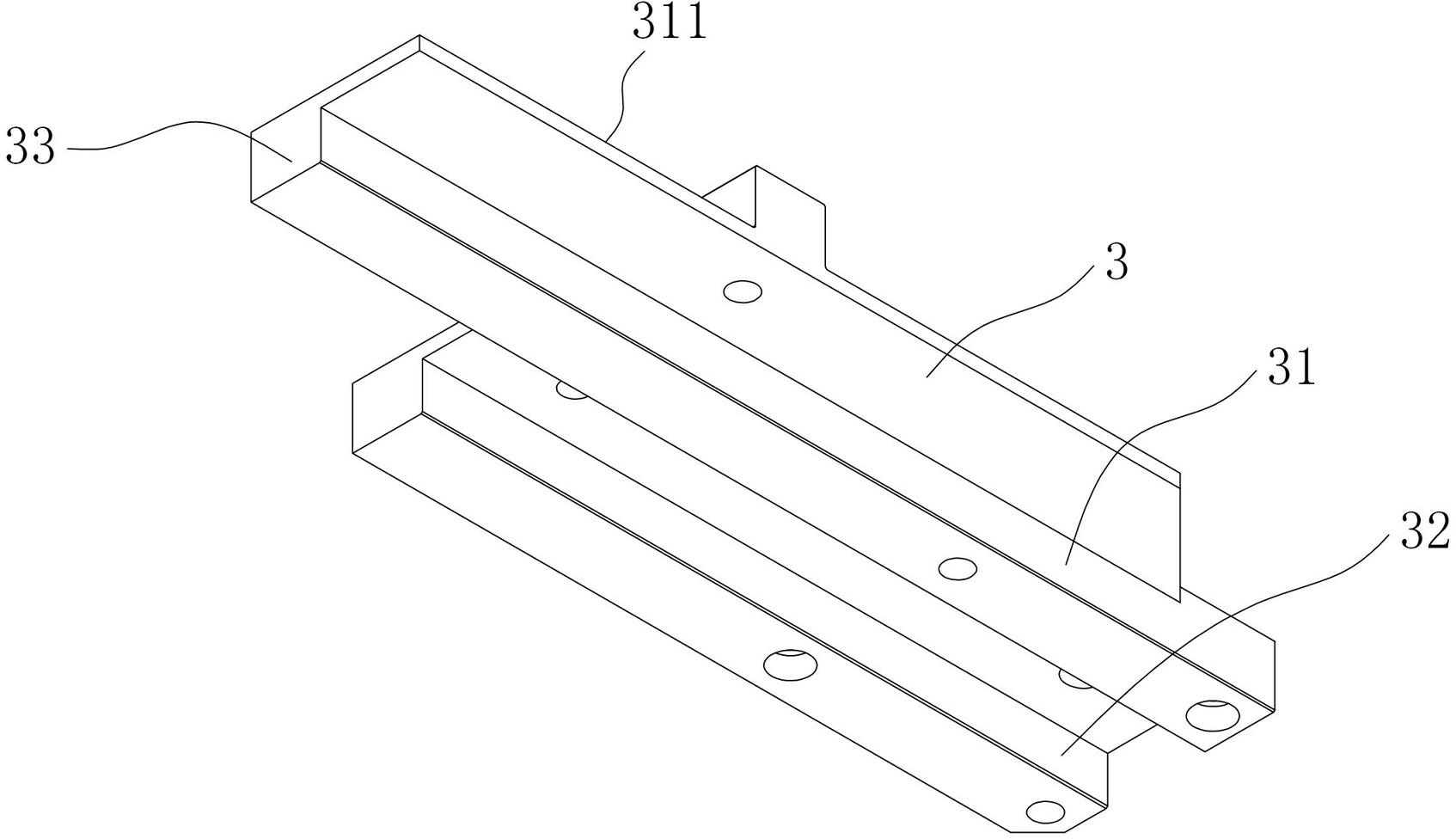

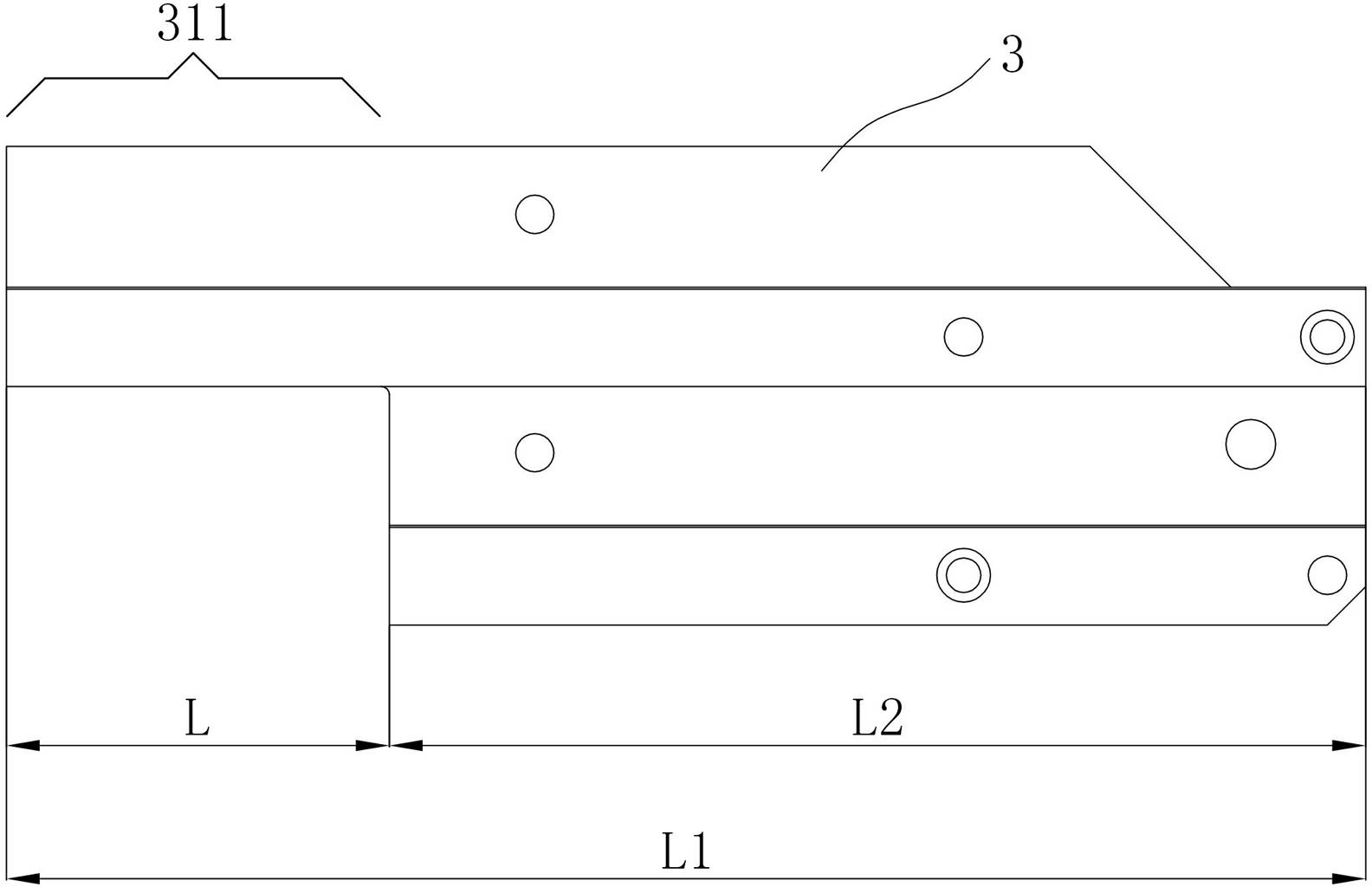

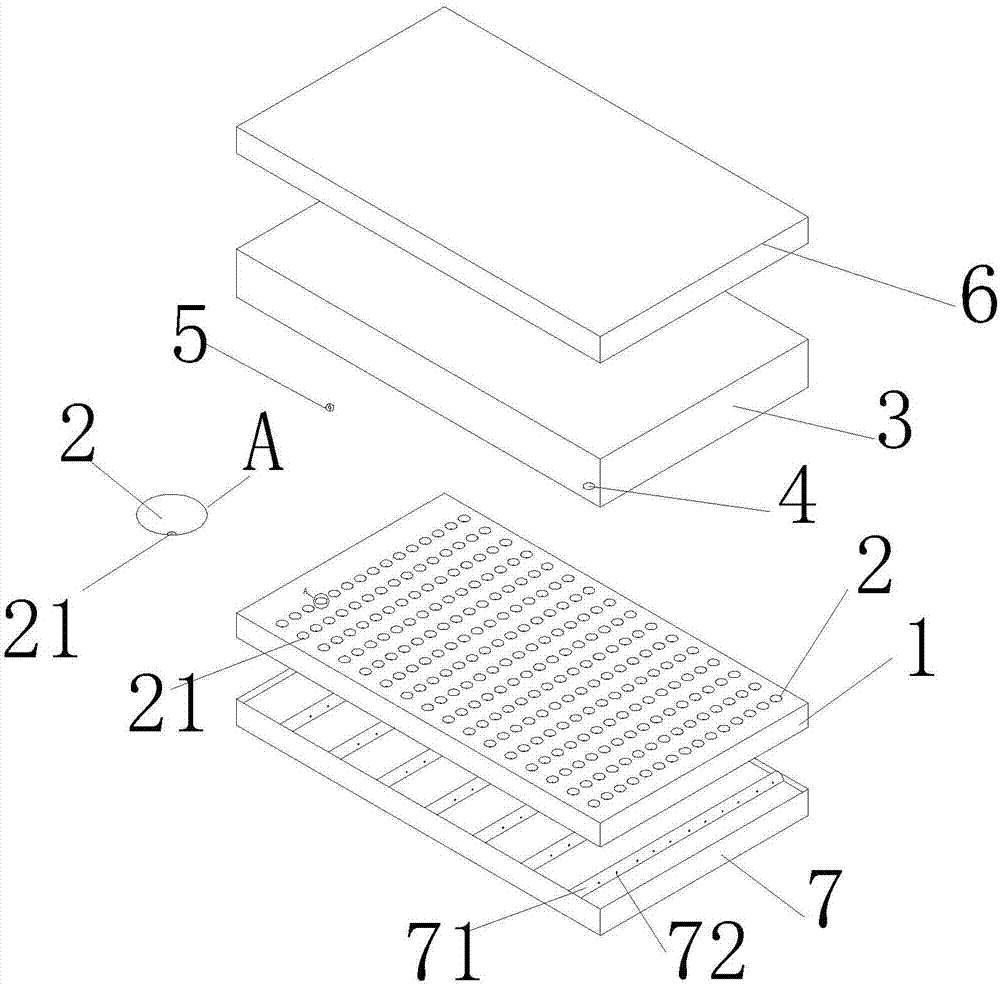

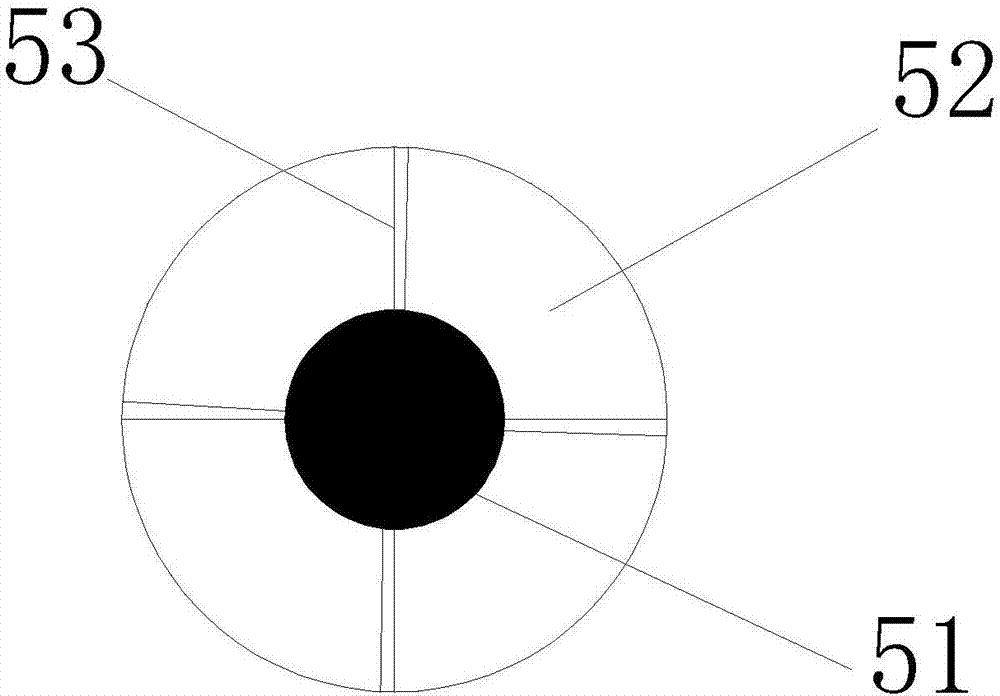

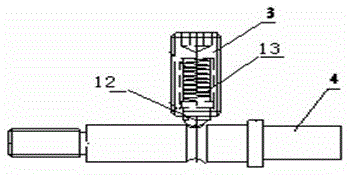

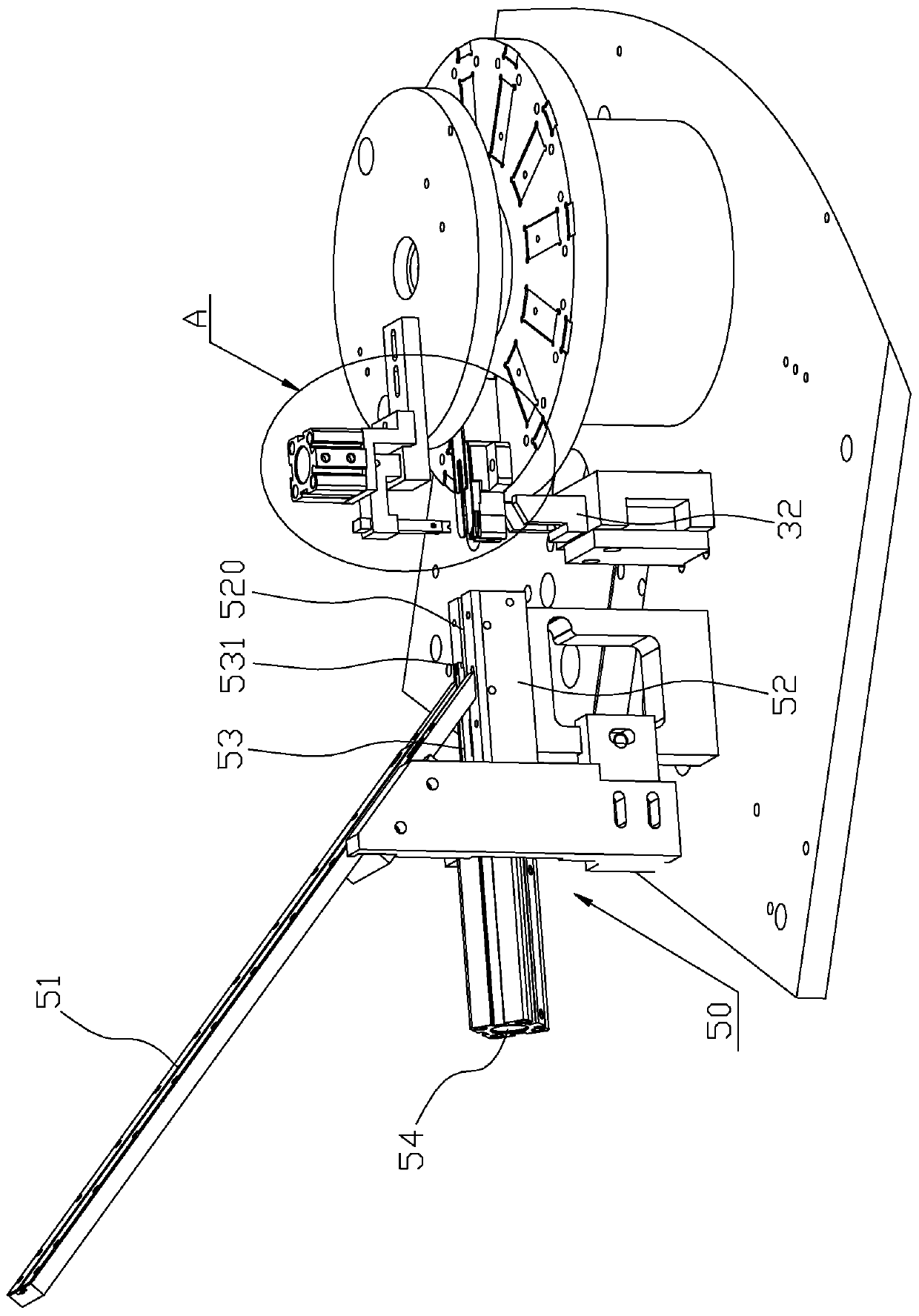

A semiconductor feeding device with anti-warping function

ActiveCN103489799BPrevent warping and deformationSemiconductor/solid-state device manufacturingConveyor partsPower semiconductor deviceWarping function

The invention provides a semiconductor charging device capable of effectively preventing the buckling deformation of a plastic-packaged lead frame in a processing process. The semiconductor charging device comprises an open type charging track and a pushing device, wherein the cavity of the charging track is matched with the plastic-packaged lead frame; one end of the charging track is provided with a limited block; the pushing device comprises a push rod, a push rod installation block, a sensor, a roller, a follower and a conveying fixed plate; a push rod connecting rod is elastically connected with the push rod installation block through an elastic screw plug, controls elastic connecting force through the elastic screw plug and keeps effective connection under the condition that the plastic-packaged lead frame is not deformed and damaged; the slant hook-shaped design of the push rod is adapted to the buckling deformation of the plastic-packaged lead frame, wherein the deformation amount of the buckling deformation is less than h. The semiconductor charging device provided by the invention enhances the stability of equipment and the perfectness ratio of a product and is convenient to operate and maintain.

Owner:TONGLING SANJIA YAMADA TECH

Comfortable wood-plastic floor

InactiveCN107489257AIncreased bending load capacityImprove comfortNon-macromolecular adhesive additivesFlooring insulationsEngineeringInverted t

The invention discloses a comfortable wood-plastic floor comprising an inverted-T-shaped base material layer. The base material layer comprises a bottom base material and a protrusion base material, and the protrusion base material is of a mutually-staggered flower cutter structure. A corresponding layer is arranged on the upper portion of the base material layer, a tough layer is arranged on the upper portion of the corresponding layer, and a sticking layer is arranged at the bottom of the base material layer. According to the comfortable wood-plastic floor, the structure is simple, convenient, practical and good in impact resistance, the upper half portion of the base material layer adopts the flower cutter structure commonly used in cooking skill, and by spraying Chinese herbal medicine components to a gap between flower cutter blocks and interiors of the flower cutter blocks, it is ensured that the wood-plastic floor has certain germ and microbe resisting effects; and the flower cutter structure is adopted, the bending load capacity of the wood-plastic floor can be greatly improved, the phenomenon of warping deformation caused by wetting can be avoided, effective damping can be achieved, the comfort of the wood-plastic floor is greatly improved, and the service life of the wood-plastic floor is ensured.

Owner:SHUCHENG ANTAI PLASTIC PROD

Manufacturing method of wooden mold core box

InactiveCN107598083AHigh surface hardnessReduce moisture contentFoundry moulding apparatusManufacturing technologyHardness

The invention discloses a manufacturing method of a wooden mold core box, and relates to the technical field of mold manufacturing. The manufacturing method of the wooden mold core box comprises the following steps that A, raw material treatment is conducted; B, preservative treatment is conducted; C, splicing molding is conducted; and D, fixed finishing is conducted. In the step D, connecting pieces used for fixing are wooden nails, the outer surfaces of the wooden nails are sleeved with wooden nail sleeves with the sizes being 1.1-1.3 times that of the wooden nails, and the wooden nail sleeves are made of resin or rubber. According to the wooden mold core box manufactured through the manufacturing method, compared with the prior art, the surface hardness of the wooden mold core box can be improved, the water content is low, deformation damage is not easy to occur, the probability of being affected by changing of the temperature and the humidity is greatly reduced, corrosion is not easy to occur, the service life of the wooden mold core box is improved, and the cost is reduced.

Owner:河池市一森机械有限责任公司

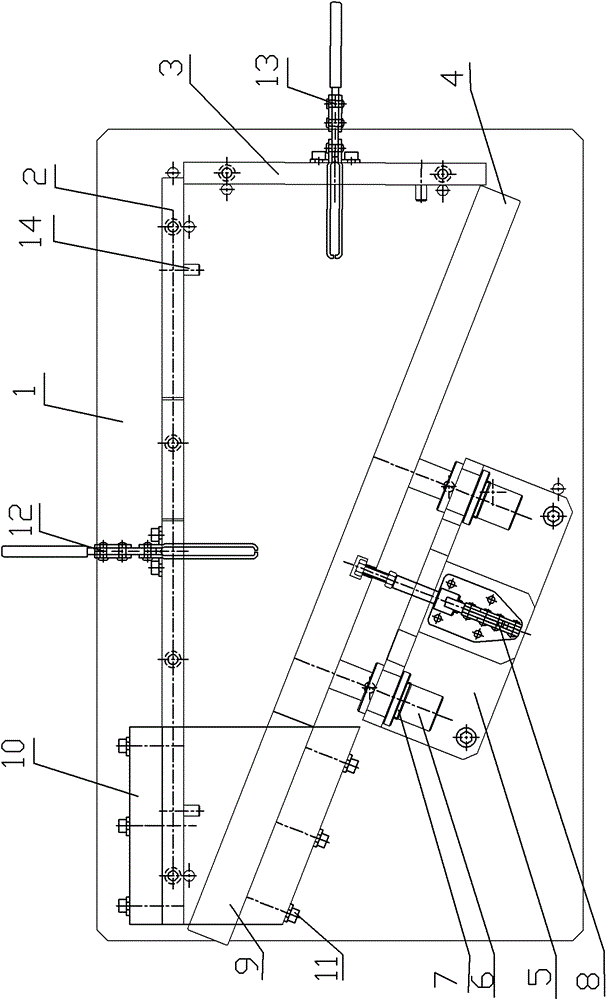

Laser welding jig of triangular titanium alloy covering and skeleton weld assembly

ActiveCN102009272BReduce labor intensityPrevent warping and deformationWelding/cutting auxillary devicesAuxillary welding devicesTitanium alloyLaser

A laser welding jig of a triangular titanium alloy covering and skeleton weld assembly relates to a laser welding jig. The invention aims to solve the existing problem that the front tip of the triangular titanium alloy covering and skeleton weld assembly upwarps and deforms in laser welding. In the laser welding jig, a first positioning plate, a second positioning plate and a guide base are fixedly connected with a bottom plate; the first positioning plate and the second positioning plate are perpendicular to each other; a first compression quick change chuck is fixed on the guide base, the first compression quick change chuck is connected with a first pressure plate; two guide sleeves are fixedly connected with the guide base, each guide post is fixedly connected with the first pressureplate; a reinforcing frame is fixed on the first positioning plate, a second pressure plate is arranged in the reinforcing frame; the first pressure plate, the second pressure plate, the first positioning plate and the second positioning plate constitute a triangle with the same shape with the triangular titanium alloy covering and skeleton weld assembly; a second compression quick change chuck is fixed on the outside surface of the first positioning plate; and a third compression quick change chuck is fixed on the outside surface of the second positioning plate. The laser welding jig in the invention is used for the laser welding of the triangular titanium alloy covering and skeleton weld assembly.

Owner:哈尔滨工大焊接科技有限公司

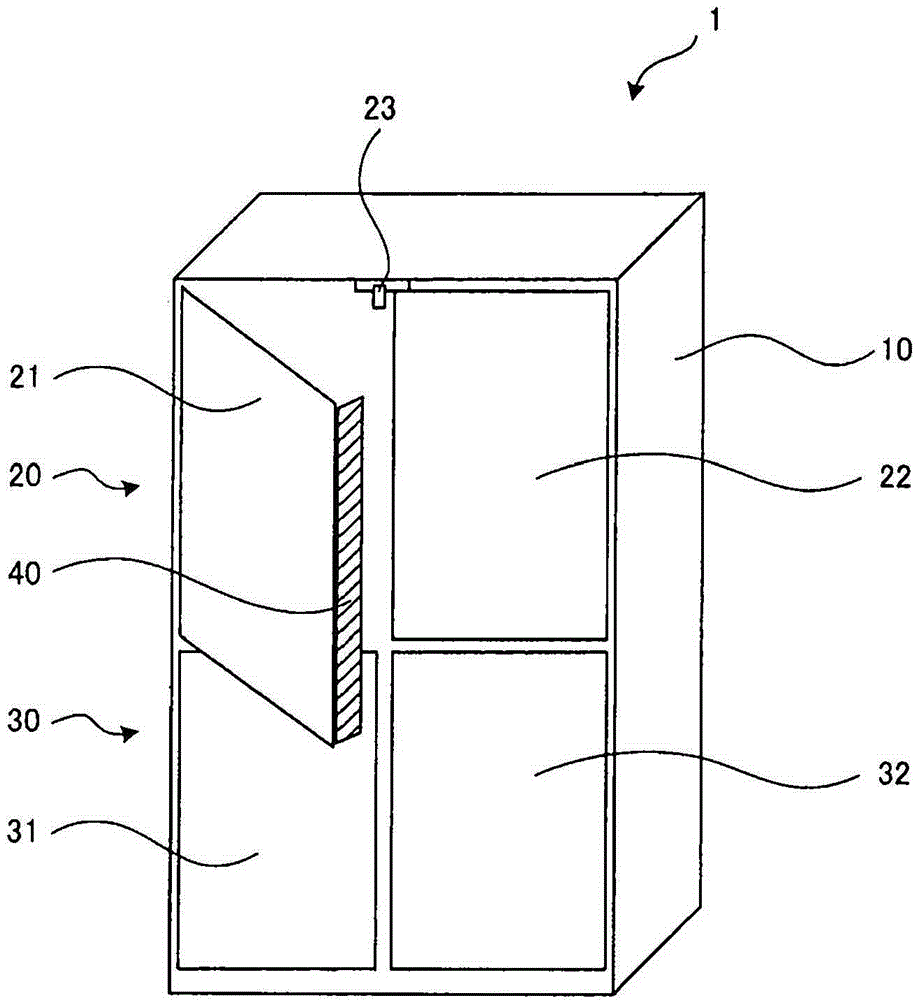

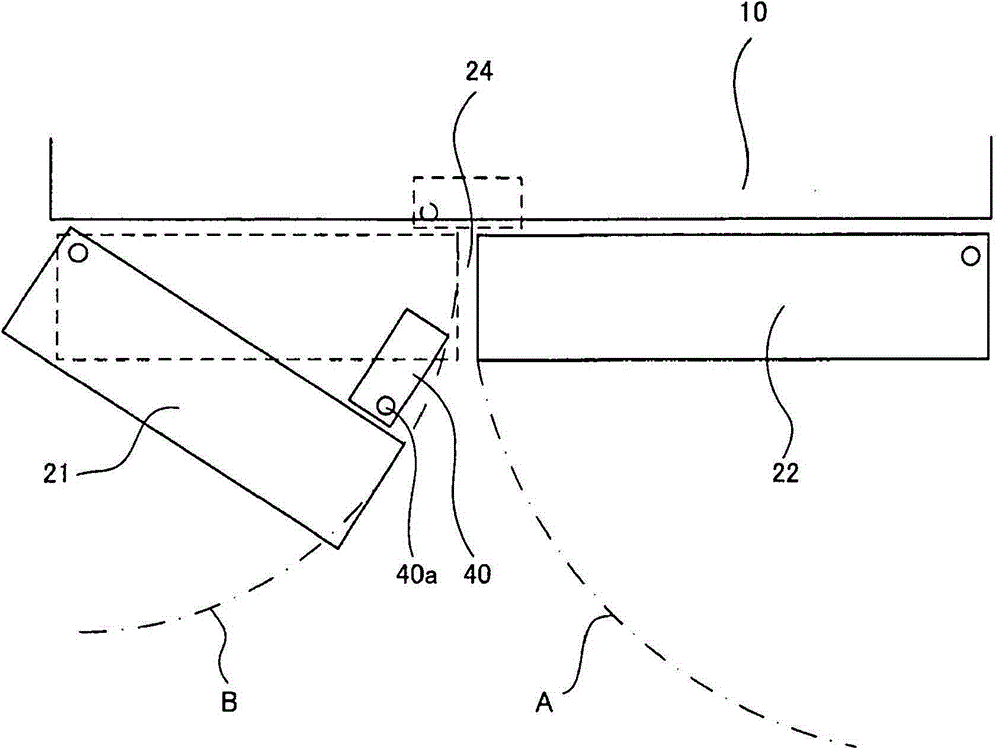

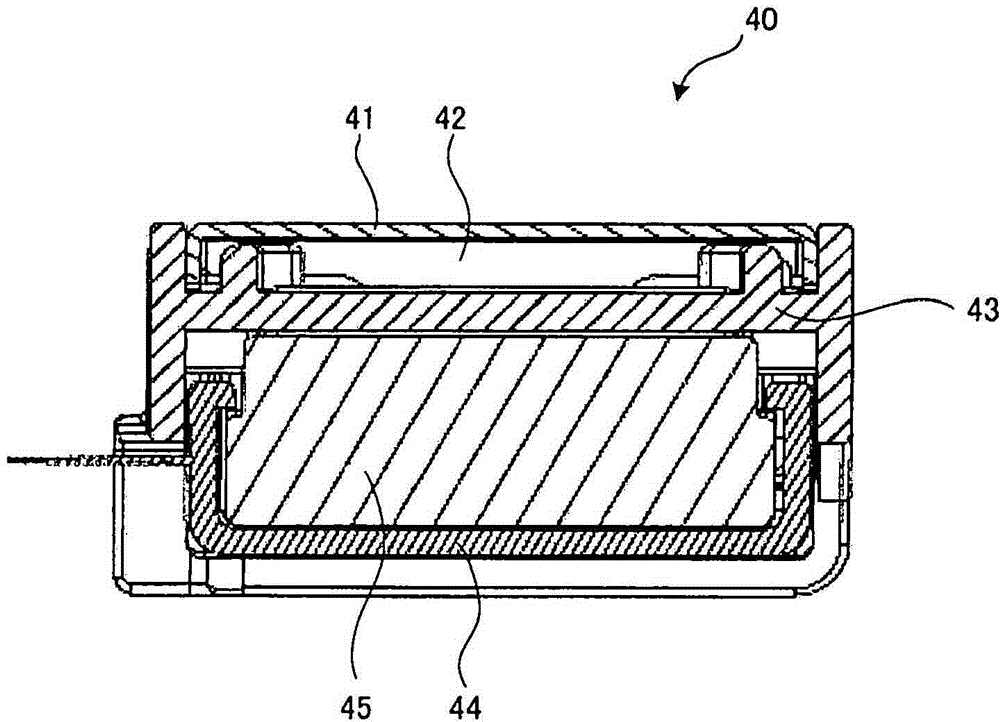

Cold Storage

InactiveCN104034117APrevent warping and deformationReduce gapLighting and heating apparatusCooling fluid circulationEngineeringMechanical engineering

A cold storage is provided with: a heat-insulating box (10) which is open at the front; a left door (21) and a right door (22), which swing open from the center and which open and close the opening; a partition body (40) which is rotatably attached through a hinge member to a portion of the free end of the left door (21), the portion facing the inside of the cold storage, and which closes the gap (24) between the left door (21) and the right door (22); and condensation-preventing heater (42) which prevents condensation from forming on the partition body (40). The partition body (40) is provided with: a front face-side member (43) which is disposed on the gap (24) side and to which the condensation-preventing heater (42) is provided; a back face-side member (44) which is fitted to the front face-side member (43) so as to be capable of sliding in the longitudinal direction and which forms a cylindrical body in cooperation with the front face-side member (43); and a heat-insulating material (45) which is provided within the cylindrical body.

Owner:MITSUBISHI ELECTRIC CORP

Combined battery

InactiveCN103441226BImprove packaging securityPackaging Safety GuaranteeCell component detailsEngineeringStructural engineering

The present invention relates to a combined battery, which includes: a cell assembly; and a first casing, which is coated on the outer surface of the cell assembly, and the first casing includes: a first substrate; a first side wall, extending from a first edge of the first substrate along a first direction, wherein the first direction is a direction perpendicular to the first substrate; and a second sidewall extending from a second edge of the first substrate along the first direction Extending, the first edge and the second edge are located on different sides of the first substrate and adjacent to each other, the first side wall is adjacent to and connected to the second side wall and has a first connection portion, and the first connection The portion has a first through hole penetrating from the outer side of the first connecting portion to the inner side of the first connecting portion, so that the first side wall part is connected with the second side wall part. In the present invention, the connecting portion is provided between the side walls of the casing to partially connect the side walls, which prevents the side walls of the casing from warping and deforming when the battery is impacted by an external force, thereby improving the safety of the battery package.

Owner:QISDA SUZHOU +1

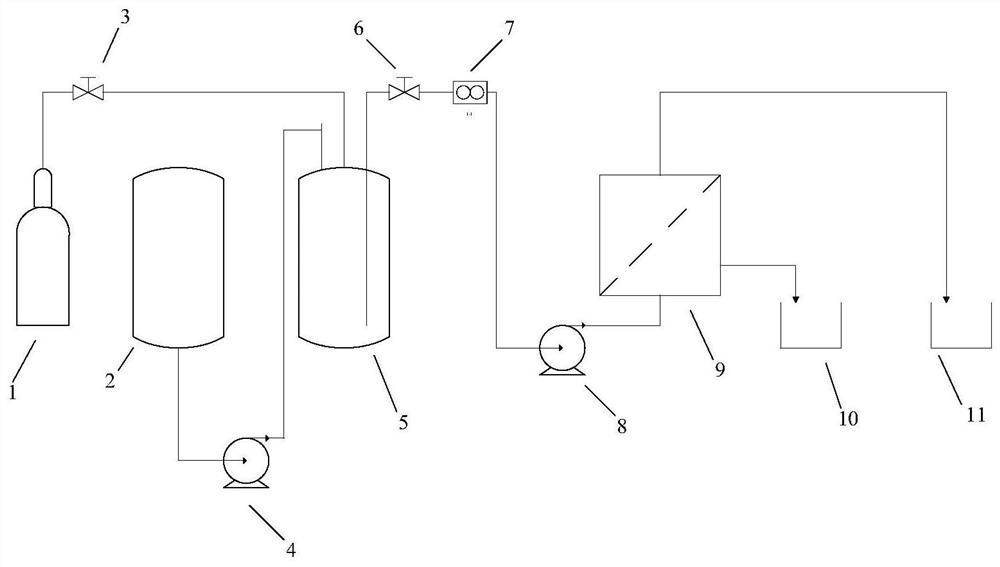

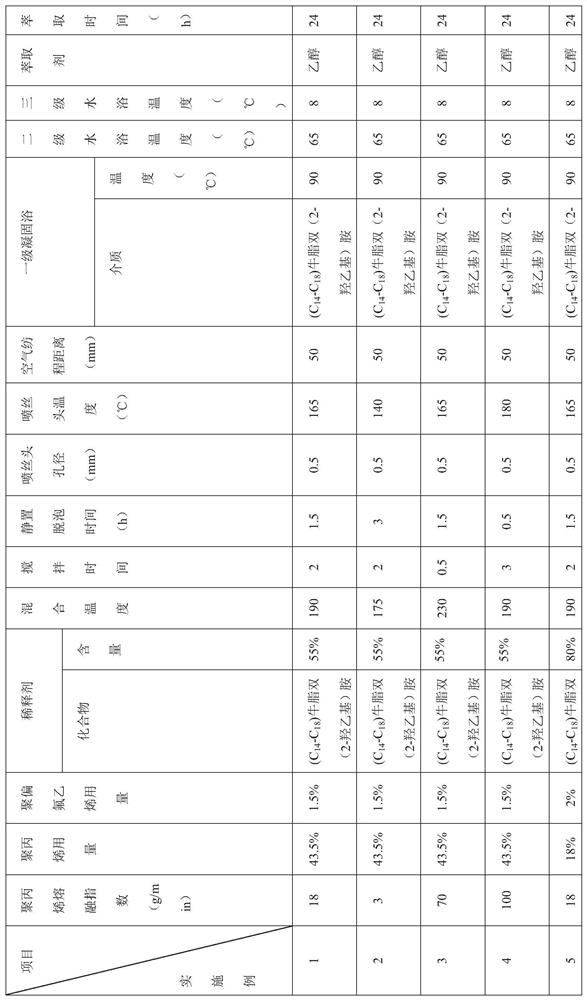

Preparation method and application of fiber material for oil-water separation

ActiveCN112442750AImprove mechanical propertiesExcellent thermalFatty/oily/floating substances removal devicesLiquid separationFiberSpinning

The invention discloses a preparation method of a fiber material for oil-water separation and the fiber material prepared by the method. The preparation method includes the steps of S1, carrying out spinning treatment on a mixture containing polypropylene, polyvinylidene fluoride and a diluent to obtain nascent fibers; S2, enabling the nascent fiber to pass through an air spinning path of 10-100 mm; S3, cooling the nascent fibers obtained in the step S2 to obtain fiber filaments; and S4, carrying out extraction treatment on the fiber filaments to obtain the fiber material. The preparation method of the fiber material for oil-water separation is simple and convenient in process and short in production path, and the fiber material prepared by the method is moderate in aperture, high in mechanical strength, excellent in separation performance, applied to oil-water separation and high in separation efficiency. The invention also provides a device for oil-water separation. The device is simple in structure and low in power consumption, and has no need of adding any medicament, favorable removal effect on oil stains in sewage, low pollution and favorable application prospects in the field of oily sewage treatment.

Owner:CHINA PETROLEUM & CHEM CORP +1

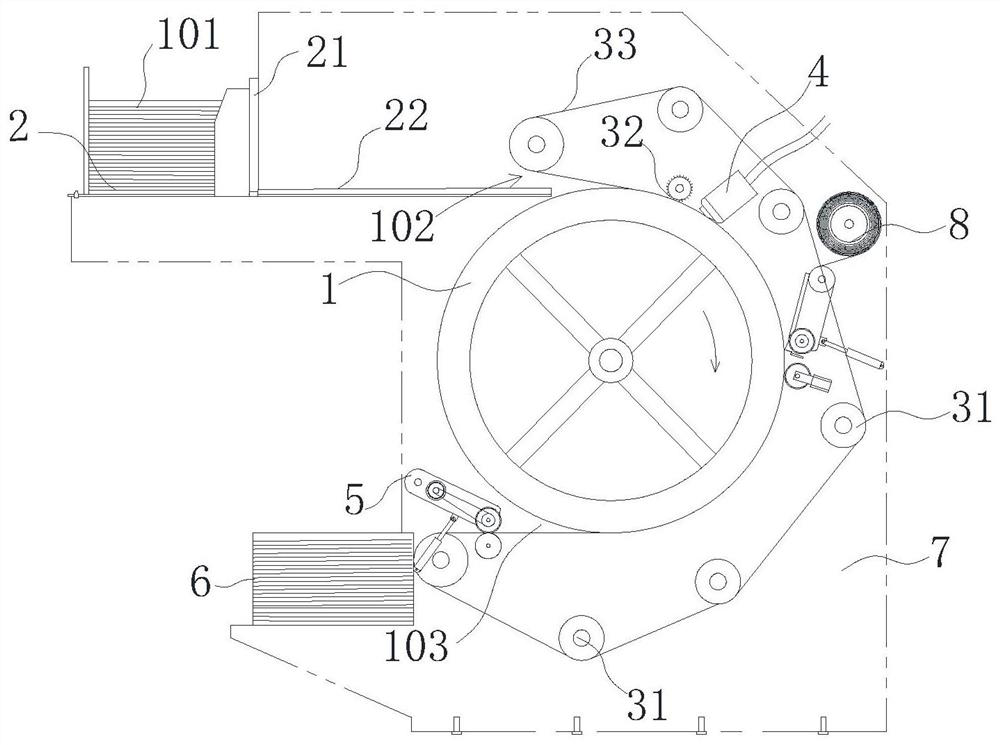

Indentation equipment suitable for corrugated boards with different thicknesses

ActiveCN113334852ARapid indentation processingNo need for frequent handlingBox making operationsPaper-makingCompressive resistancePaperboard

The invention discloses indentation equipment suitable for corrugated boards with the different thicknesses. A conveying device is used for conveying the corrugated boards from top to bottom and turning over the corrugated boards by 180 degrees in the conveying process, so that the corrugated boards are turned over from the upward film covering face to the upward indentation face, and the corrugated boards are conveyed to an indentation station; and a gluing device and a film covering device are used for conducting gluing and film covering on the corrugated boards in the turnover process of the corrugated boards. The conveying device comprises a conveying roller, a plurality of guide wheels and a plurality of conveying belts; the outer diameter of the conveying roller is adjustable; and a gap used for clamping the corrugated boards is formed between the conveying belts and the conveying roller, a paperboard inlet and a paperboard outlet are formed in a matched manner, and an indentation device is located on the downstream of the paperboard outlet and comprises an indentation wheel capable of being close to or away from the conveying belt at the paperboard outlet. According to the indentation equipment, the compressive strength of the indentation parts of the corrugated boards is improved, rapid indentation processing of the corrugated boards is achieved, and the indentation equipment is high in automation degree.

Owner:钜丰智能科技有限公司

An improved airtight air pump

ActiveCN103671079BPrevent warping and deformationImprove air tightnessPositive displacement pump componentsLiquid fuel engine componentsInlet channelAir pump

The invention discloses an air pump with improved air tightness. The air pump comprises an upper cover provided with an exhaust nozzle, a gasket, human-head-shaped exhaust one-way valves, a flow distribution device and a piston assembly, wherein the gasket is provided with a first air inlet channel and a first air outlet channel, the gasket is matched with the bottom end of the upper cover in a sealed mode, an air inlet cavity and an air outlet cavity are formed between the gasket and the upper cover, the air inlet cavity and the air outlet cavity are spaced, the first air inlet channel corresponds to the air inlet cavity, the first air outlet channel corresponds to the air outlet cavity, the air outlet cavity is communicated with the exhaust nozzle of the upper cover, the human-head-shaped exhaust one-way valves are integrally connected with the lower surface of the first air outlet channel of the gasket, and the heights of top faces of the human-head-shaped exhaust one-way valves gradually reduce from inside to outside. By the adoption of the structure, the situation that the human head portions of the human-head-shaped exhaust one-way valves tilt and deform due to the fact that compression amounts of edges of the gasket are not uniform or are exceedingly large is avoided, the situation that the human head portions of the human-head-shaped exhaust one-way valves tilt and deform due to elastic fatigue after the human-head-shaped exhaust one-way valves move many times, and accordingly the air tightness of the air pump is greatly improved.

Owner:XIAMEN KOGE MICRO TECH

Manufacturing method for comfortable wood-plastic floor

InactiveCN107447950AGuaranteed against germsGuaranteed Microbial EfficacyFlooringMedicineEnergy analysis

The invention discloses a manufacturing method for a comfortable wood-plastic floor. The manufacturing method for the comfortable wood-plastic floor is complete and novel in technology, saves energy, reduces consumption and can effectively promote the product quality and increase the yield of products; finishing coat is sprayed after Chinese herbal medicine mixed liquid spraying, the situation that after the Chinese herbal medicine mixed liquid is dried, cracking of a small part cannot occur is ensured, meanwhile Chinese herbal medicine steadiness is facilitated, the effects of Chinese herbal medicines are ensured, and it is ensured that the wood-plastic floor has a certain germ-and-microorganism-resisting effect; a flower cutter structure is adopted, the bending bearing capacity of the wood-plastic floor can be greatly improved, the phenomenon of warping deformation caused by damp can be avoided, vibration can be effectively relieved, the comfortable property of the wood-plastic floor is greatly improved, and the service life of the wood-plastic floor is ensured.

Owner:SHUCHENG ANTAI PLASTIC PROD

Alloy yg head automatic pull-up sheet assembly machine

ActiveCN106141026BPrevent warping and deformationImprove pass rateSlide fastenersMetal-working feeding devicesAlloyAssembly machine

Owner:QUANZHOU LICHENG DISTRICT ZHAN AUTOMATION EQUIP

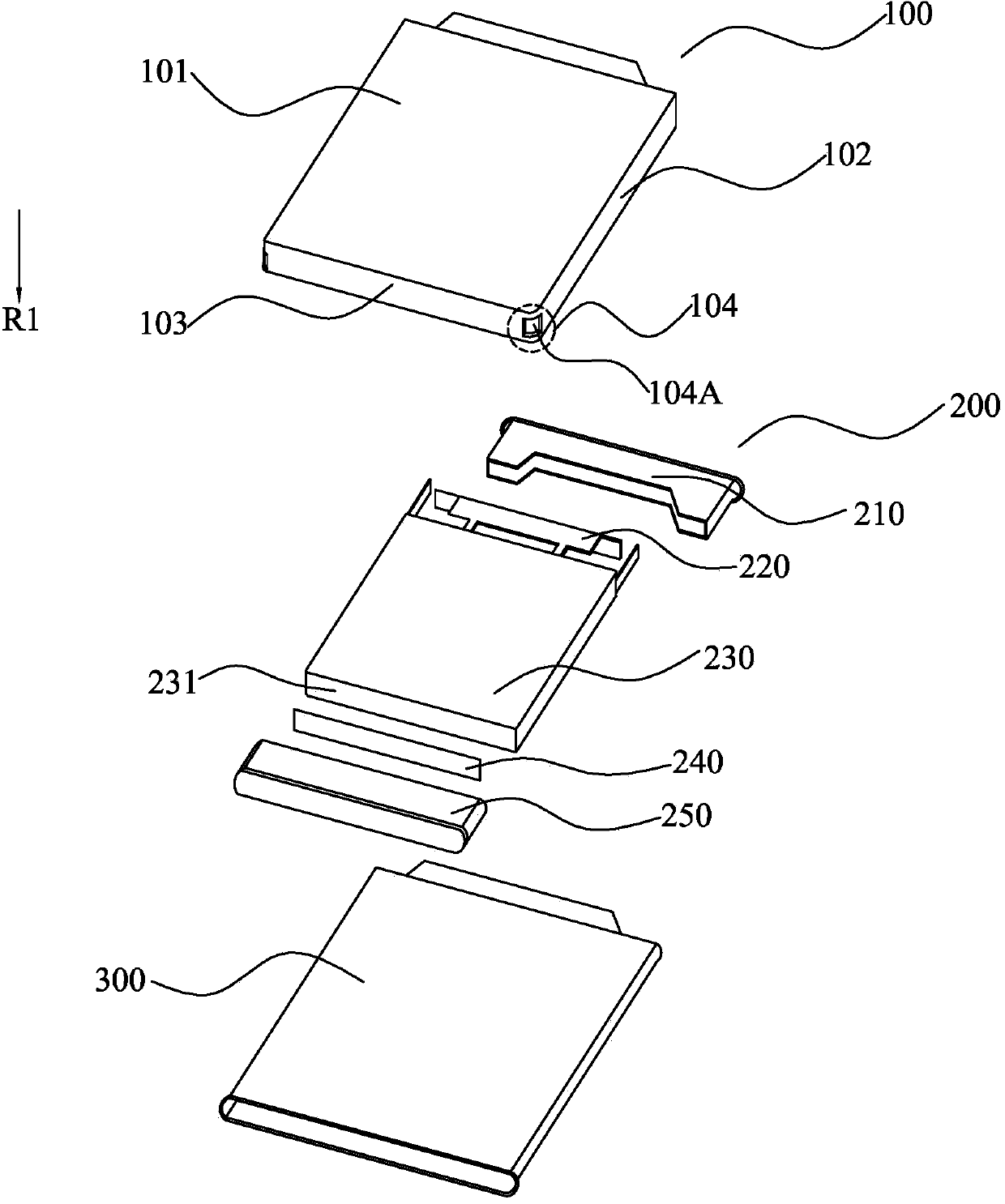

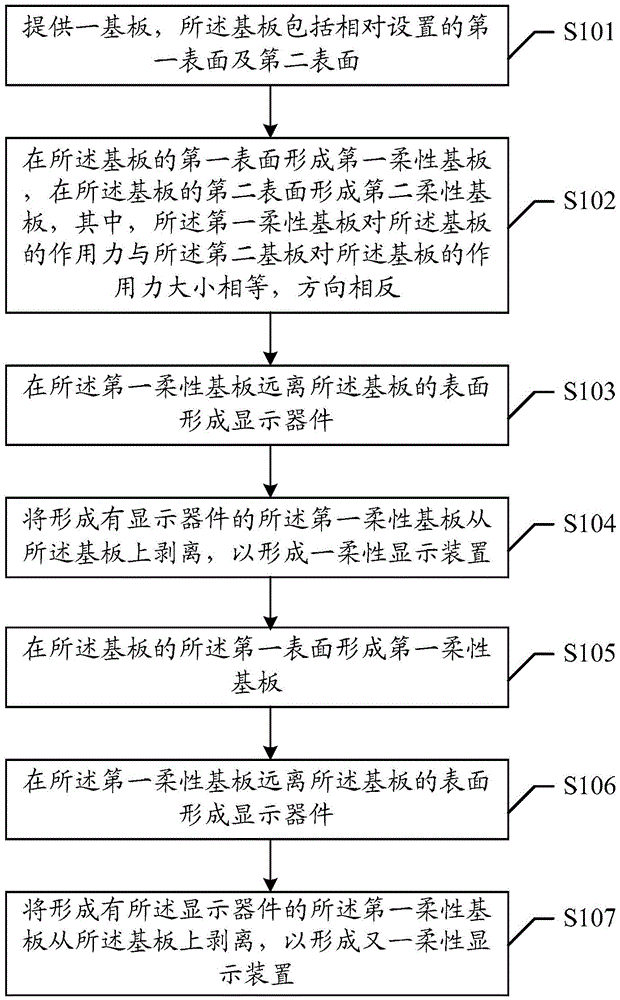

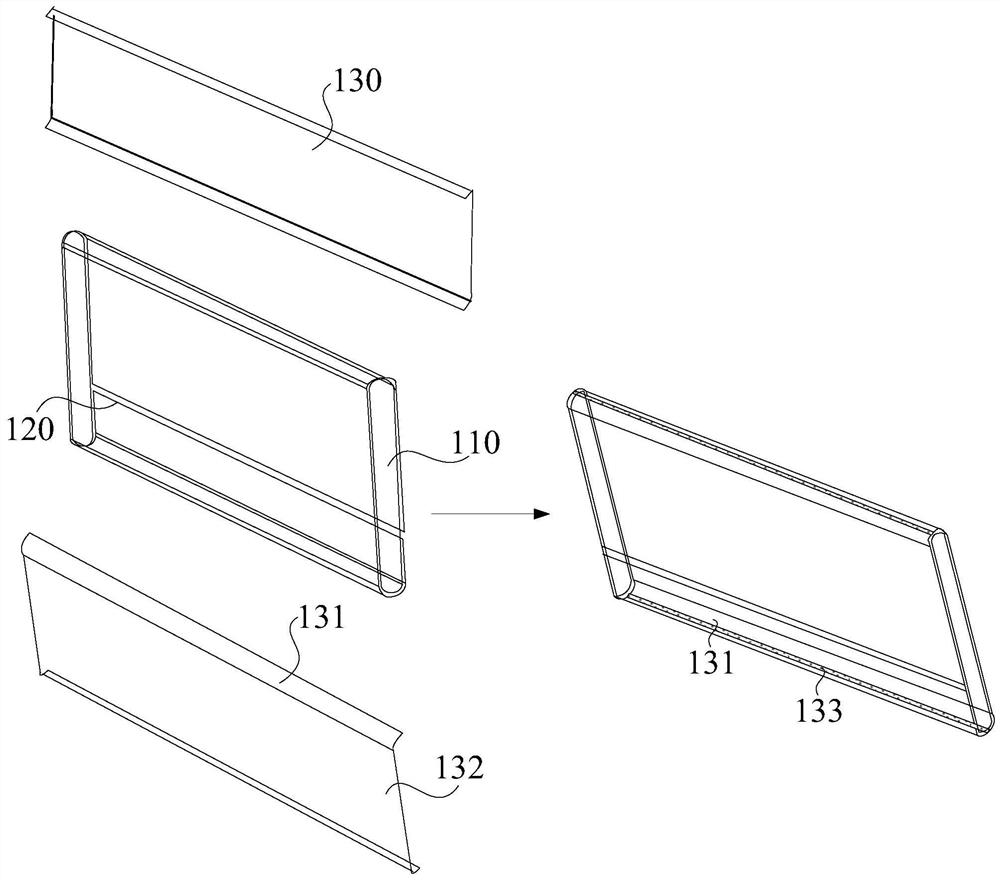

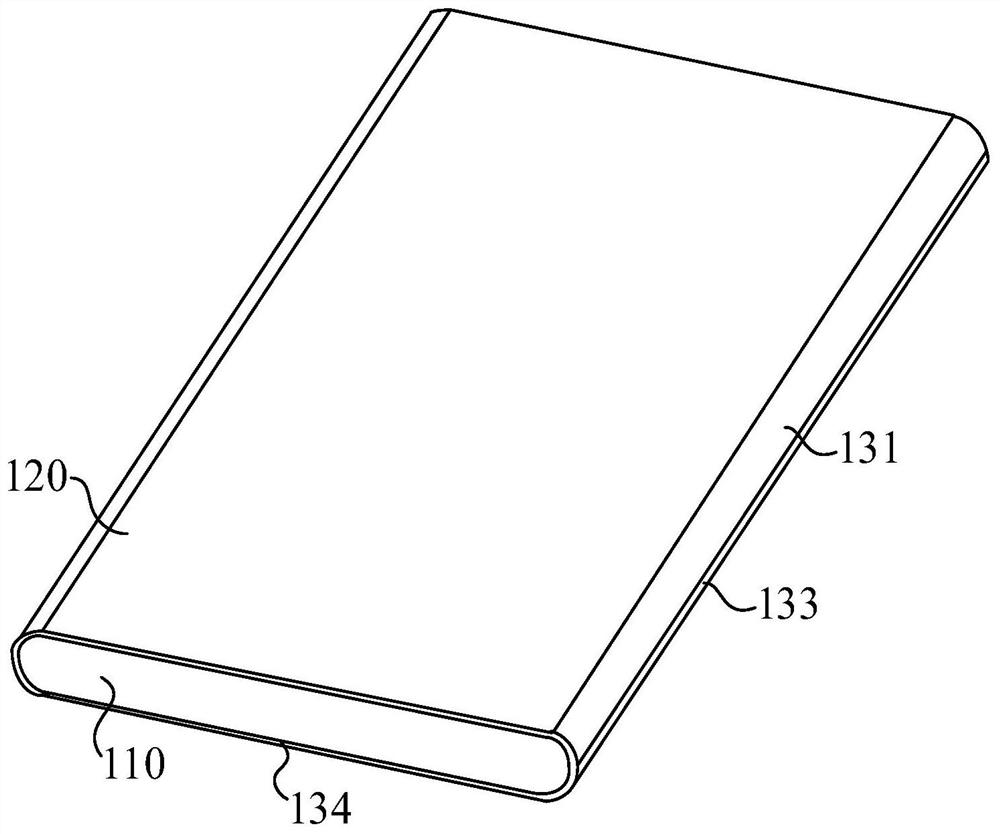

Flexible display device production method

InactiveCN104392903AImprove qualityPrevent warping and deformationSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides a flexible display device production method. The flexible display device production method comprises the following steps of providing a substrate, wherein the substrate comprises a first surface and a second surface which are oppositely arranged; a first flexile substrate is formed in the first surface of the substrate and forming a second flexible substrate on the second surface of the substrate, wherein the acting force of the first flexible substrate to the substrate and the acting force of the second flexible substrate to the substrate are identical to size and opposite in direction; forming a display device in the first flexible substrate surface which is far from the substrate; stripping the first flexible substrate which is provided with the display device from the substrate to form into a flexible display device. The flexible display device produced through the flexible display device production method is high in quality.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Bubble removing method for fitting of cover plate and curved screen, terminal equipment and assembling method of terminal equipment

ActiveCN112634749AEffective fitFit effectively denseAdhesive processesIdentification meansTerminal equipmentStructural engineering

The invention provides a bubble removing method for fitting of a cover plate and a curved screen, terminal equipment and an assembling method of the terminal equipment. The bubble removing method is used for assembling the terminal equipment, and the terminal equipment comprises a machine body, a curved screen arranged on the outer surface of the machine body and a cover plate attached to the outer surface of the curved screen. The bubble removing method comprises the steps of arranging a curved screen on the outer surface of the machine body; attaching a cover plate to the outer surface of the curved screen, and forming a first gap and a second gap, wherein the cover plate comprises a first cover plate part and a second cover plate part with the curvature less than that of the first cover plate part, the first gap comprises the edge of the first cover plate part, and the second gap comprises the edge of the second cover plate part; sealing the first gap to obtain a terminal assembly; and vacuumizing the terminal assembly so as to enable bubbles between the cover plate and the curved screen to be discharged from the second gap. According to the method, the situation that the first cover plate part and the curved screen cannot be effectively and tightly attached due to the fact that gas is exhausted from the first gap is avoided, and tilting deformation of the first cover plate part is avoided.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Mould for molding super-thin soft ferrite magnetic core

ActiveCN101700673BUniform densityPrevent warping and deformationCeramic extrusion diesInductances/transformers/magnets manufactureHigh densityHigh volume manufacturing

The invention discloses a mould for molding a super-thin soft ferrite magnetic core, comprising a case mould which is provided with a nib. The mould is characterized in that the edge of the nib is provided with a material spraying slot; by adopting the invention, powder at a higher density part in molding process can be sprayed out by the material spraying slot, thereby ensuring uniform density of each part when molding above products, avoiding or maximally reducing poor buckling deformation generated by density difference, thus reaching the purpose of massively producing super-thin soft ferrite magnetic core with the height less than 0.5mm. The mould has simple design, does not change original operation mode, has no need of specifically training operating personnel and does not increase manufacturing cost.

Owner:中山市华佑磁芯材料有限公司

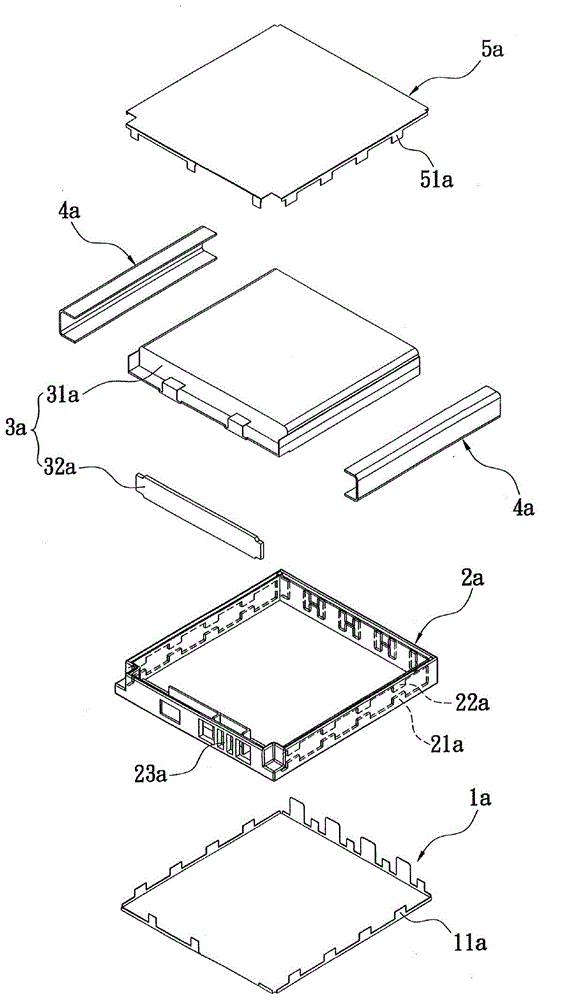

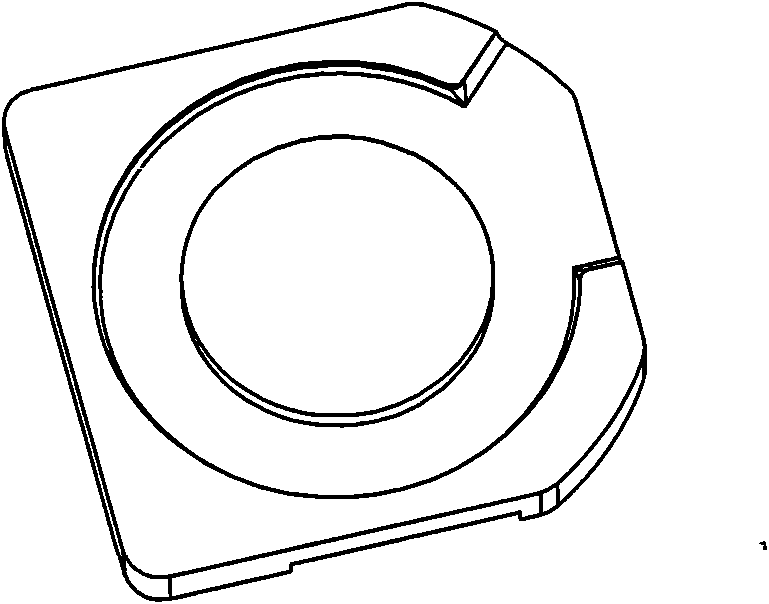

Screen and composite screen board

ActiveCN100443021CHigh strengthBeautiful appearanceScreensBuilding componentsEngineeringSurface plate

A screen is formed of screen boards which are connected collapsibly. The screen board is a composite board and includes a surface plate, a bottom plate, a perforated plate and multiple inner lining parts. The perforated plate is filled between the surface plate and the bottom plate. The inner lining parts are sandwiched between the surface plate and the bottom plate acting as connecting parts to connect the screen boards with outside components and parts, or acting as reinforce parts at the same time.

Owner:冷鹭浩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com