Cold Storage

A technology of cold insulation box and box body, which is applied to household refrigeration devices, cooling fluid circulation devices, lighting and heating equipment, etc., can solve the problem of increased heat intrusion, difficulty in increasing the size of the separator, and insufficient thickness of the insulating wall. and other problems, to achieve the effect of preventing warping deformation and reducing the amount of heat intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

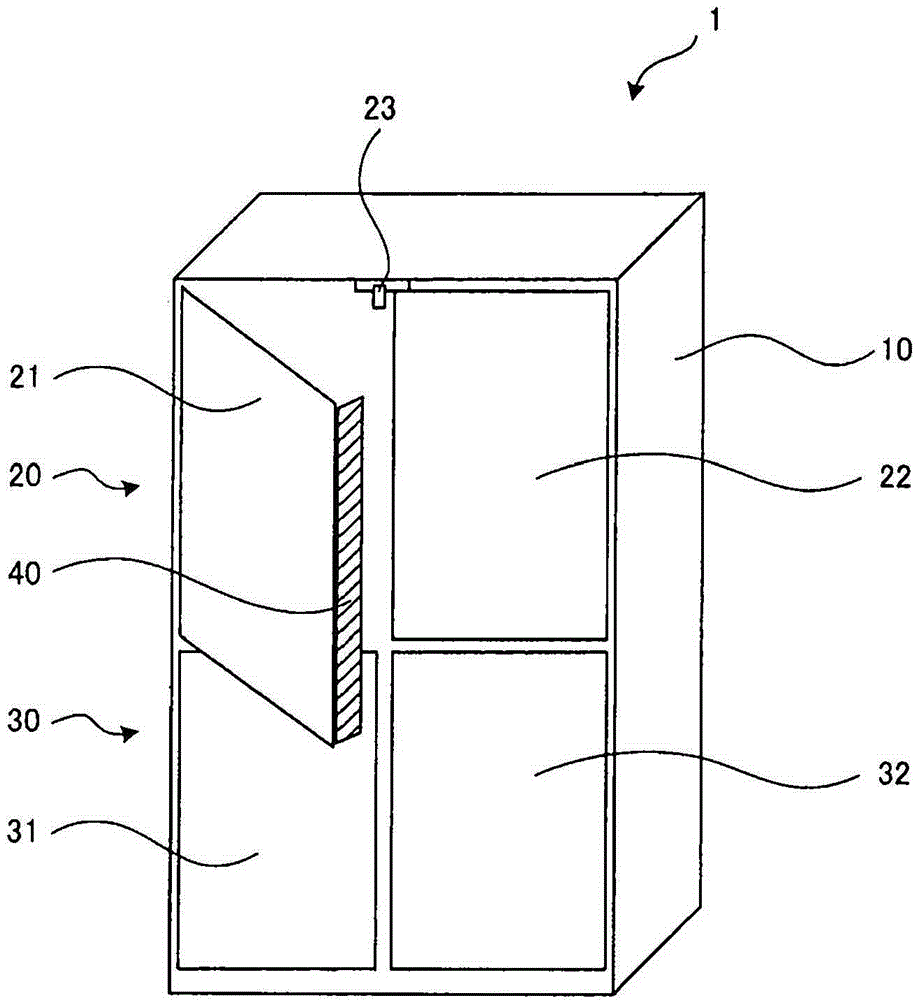

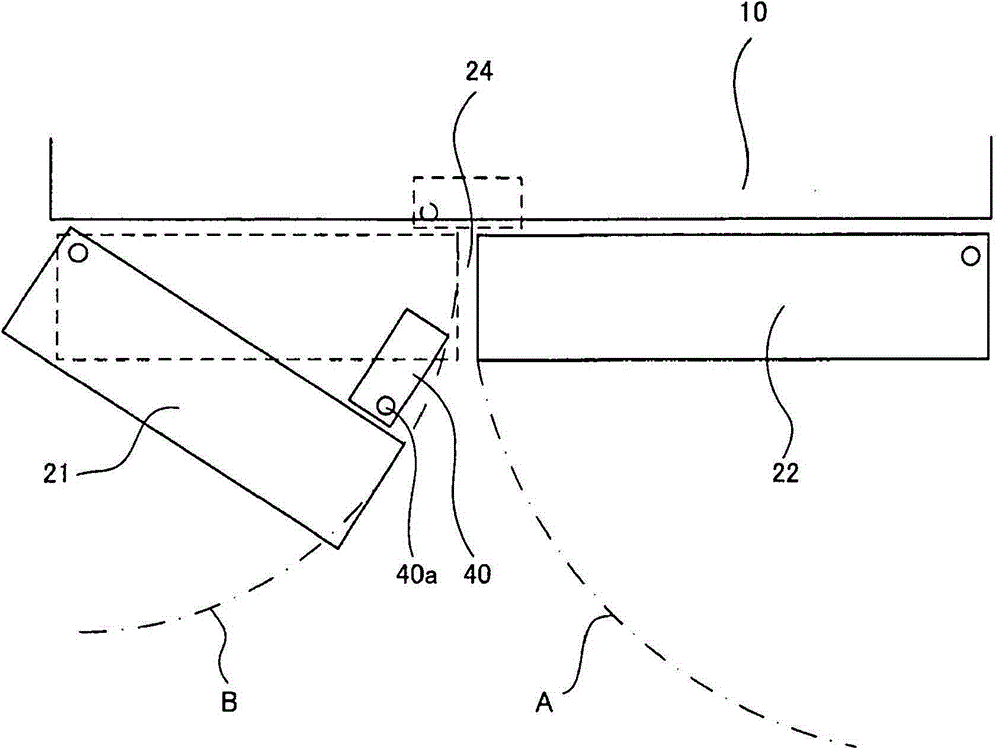

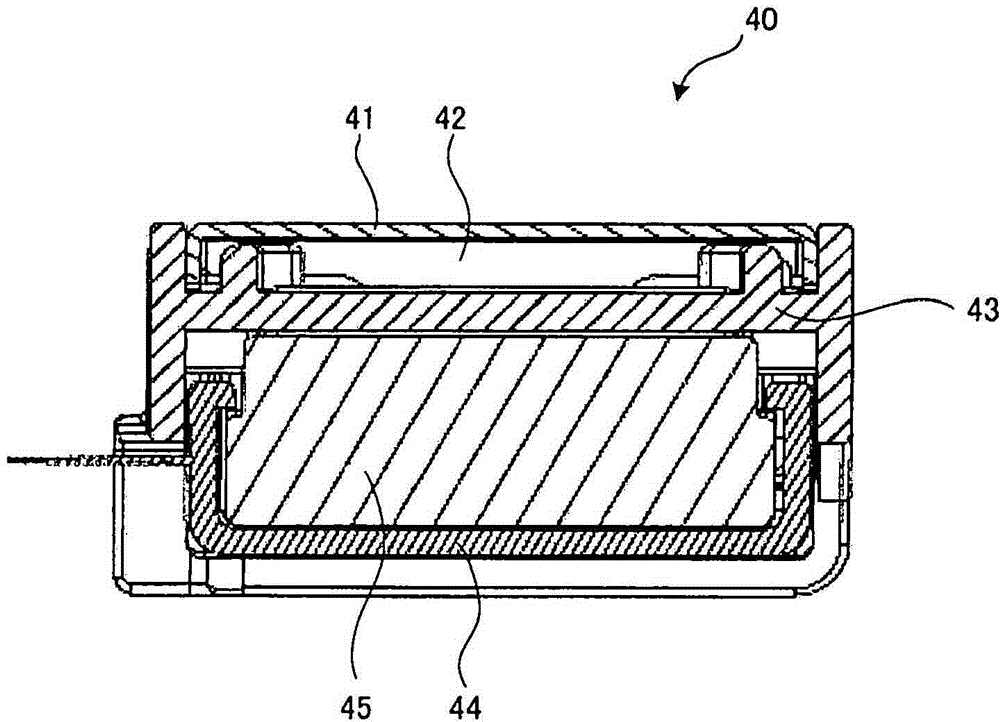

[0023] The refrigerator according to Embodiment 1 of the present invention will be described. figure 1 It is a perspective view which shows the schematic whole structure of the cool box 1 of this embodiment. figure 2 It is a plan view which shows the structure of the vicinity of the left door 21 and the right door 22 of the cooler box 1 of this embodiment. Include figure 1 and figure 2 In the accompanying drawings below, the relative dimensional relationship, shape, etc. of each constituent member may not correspond to reality. In addition, about the positional relationship and direction of each structural member in this specification, it demonstrates seeing the cold insulation box 1 installed in the usable state from the front in principle. In this embodiment, a refrigerator having a freezer compartment and a refrigerator compartment is described as an example of the cooler box 1 , but the cooler box 1 may be a refrigerator with only a refrigerator compartment or a fre...

Embodiment approach 2

[0044] Next, Embodiment 2 of the present invention will be described. Figure 7 It is an exploded perspective view showing the structure of the separator 140 of this embodiment. In addition, the same code|symbol is attached|subjected to the component which has the same function and action as the separator 40 of Embodiment 1 mentioned above, and the description is abbreviate|omitted.

[0045] Such as Figure 7 As shown, the separator 140 of this embodiment has one or both of the front side member 43 and the back side member 44 (only the front side member 43 in this example) in the longitudinal direction (in this example, approximately Central part) is divided into two structures. That is, the front side member 43 is divided into the upper member 43a and the lower member 43b. The upper member 43a and the lower member 43b each have the connection part 63a, 63b which can be connected with each other by fitting or the like.

[0046] In addition, in the present embodiment, the u...

Embodiment approach 3

[0058] Next, Embodiment 3 of the present invention will be described. Figure 8 It is an exploded perspective view showing the structure of the separator 240 of this embodiment. In addition, the same code|symbol is attached|subjected to the component which has the same function and action as the separator 40 of Embodiment 1 mentioned above, and the description is abbreviate|omitted.

[0059] Such as Figure 8 As shown, in the separator 240 of this embodiment, either one of the front side member 43 or the back side member 44 (in this example, the front side member 43) has a structure divided into the following parts: The intermediate member 43e; the upper end member 43c (an example of an end member) located at one end (upper end) in the longitudinal direction of the intermediate member 43e and having a fitting shape with the upper end side hinge member 51; and the length of the intermediate member 43e The other end (lower end) in the direction has a lower end member 43 d (an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com