Barrier plate assembly of folding machine

A fence board and folding machine technology, applied in the field of folding machines, can solve the problems that the fence positioning accuracy is also greatly affected, the installation and assembly accuracy is difficult to control, and the front end of the long fence board is easy to warp, etc., to achieve reliable locking and overhang The effect of weight reduction and reasonable force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

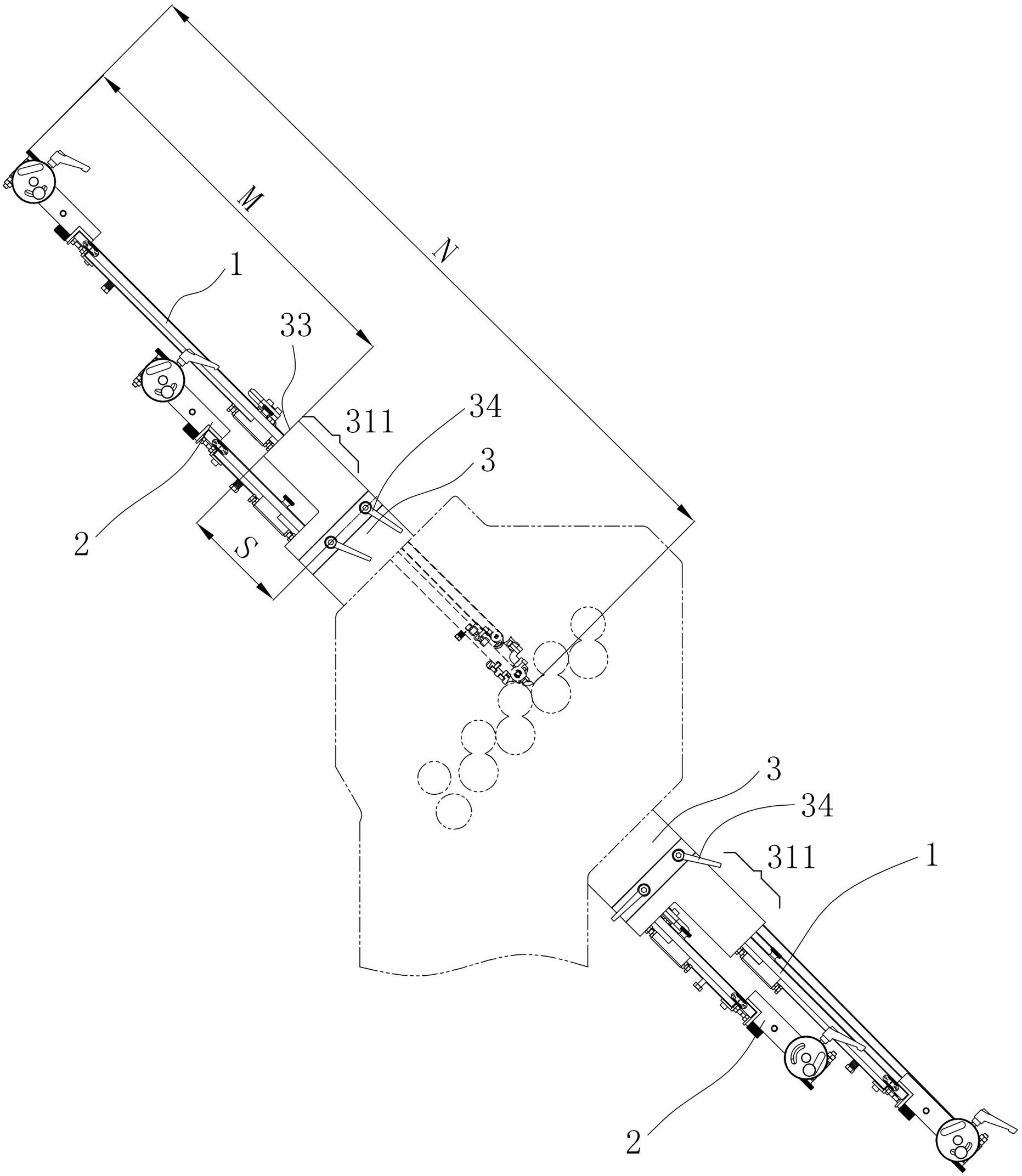

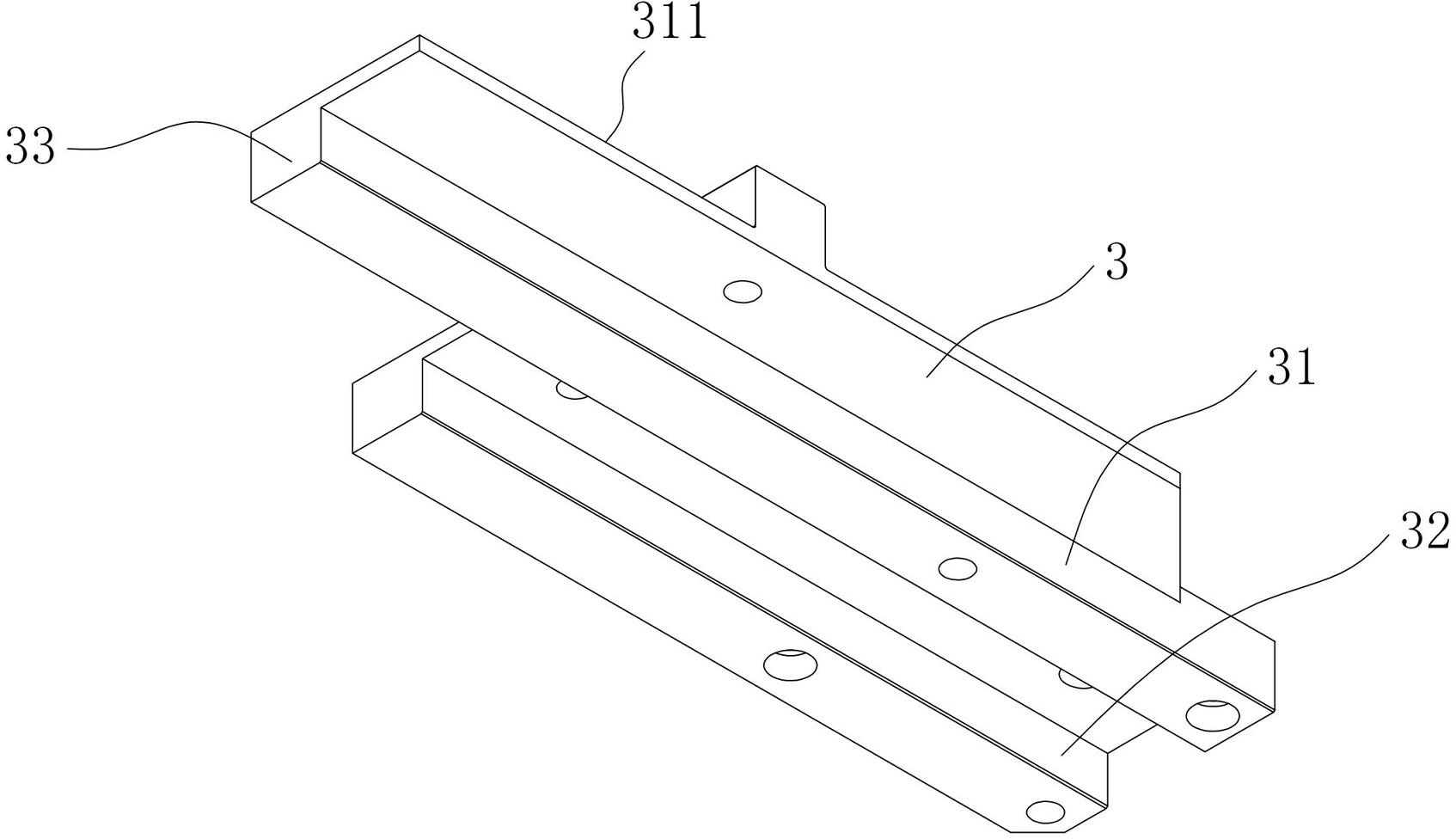

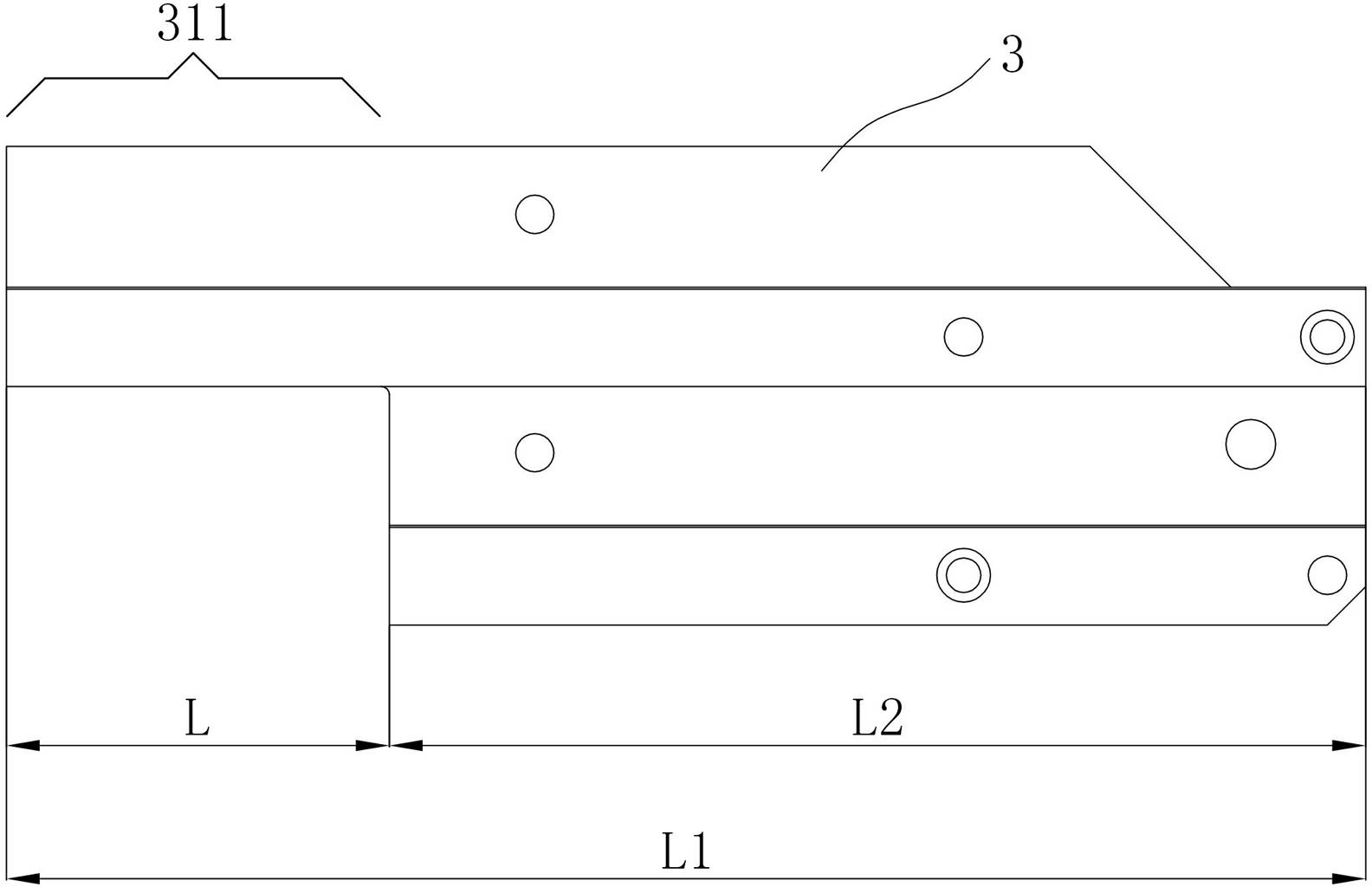

[0017] Figure 1 to Figure 3 It shows an embodiment of a folding machine fence board assembly of the present invention, which includes a short fence board 2, at least one long fence board 1 and a pair of support boards 3, and each support board 3 is provided with The long fence plate supporting surface 31 and the short fence plate supporting surface 32 arranged in parallel, the long fence plate 1 both sides are supported by a pair of long fence plate supporting surfaces 31, and the short fence plate 2 sides are supported by a pair of short fence plate supporting surfaces 32 The support surface 31 of the long fence board is provided with an upwardly extending extension section 311, which can reduce the length of the overhang of the long fence board 1, so that the support obtained by the long fence board 1 is more stable and reliable, and the positioning is more accurate, and can Prevent the warping and deformation of the long fence board 1; at the same time, the overhang of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com