A semiconductor feeding device with anti-warping function

A technology of semiconductor and pushing device, which is applied in semiconductor/solid-state device manufacturing, transportation and packaging, conveyor objects, etc., can solve the problems of easy deformation and damage of lead feet, reduced product integrity, low strength of plastic-encapsulated lead frames, etc. Easy to operate and maintain, prevent warping and deformation, and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

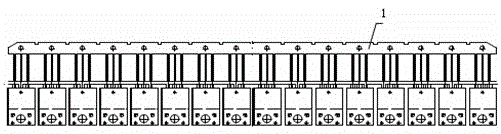

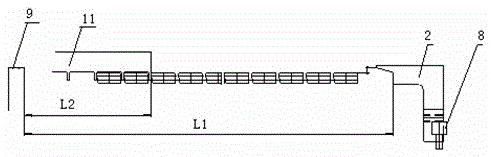

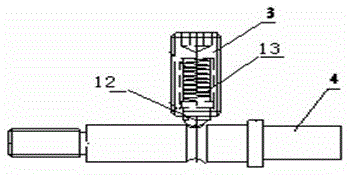

[0018] Such as figure 1 and figure 2 As shown, a semiconductor feeding device that can effectively prevent plastic lead frame 1 from warping and deforming during processing includes an open feeding track 10 and a pushing device, such as Figure 5 and Figure 6 As shown, the mold cavity of the feeding track 10 matches the shape of the pushed plastic-encapsulated lead frame 1, and there is a pushing device on the feeding track 10, such as Figure 4 , Figure 7 and Figure 8 As shown, the pushing device includes push rod 2, push rod connecting rod 4, push rod mounting block 6, sensor 5, roller follower 8 and transmission fixed plate 7, push rod mounting block 6, sensor 5 and roller follower The actuator 8 is fixed on the transmission fixed plate 7, the motor drives the transmission fixed plate 7, and then pushes the pushing device to reciprocate along the feeding track 10, and the push rod 2 is rigidly connected to the push rod connecting rod 4, such as image 3 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com