Laser welding jig of triangular titanium alloy covering and skeleton weld assembly

A technology for laser welding fixtures and welding components, applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of upturning and deformation of the front tip of the triangular titanium alloy skin, achieve control of laser welding deformation, and reduce labor intensity , Improve the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

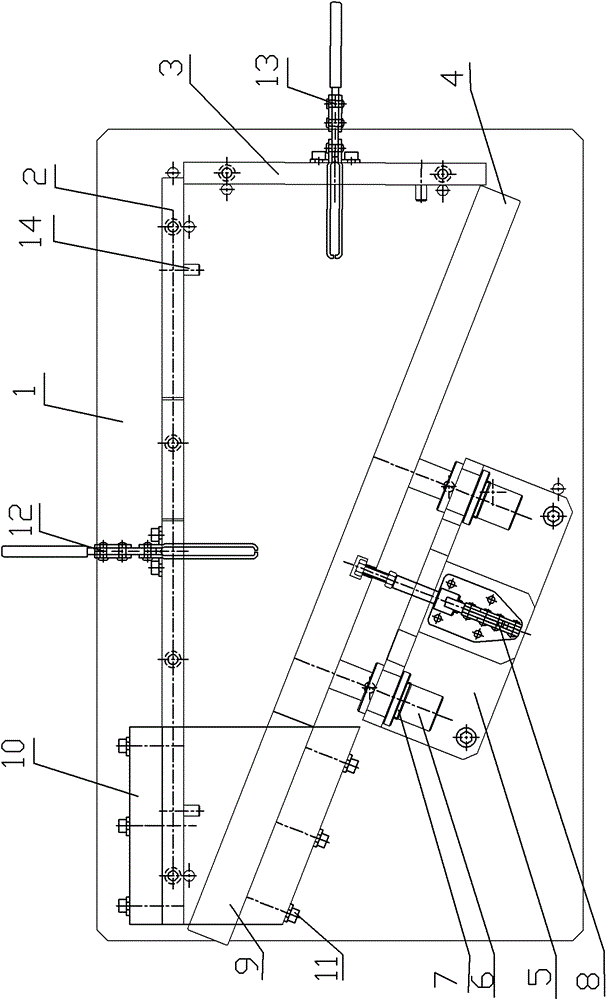

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, the fixture of this embodiment includes a bottom plate 1, a first positioning plate 2, a second positioning plate 3, a first pressing plate 4, a guide seat 5, a first fastening clamp 8, a second pressing plate 9, and a reinforcement frame 10. The second compression quick clamp 12, the third compression quick clamp 13, two guide columns 6 and two guide sleeves 7, the first positioning plate 2, the second positioning plate 3 and the guide seat 5 are all fixed to the bottom plate 5 Then, the first positioning plate 2 and the second positioning plate 3 are vertically arranged, and the first compression quick clamp 8 is fixed on the guide seat 5, and one end of the first compression quick clamp 8 is connected with the first pressure plate 4, and the two guides The sleeve 7 is fixedly connected to the guide seat 5, one end of each guide column 6 is fixedly connected to the first pressure plate 4, the...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 Describe this embodiment, the fixture of this embodiment also includes two positioning pins 14, the first positioning plate 2 and the second positioning plate 3 are respectively provided with a positioning pin 14, this structure is used for the triangular titanium alloy skin of different thickness and skeleton welded components. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the fixture of this embodiment also includes a plurality of jacking wires 11, and a plurality of jacking wires 11 pass through the reinforcement frame 10 and lean against the second pressing plate 9. This structure enables the second pressing plate 9 to press more powerfully. Tight triangular titanium alloy skin and skeleton welded assembly. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com