Screen and composite screen board

A screen board and composite board technology, which is applied to screens, building components, household appliances, etc., can solve the problems of high strength, inconvenient assembly, and low strength of screen boards, and achieve the effect of beautiful appearance, convenient connection and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

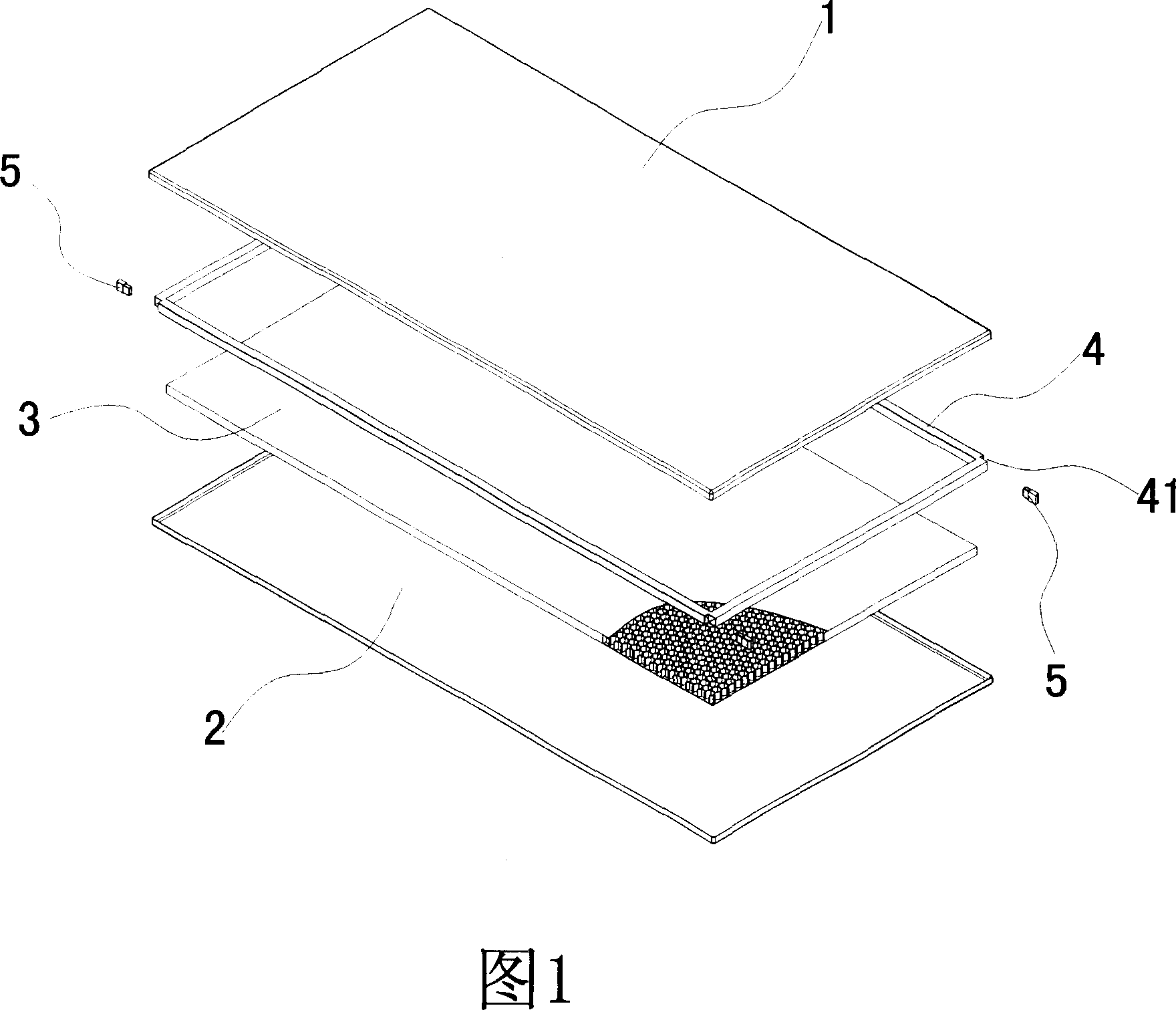

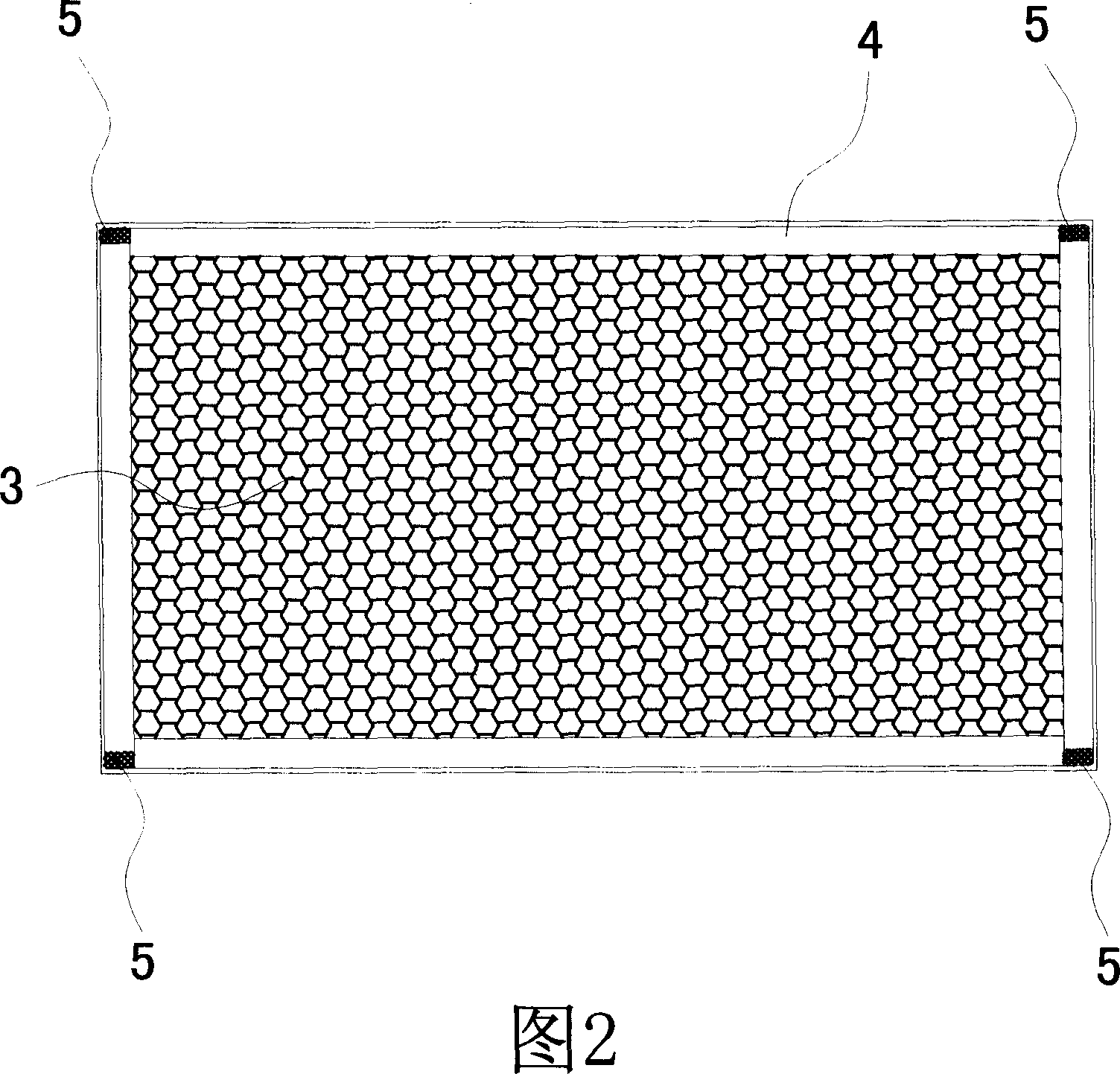

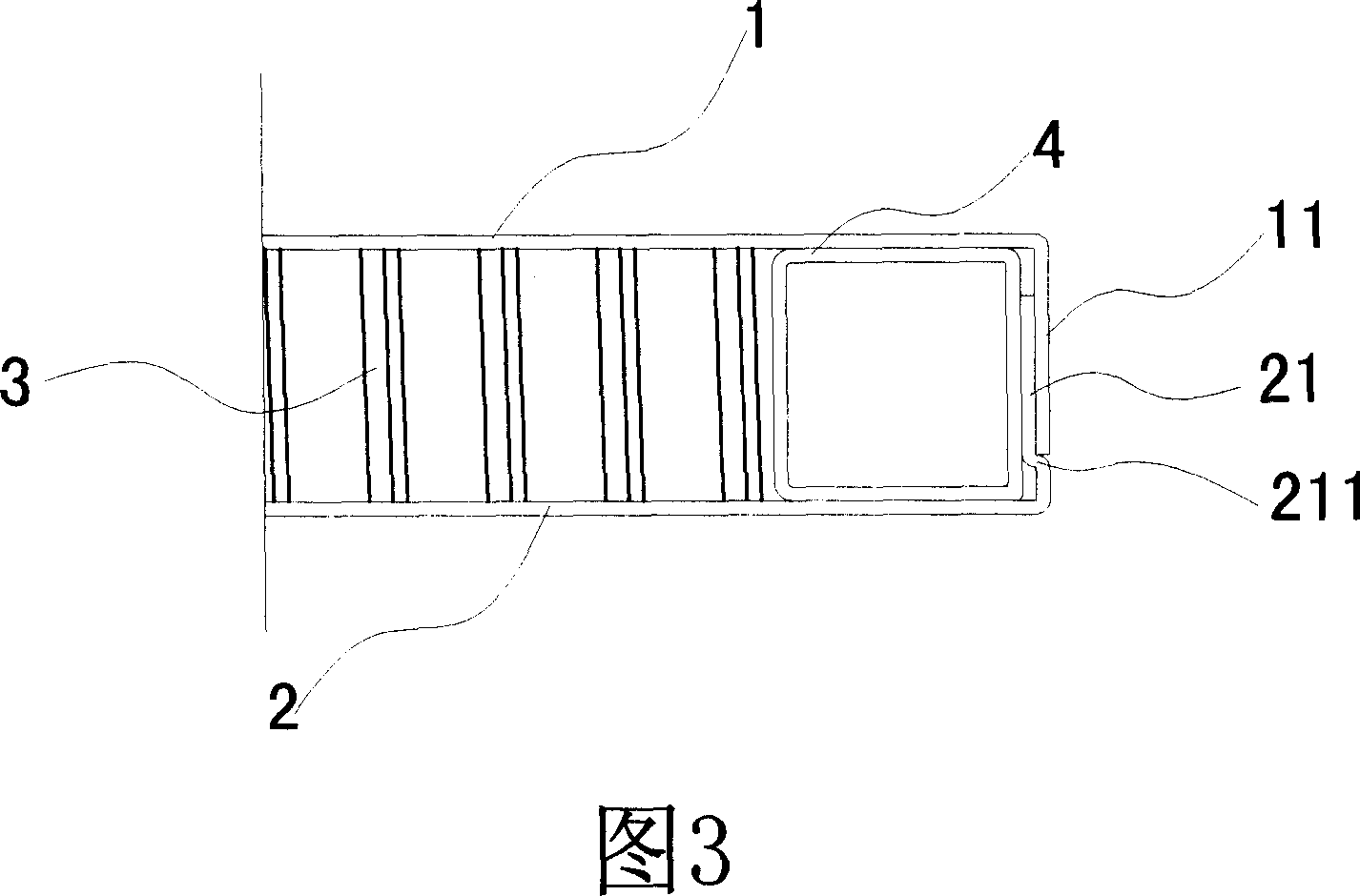

[0087] A composite screen panel, as shown in FIGS. 1 and 3 , includes a panel 1 , a bottom plate 2 , a honeycomb panel 3 , an inner lining 4 and four reinforcements 5 .

[0088] The panel 1 is directly processed by blister or plastic extruded board, which can be a single-layer board or a multi-layer board composed of the single-layer board. The thickness of the panel 1 is generally between 0.3 mm and 4 mm. , The material used for the panel 1 can be ABS, PP, PS. The surface of the panel 1 is printed with a printing layer or compounded with a film layer. The printing layer has colors of natural materials such as wood grain or marble, and the film layer has colors of natural materials such as wood grain or marble. According to the needs, the surface of the panel can be compounded with a transfer film with various wood grains, marble and other natural material colors. After the transfer, the film is removed, and a heat-cured or light-cured varnish layer is sprayed to increase the ...

Embodiment 2

[0096] This embodiment differs from Embodiment 1 in that: as shown in Figures 4 and 5, the inner lining 4 is fixedly bonded and coated with the honeycomb plate 3 along the intervals around the periphery of the honeycomb plate 3, and the fixed bond is sandwiched between the panel 1 and the bottom plate 2 between. The overall shape of the inner liner 4 is a U-shaped frame, and it is a rectangular hollow tube. Four corners of the inner liner 4 are provided with a positioning groove 41 .

Embodiment 3

[0098] This embodiment differs from Embodiment 1 in that: as shown in Figures 6 and 7, the honeycomb panel 3 is divided into three pieces, which are respectively the first honeycomb panel 31, the second honeycomb panel 32 and the third honeycomb panel 33, wherein , the second honeycomb panel 32 and the third honeycomb panel 33 have the same structure. The entire shape of the inner liner 4 is a type II frame, and it is a rectangular hollow tube, wherein, the inner liner 4 is completely fixed and bonded to cover the first honeycomb panel 31 along the periphery of the honeycomb panel 3, and the interval part is fixed and bonded to cover the second honeycomb panel. The honeycomb panel 32 and the third honeycomb panel 33 . Four corners of the inner liner 4 are provided with a positioning groove 41 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com