Wooden container making process

A container manufacturing and manufacturing method technology, which is applied in the field of circular wooden container manufacturing, can solve the problems of plank bending, uneven drying shrinkage, and container deformation, etc., so as to improve the strength and service life, save raw materials, prevent split effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

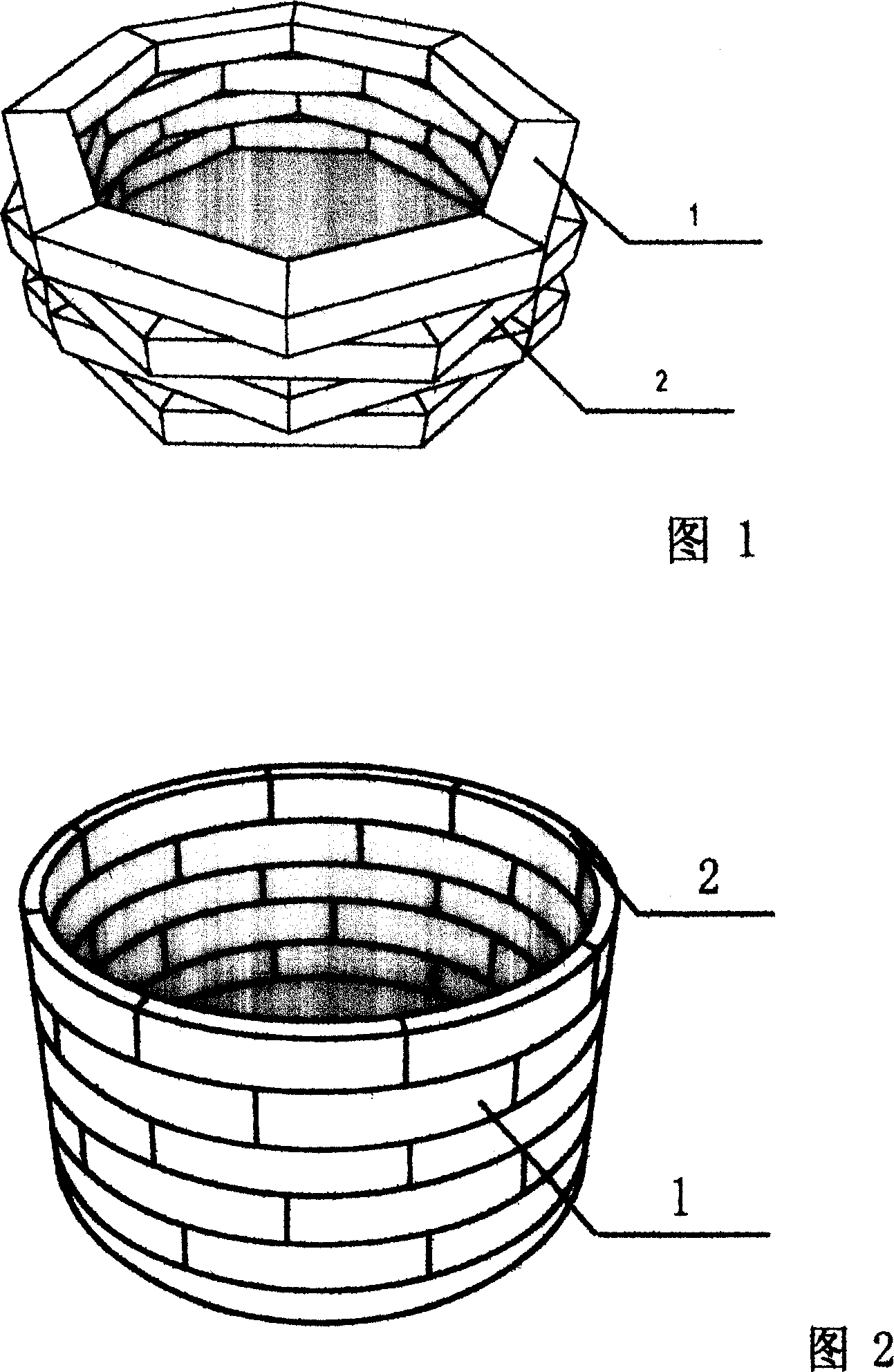

[0009] Utilize the excess material head after wood product processing, take local materials, make it into a batch of small isosceles trapezoidal wooden blocks with equal size and bottom angle of 22.5°, and then sand each plane of the wooden blocks to make them smooth, and then each block isosceles trapezoidal The upper bottom of the wooden block is glued horizontally inward, just enough to form a regular octagonal wooden circle. To make multiple such wooden circles, first glue the first layer of wooden circles on the prepared bottom plate, and then glue the second layer of wooden circles on top of the first layer. When stacking, pay attention to the second layer of regular octagonal The outer corners of the wooden circle and the outer corners of the regular octagonal wooden circle of the first layer are staggered up and down, or the outer corners of the upper layer are roughly facing the middle of the side of the next layer, and the operation of each subsequent layer is the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com