Low-warpage UV-resistant reflective film and its preparation method

A UV-resistant, low-warping technology, applied in the field of reflective film and reflective film preparation, can solve the problems of reflective film aging, diaphragm color yellowing, diaphragm deformation, etc., and achieve the effect of avoiding warping and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

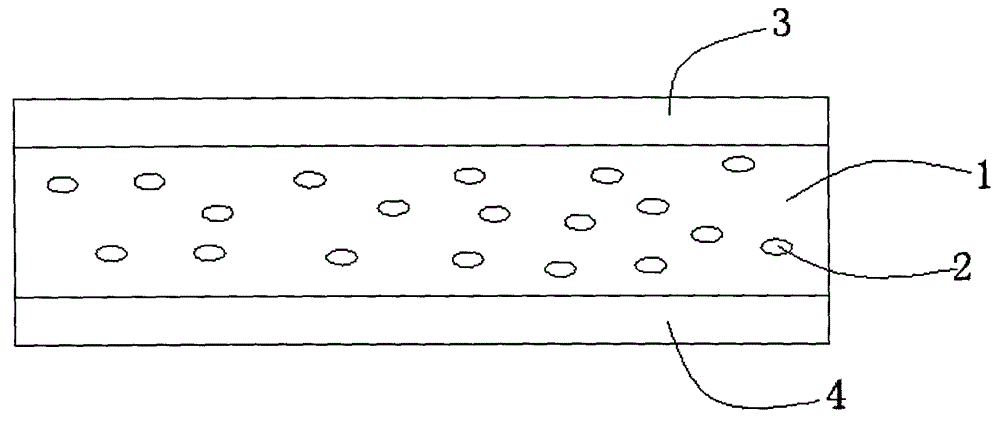

[0029] A low warpage UV-resistant reflective film, comprising a core layer 1, microbubbles 2 are distributed in the core layer 1, and the core layer 1 is composed of the following components according to mass percentage:

[0030] PET: 80%;

[0031] TOPAS6013 produced by Japan Polyplastics Co., Ltd.: 6%;

[0032] Ethylene-ethyl acrylate-glycidyl methacrylate triblock copolymer: 6%;

[0033] Titanium dioxide particles: 8%;

[0034] The low warpage UV-resistant reflective film also includes an upper surface layer 3 and a lower surface layer 4, the upper surface layer 3 covers the upper surface of the core layer 1, and the lower surface layer 4 covers the lower surface of the core layer 1 surface;

[0035] Both the upper surface layer 3 and the lower surface layer 4 are composed of the following components according to mass percentage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com