Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Prevent processing deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

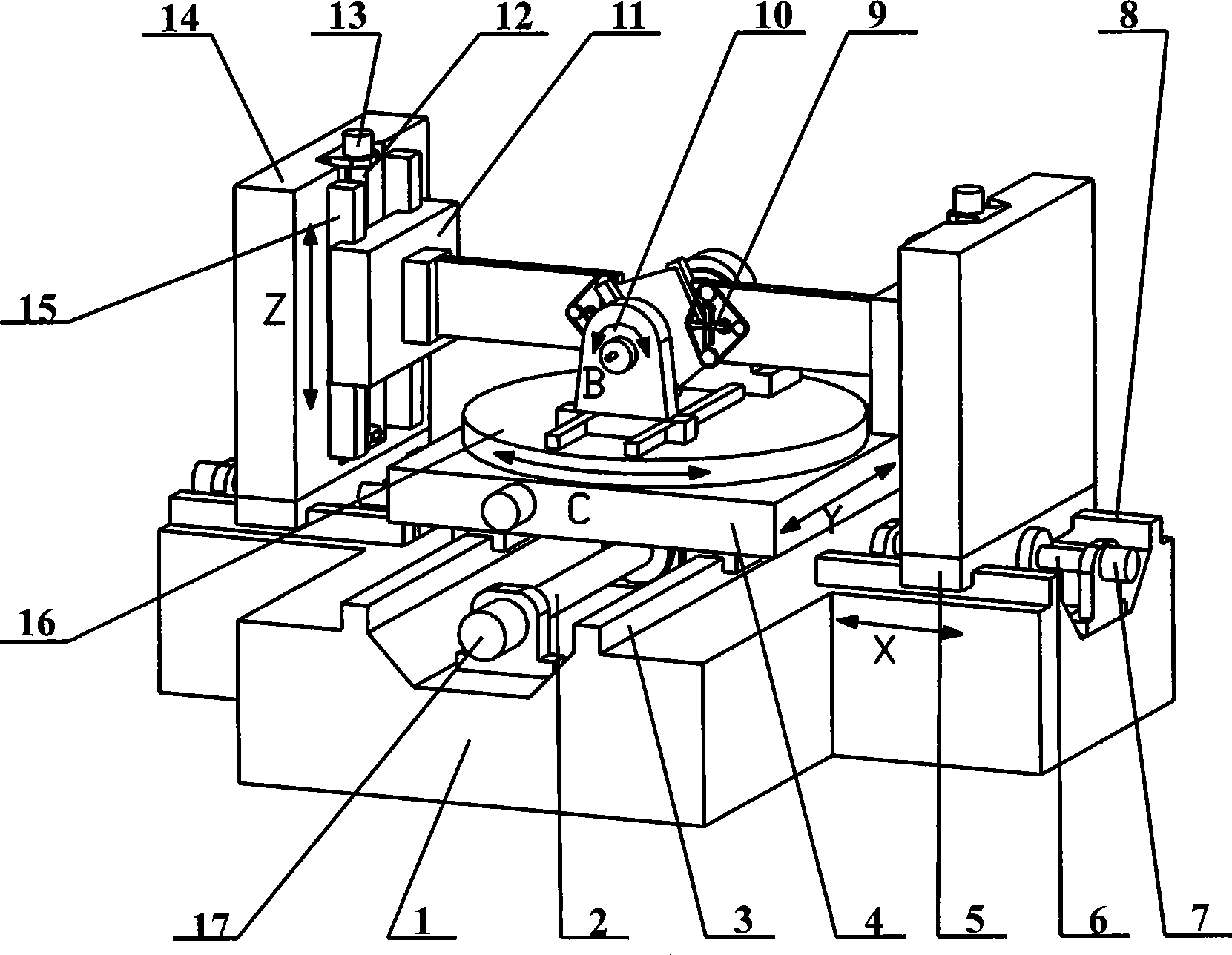

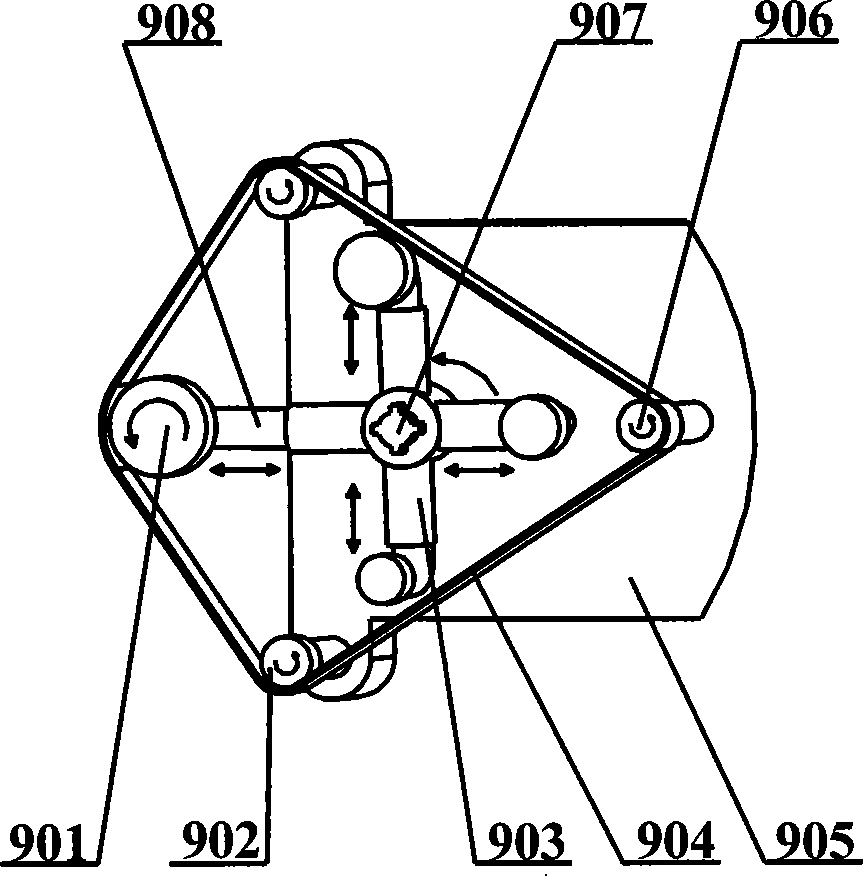

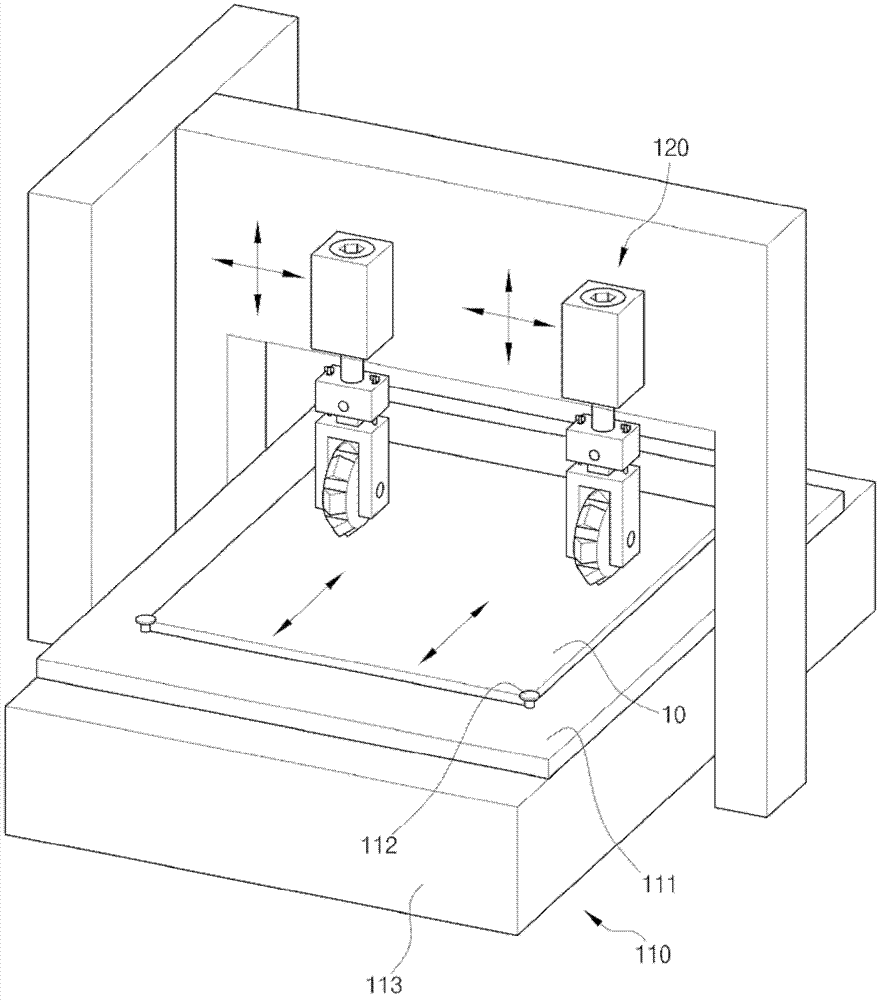

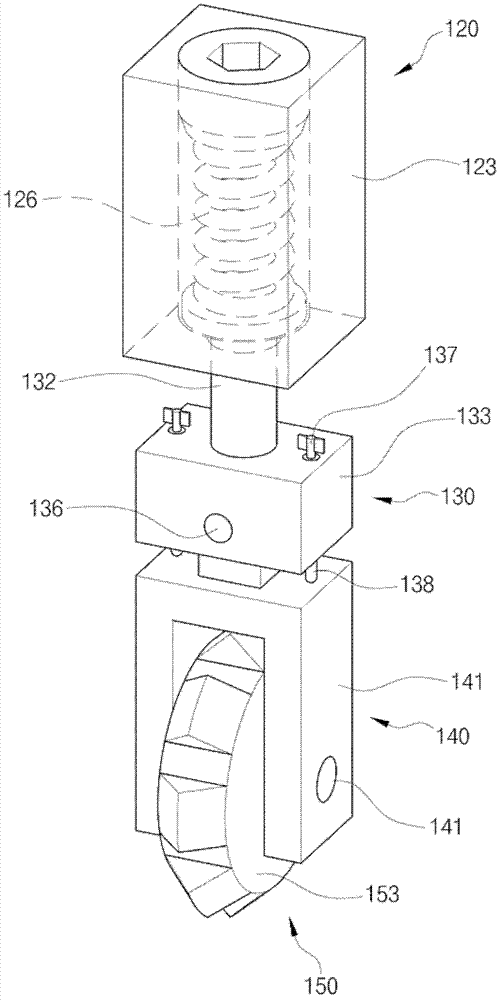

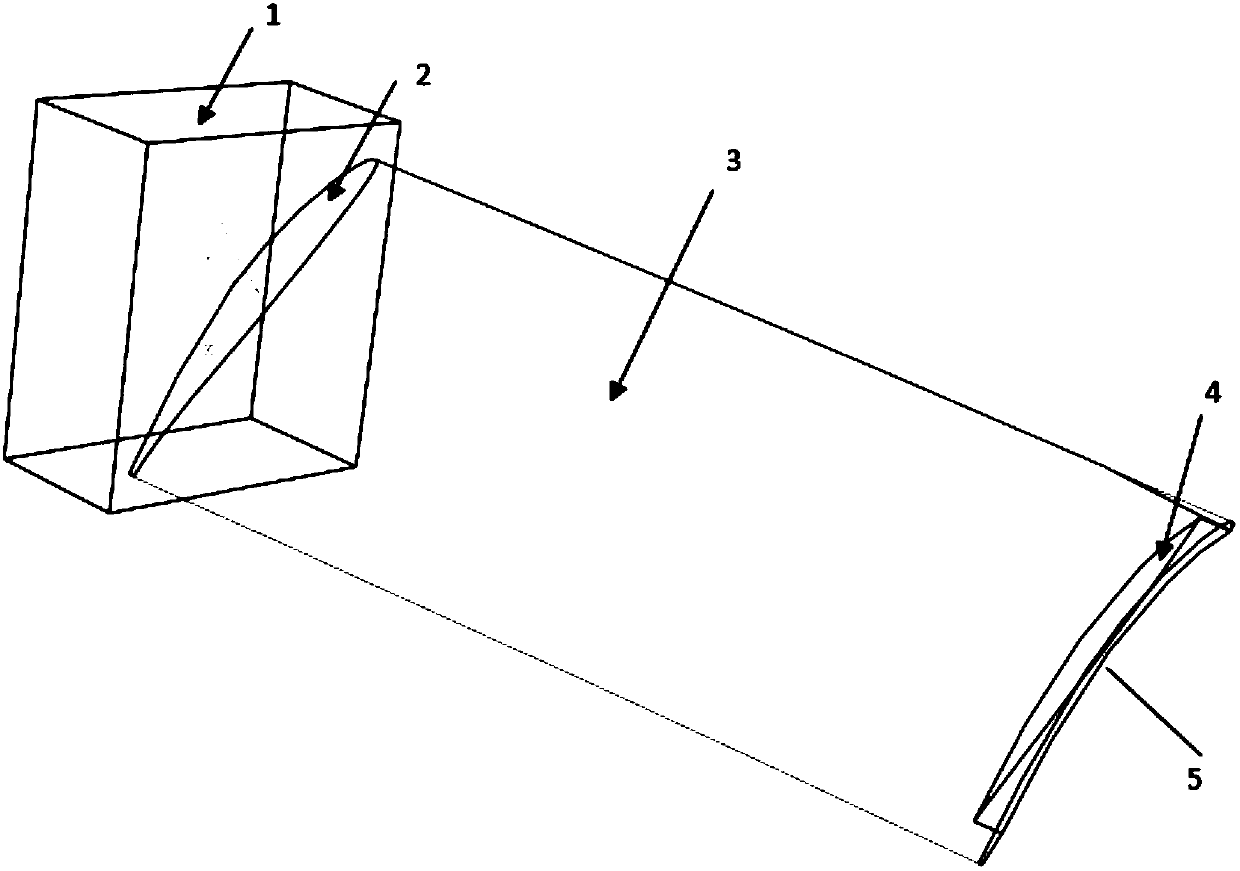

Two-sided synchronous high-efficiency milling and casting machine tool for impeller vane

InactiveCN101244531APrevent processing deformationImprove grinding and polishing efficiencyGrinding machinesImpellerEngineering

The invention relates to a grinding and polishing machine tool of synchronous double-faced blade with a high efficiency, belonging to the mechanical manufacturing field. A moving mechanism in Y direction and two moving mechanism in X direction are fixed on the bed, two moving mechanism in X direction are coaxial and are distributed in symmetrically horizontally vertical to the moving mechanism in Y direction; two grinding and polishing tool system of sand belt variable gear trains are respectively connected with two moving mechanism in Z direction; the two moving mechanism in Z direction are respectively connected with two upright columns; the two upright columns are respectively connected with the two moving mechanism in X direction; a reversing jig is arranged on the rotary worktable, and the reversing jig can achieve the clamping of the blade and the rotation of the blade around the central shaft B of the reversing jig; the rotary worktable is connected with the moving mechanism in Y direction, and the rotary worktable provides the rotation around the central shaft C. The grinding and polishing machine tool of synchronous double-faced blade with a high efficiency has the advantages that the faces of the blade at double sides has synchronous grinding and polishing, not only the efficiency of grinding and polishing is improved obviously, but also because force is exposed on double sides of the blade during grinding and polishing process, the process deformation of the blade is effectively avoided.

Owner:JILIN UNIV

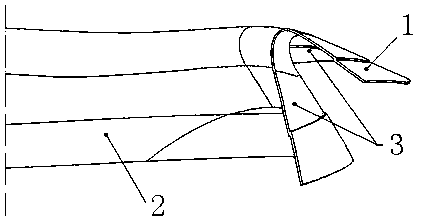

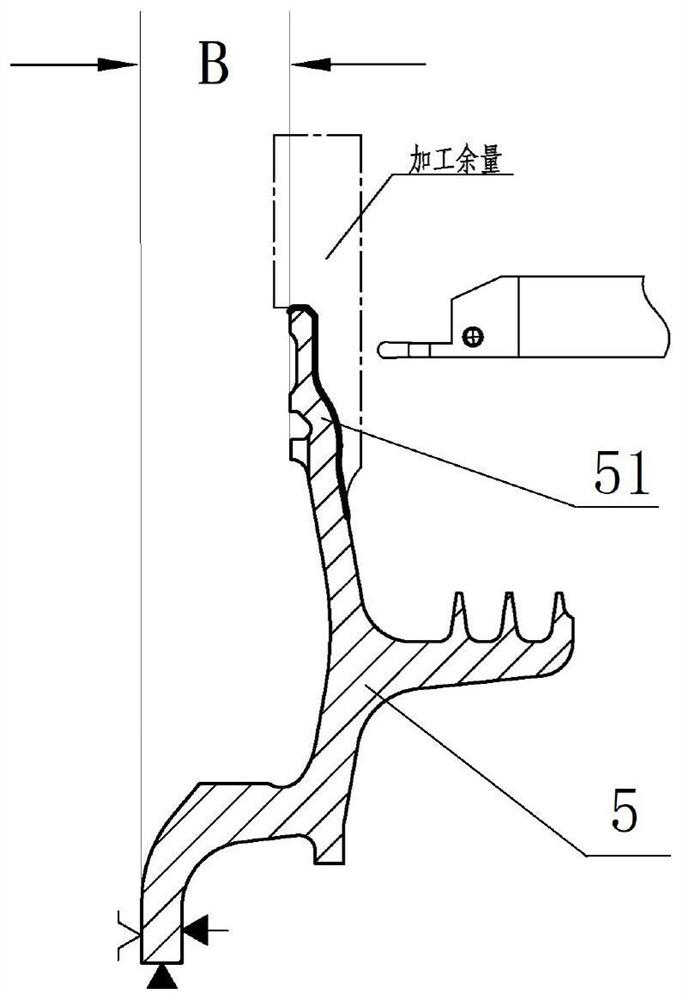

Manufacturing process for high-curvature full-profile thin-wall part

ActiveCN103639655ASolve Vibration ProblemsGuaranteed sizeAircraft componentsWorkpiecesMaterial removalNatural aging

The invention provides a manufacturing process for a high-curvature full-profile thin-wall part so as to solve the problem of processing deformation and vibration of an ultra-complex spatial thin-wall curved surface. By reasonable process layout, a segmented layer-by-layer processing mode is adopted, an appropriate cutter and a cutter handle are selected, working allowance of every process is set, natural aging time is set, cutting process parameters and feeding strategies are optimized, the uniform material removal amount of the part is guaranteed, an adding cushion block location and gypsum filling method is adopted simultaneously, the problem of clamping difficulty and vibration in part processing is solved, processing rigidity and clamping stability of the part are improved, deformation in the part processing process is controlled, and the part size and precision are guaranteed.

Owner:江西洪都航空工业股份有限公司

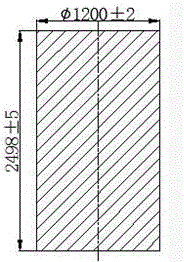

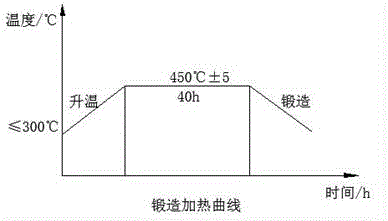

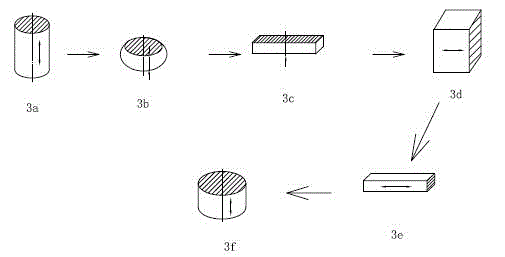

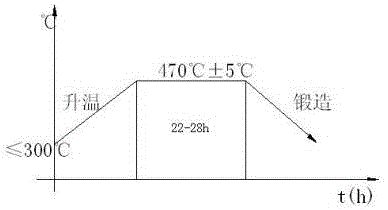

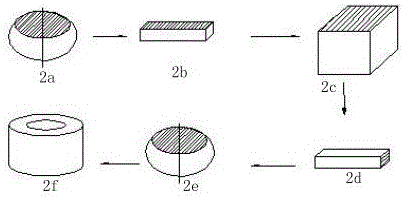

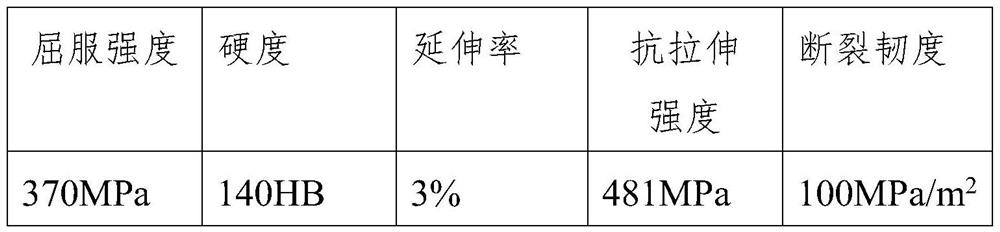

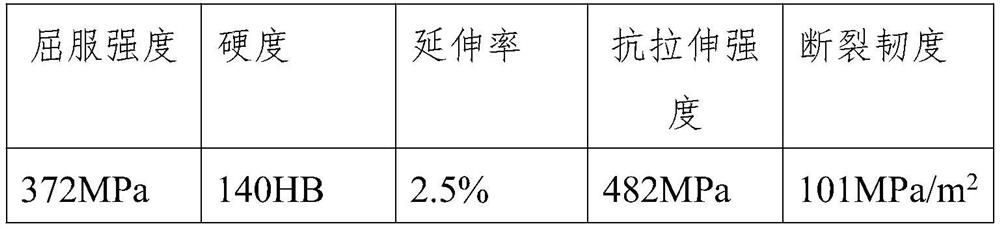

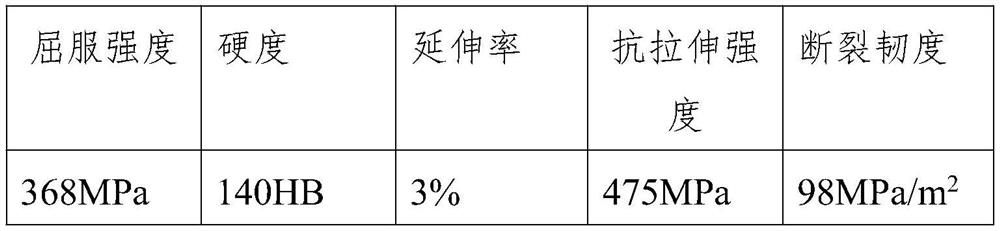

Forging forming technology of aluminum alloy straight-flanked ring with extra-large specification

The invention relates to a forging forming process of an aluminum alloy straight-flanked ring with an extra-large specification. The forging forming process comprises the fist step of blanking; the second step of a first heating before forging, wherein two heating stages are included; the third step of billet fabricating, wherein four stages are included; the fourth step of machining and damage removing; the fifth step of a second heating before forging; the sixth step of forging and ring rolling; the seventh step of heat treatment, wherein two heat treatment stages are included; the eighth step of machining to appropriate dimensions. By means of the forging forming process of the aluminum alloy straight-flanked ring with the extra-large specification, forging formability and mechanical performance of the aluminum alloy straight-flanked ring with the extra-large specification are improved.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

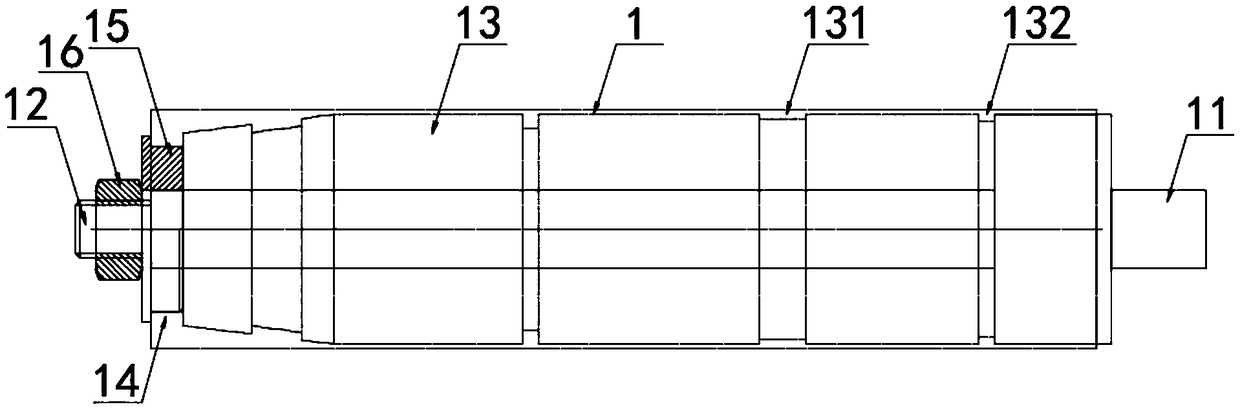

Thin-wall shell processing method

ActiveCN109396766ARestricted degrees of freedomGuarantee quality requirementsWork clamping meansPositioning apparatusEngineeringThermal treatment

The invention discloses a thin-wall shell processing method which comprises a tool clamp, wherein the tool clamp comprises a mandrel; one end of the mandrel is equipped with a mounting column; the outer part of the mandrel is fixedly equipped with an outer ring body in a sleeving mode; a wide ring-shaped slot and a narrow ring-shaped slot are formed in the outer ring body; a step is arranged between one end of the outer ring-shaped body and the mandrel; an auxiliary pressure plate is arranged on the outer part of the step in the sleeving mode; one side of the auxiliary pressure plate is equipped with a nut; and the nut is in threaded connection with the mounting column. The thin-wall shell processing method comprises the following specific steps: step I, outer wall rough turning; step II,high-temperature tempering; step III, left end surface turning; step IV, right end surface turning; step V, clamp mounting; step VI, outer wall fine turning; and step VII, appearance processing. The thin-wall shell processing method performs processing through a high-efficiency machine tool, and a thermal-treatment tempering distressing process is added to release part processing inner stress; andthe necessity of designing a special clamp is combined, so that processing deformation is prevented, and part processing quality requirements are guaranteed.

Owner:河南红宇精密机械有限公司

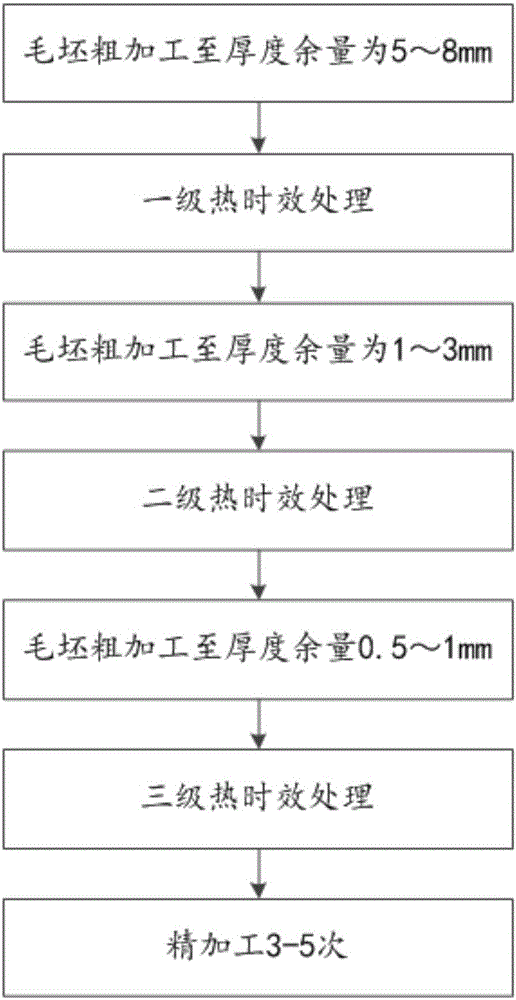

Heat treatment method for machining deformation prevention of 7055 aluminium alloy thin-walled structure

The invention provides a heat treatment method for machining deformation prevention of a 7055 aluminium alloy thin-walled structure. The heat treatment method comprises the following steps: performing rough machining on a member blank till the thickness allowance is 5-8 mm; performing first-level aging treatment; re-performing rough machining on the blank subjected to first-level aging treatment till the thickness allowance is 1-3 mm; performing second-level aging treatment; re-performing rough machining on the blank subjected to second-level aging treatment till the thickness allowance is 0.5-1 mm; performing third-level aging treatment; and finally, performing finish machining on the blank subjected to third-level aging treatment into an end product, wherein the temperatures of the first-level, second-level and third-level aging treatment are 150-250 DEG C and maintained for 25-35 h. The three-level of aging treatment can reduce the residual stress of the 7055 aluminium alloy thin-walled structure after each time of machining, further can prevent the 7055 aluminium alloy thin-walled structure from machining deformation in the machining process, improves the product dimensional accuracy and ensures that a product can maintain the original strength level.

Owner:CHINA HELICOPTER RES & DEV INST

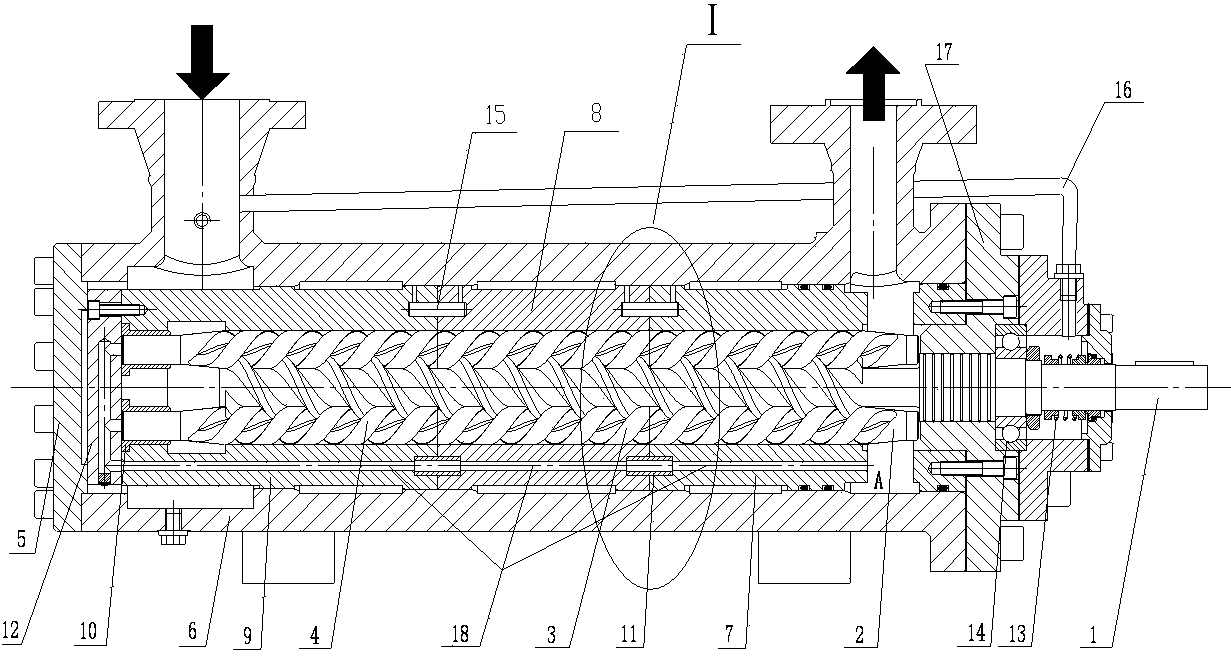

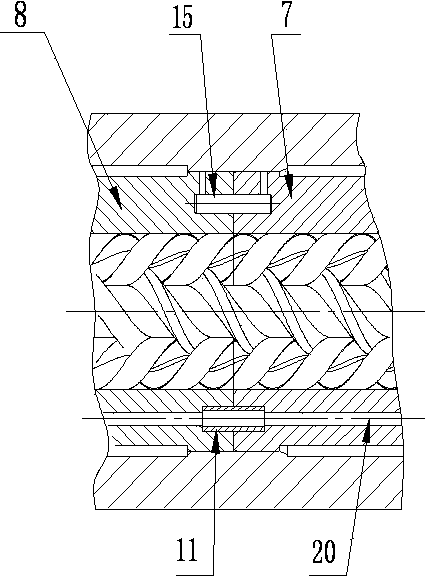

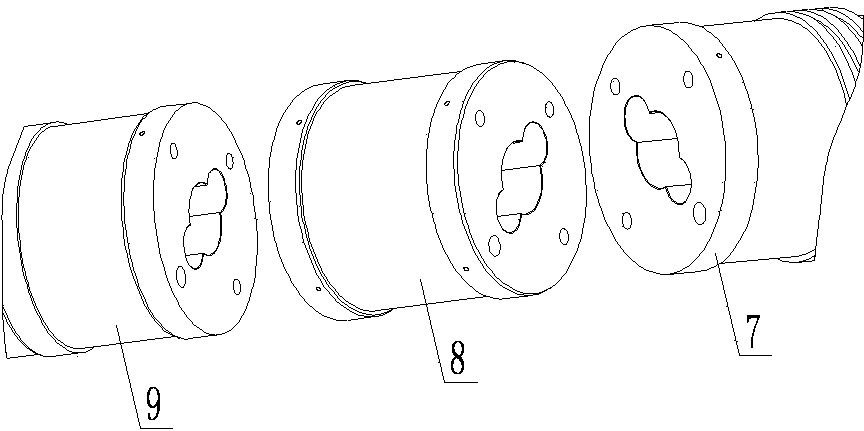

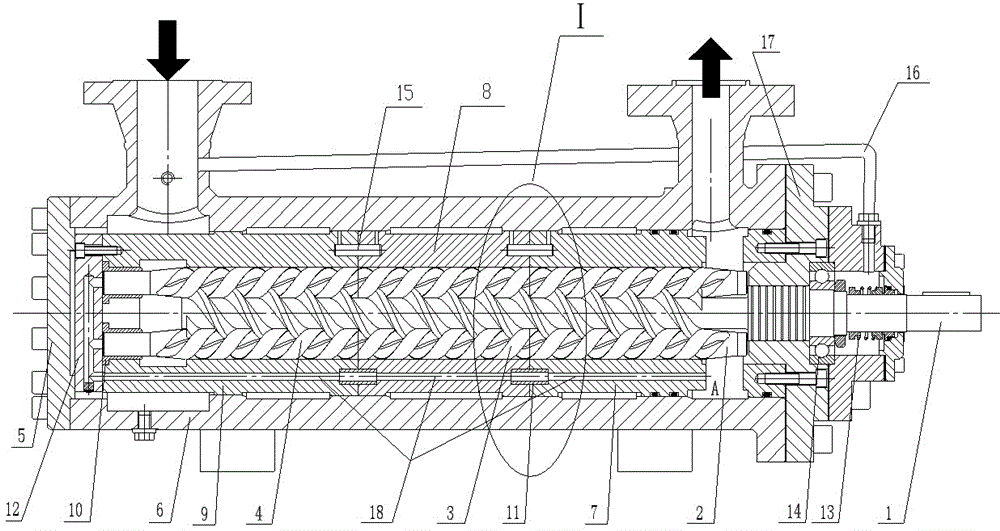

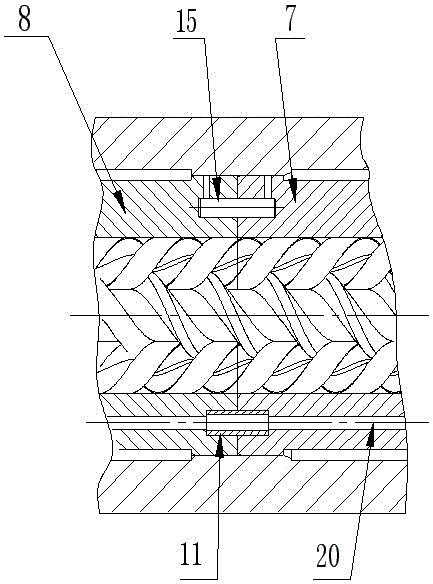

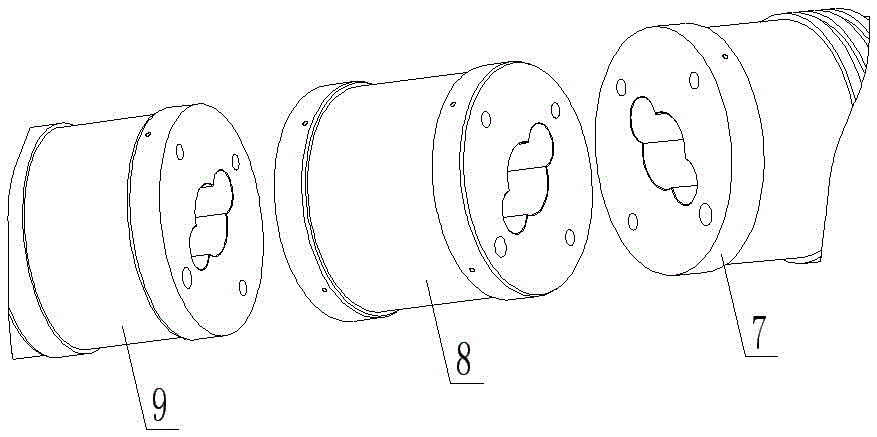

High-property high-pressure three-screw pump

ActiveCN103711690AReduce difficultyGuaranteed machining accuracyRotary piston pumpsRotary piston liquid enginesWorking pressureEngineering

The invention relates to a high-property high-pressure three-screw pump. The high-property high-pressure three-screw pump comprises a pump body, a liner, a driving screw and two driven screws, wherein the liner is formed by connecting three sections of split liners in sequence; three matching holes matched with the driving screw and the driven screws are respectively formed in the both axial ends of each section of the split liner; the three sections of the split liners respectively comprise a front liner, a middle liner and a rear liner; each driven screw consists of a front section screw, a middle section screw and a rear section screw; the outer ends of the front section screws of the two driven screws are respectively arranged on the pump body and are in the shape of a cantilever; the outer ends of the rear section screws of the two driven screws are respectively arranged in the three matching holes in the outer end of the rear liner through axle sleeves in the cantilever shape; the both ends of the middle section screw of each driven screw respectively are in contact with the corresponding front section screw and rear section screw, so that the middle section screws are in a shape of a float rod. According to the high-property high-pressure three-screw pump provided by the invention, the highest working pressure is 20.0MPa, the machining difficulty is reduced, and the matching precision among parts is improved, so that the reliability and the volume efficiency of the pump can be improved.

Owner:黄山工业泵制造有限公司

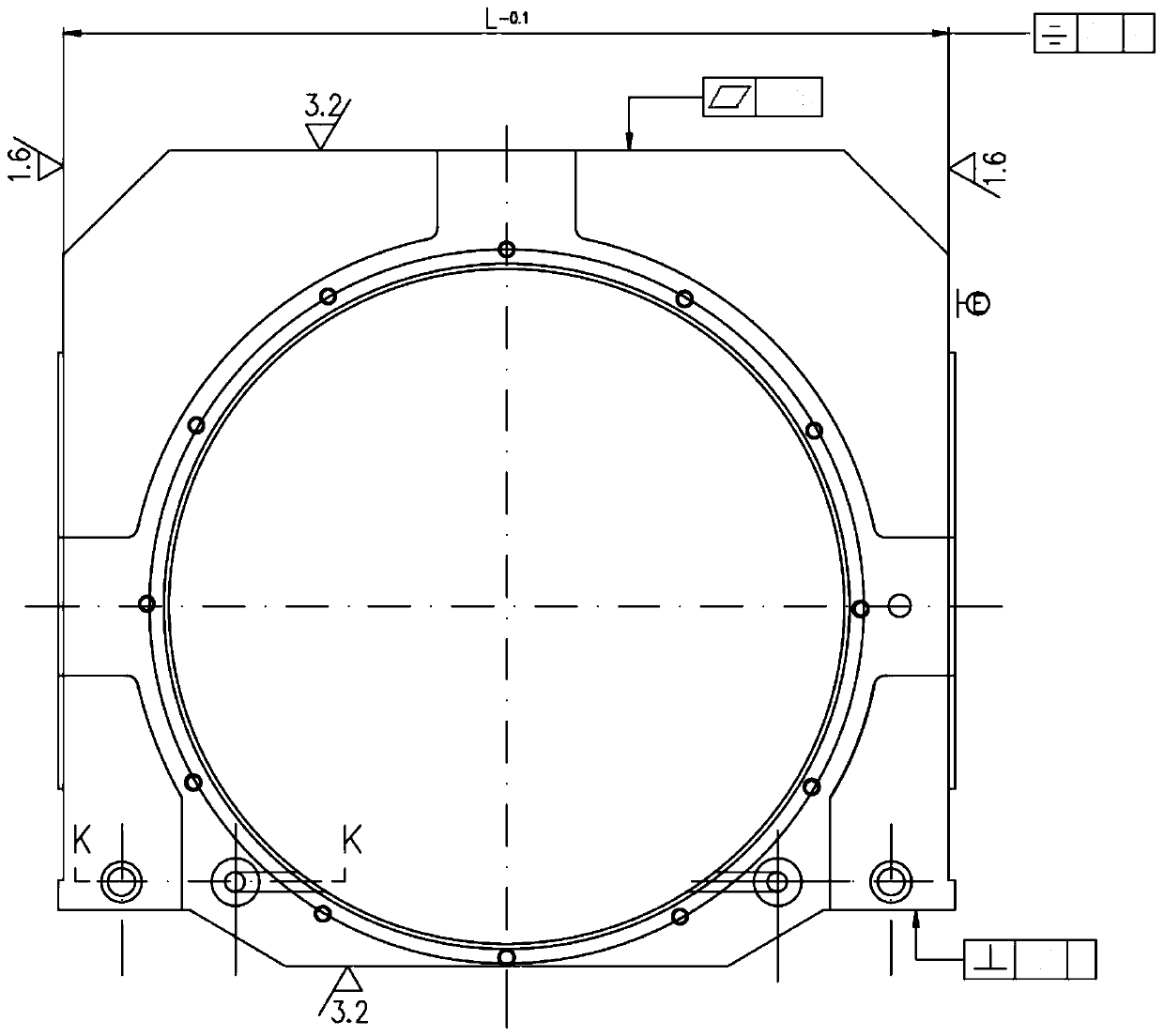

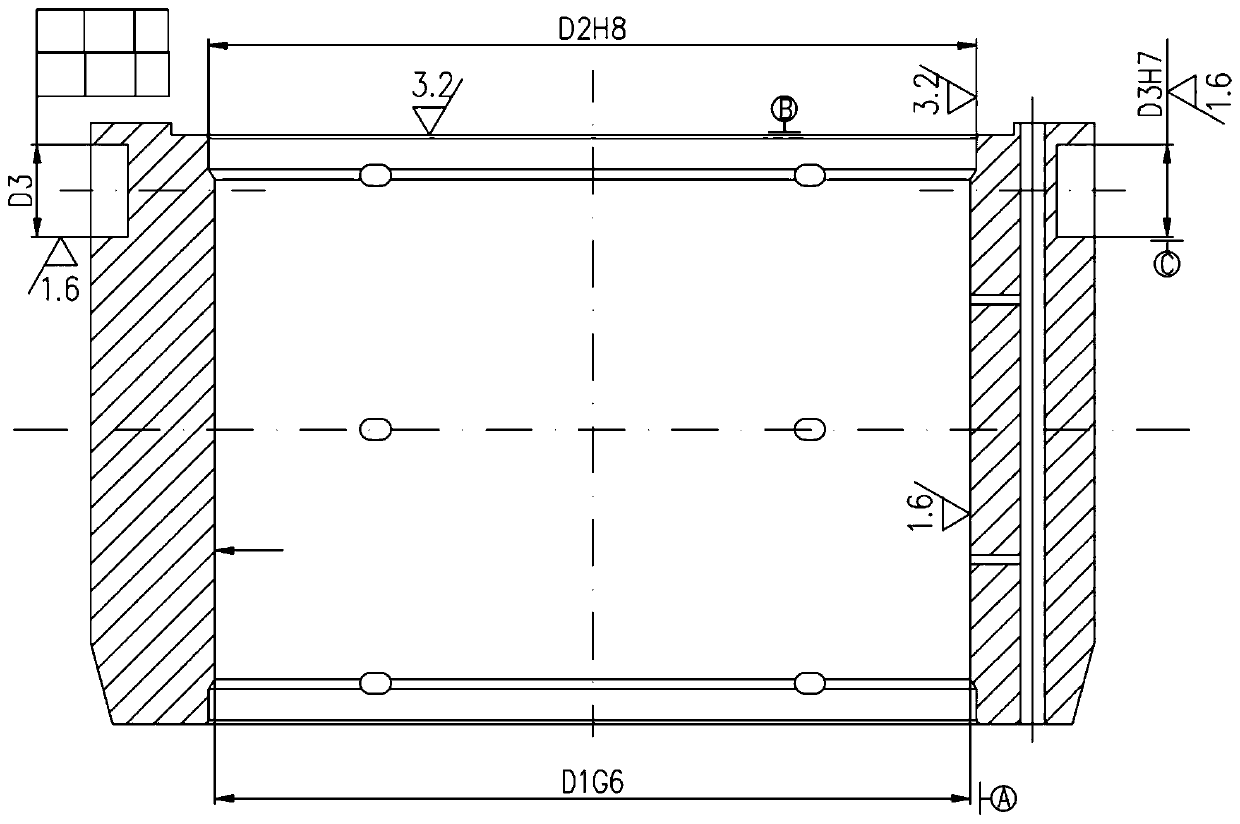

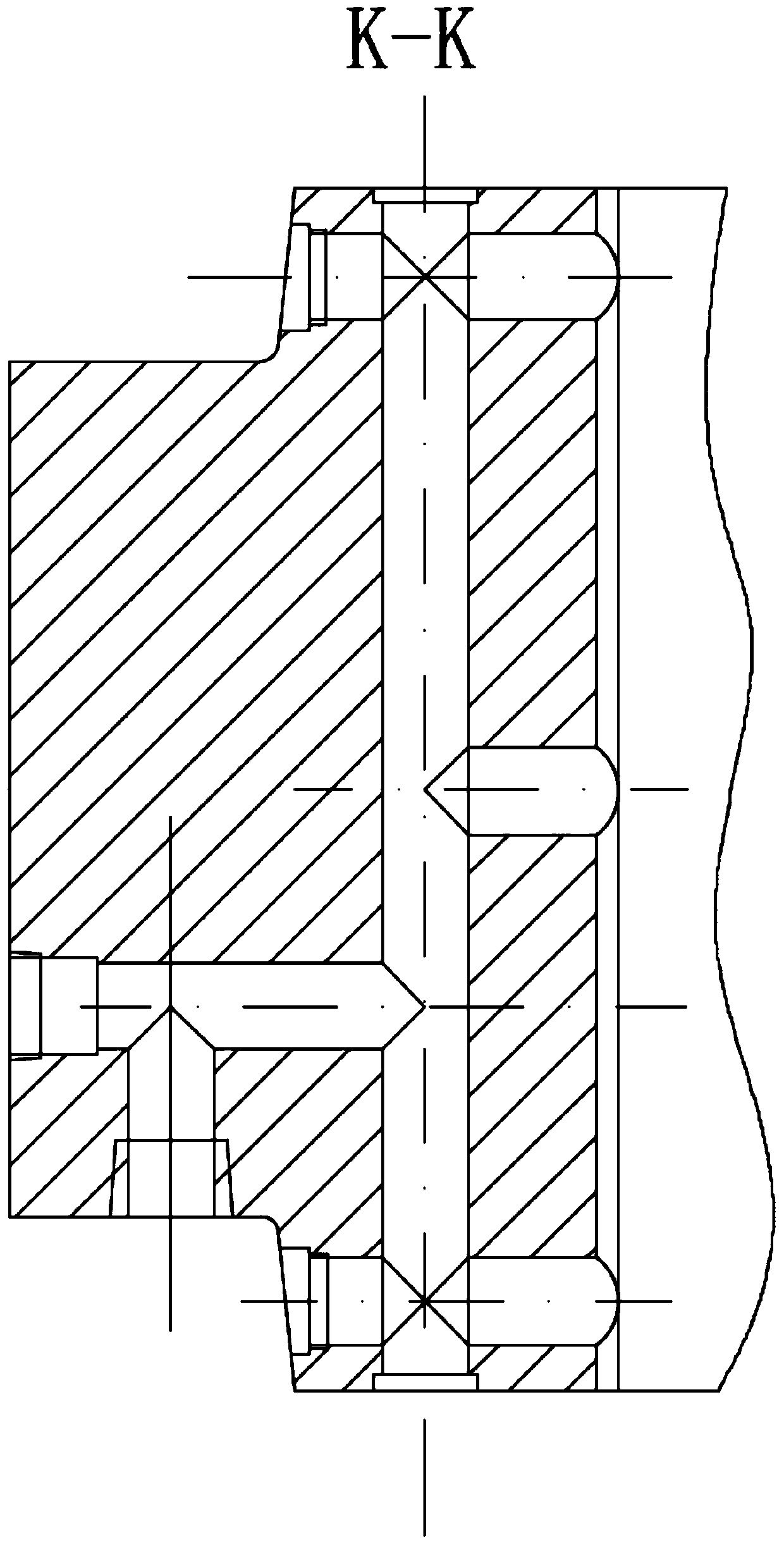

Rolling mill bearing base and manufacturing method thereof

ActiveCN109731916AMeet quick replacement requirementsAxial positioning is accurateMetal rolling stand detailsFurnace typesSurface roughnessSlide plate

The invention discloses a rolling mill bearing base and a manufacturing method thereof. The rolling mill bearing base is forged and processed from high-quality alloy steel, and is mounted at the two ends of a supporting roller of a symmetrical structure on a large rolling mill; the sliding surface which is in contact with a rolling mill memorial gate is equipped with a copper slide plate; precision of a bearing hole is G6, surface roughness of the bearing hole is Ra1.6 and cylindricity of the bearing hole is 0.03mm; precision of a bearing end cover matching hole is H8, surface roughness of thebearing end cover matching hole is Ra3.2, surface roughness of sliding surfaces at the two sides is Ra1.6, degree of symmetry on the bearing hole is 0.1 mm, flatness of an upper surface is 0.05mm, perpendicularity, to the sliding surfaces, of a lower surface is 0.2 mm, the two sliding surfaces are symmetrically equipped with dowel pin holes, precision of the dowel pin holes is H7, surface roughness of the dowel pin holes is Ra1.6, degree of symmetry on the bearing hole is 0.1 mm, and center perpendicularity to the bearing hole is 0.1 mm. An intensive lubricating system is adopted, and a ratioof hole depth to hole diameter of an oil inlet and outlet is 20 or higher. The rolling mill bearing base can meet the requirements of quickly replacing and interchanging a supporting roller, is accurate in positioning, is good in cooling and lubricating effect, is high in precision, reduces rolling mill faults, and guarantees the processing quality.

Owner:武汉钢铁有限公司

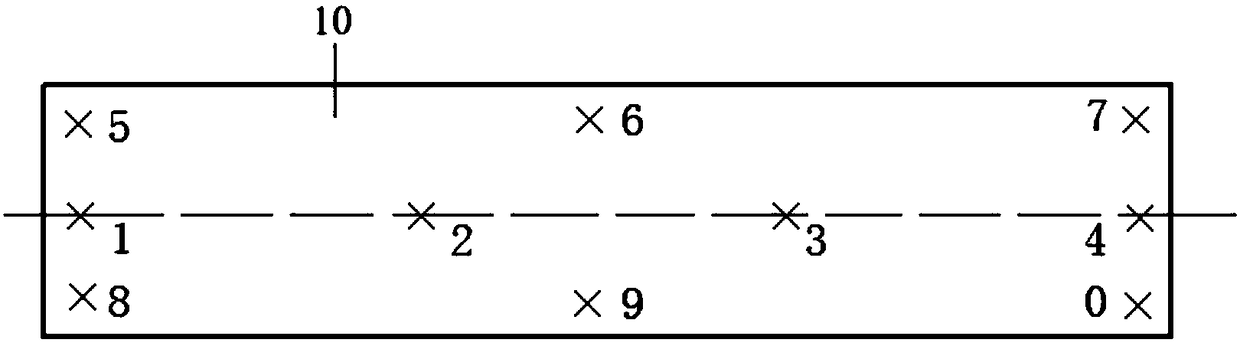

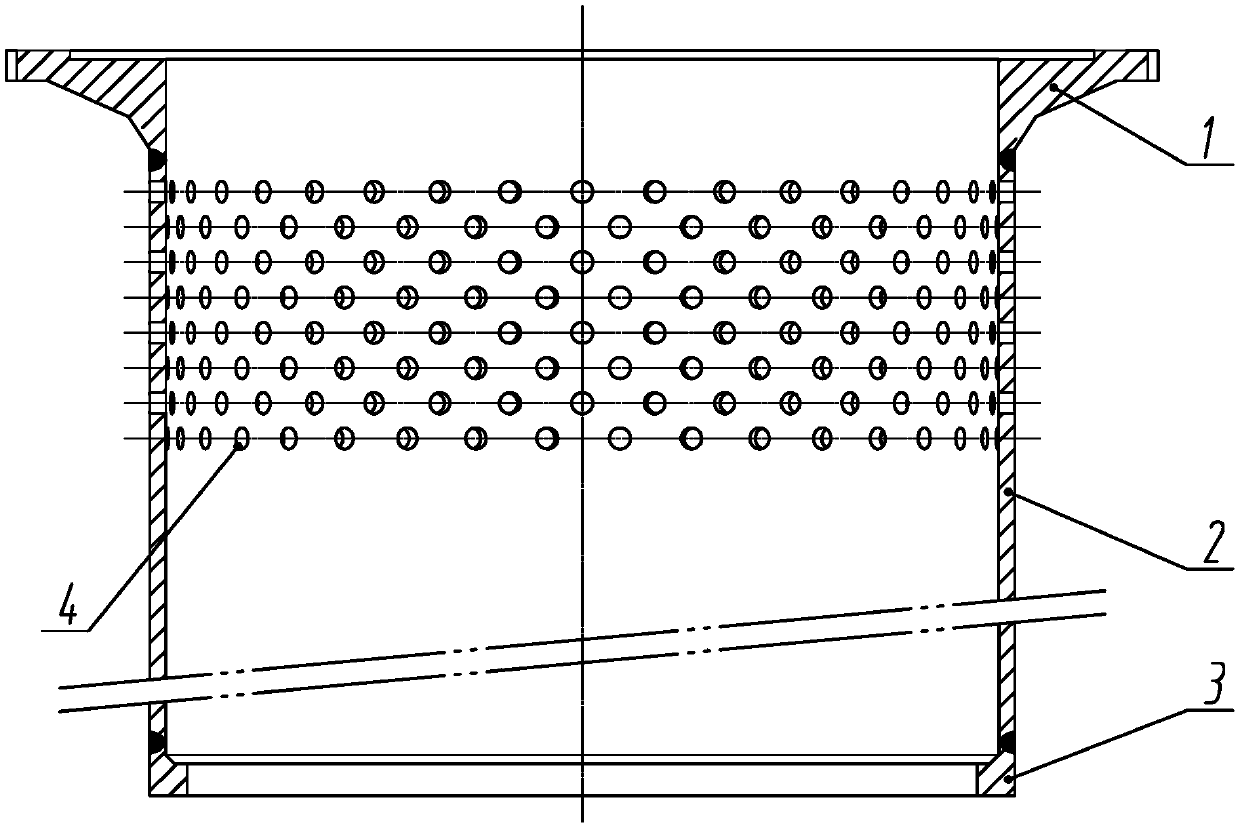

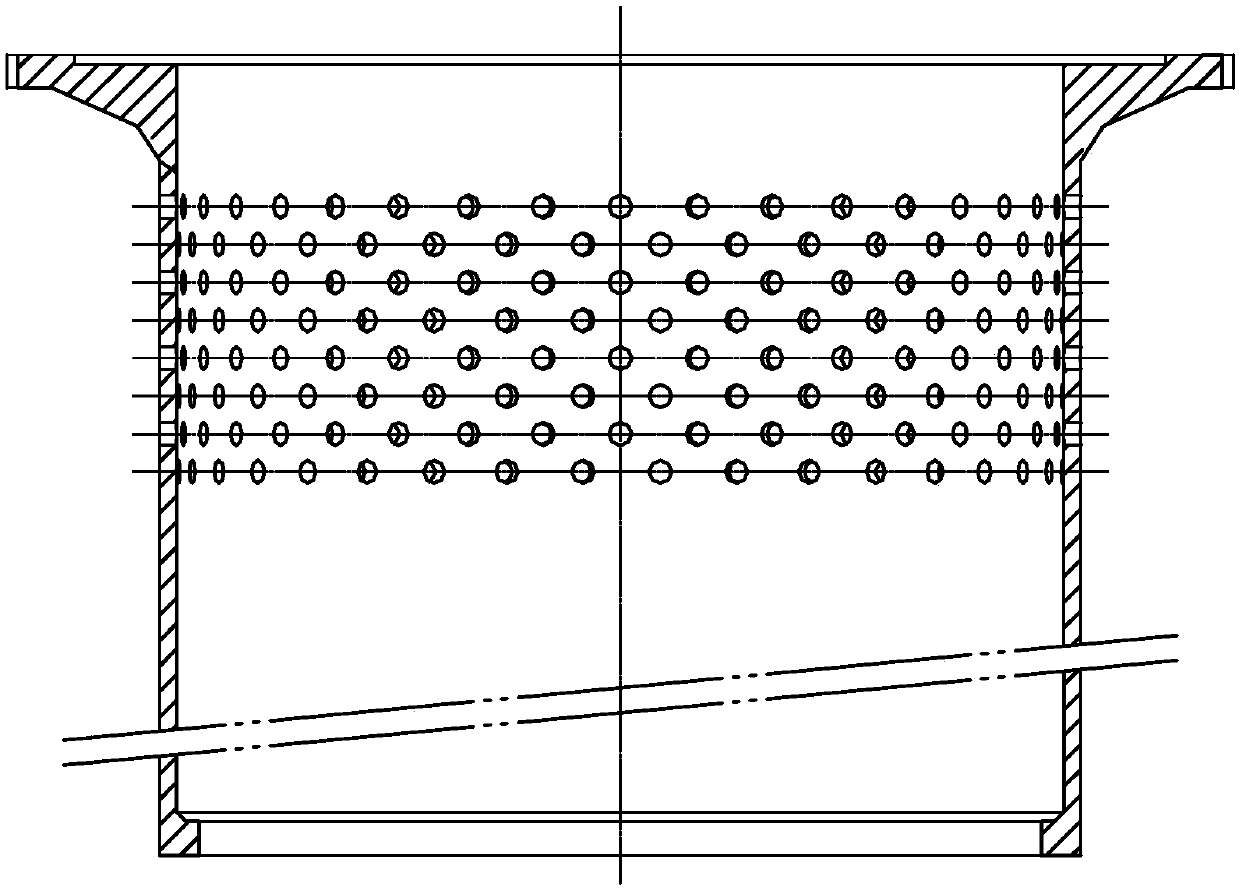

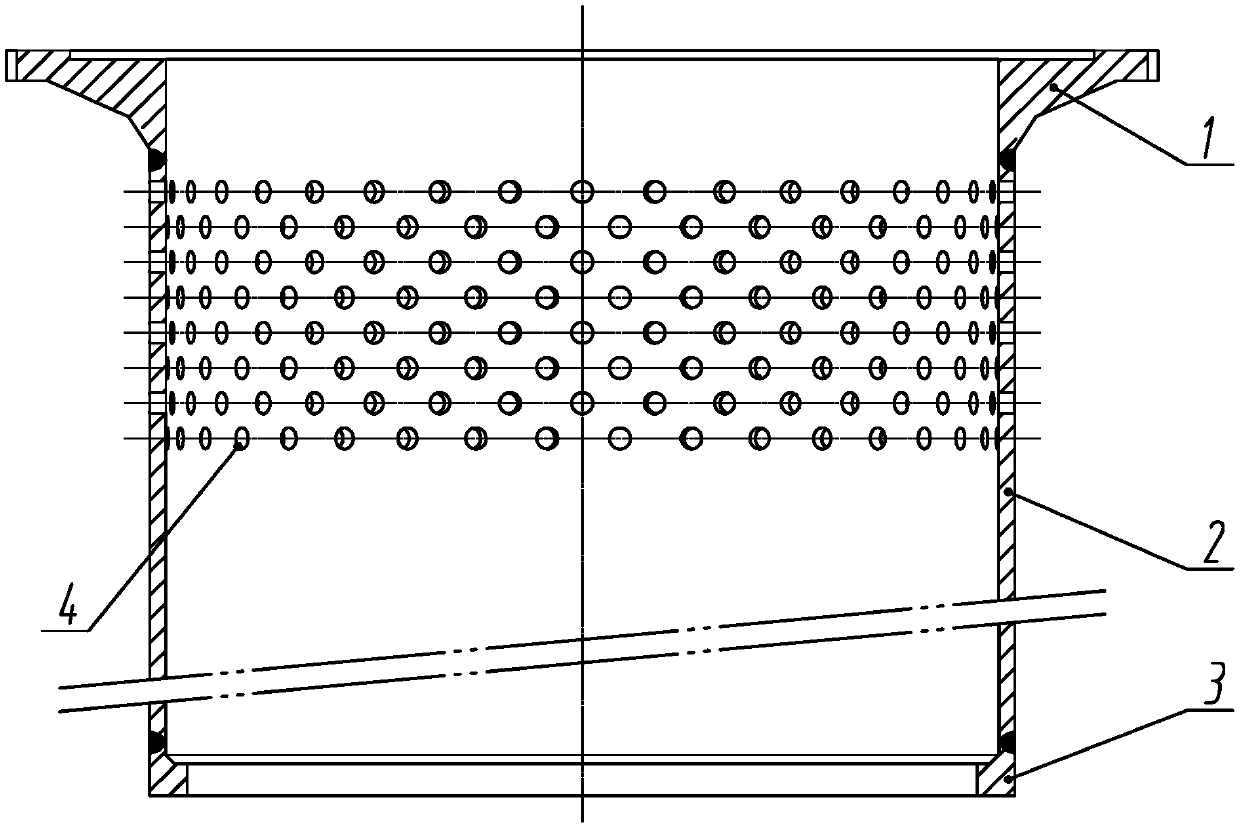

Apparatus having negative dot pattern used in machining thin light guide plate

InactiveCN102764913AReduce foulingPrevent processing deformationMetal working apparatusOptical light guidesLight guideEngineering

An apparatus having a negative dot pattern used in machining a light guide plate. The apparatus includes a machining table unit disposed under the light guide plate, a drive unit disposed over the machining table unit, a plurality of adjustment units disposed over the light guide plate, a plurality of machining support units disposed over the light guide plate, and a plurality of machining units disposed over the light guide plate. When each machining unit has reached a machining position by being transported in transverse and vertical directions above the light guide plate by the drive device, each machining unit engraves dots while the light guide plate is being carried in the machining direction. After the light guide plate is machined, the drive device is transported to an upper position and to a position where next dots are intended to be engraved, and the next dots are sequentially engraved.

Owner:IST KOREA

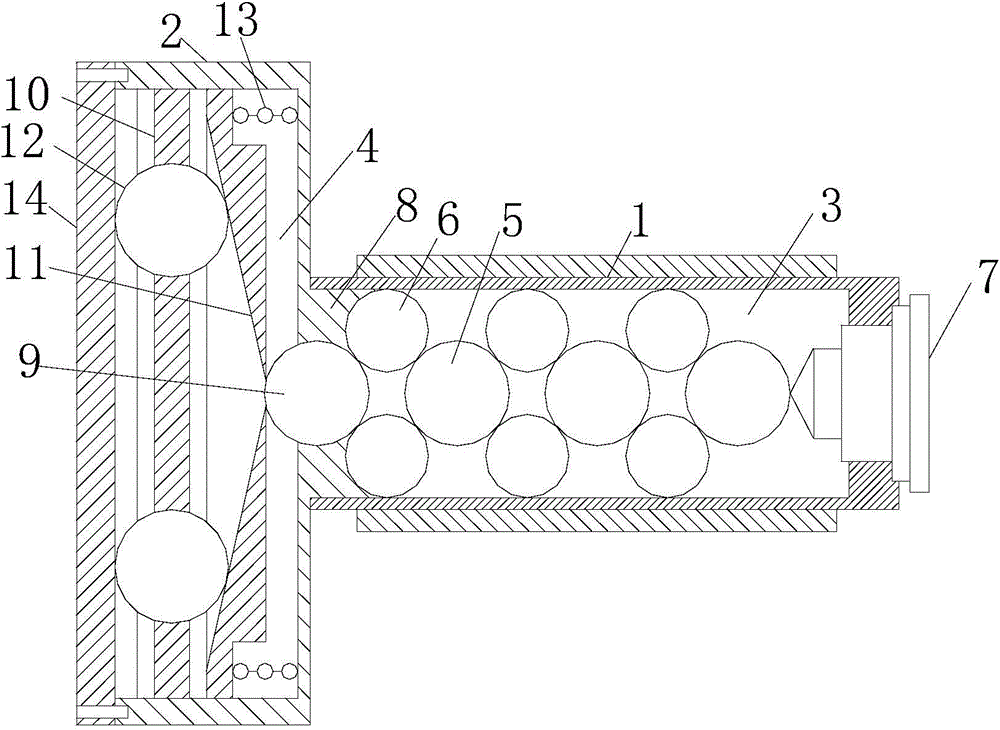

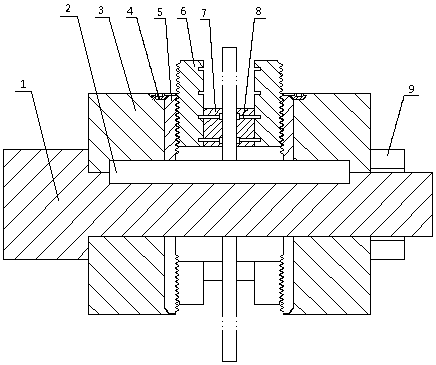

Centrifugal ball clamping fixture

The invention relates to a centrifugal ball clamping fixture comprising an expanding sleeve type mandrel. One end of the coupling mandrel is connected to a housing, the coupling mandrel is provided with a first cavity fulfilled with steel balls, one end of the first cavity, at the connecting position with the housing, is provided with a limit step inside, and the other end of the expanding sleeve type mandrel seals the first cavity through a movably-connected moving part; the housing is provided with a second cavity inside; the first cavity and the second cavity are connected through a first ball, and the first ball and the limit step form a partitioning wall partitioning the first cavity and the second cavity; the second cavity is provided with an automatic extruding device used for extruding the first ball to move in a reciprocating manner. The centrifugal ball clamping fixture has the advantages that the fixture is simple in structure and convenient to use and is capable of clamping thin-wall cylindrical workpieces rapidly and tightly.

Owner:常州市文每机械配件厂

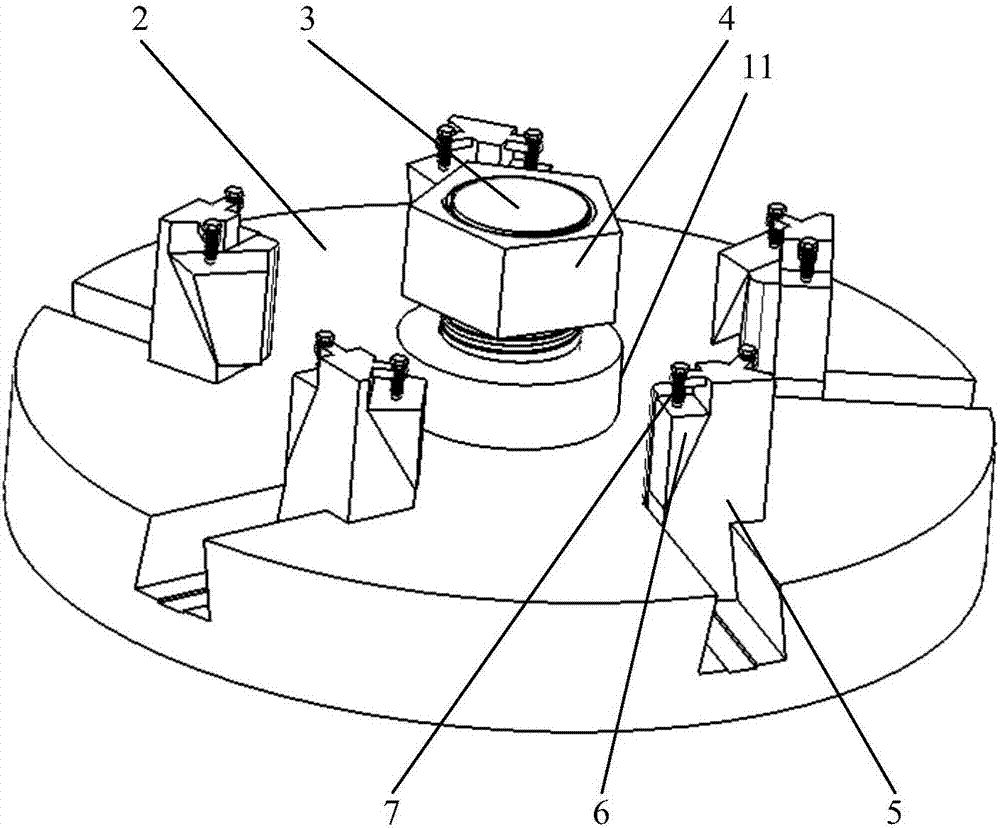

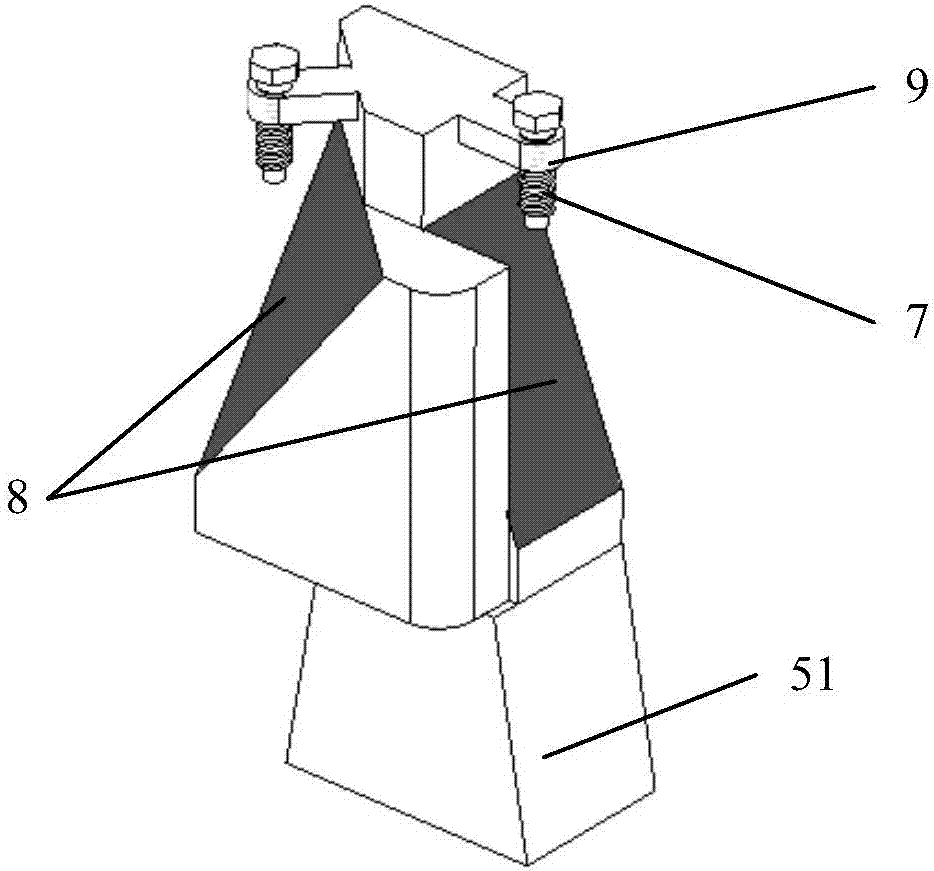

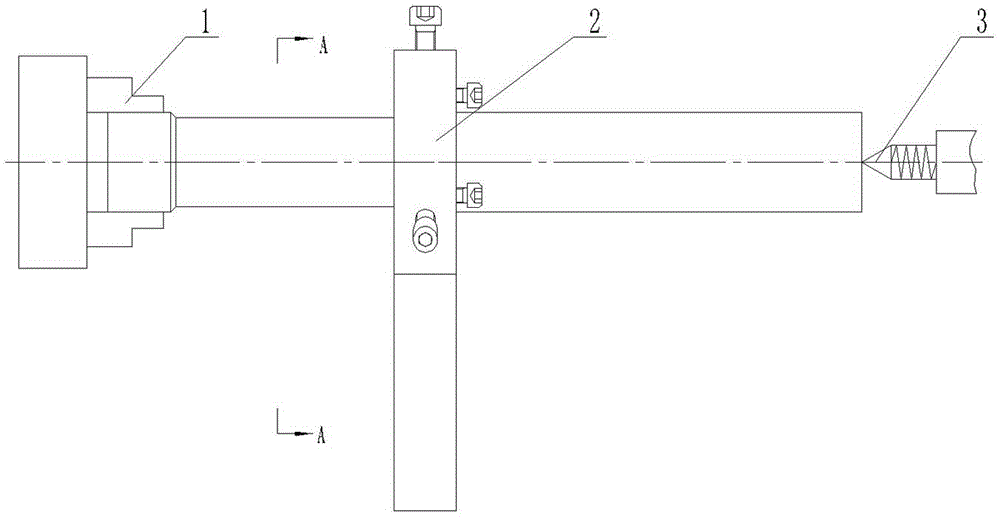

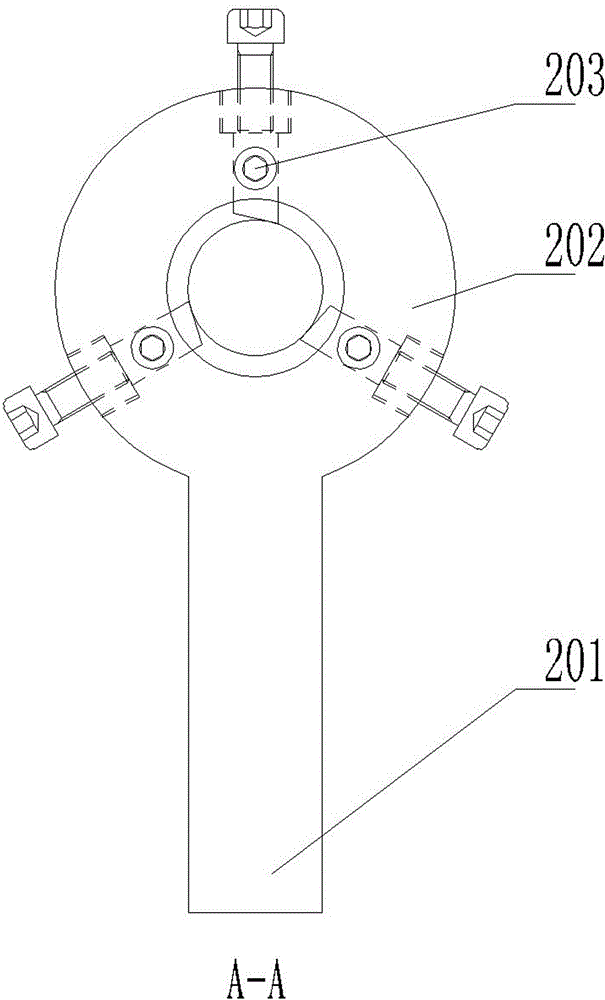

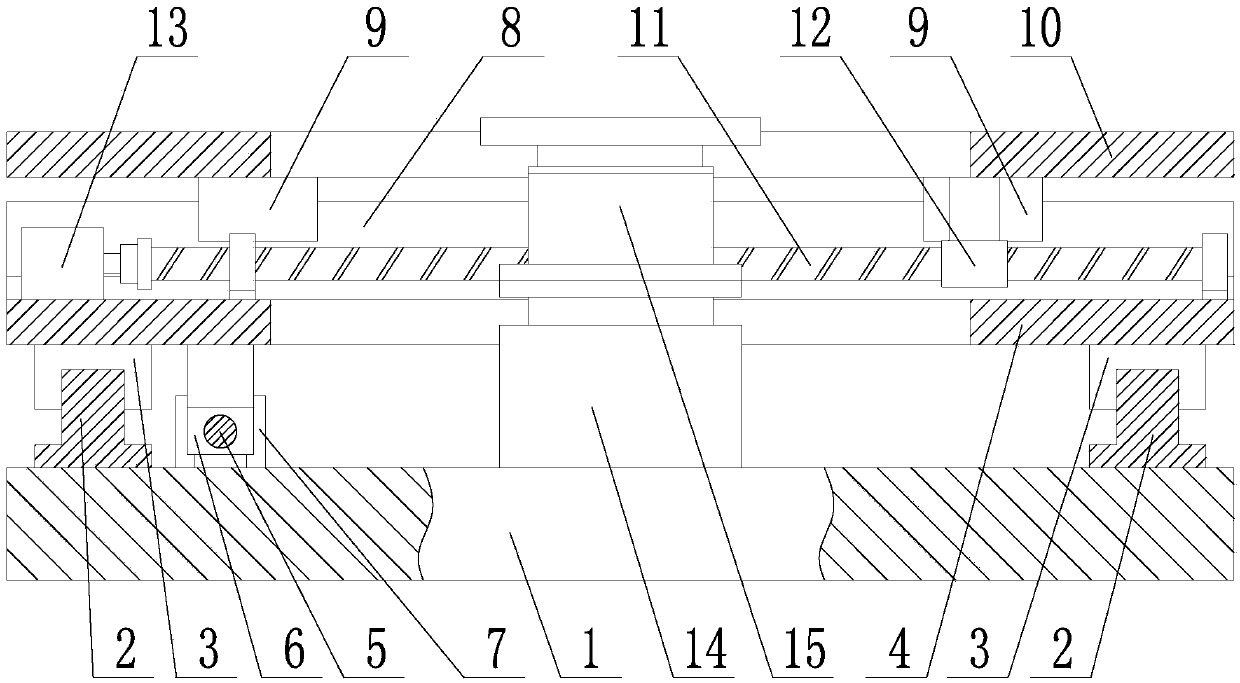

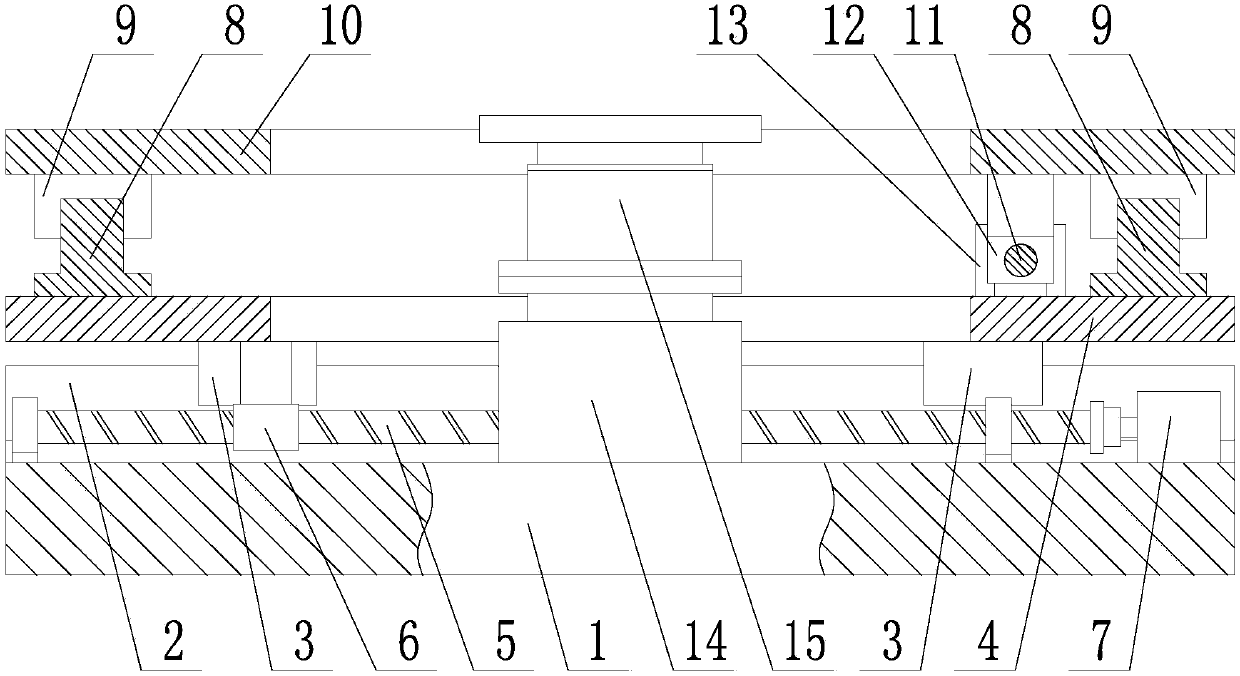

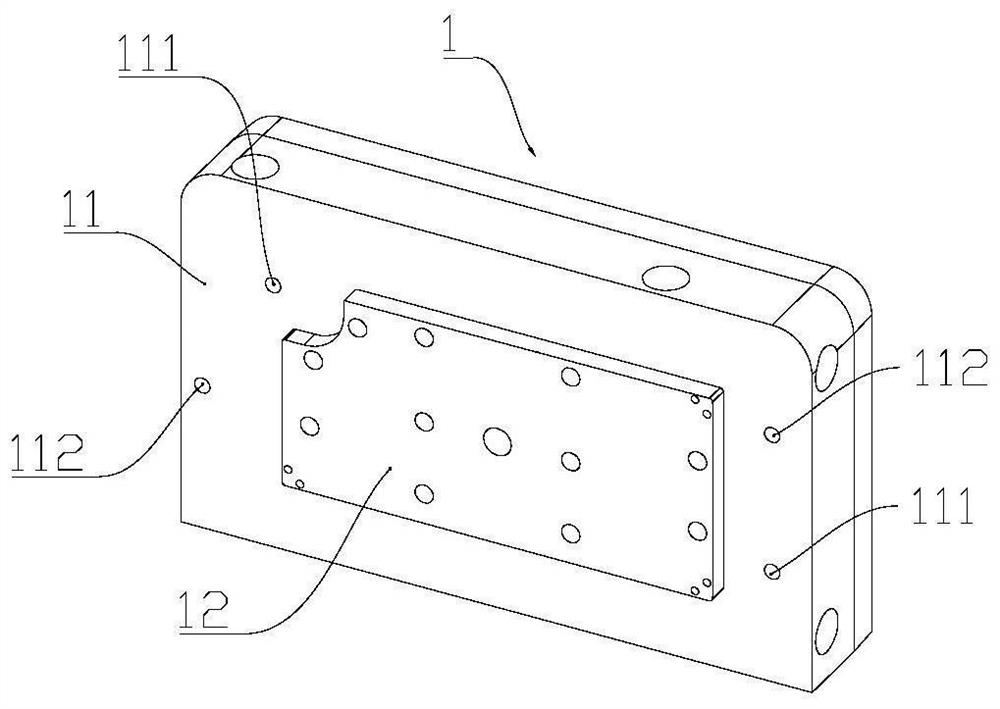

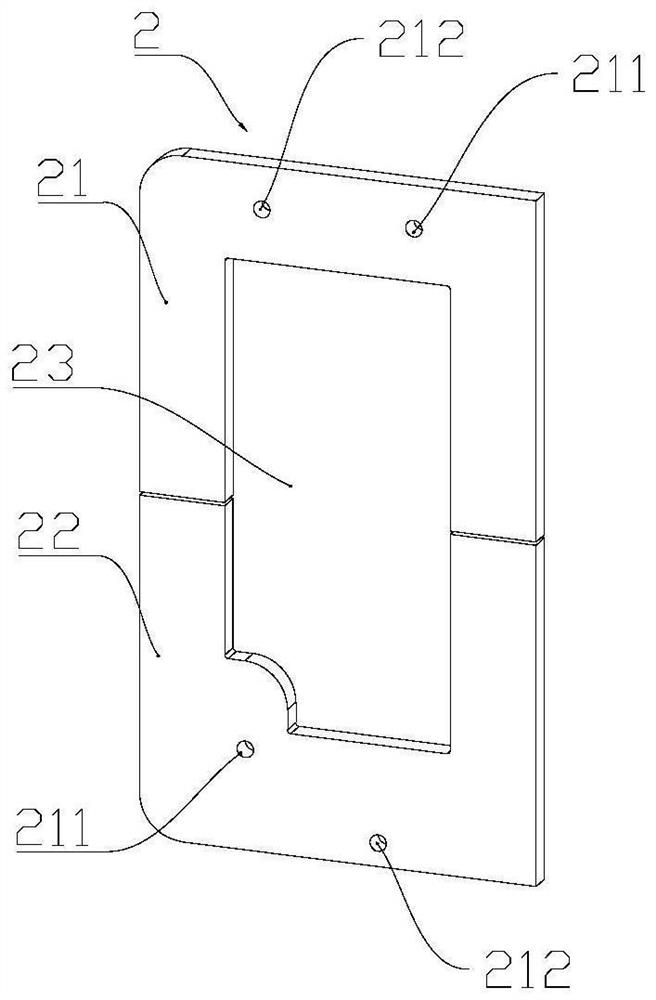

Positioning and clamping device for machining plate parts and using method of positioning and clamping device

InactiveCN106903528APrevent processing deformationCounteracts circumferential cutting forcesPositioning apparatusMetal-working holdersEngineeringCutting force

The invention discloses a positioning and clamping device for processing disc parts and a method for using the same. It comprises a clamp base and a moving slider. The center of the clamp base is provided with a positioning boss, and the radial direction of the clamp base is provided with several slide rails. , each slide rail is equipped with a matching moving slider, the bottom of the moving slider moves back and forth along the sliding rail, and the middle part of the moving slider is provided with two sliding block slopes, and the sliding block slopes are equipped with matching The top of the moving slider is provided with a threaded hole, and the threaded hole is provided with a compression bolt for controlling the clamping of the corresponding compression block. The invention can effectively offset the cutting force in the circumferential direction, avoid the processing deformation caused by insufficient rigidity of parts, and improve the processing quality and pass rate.

Owner:JIANGSU UNIV OF SCI & TECH

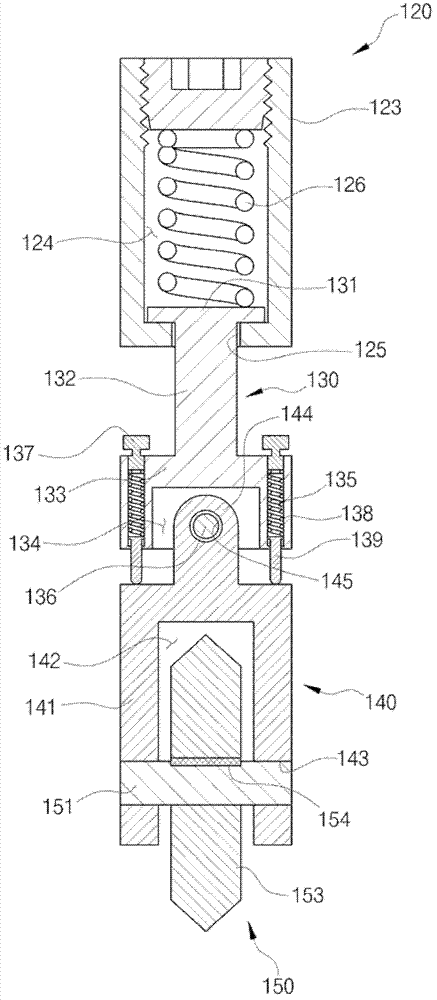

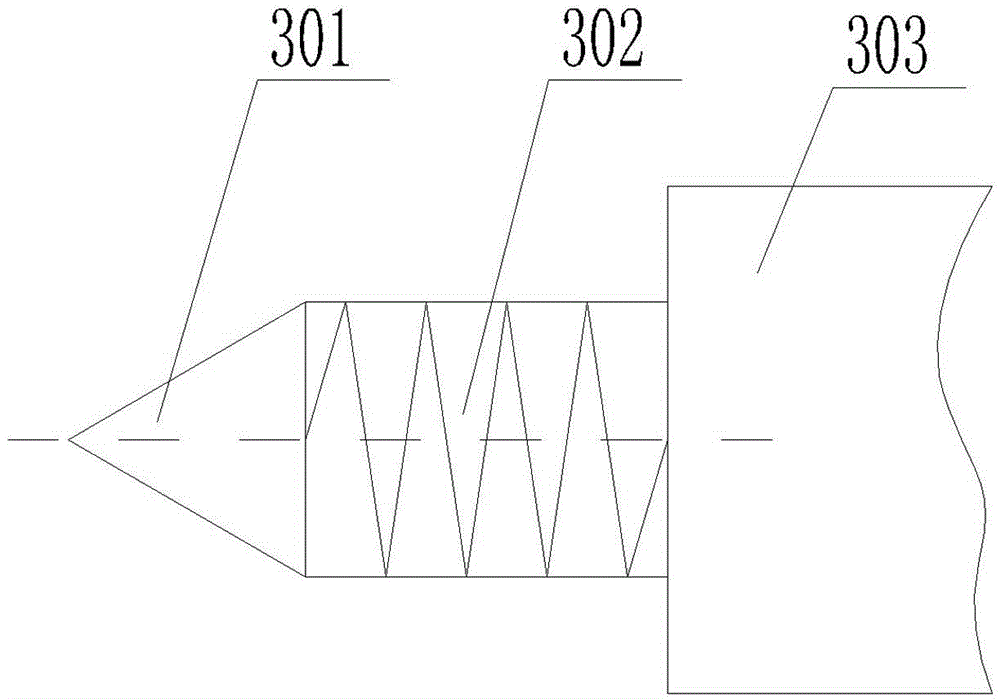

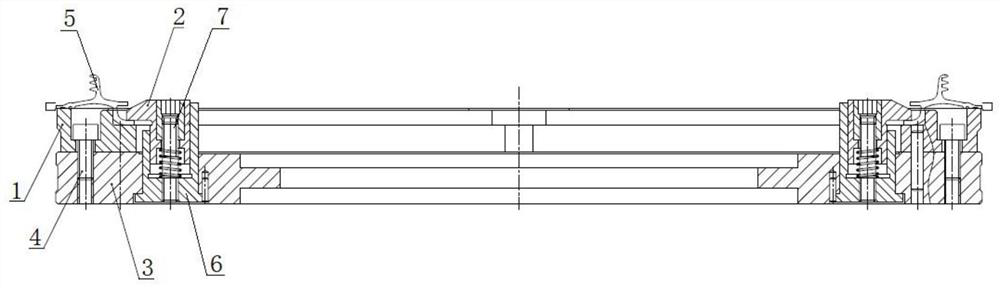

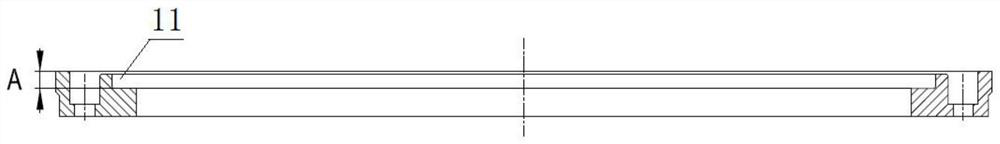

Device for machining slender shaft

InactiveCN104889422AAvoid bending deformationEasy to replaceTailstocks/centresTurning machinesElastic componentMachining deformation

The invention discloses a device for machining a slender shaft. The device comprises a fixture and a cutting device, the fixture is used for fixing the slender shaft, the cutting device is used for cutting the slender shaft, the fixture comprises a chuck and a tip which are used in a matched manner, an ejector pin is an elastic tip and comprises a tip head, a tip body and an elastic component positioned in the tip body, the cutting device comprises a cutter handle, a cutter head and turning tool components, the cutter head is connected with the cutter handle, the turning tool components are uniformly distributed on the cutter head, each turning tool component comprises a square hole, a positioning device and an adjusting device, and the square holes for mounting blades are formed in the cutter head. The cutter head is a small part, small in size, light in weight and applicable to a common latch, the problems of radial and axial cutting force can be simultaneously solved, the device has an excellent effect for effectively preventing machining deformation of a slender shaft workpiece, and machining accuracy of parts is effectively improved.

Owner:GUIZHOU HANGRUI AVIATION PRECISION PARTS MFG

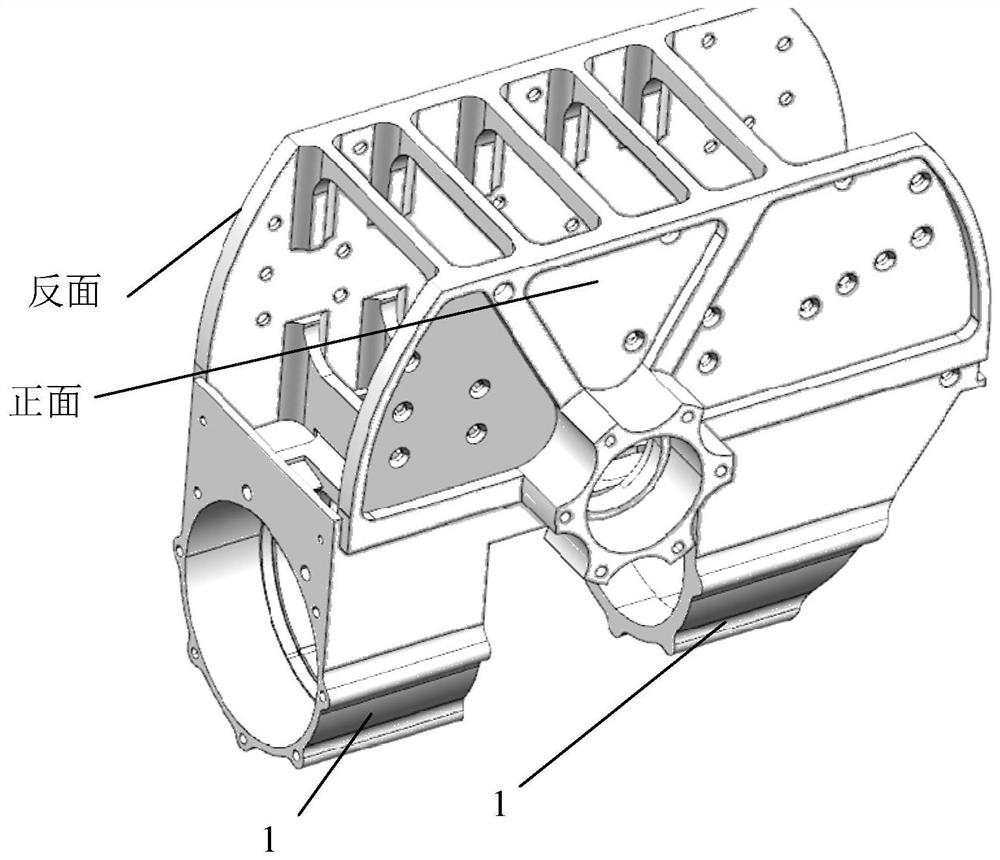

Machining method of weak-rigidity thin-wall hollow structure part

InactiveCN112643101APrevent processing deformationAvoid breaking accidentsMilling equipment detailsPositioning apparatusMachining deformationClassical mechanics

A machining method of a weak-rigidity thin-wall hollow structure part comprises the following steps that the front face and the back face of the weak-rigidity thin-wall hollow structure part are subjected to rough cutting machining, allowance is reserved at a laser cabin, and the reserved allowance serves as a process block; vibration aging treatment is conducted on the weak-rigidity thin-wall hollow structure part through a vibration stress relief device, and the residual stress of the structure part is eliminated; the outer side structure or the inner side structure of the weak-rigidity thin-wall hollow structure part is subjected to finish cutting machining; and the flying wall process block is fixedly installed on the inner side surface or the outer side surface of the weak-rigidity thin-wall hollow structure part, and the inner side structure or the outer side structure of the weak-rigidity thin-wall hollow structure part is subjected to finish cutting machining. By means of the machining method, machining deformation of the weak-rigidity thin-wall structure part is effectively controlled and reduced, and the machining quality is guaranteed.

Owner:SHANGHAI RADIO EQUIP RES INST

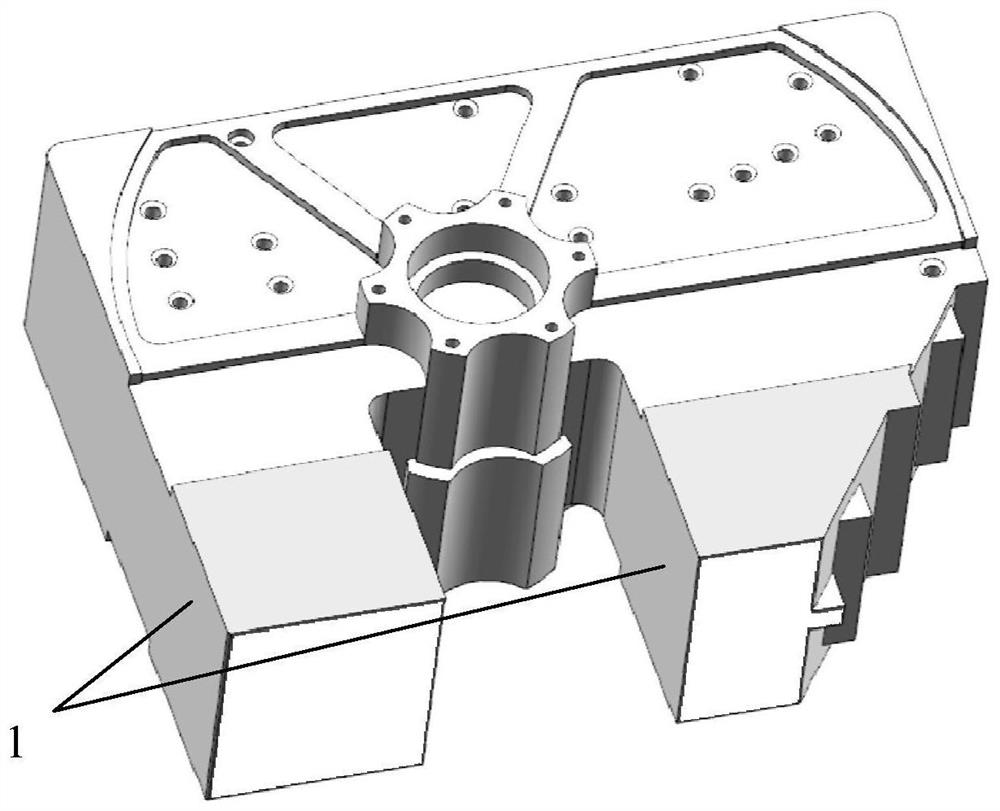

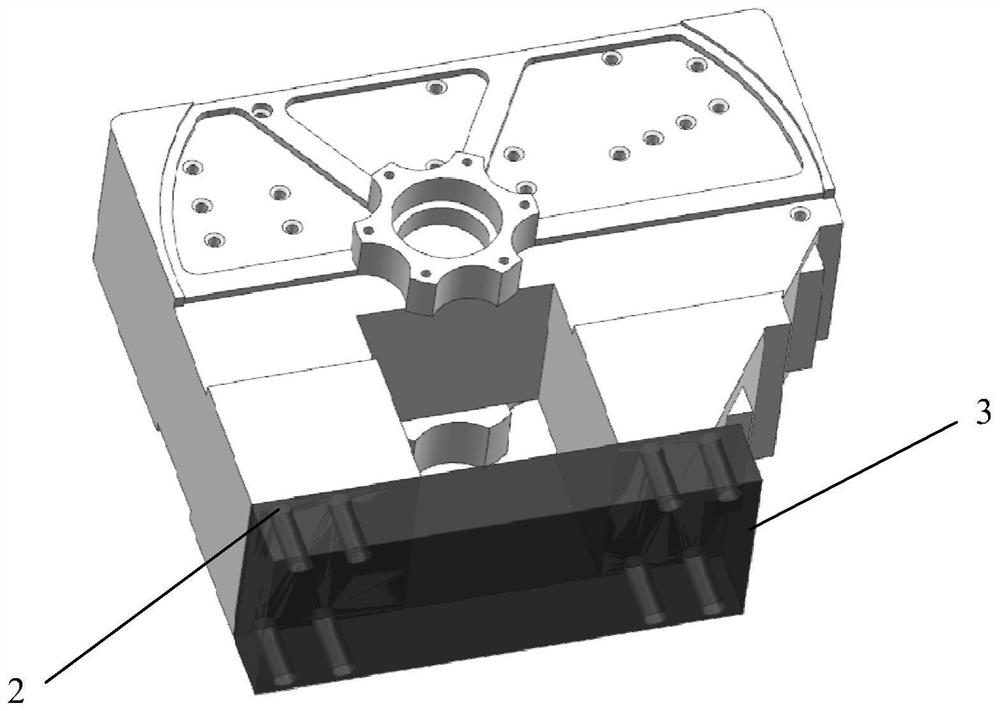

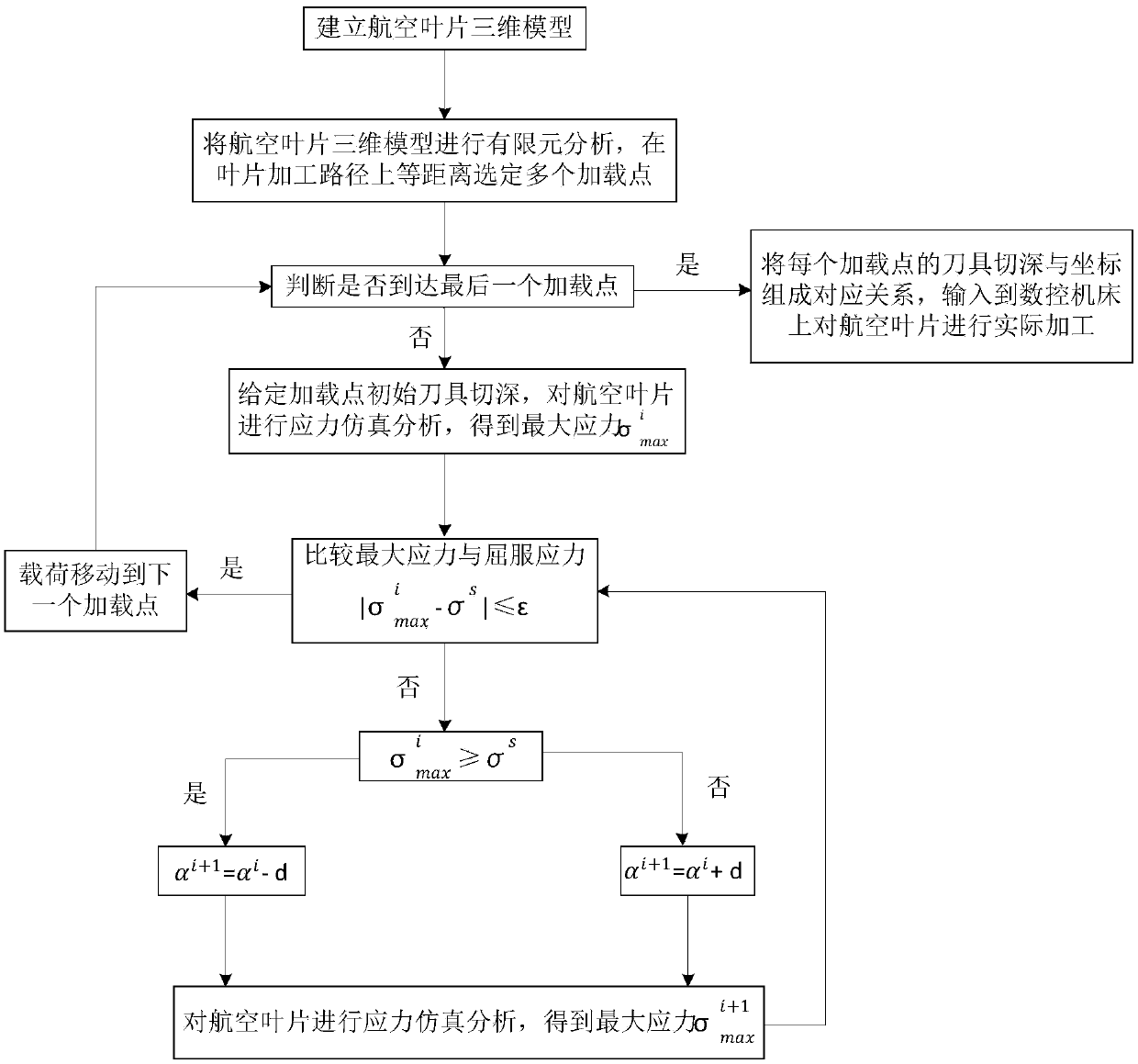

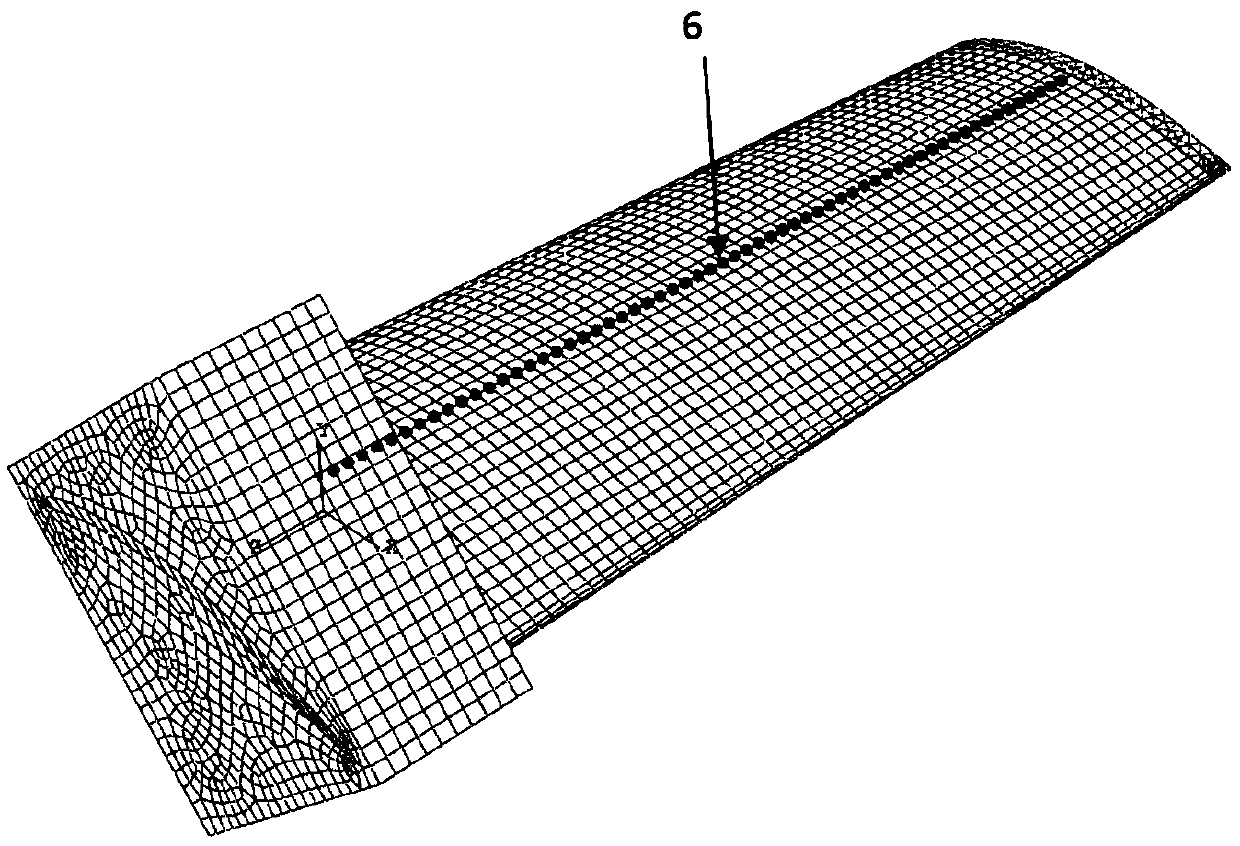

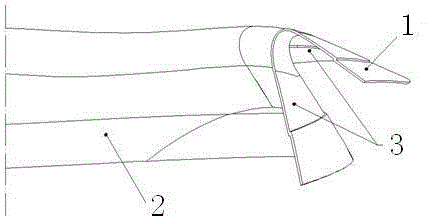

Method for improving yield rate of aviation blade machining

ActiveCN109605120APrevent processing deformationTool depth of cutAutomatic control devicesFeeding apparatusCutting forceMachine tool

The invention discloses a method for improving the yield rate of aviation blade machining. According to the method for improving the yield rate of the aviation blade machining, the cutting force applied on cutting points of a cutter on a blade model machining path is simulated and analyzed by a finite element analysis software, the obtained maximum stress is compared with the yield stress, and optimal cutter cutting depth of the cutting points is obtained by iterative adjustment; the optimal cutter cutting depth of each of the cutting points in the blade machining is obtained by iterative computations on the multiple cutting points of the machining path, the cutter cutting depths and coordinates of the points are input into a cutter machining run code of a numerically-controlled machine tool, and actual blade machining is carried out by the numerically-controlled machine tool; blade machining deformation is prevented under the machining parameters, and the cutting depth of the cutter is maximum; and the blade machining efficiency and the blade machining yield rate are improved under the premise that the machining quality is guaranteed.

Owner:ZIGONG INNOVATION CENT OF ZHEJIANG UNIV

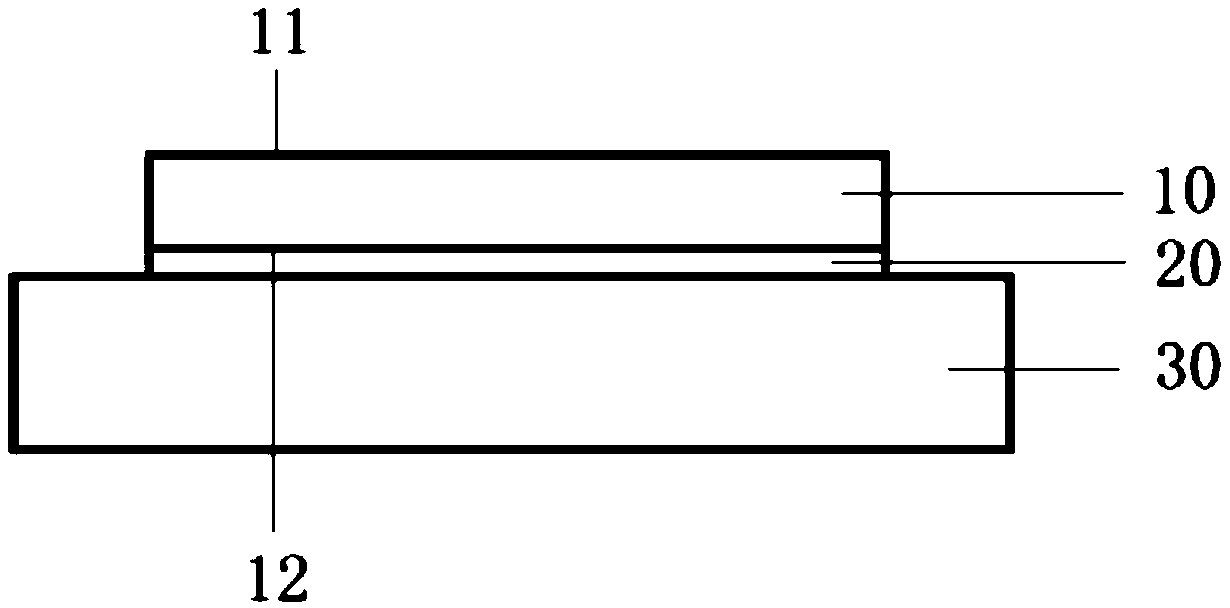

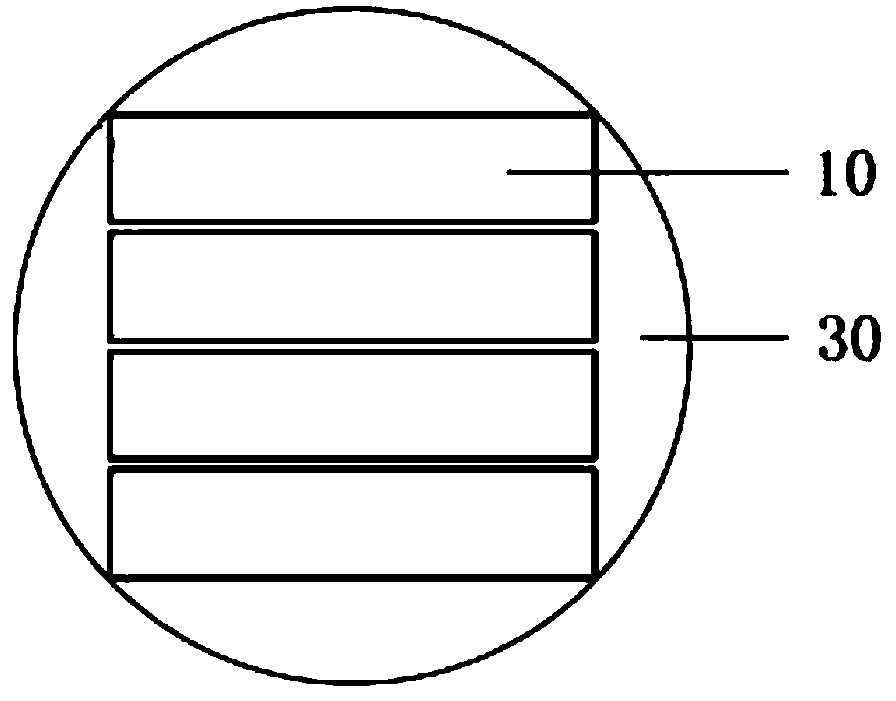

Precision reprocessing method of leaf spring

The invention discloses a precision reprocessing method of a leaf spring, and relates to a processing method of leaf spring parts. The precision reprocessing method mainly comprises the following steps that the second reference surface of the leaf spring is adhered to a first-level optical contact pad plate by yellow wax rosin size with a ratio of 1: 3; the optical contact pad plate is turned upside down onto a grinding disc of a single-shaft machine special for grinding, and the first reference surface of the leaf spring is ground successively with W28, W14 and W7 white corundum, and finallya sanded hole with low aperture and without scratches is formed by grinding; the optical contact pad plate is continued to be turned upside down to a polishing disc of a single-shaft machine special for polishing, the first reference surface of the leaf spring is polished with cerium oxide polishing powder, and finally the first reference surface of the leaf spring is detected as lambda / 2@633nm byan interferometer; and the first reference surface is then processed in the same way. According to the precision reprocessing method, the stress is uniform during the grinding and polishing processes, and the processing deformation of the leaf spring is avoided; the method of optical contact is adopted to avoid the influence of adhesive layer error on the end face processing of the leaf spring; and the thickness error of the leaf spring is increased from + / -0.01 mm to + / -0.004 mm, and the qualified rate of leaf spring assembly is increased by 67%.

Owner:湖北省地震局 +1

A method for preparing copper-tungsten composite contacts using copper-tungsten mixed powder 3D printing

ActiveCN112792354BImprove brazing rateImprove conductivityAdditive manufacturing apparatusElectric switchesPunchingCopper–tungsten

The invention discloses a method for preparing a copper-tungsten composite contact by using copper-tungsten mixed powder 3D printing, which mainly includes the following steps: preparation of copper powder and tungsten powder, preparation of copper-tungsten mixed powder, 3D printing, and final treatment of samples. In the method, the specific method of copper-tungsten composite contact is to connect and print copper-tungsten parts on the stamped copper parts, which can save manufacturing costs, and the printed parts and composite interface are fine and free of holes, and the printed copper-tungsten end parts are dense and uniform in composition , excellent performance, and at the same time, this method supports personalized customization and small batch production, which just fits the market development trend of continuous reduction in product cost and continuous improvement in performance and appearance.

Owner:陕西斯瑞铜合金创新中心有限公司

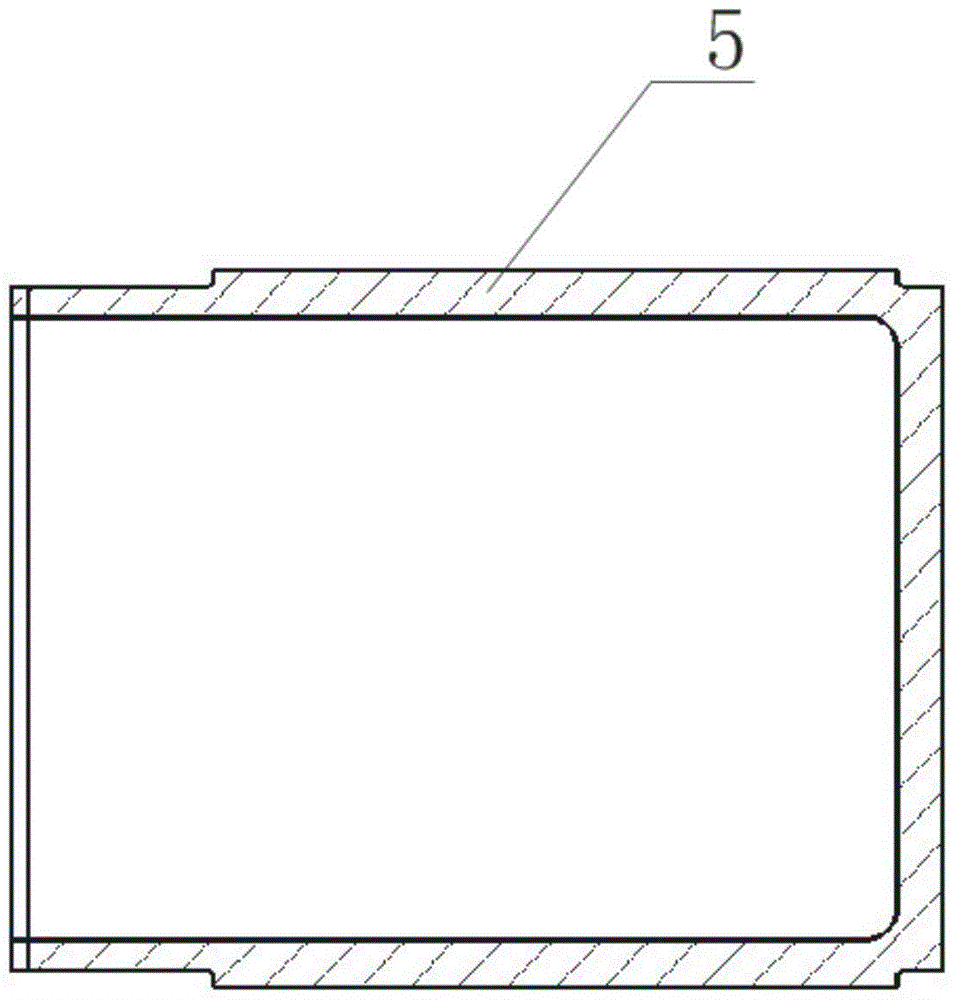

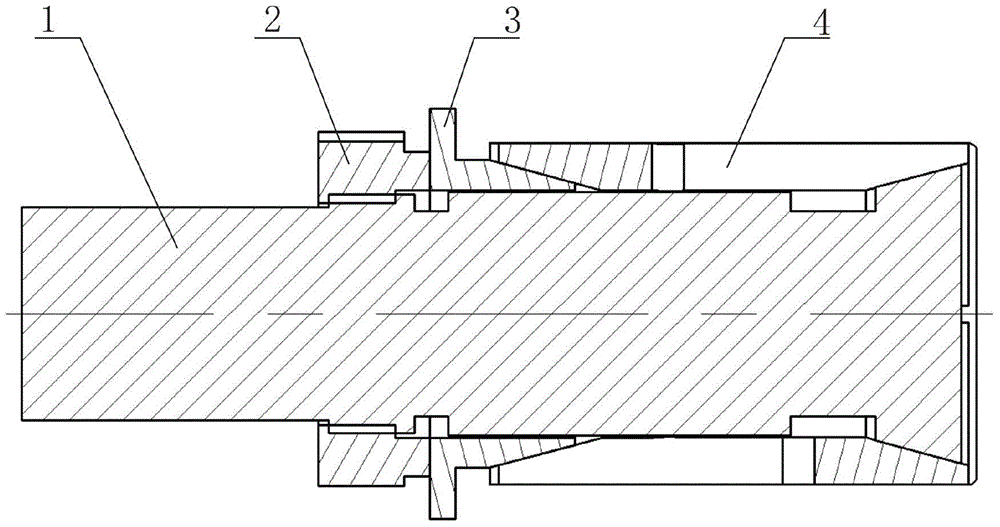

A jig for processing the outer wall of thin-walled sleeve parts without a through hole and its use method

ActiveCN103495755BImprove clamping effectAvoid clampingExpansion mandrelsMachining deformationScrew thread

The invention discloses a machining clamp for the outer wall of a blind-hole thin-wall sleeve part and a using method of the machining clamp. The clamp comprises a core shaft and a fastening nut connected on the core shaft through threads. The core shaft is sleeved with an elastic clamping sleeve, the elastic clamping sleeve is overall cylindrical, cones with the large outsides and the small insides are arranged at the two ends of the elastic clamping sleeve, a conical surface is arranged at the tail end of the core shaft, the tail end of the core shaft is matched with the elastic clamping sleeve, the core shaft is further sleeved with a taper sleeve, the taper sleeve is arranged between the fastening nut and the elastic clamping sleeve, and the conical surface of the tapper sleeve is arranged in the elastic clamping sleeve. The design of the elastic clamping sleeve with two expansile ends is adopted in the clamp, the inner diameter of the part is centered when the elastic clamping sleeve expands, the opening end and the inner bottom end of the part are simultaneously clamped, the function of bidirectional clamping is achieved, then the locating and clamping effect of the clamp is enhanced, the clamping and machining deformation of the external circle of the thin-wall sleeve part can be effectively prevented when finish machining is carried out on a lathe and a grinding machine, machining quality is guaranteed and improved, and therefore production efficiency is improved, and machining cost is lowered.

Owner:贵州凯星液力传动机械有限公司

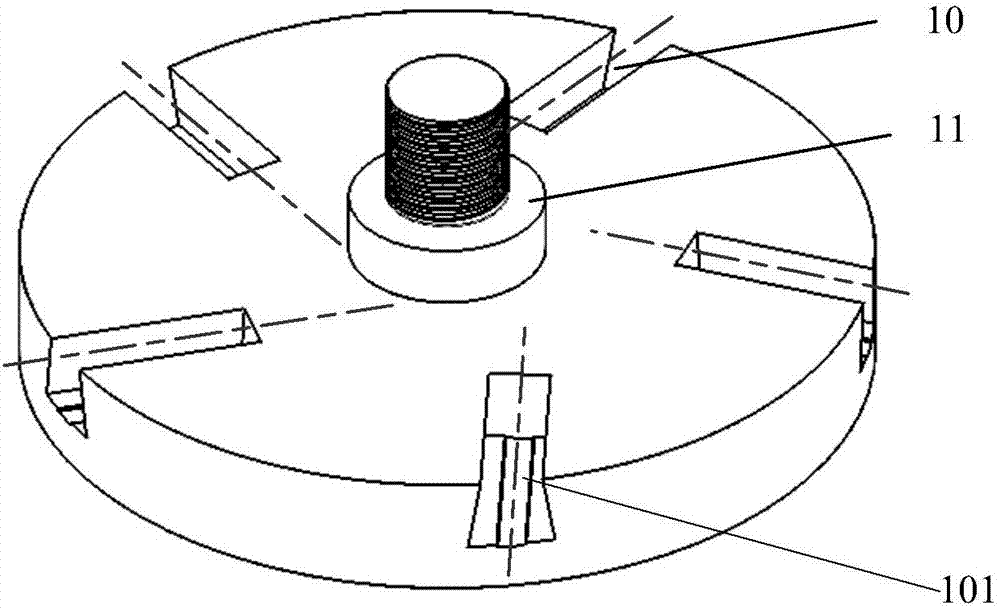

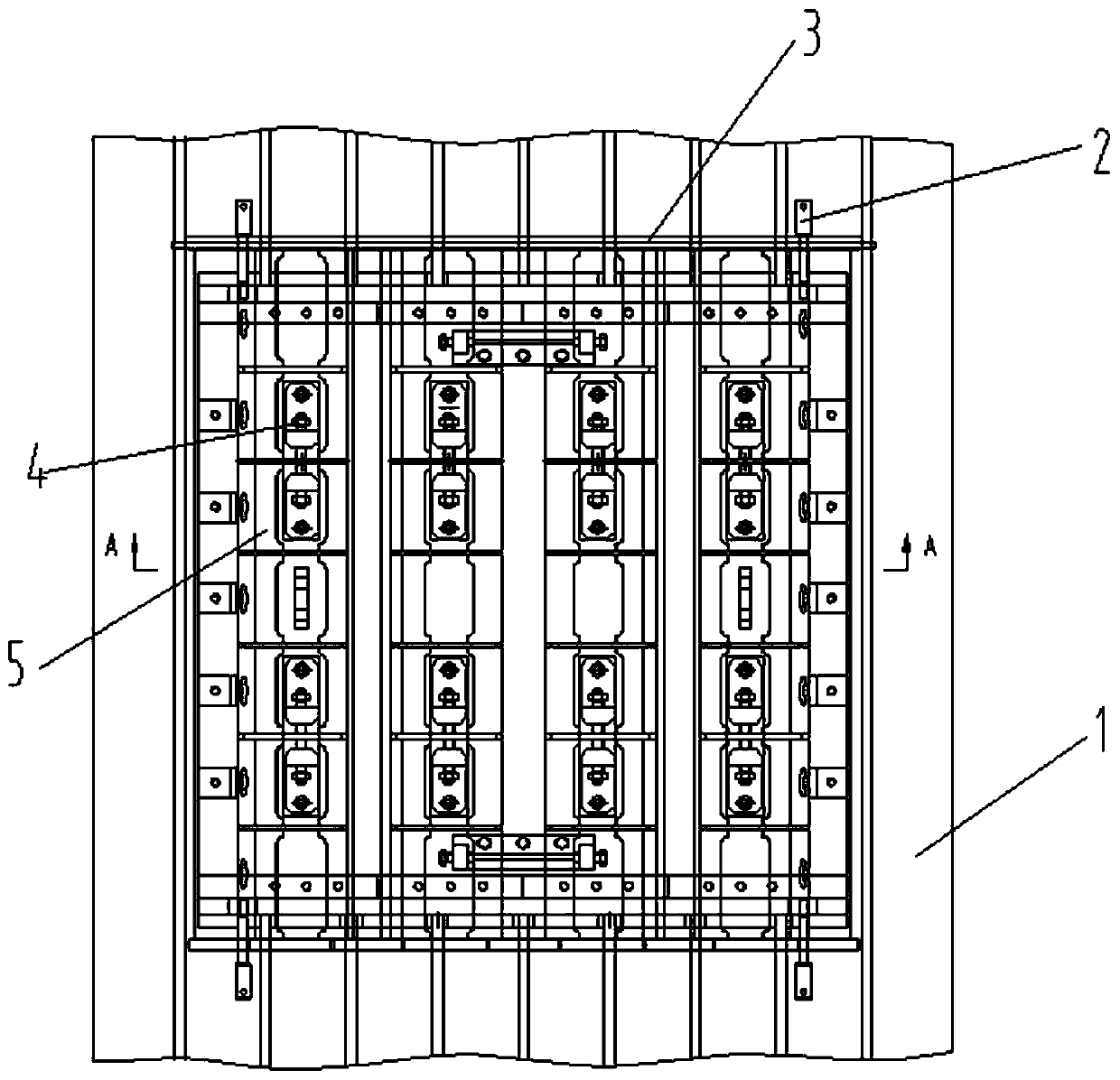

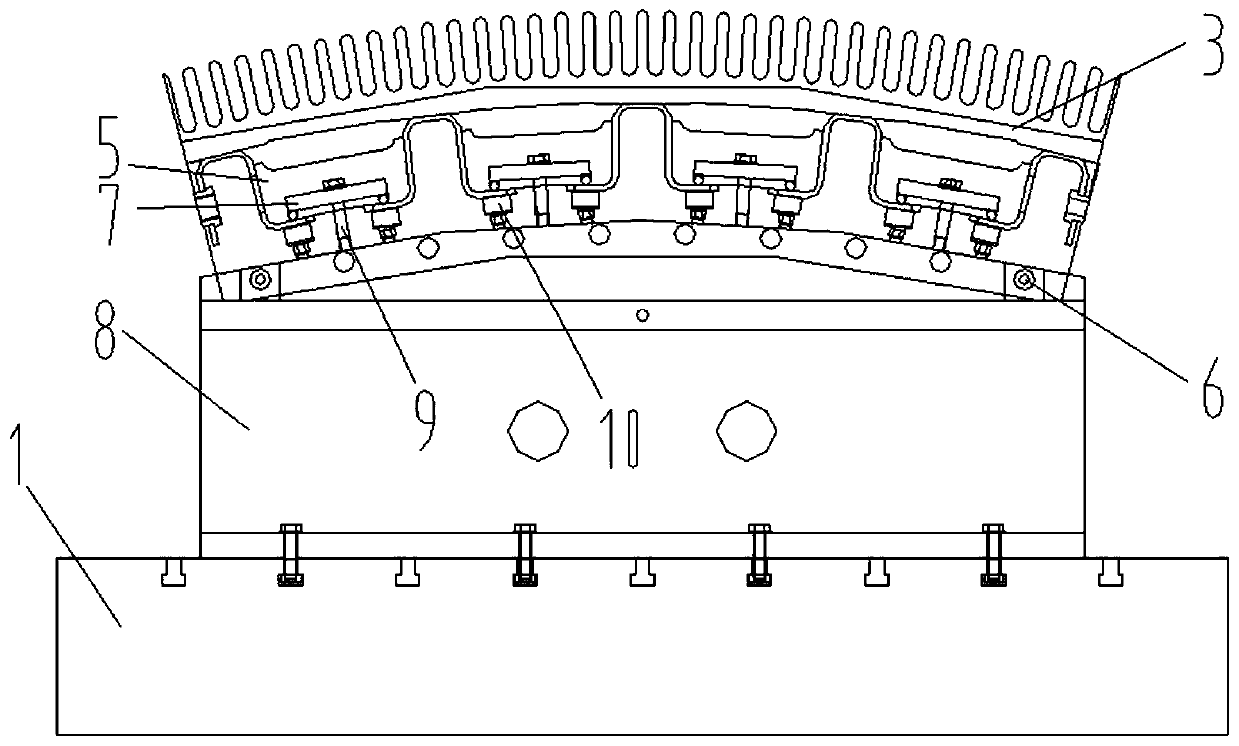

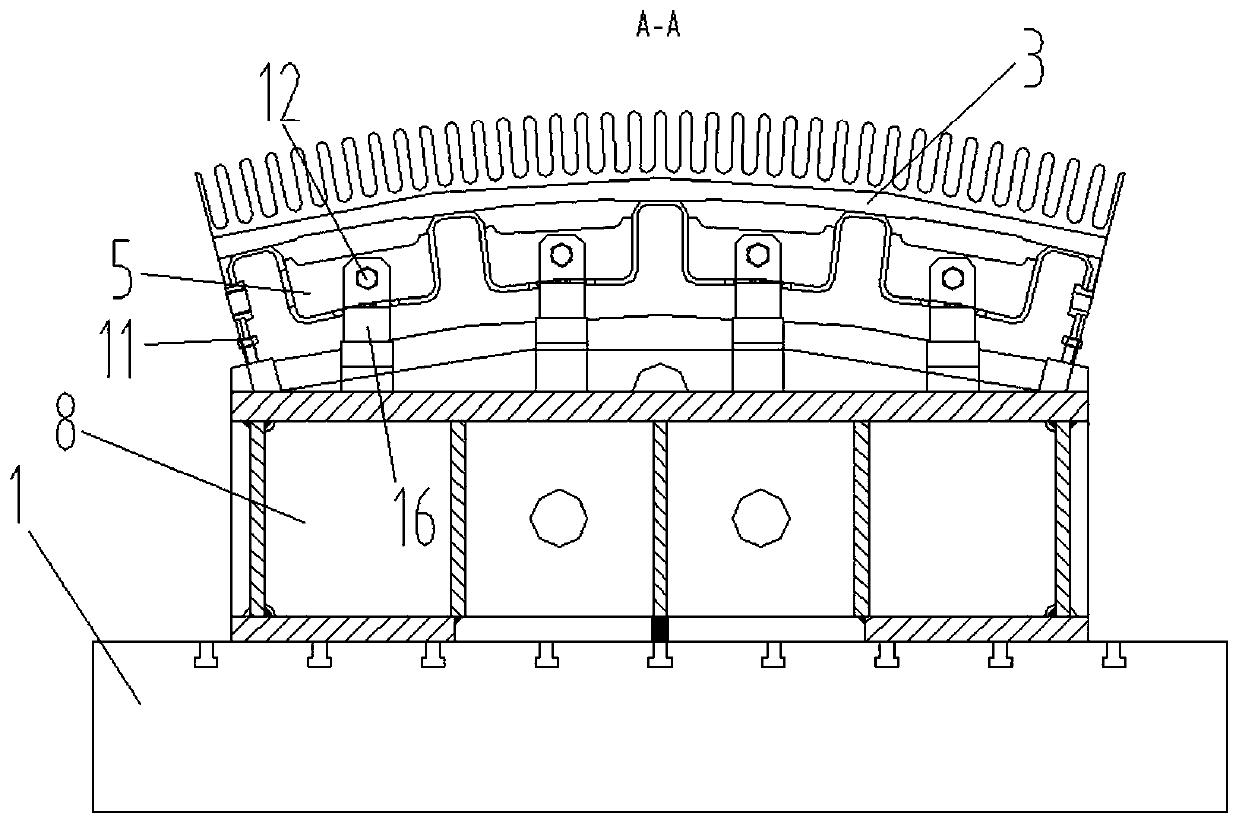

Stator section machining clamping device and clamping method

PendingCN111531385APrevent processing deformationImprove machining accuracyMilling equipment detailsPositioning apparatusEngineeringMachining

The invention discloses a stator section machining clamping device and a clamping method. The stator section machining clamping device comprises a milling support which is installed on a gantry milling workbench through bolts, a plurality of concave cavities are evenly formed in the outer surface of a stator section, a plurality of evenly-distributed transverse plates are arranged in the concave cavities, and the two ends of each transverse plate are fixedly connected with the side walls of the concave cavities; a plurality of pairs of top heads, a plurality of pairs of nut seats, a pluralityof supporting bolts, two adjusting frames and at least four first positioning holes are arranged on the milling support; and each pair of top heads support the inner walls of the concave cavities, each pair of nut seats top support the transverse plates, the adjustment frames support the side walls of the concave cavities, and the first positioning holes achieve positioning installation. Furthermore, the stator section can be supported, fixed and accurately positioned, the central symmetry degree of the stator section is guaranteed, meanwhile, the device does not adopt vertical clamping, secondary turn-over machining can be avoided, the labor intensity is reduced, and the working efficiency is improved.

Owner:JIANGSU ZHENJIANG NEW ENERGY EQUIP

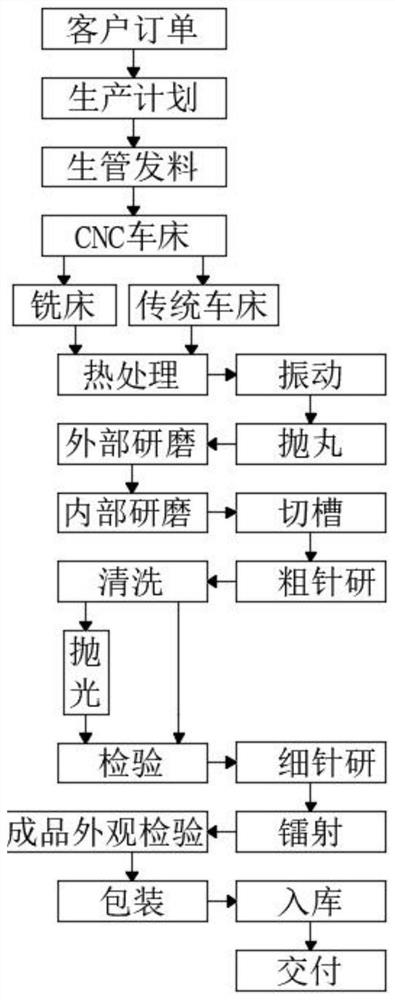

Machining method for milling cutter collet of numerical control machine tool

ActiveCN114523268AGuaranteed progressQuality assuranceMilling equipment detailsTotal factory controlNumerical controlMilling cutter

The invention relates to the technical field of collet machining, in particular to a numerical control machine tool milling cutter collet machining method which comprises the following steps of early-stage preparation, raw pipe rough machining, raw pipe semi-finish machining, heat treatment, vibration grinding, shot blasting, grinding treatment, grooving, needle grinding treatment and detection packaging. According to the overall process, through multiple times of machining and grinding and polishing treatment, the overall progress and the surface quality of the collet chuck can be effectively guaranteed, and good practical value and popularization value are achieved.

Owner:漳州升源机械工业有限公司

Method for forming reactor internal integral compression structure

ActiveCN109986284AShorten the production cycleAvoid welding deformationAdditive manufacturing apparatusMachining deformationStructural engineering

The invention belongs to the field of reactor structure design, and particularly relates to a method for forming a reactor internal integral compression structure. The invention aims to provide a method for forming a reactor internal integral compression structure in order to overcome the defects in the prior art. The production of section bars and matched welding materials is canceled, so that the production period is shortened; all full penetration weld joints are canceled, so that the welding deformation of the structure is avoided, and the forming quality is improved; the procedure of machining a large number of flowing water through holes is omitted, and machining deformation of the structure is avoided; an integrally-formed pressing structure is adopted, the structural continuity isgood, and the mechanical property is better; the integrally-formed pressing structure is uniform in structural material performance, and particularly, the material performance in the thickness direction of the structure is not different; the manufacturing process is greatly simplified, and the manufacturing period is greatly shortened.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

High pressure three screw pump

ActiveCN103711690BReduce difficultyGuaranteed machining accuracyRotary piston pumpsRotary piston liquid enginesWorking pressureEngineering

The invention relates to a high-property high-pressure three-screw pump. The high-property high-pressure three-screw pump comprises a pump body, a liner, a driving screw and two driven screws, wherein the liner is formed by connecting three sections of split liners in sequence; three matching holes matched with the driving screw and the driven screws are respectively formed in the both axial ends of each section of the split liner; the three sections of the split liners respectively comprise a front liner, a middle liner and a rear liner; each driven screw consists of a front section screw, a middle section screw and a rear section screw; the outer ends of the front section screws of the two driven screws are respectively arranged on the pump body and are in the shape of a cantilever; the outer ends of the rear section screws of the two driven screws are respectively arranged in the three matching holes in the outer end of the rear liner through axle sleeves in the cantilever shape; the both ends of the middle section screw of each driven screw respectively are in contact with the corresponding front section screw and rear section screw, so that the middle section screws are in a shape of a float rod. According to the high-property high-pressure three-screw pump provided by the invention, the highest working pressure is 20.0MPa, the machining difficulty is reduced, and the matching precision among parts is improved, so that the reliability and the volume efficiency of the pump can be improved.

Owner:黄山工业泵制造有限公司

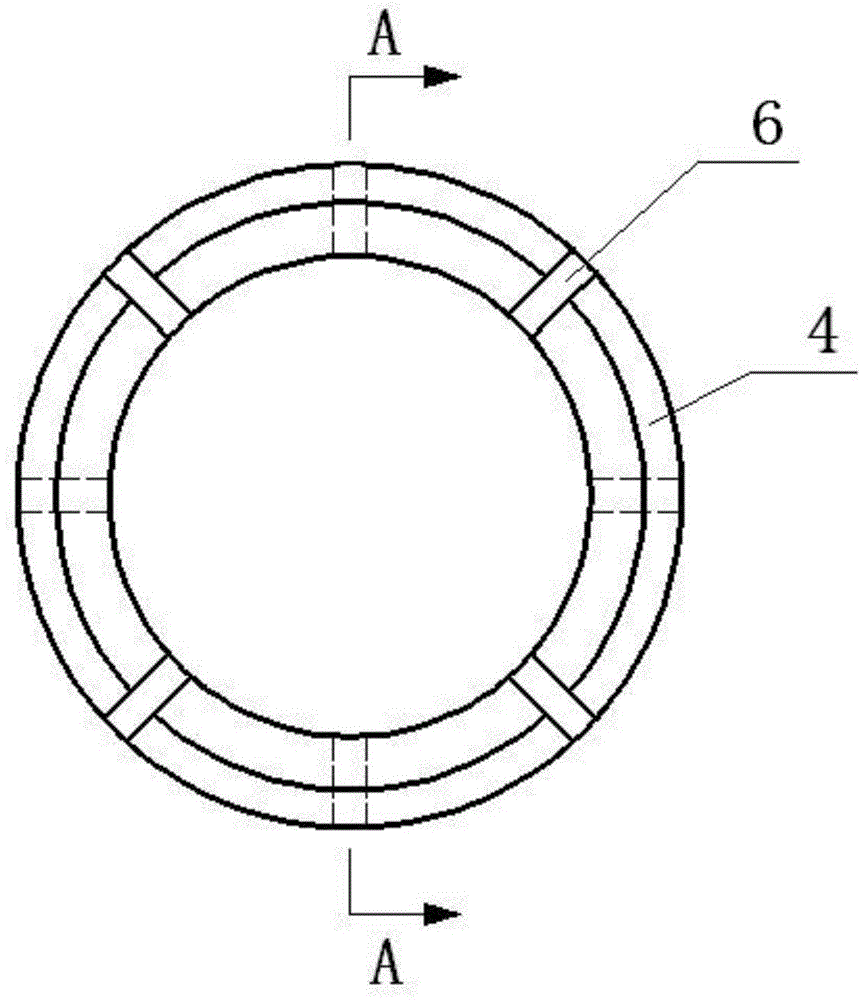

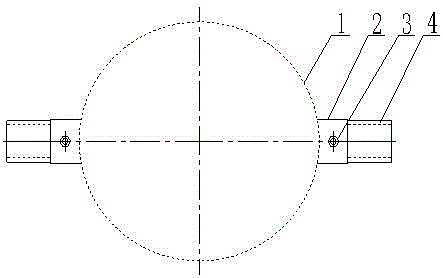

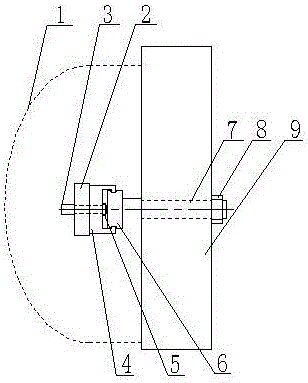

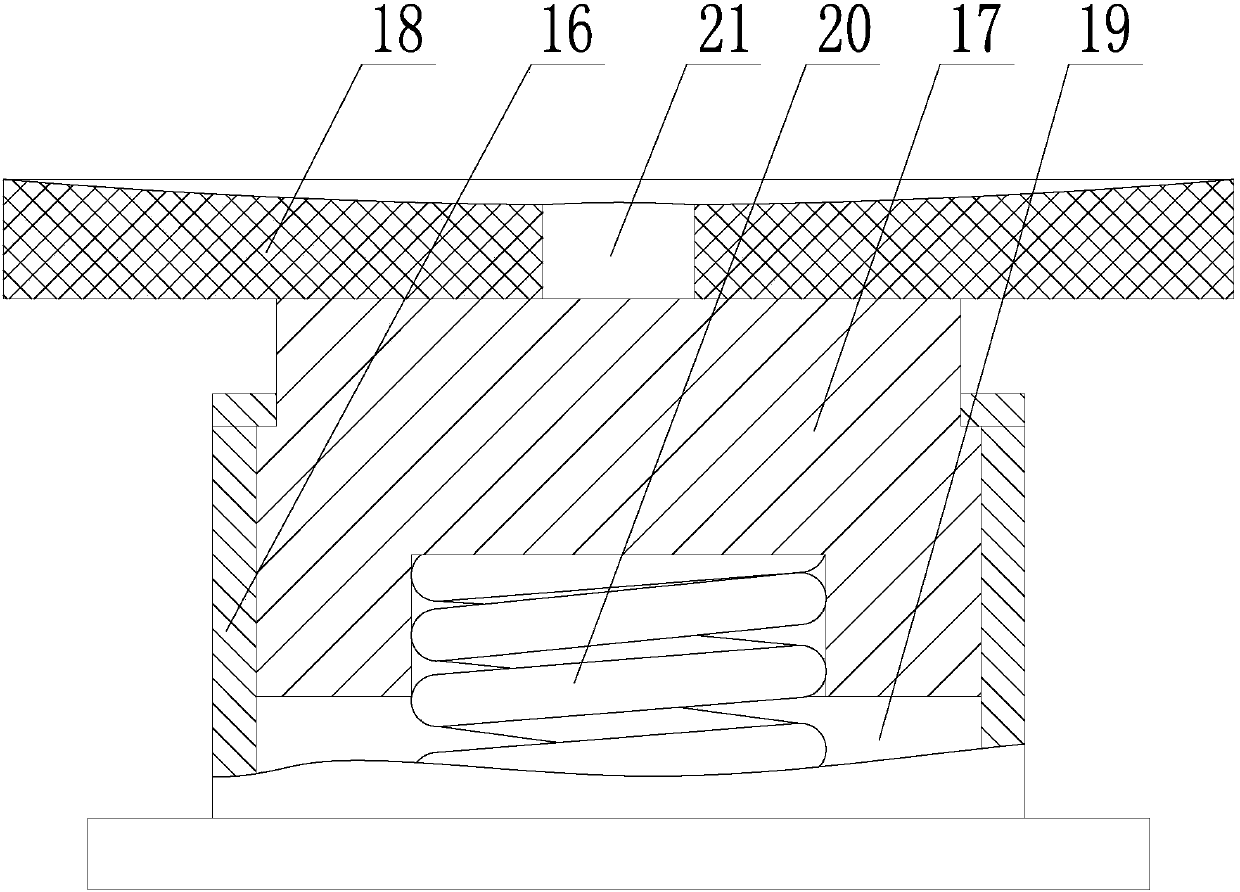

Thin-walled vessel head processing and fixing device and application method thereof

InactiveCN105729154AEasy to fixPrevent processing deformationPositioning apparatusMetal-working holdersScrew threadBiomedical engineering

The invention provides a thin-walled vessel head processing and fixing device and an application method thereof, belongs to the field of vessel head processing in the mechanical manufacturing industry, and aims at overcoming the defect that a thin-walled vessel head is easy to deform in processing. The thin-walled vessel head processing and fixing device structurally comprises vessel head support lugs 2, hexagon socket screws 3, a slide block 4, a slide block nut 5, a slideway 6, a fixed shaft 7 and a rack nut 8, wherein holes are formed in the vessel head support lugs 2 in the axial direction; the vessel head support lugs 2 can be inserted into the slide block; matching holes are transversely formed in the vessel head support lugs 2 and the slide block 4; the slide block 4 is connected to the vessel head support lugs 2 through the hexagon socket screws 3 via the transverse matching holes; the slide block 4 can slide on the slideway 6; the fixed shaft 7 and the slideway 6 are welded into a whole; the two vessel head support lugs 2 are symmetrically welded at two sides of the outer wall edge of the thin-walled vessel head 1 in use; a screw thread at the tail part of the fixed shaft 7 is fixed on a drilling machine processing rack 9 through the rack nut 8; the hexagon socket screws are inserted into the transverse holes of the vessel head support lugs 2 and the slide block 4; and the slide block nut 5 is screwed down. The thin-walled vessel head processing and fixing device is simple in structure, convenient and fast to operate and accurate in size positioning; and the processing quality of the thin-walled vessel head is ensured.

Owner:LANZHOU LS HEAVY EQUIP

Auxiliary support device for processing large thin-walled components and using method

ActiveCN106393250BImprove processing efficiencyImprove processing qualityMetal working apparatusDrive motorMachine tool

Owner:SHENYANG AEROSPACE UNIVERSITY

A Forging Forming Process of High Cylindrical Aluminum Alloy Forgings

Owner:WUXI PAIKE HEAVY CASTING & FORGING

A Manufacturing Process of Thin-walled Parts with Large Curvature and Full Surface

ActiveCN103639655BSolve Vibration ProblemsGuaranteed sizeAircraft componentsWorkpiecesMaterial removalEngineering

The invention provides a manufacturing process for a high-curvature full-profile thin-wall part so as to solve the problem of processing deformation and vibration of an ultra-complex spatial thin-wall curved surface. By reasonable process layout, a segmented layer-by-layer processing mode is adopted, an appropriate cutter and a cutter handle are selected, working allowance of every process is set, natural aging time is set, cutting process parameters and feeding strategies are optimized, the uniform material removal amount of the part is guaranteed, an adding cushion block location and gypsum filling method is adopted simultaneously, the problem of clamping difficulty and vibration in part processing is solved, processing rigidity and clamping stability of the part are improved, deformation in the part processing process is controlled, and the part size and precision are guaranteed.

Owner:江西洪都航空工业股份有限公司

Track aluminum profile

ActiveCN114438382AHigh strengthImprove room temperature tensile propertiesExtrusion control devicesSolution treatmentUltimate tensile strength

The invention discloses a rail aluminum profile and a preparation method thereof. The rail aluminum profile comprises the following main components in percentage by mass: 1.35-1.5% of Mg, 0.1-0.2% of Si, 2.0-4.0% of Zn (Zn = 2.7 Mg), 0.09-0.12% of V, 1.0-2.2% of Mn, 3.5-4.5% of Cu, 0.1-1.3% of Cd, 0.1-0.3% of Cr, 0.1% of mischmetal, 0.01-0.05% of Ti and the balance of aluminum and inevitable impurities, the content of Zr accounts for 0.04-0.08%, and the balance is Al. According to the method, raw materials are prepared according to the mass ratio, semi-continuous casting is used, and the extrusion process and the solution treatment process are optimized, so that the strength and the tensile property of the track are greatly improved, the loading capacity of the track is enhanced, meanwhile, the stability of a track sliding groove is improved, and the requirement for the performance of the track in industrial manufacturing is met.

Owner:JIANGYIN MUXIANG ENERGY SAVING DECORATION MATER

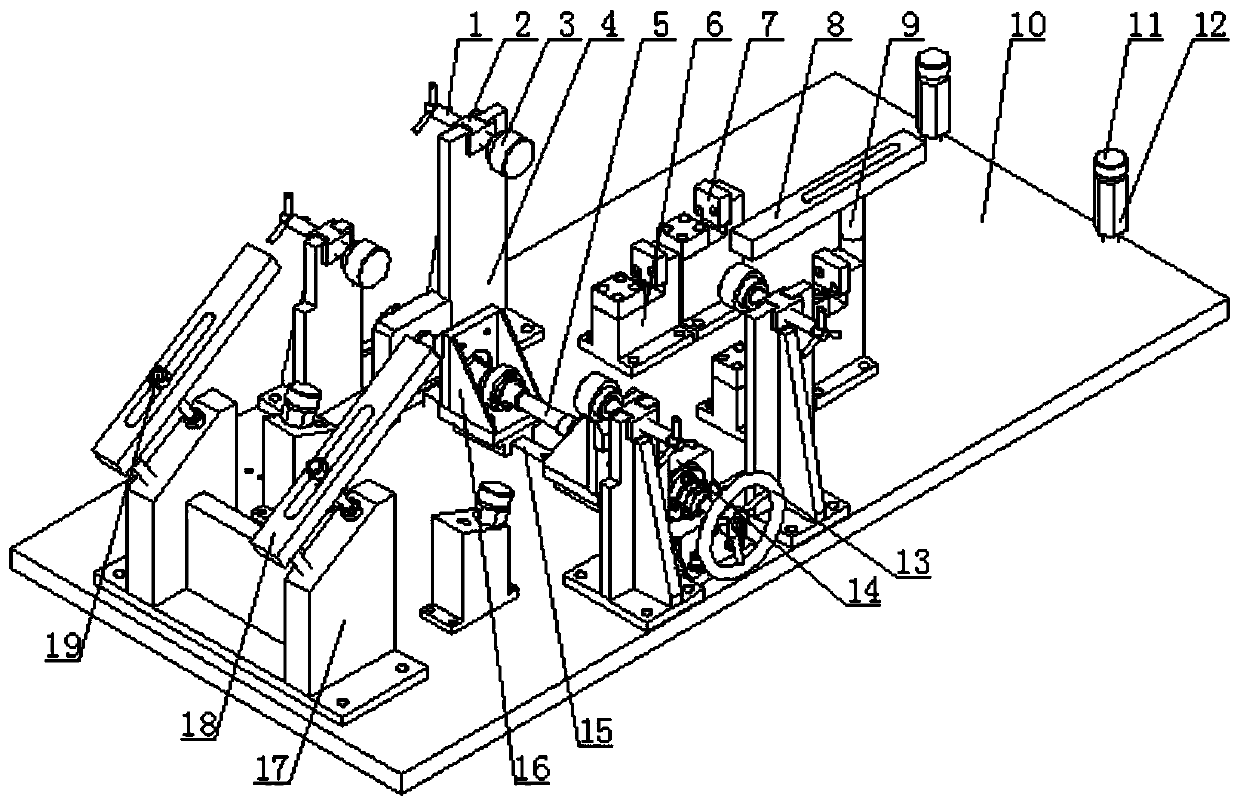

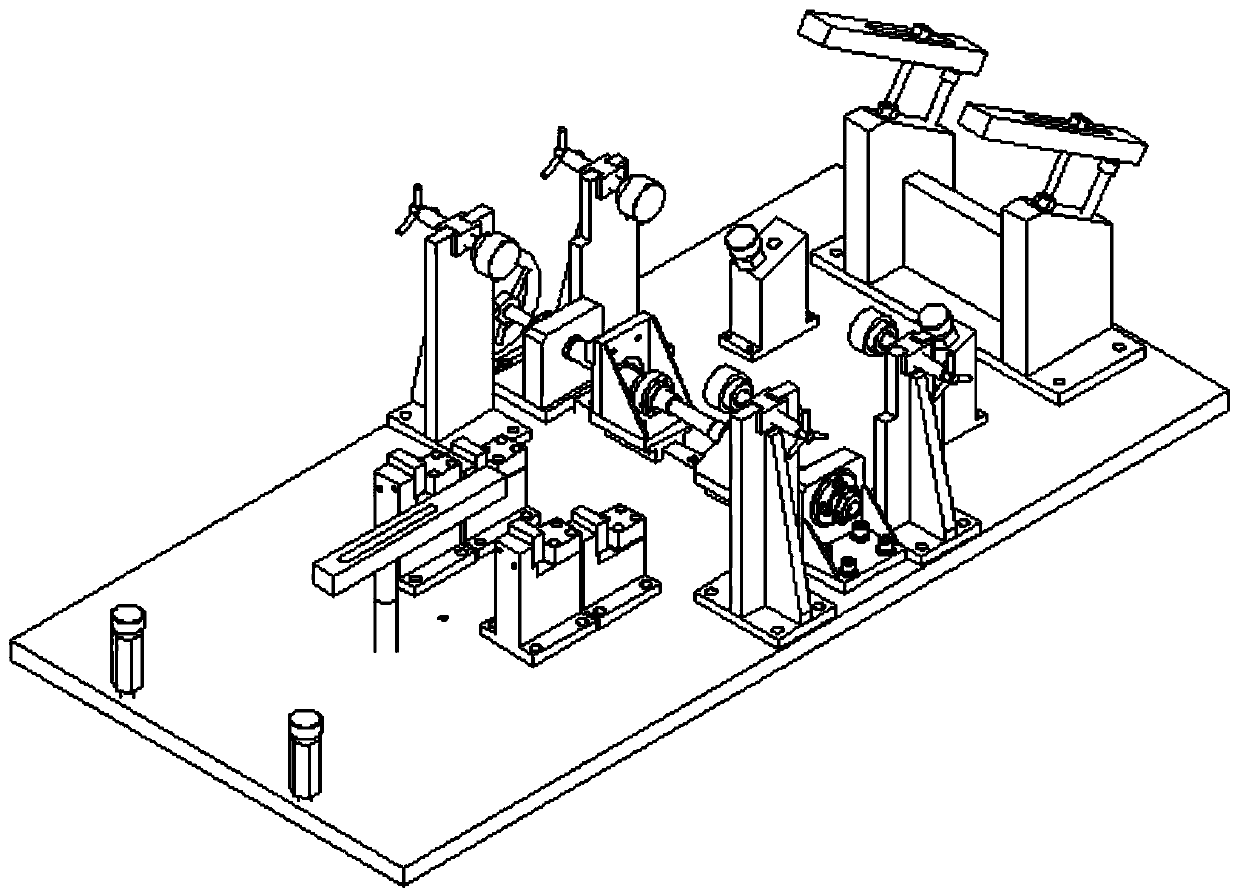

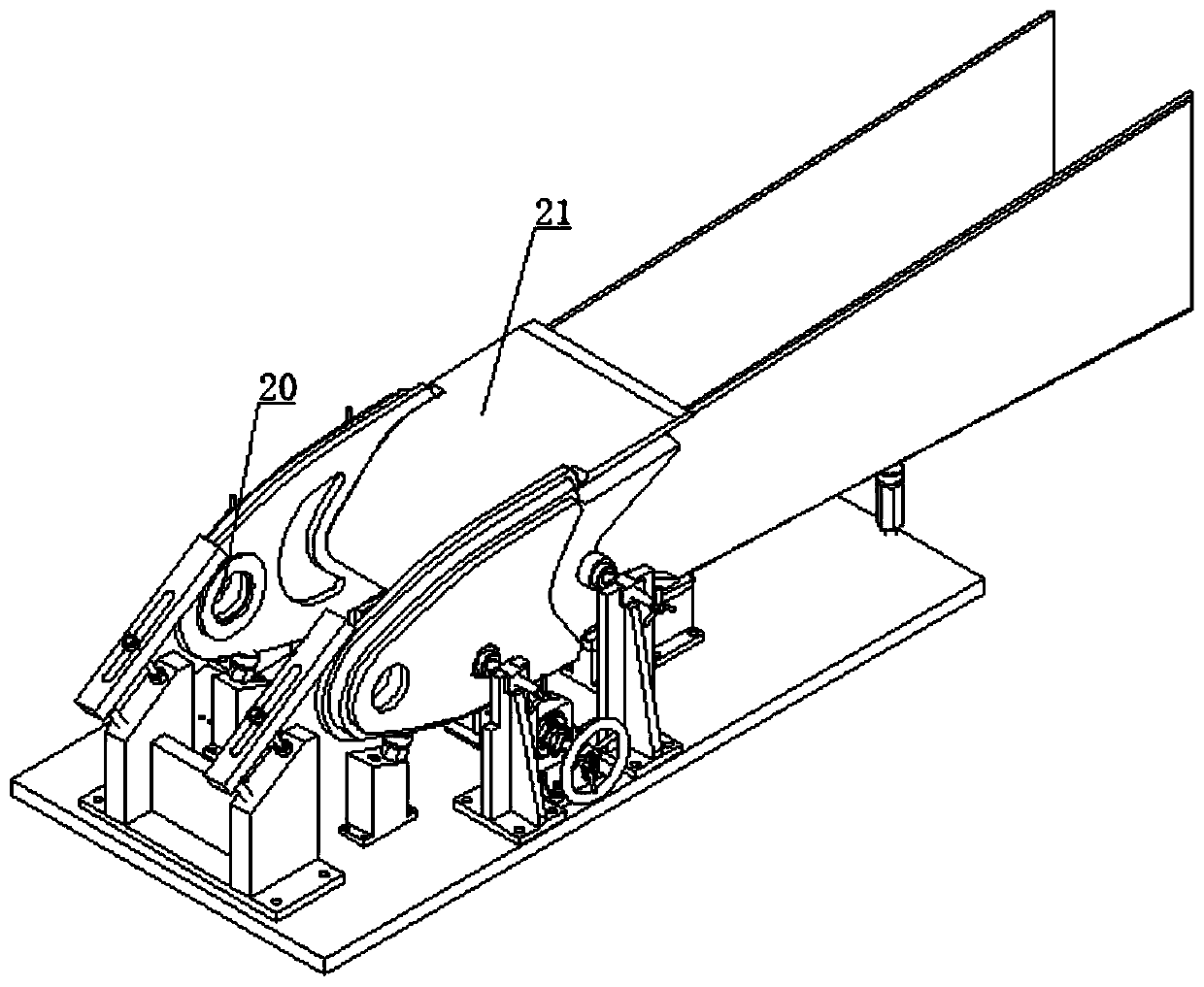

Mounting equipment used for machining excavator big arm front fork holes

InactiveCN111376080AFast loadingHigh degree of fitPositioning apparatusMetal-working holdersExcavatorMachining time

The invention relates to mounting equipment used for machining excavator big arm front fork holes. The equipment comprises a bottom plate, a front end pressing mechanism, a middle fixing mechanism, apartition plate fixing mechanism, side plate fixing mechanisms and a lower portion jacking mechanism. The front end pressing mechanism is mounted at the front end of the upper surface of the bottom plate. The middle fixing mechanism is mounted in the middle of the upper surface of the bottom plate. The partition plate fixing mechanism is mounted in the middle-rear portion of the upper surface of the bottom plate. The side plate fixing mechanisms are arranged on the left and right sides of the upper surface of the bottom plate correspondingly, and the lower portion jacking mechanism is mountedon the upper surface of the bottom plate. The mounting equipment used for machining the excavator big arm front fork holes is reasonable in design, scientific in structure, high in practicability, high in rate of matching with workpieces and good in fastening effect, by using the equipment, the workpieces can be fast and accurately clamped and positioned, therefore, the machining precision and themachining quality are improved, and the workpiece dismounting, mounting and machining time is shortened.

Owner:TIANJIN BAOLAI PRECISION MACHINERY

Radially-adjustable three-jaw self-centering spindle clamp

The invention relates to an adjustable spindle clamp, and particularly relates to a radially-adjustable three-jaw self-centering spindle clamp. The spindle clamp is structurally characterized in thata spindle is fixed to a machine tool through a lathe chuck, the spindle is a stepped shaft, a key groove is formed in the spindle, and the position of an adjusting disk can be fixed through a steppedtable and a flat key. The adjusting disk has a self-centering function by using a three-jaw lathe chuck principle, and the transmission of a large bevel gear is driven by adjusting a square adjustinghole in a small bevel gear so that it can be achieved the positions of adjusting jaws are adjusted; a supporting jaw is fixed to the adjusting jaw through fastening bolts, the fastening position of the supporting jaw can be adjusted so that the adjusting range can be effectively expanded, and the obstruction to the feed path is reduced. The position of a right adjusting disk body is adjusted through a fastening nut so as to clamp a workpiece, it is achieved that a thin-plate disk-like part is quickly clamped, the clamping rigidity is ensured, and the machining quality is improved.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Machining process of water-cooled motor shell of new energy automobile

The invention discloses a machining process of a water-cooled motor shell of a new energy automobile. Five-axis one-step machining is completed; after clamping, the pressing plate is tightened, the auxiliary supporting cylinders completely prop against the product to prevent machining deformation during inner circle machining; prevention of improper clamping is realized in gas detection, the clampis prevented from being crushed by an aluminum pin in water detection. Firstly two large surfaces are roughened, two inclined holes in the clamp are machined by rotating an angle, then a central holeand an excircle are roughened, the clamp is loosened and suspended for 5 seconds after he peripheral through hole is machined and then tightened, automatic detecting and compensating are performed bya probe and then the two large surfaces are finely machined and the diameter of the central hole and the excircle is machined so that the mesh surface requirement, the coaxiality and the roundness requirement are ensured.

Owner:天津雄邦压铸有限公司

A processing method of metal mold with cutting edge

ActiveCN111002060BGuaranteed machining accuracyPrevent processing deformationPositioning apparatusMetal-working holdersMetal moldDigital control

The invention discloses a processing method of a metal mold with a cutting edge, which belongs to the technical field of mold processing and comprises the following steps: a. using a numerical control machine tool to process the contour of the mold to obtain a mold blank; b. The mold blank is fixed, and the clamp is fixed at the edge processing position where the mold blank is to be processed into an edge; at the edge processing position, the clamp is matched with the shape of the mold blank; the processing method can be Provide effective support for the cutting edge processing part of the mold to ensure the cutting edge processing quality.

Owner:四川科思精密模具股份有限公司

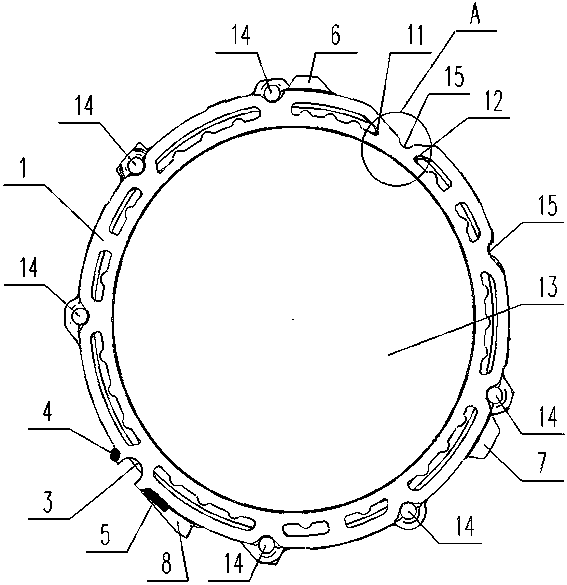

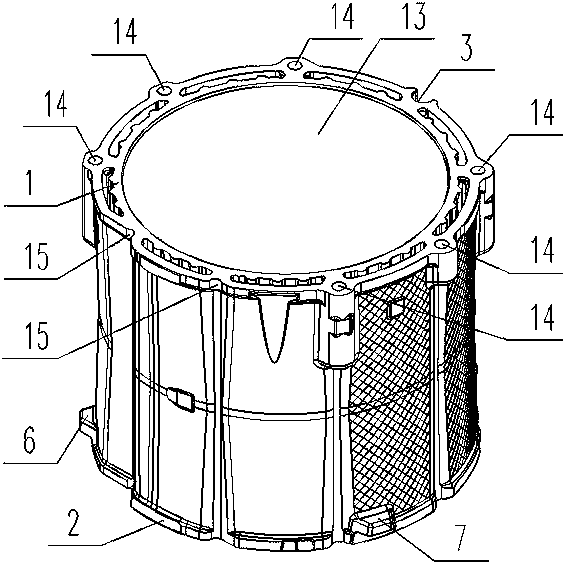

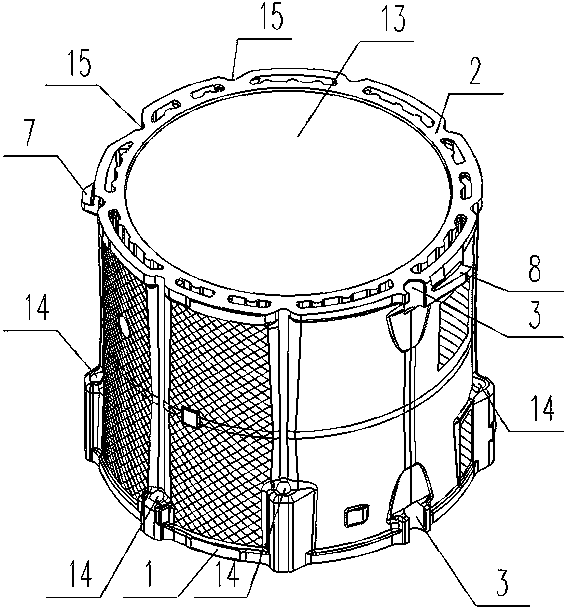

Machining anti-deformation clamp for thin-wall baffle part

PendingCN113369937AWill not deformAvoid deformationPositioning apparatusMetal-working holdersThin walledMachine parts

A machining anti-deformation clamp for a thin-wall baffle part comprises a positioning clamp body, a pressing hook and a clamp base. The positioning clamp body is annular and is provided with an annular step groove, the to-be-machined part is installed in the annular step groove, and the back of a to-be-machined portion at the outer side of the to-be-machined part tightly abuts against the outermost step face of the positioning clamp body; the clamp base is fixedly connected with the lower portion of the positioning clamp body; and the pressing hook is L-shaped, the upper end of the pressing hook is buckled to the to-be-machined part, and the lower end of the pressing hook penetrates through the clamp base and fastens the to-be-machined part on the positioning clamp body. By means of the machining anti-deformation clamp, the to-be-machined part is supported by the clamp in an auxiliary manner, it is guaranteed that when the part is in a pressed state, the back face of the part is completely attached to the auxiliary supporting plane, the part cannot deform in the cutting process, and the machining quality of the part is effectively improved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com