Radially-adjustable three-jaw self-centering spindle clamp

A self-centering and mandrel technology, applied in the direction of the chuck, can solve the problems affecting the accuracy of the experimental results, the low rigidity of the disc specimen, and increasing the experimental cost, and achieves a simple structure, good clamping rigidity, and clamping. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

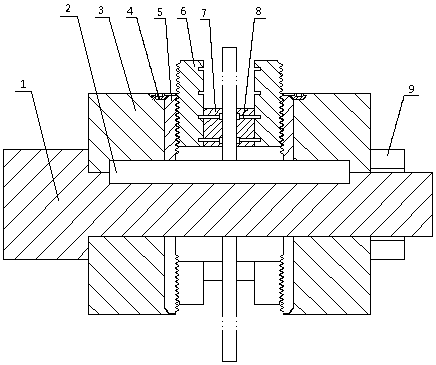

[0017] Mandrel 1, flat key 2, adjusting disc body 3, small bevel gear 4, large bevel gear 5, adjusting claw 6, supporting claw 7, fastening bolt 8 and fastening nut 9, see figure 1 . The mandrel 1 is fixed on the machine tool through the lathe chuck. There is a keyway on the mandrel. The flat key 2 is used to fix the position of the adjustment disc body 3. The adjustment square hole on the small bevel gear 4 is used to drive the large bevel gear 5. To adjust the position of the adjusting claw 6, the supporting claw 7 is fixed on the adjusting claw by the fastening bolt, and the fastening position of the supporting claw is adjustable, which can effectively increase the adjustment range, and the position of the right adjusting disc is adjusted by the fastening nut to clamp Workpieces, realizing fast and reliable clamping of thin-walled disk parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com