An internal combustion engine valve clamping manipulator

A technology for internal combustion engines and manipulators, applied in the field of clamping manipulators for internal combustion engine valves, can solve the problems of poor valve delivery position accuracy, affect production efficiency, and affect stability, and achieve the effects of ensuring accuracy, good clamping rigidity, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

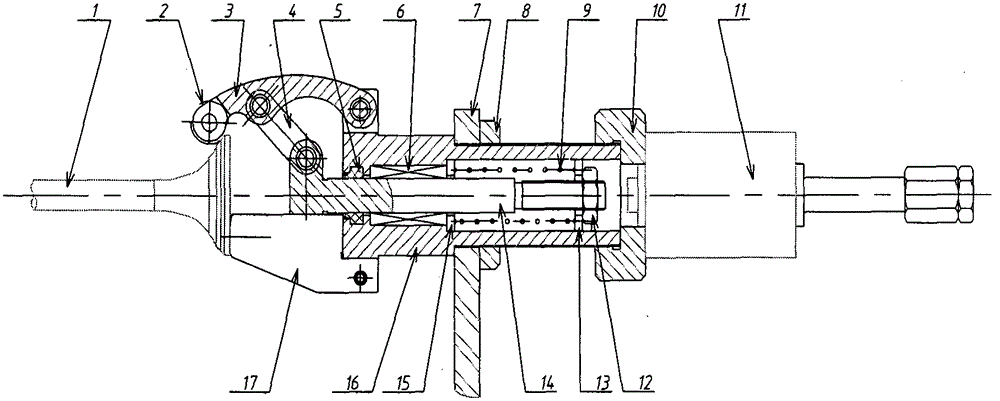

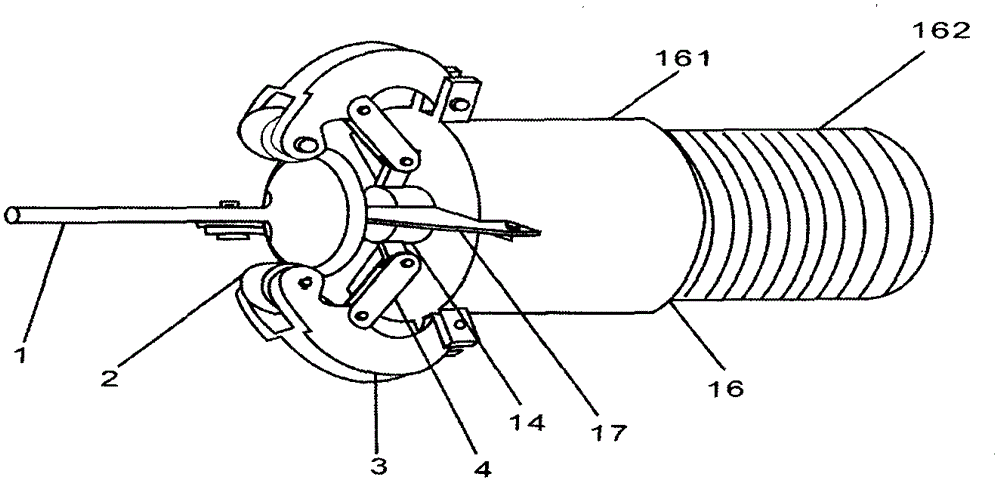

[0026] Embodiment 1: as figure 1 and 2 As shown, a clamping manipulator for an internal combustion engine valve includes a plurality of support blocks 17 and a pressing mechanism for clamping and positioning the disc plane of the valve. The disk plane is evenly distributed radially to realize the axial positioning of the valve. The pressing mechanism presses the valve on the cone surface of the valve disk to realize the radial positioning of the valve. The pressing mechanism and the support block are clamped Pressure is created, which locks the valve.

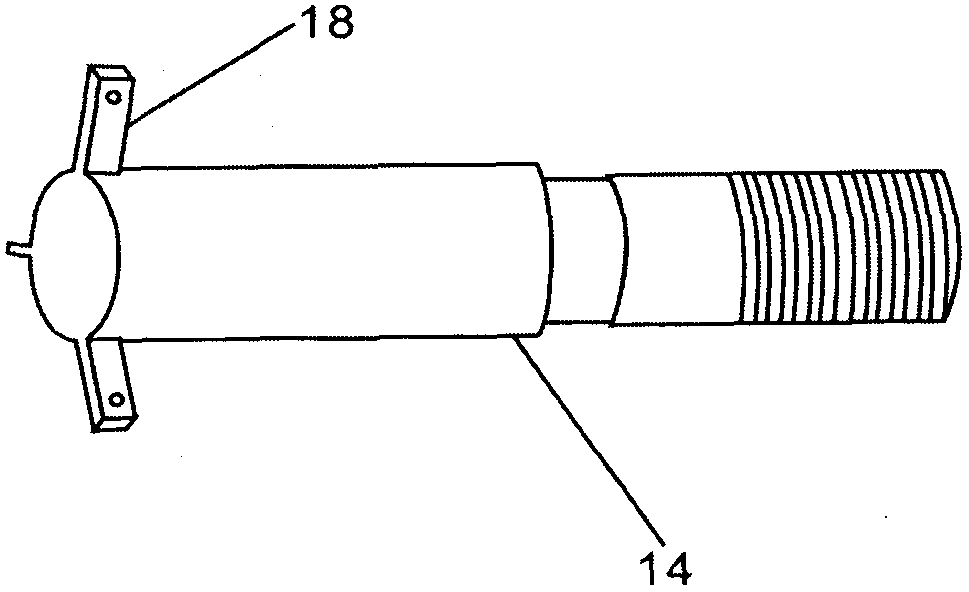

[0027] The clamping mechanism includes a clamp body 16 with a hollow cavity structure. A pull rod 14 that reciprocates along the axial direction of the clamp body is arranged in the hollow cavity of the clamp body 16. The left end of the pull rod 14 extends outside the clamp body, and is provided with There are a plurality of connection holes; the left end face of the clamp body 16 is the valve positioning end, and a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com