A fully automatic universal CNC machine tool fixture

A CNC machine tool, fully automatic technology, applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems of insufficient adaptability, huge difference in processing parameters, hindering the development and production of universal fixtures for CNC machine tools, etc., to achieve clamping The effect of good rigidity and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

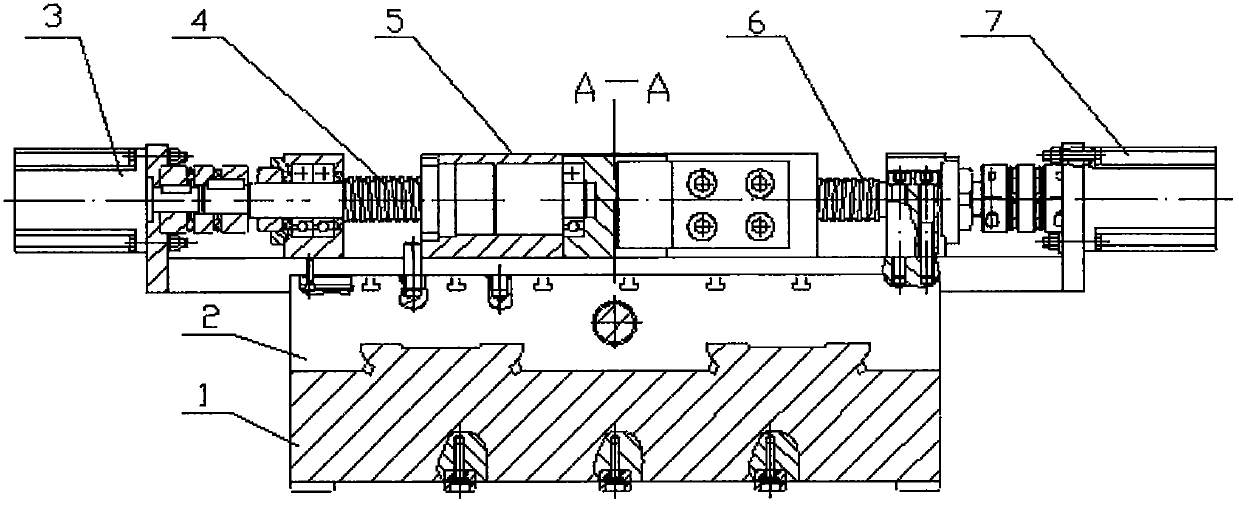

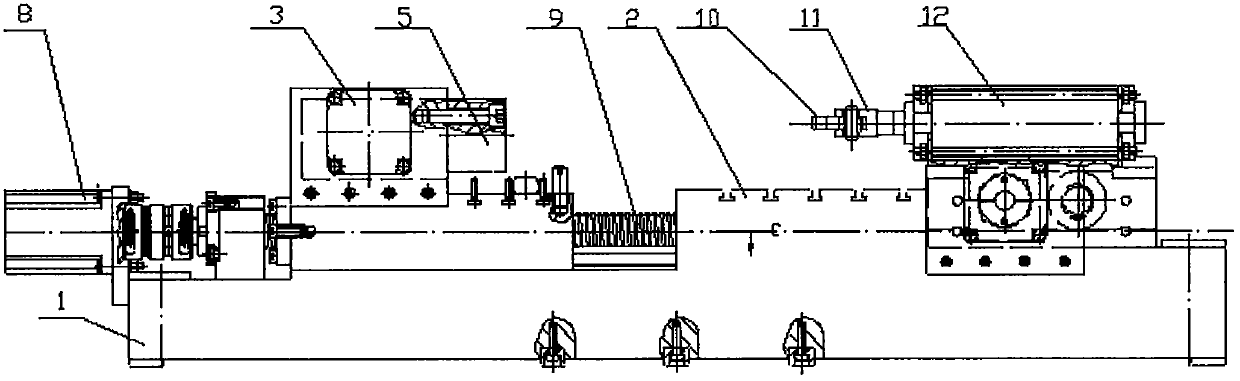

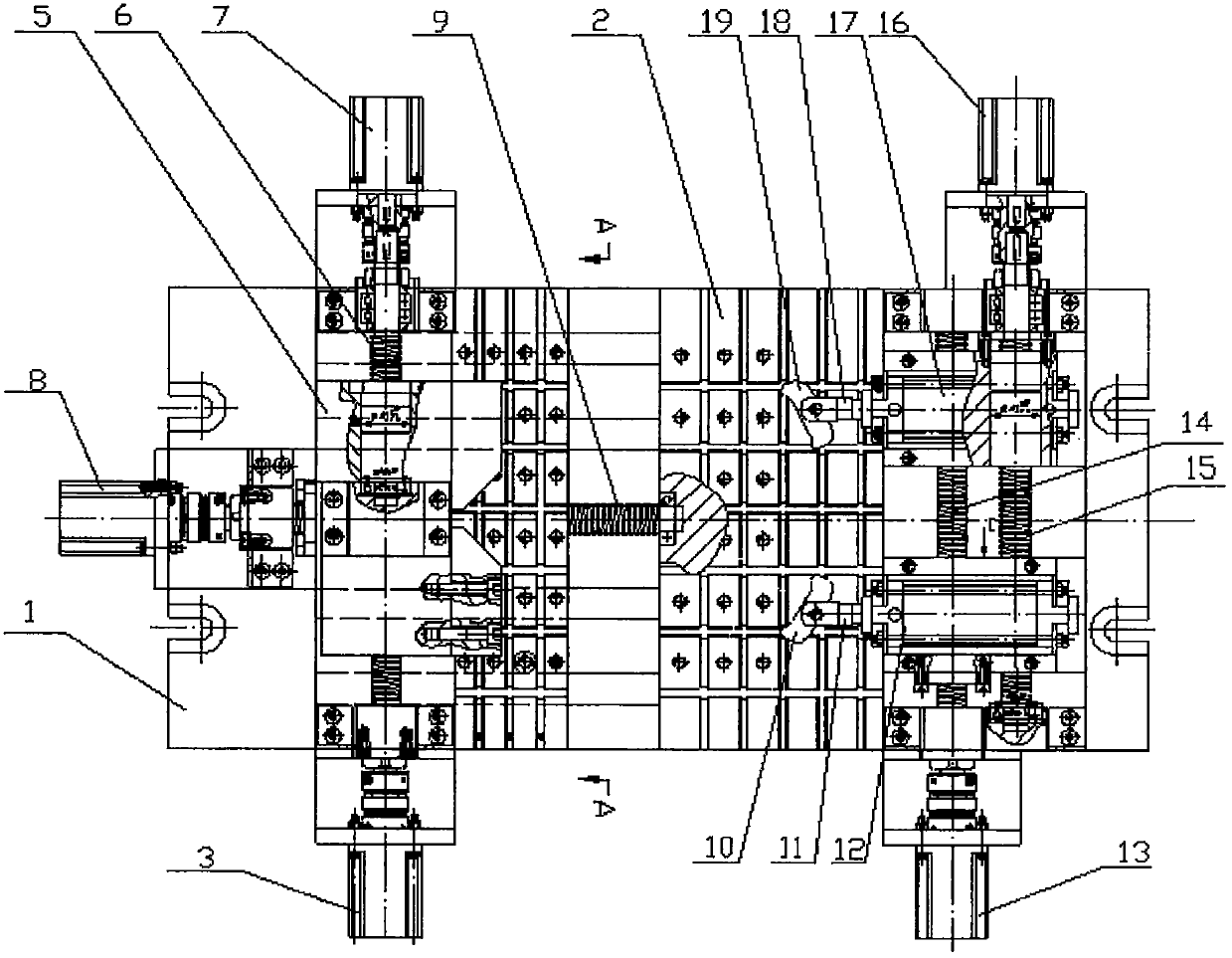

[0015] This implementation example is a specific structure of a fixture for a fully automatic universal numerical control machine tool, and illustrates the composition and working principle of the fixture of the present invention through an example.

[0016] According to this implementation example, the specific structural composition is shown in the accompanying drawings, 1 is the clamp body, 2 is the fixture table, 3 is the left-opening stepping motor, 4 is the left-opening ball screw, 5 is the separable V-shaped positioning block, and 6 is the Right open ball screw, 7 is right open stepper motor, 8 is traverse stepper motor, 9 is traverse ball screw, 10 is left floating chuck, 11 is left chuck body, 12 is left air-liquid cylinder , 13 is the stepping motor of the left chuck, 14 is the ball screw of the left chuck, 15 is the stepping motor of the right chuck, 16 is the ball screw of the right chuck, 17 is the right air-hydraulic cylinder, 18 is the body of the right chuck , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com