Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Ensure support rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

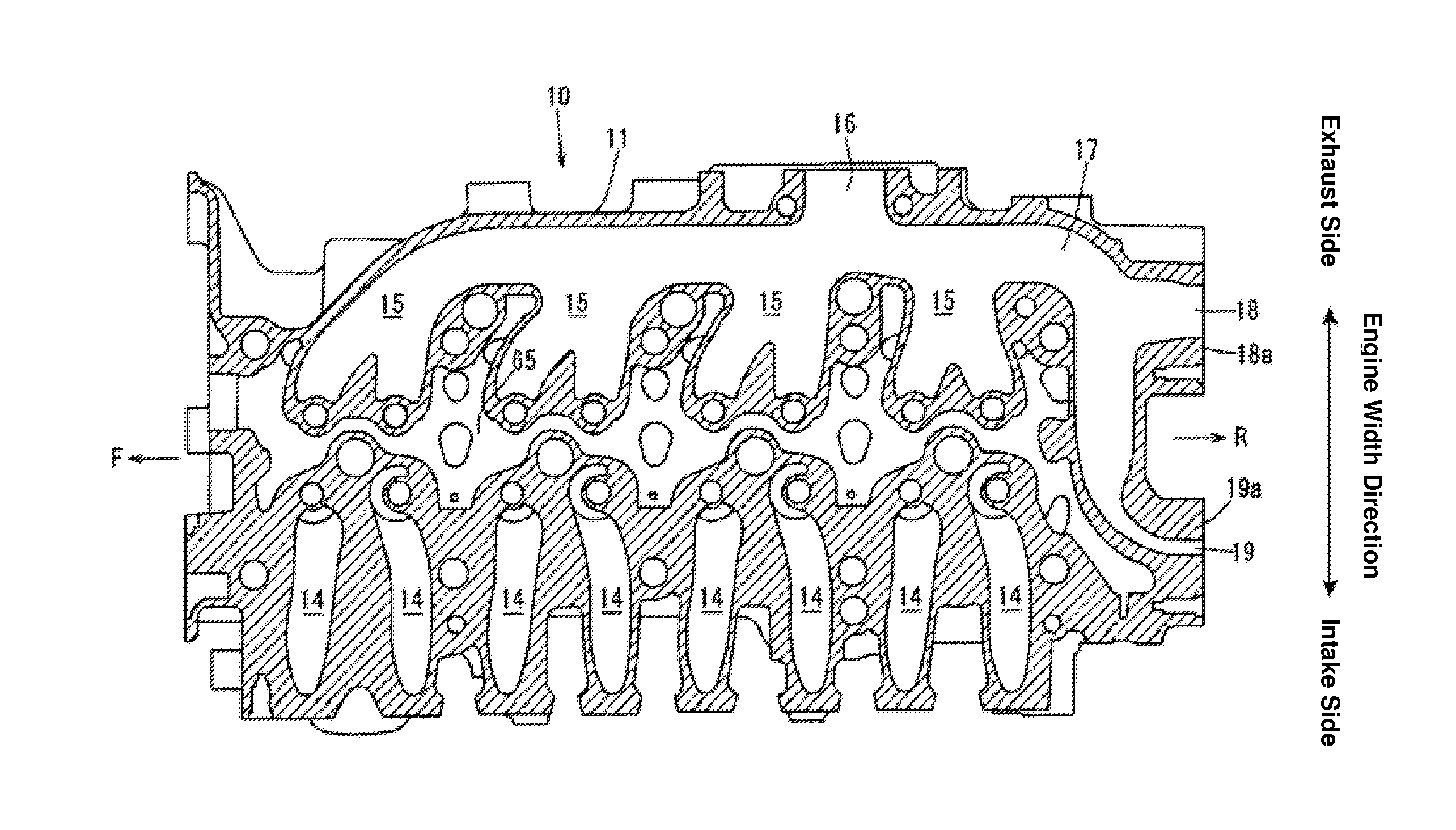

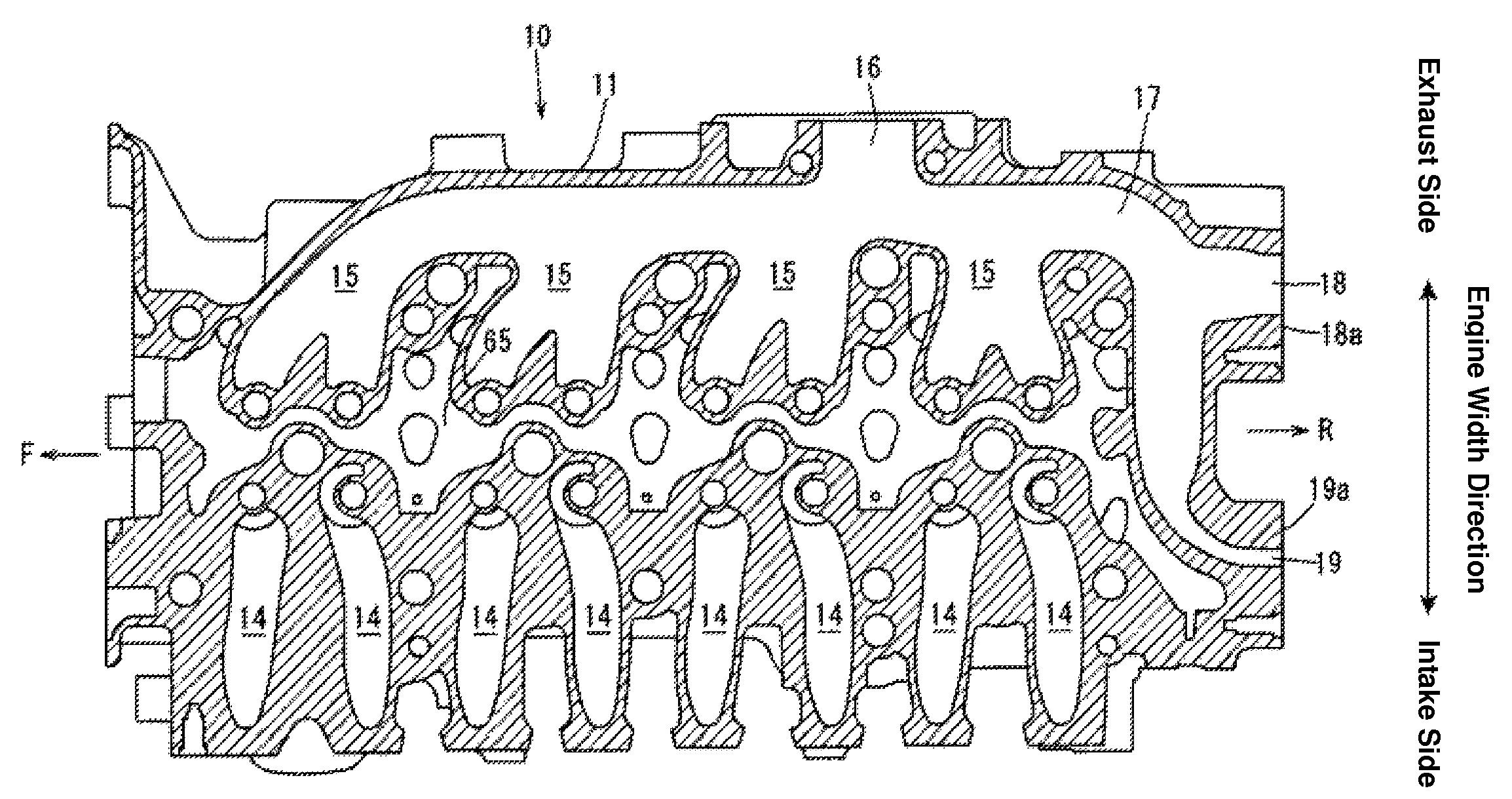

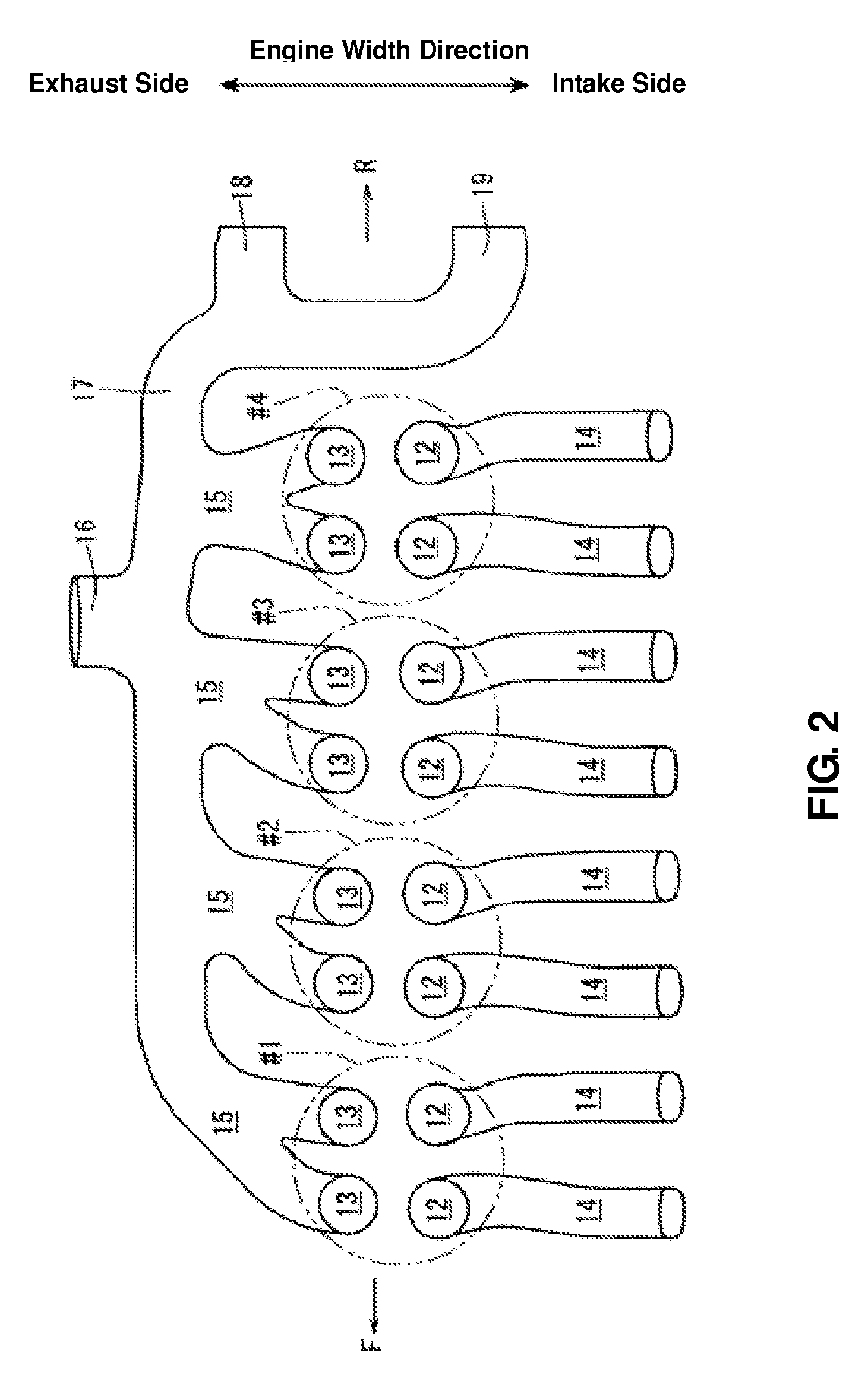

Exhaust gas recirculation device of engine

InactiveUS20110315129A1Small device sizeBypass pipe can be easierNon-fuel substance addition to fuelInternal combustion piston enginesCylinder headEngineering

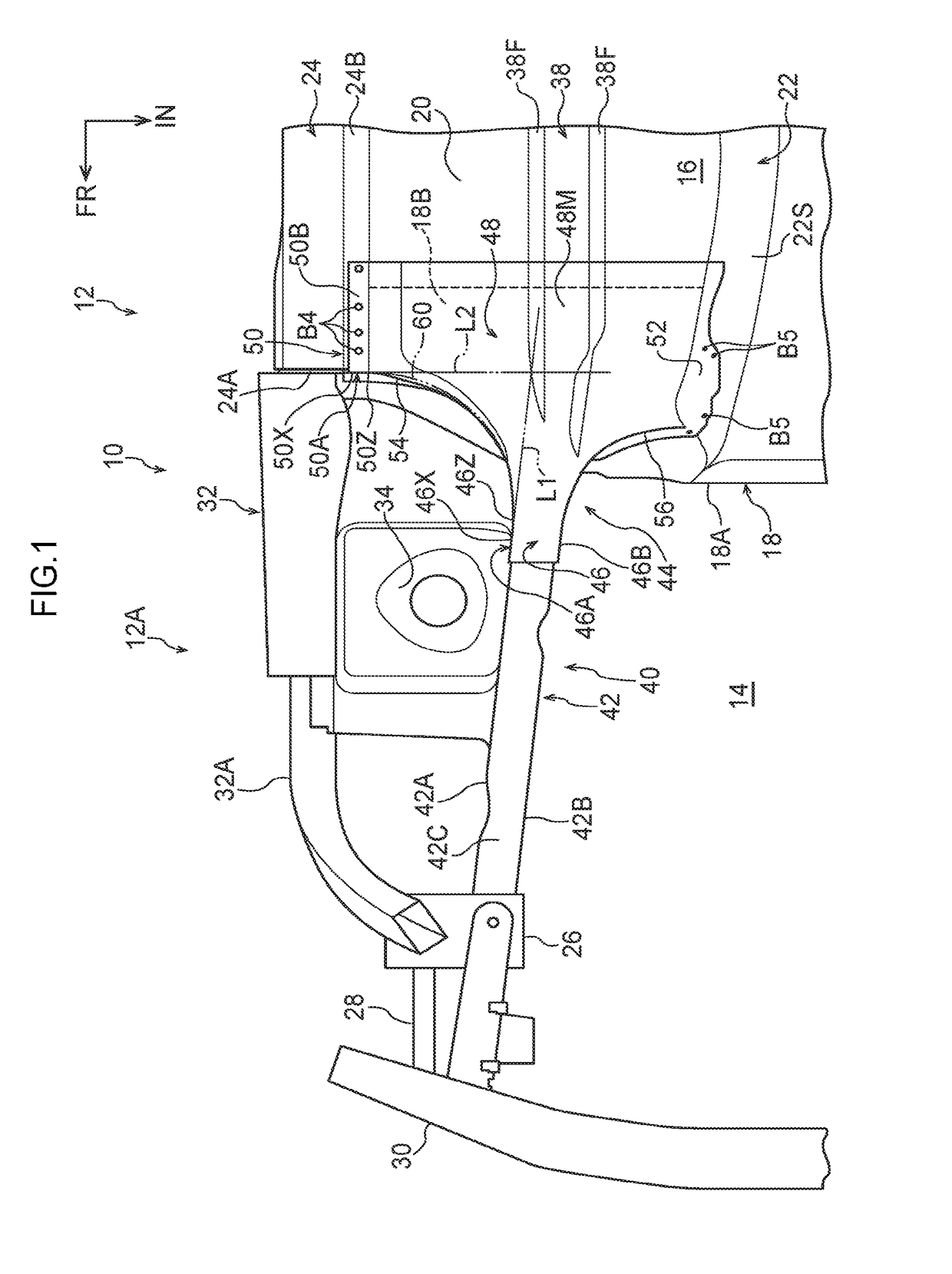

A connecting passage is formed inside a cylinder head, which extends rearward from an exhaust passage and connects to the exhaust passage. The connecting passage branches inside the cylinder head into two branch passages, which open at a rear end face of the cylinder head, respectively. An opening portion, one of opening portions of the branch passages, connects to an EGR cooler, and another opening portion, the other of opening portions of the branch passages, connects to a bypass pipe. Accordingly, the exhaust gas recirculation device of an engine which can restrain the device from being improperly large sized, providing the EGR cooler and the bypass pipe, can be provided.

Owner:MAZDA MOTOR CORP

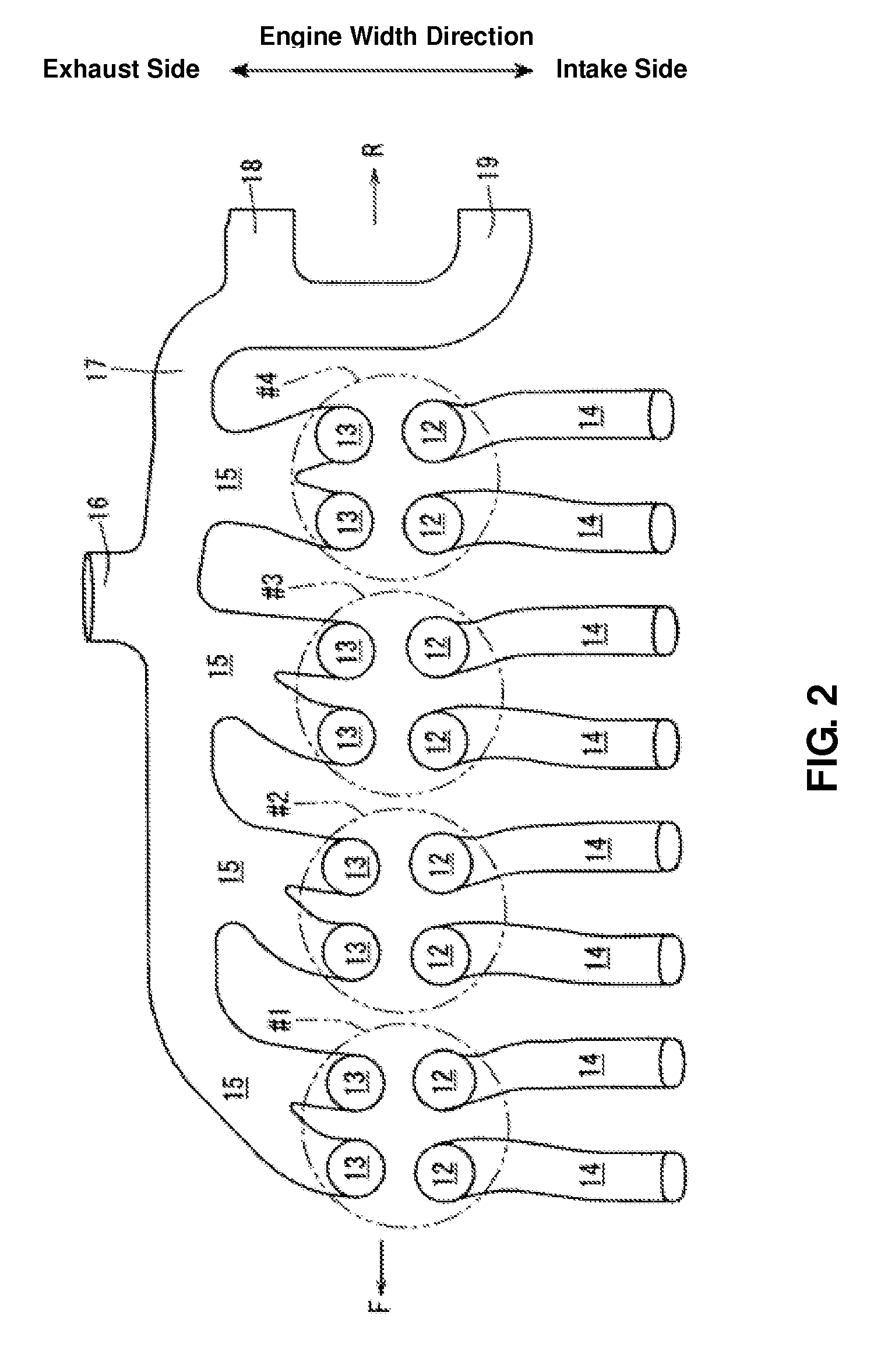

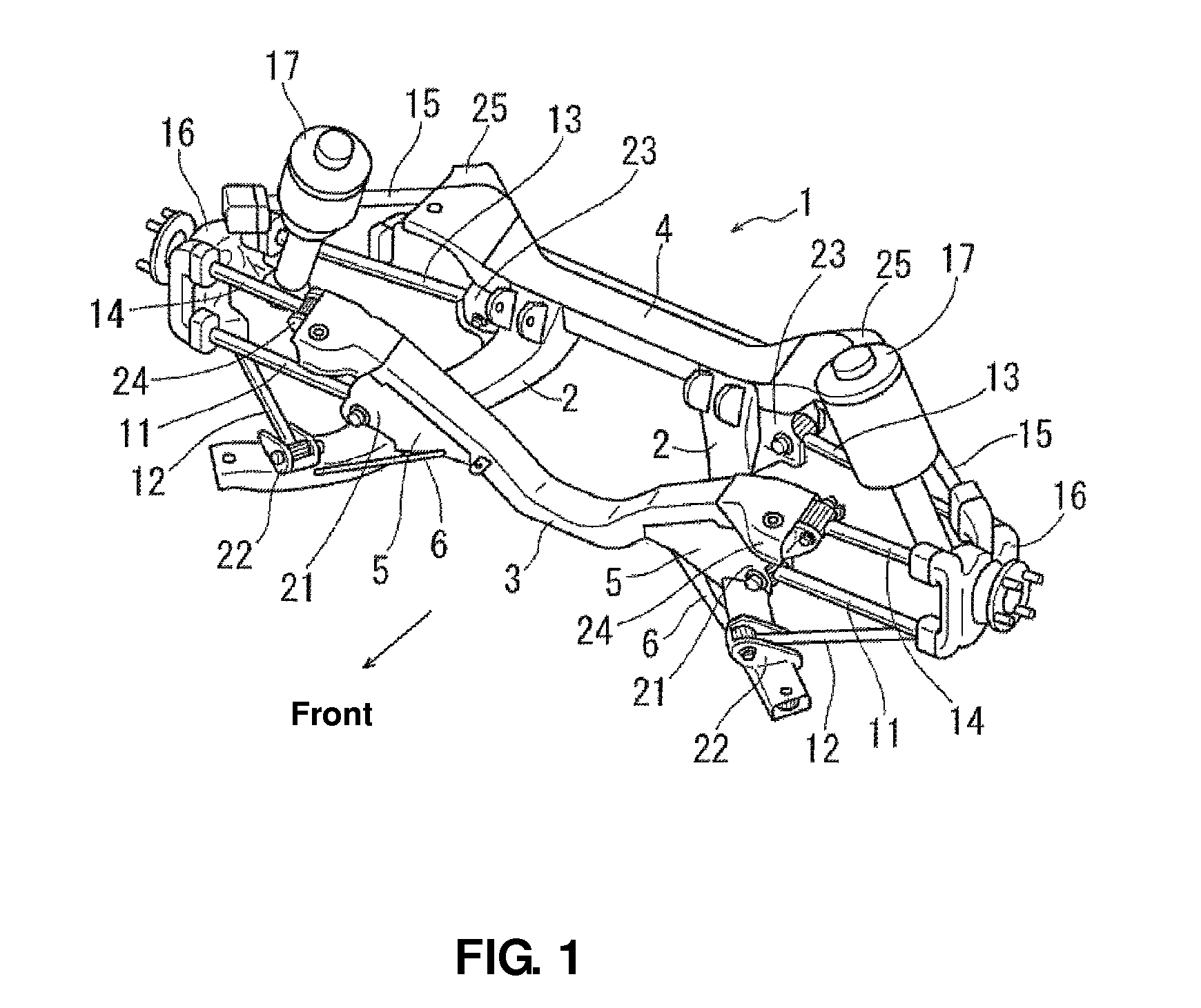

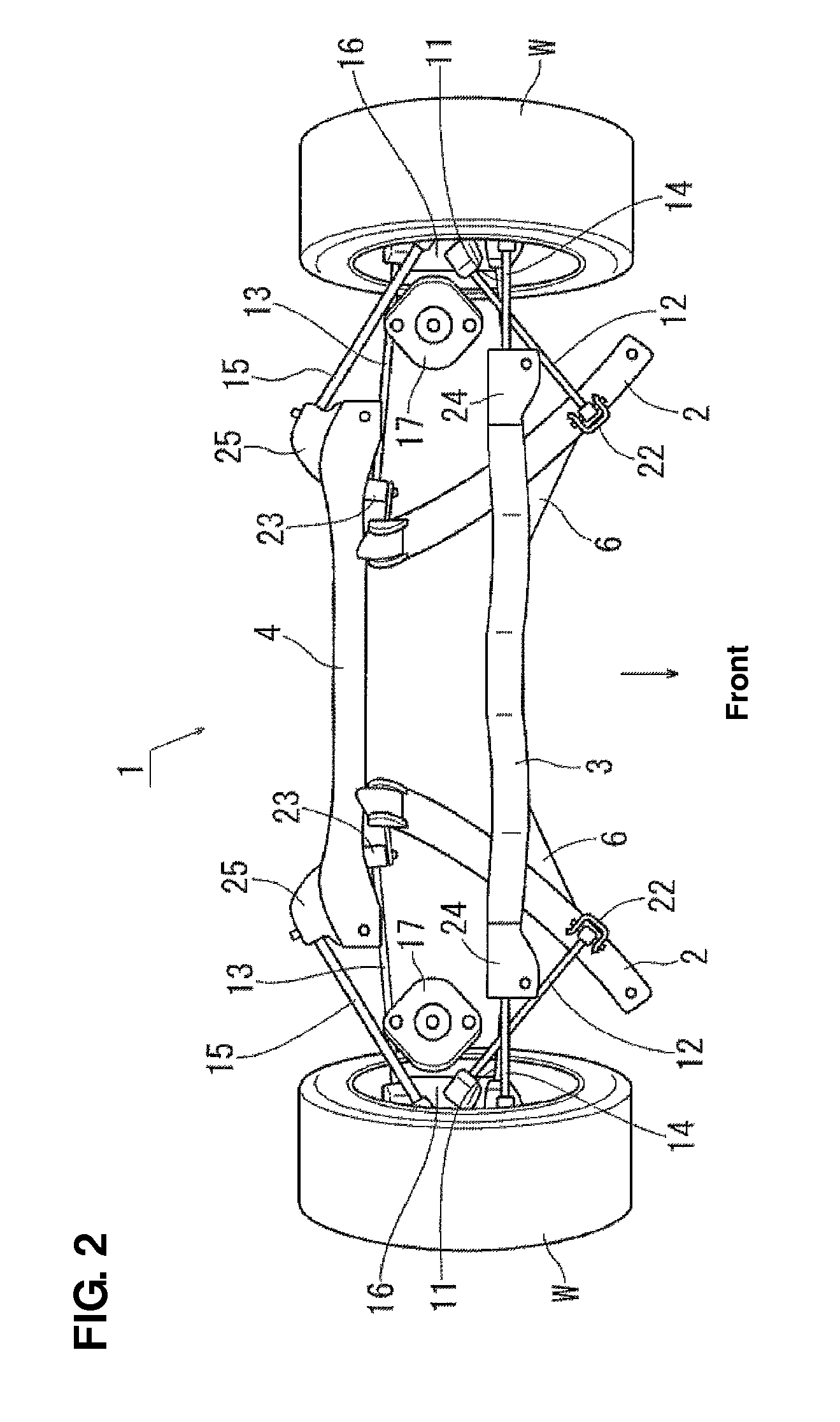

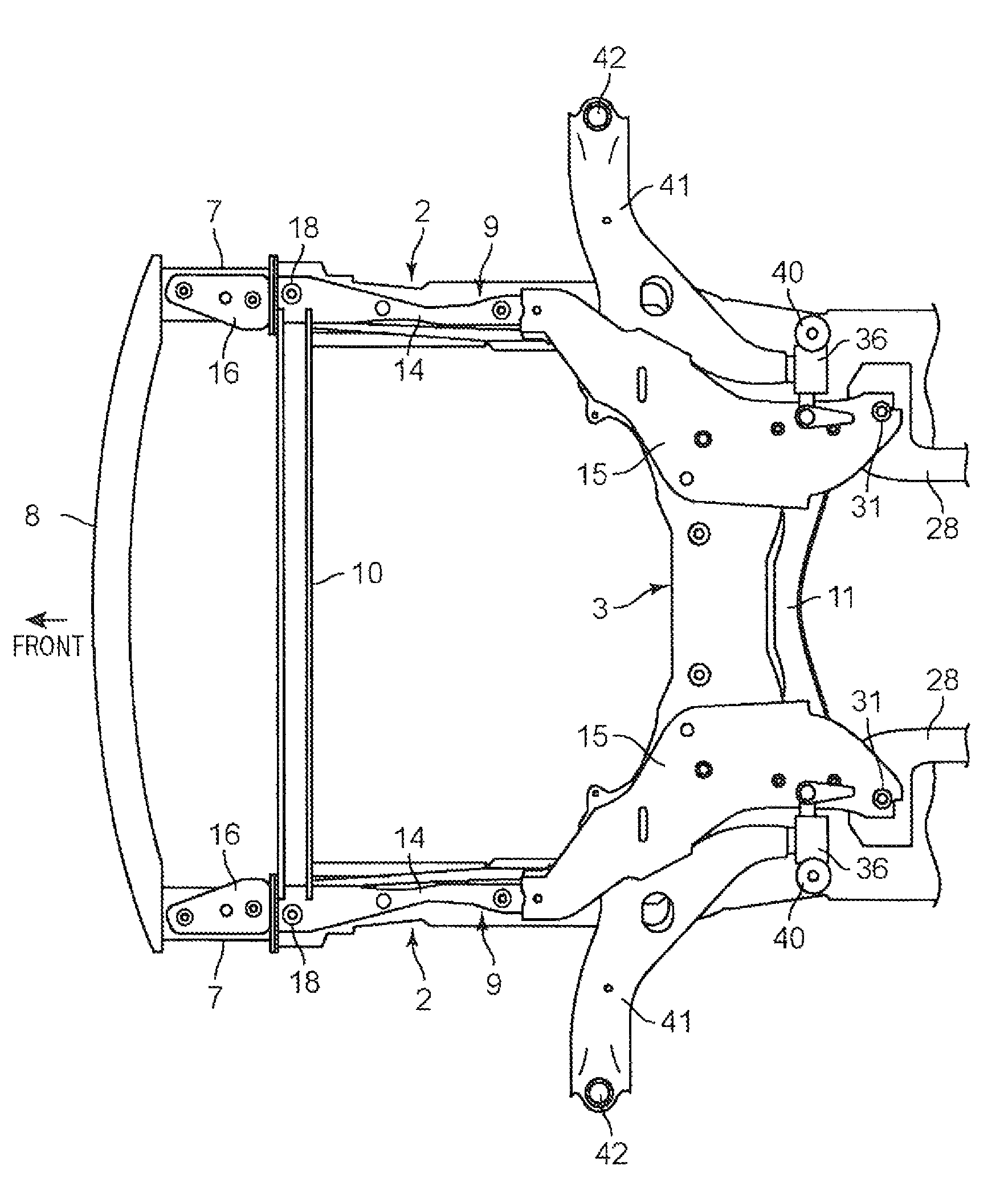

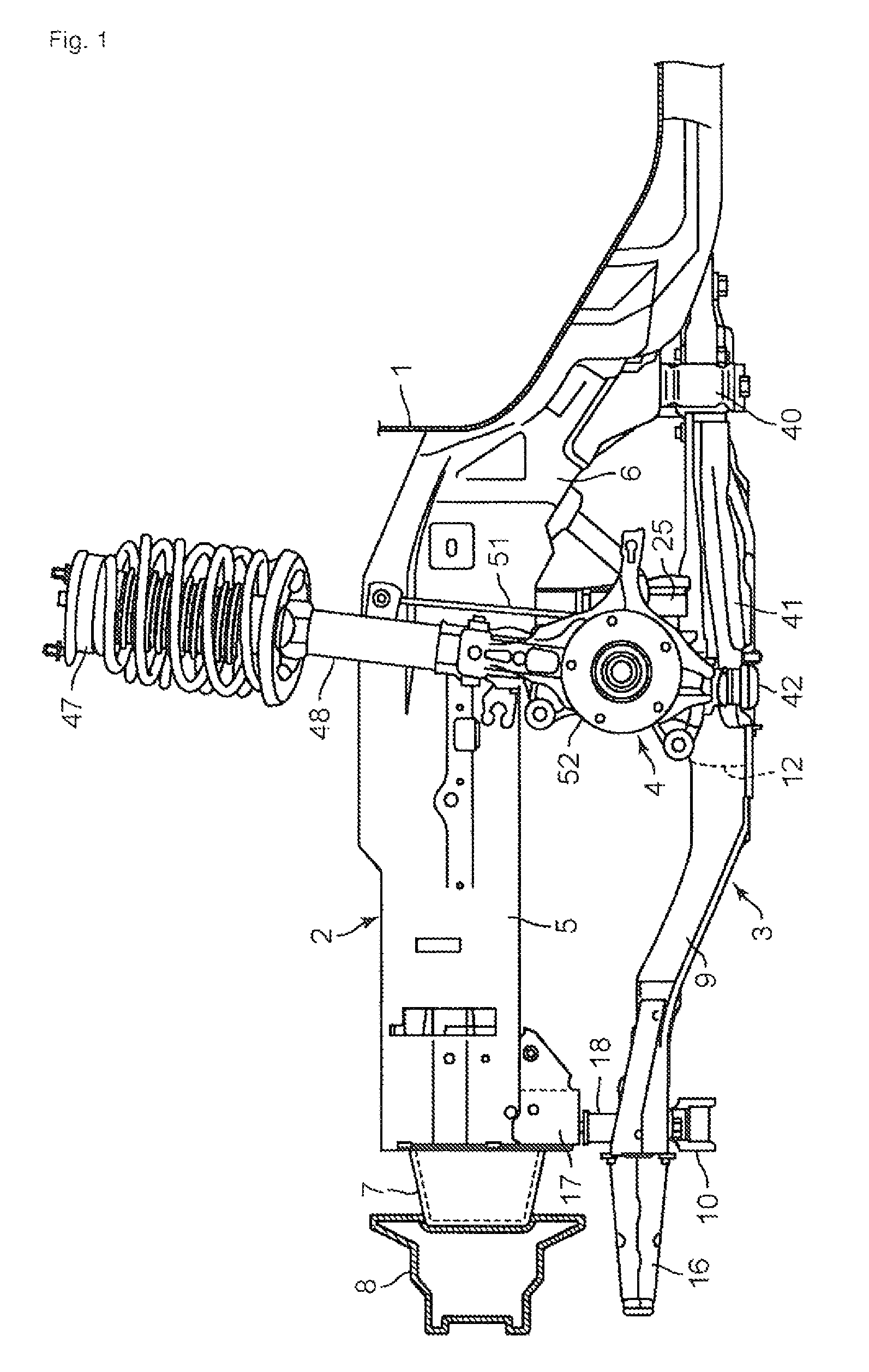

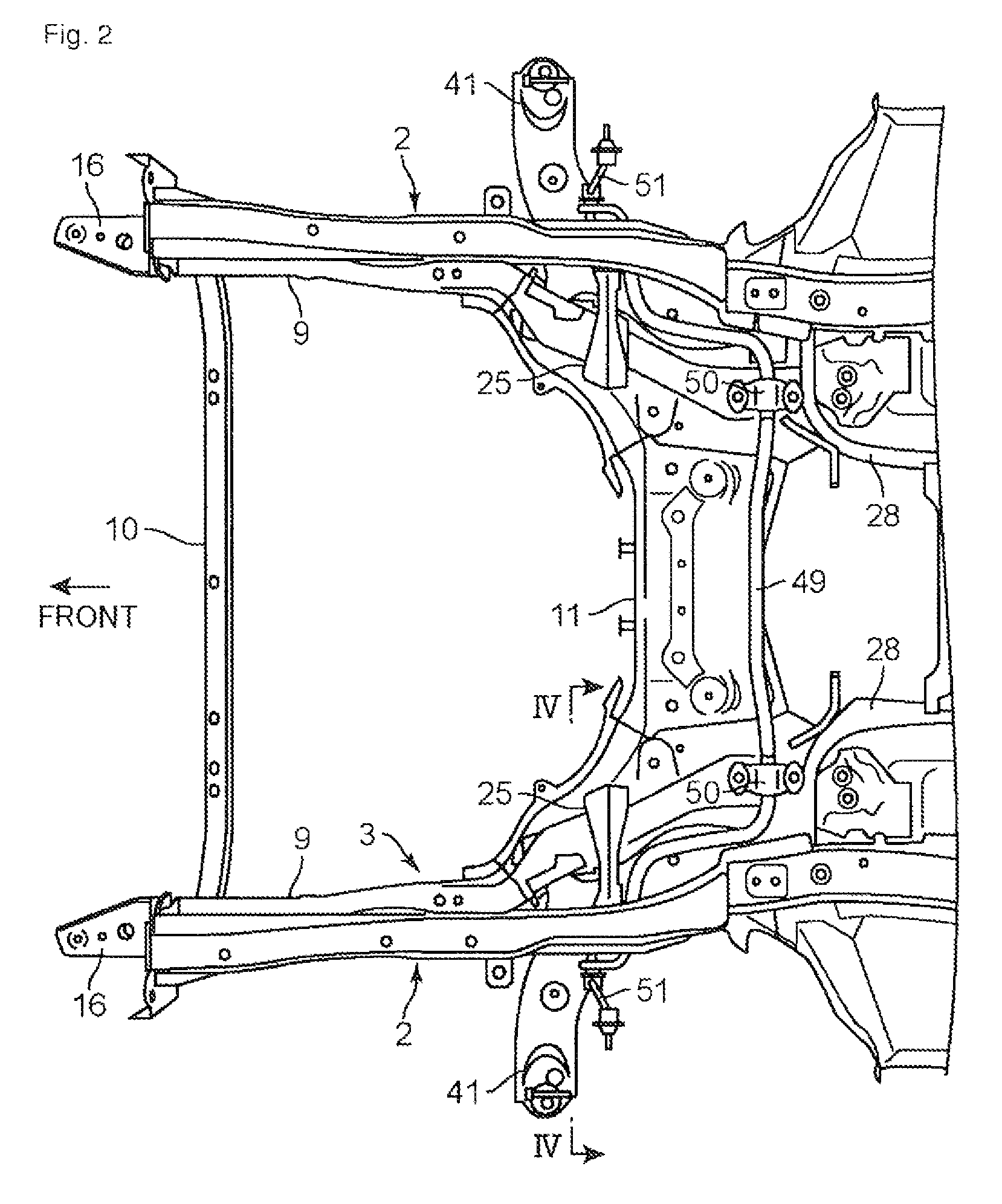

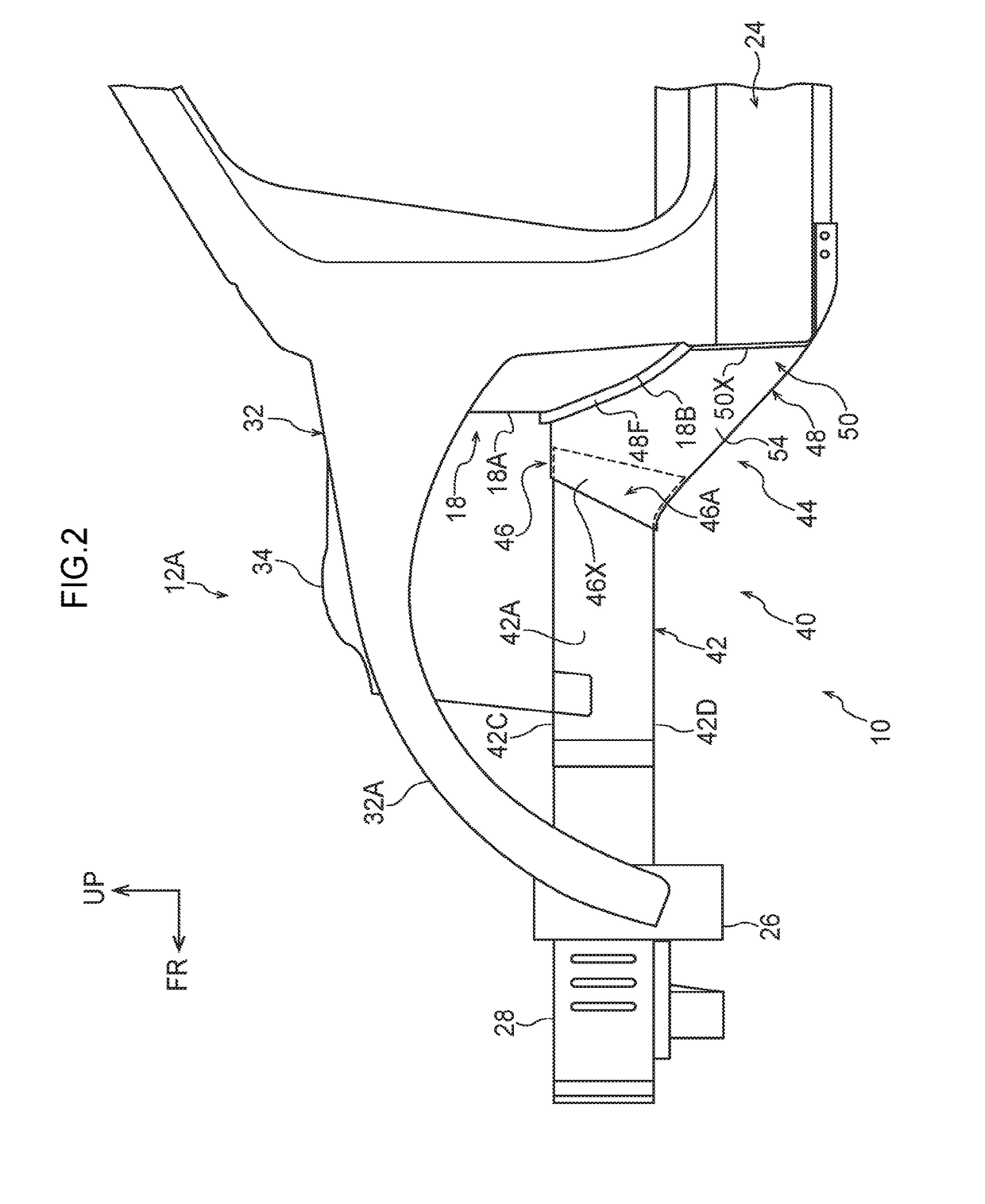

Sub frame structure of automotive vehicle

InactiveUS8857836B2Super light weightLight weightUnderstructuresResilient suspensionsInterconnectionMechanical engineering

A sub frame attached to a vehicle-body rear portion from below comprises a pair of right-and-left side members and a front cross member which interconnects substantially respective central portions, in a vehicle longitudinal direction, of the side members. As attachment portions for attaching lower links, there are provided a central attachment portion which is provided at an interconnection portion between the side member and the front cross member, a front attachment portion which is provided at the side member at a position located in front of the interconnection portion, and a rear attachment portion which is provided at the side member at a position located in back of the interconnection portion. Thereby, a sub frame structure of an automotive can be superior in the light weight, ensuring the support rigidity of the suspension links.

Owner:MAZDA MOTOR CORP

Suspension mounting structure for vehicle

ActiveUS8746718B2Effectively ensureReduce weightVehicle seatsVehicle body-frame connectionsEngineeringMechanical engineering

Owner:MAZDA MOTOR CORP

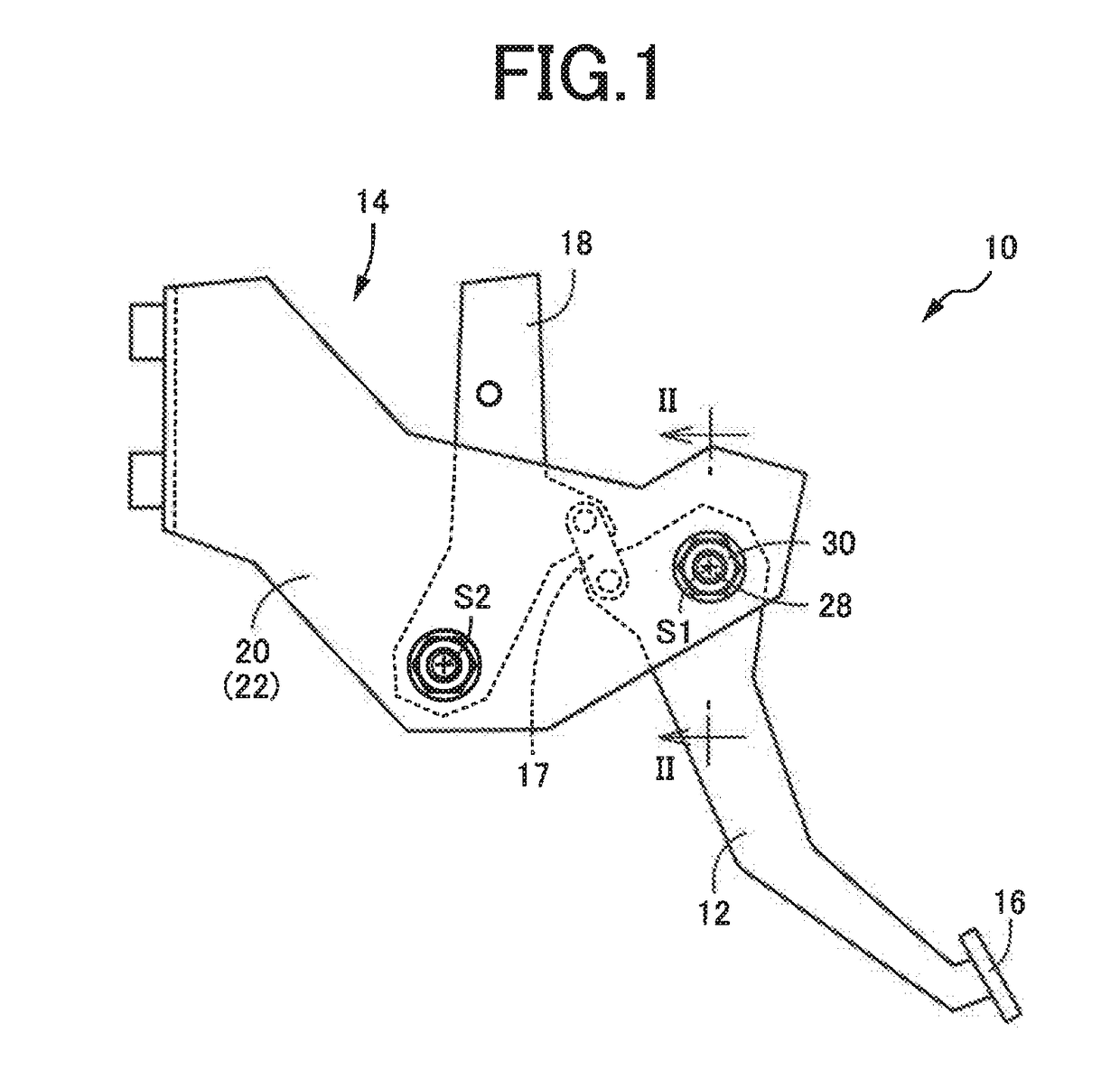

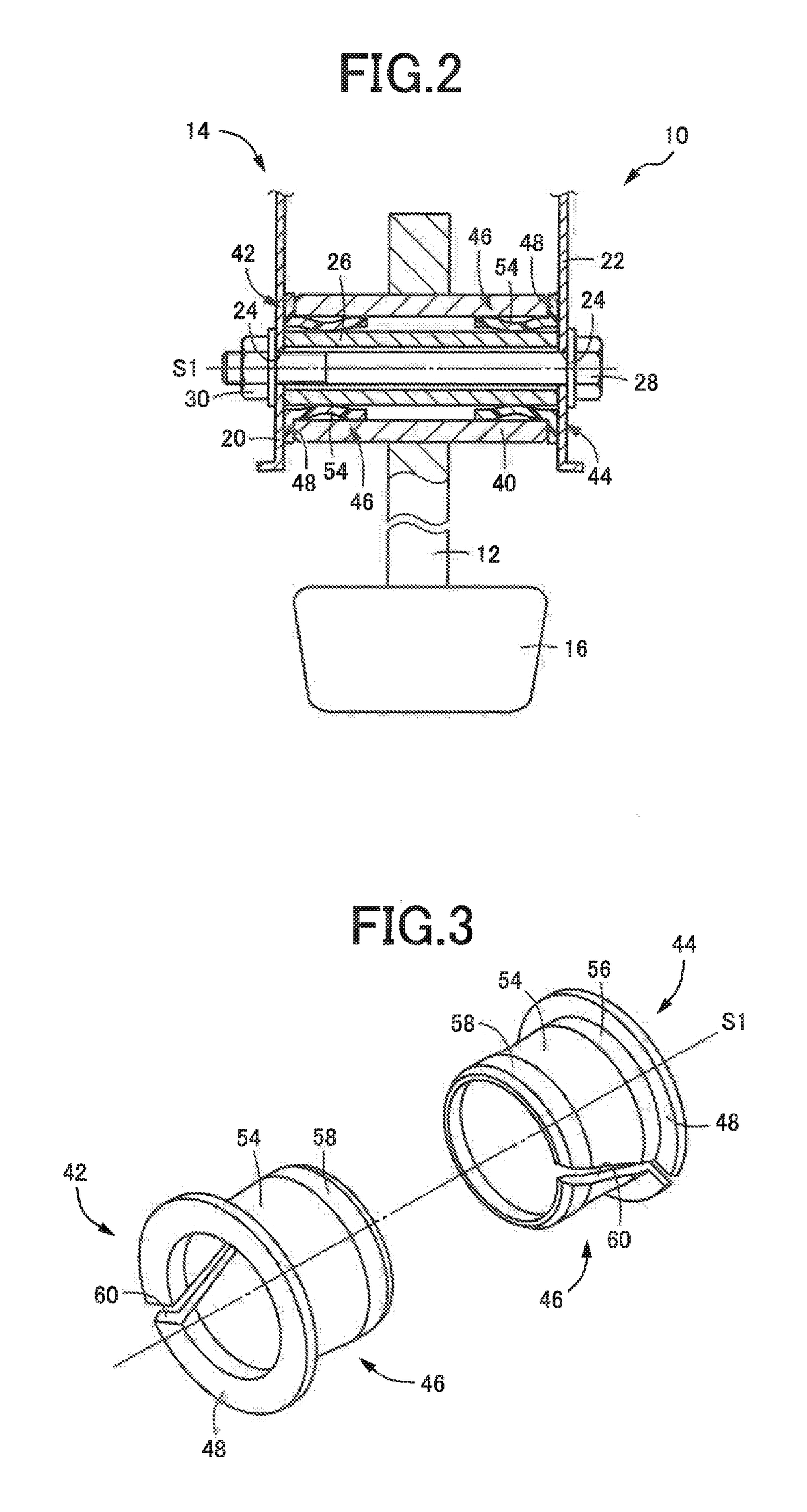

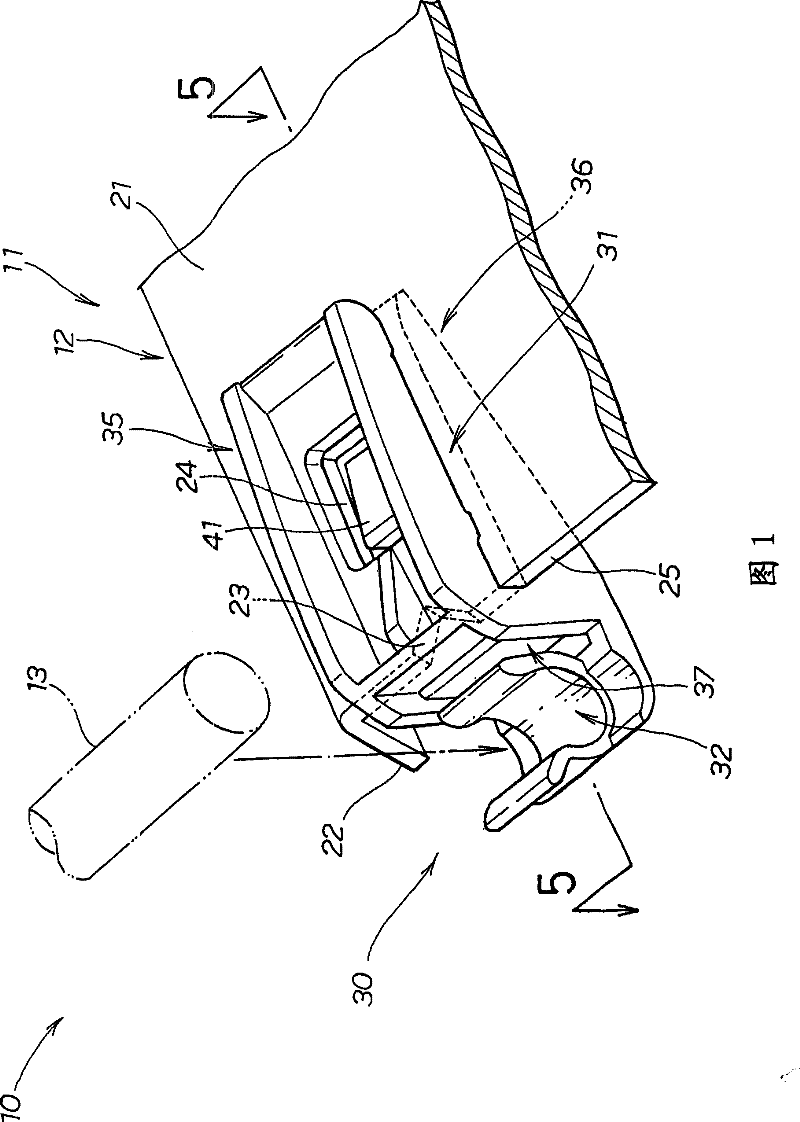

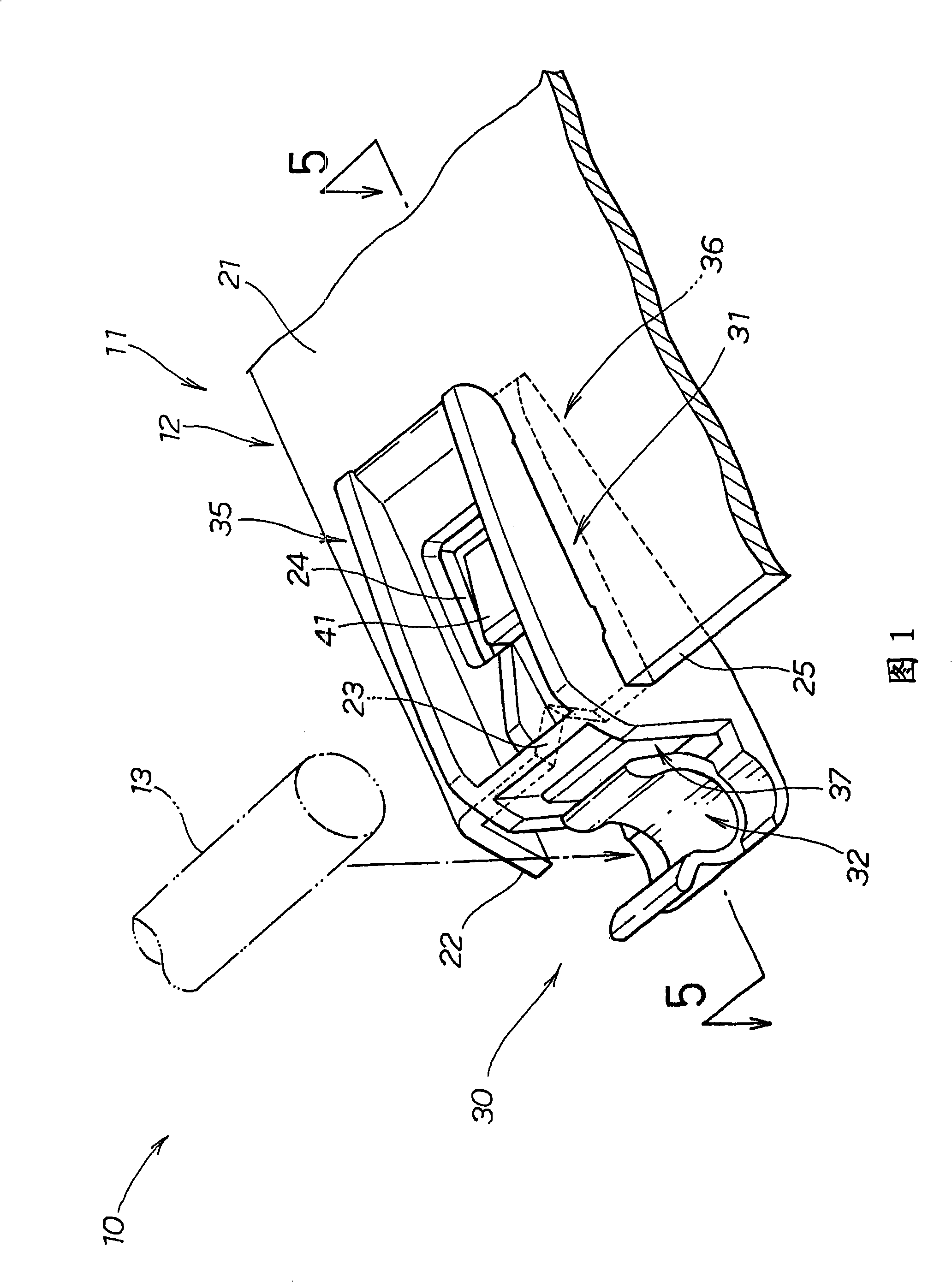

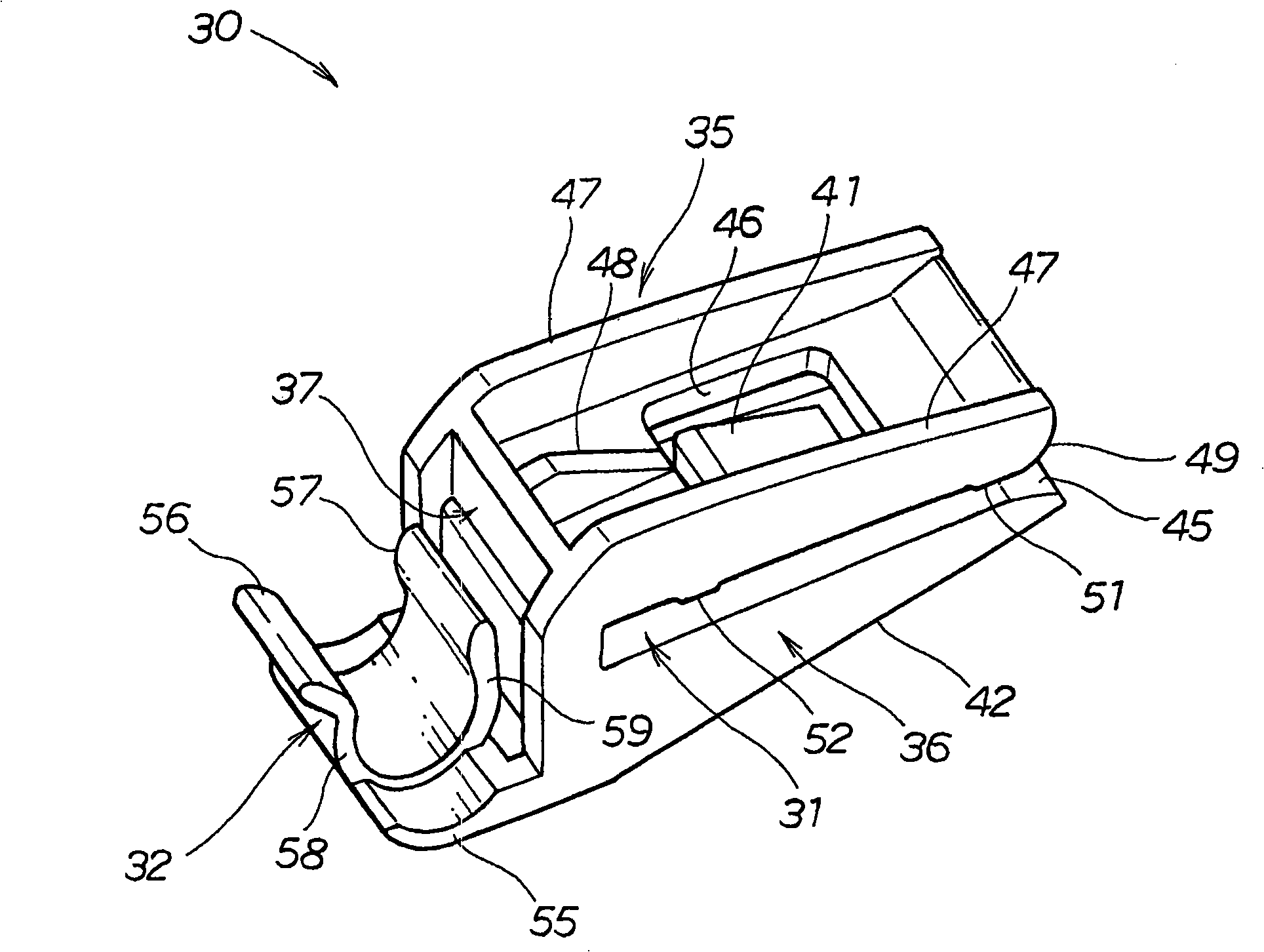

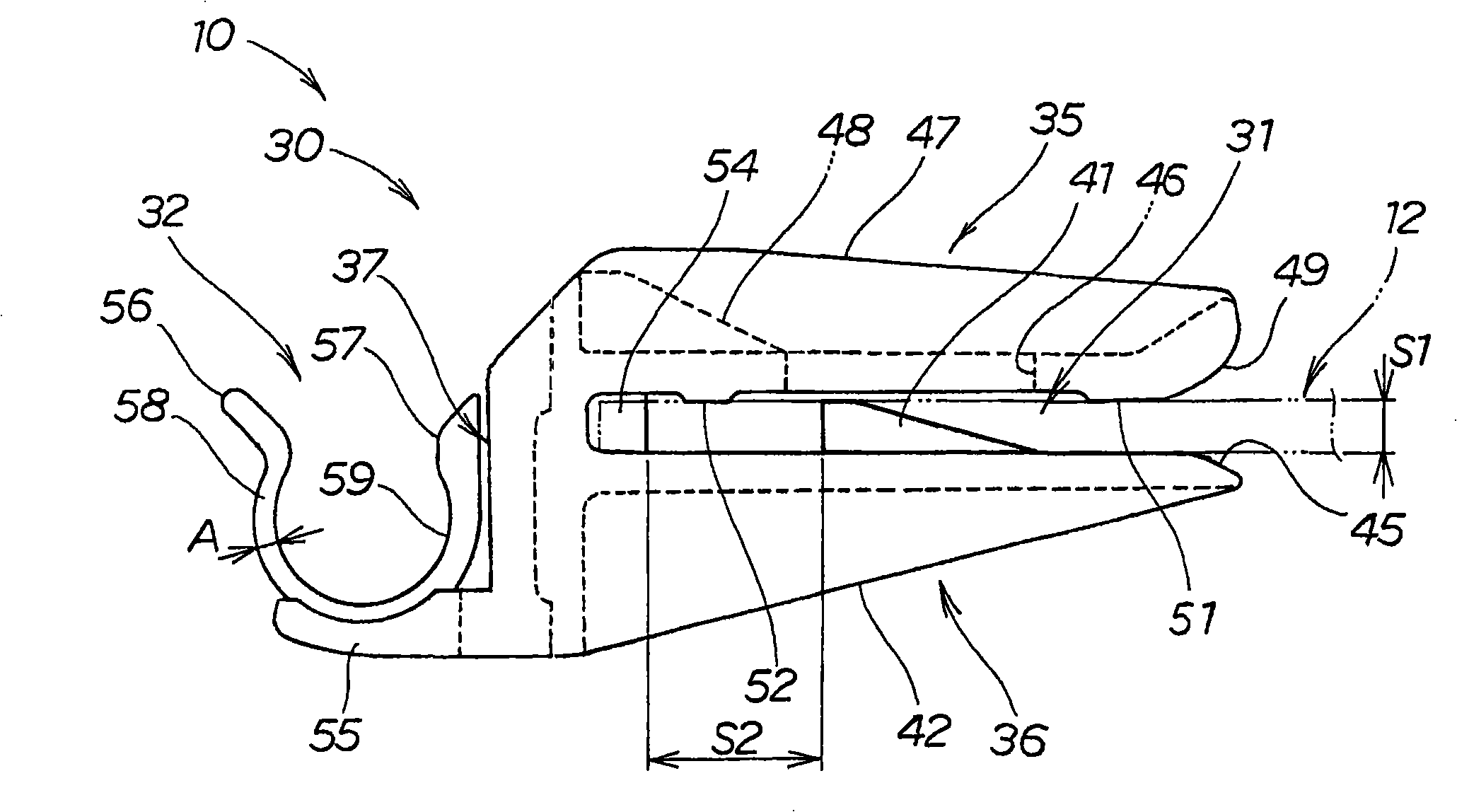

Bearing structure for vehicle pedal device and flanged bushing

InactiveUS20170227047A1Abnormal noise be generateEasily insertControlling membersShaftsEngineeringMechanical engineering

Bearing structure of a pedal device, wherein a support member having a cylindrical outer peripheral surface is fixedly attached to a pedal bracket to be substantially horizontal, a boss of a pivot member radially outside the support member via a pair of flanged bushings each made of resin and having a flange portion at one end of a cylindrical portion so the boss turns about an axis, both axial ends of the flanged bushing cylindrical portion closely contact the boss inner peripheral surface; the flanged bushing cylindrical portion have, in intermediate portion, in an axial direction, a narrow portion having both inner and outer peripheral surfaces reduced in diameter so the narrow portion is curved inward in radial direction; the narrow portion smallest inside diameter being smaller than the support member outside diameter having interference; at least the narrow portion smallest diameter portion of elastically closely contact the support member outer peripheral surface.

Owner:TOYODA IRON WORKS CO LTD

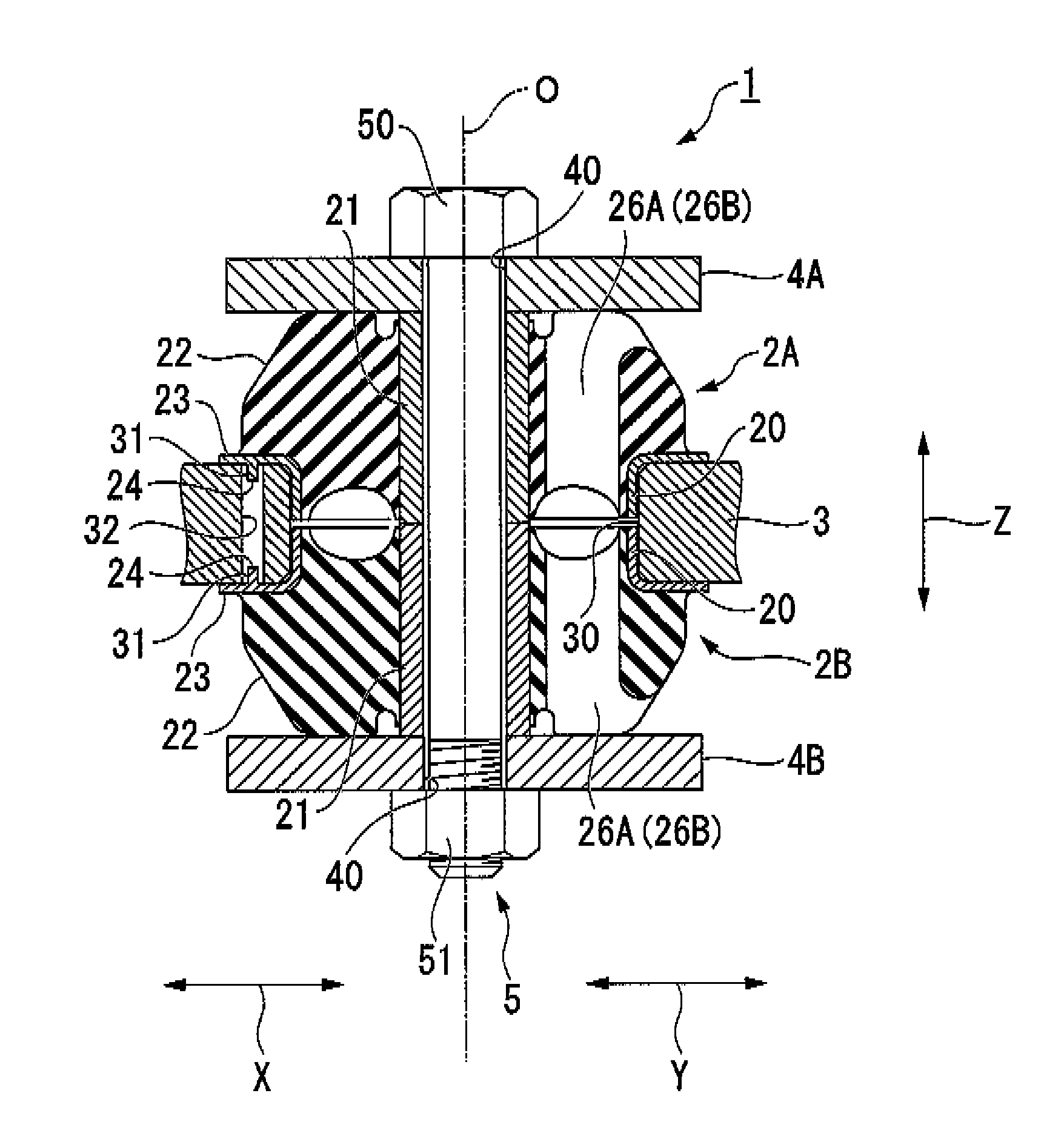

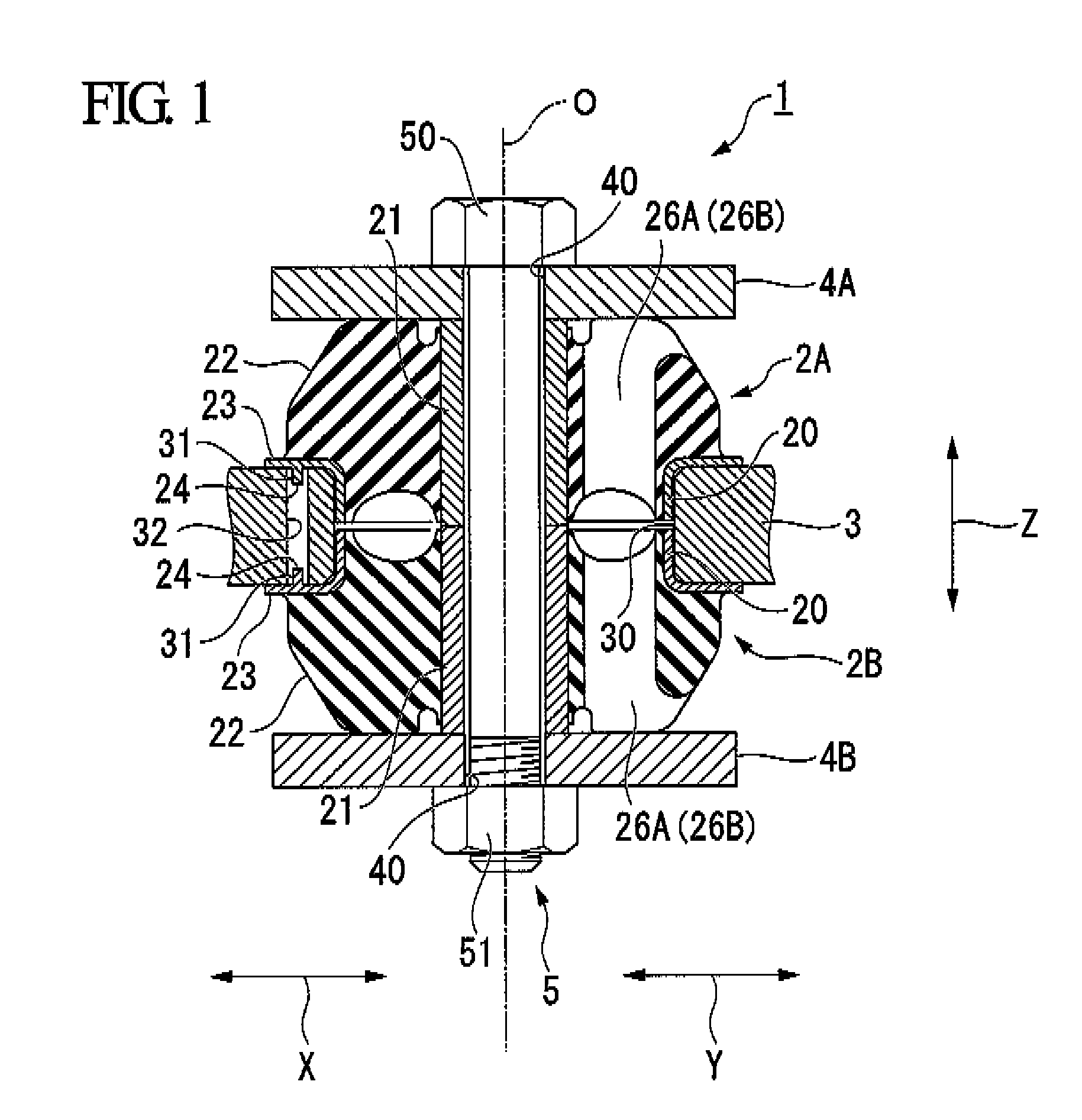

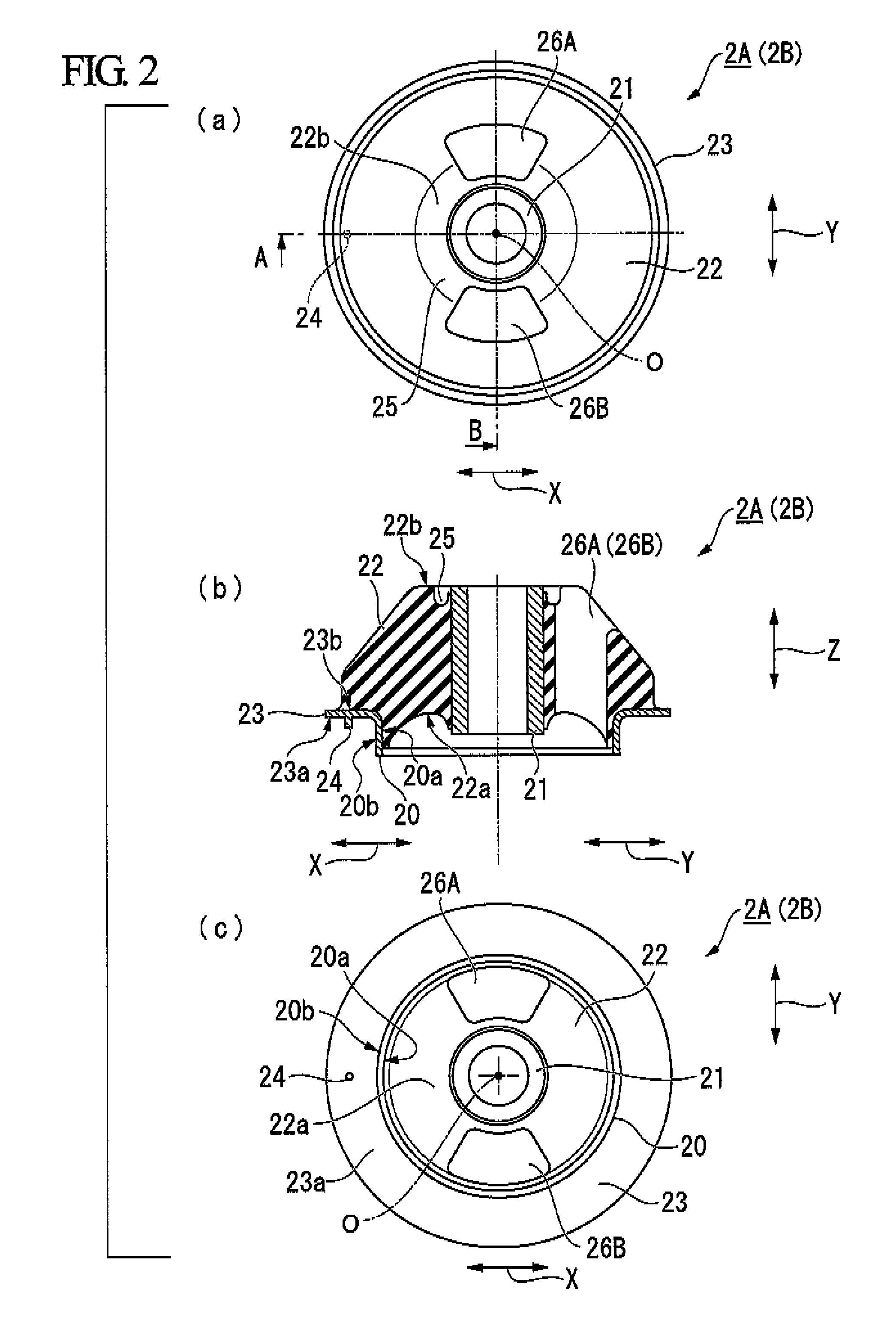

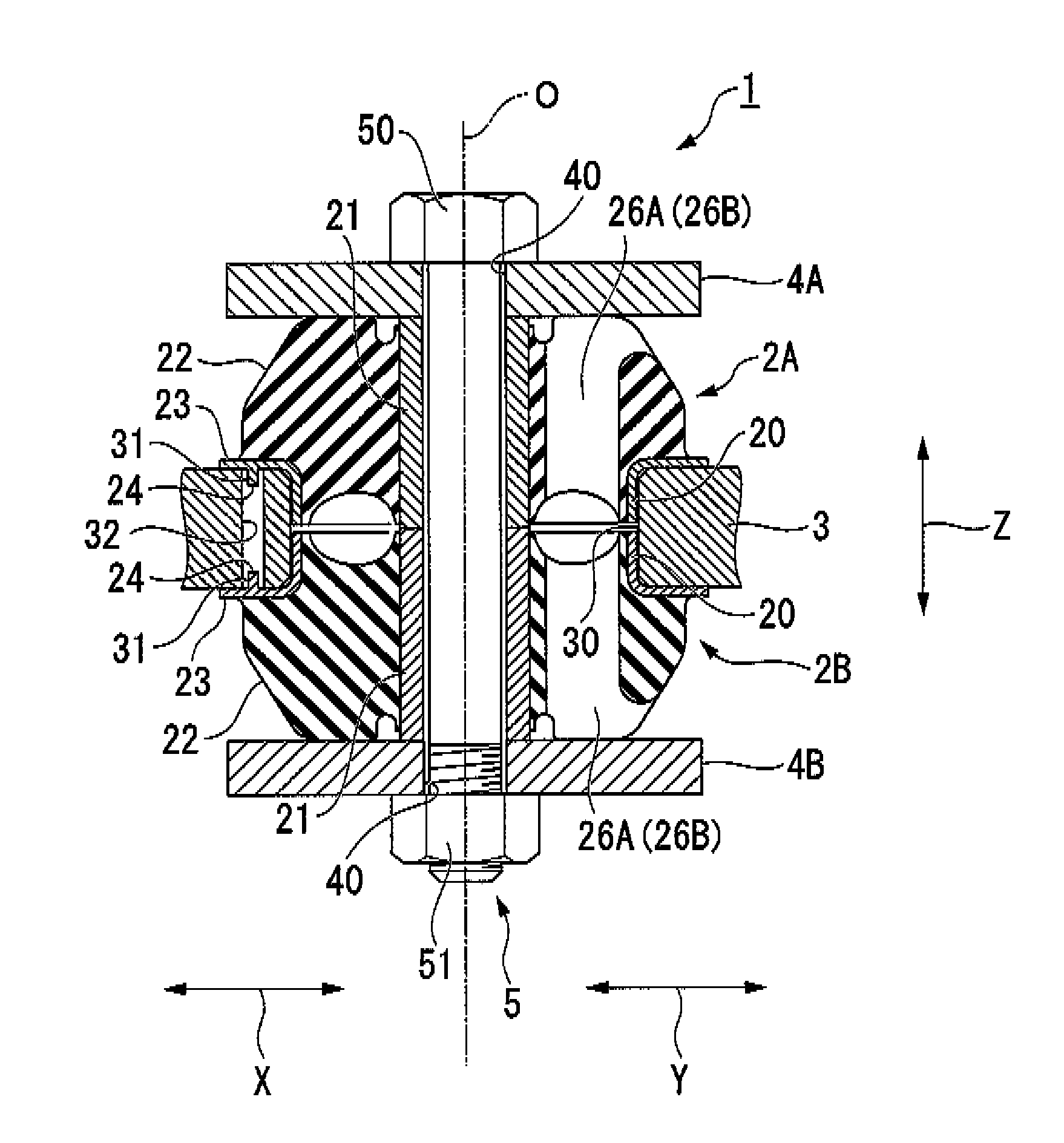

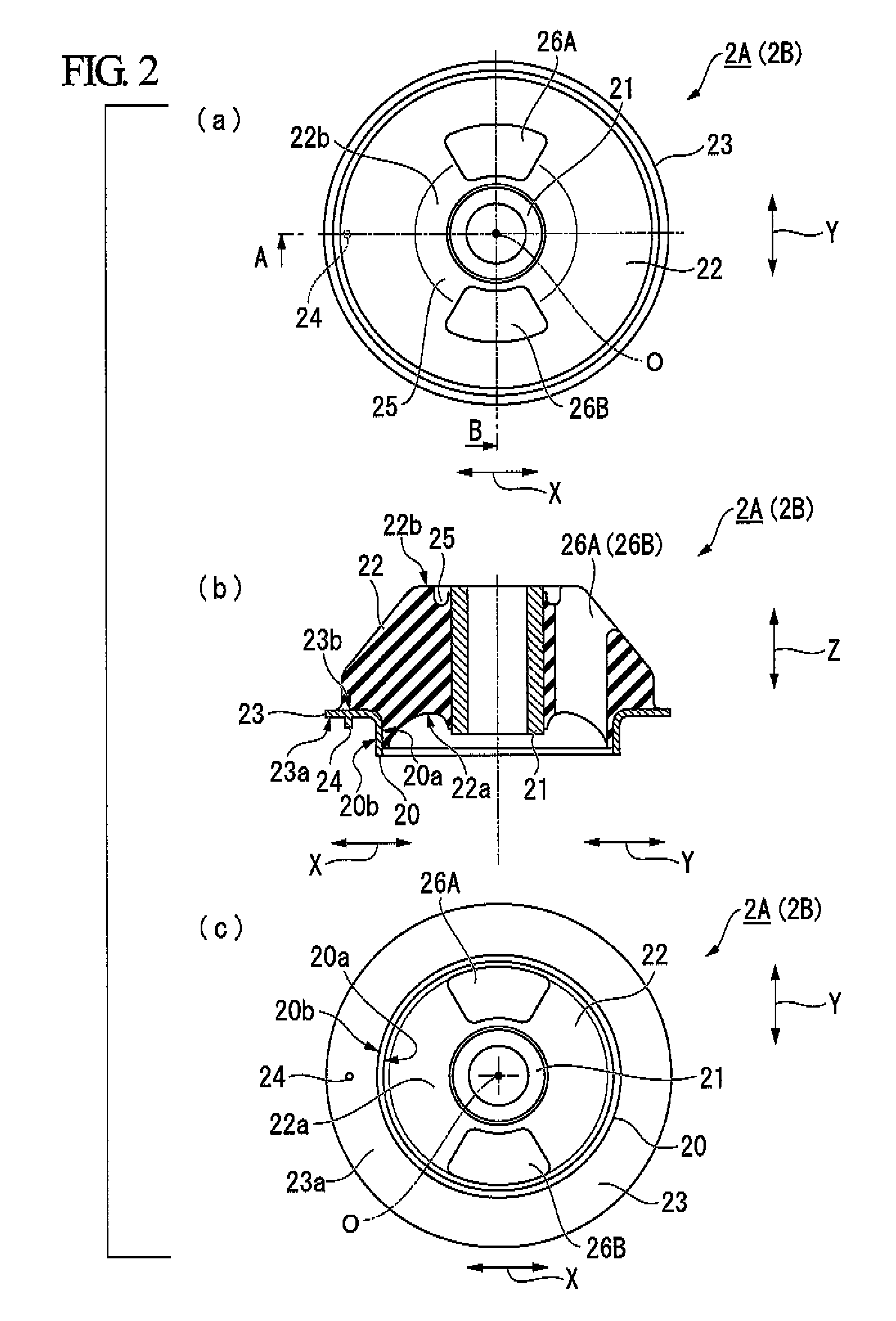

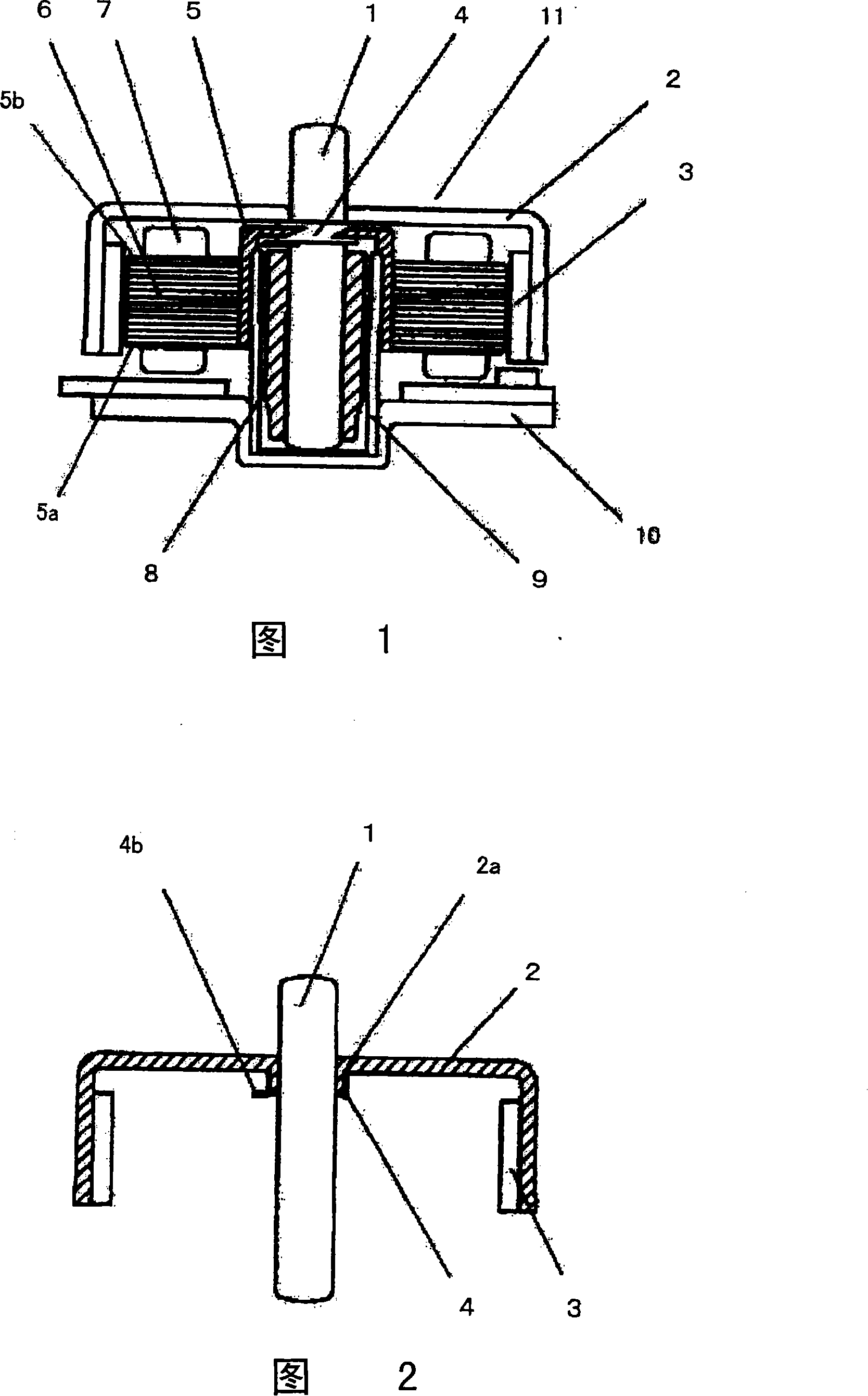

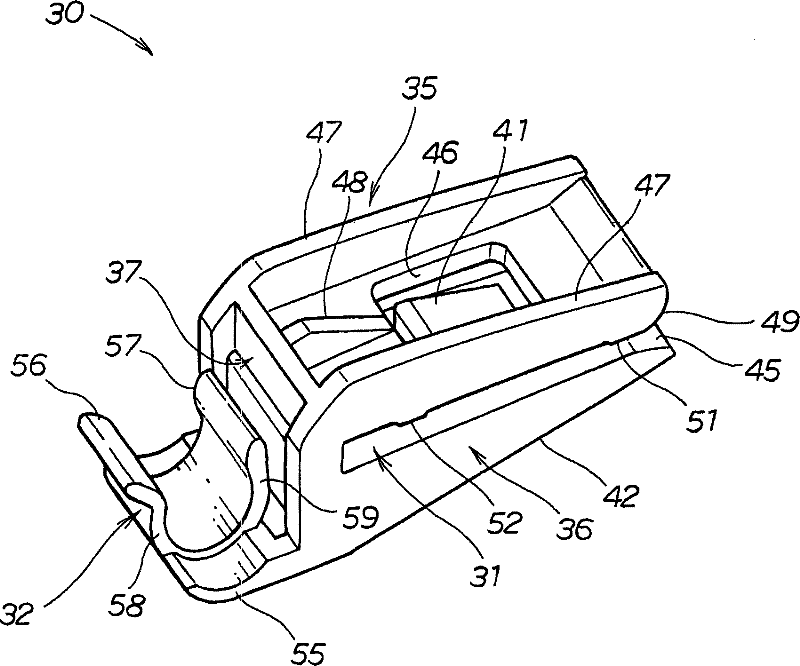

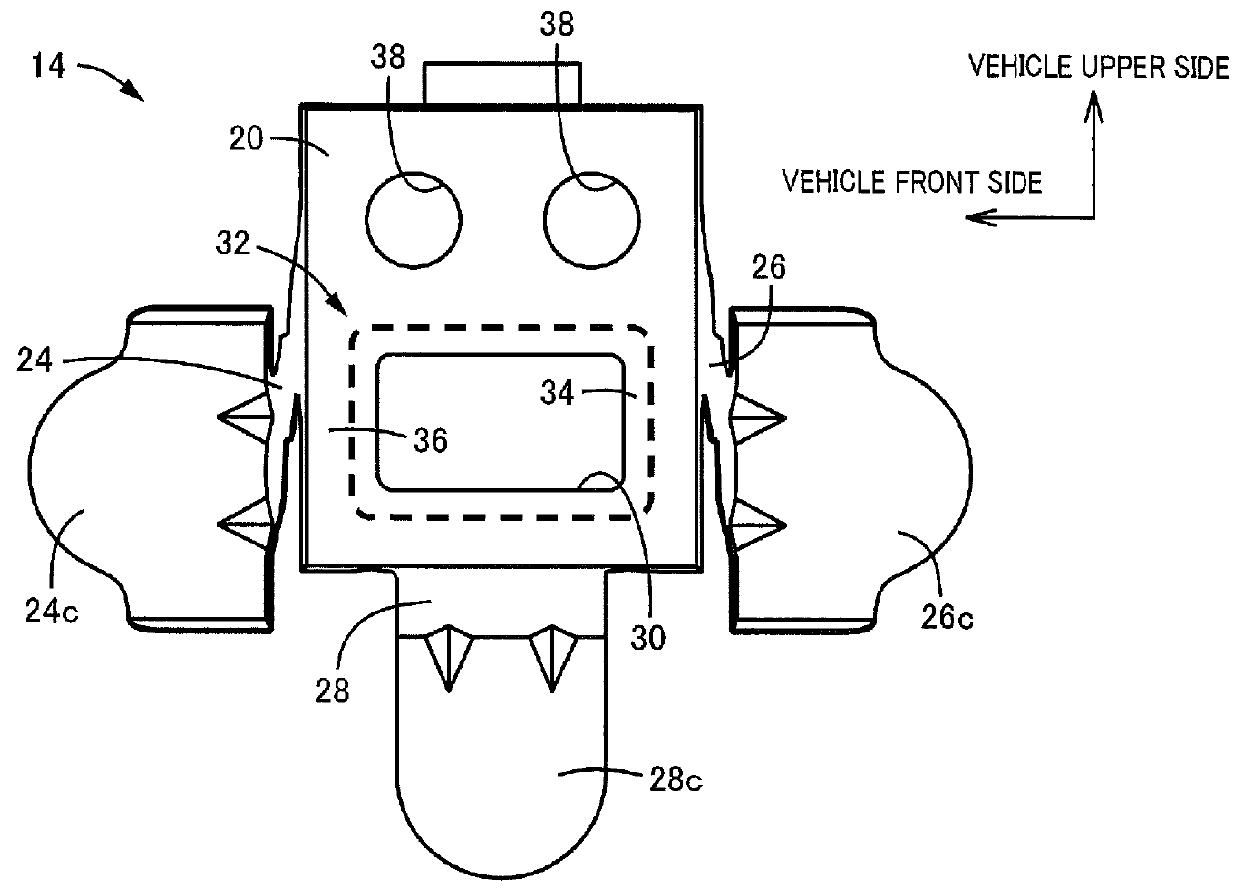

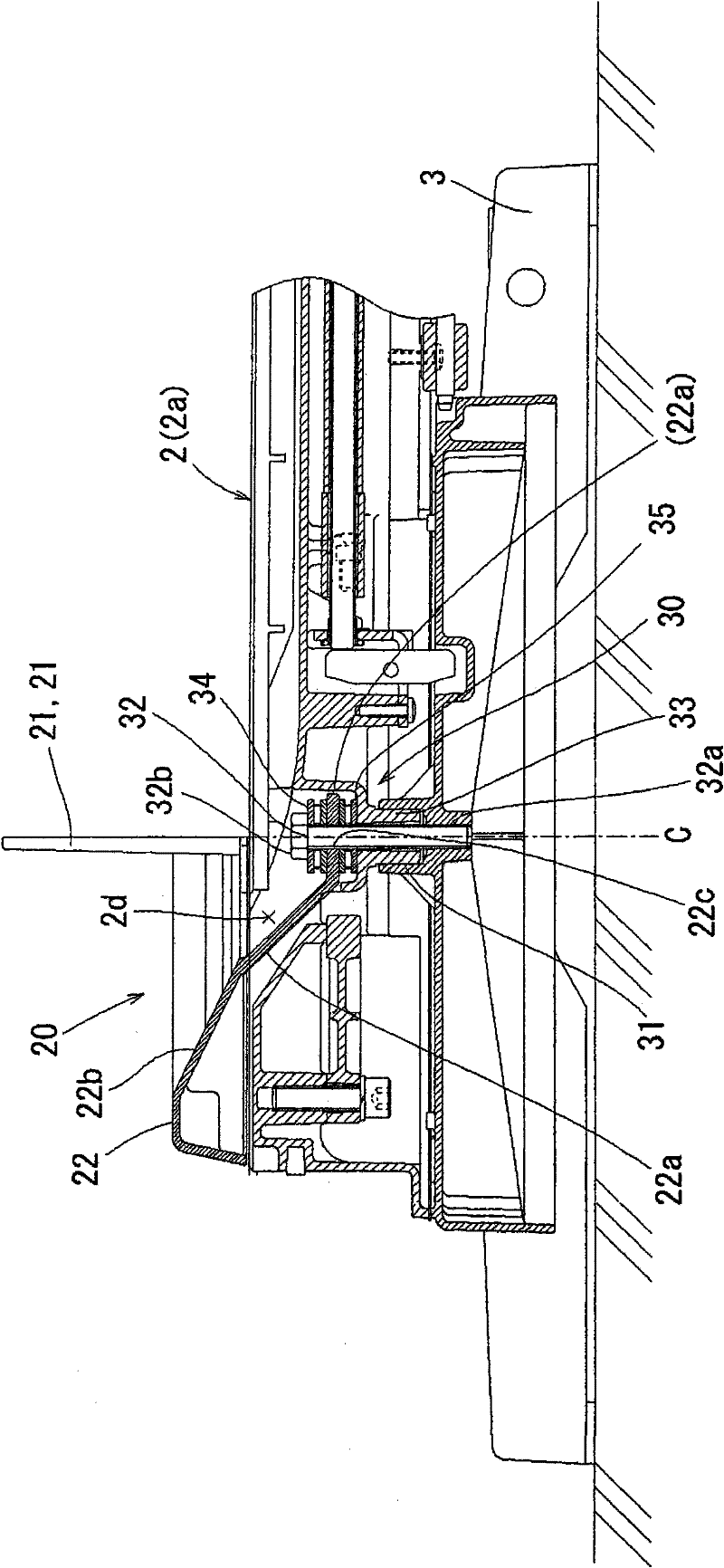

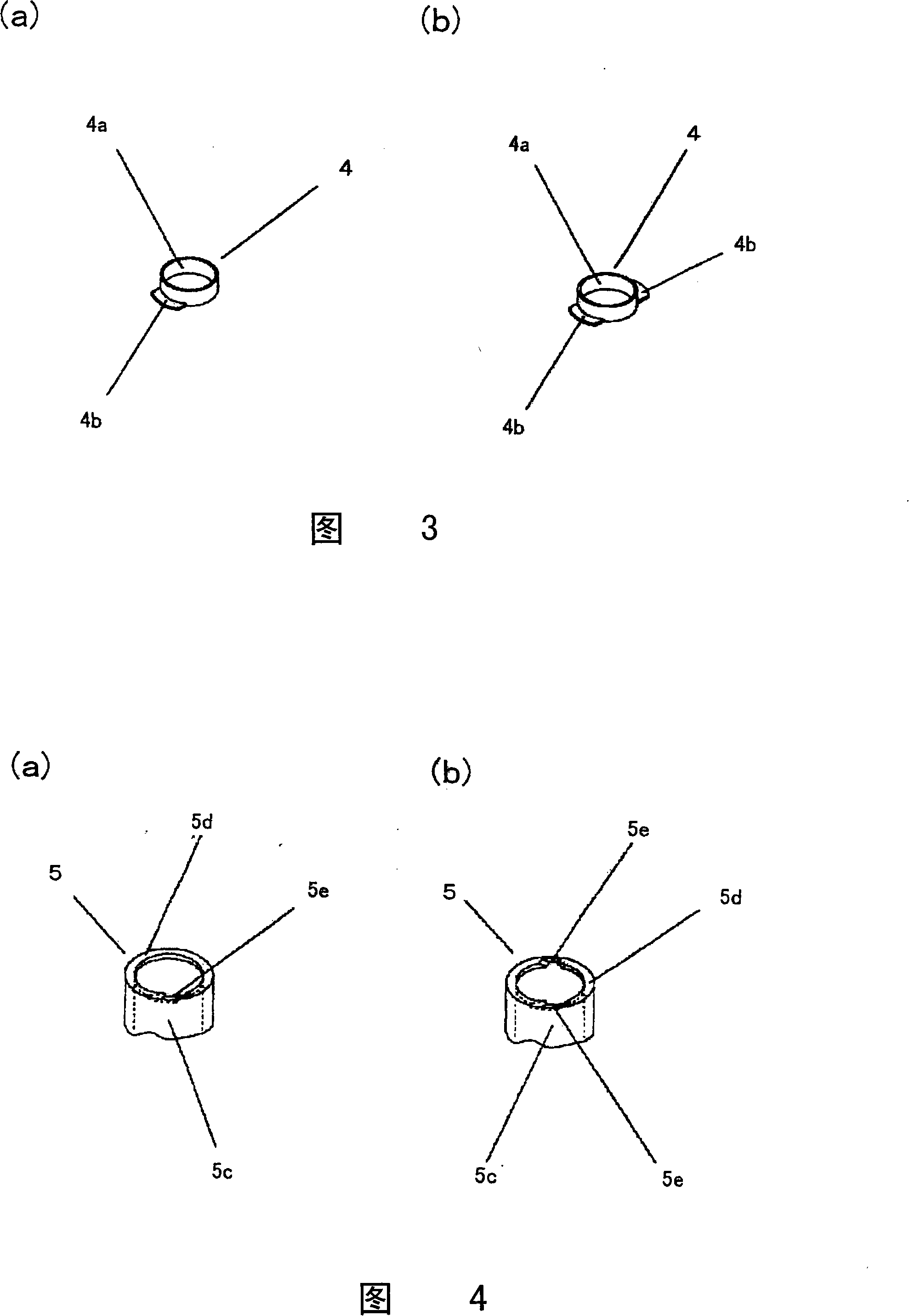

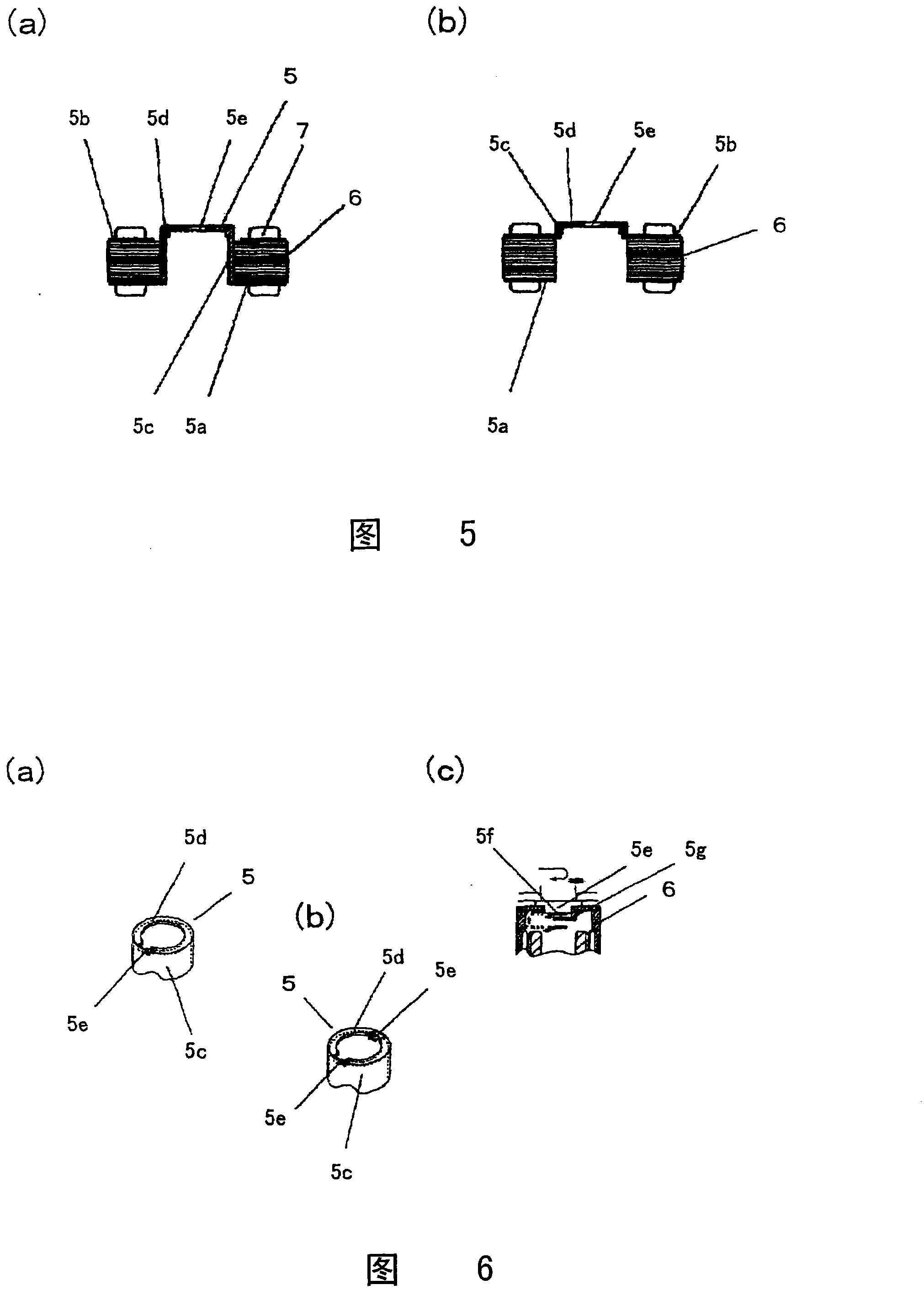

Vibration control equipment

InactiveCN101646880AEasy to assembleEnsure support rigidityNon-rotating vibration suppressionMultiple spring combinationsElastomerVibration control

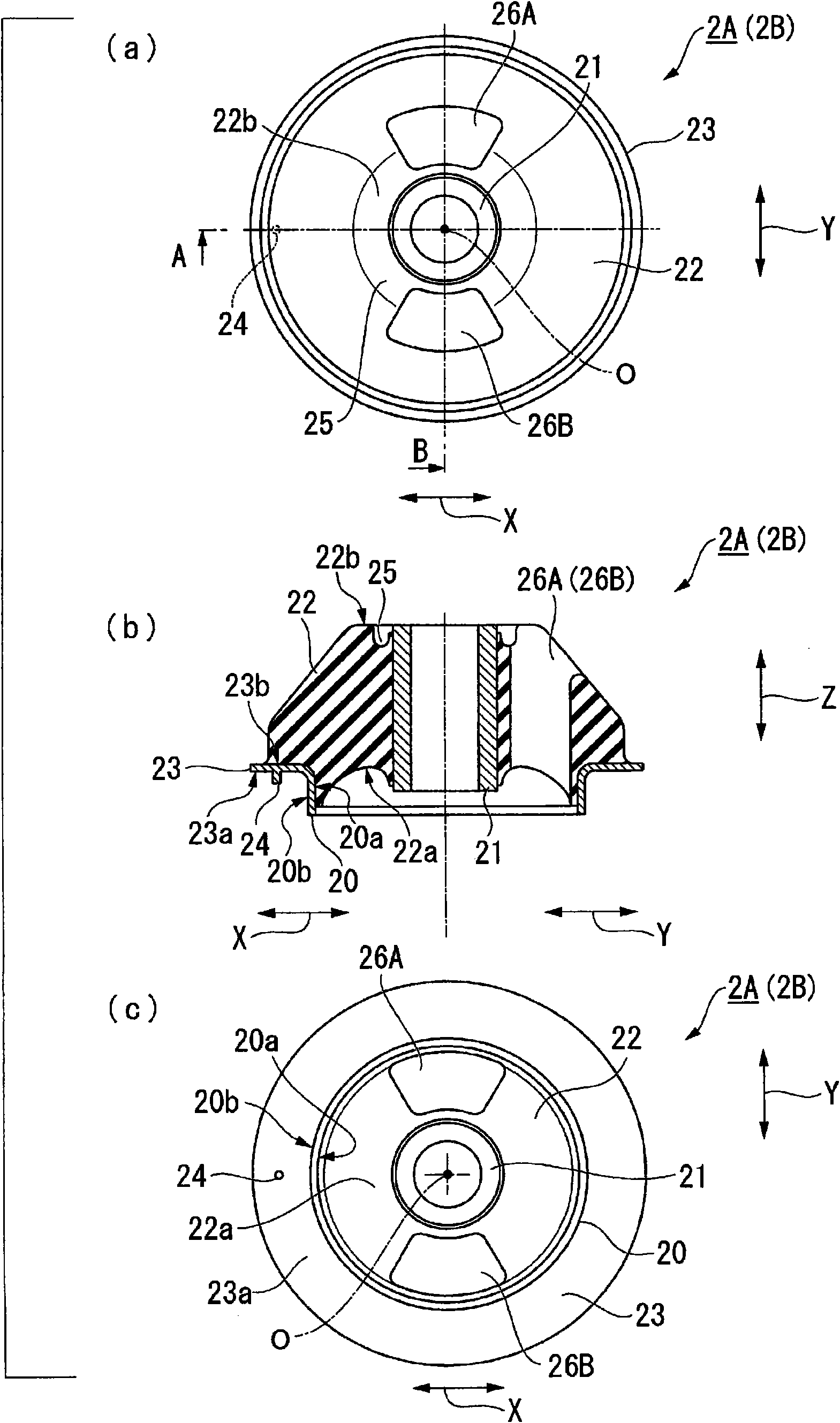

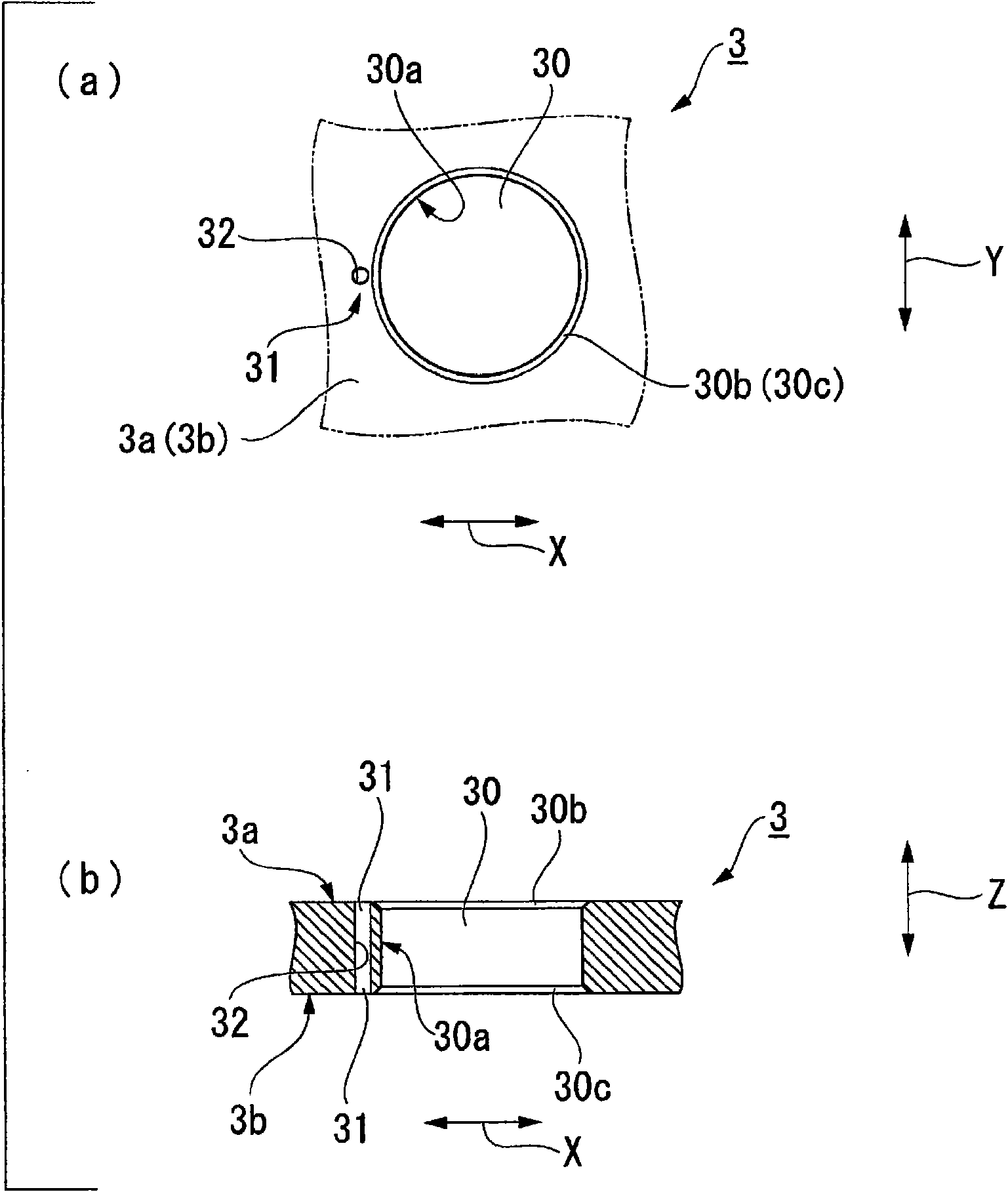

In vibration control equipment (1) constituted by inserting the outer tube (20) of a pair of damping rubbers (2A, 2B) into the opening (30) of a bracket member (3), clamping the pair of damping rubbers (2A, 2B) by means of plate members (4A, 4B), tightening a fastening member (5) for coupling the plate members (4A, 4B), and then compressing the rubber elastic bodies (22) of the damping rubbers (2A, 2B) in the axial direction, outside diameter of the outer tube (20) before tightening the fastening member (5) is smaller than the inside diameter of the fixing hole (30), the rubber elastic bodies(22) are compression deformed by tightening the fastening member (5) and thus a bracket member (3) is clamped by means of upper and lower flanges (23), at least one of the rubber elastic bodies (22) is provided with mold cavity portions (26A, 26B) and at least one of the pair of outer tubes (20) is provided with a portion (24) for determining the circumferential position of the pair of damping rubbers (2A, 2B) relative to the bracket member (3). According to the invention, assembling work is facilitated by arranging the mold cavity portions in accordance with the direction of vibration and the production cost can be reduced.

Owner:BRIDGESTONE CORP

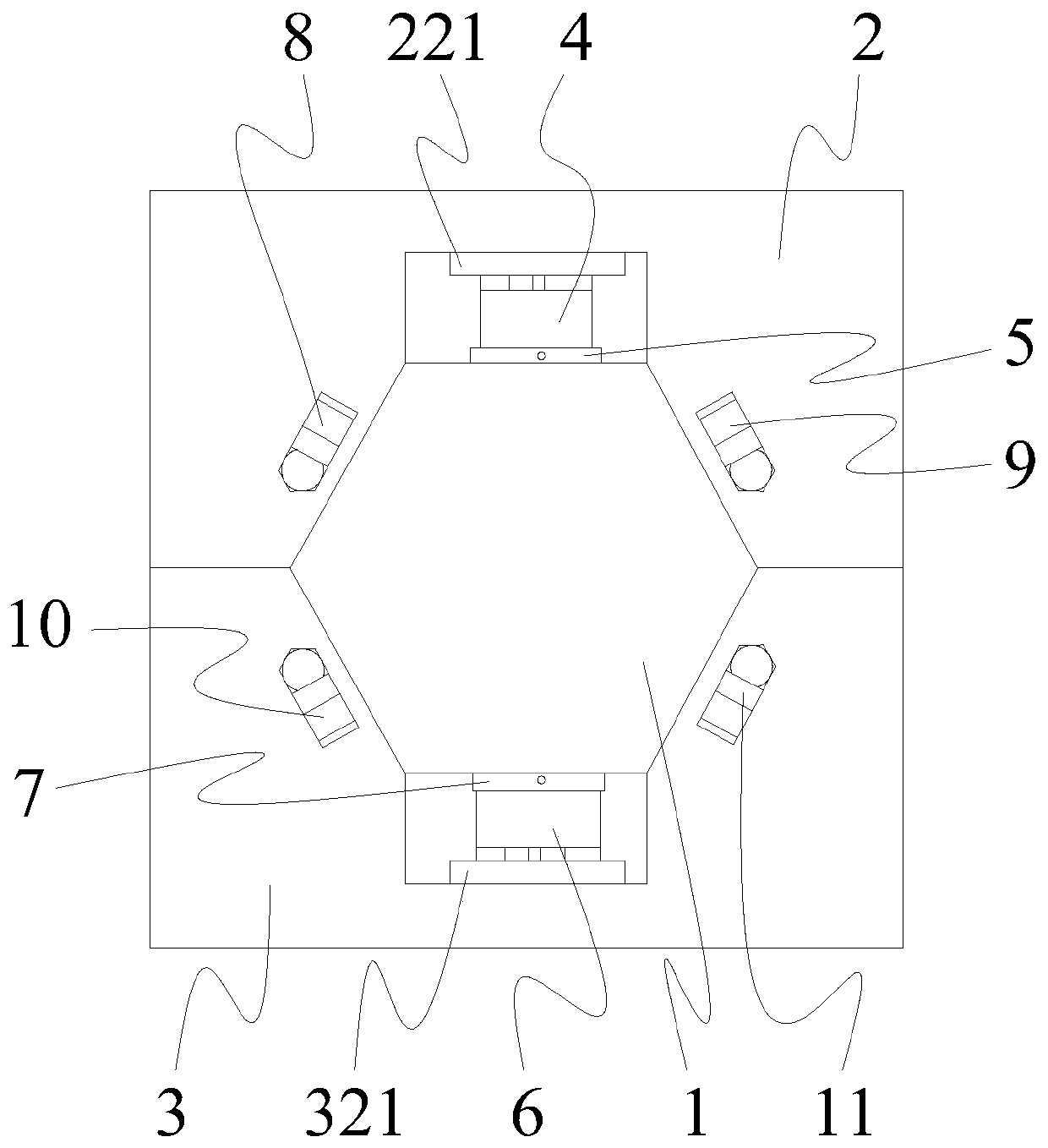

Vertically used direct drive precise air lubricated hydrostatic guide pair

InactiveCN107044486AAchieving a symmetrical layoutEnsure support rigidityGas cushion bearingsLinear motorBorn rigidity

The invention discloses a vertically used direct drive precise air lubricated hydrostatic guide pair which comprises a guide base in a regular hexagonal prism shape, a slide carriage capable of sliding along the guide base, a first linear motor and a second linear motor. The first linear motor and the second linear motor are mounted between the guide base and the slide carriage. The inner wall section of the slide carriage is a hexagon. A hexagonal section square pillow serves as the guide base. The hexagonal air lubricated hydrostatic guide pair adopts four faces as the bearing faces, symmetrical arrangement of the bearing faces is achieved, high movement straightness and structural rigidity and high movement positioning and repeating precision can be achieved, and deformation caused by temperature fluctuation is minimized; the four faces are adopted as the air lubricated hydrostatic bearing faces, the other two symmetrical side wall faces are separately provided with the linear motors, and symmetrical layout of guide pair bearing and driving is achieved; and bearing rigidity of the guide pair is ensured by adoption of a porous restrictor, the structure has the characteristics of high precision and good symmetry, and the guide pair is particularly suitable for vertical using conditions.

Owner:中原工学院信息商务学院

Vehicle frame structure

ActiveUS20170096170A1Preventing or suppressing bending of the supporting portionReduce loading burdenUnderstructuresSuperstructure subunitsVehicle frameFlange

The present disclosure provides a vehicle frame structure including a front side member base portion in which a rear end portion of an outer-side side wall portion of a front side connecting portion that is joined to the front side member main body portion, and a front end flange portion of a rear side first connecting portion that is joined to a rocker, are connected by a first curved wall portion. Further, a rear end portion of an inner-side side wall portion of the front side connecting portion, and a front end portion of a rear side second connecting portion that is joined to a tunnel, are connected by a second curved wall portion. A minimum radius curvature at a curve of the first curved wall portion is set to be larger than a minimum radius curvature at a curve of the second curved wall portion.

Owner:TOYOTA JIDOSHA KK

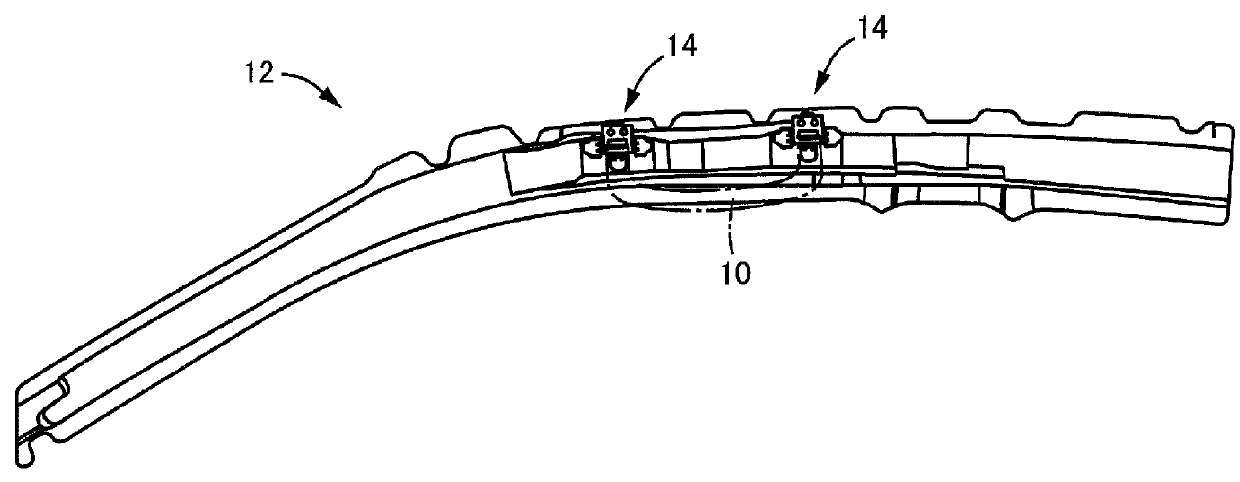

Vibration control equipment

ActiveUS8523154B2Improve seismic performanceEasy to assembleMultiple spring combinationsResilient suspensionsVibration controlEngineering

In a vibration control equipment 1 constituted by inserting an outer tube 20 of pair of damping rubbers 2A, 2B into an opening 30 of a bracket member 3, clamping the pair of damping rubbers 2A, 2B by means of plate members 4A, 4B, tightening a fastening member 5 for coupling the plate members 4A, 4B, and then compressing the rubber elastic bodies 22 of the damping rubbers 2A, 2B in the axial direction, the outside diameter of the outer tube 20 before tightening the fastening member 5 is smaller than the inside diameter of the fixing hole 30, the rubber elastic bodies 22 are compression deformed by tightening the fastening member 5 and thus a bracket member 3 is clamped by means of upper and lower flange portions 23, at least one of the rubber elastic bodies 22 is provided with mold cavity portions 26A, 26B and at least one of the pair of outer tubes 20 is provided with a positioning portion 24 for determining the circumferential position of the pair of damping rubbers 2A, 2B relative to the bracket member 3. According to the present invention, assembling work is facilitated by arranging the mold cavity portions in accordance with the direction of vibration and the production cost can be reduced.

Owner:PROSPIRA CORP

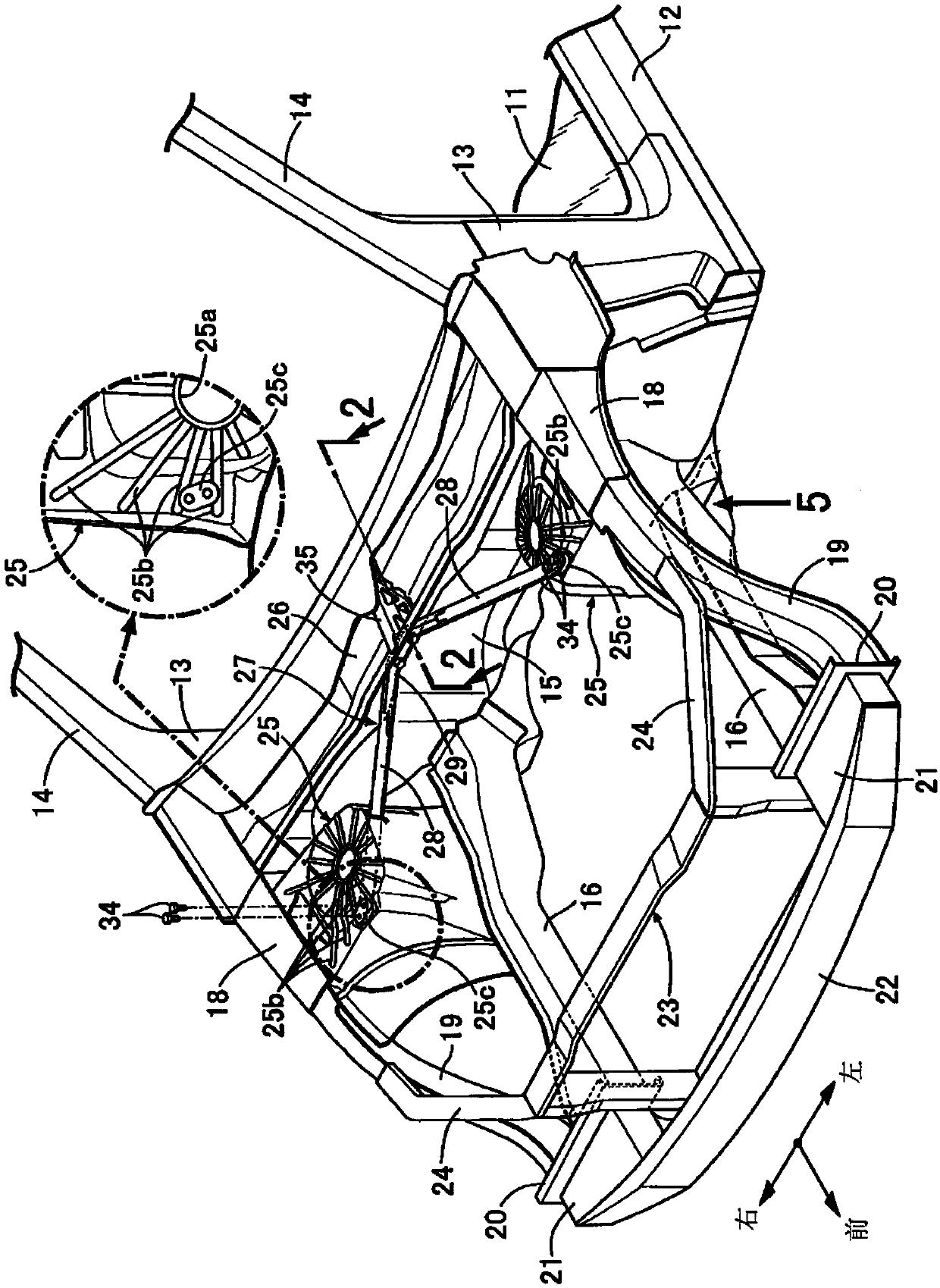

Body structure of car

The invention provides a body structure of a car, which not only avoids increase of number of parts or weight but also allows a damper shell and a balancing rod made from aluminum alloy to be connected firmly. A plurality of ribs (25b), which extended from center radially, are formed on the upper surface of the damper shell (25), made from aluminum alloy, on the upper end of a bearing damber; a mounting base (25c) connects adjacent ribs (25b) among the ribs; one end of the balancing rod (27) is connected to hte mounting base (25c). By means of the ribs (25b) for beraing the load at the connection position between one end of the balancing rod (27) and the upper surface of the damper shell (25), the wall thickness of the whole upper surface of the damper shell (25) is reduced and further weight is reduced, and the balancing rod (27) is connected firmly.

Owner:HONDA MOTOR CO LTD

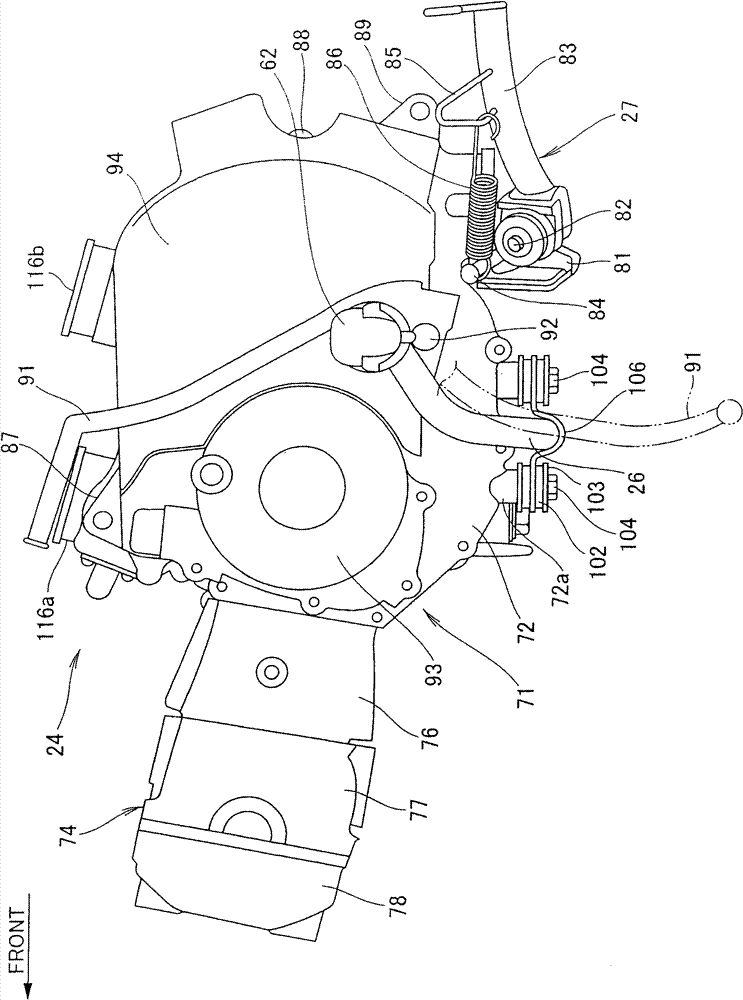

Exhaust gas recirculation device of engine

InactiveUS9010304B2Small device sizeBypass pipe can be easierInternal combustion piston enginesNon-fuel substance addition to fuelCylinder headEngineering

A connecting passage is formed inside a cylinder head, which extends rearward from an exhaust passage and connects to the exhaust passage. The connecting passage branches inside the cylinder head into two branch passages, which open at a rear end face of the cylinder head, respectively. An opening portion, one of opening portions of the branch passages, connects to an EGR cooler, and another opening portion, the other of opening portions of the branch passages, connects to a bypass pipe. Accordingly, the exhaust gas recirculation device of an engine which can restrain the device from being improperly large sized, providing the EGR cooler and the bypass pipe, can be provided.

Owner:MAZDA MOTOR CORP

Vibration control equipment

ActiveUS20100133734A1Improve damping propertyLower costNon-rotating vibration suppressionMultiple spring combinationsEngineeringFlange

In a vibration control equipment 1 constituted by inserting an outer tube 20 of pair of damping rubbers 2A, 2B into an opening 30 of a bracket member 3, clamping the pair of damping rubbers 2A, 2B by means of plate members 4A, 4B, tightening a fastening member 5 for coupling the plate members 4A, 4B, and then compressing the rubber elastic bodies 22 of the damping rubbers 2A, 2B in the axial direction, the outside diameter of the outer tube 20 before tightening the fastening member 5 is smaller than the inside diameter of the fixing hole 30, the rubber elastic bodies 22 are compression deformed by tightening the fastening member 5 and thus a bracket member 3 is clamped by means of upper and lower flange portions 23, at least one of the rubber elastic bodies 22 is provided with mold cavity portions 26A, 26B and at least one of the pair of outer tubes 20 is provided with a positioning portion 24 for determining the circumferential position of the pair of damping rubbers 2A, 2B relative to the bracket member 3. According to the present invention, assembling work is facilitated by arranging the mold cavity portions in accordance with the direction of vibration and the production cost can be reduced.

Owner:PROSPIRA CORP

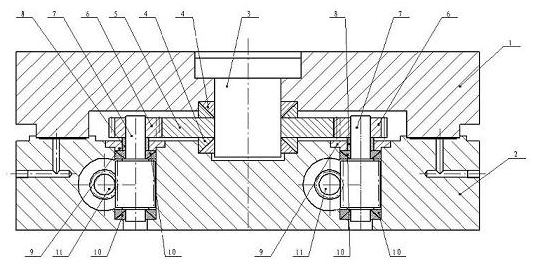

Heavy-duty precision rotary table

InactiveCN102091946AImprove support rigidityEnsure support rigidityLarge fixed membersGear wheelEngineering

The invention relates to the machinery manufacturing industry, in particular to a heavy-duty precision rotary table, which comprises an upper body of the table, a lower body of the table, a spindle, a bearing a, a big gear wheel, a pinion, a worm wheel shaft, a flange plate, a spacer bush, a bearing b and a worm shaft, wherein the upper body of the table is connected with the lower body of the table through the spindle; the spindle is supported by the bearing a; the big gear wheel is arranged on the spindle; the pinion is arranged on the worm wheel shaft and meshed with the big gear wheel at different positions; the worm wheel shaft is supported in the lower body of the table through the bearing b and is meshed with the worm shaft; the worm wheel shaft is arranged in the lower body of the table through the flange plate; and the spacer bush is arranged between the pinion and the worm wheel. The heavy-duty precision rotary table has the advantages that: a static pressure support is formed between the upper body and the lower body of the table, and is high in bearing capacity and high in supporting rigidity; double gear meshing is adopted, the back lash between gear pairs is eliminated, and the upper body of the table has high rotary precision.

Owner:JIANGSU GAOJING MECHANICAL & ELECTRICAL EQUIPMENT CO LTD

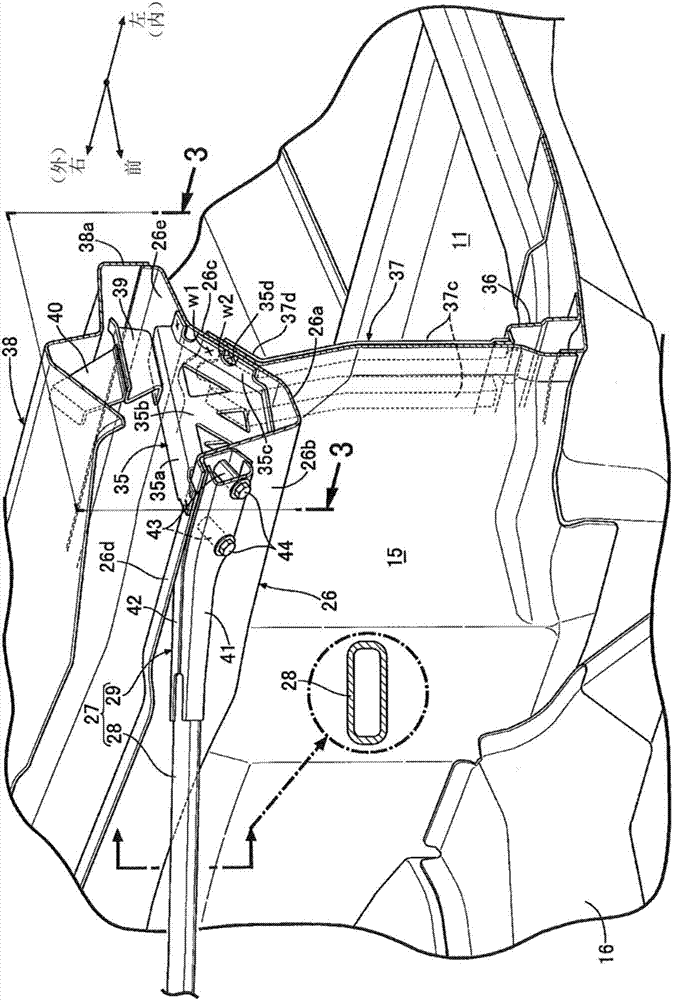

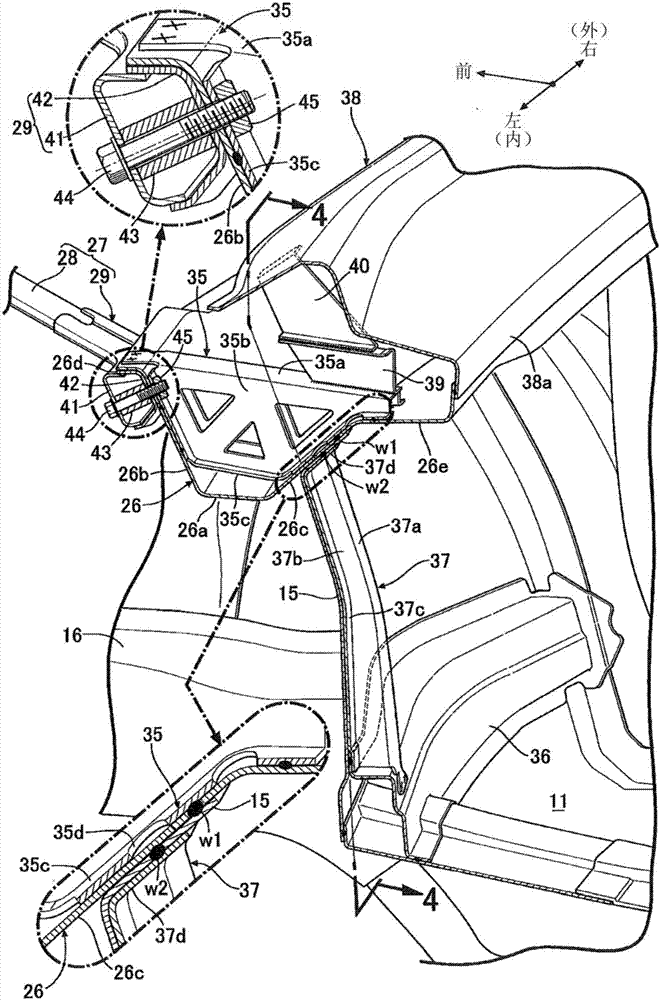

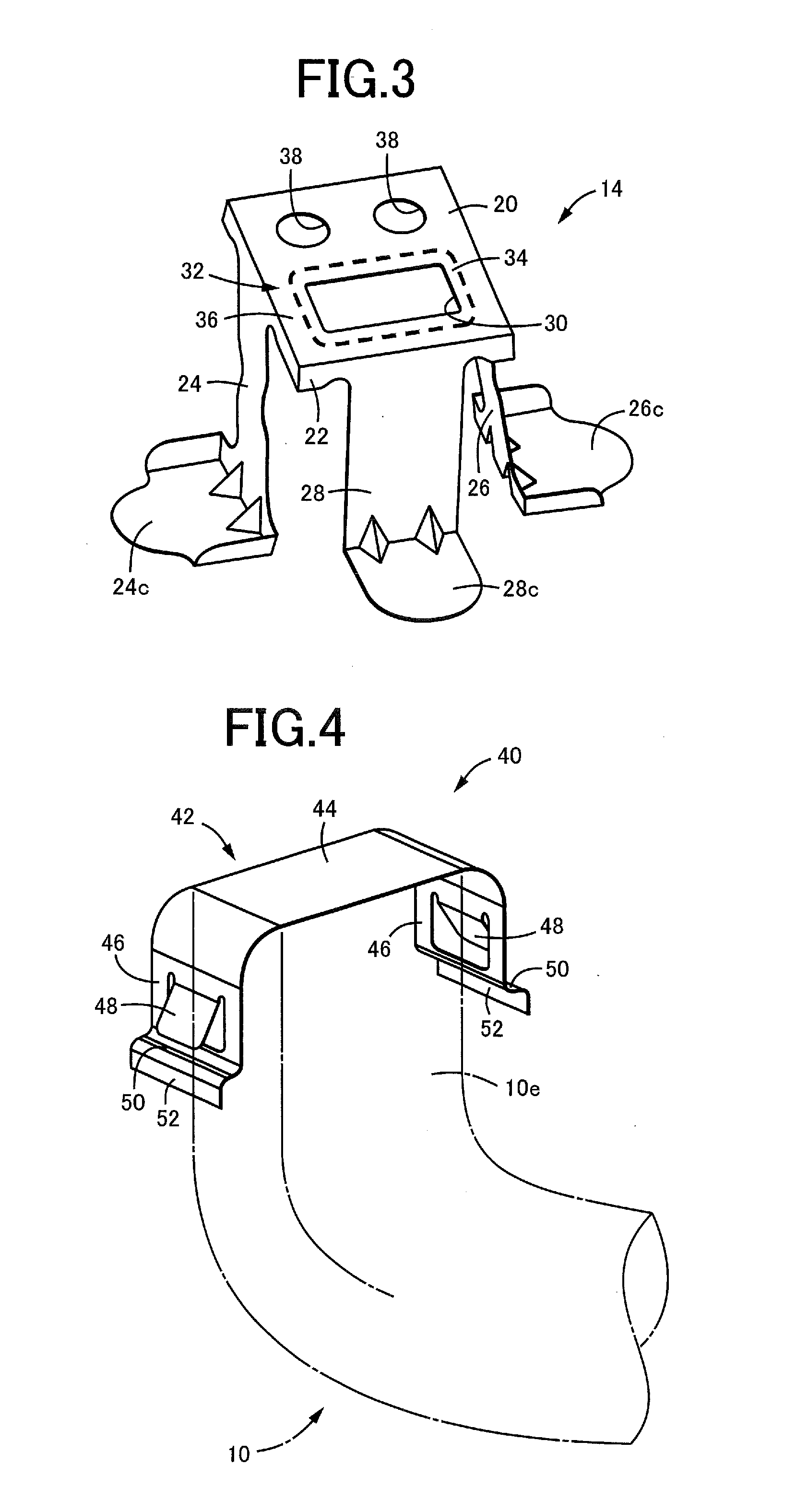

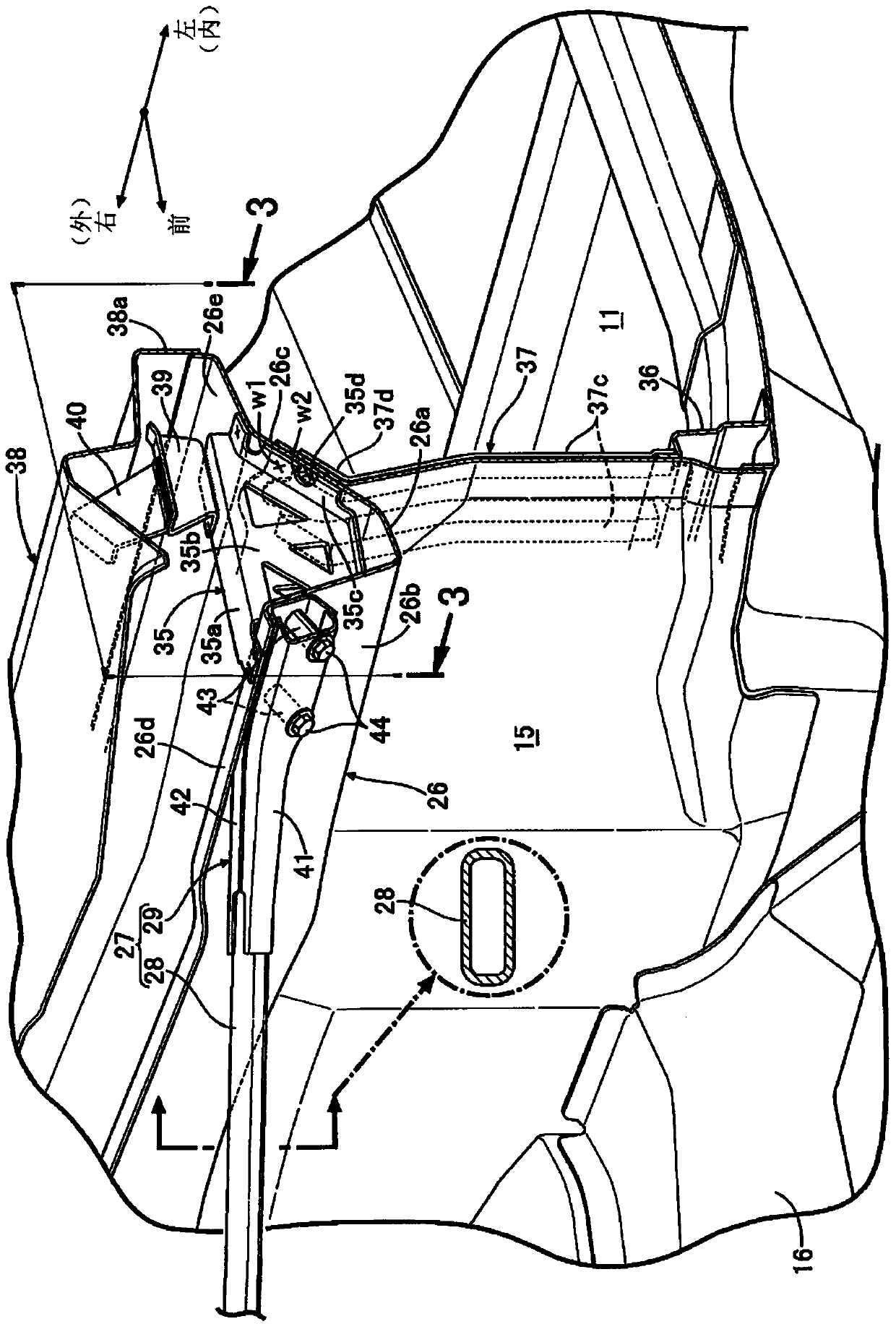

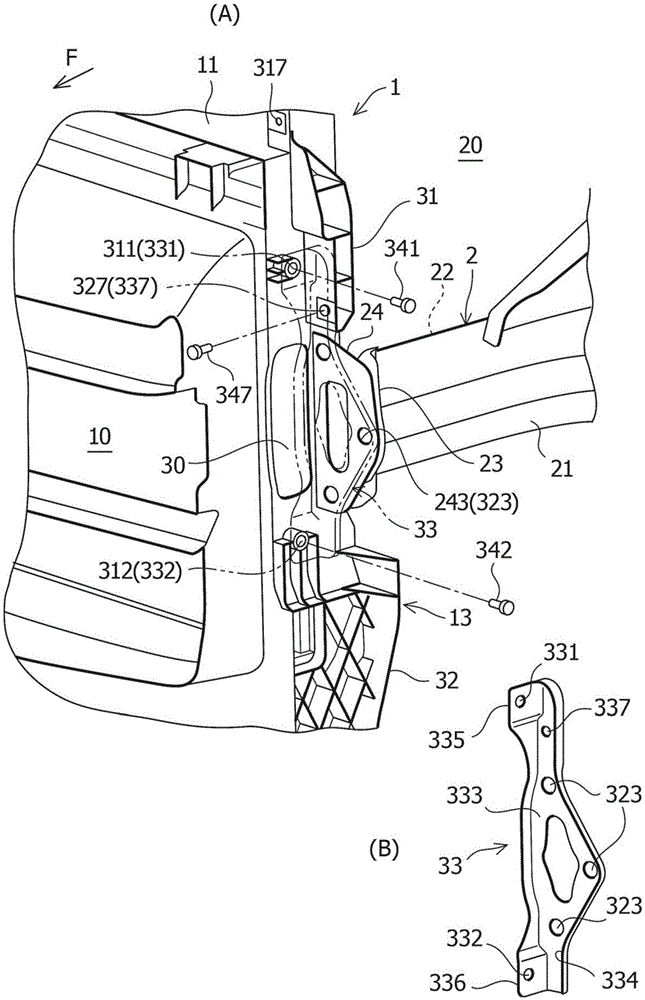

Assist grip attachment structure

InactiveUS20140312643A1Improve rigidityEnsure support rigidityVehicle arrangementsMonocoque constructionsEngineering

An assist grip attachment structure in which an assist grip is attached to a vehicle body-side attachment portion, the assist grip is supported with prescribed rigidity by the vehicle body-side attachment portion when a tensile load in a direction in which the assist grip is pulled toward an inside of a vehicle cabin is applied to the assist grip, and an impact of a pressing load is absorbed through deformation of the vehicle body-side attachment portion when the pressing load is applied to the assist grip from the inside of the vehicle cabin.

Owner:TOYODA IRON WORKS CO LTD

Brushless motor

InactiveCN101174780AEnsure support rigidityReduce the numberRecord information storageSupports/enclosures/casingsBrushless motorsEngineering

An brushless motor, which use bearing and bearing shell rotatable support the axes of roter on the dish driving mchanism of motor panel of the stator, the character is that, the bearing shell mold as barrel-type which in the internal circumstance of the bearing, and support the butt end on the said motor panel; freely revolve support the end panel of axile of the said bearing, immediacy touch the motor panel or separate by the axial thrust baffle, so as to get axis supporting.

Owner:MINEBEA MOTOR MFG

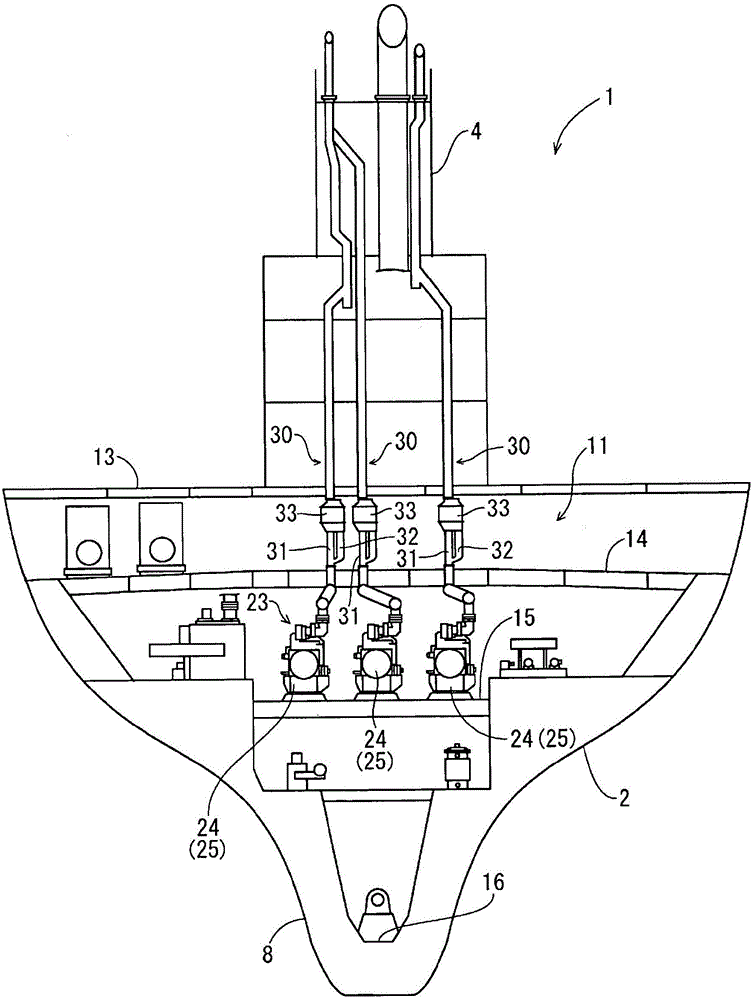

Engine device

ActiveCN105683522ASimplified supply air cooling configurationSimplified support structureInternal combustion piston enginesExhaust apparatusEngineeringSupercharger

The present invention addresses the problem of providing an engine device which enables a support structure of a first supercharger (56) and a second supercharger (58) to be simplified, and which enables an air cooling structure of an engine (25) to be simplified. Provided is an engine device in which a first supercharger (56) and a second supercharger (58) are provided in series to a midpoint of an exhaust-gas discharge path of an engine (25). The engine device is a structure in which the first supercharger (56) and the second supercharger (58) are provided to one side surface of the engine (25). The second supercharger (58) is provided close to the one side surface of the engine (25), and the first supercharger (56) is provided at a distance from the one side surface of the engine (25).

Owner:YANMAR POWER TECHNOLOGY CO LTD

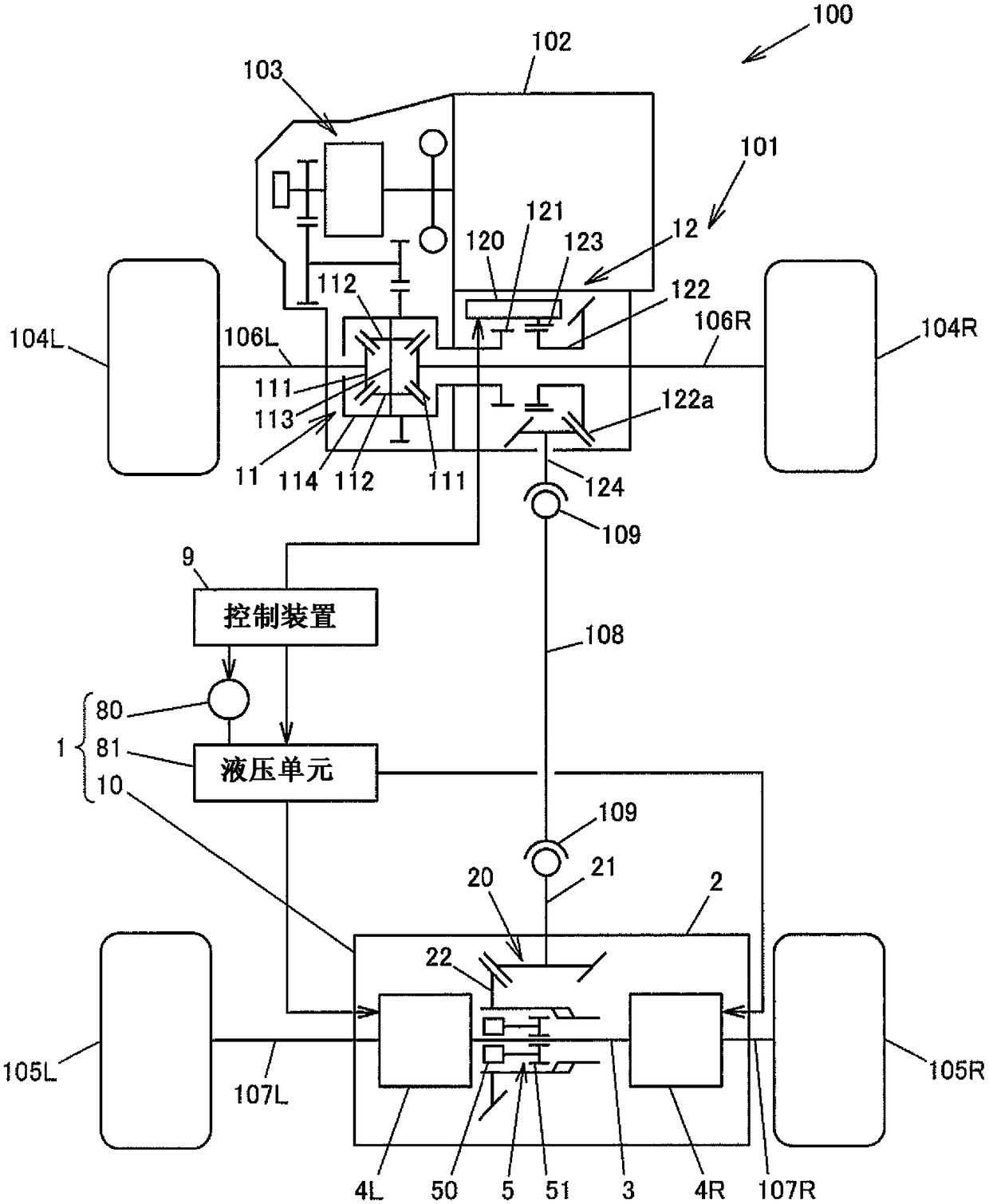

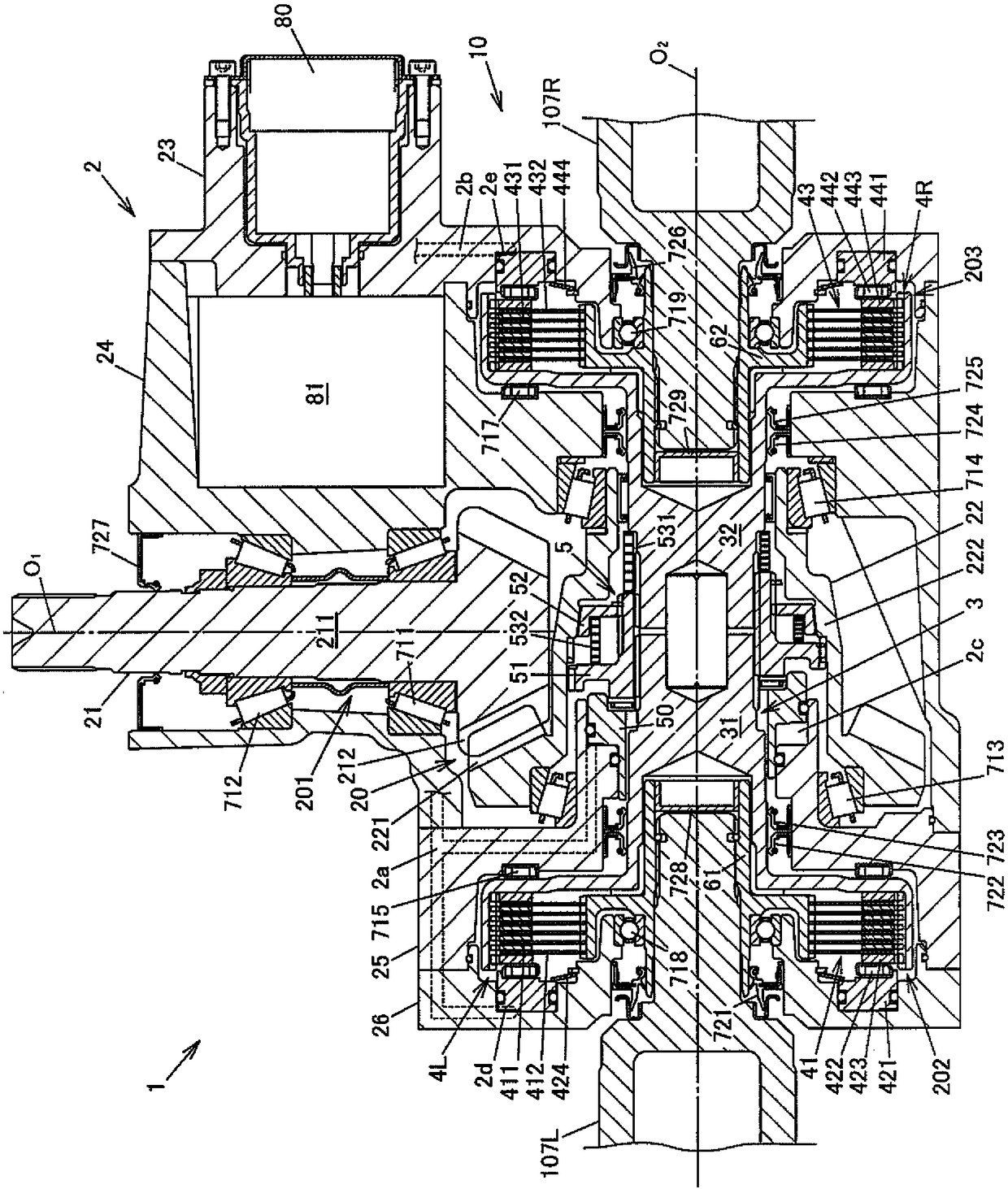

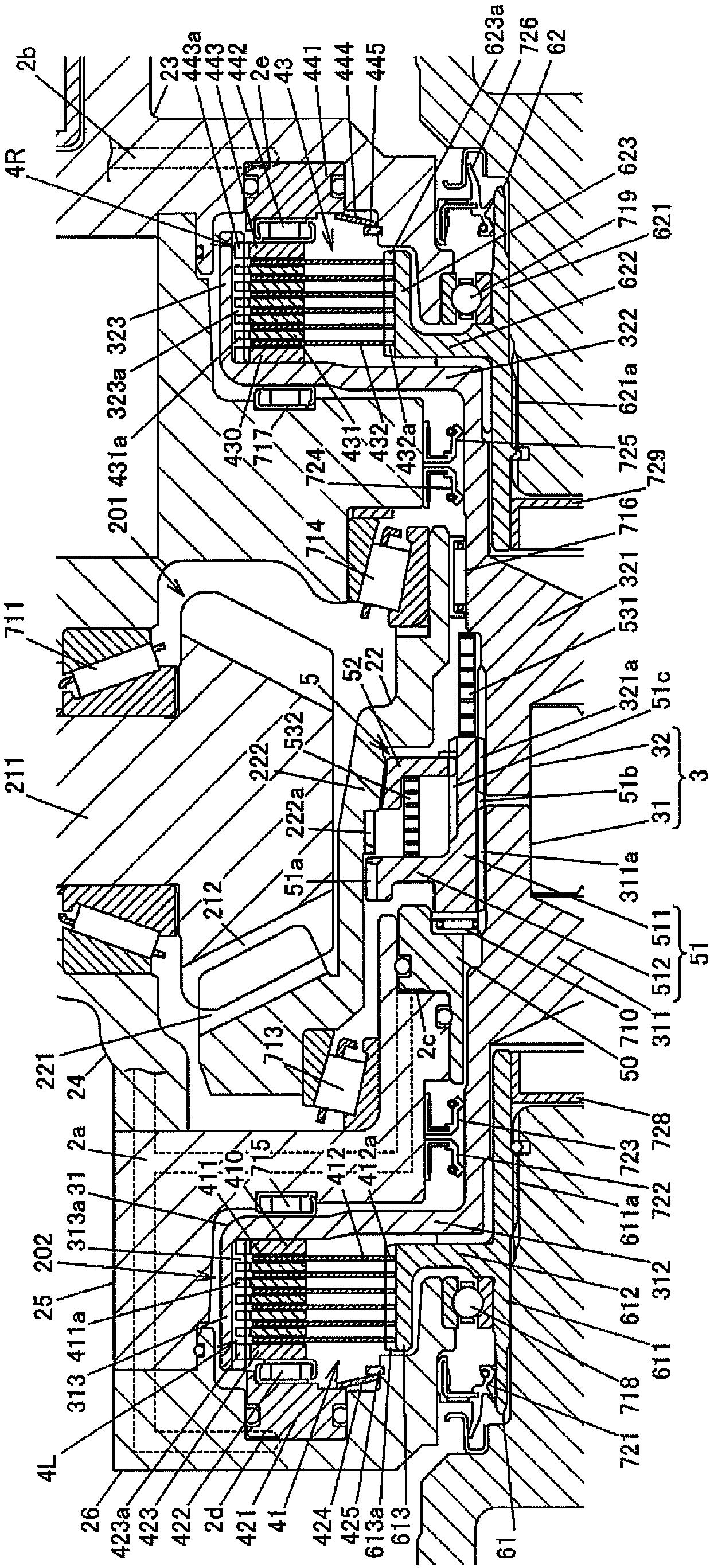

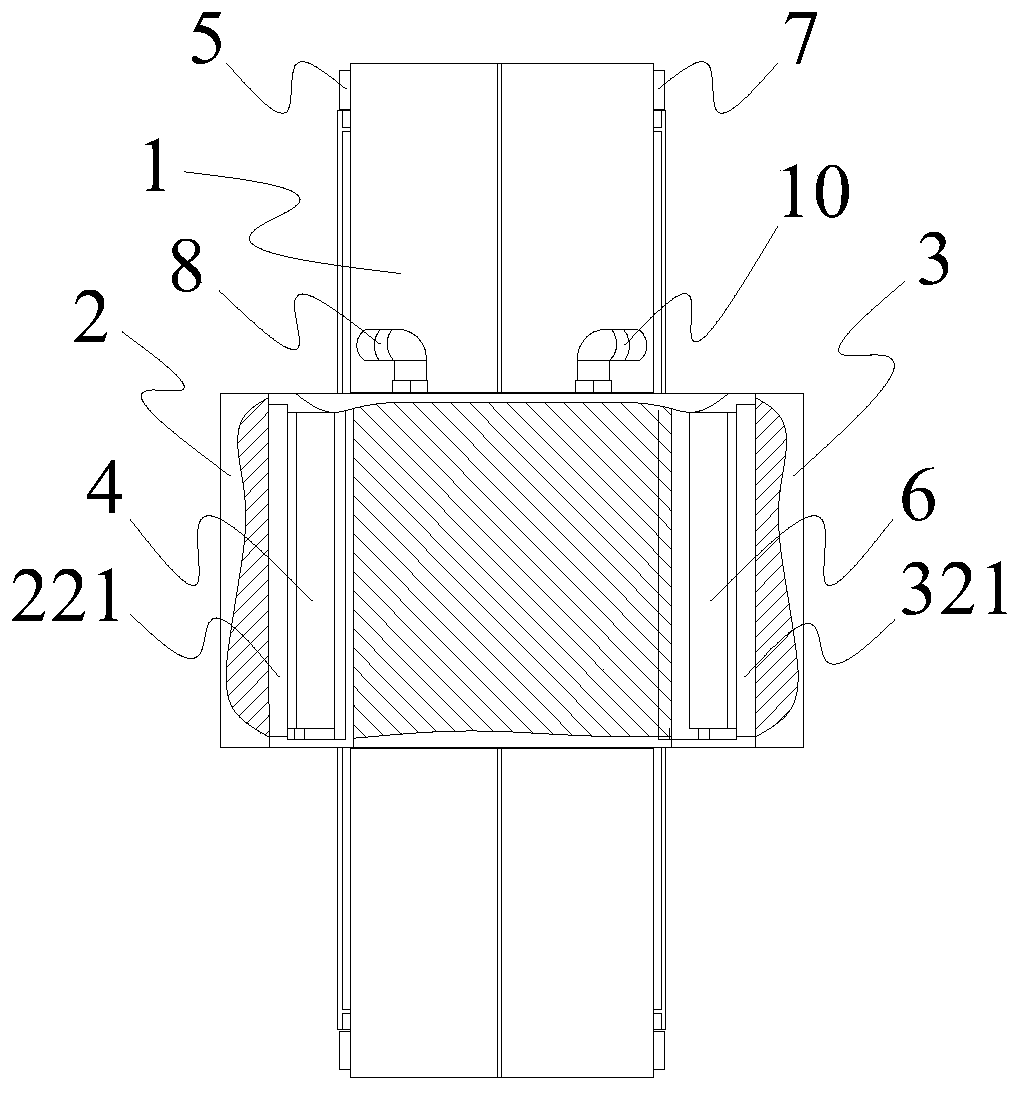

Driving force distribution apparatus

ActiveCN108437789AEnsure support rigidityReduce sizeFluid actuated clutchesToothed gearingsGear wheelPinion

The present invention provides a driving force distribution apparatus (1). The driving force distribution apparatus includes an orthogonal gear pair (20) constituted by a pinion gear shaft (21) and aring gear member (22), a casing (2) that houses the orthogonal gear pair (20), an intermediate rotational member (3) coaxially rotatable relative to the ring gear member (22), a clutch member (51) configured to couple the ring gear member (22) and the intermediate rotational member (3) to each other, and first and second driving force adjustment mechanisms (4L, 4R) configured to adjust a driving force to be transmitted from the intermediate rotational member (3) to first and second output rotational members (61, 62). The ring gear member (22) has a ring gear portion (221) and a tubular portion(222). At two positions between which the ring gear portion (221) is interposed in an axial direction, the tubular portion (222) is rotatably supported by a pair of bearings (713, 714).

Owner:JTEKT CORP

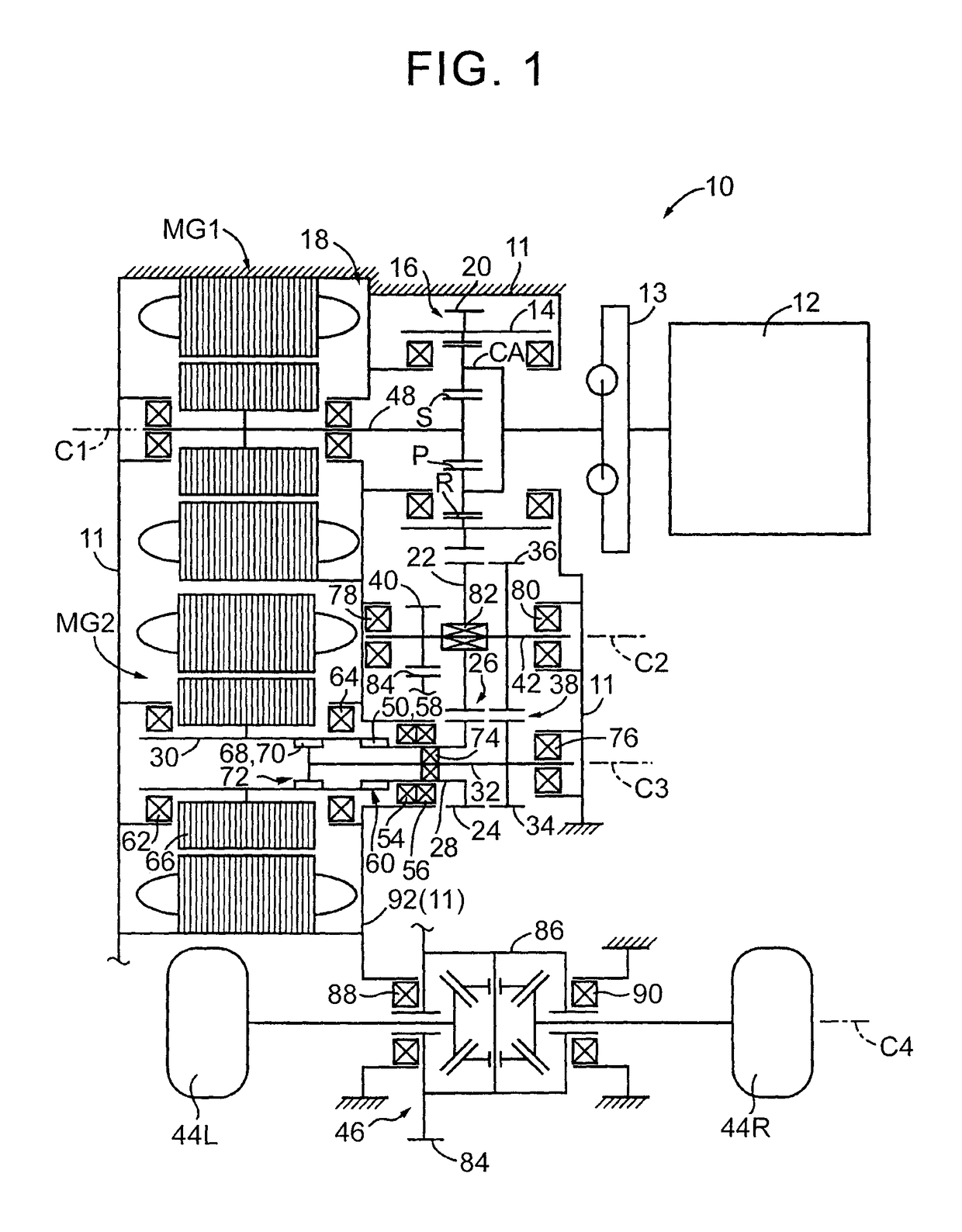

Drive device for hybrid vehicle

ActiveUS10112472B2Suppress rattling soundEnsure support rigidityHybrid vehiclesGearboxesRotational axisHybrid car

Owner:TOYOTA JIDOSHA KK

Pressure generation device

InactiveUS7922459B2Small sizeCompact configurationPositive displacement pump componentsHubsPressure generationPump chamber

A pressure-generating device includes an axle hub having a rotary shaft portion supported rotatably in a nonrotatable cylindrical support portion via bearings; a piston attached to the rotary shaft portion in a unitarily rotatable manner and so as to perform a pumping action, and, in cooperation with the rotary shaft portion, forming a pump chamber therebetween; a cam member and cam followers for converting a rotary motion of the axle hub in relation to the cylindrical support member to the pumping action of the piston; a suction path formed in the axle hub and enabling introduction of air into the pump chamber; and a discharge path formed in the axle hub and enabling discharge of air from the pump chamber.

Owner:TOYOTA JIDOSHA KK

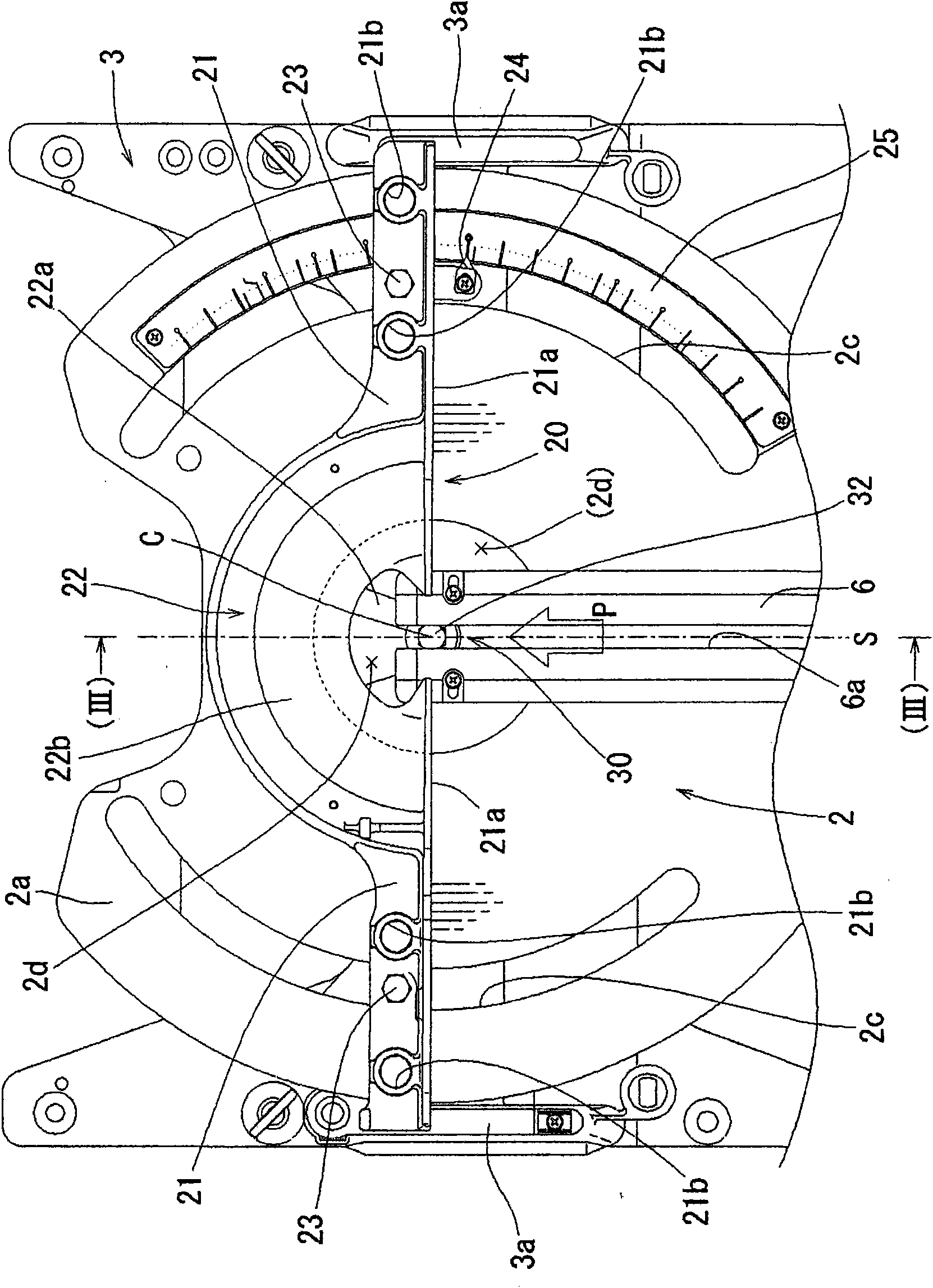

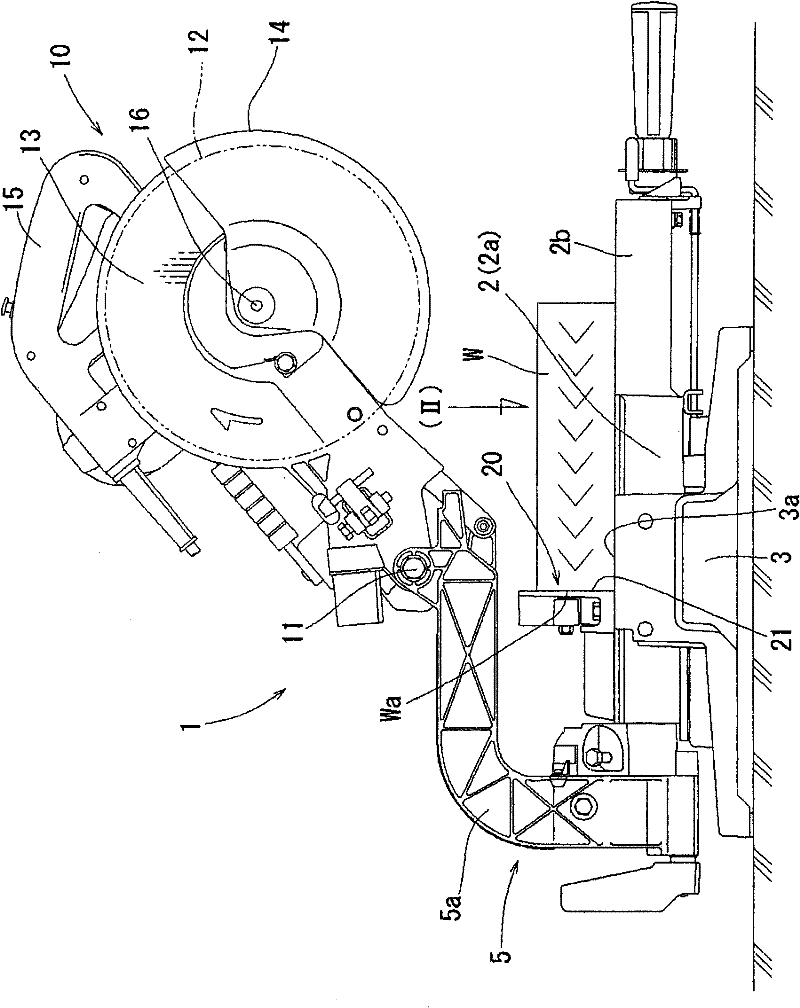

Table-top cutter

InactiveCN101888913AEliminates or greatly reduces deflectionReduce deflectionMetal sawing devicesCircular sawsStructural engineering

A table-top cutter having a rotation table supported by a base in a horizontally rotatable manner and also having a fence for positioning a material to be cut, the fence being supported at opposite ends thereof by the base so as to radially straddle over the rotation table. The positioning fence has increased supporting rigidity to eliminate deflection of the fence at the center thereof, and this solves problems of conventional products in which the center of the fence is prone to deflect due to the fence being supported only at opposite ends thereof in order to allow rotation of the rotation table. A center support section (22a) is provided at the center of the span of the positioning fence (20). The center support section (22a) is extended to the lower surface of the rotation table (2) through a center recess (2d) of the table and connected to a rotation support section (30) of the base (3).As a result, supporting rigidity of the positioning fence (20) particularly at the center thereof is increased.

Owner:MAKITA CORP

Mounting structure of pedestal for cover opening prop

InactiveCN101323321BEnsure support rigiditySeek assemblySuperstructure subunitsEngineeringStructural engineering

Owner:HONDA MOTOR CO LTD

car body structure

The invention provides a body structure of a car, which not only avoids increase of number of parts or weight but also allows a damper shell and a balancing rod made from aluminum alloy to be connected firmly. A plurality of ribs (25b), which extended from center radially, are formed on the upper surface of the damper shell (25), made from aluminum alloy, on the upper end of a bearing damber; a mounting base (25c) connects adjacent ribs (25b) among the ribs; one end of the balancing rod (27) is connected to hte mounting base (25c). By means of the ribs (25b) for beraing the load at the connection position between one end of the balancing rod (27) and the upper surface of the damper shell (25), the wall thickness of the whole upper surface of the damper shell (25) is reduced and further weight is reduced, and the balancing rod (27) is connected firmly.

Owner:HONDA MOTOR CO LTD

Assist grip attachment structure

An assist grip attachment structure in which an assist grip is attached to a vehicle body-side attachment portion, the assist grip is supported with prescribed rigidity by the vehicle body-side attachment portion when a tensile load in a direction in which the assist grip is pulled toward an inside of a vehicle cabin is applied to the assist grip, and an impact of a pressing load is absorbed through deformation of the vehicle body-side attachment portion when the pressing load is applied to the assist grip from the inside of the vehicle cabin.

Owner:TOYODA IRON WORKS CO LTD

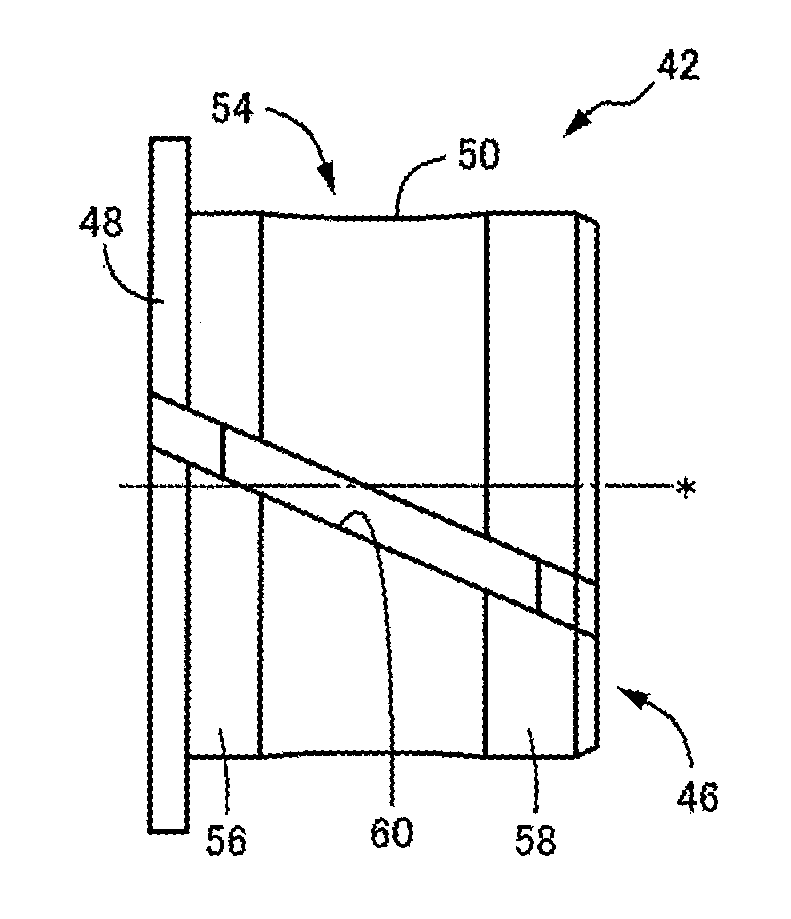

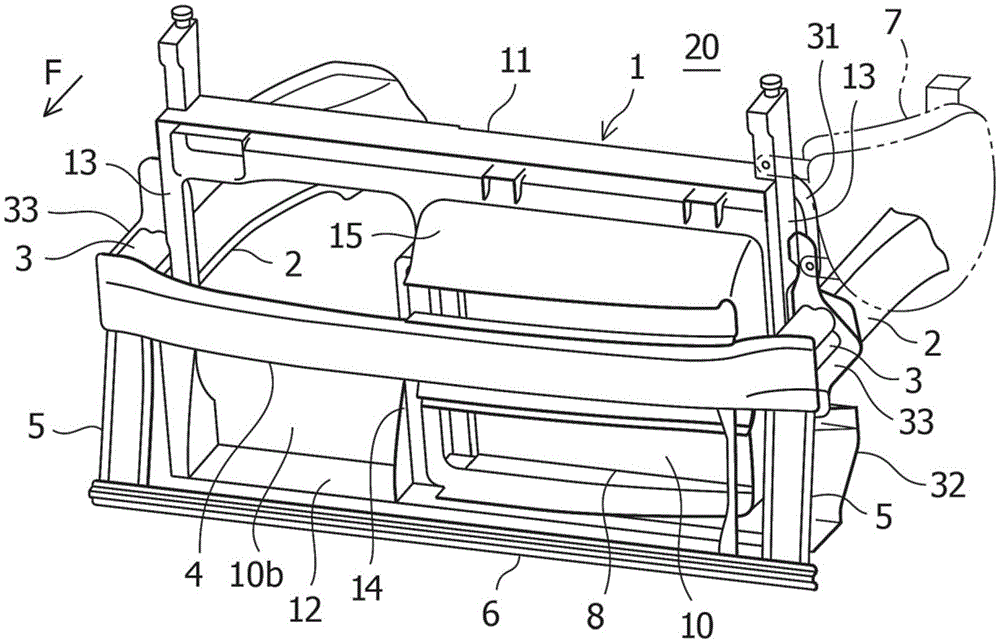

Resin front body holding structure

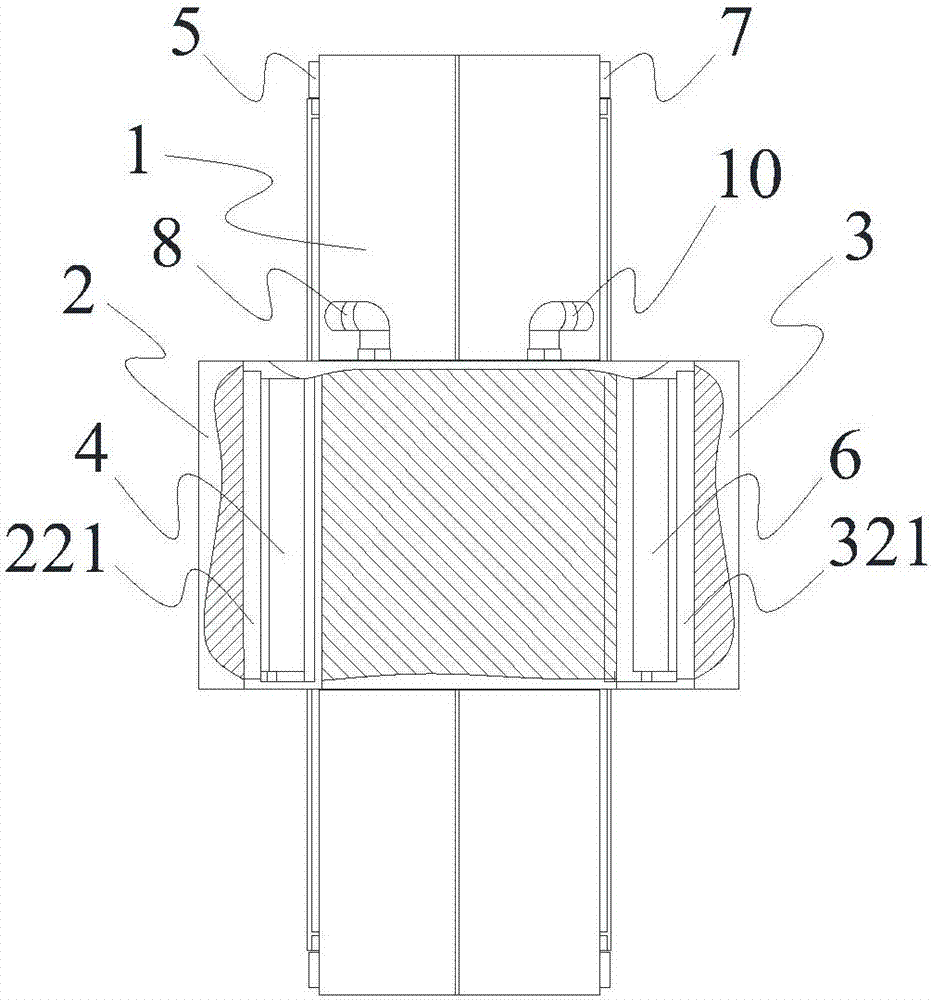

InactiveCN103979020BReduce front projected areaEnsure support rigiditySuperstructure subunitsPropulsion coolingMechanical engineeringEngineering

The present invention provides a vehicle body holding structure of a resin front end. It can ensure the accommodation space of the cooling device and can ensure its supporting rigidity. The body holding structure of the resin front end is such that the resin front end constituting a cooling device accommodation portion at the front end of the vehicle body is held between the left and right front side member front ends, and the resin front end is integrally formed in a rectangular frame shape and includes an upper member portion, which Extending in the vehicle width direction on the upper side of the housing portion; the lower member portion extending in the vehicle width direction on the lower side of the housing portion; Extending, the upper and lower parts of the above-mentioned left and right side support parts include a block part of a rib grid-like joint structure protruding sideways, and a reinforcing bracket is erected between the above-mentioned upper block part and the above-mentioned lower part of the block part, The intermediate portion of the reinforcement bracket has an attachment portion for attachment to the front end portion of the front side member.

Owner:SUZUKI MOTOR CORP

Table-top cutter

InactiveCN101888913BEliminates or greatly reduces deflectionReduce deflectionMetal sawing devicesCircular sawsClassical mechanicsStructural engineering

A table-top cutter having a rotation table supported by a base in a horizontally rotatable manner and also having a fence for positioning a material to be cut, the fence being supported at opposite ends thereof by the base so as to radially straddle over the rotation table. The positioning fence has increased supporting rigidity to eliminate deflection of the fence at the center thereof, and thissolves problems of conventional products in which the center of the fence is prone to deflect due to the fence being supported only at opposite ends thereof in order to allow rotation of the rotationtable. A center support section (22a) is provided at the center of the span of the positioning fence (20). The center support section (22a) is extended to the lower surface of the rotation table (2) through a center recess (2d) of the table and connected to a rotation support section (30) of the base (3).As a result, supporting rigidity of the positioning fence (20) particularly at the center thereof is increased.

Owner:MAKITA CORP

Direct drive precision gas static pressure guide rail pair used in vertical direction

InactiveCN107044486BAchieving a symmetrical layoutEnsure support rigidityGas cushion bearingsElectric machineEngineering

The invention discloses a vertically used direct drive precise air lubricated hydrostatic guide pair which comprises a guide base in a regular hexagonal prism shape, a slide carriage capable of sliding along the guide base, a first linear motor and a second linear motor. The first linear motor and the second linear motor are mounted between the guide base and the slide carriage. The inner wall section of the slide carriage is a hexagon. A hexagonal section square pillow serves as the guide base. The hexagonal air lubricated hydrostatic guide pair adopts four faces as the bearing faces, symmetrical arrangement of the bearing faces is achieved, high movement straightness and structural rigidity and high movement positioning and repeating precision can be achieved, and deformation caused by temperature fluctuation is minimized; the four faces are adopted as the air lubricated hydrostatic bearing faces, the other two symmetrical side wall faces are separately provided with the linear motors, and symmetrical layout of guide pair bearing and driving is achieved; and bearing rigidity of the guide pair is ensured by adoption of a porous restrictor, the structure has the characteristics of high precision and good symmetry, and the guide pair is particularly suitable for vertical using conditions.

Owner:中原工学院信息商务学院

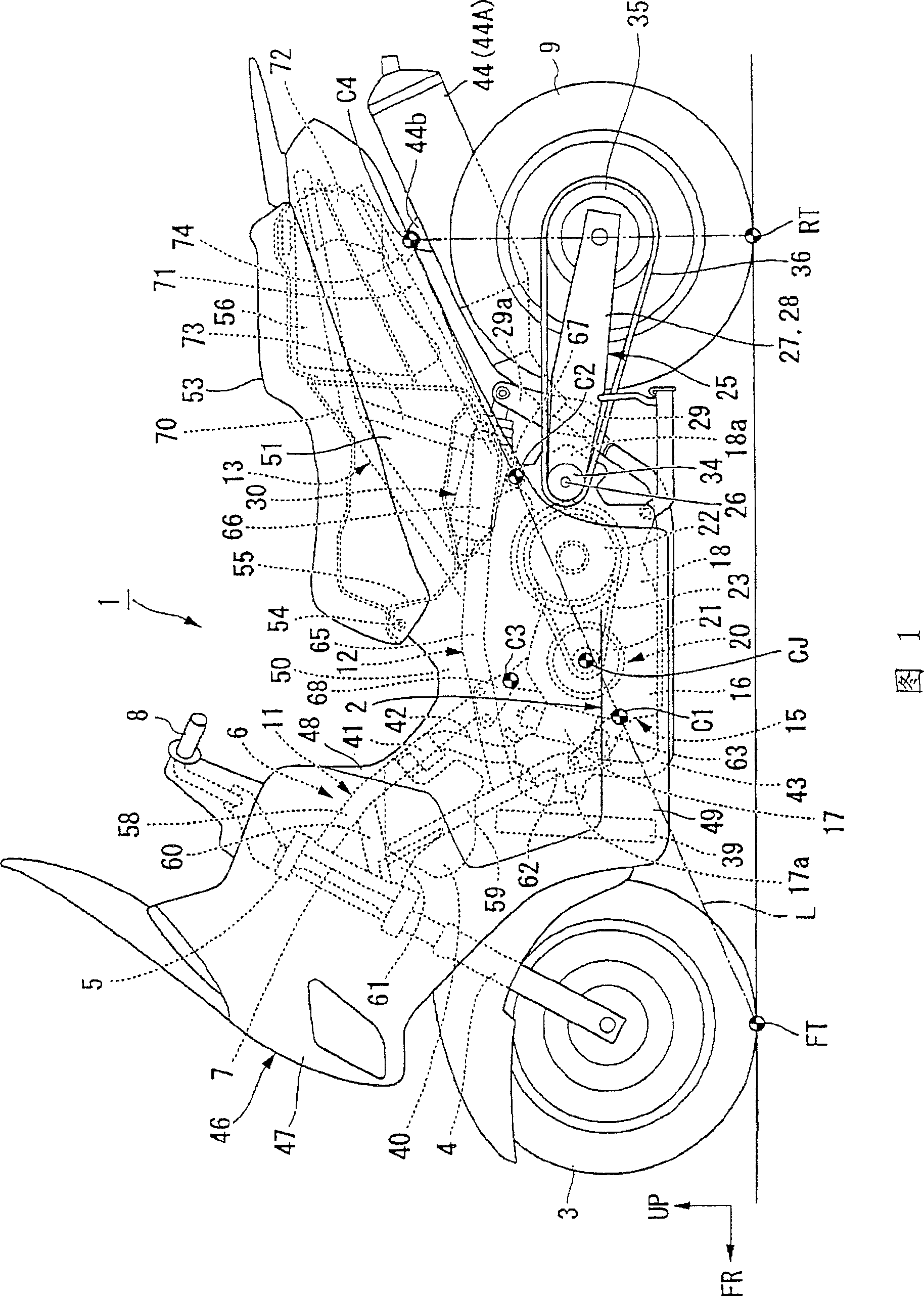

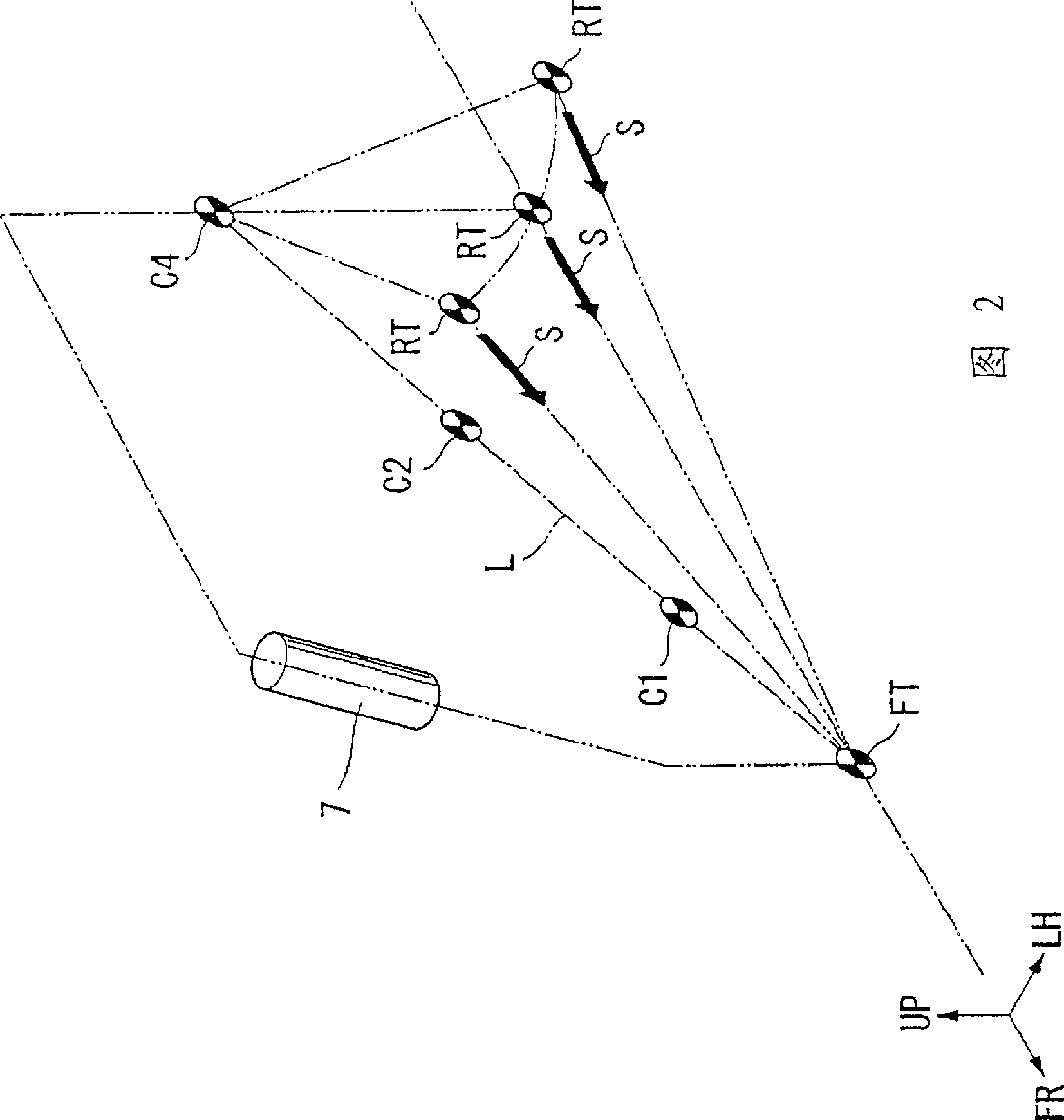

Motor cycle

ActiveCN101850809BEnsure support rigidityOverall small sizeCycle standsFoot-restsEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

Brushless motor

InactiveCN101174780BEnsure support rigidityReduce the numberRecord information storageSupports/enclosures/casingsBrushless motorsEngineering

An brushless motor, which use bearing and bearing shell rotatable support the axes of roter on the dish driving mchanism of motor panel of the stator, the character is that, the bearing shell mold as barrel-type which in the internal circumstance of the bearing, and support the butt end on the said motor panel; freely revolve support the end panel of axile of the said bearing, immediacy touch themotor panel or separate by the axial thrust baffle, so as to get axis supporting.

Owner:MINEBEA MOTOR MFG

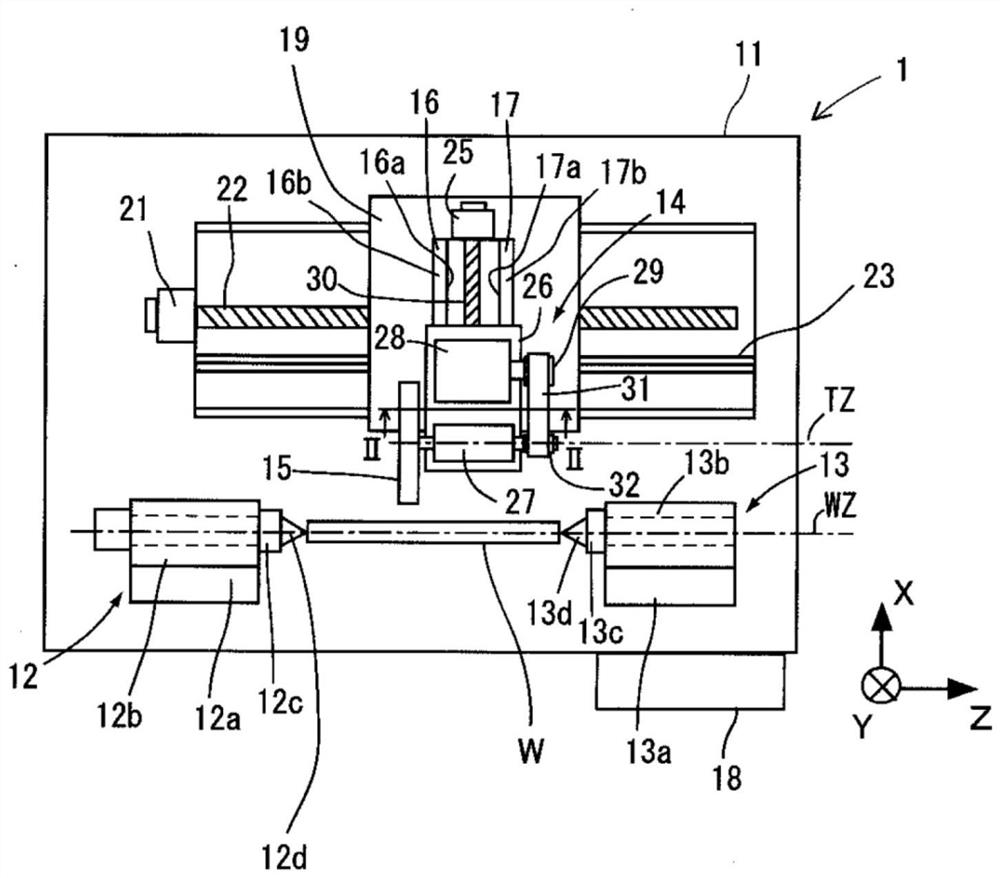

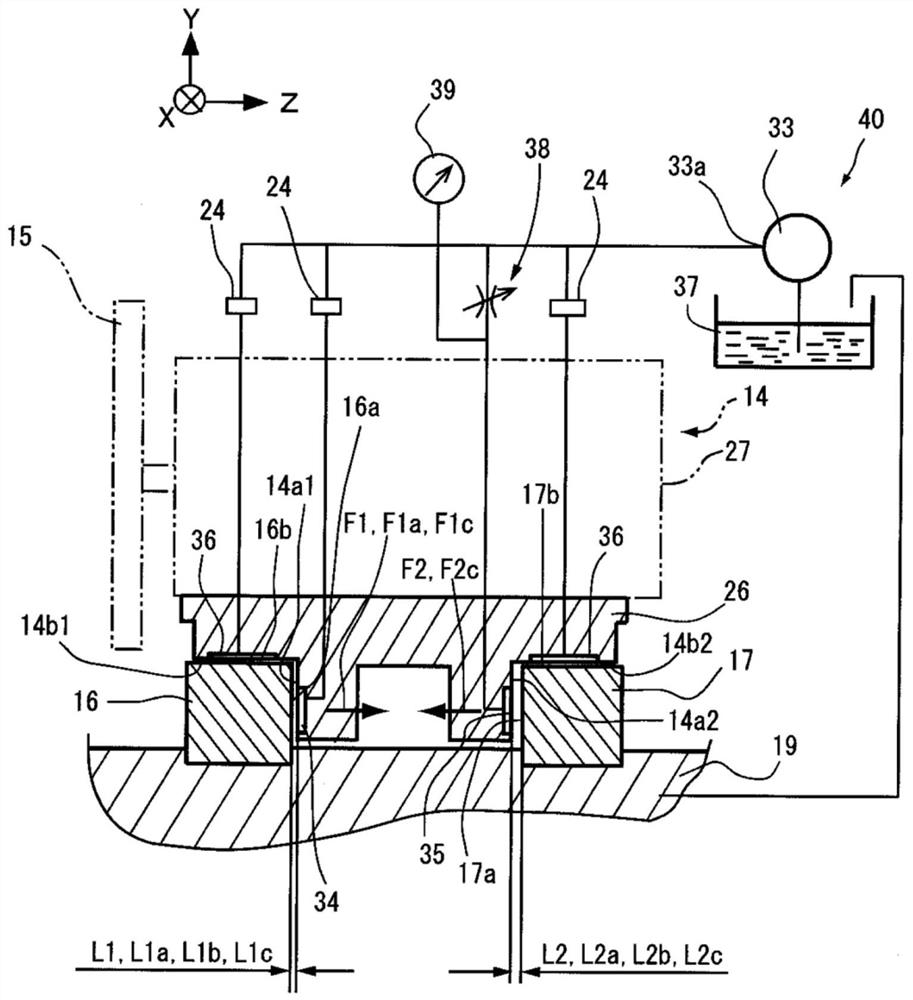

Hydrostatic sliding guide device and machine tool equipped with hydrostatic sliding guide device

ActiveCN108942655BLow costEnsure support rigidityGrinding carriagesLinear bearingsEngineeringMachine tool

The present invention provides a static pressure slide guide device and a machine tool provided with the static pressure slide guide device. The static pressure sliding guide device (40) comprises: a fixed body (19) having a first longitudinal guiding surface (16a) and a second longitudinal guiding surface (17a); a movable body (14) having a first longitudinal sliding surface (14a1) and the second longitudinal sliding surface (14a2); fluid supply device (33); pressure regulating device (38); static pressure bearing part (34), supplied with fluid by the fluid supply device, by being acted on the first longitudinal guide surface and the second A fluid pressure (P1) corresponding to the size of the first gap (L1) between the longitudinal sliding surfaces forms a support stiffness (G) corresponding to the size of the first gap with respect to the movable body; and the force generating part ( 35) The movable body is urged toward the first longitudinal guide surface by being supplied with the fluid whose pressure is regulated to a predetermined fluid pressure (P2a) by the pressure regulating device. The pressure regulating device regulates the pressure of the prescribed fluid so that the size of the first gap reaches the set value.

Owner:JTEKT CORP

Low-floor vehicle

InactiveCN100480126CImprove the rotation effectImprove the sense of unityMotorised scootersAxle suspensionsGround contactEngineering

A main frame 12 extends from a front upper portion of an engine 15 in a vicinity of a low-floor part 2 to an upper part of a swing arm pivotably-supporting part 18a. A hindmost engine mount part C2 is provided on a rear portion of the main frame 12. A foremost engine mount part C1 is provided on a down frame 11. The foremost engine mount part C1 is located on the line L to connect the hindmost engine mount part C2 to a ground contact part FT of a front wheel 3 in side view of a vehicle.

Owner:HONDA MOTOR CO LTD

Mounting structure of pedestal for cover opening prop

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com