Precise ball lock positioning gripping head

A positioning clip and ball lock technology, which is used in the direction of grinding workpiece supports, etc., to achieve high repeat positioning accuracy, improve work efficiency, and good clamping concentricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

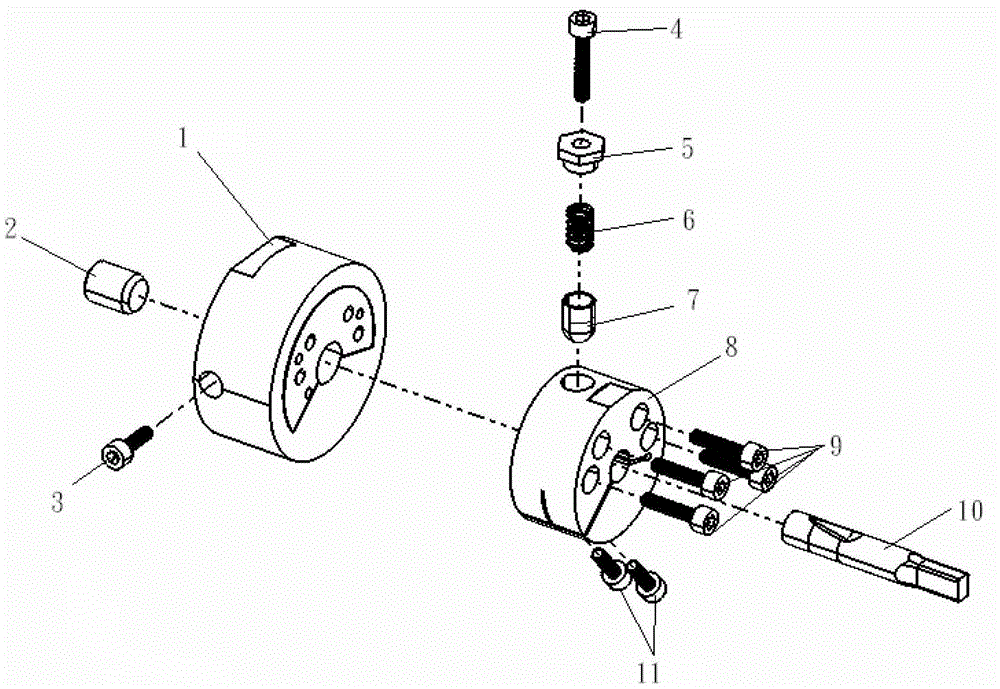

[0021] Such as figure 1 , figure 2 Shown is a precision ball lock chuck, including base ring 1, limit pin 2, limit pin locking screw 3, clamping ring 8, ball pin 7, spring 6, ball pin limit nut 5 The screw 4 is pulled out with the ball stud, and the base ring 1 and the clamping ring 8 are matched through a concave-convex step structure and coaxially fixed by a connecting screw 9 .

[0022] On the central axis of the clamping ring 8, a clamping hole communicating with the two end faces of the clamping ring 8 is provided; on the side wall of the clamping ring 8, a step hole vertically facing the clamping hole and communicating with the clamping hole is provided, The orifice end of the step hole is provided with a thread for fitting the ball stud stop nut 5, the middle end is a straight hole for fitting the ball stud 7, and the end of the hole near the clamping hole fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com