Turbocharger housing machining fixture with on-line adjustment of rotary positioning datum

A turbocharger and positioning reference technology, applied in the field of fixtures, can solve problems such as unsatisfactory clamping effect of machining fixtures, complex turbocharger shell structure, and difficult adjustment, so as to reduce abnormal downtime, The structure is compact and the effect of improving the economic benefits of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

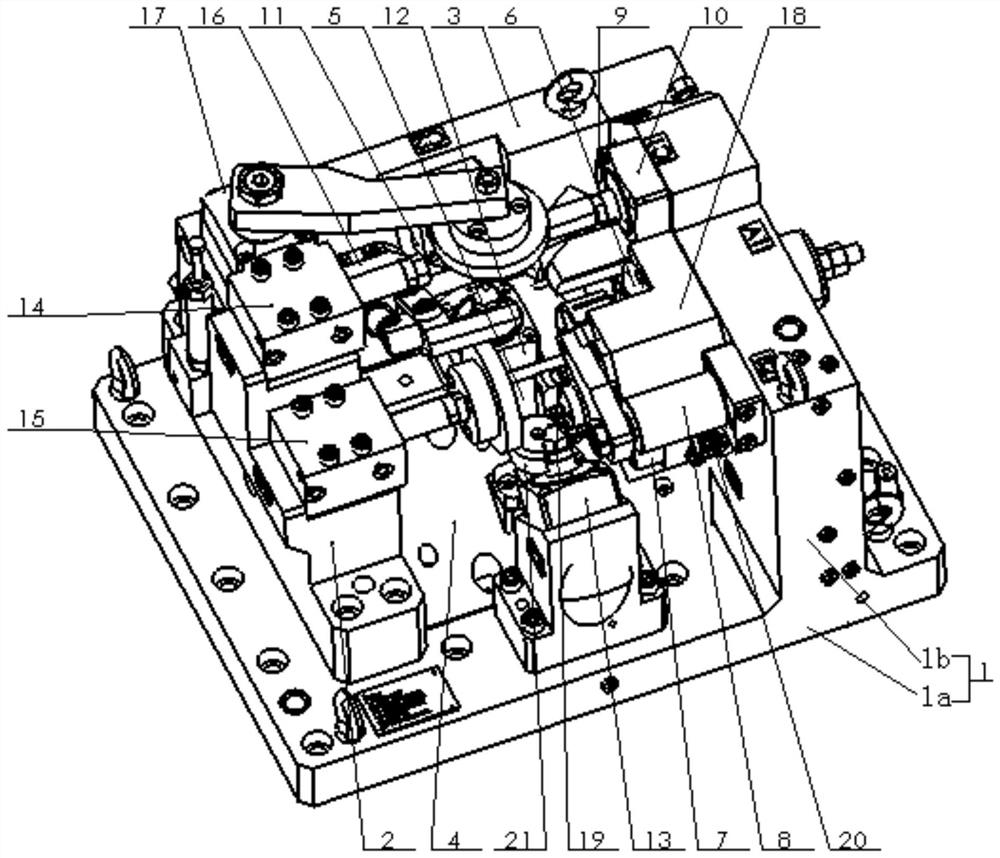

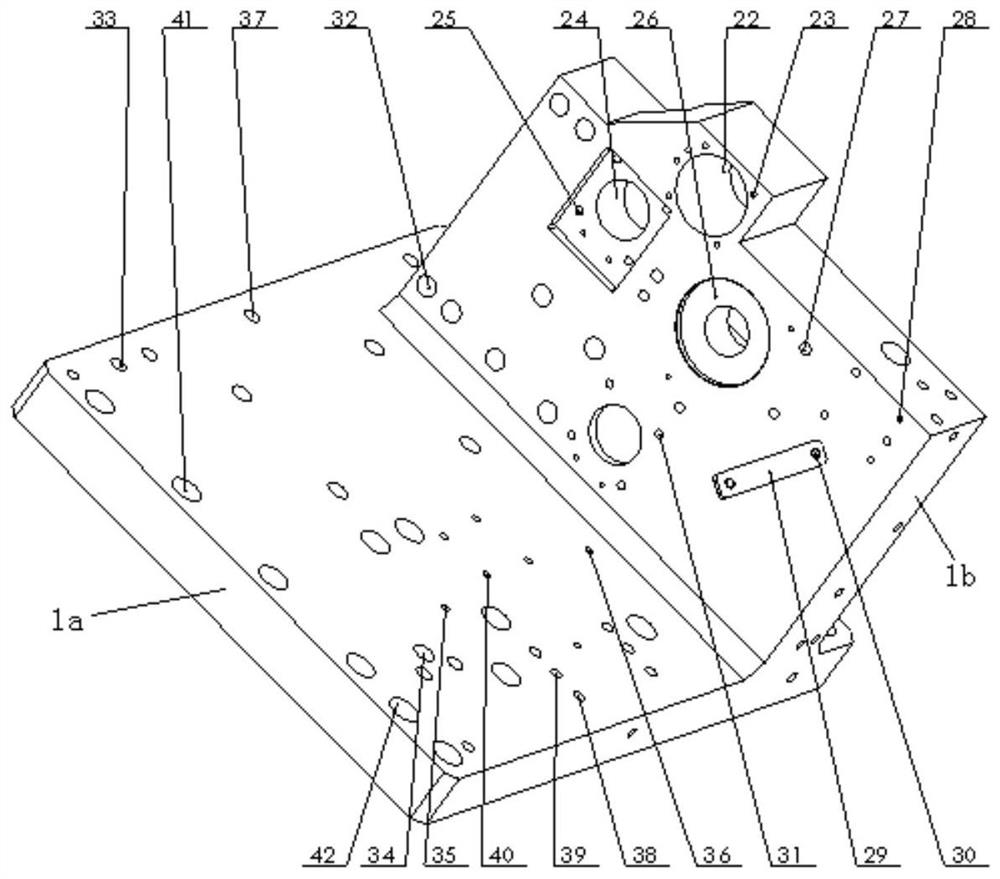

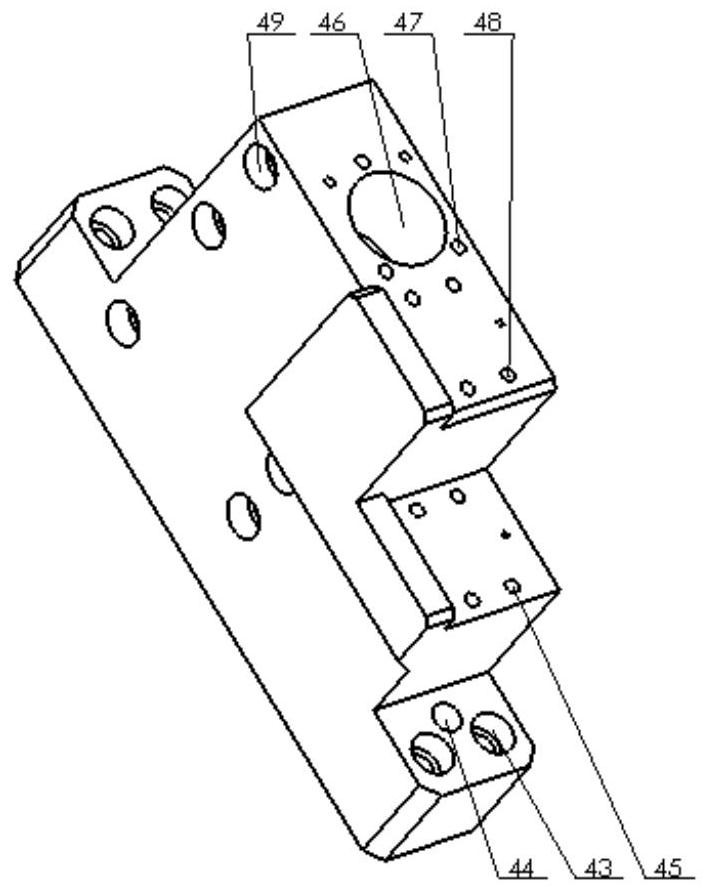

[0054] like figure 1 As shown in the figure, a machining fixture for a turbocharger housing with an on-line adjustment of the rotational positioning datum includes a base 1, the base 1 has a horizontal bottom plate 1a and a vertical plate 1b arranged vertically, and the horizontal bottom plate 1a is connected with A first vertical plate 2 is arranged opposite the vertical plate 1b, and a second vertical plate 3 is arranged on the horizontal bottom plate 1a on the same side of the vertical plate 1b and the first vertical plate 2; A positioning seat 18 is installed on the upper and middle part of the vertical plate 1b, the positioning seat 18 is sleeved with the expansion mandrel assembly 6, and one end of the positioning seat 18 away from the vertical plate 1b is provided with an angular positioning Pin 19, the vertical plate 1b is provided with a positioning reference adjusting mechanism 20 for adjusting the positioning seat 18 near the positioning seat 18; The first position...

Embodiment 2

[0081] This embodiment provides a method of using the clamp in the first embodiment.

[0082] like Figure 25 As shown, the positioning reference of the turbocharger housing is the inner hole 119 on the flange face of the outlet, the end face 120 of the outlet flange, and the locating pin hole 118 of the lug.

[0083] During operation, the action sequence of the fixture in this embodiment is as follows:

[0084] Step 1: The hollow oil cylinder 77 is tightened, the expansion mandrel 80 is radially expanded, and the inner hole 119 of the air outlet flange surface of the turbocharger casing is centered;

[0085] Step 2: Each pressure plate of the first positioning and clamping cylinder 7, the second positioning and clamping cylinder 8 and the third positioning and clamping cylinder 9 respectively clamps the back of the air outlet flange end face 120, so that the air outlet of the turbocharger casing is The blue end face 120 is fitted with the end face of the positioning seat 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com