Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Not easy to throw out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

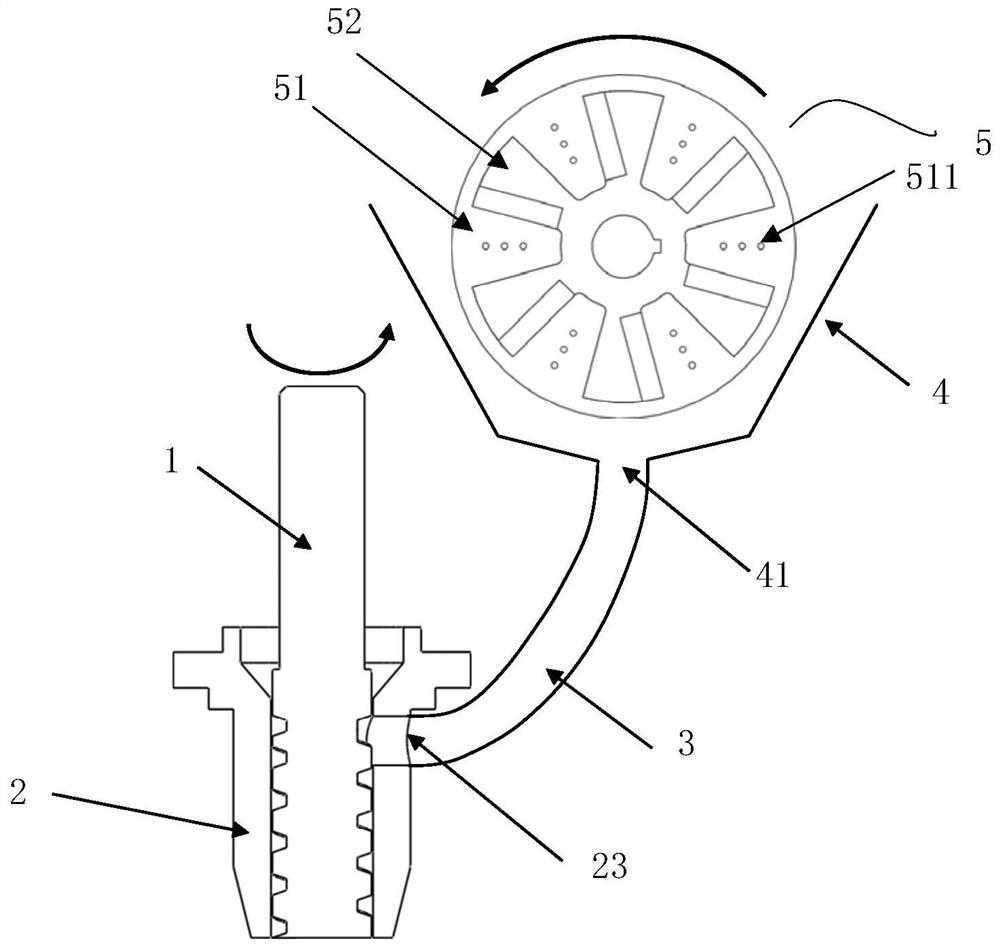

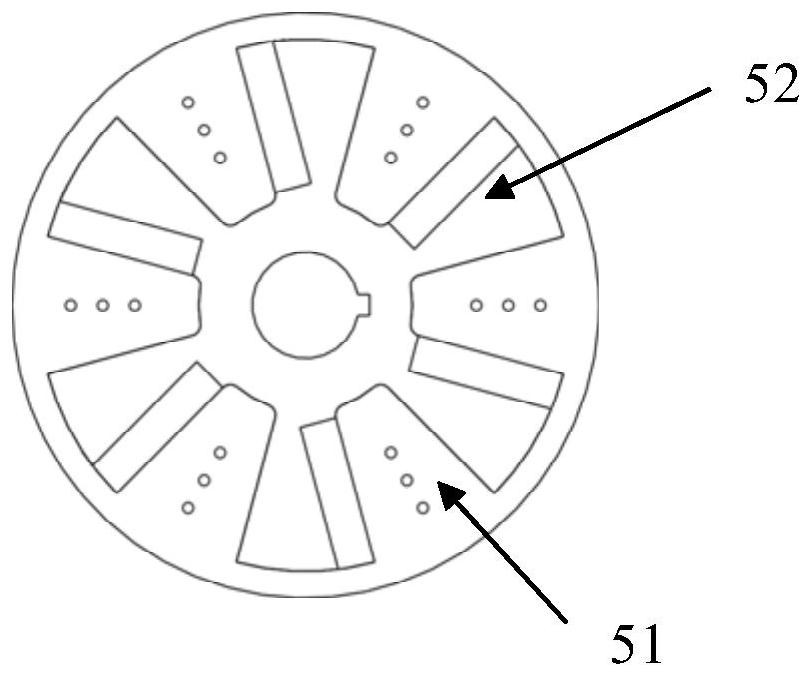

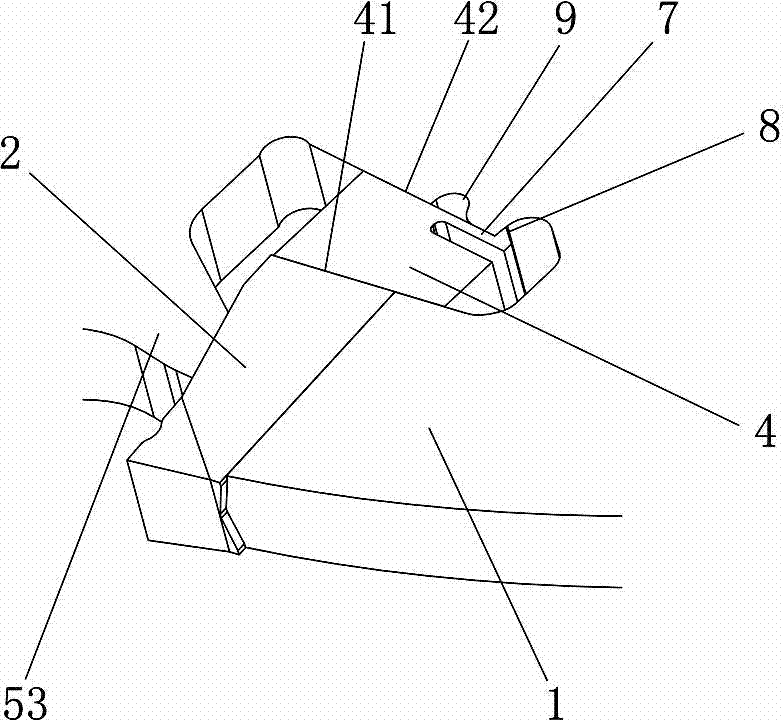

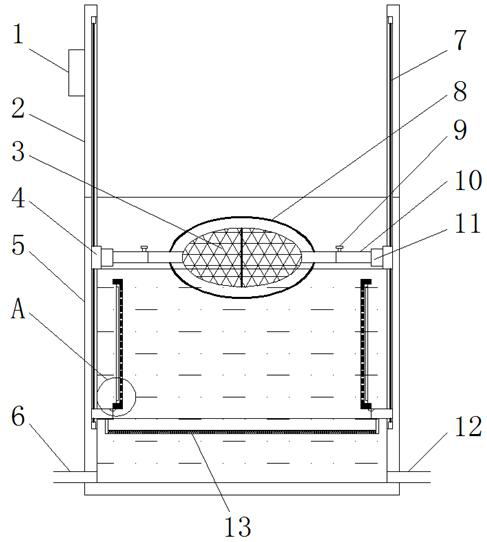

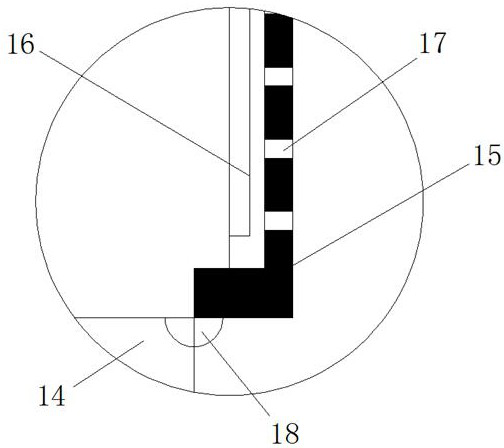

Particle type friction stir additive manufacturing device and method

ActiveCN113118612ANot easy to throw outLess impuritiesAdditive manufacturing apparatusIncreasing energy efficiencyMechanical engineeringAdditive layer manufacturing

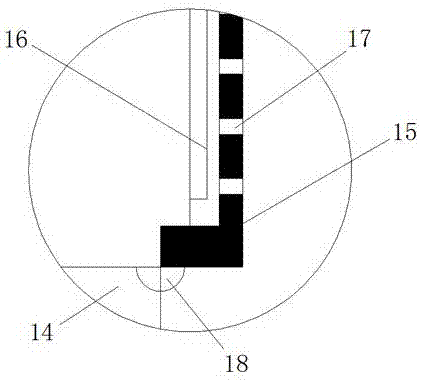

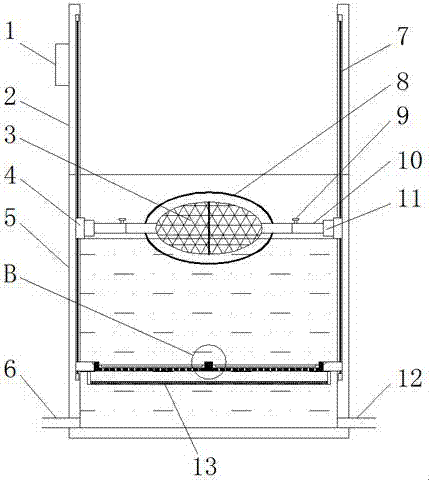

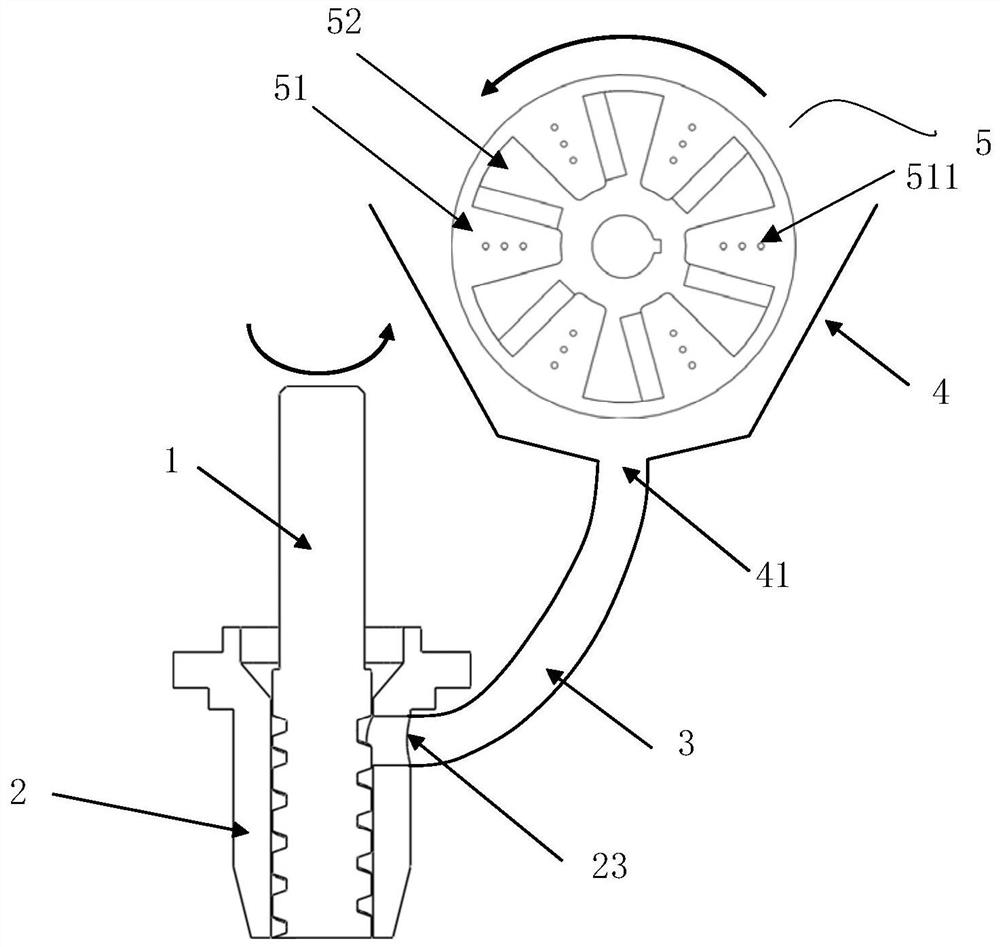

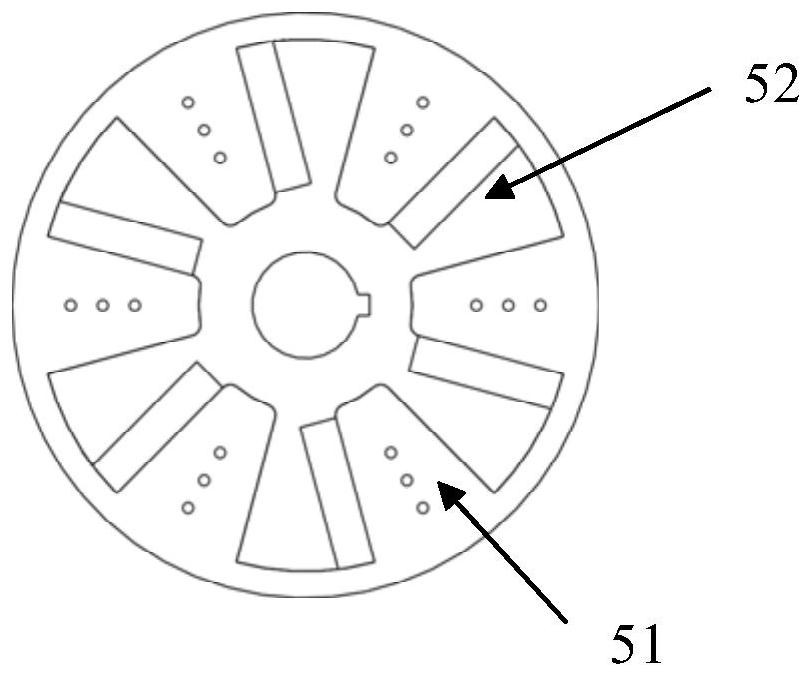

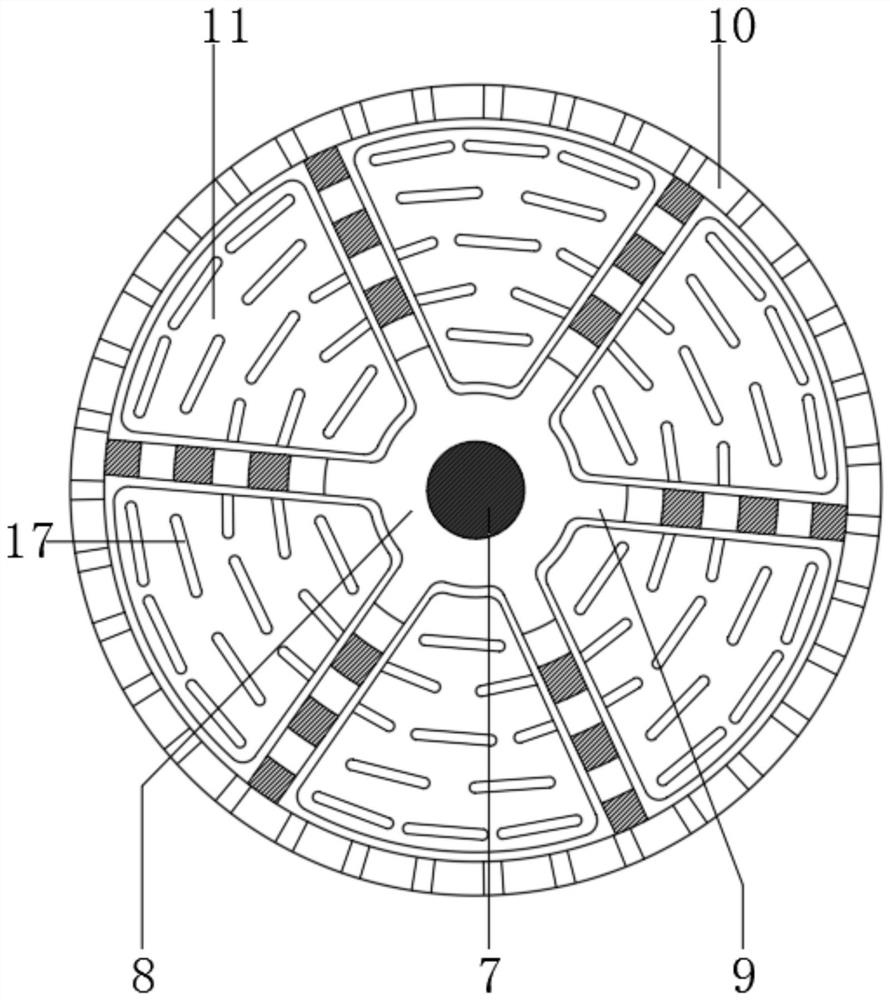

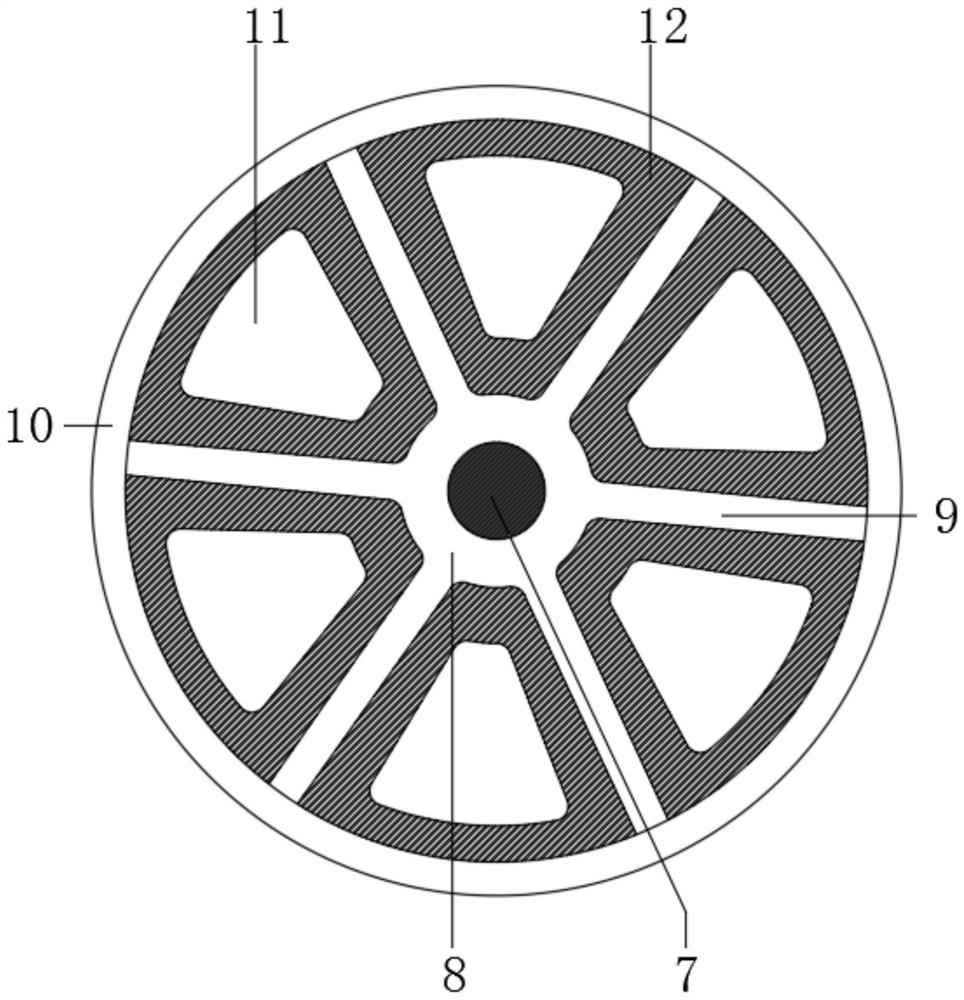

The invention provides a particle type friction stir additive manufacturing device and method. The particle type friction stir additive manufacturing device comprises a wire shearing mechanism, the wire shearing mechanism comprises a base and a shearing part with a cutting edge, a wire guide hole is formed in the base, and a wire can pass through the wire guide hole. The particle type friction stir additive manufacturing device is characterized in that the shearing part is in close contact with the base, the shearing part rotates with the geometric center of the base as the axis, so that the cutting edge intermittently cuts the wire sent out from the wire guide hole. According to the particle type friction stir additive manufacturing device, additive particles of different diameters, different lengths and different materials can be obtained at the same time, friction stir additive manufacturing of gradient composite materials is achieved, and it can be guaranteed that the additive particles are continuously and stably provided; and meanwhile, operation is easy, and multi-layer additive manufacturing can be achieved under the condition that an additive device does not need to be adjusted.

Owner:安徽万宇机械设备科技有限公司

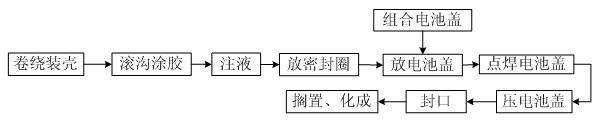

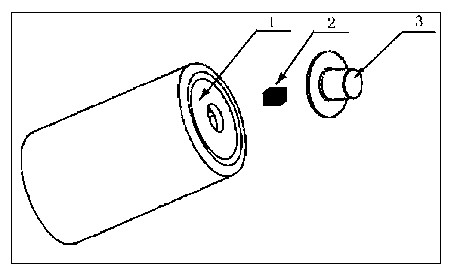

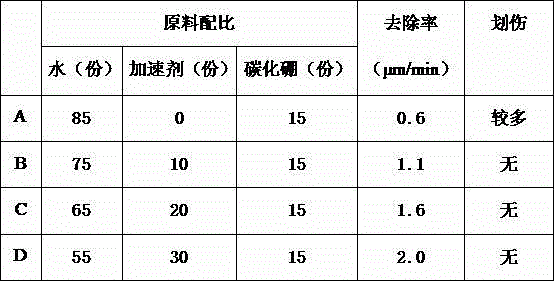

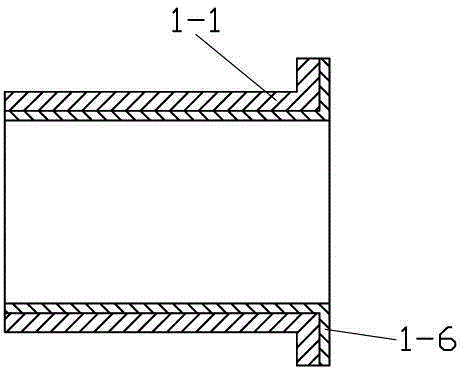

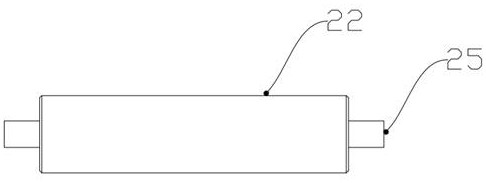

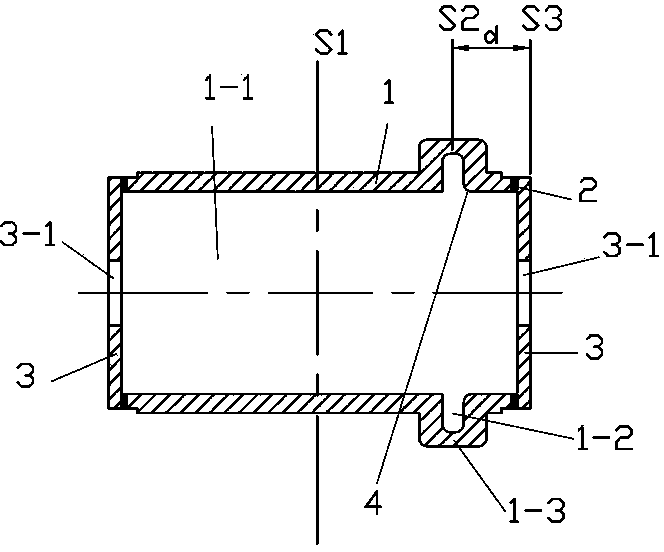

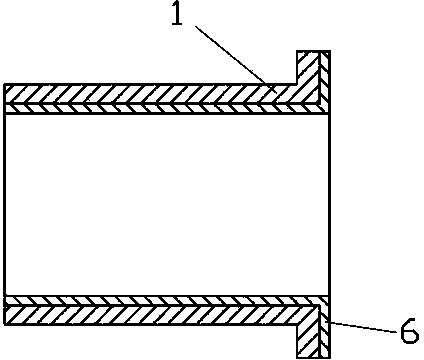

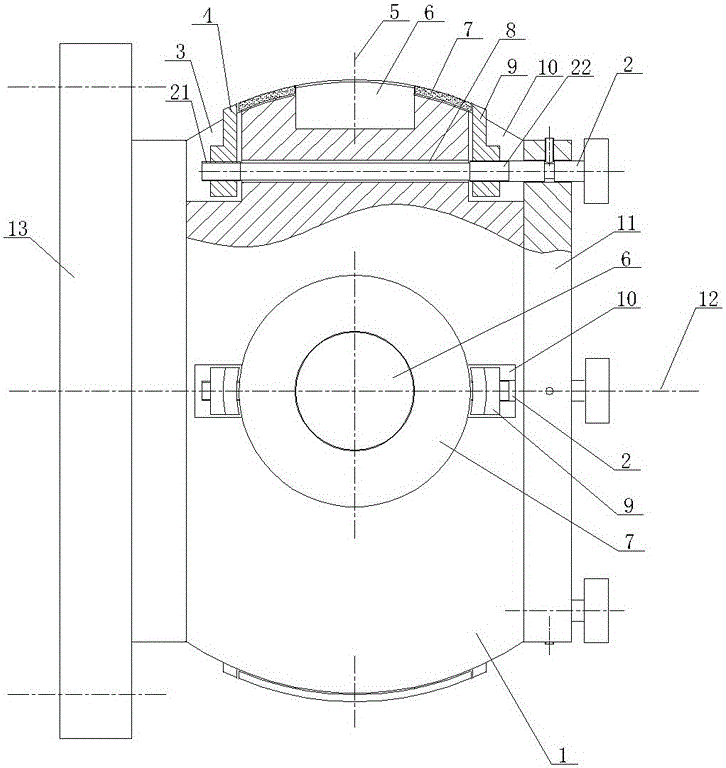

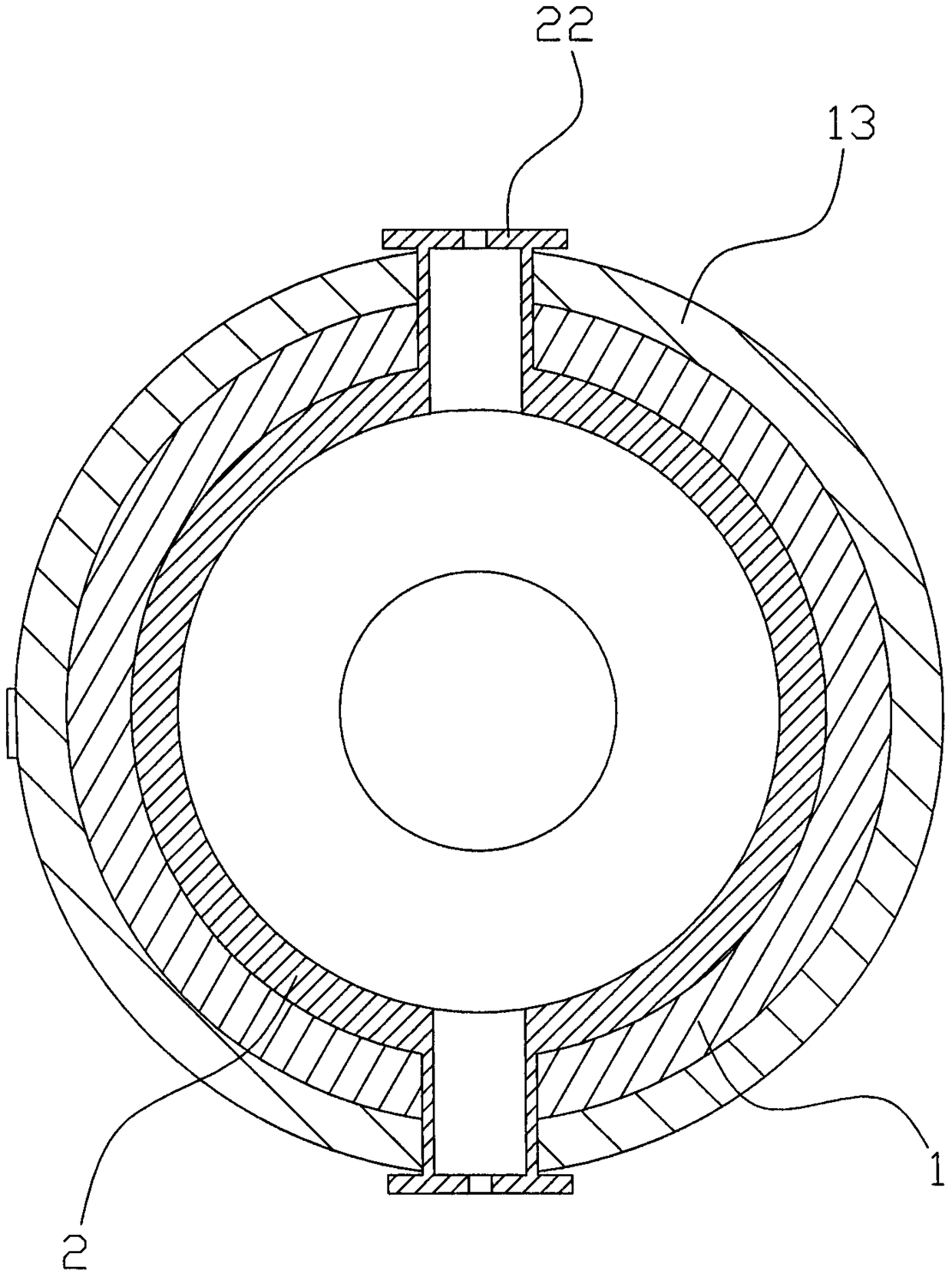

Method for assembling rechargeable battery

ActiveCN102064292AImprove performanceExtend your lifeFinal product manufactureCell component detailsElectrical batteryMechanical engineering

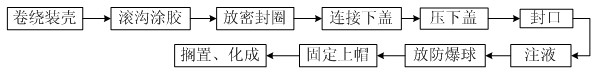

The invention discloses a method for assembling a rechargeable battery. The rechargeable battery comprises a battery core, a steel shell and a battery cover; the battery core comprises an anode, a cathode and a diaphragm, a pole lug is led out from the anode, the battery cover comprises a lower cover, an explosion-proof ball and an upper cap, and the lower cover is provided with a hole. The method comprises the following steps of: 1. shell assembly by coiling: coiling the anode, the cathode and the diaphragm into the battery core and then assembling the battery core into the steel shell; (2) trenching and glue spreading: trenching and spreading glue on the opening of the steel shell; (3) sealing ring arrangement: arranging a sealing ring on the battery core; (4) lower cover connection: fixing the pole lug on the lower bottom surface of the lower cover and connecting the lower cover with the anode; (5) lower cover pressing: pressing the lower cover in the sealing ring; (6) sealing: sealing the lower cover with a sealing machine; (7) liquid injection: injecting electrolyte through the hole in the lower cover; (8) explosion-proof ball arrangement: arranging the explosion-proof ball on the lower cover; (9) upper cap fixing: holding the explosion-proof ball with the upper cap and fixing the upper cap on the lower cover; and (10) standing and forming. The method for assembling the rechargeable battery can be used for greatly reducing alkali climbing phenomenon and improving the percent of pass of products and prolonging the service life of the products.

Owner:SHENZHEN EPT BATTERY

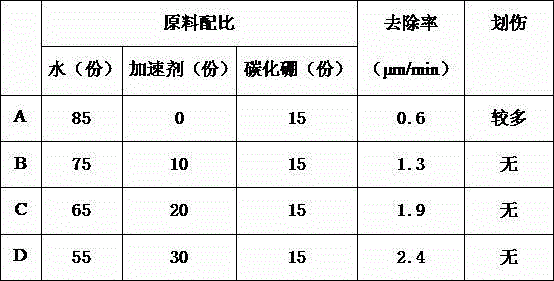

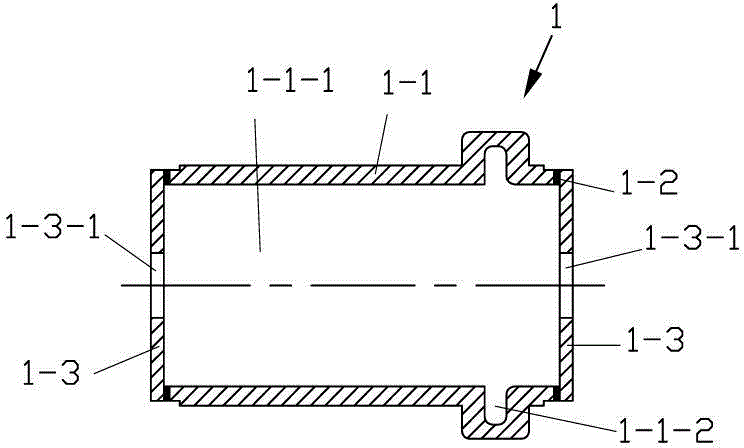

Accelerator used in grinding hard material

ActiveCN104592935AImprove mechanical frictionStop scratchesOther chemical processesChemistryAcrylate polymer

The invention discloses an accelerator used in grinding a hard material. The accelerator comprises the following components in parts by weight: 4-16 parts of an alcohol amine compound, 4-40 parts of an alcohol compound, 1-10 parts of polyacrylate, 10-50 parts of an acrylate polymer, 3-17 parts of a surfactant, 1-15 parts of a cellulosic polymer and 2-27 parts of water and has a pH value of 7-13. The accelerator has better suspension dispersion effect on a large-particle friction agent so that the prepared grinding fluid is difficult to deposit to the bottom of the machine during the circular processing, the chemical interaction between the grinding fluid and sapphire wafers can be enhanced, the hydration of the surface of the wafer is effectively promoted, the interfacial damage layer caused by the purely mechanical effect of the wafer is reduced and thus the grinding removal rate is greatly improved and the production efficiency is significantly increased.

Owner:JIANGSU SINO KRYSTALS OPTROINCS

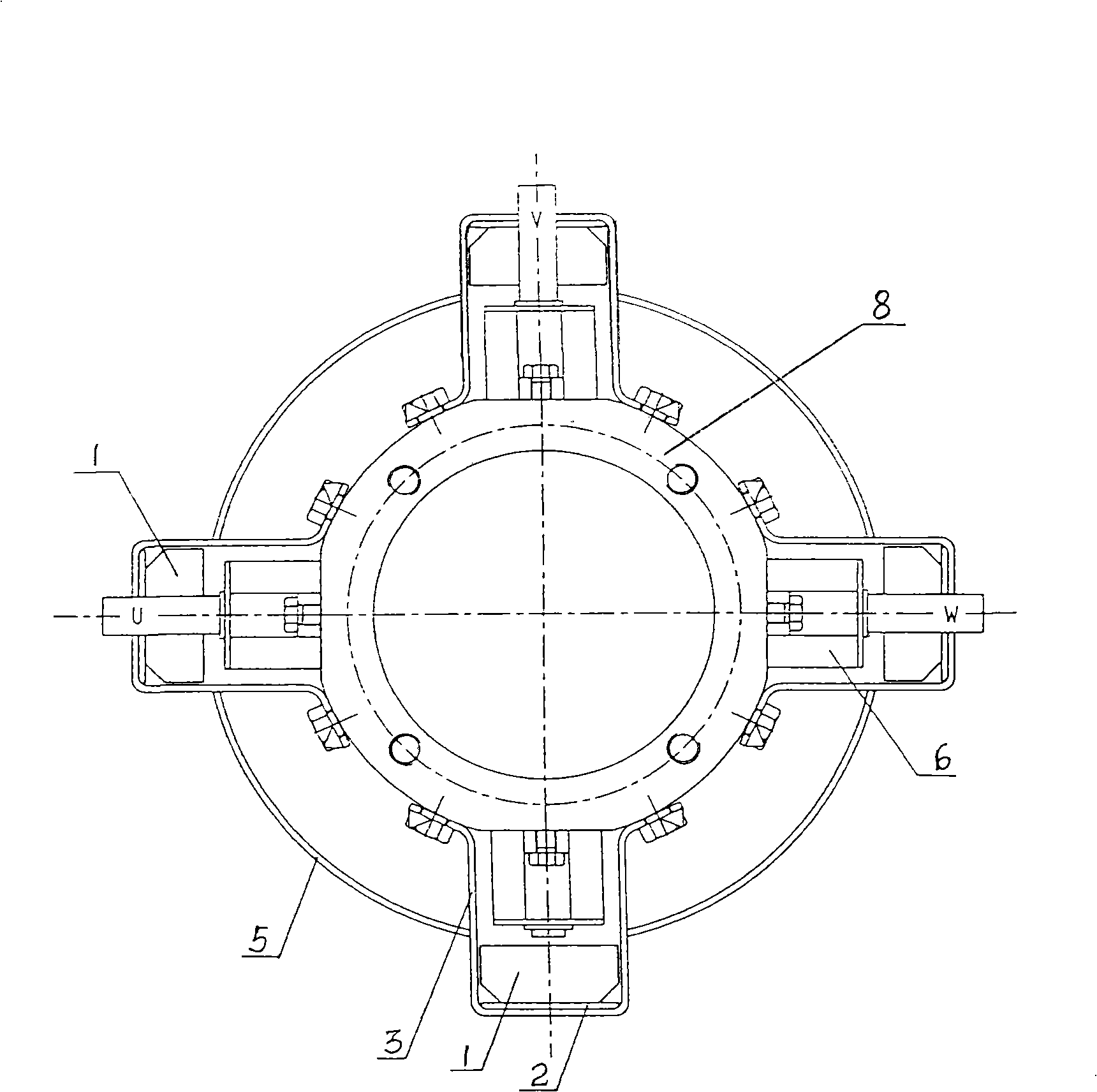

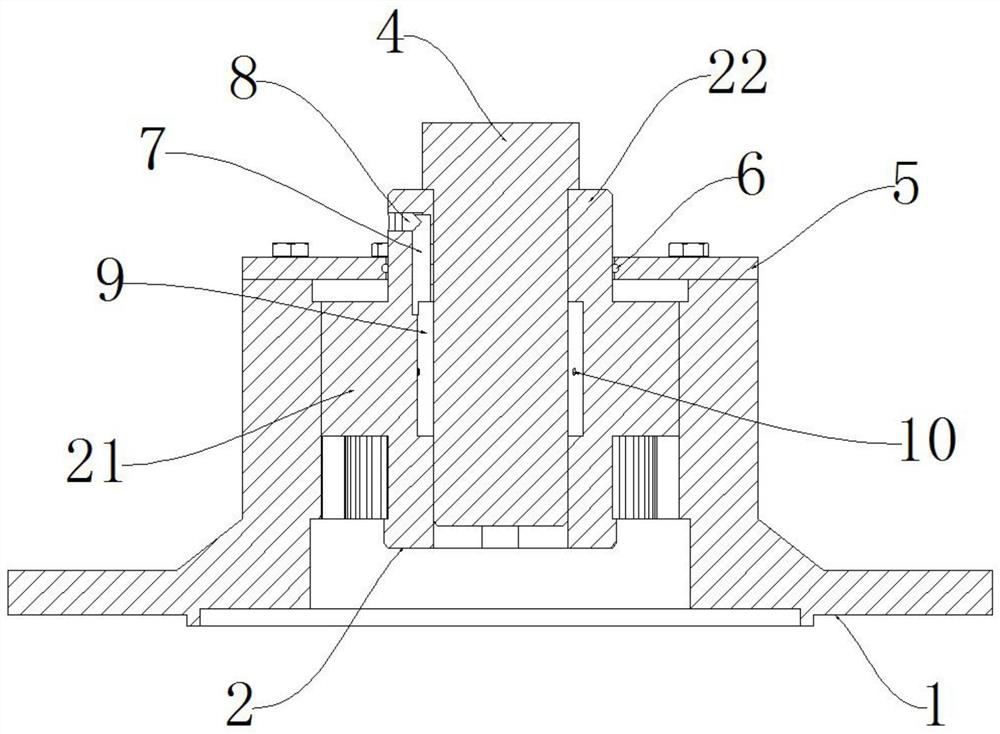

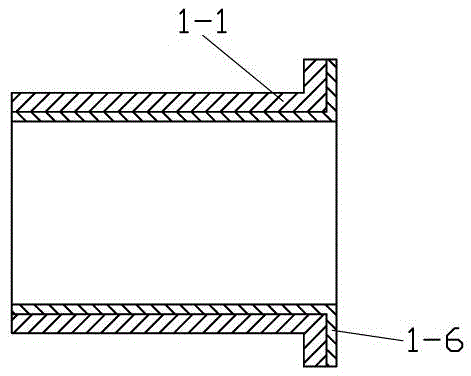

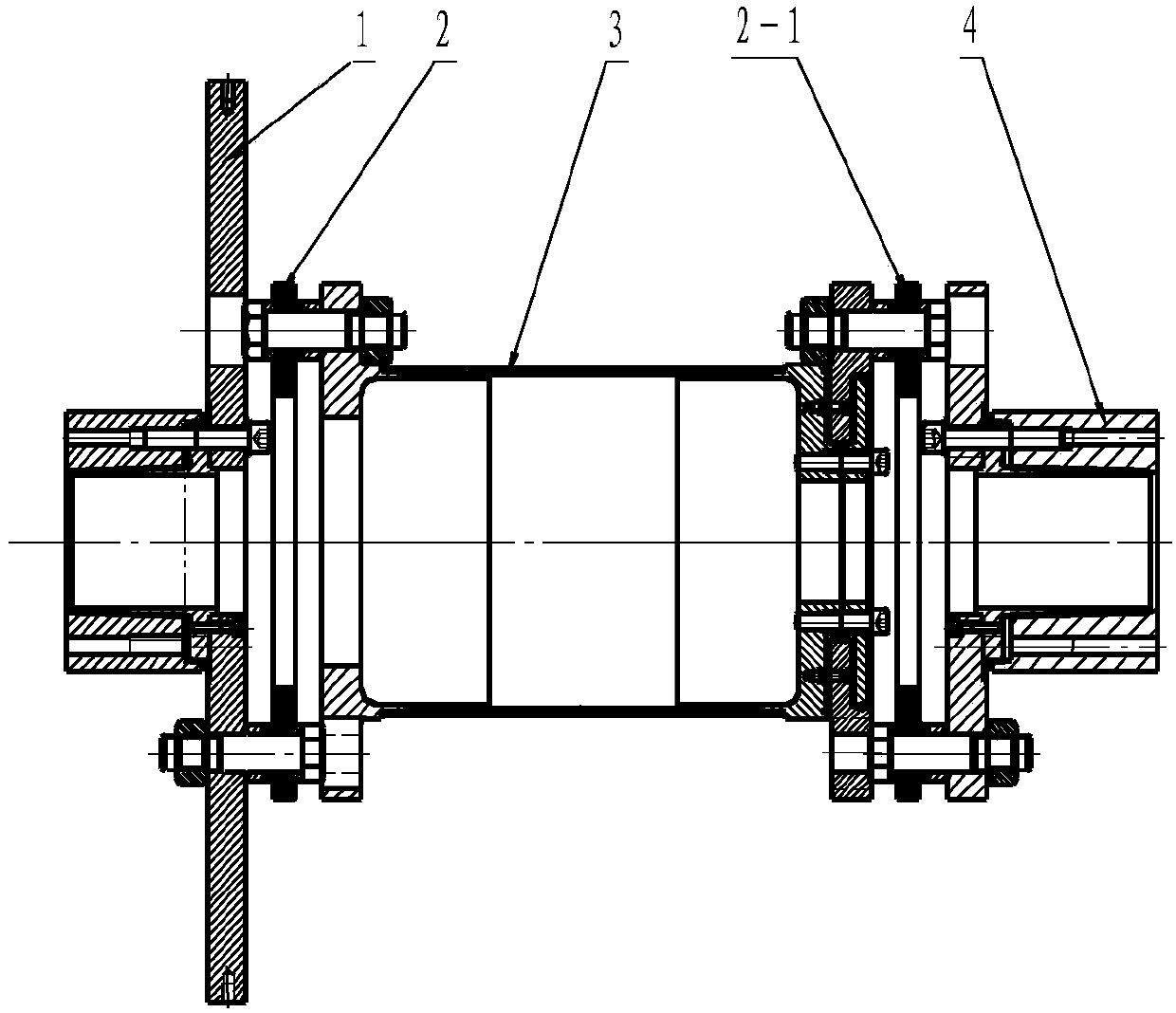

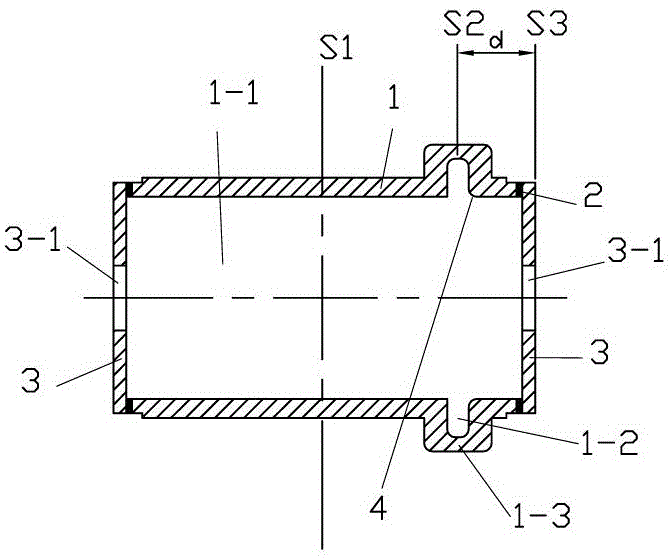

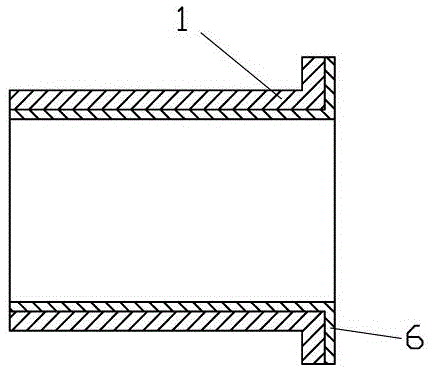

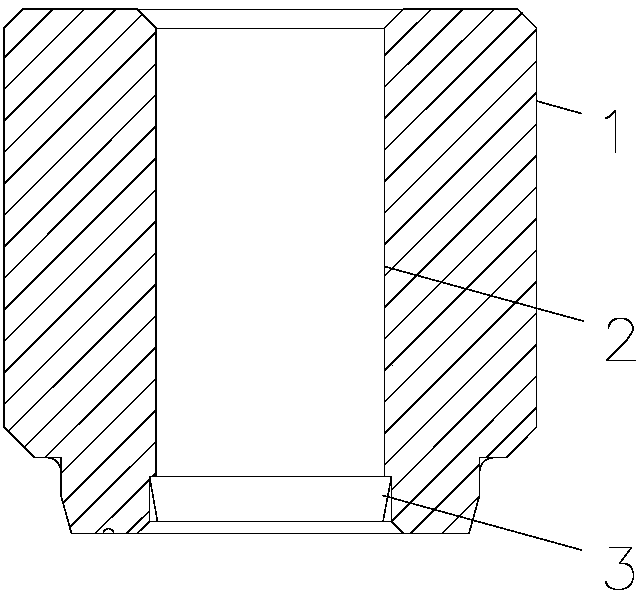

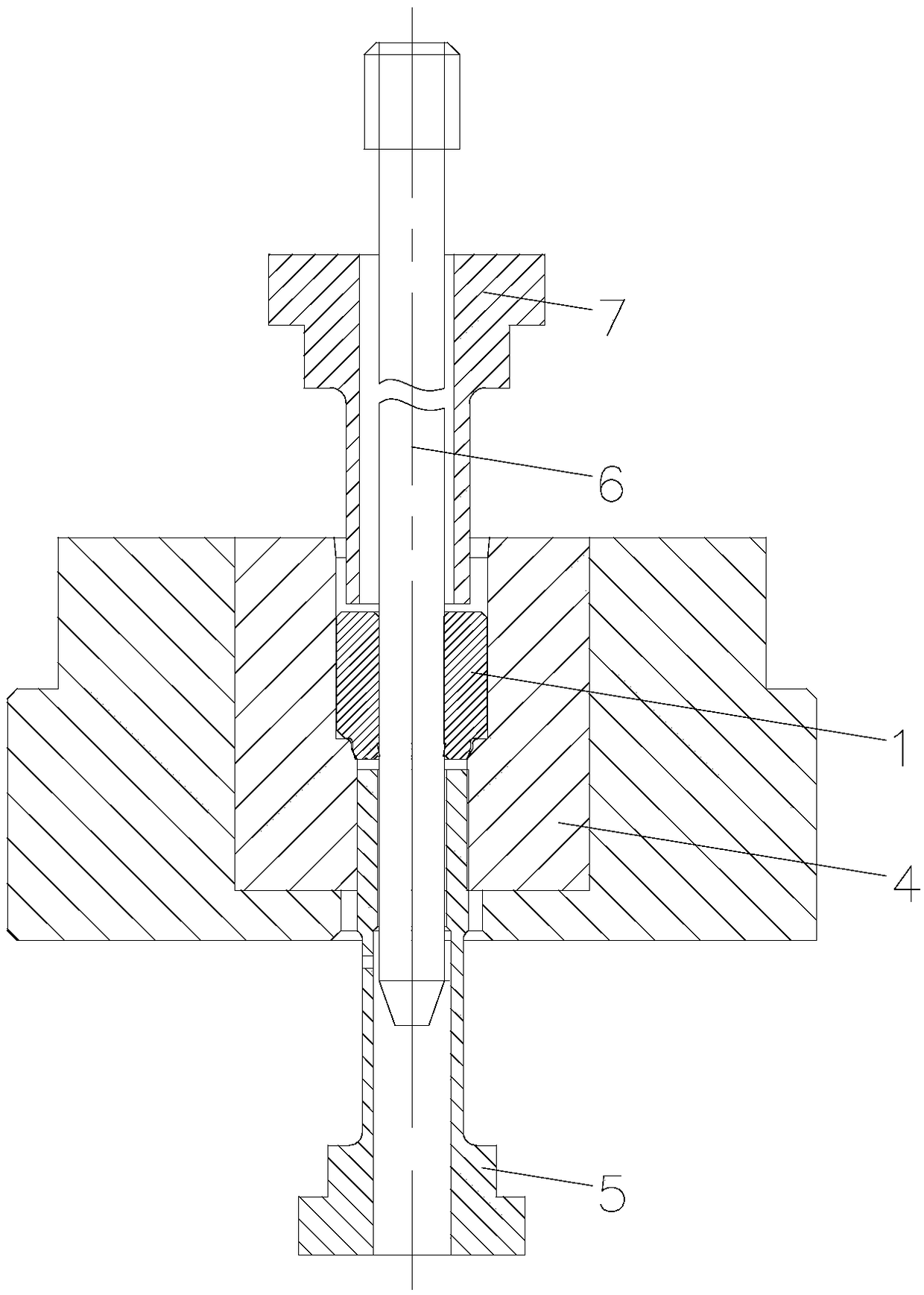

Dual-metal thrust sliding bearing blank preparation method and tooling used by same

The invention discloses a dual-metal thrust sliding bearing blank preparation method and a tooling used by the same. The method includes the following steps: in the first step, alloy material and auxiliary materials are mixed: copper alloy particles, copper gas welding flux and charcoal particles are uniformly mixed; in the second step, the mixed alloy material and auxiliary materials are loaded into a mould, and two clamping flange devices respectively press both ends of the mould by means of external force-applying devices; in the third step, an induction heater is arranged on the periphery of the mould, the mould is then rotated, centrifugal rotational speed and the heating power of the induction heater are regulated, and the alloy particle mixture is molten; in the fourth step, the induction heater is removed, the dual-metal blank produced in the third step is put into a movable cooler, a lower water sprayer is first adopted to cool the dual-metal blank for a certain period of time, and an upper water sprayer is then opened to cool the dual-metal blank to room temperature along with the lower water sprayer. The tooling comprises the mould, the clamping flange device and the movable cooler. The process is reasonable, and the defects of dual-metal blanks can be reduced.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

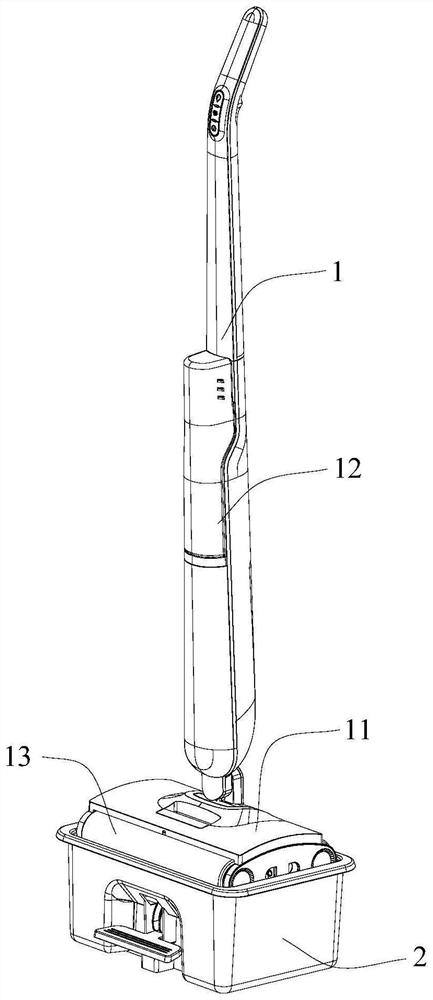

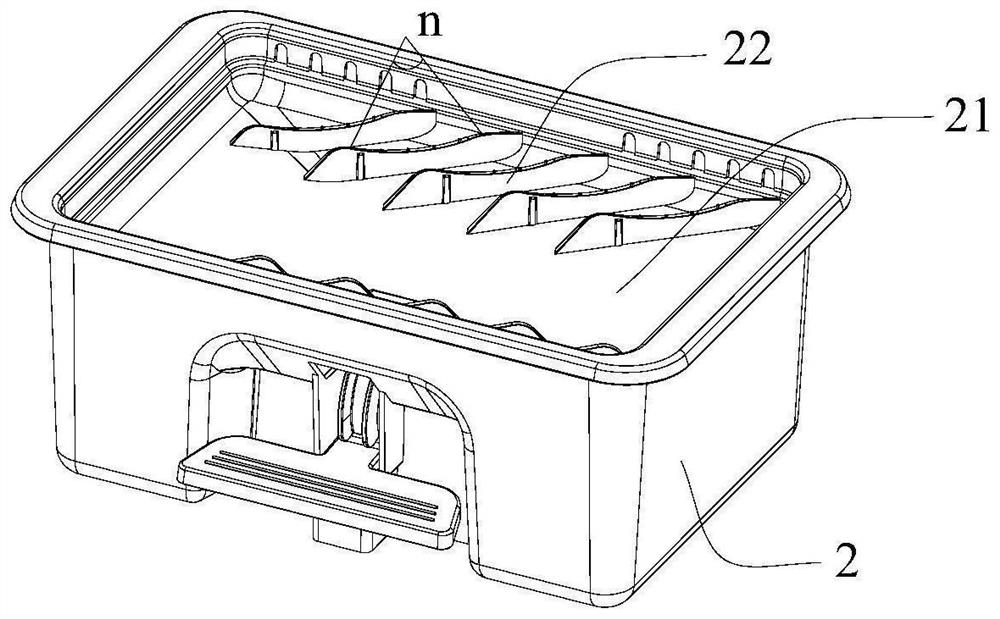

Self-cleaning method of surface cleaning system

ActiveCN114246519APlay a kneading effectReduce dirt residueCarpet cleanersFloor cleanersSurface cleaningCleaning methods

The invention provides a self-cleaning method of a surface cleaning system.The surface cleaning system comprises a surface cleaning device and a cleaning assembly, the surface cleaning device is provided with a mopping piece, the cleaning assembly is provided with a cleaning tank used for containing the mopping piece, and a cleaning rib used for abutting against the mopping piece is arranged in the cleaning tank; the self-cleaning method comprises the steps that the mopping and wiping piece is made to rotate in the cleaning tank in the first rotating direction for cleaning till the mopping and wiping piece rotates by an angle a; enabling the mopping and wiping piece to rotate in the cleaning tank in a second rotating direction opposite to the first rotating direction for cleaning until the mopping and wiping piece rotates by an angle b; the first cleaning step and the second cleaning step are cyclically carried out, so that the mopping piece rotates by at least one circle relative to the initial position after cleaning is finished. According to the self-cleaning method, the fluff of the mopping and wiping piece can be turned over easily, and therefore the cleaning effect of the mopping and wiping piece is improved.

Owner:SHARKNINJA CHINA TECH CO LTD

Sorting and transporting device capable of conveying cargoes in middle and facilitating turning of cargoes

ActiveCN113289907ANot easy to dropImprove shipping speedBio-organic fraction processingSortingEngineeringStructural engineering

Owner:广东新琦智能科技有限公司

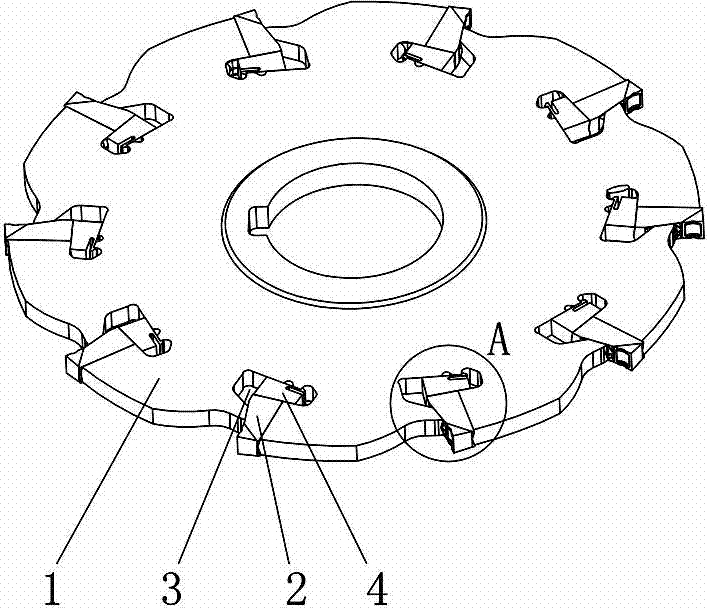

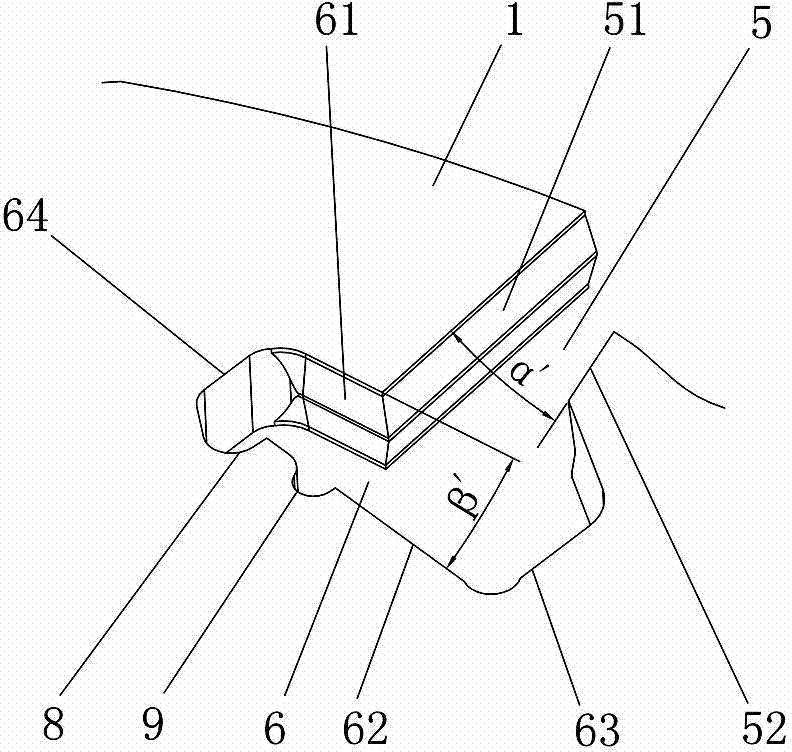

Milling cutter

The present invention discloses a milling cutter, which comprises a disk-like cutter body, cutting blades and cutter grooves arranged on the outer edge of the disk-like cutter body, wherein the cutter groove comprises a cutting blade clamping groove and a pressing block installation groove, the bottom surface and the top surface of the cutting blade respectively bear against the first clamping surface and the second clamping surface of the cutting blade clamping groove, the radially-extending surfaces of the bottom surface and the top surface toward the external of the disk-like cutter body intersect so as to form an included angle alpha, the radially-extending surfaces of the first clamping surface and the second clamping surface toward the external of the disk-like cutter body intersect so as to form an included angle alpha', the alpha' is more than or equal to the alpha, and pressing blocks for radially and tightly pressing the cutting blades are arranged inside the pressing block installation grooves. The milling cutter has advantages of safety, reliability, accurate assembly positioning, high cutting efficiency and the like.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

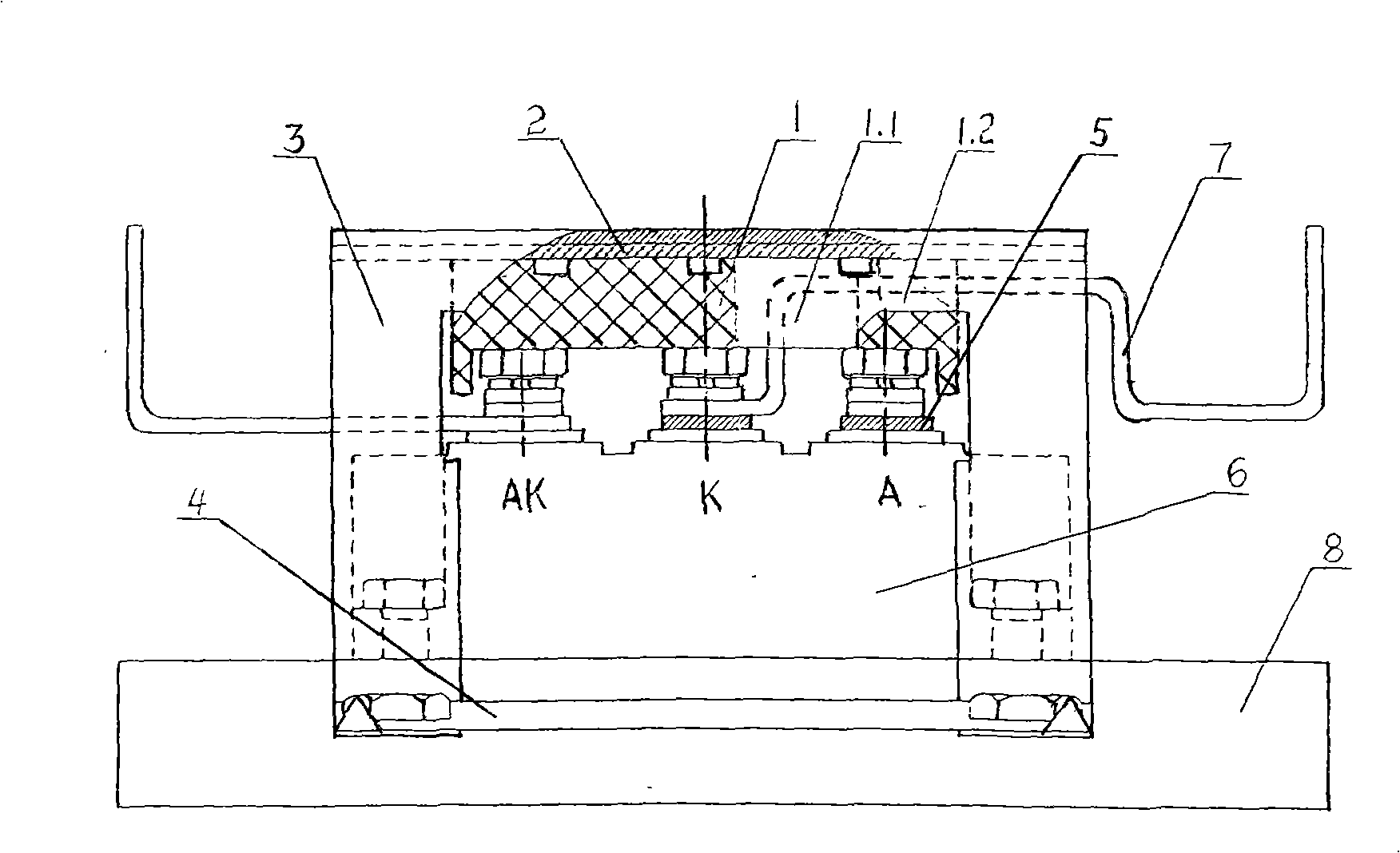

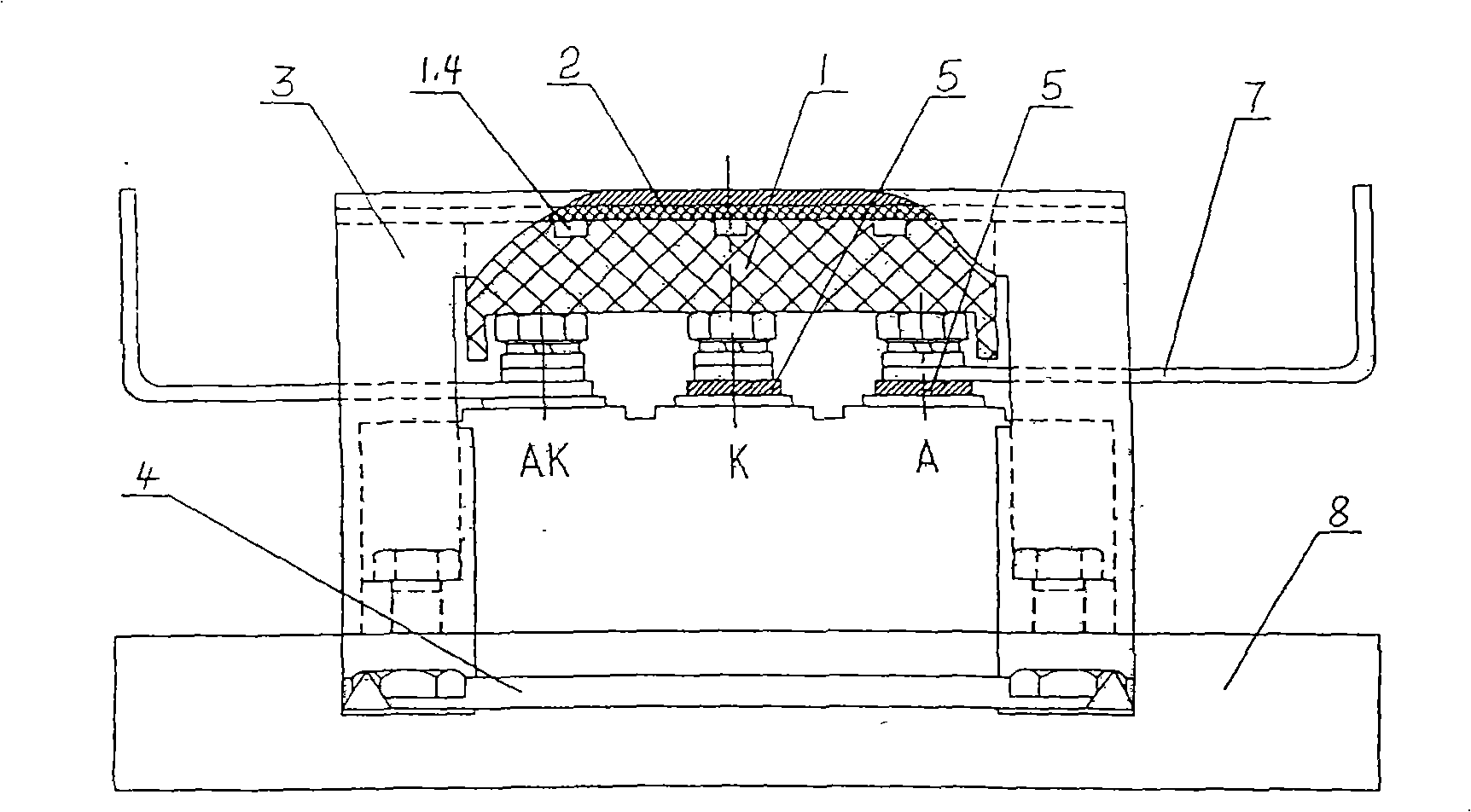

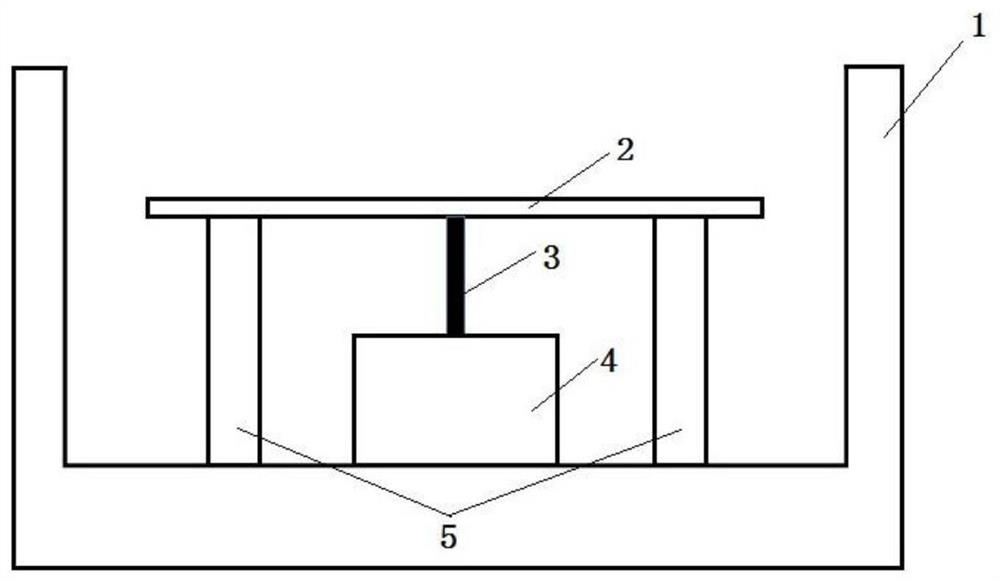

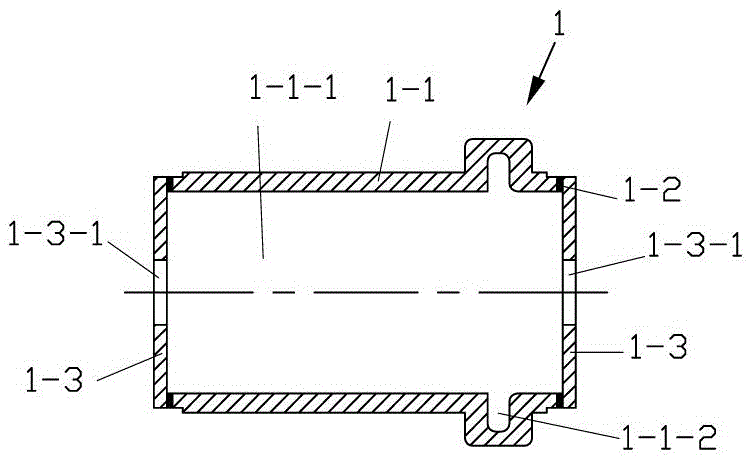

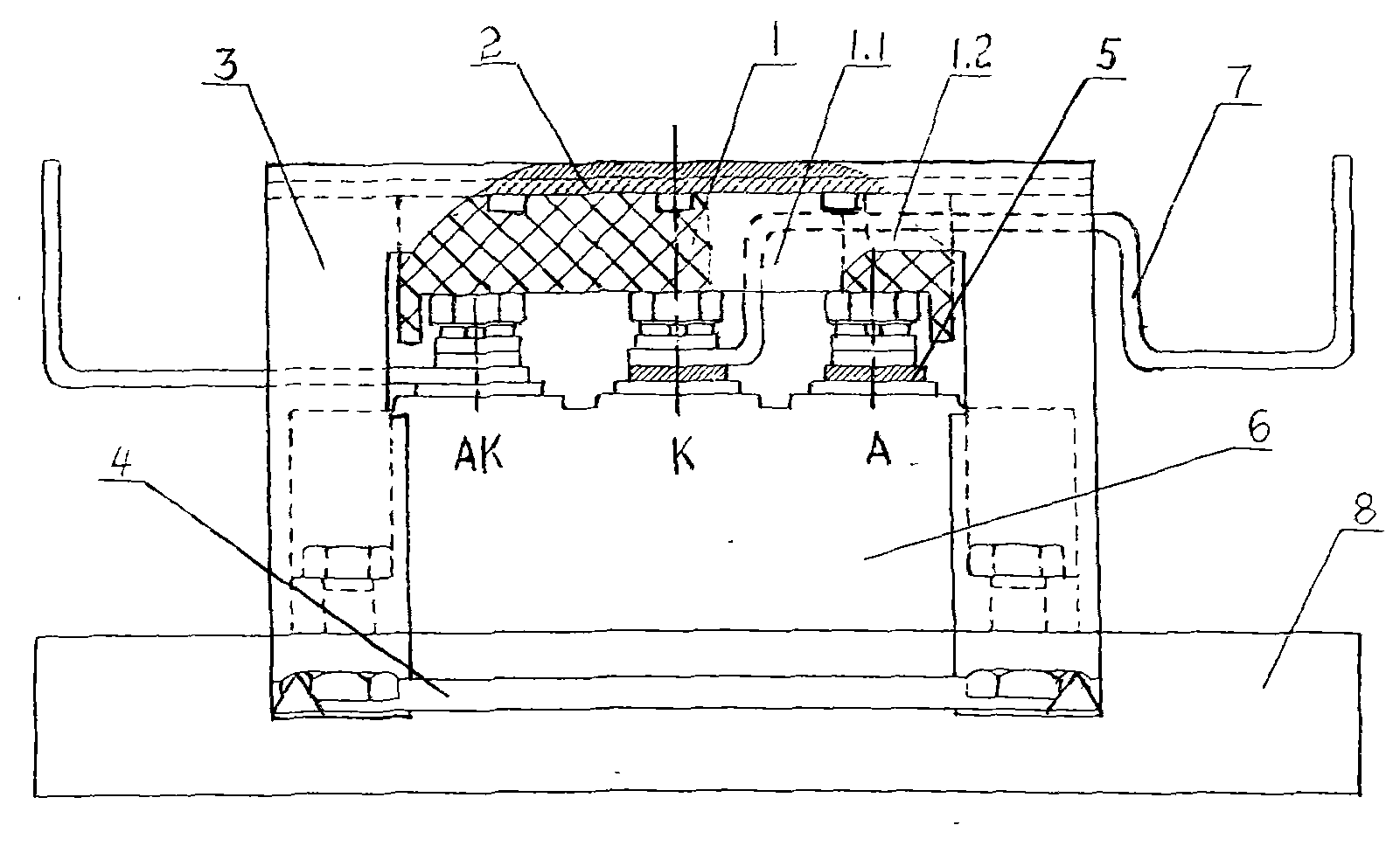

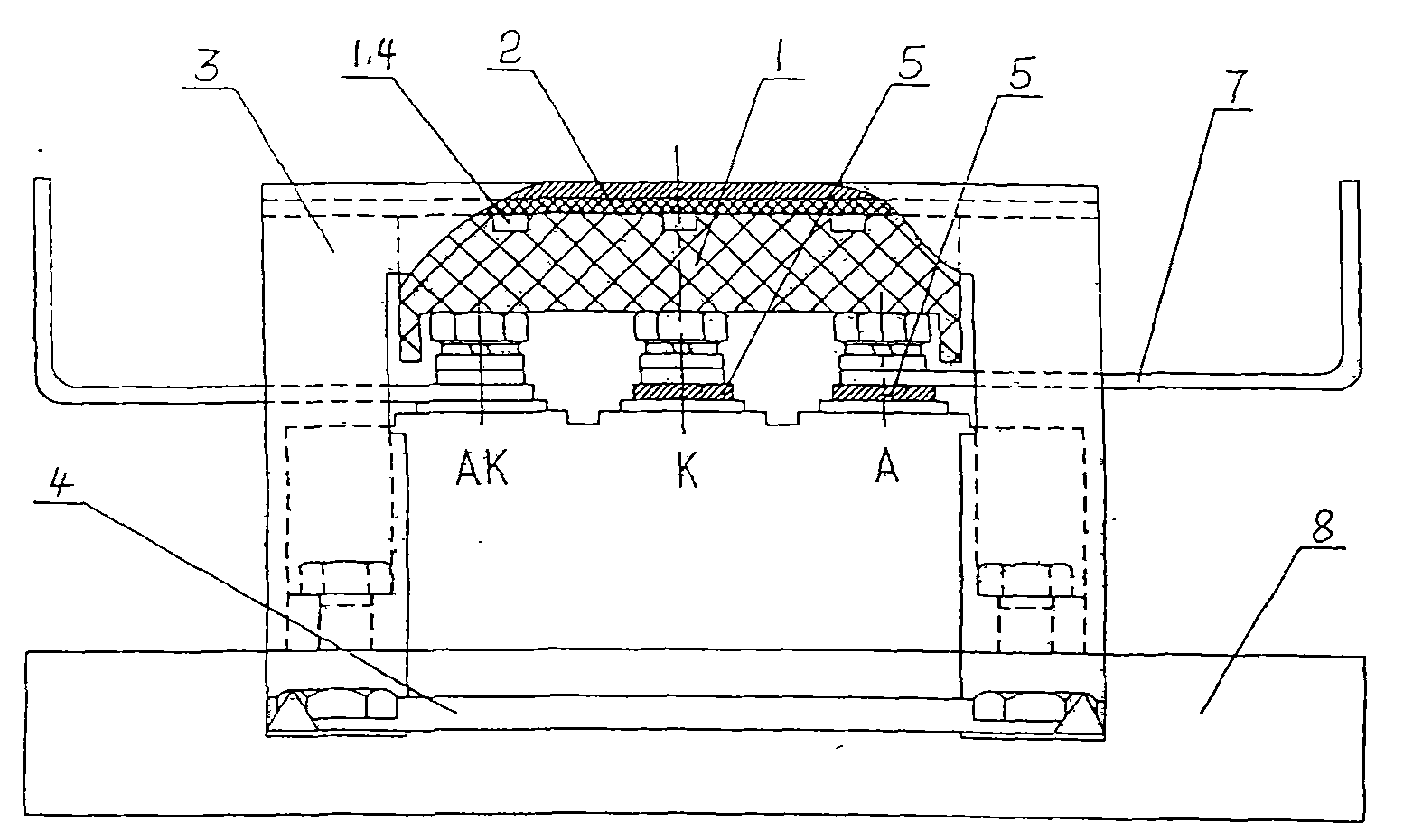

Brushless excitation synchronous generator

InactiveCN101494408AEasy to fixReasonable wiringSynchronous generatorsStructural associationDirect currentElectric generator

The invention relates to a generator, in particular to a brushless excitation synchronous generator, which solves the problems of unreasonable structures in the existing brushless excitation synchronous generators. The brushless excitation synchronous generator comprises a main generator and a rectifier device fixed on a rectifier wheel of same axis as a main generator rotor; the rectifier device is formed by connecting three rectifier modules and a voltage sensitive module fixed on the rectifier wheel through two conducting rings respectively connected with corresponding connection bolts on the rectifier modules and the voltage sensitive module; two direct current leading-out wires are fixed on the rectifier device; and both the rectifier modules and the voltage sensitive module are provided with pressing boards which are covered by a pressing cover fixed on the rectifier wheel. Achieving the target of ensuring the rectifier modules and the two direct current leading-out wires not to be thrown away easily during the working of the brushless excitation synchronous generator, and the brushless excitation synchronous generator enables the two direct current leading-out wires to be fixed more stably and the wiring to be more reasonable, thus forming a convenient and practical protection device with reliable structure.

Owner:CRRC YONGJI ELECTRIC CO LTD

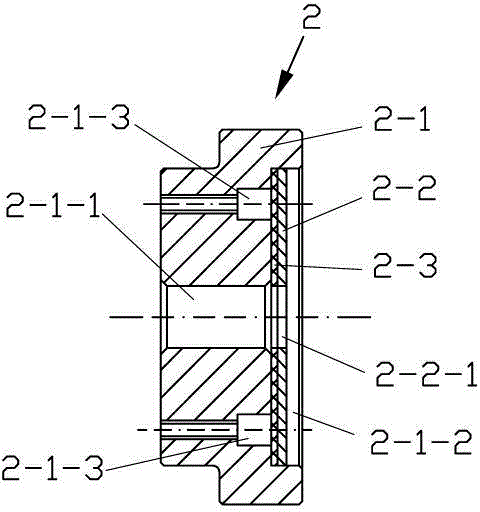

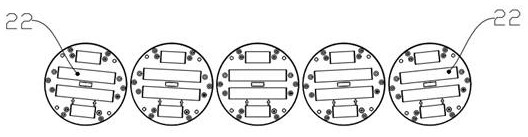

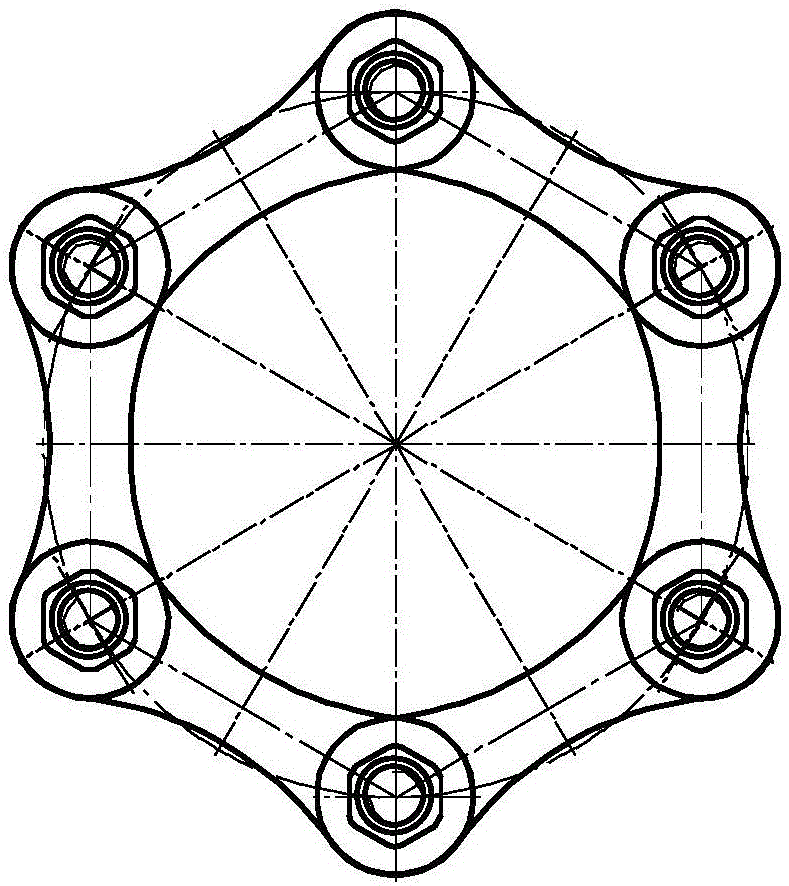

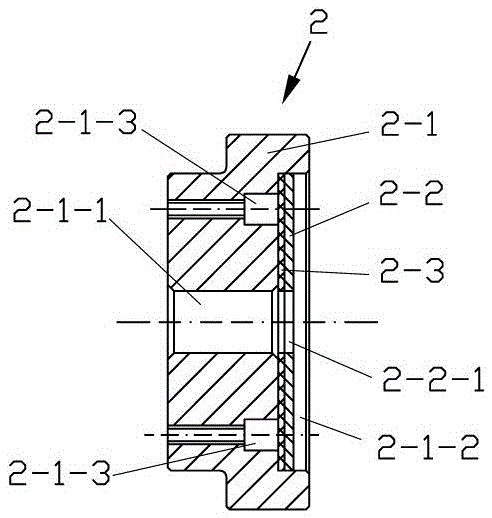

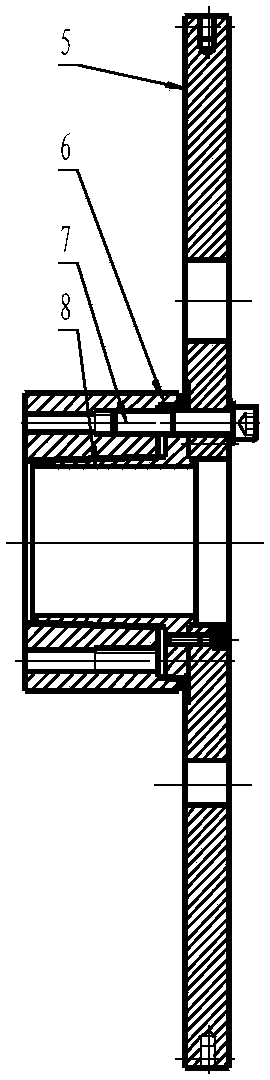

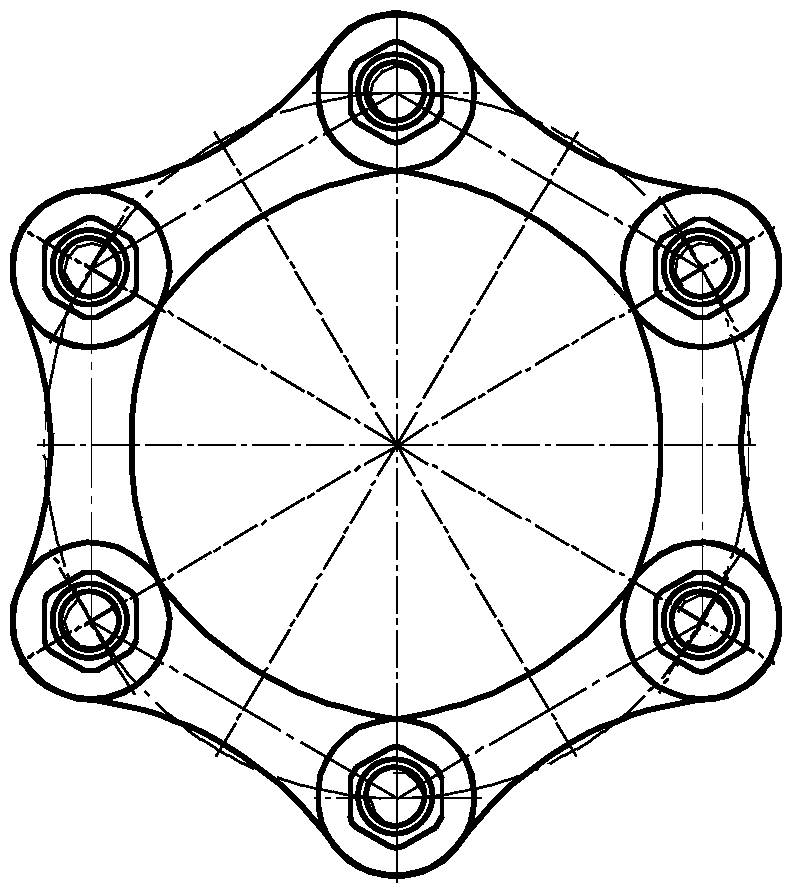

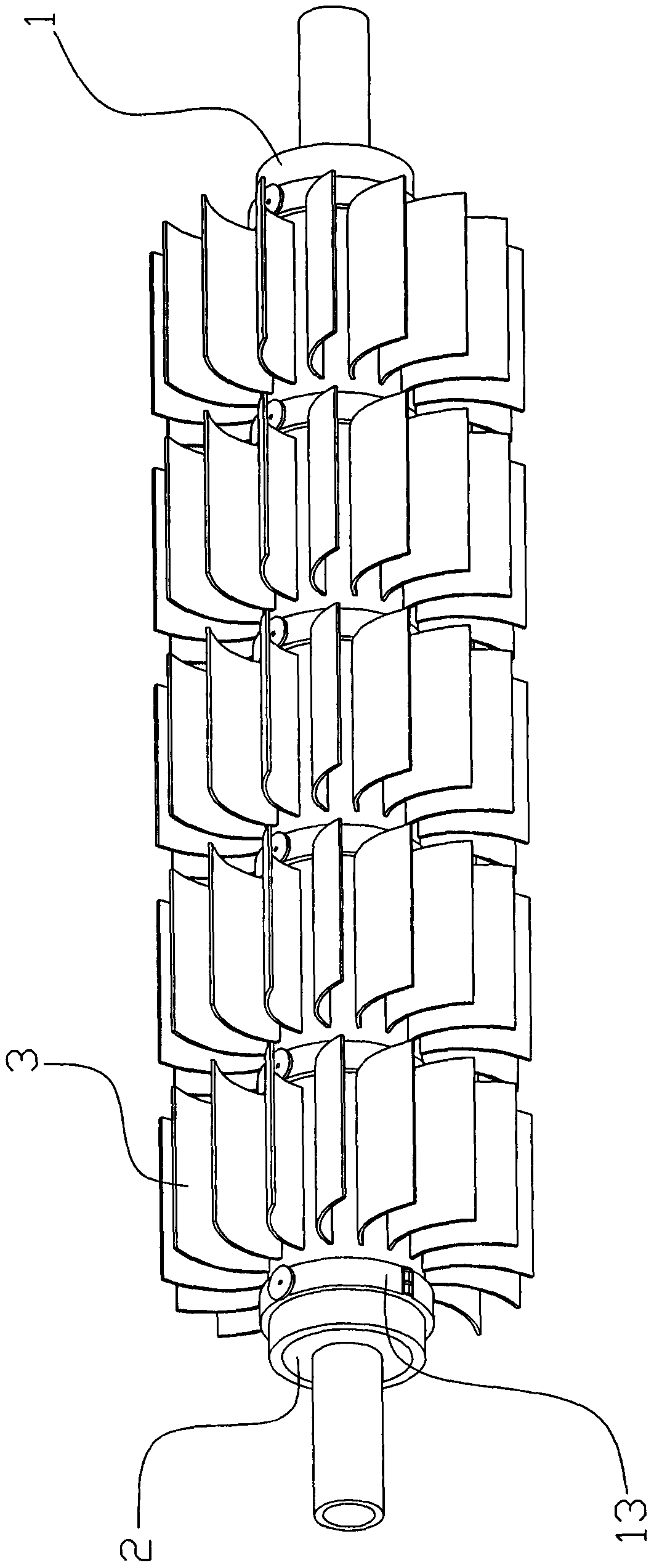

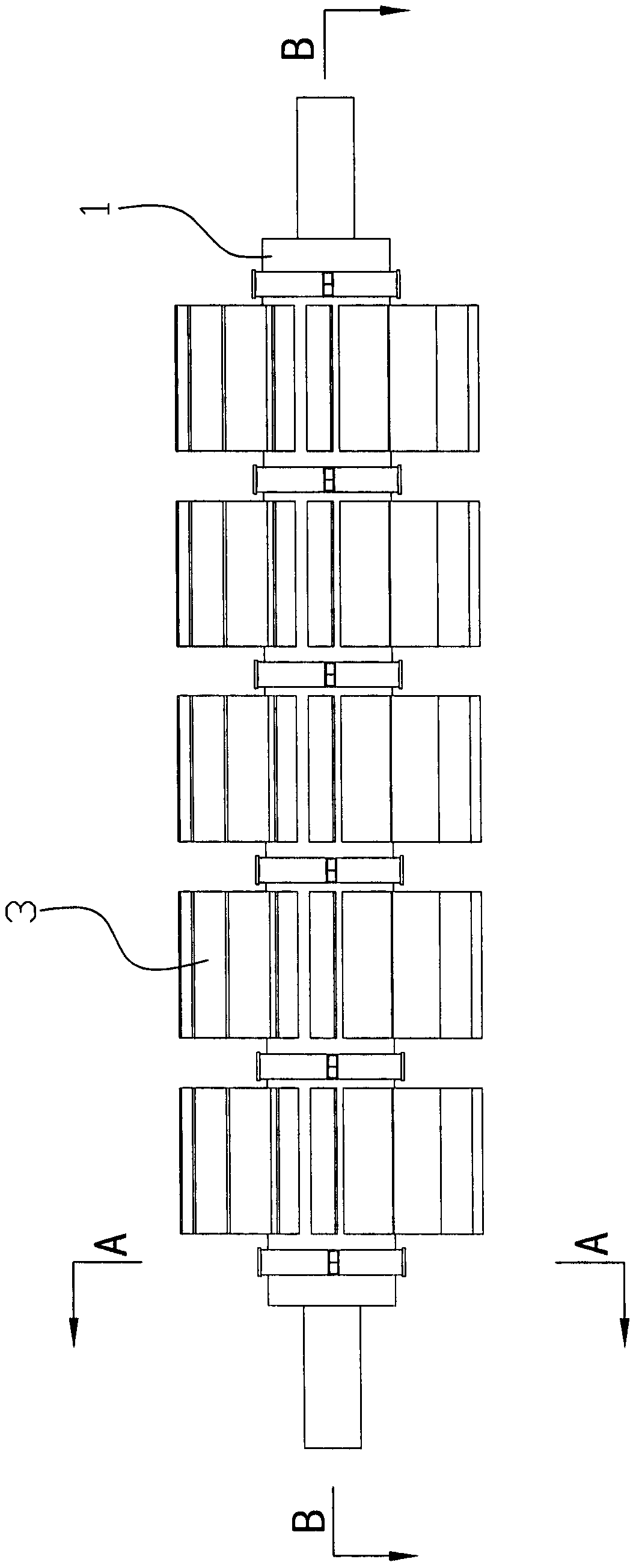

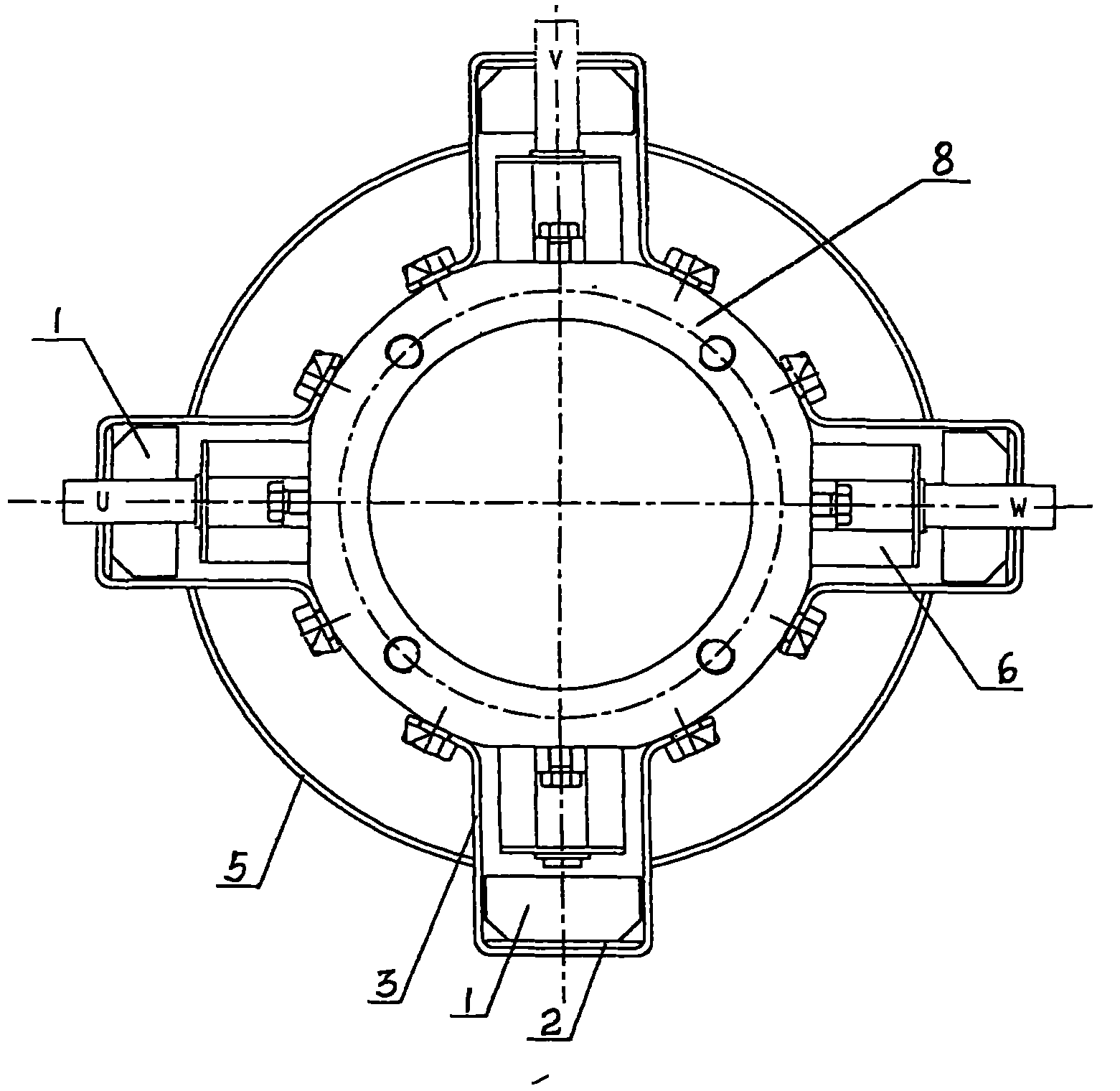

Flexible coupling of wind generator set and assembling or replacing method of flexible coupling

ActiveCN106050959AAvoid leasingShorten maintenance timeClutchesYielding couplingDynamic balanceCoupling

The invention discloses a flexible coupling of a wind generator set and an assembling or replacing method of the flexible coupling. The assembling or replacing method is characterized by comprising the following steps: designing and manufacturing parts by unit, assembling the parts to form five unit components, namely a brake disc component, a left flexible connecting sheet component, a middle connector component, a right flexible connecting sheet component and a generator side coupling component; carrying out dynamic balance tests and adjustments of the unit components separately so that the unit components have symmetric structures and dynamically balanced configuration; assembling the unit components to form the flexible coupling; and carrying out a dynamic balance test and an adjustment of the whole flexible coupling so that the whole flexible coupling has dynamically balanced configuration. According to the invention, the parts of the flexible coupling, which are designed and manufactured by unit, can be reliably assembled and conveniently and separately disassembled and replaced, so that the problem of inconvenience caused by breakdown maintenance of the conventional flexible coupling is effectively solved, the maintenance time is greatly shortened, a great amount of maintenance cost is saved, and the flexible coupling has high practicability.

Owner:绵阳国顺电气有限公司

Mould and method for manufacturing bimetal plain thrust sliding bearing blank and manufacturing method thereof

ActiveCN104043802AGuaranteed performanceSolve the situation that is prone to crack defectsAsbestos sheetAlloy

The invention discloses a mould for manufacturing a bimetal plain thrust sliding bearing blank and a manufacturing method of the mould. The mould comprises a steel billet and asbestos plates. The steel billet is provided with an inner hole and an annular groove, the annular groove is formed in the hole wall of the inner hole, the inner hole is communicated with the annular groove, the two ends of the steel billet are provided with the corresponding asbestos plates in an adherence mode through high-temperature-resisting binding agents, central holes are formed in the asbestos plates, and the central holes of the asbestos plates are communicated with the inner hole of the steel billet. The mould is simple in structure and can solve the problem that alloy layers at the two ends of the bimetal plain thrust sliding bearing blank are prone to being cracked. The manufacturing method of the mould is further disclosed.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

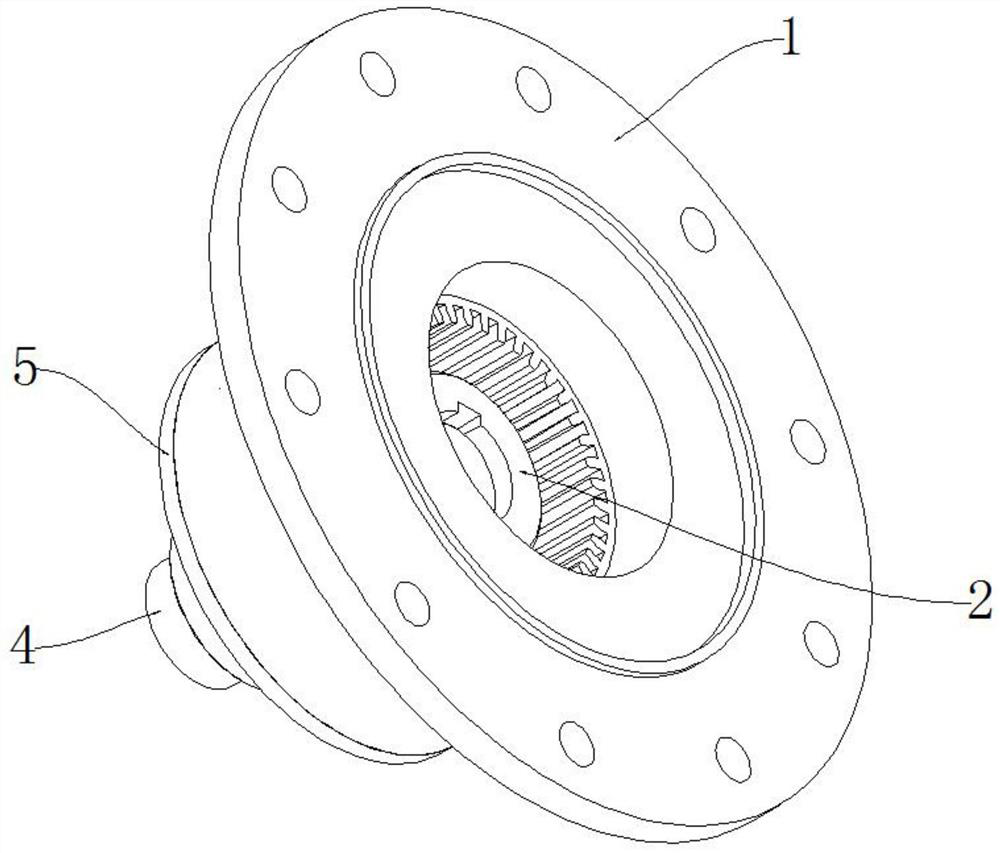

Efficient lubricating gear coupling

InactiveCN111692220ANot easy to throw outImprove lubrication efficiencyYielding couplingEngine lubricationCouplingGear wheel

The invention discloses an efficient lubricating gear coupling, and relates to the technical field of couplings. In order to solve the problems that an existing gear coupling is low in lubricating efficiency, and lubricating oil is prone to being thrown out during working, the efficient lubricating gear coupling comprises inner gear rings and outer gear sleeves, the outer gear sleeves are mountedat one ends of shafts and fixedly connected with the shafts through flat keys, meshing areas are arranged in the middles of the outer gear sleeves, the outer gear sleeves are mounted in the inner gearrings and mesh with the inner gear rings, the outer ends of the outer gear sleeves extend out of the inner gear rings, a circle of groove is formed in the inner side of each meshing area, oil cavities are formed between the groove walls and the shafts, L-shaped oil circuits are formed inside the outer ends of the outer gear sleeves, one ends of the L-shaped oil circuits pass through the outer circumferences of the outer ends of the outer gear sleeves and are provided with plugs, the other ends of the L-shaped oil circuits communicate with the grooves, and the meshing areas are provided with aplurality of oiling holes enabling the oil cavities and the junctions between the inner gear rings and the outer gear sleeves to communicate. In the efficient lubricating gear coupling, lubricating grease is high in lubricating efficiency and not prone to being thrown out, and thus resources and the cost are saved.

Owner:MAANSHAN IRON & STEEL CO LTD

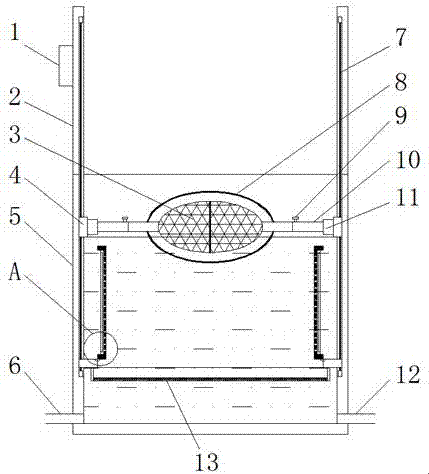

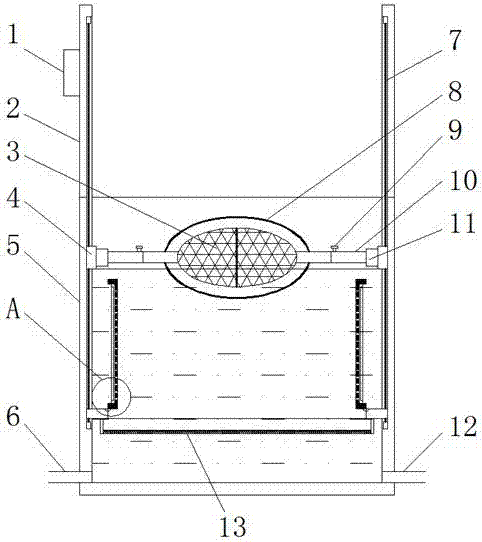

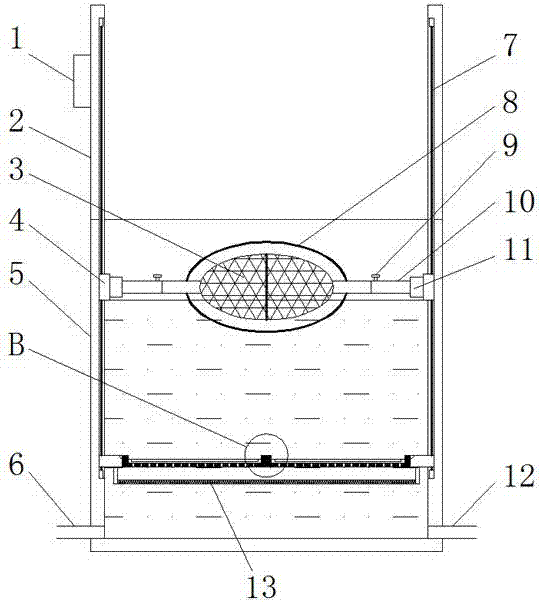

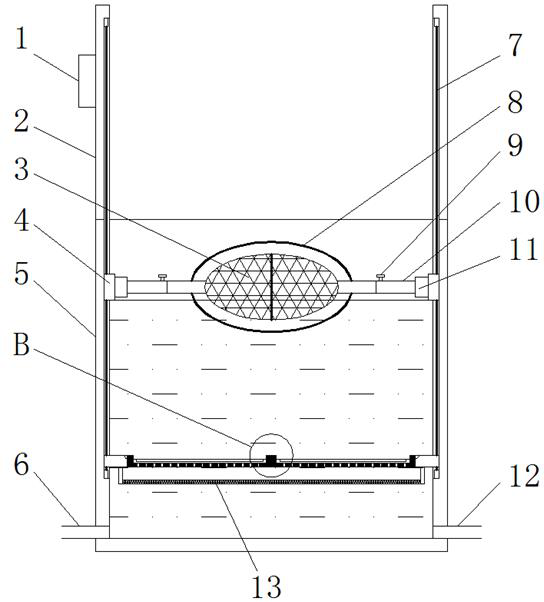

Cibotium barometz fuzz removal and reuse equipment

InactiveCN107569521AHigh economic valueEasy to reprocessPteridophyta/filicophyta medical ingredientsBlood disorderWater storageEngineering

The invention discloses cibotium barometz fuzz removal and reuse equipment, and belongs to the field of fuzz removal and reuse equipment. The cibotium barometz fuzz removal and reuse equipment comprises a water storage bucket, wherein the upper end of the water storage bucket is symmetrically connected with a pair of extension rods, and a control box is fixedly connected with the extension rod; one side of the lower end of the water storage bucket is connected with a water inlet pipe, and the other side of the lower end of the water storage bucket is connected with a drain pipe; first slidinggrooves are formed in the inner side wall of the water storage bucket, and second sliding grooves are formed in the two extension rods; the first sliding grooves are communicated with the second sliding grooves, and electric sliding tables are arranged in the first sliding grooves and the second sliding grooves, and are respectively connected with upper sliding blocks and lower sliding blocks; andthe upper sliding blocks are positioned above the lower sliding blocks. The fuzz removal rate can reach to 95% or more, the removed fuzz can be recovered, and the recovered fuzz does not contain finesand and is easily reprocessed into a hemostatic medicine, so that the economic value of cibotium barometz can be improved.

Owner:段小萍

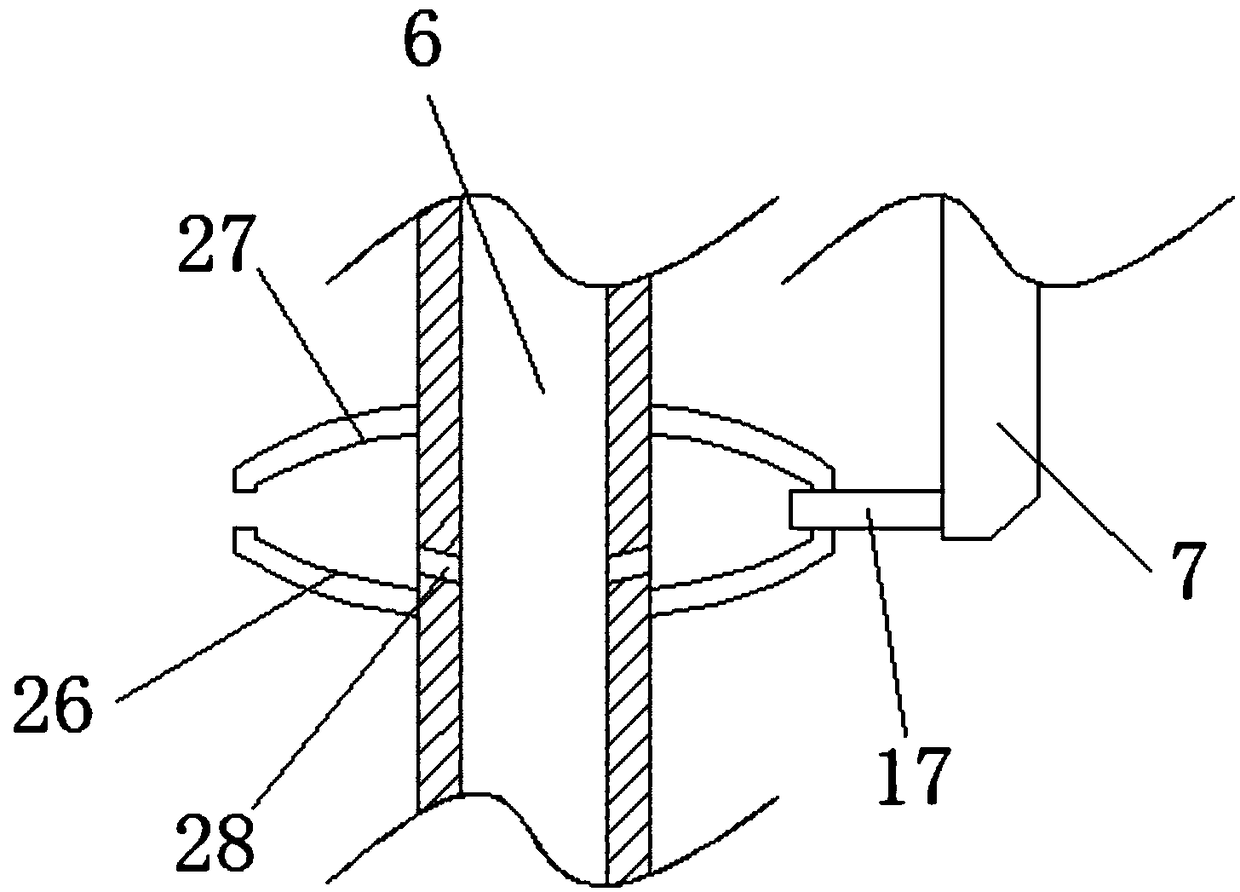

A particle type friction stir additive manufacturing device and method

ActiveCN113118612BNot easy to throw outLess impuritiesAdditive manufacturing apparatusIncreasing energy efficiencyWire cuttingEngineering

The invention provides a particle type friction stir additive manufacturing device and method. The device includes a wire cutting mechanism, the wire cutting mechanism includes a base and a cutting part with a cutting edge, the base is provided with a wire guide hole, and the wire guide hole is suitable for the passage of the wire; It is characterized in that the cutting part is in close contact with the base, and the cutting part rotates with the geometric center of the base as the axis, so that the cutting edge intermittently cuts the wire sent out from the wire guide hole. material. The particle-type friction stir additive manufacturing device provided by the present invention can simultaneously obtain the additive particles of different diameters, different lengths and materials, realizes the friction stir additive manufacturing of gradient composite materials, and can ensure the continuous and stable supply of the additive particles. . At the same time, the operation is simple, and multi-layer additive manufacturing can be realized without adjusting the additive device.

Owner:安徽万宇机械设备科技有限公司

Special grinding fluid for synthetic sapphire camera lens

InactiveCN107057641AEvenly dispersedNot easy to depositOther chemical processesPolishing compositions with abrasivesCamera lensMetallurgy

The invention discloses a special grinding fluid for a synthetic sapphire camera lens. The sapphire grinding fluid comprises the following components in percentage by weight: 20-30% of a grinding agent, 10-15% of a suspending agent, 5-10% of a cutting agent, 3-5% of an accelerator and the balance of water; and the pH value of the grinding fluid is 7 to 8. The grinding fluid is evenly dispersed, the grinding agent is suspended stably and is difficultly precipitated at the bottom of a machine in recycling use during grinding process, and a grinding fluid membrane can be better adhered to a grinding disc so as to prevent a wafer from being in direct contact with the grinding disc and causing scratch, so that the grinding efficiency can be improved, the yield of ground products is increased, throwing is difficultly caused due to an overlarge rotating speed, in addition, the removal rate of the grinding fluid is high and the recycling service life is long.

Owner:东莞市淦宏信息科技有限公司

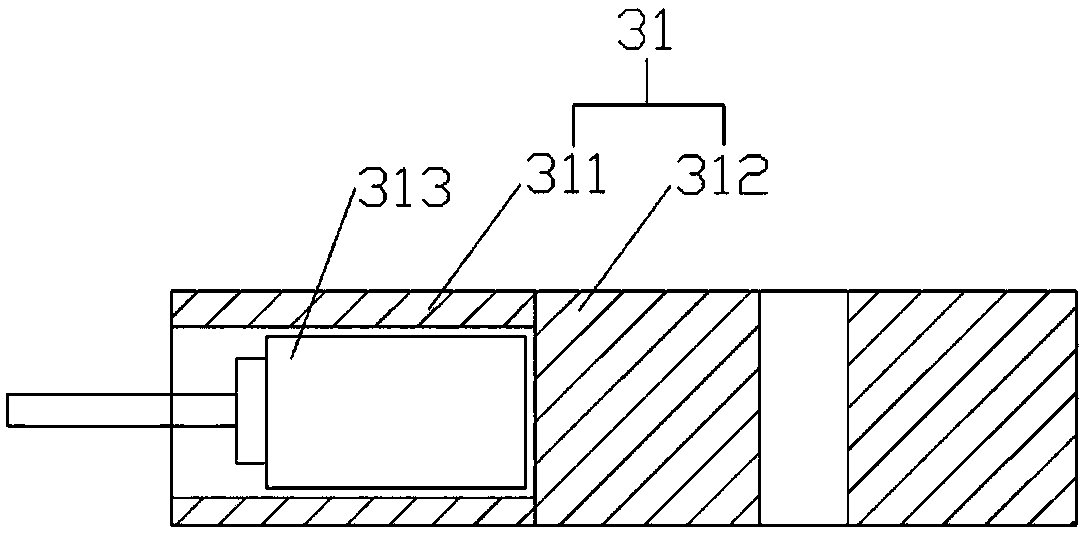

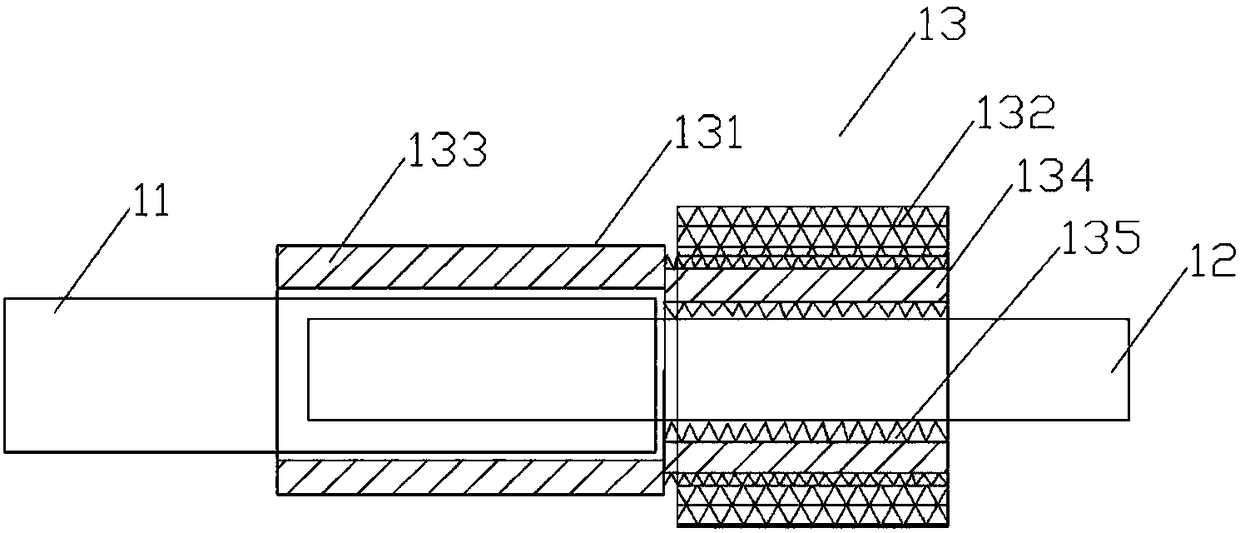

Wiping sampling tool of surfaces of buildings and structures and sampling method of sampling tool

PendingCN108362513AReasonable structureEasy to operateWithdrawing sample devicesCircular discWipe sampling

The invention discloses a wiping sampling tool of the surfaces of buildings and structures and a sampling method and belongs to the field of pollutant sampling. The sampling tool comprises a wiping rod main body, an auxiliary wiping rod and a wiping head, wherein one end of the auxiliary wiping rod is mounted at one end of the wiping rod main body via a first connecting shaft; the wiping head comprises a connecting rod, a rotating disc and wiping cloth; the connecting rod comprises a mounting section and a connecting section that are arranged vertically; the connecting section is mounted on the auxiliary wiping rod via a pivot; a micro-motor is fixedly mounted in the mounting section; and the center of the rotating disc is fixedly mounted on a rotating shaft of the micro-motor. The tool has the benefits that the wiping rod main body, the auxiliary wiping rod and the wiping head are matched; the rotating disc rotates to drive the wiping cloth to rotate to rub with the surfaces of the buildings and the structures to achieve the purpose of sampling; the design of the wiping rod main body and the auxiliary wiping rod can achieve the wiping sampling of the surfaces of the buildings andthe structures in inaccessible or invisible positions; a sampling scope is enlarged; and the safety of samplers is improved.

Owner:CHINESE ACADEMY FOR ENVIRONMENTAL PLANNING

Cibotium barometz hair removing and recycling equipment

ActiveCN107468723AHigh economic valueEasy to reprocessPteridophyta/filicophyta medical ingredientsBlood disorderHair removalWater storage

The invention discloses cibotium barometz hair removing and recycling equipment and belongs to the field of cibotium barometz hair removing and recycling equipment. The cibotium barometz hair removing and recycling equipment comprises a water storage barrel, wherein the upper end of the water storage barrel is symmetrically connected with a pair of extension rods; the extension rods are fixedly connected with a control box; one side of the lower end of the water storage barrel is connected with a water inlet pipe; the other side of the lower end of the water storage barrel is connected with a drain pipe; a first sliding chute is formed in the inner side wall of the water storage barrel; a second sliding chute is formed in each of the extension rods; the first sliding chute is communicated with the second sliding chute; electric sliding tables are mounted in the first sliding chute and the second sliding chute; an upper sliding block and a lower sliding block are connected to the electric sliding tables respectively; the upper sliding block is positioned above the lower sliding block. According to the equipment, the hair removal rate can reach 95% or more; the removed fine hair can be recycled; the recycled fine hair does not contain fine sand and is easily processed into a hemostatic drug, thereby increasing the economic value of cibotium barometz.

Owner:宋春叶 +1

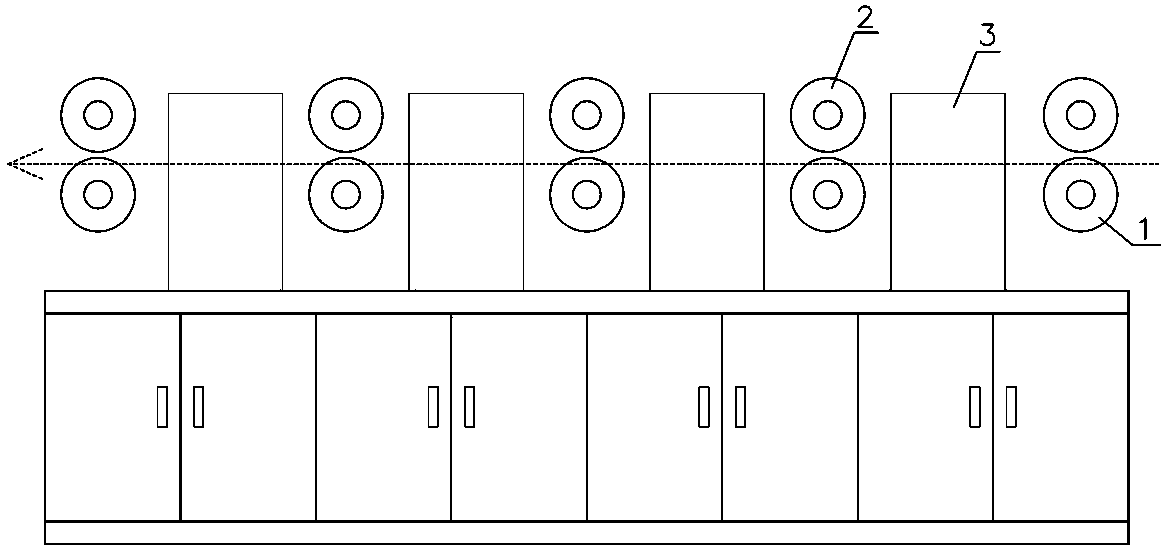

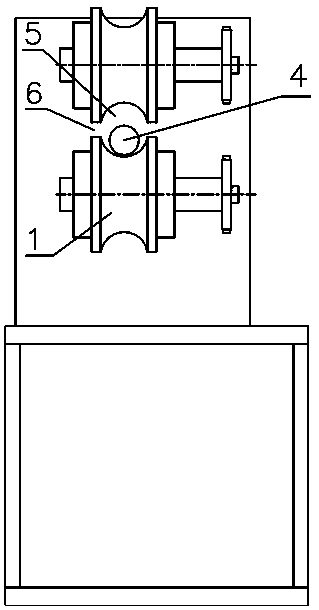

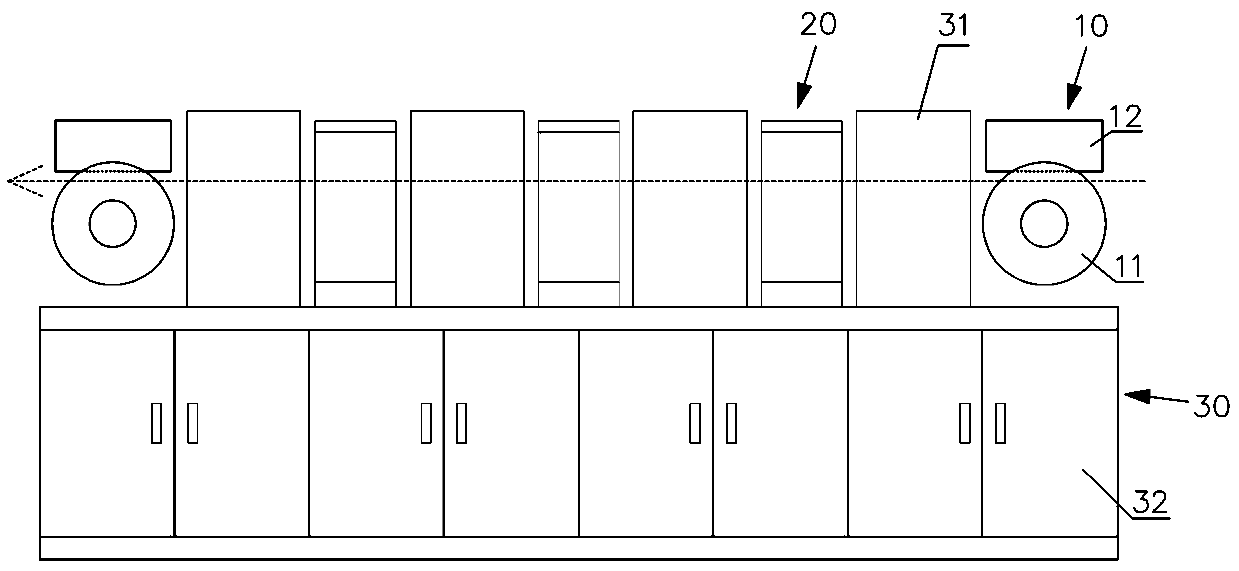

Feeding and fixing core device for steel ball rolling mill production line

PendingCN110238333AFree from damageReduce gap distanceBearing componentsWork heating devicesProduction lineStrip mill

The invention relates a feeding and fixing core device for steel ball rolling mill production line. The device comprises an intermediate frequency heating furnace assembly, a feeding roller wheel assembly and a fixed core assembly, wherein the intermediate frequency heating furnace assembly comprises at least one heating coil mechanism, the feeding roller wheel assembly is arranged at the input end and / or the output end of the medium-frequency heating furnace assembly, the feeding roller wheel assembly comprises a rotatable roller wheel, a circle of groove I for supporting bar materials is formed in the circumferential surface of the roller wheel, the fixed core assembly is arranged between the adjacent heating coil mechanisms and comprises a sliding block and a groove II arranged above the sliding block, the groove II is provided with a third inclined surface and a fourth inclined surface which are formed on the surface of the sliding block, and when the bar materials are placed in the groove II, the bar materials is correspondingly simultaneously in contact with the third inclined surface and the fourth inclined surface. According to the feeding and fixing core device for the steel ball rolling mill production line, the material throwing problem of the bar materials of a rolling mill can be solved, the gap distance between the adjacent heating coil mechanisms can be reduced, and the heat loss of the bar materials can be reduced.

Owner:CHANGSHU LONGTE WEAR RESISTING BALL CO LTD +1

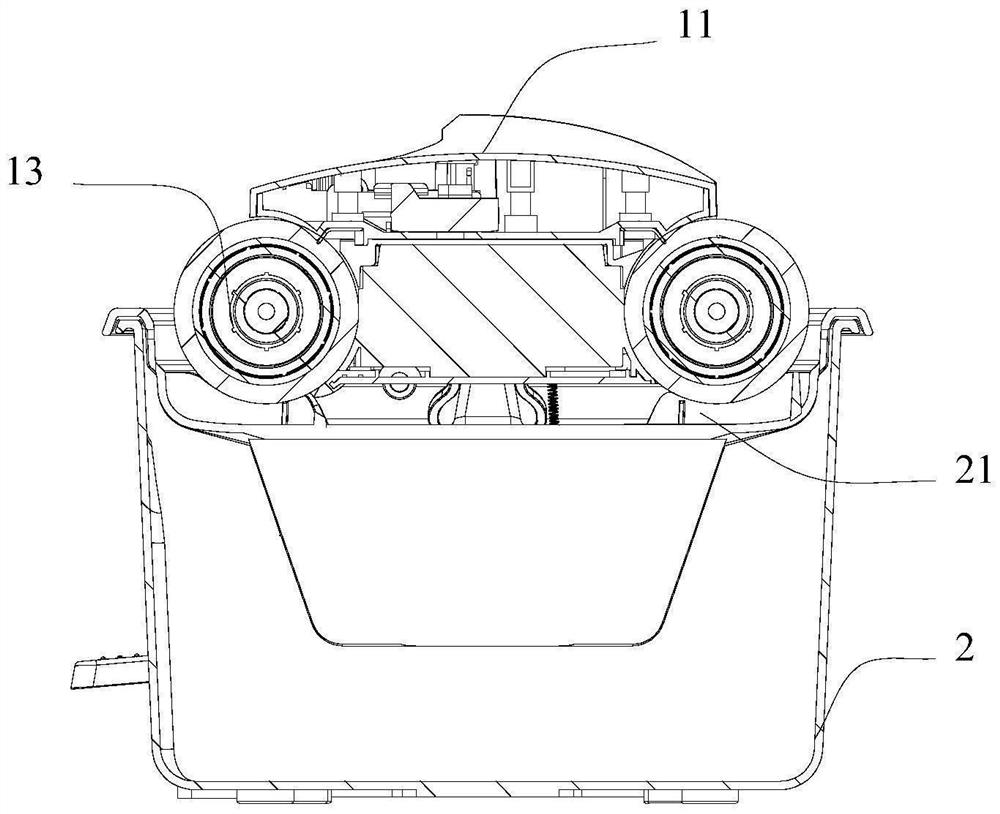

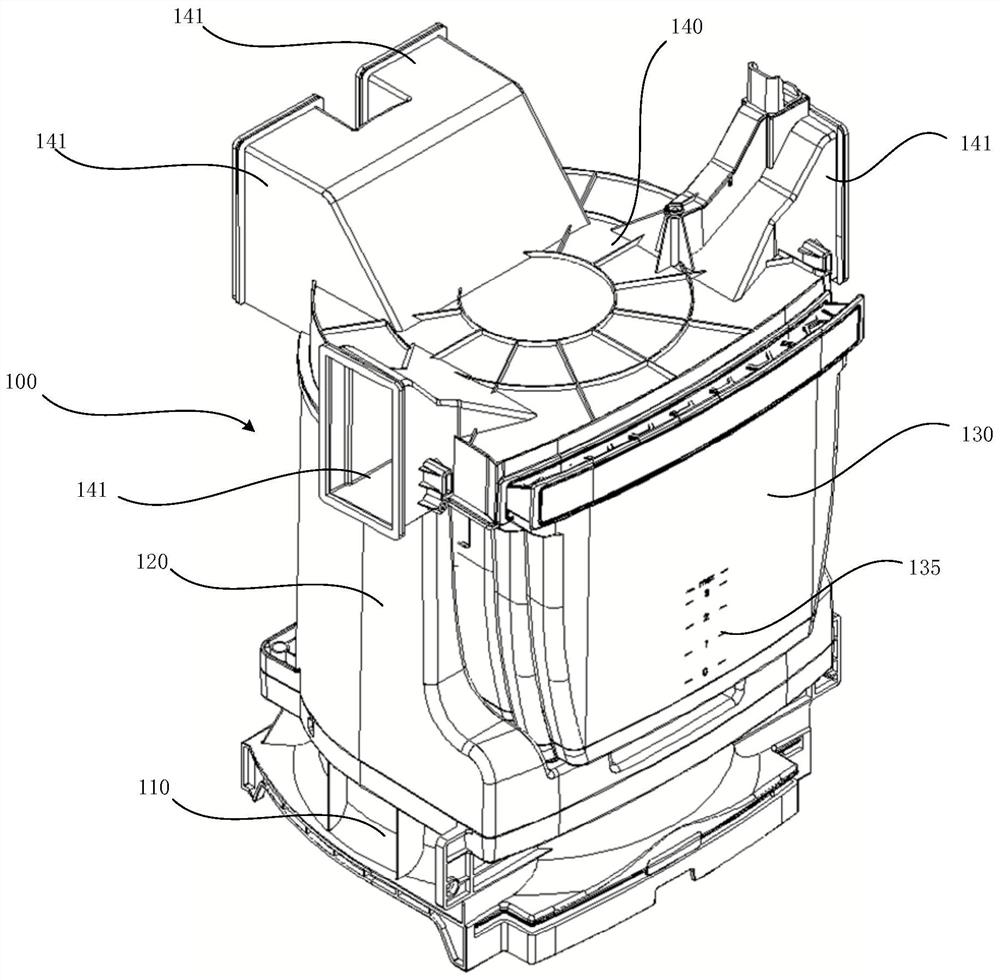

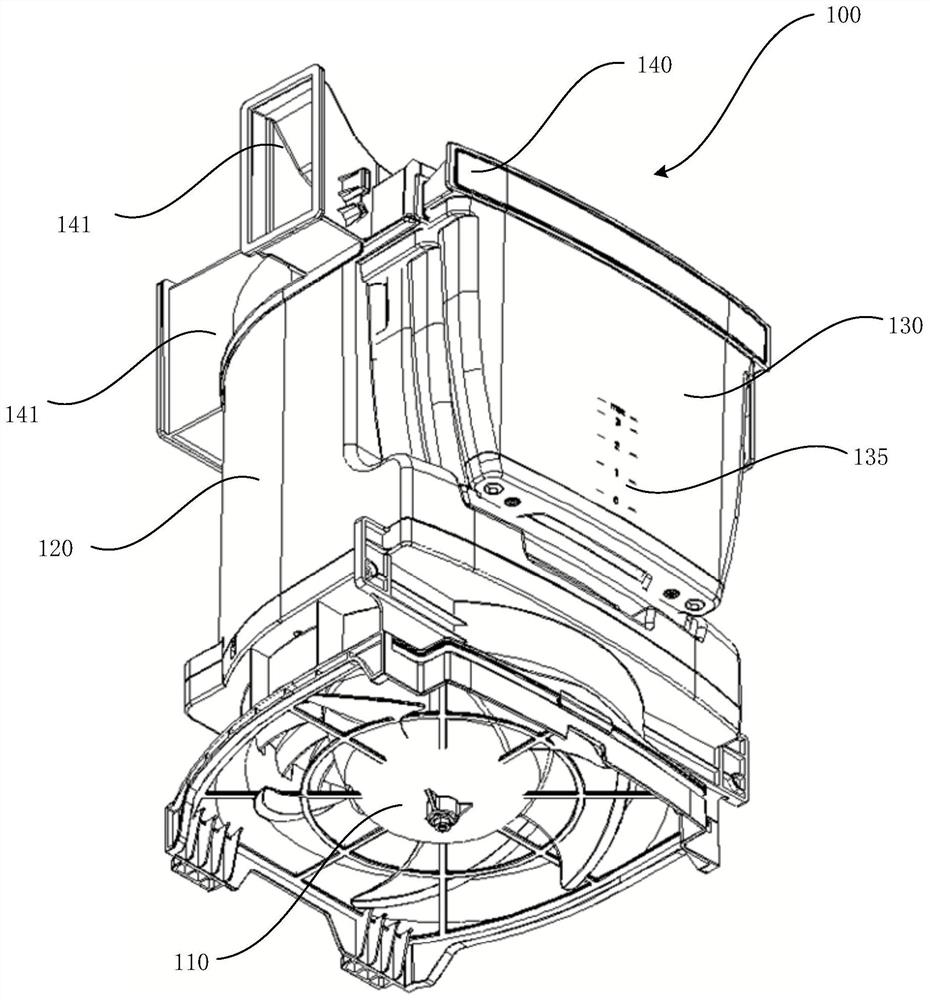

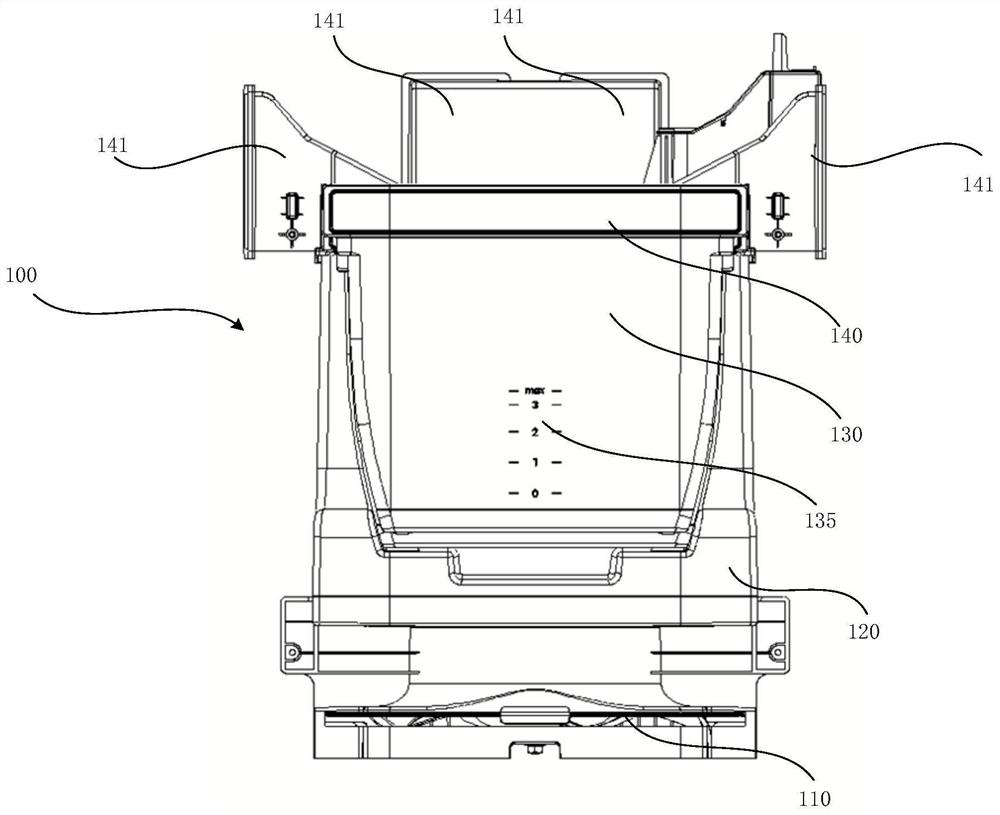

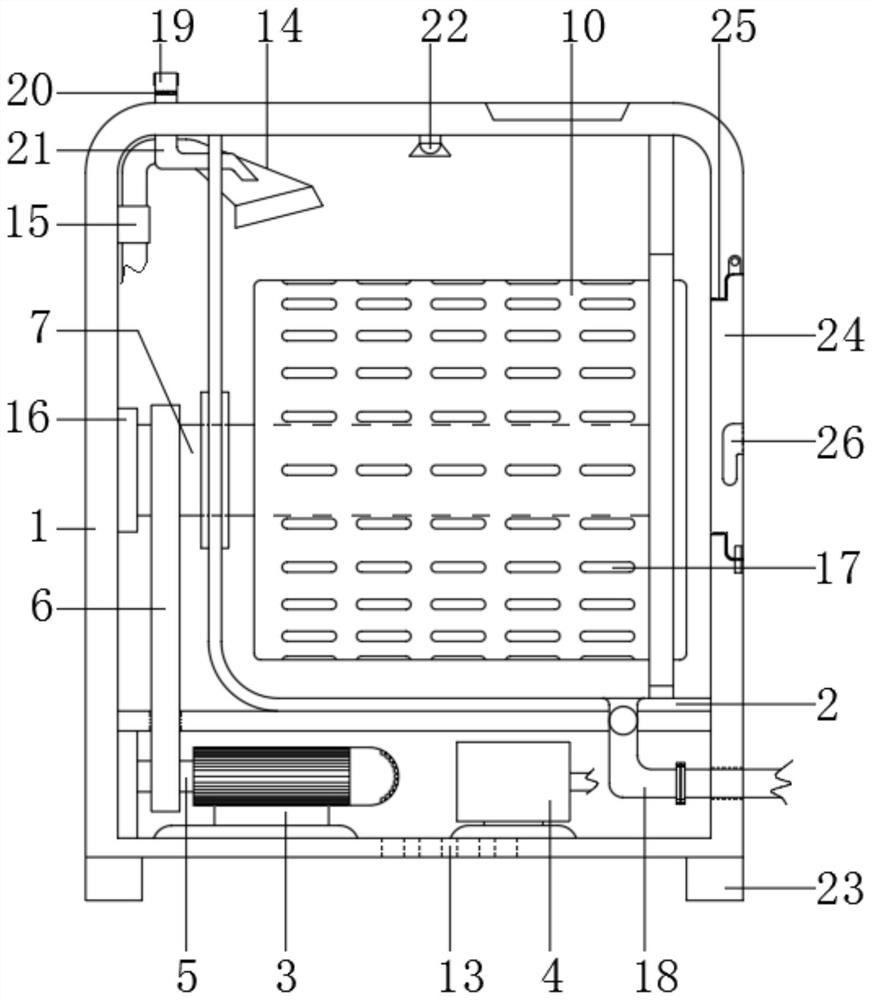

Air washing device, air conditioner indoor unit and air conditioner

PendingCN113639331AIncrease humidityGuaranteed washing effectLighting and heating apparatusAir conditioning systemsMicroorganismEnvironmental engineering

The invention provides an air washing device, an air conditioner indoor unit and an air conditioner. The air washing device comprises a fan, a base, a water tank and a top cover, wherein the water tank is arranged on the base, the fan is arranged below the bottom wall, the top cover is arranged above the water tank, an air inlet is formed in the fan, an air channel connected with the water tank is arranged in the base, air enters from the air inlet, passes through an air channel and then reaches the water tank, a water throwing part is arranged in the water tank, and the top cover communicates with the water tank and is provided with an air outlet; and a water-retaining humidifying net is arranged in the water tank, a gap is formed between the water-retaining humidifying net and the air inlet of the water tank, and the height of the lower end of the water-retaining humidifying net is less than or equal to that of the upper end of the water throwing part. According to the air washing device, air can be cleaned through a water curtain generated by the water throwing part, dust and microorganisms carried in the air are removed, the problem of indoor air drying can further be solved, and the quality of the indoor air is effectively improved; and on the premise that the air washing efficiency is guaranteed, water is not easily thrown out of the air inlet of the water tank.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

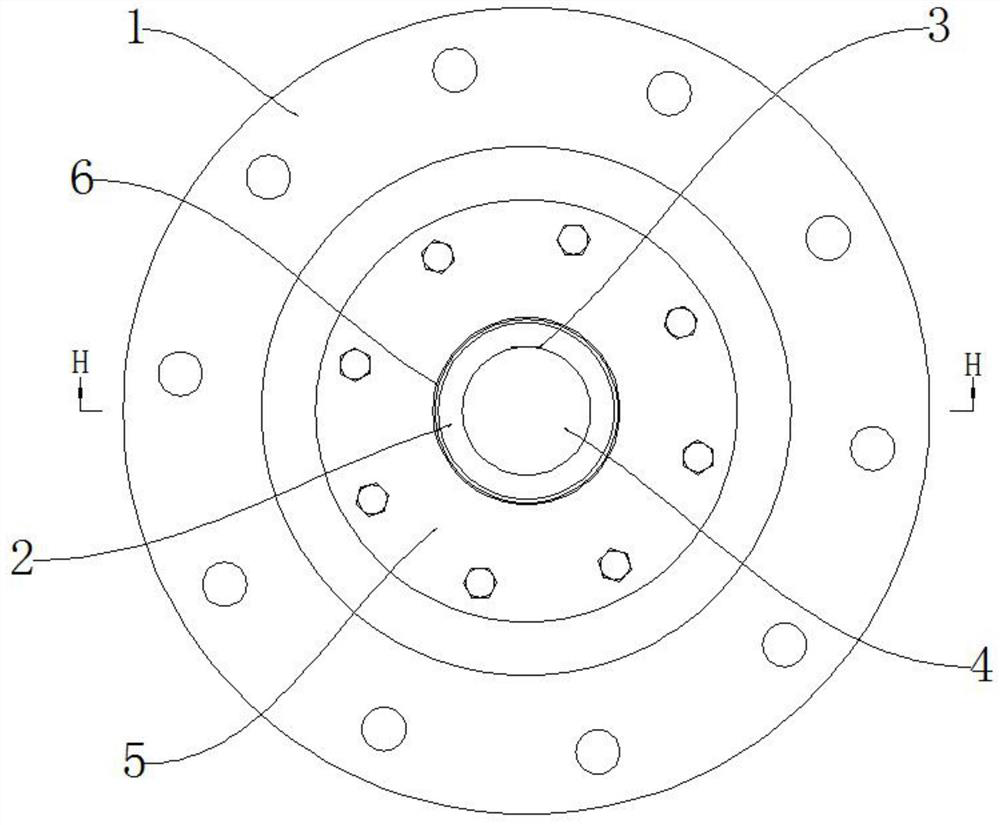

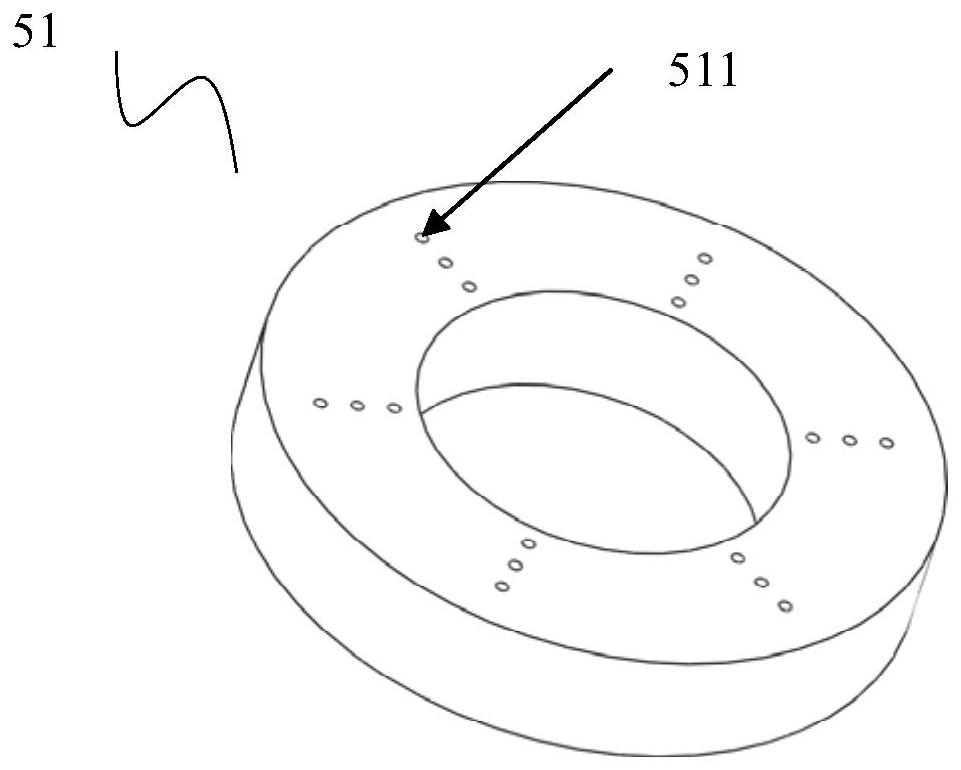

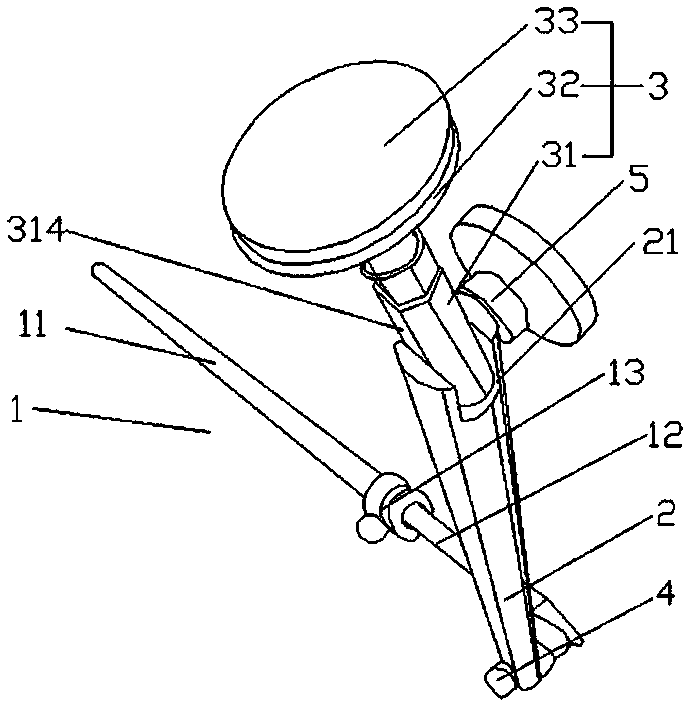

Clamp for grinding of external spherical surface of spherical surface washer

InactiveCN105081923AEasy to fixNot easy to throw outSpherical surface grinding machinesGrinding work supportsEngineeringScrew thread

The invention discloses a clamp for grinding of the external spherical surface of a spherical surface washer. The clamp comprises a flange plate and a chuck which are fixedly connected, the chuck is provided with a spherical cambered surface, and a plurality of positioning pins are arranged on the spherical cambered surface. The clamp is characterized in that left and right clamping blocks are arranged on the two sides of a positioning pin; a left cavity corresponding to the left clamping block and a right cavity corresponding to the right clamping block are formed in the spherical cambered surface of the chuck; the left clamping block is movably arranged in the left cavity, and the right clamping block is movably arranged in the right cavity; the head portions of the left and right clamping blocks are higher than the spherical cambered surface of the chuck; the outer end face of the chuck is fixedly connected with a flange cover; an adjusting screw is arranged on the outer end face of the flange cover in a rotating manner; a through hole is formed in the portion, between the left cavity and the right cavity, of the chuck, and the adjusting screw movably penetrates the through hole; and the adjusting screw is provided with a left-hand thread connected with the left clamping block and a right-hand thread connected with the right clamping block. By means of the clamp, the spherical surface washer can be quickly clamped and reliably fixed, grinding equipment can conduct finish machining on the spherical surface washer conveniently, and the working efficiency is improved.

Owner:RUIAN VEHICLE FITTING FACTORY

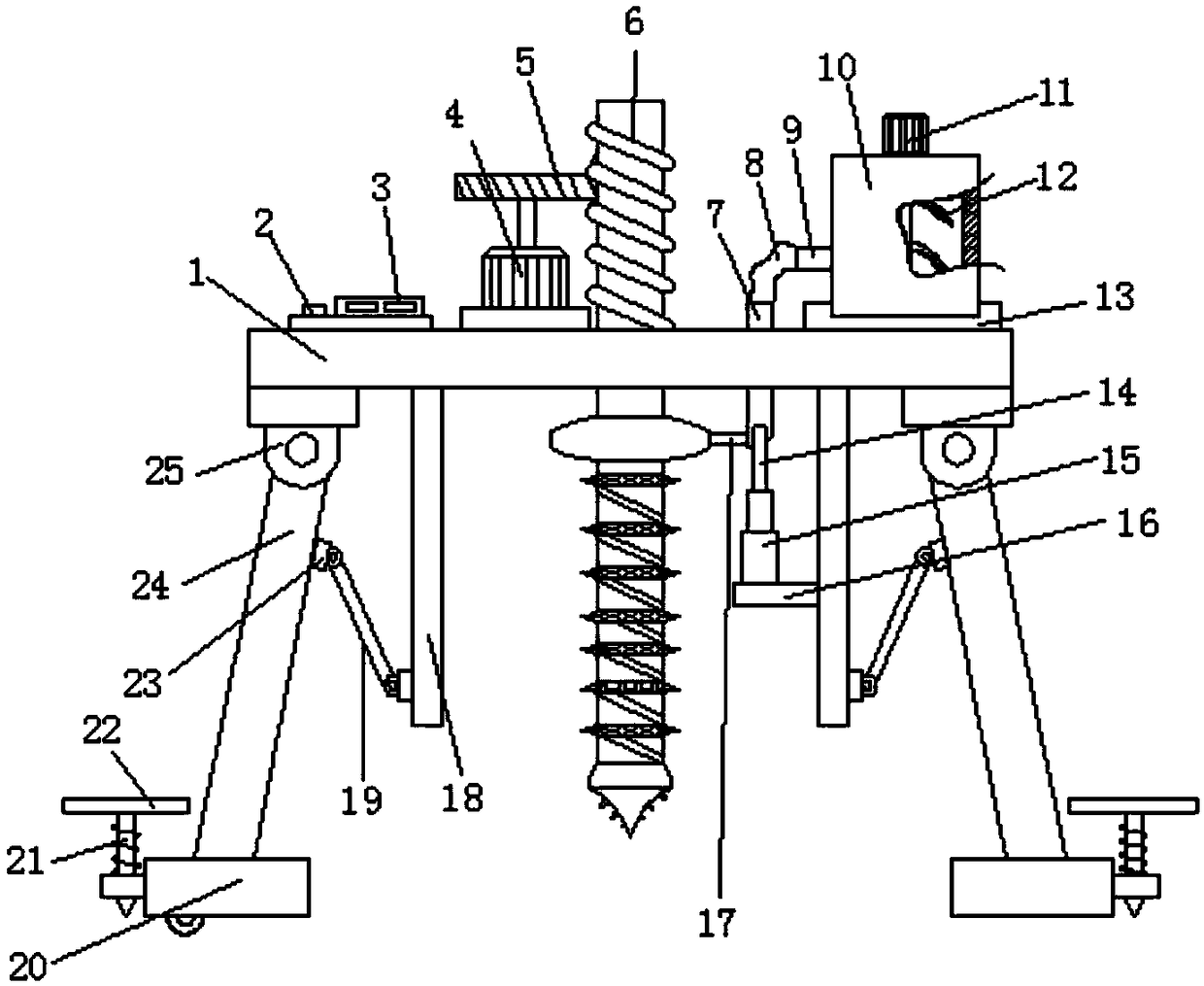

Deep-layer soil fertilizing device for directly promoting soil remediation

The invention discloses a deep-layer soil fertilizing device for directly promoting soil remediation. The device comprises a top plate and an inner-layer pipe; the outer wall of the top of the top plate is fixedly provided with a mounting plate through bolts, the outer wall of the top of the mounting plate is fixedly provided with a controller and a switch through bolts, the outer wall of the topof the top plate is fixedly provided with a first motor through bolts, a gear disc is welded to an output shaft of the first motor, a hollow threaded rod is in threaded connection with the center of the outer wall of the top of the top plate, the outer wall of one side of the threaded rod is provided with a thread, and the specifications of the thread are matched with those of the gear disc. According to the device, the pressure of a drill bit on soil per unit area is increased through a conical arc-surface structure, staggered teeth of different specifications can crush the soil at differentlevel heights around the drill bit, at the same rotation speed, the rotation speed of the inner-layer pipe gets slow, so that the inner-layer pipe and a threaded pipe are misaligned, through holes areexposed, and fertilizer liquid can be splashed out through the through holes in the rotation process.

Owner:张锐

Rotary drum type medical instrument cleaning device

InactiveCN113020091AImprove cooling effectReduce energy lossNon-rotating vibration suppressionDrying gas arrangementsPhysicsElectric machinery

The invention discloses a drum type medical instrument cleaning device. The device comprises a shell, wherein a partition plate is welded to the lower portion of the inner wall of the shell, a motor and a warm air pump are fixedly arranged at the bottom of the shell, a rotating shaft is rotatably arranged on the front end face of the motor, a belt is rotatably arranged on the outer surface of the rotating shaft, a driven shaft is rotatably arranged on the inner side face of the belt, and a rotary drum body is fixedly arranged on the outer surface of the driven shaft. According to the medical instrument cleaning device, medical instruments can be prevented from being thrown out from an opening of a cleaning cavity in the cleaning process, the situation that a user difficultly takes out the cleaned medical instruments is avoided, part of heat generated by the motor can be used for drying the medical instruments, the heat dissipation effect is improved, and meanwhile part of energy loss can be reduced; and When water splashes into an air pipe during cleaning of the medical instruments, the water cannot flow into the warm air pump, the warm air pump is prevented from being damaged, the bottom of the shell is higher than the ground by a certain distance, and the situation that heat dissipation of the motor and air suction of the warm air pump are affected due to the fact that ventilation holes are blocked by the ground is avoided.

Owner:ZHENGZHOU UNIV

A measuring device and measuring method for the bulging degree of a square lithium-ion battery

ActiveCN112556555BObjective science of measurement methodsEasy to measureMechanical solid deformation measurementsCircular discElectric machine

Owner:深圳市德罗伏特科技有限公司

Bimetal thrust sliding bearing blank preparation method and used tooling

The invention discloses a method for preparing a blank of a bimetallic thrust sliding bearing and the tooling used. The method includes the following steps: the first step, mixing alloy materials and auxiliary materials: uniformly mixing copper alloy particles, copper gas flux, and charcoal particles; The second step is to put the mixed alloy material and auxiliary materials into the mold, and press the two clamping flange devices on the two ends of the mold respectively through the external force application device; the third step is to place the induction heating device on the outer periphery of the mold , then rotate the mold, adjust the centrifugal speed and the heating power of the induction heating device, and melt the alloy particle mixture; the fourth step, remove the induction heating device, and place the bimetallic blank prepared in the third step in a mobile cooling device, First use the lower water spray device to cool for a certain period of time, and then turn on the upper water spray device to work together to cool the bimetallic blank to room temperature. Tooling consists of moulds, clamping flange units and mobile cooling units. The invention has reasonable process and can reduce the defects of bimetallic blanks.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

A Golden Retriever Dog Ridge Hair Removal and Reuse Equipment

ActiveCN107468723BHigh economic valueEasy to reprocessPteridophyta/filicophyta medical ingredientsBlood disorderWater storageEnvironmental engineering

The invention discloses cibotium barometz hair removing and recycling equipment and belongs to the field of cibotium barometz hair removing and recycling equipment. The cibotium barometz hair removing and recycling equipment comprises a water storage barrel, wherein the upper end of the water storage barrel is symmetrically connected with a pair of extension rods; the extension rods are fixedly connected with a control box; one side of the lower end of the water storage barrel is connected with a water inlet pipe; the other side of the lower end of the water storage barrel is connected with a drain pipe; a first sliding chute is formed in the inner side wall of the water storage barrel; a second sliding chute is formed in each of the extension rods; the first sliding chute is communicated with the second sliding chute; electric sliding tables are mounted in the first sliding chute and the second sliding chute; an upper sliding block and a lower sliding block are connected to the electric sliding tables respectively; the upper sliding block is positioned above the lower sliding block. According to the equipment, the hair removal rate can reach 95% or more; the removed fine hair can be recycled; the recycled fine hair does not contain fine sand and is easily processed into a hemostatic drug, thereby increasing the economic value of cibotium barometz.

Owner:宋春叶 +1

A flexible coupling of a wind power generating set and its assembly or replacement method

ActiveCN106050959BAvoid leasingShorten maintenance timeClutchesYielding couplingCouplingDynamic balance

The invention discloses a flexible coupling of a wind generator set and an assembling or replacing method of the flexible coupling. The assembling or replacing method is characterized by comprising the following steps: designing and manufacturing parts by unit, assembling the parts to form five unit components, namely a brake disc component, a left flexible connecting sheet component, a middle connector component, a right flexible connecting sheet component and a generator side coupling component; carrying out dynamic balance tests and adjustments of the unit components separately so that the unit components have symmetric structures and dynamically balanced configuration; assembling the unit components to form the flexible coupling; and carrying out a dynamic balance test and an adjustment of the whole flexible coupling so that the whole flexible coupling has dynamically balanced configuration. According to the invention, the parts of the flexible coupling, which are designed and manufactured by unit, can be reliably assembled and conveniently and separately disassembled and replaced, so that the problem of inconvenience caused by breakdown maintenance of the conventional flexible coupling is effectively solved, the maintenance time is greatly shortened, a great amount of maintenance cost is saved, and the flexible coupling has high practicability.

Owner:绵阳国顺电气有限公司

Mold for preparing blank of bimetallic thrust sliding bearing and its preparation method

ActiveCN104043802BGuaranteed performanceSolve the situation that is prone to crack defectsPlain bearingAsbestos

The invention discloses a mould for manufacturing a bimetal plain thrust sliding bearing blank and a manufacturing method of the mould. The mould comprises a steel billet and asbestos plates. The steel billet is provided with an inner hole and an annular groove, the annular groove is formed in the hole wall of the inner hole, the inner hole is communicated with the annular groove, the two ends of the steel billet are provided with the corresponding asbestos plates in an adherence mode through high-temperature-resisting binding agents, central holes are formed in the asbestos plates, and the central holes of the asbestos plates are communicated with the inner hole of the steel billet. The mould is simple in structure and can solve the problem that alloy layers at the two ends of the bimetal plain thrust sliding bearing blank are prone to being cracked. The manufacturing method of the mould is further disclosed.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

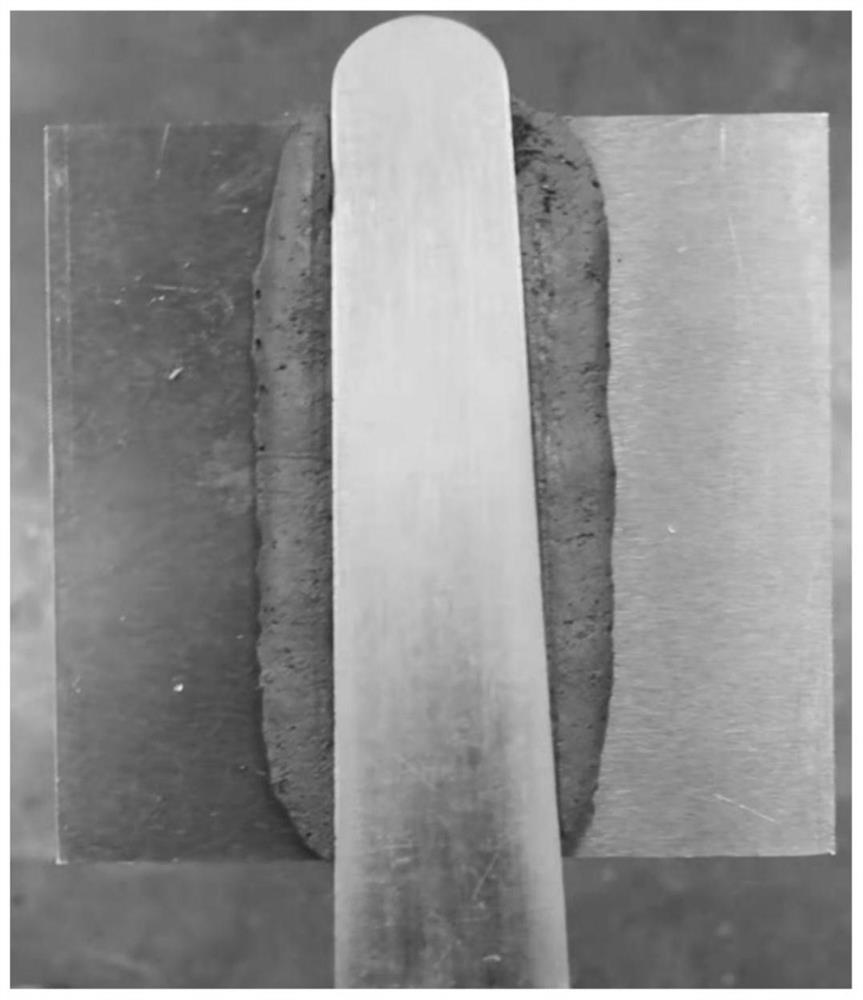

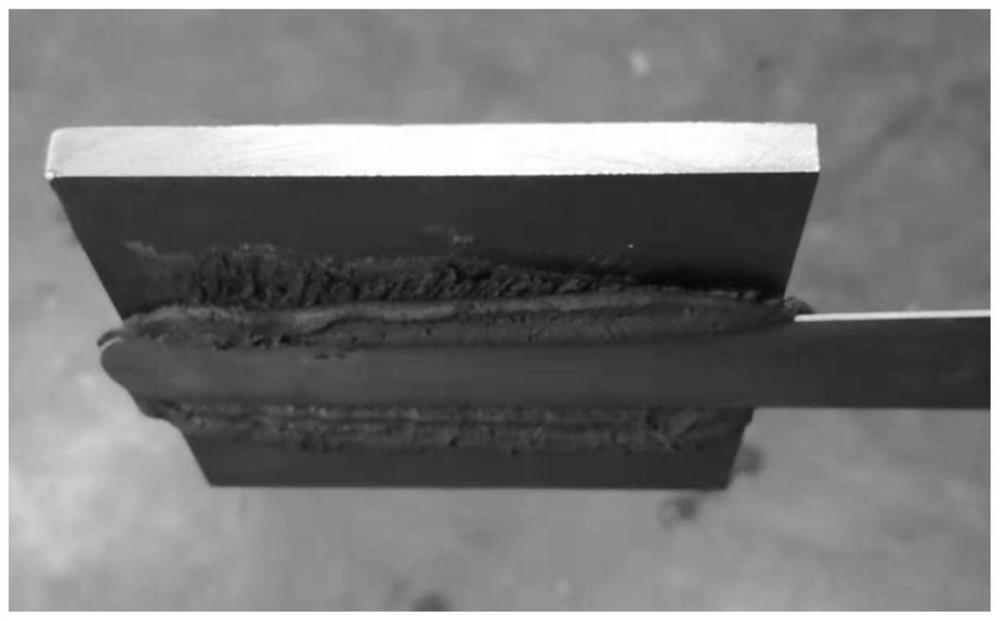

Tubular pile joint closing and grout stopping slurry as well as preparation method and application thereof

ActiveCN112759310ANot easy to throw outOvercome the impact of the work environmentSolid waste managementCentrifugationWorking environment

The invention discloses tubular pile joint closing and grout stopping slurry as well as a preparation method and application thereof, and belongs to the technical field of tubular piles. The tubular pile joint closing and grout stopping slurry has little elasticity, can only fill gaps after being clamped by a mold, cannot cause mold deformation caused by the fact that the gaps are jacked up, and is good in deformation resistance; and the slurry has certain viscosity, so that the slurry is not easily thrown out of gaps during centrifugation, and a good slurry stopping effect is achieved. And meanwhile, too large viscosity cannot be generated on the mold, and the slurry can form blocks after being evaporated to dryness, so that the slurry can be smoothly removed during demolding and cleaning, and the defects that the working environment is influenced due to flying dust generated when the powdery slurry is removed are overcome.

Owner:GUANGDONG SANHE PILE CO LTD

Juicer transmission shaft sleeve and manufacturing method thereof

PendingCN108338647AThe processing technology is simpleIncrease productivityStrainersPowder metallurgyOil storage

The invention relates to the technical field of powder metallurgy equipment and particularly relates to a juicer transmission shaft sleeve and a manufacturing method thereof. The juicer transmission shaft sleeve comprises a body, wherein a through hole is formed in the body; the through hole extends from an upper surface to a lower surface in an axial direction of the body; an oil storage tank isarranged on an inner peripheral wall of the through hole; the cross sectional area of the oil storage tank is gradually reduced from the interior to exterior in the axial direction of the body. Duringuse of the juicer transmission shaft sleeve and the manufacturing method thereof disclosed by the invention, the oil storage tank is arranged on the inner peripheral wall of the through hole, and thecross sectional area of the oil storage tank is gradually reduced from the interior to exterior in the axial direction of the body, and a closing opening is formed in one end of the oil storage tank.Due to the closing opening, oil in the through hole is difficultly thrown out, the processing technology is simple and convenient, and the production efficiency of the juicer transmission shaft sleeve is improved.

Owner:常州汇丰粉末冶金有限公司

Cleaning device capable of drying the body of a car

ActiveCN105966368BGuaranteed performanceFunction increaseCleaning apparatus for vehicle exteriorsEngineeringUltimate tensile strength

Provided is a cleaning device capable of thoroughly wiping an automobile body. The cleaning device comprises a brush and a rotating shaft capable of fixing the brush. The rotating shaft is connected with a drive mechanism. The cleaning device is characterized in that the brush comprises a flexible base and a wiping part which are capable of being twisted and bent; the wiping part is arranged on the flexible base, and the flexible base is detachably arranged on the peripheral face of the rotating shaft in a sleeving mode; and a fixing through hole is formed in the flexible base, a fixing part is arranged in the position, corresponding to the fixing through hole, of the rotating shaft, and when the peripheral face of the rotating shaft is sleeved with the flexible base, the fixing through hole and the fixing part are buckled. The cleaning device has the advantages that the flexible base and the wiping part can be twisted and bent, the cleaning device is soft in structure, suitable for being washed with a machine and quite convenient to assemble and disassemble, the actual requirement that the automobile cleaning device needs to be cleaned and maintained frequently is met, the labor intensity is relieved, and the working efficiency is improved; and besides, the flexible base can be assembled and disassembled with hands instead of using various tools, so that the maintenance cost is reduced, and using is more convenient.

Owner:绍兴市中令汽车服务有限公司

Brushless excitation synchronous generator

InactiveCN101494408BEasy to fixReasonable wiringSynchronous generatorsStructural associationEngineeringDynamo

The invention relates to a generator, in particular to a brushless excitation synchronous generator, which solves the problems of unreasonable structures in the existing brushless excitation synchronous generators. The brushless excitation synchronous generator comprises a main generator and a rectifier device fixed on a rectifier wheel of same axis as a main generator rotor; the rectifier deviceis formed by connecting three rectifier modules and a voltage sensitive module fixed on the rectifier wheel through two conducting rings respectively connected with corresponding connection bolts on the rectifier modules and the voltage sensitive module; two direct current leading-out wires are fixed on the rectifier device; and both the rectifier modules and the voltage sensitive module are provided with pressing boards which are covered by a pressing cover fixed on the rectifier wheel. Achieving the target of ensuring the rectifier modules and the two direct current leading-out wires not tobe thrown away easily during the working of the brushless excitation synchronous generator, and the brushless excitation synchronous generator enables the two direct current leading-out wires to be fixed more stably and the wiring to be more reasonable, thus forming a convenient and practical protection device with reliable structure.

Owner:CRRC YONGJI ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com