Cleaning device capable of drying the body of a car

A technology for cleaning devices and car bodies, which is applied to vehicle exterior cleaning devices, etc. It can solve the problems of difficult rinsing and dehydration of brush cloth, time-consuming brush disassembly and assembly, and complicated processing technology, so as to achieve better drying effect and small equipment installation space , the effect of simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

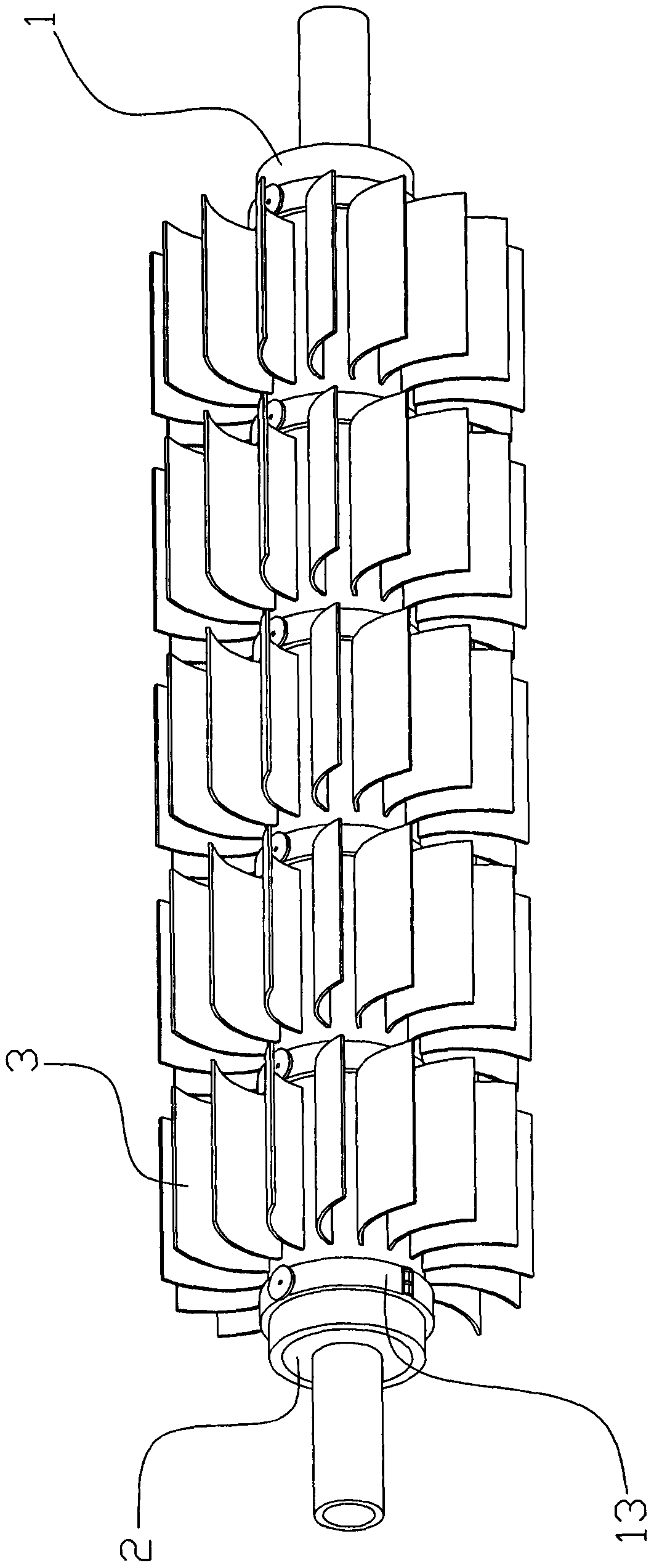

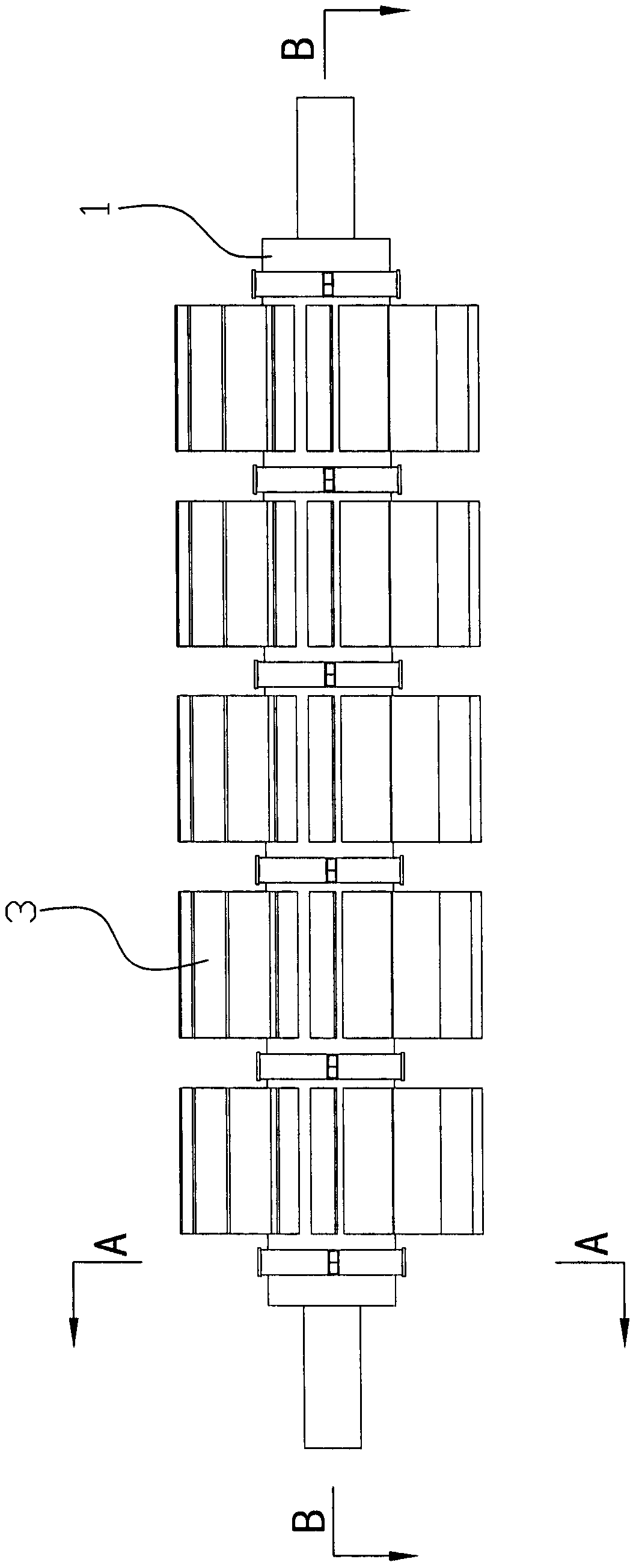

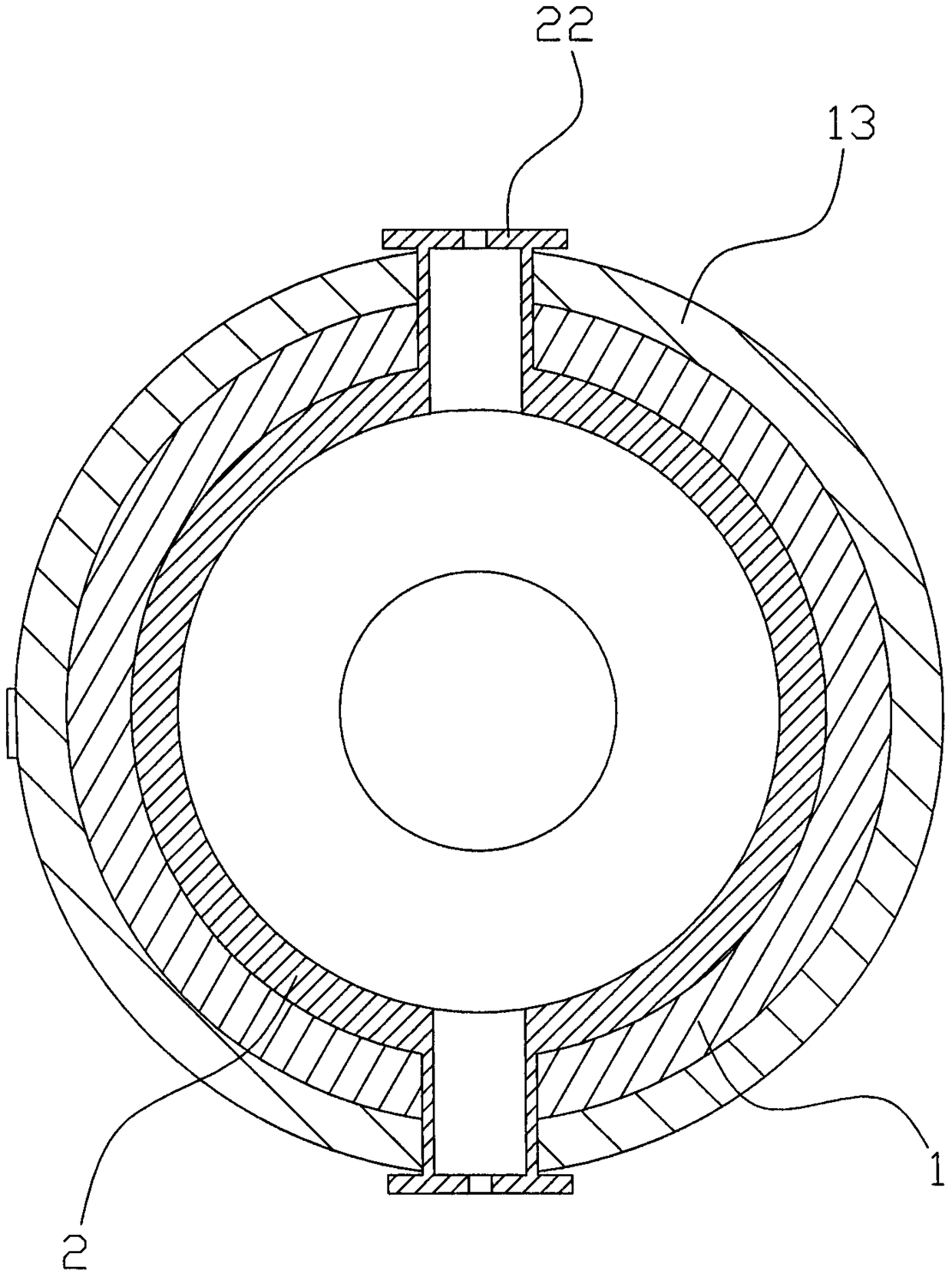

[0031] Such as Figure 1 to Figure 7 , Figure 13 As shown, the cleaning device capable of drying the automobile body of the present embodiment includes a brush body and a rotating shaft 2 capable of fixing the brush body. The rotating shaft 2 is connected with the drive mechanism 26, and the brush body includes a The flexible base 1 and the wiper part, the wiper part is arranged on the flexible base 1, and the flexible base 1 can be detachably sleeved on the outer peripheral surface of the rotating shaft 2, and the flexible base 1 A fixed through hole 11 is provided, and a fixed portion is provided at a position corresponding to the fixed through hole 11 on the rotating shaft 2. When the flexible base 1 is sleeved on the outer peripheral surface of the rotating shaft 2, the fixed through hole 11 and The fixed parts are fastened together. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com