Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Not affected by size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

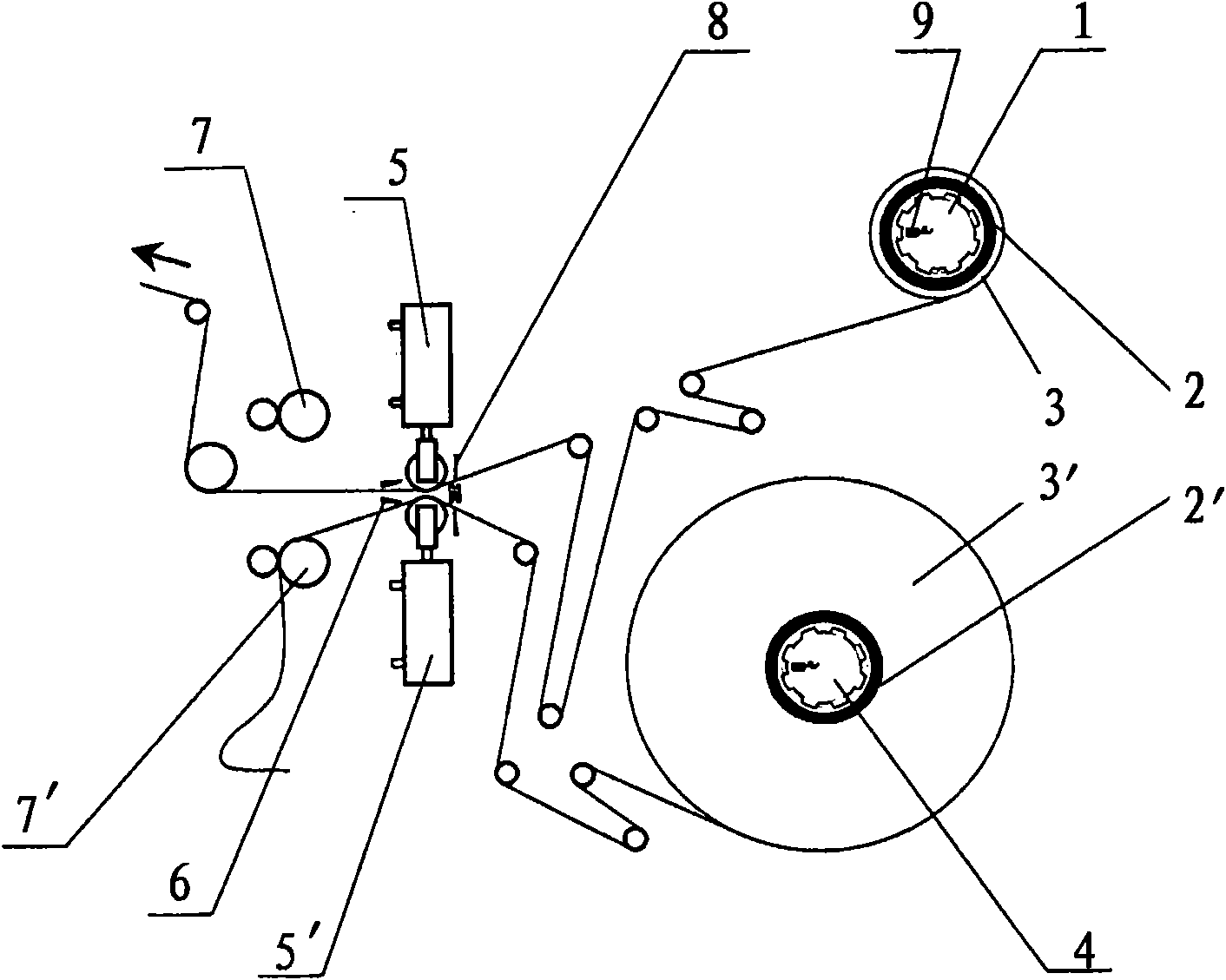

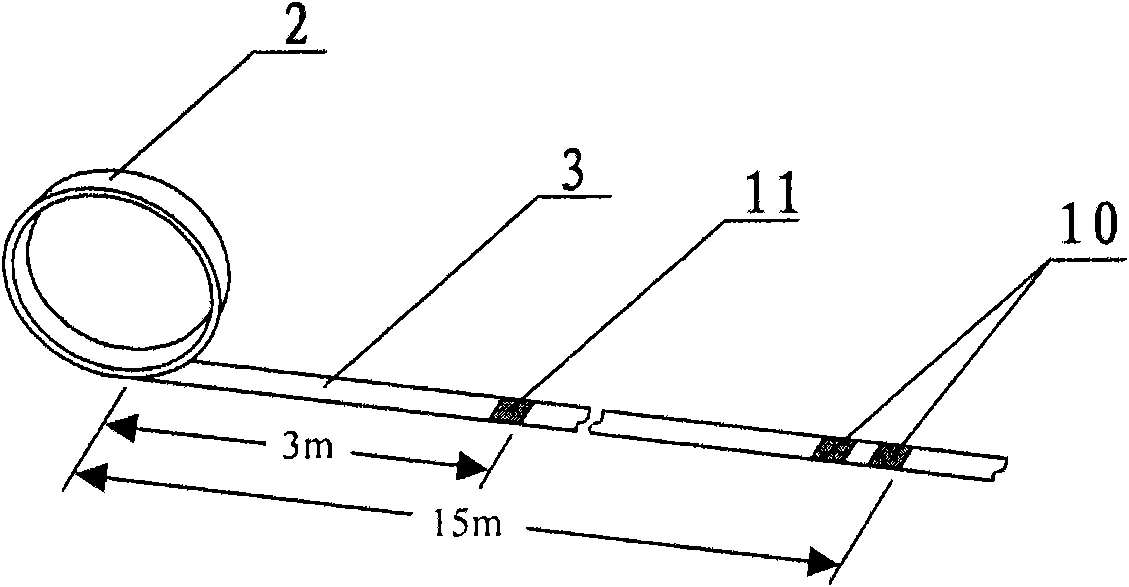

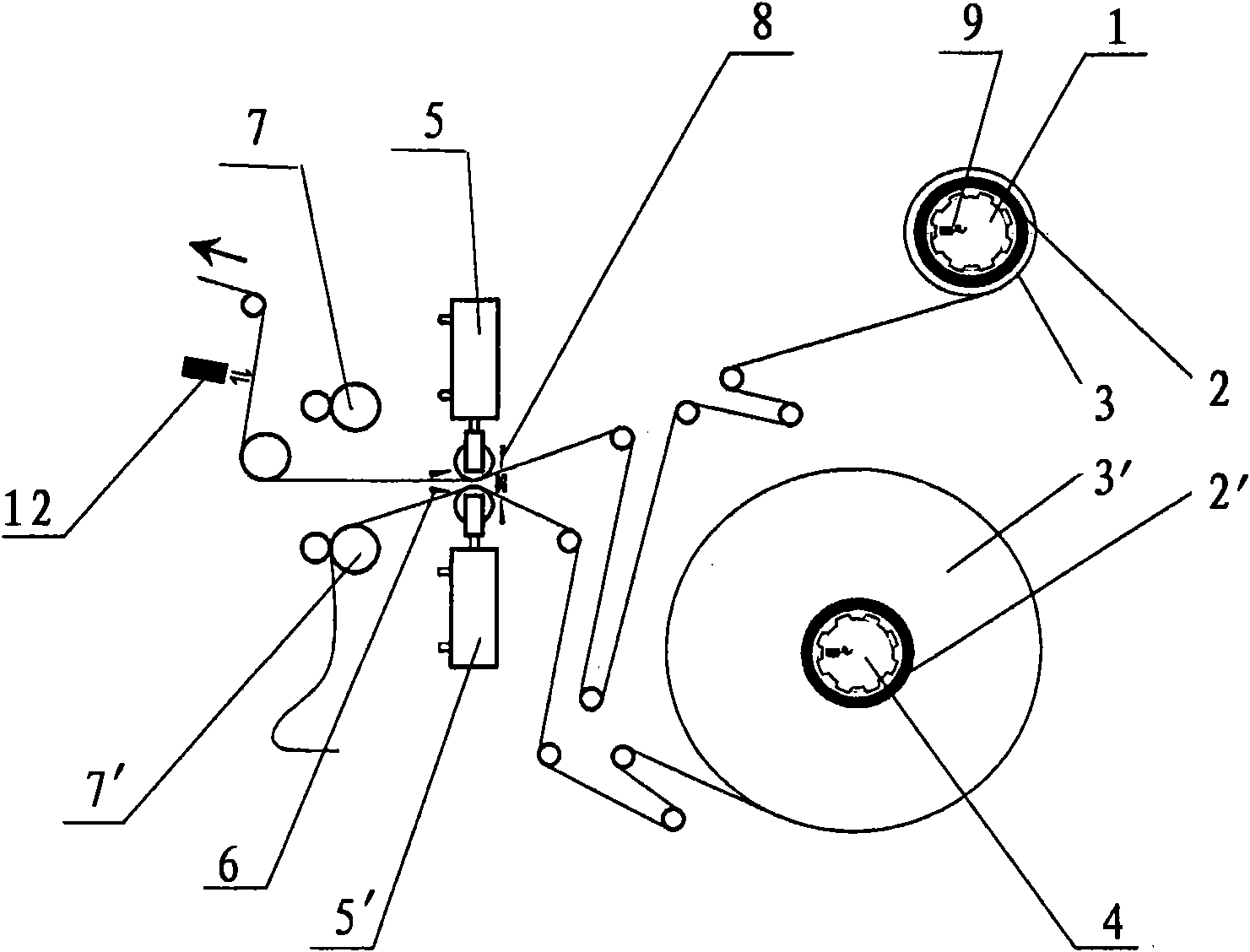

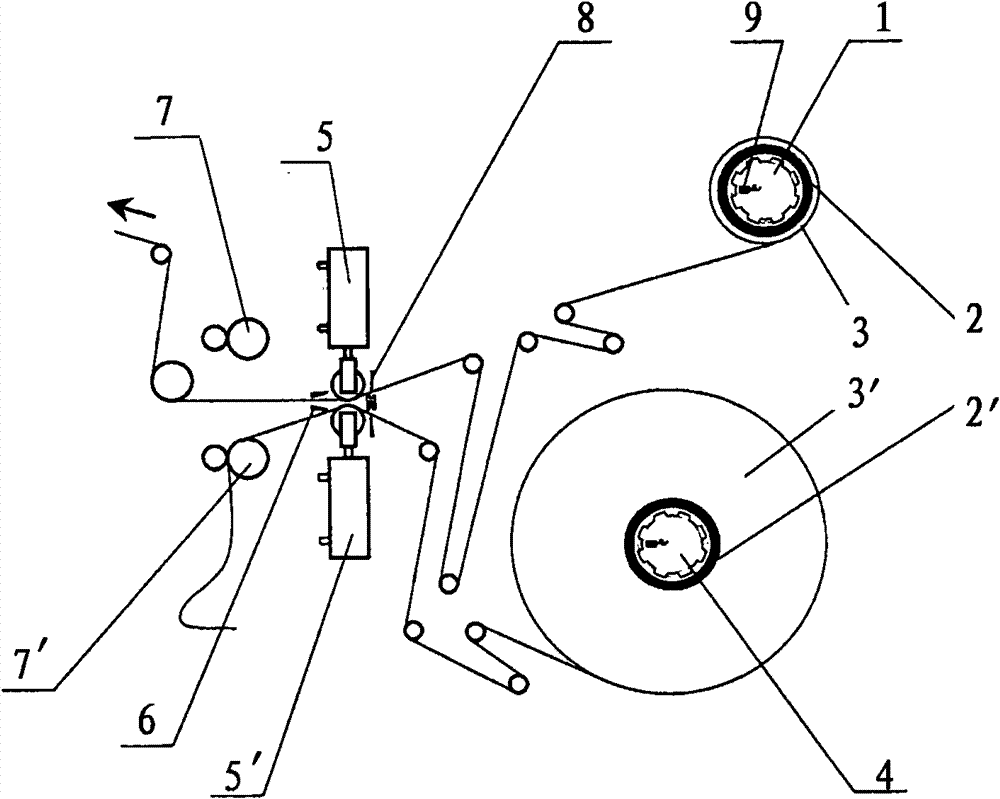

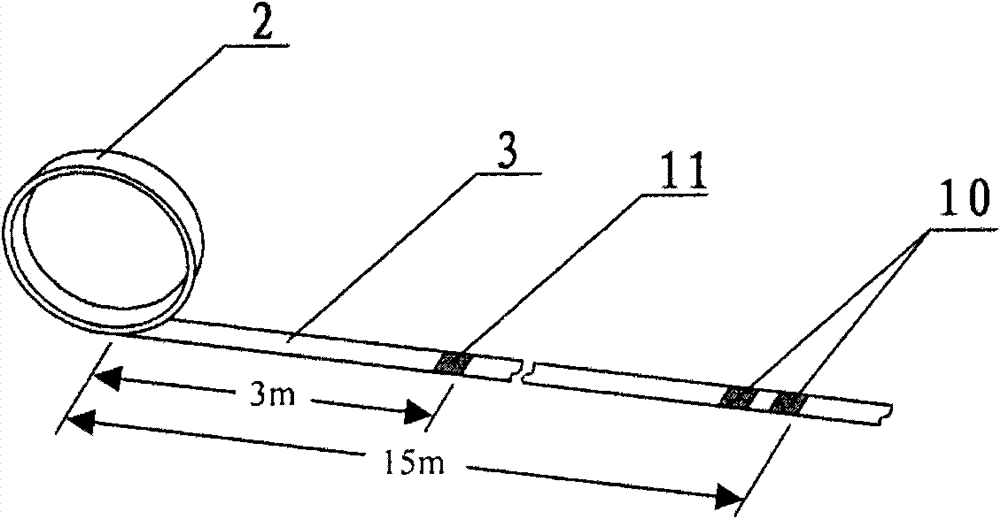

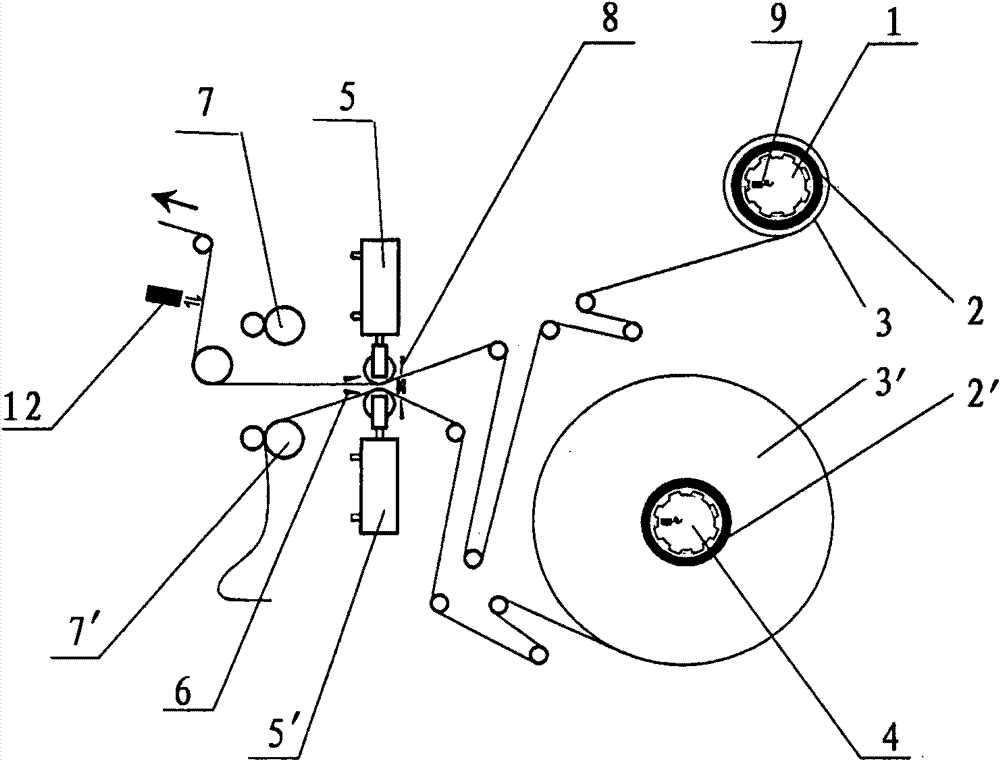

Method for splicing bobbin paper of cigarette making machine

ActiveCN102090713ASplicing is reliableSplicing leftover is smallCigarette manufactureWebs handlingBobbinAdhesive

The invention discloses a method for splicing bobbin paper of a cigarette making machine. The method comprises the following steps that: a controller operably connected with each air cylinder, a bobbin paper cutter and a bobbin paper drive roller is provided; the controller starts a second bobbin paper drive roller to transmit second bobbin paper till the transmitting speed of the second bobbin paper is the same as the transmitting speed of the first bobbin paper when a mark detector detects a first mark, wherein the mark detector is arranged on the downstream of a first air cylinder and a second air cylinder along a work bobbin paper adjacent path, and the first mark is arranged on the first bobbin paper and keeps a first distance with an inner ring of the first bobbin paper; the second air cylinder moves to jack the second bobbin paper wound around a tension roller of the second air cylinder outside to be propped against the first bobbin paper when the mark detector detects a second color block, and the second bobbin paper is adhered and lapped with the first bobbin paper wound around the tension roller of the first air cylinder through an adhesive, wherein the second mark is arranged on the first bobbin paper and keeps a second distance with the inner ring of the first bobbin paper, and the second distance is smaller than the first distance; and the controller drives a bobbin paper cutter arranged on the downstream side of the tension roller of the second air cylinder and a bobbin paper cutter arranged on the upstream side of the tension roller of the first air cylinder to respectively cut off the first bobbin paper and the second bobbin paper, thus the second bobbin paper as a spare bobbin paper is converted into working bobbin paper.

Owner:LONGYAN CIGARETTE FACTORY

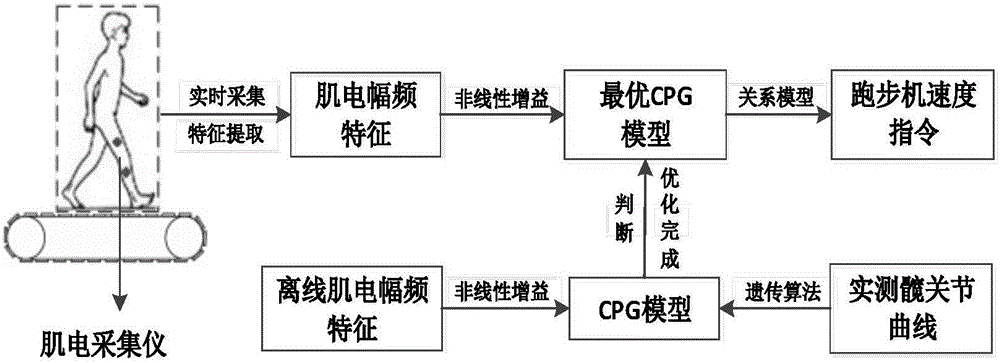

Human-body-exercising-running-machine self-adaption active control method based on CPG model

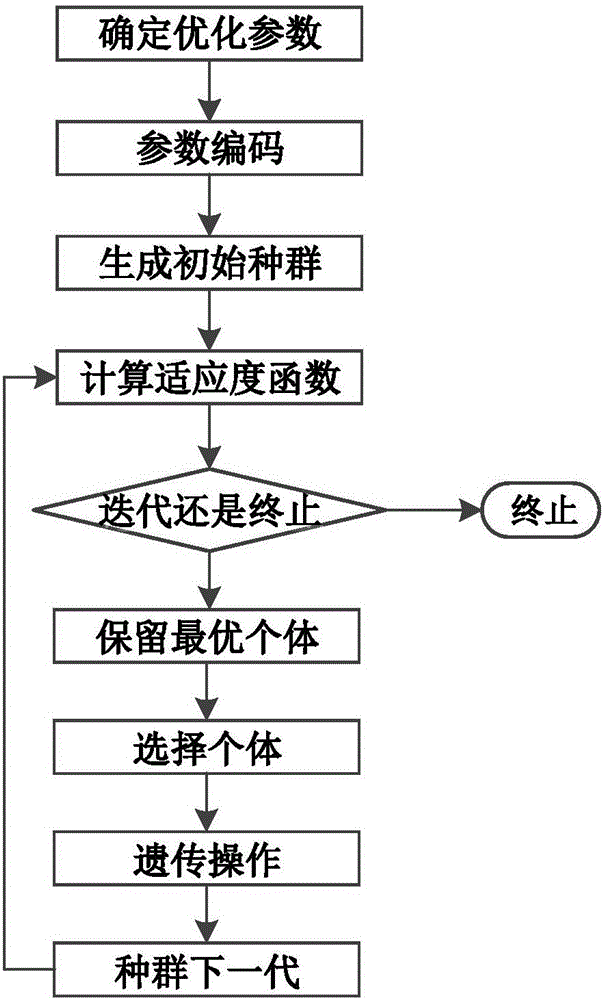

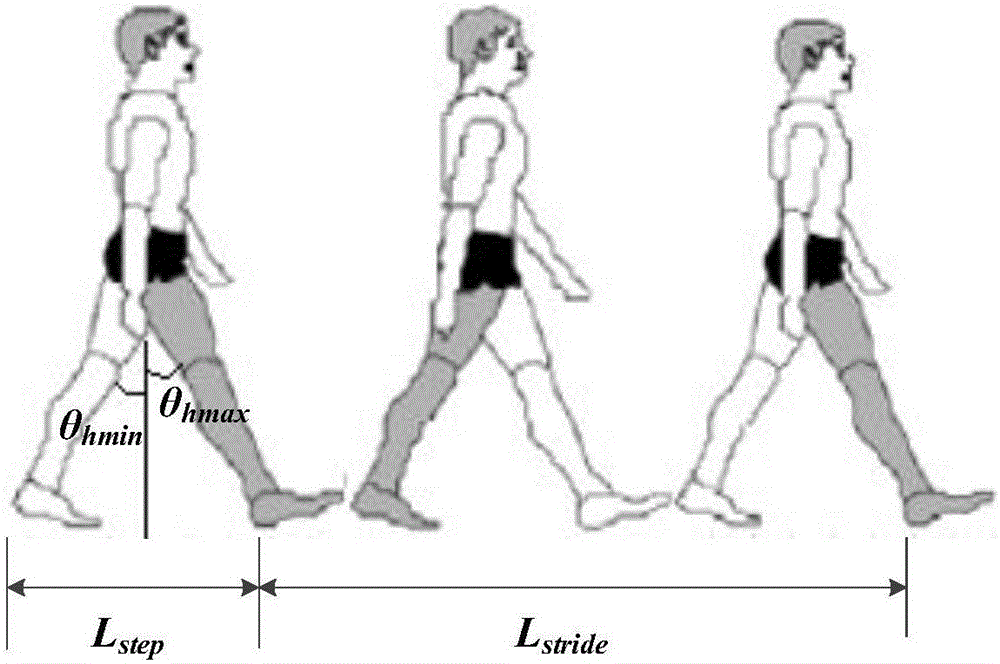

ActiveCN106730604AFast operationGood flexibility and promotionMovement coordination devicesCardiovascular exercising devicesSelf adaptiveGait cycle

The invention discloses a human-body-exercising-running-machine self-adaption active control method based on a CPG model. The human-body-exercising-running-machine self-adaption active control method includes the steps that surface electromyographic signals of the lower limb rectus femoris and biceps femoris muscles in a gait cycle are collected in real time through an electromyographic collecting apparatus when the human body moves on a running machine, and the amplitude characteristics and the frequency characteristics are extracted; the amplitude characteristics and the frequency characteristics serve as the parameters to be substituted into the CPG model optimized by the genetic algorithm, and a periodicity-human-body-lower-limb hip joint angle curve is fitted; according to the periodicity-human-body-lower-limb hip joint angle curve, the angle extreme value and the frequency are obtained and substituted into a relationship model to obtain a speed control command of the running machine, the speed control command of the running machine is sent to a driving module though a computer, and self-adaption active control of the running machine is achieved. According to the human-body-exercising-running-machine self-adaption active control method based on the CPG model, the amplitude-frequency characteristics of the human-body lower-limb sEMG are extracted to serve as the parameters of the CPG model, the expected periodicity hip-joint gait curve is obtained, the angle extreme value and the frequency are extracted, a speed command of the running machine is obtained through the relationship model, and self-machine self-adaption active control, and self-adaption active control of the running machine is achieved.

Owner:XI AN JIAOTONG UNIV

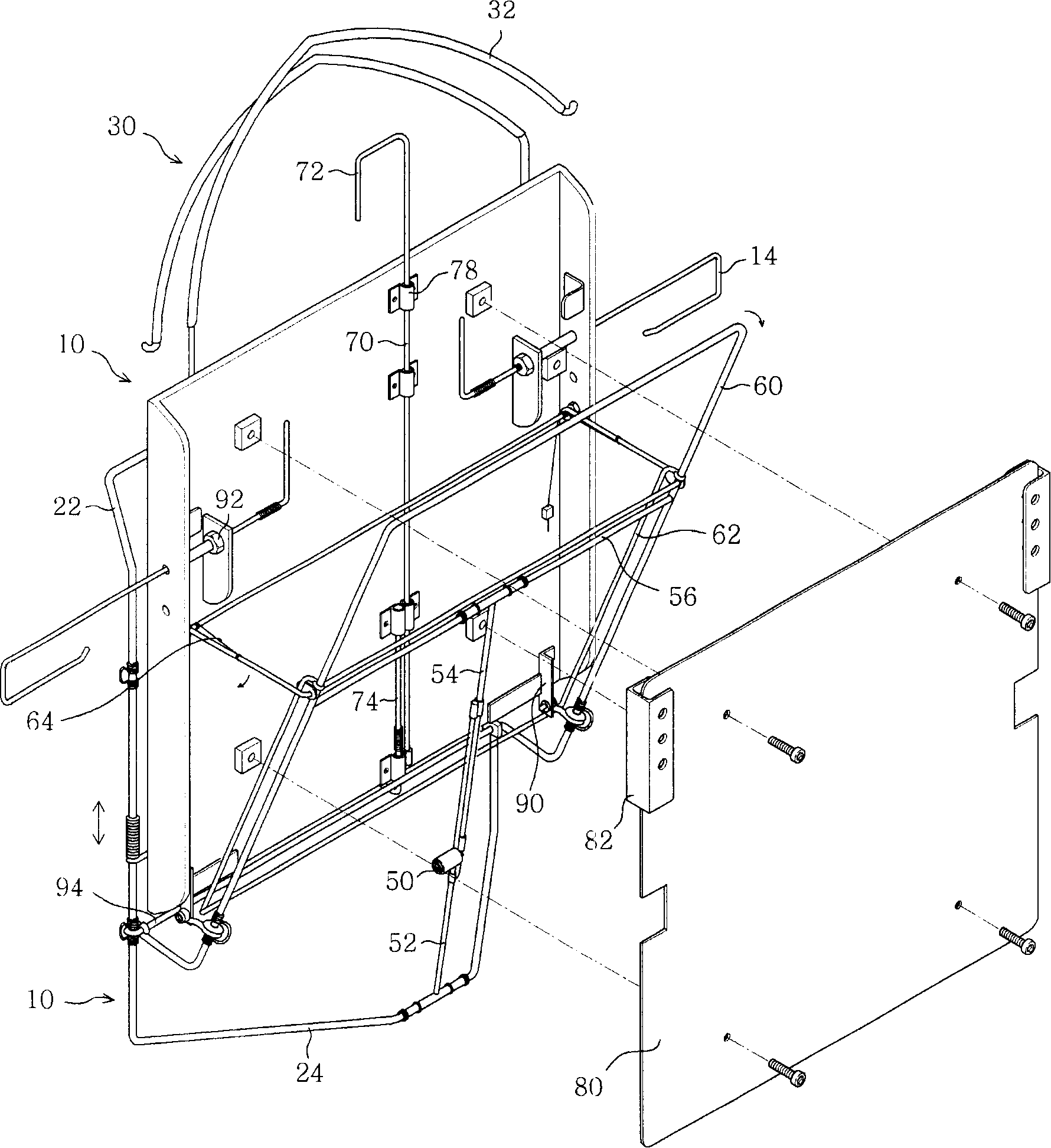

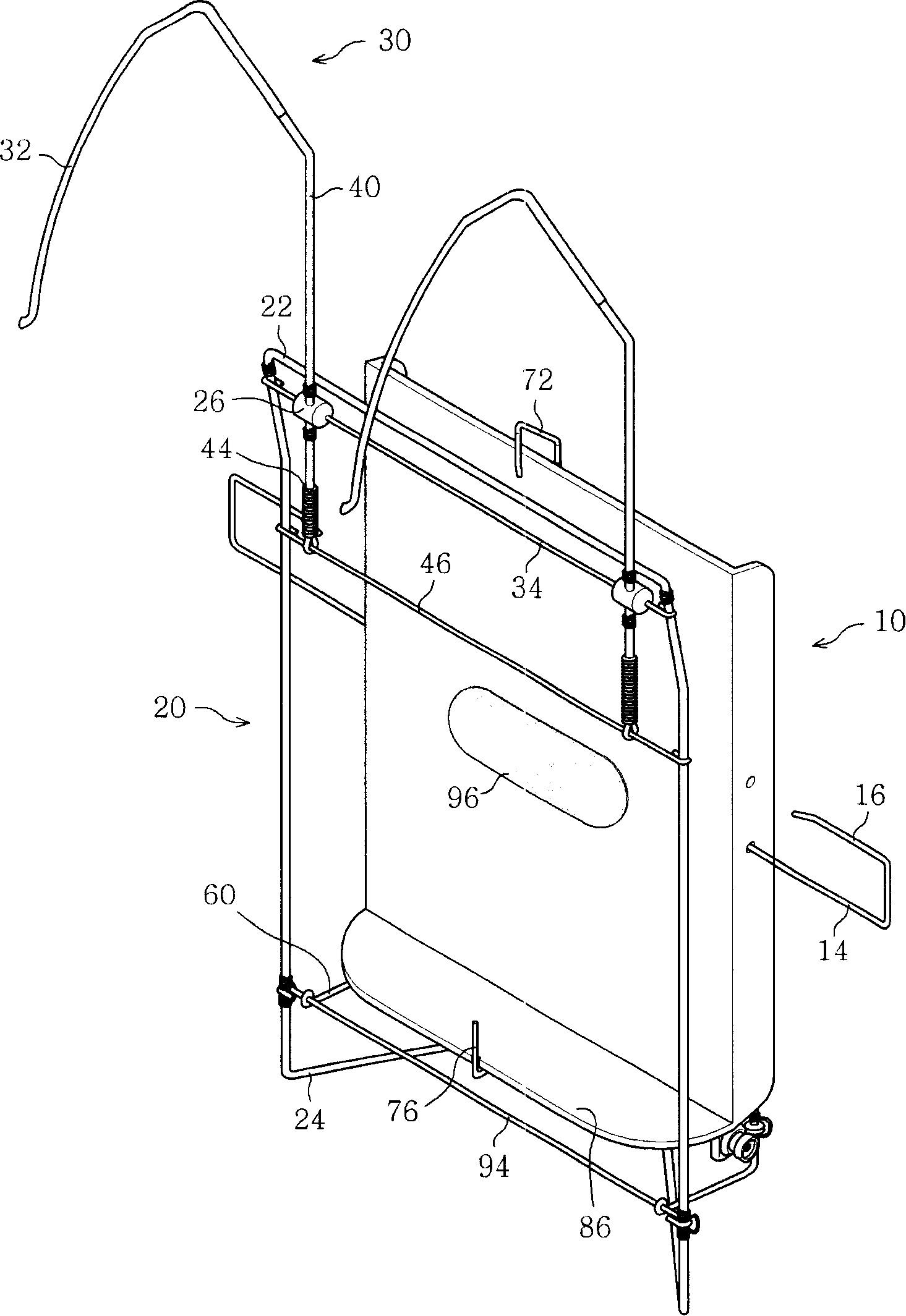

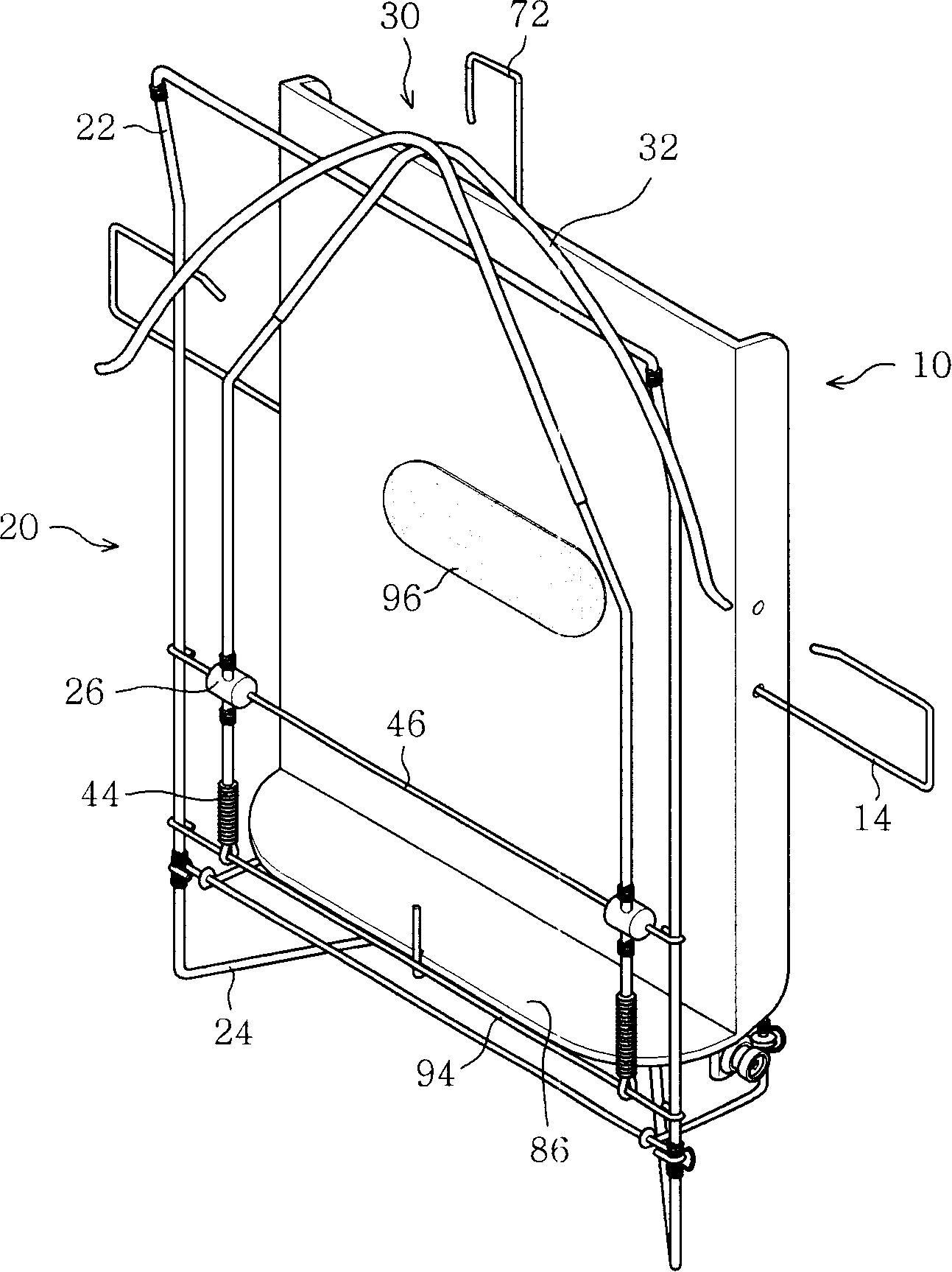

Portable reading desk with shoulder strap

InactiveCN101171997AKeep hangingStable reading statusHanging devicesBook-restsEngineeringMobile electronics

The invention relates to a portable desk, which can be conveniently and stably fixed at the shoulder of users through being detachably combined at a hook (30) of a support frame (20) for supporting a desk board (10). Also a mobile electronic device is used, in particular a convenient portable desk without the restriction of the using location and physical condition, arranging books or electronic devices under any environment or posture. The desk with the convenient function has a hook (30) whose upper side respectively bends to an armhole (10) at the two sides of the support frame (20). Simultaneously, the desk board (10) takes the desk board support frame (60) articulated at the support frame (20) as the medium through the guiding movement of an inclined mobile rod (54) and an inclined leader (52) to have inclined adjustment and position.

Owner:郑仁基

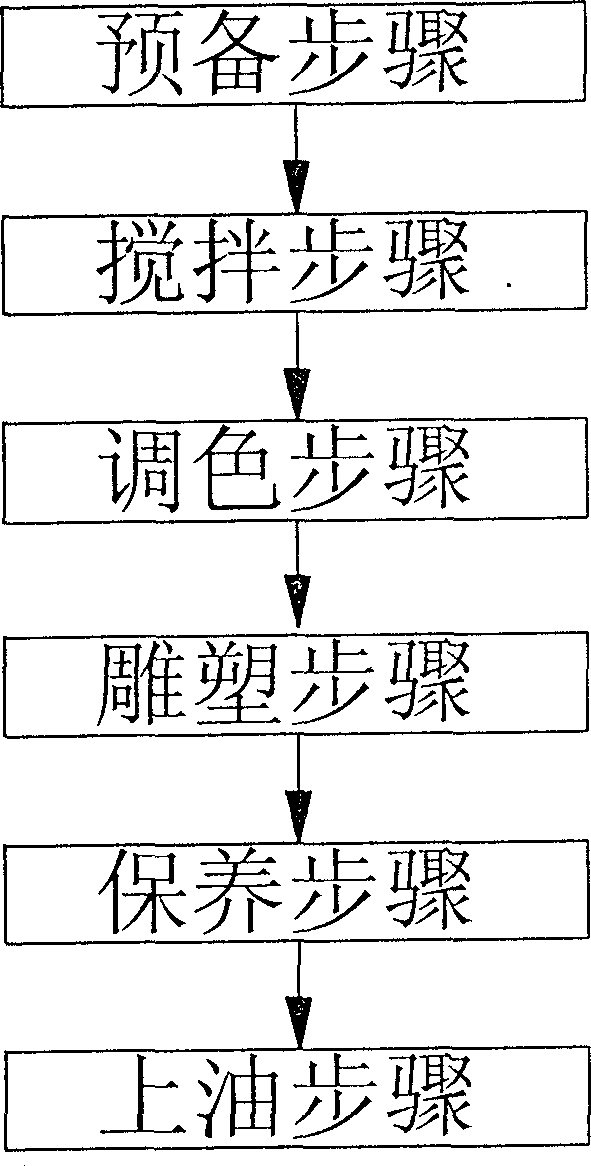

Method for making colored cement sculpture

InactiveCN1840362AEasy to processReduce manufacturing costDecorative surface effectsOrnamental structuresGreenhouseColor mixing

The invention discloses a cement colored drawing sculpture method, which comprises the following steps: preparing step for mixing homogeneously up the mud and cement; mixing step, adding water in mix and mix until homogeneous; color mixing step, adding the cement color material in mixed mix to palette; sculpture step, sculpturing to form figure on the colored mix; maintaining step, placing the sculptured colossal figure in greenhouse for a plurality of days; oiling step, coating the achromatic color bright optical oil on the surface of maintained sculpture. The invention simplifies the fabrication, which reduces the cost.

Owner:涂华平

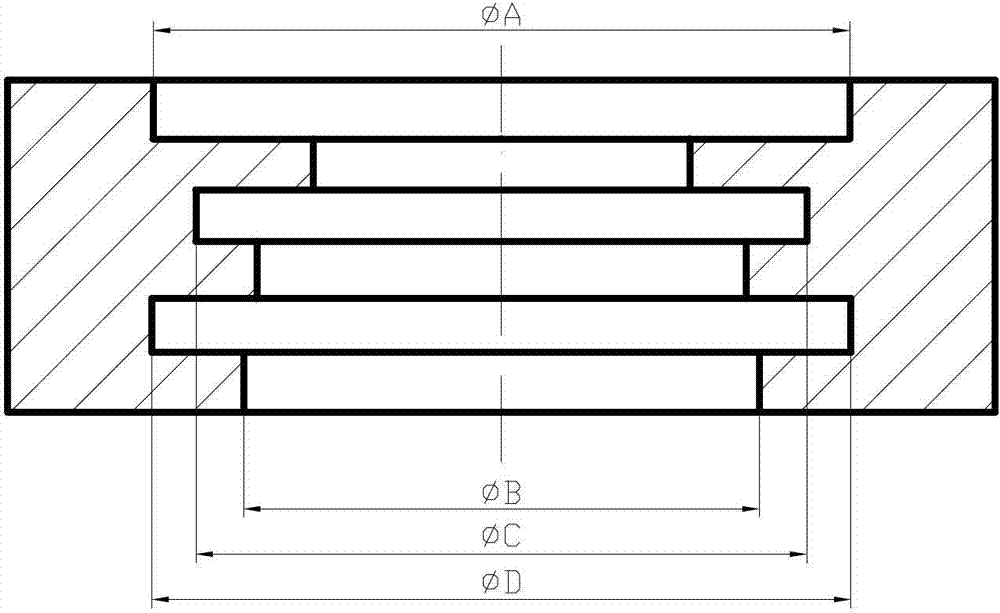

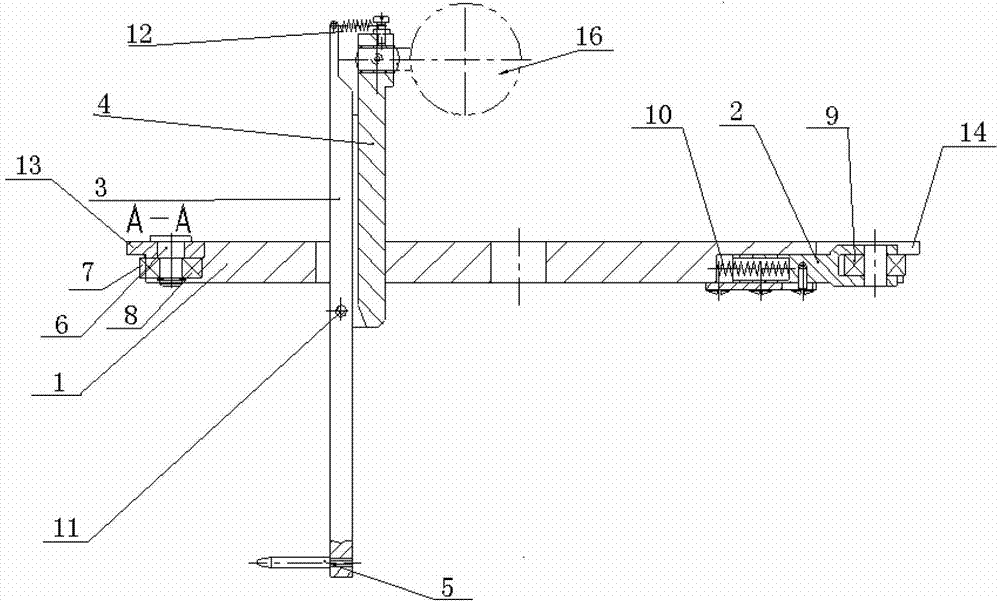

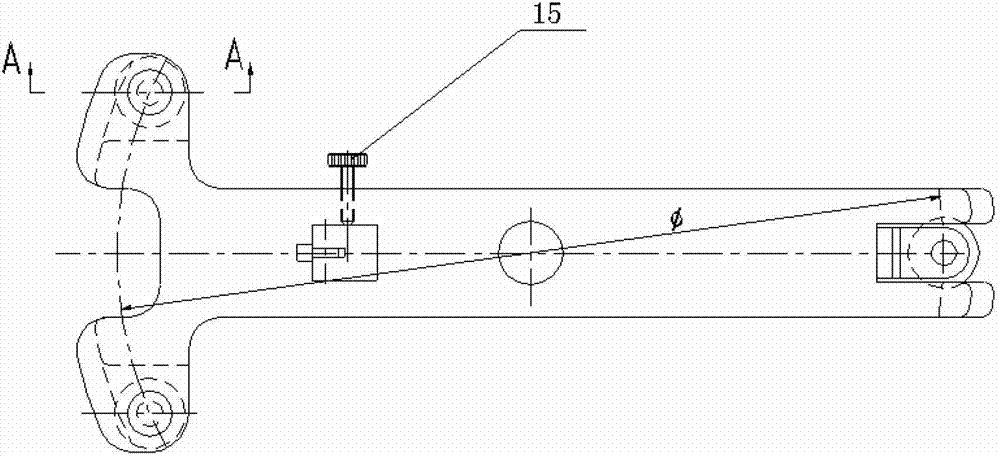

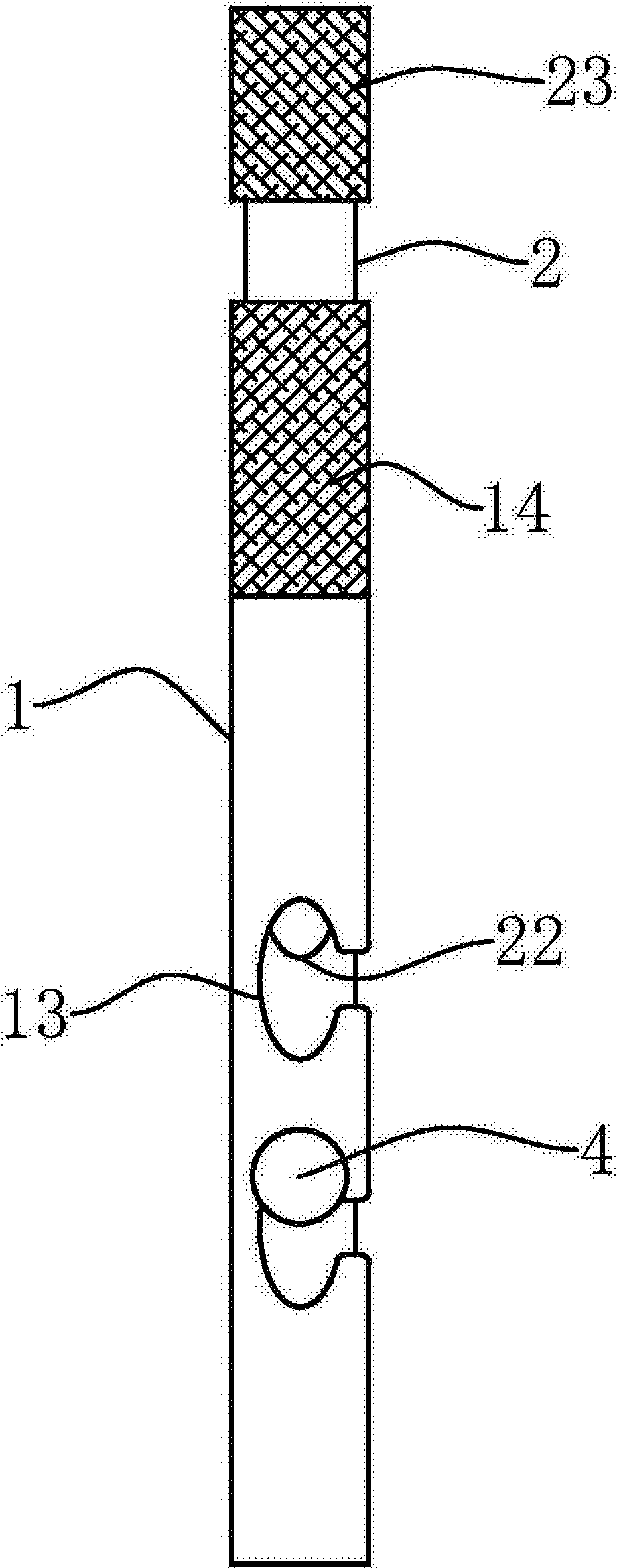

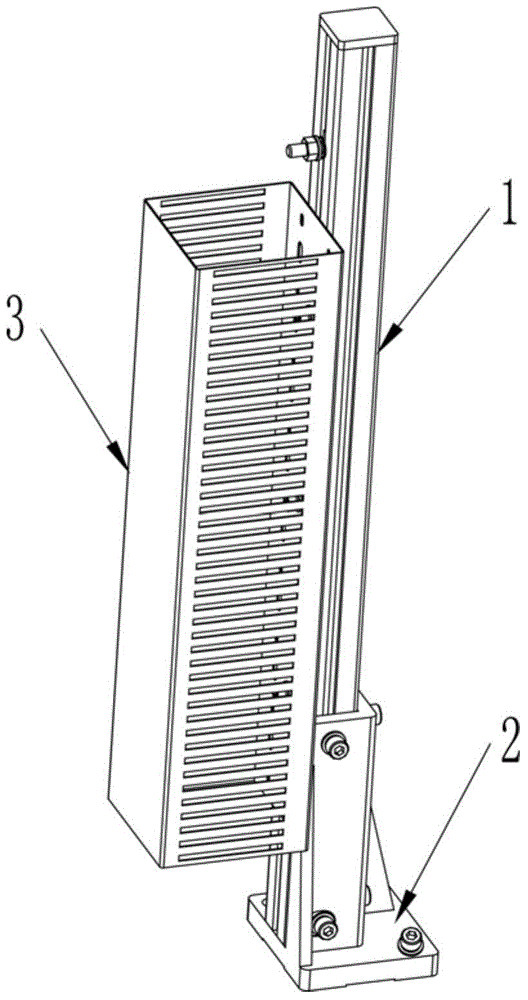

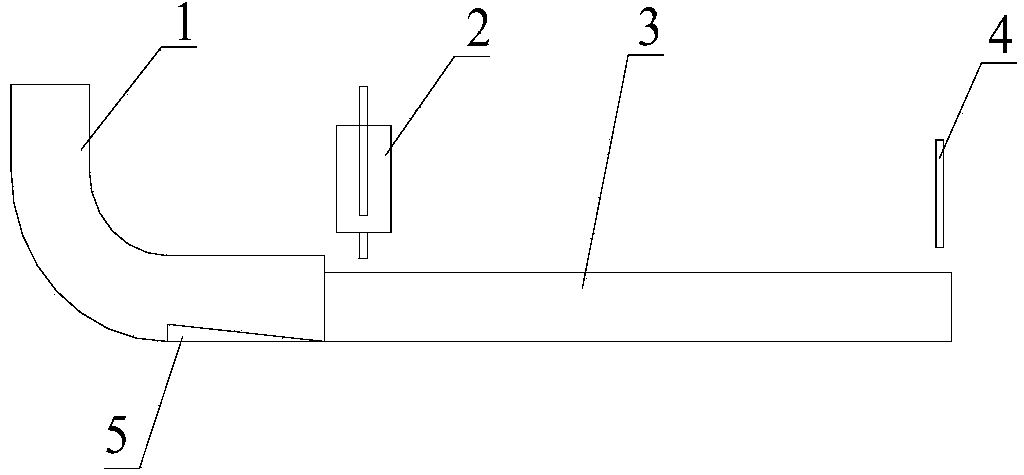

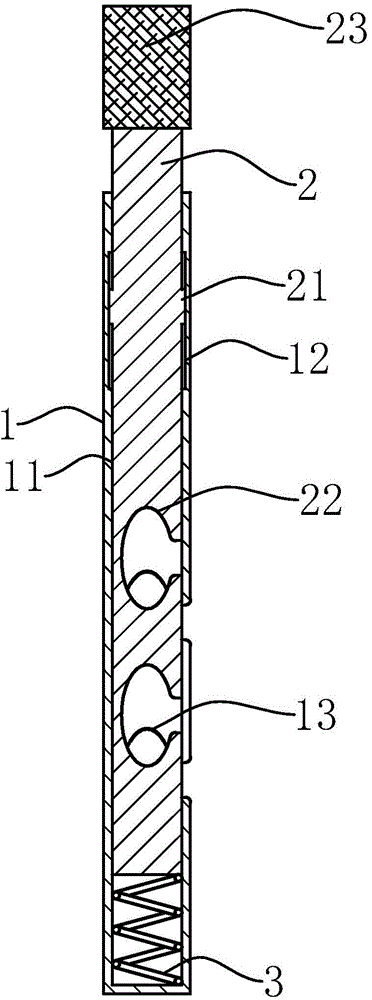

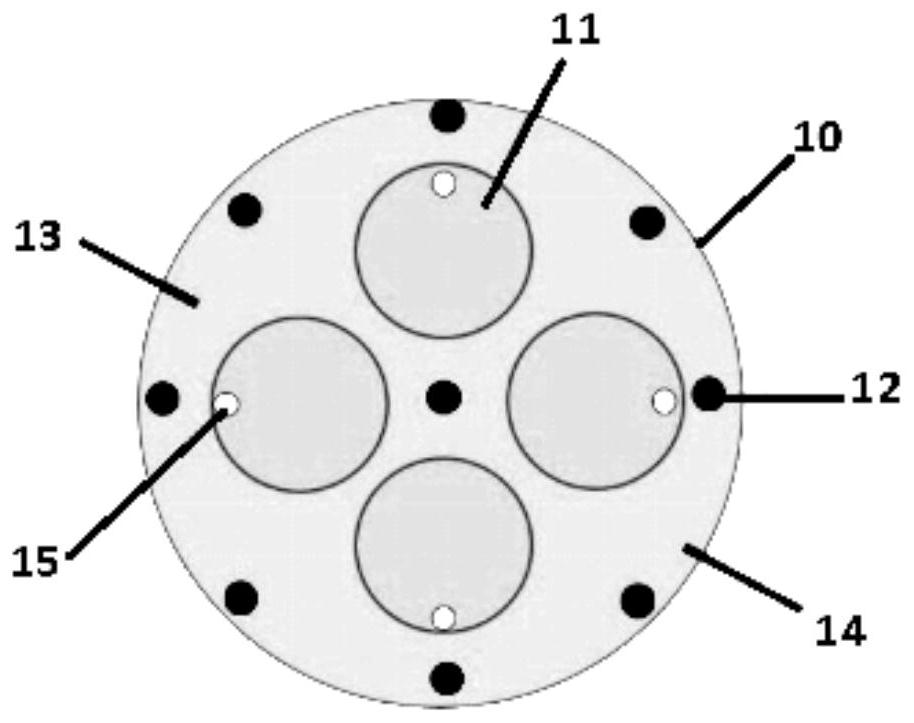

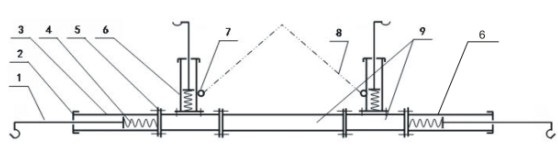

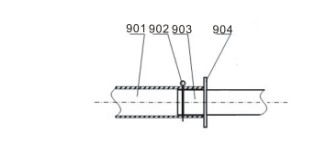

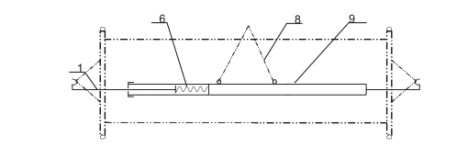

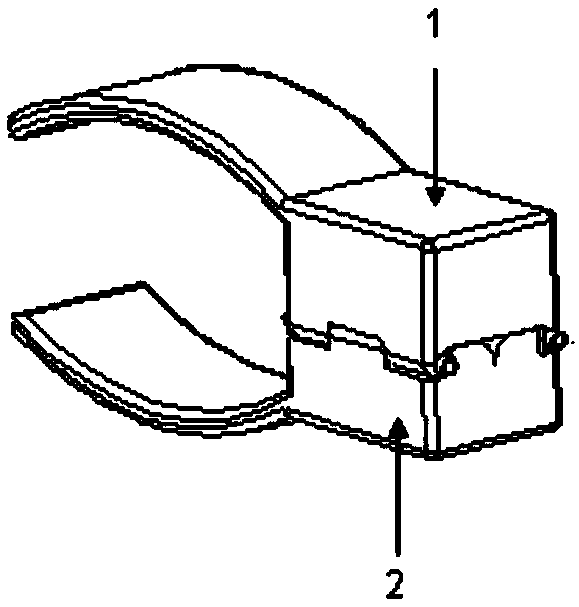

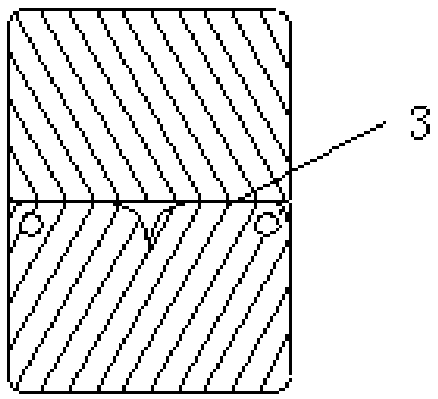

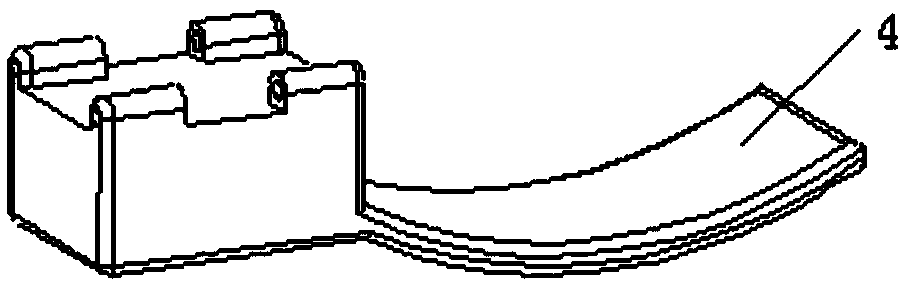

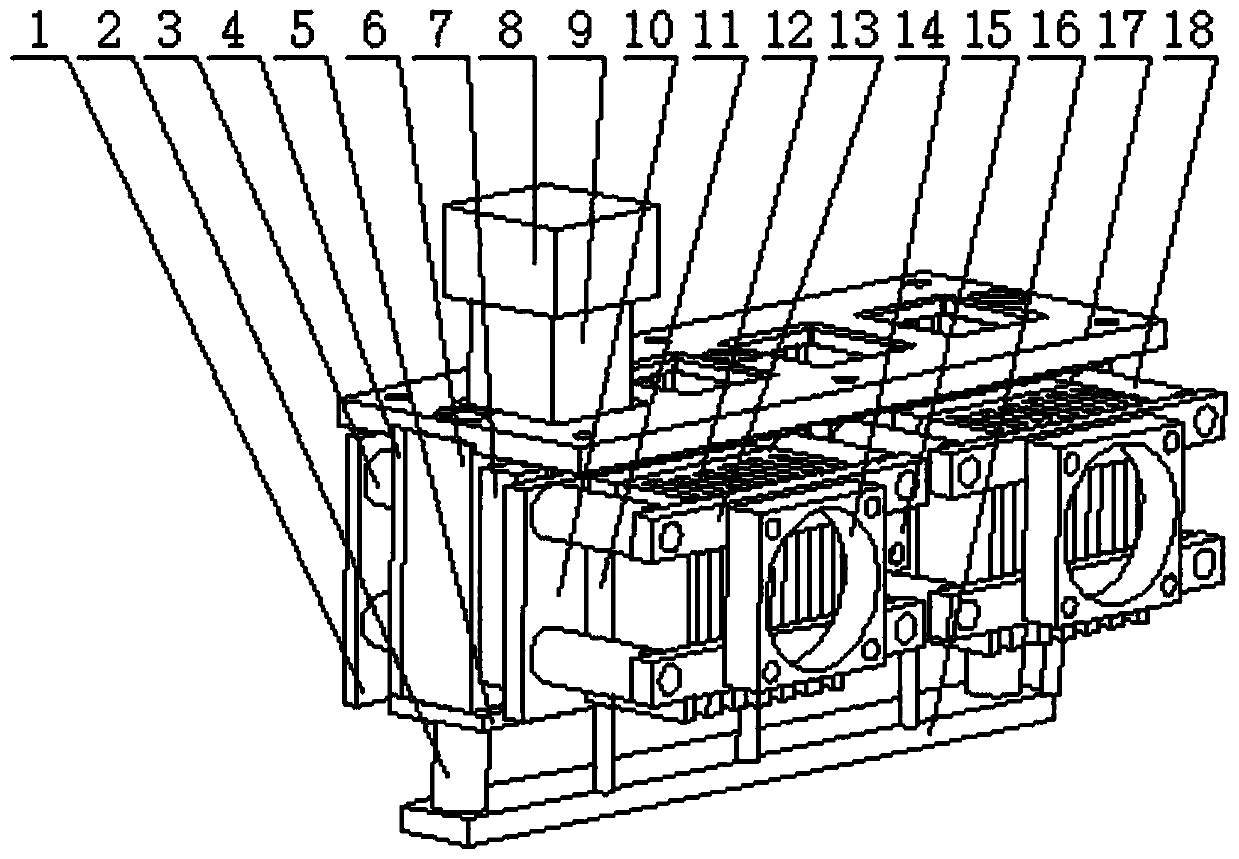

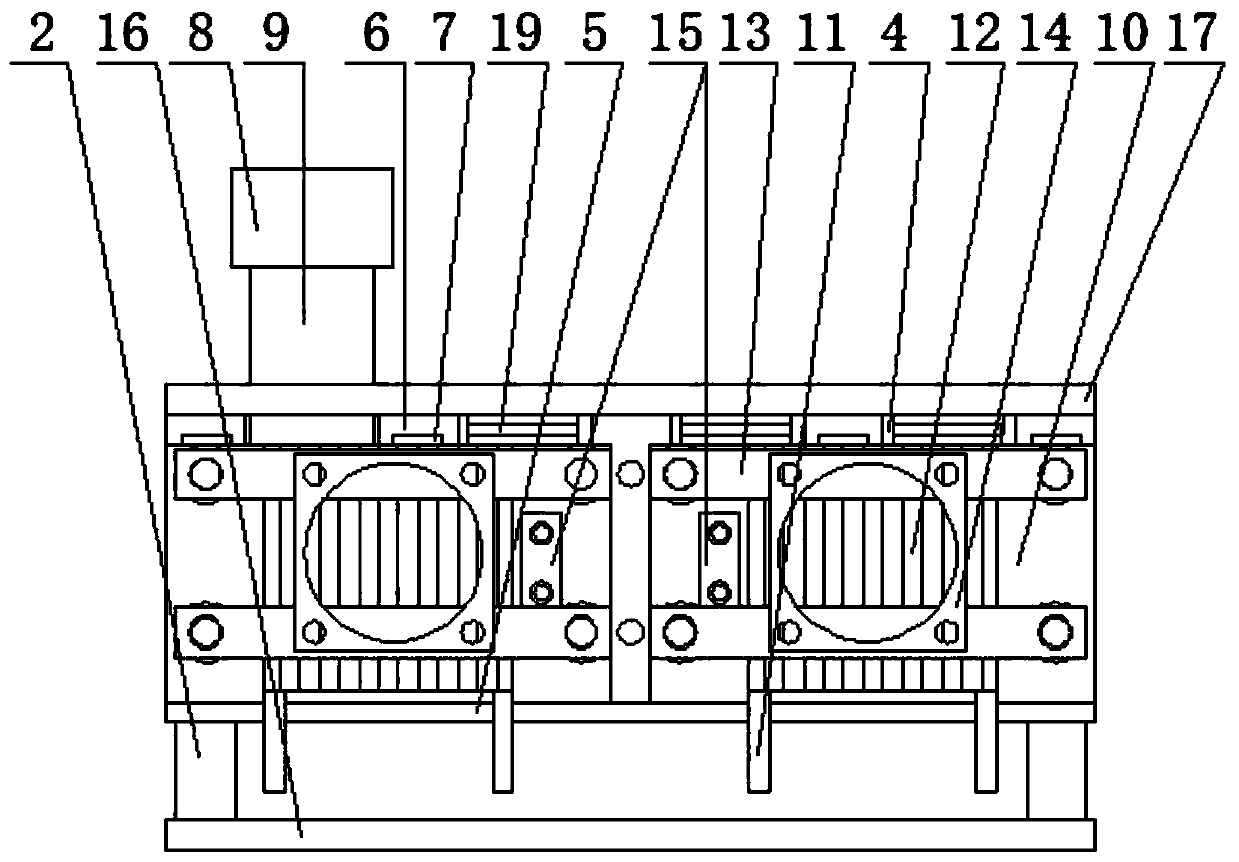

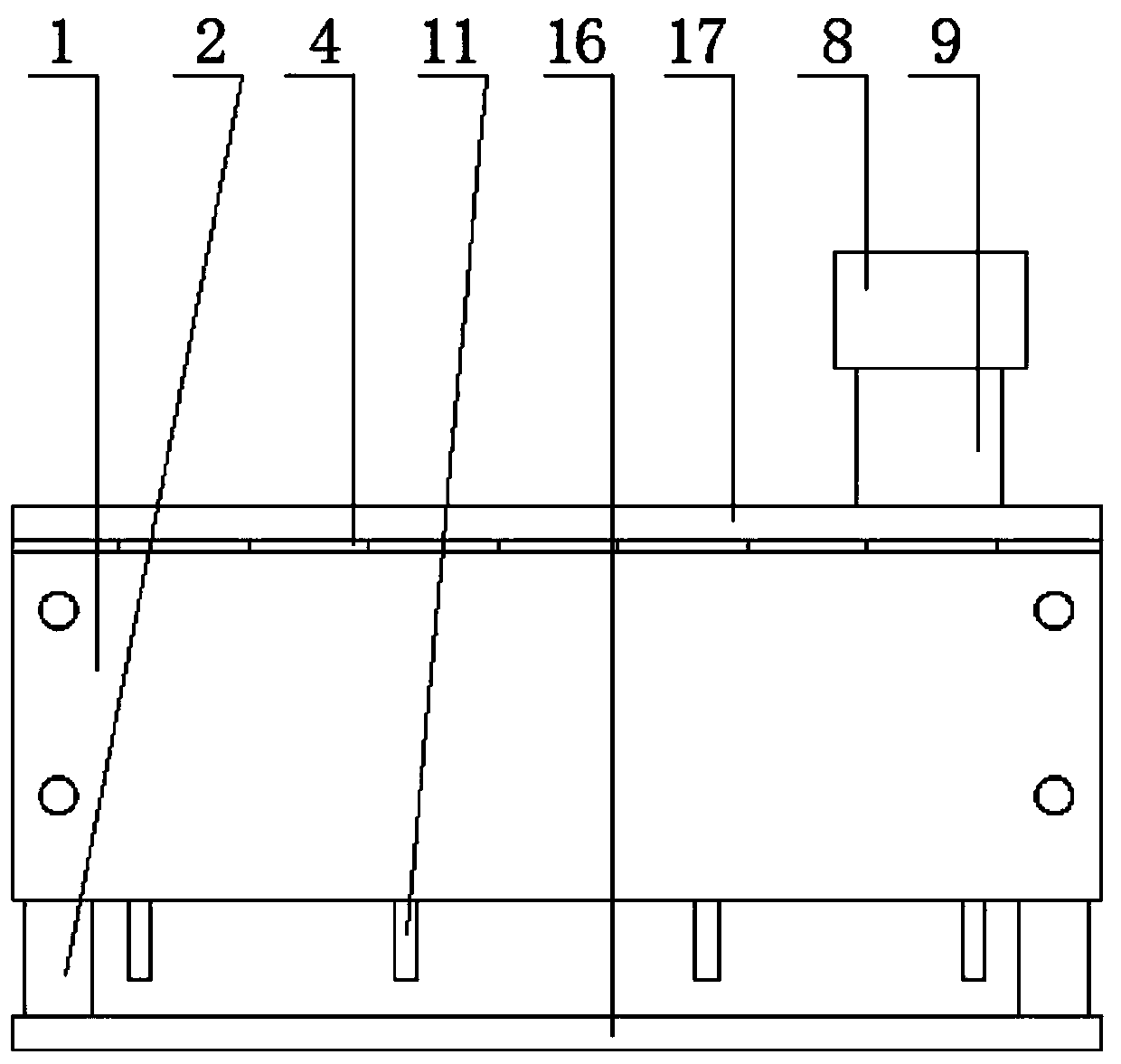

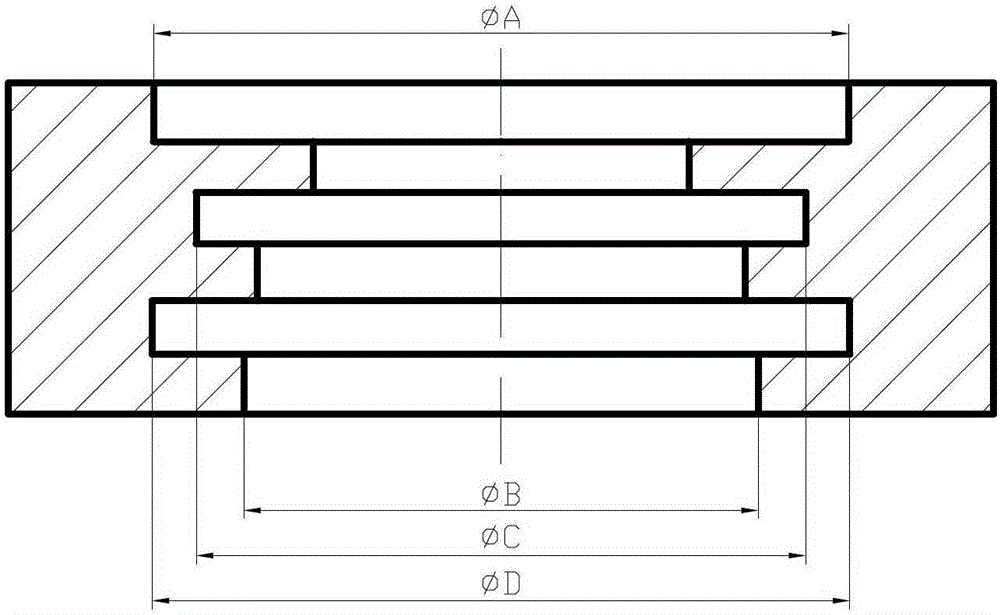

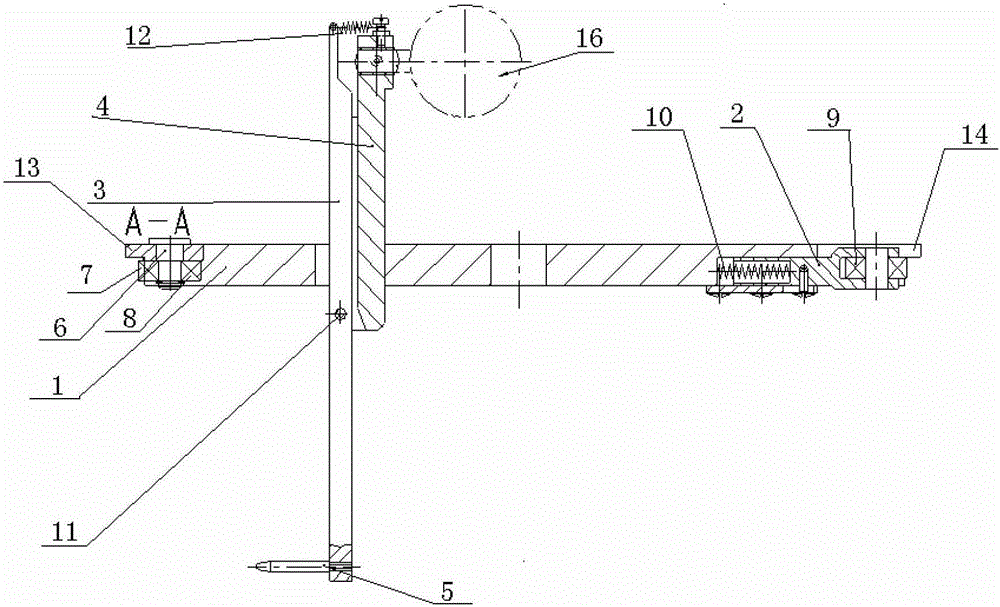

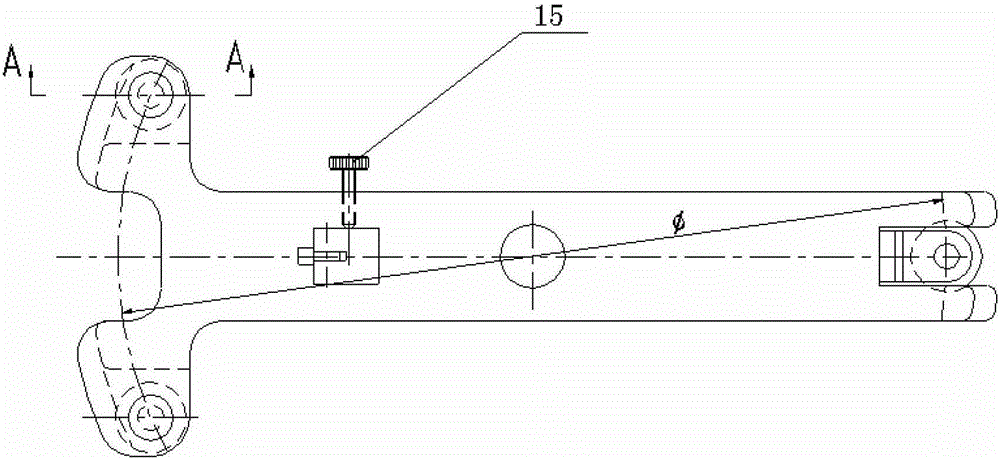

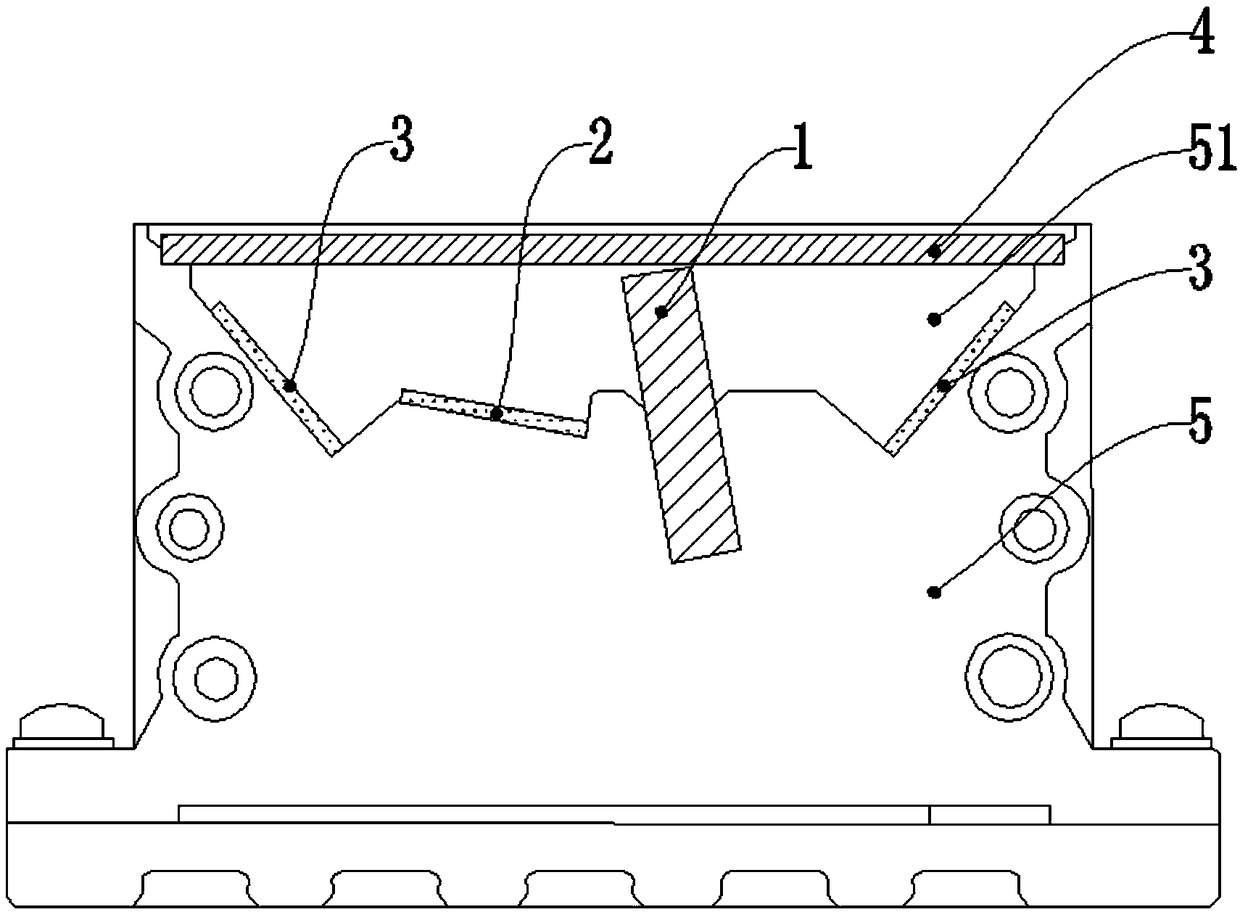

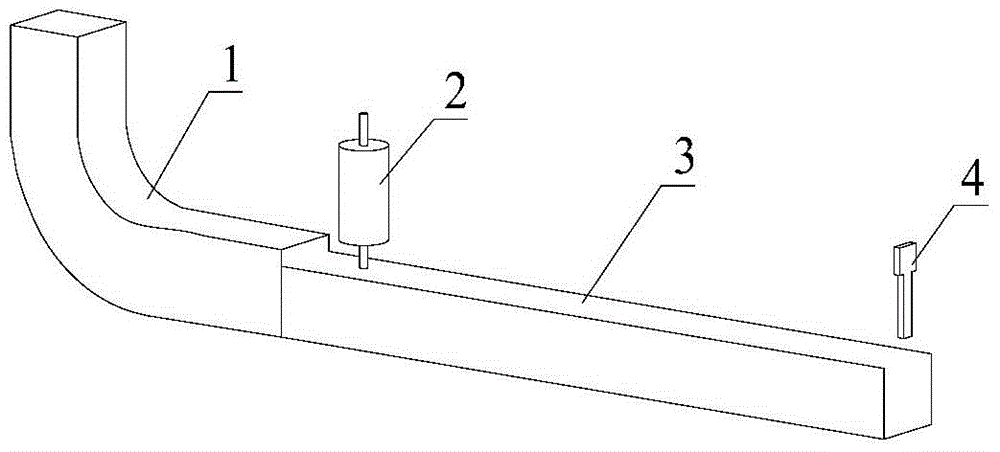

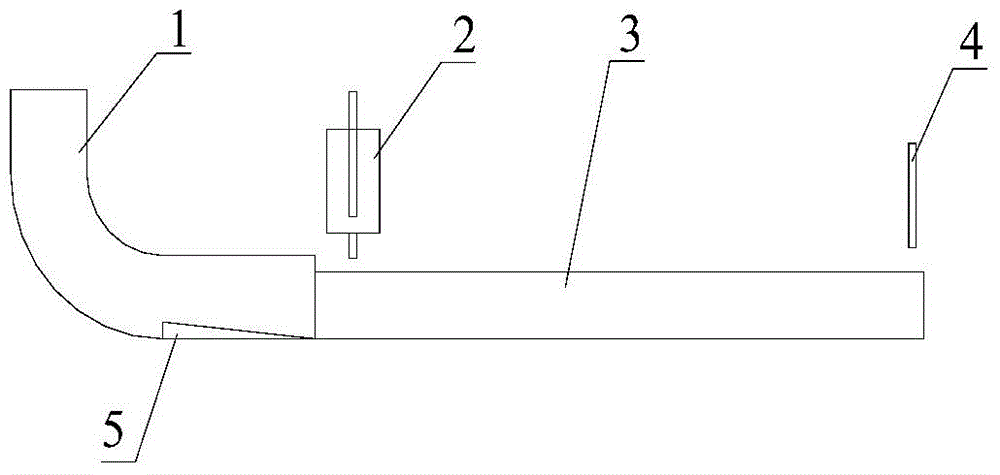

Measuring tool for multiple round mouth pulsation measurement based on parts

InactiveCN102967249ANot affected by sizeVarious locationsMechanical measuring arrangementsBody positionsEngineering

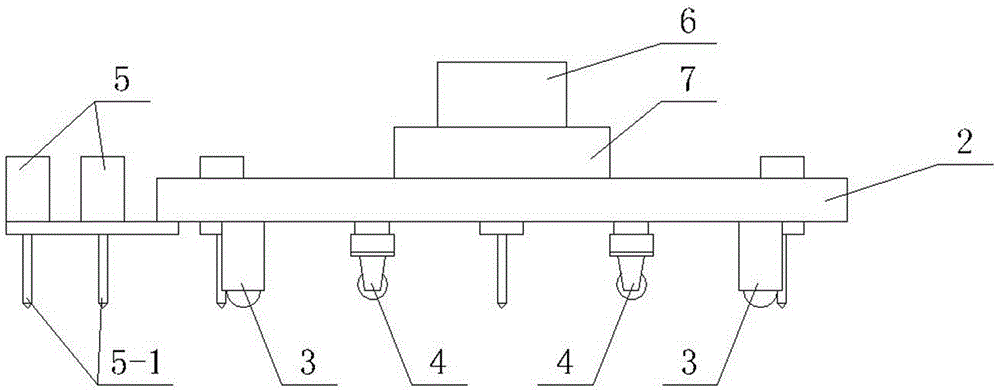

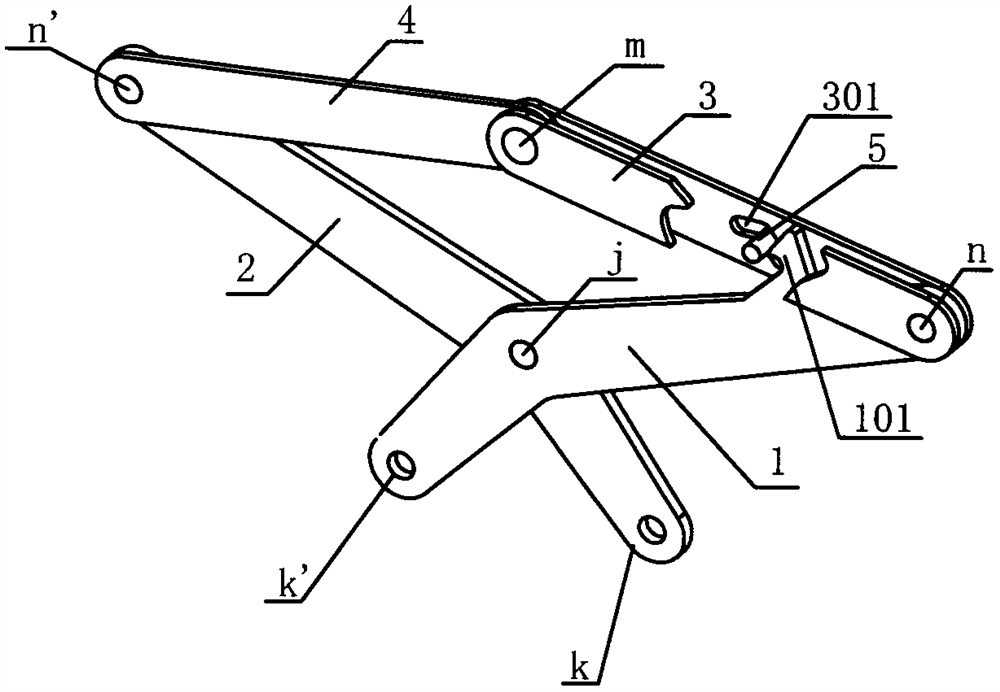

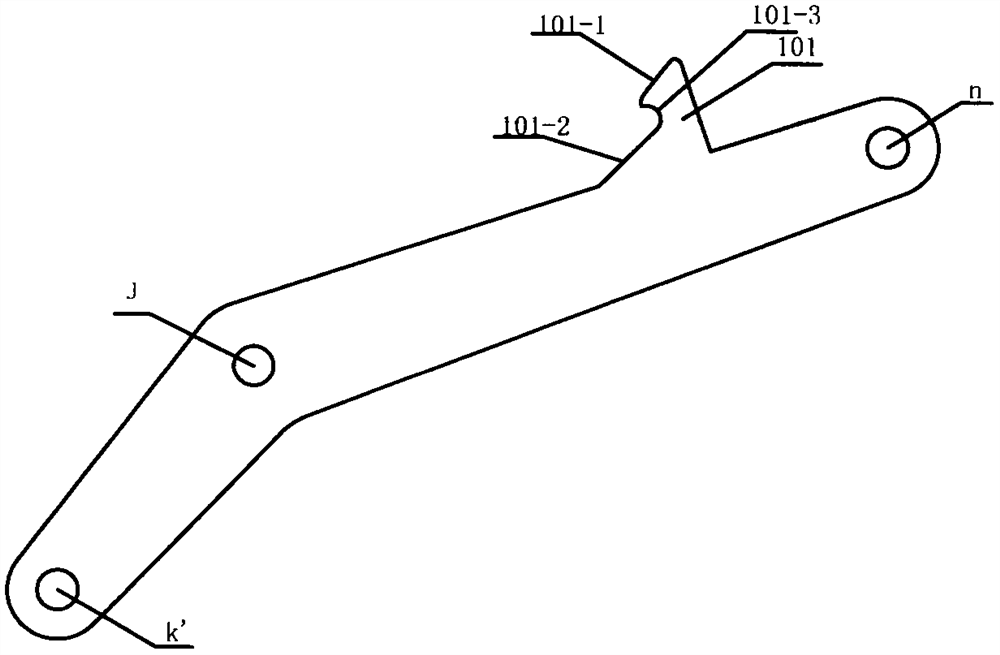

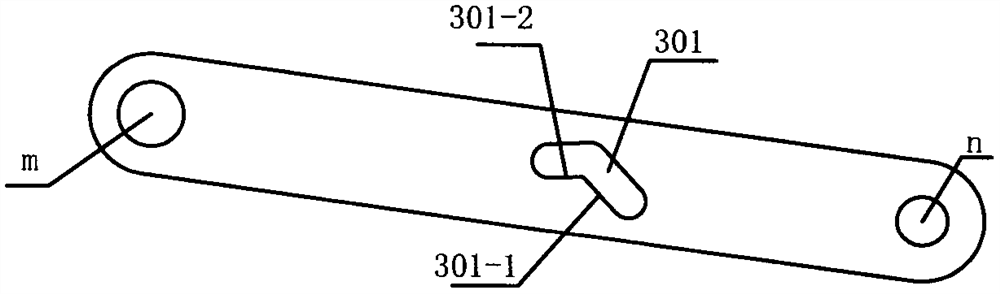

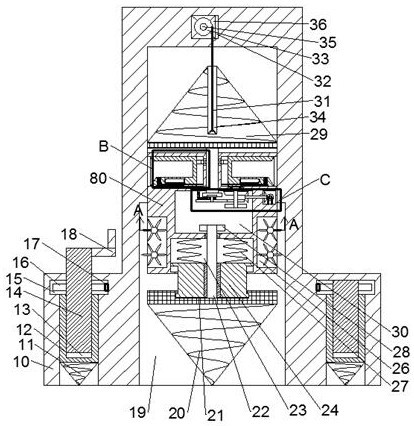

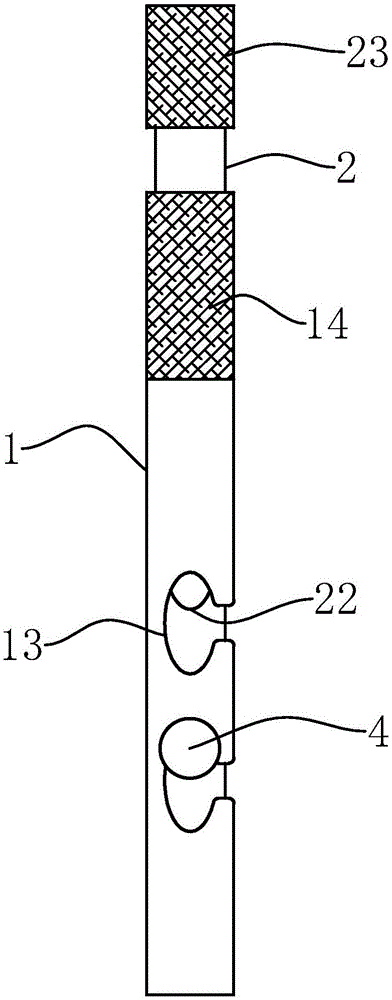

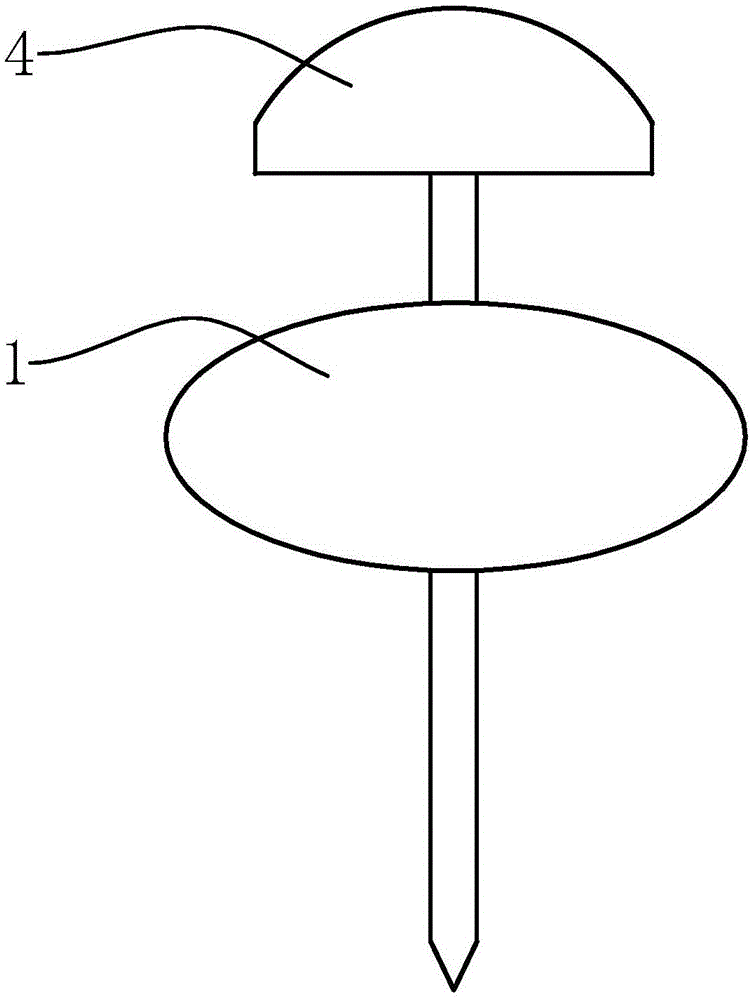

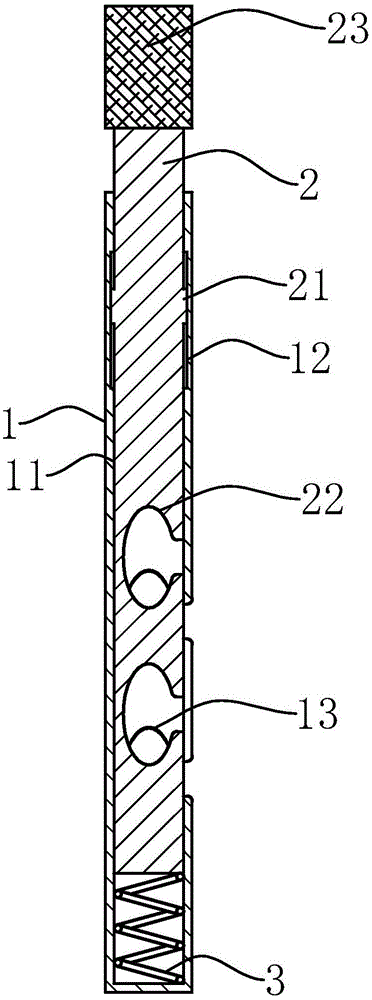

The invention relates to a measuring tool for multiple round mouth pulsation measurement based on parts. The measuring tool comprises a main body positioning device and a measuring device vertically connected. The main body positioning device mainly comprises a positioning base (1) and a roller frame (2). The roller frame (2) is connected with the right end of the positioning base (1). The measuring device mainly comprises a lever (3), a gauge stand (4) for installing a dial indicator and a measuring head (5), wherein the upper end of the lever (3) is connected with the upper end of the gauge stand (4) for installing the dial indicator, the lower end of the lever (3) is connected with the measuring head (5), and the lever (3) is vertically connected with the positioning base (1). The measuring tool for multiple round mouth pulsation measurement based on parts provided by the invention particularly can ensure accurate measurement of parts, and reduce the manufacturing cost of tools, in particular to measurement of large parts. As the measuring tool is small in size, the measuring tool can be directly placed on the parts, therefore, the measuring tool is light and convenient to use, and is not affected by fields and part placing states.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

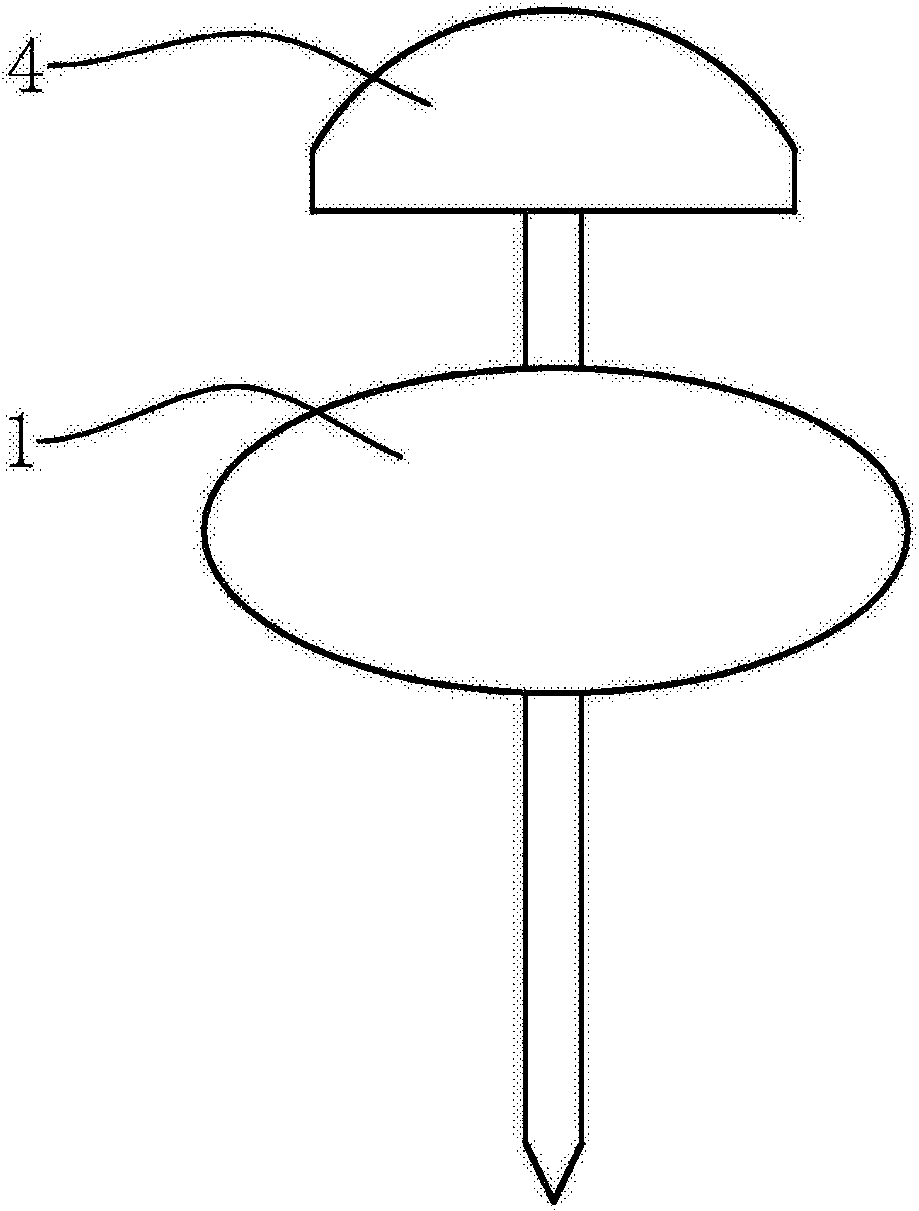

Apparatus for protecting hands during nail hammering of steel hammer

InactiveCN107838874AEasy to removeNot affected by sizeDispensing apparatusNail dispensersRetaining ringEngineering

Owner:潜江传家电子商务有限公司

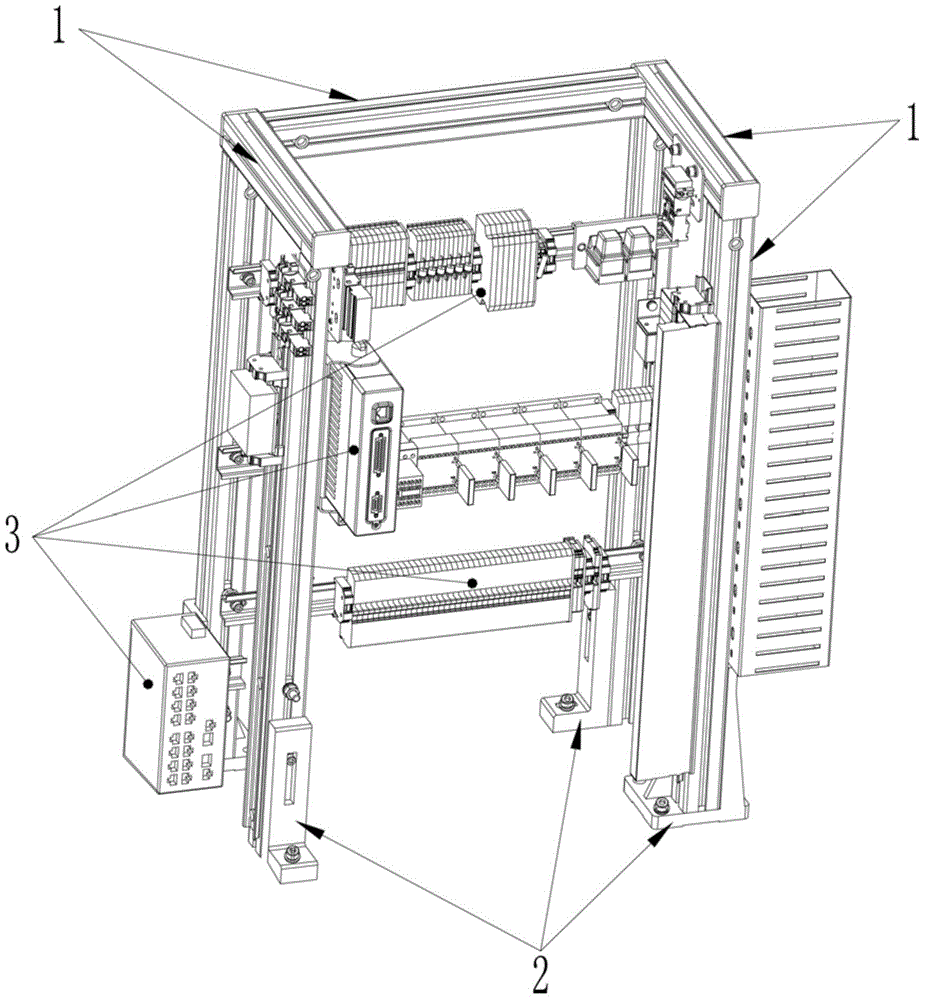

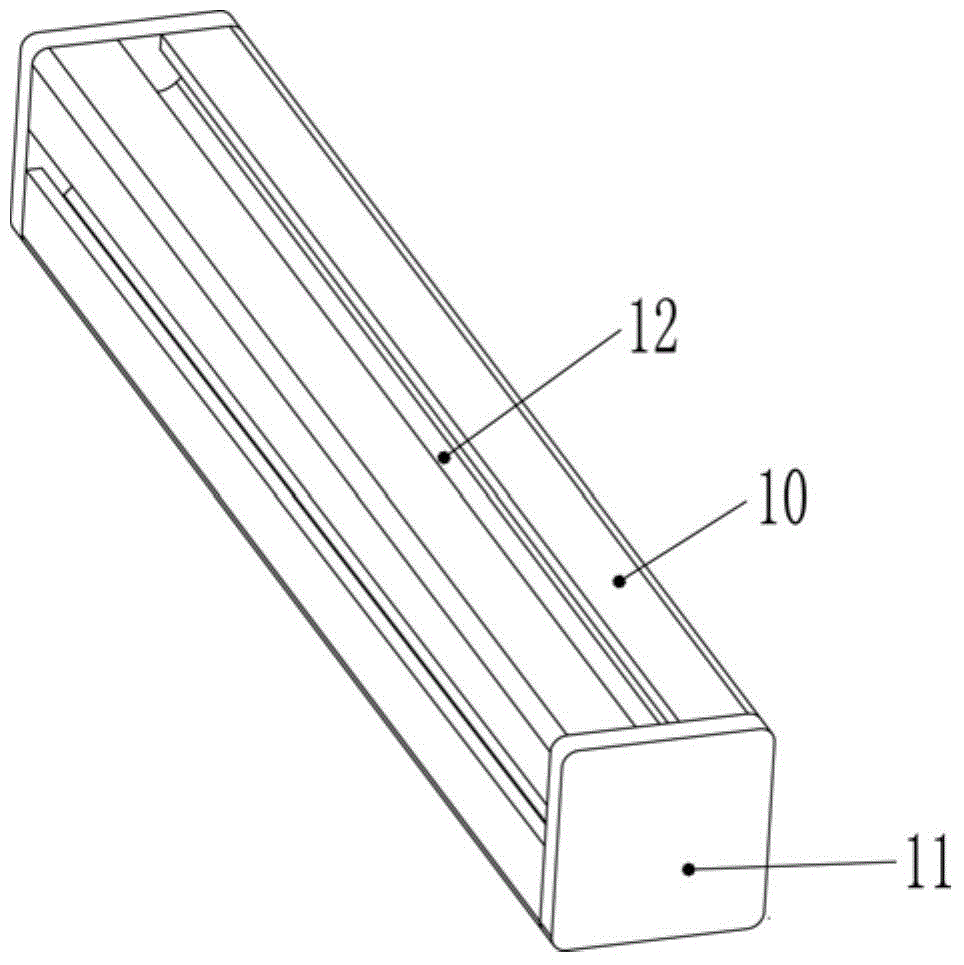

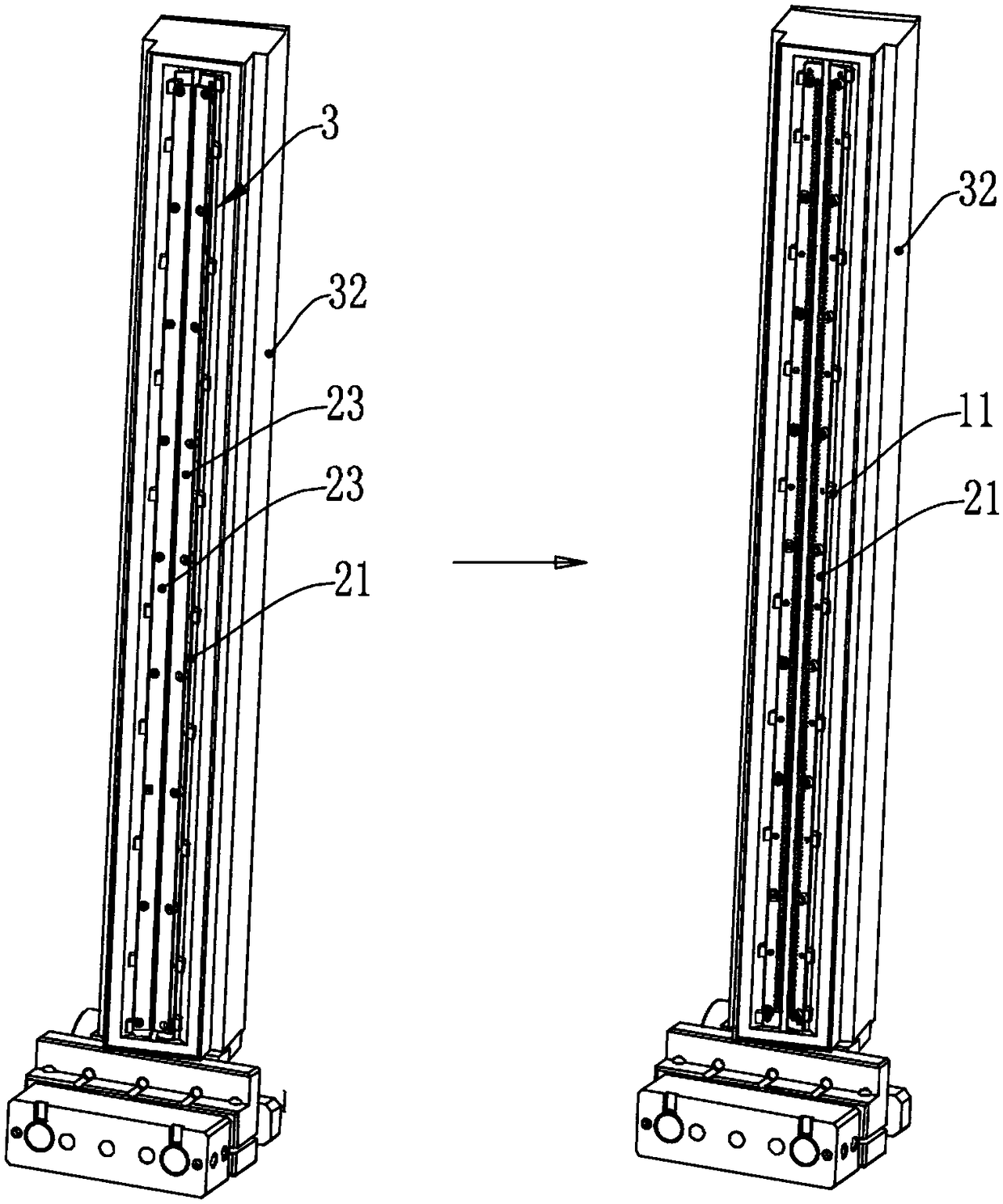

Fixing element and fixing frame for electric control equipment of low-floor vehicle

The invention belongs to the field of mounting and fixing of equipment, and discloses a fixing element and a fixing frame for electric control equipment of a low-floor vehicle. The fixing element comprises a plurality of parallel sliding rails and two end plates, wherein a slide chute is formed between every two adjacent sliding rails; each sliding rail is composed of two plates which are connected with each other; two plates on two sides of each slide chute are coplanar; the two end plates are respectively connected with two ends of the plurality of sliding rails; both upright posts and cross bars of the fixing frame are the fixing elements. By virtue of the fixing element with the plurality of slide chutes, connection of electric control equipment in different directions is facilitated; the fixing frame is composed of a plurality of fixing elements, and can be assembled according to the requirements, and the occupied space in a cab is relatively small after the fixing frame is assembled, so that the space of the cab can be relatively flexibly, effectively and reasonably utilized; the problem of space shortage caused by multiple pieces of electric control equipment in the cab is solved; the utilization rate of the space in the cab is improved. The fixing elements are carried in the cab before being assembled, and then are assembled, so that the fixing frame is not affected by the size of the inlet of the cab.

Owner:CRRC QINGDAO SIFANG CO LTD

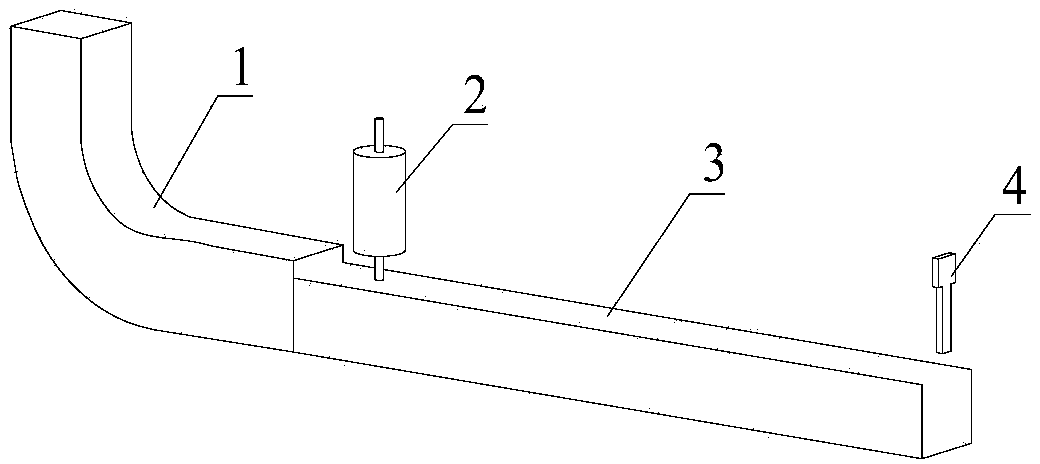

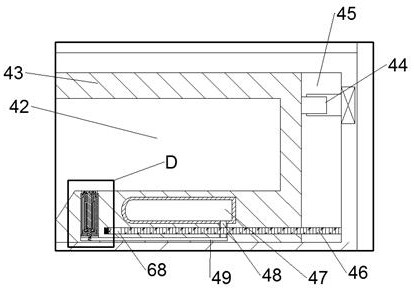

Solution type flow measuring device

ActiveCN104048716AHigh measurement accuracyThe flow calculation formula is simpleStationary measuring chambersMeasuring instrumentDischarge measurements

The invention discloses a solution type flow measuring device. The solution type flow measuring device is designed on the basis of a solution dilution method flow measuring principle. The solution type flow measuring device comprises a 90-degree bent cavity used for containing water flow to be measured, a water tank, a Marriott bottle used for feeding a solution at a constant-speed, and a solution concentration measuring instrument, wherein the cavity is communicated with the water tank, the Marriott bottle is arranged above the starting end of the water tank, a water damming bank is arranged at the tail end of the cavity so that the water depth and flow velocity of water flowing out of the cavity can be transversely distributed more uniform, the longitudinal section of the water damming bank is triangular, the water tank is a prism with the top open, and the length of the water tank is no smaller than nine times of the side length of the cross section of the cavity. The solution type flow measuring device is high in measuring precision of large flow, can be used for measuring the flow of water flow ejected out of a pipe, and is particularly suitable for measuring the flow under the conditions that a downhole drainage drilled hole is large in flow of outlet water.

Owner:SUZHOU MAICHUANG INFORMATION TECH

Hand guard device during nail hammering

ActiveCN104552161AEasy to removeNot affected by sizeDispensing apparatusNail dispensersHardware toolEngineering

Owner:NANTONG YAOLONG METAL MFG

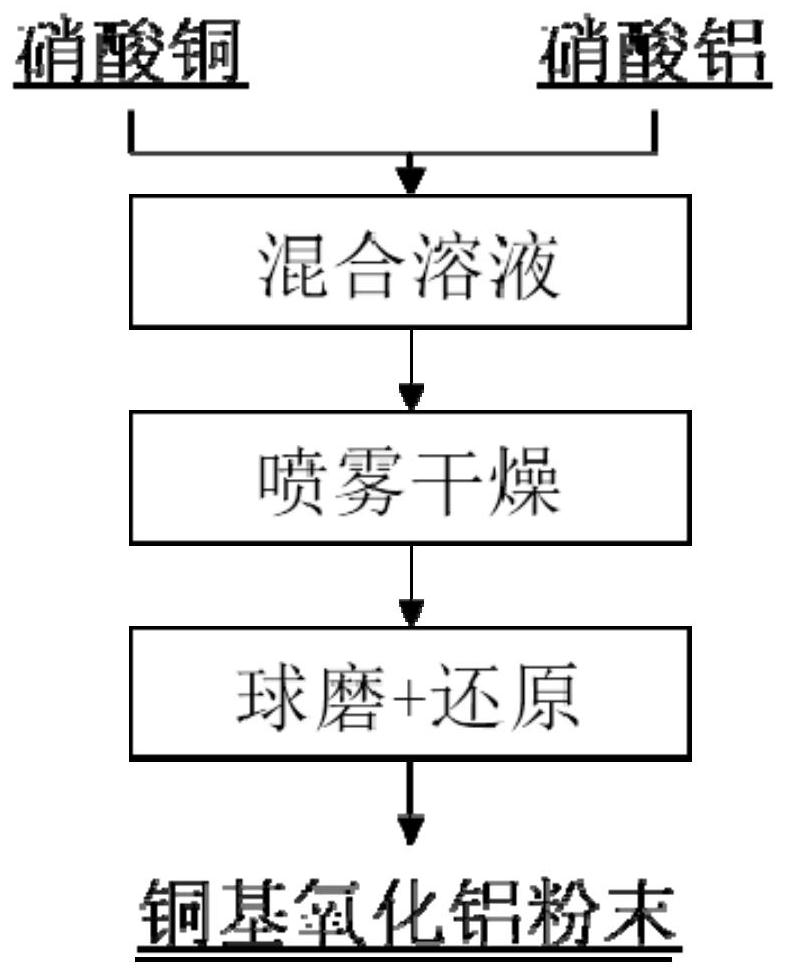

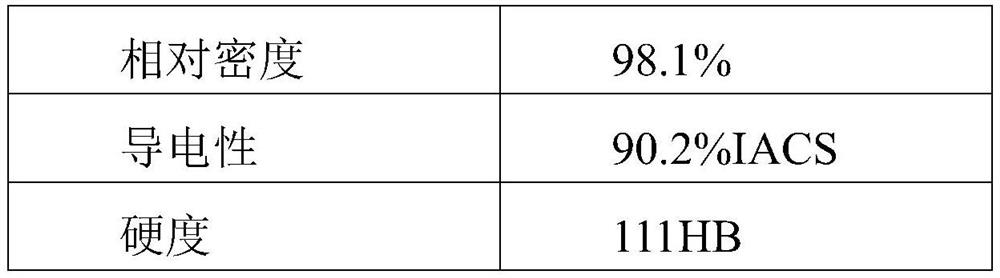

Preparation method of copper-matrix aluminum oxide nano material

The invention discloses a preparation method of a copper-matrix aluminum oxide nano material. The preparation method comprises the following steps of taking copper nitrate and aluminum nitrate as raw materials, quickly drying the raw materials to prepare precursor powder, and heating and ball-milling the precursor powder in a reducing atmosphere to prepare the copper-matrix aluminum oxide nano material. According to the method, the cost of the raw materials is lower, and nanoscale aluminum oxide particles do not need to be used as a strengthening phase; the precursor powder is prepared through quick drying so that the raw material mixing uniformity can be ensured; ball milling and reduction are combined, so that the problem of crystal particle growth caused by reduction after ball milling can be avoided; and the technological process is shortened, and the copper-matrix aluminum oxide nano material with more excellent performance can be economically and efficiently prepared.

Owner:CHINA ENFI ENGINEERING CORPORATION

Suspension device for calligraphic and painting works

InactiveCN102512041AIncreased Strength and DurabilityEasy to usePicture framesDomestic mirrorsStructural engineeringMechanical engineering

Owner:HENAN UNIV OF SCI & TECH

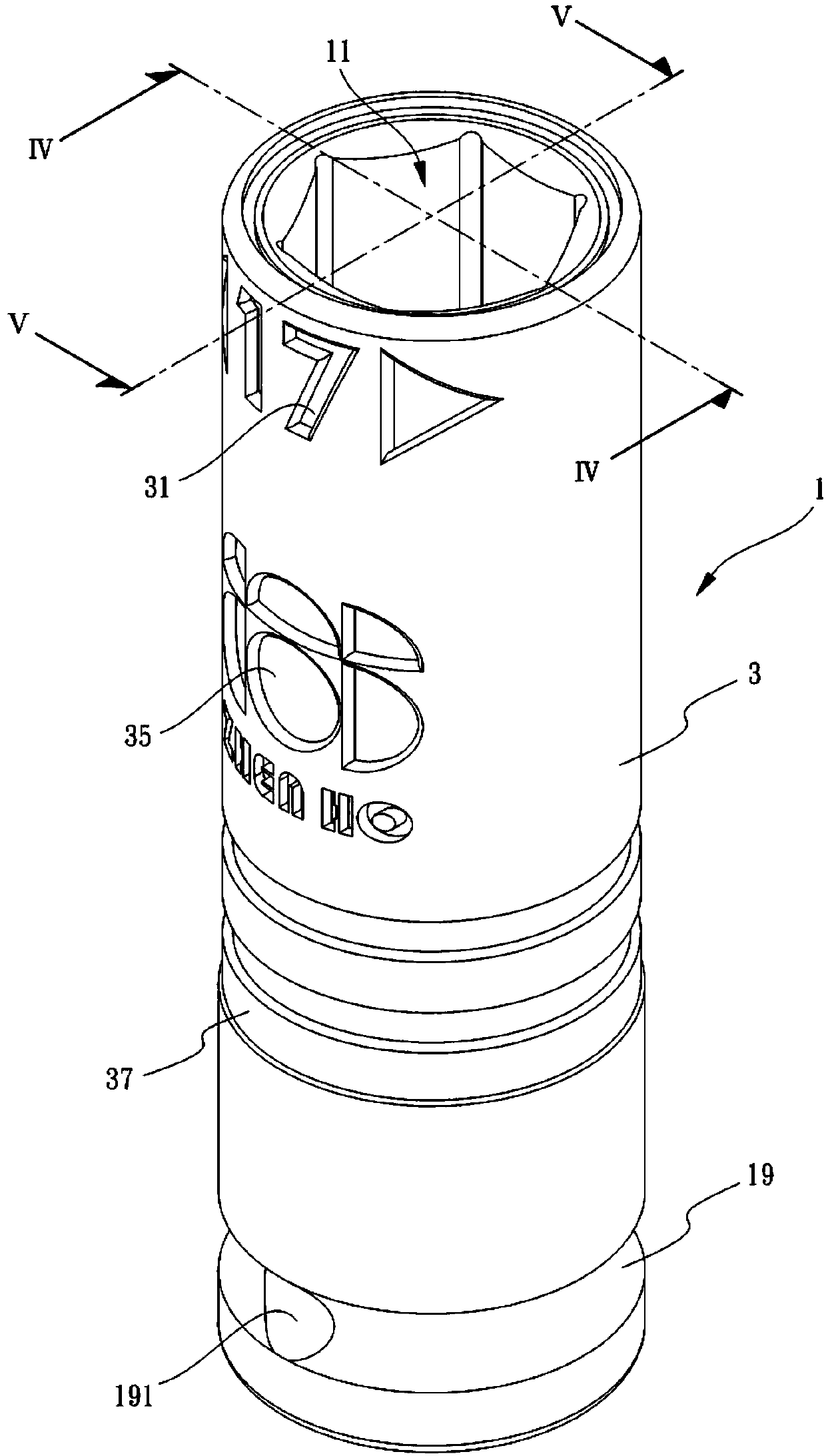

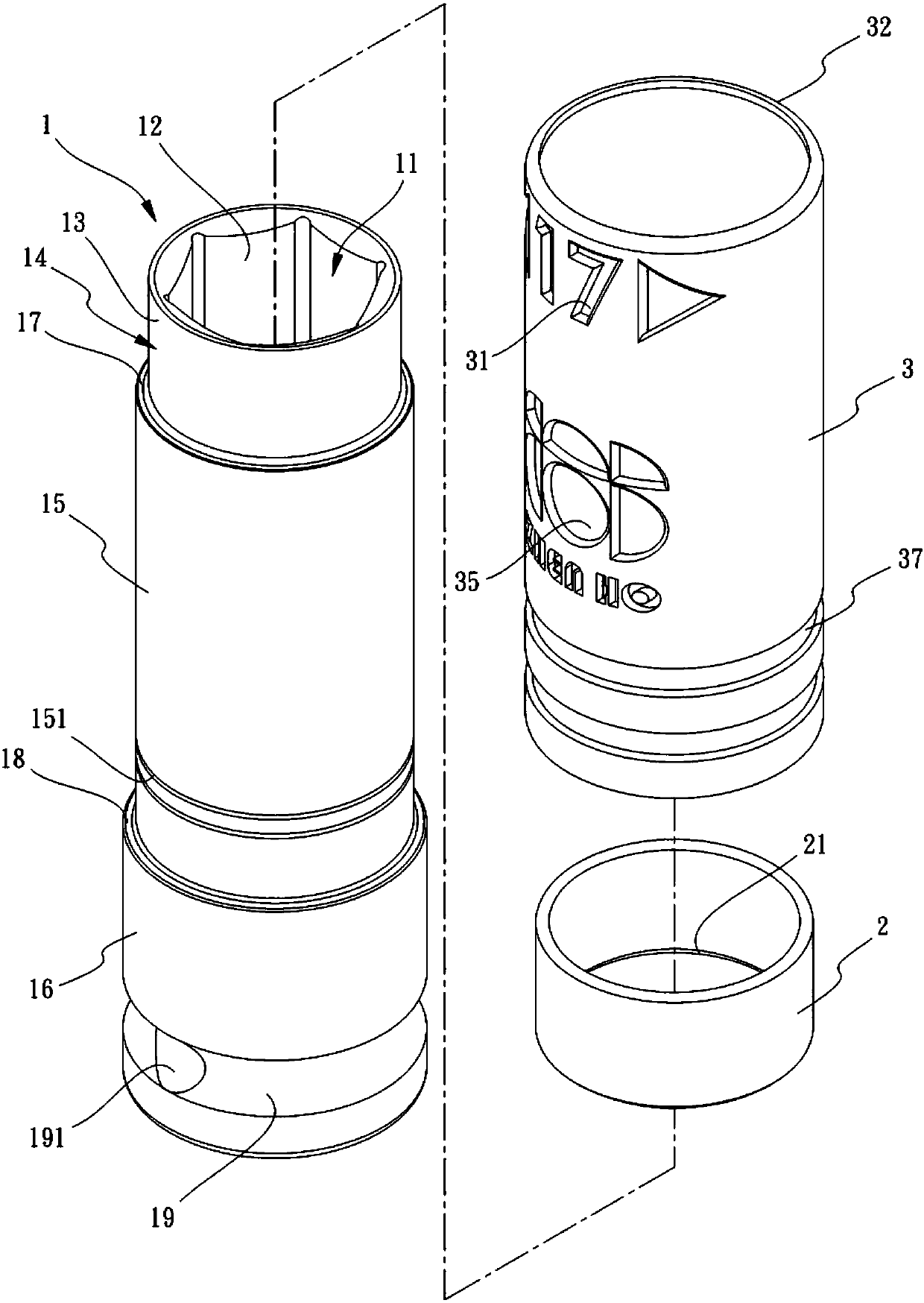

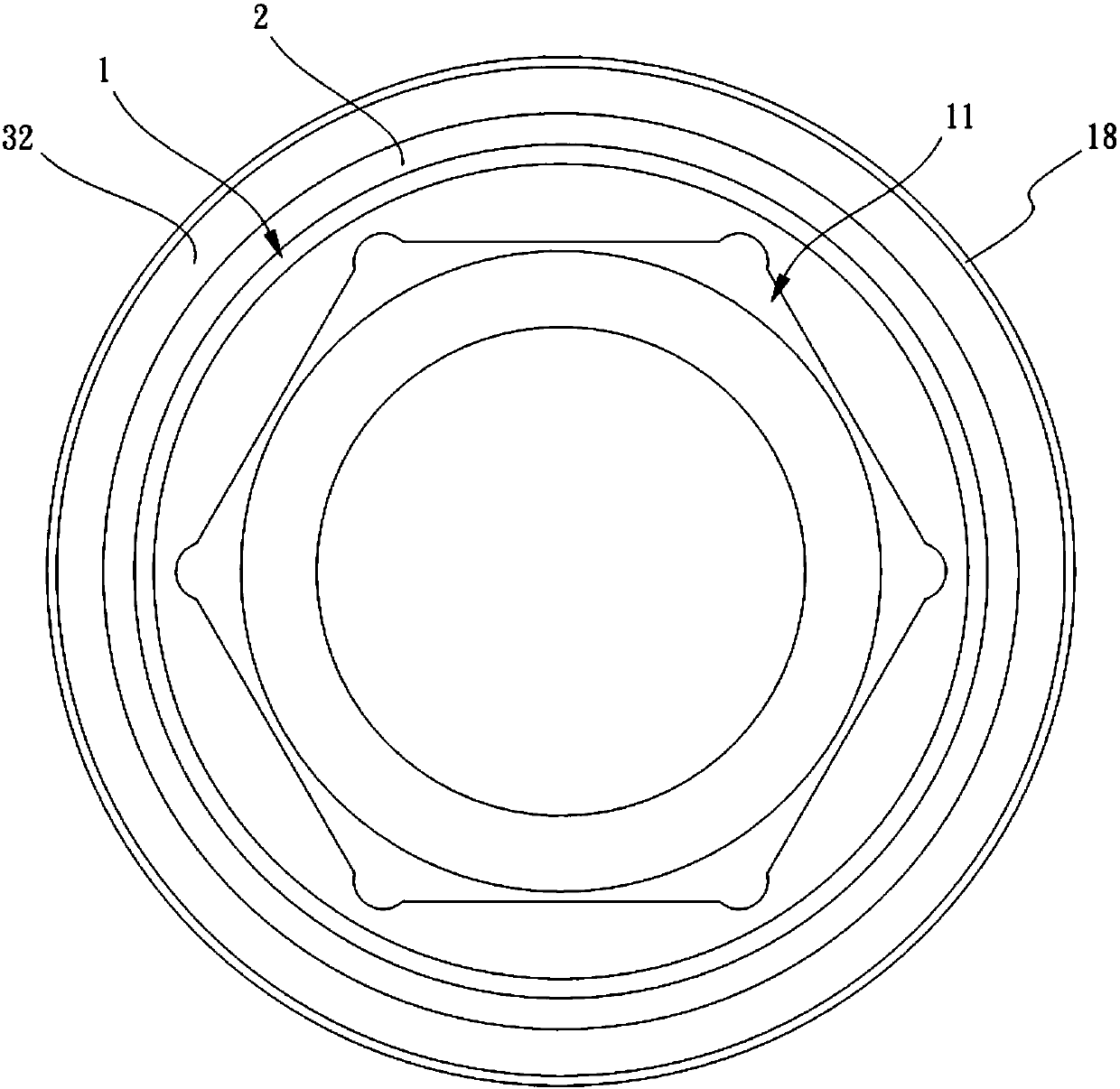

Composite sleeve

InactiveCN110405672AMaintain aestheticsGuaranteed aestheticsSpannersWrenchesContinuous useEngineering

The invention discloses a composite sleeve. The composite sleeve is characterized in that a driving hole is formed in sleeve body, the sleeve body can be divided into a first sleeve section, a secondsleeve section and a third sleeve section, a first step portion is formed between the first sleeve section and the second sleeve section, a second step portion is formed between the second sleeve section and the third sleeve section, a stress ring piece sleeves the outer side of the first sleeve section of the sleeve body and abuts against the first step portion, a protective sleeve is assembled on the sleeve body in a sleeving mode, is attached to the outer wall surface of the second sleeve section and abuts against the second step portion, a gap is formed between the protective sleeve and the outer wall surface of the first sleeve section, the stress ring piece is located in the gap, and an identification hole is formed in the protective sleeve in a hollow mode. Due to hollow arrangementof the identification hole, the oil stain can be accommodated in the identification hole, in addition, due to the design of the thickness of the protective sleeve, the integrity of the sleeve body inoperation can be completely protected through installation of the protective sleeve, and the continuous use can also can be achieved without separating of the protective sleeve.

Owner:蔡 人举

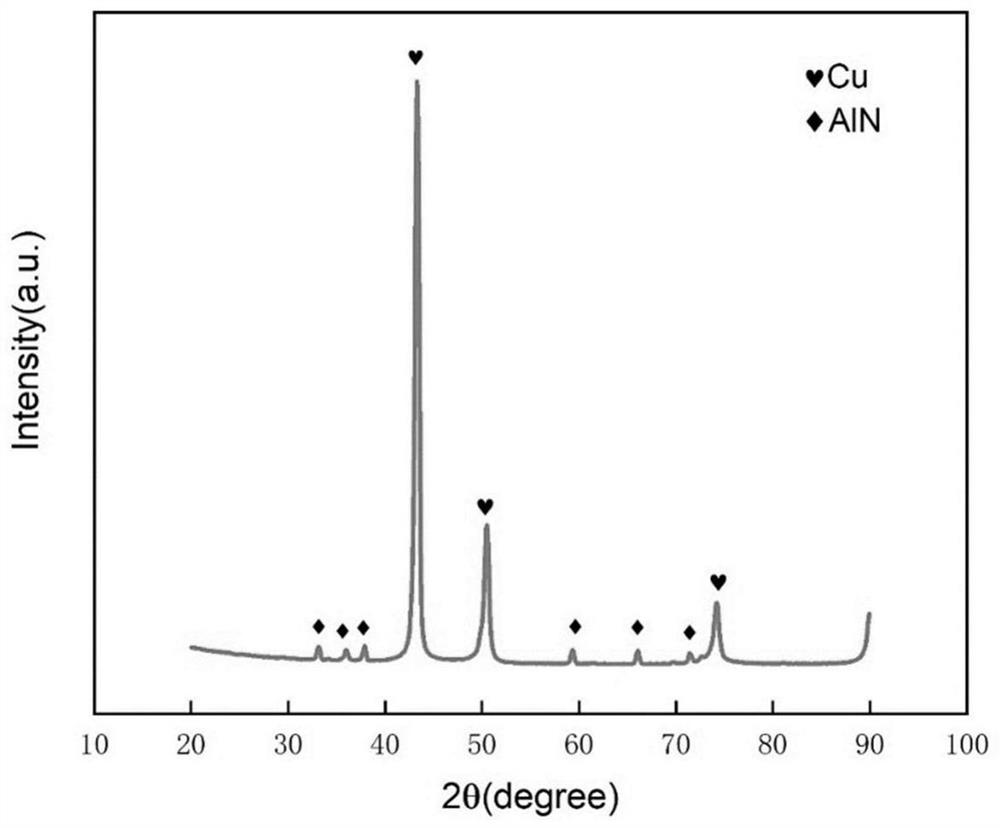

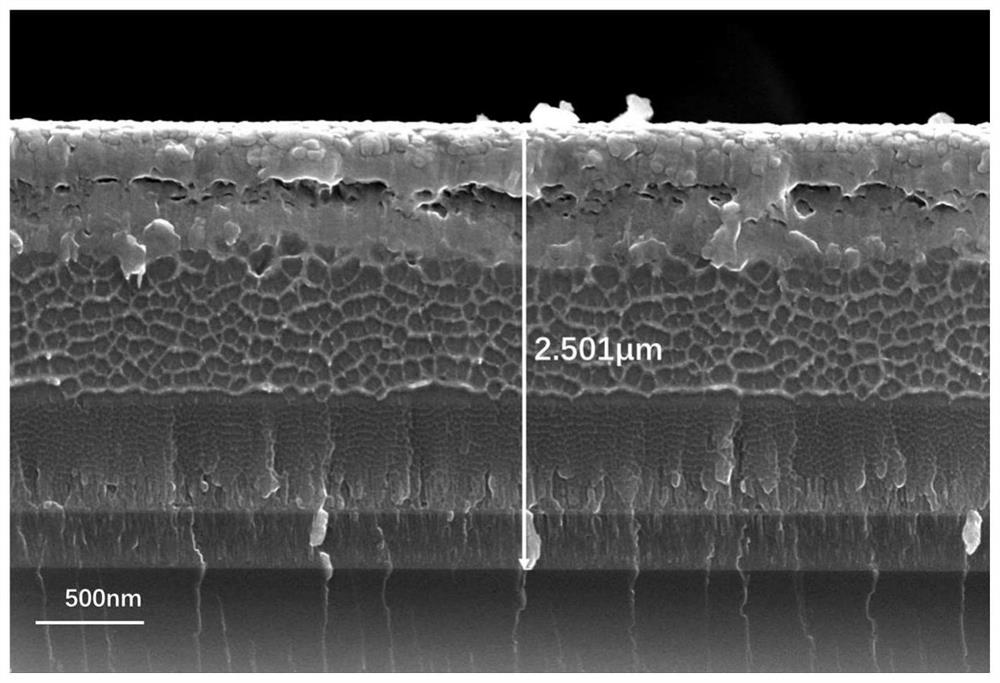

Metallization and heat sink integrated preparation method of AlN ceramic substrate

ActiveCN113174575AImprove package strengthReduce packaging process flowFinal product manufactureSemiconductor/solid-state device detailsDeposition processHeat sink

The invention discloses a metallization and heat sink integrated preparation method of an AlN ceramic substrate. According to the preparation method, a Ti metallization layer, a Ti-Cu gradient transition layer and a Cu heat sink layer are sequentially formed on the AlN ceramic substrate by the aid of a physical vapor deposition technology, and a transition layer Al3Ti+TiN is formed between an AlN layer and a Ti layer in the deposition process. The method specifically comprises the steps that surface polishing treatment is performed on the AlN ceramic substrate; the polished AlN ceramic substrate is soaked, cleaned and then dried; the surface of the cleaned AlN ceramic substrate is sequentially plated with the Ti metallization layer, the Ti-Cu gradient transition layer and the Cu heat sink layer by the aid of a magnetron sputtering deposition method, in the deposition process, the transition layer Al3Ti+TiN is automatically formed between the AlN layer and the Ti layer, and finally, the metallization and heat sink integrated AlN ceramic substrate is formed. According to the method, the metallization and heat sink integrated plating layer is deposited on the AlN ceramic substrate by the aid of the high vacuum magnetron sputtering technology, so that the overall packaging strength is greatly improved, the packaging process flow is shortened, the packaging consumption is reduced, and the production cost is remarkably reduced.

Owner:XI AN JIAOTONG UNIV

Handheld type forming device for R-zone filler and forming method

Owner:XIAN AIRCRAFT IND GROUP

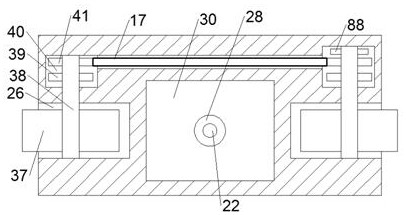

Constant-temperature incubation system

ActiveCN111307566AAdaptableImprove compatibilityHeating or cooling apparatusPreparing sample for investigationLoop controlControl system

The invention discloses a constant-temperature incubation system. The constant-temperature incubation system comprises a container and incubation units. Each incubation unit comprises a rack, a graphene heat conduction plate, a constant temperature module, a cooling fin, a temperature feedback circuit board and an upper cover; a container groove is formed in an upper cover. Each graphene heat conduction plate is arranged on the side surface of a container groove. Each constant temperature module abuts against each graphene heat conduction plate. Each cooling fin is arranged on the outer side of each constant-temperature module. Each temperature feedback circuit board is integrated with each temperature sensor and is arranged on the side surface of each graphene heat conduction plate; and each main control board comprises a heating control module and a communication module, and each heating control module is connected with each constant temperature module and the temperature feedback circuit board of each incubation unit through the communication module to form a temperature closed-loop control system of each incubation unit. The constant-temperature incubation system can carry outindependent closed-loop control on the constant-temperature module of each incubation unit so as to realize accurate control on different constant-temperature incubation temperatures of different samples or products.

Owner:北京倍肯恒业科技发展股份有限公司

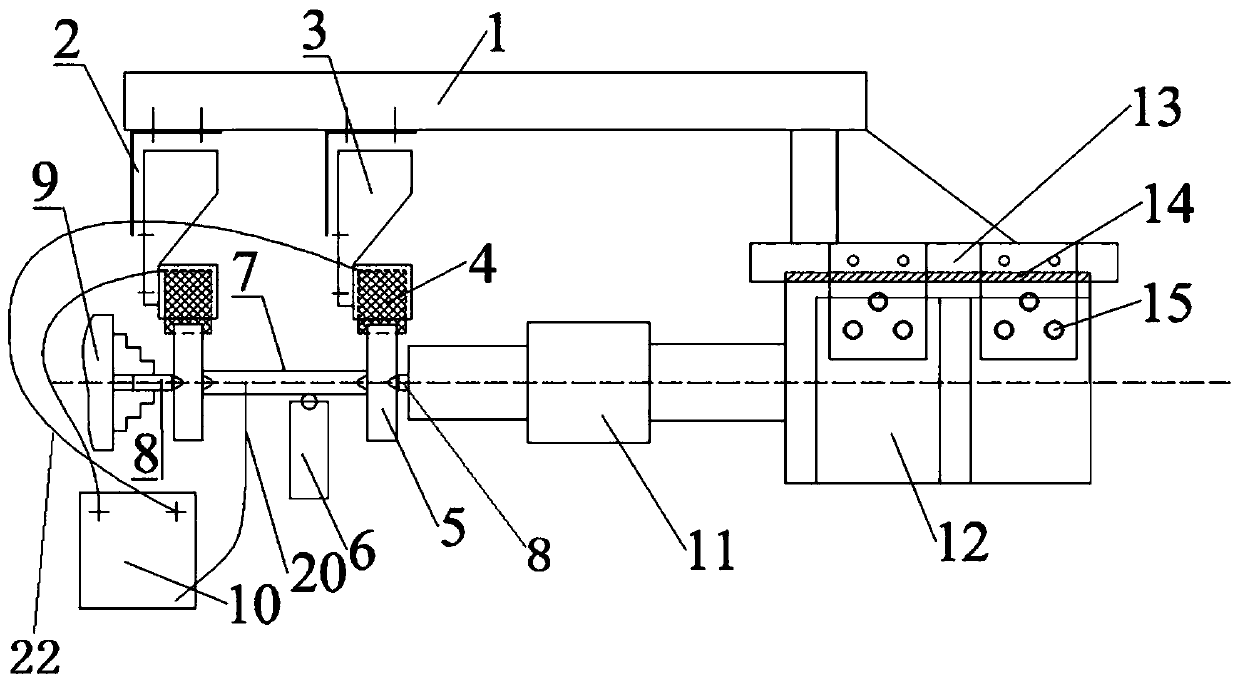

A high-frequency direct current heating auxiliary rolling processing device and processing method thereof

ActiveCN108406224BReduce deformation resistanceRolling processing effect is obviousMetal working apparatusClosed loopCopper electrode

The invention relates to a high-frequency direct-current heating auxiliary rolling device added on a machine tool. The high-frequency direct-current heating auxiliary rolling device comprises a rolling device, a heating component and a loading component; the rolling device is fixedly mounted on a cutter frame of the machine tool; and a rolling head is towards parts to be machined. The heating component comprises a high-frequency direct-current power supply, two copper electrodes and two electric brushes; and the high-frequency direct-current power supply, the two electric brushes, the two copper electrodes and the parts to be machined are connected through leads to form a closed loop. The loading component comprises an electric brush frame, two insulation fixed thimbles and an insulation revolving thimble; and in the horizontal direction of the machine tool, a machine tool tail base, the insulation revolving thimble, the first insulation fixed thimble, the first copper electrode, the parts to be machined, the second copper electrode, the second insulation fixed thimble and a power tool power chuck are coaxially clamped in sequence. The invention further relates to a machining method of the high-frequency direct-current heating auxiliary rolling device. The device is simple in structure, convenient to operate and high in practicability, and belongs to the field of metal machining equipment.

Owner:SOUTH CHINA UNIV OF TECH

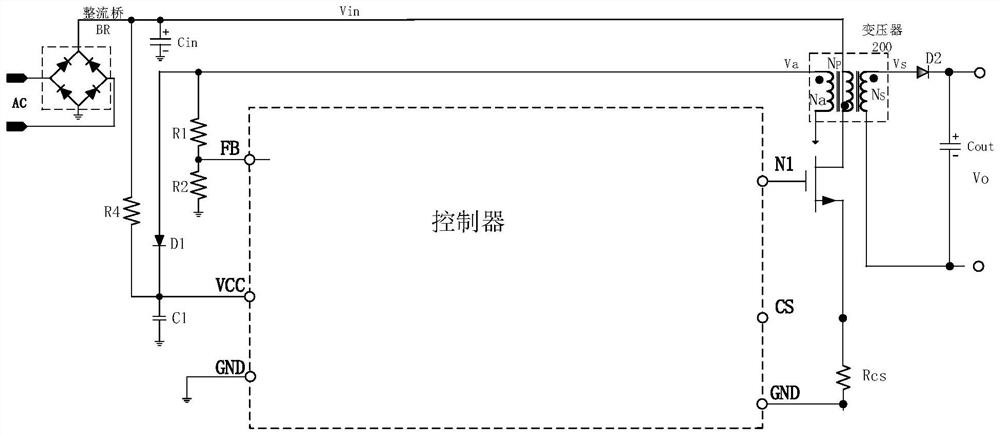

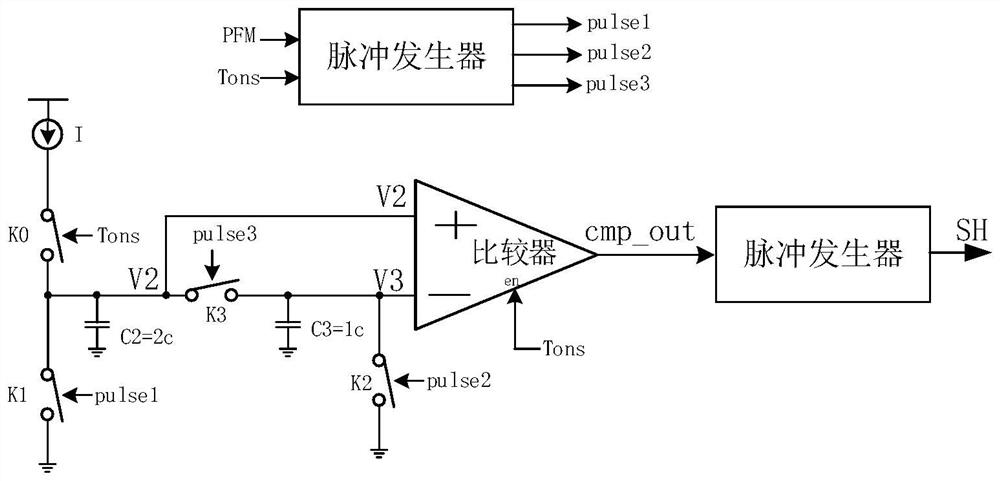

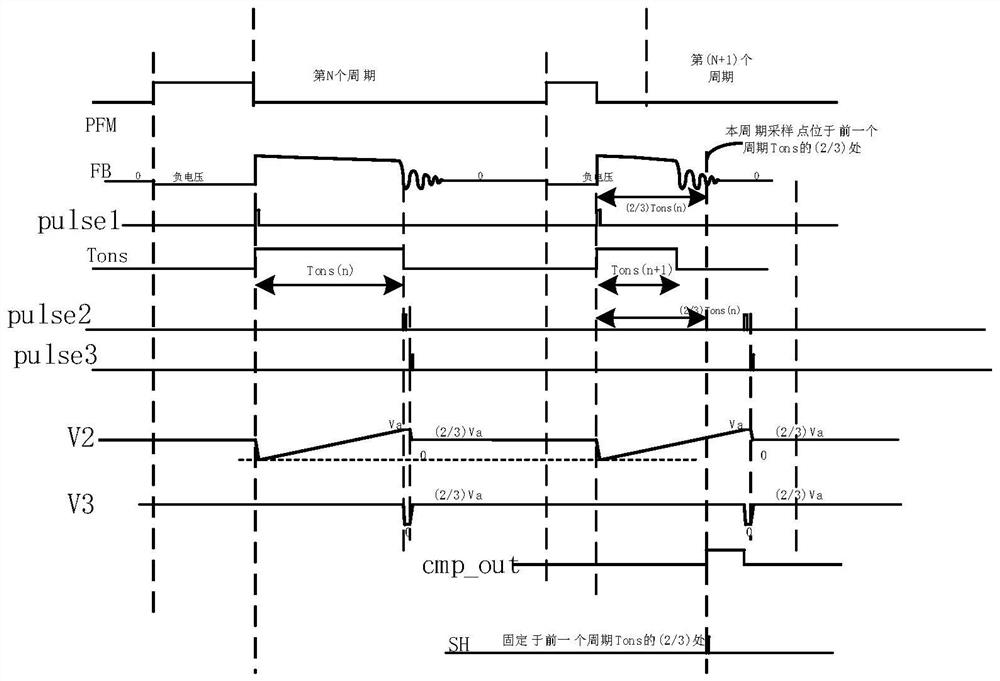

Sampling and holding structure, controller, alternating current-to-direct current switching power supply and sampling method

PendingCN114726238ANot subject to changeNot affected by sizeEfficient power electronics conversionCurrent/voltage measurementCharge currentControl engineering

The invention provides a sampling and holding structure, a controller, an AC-to-DC switching power supply and a sampling method, the sampling and holding structure comprises a charging module, a discharging module, a control module and a sampling module, the discharging module comprises an energy storage element and a discharging unit, the charging module is used for charging the energy storage element, and the discharging unit is used for discharging the energy storage element. The sampling module is used for collecting voltage of a feedback end of a transformer auxiliary winding of the AC-DC switching power supply, the control module is used for sending a sampling signal to the sampling module at a set proportion of transformer secondary side degaussing time, and the set proportion is in direct proportion to a ratio of a charging current during charging of an energy storage element to a discharging current during discharging of the energy storage element. According to the invention, the sampling time of the period can be determined according to the demagnetization time of the period, and the sampling time is not influenced by the change and magnitude of the primary peak current of any period.

Owner:西安致芯微电子有限公司

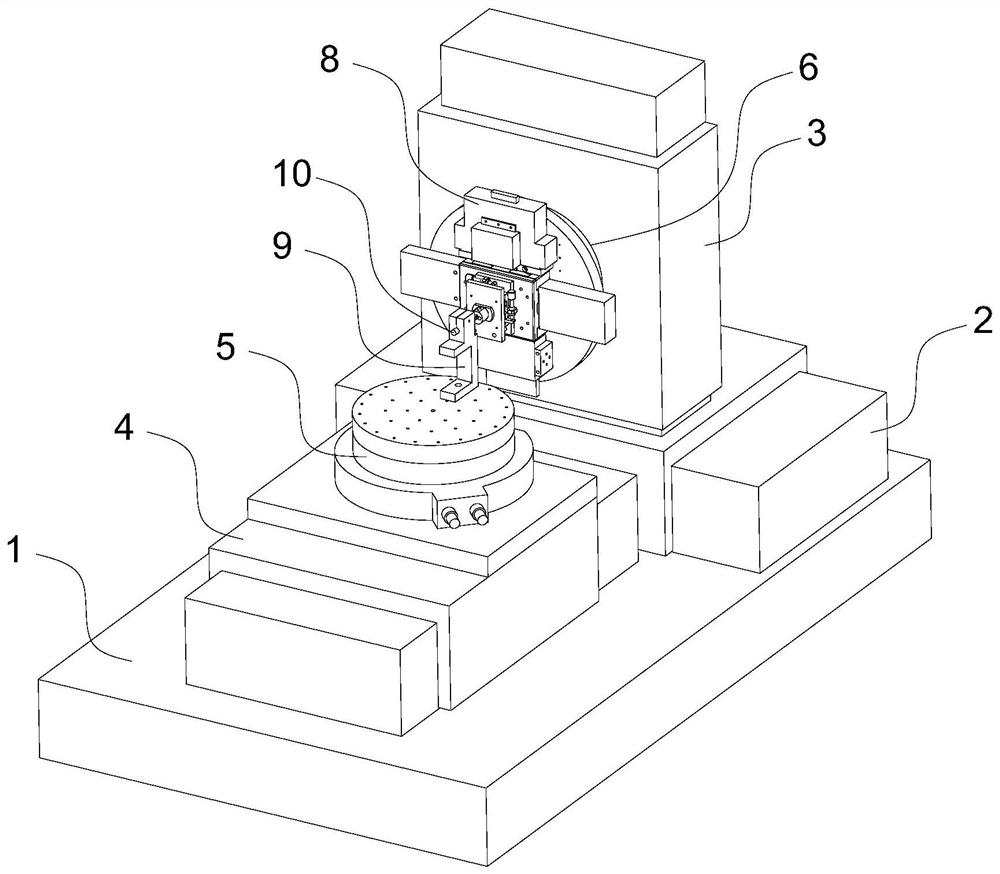

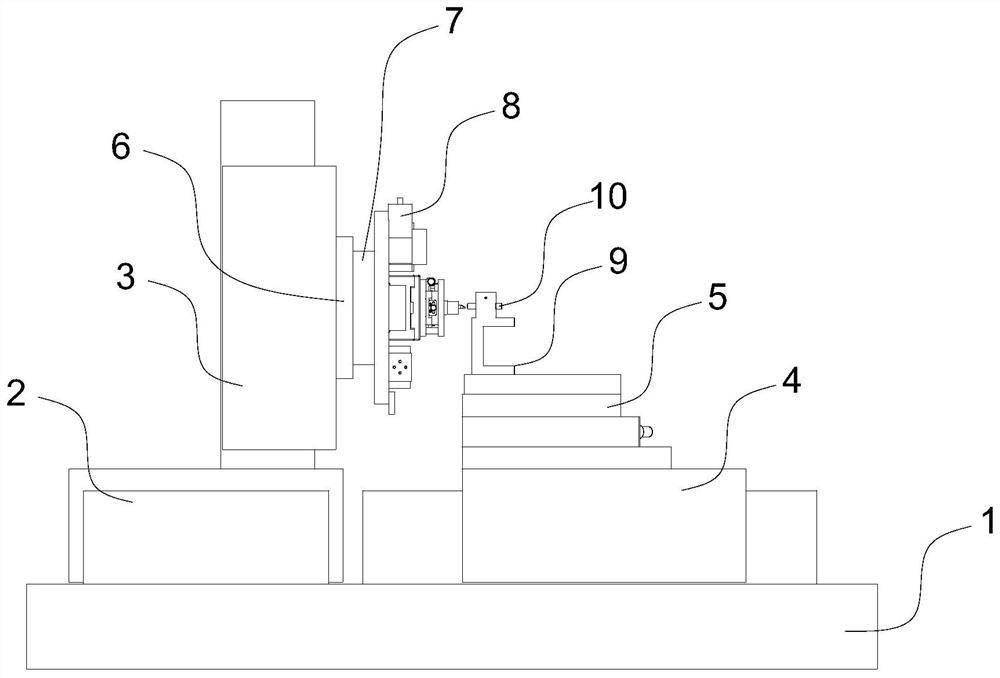

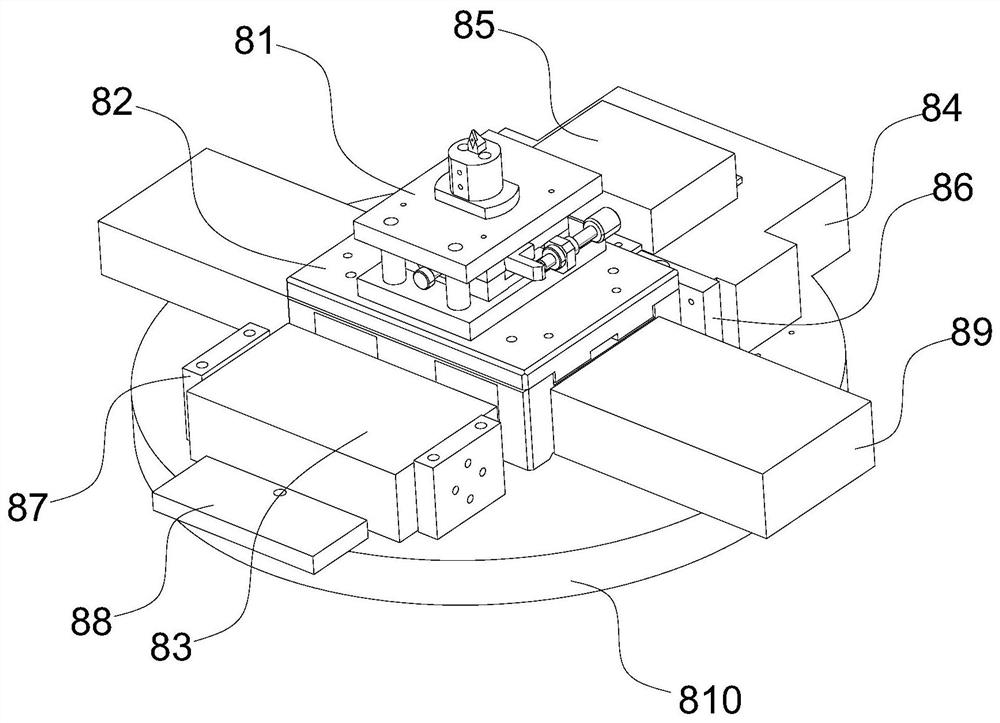

Micro-structure array processing device and method based on variable-pitch fly cutter cutting

ActiveCN113601257AProcessing hasOptimizing centrifugal forceAutomatic control devicesFeeding apparatusElectric machineEngineering

The invention discloses a micro-structure array processing device and method based on variable-pitch fly cutter cutting, and belongs to the technical field of ultra-precision turning. The processing device comprises a base, a machine tool X axis, a machine tool Y axis, a machine tool Z axis, a machine tool B axis, a machine tool C axis, a vacuum suction cup, a variable-pitch fly cutter x axis and a workpiece clamp. In the micro-structure processing process, a linear motor, a voice coil motor and a piezoelectric positioning platform which are subjected to high-rigidity and high-frequency processing are selected to precisely control the rotation radius of a tool, so that the centrifugal force condition caused by eccentric rotation of the tool can be optimized to a certain extent, and fly-cutting processing has the capability of processing common micro-structures under the condition that slow tool or fast tool servo is not relied on; and compared with common turning processing, the fly-cutting processing has the advantage that the rotation axis is variable, therefore, the fly-cutting processing has the capability of processing a micro-structure array.

Owner:霖鼎光学(上海)有限公司

A Measuring Tool Based on the Part's Own Runout Measurement

InactiveCN102967249BNot affected by sizeVarious locationsMechanical measuring arrangementsBody positionsEngineering

The invention relates to a measuring tool for multiple round mouth pulsation measurement based on parts. The measuring tool comprises a main body positioning device and a measuring device vertically connected. The main body positioning device mainly comprises a positioning base (1) and a roller frame (2). The roller frame (2) is connected with the right end of the positioning base (1). The measuring device mainly comprises a lever (3), a gauge stand (4) for installing a dial indicator and a measuring head (5), wherein the upper end of the lever (3) is connected with the upper end of the gauge stand (4) for installing the dial indicator, the lower end of the lever (3) is connected with the measuring head (5), and the lever (3) is vertically connected with the positioning base (1). The measuring tool for multiple round mouth pulsation measurement based on parts provided by the invention particularly can ensure accurate measurement of parts, and reduce the manufacturing cost of tools, in particular to measurement of large parts. As the measuring tool is small in size, the measuring tool can be directly placed on the parts, therefore, the measuring tool is light and convenient to use, and is not affected by fields and part placing states.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

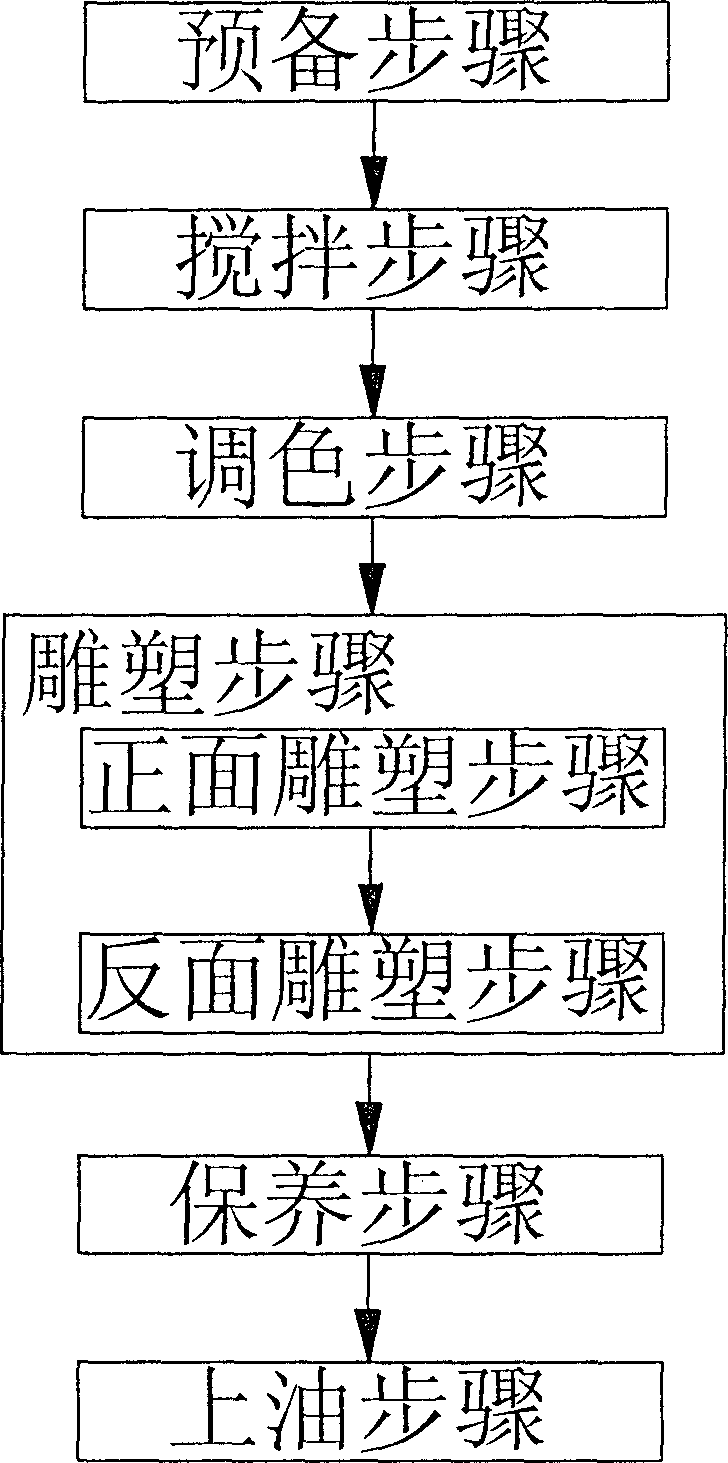

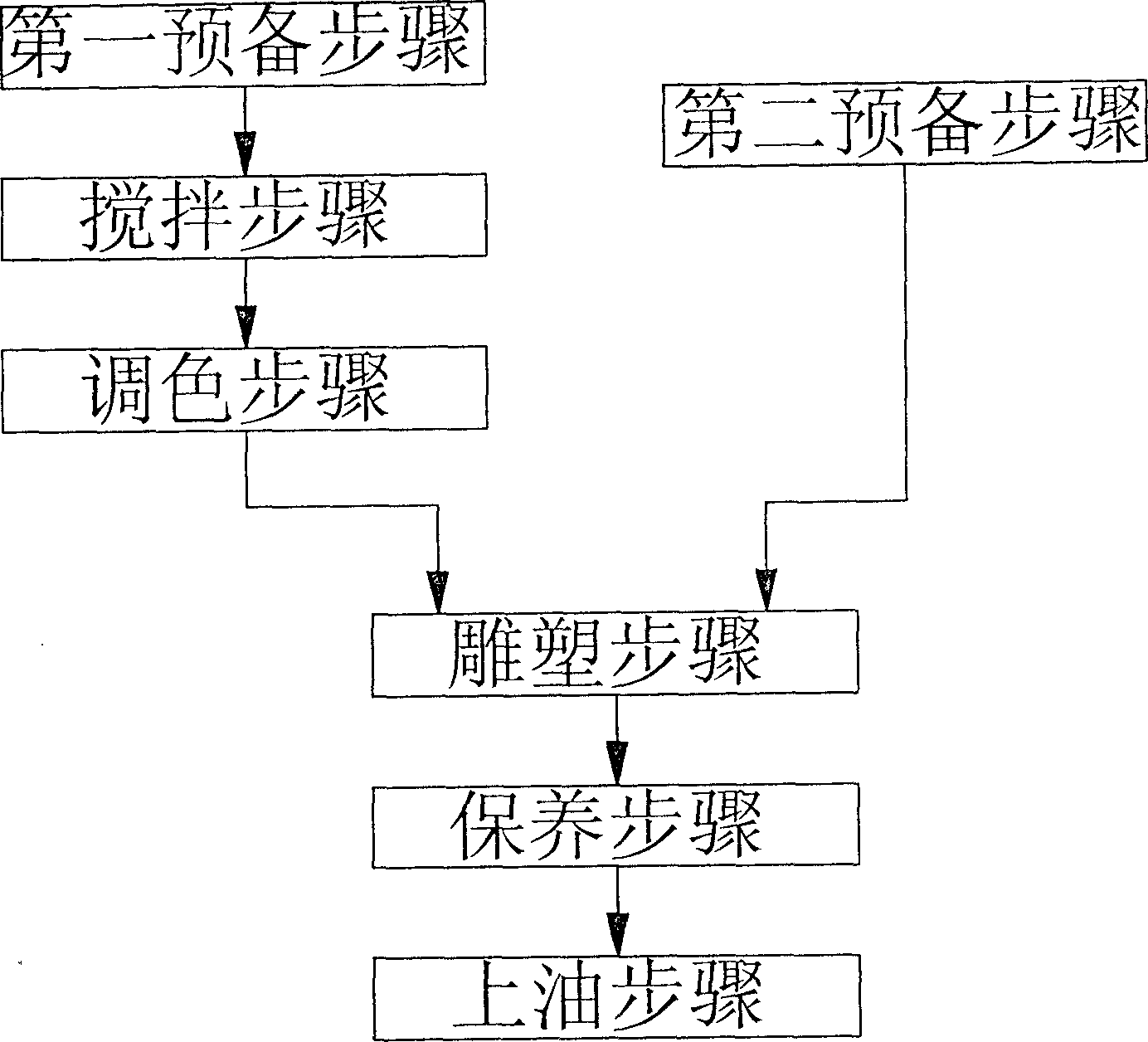

Cement colored painting and sculpturing method

InactiveCN107323150AEasy to processReduce manufacturing costOrnamental structuresGreenhouseColourant

The invention discloses a cement color painting sculpture method. A method for cement painted sculptures, comprising: a preparatory step; for uniformly mixing sand and cement; a stirring step: adding water to the mixture and stirring until uniform; a coloring step: adding cement colorants to the uniformly stirred mixture Carry out toning; Sculpture step: Sculpture an image on the mixed material after toning; Maintenance step: Place the sculpted sculpture in the greenhouse for maintenance for several days; Oiling step: On the outer surface of the maintained sculpture Apply Colorless Brightening Oil. The invention has the advantages of simple processing, low manufacturing cost and high manufacturing efficiency.

Owner:蒋华

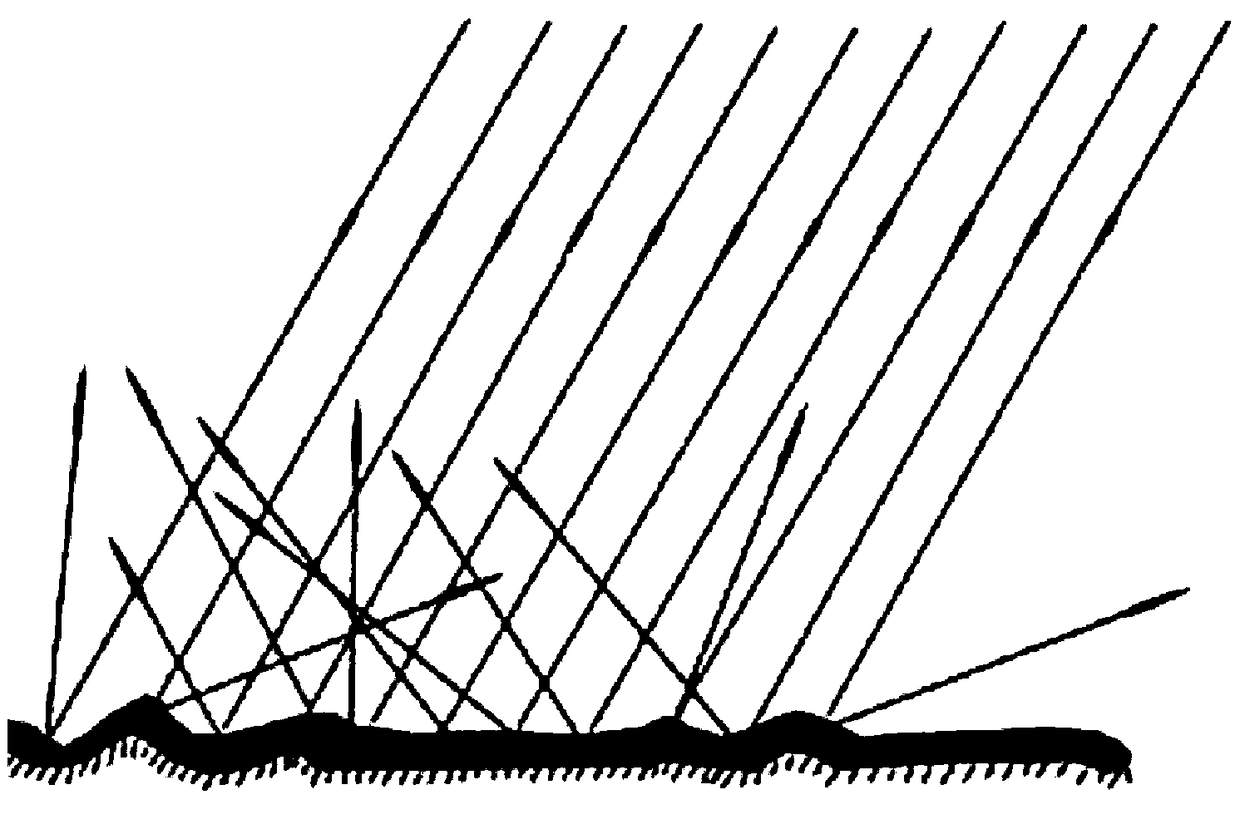

CIS (Contact Image Sensor) camera for circuit board and light source module

PendingCN108801921AImprove detection efficiencyImprove detection accuracyOptically investigating flaws/contaminationUsing optical meansContact image sensorOptical axis

The invention discloses a CIS (Contact Image Sensor) camera for a circuit board and a light source module. The CIS camera comprises a CIS line-scan digital camera, a main light source and an auxiliarylight source, wherein both the main light source and the auxiliary light source are linear light sources; the main light source and the auxiliary light source are positioned on a side of the CIS line-scan digital camera and are used for providing a light source for camera shooting; the main source is arranged on at least one of both sides of the optical axis of the CIS line-scan digital camera; the auxiliary light source is arranged on the other side of the optical axis of the CIS line-scan digital camera; shot surfaces are arranged on light outgoing directions of the main light source and the auxiliary light source; the optical axis of the CIS line-scan digital camera is not perpendicular to the shot surfaces; main light of both the main light source and the auxiliary light source is notperpendicular to the shot surfaces; and main light of the optical axis of the CIS line-scan digital camera, the main light of the main light source and the main light of the auxiliary light source isintersected on a same straight line of the shot surfaces. The CIS camera is high in application flexibility, low in equipment cost and high in detection precision.

Owner:佛山市坦斯盯科技有限公司

Method for splicing bobbin paper of cigarette making machine

ActiveCN102090713BSplicing is reliableSplicing leftover is smallCigarette manufactureWebs handlingBobbinAdhesive

The invention discloses a method for splicing bobbin paper of a cigarette making machine. The method comprises the following steps that: a controller operably connected with each air cylinder, a bobbin paper cutter and a bobbin paper drive roller is provided; the controller starts a second bobbin paper drive roller to transmit second bobbin paper till the transmitting speed of the second bobbin paper is the same as the transmitting speed of the first bobbin paper when a mark detector detects a first mark, wherein the mark detector is arranged on the downstream of a first air cylinder and a second air cylinder along a work bobbin paper adjacent path, and the first mark is arranged on the first bobbin paper and keeps a first distance with an inner ring of the first bobbin paper; the second air cylinder moves to jack the second bobbin paper wound around a tension roller of the second air cylinder outside to be propped against the first bobbin paper when the mark detector detects a second color block, and the second bobbin paper is adhered and lapped with the first bobbin paper wound around the tension roller of the first air cylinder through an adhesive, wherein the second mark is arranged on the first bobbin paper and keeps a second distance with the inner ring of the first bobbin paper, and the second distance is smaller than the first distance; and the controller drives a bobbin paper cutter arranged on the downstream side of the tension roller of the second air cylinder and a bobbin paper cutter arranged on the upstream side of the tension roller of the first air cylinder to respectively cut off the first bobbin paper and the second bobbin paper, thus the second bobbin paper as a spare bobbin paper is converted into working bobbin paper.

Owner:LONGYAN CIGARETTE FACTORY

ATM equipment terminal wind and rain testing method

InactiveCN110440992ANot affected by sizeThe test result is accurateDetection of fluid at leakage pointVery high resistance measurementsEngineeringAir blower

The invention discloses an ATM equipment terminal wind and rain testing method. The method comprises the following steps: step one, placing an ATM testing machine in a rainwater testing region; step two, mounting an air blower, enabling the height of the air blower to be consistent with the ATM testing machine panel region height; step three, mounting a raining device, wherein the raining device is arranged at a location between the air blower and the ATM testing machine; step four, setting a testing condition: the rain is existent and the wind is inexistent at the first level; the rain is existent and the wind speed is 20km / h at the second level, the rain is existent and the wind speed is 40km / h at the third level, and the rain is existent and the wind speed is 60km / h at the fourth level;performing the testing in an order to the fourth level from the first level, testing and evaluating the ATM testing machine at each level and performing trice cash transaction testing to verify the terminal and the module functions; step five, debugging a testing mechanism; and step six, beginning testing and recording a testing result, and obtaining the testing score by referring to the criterion standard. Through the above way, the design defect can be more discovered at a design end in comparison with the existing rain test.

Owner:INSPUR FINANCIAL INFORMATION TECH CO LTD

CIS detecting device for circuit boards

PendingCN108760769AImprove luminous performanceEasy to installOptically investigating flaws/contaminationControl using feedbackOptical axisLine array

The invention discloses a CIS detecting device for circuit boards. The CIS detecting device comprises CIS line array cameras, linear light sources and a circuit board conveying mechanism; the linear light sources are arranged at the two sides of the CIS line array cameras, the optical axes of the CIS line array cameras and main light of the linear light sources intersect on the same straight lineof the circuit boards on the circuit board conveying mechanism; the length of the CIS line array cameras is the same as that of the linear light sources, the linear light sources are installed at thebottoms of the CIS line array cameras, and the CIS line array cameras and the linear light sources stretch across the circuit board conveying mechanism. The CIS line array cameras can simultaneously take continuous images of a portion which is located below the cameras and is comparable to the camera in length. When the number of the circuit boards needs which need to be simultaneously detected ischanged, the number of the circuit boards can be increased or decreased by adjusting the distance between every two circuit boards, so that the number of the detected circuit boards is flexibly set within a certain range without being influenced by the size of the circuit boards. Therefore, the application flexibility of the detecting device is higher, and the equipment cost is reduced.

Owner:佛山市坦斯盯科技有限公司

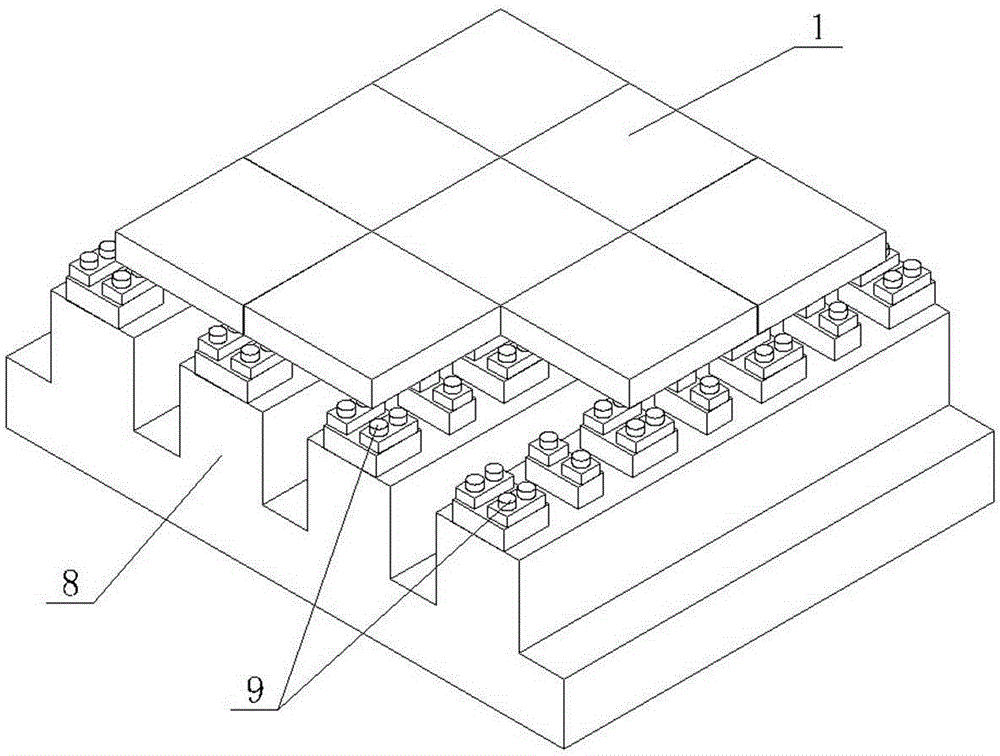

Mesa detection method and system for super large splicing platform

InactiveCN103487027BQuick checkNot affected by sizeTransmission systemsHeight/levelling measurementComputer hardwareControl cell

The invention discloses a tabletop detection method for a super-large splicing platform. The tabletop detection method comprises the steps as following: detecting all subplatforms of the splicing platform one by one through automatic walking equipment with an inclination sensor and a step difference sensor, detecting the levelness of each subplatform each time, and detecting a step difference between one subplatform and two adjacent subplatforms respectively; and transmitting detection parameters to a main control unit, and performing data processing to obtain tabletop parameters of the splicing platform, wherein the two adjacent subplatforms are subplatforms in contact with two adjacent sides of the detected subplatform. The tabletop detection system integrates a detection trolley, a walking system, an inclination detection system, a step difference detection system and a data transmission system, and can quickly detect the inclination and the step difference of the splicing platform, so that the problems of high manual detection workload, large error and high possibility of error are avoided.

Owner:BEIJING INST OF CONTROL ENG +1

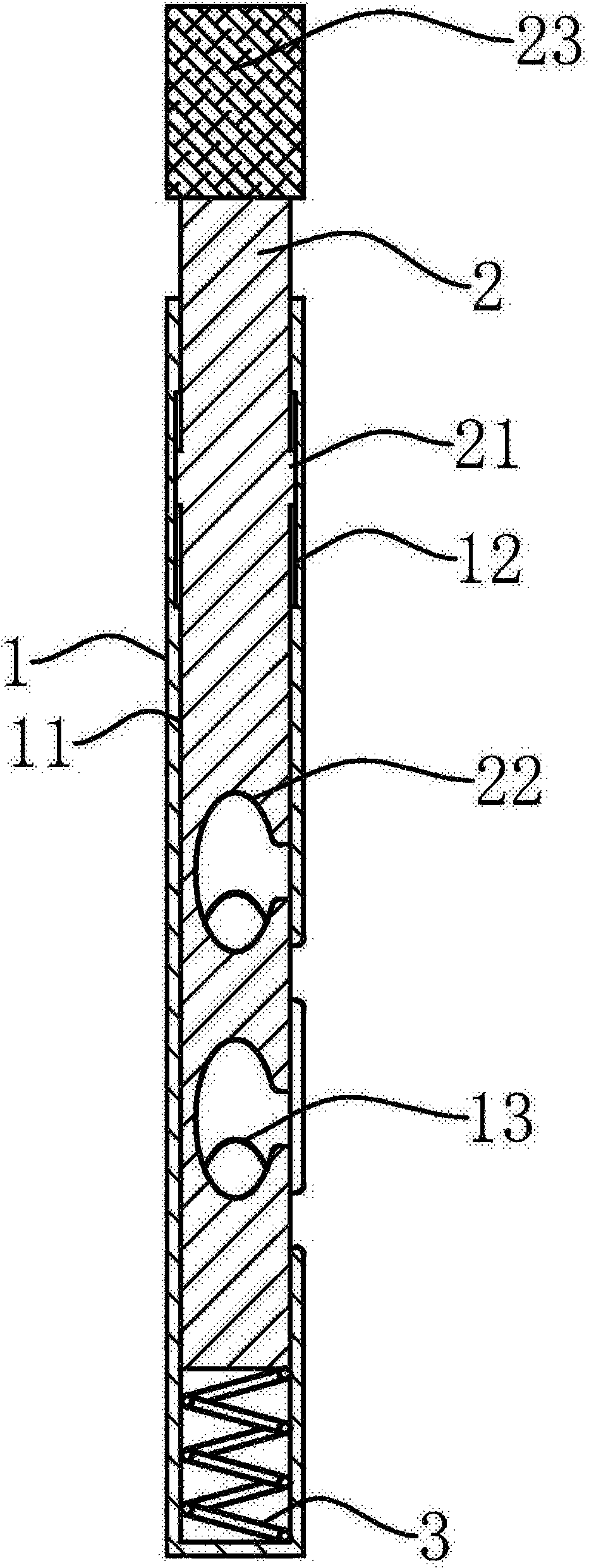

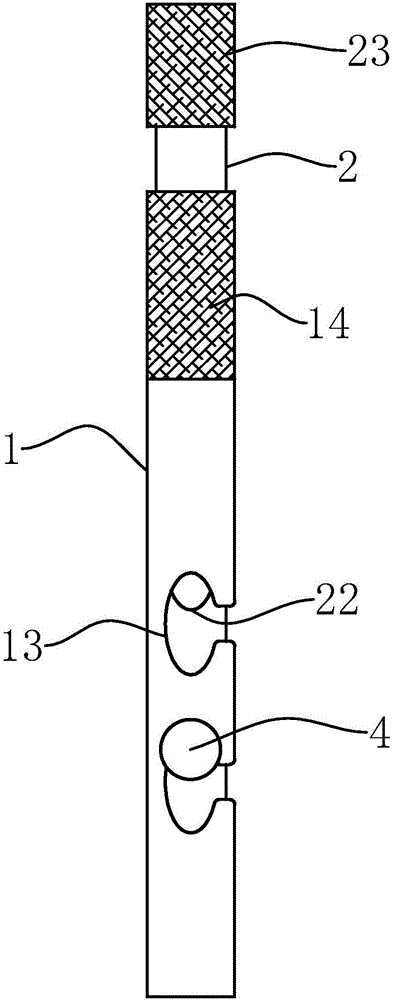

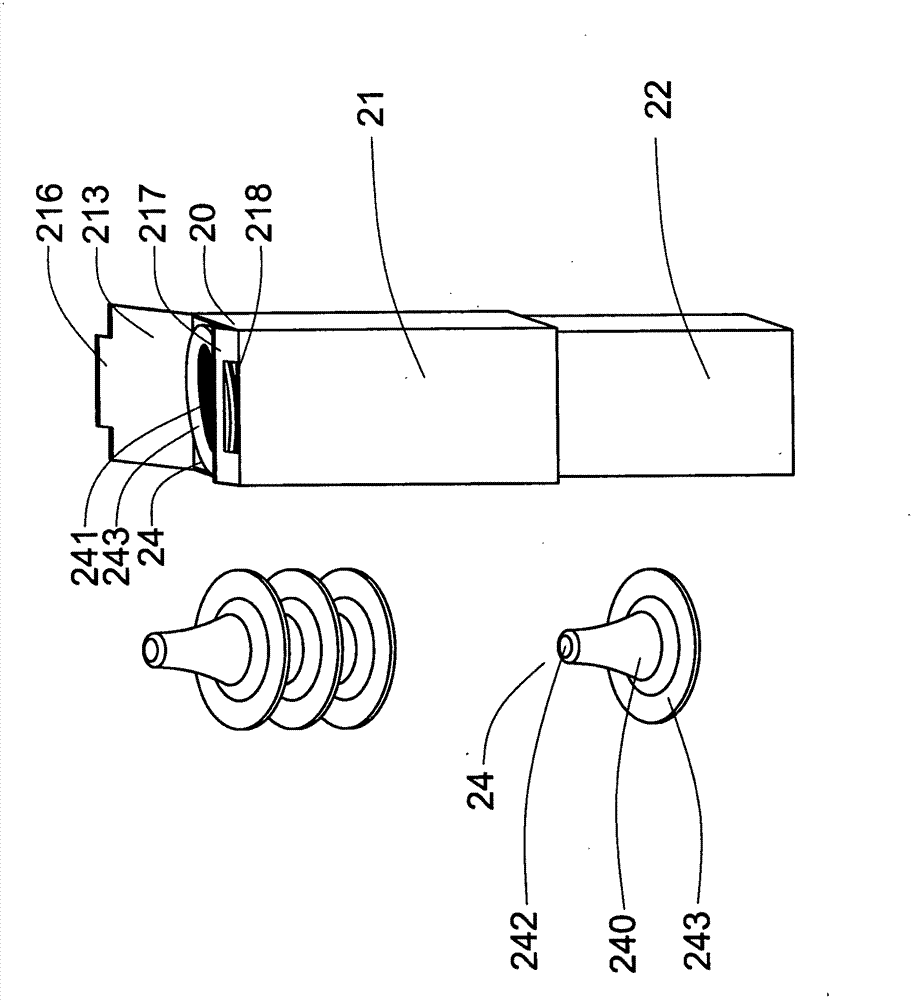

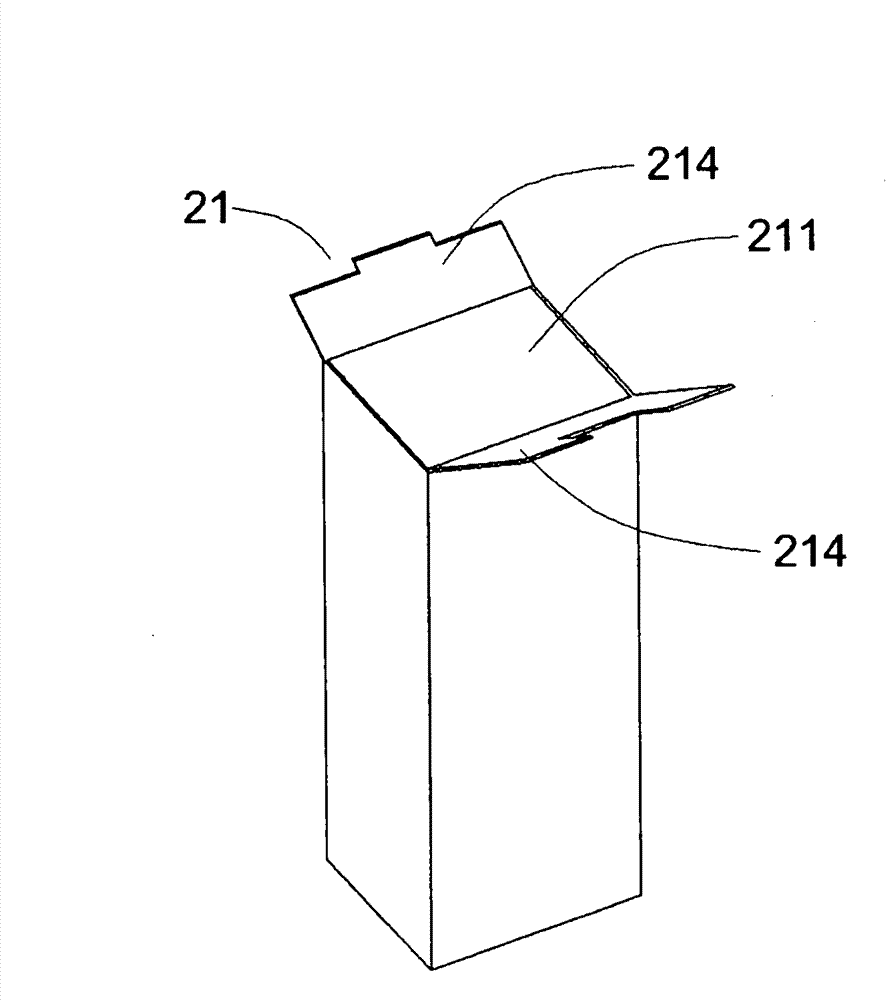

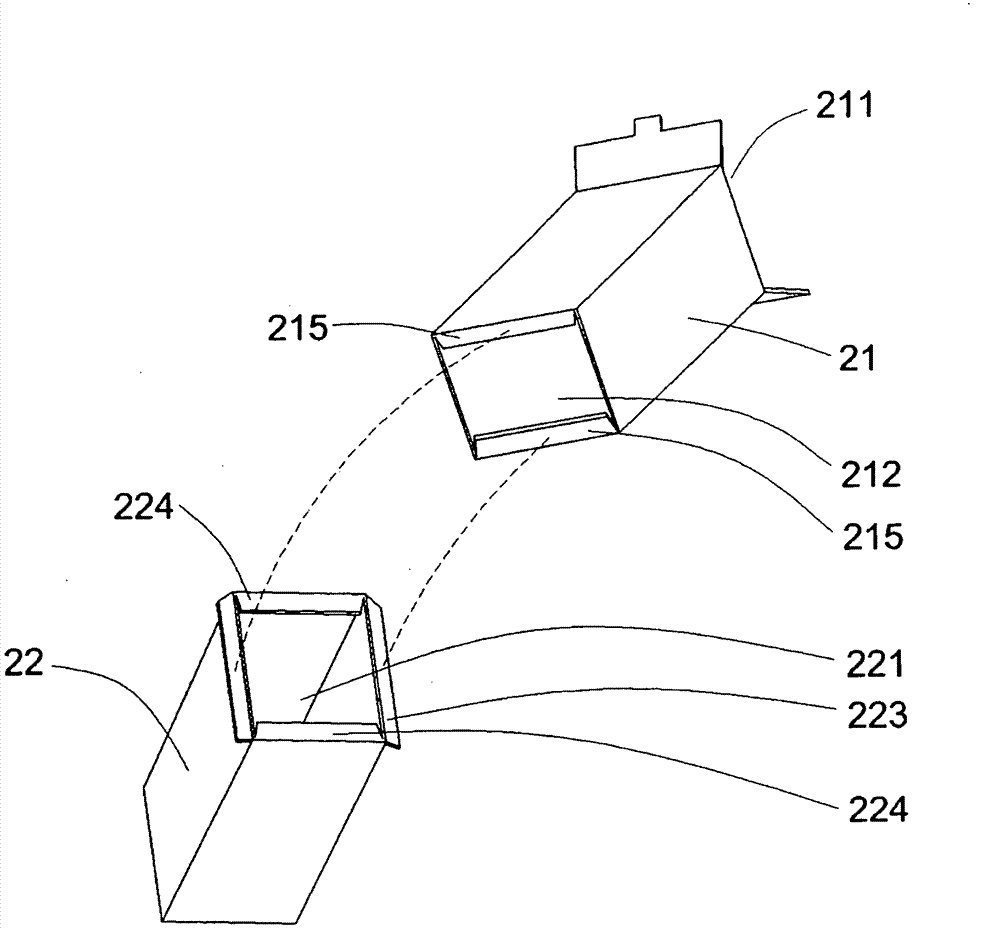

Dispensing container box for ear thermometer sheath and manufacture method thereof

InactiveCN102215769BIncrease the number of installationsEasy to installThermometer detailsRadiation pyrometryEngineeringMechanical engineering

An ear thermometer sheath configuration box (20), comprising a hollow shell (21) and a support seat (22). One end of the hollow shell (21) has a first opening (211), and the open end (241) of the ear thermometer sheath (24) faces the first opening (211) of the hollow shell (21). The other end of the hollow casing (21) opposite to the first opening (211) has a second opening (212), and at least a pair of first blocking parts (215) are arranged adjacent to the second opening (212). One end of the support seat (22) is arranged in the hollow casing (21), and the other end passes through the second opening (212) of the hollow casing (21). The support seat (22) has a third opening (221) facing the first opening (211) to accommodate the hollow body (240) of the ear thermometer sheath (24). The outer side of the support seat (22) is provided with at least one pair of second blocking portions (223) adjacent to the third opening (221) to resist the pair of first blocking portions (215h), thereby preventing the support seat (22 ) from the second opening (212).

Owner:ACTHERM INC

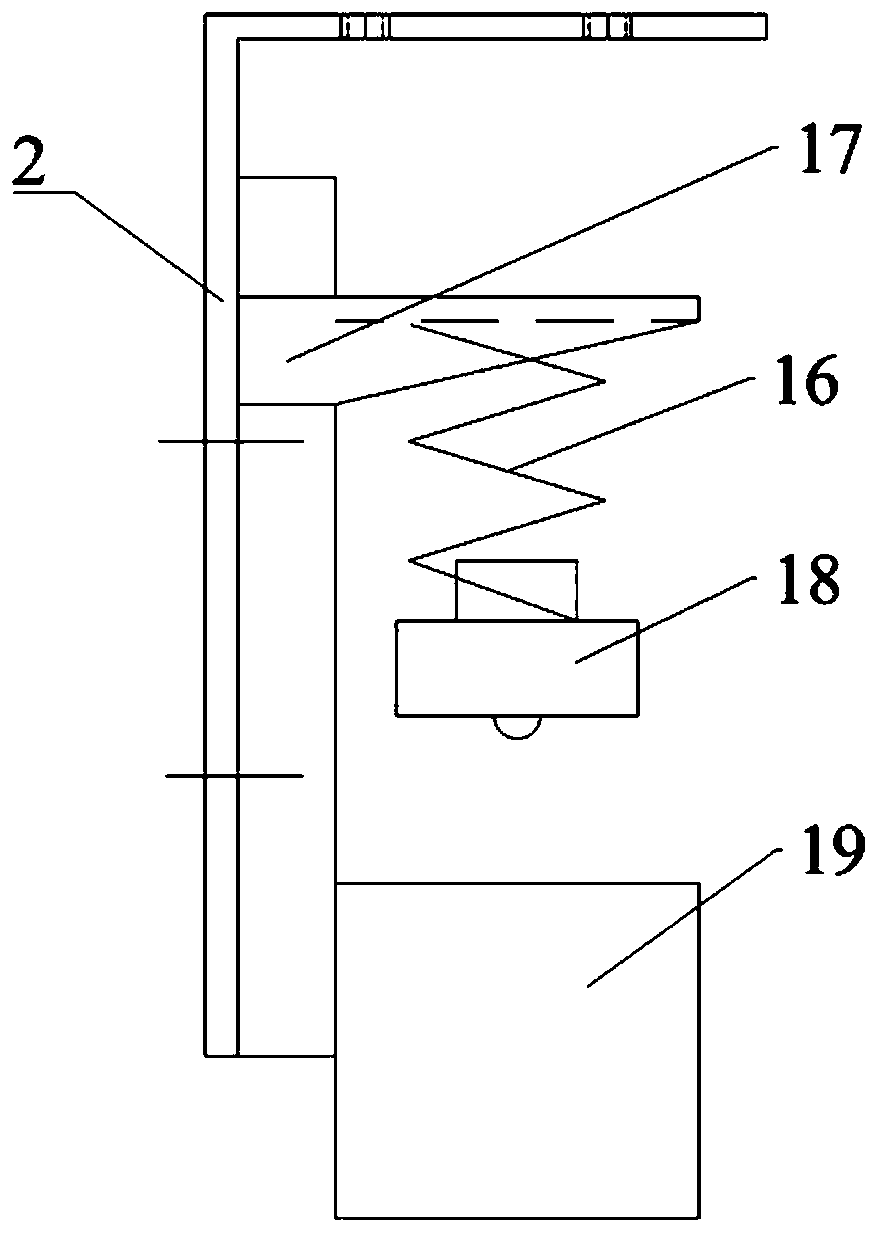

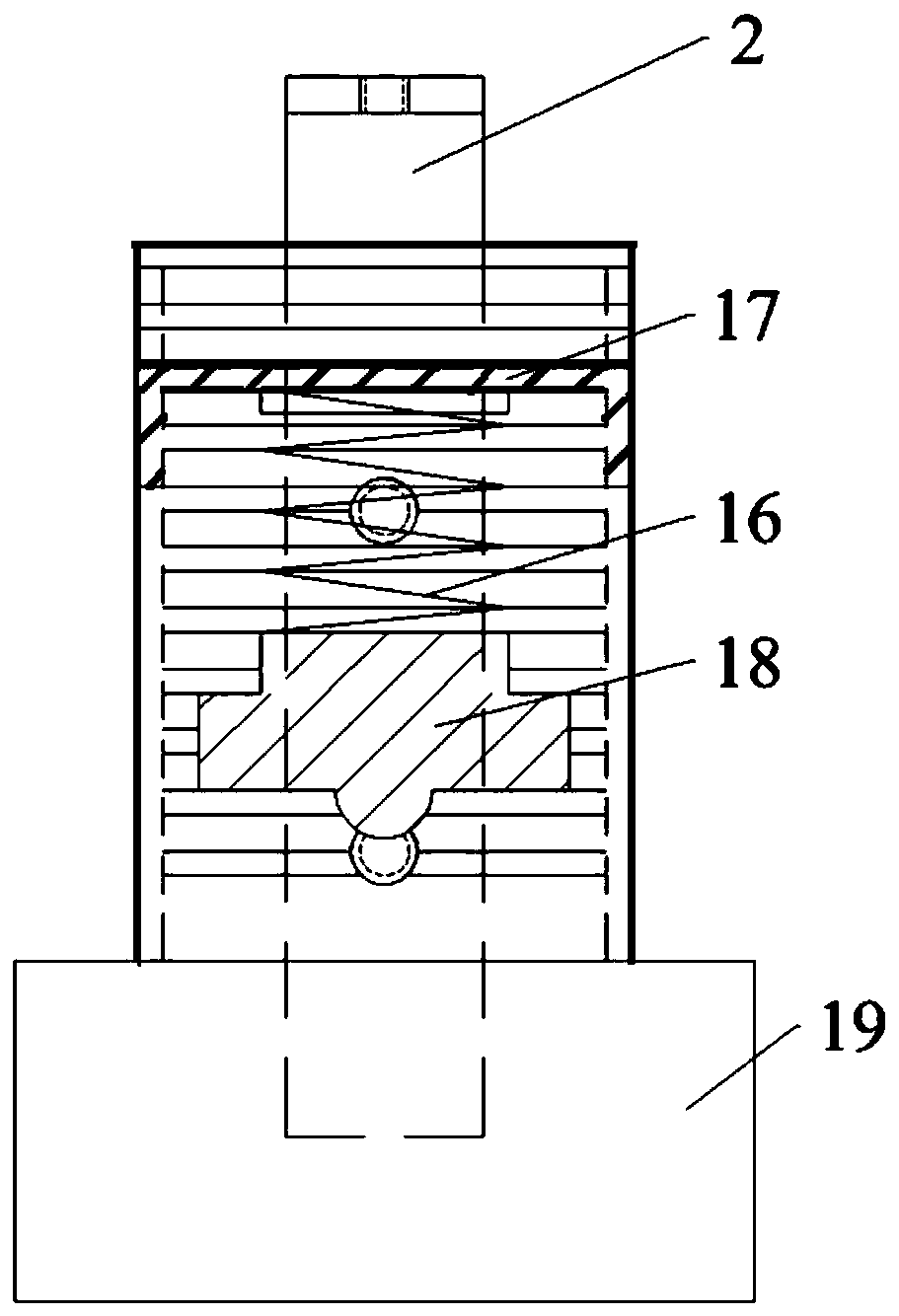

Automatic structure for scissor type clamp

PendingCN113213329ARealize automatic opening and closingNot affected by sizeLoad-engaging elementsClassical mechanicsStructural engineering

The invention relates to an automatic clamp, in particular to a clamp of a scissor type structure. The invention provides another scissor type clamp grabbing and releasing mechanism, a hook-shaped structure is arranged on a scissor arm 1, a sliding groove is formed in a connecting rod 3, a pin 5 capable of sliding in the sliding groove is additionally arranged, and automatic opening and closing of the clamp are achieved through one-hand lifting and releasing actions. According to the structure, the scissor arm 1 and the connecting rod 3 can be directly formed by means of laser cutting, additional automatic devices do not need to be added, the operation process steps are completely consistent with those of an existing automatic clamp, and are not influenced by the size of a scissor type clamp, so that wide universality and economical efficiency are achieved.

Owner:常州安兰克机械有限公司

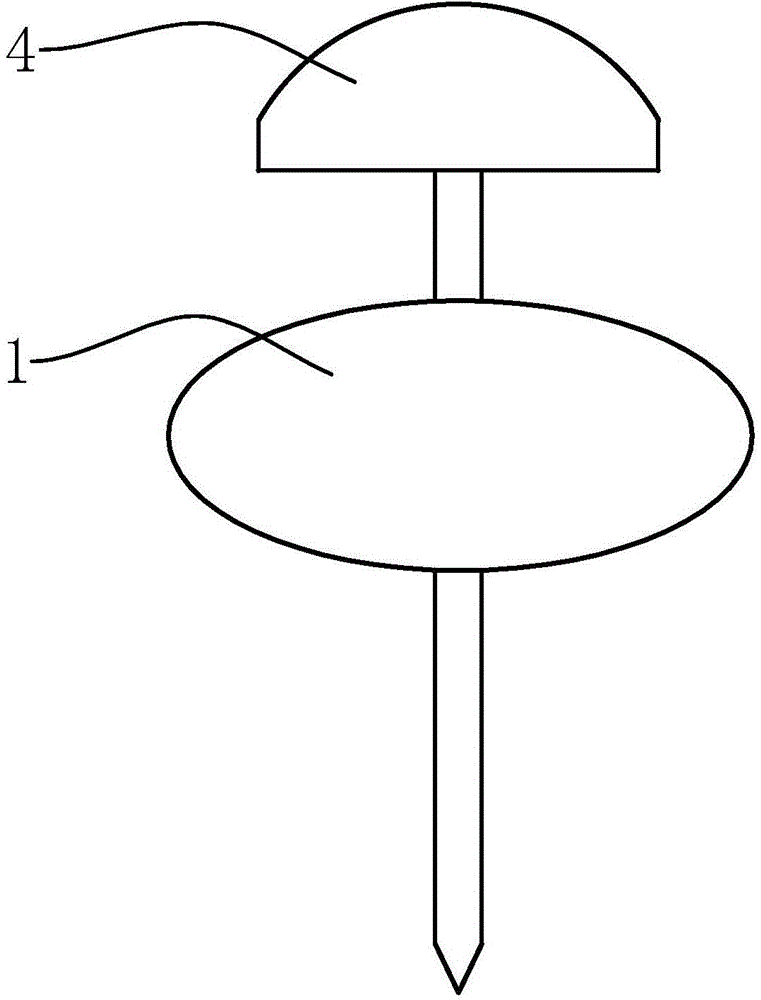

Device for exploring and collecting soil components

InactiveCN112525594AReduce volumeNot affected by sizeWithdrawing sample devicesSoil scienceStructural engineering

The invention discloses a device for exploring and collecting soil components. The device comprises a fixed shell, an exploration cavity with a downward opening is formed in the lower end face of thefixed shell, an exploration shell is installed in the exploration cavity in a sliding mode, a connecting cavity with a downward opening is formed in the lower end face of the exploration shell, and amoving block is installed in the connecting cavity in a sliding mode; An exploration drill bit is arranged on the lower side of the exploration shell, an open groove with an upward opening is formed in the upper end face of the exploration drill bit, and the lower end of the moving block is rotationally installed in the open groove. according to the present invention, the soil quality of the soillayer at the designated exploration position can be collected, and then the soil is brought to the ground, the size of the device is small, the large-scale vehicle transportation is not needed so thatthe device can be used in more environments, is not influenced by the size, and has a wider application range.

Owner:宁海牧烨农业机械科技有限公司

Solution type flow measurement device

ActiveCN104048716BHigh measurement accuracyThe flow calculation formula is simpleStationary measuring chambersMeasuring instrumentPrism

The invention discloses a solution type flow measuring device. The solution type flow measuring device is designed on the basis of a solution dilution method flow measuring principle. The solution type flow measuring device comprises a 90-degree bent cavity used for containing water flow to be measured, a water tank, a Marriott bottle used for feeding a solution at a constant-speed, and a solution concentration measuring instrument, wherein the cavity is communicated with the water tank, the Marriott bottle is arranged above the starting end of the water tank, a water damming bank is arranged at the tail end of the cavity so that the water depth and flow velocity of water flowing out of the cavity can be transversely distributed more uniform, the longitudinal section of the water damming bank is triangular, the water tank is a prism with the top open, and the length of the water tank is no smaller than nine times of the side length of the cross section of the cavity. The solution type flow measuring device is high in measuring precision of large flow, can be used for measuring the flow of water flow ejected out of a pipe, and is particularly suitable for measuring the flow under the conditions that a downhole drainage drilled hole is large in flow of outlet water.

Owner:SUZHOU MAICHUANG INFORMATION TECH

A hammer nail guard

Owner:NANTONG YAOLONG METAL MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com