Automatic structure for scissor type clamp

An automatic structure and fixture technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems that the fixture cannot be standardized and the scenes are different.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Now in conjunction with embodiment, accompanying drawing, automatic structure of the present invention is described further.

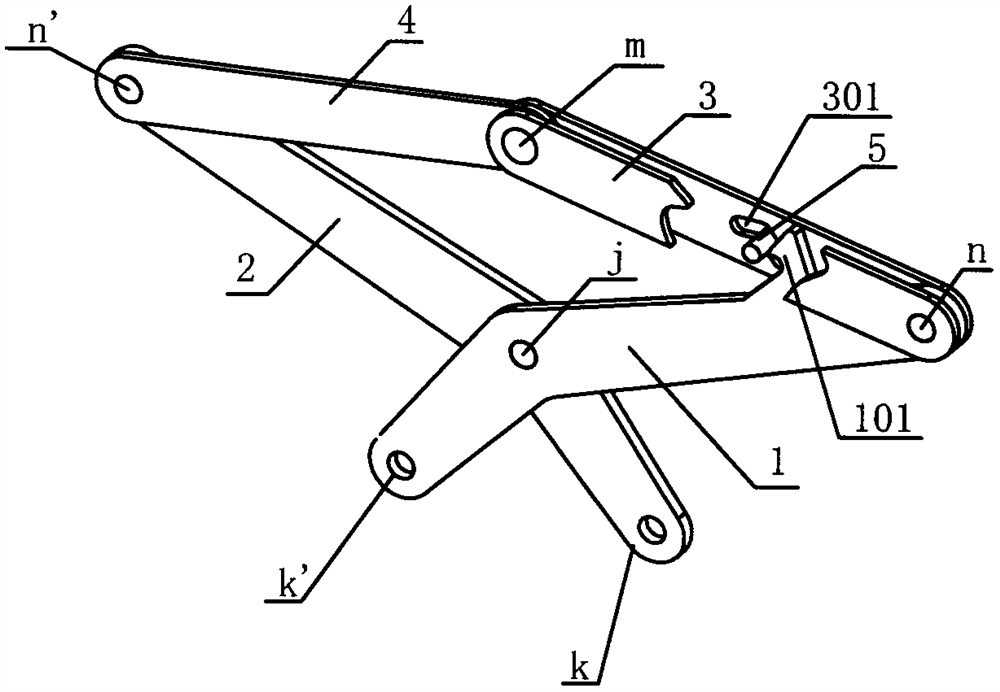

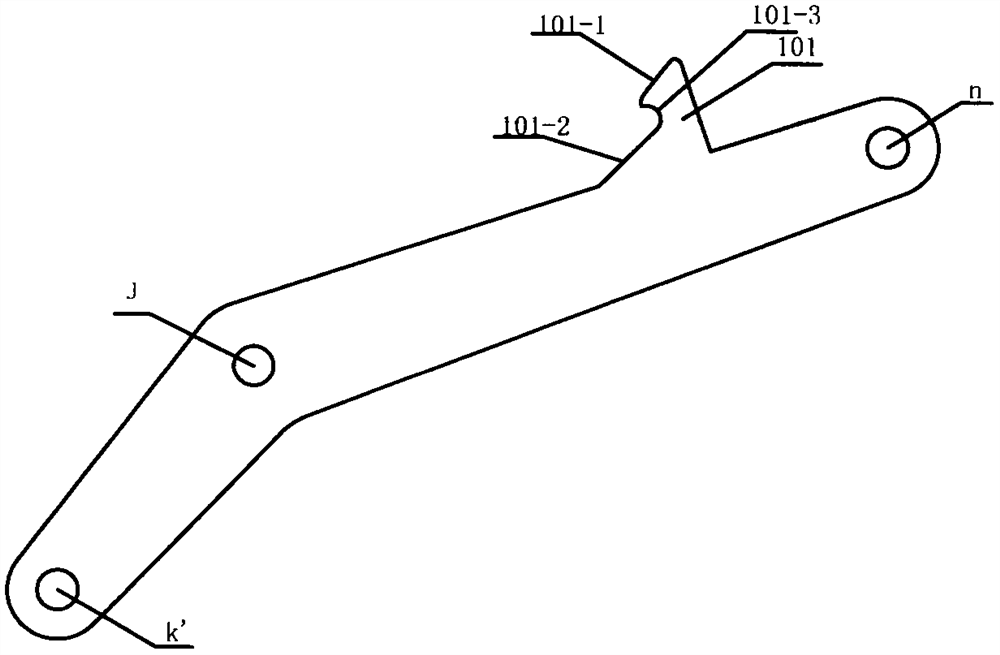

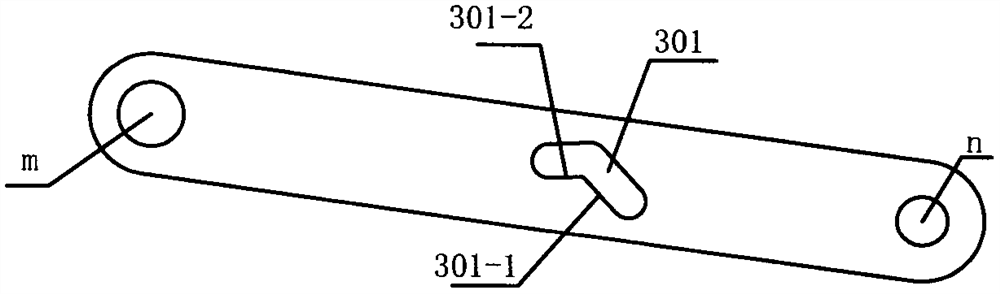

[0041] like figure 1 , Figure 5A kind of automatic structure for scissors fixture shown is characterized in that: comprise scissors arm 1, scissors arm 2, connecting rod 3, connecting rod 4, pin shaft 5, splint 6; Said scissors arm 1 and scissors arm 2 It is hinged at "j"; the upper end of scissors arm 1 is hinged at "n" with (two) connecting rods 3; the upper end of scissors arm 2 is hinged at "n'" with connecting rod 4; connecting rod 3, connecting rod 4 Hinged to each other at "m"; the two connecting rods 3 are respectively arranged on both sides of the connecting rod 4 and the scissor arm 1; there is a chute 301 on the connecting rod 3; the chute 301 is designed in an "L" shape The pin shaft 5 is limited in the chute 301 and can only roll in the chute 301; the scissor arm 1 is provided with a hook structure 101; the guide rod 601 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com