Metallization and heat sink integrated preparation method of AlN ceramic substrate

A ceramic substrate and metallization technology, which is applied in metal material coating technology, electric solid devices, semiconductor devices, etc., can solve the problem of package thermal conductivity, connection strength, package air tightness, poor bonding strength, and surface metallization difficulties, etc. Problems, achieve the effect of shortening the packaging process, reducing adverse effects, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

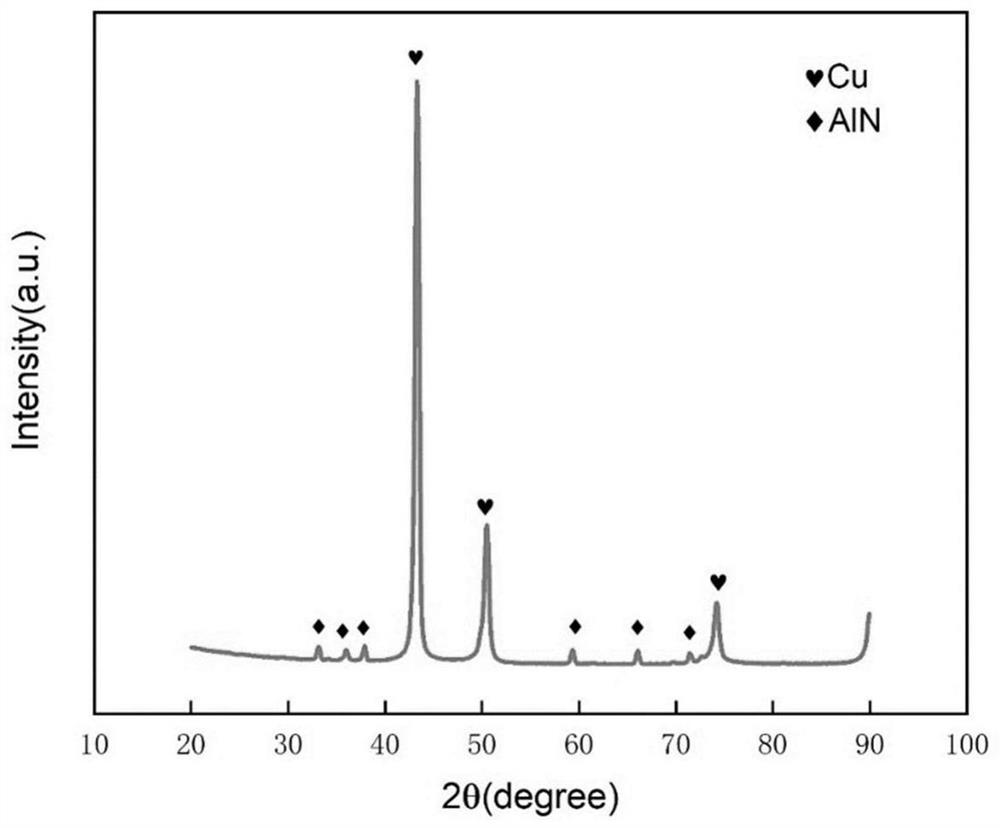

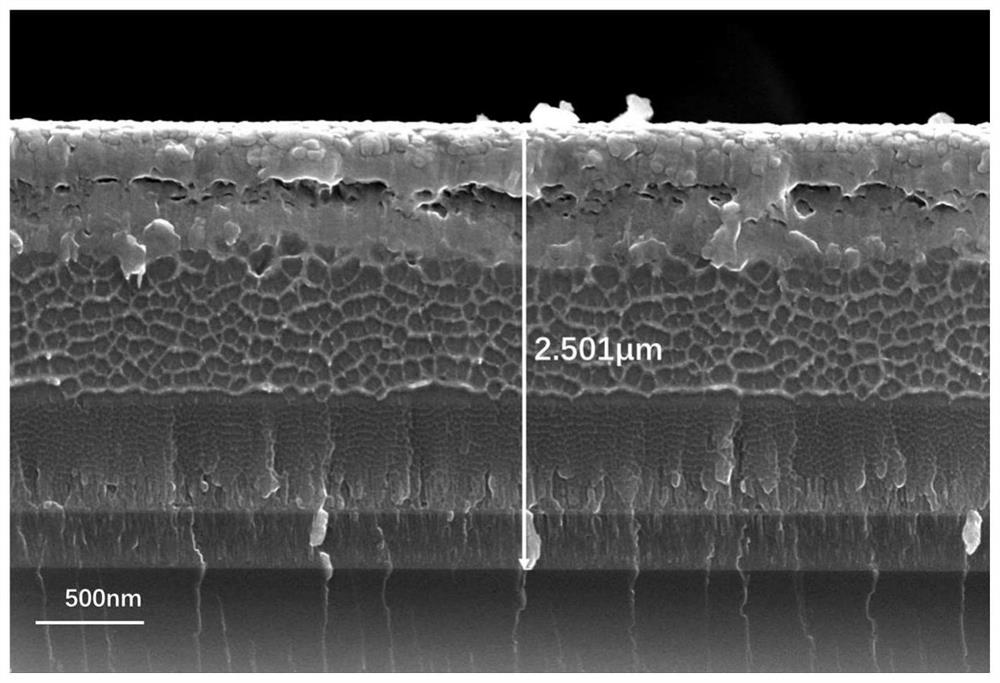

[0031] The method for preparing AlN ceramic substrate metallization and heat sink integrated coating by magnetron sputtering technology comprises the following steps:

[0032] Step 1, smoothing the surface of the aluminum nitride ceramic substrate to a surface roughness Ra≤0.03 μm.

[0033] Step 2, cleaning the aluminum nitride ceramic substrate: soak in absolute ethanol for 120 minutes, dry in an oven at 120°C for 5 minutes, then ultrasonically clean in acetone and absolute ethanol solutions for 10 minutes, and finally bake in an oven at 120°C 3min.

[0034] Step 3, block the aluminum nitride ceramic substrate with the chamber sample baffle, pass high-purity argon gas containing 4% hydrogen, the air flow is 30sccm, adjust the air pressure in the chamber to 0.3Pa, and use a DC power supply of 150W for a purity of 99.99% The surface of the titanium target and the copper target with a purity of 99.99% were cleaned by plasma for 20 minutes. Then apply a base negative bias of -7...

Embodiment 2

[0036]The method for preparing AlN ceramic substrate metallization and heat sink integrated coating by magnetron sputtering technology comprises the following steps:

[0037] Step 1, smoothing the surface of the aluminum nitride ceramic substrate to a surface roughness Ra≤0.03 μm.

[0038] Step 2, cleaning the aluminum nitride ceramic substrate: soak in absolute ethanol for 150 minutes, dry in an oven at 180°C for 10 minutes, then ultrasonically clean in acetone and absolute ethanol solutions for 20 minutes, and finally bake in an oven at 180°C 5min.

[0039] Step 3, block the aluminum nitride ceramic substrate with the chamber sample baffle, pass high-purity argon gas containing 4% hydrogen, the air flow is 20sccm, adjust the air pressure in the chamber to 0.3Pa, and use a DC power supply of 150W for a purity of 99.99%. The surface of the titanium target and the copper target with a purity of 99.99% were cleaned by plasma for 20 minutes. Then apply a base negative bias of -...

Embodiment 3

[0041] The method for preparing AlN ceramic substrate metallization and heat sink integrated coating by magnetron sputtering technology comprises the following steps:

[0042] Step 1, smoothing the surface of the aluminum nitride ceramic substrate to a surface roughness Ra≤0.03 μm.

[0043] Step 2, cleaning the aluminum nitride ceramic substrate: soak in absolute ethanol for 120 minutes, dry in an oven at 120°C for 5 minutes, then ultrasonically clean in acetone and absolute ethanol solutions for 10 minutes, and finally bake in an oven at 120°C 3min.

[0044] Step 3, block the aluminum nitride ceramic substrate with the chamber sample baffle, pass high-purity argon gas containing 4% hydrogen, the air flow is 40sccm, adjust the air pressure in the chamber to 0.3Pa, and use a DC power supply of 150W for a purity of 99.99% The surface of the titanium target and the copper target with a purity of 99.99% were cleaned by plasma for 20 minutes. Then apply a base negative bias of -7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com