Method for making colored cement sculpture

A sculpture and cement technology, applied in special decorative structures, processes for producing decorative surface effects, decorative arts, etc., can solve the problems of time-consuming processing, high resin cost, and troublesome manufacturing, and achieve a wide range of applications and high manufacturing efficiency. , the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

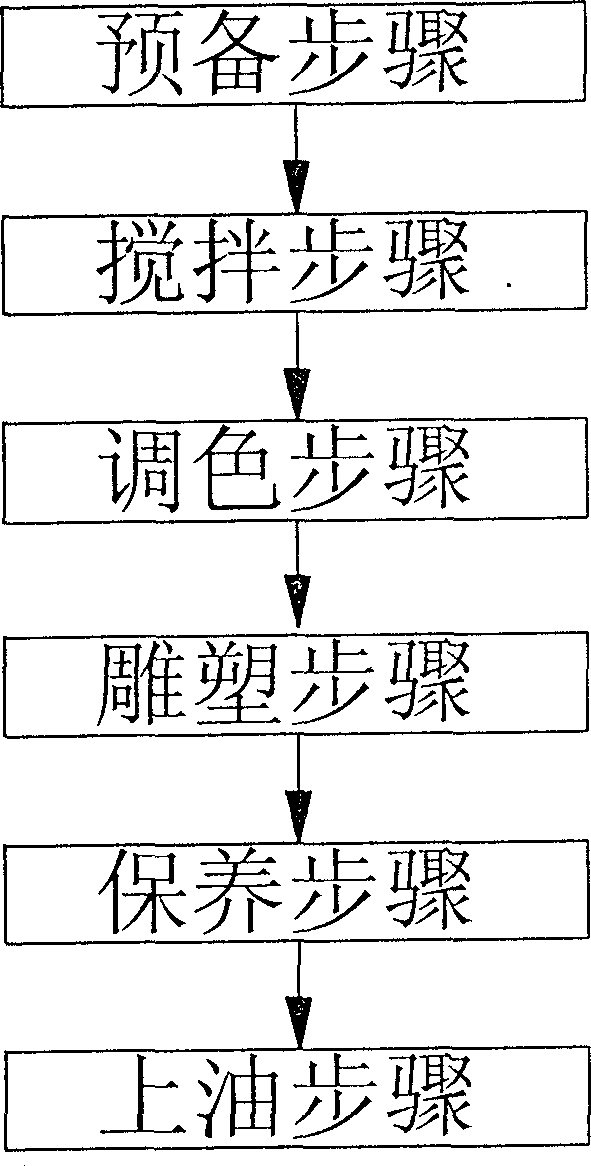

[0057] A method of cement painted sculpture, such as figure 1 shown, including:

[0058] a. Preparatory step: for uniform mixing of sand, cement and coagulant;

[0059] b. Stirring step: add water to the mixture and stir until uniform;

[0060] c. Toning step: add cement colorant to the mixture that is stirred until uniform;

[0061] d. Sculpture step: the mixed material after toning is attached to the cement wall and the board according to the physical structure of the object image, and the object image is sculpted, and the working surface of the cement wall and the board is a plane;

[0062] e. Maintenance steps: it is used to place the sculpture in the greenhouse for maintenance for three to five days;

[0063] f. Oiling step: Apply colorless clear oil on the outer surface of the sculpture after maintenance.

[0064] In the preparatory step: where the proportion of sand and cement is adjusted according to the thickness of the sculpture. If the thickness of the sculptur...

Embodiment 2

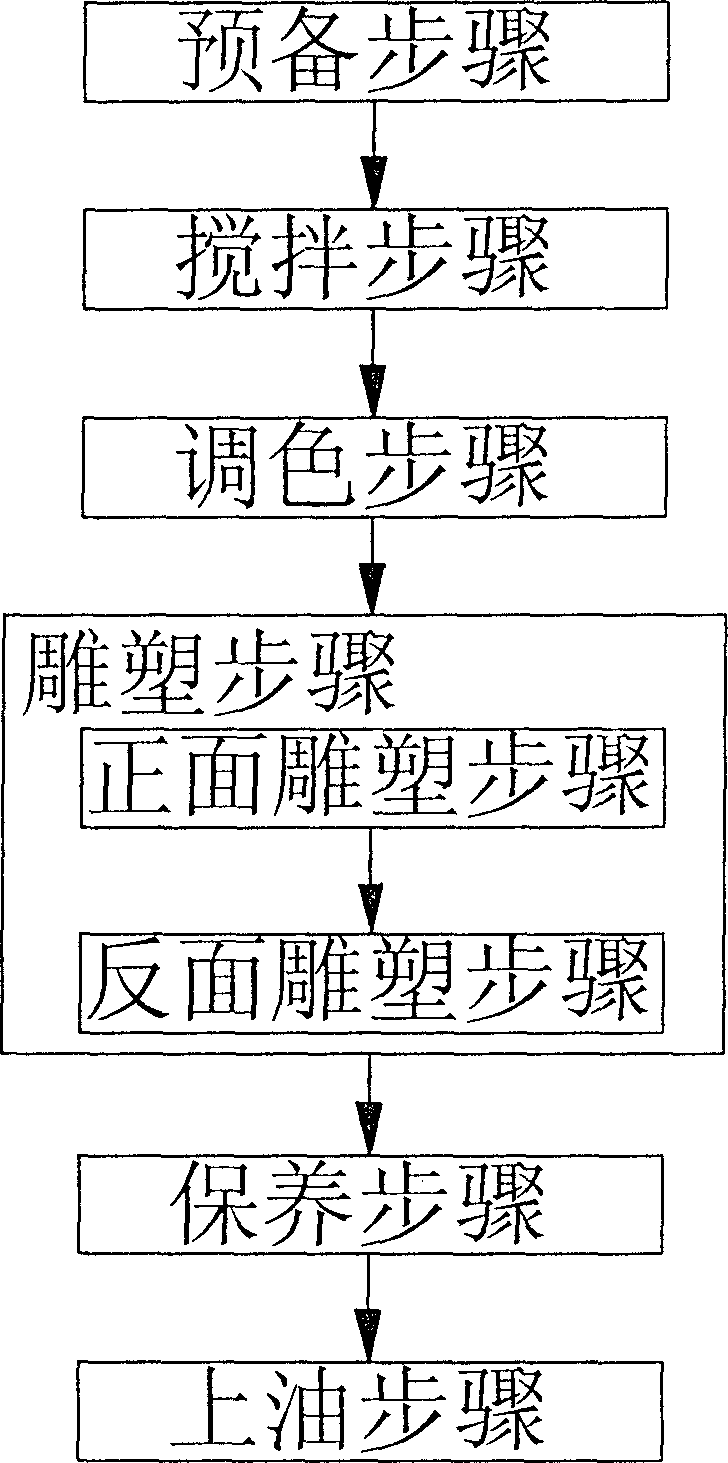

[0070] The difference between this embodiment and the first embodiment is: a method of cement color painting sculpture, such as figure 2 shown, including:

[0071] a. Preparatory step: for uniform mixing of sand, cement, glue and coagulant;

[0072] b. Stirring step: add water to the mixture and stir until uniform;

[0073] c. Toning step: add cement colorant to the mixture that is stirred until uniform;

[0074] d. Sculpture steps: Sculpture steps include: front sculpture step: attach the mixed material after toning to the front of the glass according to the shape structure of the object image, and flat carving, embossing, and carving out the object image; reverse sculpture step: divide on the back of the glass Layered composition draws a pattern that is integrated with the front image of the glass, making the sculpture a three-dimensional effect;

[0075] e. Maintenance steps: it is used to place the sculpture in the greenhouse for maintenance for three to five days;

[0...

Embodiment 3

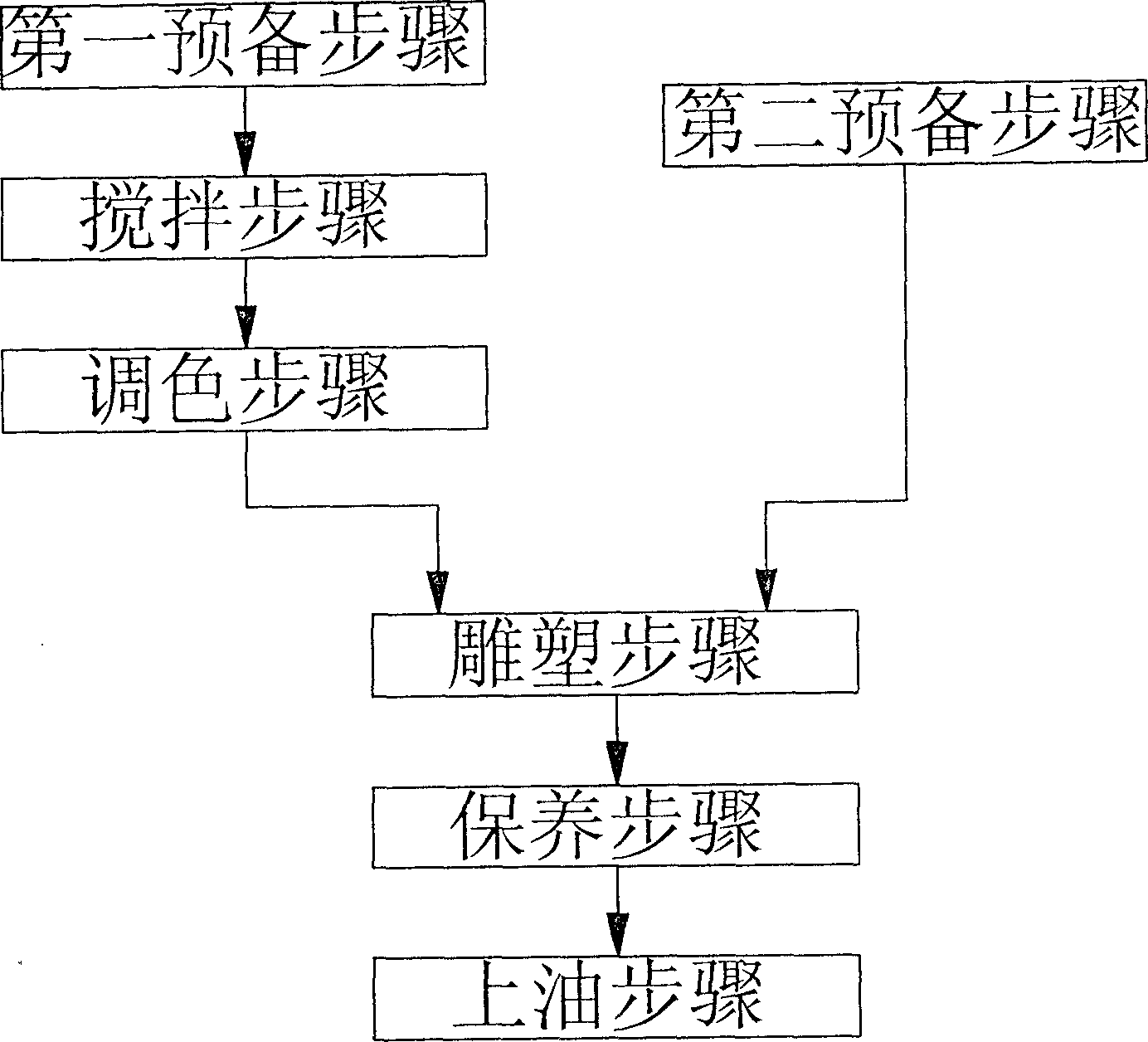

[0081] The difference between this embodiment and the first embodiment is: a method of cement color painting sculpture, such as image 3 shown, including:

[0082] a. The first preparatory step: for uniform mixing of sand, cement and coagulant;

[0083] a1. The second preparatory step: for manufacturing the support frame embedded in the sculpture designed according to the structure of the object image;

[0084] b. Stirring step: add water to the mixture and stir until uniform;

[0085] c. Toning step: add cement colorant to the mixture that is stirred until uniform;

[0086] d. Sculpture step: for attaching the mixed material after toning to the support frame, and three-dimensionally sculpting the image;

[0087] e. Maintenance steps: it is used to place the sculpture in the greenhouse for maintenance for three to five days;

[0088] f. Oiling step: Apply colorless clear oil on the outer surface of the sculpture after maintenance.

[0089] According to needs, it may also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com