Handheld type forming device for R-zone filler and forming method

A molding device and filler technology, which is applied in the field of composite material parts manufacturing, can solve the problems of long manufacturing cycle of special molding tooling, low shape accuracy of fillers in R area, and difficult demoulding of fillers in R area, etc., and achieves strong applicability. , to avoid breakage or accumulation problems, the effect of high product quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

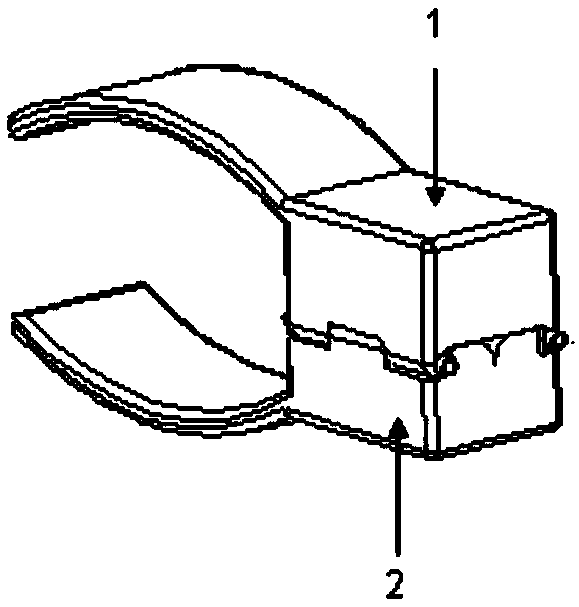

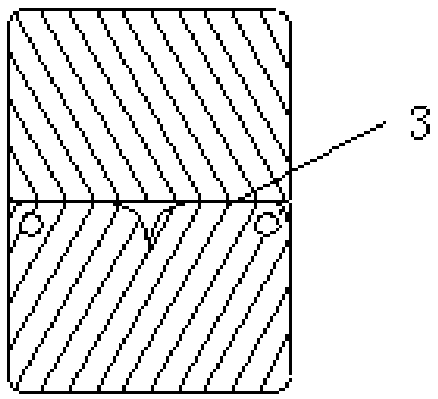

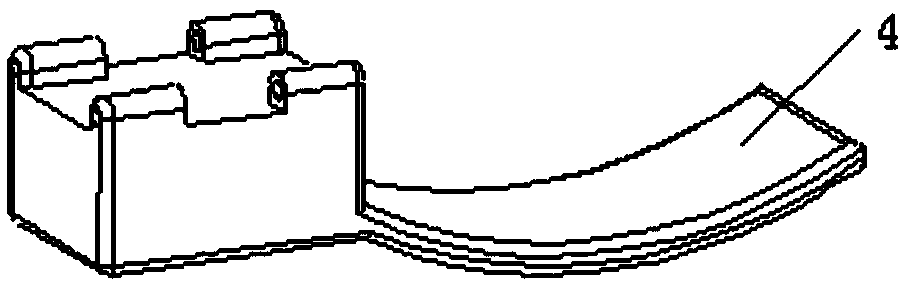

[0022] In the present invention, taking the R-zone filler required for making T-shaped stringers as an example, a hand-held molding device for the R-zone filler includes an upper former 1 and a lower former 2 used in conjunction, and the upper and lower formers are paired. The joint surface is the working surface 3, and the side is provided with a handle 4. The working surface of the lower former 2 is engraved with a gradual groove 5 similar in shape to the filler in the R zone. The cross-sectional size is consistent, the cross-sectional size of the inlet end is 1-2 times the cross-sectional size of the filler in the R zone, and the cross-section smoothly transitions from the inlet end to the outlet end, and the length of the transition zone is 1 / 3 to 1 / 2 of the length of the working surface of the lower former. .

[0023] Forming method of the present invention is as follows:

[0024] 1. Knead the raw materials required for making the filling in the R zone into a loose cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com