Micro-structure array processing device and method based on variable-pitch fly cutter cutting

A technology of microstructure array and processing device, applied in feeding device, metal processing, automatic control device, etc., can solve the problems of poor processing quality, complex device structure, limited cutting efficiency, etc., and achieve good processing consistency and processing efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

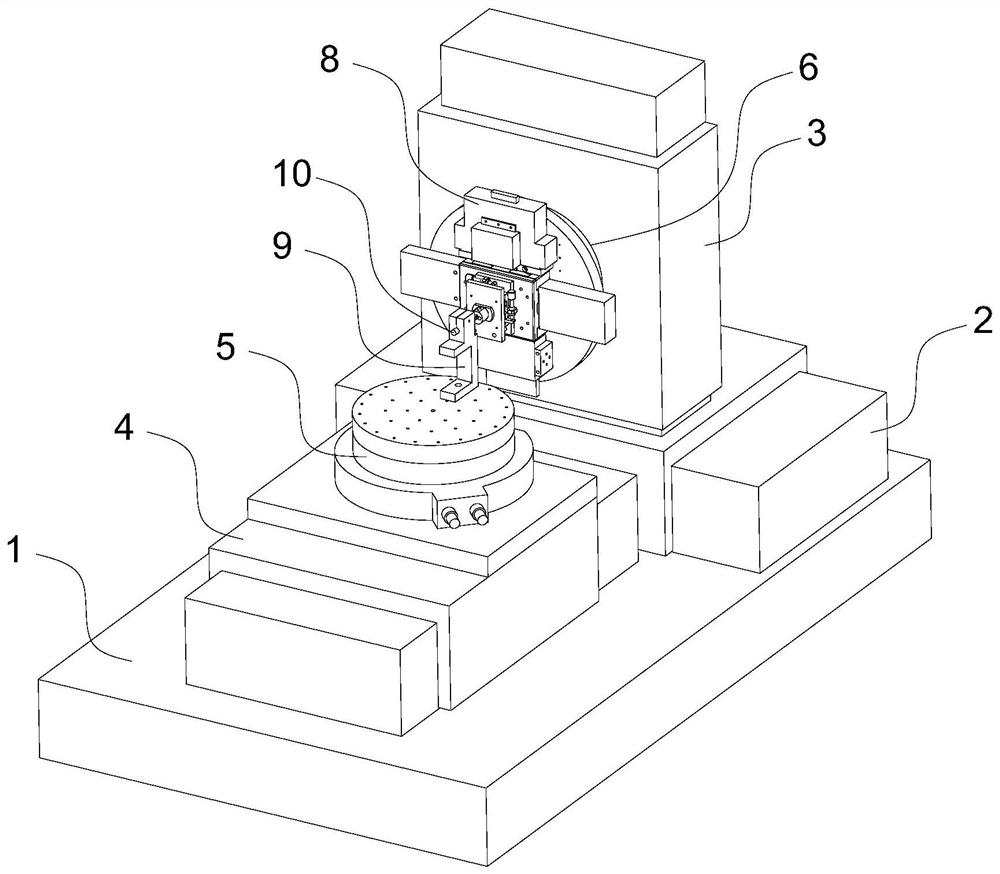

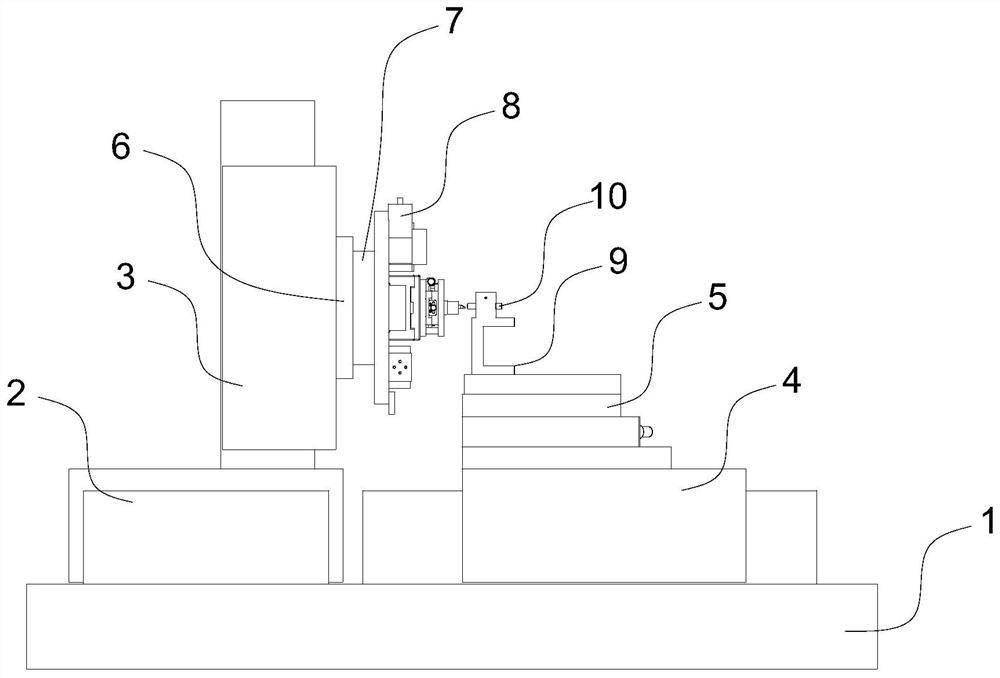

[0041] Such as Figure 1-Figure 2As shown, the embodiment of the present invention provides a microstructure array processing device based on variable-pitch flying knife cutting, including a base 1, a machine tool X-axis 2, a machine tool Y-axis 3, a machine tool Z-axis 4, a machine tool B-axis 5, a machine tool C-axis 6, vacuum chuck 7, variable-pitch flying knife x-axis 8, and workpiece fixture 9; machine tool X-axis 2 and machine tool Z-axis 4 are arranged on the base 1 in a T-shaped structure, and machine tool Y-axis 3 is vertically fixed on the machine tool X On the sliding table of the axis 2, the B-axis 5 of the machine tool and the C-axis 6 of the machine tool are respectively installed on the sliding table of the Z-axis 4 of the machine tool and the Y-axis 3 of the machine tool. Connection, the workpiece holder 9 is connected with the turntable of the B-axis 5 of the machine tool.

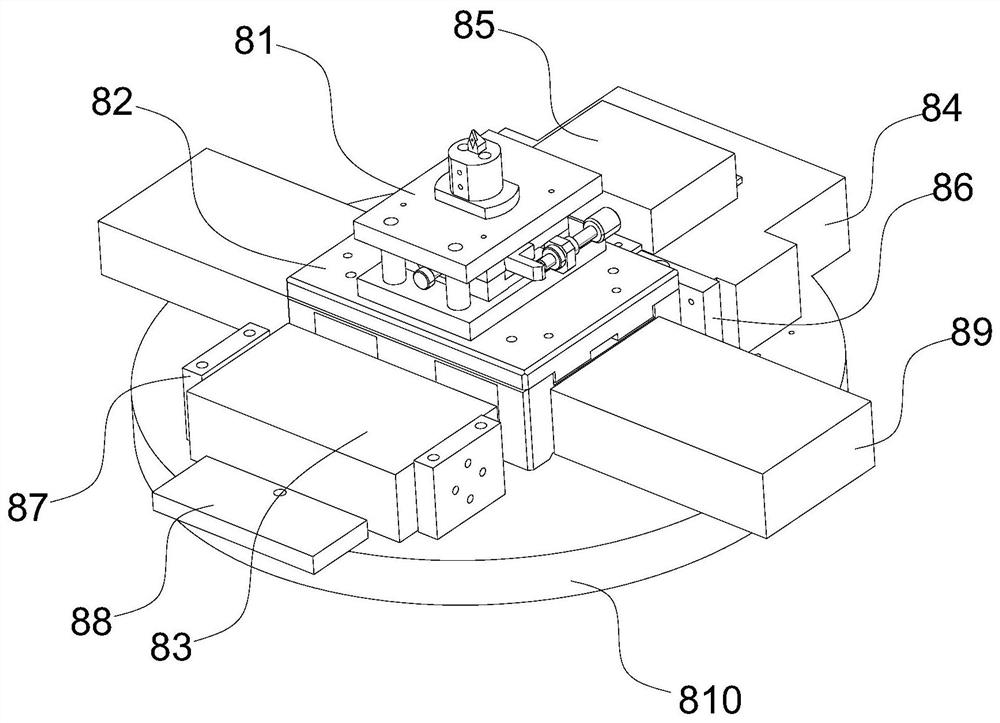

[0042] Among them such as Figure 3-Figure 4 As shown, the variable-pitch flying kni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com