Composite sleeve

A composite, sleeve technology, applied in the direction of wrenches, manufacturing tools, wrenches, etc., can solve the problem that the transparent bushing cannot be clearly identified, and achieve the effect of maintaining aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

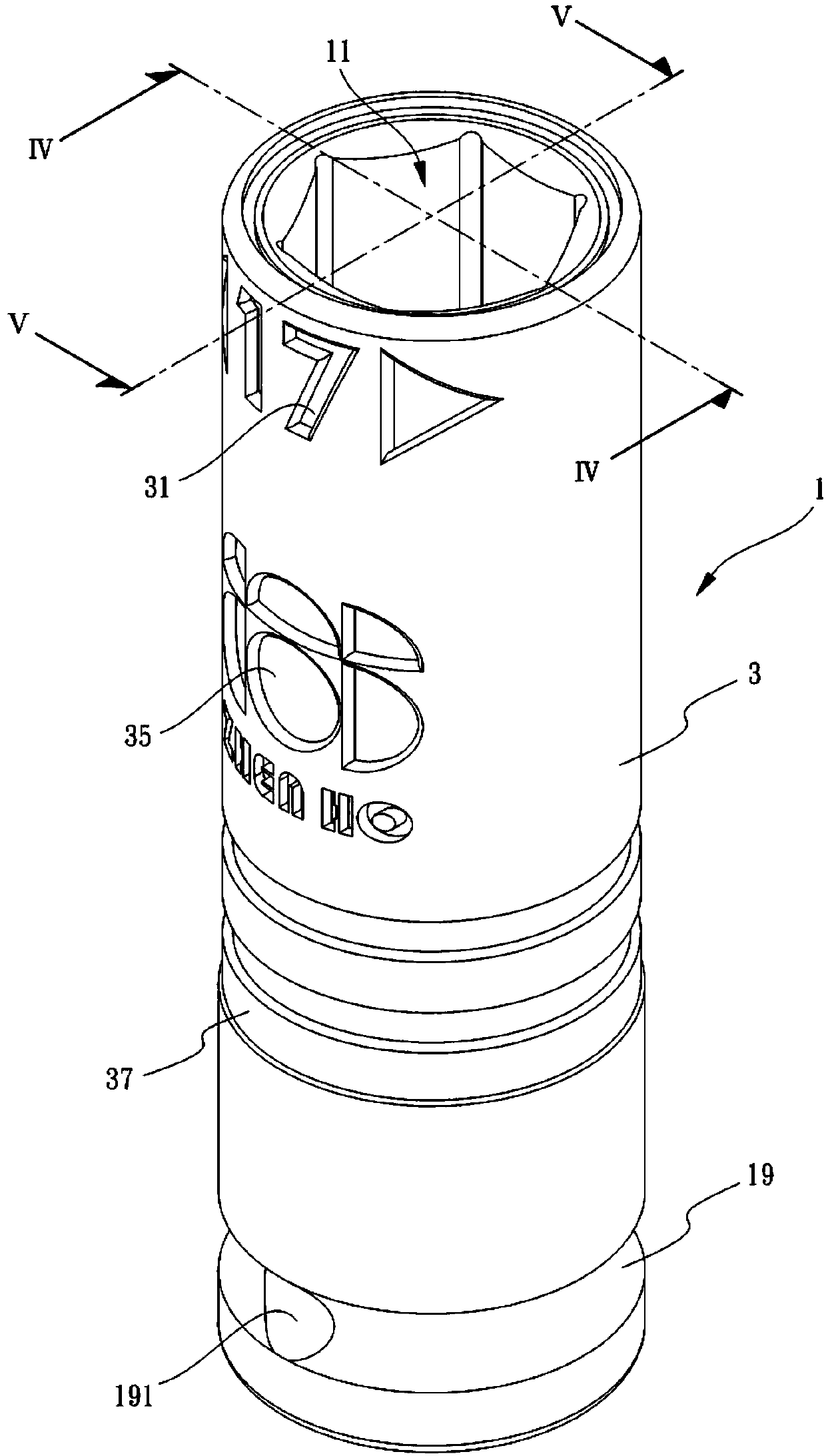

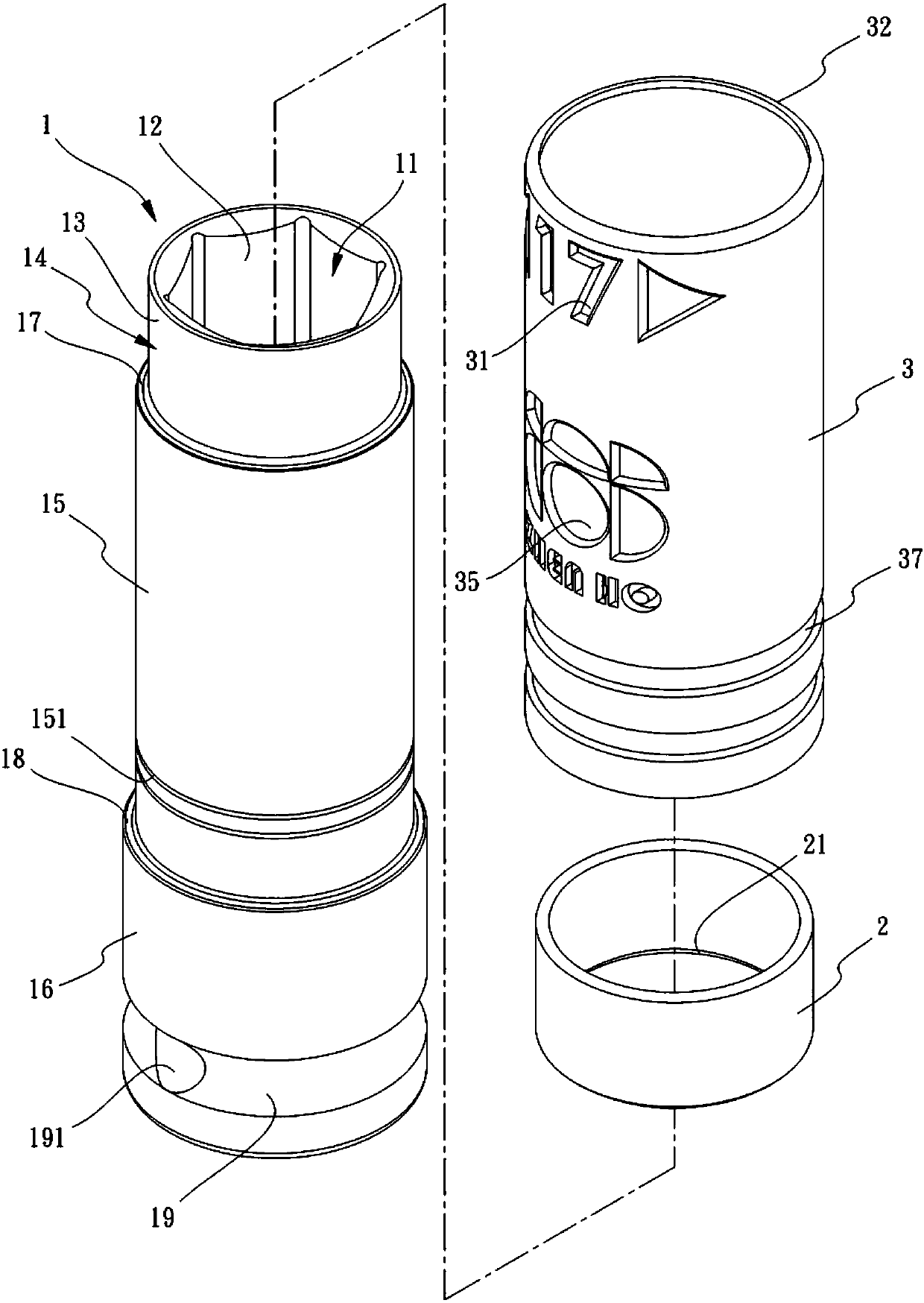

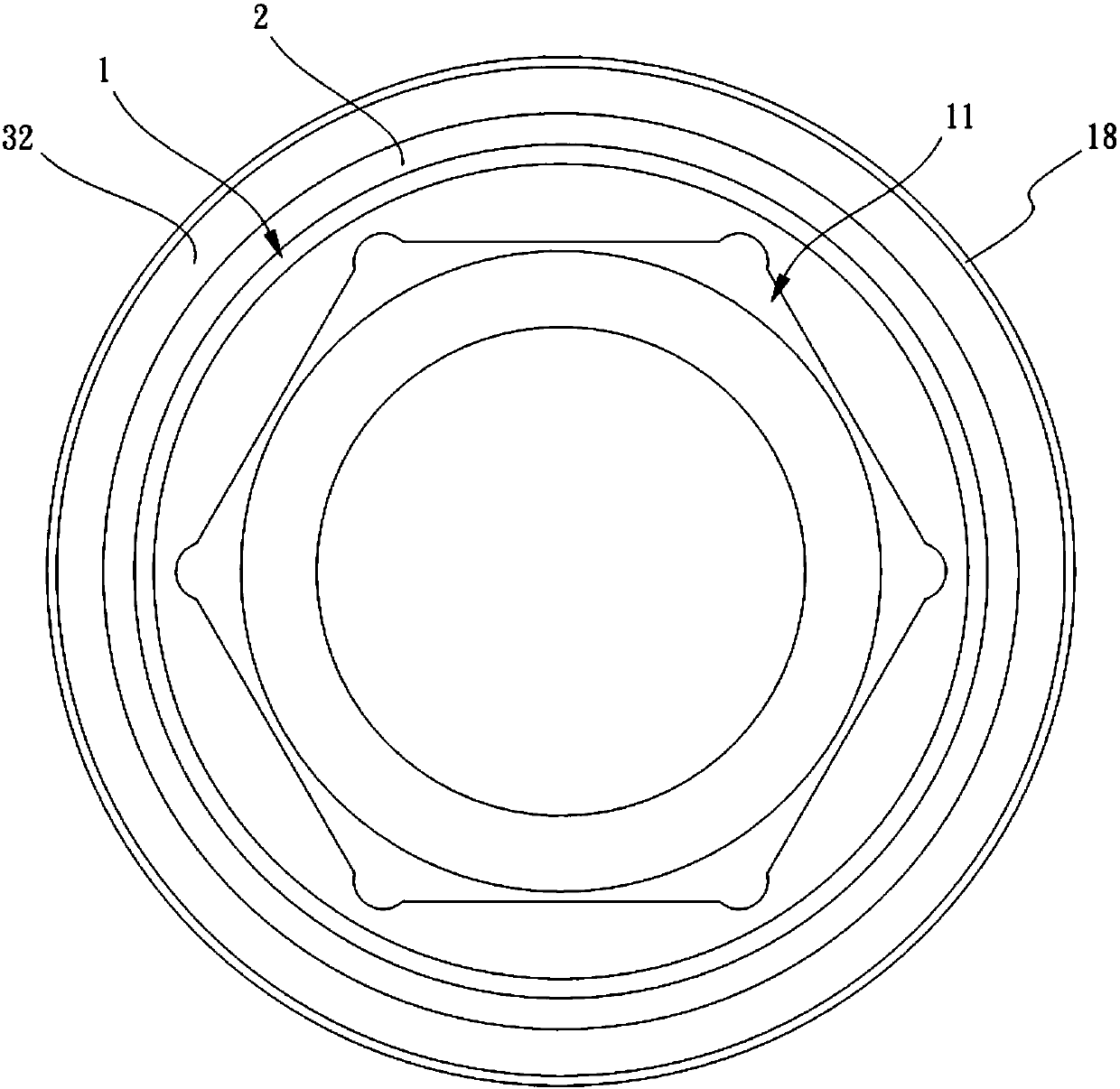

[0071] In order to clearly illustrate that the present invention can achieve the above objectives and effects, the features and effects of the embodiments of the present invention are described in detail with reference to the accompanying drawings. see Figure 1 to Figure 10 As shown, a composite sleeve of the present invention is mainly engaged with a wrench 10, and is used to be inserted into the lock hole 201 of the rim 20 to carry out the operation of turning screws 30, nuts, and bolts. It includes: a barrel The body 1 is cylindrical, and the cylinder body 1 is provided with a driving hole 11, and the driving hole 11 penetrates from one end of the cylinder body 1 to the other end and forms an inner wall surface 12 and an outer wall surface 13, and the cylinder body 1 can be divided into A first cylinder section 14, a second cylinder section 15 and a third cylinder section 16, and the first cylinder section 14, the second cylinder section 15 and the third cylinder section 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com