A Measuring Tool Based on the Part's Own Runout Measurement

A multi-round mouth and measuring tool technology is applied in the field of measuring tools for multi-round mouth runout measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

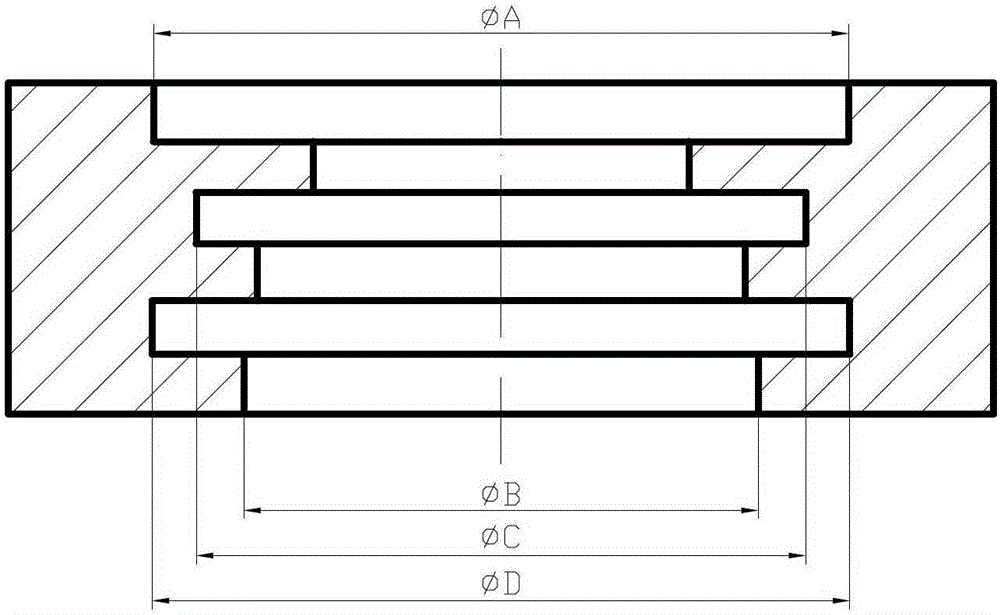

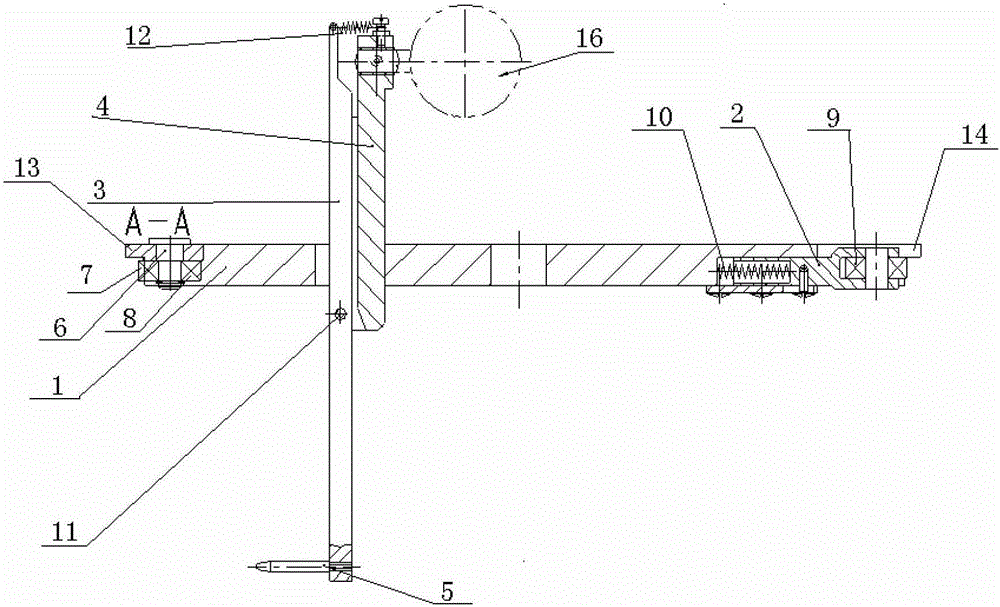

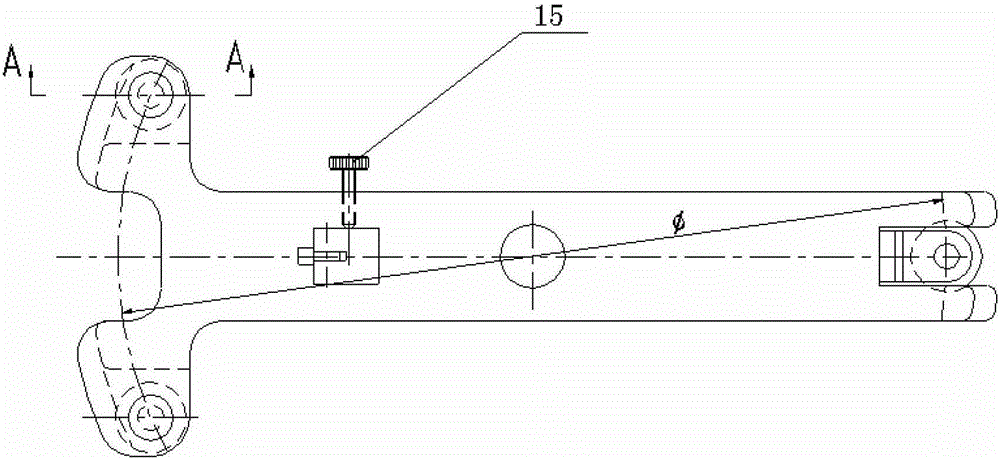

[0026] The measuring tool based on the multi-circle runout measurement of the part itself described in this embodiment, such as figure 2 , 3 shown including vertically attached main body positioning means and measuring means;

[0027] The measuring tool mainly includes a main body positioning device and a measuring device that are vertically connected;

[0028] The main body positioning device mainly includes a positioning base (1), a roller frame (2), and the roller frame (2) is connected with the right end of the positioning base (1);

[0029] The measuring device mainly includes a lever (3), a table seat (4) for installing a dial indicator, and a measuring head (5), wherein the upper end of the lever (3) is connected to the table seat (4) for installing the dial indicator. ) is connected to the upper end, the lower end of the lever (3) is connected to the probe (5), and the lever (3) is vertically connected to the positioning base (1);

[0030] In the measuring tool bas...

Embodiment 2

[0034] The measuring tool based on the multi-circle runout measurement of the part itself described in this embodiment, such as figure 2 , 3 shown including vertically attached main body positioning means and measuring means;

[0035] The measuring tool mainly includes a main body positioning device and a measuring device that are vertically connected;

[0036] The main body positioning device mainly includes a positioning base (1) and a roller frame (2). The roller frame (2) is connected to the right end of the positioning base (1) through a spring a (10).

[0037] The measuring device mainly includes a lever (3), a watch seat (4) for installing a dial indicator, and a measuring head (5), wherein the upper end of the lever (3) is connected to the upper end of the lever (3) for installing the dial indicator through a spring b (12). The upper end of the table seat (4) of the sub-meter is connected, the lower end of the lever (3) is connected with the measuring head (5), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com