Method for splicing bobbin paper of cigarette making machine

A technology of cigarette making machines and paper coils, which is applied in the direction of tobacco, application, and winding rods, etc., and can solve the problems of different diameters of working coils, failure of splicing, and large waste of coils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

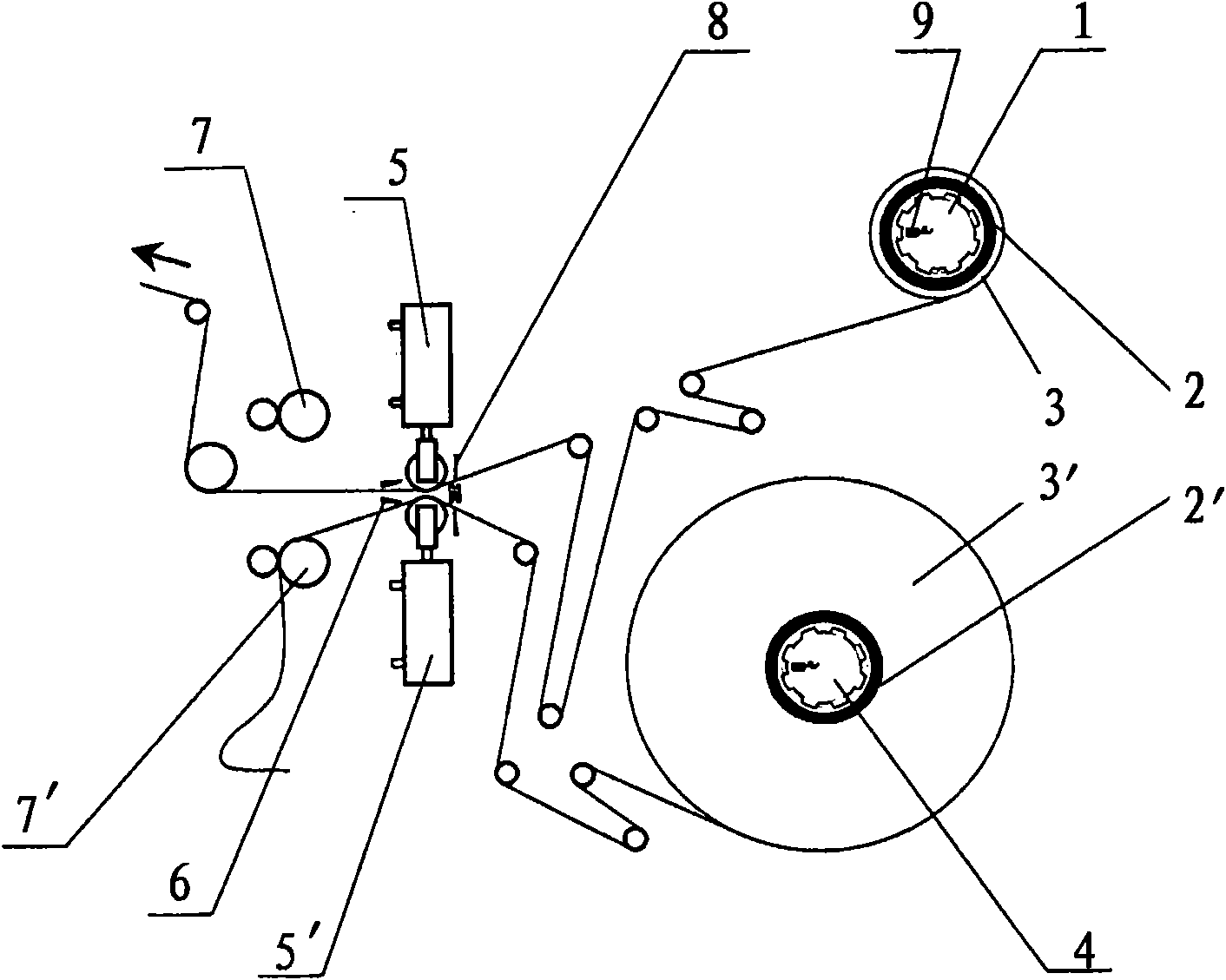

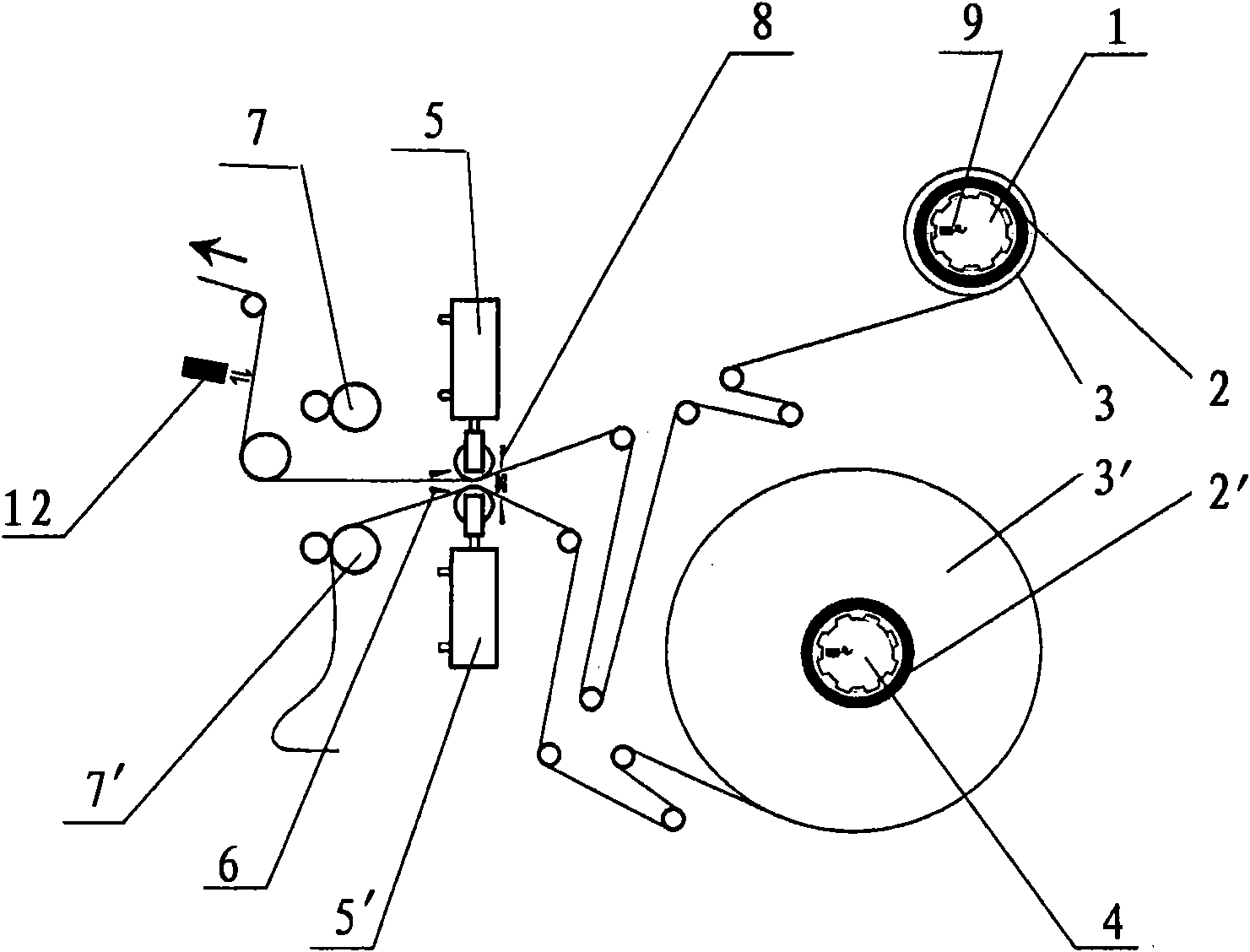

[0019] The invention provides a coil splicing method for a cigarette machine. The coil itself provides a signal to the cigarette machine, and the signal is used to control the cigarette machine to start a splicing program for splicing.

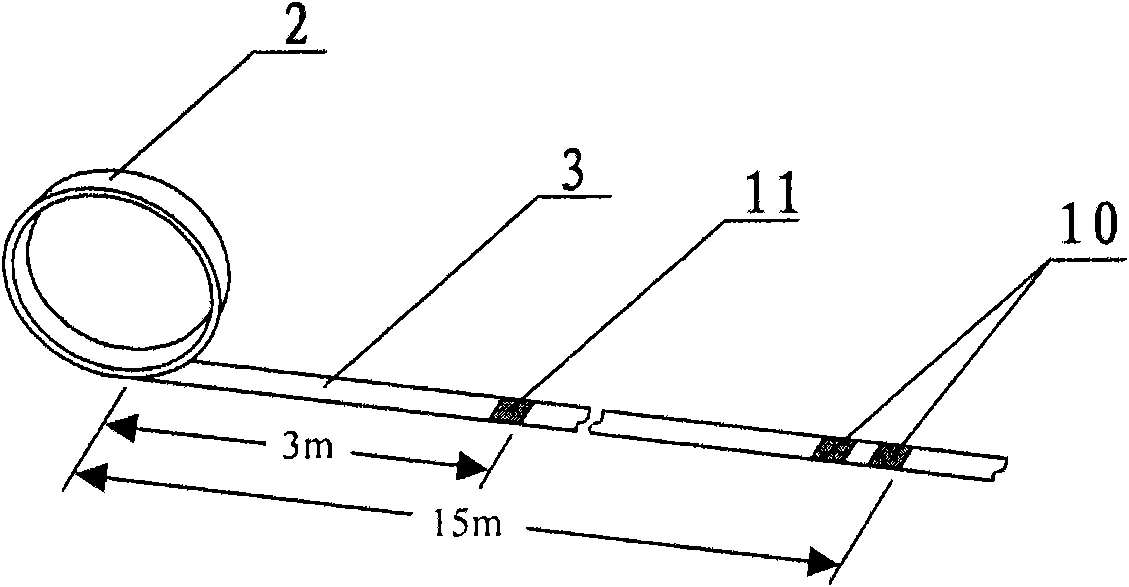

[0020] Such as figure 2 As shown, a first marking 10 is provided by the coil manufacturer on the first and second coils 3 and 3' at a first distance from the inner coil 2 and at a second distance from the inner coil 2 A second mark 11 is provided, the first distance is in the range of 10-18 meters, preferably 15 meters, and the second distance is in the range of 3-5 meters, preferably 3 meters. Marks can be color blocks, barcodes, patterns, cutouts, etc. or their combination, for example, the first mark 10 is a color block, the second mark 11 is composed of two spaced apart color blocks, the width of the color block and the width of two color blocks The spacing can be set according to actual needs, for example, 1 cm.

[0021] Combine below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com