Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

111results about How to "Minimizes gradient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

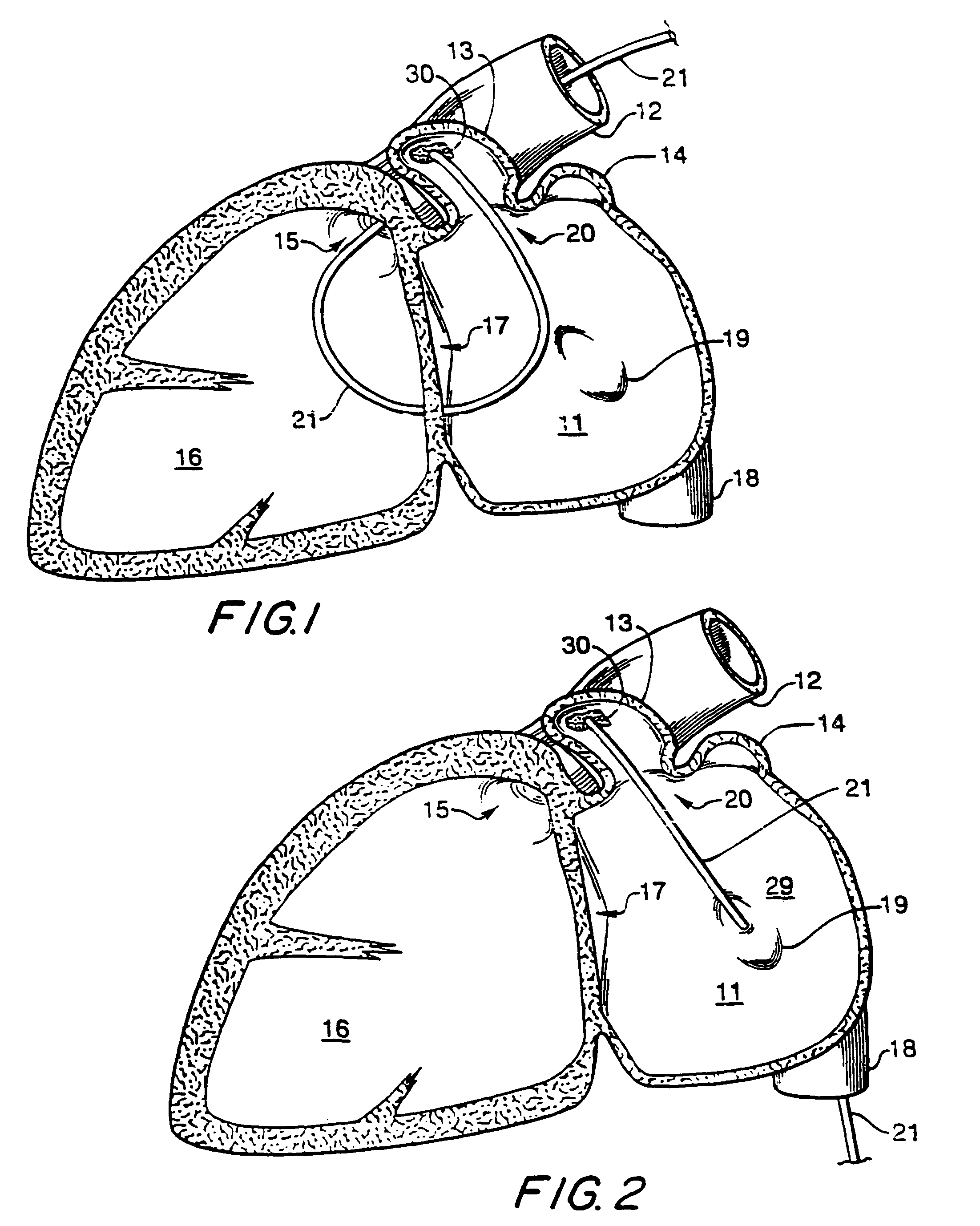

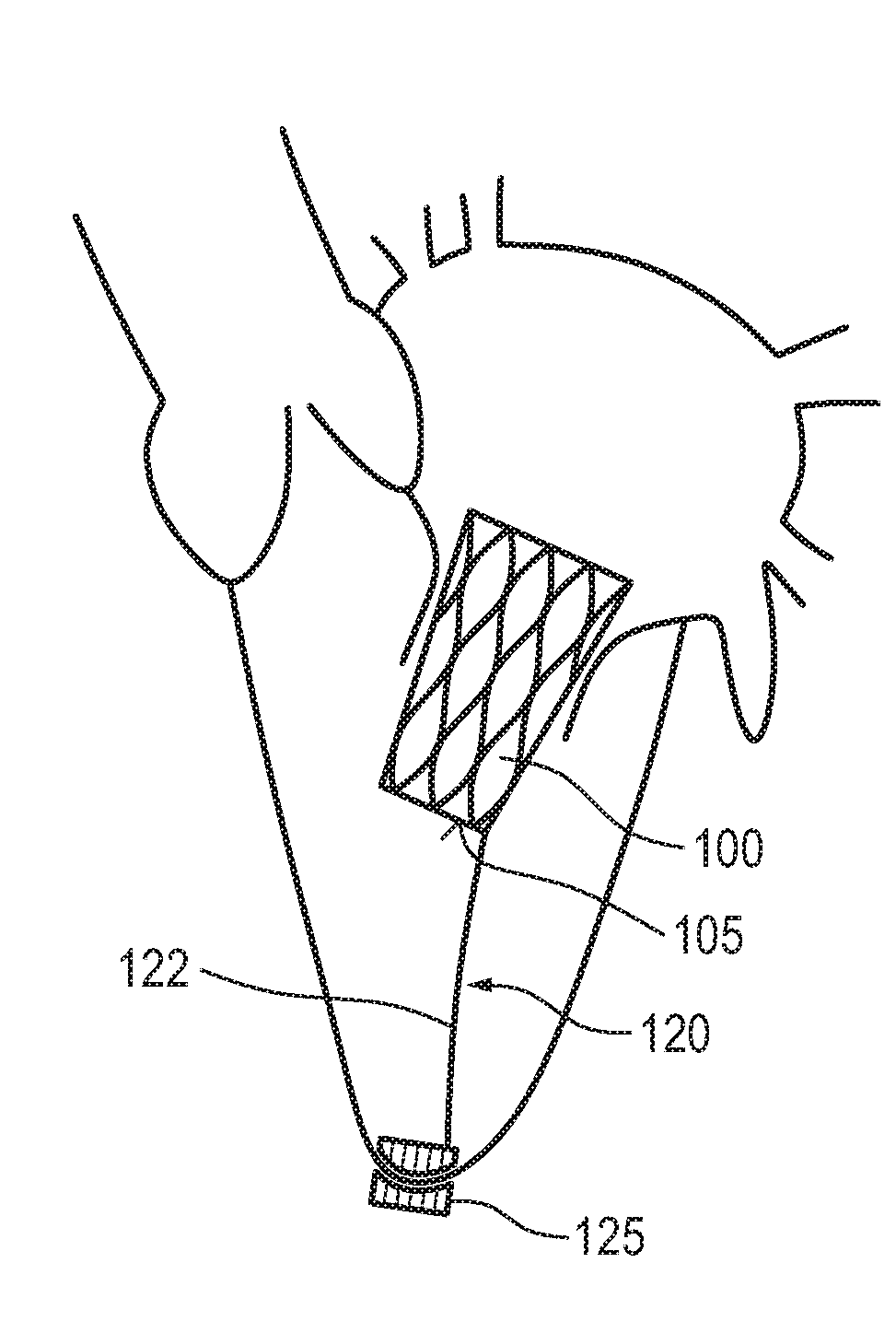

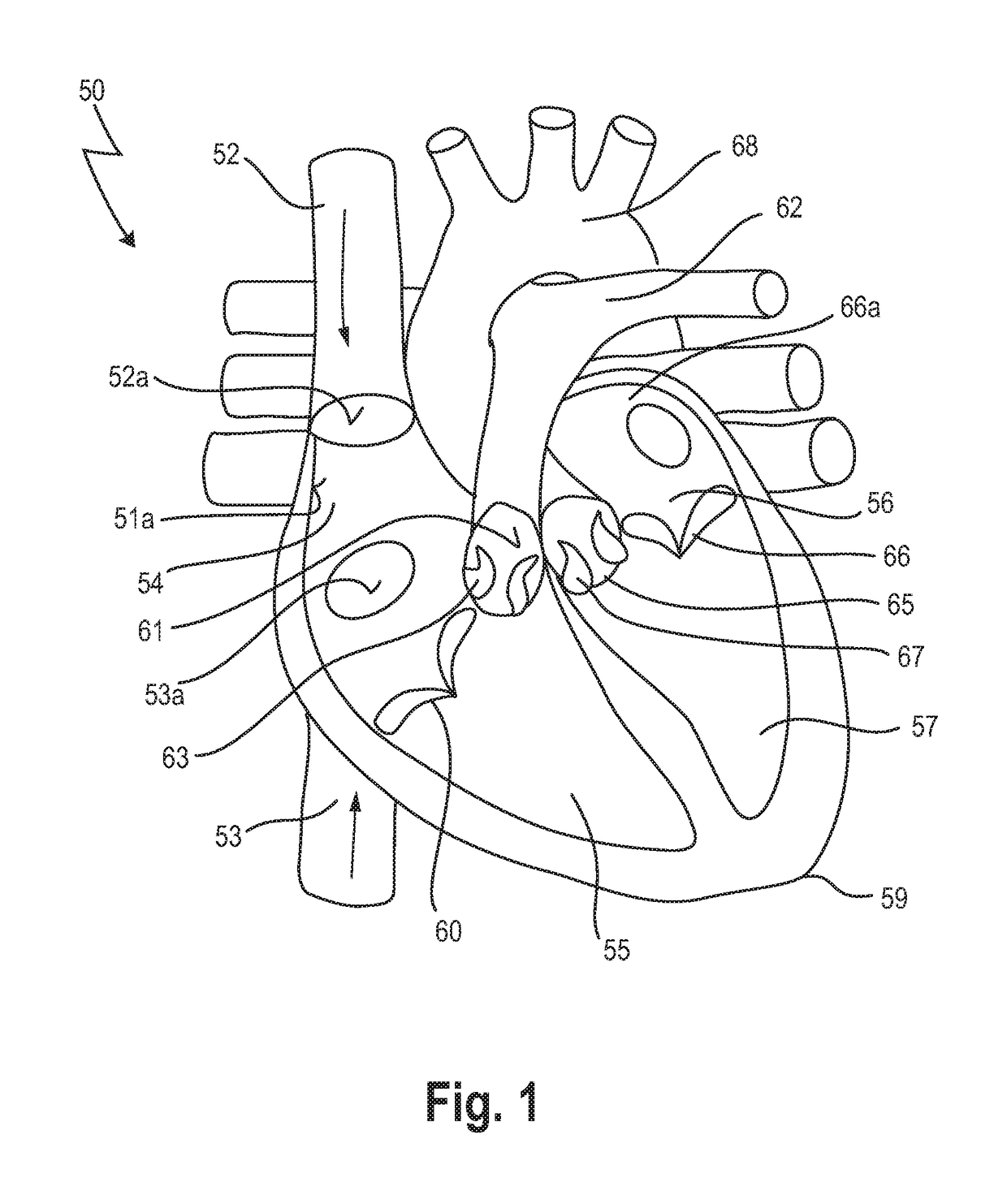

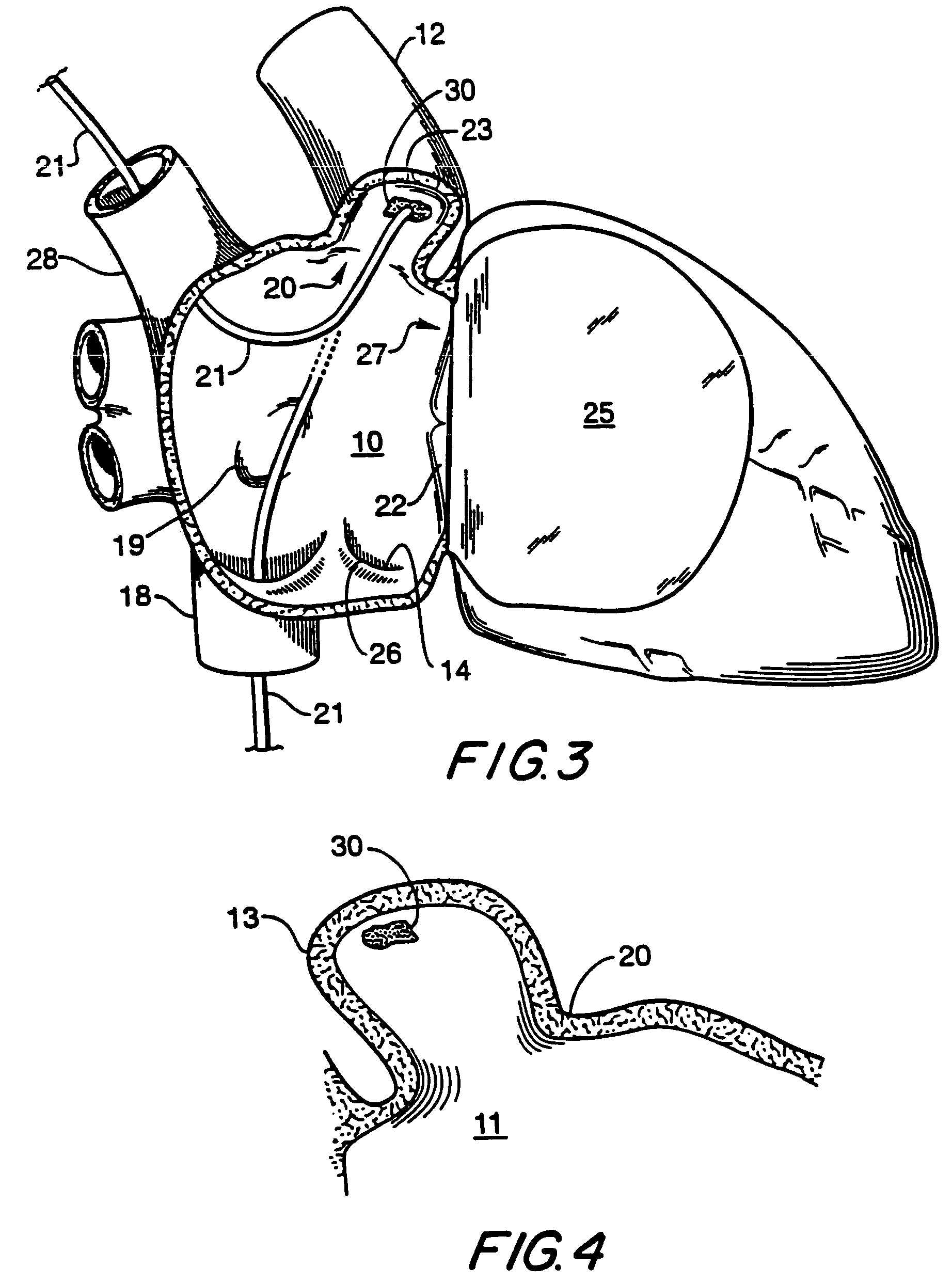

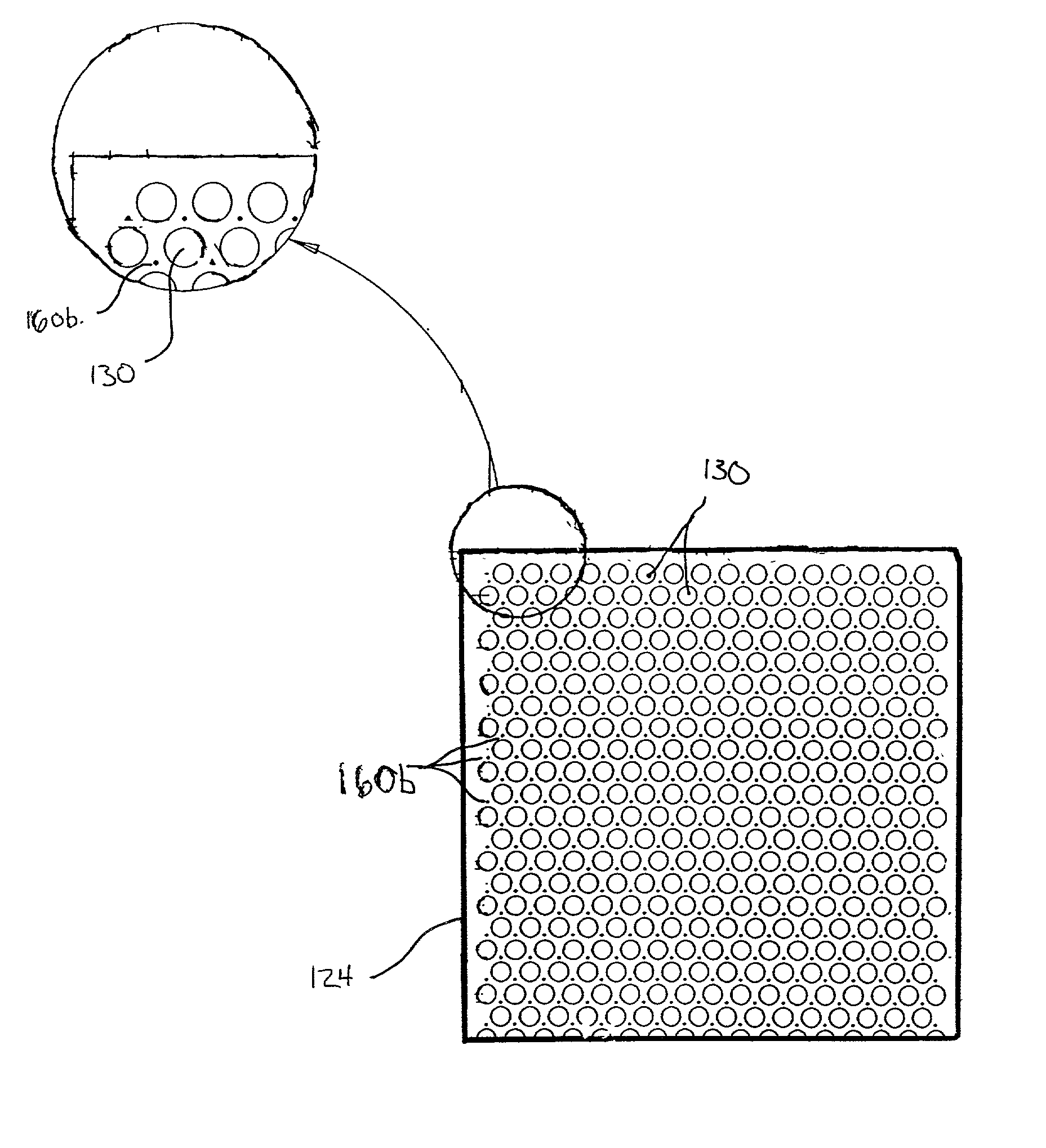

Filter apparatus for ostium of left atrial appendage

Apparatus for permanent placement across an ostium of a left atrial appendage in a patient, which includes a filtering membrane configured to extend across the ostium of the left atrial appendage. The filtering membrane has a permeable structure which allows blood to flow through but substantially inhibits thrombus from passing therethrough. The apparatus also includes a support structure comprising a plurality of fingers which are radially outwardly expandable with respect to a longitudinal axis to permanently engage the interior wall of the left atrial appendage, wherein the filtering membrane is attached to the support structure extending across the ostium of the left atrial appendage.

Owner:BOSTON SCI SCIMED INC

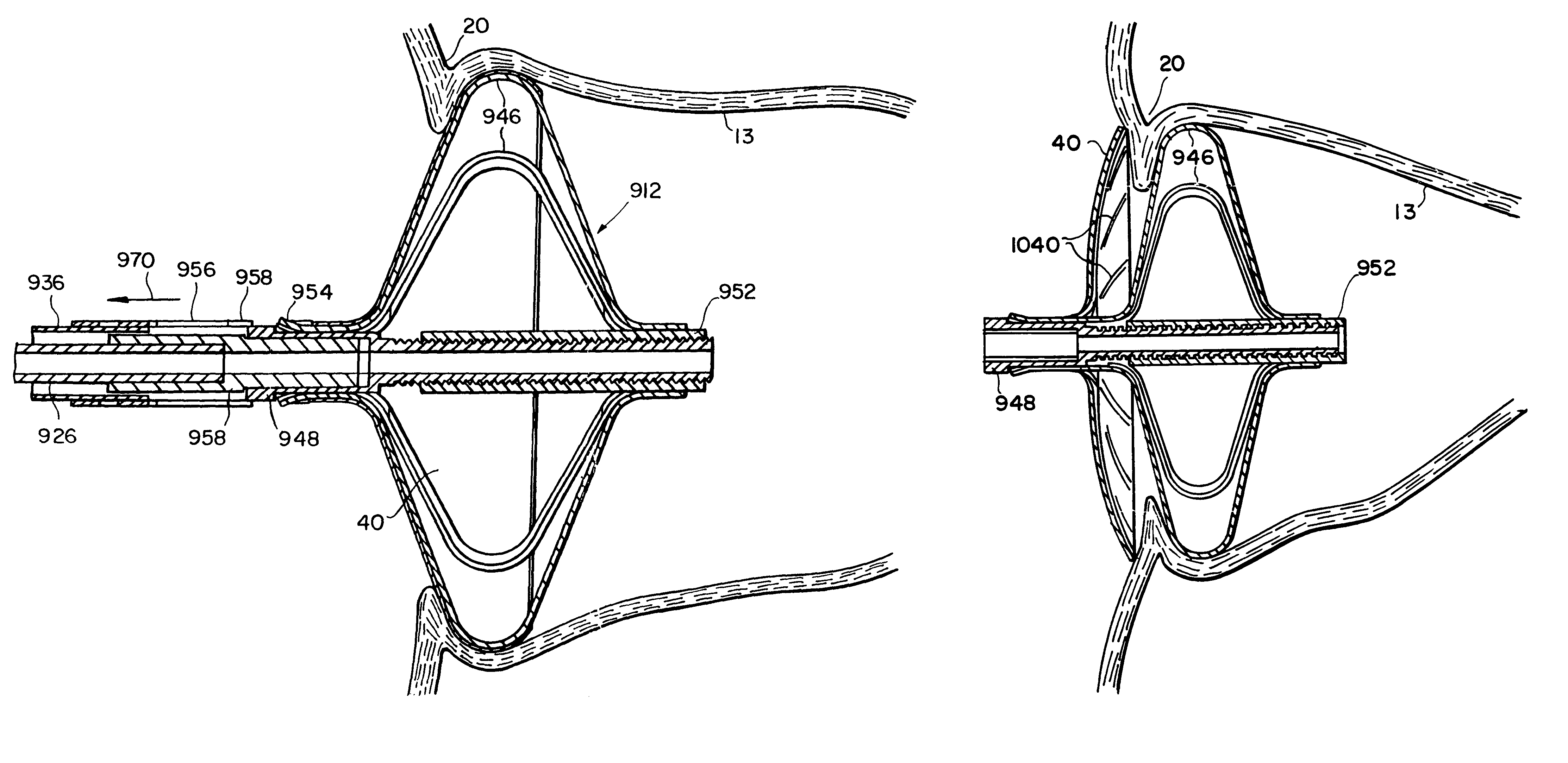

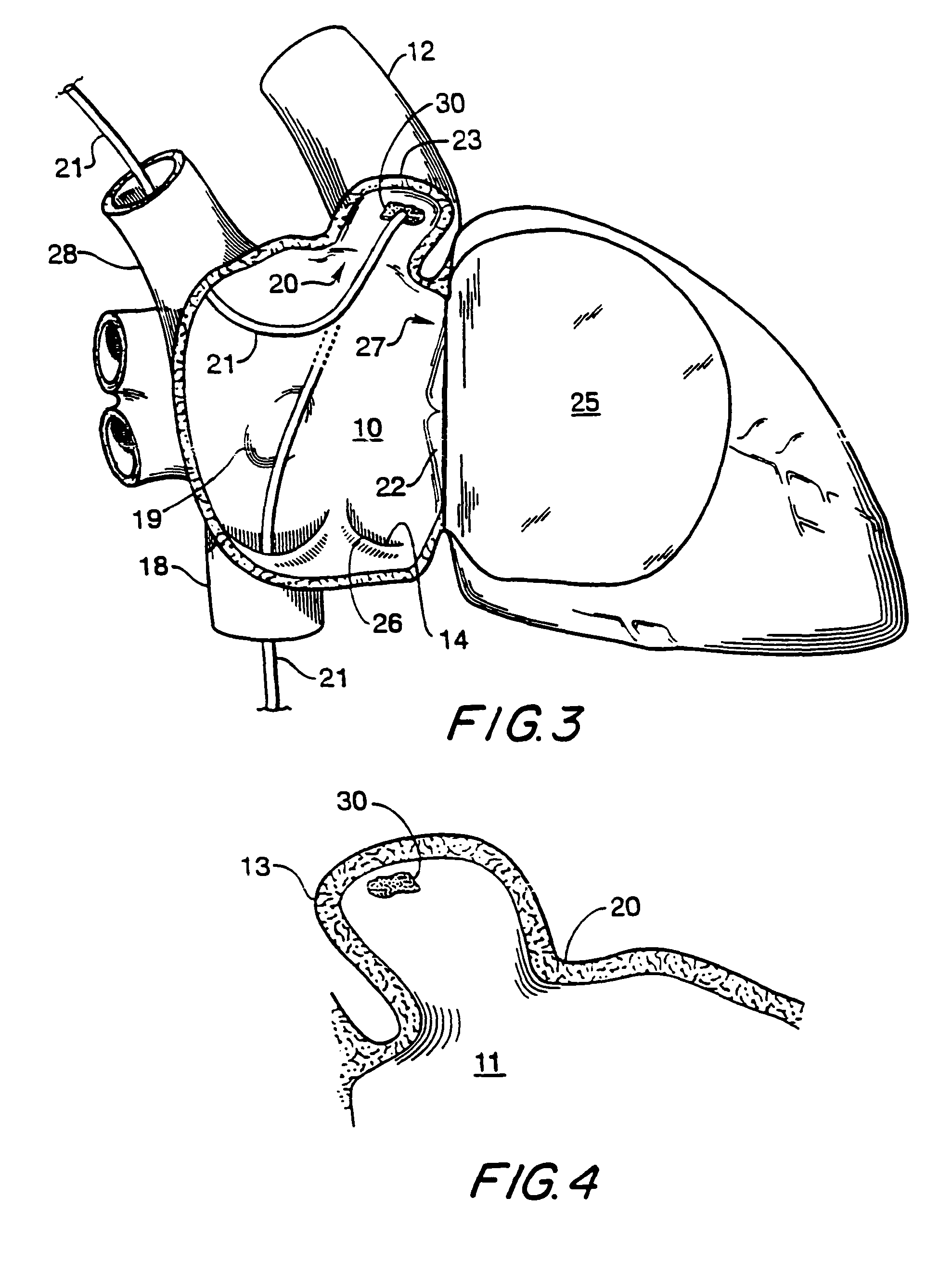

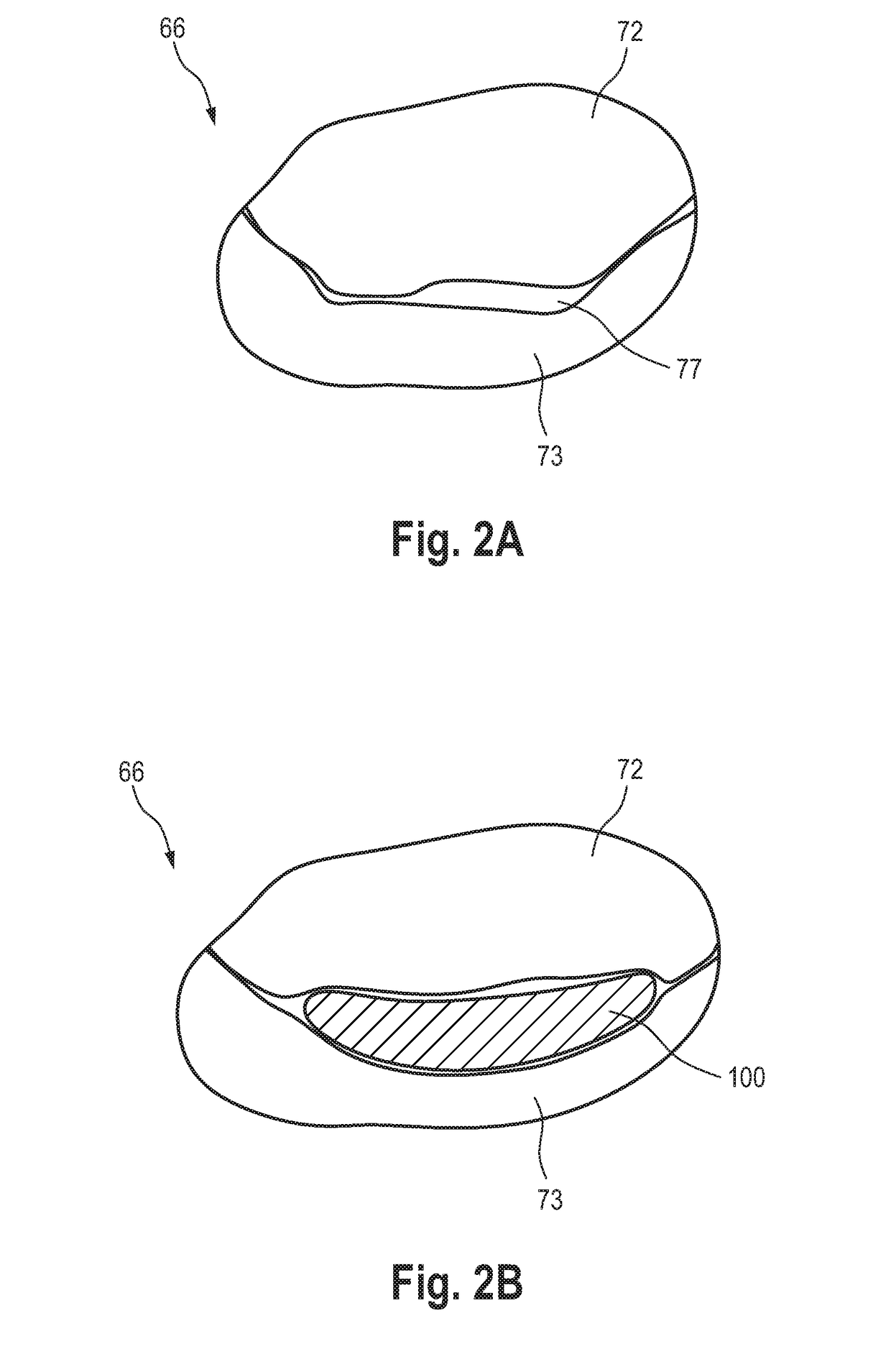

Prosthetic mitral valve coaptation enhancement device

ActiveUS20170172737A1Mitral regurgitation can be reduced and evenMinimizes gradientAnnuloplasty ringsSystoleMitral valve flow

The present invention relates to a prosthetic mitral valve device for implanting at the native mitral valve region of a heart. The prosthetic mitral valve coaptation enhancement device comprises a main body consisting of a stentframe and a valve element attached thereto, wherein the main body has a sealing section and a valve-bearing section, the valve-bearing section; the shape of the sealing section of the main body, in the compressed state, has a form that is adapted to the coaptation zone of the native mitral valve during systole, and the sealing section of the main body, the radial rigidity of the stentframe is lower than the radial rigidity of the valve-bearing section; the prosthetic mitral valve coaptation enhancement device further comprises at least one anchoring element, which anchoring element is coupled to the main body and is capable to anchor the main body within the native mitral valve region of a heart.

Owner:MEDIRA AG

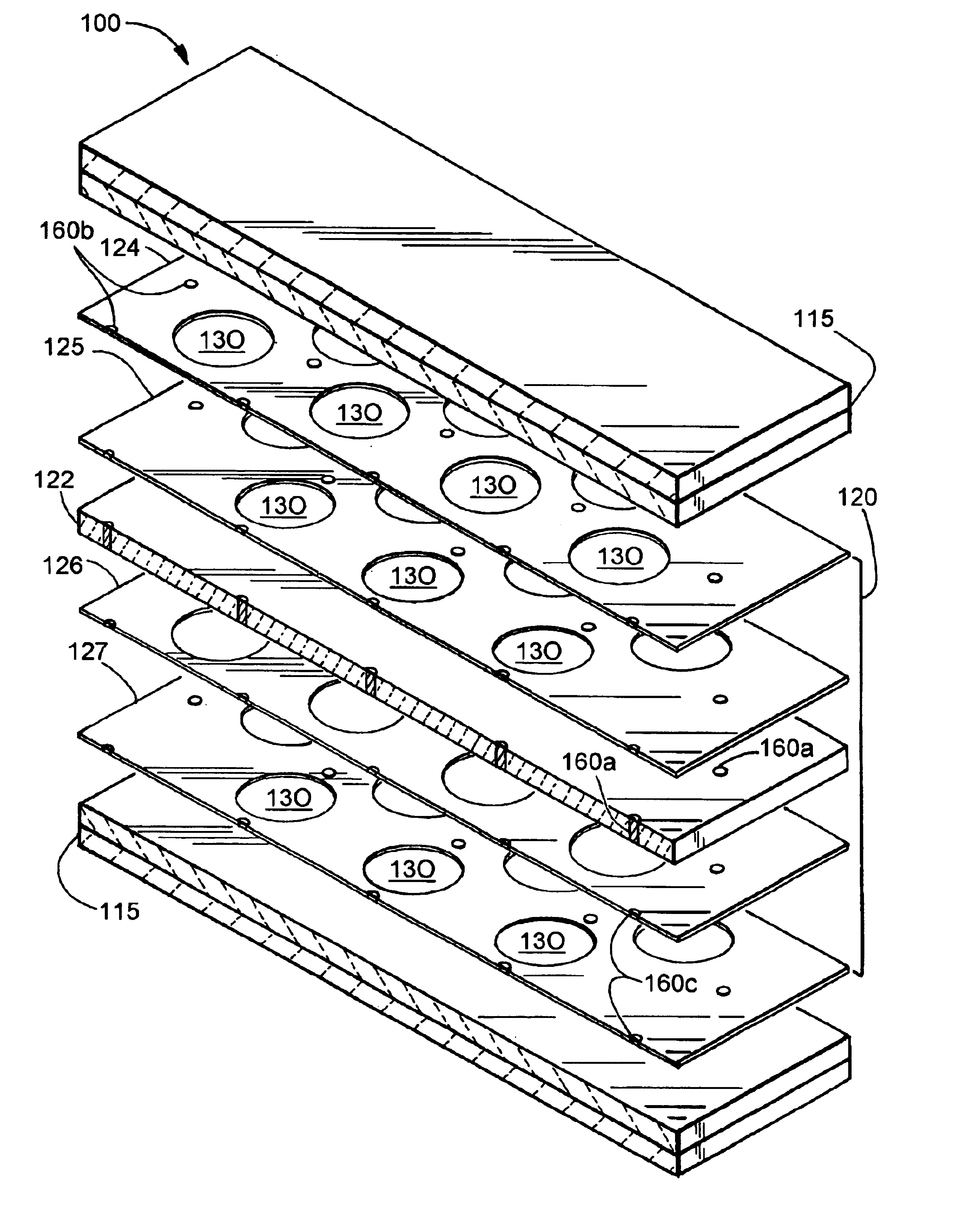

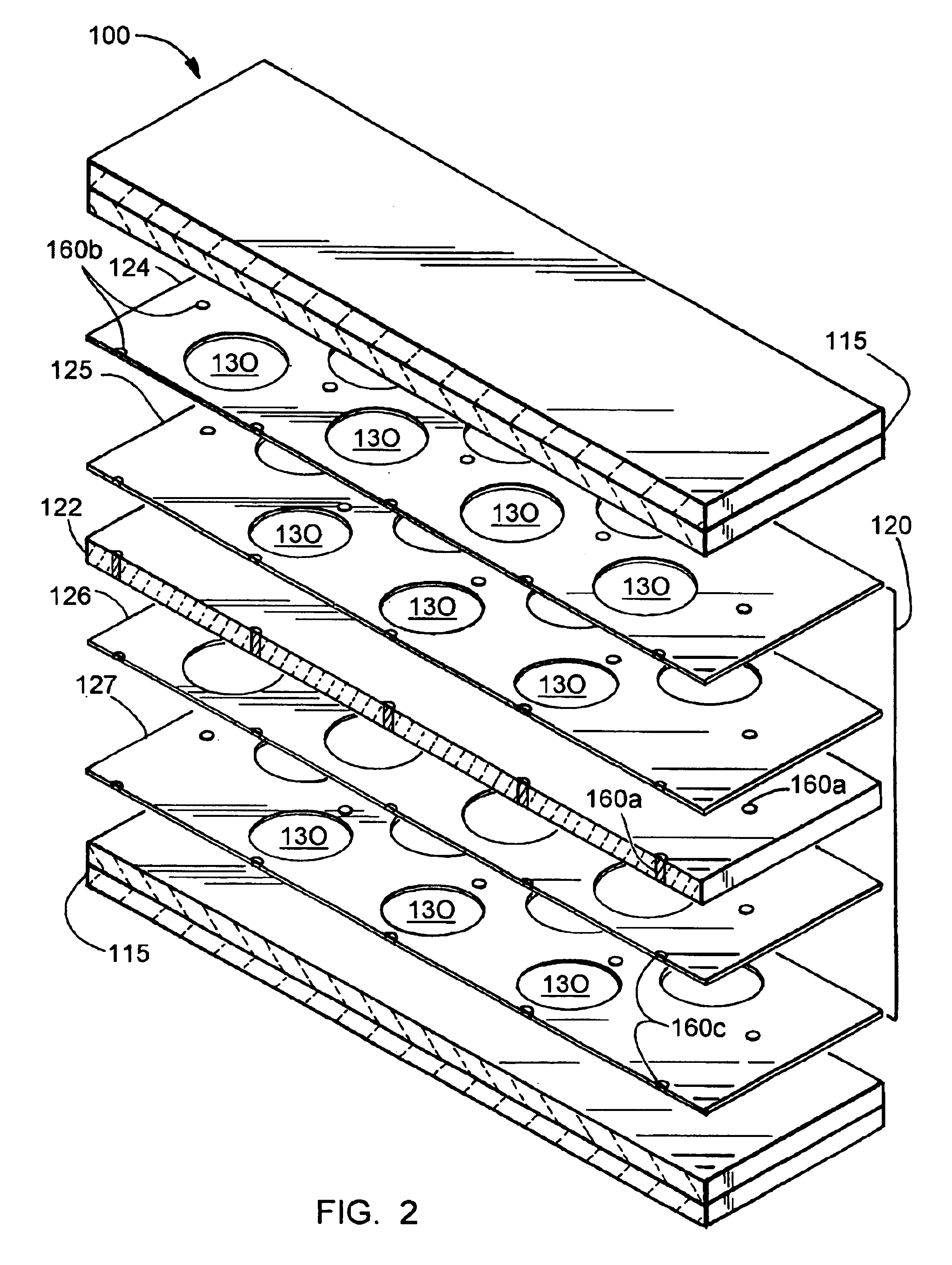

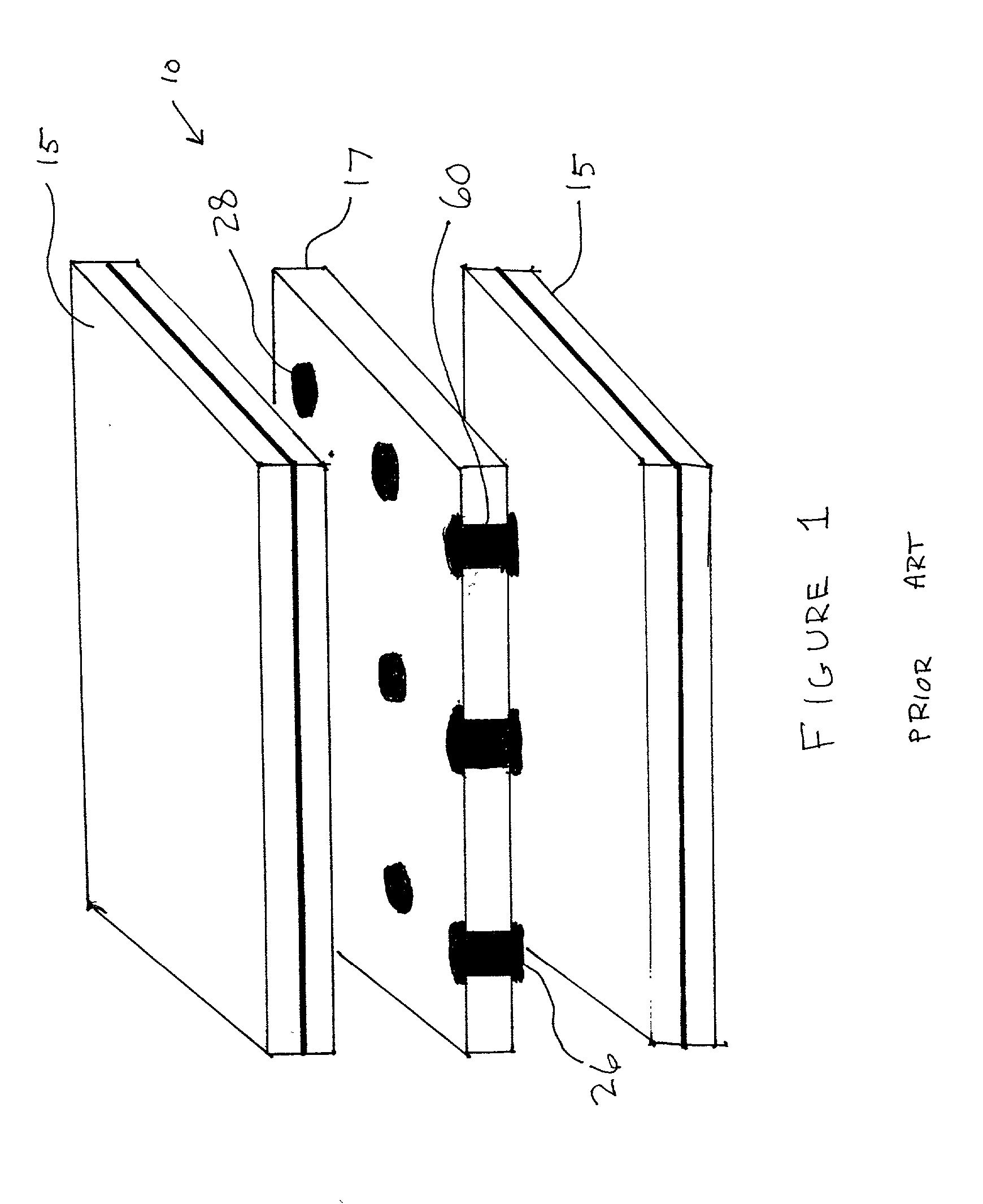

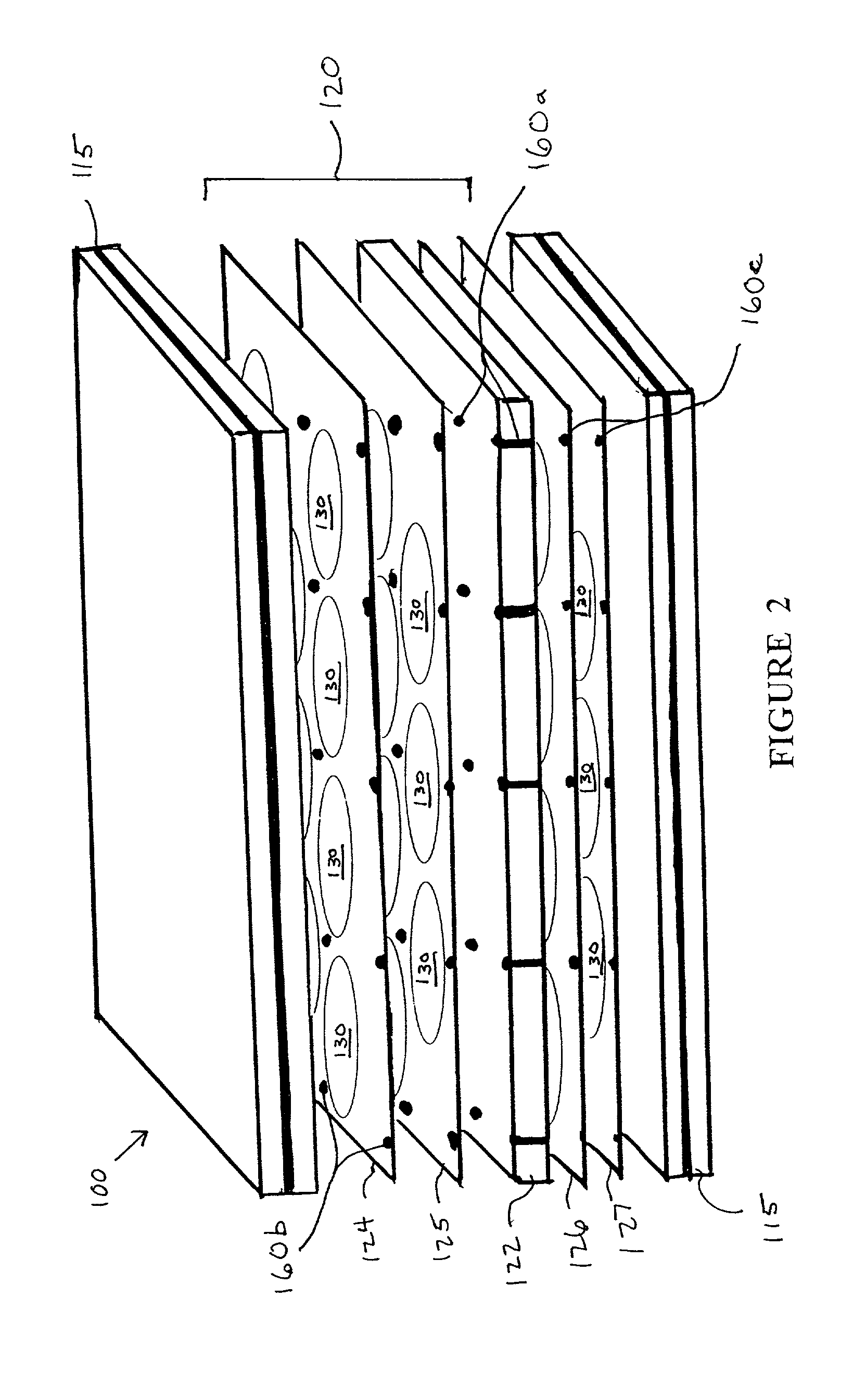

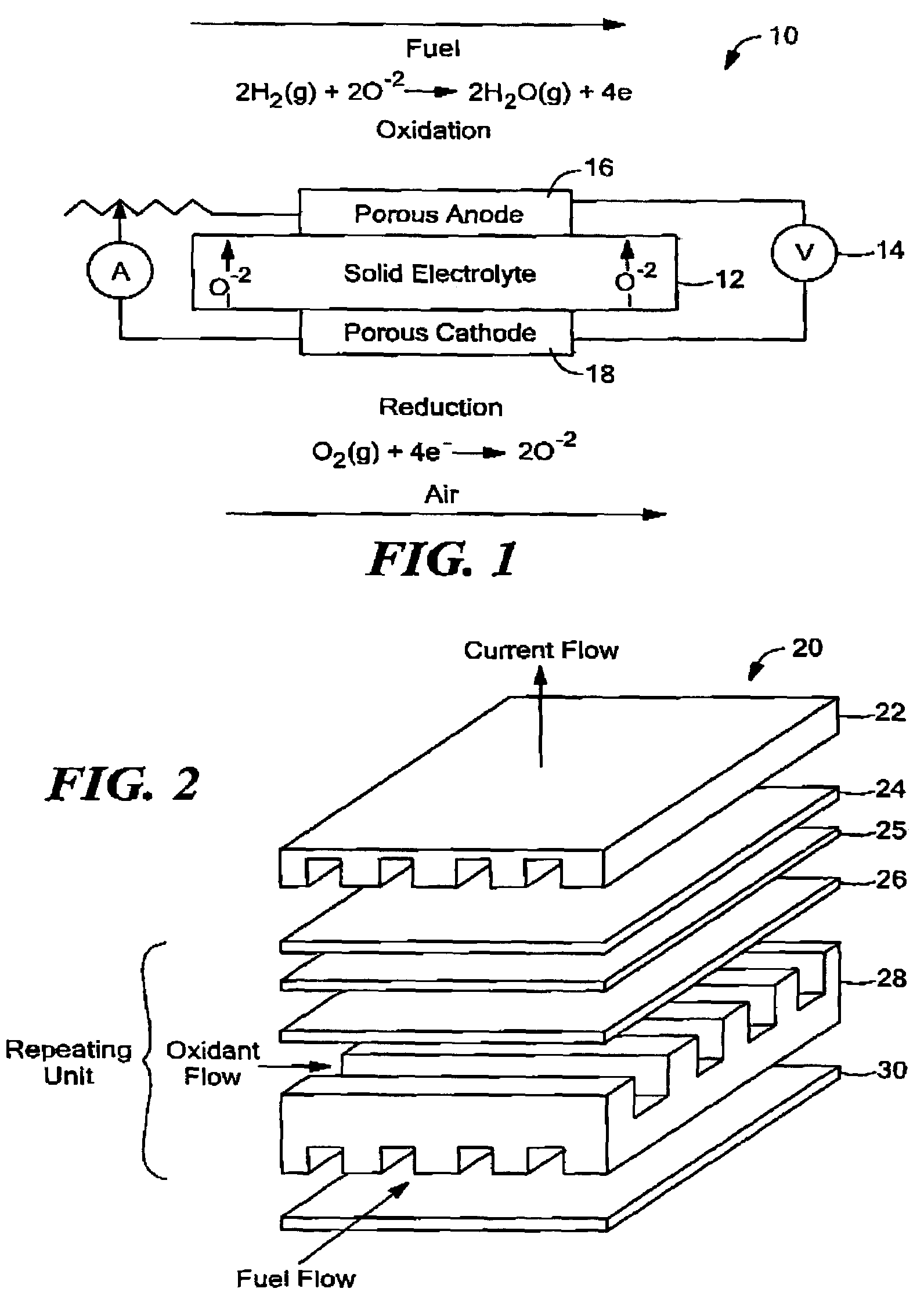

High performance ceramic fuel cell interconnect with integrated flowpaths and method for making same

InactiveUS6949307B2Overcome lack of conductivityMinimal resistive lossesFuel cells groupingFinal product manufactureFuel cellsElectrical connection

A method, apparatus and assembly related to solid oxide fuel cell interconnects is disclosed. In its broadest embodiment, the invention contemplates a multi-layered ceramic interconnect having integrated flow fields and electrical connections. The method of making this interconnect includes judicious selection of materials, formation of appropriate apertures for the flow fields and electrical connectors, and the joining of the layers through a firing and / or sealing process.

Owner:LG FUEL CELL SYST

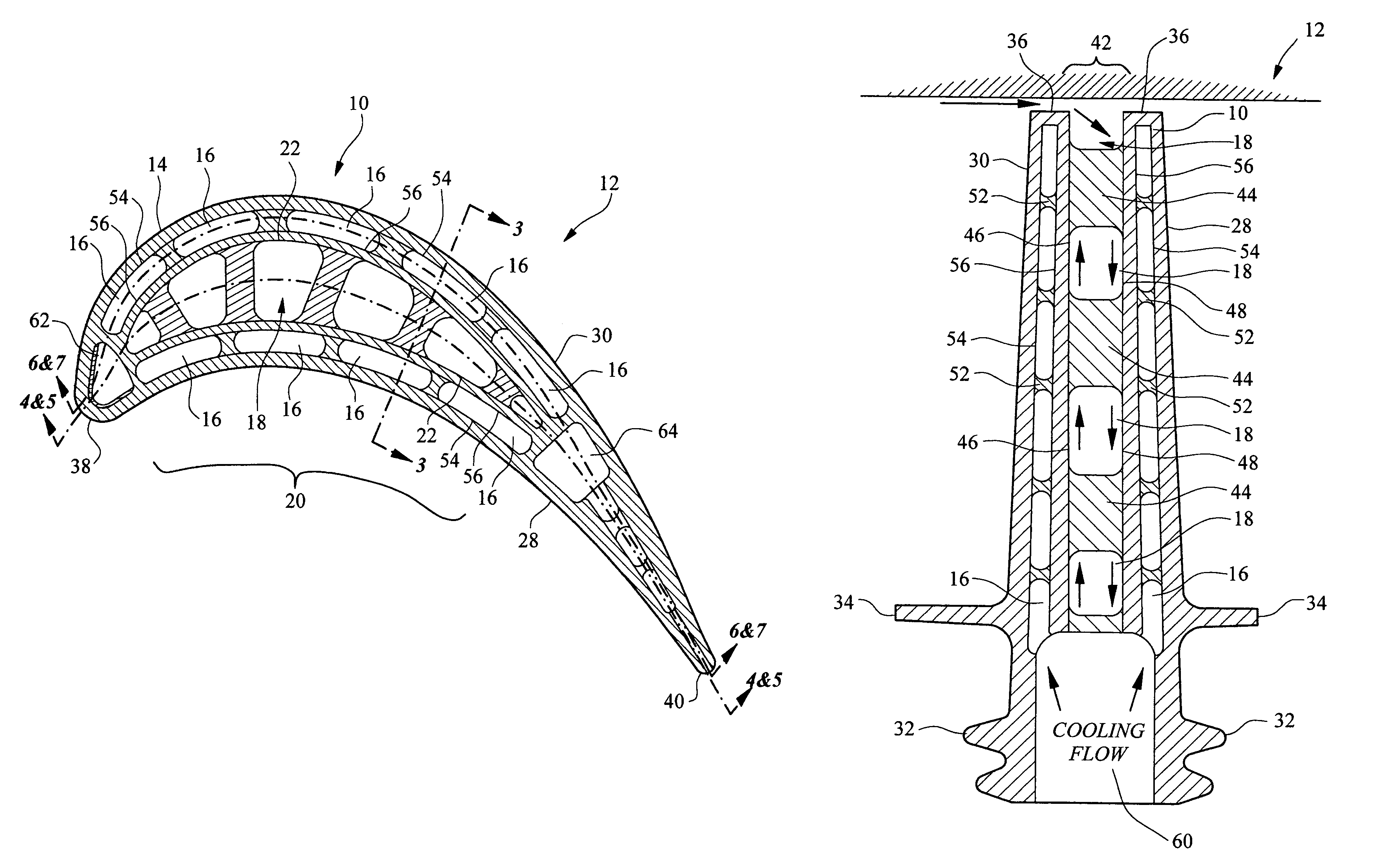

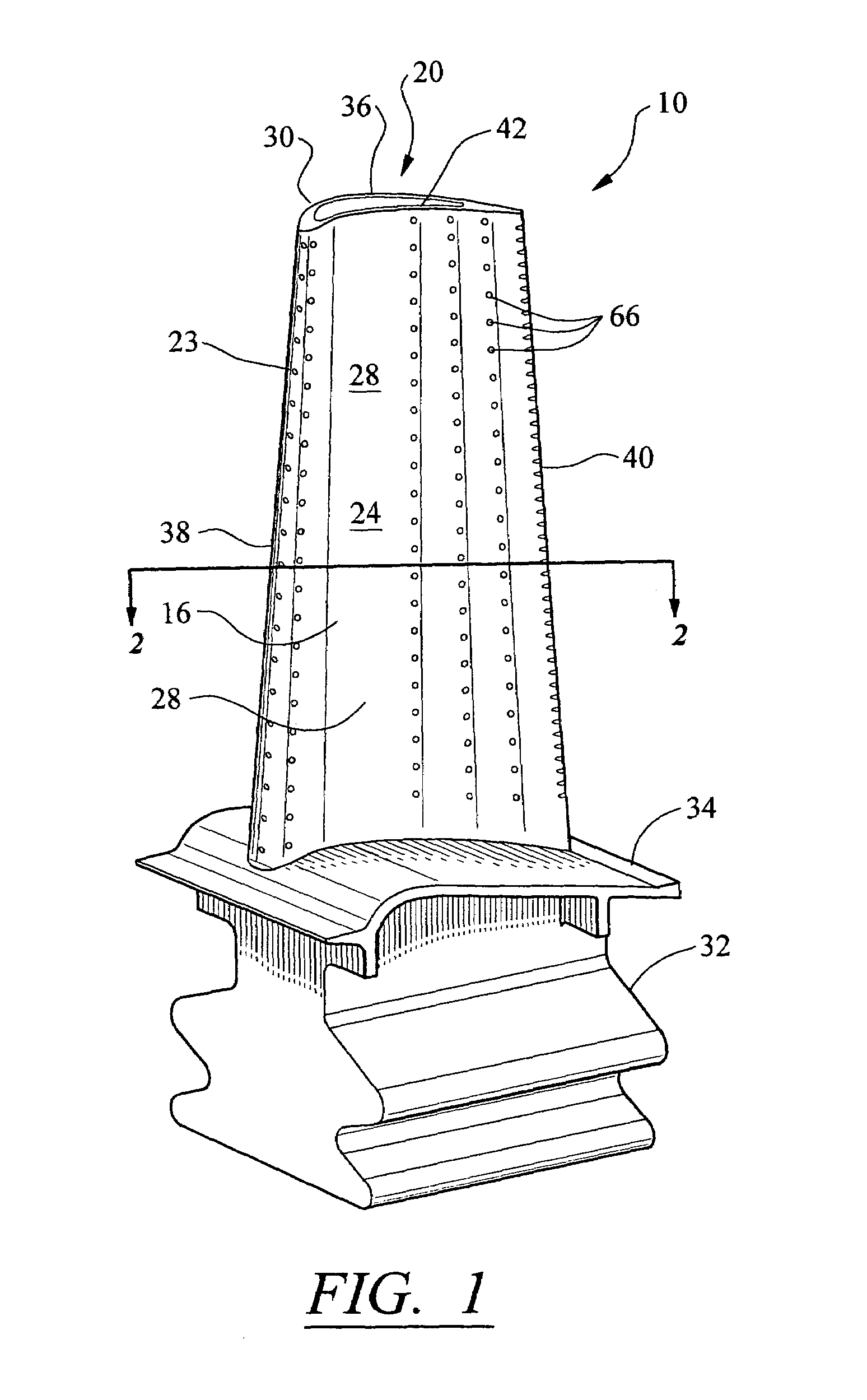

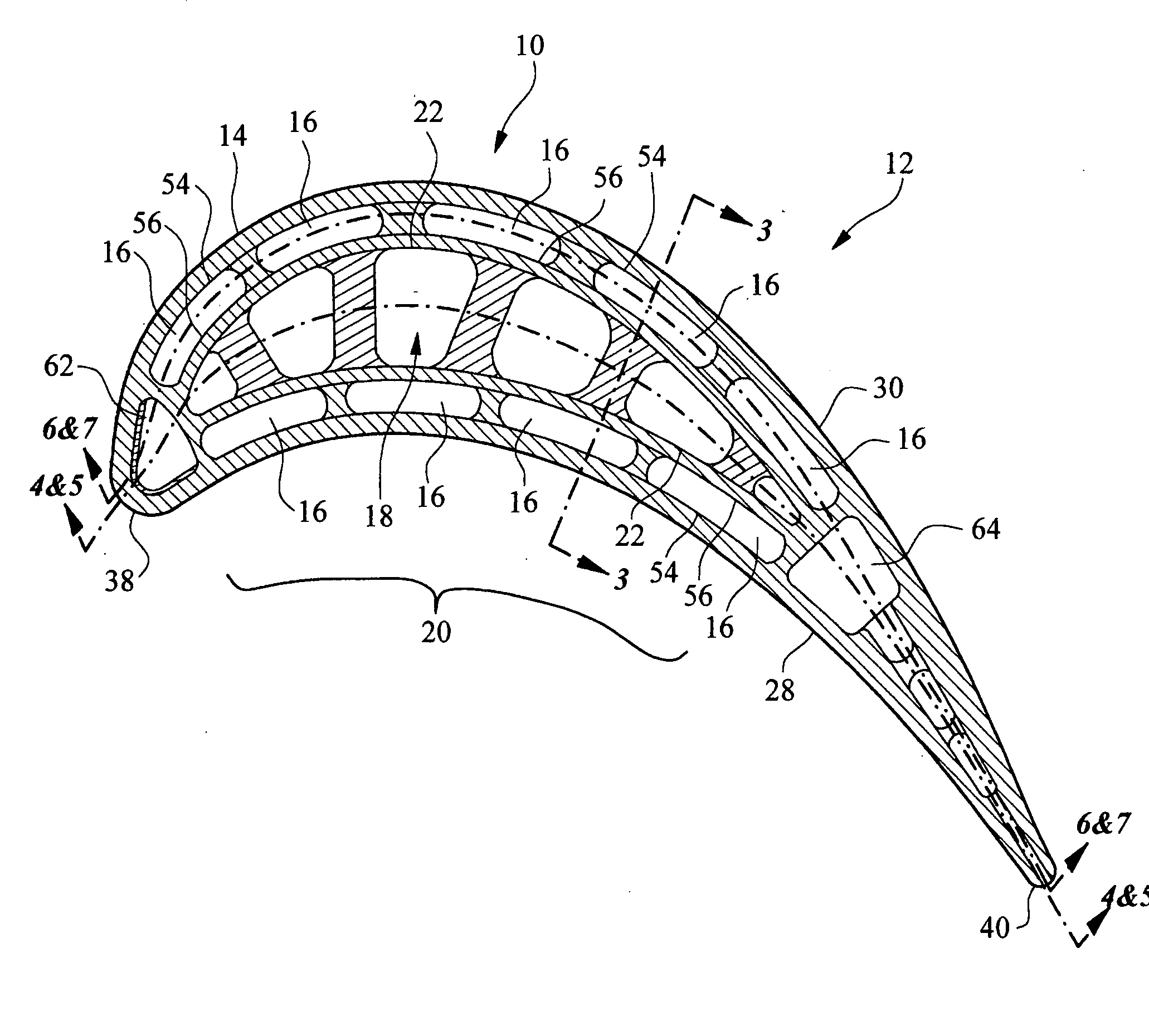

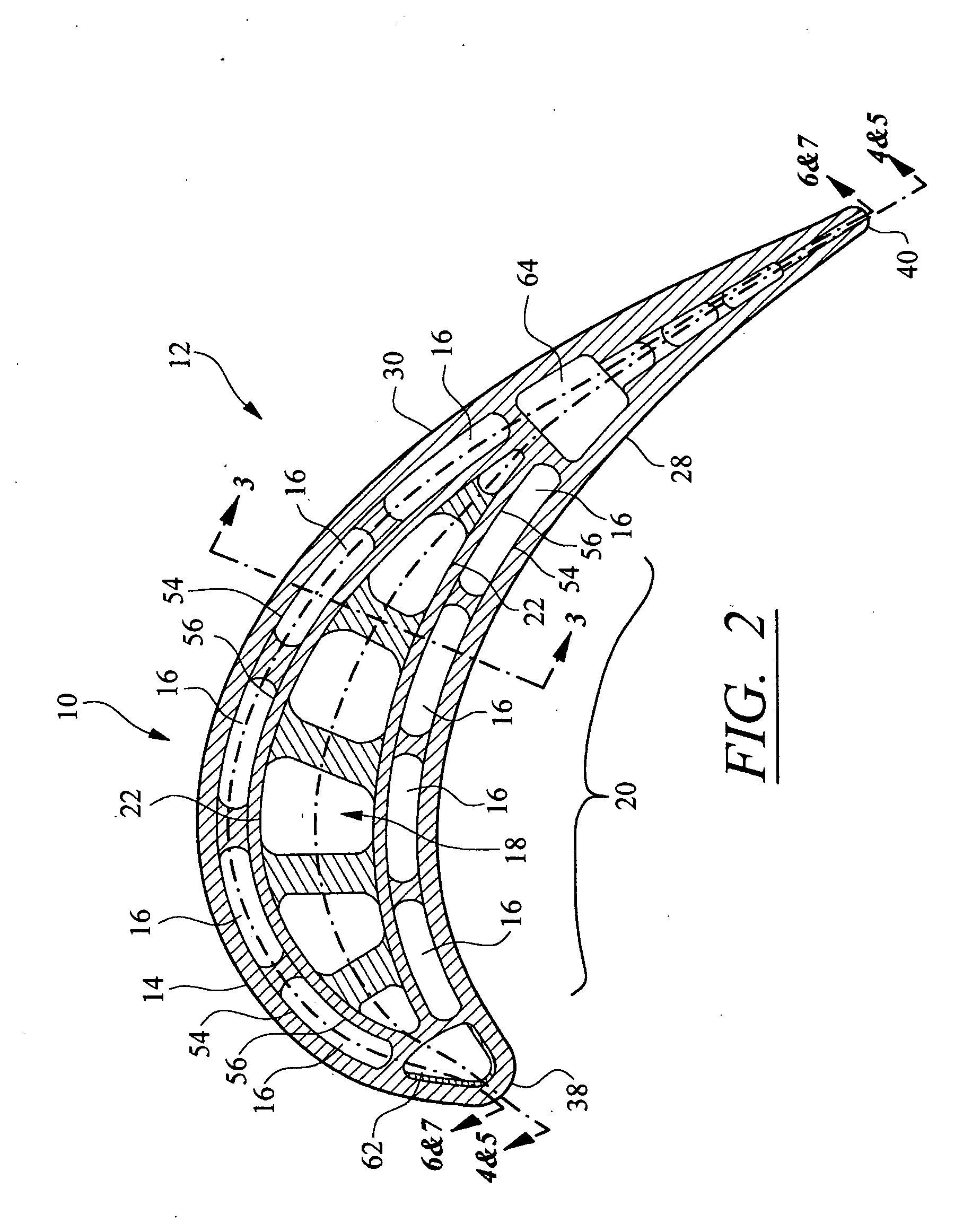

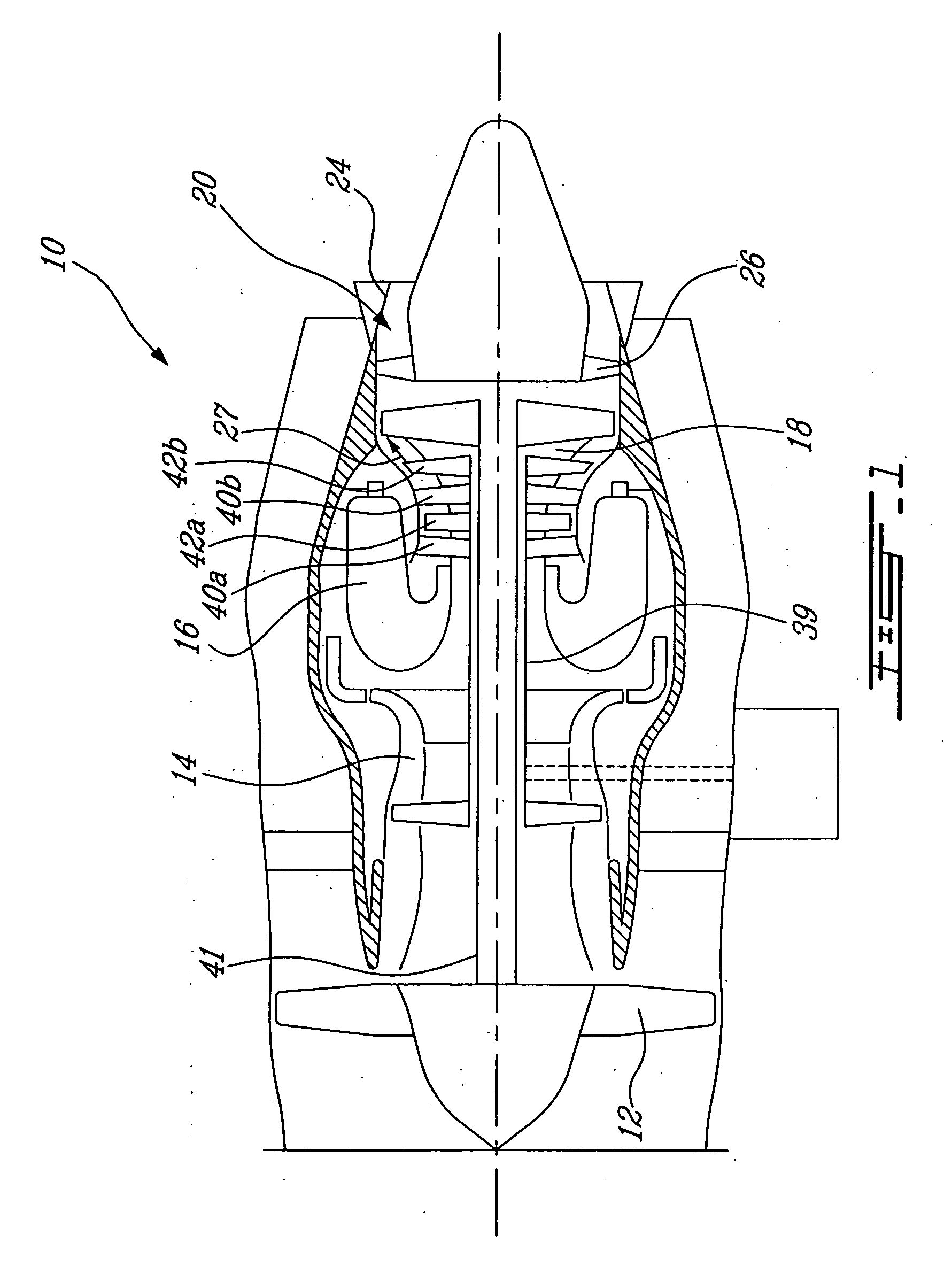

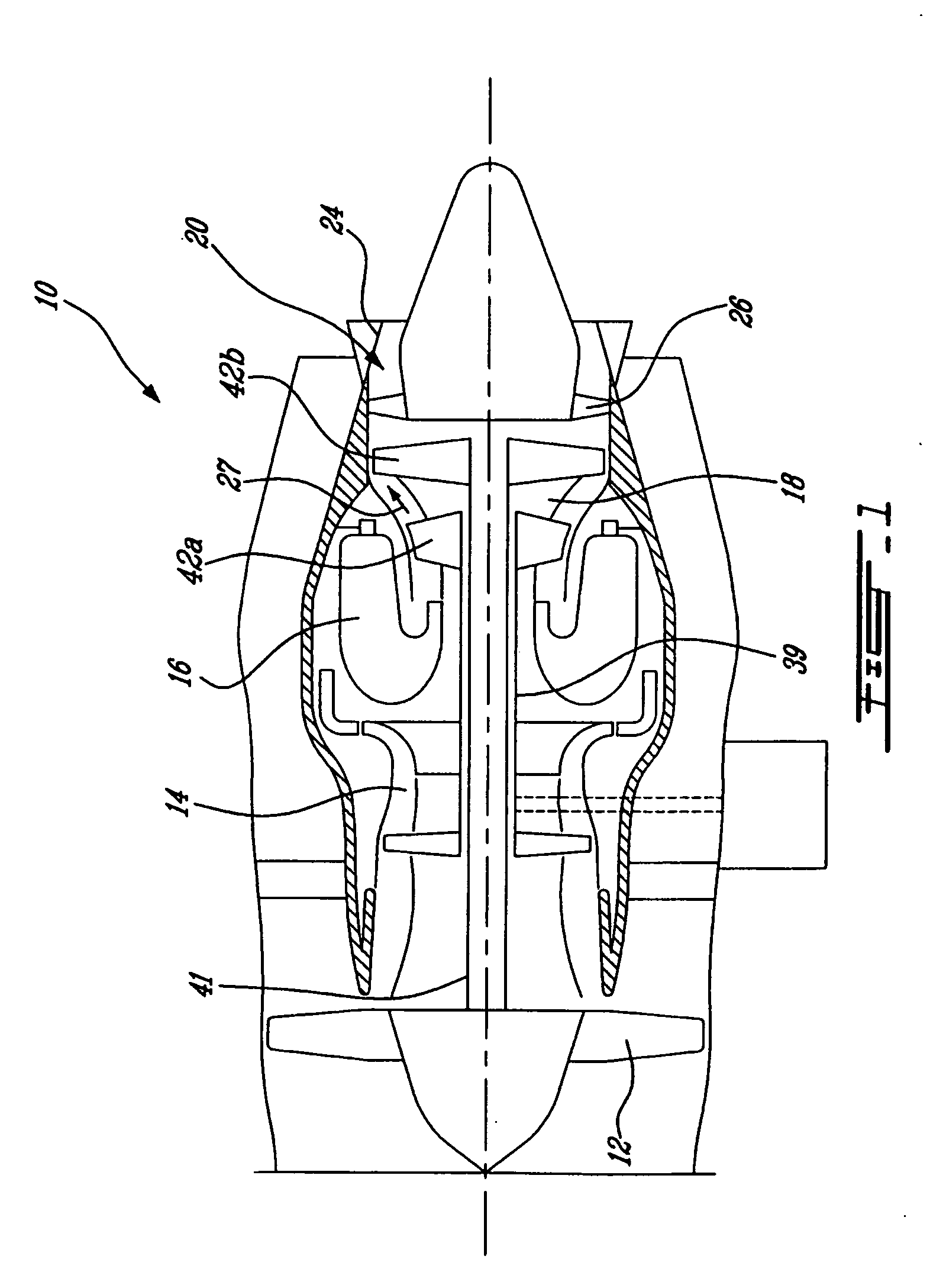

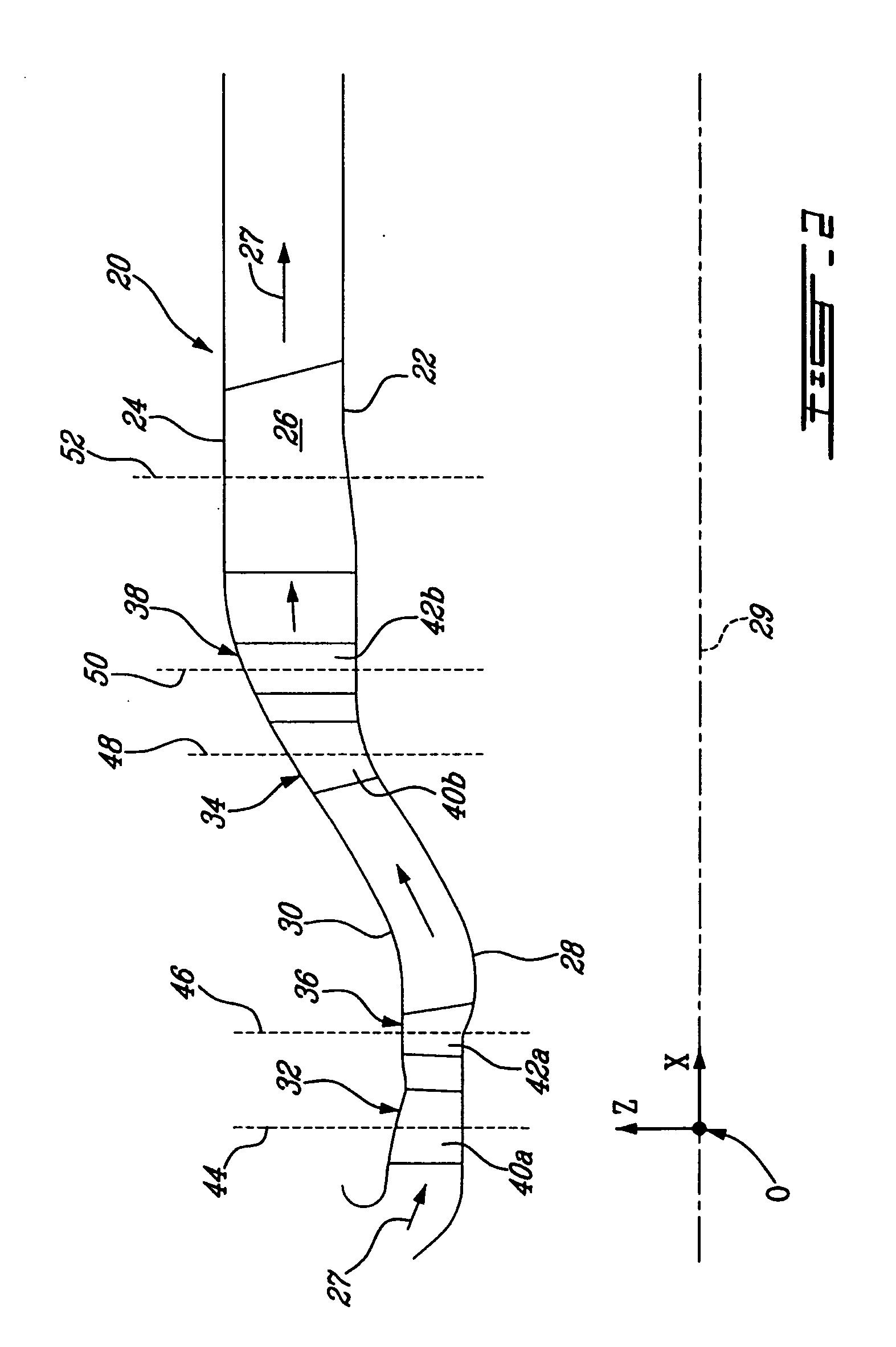

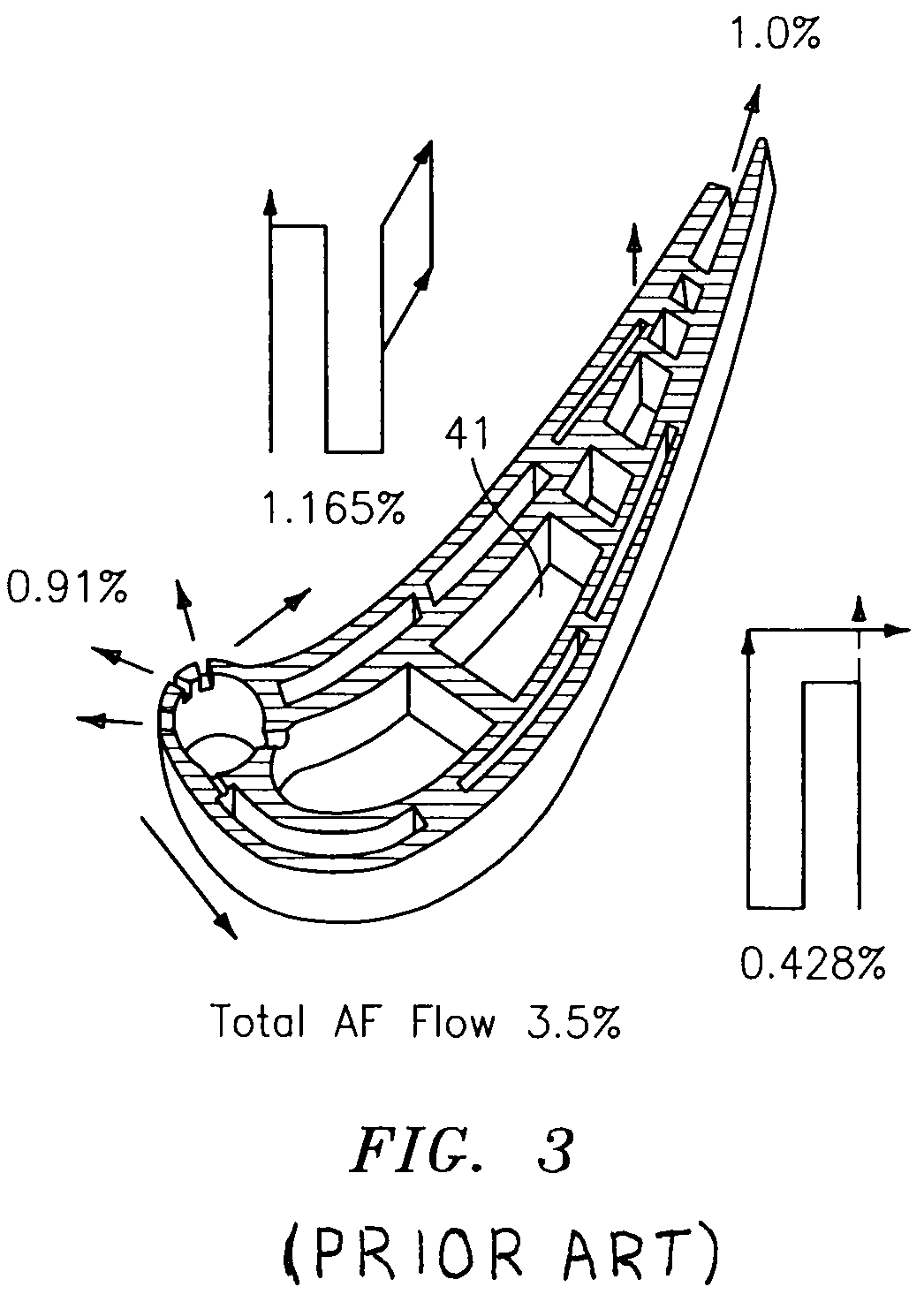

Turbine airfoil with outer wall cooling system and inner mid-chord hot gas receiving cavity

A turbine airfoil usable in a turbine engine and having at least one cooling system. The cooling system may be positioned in an outer wall of the turbine airfoil, and the airfoil may include a hot gas receiving cavity positioned in a mid-chord region of the airfoil. The hot gas receiving cavity may have an opening in a tip of the airfoil to enable hot gases to circulate into the hot gas receiving cavity. In at least one embodiment, the cooling system in the outer wall and the hot gas receiving cavity may include a plurality of ribs. Cooling fluids may be passed through the cooling system in the outer wall, and hot combustion gases may be passed into the hot gas receiving cavity to moderate the temperature of the inner portions of the outer wall to reduce the temperature gradient in the outer wall.

Owner:SIEMENS ENERGY INC

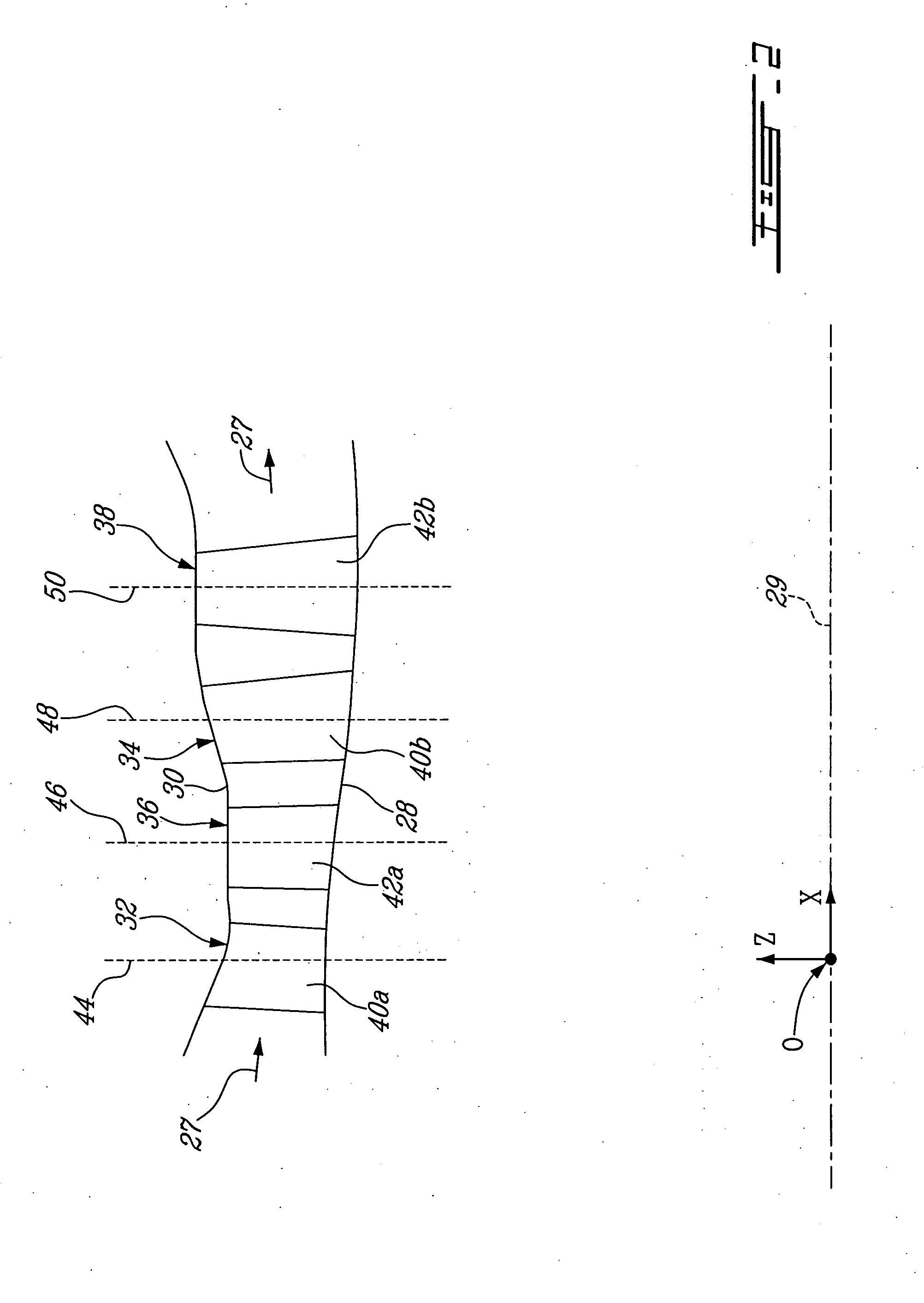

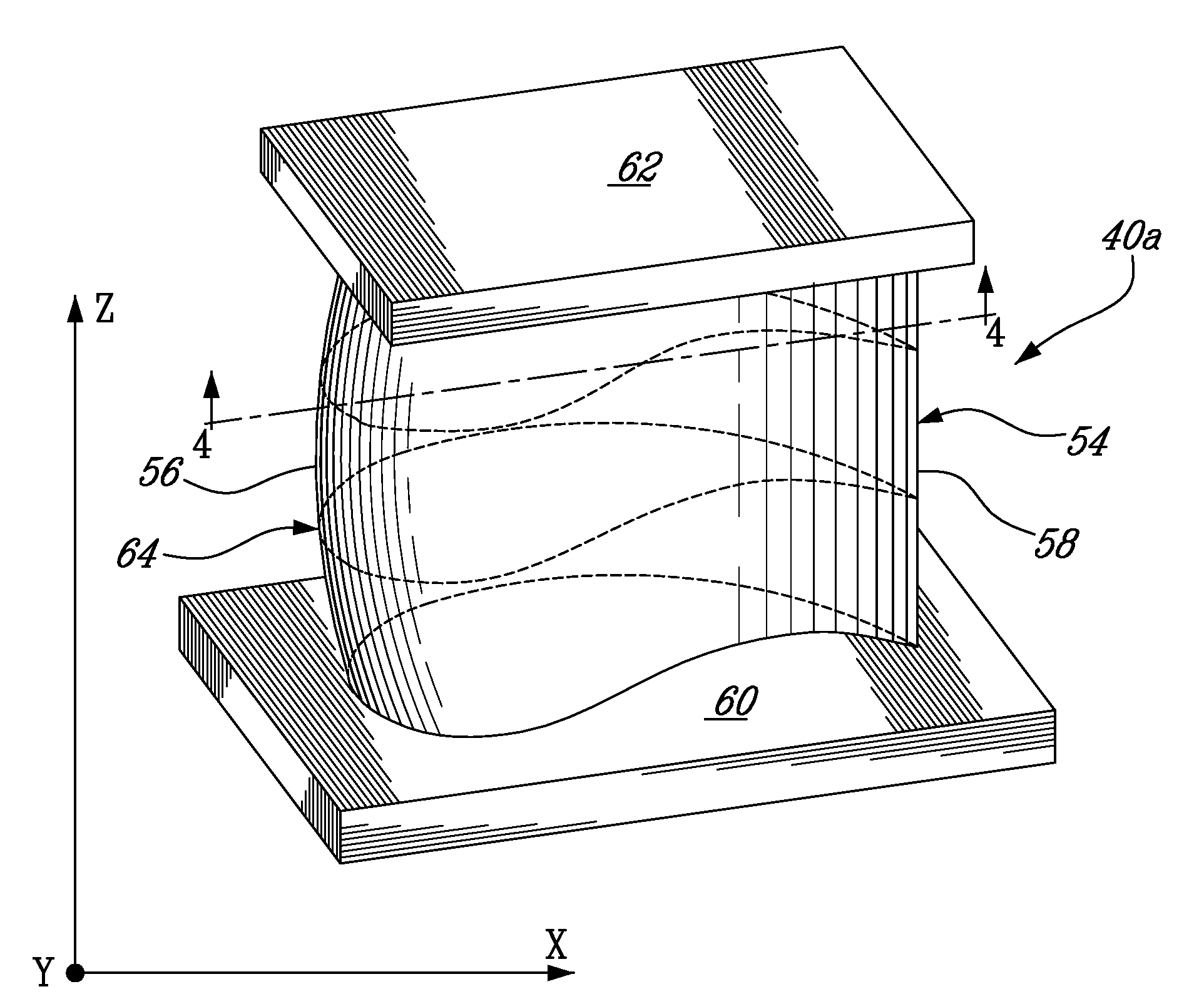

HP turbine vane airfoil profile

ActiveUS7520728B2Minimizes gradientMinimize secondary lossesEngine manufactureBlade accessoriesHigh pressureTurbine

Owner:PRATT & WHITNEY CANADA CORP

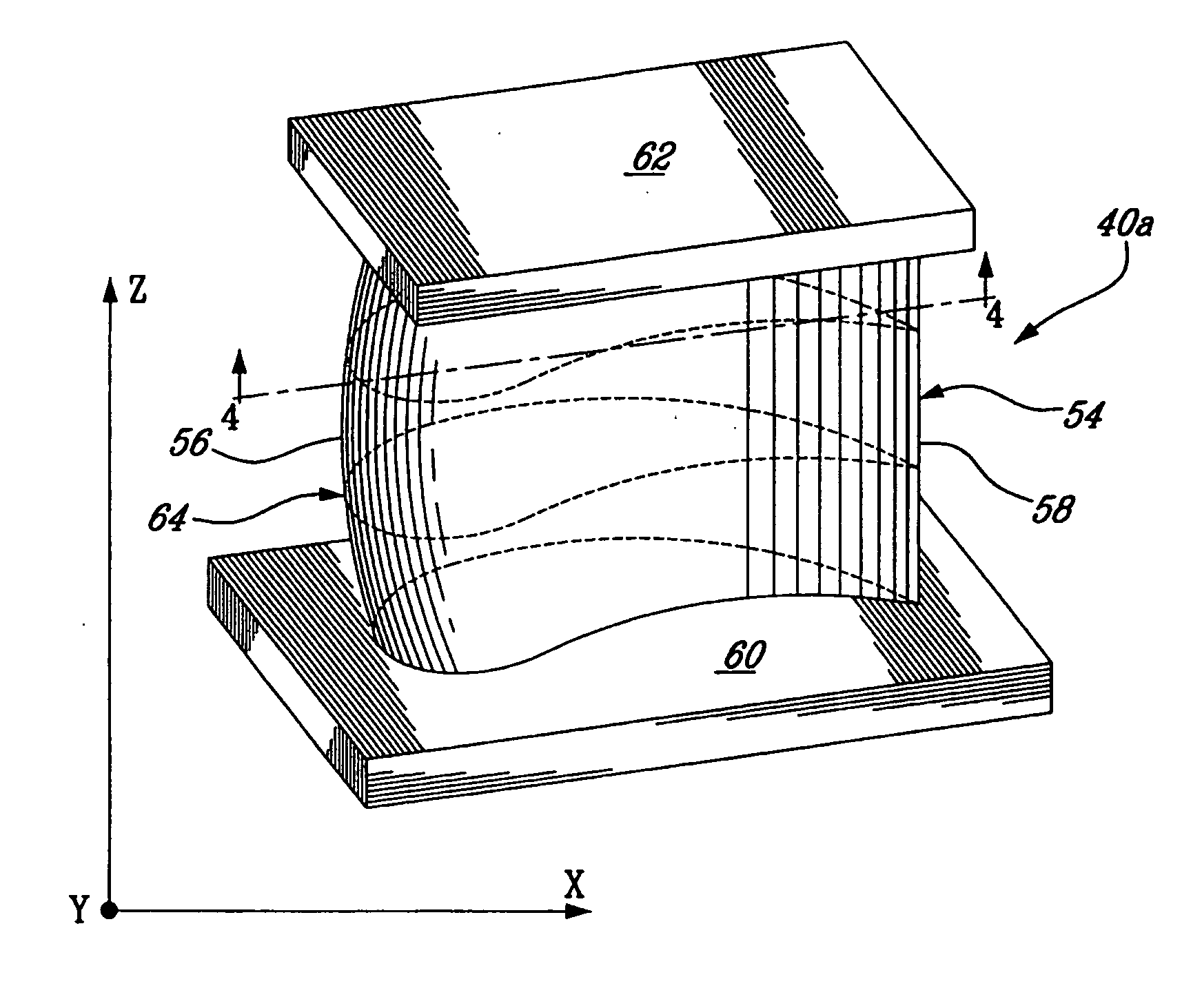

HP Turbine Vane Airfoil Profile

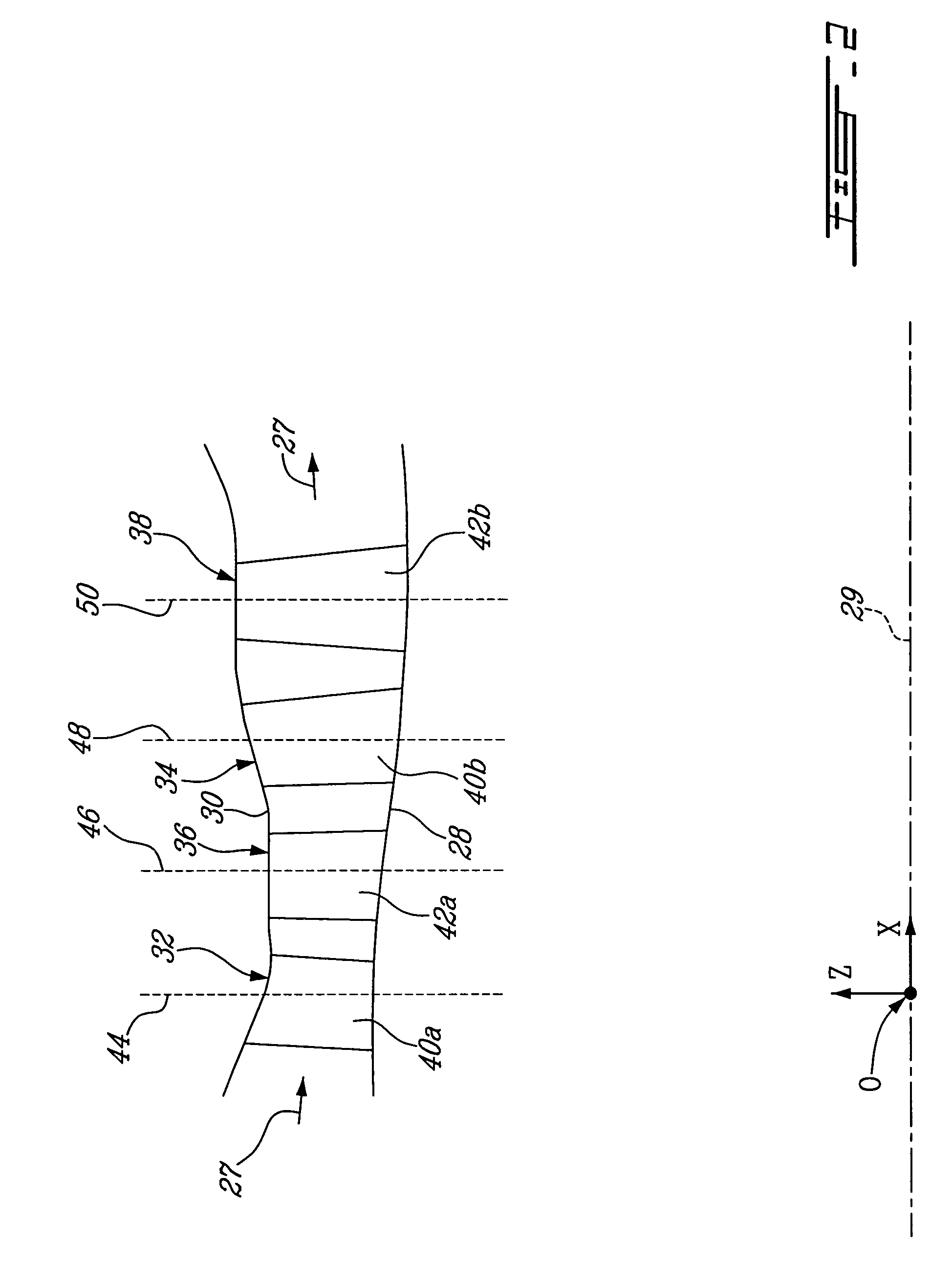

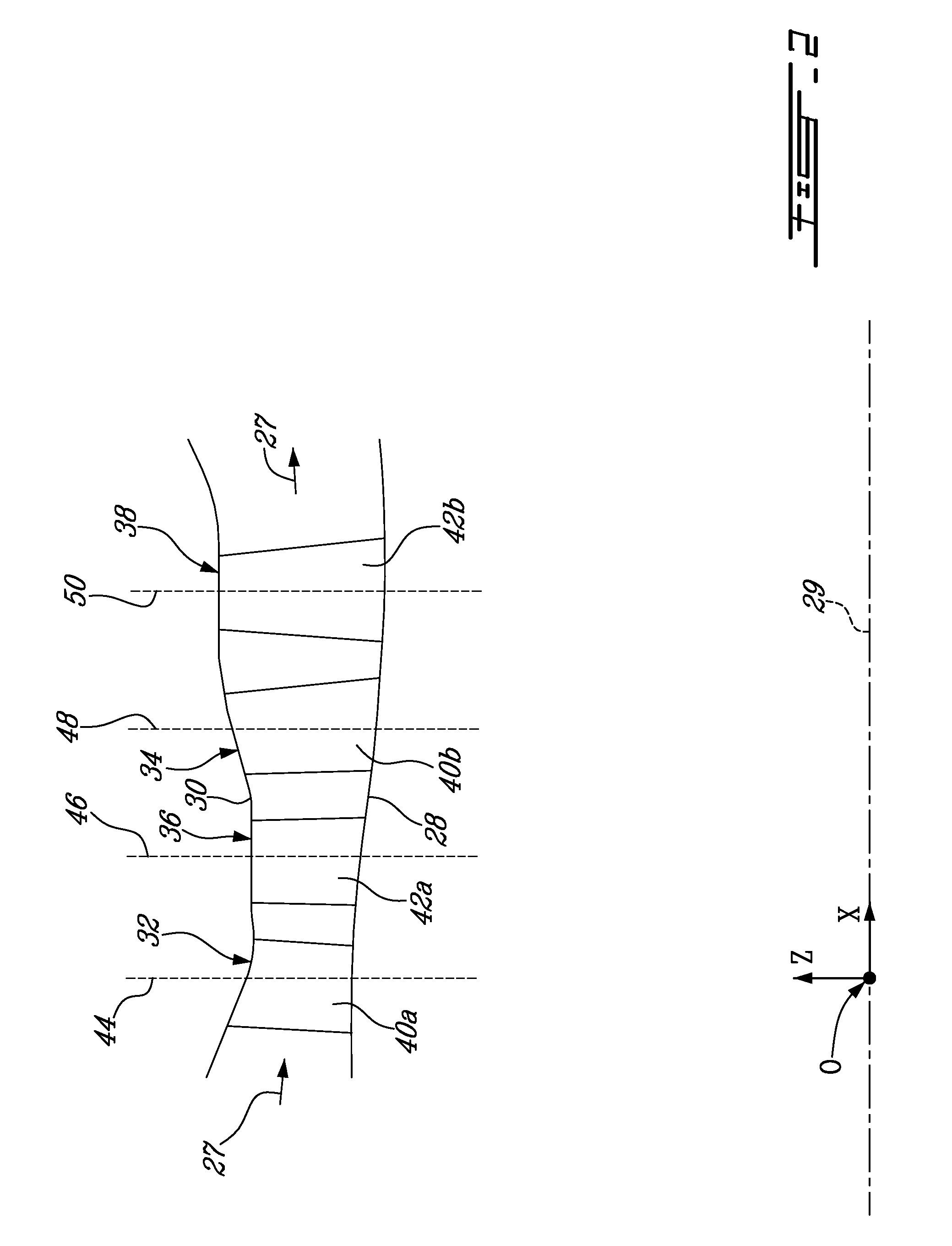

ActiveUS20080056896A1Improve aerodynamic performanceMinimizes static pressure gradientEngine manufacturePump componentsHigh pressureTurbine

A two-stage high pressure turbine includes a first stage vane having an airfoil with a profile substantially in accordance with at least an intermediate portion of the Cartesian coordinate values of X, Y and Z set forth in Table 2. The X and Y values are distances, which when smoothly connected by an appropriate continuing curve, define airfoil profile sections at each distance Z. The profile sections at each distance Z are joined smoothly to one another to form a complete airfoil shape.

Owner:PRATT & WHITNEY CANADA CORP

Filter apparatus for ostium of left atrial appendage

InactiveUS8685055B2Avoid formingEffective isolationDilatorsMedical devicesThrombusRight Atrial Appendage

Apparatus for permanent placement across an ostium of a left atrial appendage in a patient, which includes a filtering membrane configured to extend across the ostium of the left atrial appendage. The filtering membrane has a permeable structure which allows blood to flow through but substantially inhibits thrombus from passing therethrough. The apparatus also includes a support structure attached to the filtering membrane which retains the filtering membrane in position across the ostium of the left atrial appendage by permanently engaging a portion of the interior wall of the left atrial appendage. The support structure may be radially expandable from a first configuration to a second configuration which engages the ostium or the interior wall of the left atrial appendage. The filtering membrane may define an opening therethrough that is configured to expand from a first size which inhibits the passage of thrombus therethrough to a second size which allows an interventional device, e.g., an expansion balloon, to pass therethrough, and wherein the opening is resiliently biased towards the first size.

Owner:BOSTON SCI SCIMED INC

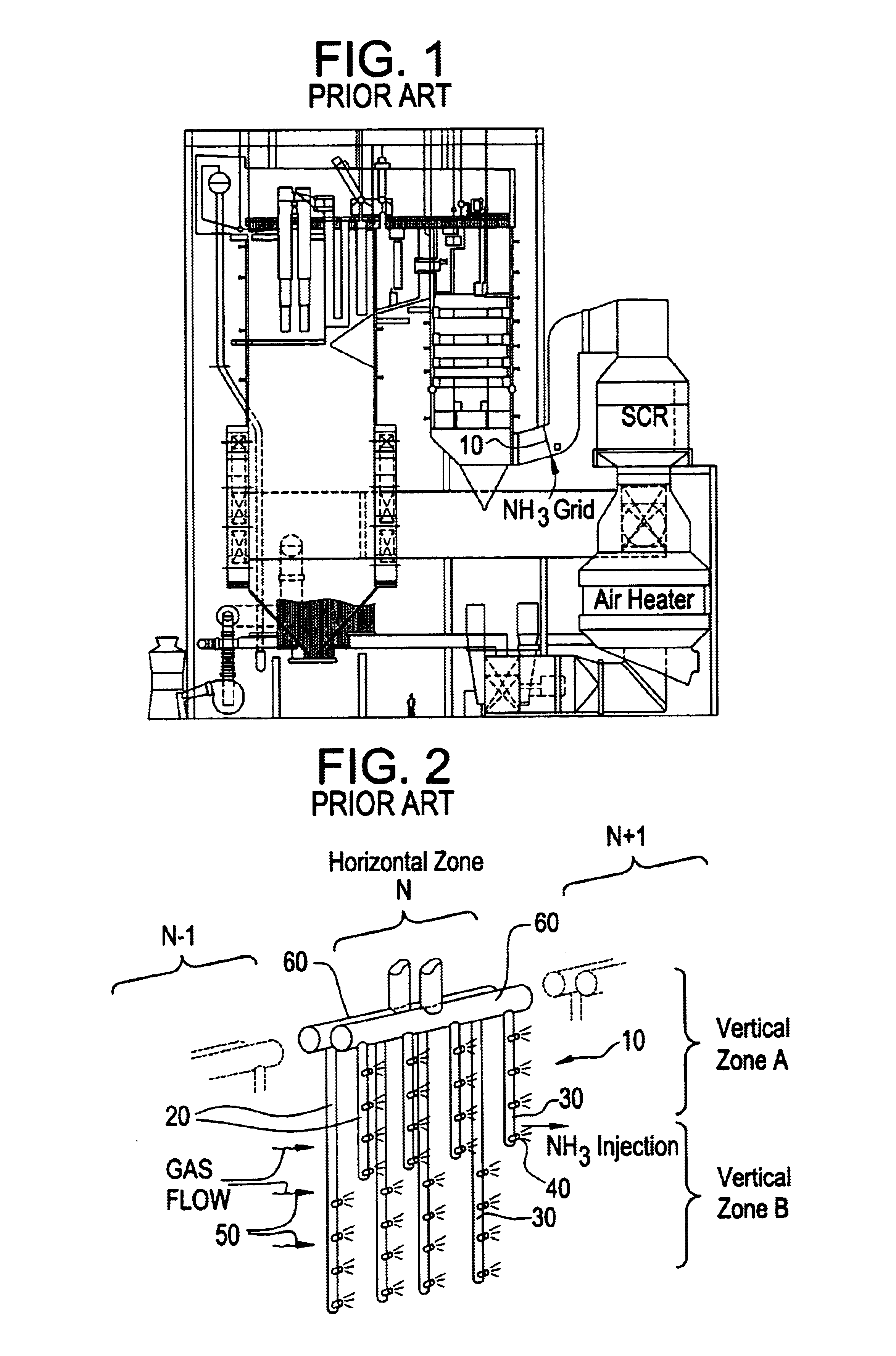

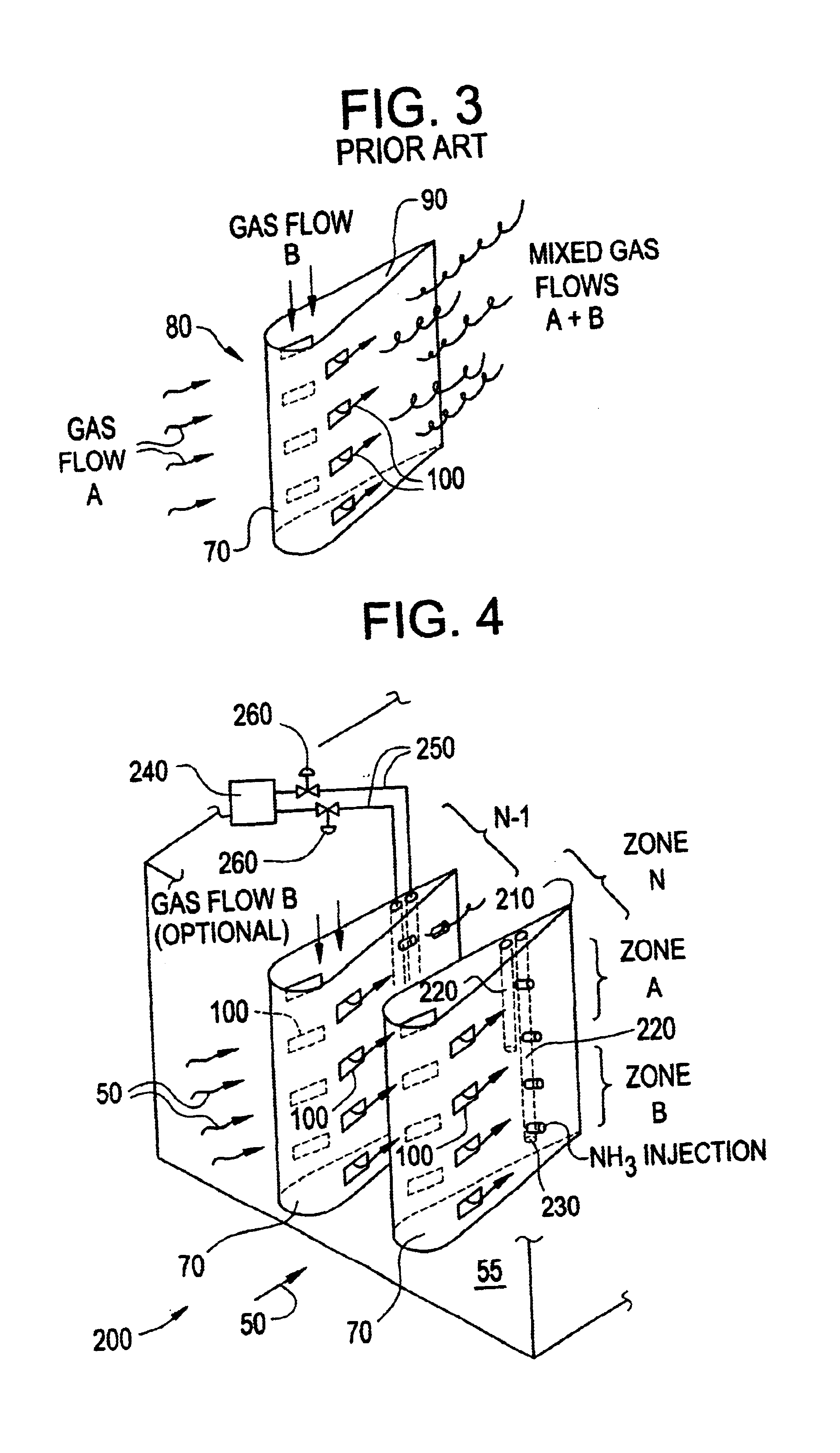

Integrated air foil and ammonia injection grid for SCR systems

InactiveUS6887435B1Minimizes unrecoverable pressure lossReduce total pressure lossCombination devicesFlow mixersFlue gasEngineering

An integrated air foil and ammonia injection grid provides a plurality of air foils across a flue conveying flue gas. Each air foil has a leading curved edge and a tapered, pointed, trailing end. At least one injection pipe is positioned inside each air foil, and has at least one nozzle for injecting ammonia into the flue gas flowing across the air foils. Preferably, plural injection tubes are provided and positioned one behind the other in each air foil, and each injection tube in a given air foil has a length different than a length of the other injection tubes in the same air foil. A longest injection tube in a given air foil is located furthest downstream and proximate the tapered trailing edge and a shortest injection tube in the same air foil is located furthest upstream, remaining injection tubes in the same air foil being progressively shorter the further upstream any injection tube is located. Apertures may be provided on opposed lateral sides of the air foils for introducing a gas flow into the flue gas passing across the air foils. Ammonia flow to each injection pipe may be individually controlled.

Owner:THE BABCOCK & WILCOX CO

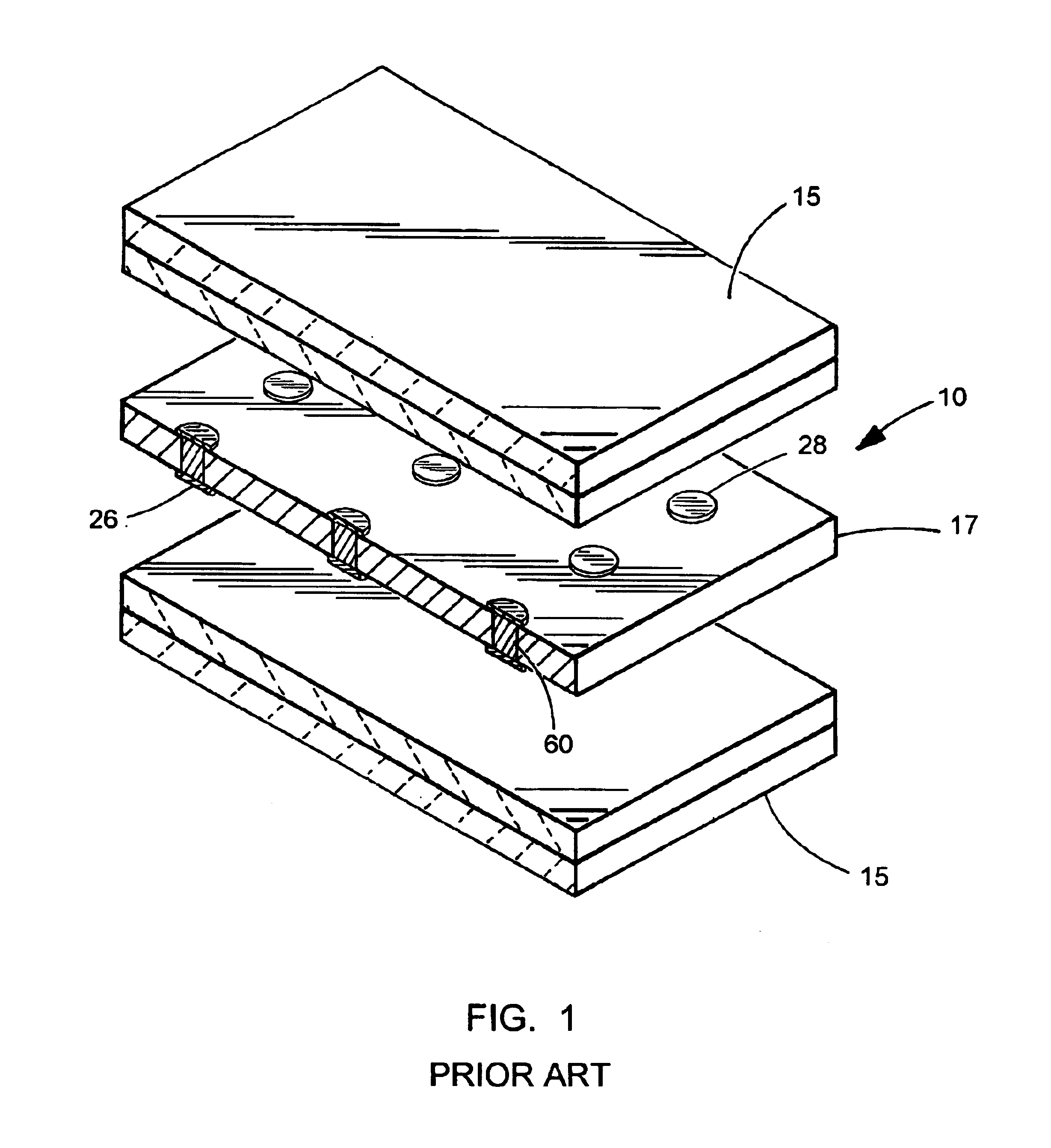

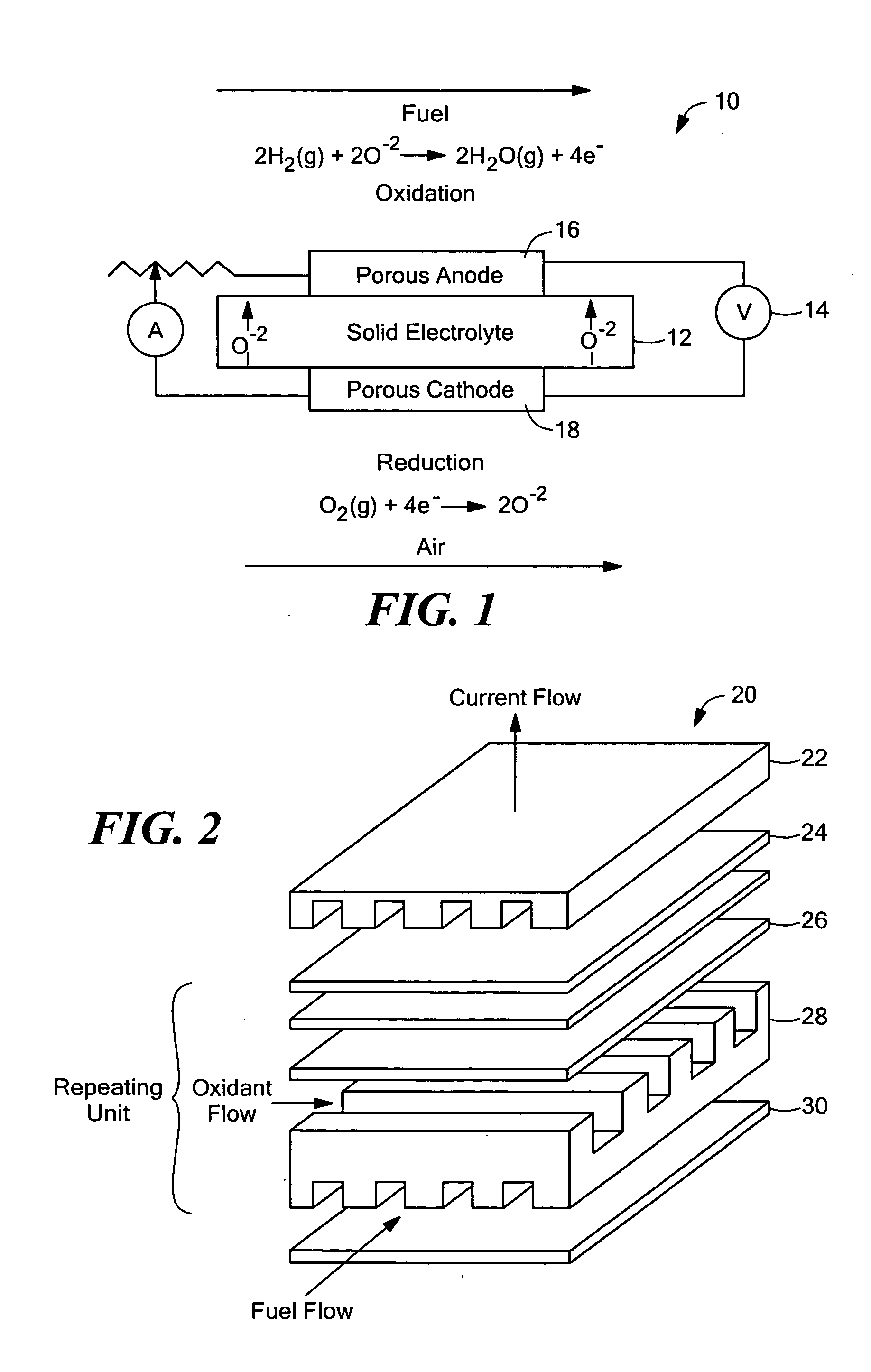

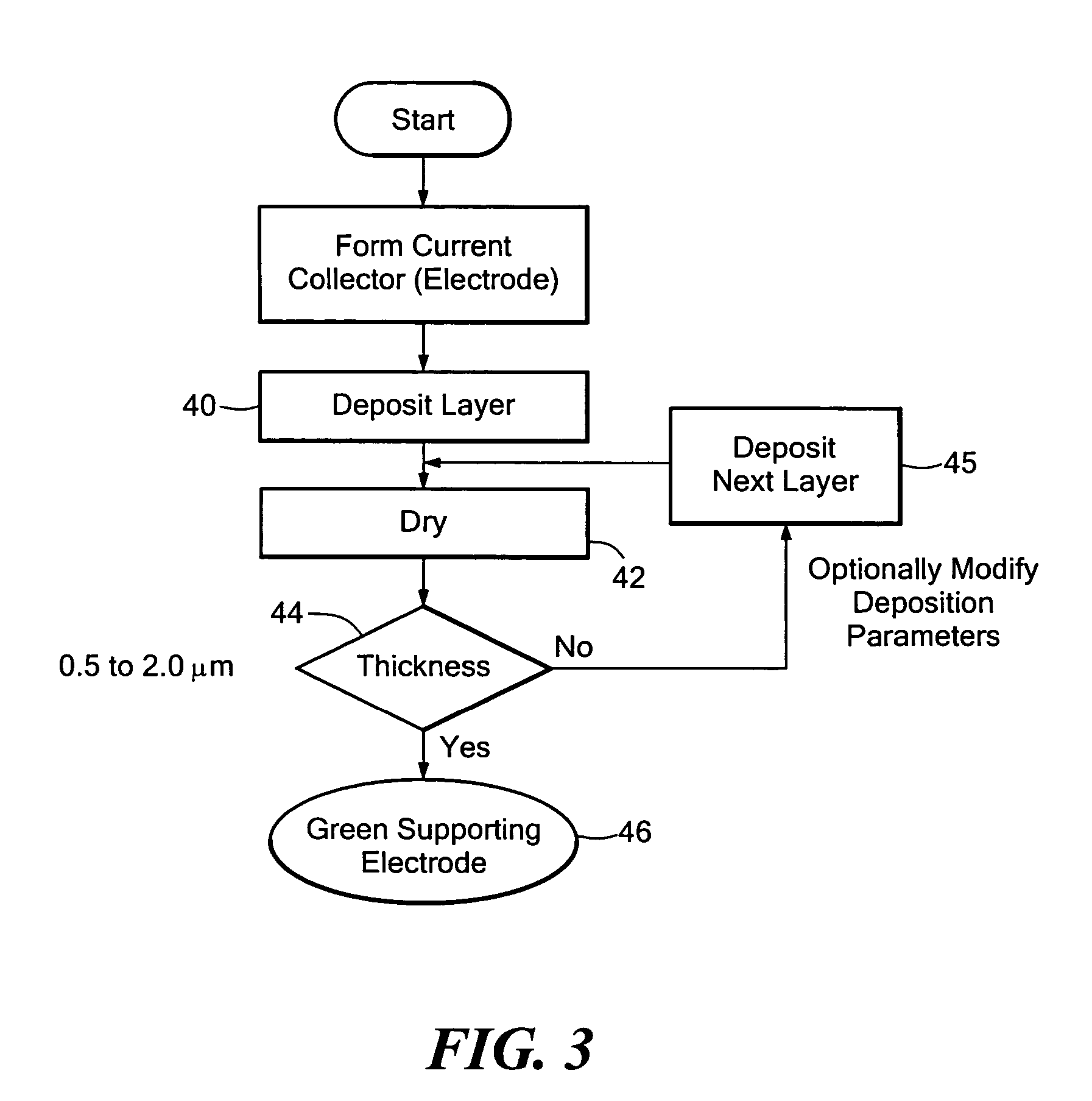

Process for solid oxide fuel cell manufacture

InactiveUS20050089739A1Minimize temperature gradientMinimizes gradientFuel cells groupingCell electrodesOxideBi layered

The present invention provides a method for conveniently manufacturing a solid oxide fuel cell (SOFC) at a cost that is less than five-hundred dollars per kilowatt of electricity. The method comprises forming an electrode layer and depositing an electrolyte material on the surface of the electrode. The formed structure is an electrode-electrolyte bi-layer. A second electrode is deposited onto this bi-layer to form a multilayer fuel cell structure comprising an electrolyte positioned between two electrodes. This multilayer structure is then heated and fired in a single thermal cycle to remove any binder materials and sinter, respectively, the fuel cell. This thermal cycle can be performed in a furnace having one or more chambers. The chamber(s) preferably contains a variable or multiple frequency microwave source for heating the cell and removing binder materials in the electrolyte and electrode structures. The chamber(s) also preferably include a convection and / or radiation source for sintering the fuel cell. In addition, the method of the invention harmonizes and minimizes the deviation among the thermophysical properties of the electrolyte and electrode structures. This harmonization reduces and minimizes the temperature gradient within the cell such that the structure can be uniformly heated and fired during the thermal cycle. The multilayer structure is also unlikely to distort and fracture by minimizing the temperature gradient in the cell. An SOFC can also be manufactured by the present method in an order of magnitude less time than standard processes.

Owner:TRUSTEES OF BOSTON UNIV +1

High performance ceramic fuel cell interconnect with integrated flowpaths and method for making same

InactiveUS20030077498A1Overcome lack of conductivityMinimal resistive lossFuel cells groupingFinal product manufactureFuel cellsElectrical connection

A method, apparatus and assembly related to solid oxide fuel cell interconnects is disclosed. In its broadest embodiment, the invention contemplates a multi-layered ceramic interconnect having integrated flow fields and electrical connections. The method of making this interconnect includes judicious selection of materials, formation of appropriate apertures for the flow fields and electrical connectors, and the joining of the layers through a firing and / or sealing process.

Owner:LG FUEL CELL SYST

HP turbine blade airfoil profile

ActiveUS20080063531A1Minimizing flow separation disadvantageMinimize airfoil pulseEngine manufactureBlade accessoriesTurbine bladeEngineering

A second stage blade of a two-stage high pressure turbine includes an airfoil having a profile substantially in accordance with at least an intermediate portion of the Cartesian coordinate values of X, Y and Z set forth in Table 2. The X and Y values are distances, which when smoothly connected by an appropriate continuing curve, define airfoil profile sections at each distance Z. The profile sections at each distance Z are joined smoothly to one another to form a complete airfoil shape.

Owner:PRATT & WHITNEY CANADA CORP

HP turbine vane airfoil profile

ActiveUS7611326B2Minimizes gradientMinimize secondary lossesEngine manufacturePump componentsHigh pressureTurbine

A two-stage high pressure turbine includes a first stage vane having an airfoil with a profile substantially in accordance with at least an intermediate portion of the Cartesian coordinate values of X, Y and Z set forth in Table 2. The X and Y values are distances, which when smoothly connected by an appropriate continuing curve, define airfoil profile sections at each distance Z. The profile sections at each distance Z are joined smoothly to one another to form a complete airfoil shape.

Owner:PRATT & WHITNEY CANADA CORP

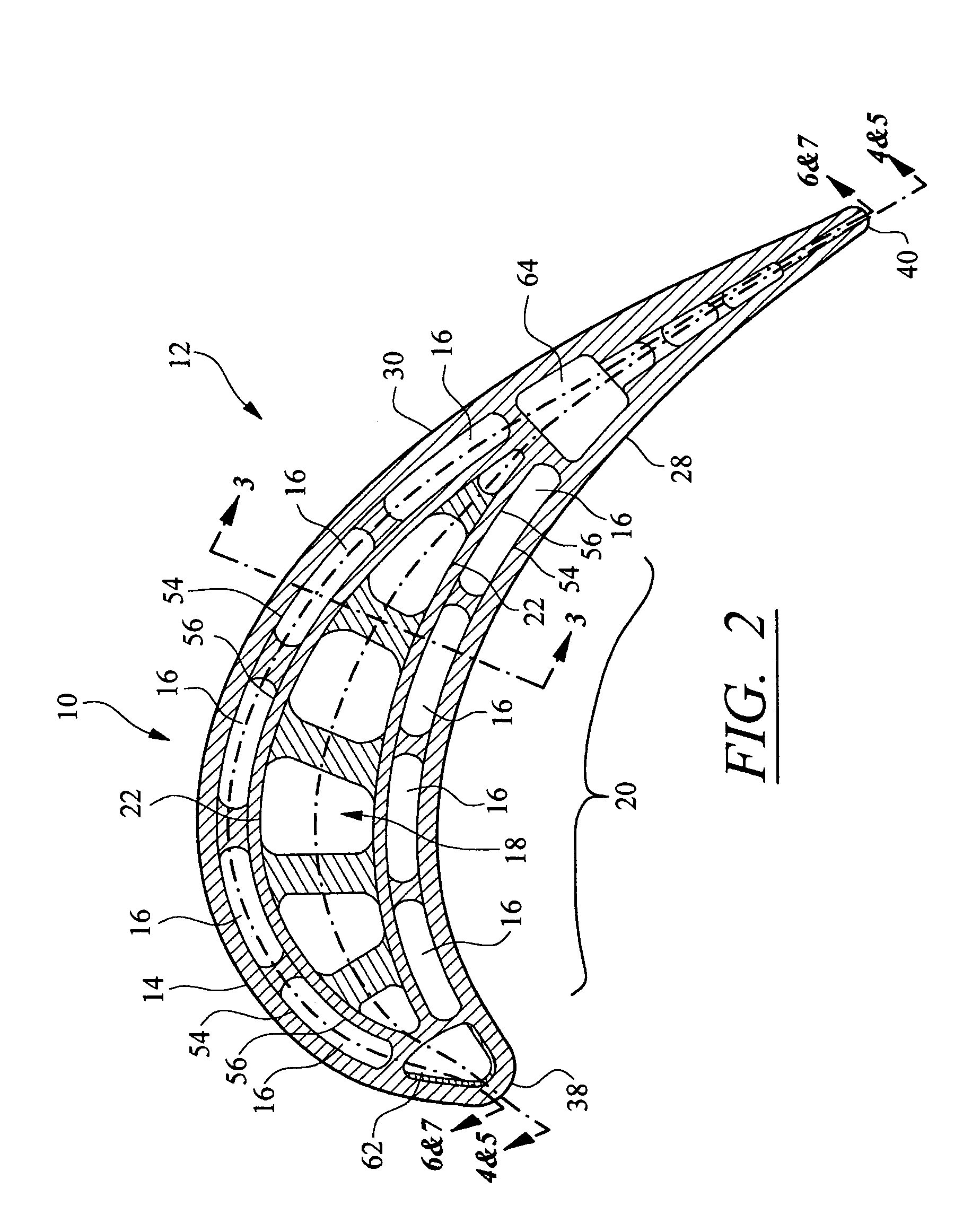

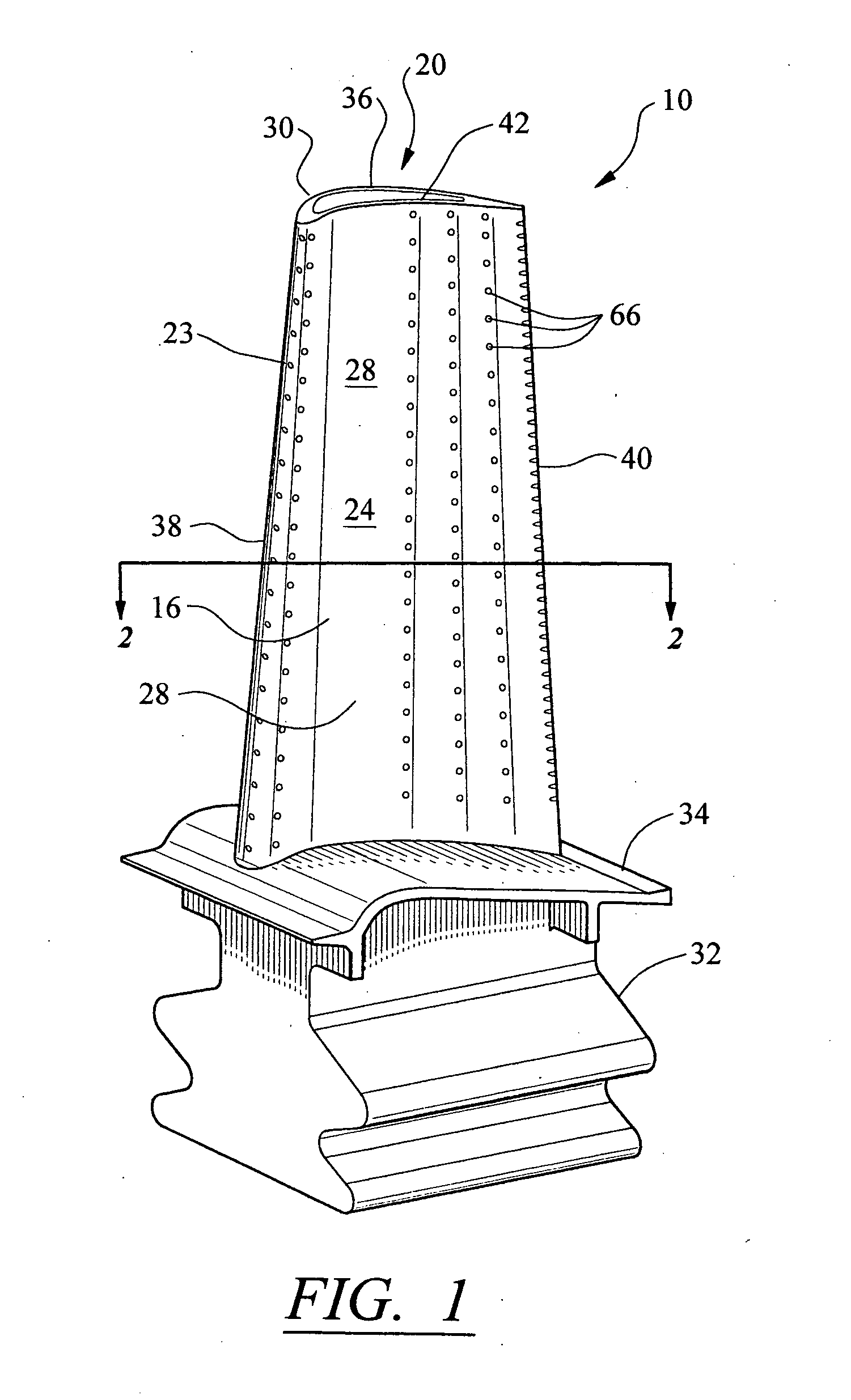

High aspect ratio blade main core modifications for peripheral serpentine microcircuits

ActiveUS20080138209A1Minimize thermal gradientAvoid back flow margin problemEngine manufactureEngine fuctionsTurbine bladeCooling fluid

A turbine engine component, such as a turbine blade, has an airfoil portion having a pressure side wall and a suction side wall, a first cooling circuit embedded within the pressure side wall, which first cooling circuit has at least two passageways embedded within the pressure side wall, a second cooling circuit embedded within the suction side wall, which second cooling circuit has at least two passageways embedded within the suction side wall, at least one cooling fluid supply cavity located between the pressure and suction side walls, each cooling fluid supply cavity having at least one projecting portion extending between adjacent ones of the embedded passageways in the first cooling circuit or adjacent ones of the embedded passageways in the second cooling circuit, and each projecting portion communicating with at least one film cooling hole. A method for forming the turbine blade component is also described.

Owner:RAYTHEON TECH CORP

HP turbine vane airfoil profile

ActiveUS20080056893A1Minimizes gradientMinimize secondary lossesEngine manufacturePump componentsSingle stageTurbine blade

A single stage high pressure turbine vane includes an airfoil having a profile substantially in accordance with at least an intermediate portion of the Cartesian coordinate values of X, Y and Z set forth in Table 2. The X and Y values are distances, which when smoothly connected by an appropriate continuing curve, define airfoil profile sections at each distance Z. The profile sections at each distance Z are joined smoothly to one another to form a complete airfoil shape.

Owner:PRATT & WHITNEY CANADA CORP

Turbine airfoil with outer wall cooling system and inner mid-chord hot gas receiving cavity

A turbine airfoil usable in a turbine engine and having at least one cooling system. The cooling system may be positioned in an outer wall of the turbine airfoil, and the airfoil may include a hot gas receiving cavity positioned in a mid-chord region of the airfoil. The hot gas receiving cavity may have an opening in a tip of the airfoil to enable hot gases to circulate into the hot gas receiving cavity. In at least one embodiment, the cooling system in the outer wall and the hot gas receiving cavity may include a plurality of ribs. Cooling fluids may be passed through the cooling system in the outer wall, and hot combustion gases may be passed into the hot gas receiving cavity to moderate the temperature of the inner portions of the outer wall to reduce the temperature gradient in the outer wall.

Owner:SIEMENS ENERGY INC

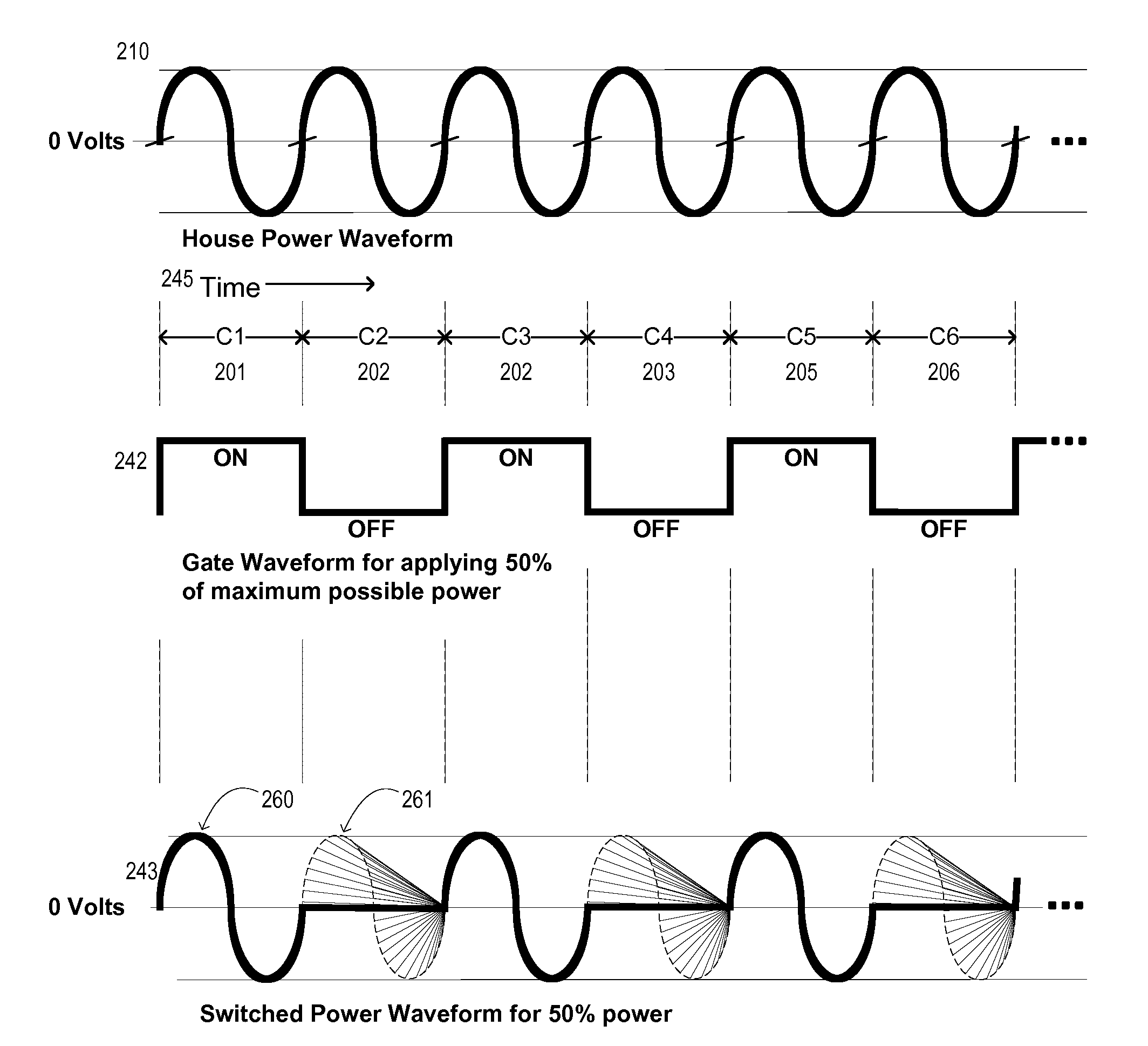

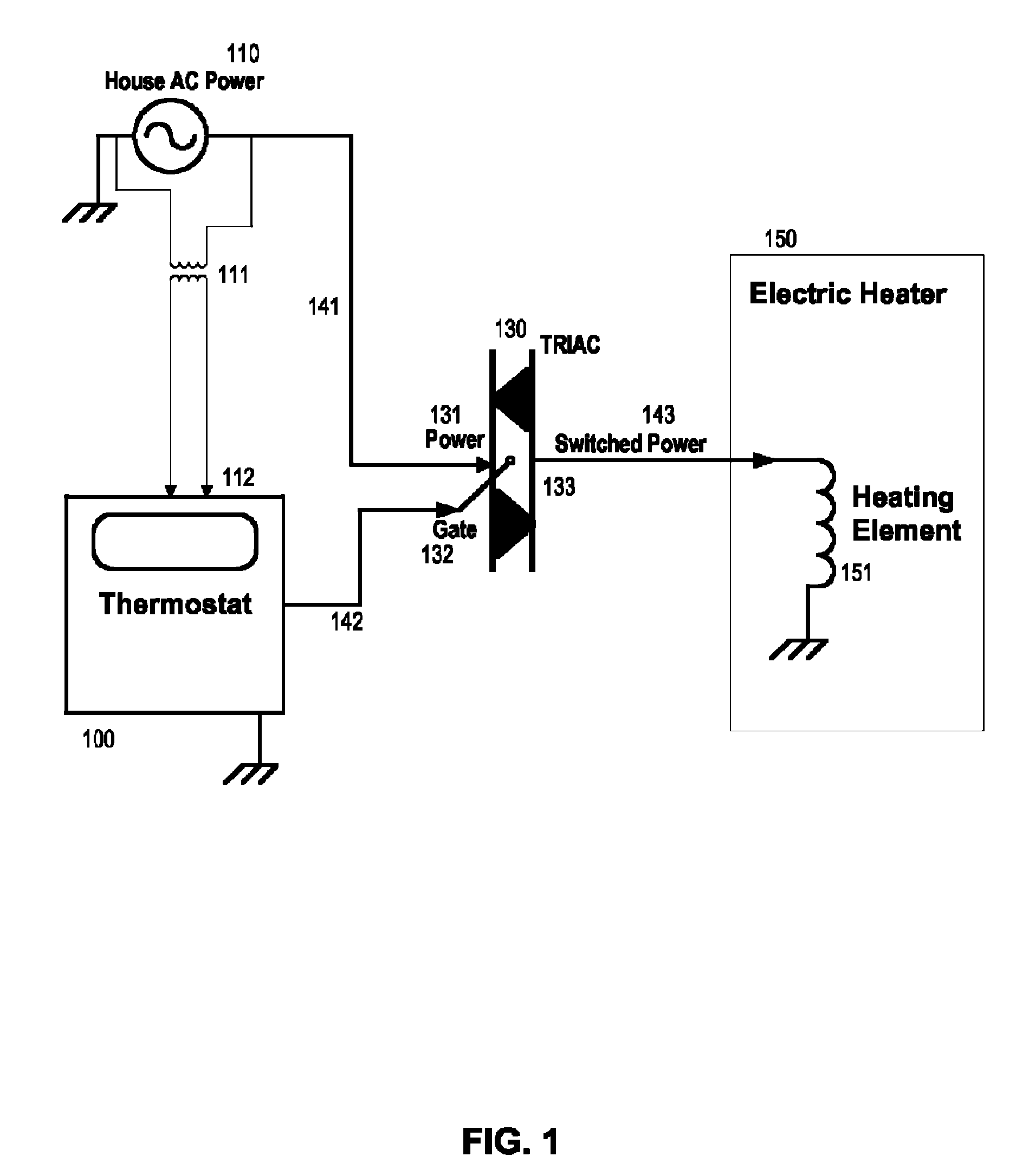

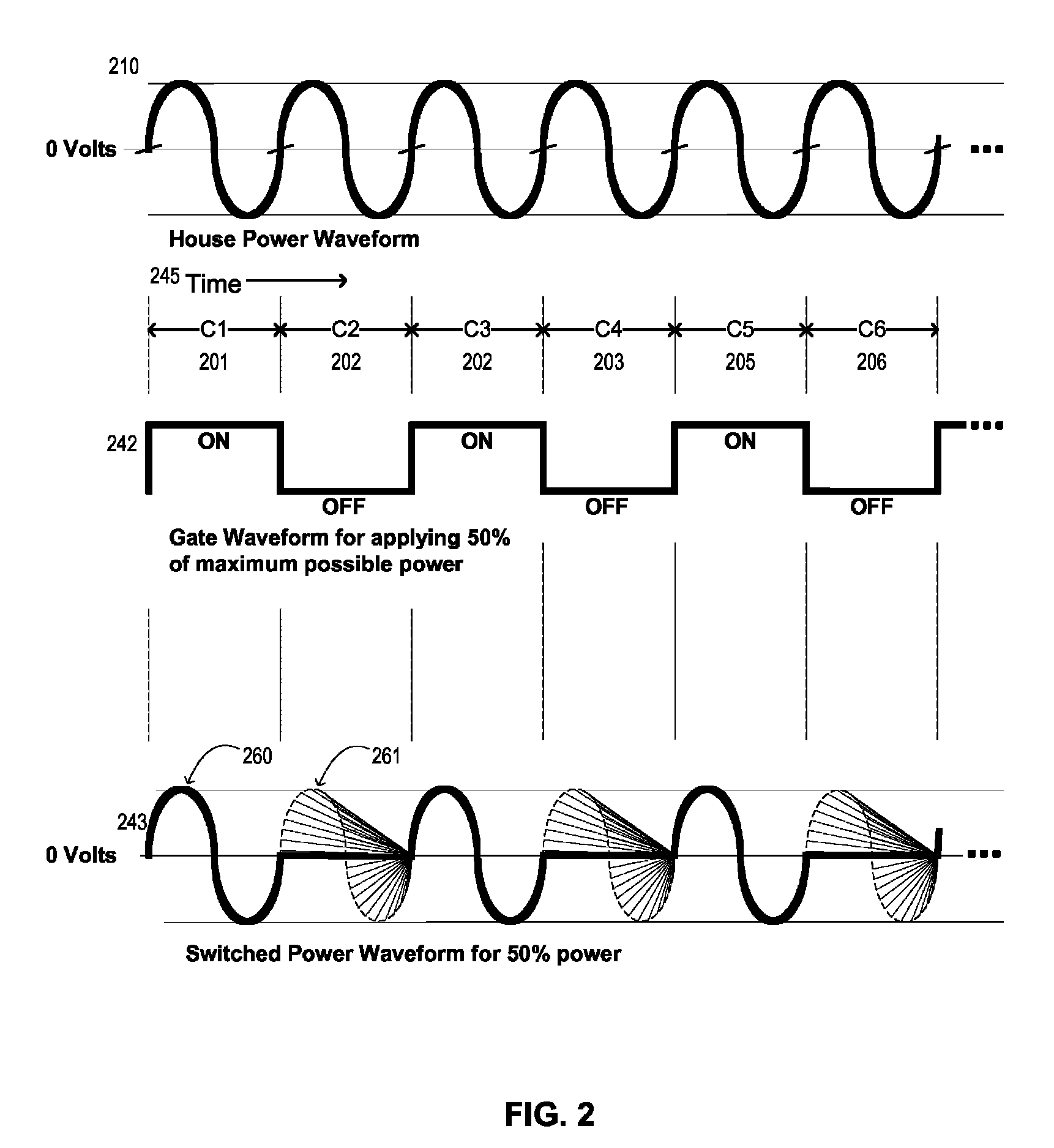

Electric baseboard heater control

ActiveUS7838803B1Reduce mechanical noiseSteady and therefore more comfortable source of heatTemperature control without auxillary powerTemperature control with auxillary non-electric powerEngineeringHeating system

In order to provide an electric heat system that is quieter than those of the prior art, a switching circuit is incorporated into the controls for the heating system which provides for the heating elements of the electric heater to be kept at a more constant temperature than those of the prior art. The switching circuit regulates the output power to the degree desired while not inducing sharp changes in temperature of the coils of the electric heater and thus reduces the degree of rapid expansion and contraction of the coils and the enclosure for the heater. This in turn reduces the amount of mechanical noise produced by the electric heater while also reducing wear and tear on the heating element, the heater enclosure and objects near to the heater.

Owner:ROSEN TECH LLC

HP turbine vane airfoil profile

ActiveUS7537432B2Minimizes gradientMinimize secondary lossesEngine manufacturePump componentsSingle stageTurbine blade

A single stage high pressure turbine vane includes an airfoil having a profile substantially in accordance with at least an intermediate portion of the Cartesian coordinate values of X, Y and Z set forth in Table 2. The X and Y values are distances, which when smoothly connected by an appropriate continuing curve, define airfoil profile sections at each distance Z. The profile sections at each distance Z are joined smoothly to one another to form a complete airfoil shape.

Owner:PRATT & WHITNEY CANADA CORP

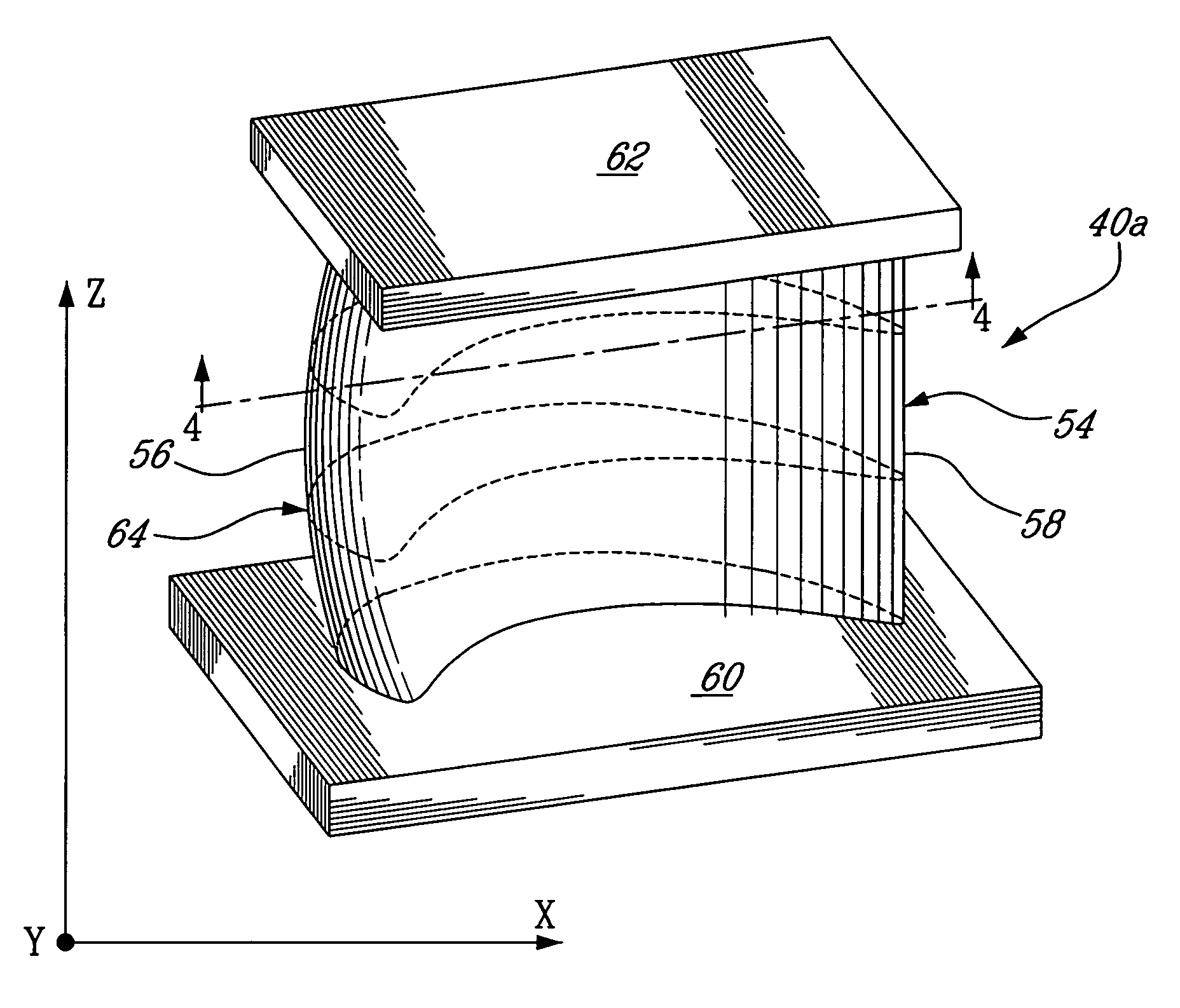

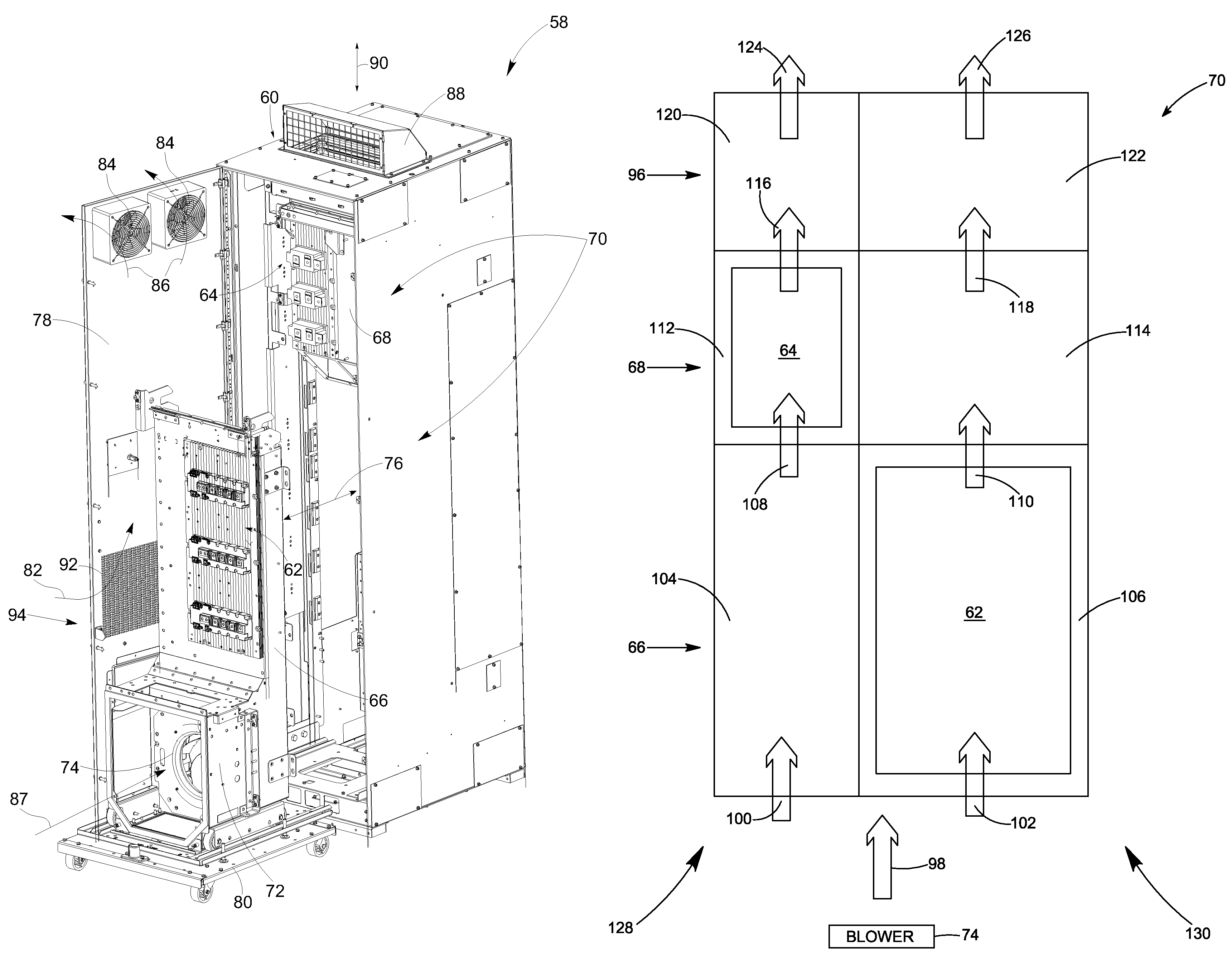

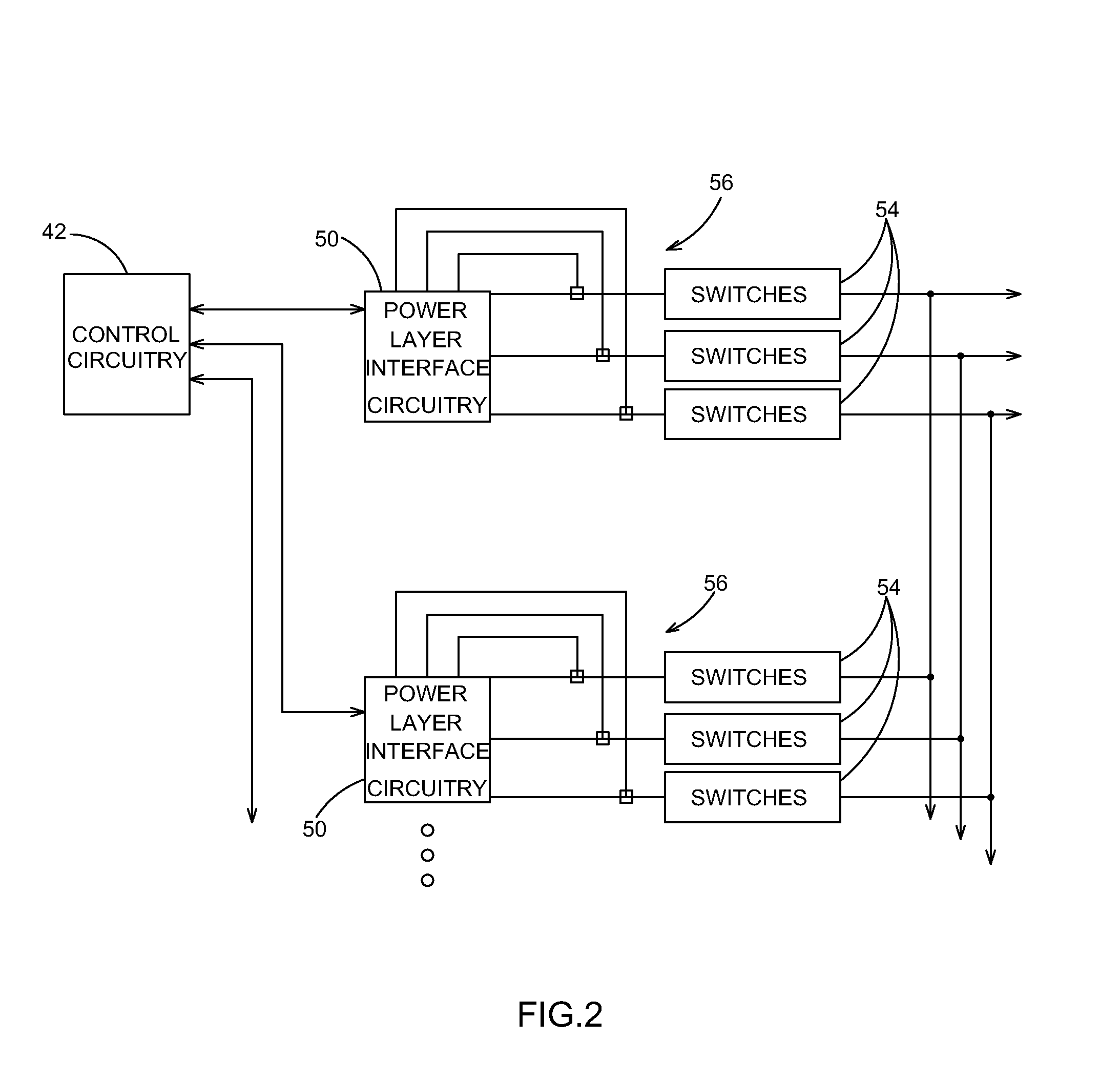

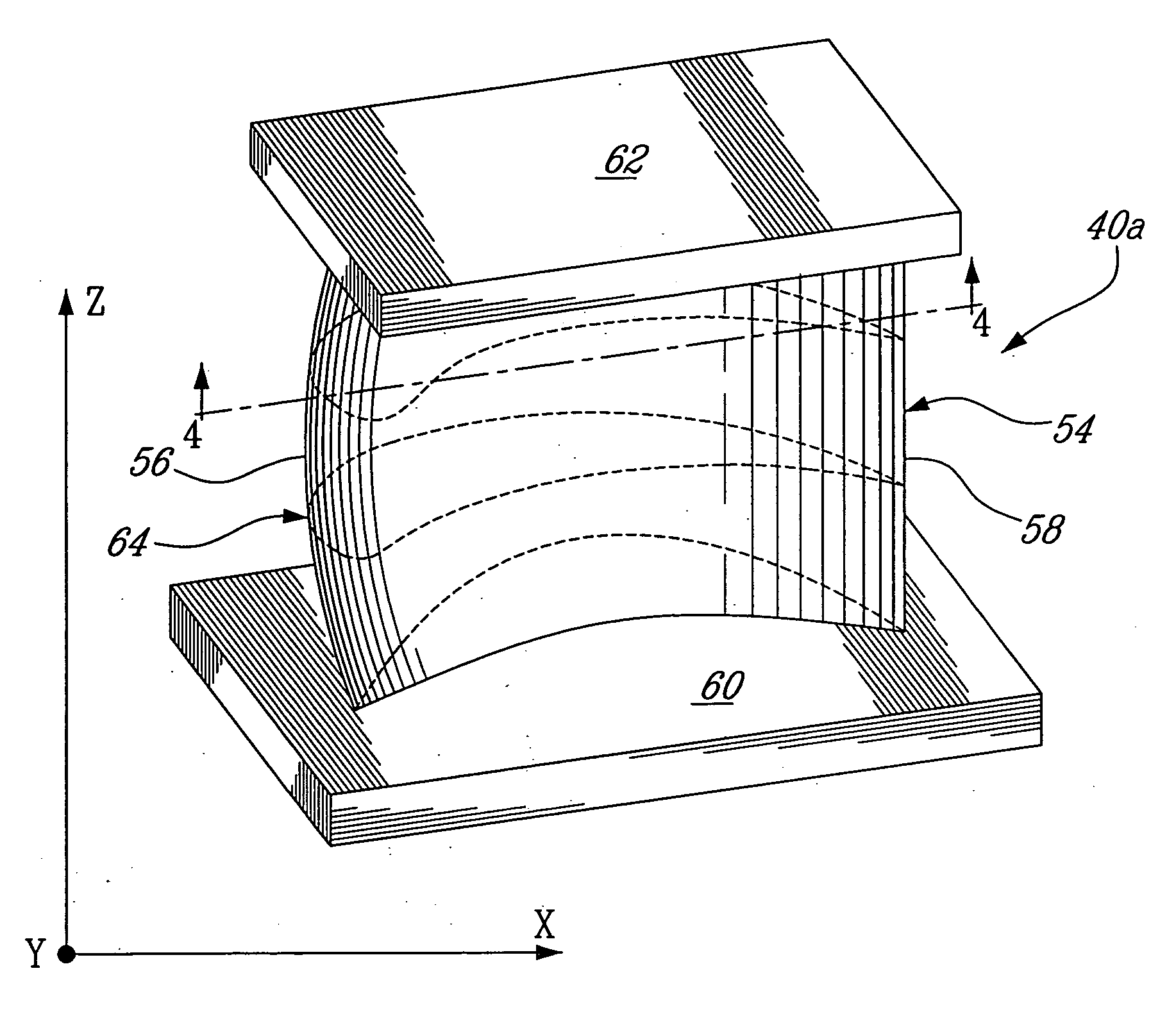

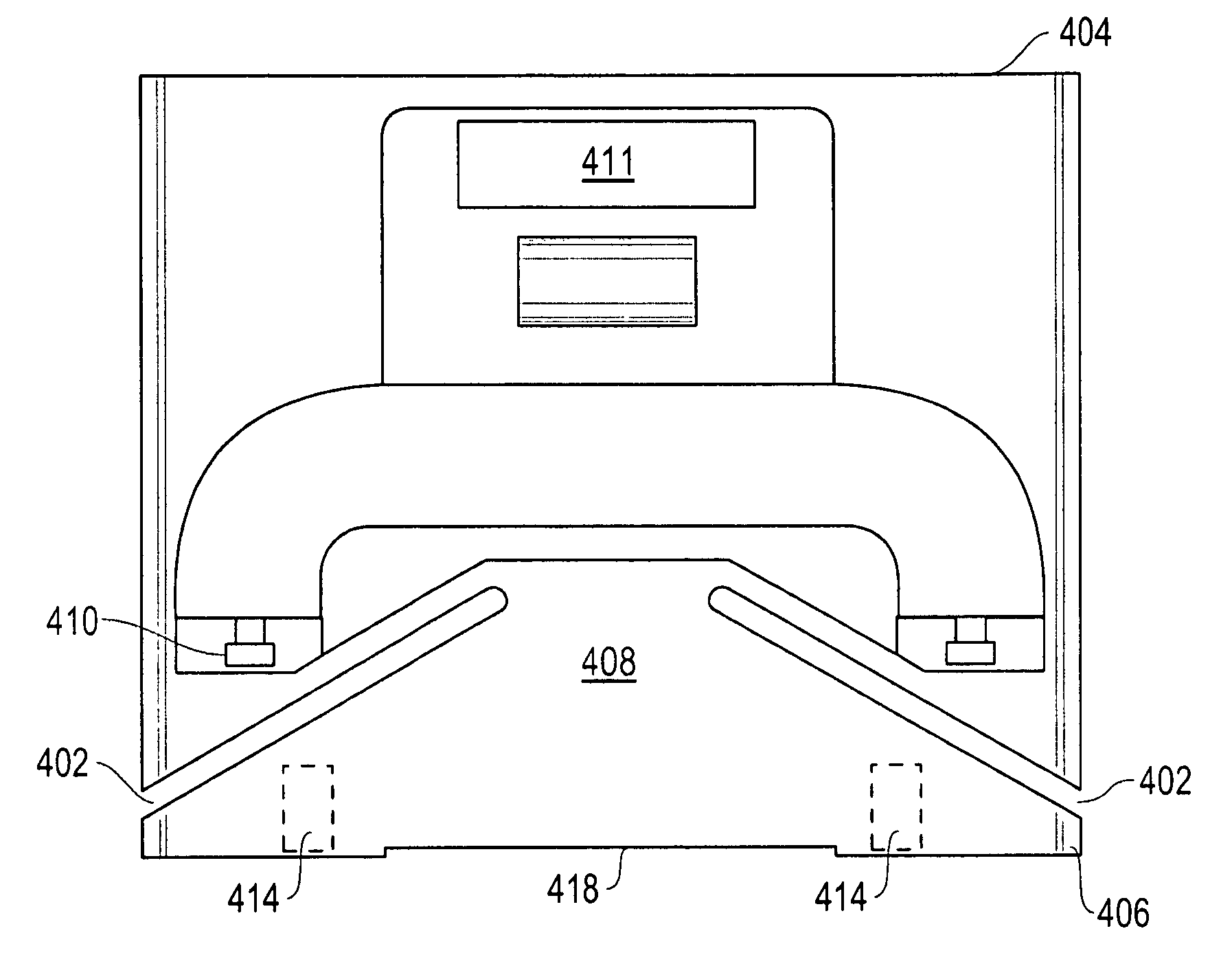

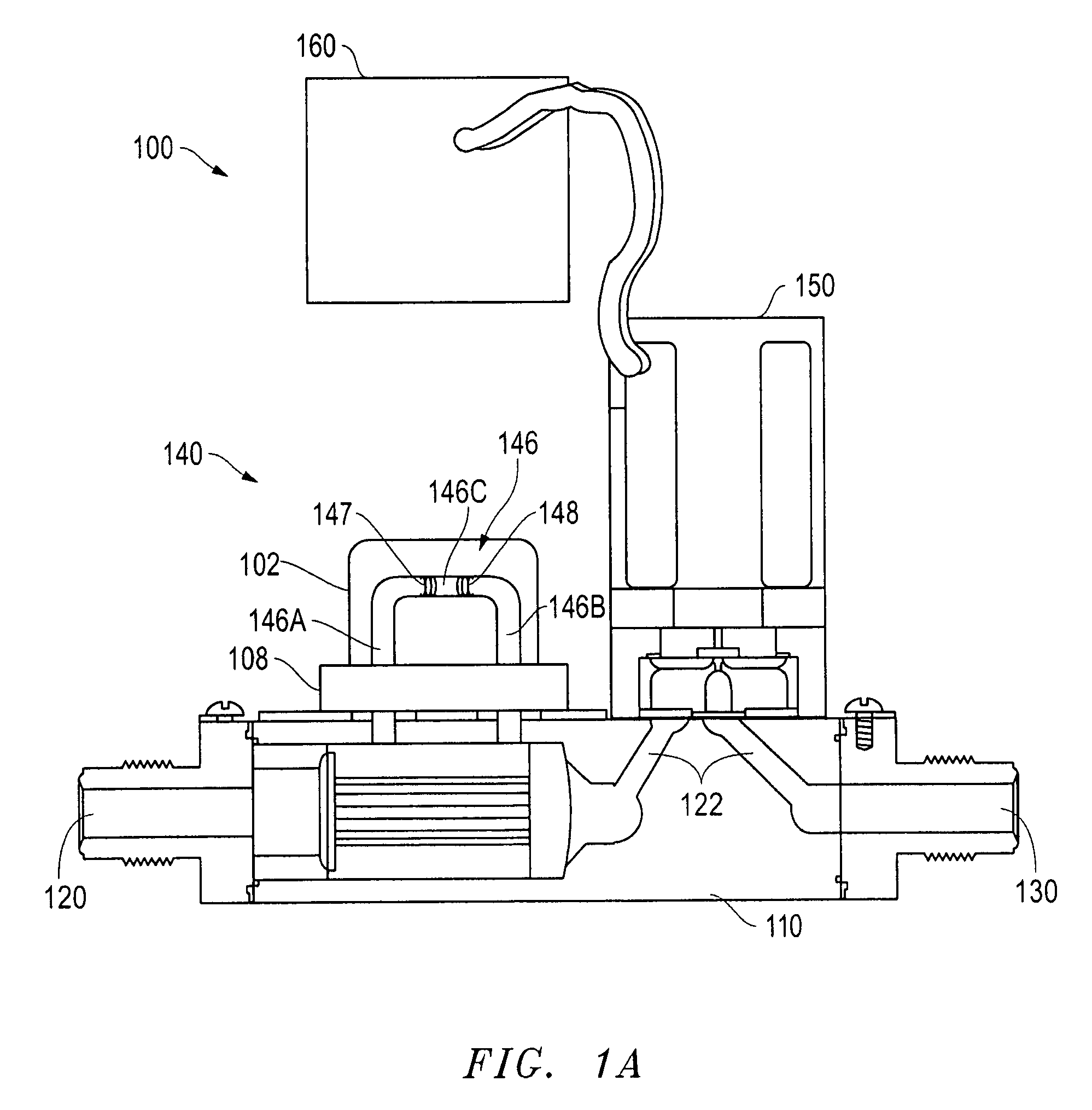

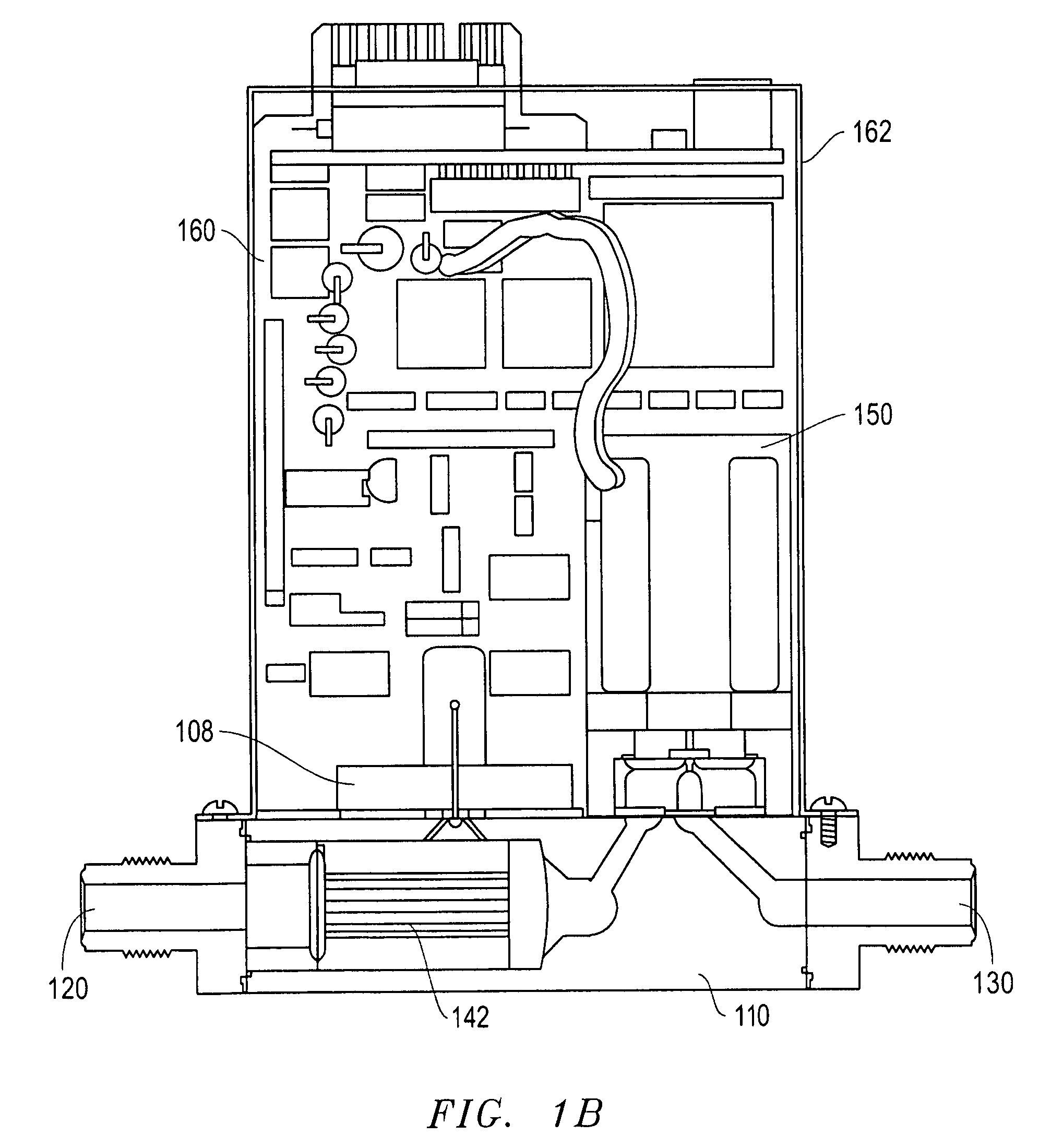

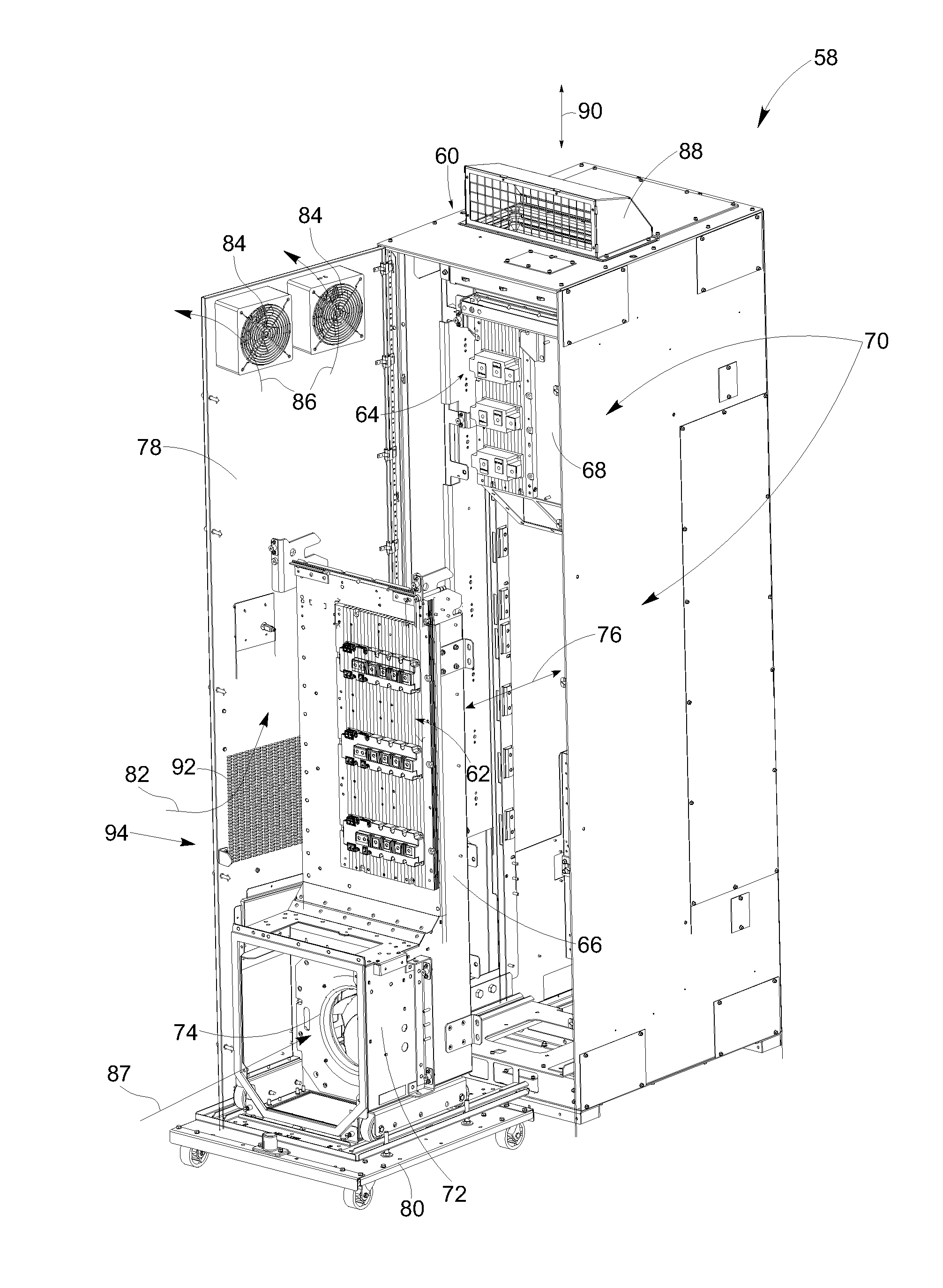

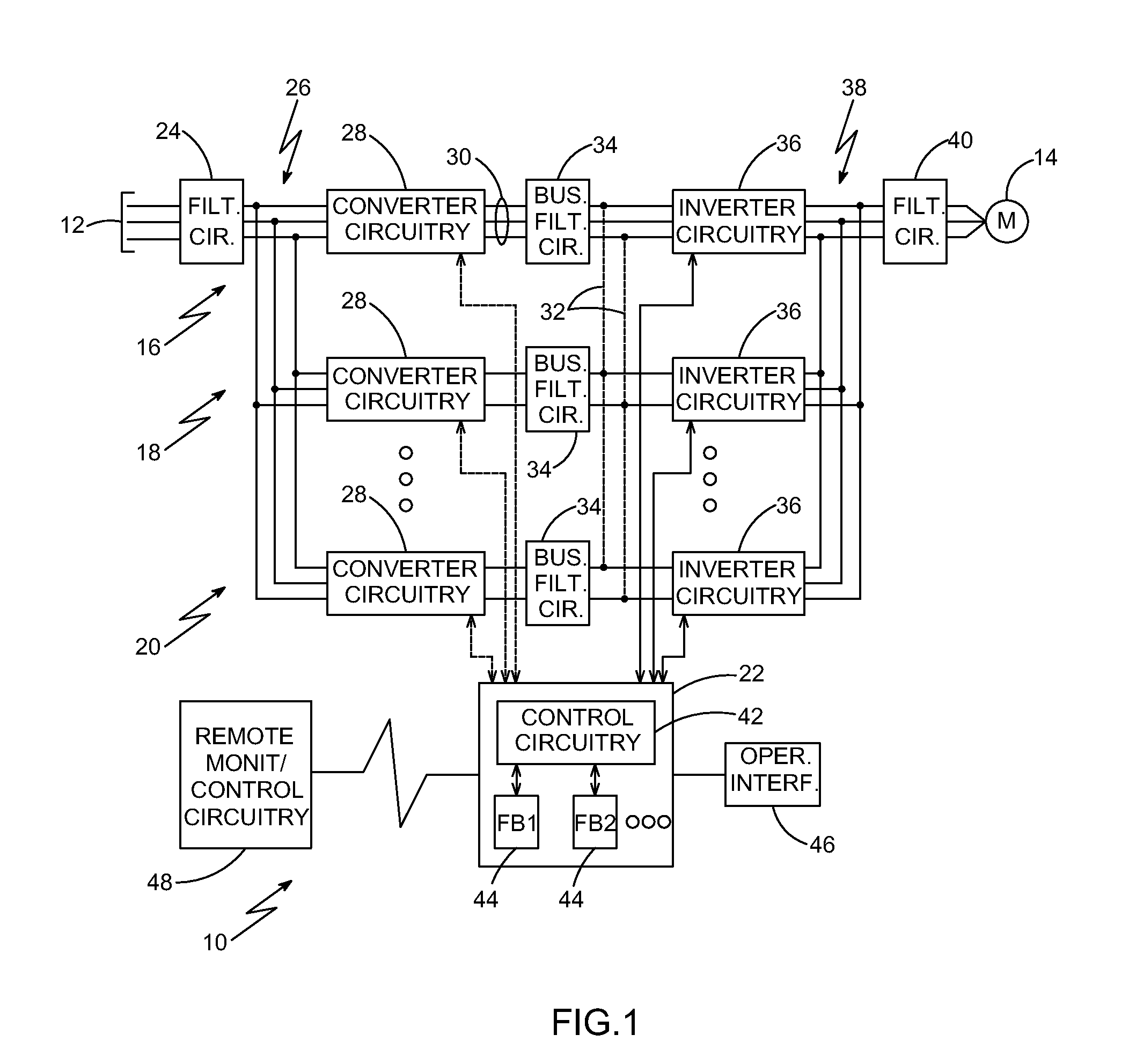

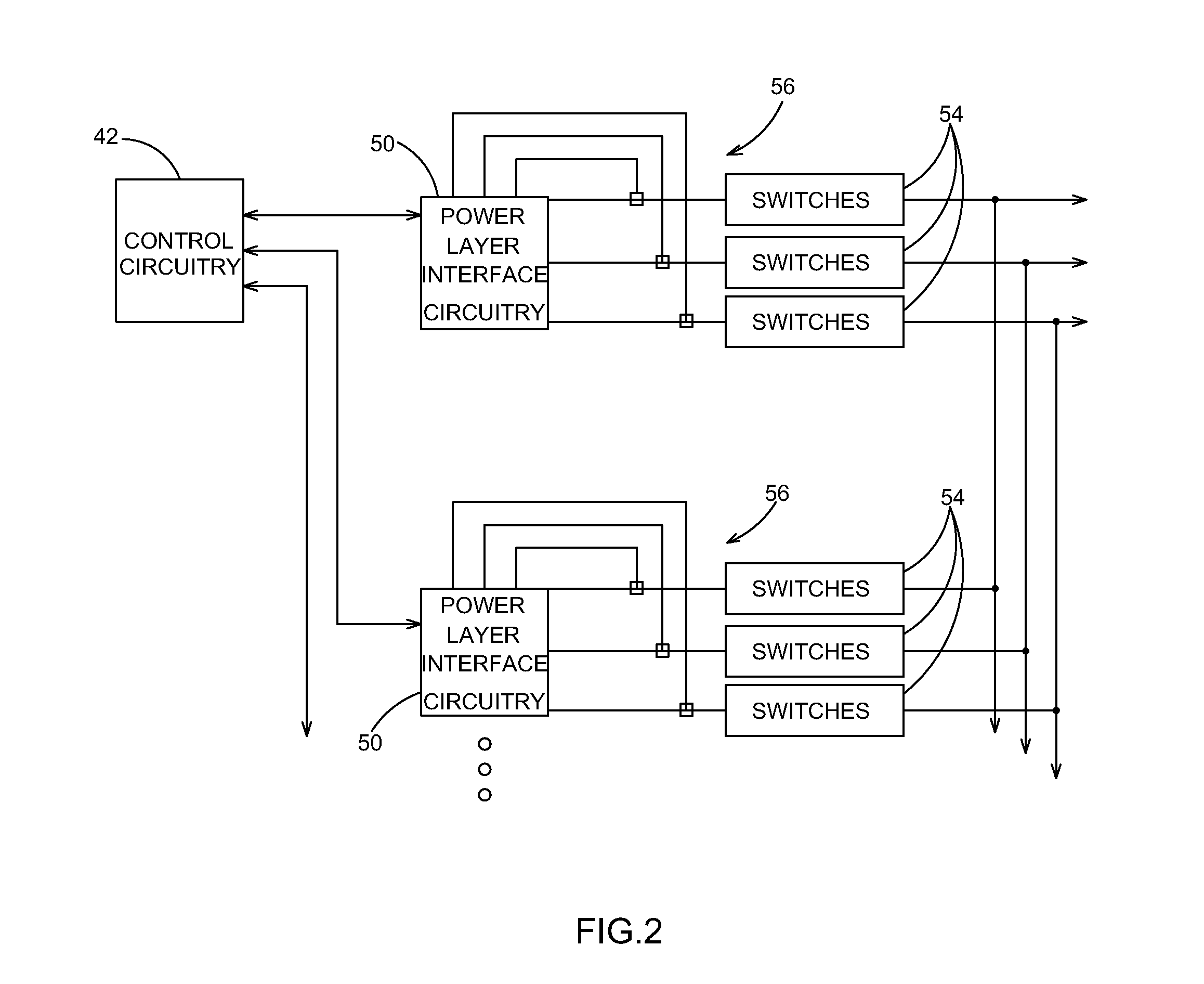

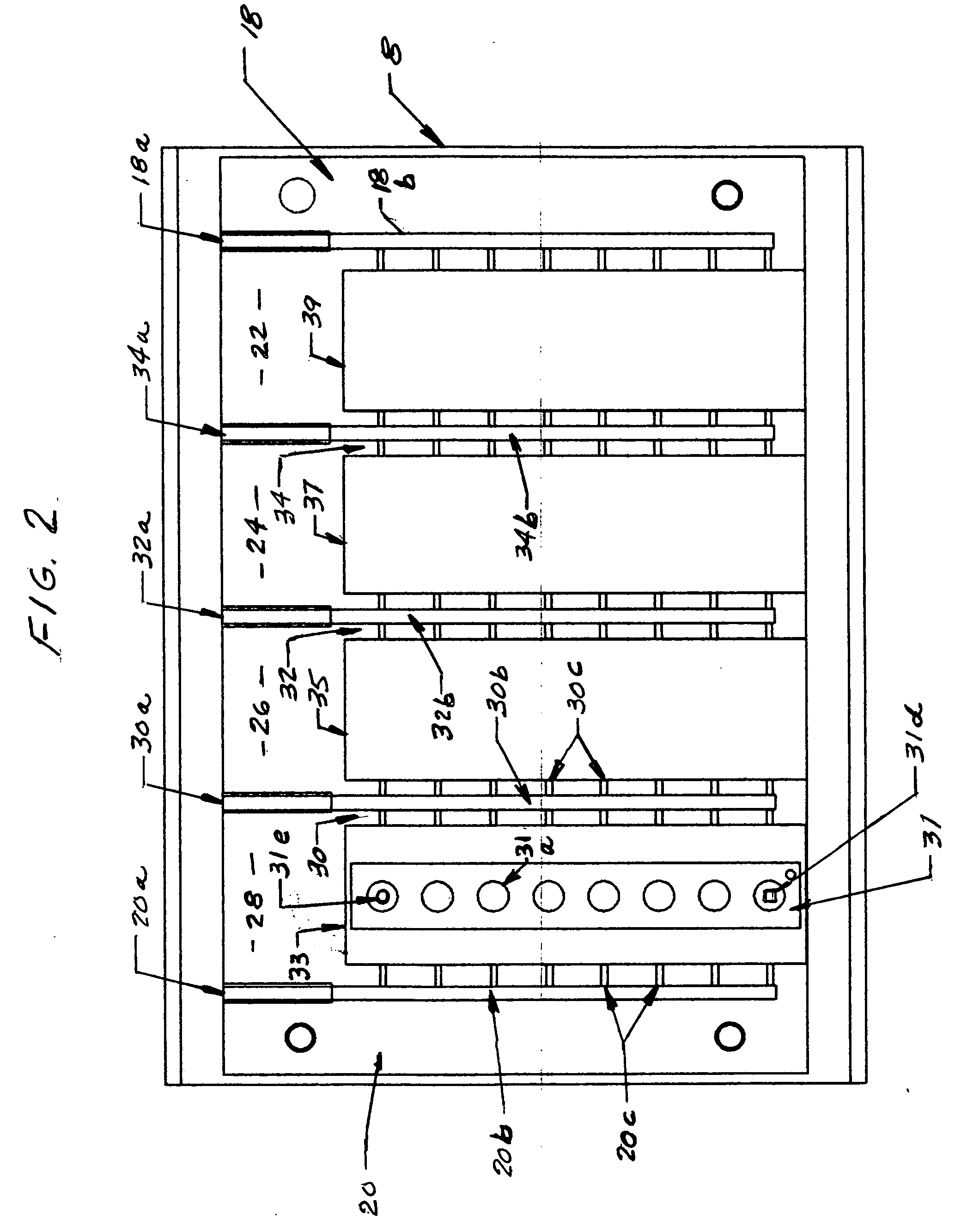

Motor drive cooling duct system and method

ActiveUS8325479B2Temperature gradients across the heat sinks are minimizedMinimizes gradientDigital data processing detailsSubstation/switching arrangement cooling/ventilationMotor driveHeat spreader

The present invention relates generally to tuning the flow of cooling air across converter and inverter heat sinks in a motor drive system. More specifically, present techniques relate to motor drive duct systems having parallel cooling air duct channels dedicated to providing cooling air for a converter heat sink and an inverter heat sink, respectively. In particular, a first duct channel through an inverter duct and a converter duct is dedicated to providing cooling air to the converter heat sink without cooling the inverter heat sink, whereas a second duct channel through the inverter duct and the converter duct is dedicated to providing cooling air to the inverter heat sink without cooling the converter heat sink.

Owner:ROCKWELL AUTOMATION TECH

HP turbine vane airfoil profile

ActiveUS20080273970A1Minimizes static pressure gradientMinimizes gradientEngine manufacturePump componentsEngineeringHigh pressure

A two-stage high pressure turbine comprises a second stage vane having an airfoil with a profile substantially in accordance with at least an intermediate portion of the Cartesian coordinate values of X, Y and Z set forth in Table 2. The X and Y values are distances, which when smoothly connected by an appropriate continuing curve, define airfoil profile sections at each distance Z. The profile sections at each distance Z are joined smoothly to one another to form a complete airfoil shape.

Owner:PRATT & WHITNEY CANADA CORP

HP turbine vane airfoil profile

ActiveUS20070207036A1Minimize lossMinimize gradientEngine manufactureOther chemical processesTurbine bladeHigh pressure

A single stage high pressure turbine vane includes an airfoil having a profile substantially in accordance with at least an intermediate portion of the Cartesian coordinate values of X, Y and Z set forth in Table 2. The X and Y values are distances, which when smoothly connected by an appropriate continuing curve, define airfoil profile sections at each distance Z. The profile sections at each distance Z are joined smoothly to one another to form a complete airfoil shape.

Owner:PRATT & WHITNEY CANADA CORP

High aspect ratio blade main core modifications for peripheral serpentine microcircuits

ActiveUS7717676B2Minimizes gradientAvoid problemsEngine manufactureEngine fuctionsTurbine bladeCooling fluid

Owner:RTX CORP

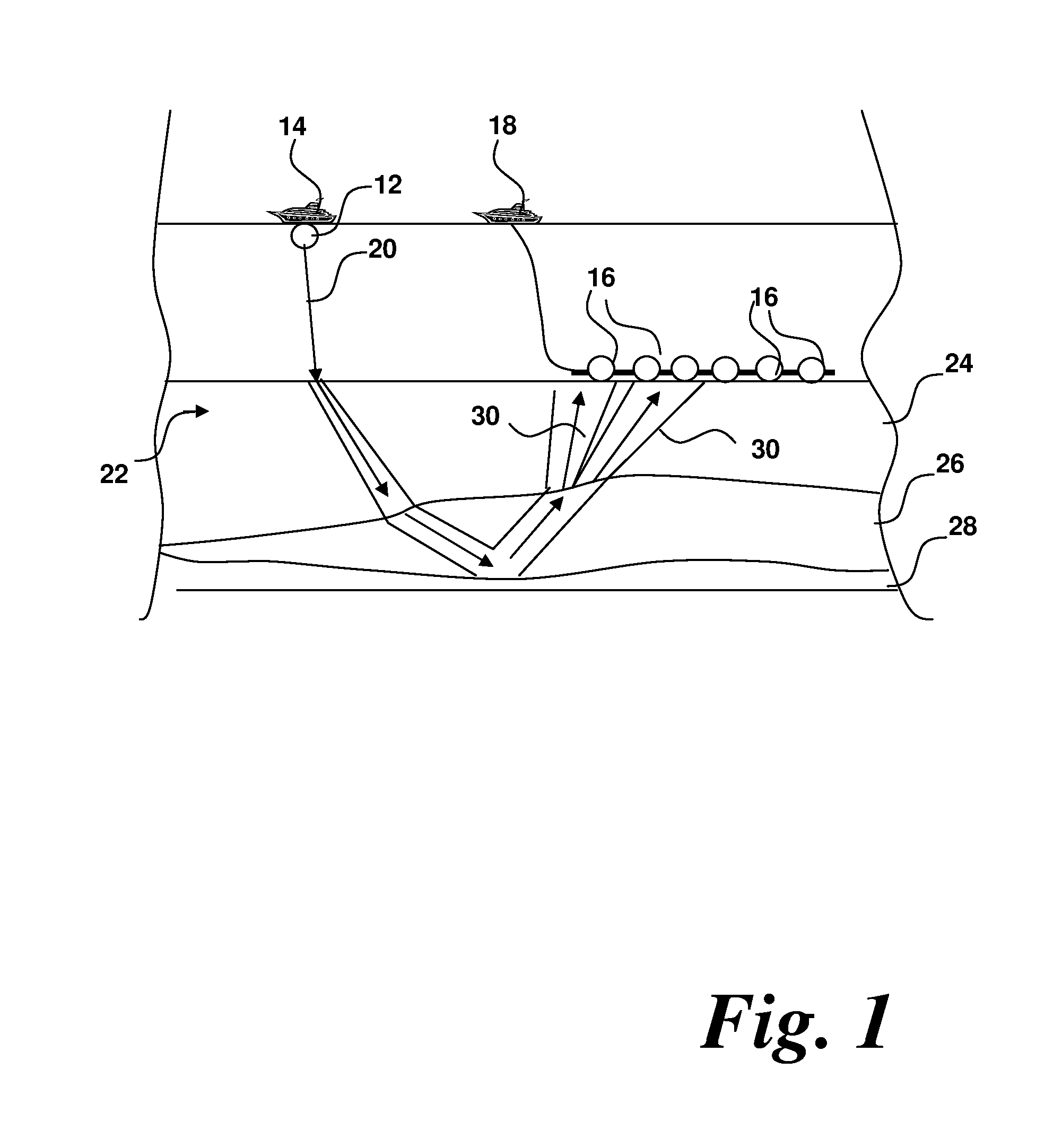

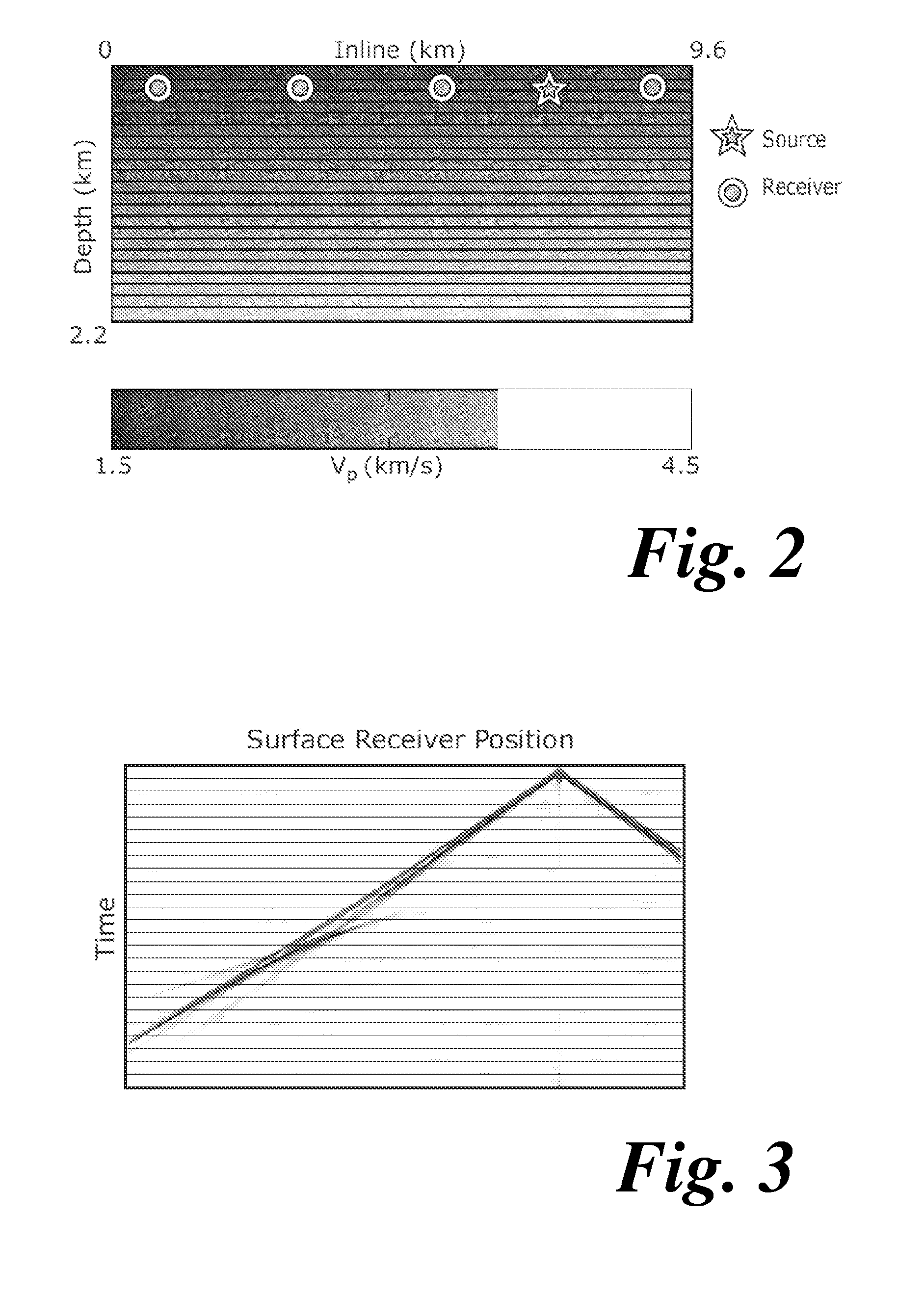

Method of, and apparatus for, full waveform inversion

Owner:IMPERIAL INNOVATIONS LTD

Thermal flow meter

ActiveUS7748268B2Reduce heat transferMinimizes thermal gradientVolume/mass flow by thermal effectsVolume meteringThermal isolationEngineering

A thermal mass flow controller or mass flow meter having a novel sensor housing that reduces heat conduction from the housing mounting plate or base to the sensor itself. The housing also greatly minimizes the thermal gradient that can result from the uneven application of heat to the housing base. This reduction is accomplished in part by the use of one or more thermal isolation slots to isolate the upper portion of the housing (which holds the sensor) from the lower portion of the housing. Heat transfer to the sensor housing is also minimized by raising the middle portion of the bottom of the housing so that thermal contact is made between the base and the housing only at the two ends of the housing.

Owner:BROOKS INSTRUMENT

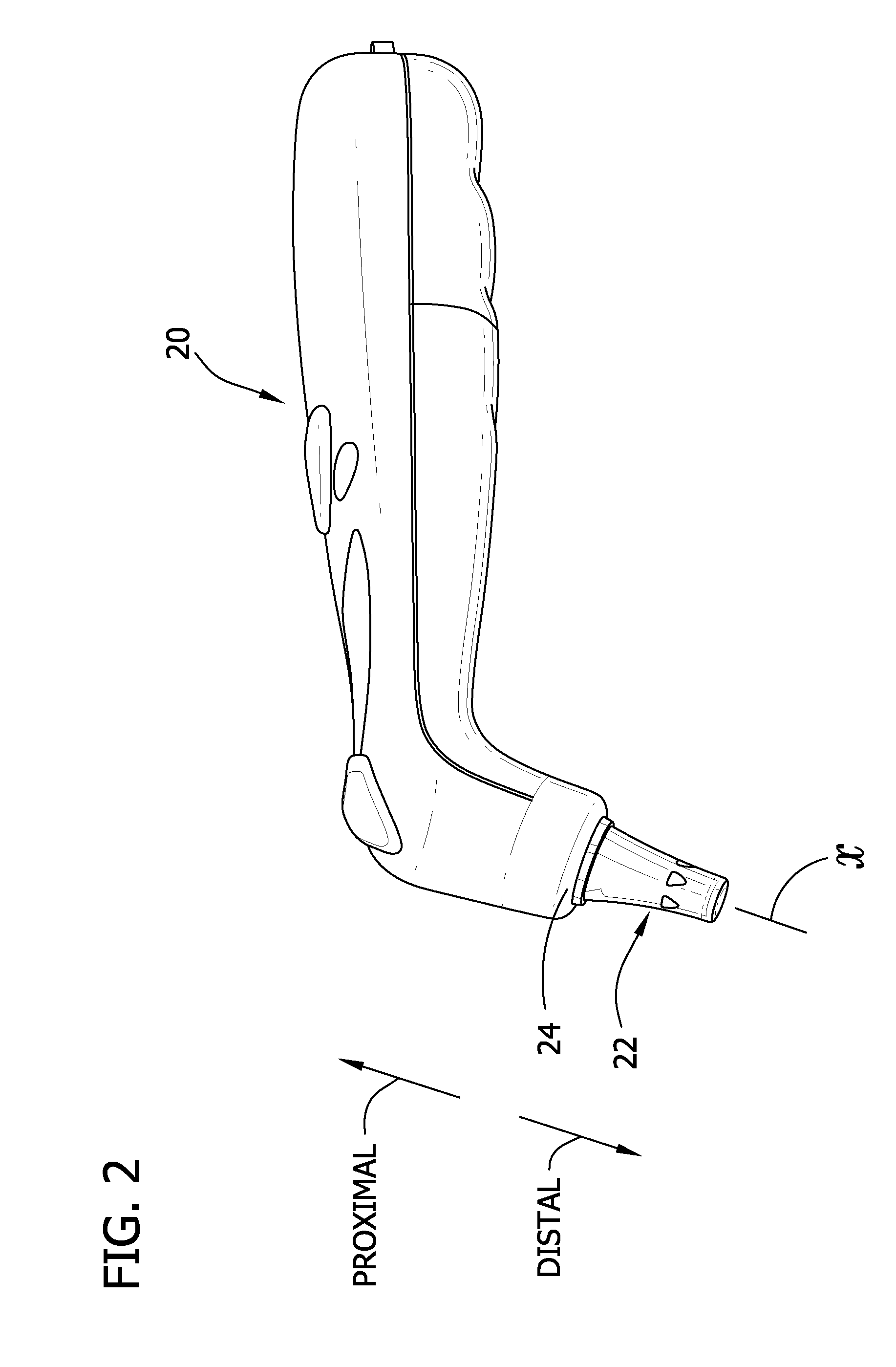

Thermal tympanic thermometer

InactiveUS7434991B2Minimizes gradientImprove heat transfer performanceThermometer detailsDiagnostic recording/measuringSpray nozzleEngineering

A tympanic thermometer includes a thermally conductive nozzle extending from a distal end of the thermometer. A base of a sensor can is thermally connected to the nozzle to define a path of conductive heat transfer from the nozzle to the base of the can thereby minimizing a thermal gradient between proximal and distal ends of the sensor can when temperature is measured in the ear.

Owner:CARDINAL HEALTH IRELAND UNLTD

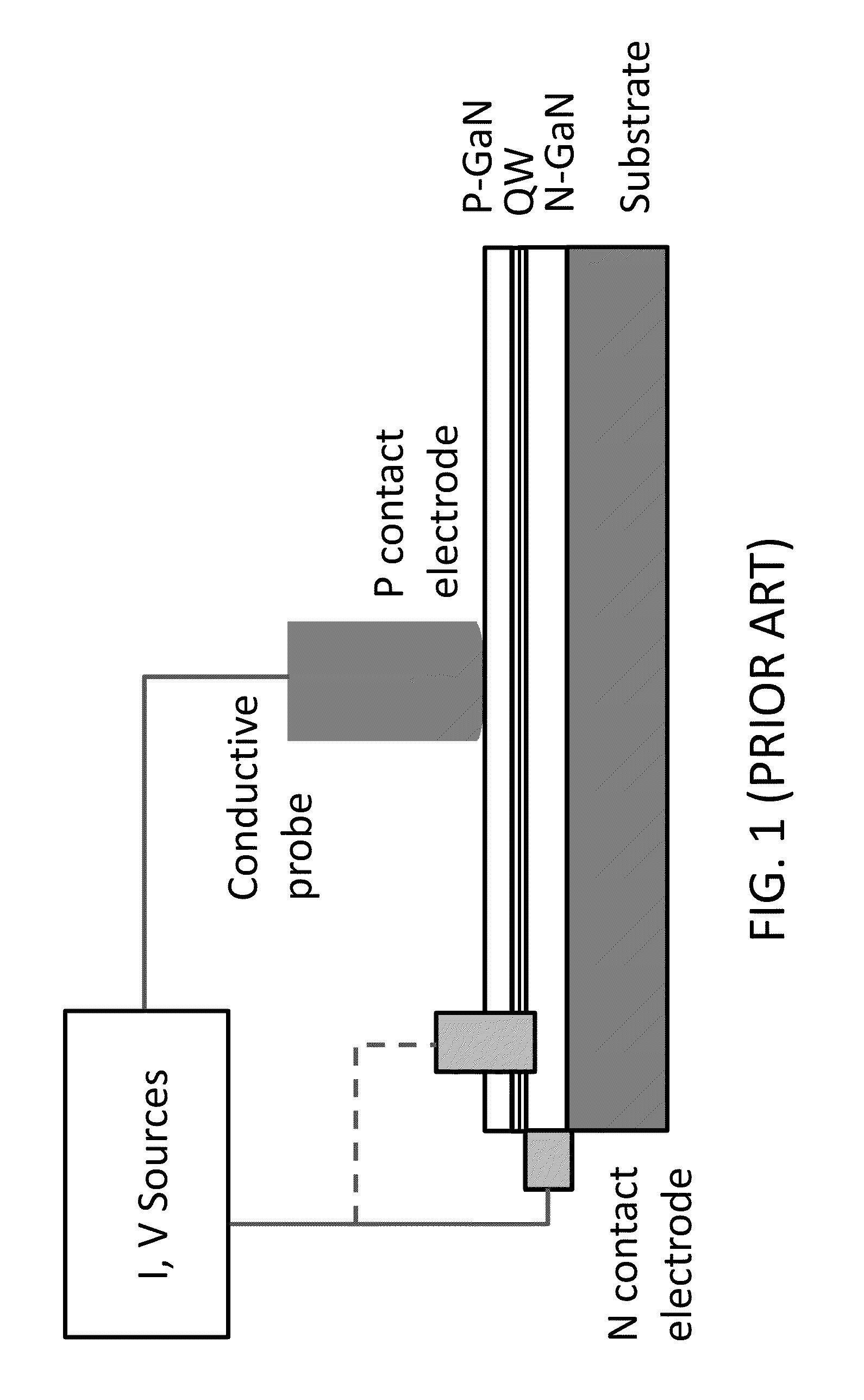

Testing of electroluminescent semiconductor wafers

ActiveUS20130043875A1Reduce memory effectMinimize temperature gradientElongate light sourcesLighting heating/cooling arrangementsEngineeringSet point

Forward voltage drift in a probe system for the characterization of a light-emitting wafer is virtually eliminated by directing compressed air to the probe so as to ensure that the exact same temperature conditions exist during repeated measurements of the wafer. In one embodiment of the invention, an air flow at room temperature is used, either continuously or intermittently. In another embodiment, the temperature of the probe is controlled by flowing a liquid or a gas through micro-channels built into the probe. In yet another embodiment, the probe is connected to a solid-state Peltier cell that is computer-controlled to maintain the probe's temperature at a predetermined set-point. A temperature-controlled chamber or a thermal reservoir enclosing the probe could be used as well. The results obtained showed remarkable repeatability.

Owner:BRUKER NANO INC

Motor drive cooling duct system and method

ActiveUS20120014154A1Temperature gradients across the heat sinks are minimizedMinimizes gradientDigital data processing detailsSubstation/switching arrangement cooling/ventilationAerospace engineeringMotor drive

The present invention relates generally to tuning the flow of cooling air across converter and inverter heat sinks in a motor drive system. More specifically, present techniques relate to motor drive duct systems having parallel cooling air duct channels dedicated to providing cooling air for a converter heat sink and an inverter heat sink, respectively. In particular, a first duct channel through an inverter duct and a converter duct is dedicated to providing cooling air to the converter heat sink without cooling the inverter heat sink, whereas a second duct channel through the inverter duct and the converter duct is dedicated to providing cooling air to the inverter heat sink without cooling the converter heat sink. A guide vane adjacent to the inverter duct may control the flow of cooling air from a blower between the first and second duct channels. In addition, the inverter duct and the converter duct may both include baffled walls that direct cooling air into contact with the inverter heat sink and the converter heat sink, respectively, such that temperature gradients across the heat sinks are minimized.

Owner:ROCKWELL AUTOMATION TECH

Process for solid oxide fuel cell manufacture

InactiveUS7485385B2Minimize temperature gradientMinimize propertyFuel cells groupingFinal product manufacturePresent methodEngineering

The present invention provides a method for conveniently manufacturing a solid oxide fuel cell (SOFC) at a cost that is less than five-hundred dollars per kilowatt of electricity. The method comprises forming an electrode layer and depositing an electrolyte material on the surface of the electrode. The formed structure is an electrode-electrolyte bi-layer. A second electrode is deposited onto this bi-layer to form a multilayer fuel cell structure comprising an electrolyte positioned between two electrodes. This multilayer structure is then heated and fired in a single thermal cycle to remove any binder materials and sinter, respectively, the fuel cell. This thermal cycle can be performed in a furnace having one or more chambers. The chamber(s) preferably contains a variable or multiple frequency microwave source for heating the cell and removing binder materials in the electrolyte and electrode structures. The chamber(s) also preferably include a convection and / or radiation source for sintering the fuel cell. In addition, the method of the invention harmonizes and minimizes the deviation among the thermophysical properties of the electrolyte and electrode structures. This harmonization reduces and minimizes the temperature gradient within the cell such that the structure can be uniformly heated and fired during the thermal cycle. The multilayer structure is also unlikely to distort and fracture by minimizing the temperature gradient in the cell. An SOFC can also be manufactured by the present method in an order of magnitude less time than standard processes.

Owner:TRUSTEES OF BOSTON UNIV +1

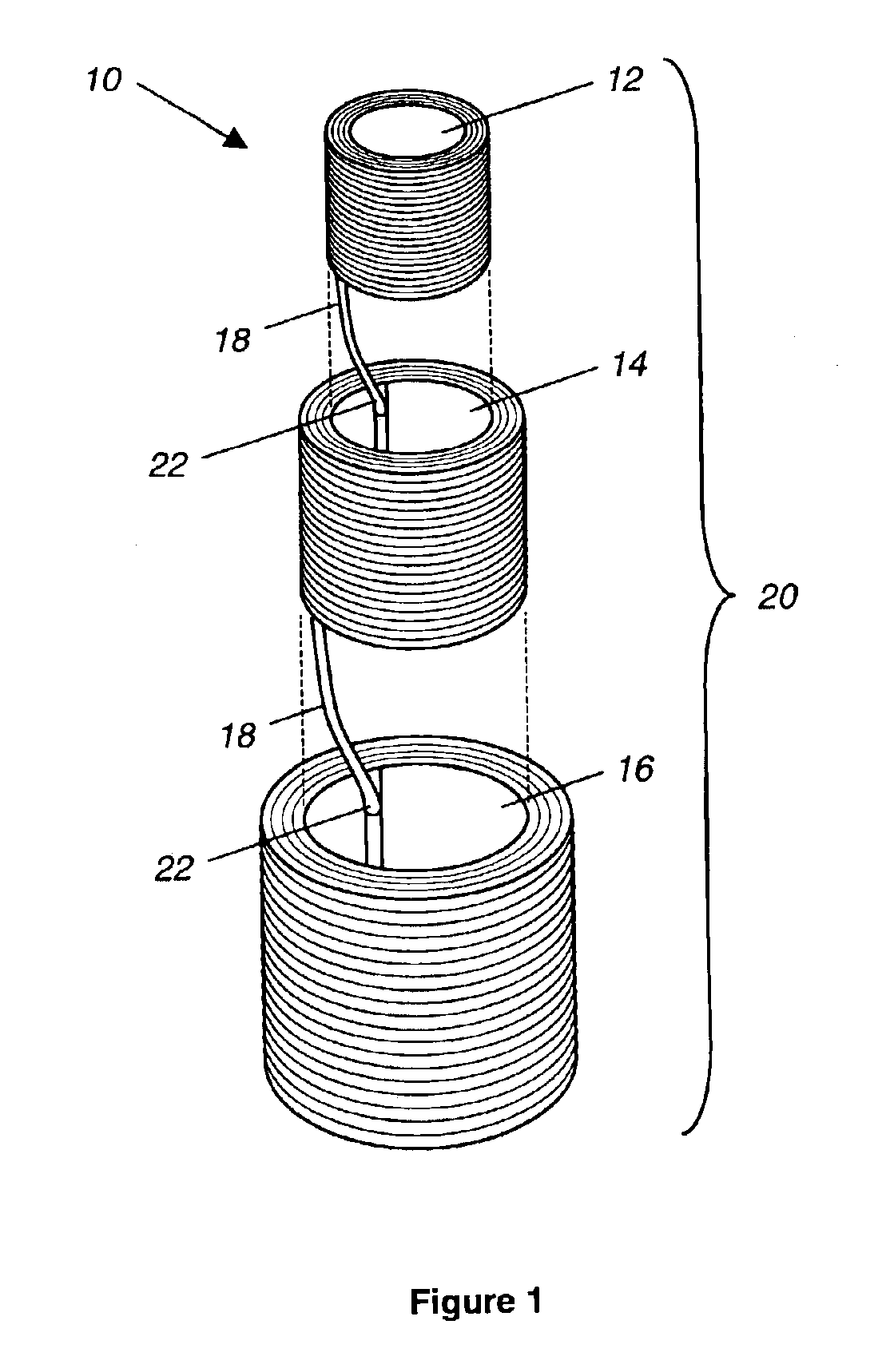

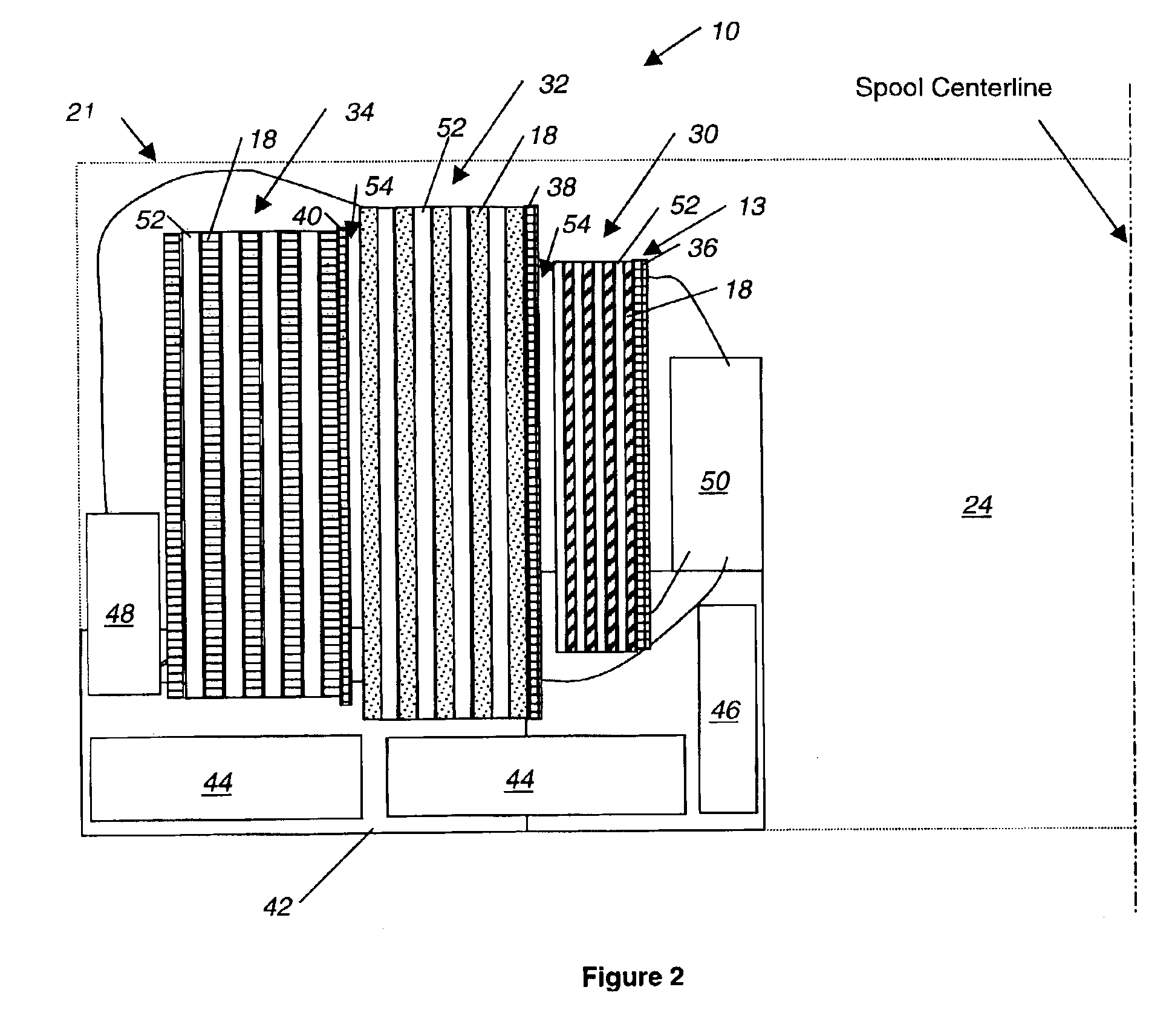

Compact packaging of multiple fiber lasers

InactiveUS6968112B2Small volumeEfficient fillingContainers for annular articlesFilament handlingEngineeringAvailable Volume

A compact fiber packaging system for fiber lasers is provided that comprises a series of spools nested inside one another for efficient volume utilization. The spools comprise an inner spool nested inside at least one outer spool to form a module. Generally, the fiber lasers are wrapped around the inner spool, and then around successive outer spools as required to form the module. Furthermore, the modules may be stacked to form a fiber assembly. The compact fiber packaging system further comprises devices and methods for minimizing thermal gradients between fibers and for removing Waste heat from the system. Additionally, the available volume is further utilized by disposing equipment and materials for operation of the fibers inside a hollow center defined by the inner spool, between the nested spools, and adjacent the nested spools.

Owner:NORTHROP GRUMMAN SYST CORP

Controlled evaporation, temperature control and packaging for optical inspection of biological samples

InactiveUS20050079517A1Increase effective analyte concentrationIncrease volumeBioreactor/fermenter combinationsBiological substance pretreatmentsDiffusionTemperature control

Controlling humidity at the surface of a solution containing analyte and ligand, e.g., for an assay, is disclosed, wherein the control of the humidity induces evaporative stirring in the solution to bring analyte and ligand into contact more quickly than when using diffusion. An oven which blows air in a controlled stream across slides, with wells containing reagent and analyte, is disclosed. Also disclosed is optical tape which can replace a conventional glass coverslip used for viewing of the reaction results.

Owner:GONCHARKO MICHAEL +2

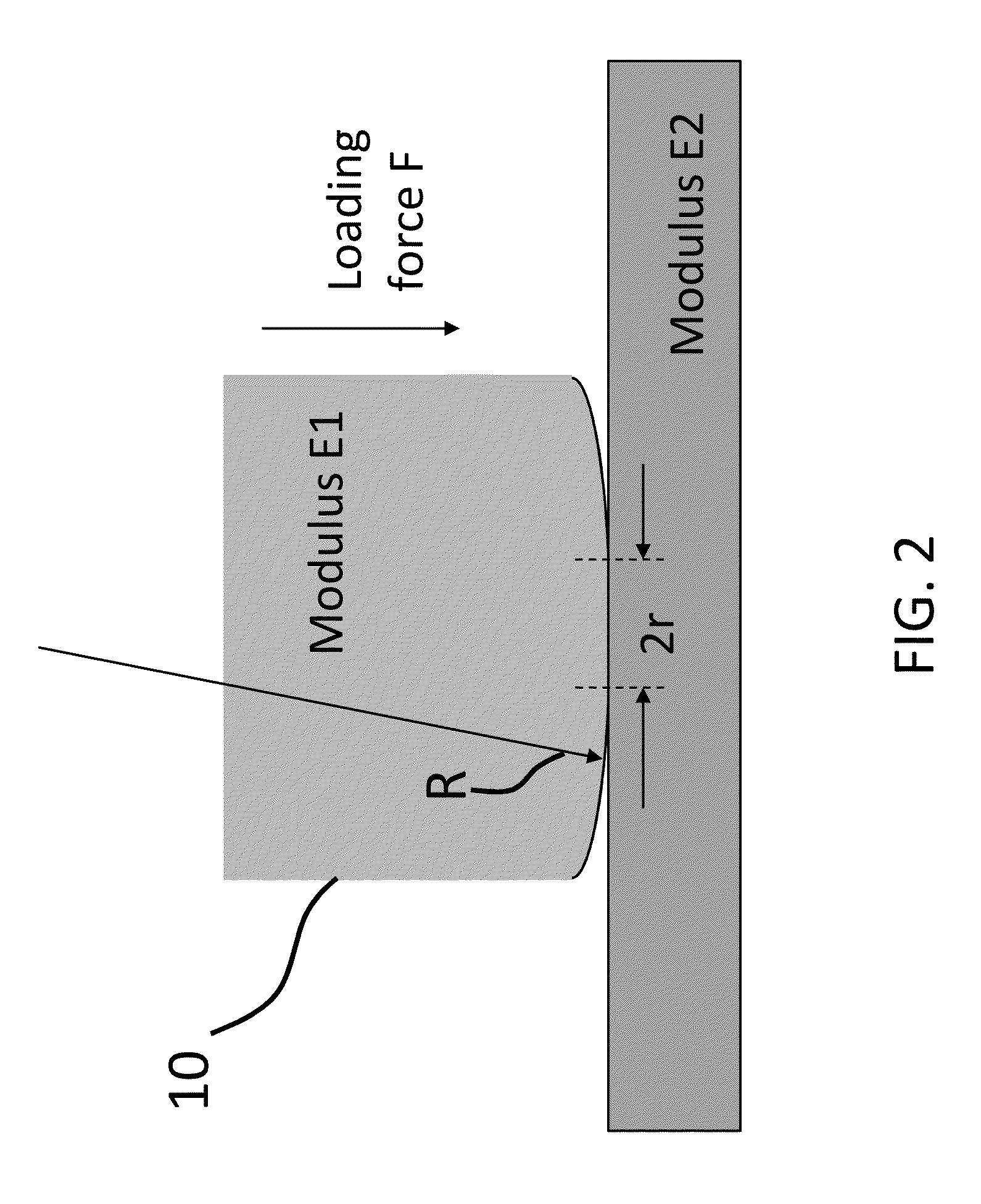

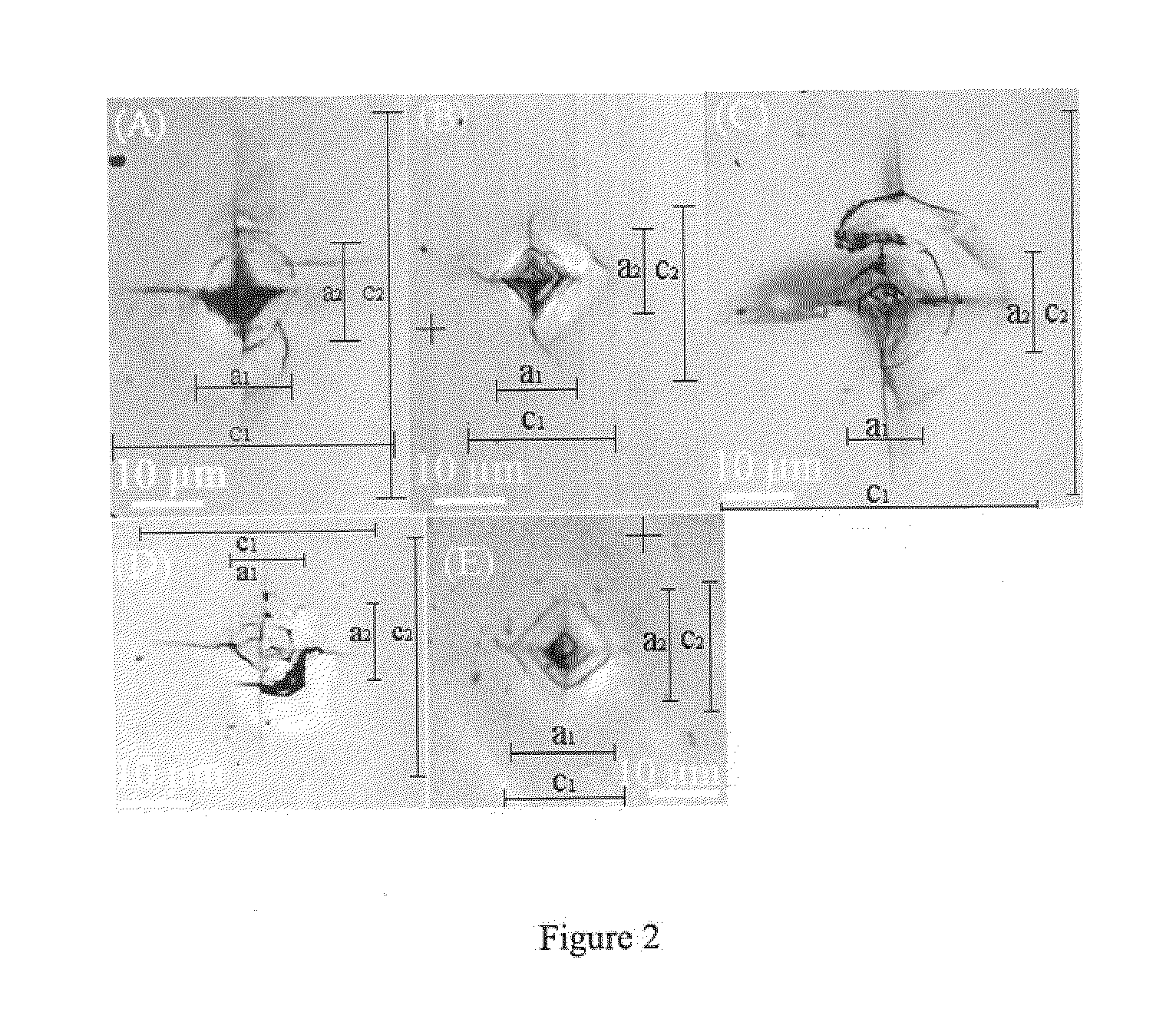

Ultratough single crystal boron-doped diamond

ActiveUS20100123098A1Minimizes gradientHigh melting pointPolycrystalline material growthOther chemical processesSingle crystalBoron

The invention relates to a single crystal boron doped CVD diamond that has a toughness of at least about 22 MPa m1 / 2. The invention further relates to a method of manufacturing single crystal boron doped CVD diamond. The growth rate of the diamond can be from about 20-100 μm / h.

Owner:CARNEGIE INSTITUTION OF WASHINGTON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com