Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Meet building needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

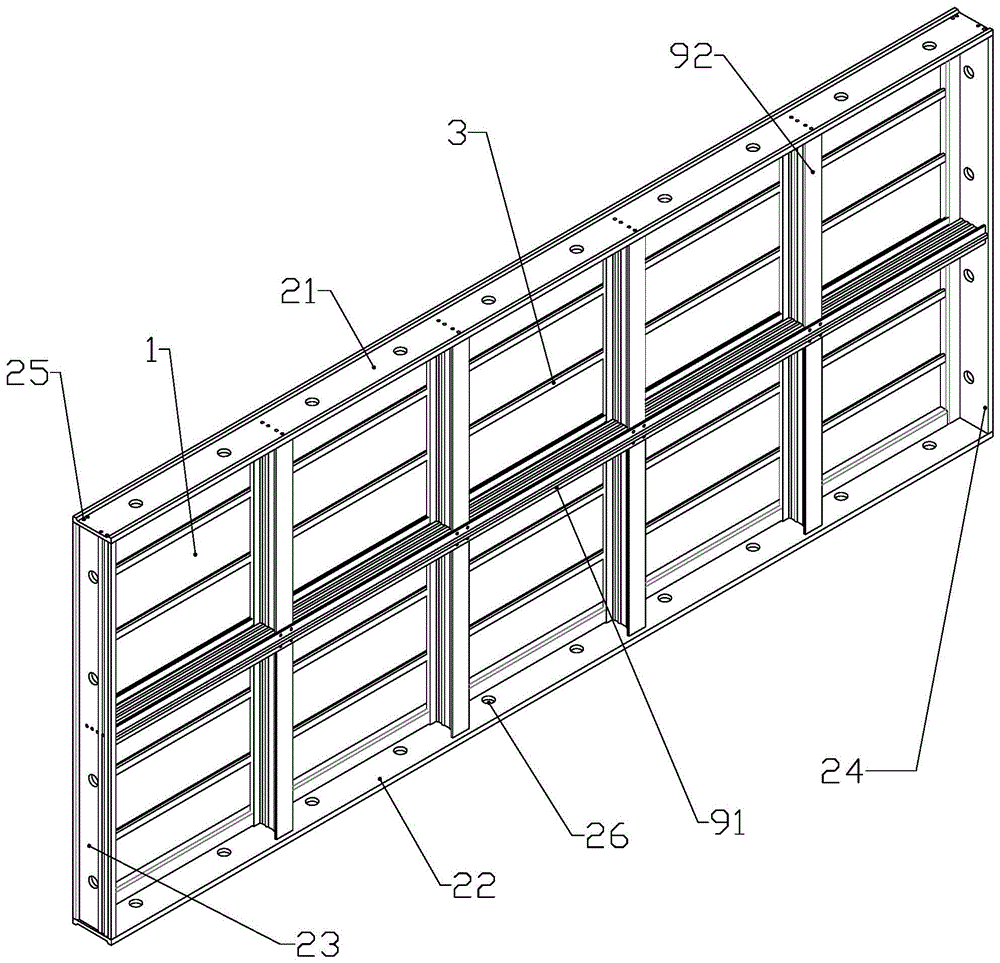

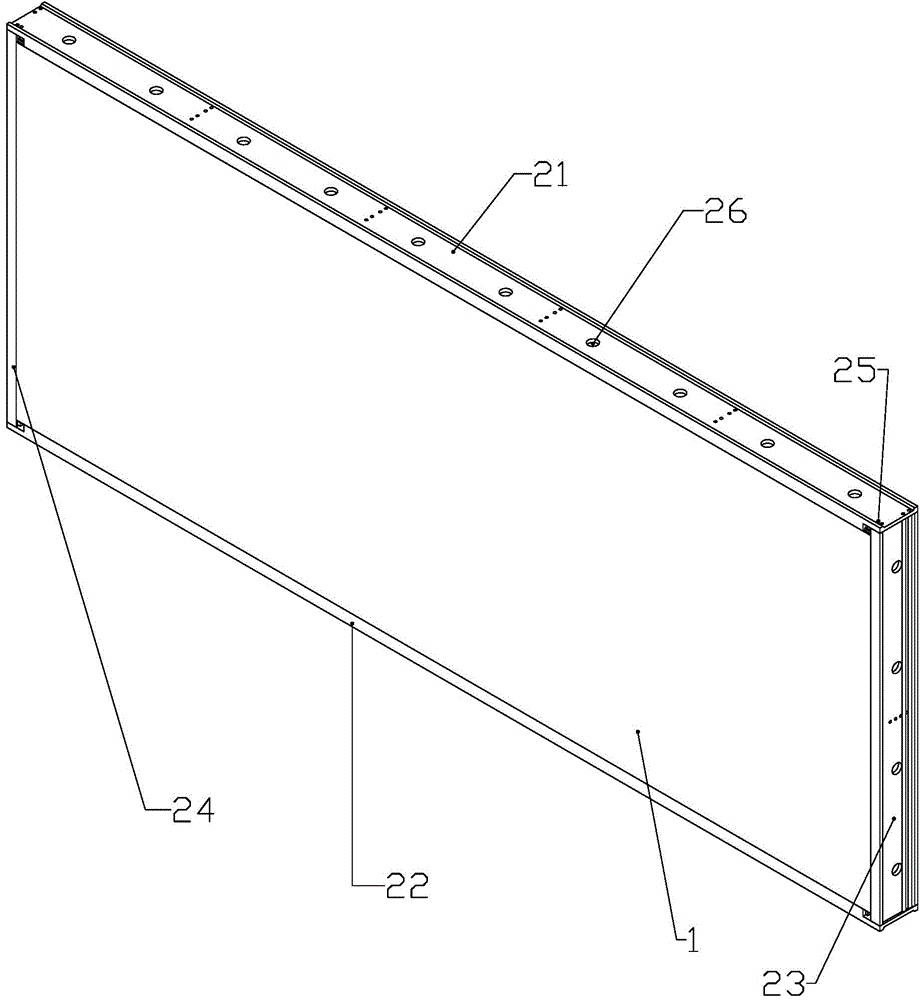

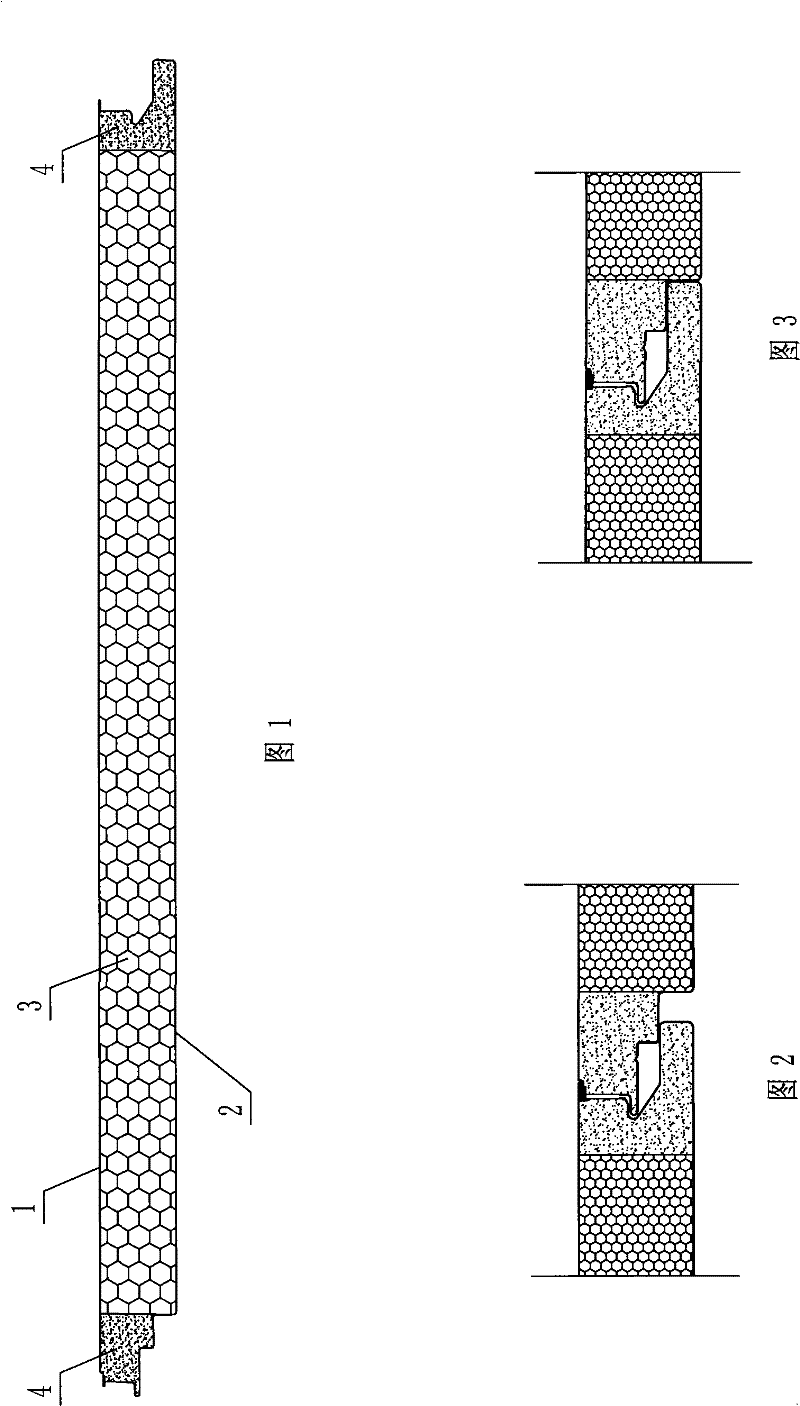

Composite building template

ActiveCN104975713AEasy constructionReduce construction costsForming/stuttering elementsPlastic materialsEngineering

The present invention discloses a composite building template, and belongs to the building template. The composite building template structurally comprises a face plate and a side frame, wherein the side frame is arranged around the face plate and comprises an upper side frame body, a lower side frame body, a left side frame body and a right side frame body; the upper side frame body, the lower side frame body, the left side frame body and the right side frame body are assembled and connected; the face plate is made of a modified PC plastic material while the side frame is made of aluminum alloy sections. The composite building template is light, inexpensive, convenient and easy to assemble; with the assembling type structure, the specifications of the composite building template are rich; the side frame, a crosswise back ridge and lengthwise back ridges are made of aluminum alloy sections, the strength is high, and the integrated using cost is low; the product life cycle is long, components are of an assembling type structure, and the product is very easy to maintain, only components at damaged positions need to be replaced, and thus the life cycle is greatly prolonged; the face plate is made of the modified PC plastic material, the bonding force of the template and concrete is small, the template is labor-saving in removal and easy to clean, and smearing of template oil is avoided.

Owner:潘庆功

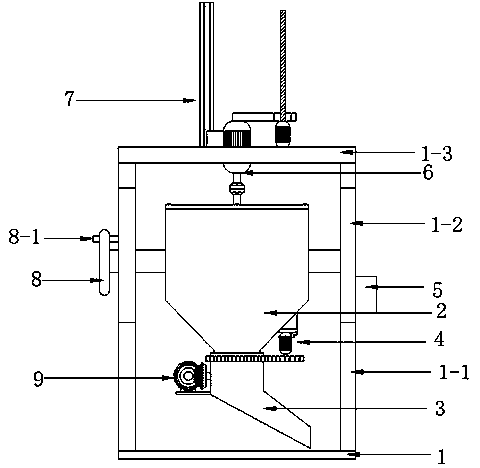

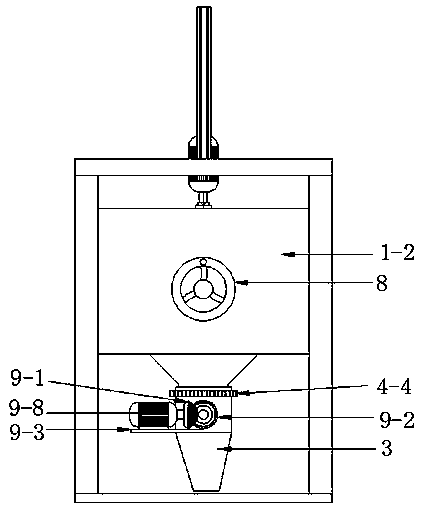

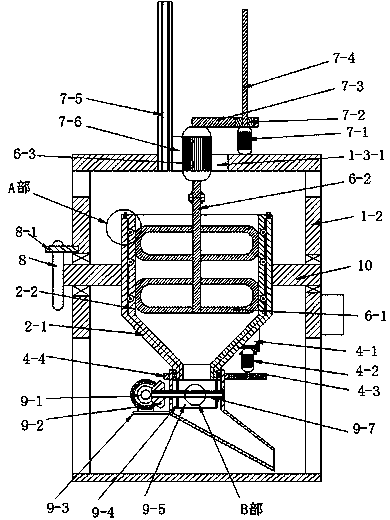

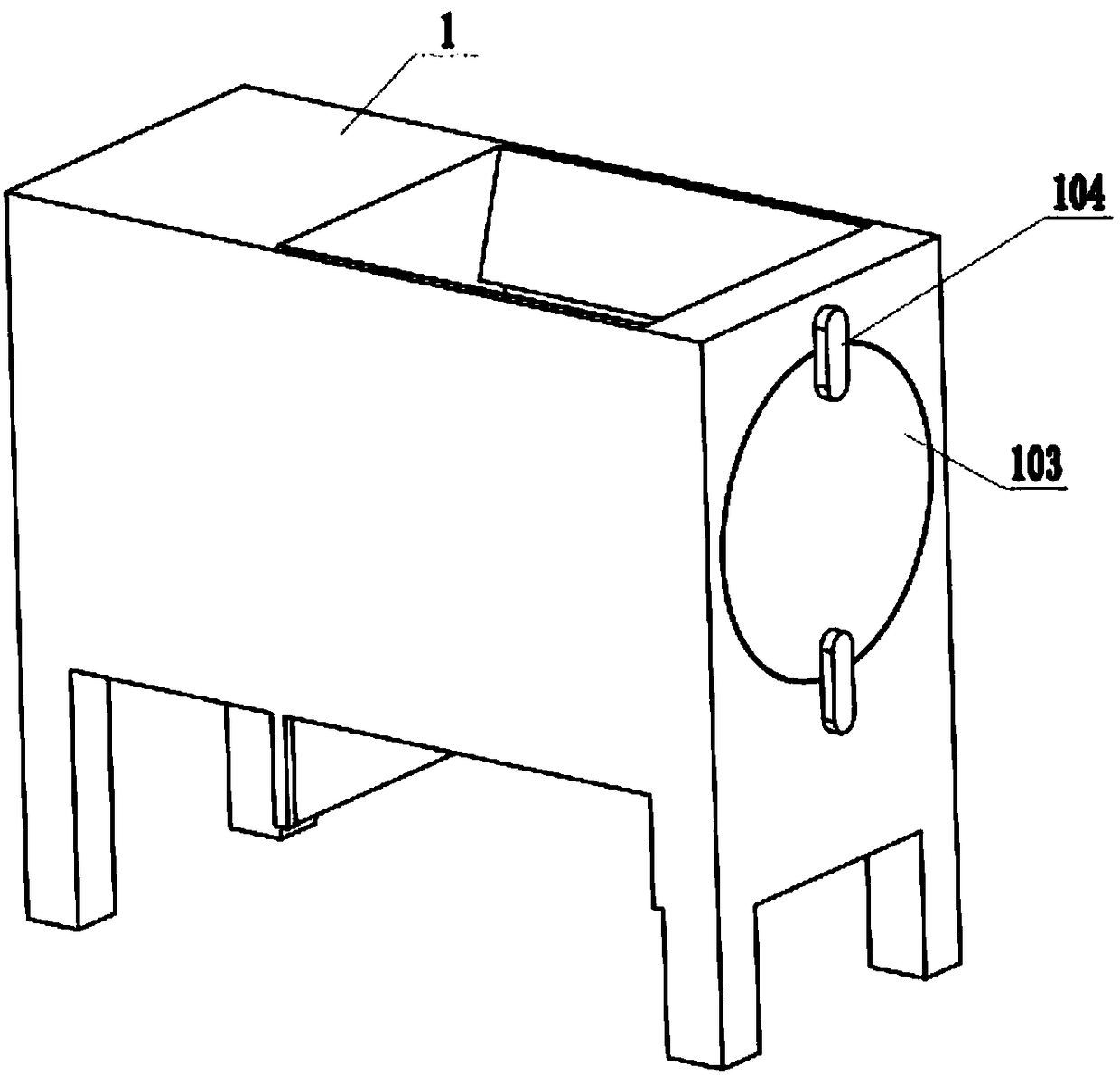

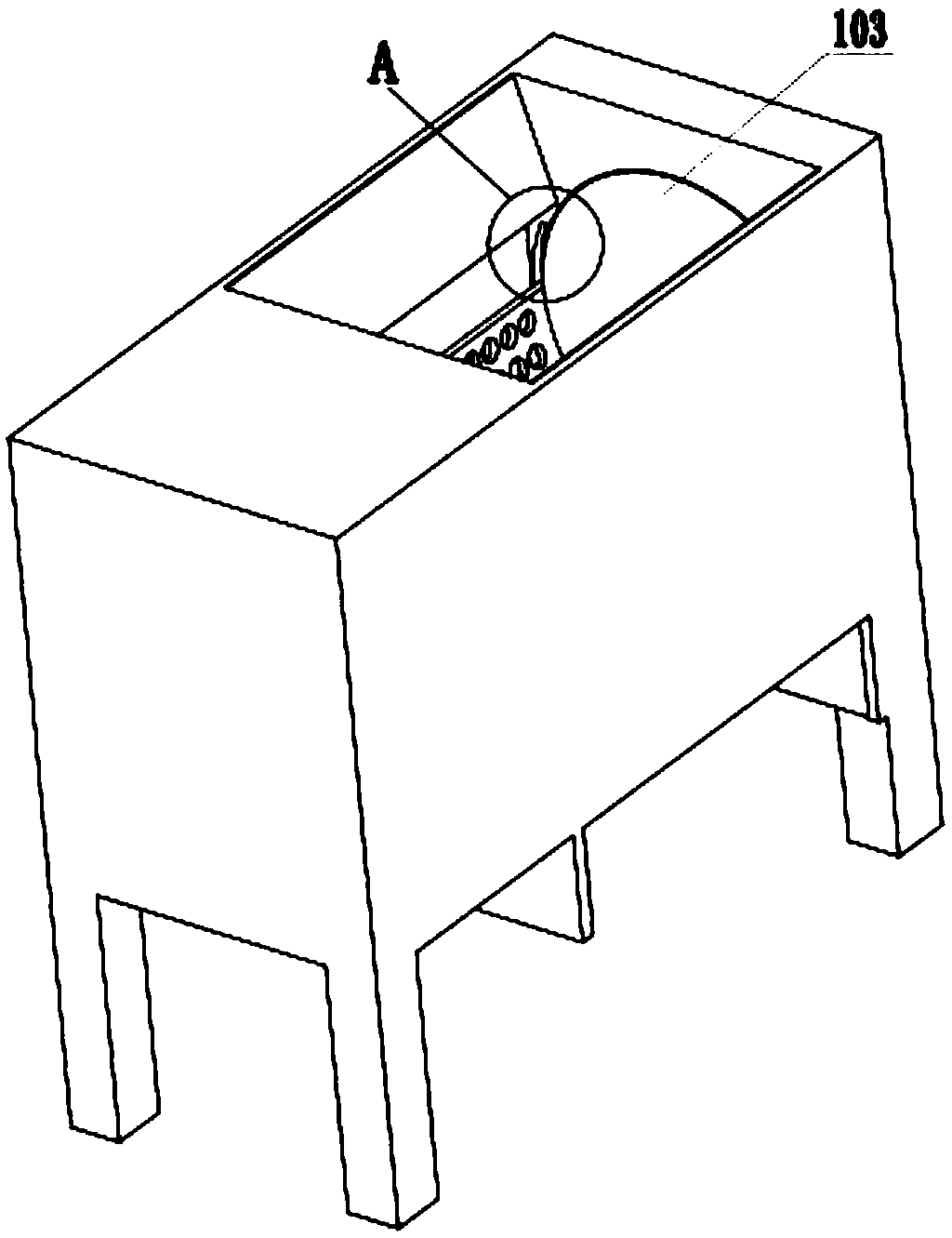

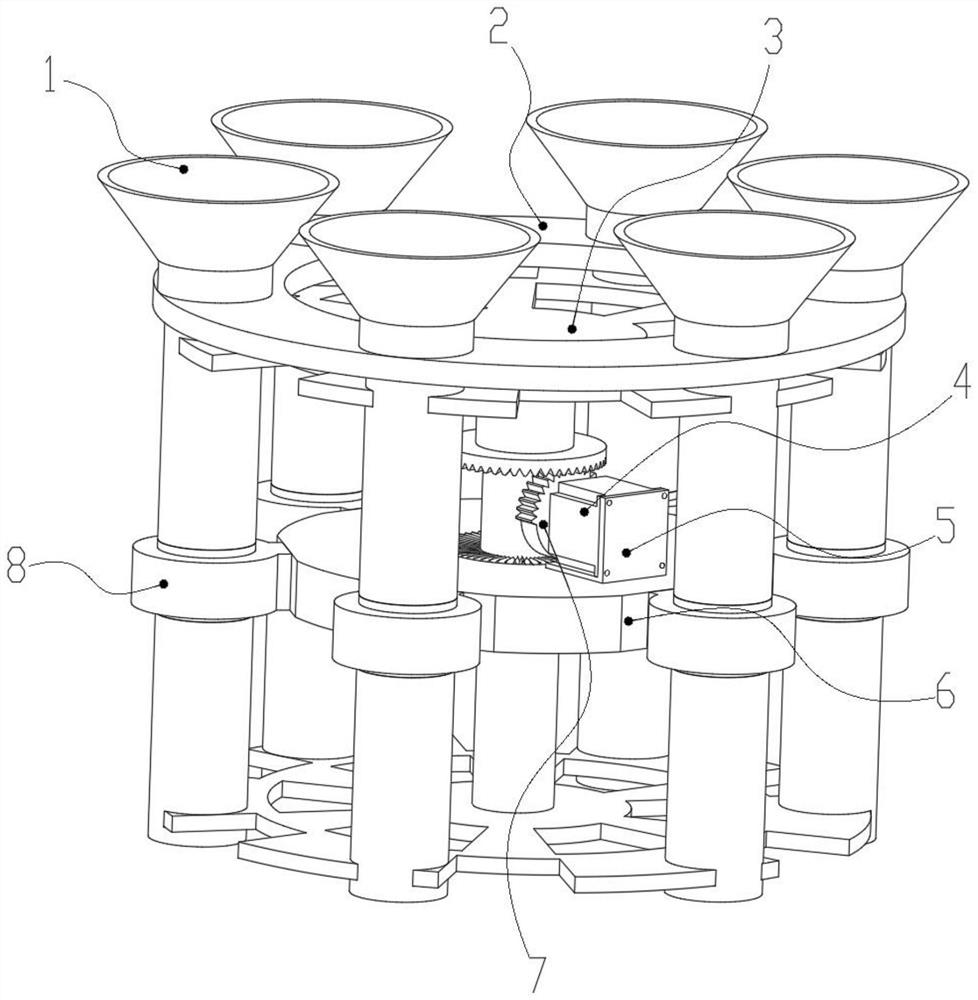

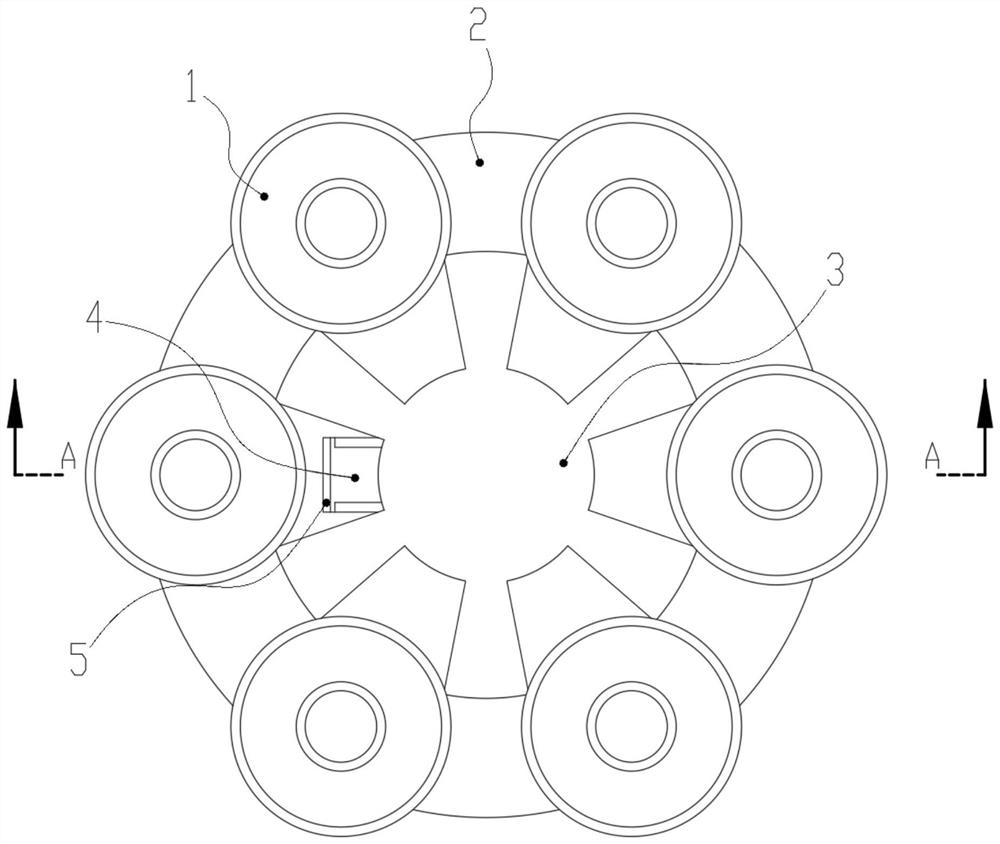

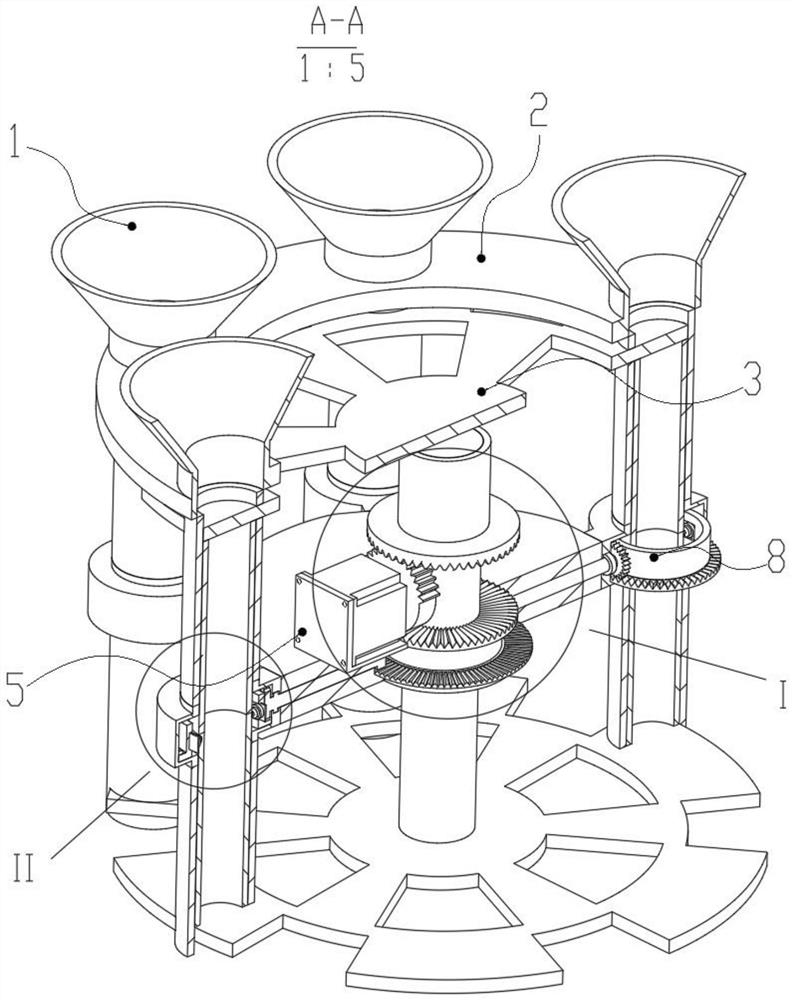

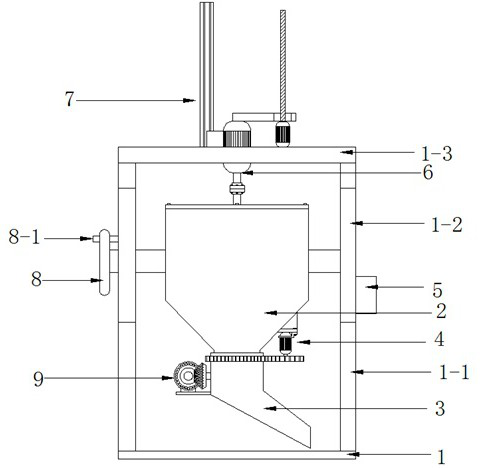

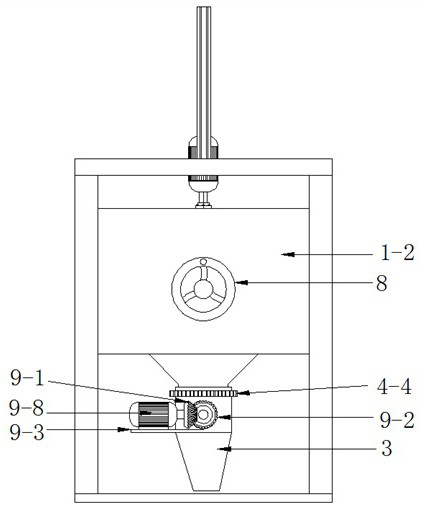

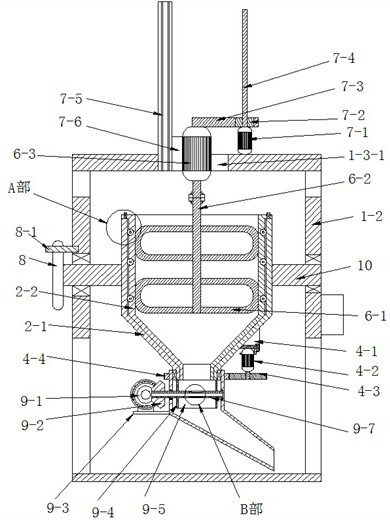

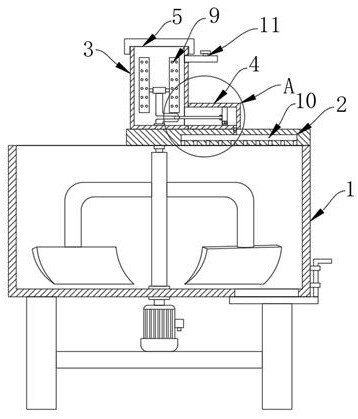

Multifunctional concrete pouring hopper for building construction

ActiveCN110130645AMeet building needsEasy to cleanBuilding material handlingArchitectural engineeringBuilding construction

The invention provides a multifunctional concrete pouring hopper for building construction, and relates to the technical filed of building equipment. Vertical columns are connected to the four cornersof the upper surface of a base correspondingly, and the top ends of the vertical columns are connected and fixed to the four corners of a top plate; transverse plates are connected between the vertical columns located on the front part and the rear part of the left side and between the vertical columns located on the front part and the rear part of the right side correspondingly; a hopper body isarranged between the transverse plates on the left side and the right side, hopper rotating shafts are fixed to the left side wall and the right side wall of the hopper body correspondingly, and theouter ends of the hopper rotating shafts on the left side and the right side are rotatably connected into the transverse plates on the left side and the right side through bearings correspondingly, wherein the outer end of the hopper rotating shaft on the left side penetrates through the transverse plate on the left side and then is connected and fixed to a rotary handle, a positioning pin is inserted on the rotary handle, and the inner end of the positioning pin is detachably inserted in the transverse plate on the left side. Discharging of the multifunctional concrete pouring hopper can be adjusted, the application range of the multifunctional concrete pouring hopper is expanded greatly, building demands of multiple structures are met, meanwhile, cleaning can further be convenient, the construction progress is accelerated, and practicality is higher.

Owner:宝鸡二建集团有限公司

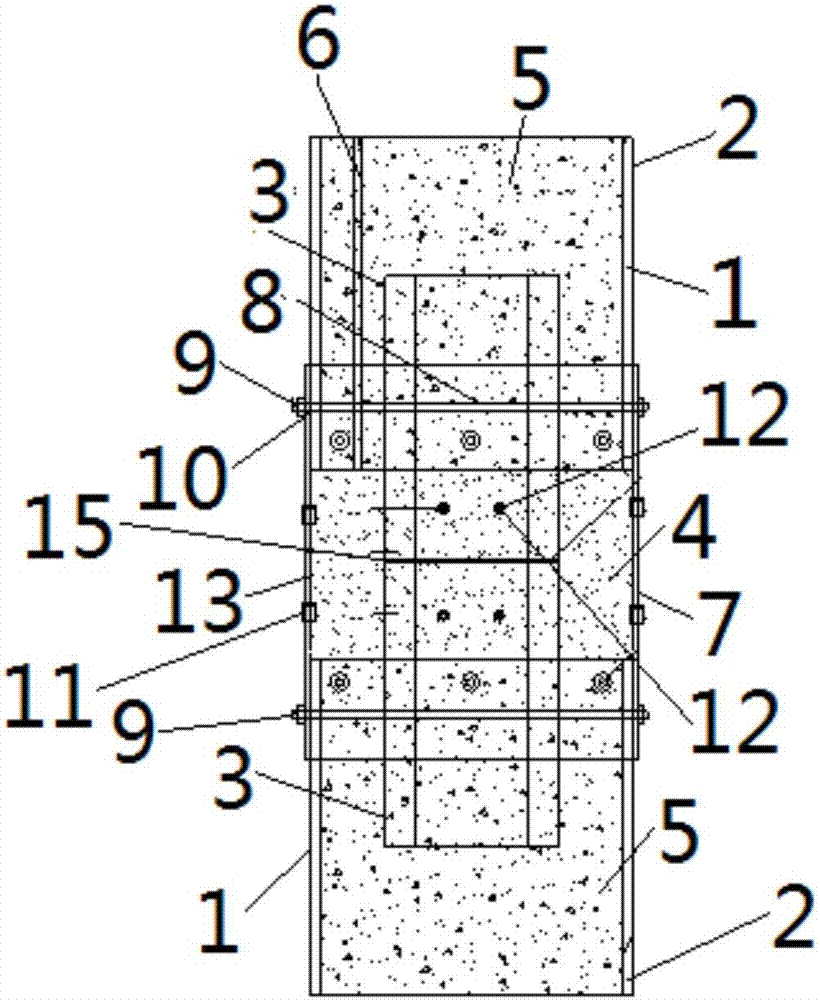

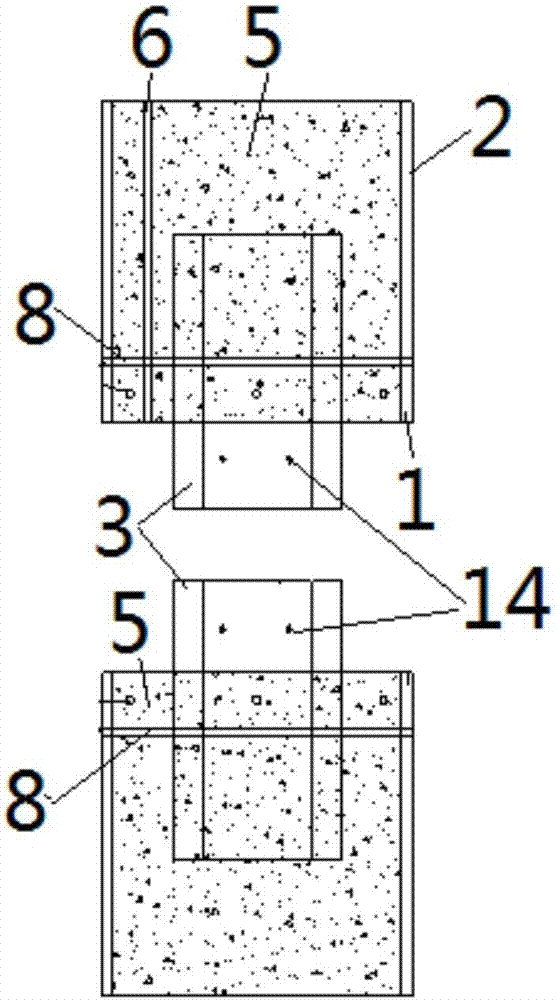

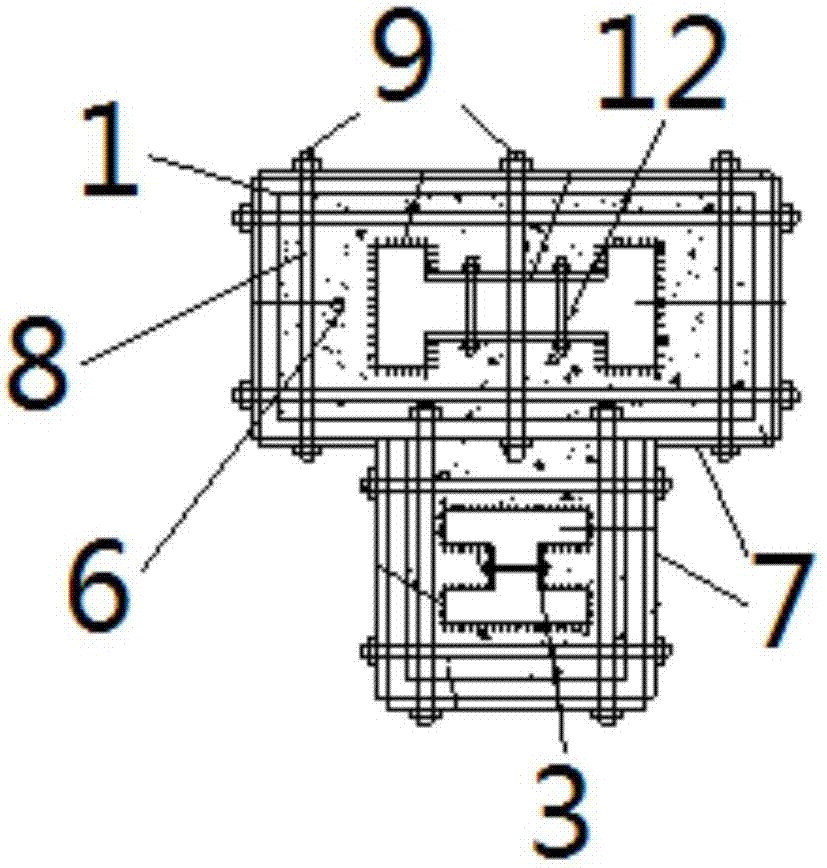

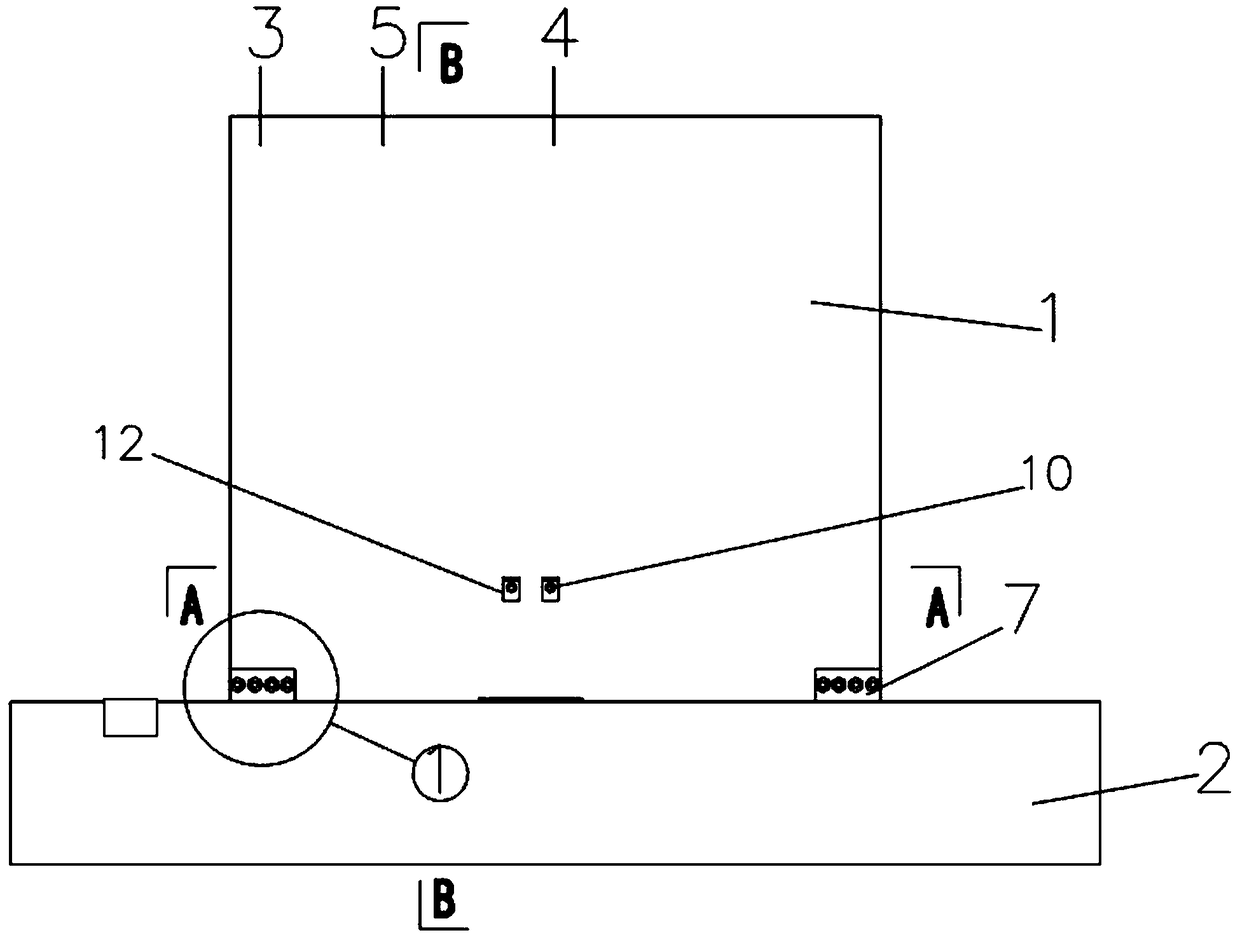

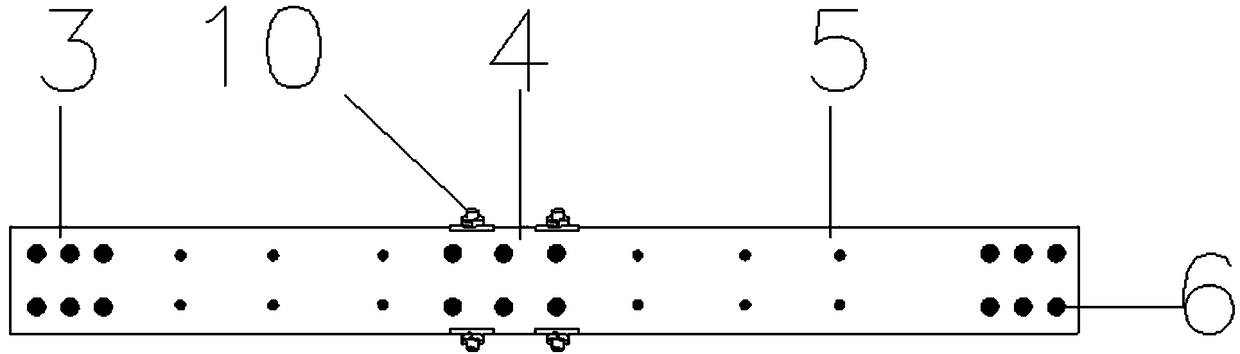

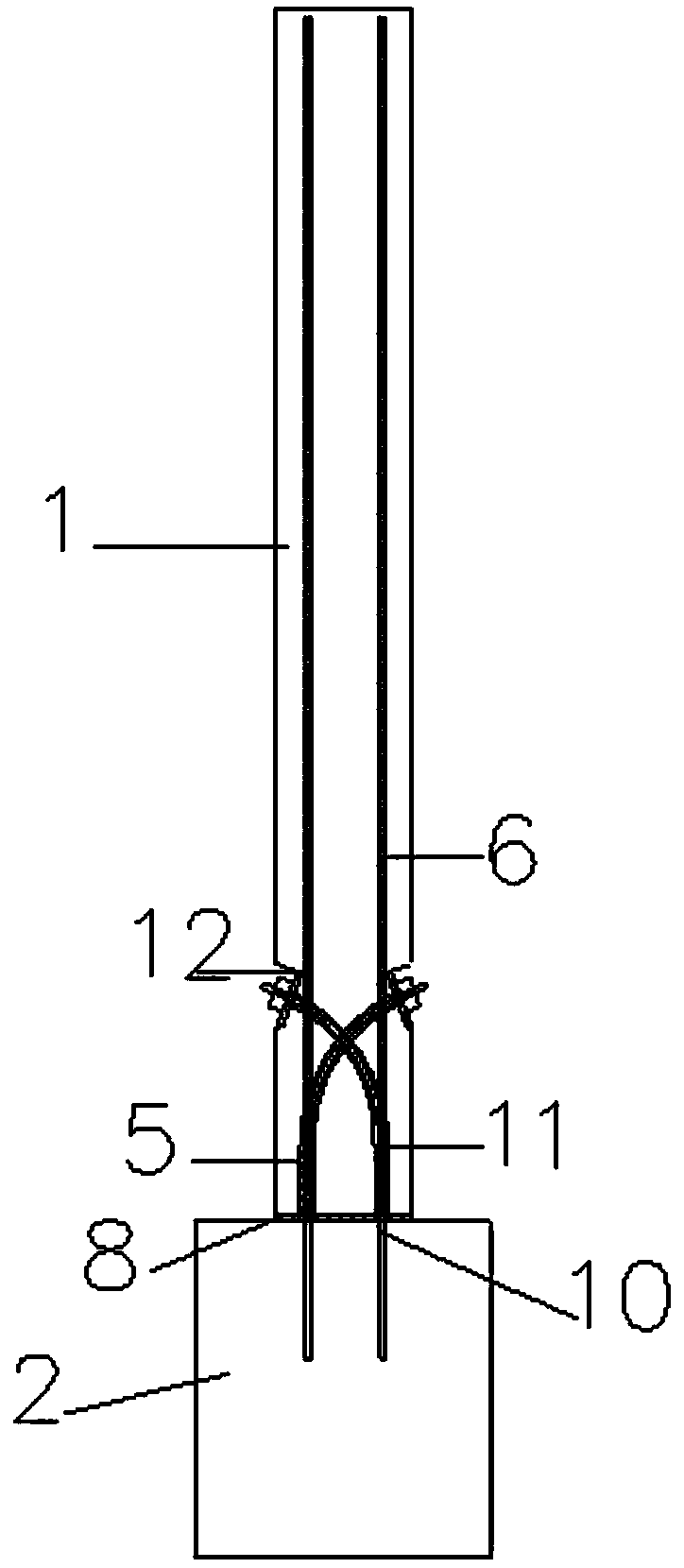

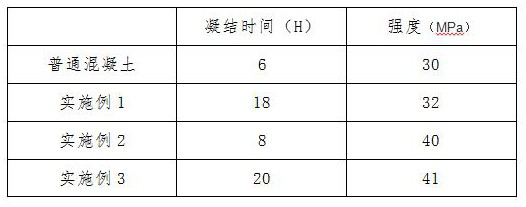

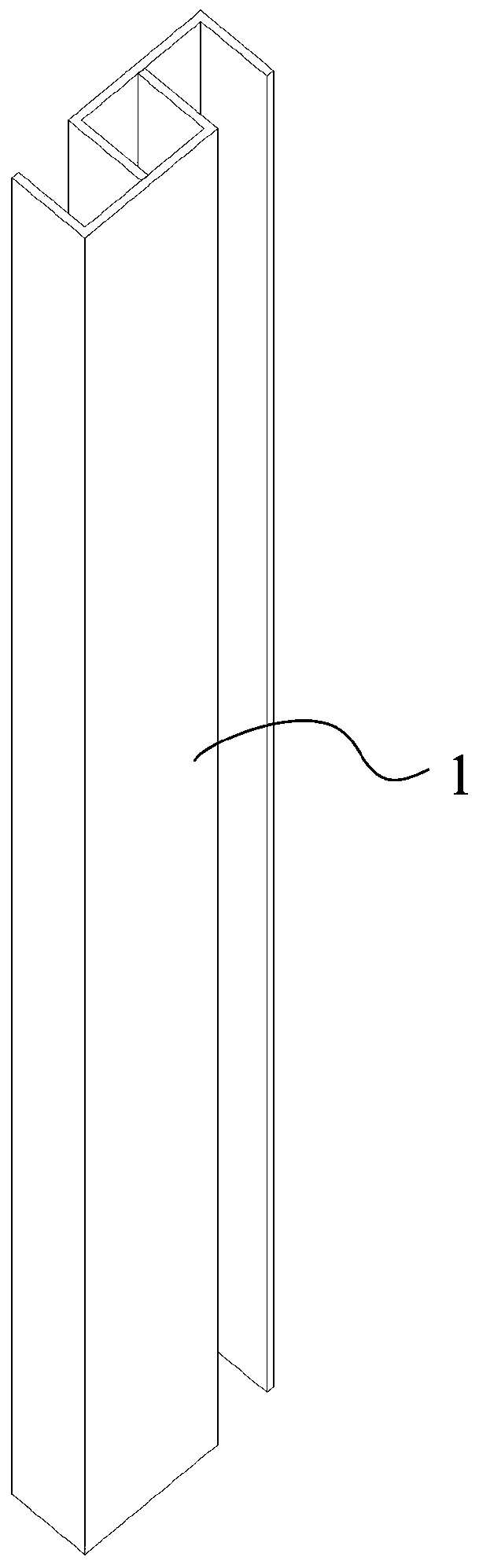

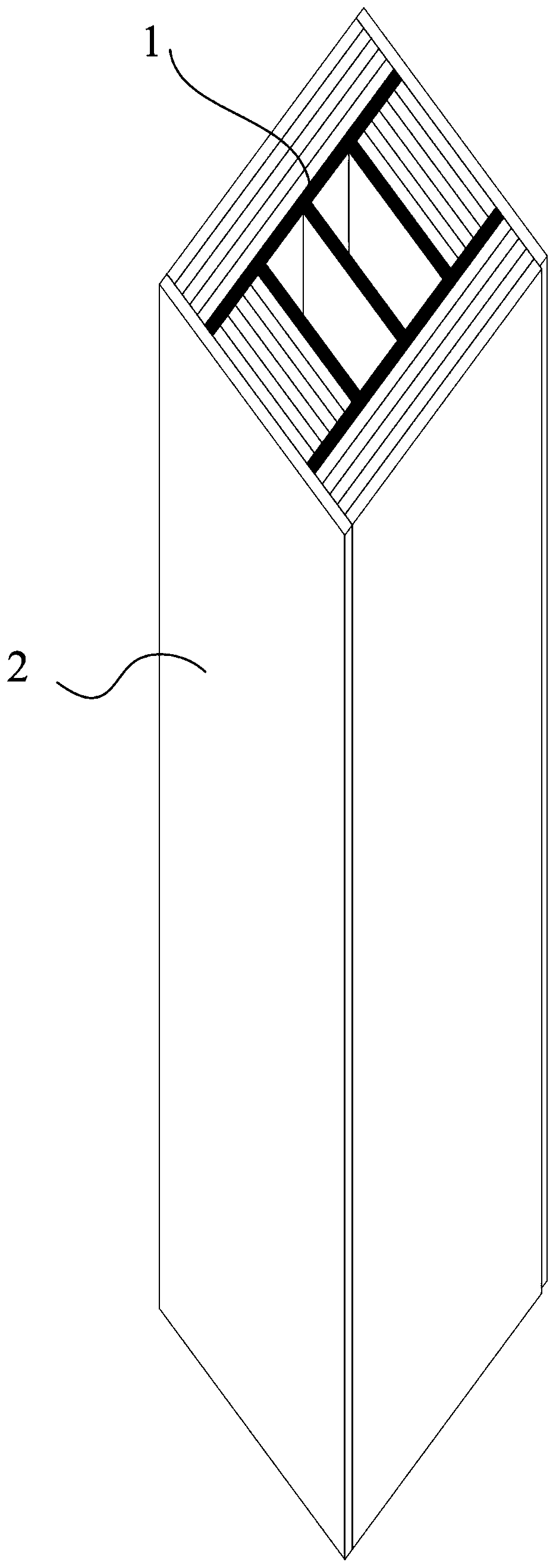

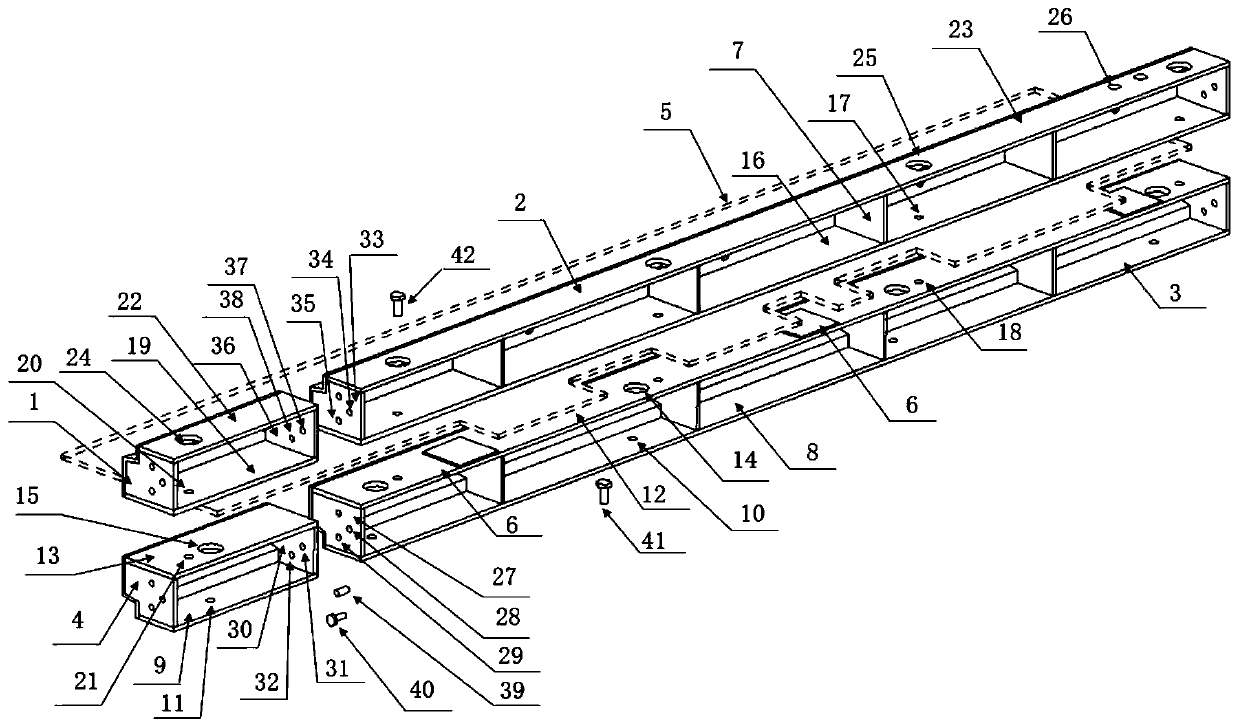

Profile steel built-in special-shaped steel pipe concrete column structure and manufacturing method thereof

PendingCN106906954AEasy constructionDuring construction, it is convenient to connect multiple prefabricated columns as neededArched girdersPortal framesEarthquake resistanceClassical mechanics

The invention provides a profile steel built-in special-shaped steel pipe concrete column structure applied to the field of novel building structures and further relates to a manufacturing method of the profile steel built-in special-shaped steel pipe concrete column structure. Profile steel (3) of each prefabricated column (1) of the profile steel built-in special-shaped steel pipe concrete column structure is arranged in a special-shaped steel pipe (2). A concrete block (5) is arranged between the profile steel (3) and the special-shaped steel pipe (2) and provided with an embedded pipe (6). The profile steel (3) of each prefabricated column (1) is arranged to be of a structure which can be connected with the profile steel (3) of another prefabricated column (1). The outer circles of the special-shaped steel pipes (2) of every two connected prefabricated columns (1) are connected through a closing steel plate (7). The profile steel built-in special-shaped steel pipe concrete column structure has the advantages of being high in bearing capacity, good in ductility, superior in anti-seismic performance, safe and reliable in connection, convenient to construct and the like, and performance of a building is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Method for preparing road/site foundation in sludge soft soil environment

InactiveCN107313422AEfficient and cheap means of realizationMeet building needsRoadwaysSoil preservationSludgeEngineering

The invention discloses a method for preparing a road / site foundation in a sludge soft soil environment. Through solidification treatment of sludge soft soil, a high-strength material for the road / site foundation can be formed, and thus standardized road or site construction treatment can be conducted on non-ideal soil. According to the method for preparing the road / site foundation in the sludge soft soil environment, solidification treatment of the sludge soft soil can be achieved in the excavating process of a foundation ditch in the actual operation process, the laying process of the road / site foundation is executed in the mode of using local materials, and therefore the construction cost can be reduced remarkably and the efficiency can be improved obviously.

Owner:JIANGSU NATURE WAY TECH

Self-resetting fabricated shear wall structure connecting device

The invention provides a self-resetting fabricated shear wall structure connecting device. The connecting device comprises a prefabricated shear wall and a foundation shear wall, and the prefabricatedshear wall is internally provided with a steel reinforcement cage and a plurality of longitudinal bars. The connecting device is characterized in that the prefabricated shear wall comprises an end confined region, a middle confined region and a distributing reinforcement region, wherein the middle confined region is located in the middle of a wall body of the prefabricated shear wall, the end confined region is located at both ends of the wall body of the prefabricated shear wall, and the distributing reinforcement region is located between the end confined region and the middle confined region; the purpose is to apply energy-dissipation earthquake-reduction to the fabricated structure, according to the connecting mode, the energy dissipation capacity of the shear wall structure is improved, the shear wall has self-resetting capacity under lateral loads, the seismic demand of the whole structure can be reduced, and the seismic performance of the main structure is improved; and at thesame time, the connecting device has the characteristic of easy industrial production and is more efficient and quicker, and the problems of inconvenience and pollution of energy consumption caused byon-site wet working are avoided.

Owner:CHINA MCC17 GRP

Tailing slag aerated blocks, and production method thereof

The invention belongs to the technical field of aerated block production, and especially relates to tailing slag aerated blocks, and a production method thereof. The production method comprises stepsof raw material treatment and blending, aging treatment, rolling treatment, standing treatment, and autoclave curing treatment. The appearance of the tailing slag aerated blocks is excellent; no surface crack is caused; size standard is reached, the durability is excellent; the compressive strength and the rupture strength are capable of satisfying building requirements; full utilization of tailing slag is realized; and the production method is green, and is friendly to the environment.

Owner:DINGSHENG INC

Environmental-protection acoustical building panel and production method thereof

InactiveCN106892607AStrong double layer structureGood sound absorptionSound proofingCoal gangueBuilding material

Disclosed is an environment-friendly acoustical building panel which is of a double-layer porous structure formed by a surface material layer and a substrate layer. The surface material layer is made from construction waste regeneration fine aggregate, coal gangue, cement, lime and slurry; the substrate layer is made from the construction waste regeneration fine aggregate, the cement and the slurry. The environment-friendly acoustical building panel with solid waste of the slurry, the coal gangue and the like as main materials is of the porous structure, even pores are arranged in the surface and the interior of the material, and the acoustical effect of the material is higher when porosity is higher.

Owner:河南永泽环境科技有限公司

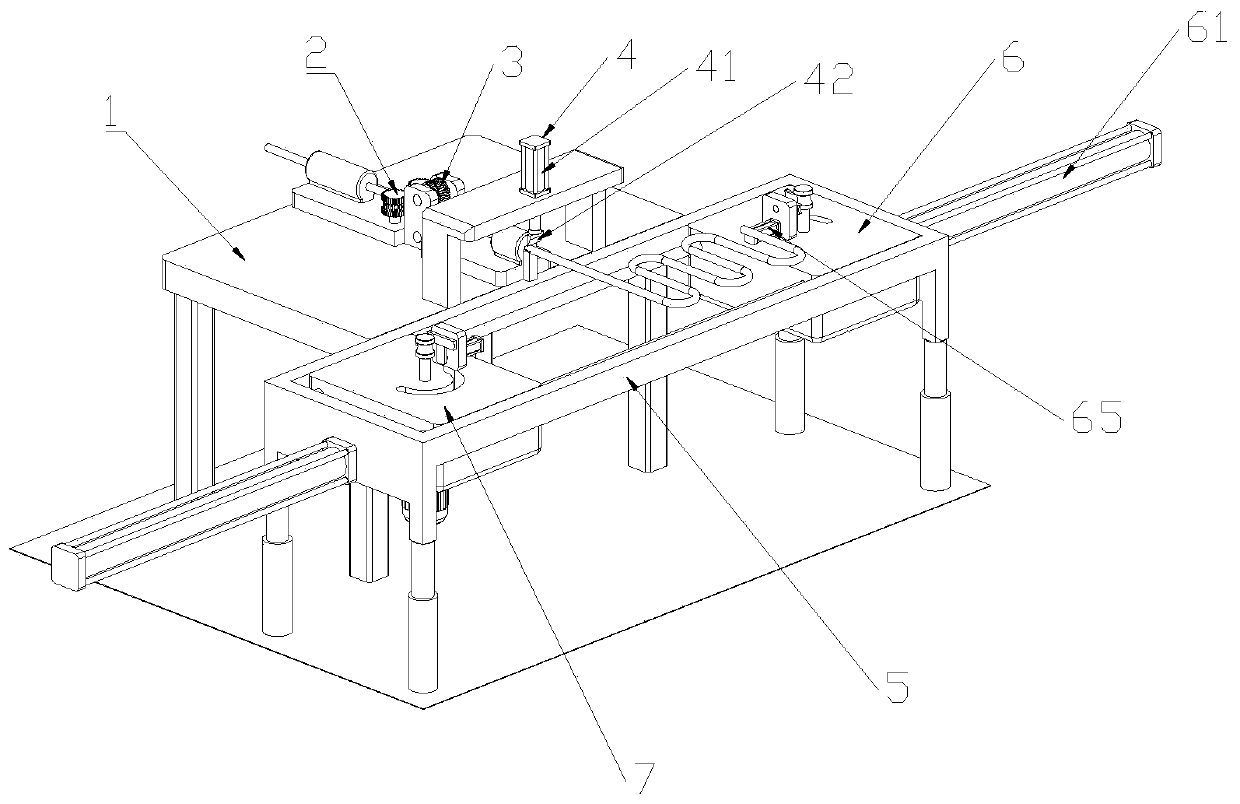

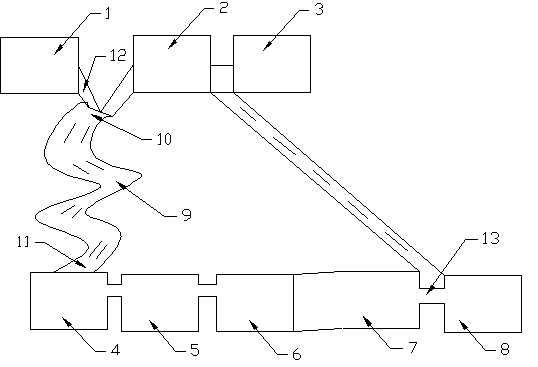

Automatic bending device for rebars

The invention discloses an automatic bending device for rebars. The automatic bending device includes a first support, the first support includes a working table, the working table is provided with atransmission device for driving feed of the rebars in the bending device, a second support is arranged on one side of the first support, the second support includes a square frame, the second supportincludes a telescopic cylinder for moving the square frame up and down, and the second support is provided with a first bending molding device and a second bending molding device. According to the automatic bending device, the feed of the rebars in the bending device is controlled by the transmission device, the rebars are routinely molded by any one of the first bending molding device and the second bending molding device, the rebars are molded in S shapes through matching of the first bending molding device and the second bending molding device, bending operation of the various rebars is achieved, and the building needs are met; and manual bending is reduced, the working efficiency is improved, the labor intensity of staff is lowered, and the requirement for rapid development of modern buildings is met.

Owner:安徽晶宫绿建集团有限公司

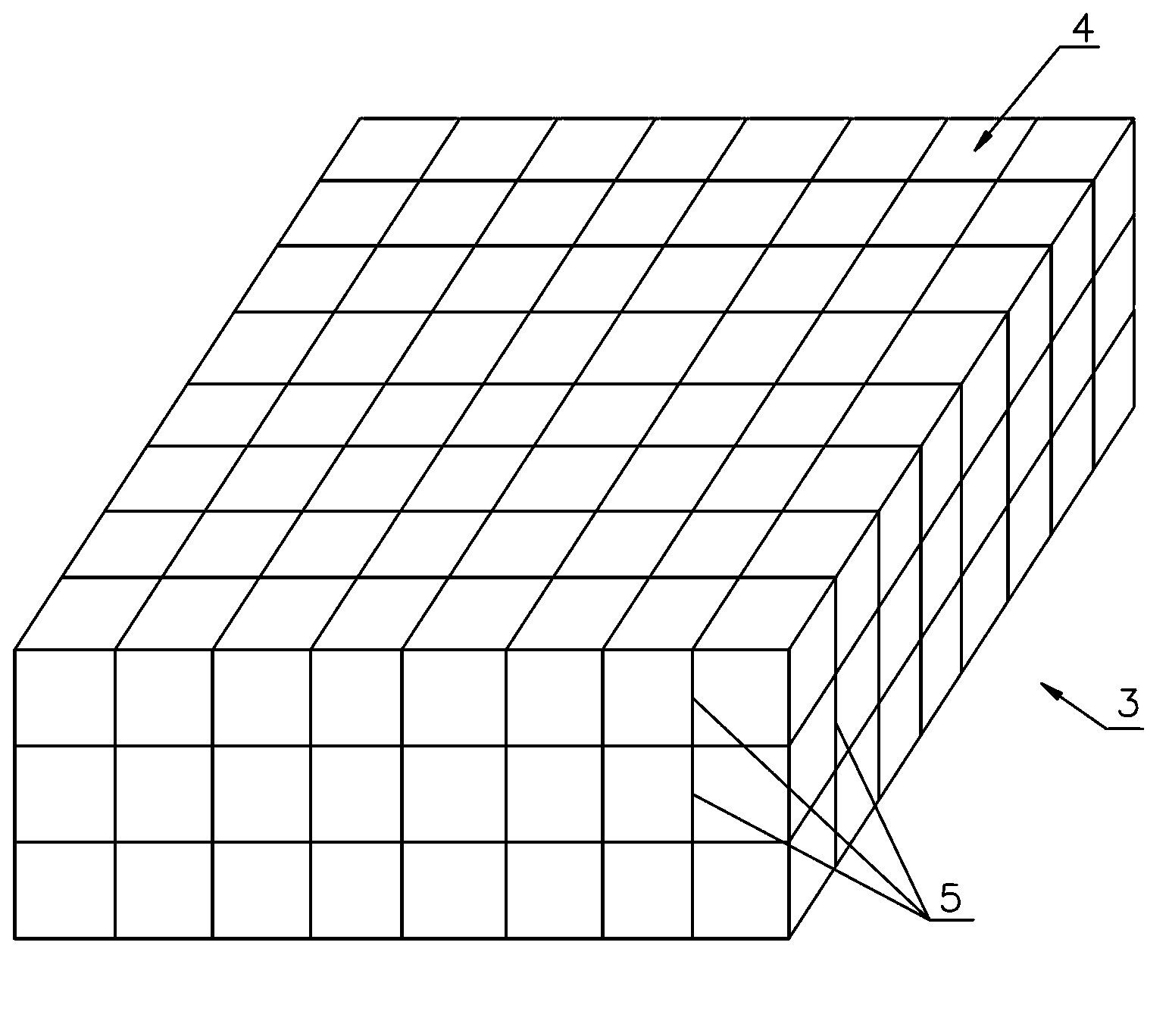

High-strength light wall board

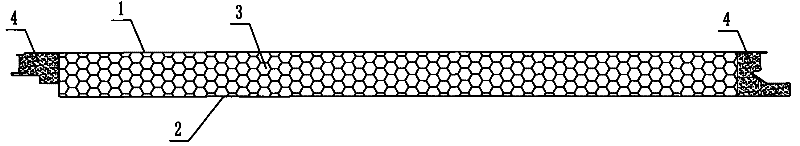

InactiveCN103061447AImprove bending resistanceHigh strengthBuilding componentsWater-setting substance layered productMetasilicatePlastics engineering

The invention relates to a high-strength wall board which comprises calcium metasilicate layers located at the uppermost layer and the lowest layer, wherein an insulating layer is between the two calcium metasilicate layers and is internally embedded with a plastic engineering grid, the plastic engineering grid is integrally formed by three layers of latticed grid meshes, and each grid end point of the middle-layer grid mesh is connected with the grid end points of the upper-layer grid mesh and the lower-layer grid mesh through a plastic bar. As the plastic engineering grid is additionally arranged during the pouring forming of the wall board, the fracture resistance and the anti-shearing strength are greatly enhanced, the plastic engineering grid does not rust or carbonize and has advantages compared with a steel bar truss, in addition, the weight is light, the construction requirements are completely met, and the high-strength light wall board is an excellent high-strength light insulating wall body.

Owner:PENGCHENG RESIDENTIAL INDZED MATERIALS JIANGSU

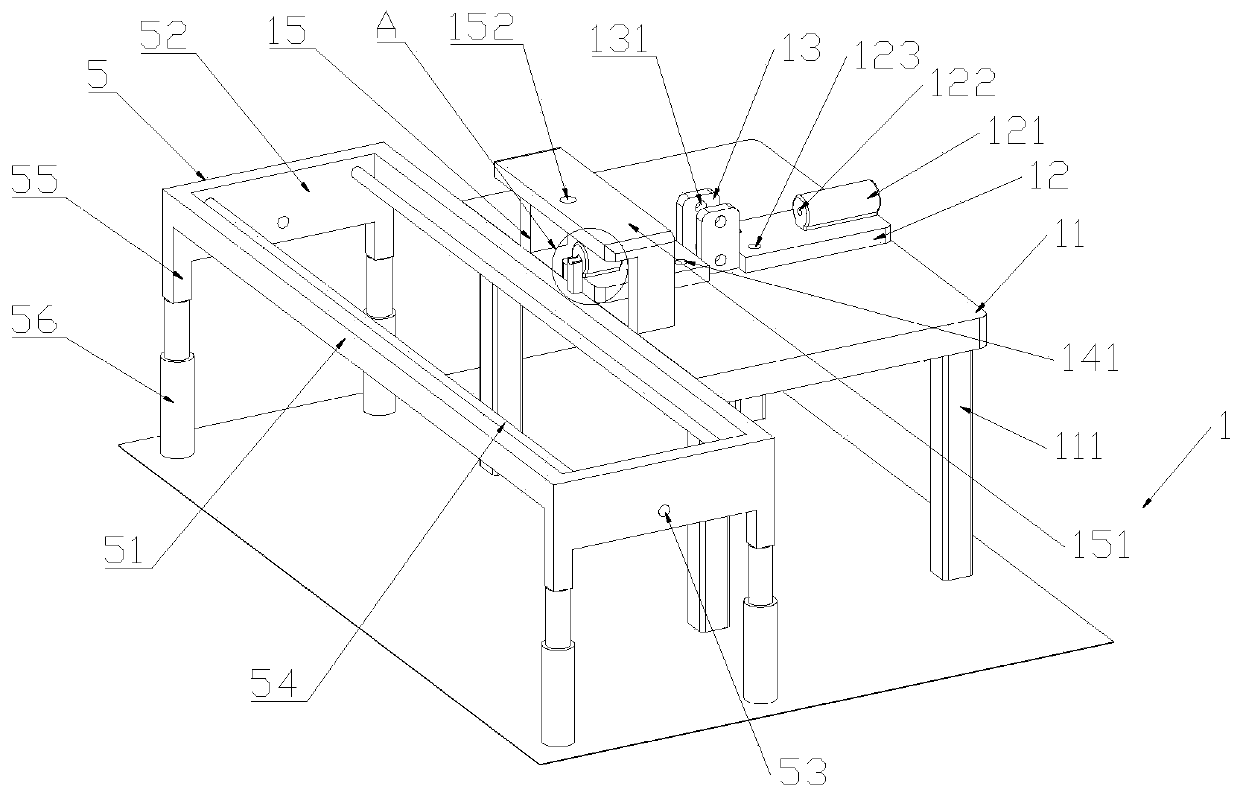

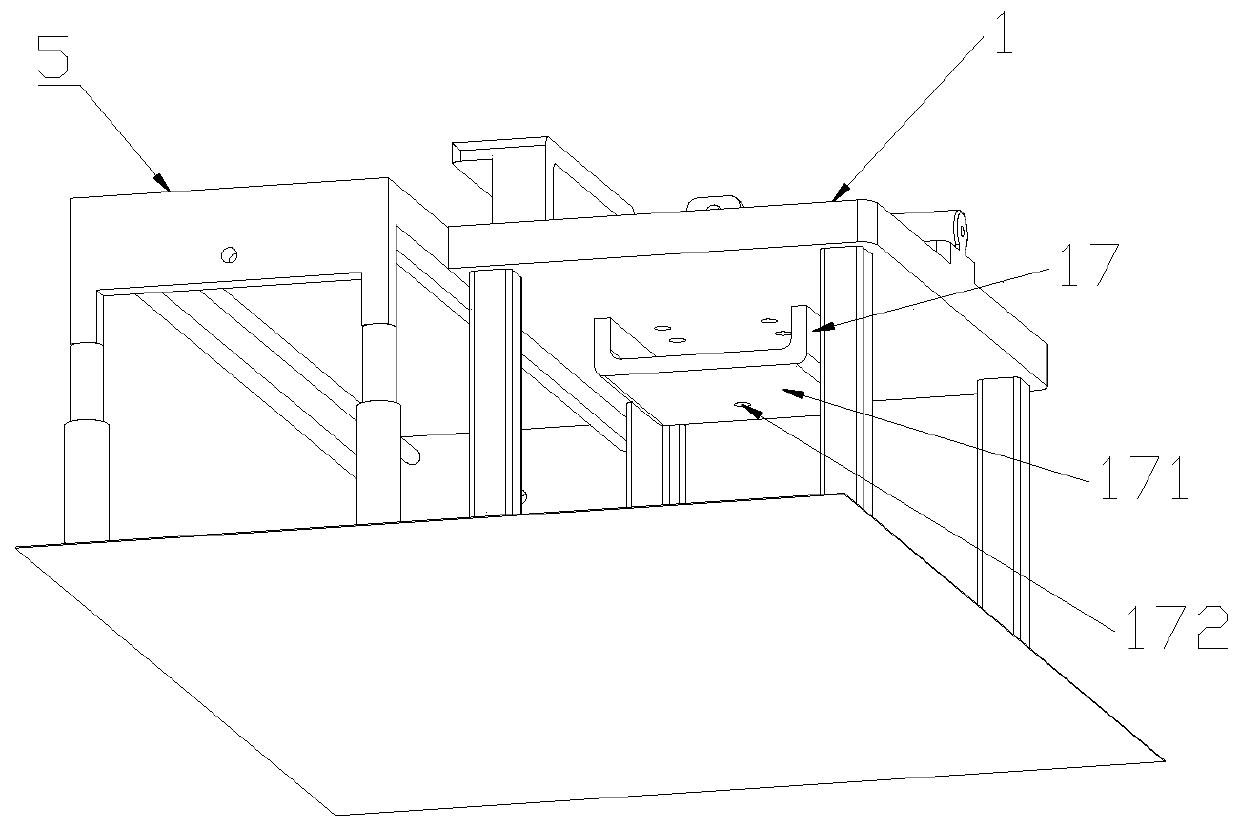

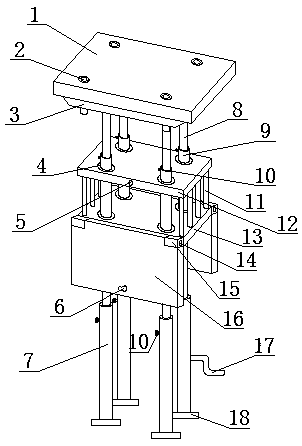

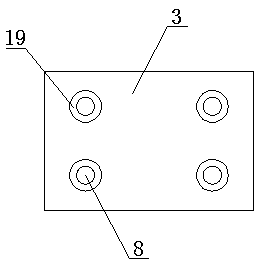

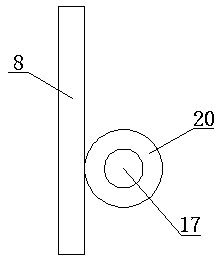

Prefabricated building combined adjustable supporting frame

InactiveCN109386143ATo achieve the purpose of height adjustmentImprove the safety of useShoresRubber ringArchitectural engineering

Owner:刘浩荫

Sand screening device

PendingCN108372109ASolve the problem of low efficiency and unable to meet work needsSave human effortSievingScreeningEngineering

Owner:BEIFANG UNIV OF NATITIES

High-structural-strength concrete for building foundation casting

InactiveCN105384418AImprove structural strengthAvoid oxidative crackingHigh strength concreteSodium sulfate

The invention discloses high-structural-strength concrete for building foundation casting. Each square of a foundation includes, by mass, 100-200 parts of ordinary Portland cement, 50-80 parts of gravels, 100-150 parts of silt, 15-25 parts of quick lime, 15-25 parts of iron powder, 40-50 parts of iron ore powder, 15-35 parts of sodium sulfate powder, 15-20 parts of limestone powder, 100-150 parts of rock flour, 100-120 parts of melon seed-shaped drug slices, 200-250 parts of limewater and 50-150 parts of potassium nitrate powder. The concrete does not need a CTF concrete synergistic agent, can have higher structural strength and meet the building needs through matching of the ordinary Portland cement and the iron powder, can effectively reduce the oxidation effect of the iron powder through the sodium sulfate powder and is suitable for popularization and usage, and oxidation and cracking of the concrete are avoided.

Owner:GUANGXI JUBANG TECH

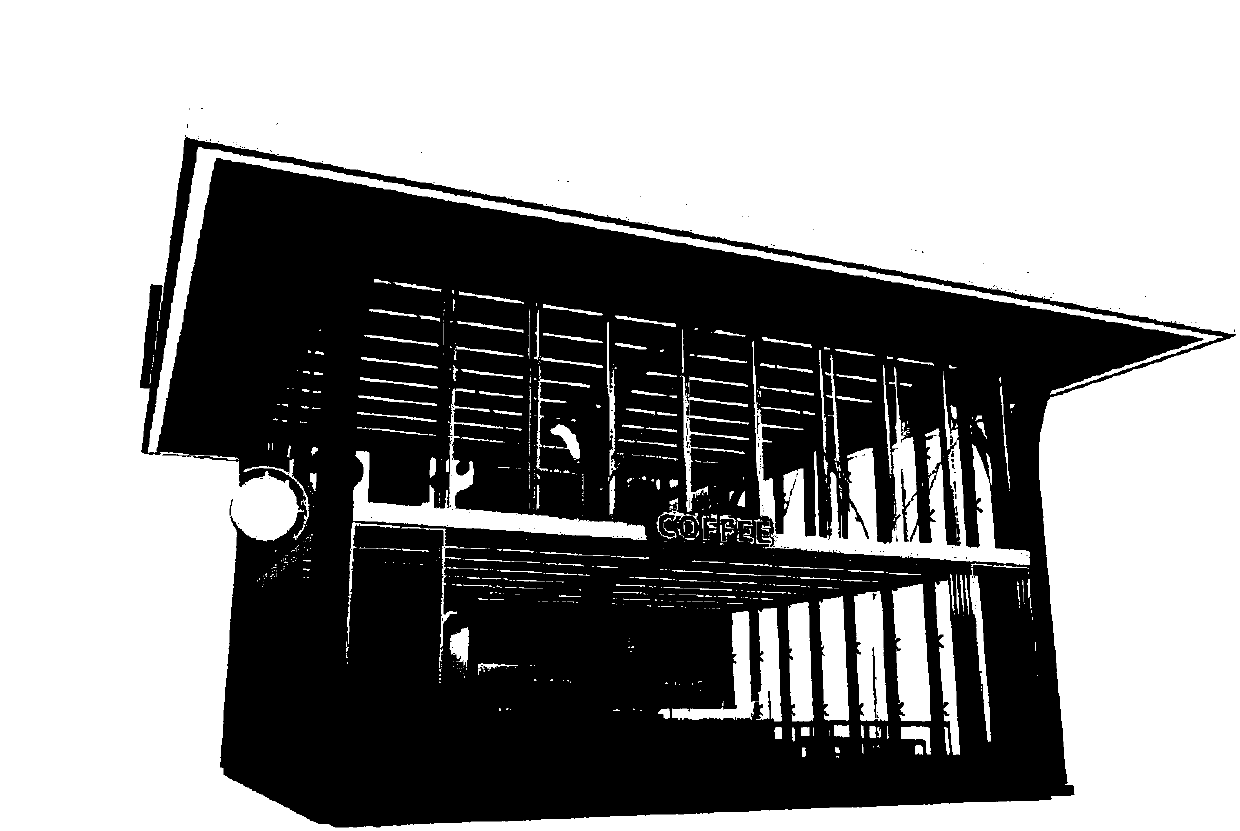

Ecological building with bamboo structure

InactiveCN107740494AAchieve lightweightIncrease profitBuilding constructionsModular designEngineering

The invention discloses an ecological building with a bamboo structure. The ecological building sequentially comprises a bamboo roof, bamboo transverse beams, bamboo vertical columns, bamboo wall bodies and a foundation from top to bottom. According to the building, the top ends of the bamboo vertical columns adopt diverging design, the bamboo vertical columns are connected with the bamboo transverse beams in a multi-point mode to support the bamboo transverse beams, and the defect that in a current environment-friendly building, typically, beam-column rigid joints are not allowed in wood structure design and bamboo structure design is made up. The ecological building with the bamboo structure has the advantages that light catching is good, heat preservation, energy saving and environmentfriendliness are achieved, and the stability is excellent; in the building process, modular design and manufacture are adopted, the building can be rapidly dismounted and built, the construction efficiency is high, the cost is saved, the ecological building is suitable for serving as a book bar of students in a school and also suitable for serving as a coffee shop, a supermarket and the like withgood landscapes at street corners, reliable ensuing is provided for the energy-saving and environment-friendly building, and the requirements of the various buildings can be met.

Owner:SHANGHAI ALTPLUS ENVIRONMENTAL TECH CO LTD

Method for producing concrete block from granulated blast furnace slag

The invention relates to a novel lightweight wall material, specifically to a method for producing concrete block from granulated blast furnace slag. The concrete block is composed of granulated blast furnace slag, cement, lime, gypsum powder, aluminum and water. According to the invention, the granulated blast furnace slag is used as a production raw material, so the problems of incapable handling and environmental pollution of a great amount of granulated blast furnace slag in metallurgical engineering, etc. are overcome, cyclic utilization of resources is realized, and production of the concrete block from the granulated blast furnace slag is beneficial for reduction of enterprise cost; moreover, the concrete block produced by using the method has high strength and light weight and can meet demands of buildings.

Owner:六盘水瑞都建材有限公司

Construction technique of static pressure treatment for ground base and pile foundation

InactiveCN1916295AIncrease frictionMeet building needsBulkheads/pilesSoil preservationSoil horizonEngineering

The present invention relates to a construction process capable of utilizing static pressure to treat ground base and pile foundation. It is characterized by that according to the design-required ground base treatment depth or pile length said construction process adopts the following steps: firstly, utilizing press-in pile driver with large tonnage to press the upright with pressure head into ground base earth so as to extrude the earth body around the pile hole and make said earth body be compacted and compact its lower earth layer, then drawing out said upright with pressure head, filling lime earth into the pile hole layer-by-layer, then using pressure head to make compaction layer-by-layer until the ground surface is made into ground base; or injecting grout material into the pile hole, solidifying and forming into pile.

Owner:毛心焰

Welding device for steel structure machining

InactiveCN114012299AIncrease productivityMeet the needs of follow-up engineering and constructionWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryManufacturing engineering

The invention discloses a welding device for steel structure machining. The welding device comprises blanking sliding barrels, mounting clamping rings, a limiting mechanism, a servo motor, a motor clamping seat, a guide device, a support gear, welding devices and a connecting weldment, wherein at least six groups of welding devices for welding are uniformly and fixedly mounted on the outer end surface of the guide device at equal intervals; the mounting clamping rings used for supporting are fixedly mounted on the upper end faces of the six welding devices, and six discharging sliding barrels used for guiding are evenly and fixedly connected to the positions, directly facing the welding devices, of the upper end faces of the mounting clamping rings at equal intervals. By arranging the guide device and the welding devices, during production, the servo motor can provide power for the limiting mechanism and the guide device through the support gear, and then the limiting mechanism and the guide device can automatically conduct feeding, welding and discharging operation on the connecting weldment; and therefore, the production efficiency of welding connecting weldment in batches by the device is improved to the greatest extent, and the requirements of subsequent engineering construction are met.

Owner:江俊

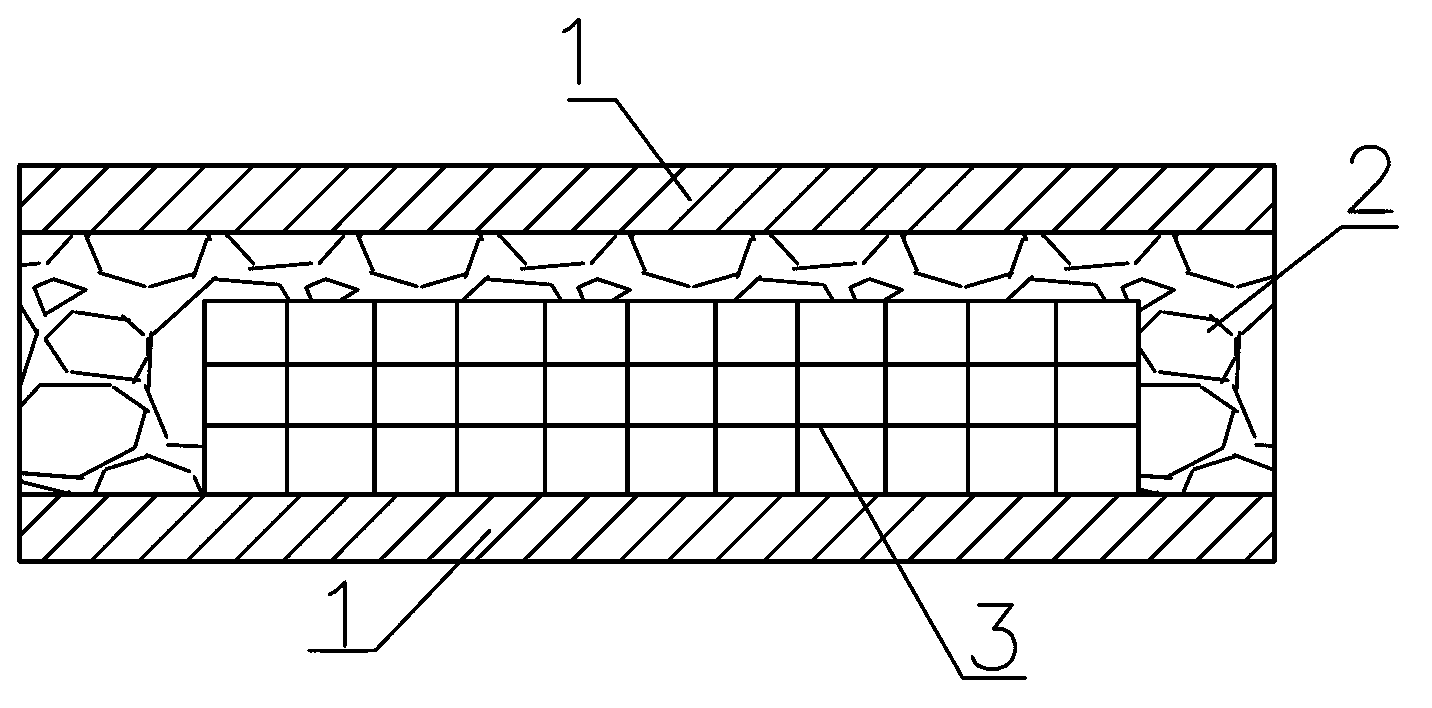

Metal faced sandwich composite board and manufacturing method thereof

InactiveCN101538912BLow costSimple designBuilding componentsMetal layered productsFoaming agentWork in process

The invention relates to a metal faced sandwich composite board and a manufacturing method thereof. The composite board comprises two metal panels and a sandwich layer arranged between the two metal face panels. The main body of the sandwich layer between two interfaces is a preformed core board and the parts of the sandwich layer at the two interfaces are polyurethane cores. The manufacturing method comprises the following steps: The upper and lower metal panels of the core board are compounded to obtain a semi-finished product of a composite board; the semi-finished product of a composite board is reserved with polyurethane foaming space positioned at the interfaces; polyurethane foaming agent is filled inside the polyurethane foaming space of the semi-finished product of a composite board; polyurethane core interfaces are formed after being formed and solidified. The main body of the sandwich layer is made from the core board, which reduces composite cost of the composite board, the joints are cured by the filled PU foaming agent, thus greatly improving strength, cohesive strength and filling saturation of the composite board joint based on a single EPS composite board, the joints are designed to be easily combined with actual engineering, and the composite board has high performance price ratio.

Owner:HENAN TIANFON ENERGY SAVING PANEL SCI & TECH

High-strength light-weight environment-friendly building material and preparation method thereof

The invention provides a high-strength light-weight environment-friendly building material and a preparation method thereof, relating to the field of novel environment-friendly building materials. Thehigh-strength light-weight environment-friendly building material is prepared from the following raw materials: building sand, low-alkalinity cement, polystyrene , sulphoaluminate, wollastonite, light-weight magnesium oxide, expanded perlite, light-weight ceramics, nano silicon dioxide, hydroxypropyl methyl cellulose, calcium formate, glass fiber, wood fiber, polyester fiber, honeycomb bamboo charcoal fiber, a high temperature resistant binder, a magnesium chloride aqueous solution, a foaming agent, a water reducing agent and water. The environment-friendly building material prepared by the invention is good in fire resistance, light in weight, good in heat preservation effect, energy-saving, environment-friendly, easy to prepare, convenient to construct, compact in texture and good in thermal insulation and sound insulation effects, and can simultaneously meet the building needs of exterior walls and interior walls, thereby having broad market prospects.

Owner:淄博正邦知识产权企划有限公司

Wall framework

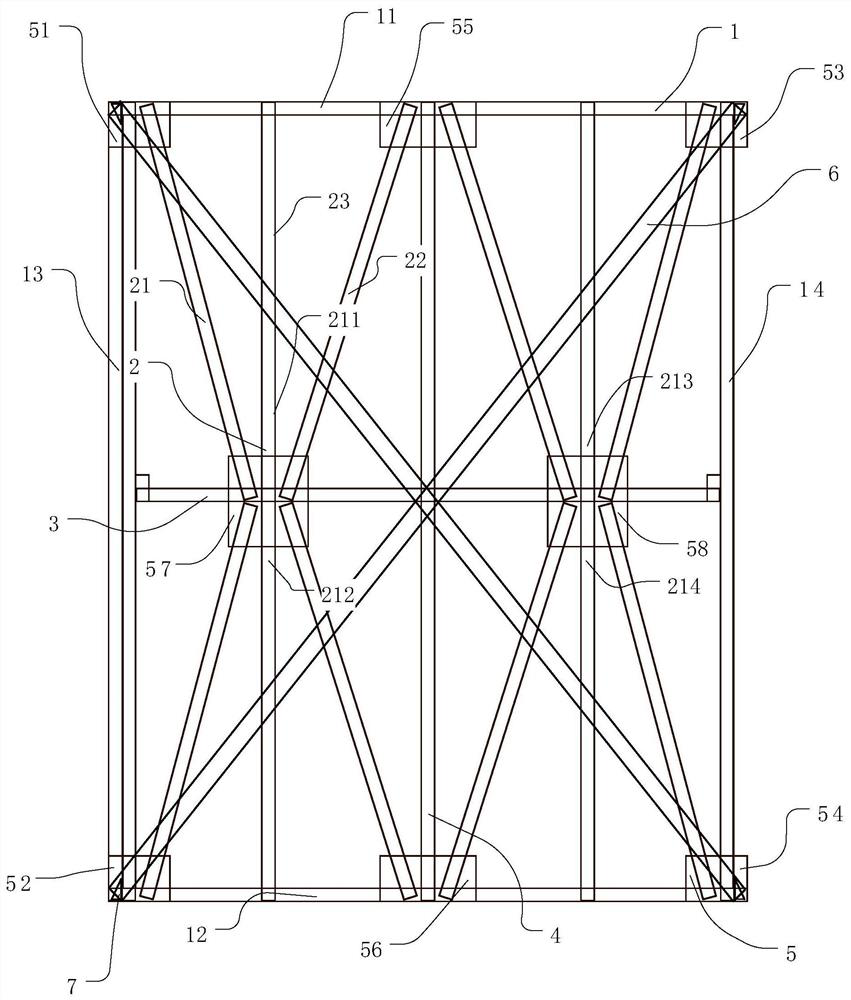

PendingCN113605564AImprove seismic performanceImprove wind resistanceWallsSupport planeCivil engineering

The invention relates to a wall framework. The wall framework comprises a first wall framework body. The first wall framework body comprises a W-shaped framework set and a frame connected with the W-shaped framework set. The W-shaped framework set is fixedly connected with the frame. The frame comprises a first guide rail, a second guide rail, a first stand column and a second stand column. The first guide rail, the first stand column, the second guide rail and the second stand column are sequentially and fixedly connected to form the frame. The W-shaped framework set comprises at least one W-shaped framework. Each W-shaped framework comprises a first inclined strut support, a second inclined strut support and a first supporting frame. The first end of each first inclined strut support is fixedly connected with the frame. The first end of each second inclined strut support is fixedly connected with the frame. The first end of each first supporting frame is fixed to the frame. The second end of each first inclined strut support, the second end of each second inclined strut support and the second end of the corresponding first supporting frame are fixedly connected and connected with the frame. By means of the wall framework, the horizontal bearing capacity and the lateral load bearing capacity of a wall are greatly improved through structural improvement.

Owner:北新国际木业有限公司

Detachable prefabricated wall mold

ActiveCN108044773AAddress length requirementsMeet architectural needs for wall lengthsMouldsMould fastening meansEconomic benefitsSteel plates

The invention relates to a detachable prefabricated wall mold. The detachable prefabricated wall mold comprises a first module, a second module, a third module and a fourth module which are assembledtogether through positioning pins and bolts, and fixed on a workbench so as to form the detachable prefabricated wall mold, wherein a crack is left among the first, second, third and fourth modules after the assembly; a water-stop steel plate is mounted in the crack; through three positioning blocks welded onto the third module, the first, second, third and fourth modules are positioned and connected with the water-stop steel plate; each of the first, second, third and fourth modules is formed by welding an upper horizontal plate, a lower horizontal plate and rib plates arranged on two sides;and reinforcing rib plates are welded into the second and third modules along the vertical direction. By adoption of the detachable prefabricated wall mold provided by the invention, the constructionrequirements for various wall length specifications can be met; the problem that the length of a conventional mold can be modified only through cutting can be solved; a lot of steel and manpower can be saved; the construction period can be shortened; and greater economic benefits can be achieved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

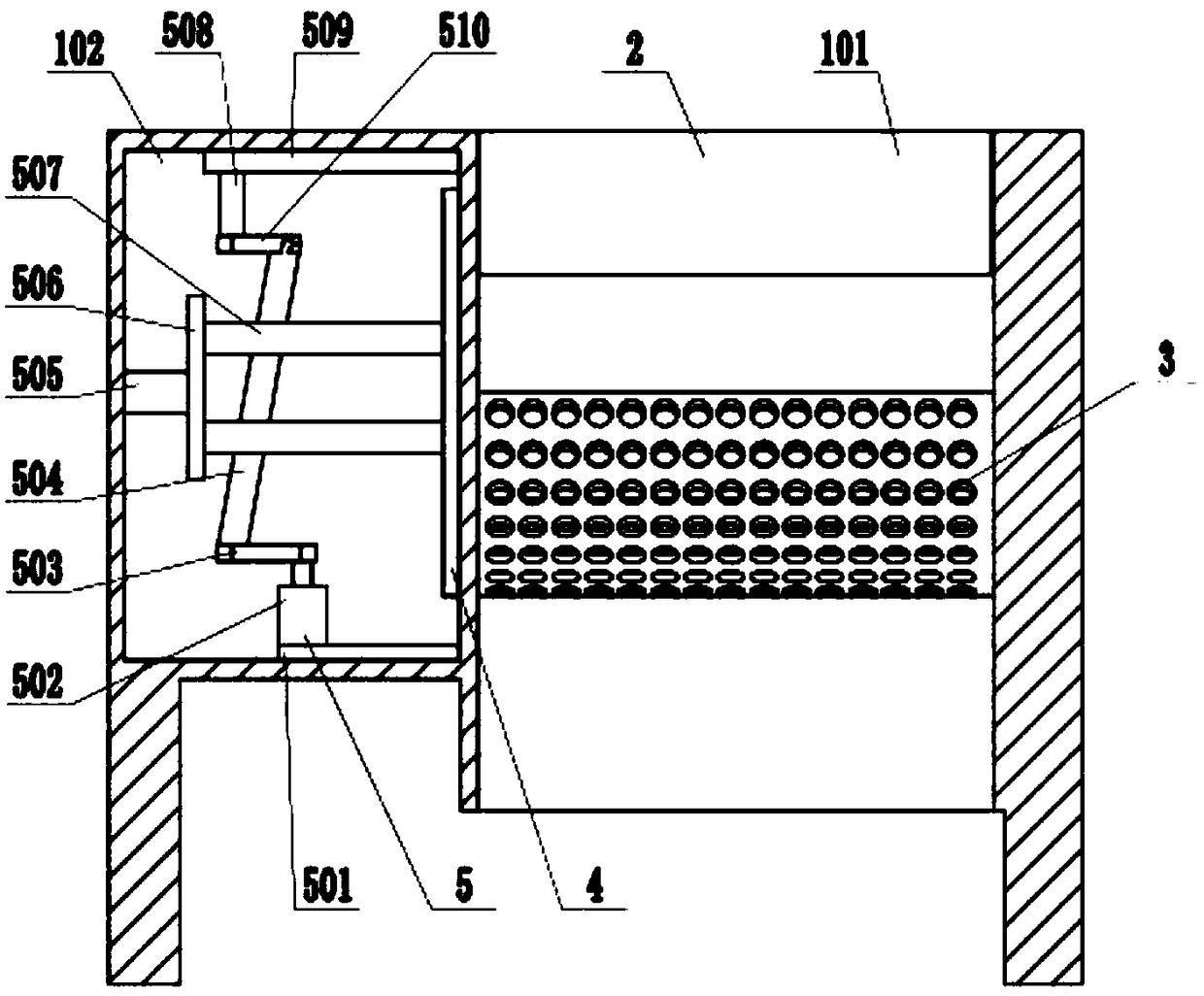

Concrete pouring hopper for building construction

ActiveCN110130645BMeet building needsEasy to cleanBuilding material handlingRotational axisArchitectural engineering

A concrete pouring hopper for building construction, the invention relates to the technical field of construction equipment; the four corners of the upper surface of the base are connected with uprights, and the tops of the uprights are connected and fixed with the four corners of the top plate; There are horizontal plates connected between them; a hopper is arranged between the horizontal plates on the left and right sides, and the hopper rotating shaft is fixed on the left and right side walls of the hopper, and the outer ends of the hopper rotating shafts on the left and right sides are respectively screwed to the left and right sides through bearings. Among the horizontal plates on both sides, the outer end of the hopper rotating shaft on the left passes through the left horizontal plate, and is connected and fixed with the rotating handle. A positioning pin is inserted on the rotating handle, and the inner end of the positioning pin is detachable. Inserted in the left cross plate. Its discharge can be adjusted, which greatly increases its scope of application and meets the needs of multi-structure buildings. At the same time, it can also facilitate cleaning, improve construction progress, and have stronger practicability.

Owner:宝鸡二建集团有限公司

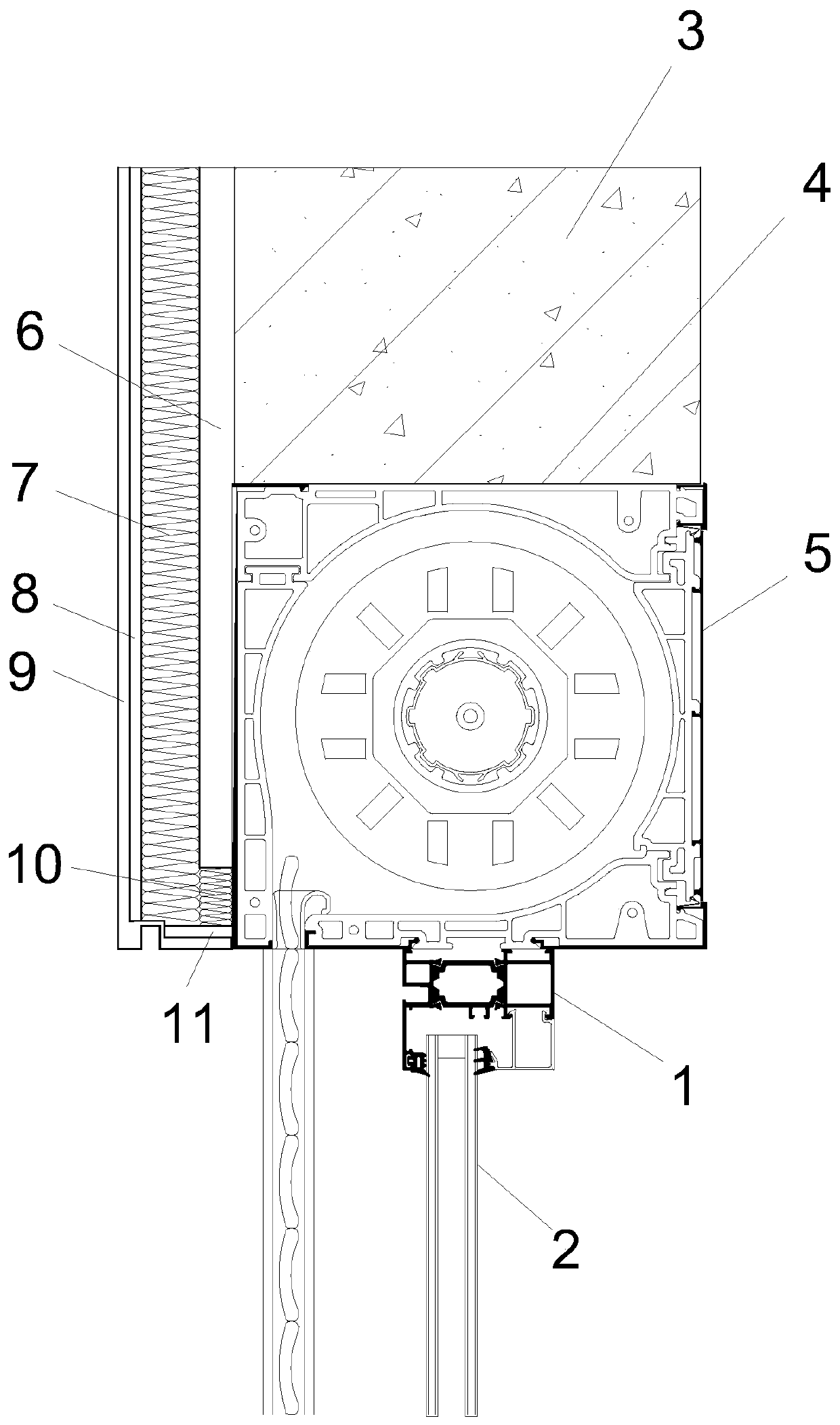

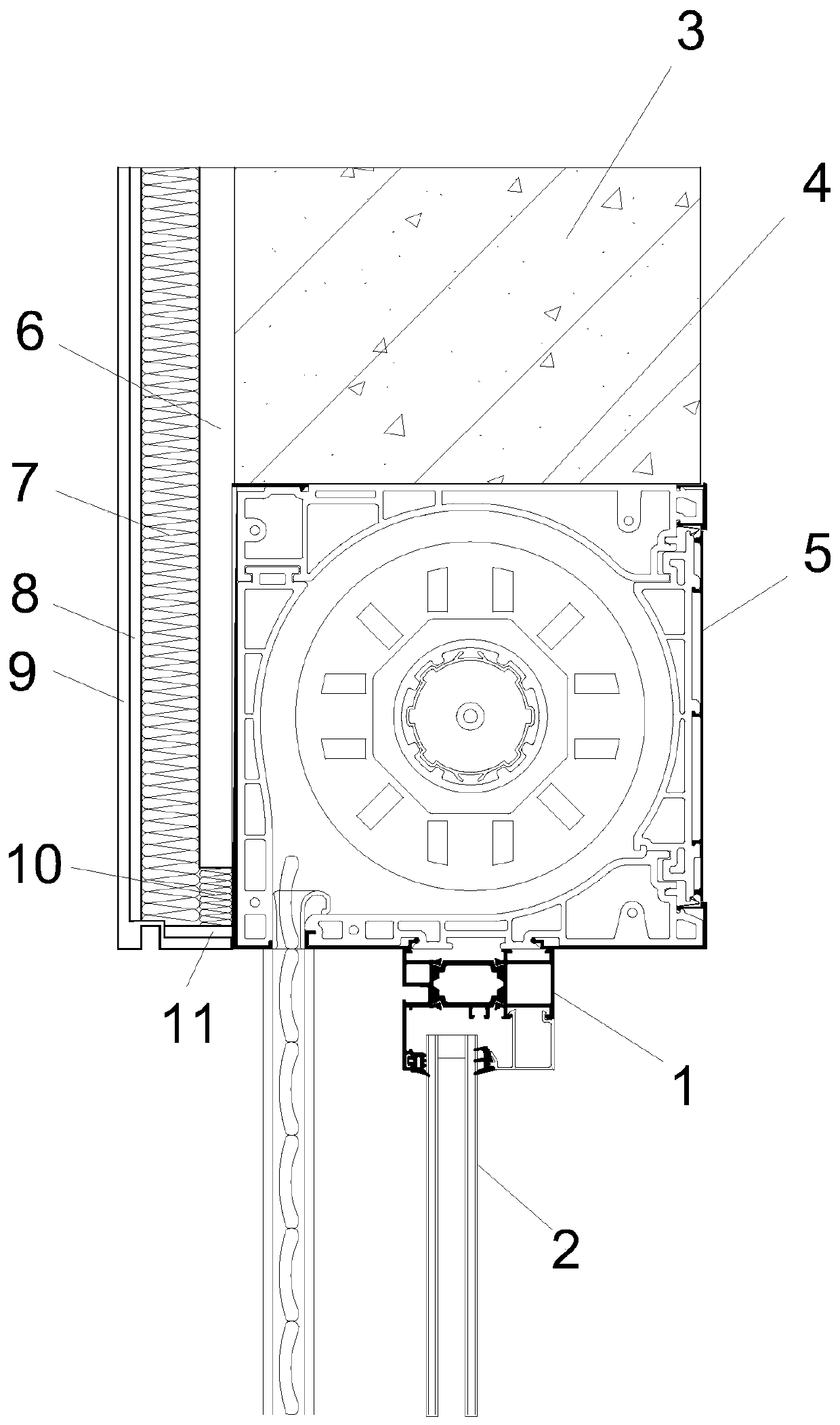

Door window provided with sunshade curtain

PendingCN111119714AImprove insulation effectAvoid replacementCovering/liningsLight protection screensEngineeringStructural engineering

The invention relates to the technical field of doors and windows, in particular to a door window provided with a sunshade curtain. The door window comprises a window frame and a sunshade curtain boxbody, wherein the window frame is provided with glass; the window frame is arranged inside a door window hole of a wall body; the sunshade curtain box body is arranged over the window frame and is fixedly connected with the top surface of the door window hole; and the lower end face of the sunshade curtain box body is fixedly connected with the upper end face of the window frame through a screw. According to the door window provided with the sunshade curtain provided by the embodiment of the invention, the sunshade curtain box body is arranged at the top of the door window hole and is fixedlyconnected to the position over the window frame, therefore replacement and maintenance, outside a building, of a roller shutter and a motor are prevented; and thus the construction risks are reduced.

Owner:浙江绿城建筑幕墙工程有限公司

Gypsum-based building mortar and preparation method thereof

The invention relates to the technical field of building mortar, in particular to gypsum-based building mortar and a preparation method thereof. The mortar comprises an aggregate A, an auxiliary material B, an emulsion C and a flavoring liquid D. Gypsum is selected as a main processing raw material and is prepared into the aggregate A, so that the cohesiveness and strength of the finished mortar are effectively improved; various kinds of soil are selected to be processed into an auxiliary material B, the auxiliary material B is mixed into the aggregate, large gaps exist between molecules of the auxiliary material, effective components of the aggregate, the emulsified liquid and the flavoring liquid can be effectively wrapped, the cohesiveness of the finished mortar is improved, and meanwhile because of addition of soil auxiliary materials, the fluidity of the finished mortar is effectively improved; furthermore, the emulsion C is added, so that the finished product mortar is smoother,but the cohesiveness is very strong, and the finished product mortar is not easy to adhere to a bricklaying tool; finally, by adding the flavoring liquid D, the smell of the finished product mortar iseffectively improved, and the original pungent smell is weakened, so that the finished product mortar has light grass fragrance, and meets building requirements of people.

Owner:贵州中能高新材料有限公司

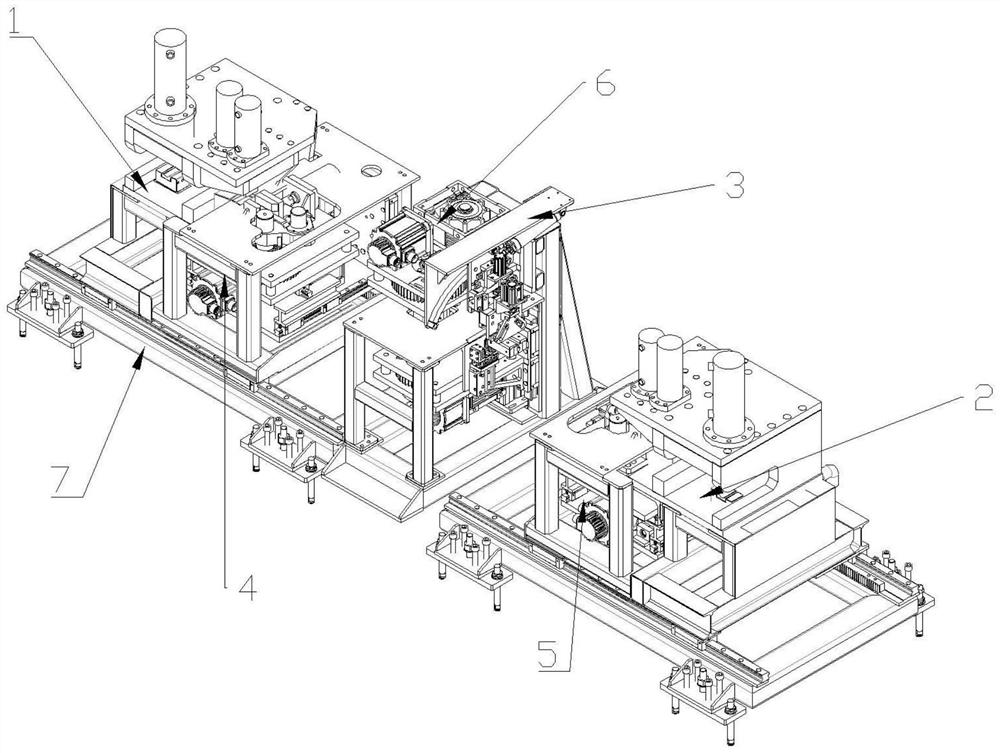

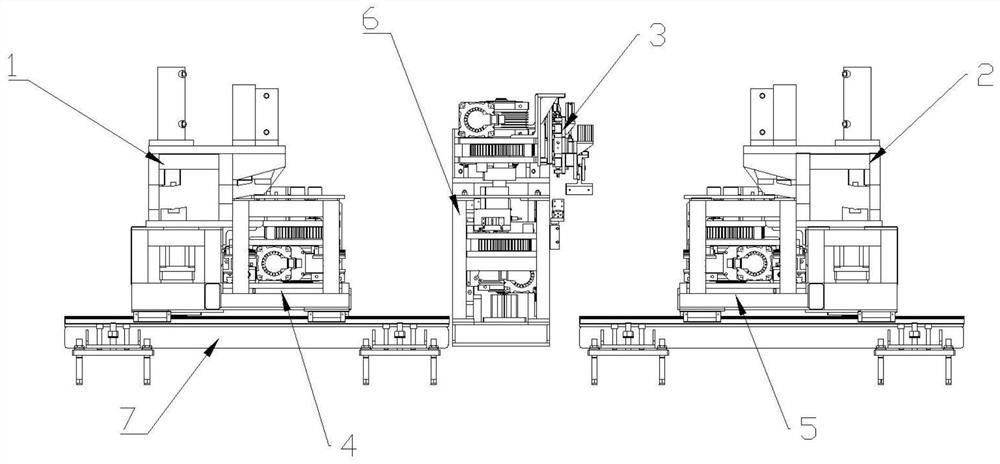

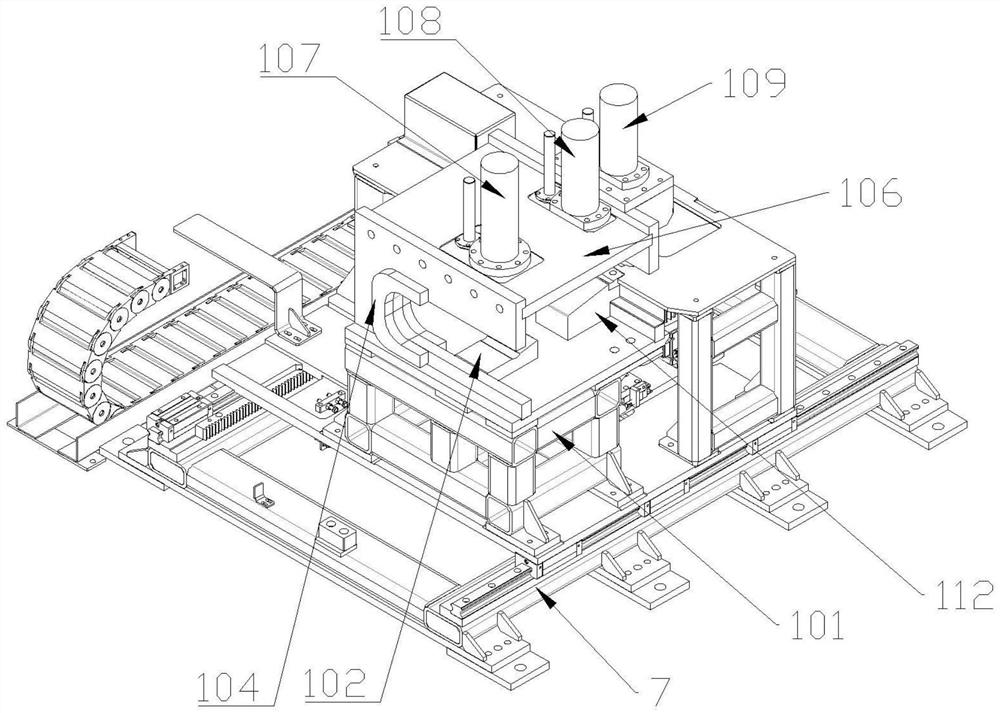

Steel bar bending forming machine and bending forming method

The invention relates to a steel bar bending forming machine and a bending forming method. The steel bar bending forming machine comprises a steel bar clamping and bending device, a left steel bar profiling device and a right steel bar profiling device, wherein the left steel bar profiling device and the right steel bar profiling device are arranged on the two sides of the steel bar clamping and bending device correspondingly; the steel bar bending forming machine further comprises a steel bar clamping rotating displacement device, a left four-axis bending device and a right four-axis bending device; the left steel bar profiling device and the right steel bar profiling device are oppositely arranged; the left four-axis bending device and the right four-axis bending device are oppositely arranged; the steel bar clamping rotating displacement device is arranged on the steel bar clamping and bending device; and a steel bar enters the left steel bar profiling device and the right steel bar profiling device to form first bending, then enters a steel bar clamping rotating mechanism to rotate by an angle, then enters the left four-axis bending device and the right four-axis bending device to form second bending, and finally is folded, bent and formed through the steel bar clamping and bending device. According to the steel bar bending forming machine and the bending forming method, multiple times of bending forming of longitudinal bars in a steel bar cage are automatically achieved, labor is saved, and the work efficiency is improved.

Owner:RBS PARTNERS S&T CO LTD

Technology for preparing top-quality yellow sand and correlative derivative, and device thereof

InactiveCN103319106AReduce manufacturing costReduce labor costsEcological environmentProcess engineering

The invention discloses a device for preparing top-quality yellow sand and correlative derivatives, comprising a channel, a NO.1 processing field, a NO.2 pool and a NO.3 pool, and further comprising a NO.4 sedimentation basin, a NO.5 sedimentation basin and a NO.6 sedimentation basin which are orderly connected and arranged, wherein a NO.7 pool and a NO.8 pool which are connected by a channel are arranged near the NO.6 pool. The invention further discloses a technology for extracting top-quality yellow sand by the device and preparing correlative derivatives. The technology and the device have advantages of low cost and high efficiency, and prepared yellow sand has high quality, and accords with a demand of building quality. And simultaneously, organic mud obtained in a yellow sand preparing process is utilized, thereby protecting ecological environment, and benefiting for long-term and health development.

Owner:浙江红佳吉管道科技有限公司

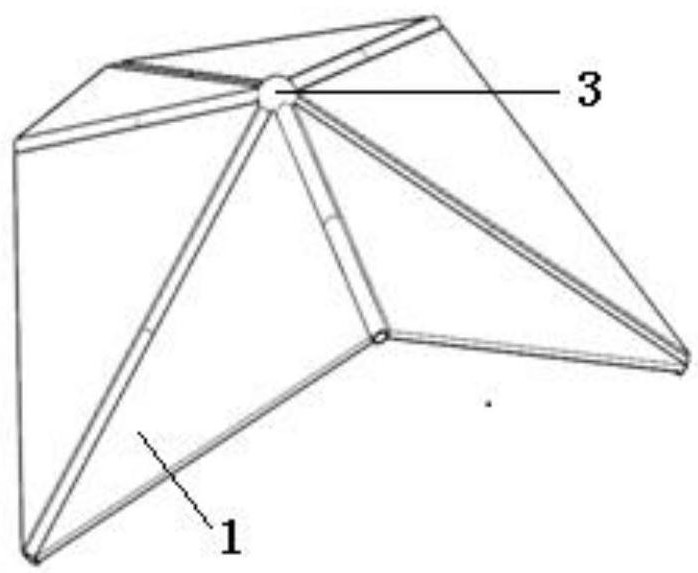

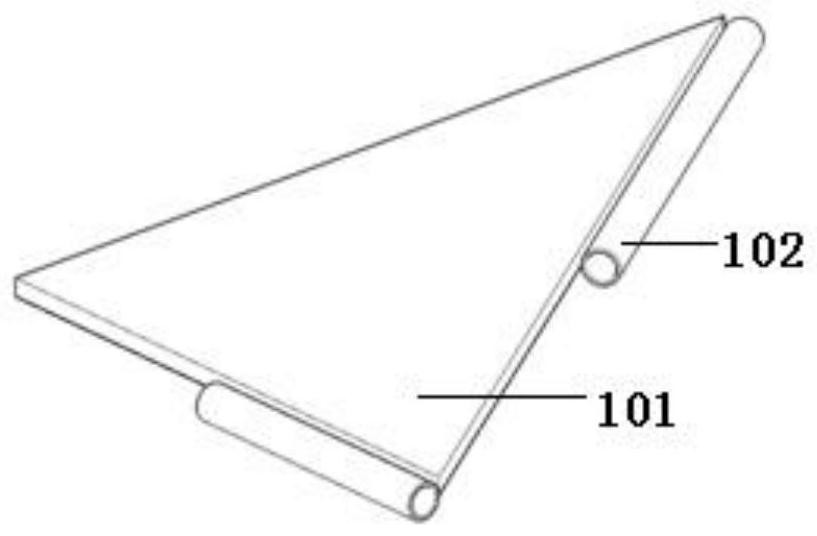

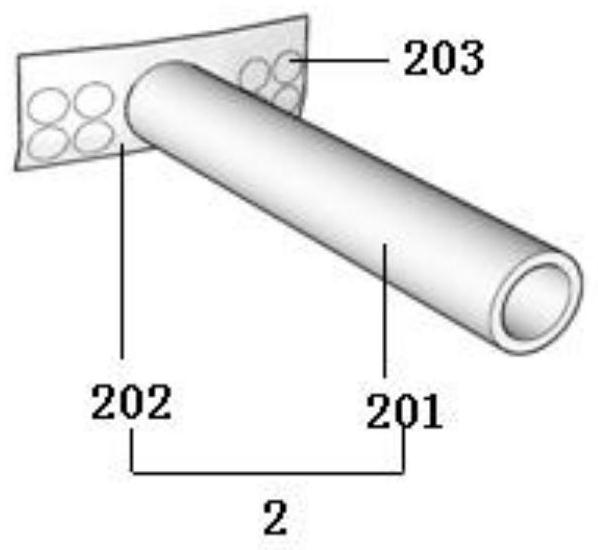

Novel parameterized deformable unit body and building structure

ActiveCN113958002ARealize free assemblyAchieve foldingExtraordinary structuresButt jointClassical mechanics

The invention relates to the technical field of buildings, and particularly relates to a novel parameterized deformable unit body and a building structure. The novel parameterized deformable unit body comprises a plurality of unit body parameterized plates, a plurality of rotary connecting shafts and a spherical hinge point, wherein the unit body parameterized plates are arranged around the spherical hinge point; each unit body parameterized plate comprises a triangular plate and two hollow pipes; the two hollow pipes are fixed on two sides of the triangular plate respectively; the two hollow pipes on one sides, which are in butt joint with each other, of two adjacent triangular plates are coaxial; the rotary connecting shafts penetrate through the hollow pipes on the two adjacent triangular plates to rotatably connect the triangular plates in series; one end of each rotary connecting shaft is detachably and fixedly connected with the spherical hinge point. The invention provides the novel parameterized deformable unit body which can deform and is convenient and quick to disassemble and assemble, and the building structure which is formed by combining a plurality of groups of unit bodies.

Owner:JINLING INST OF TECH

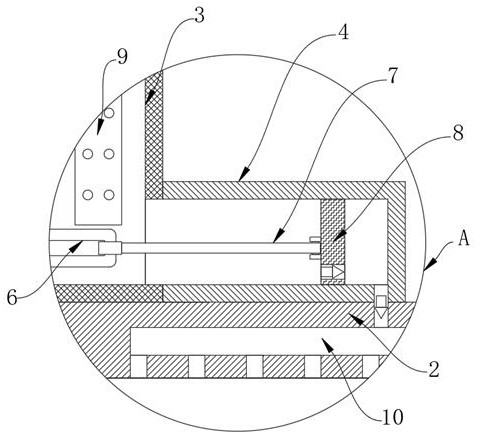

Concrete preparation method capable of prolonging concrete setting time

InactiveCN113354353AProlong clotting timeClotting time variesMaterial strength using repeated/pulsating forcesCement mixing apparatusPortland cementCrushed stone

The invention discloses a concrete preparation method capable of prolonging concrete setting time. The concrete preparation method capable of prolonging the concrete setting time comprises the following steps: S1, preparing materials: 700KG of broken stone, 800KG of washed sand, 400KG of Portland cement, 10KG of an efficient retarder and 150KG of water, and S2, mixing: sequentially adding the broken stone, the washed sand, the Portland cement, the efficient retarder and the water in the step S1 into concrete stirring equipment, and stirring for 20 minutes. According to the concrete preparation method capable of prolonging the concrete setting time, through a rotating rod, a pressurizing box, a piston, a water through hole, a water conveying hole, a water diversion cavity and a water outlet hole, a mixed solution of water and an efficient retarder can conveniently flow into a stirring machine body, the efficient retarder and concrete are fully mixed, and the phenomenon that the concrete setting time is different due to non-uniform mixing of the efficient retarder isavoided; and through the efficient retarder, the concrete setting time can be effectively prolonged, so that the building requirements are met, and the problem that the concrete setting time is short is solved.

Owner:福建新华夏建工集团有限公司

Construction process of high-strength beam columns coated with fast growing poplars out of thin-walled cold-formed steel

PendingCN110843066AMeet building needsHigh strengthWood treatment detailsWood impregnation detailsThin walledManufacturing engineering

The invention belongs to the field of fast growing poplar application equipment, and in particular, relates to a construction process of high-strength beam columns coated with fast growing poplars outof thin-walled cold-formed steel. The construction process comprises effective steps of material selection, cutting, airing, modification, drying, dipping, welding, combination and curing. Compared with the prior art, the construction process of the high-strength beam columns coated with the fast growing poplars out of the thin-walled cold-formed steel has the advantages and beneficial effects that the thin-walled cold-formed steel is effectively matched with the fast growing poplars to form high-strength and high-toughness beam columns to meet building demands.

Owner:SHANDONG JIANZHU UNIV

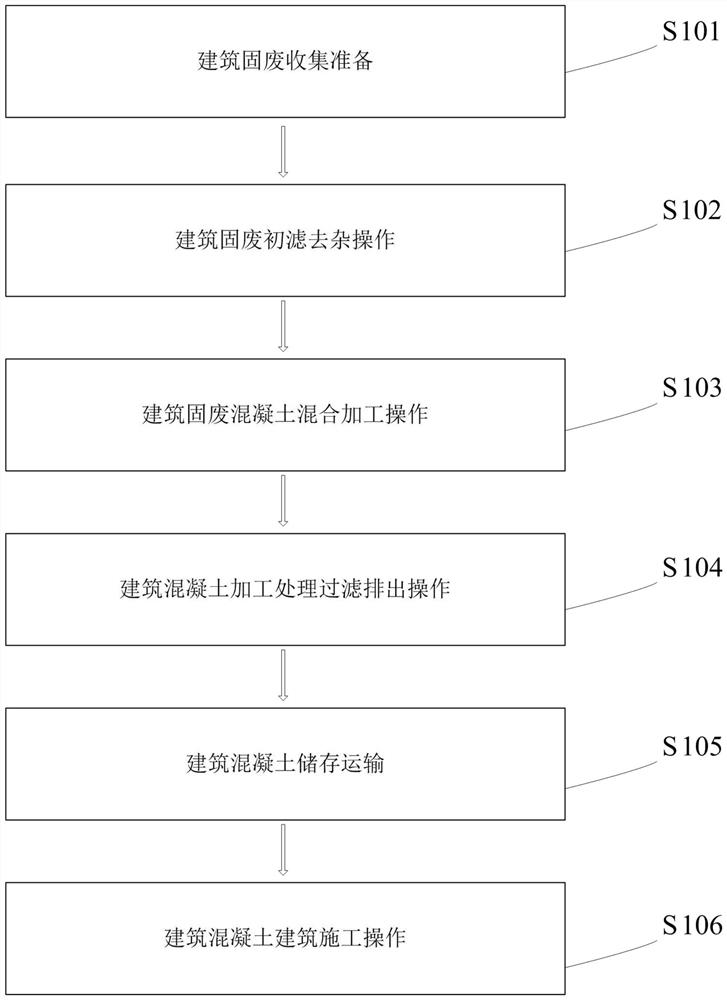

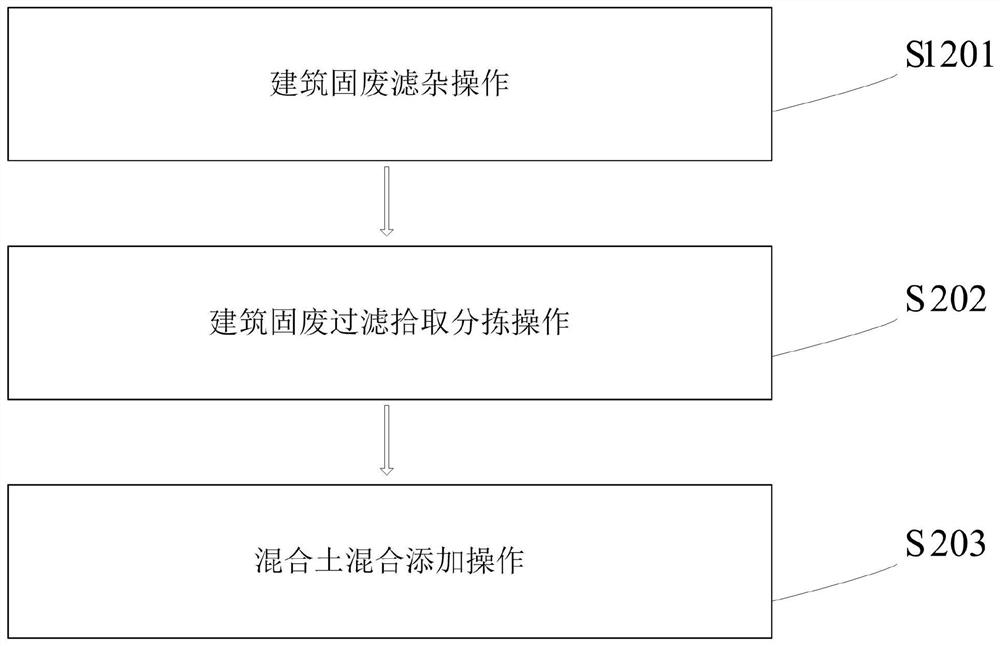

Method for manufacturing concrete by using building solid waste

PendingCN113276278AGuaranteed firmnessEasy to pourSievingScreeningEnvironmental geologySolid waste collection

The invention provides a method for manufacturing concrete by using building solid waste, and belongs to the field of building solid waste reutilization. The method for manufacturing concrete by using the building solid waste comprises the following specific steps of building solid waste collection preparation, building solid waste primary filtration and impurity removal operation, building solid waste and concrete mixing processing operation, building concrete processing, filtering and discharging operation, building concrete storage and transportation and building concrete construction operation. The method is mature in process and suitable for manufacturing a large amount of concrete, it is guaranteed that the processed concrete is smoother through treatment of the adsorption and filtration procedures, pouring or laying is convenient, operation is convenient, the concrete processing effect is guaranteed through stirring and mixing, the concrete processing stability is guaranteed through subsequent filtration, further, concrete construction stability is guaranteed, building firmness is guaranteed, the concrete can be laid or used for other buildings, and building requirements are met.

Owner:SHANDONG JIAOTONG UNIV

Removable precast wall mold

ActiveCN108044773BAddress length requirementsMeet architectural needs for wall lengthsMouldsMould fastening meansEconomic benefitsStructural engineering

The invention relates to a detachable prefabricated wall mold. The detachable prefabricated wall mold comprises a first module, a second module, a third module and a fourth module which are assembledtogether through positioning pins and bolts, and fixed on a workbench so as to form the detachable prefabricated wall mold, wherein a crack is left among the first, second, third and fourth modules after the assembly; a water-stop steel plate is mounted in the crack; through three positioning blocks welded onto the third module, the first, second, third and fourth modules are positioned and connected with the water-stop steel plate; each of the first, second, third and fourth modules is formed by welding an upper horizontal plate, a lower horizontal plate and rib plates arranged on two sides;and reinforcing rib plates are welded into the second and third modules along the vertical direction. By adoption of the detachable prefabricated wall mold provided by the invention, the constructionrequirements for various wall length specifications can be met; the problem that the length of a conventional mold can be modified only through cutting can be solved; a lot of steel and manpower can be saved; the construction period can be shortened; and greater economic benefits can be achieved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com