Steel bar bending forming machine and bending forming method

A bending forming and forming machine technology, which is applied in the field of steel bending forming machines and bending forming, can solve the problems of high labor intensity and low work efficiency, and achieve the effects of saving labor, improving work efficiency and meeting construction needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

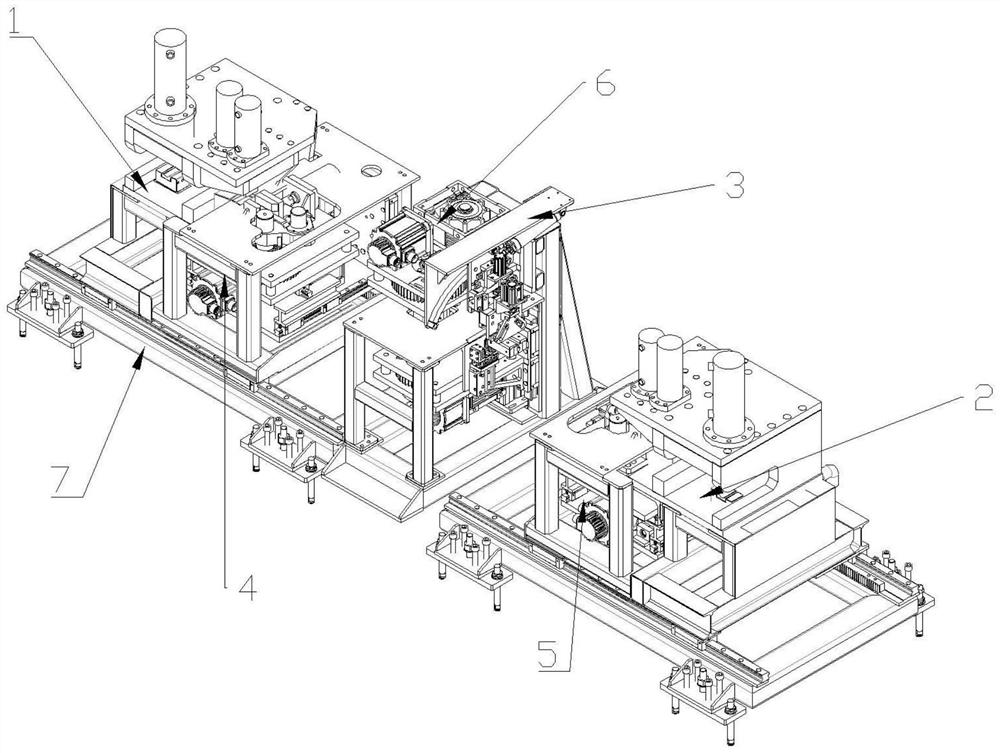

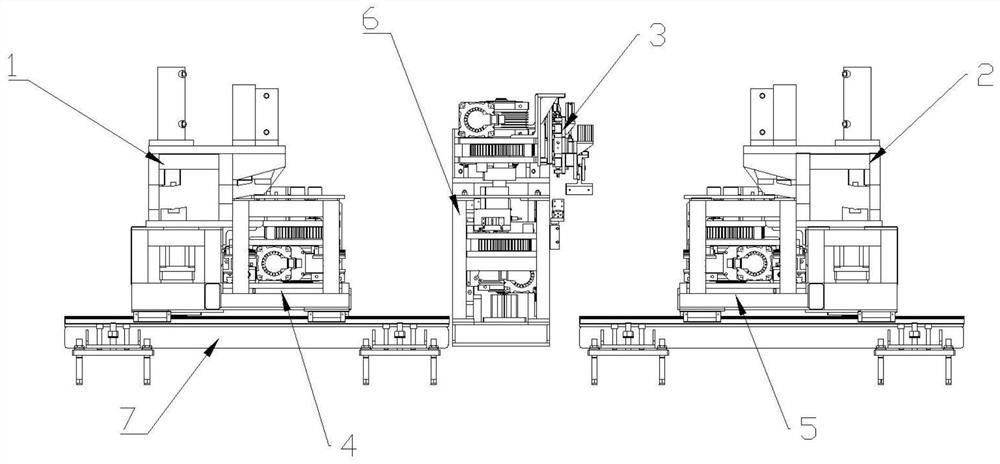

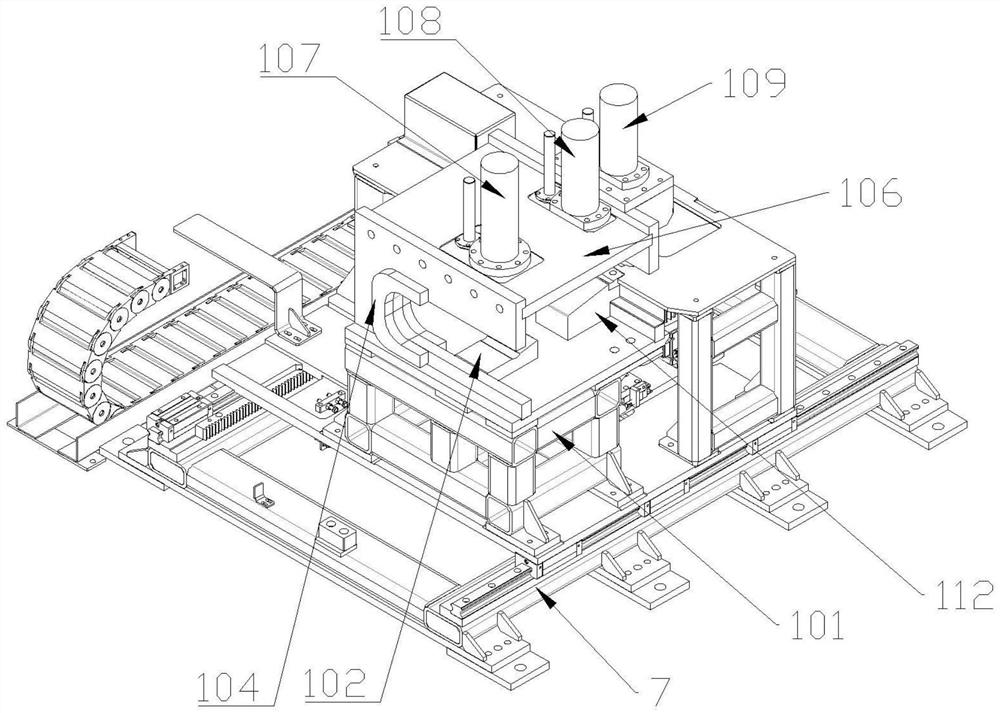

[0040] The following will combine Figure 1-14 The present invention is described in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0041] A steel bar bending forming machine, which includes a steel bar clamping and bending device 6, a left steel bar profiling device 1 and a right steel bar profiling device 2 respectively arranged on both sides of the steel bar clamping and bending device, and also includes The steel bar clamping and rotating displacement device 3, the left four-axis bending device 4 and the right four-axis bending device 5, the left steel bar profiling device and the right steel bar profiling device are arranged oppositely, and the left four-axis bending device The axial bending device and the right four-axis bending device are arranged oppositely, and the left four-axis bending device and the right four-axis bending device are located on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com