Concrete preparation method capable of prolonging concrete setting time

A technology of setting time and concrete, which is applied in the direction of clay preparation equipment, chemical instruments and methods, and the use of repeated force/pulsation force to test the strength of materials, etc., which can solve the problems of long pouring time, concrete setting, and affecting the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

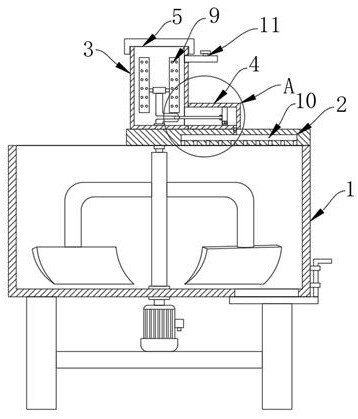

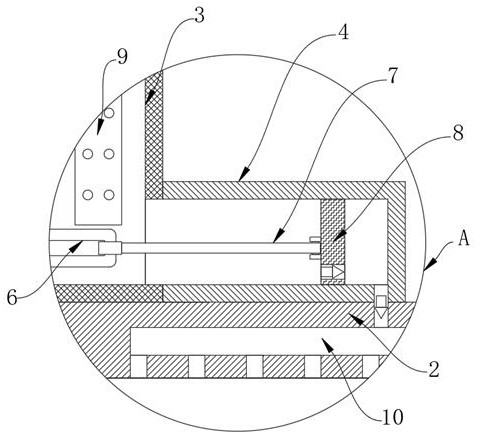

[0024] refer to Figure 1-2 , a kind of concrete preparation method that can prolong concrete setting time, the concrete preparation that can prolong concrete setting time comprises the following steps:

[0025] S1. Ingredients: gravel 700KG, washed sand 800KG, Portland cement 400KG, high-efficiency retarder 10KG and water 150KG.

[0026] S2. Mixing: add the crushed stone, washed sand portland cement, high-efficiency retarder and water in step S1 into the concrete mixing equipment and mix for 20 minutes to obtain a concrete product with prolonged concrete setting time.

[0027] S3. Detection: first time the setting time of the concrete, and after the concrete is completely set, use a testing instrument to detect the strength of the concrete.

[0028] The concrete preparation method capable of prolonging the concrete setting time can effectively prolong the concrete setting time by setting a high-efficiency retarder, so as to meet building construction requirements and solve t...

Embodiment 2

[0033] The difference from Example 1 is that 4KG of polycarboxylate superplasticizer is added during the batching process, and the high-efficiency retarder is removed, and then step S2 is mixed and step S3 is tested.

Embodiment 3

[0035] The difference from Example 1 is that 4KG of polycarboxylate superplasticizer and 10KG of high-efficiency retarder are added at the same time during the batching process, and then step S2 is mixed and step S3 is tested.

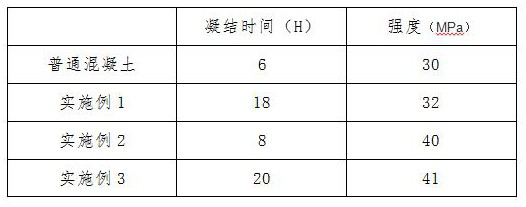

[0036] After the concrete is completely set, use the Q61 concrete strength tester to test the strength of the concrete in Example 1, Example 2 and Example 3 according to the provisions of GB50010-2010 "Code for Design of Concrete Structures", and get Table 1:

[0037]

[0038] Table 1

[0039] Working principle: When it is necessary to use the concrete preparation method that prolongs the concrete setting time, first add crushed stone and washed sand to the mixing tank of the mixer body 1 in proportion, and then add the high-efficiency retarder in the proportion to the mixing tank 3, And use the water inlet pipe 11 to connect the water source, and then make the mixer body 1 work. During the working process of the mixer body 1, the stirring shaft dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com