Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Little irregularity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

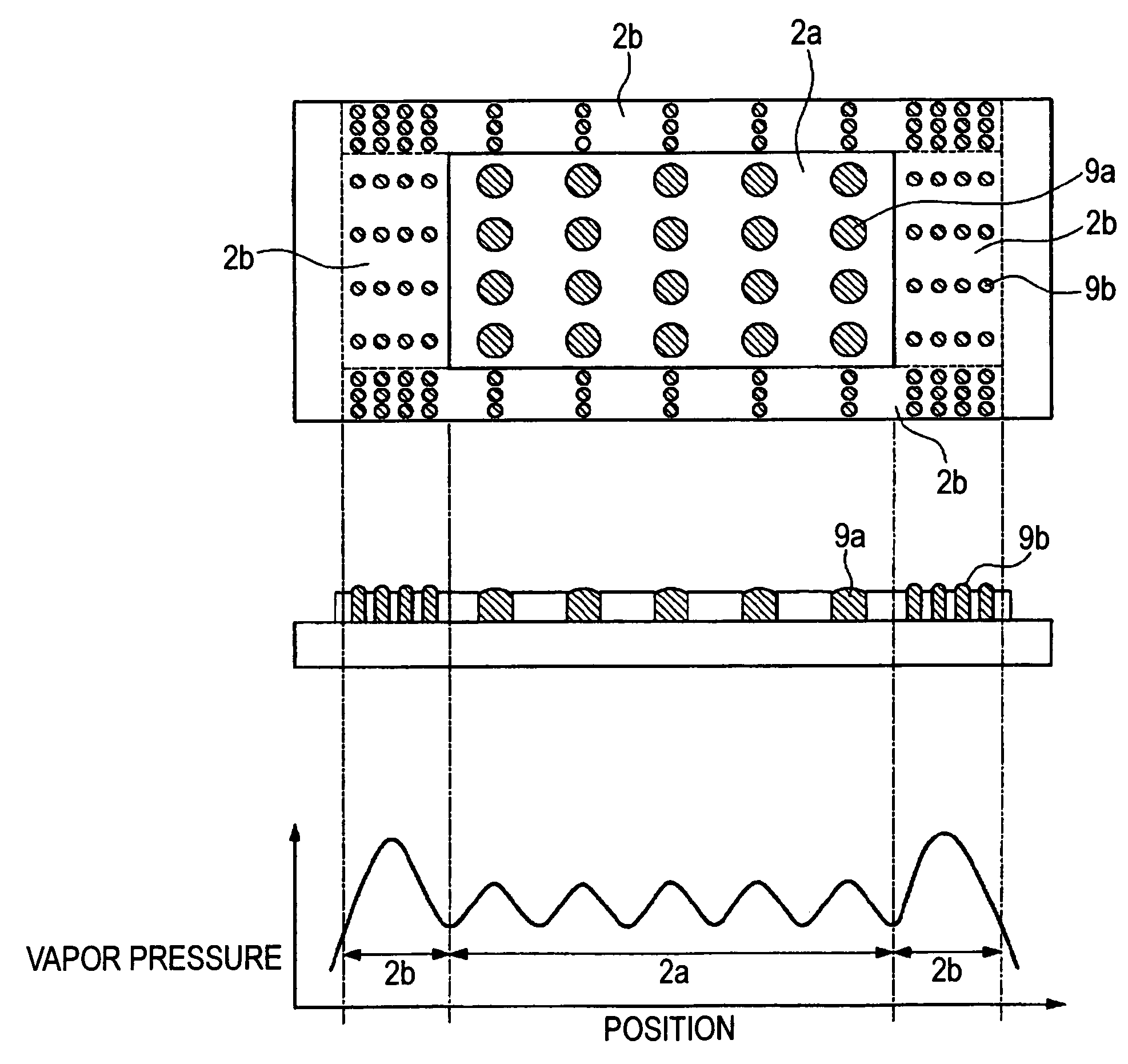

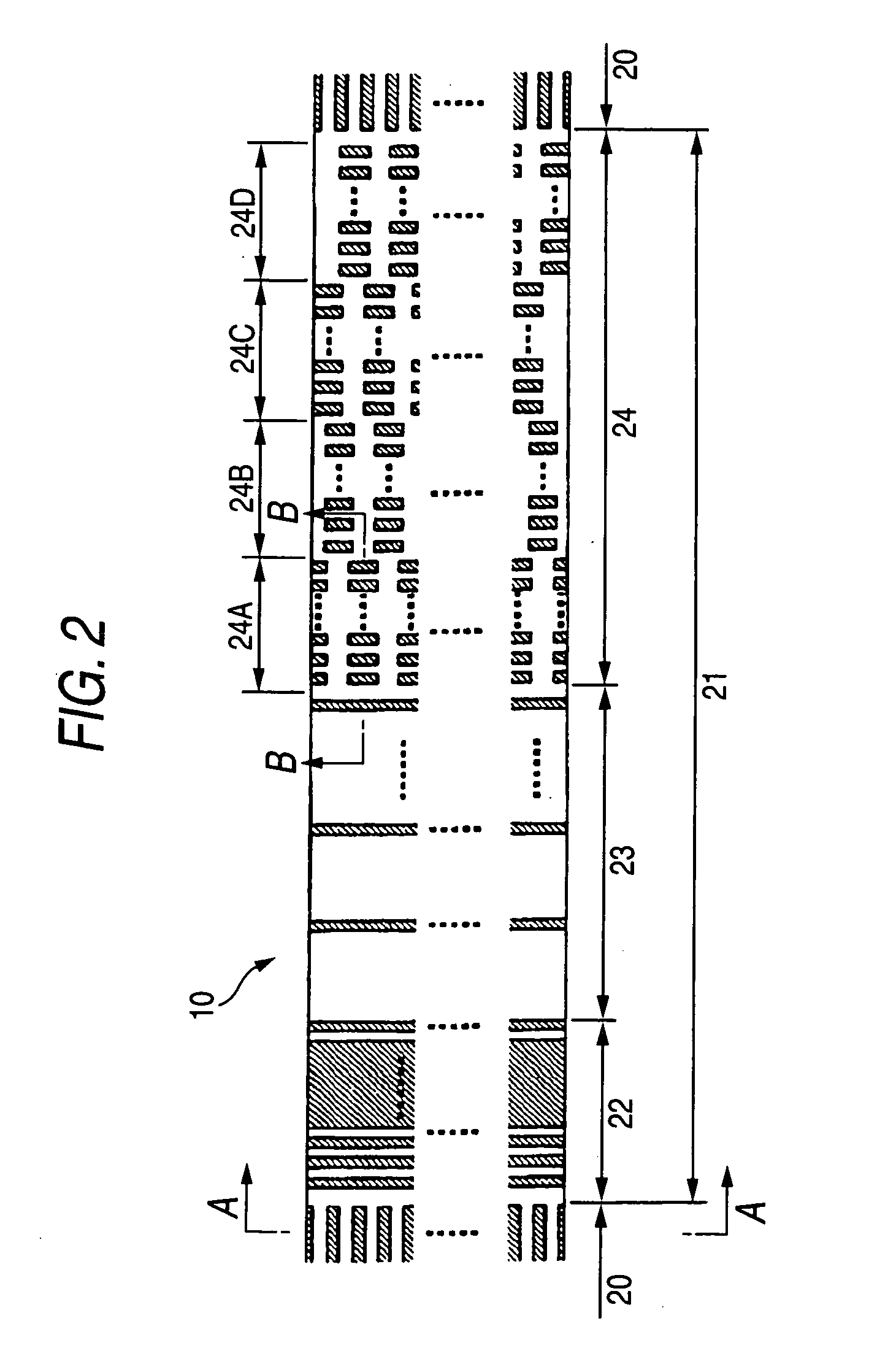

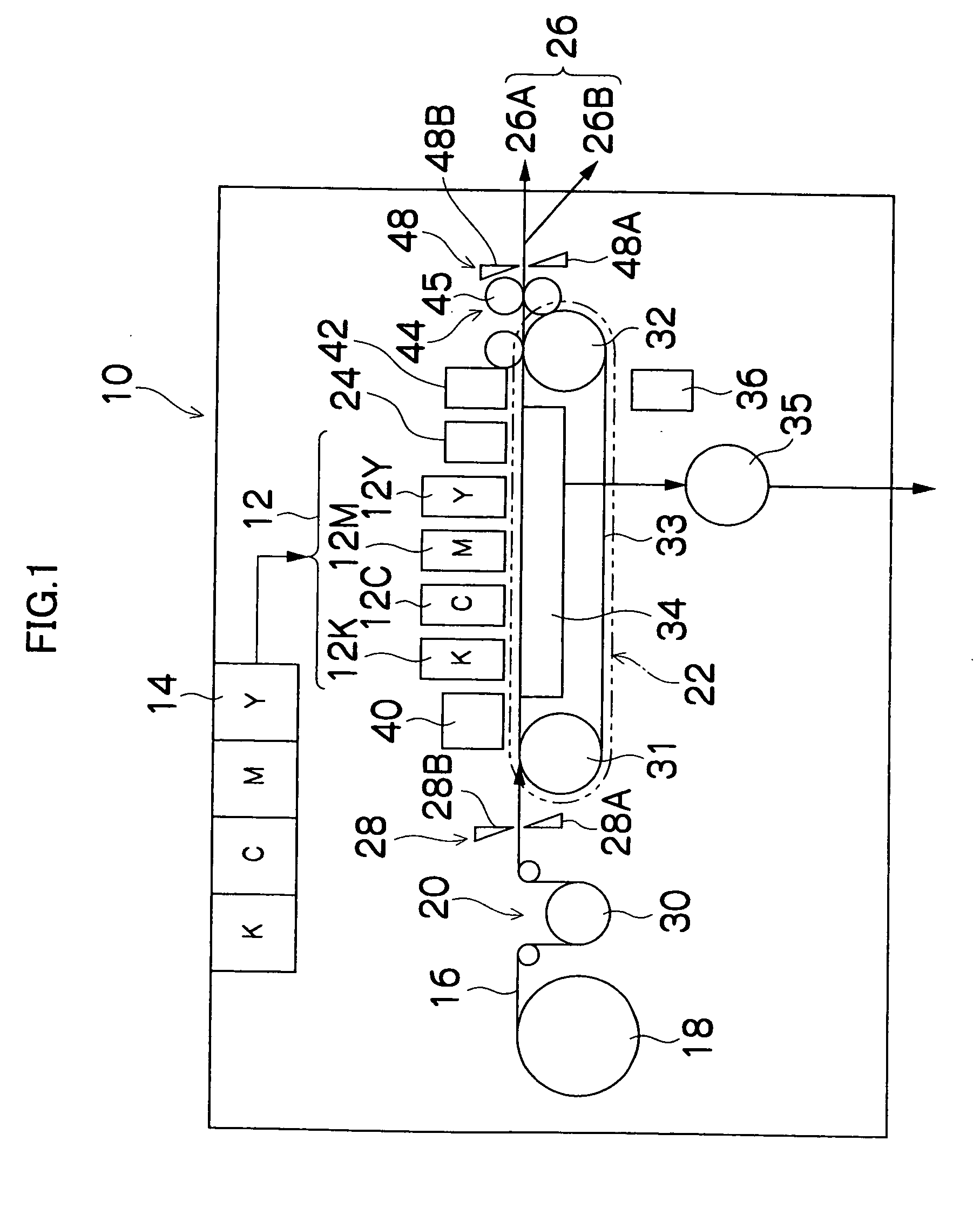

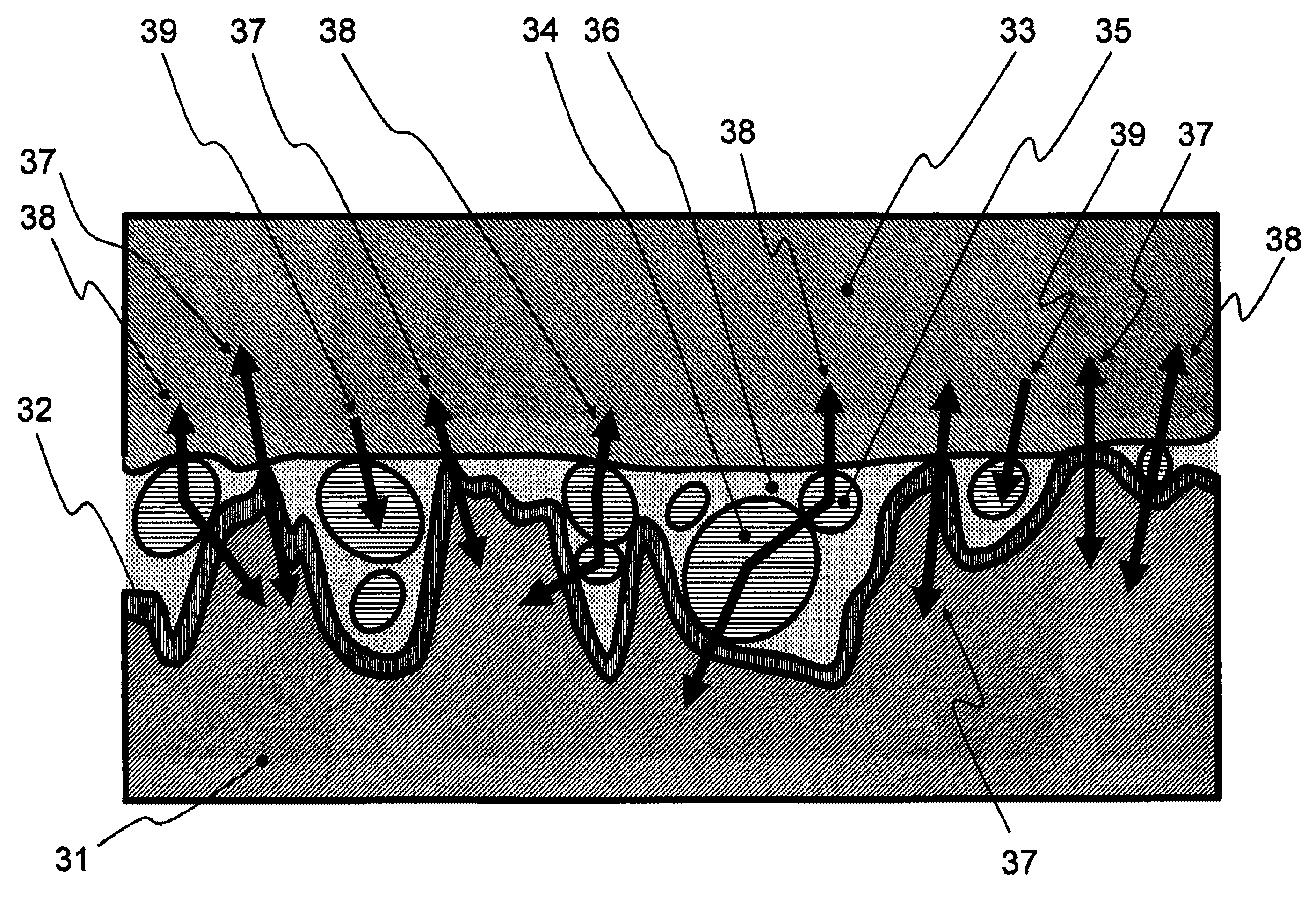

Method of manufacturing color filter substrate, method of manufacturing electro-optical device, electro-optical device, and electronic apparatus

InactiveUS7459177B2Uniform film thicknessA large amountDomestic cooling apparatusLighting and heating apparatusEngineeringSolvent

The color filter substrate has a functional region which includes a plurality of colored layers and which functions as a color filter selectively transmitting predetermined color light components and a non-functional region other than the functional region. The method includes discharging, onto a substrate, a liquid material, in which coloring materials constituting the colored layers are dissolved or dispersed into a solvent, with a liquid droplet discharge method. In the discharging of the liquid material, the liquid material is discharged onto the functional region and the liquid material or the solvent is discharged onto the non-functional region. The amount of the solvent discharged onto the non-functional region per unit area is larger than the amount of the solvent discharged onto the functional region per unit area.

Owner:KATEEVA

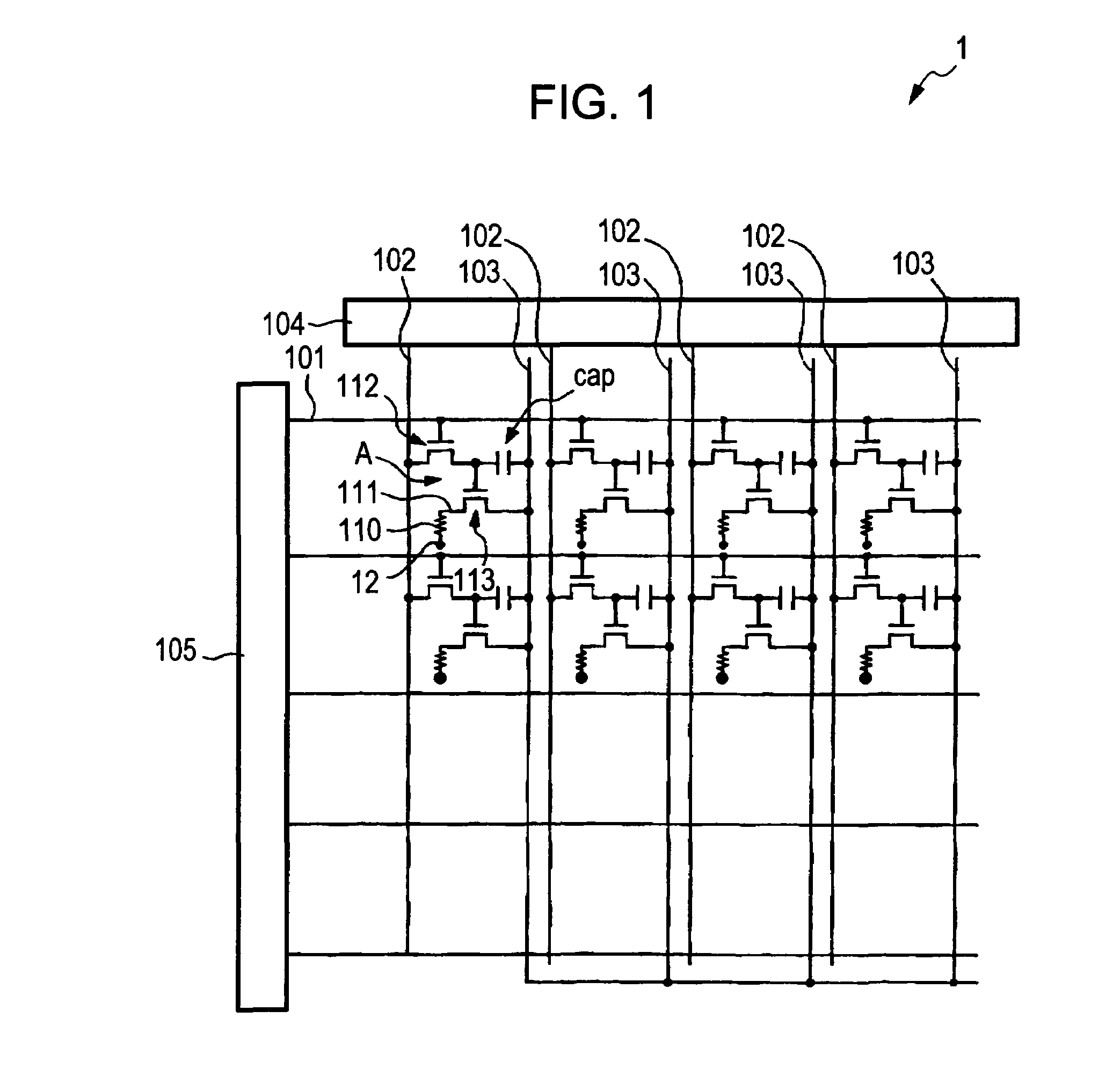

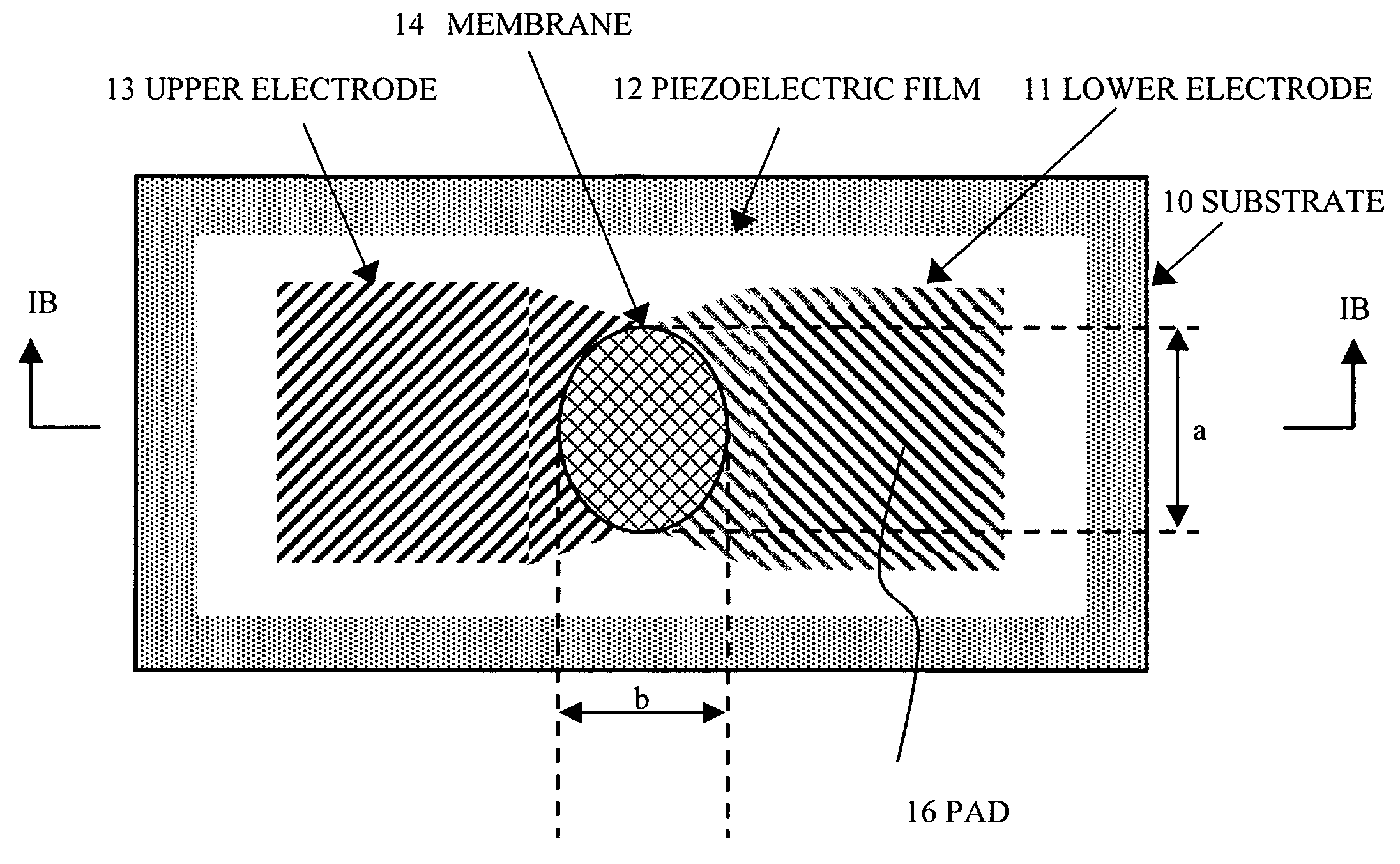

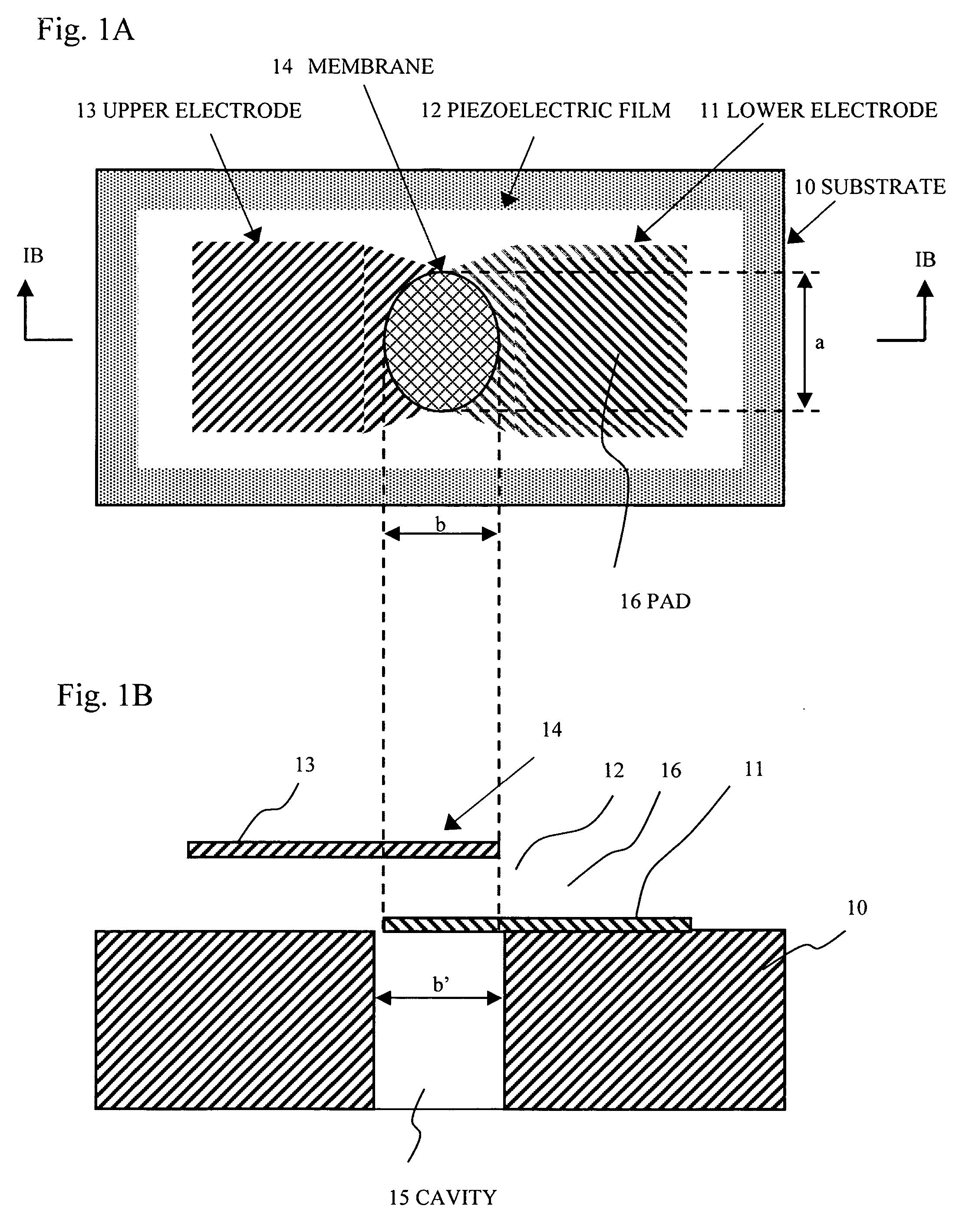

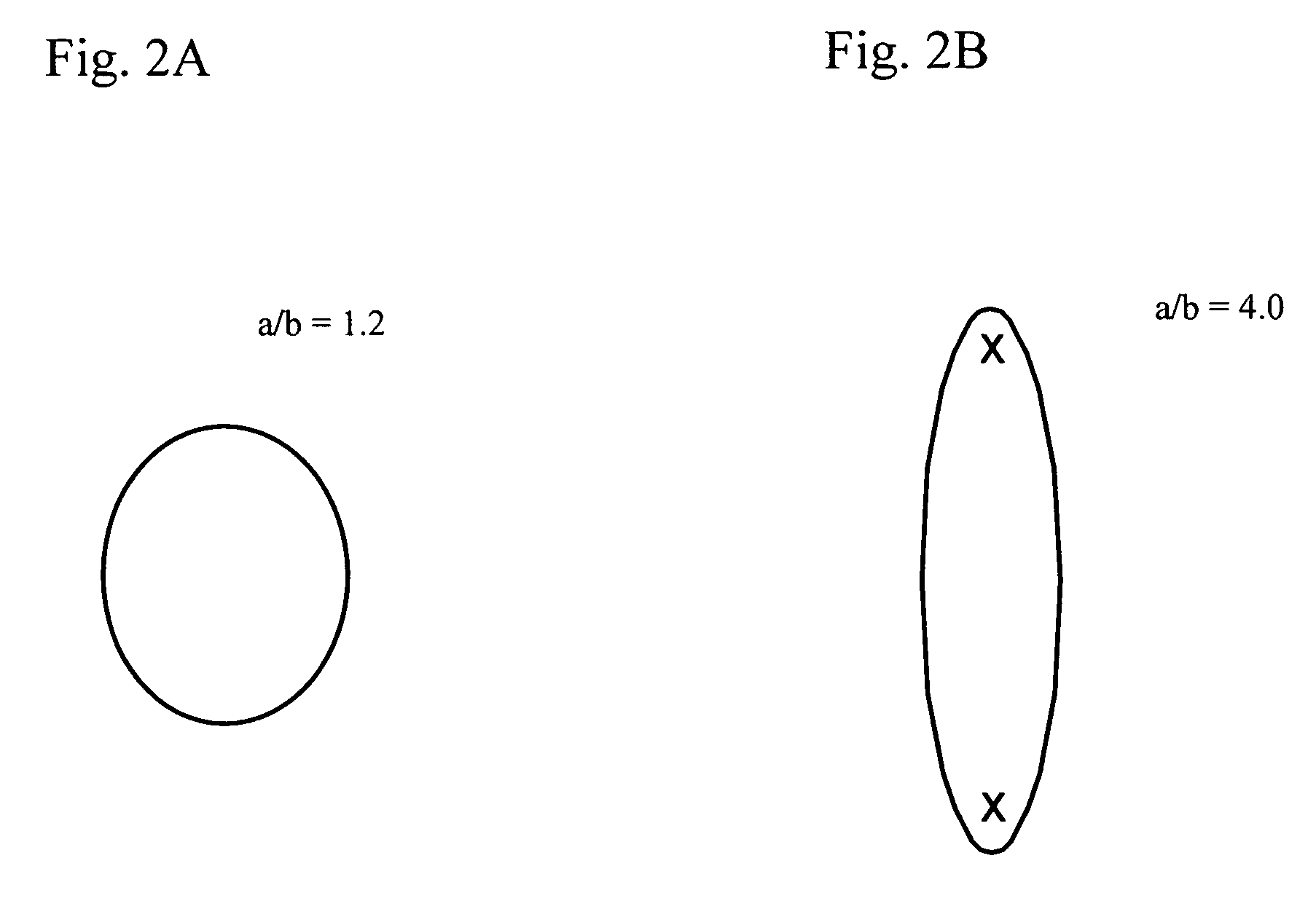

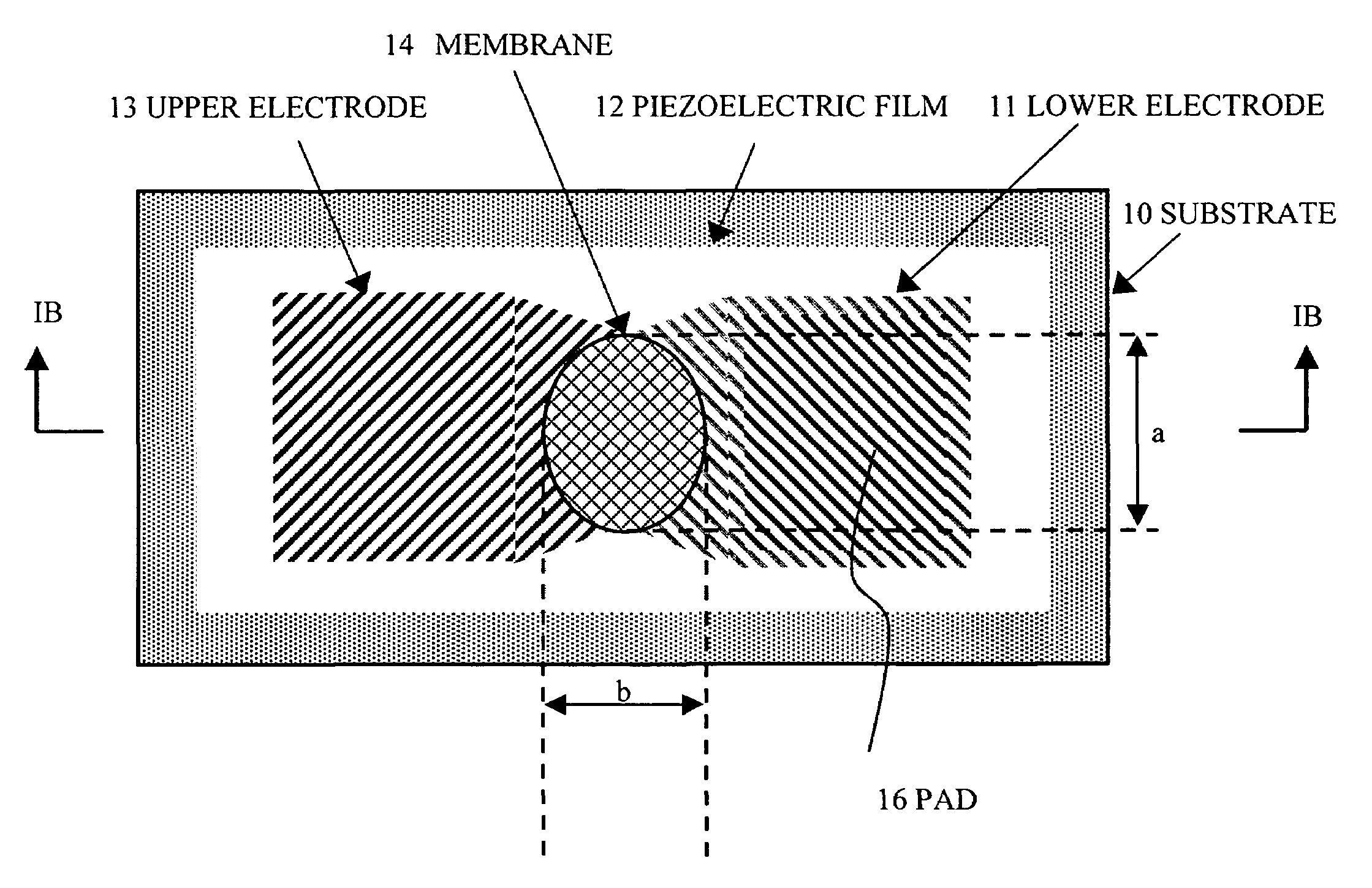

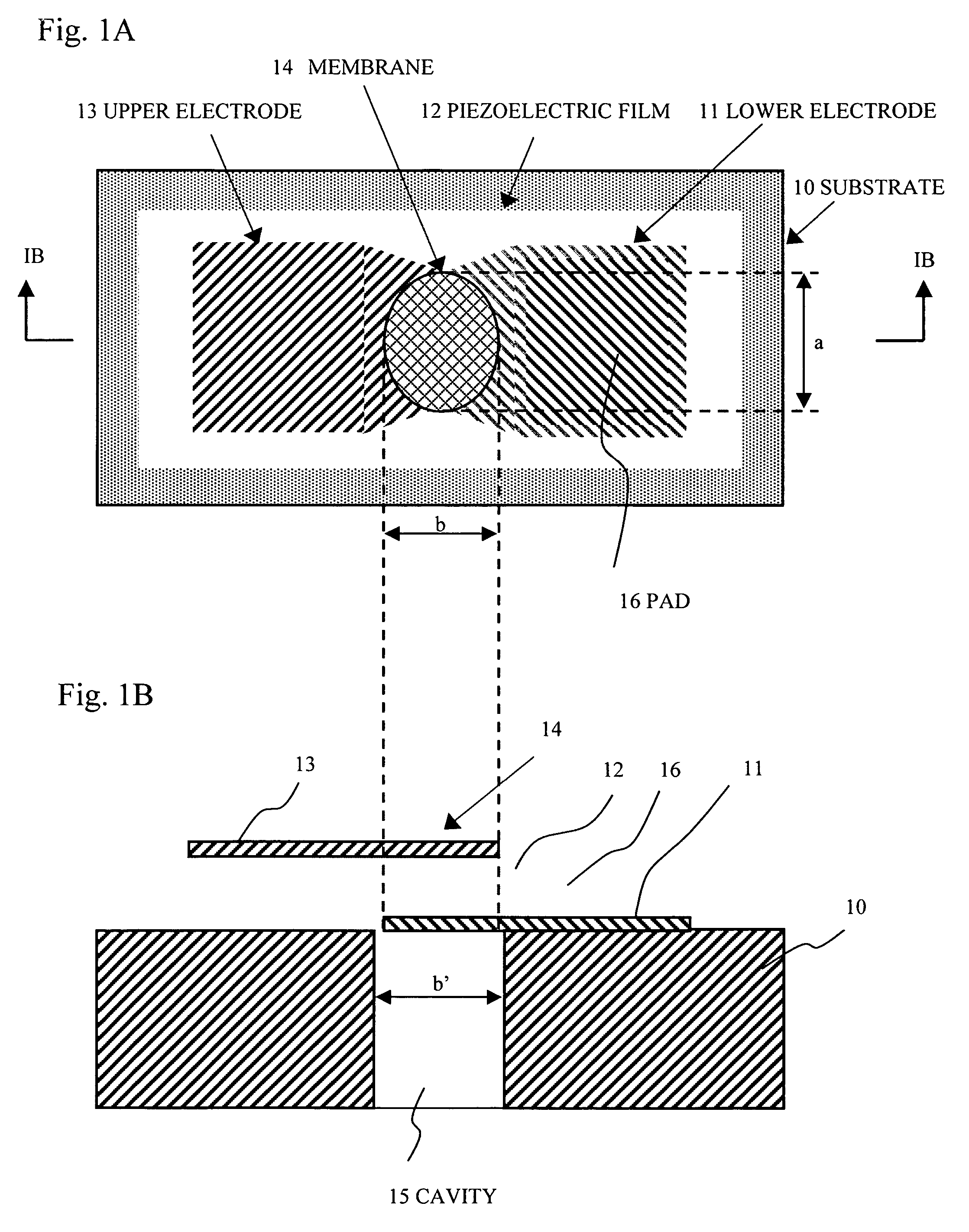

Piezoelectric thin-film resonator and filter using the same

ActiveUS20050099094A1Little irregularitySufficient membrane strengthImpedence networksPiezoelectric/electrostriction/magnetostriction machinesResonatorPiezoelectric thin films

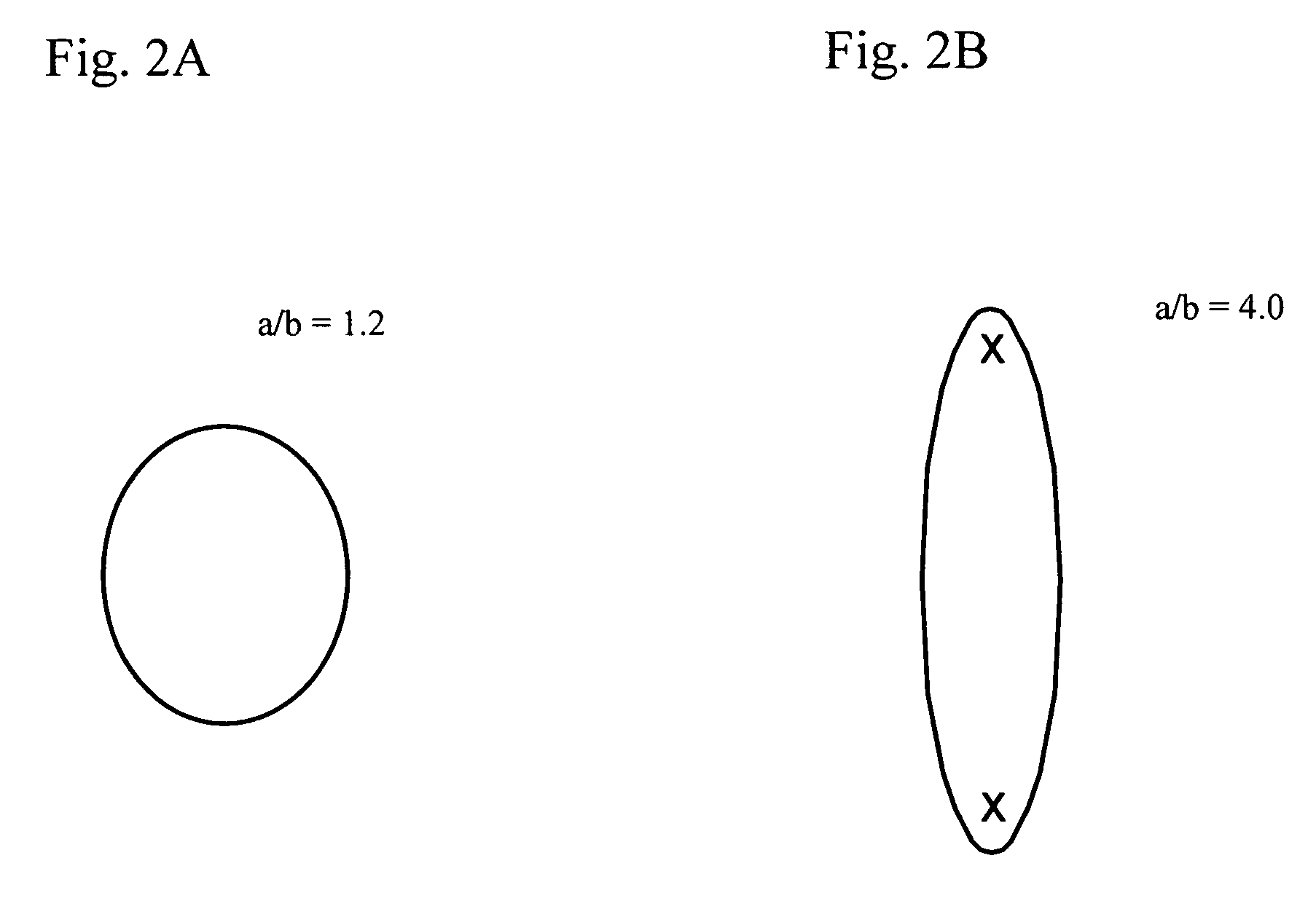

A piezoelectric thin-film resonator includes a substrate, a lower electrode arranged on the substrate, a piezoelectric film arranged on the lower electrode, and an upper electrode arranged on the piezoelectric film. A region in which the upper electrode overlaps with the lower electrode through the piezoelectric film has an elliptical shape, and a condition such that 1<a / b<1.9 is satisfied where a is a main axis of the elliptical shape, and b is a sub axis thereof.

Owner:TAIYO YUDEN KK

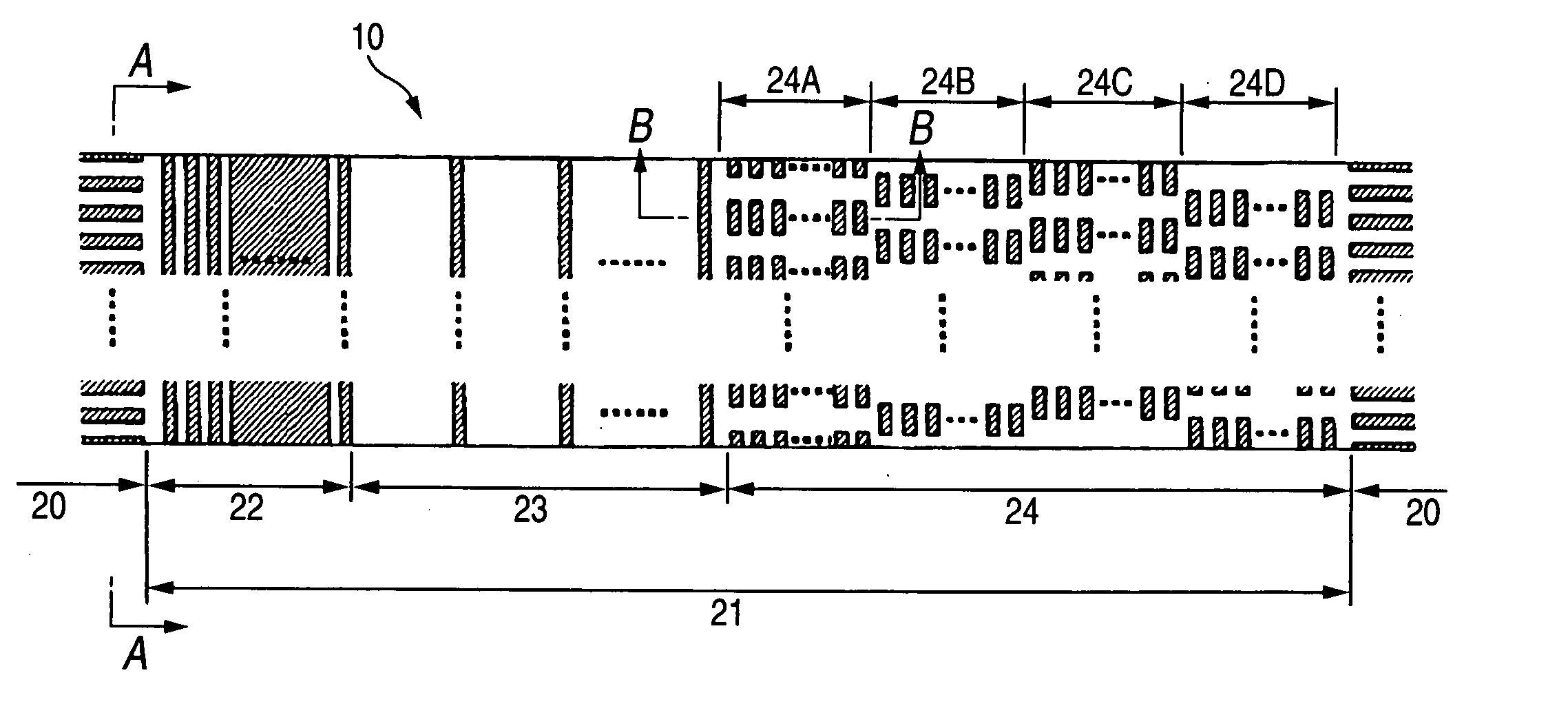

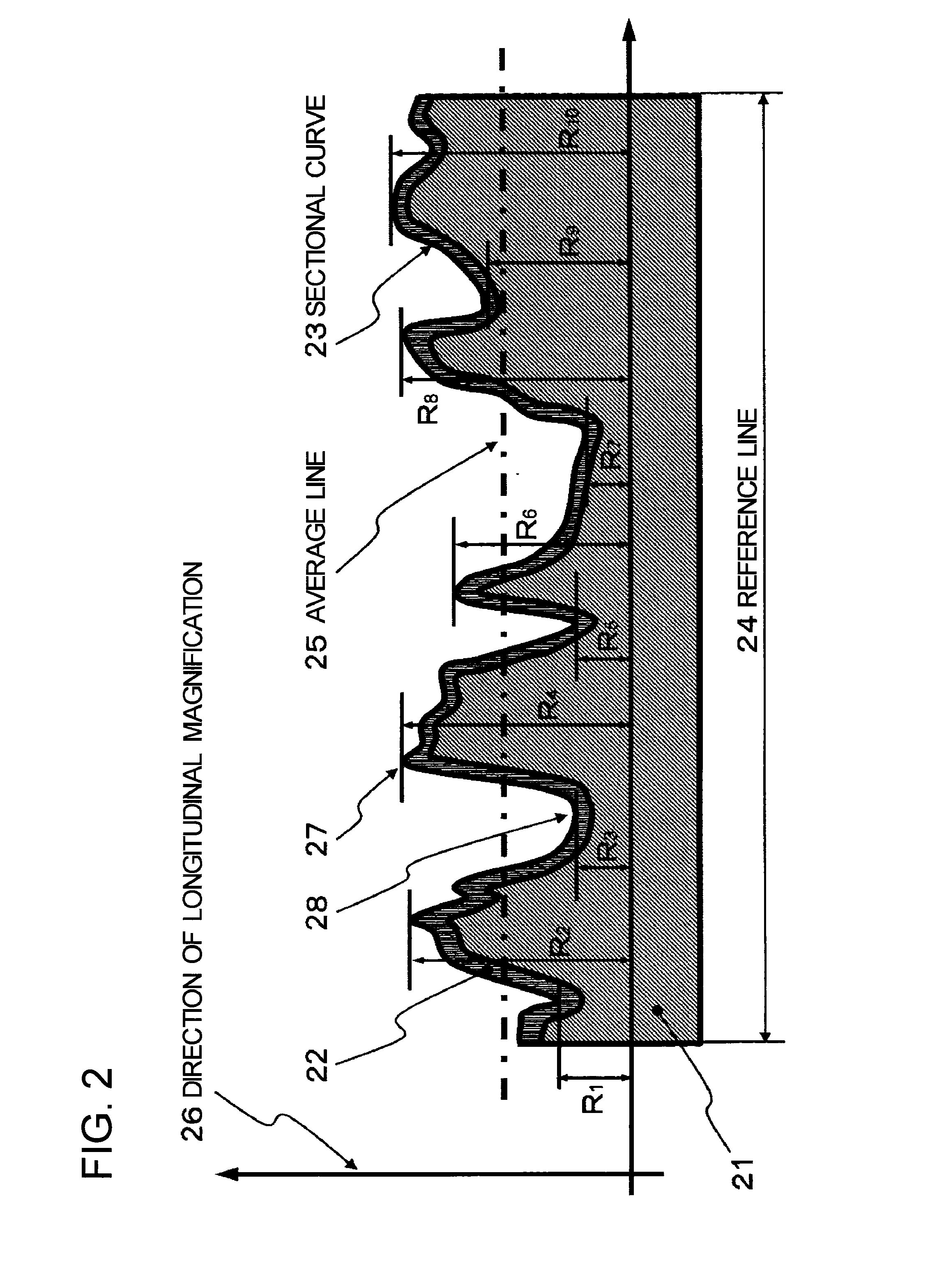

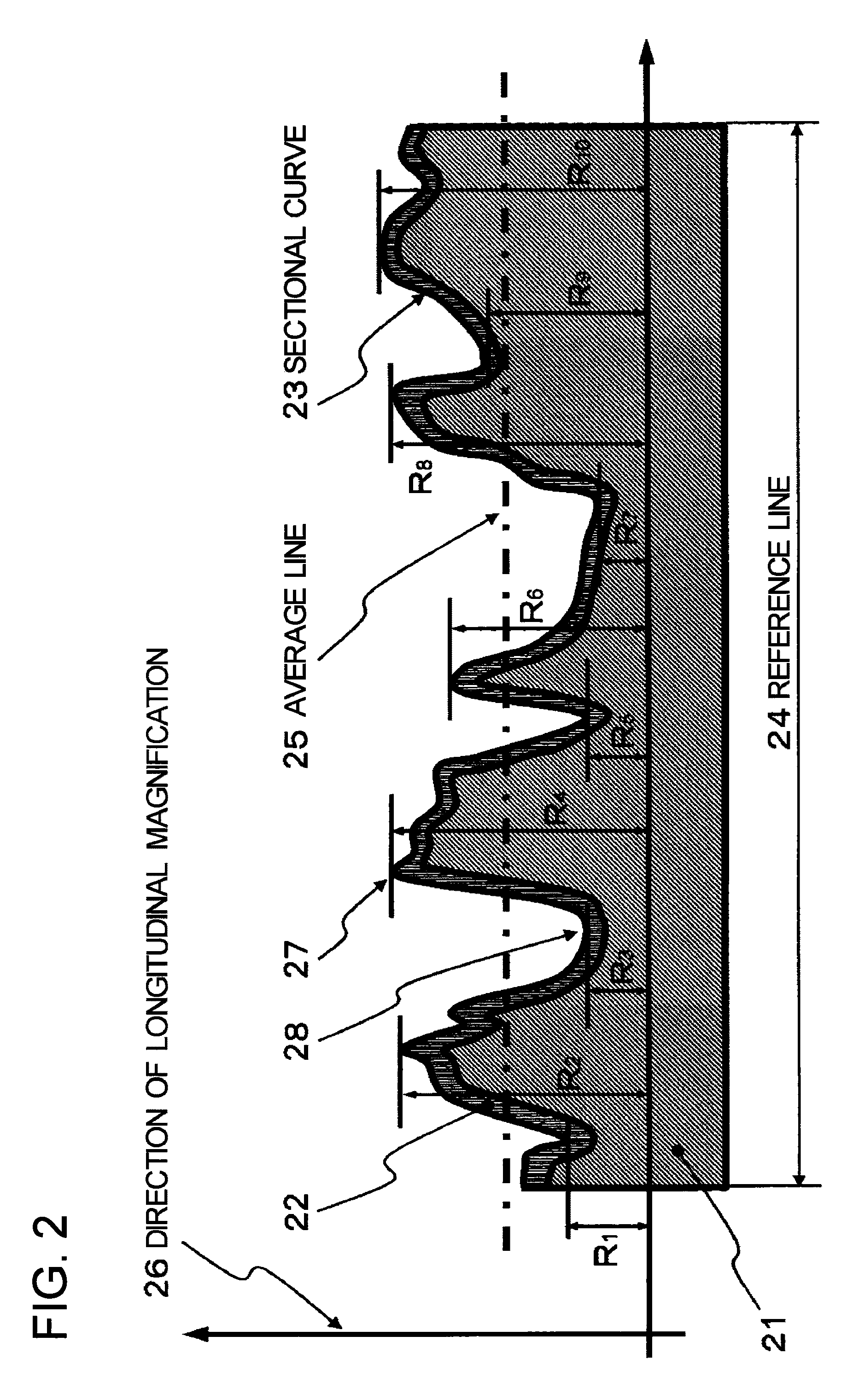

Magnetic recording medium and magnetic recording and reproducing device

InactiveUS20050213239A1Reduce frictional resistanceAvoid static frictionMagnetic materials for record carriersRecord information storageEngineeringSurface level

A magnetic recording medium including at least a disk substrate 1A, a magnetic recording layer 5 formed with a predetermined concavo-convex pattern on the disk substrate 1A, and a non-magnetic layer 6 filled into concave portions of the concavo-convex pattern, so as to have data track regions 20 and servo pattern regions 21. Due to the existence of concaves and convexes in the surface of each servo pattern region 21, the foregoing problem is solved. On this occasion, arithmetical mean deviation of the assessed profile Ra of the surface of each servo pattern region 21 is preferably not lower than 0.3 nm. The difference in surface level between each concave and each convex existing in the surface of the servo pattern region 21 is preferably not larger than 6 nm.

Owner:TDK CORPARATION

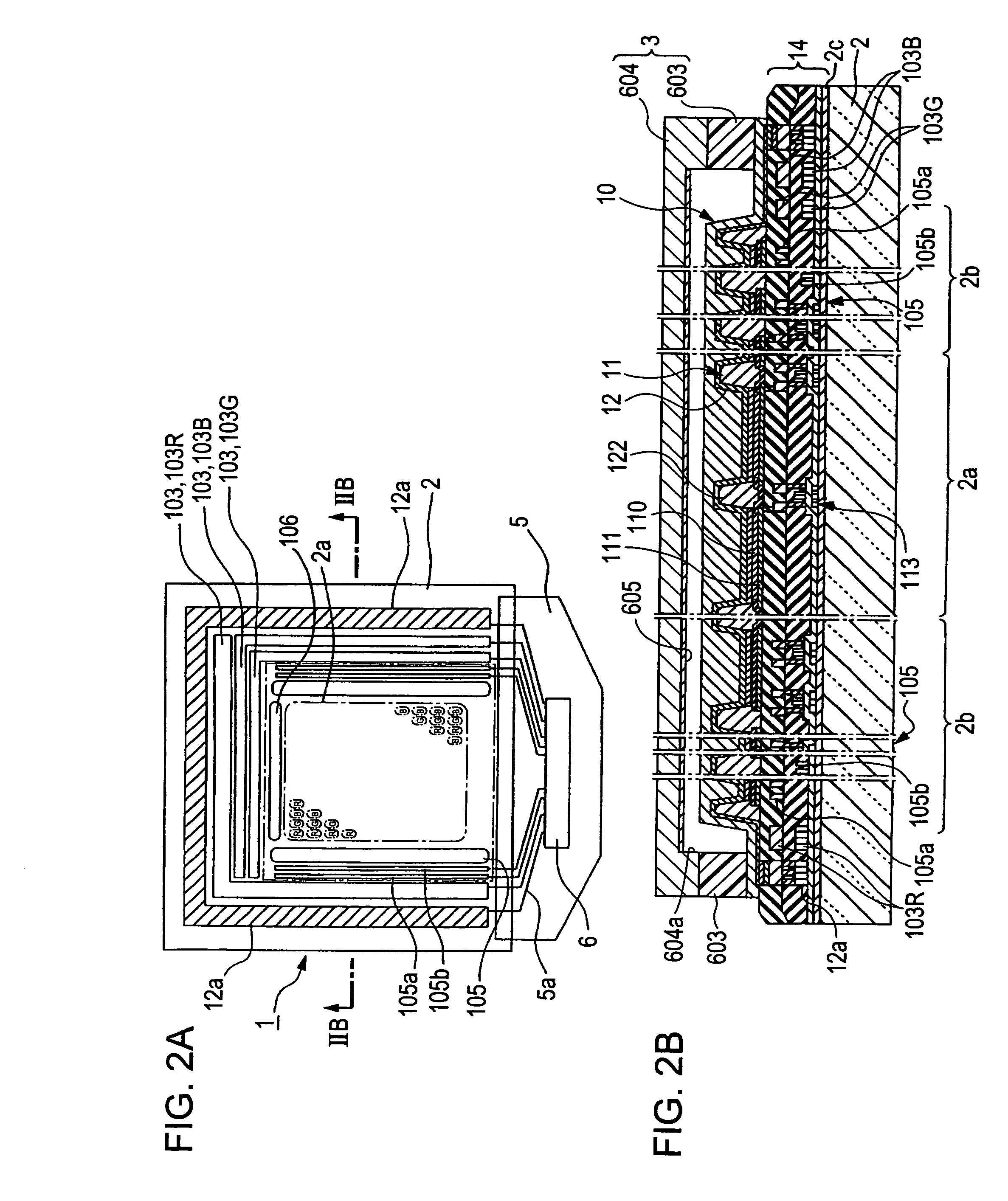

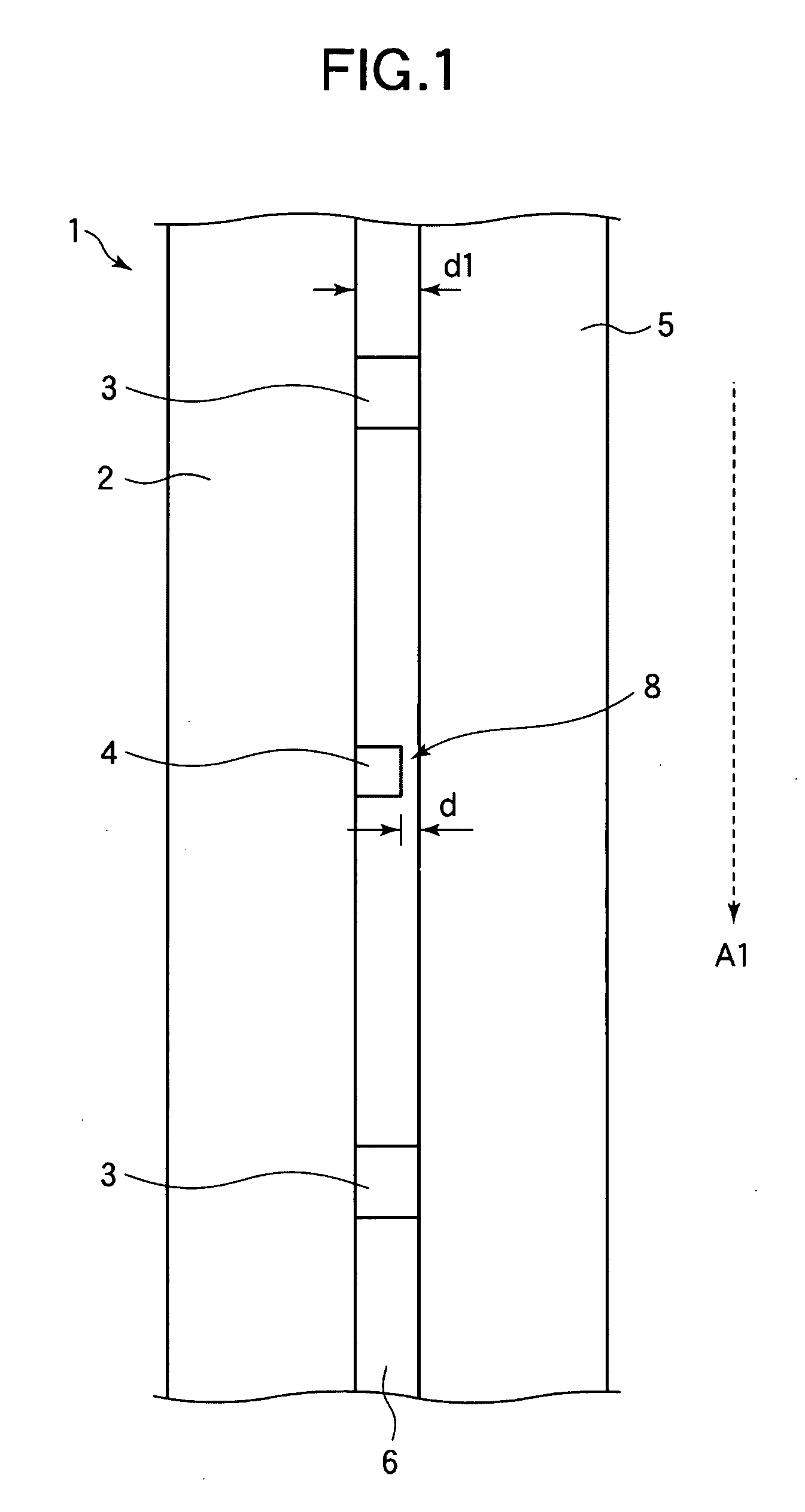

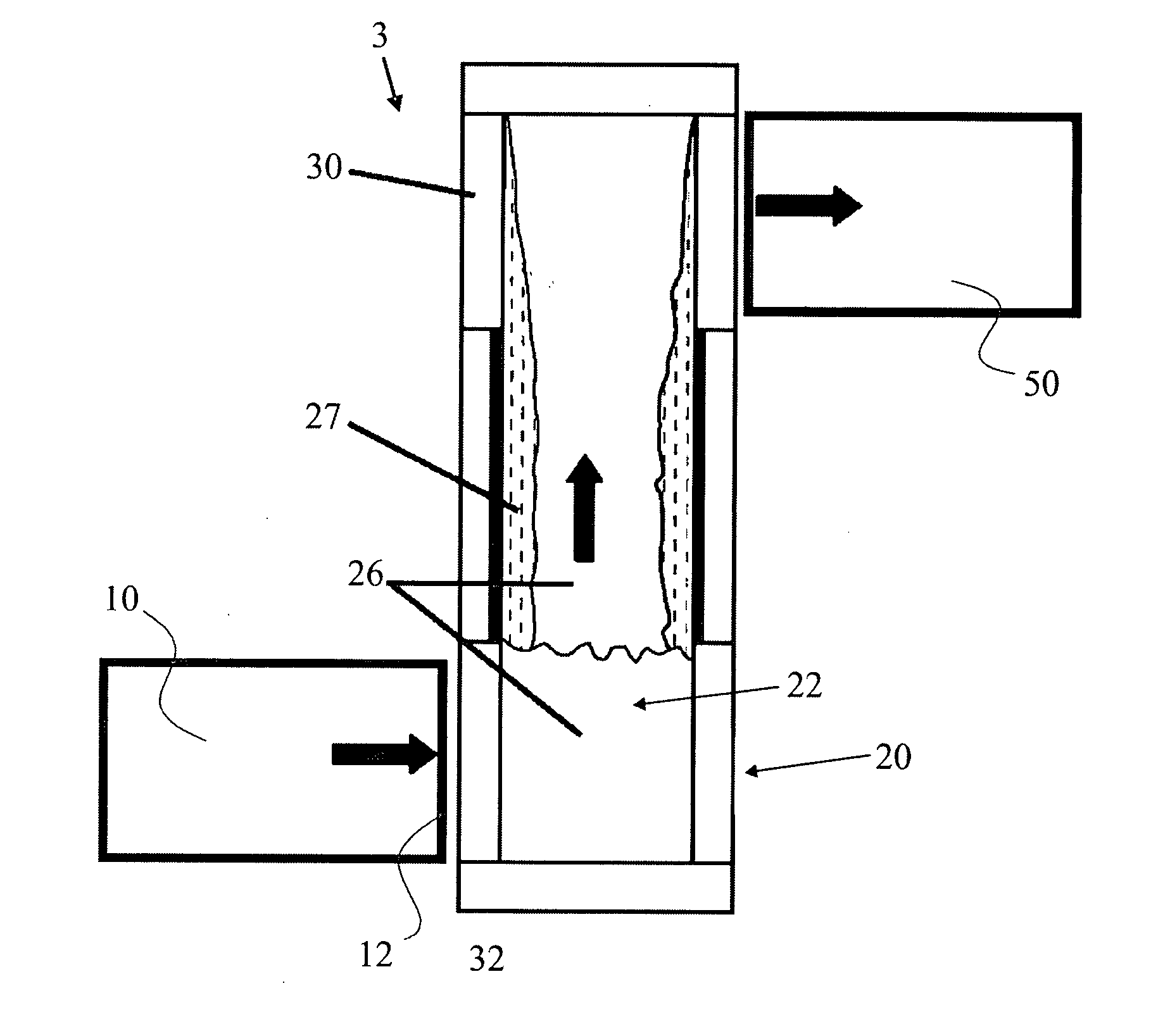

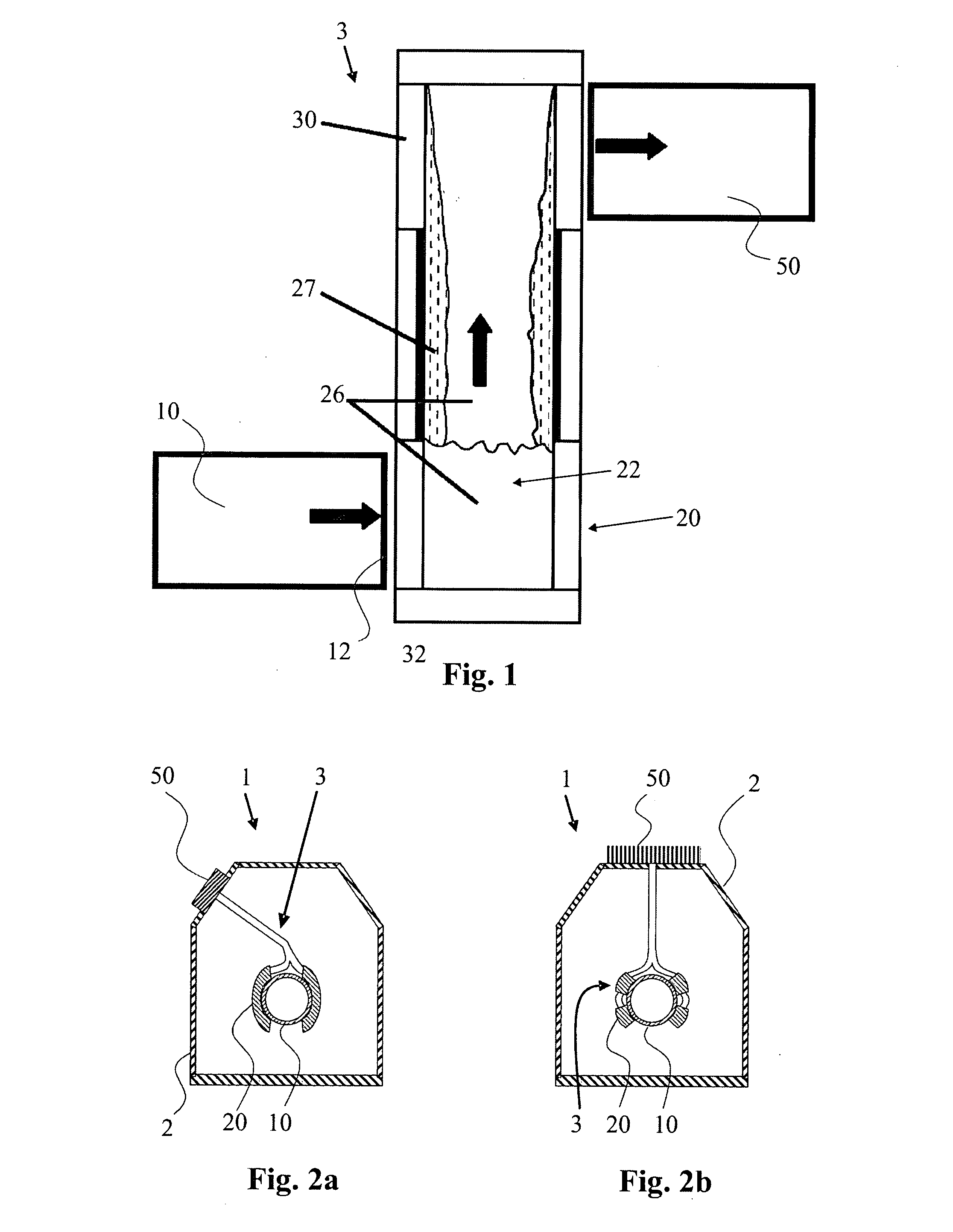

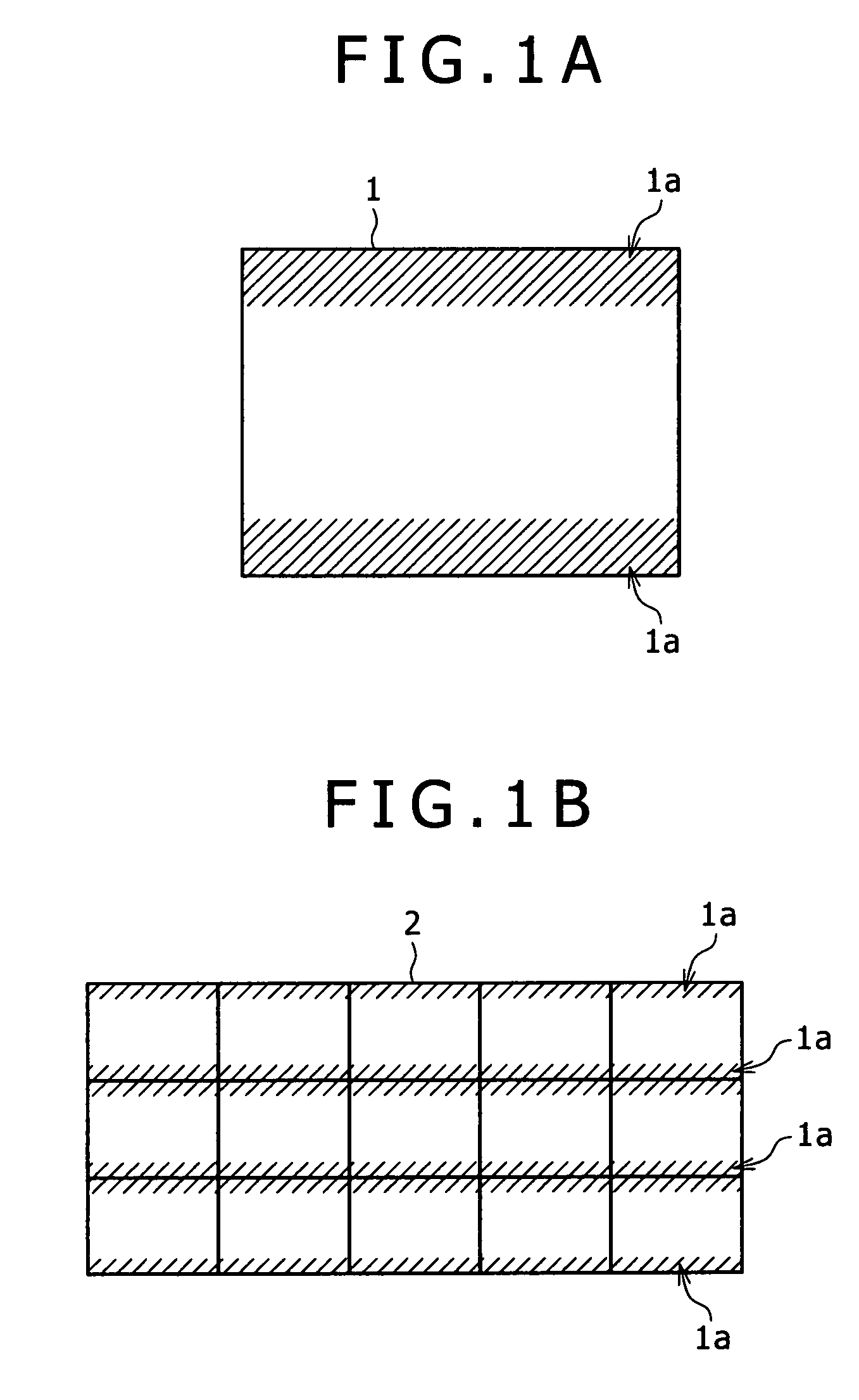

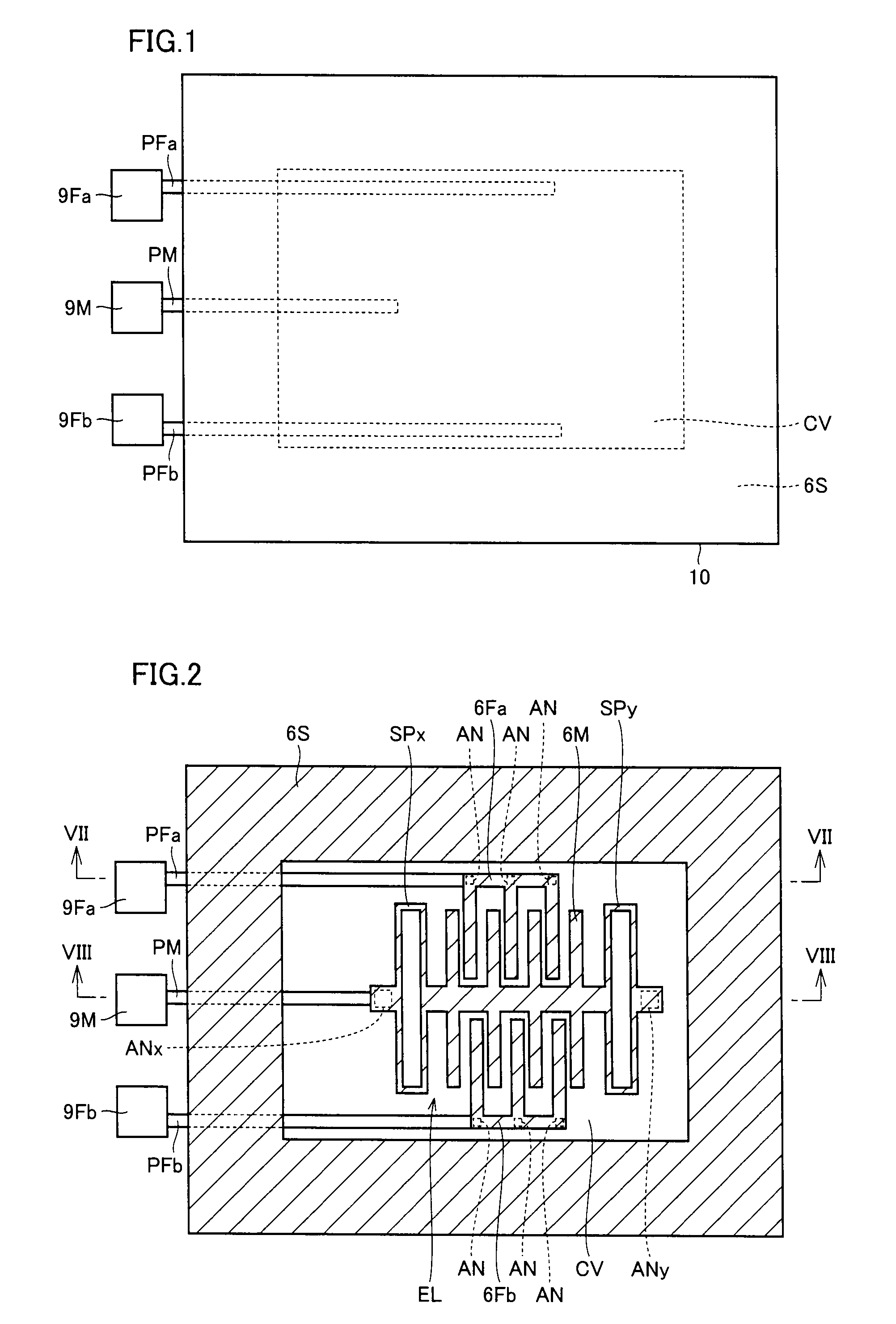

Liquid crystal display

InactiveUS20060044502A1Display quality is deterioratedLittle irregularityNon-linear opticsLiquid-crystal displayEngineering

The invention relates to a liquid crystal display filled with a liquid crystal by dispensing the liquid crystal onto a substrate, combining the substrate with an opposite substrate in vacuum with the surface of the substrate having the liquid crystal thereon facing the opposite substrate, and restoring the atmospheric pressure. The invention provides a liquid crystal display in which degradation of display quality due to an irregularity attributable to gravity can be suppressed. The liquid crystal display has a pair of substrates opposite to each other, a liquid crystal sealed between the substrates, a convex portion protruding into the liquid crystal from a surface of at least either of the pair of substrates and extending in a substantially horizontal direction when the pair of substrates is erected in the vertical direction, and a gap formed between the protruding end of the convex portion and a surface of the other substrate.

Owner:SHARP KK

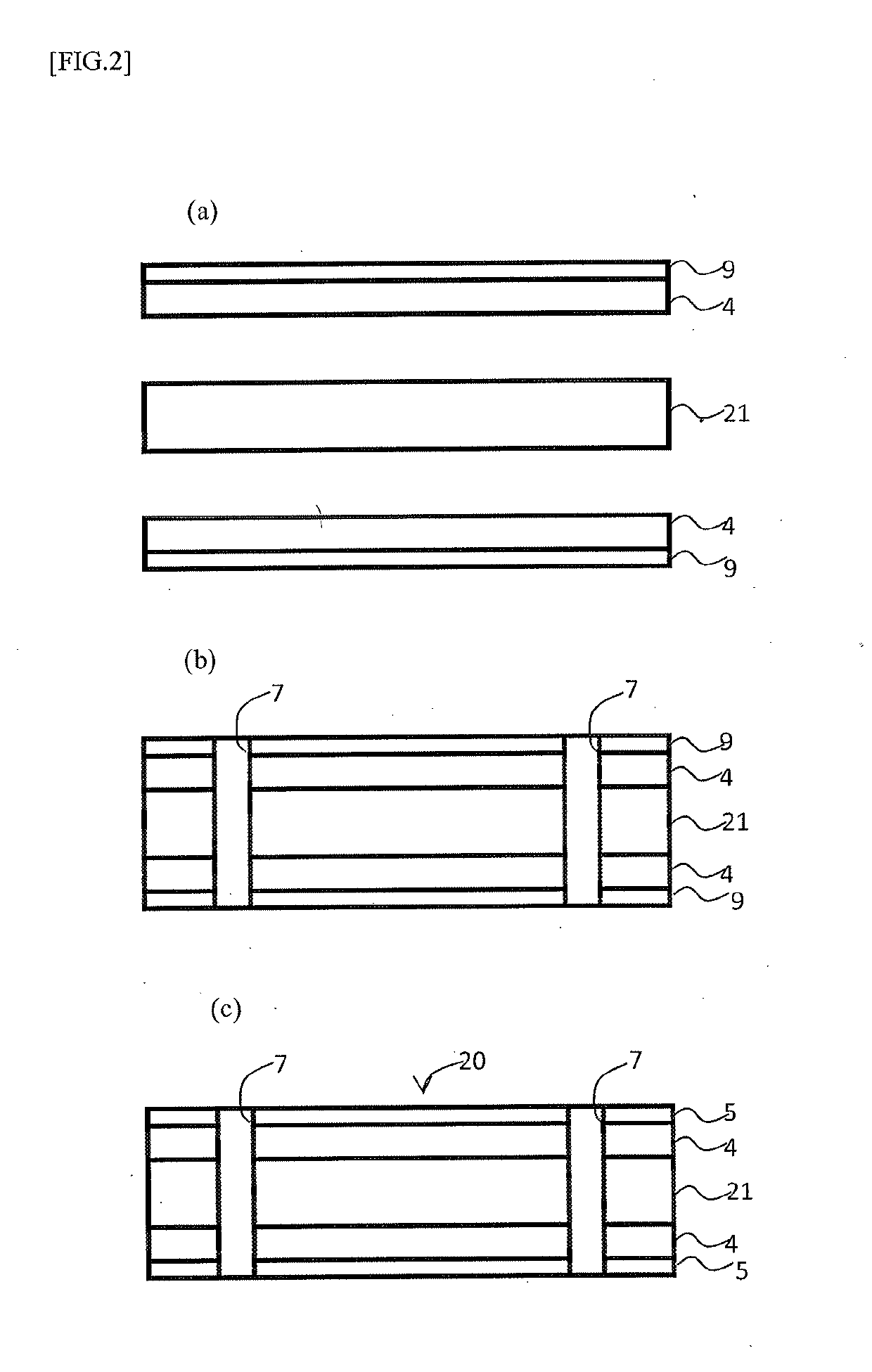

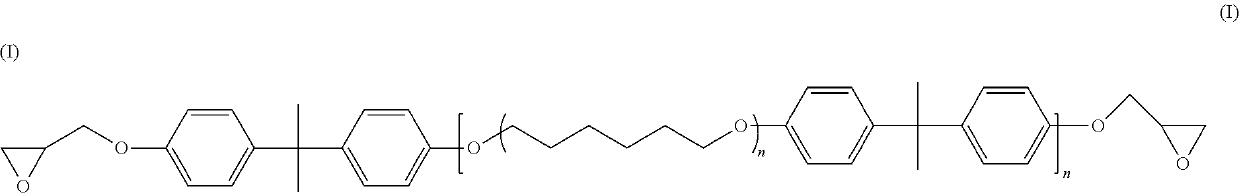

Resin composition, cured resin product, wiring board, and manufacturing method for wiring board

InactiveUS20130199830A1Improve adhesionLittle irregularityOrganic chemistrySynthetic resin layered productsEpoxyElectrical conductor

By producing a resin composition containing (A) an epoxy resin having two or more epoxy groups in one molecule thereof and containing a hexanediol structure, (B) an ultraviolet ray active ester group-containing compound, and (C) an epoxy resin curing accelerator, even in a state where an irregular shape of the surface of an insulating resin layer is small, a high adhesive force to a wiring conductor can be easily revealed.

Owner:HITACHI CHEM CO LTD

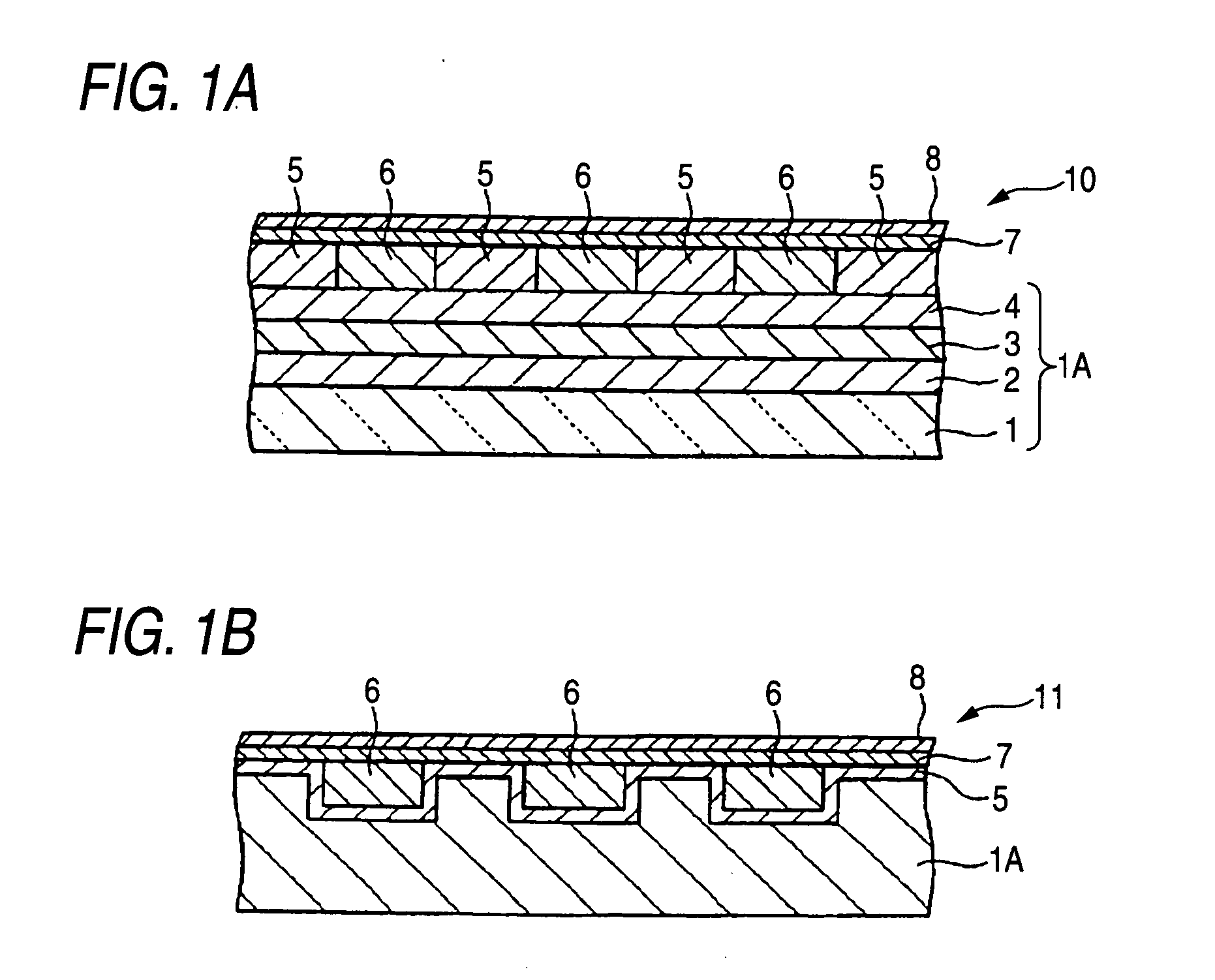

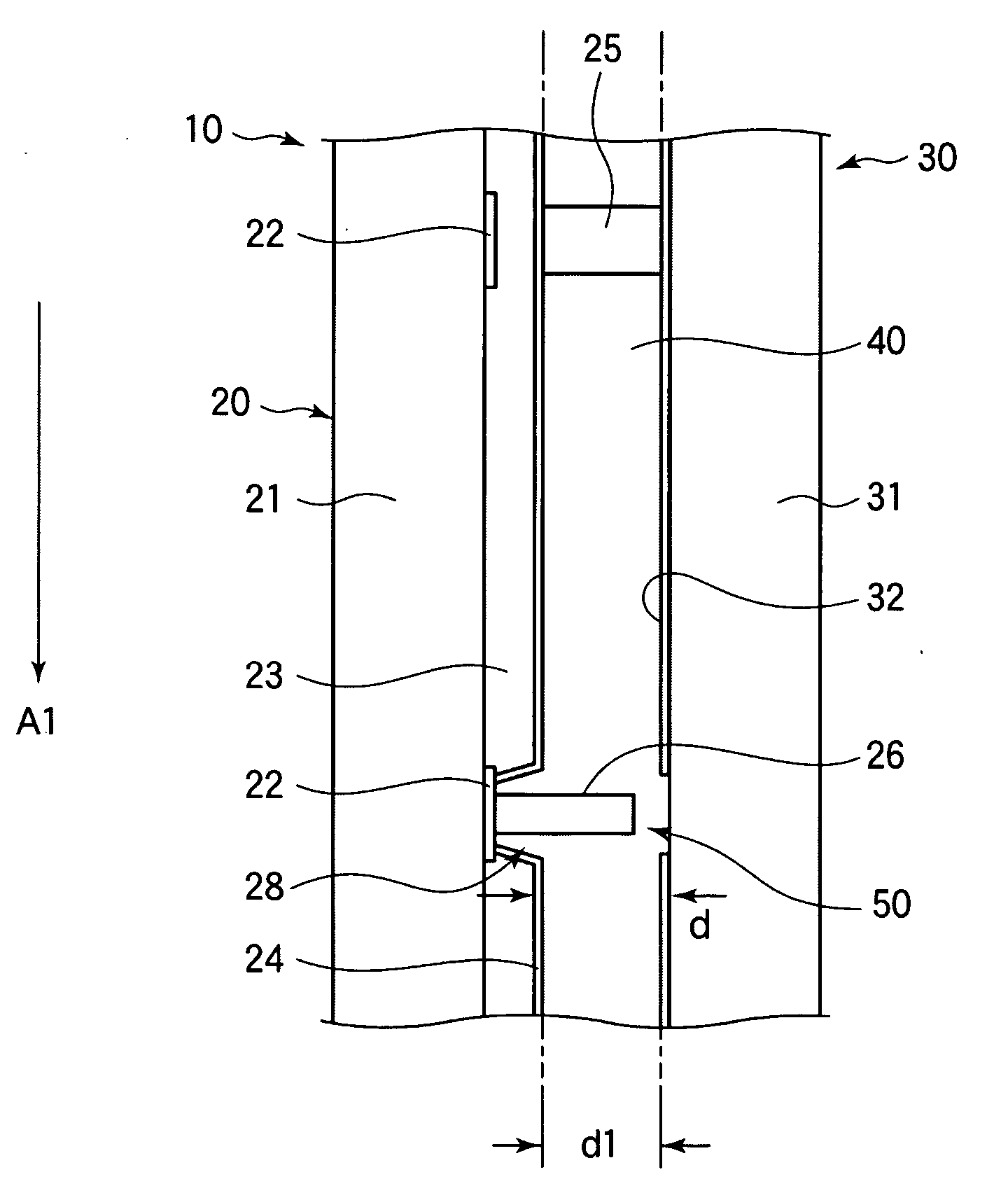

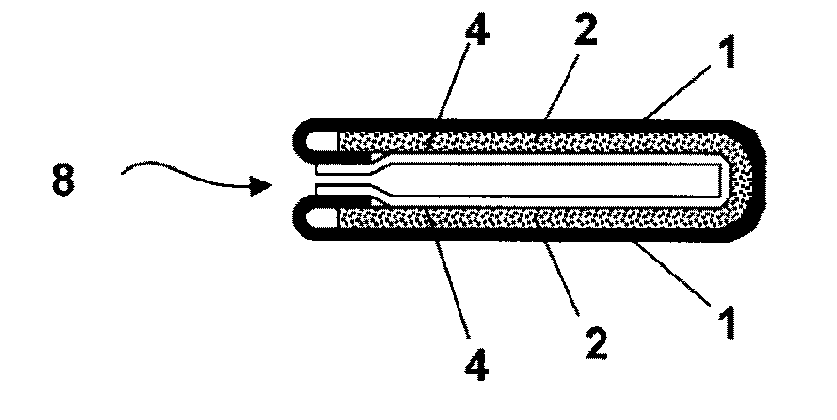

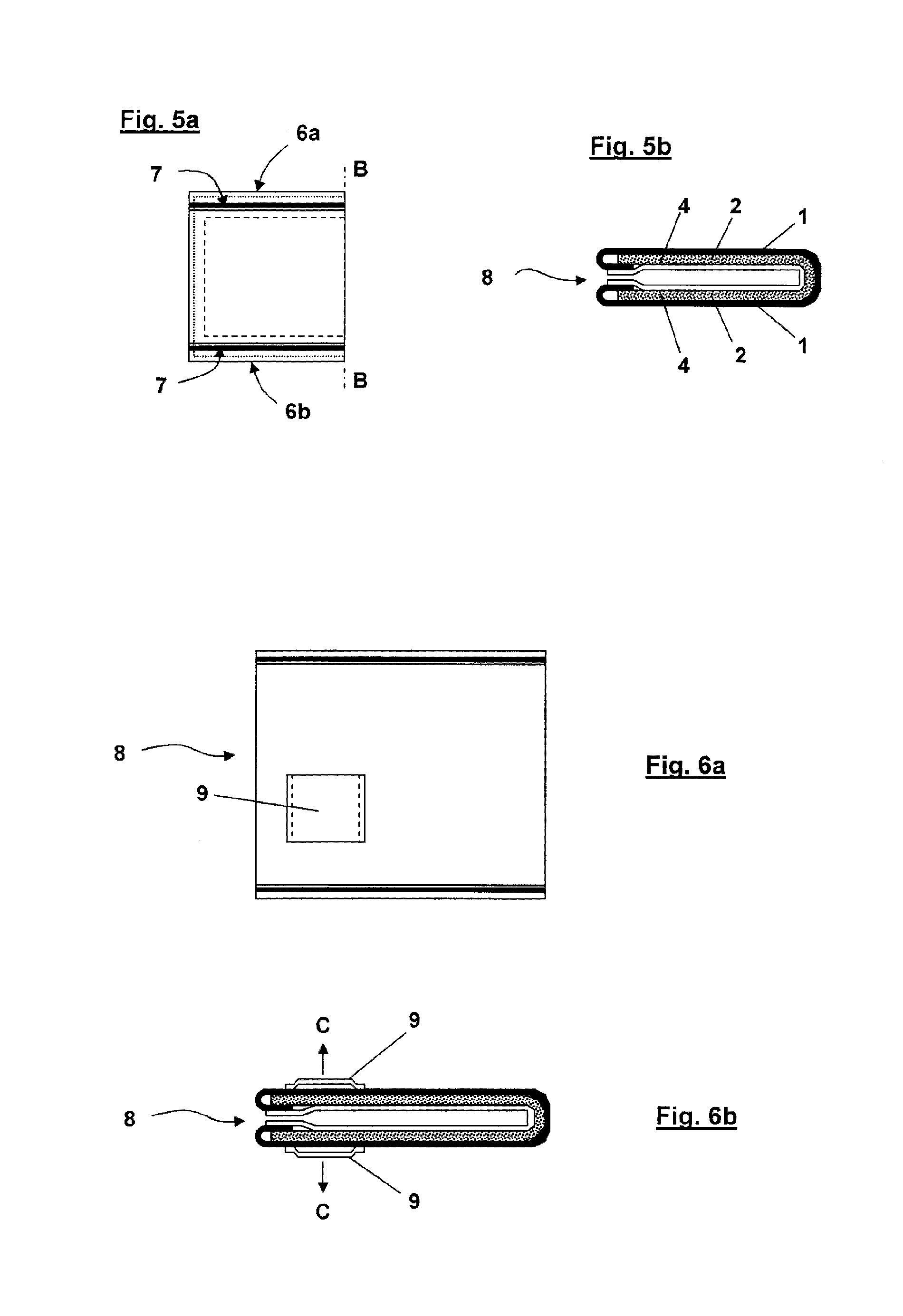

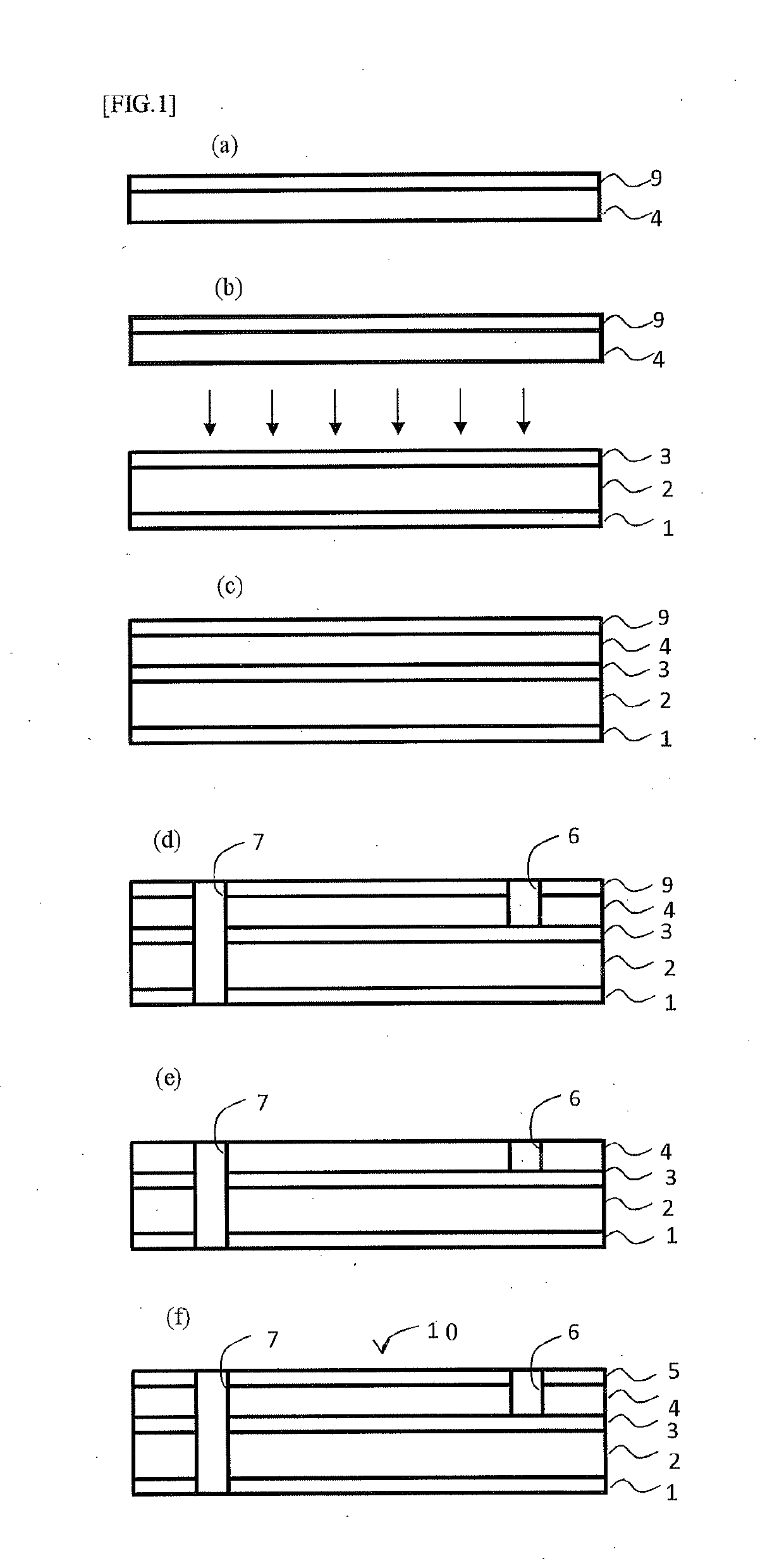

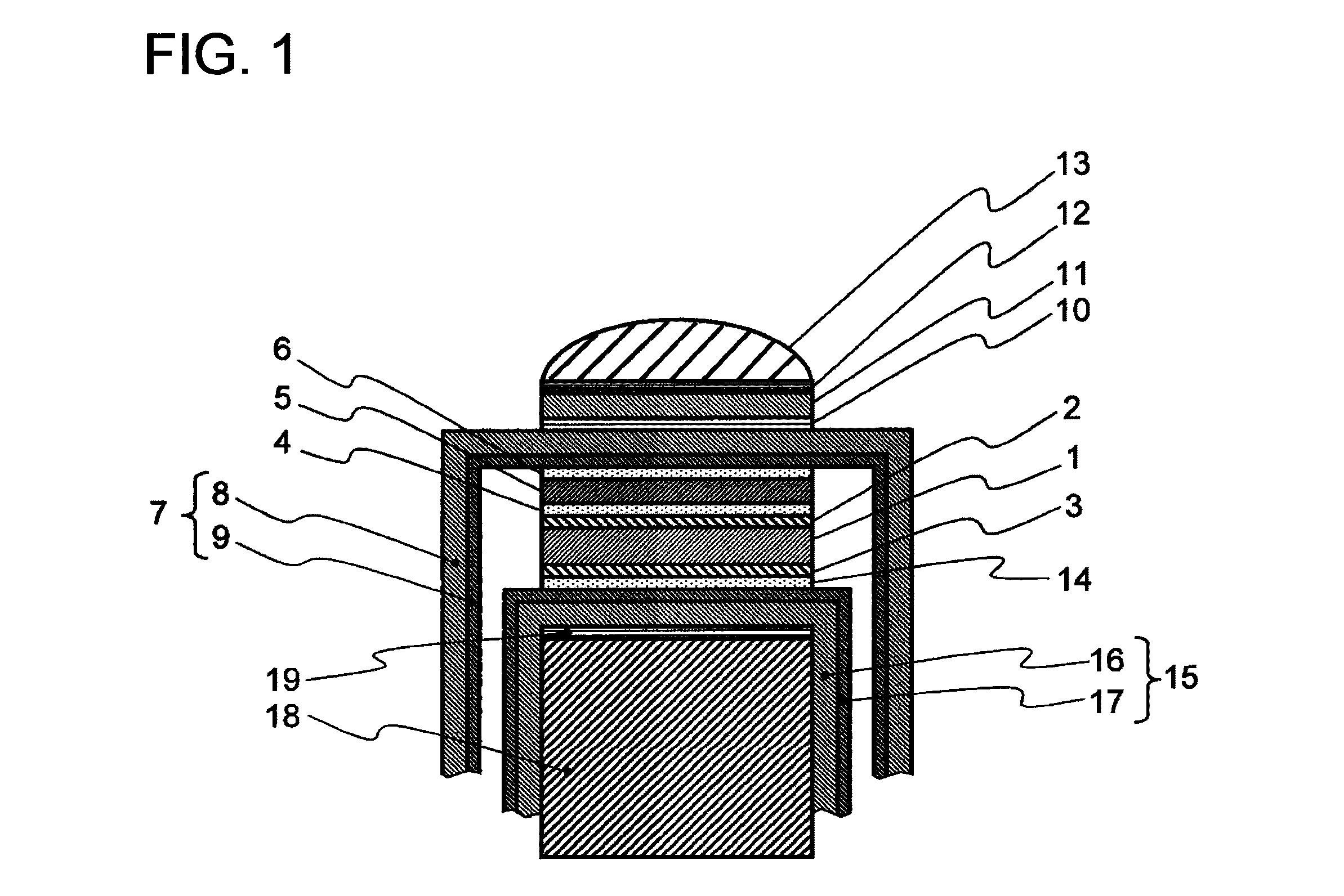

Ultrasonic probe

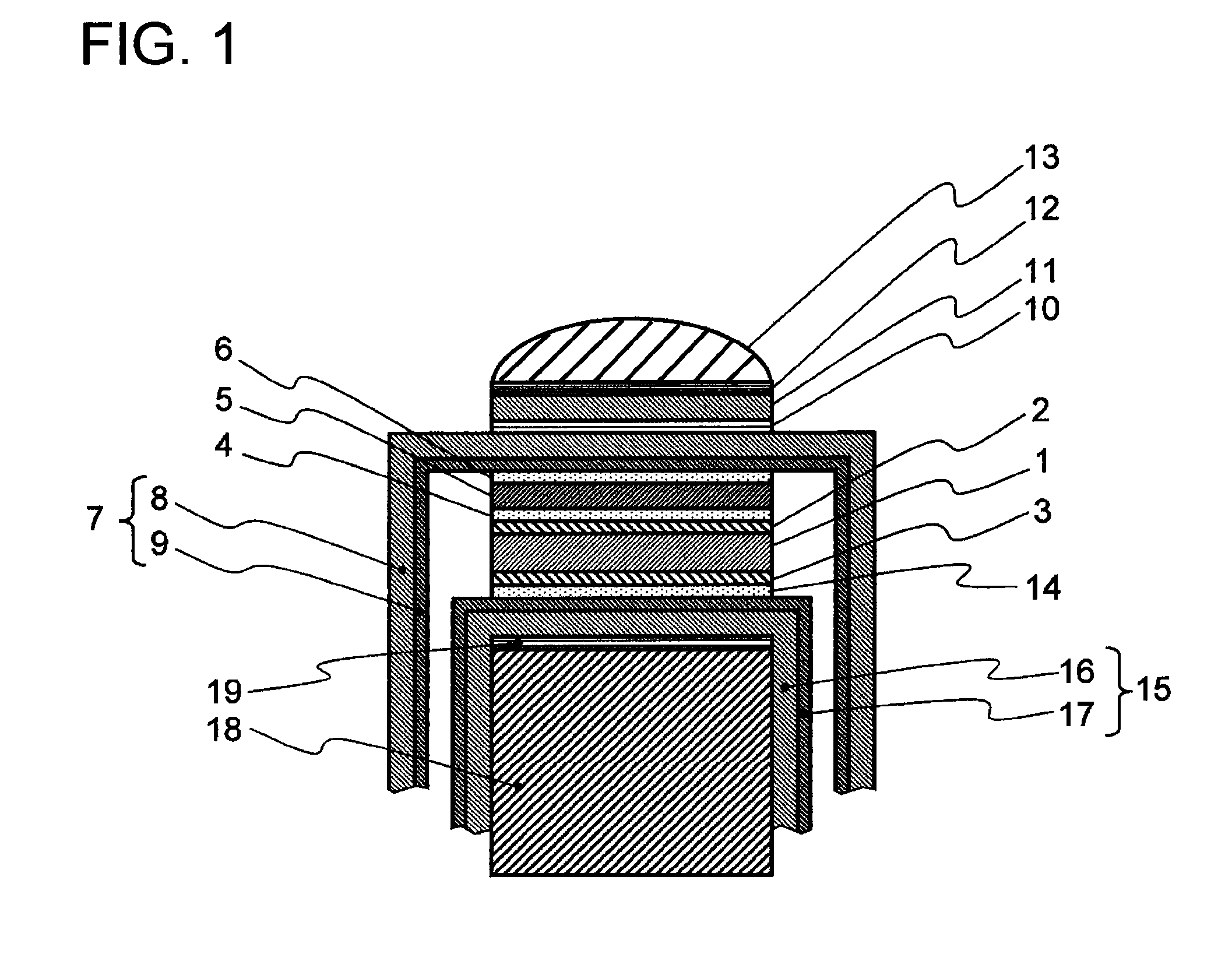

ActiveUS20100198077A1Good qualityGood working propertyOrgan movement/changes detectionMechanical vibrations separationAdhesiveUltrasound

An ultrasonic probe that enables the sensibility irregularity between arrays to be reduced is disclosed. This piezoelectric element contains: a piezoelectric element 1; a first electrode layer 2 formed on one side of the piezoelectric element 1; one or more conductive acoustic matching layers 5 layered via an adhesive layer 4 on the first electrode layer 2; a first film 7 which is layered via an adhesive layer 6 on the acoustic matching layer 5 and in which an electrode pattern is formed on the side of the adhesive layer 6; a second electrode layer 3 formed on the other side of the piezoelectric element 1; and a second film 15 which is layered via an adhesive layer 14 on the second electrode layer 3 and in which an electrode pattern is formed on the side of the adhesive layer 14, wherein the adhesive layers 4, 6 and 14 are thermosetting two-component type adhesives in which graphite powder is uniformly distributed therein.

Owner:KONICA MINOLTA INC

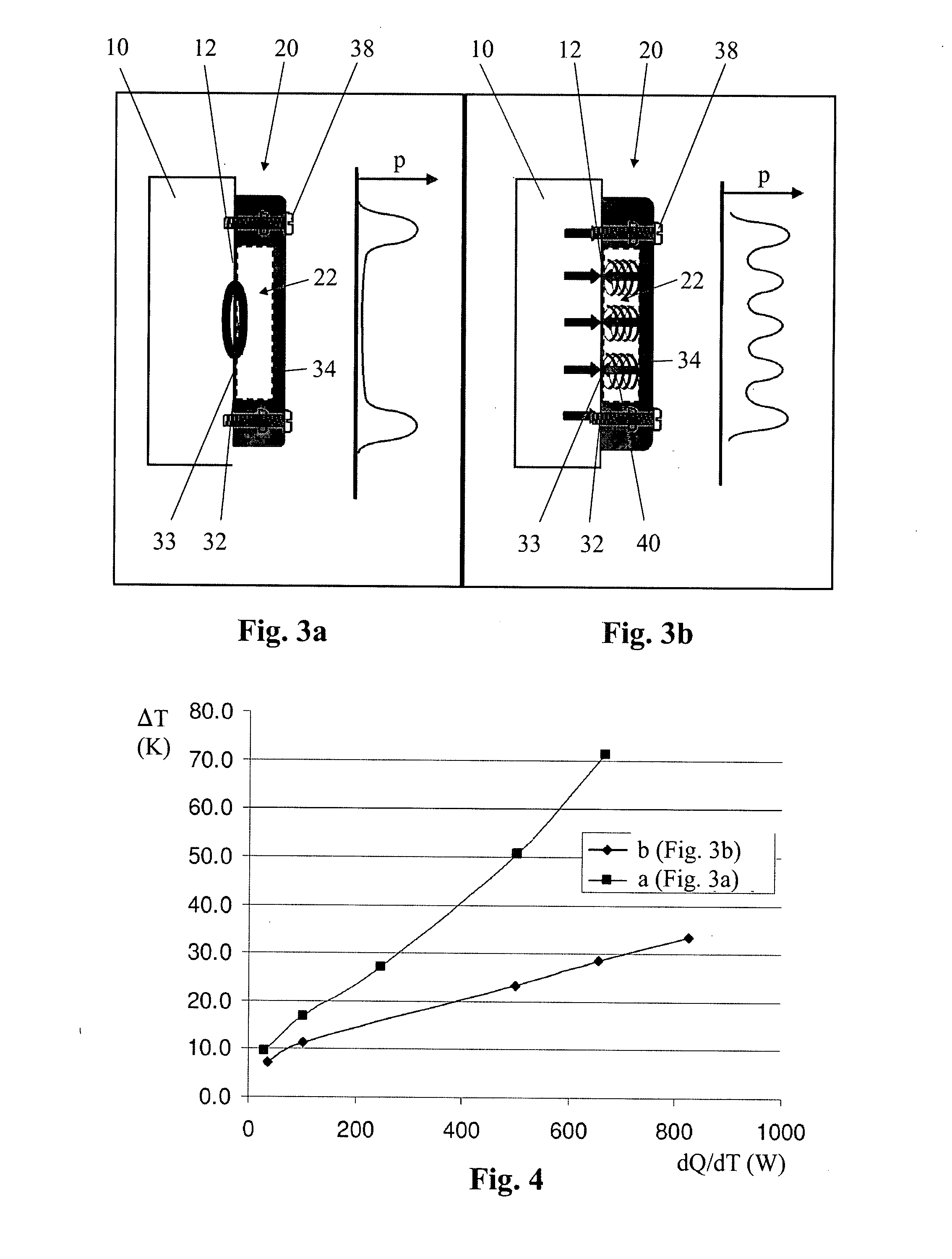

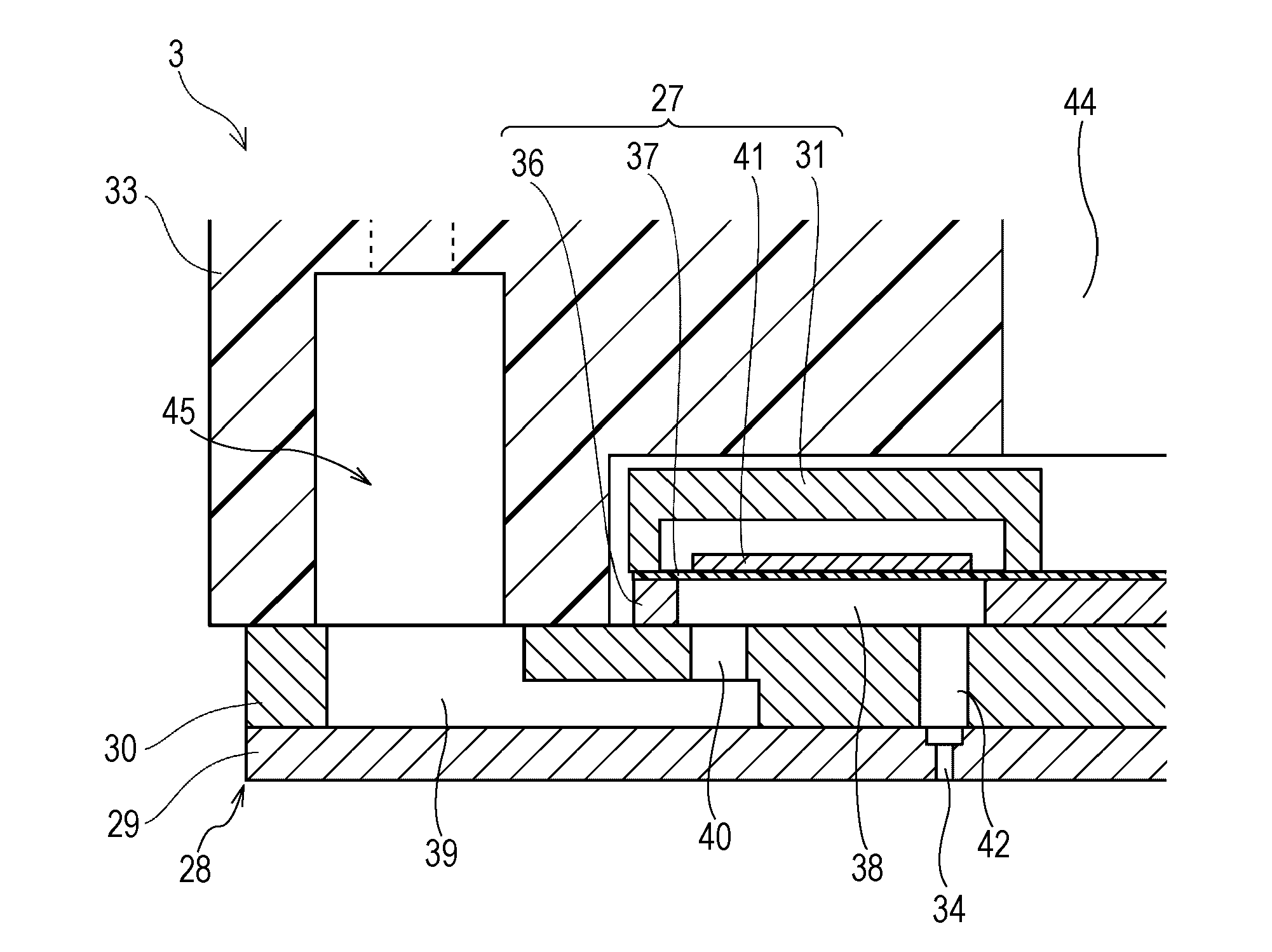

Cooling device for an electrical operating means

InactiveUS20080049384A1Good thermal contactReduce harmful effectsCooling bus-bar installationsSubstation/switching arrangement cooling/ventilationElectricityContact pressure

A cooling device is disclosed for an electrical operating means, which has a surface to be cooled. The cooling device comprises a coolant, a peripheral wall, whose interior defines a volume for the coolant, a fastening for fastening the cooling device to the electrical operating means, and a contact-pressure means. The peripheral wall has a thermally conductive contact wall with a contact face, which is designed for areal contact with the surface to be cooled. The contact-pressure means mechanically prestresses the contact wall in order to produce an areal contact pressure of the contact face against the surface to be cooled when the cooling device is fastened to the electrical operating means.

Owner:ABB RES LTD

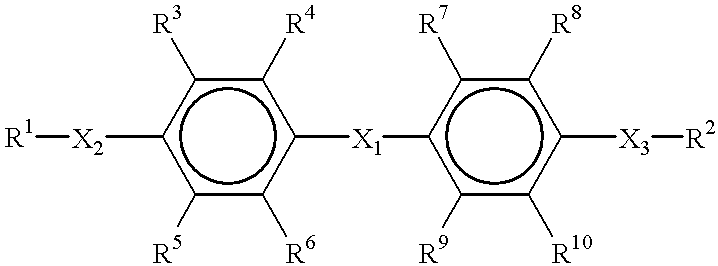

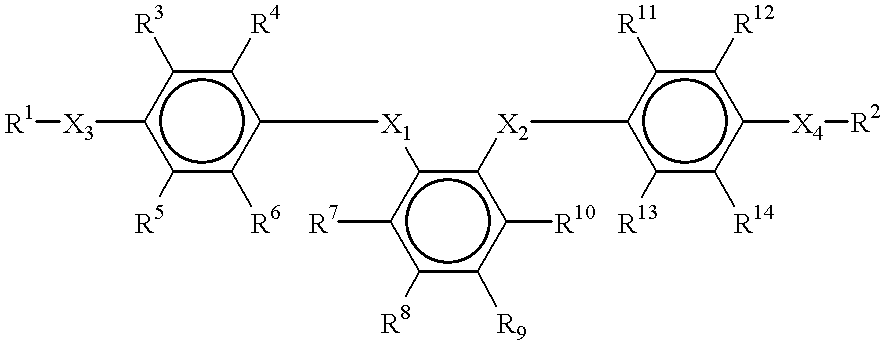

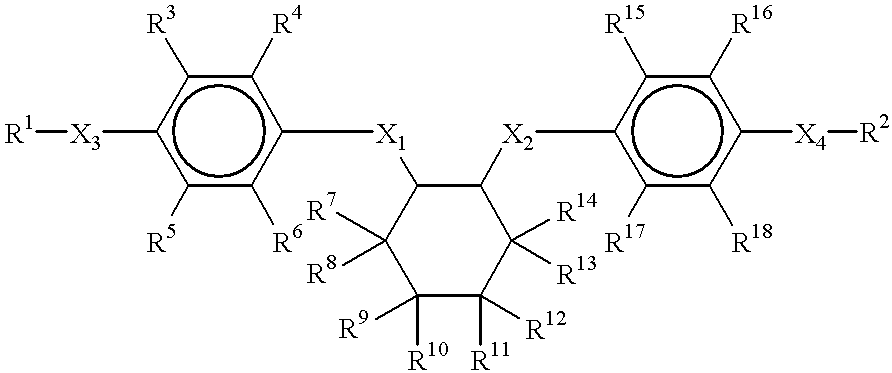

Film for optical elements

InactiveUS6294229B1Good effectWiden perspectiveLiquid crystal compositionsPolarising elementsPolycyclic compoundLiquid crystalline

A film for optical elements is formed by a liquid crystalline composition comprising the following components (a) and (b):(a) a liquid crystalline polymer which exhibits an optically positive uniaxial property; and(b) a polycyclic compound having a molecular weight of not more than 1,000 and wherein a plurality of alicyclic rings and / or aromatic rings are connected together through a linkage chain of 0 to 4 main-chain carbon atoms bonded to different ring carbon atoms, with hydrocarbon groups each having 1 to 20 carbon atoms being bonded respectively to both end rings through a linkage chain of 0 to 4 main-chain carbon atoms,an orientation form formed in the state of liquid crystal of said liquid crystalline composition being fixed.

Owner:NIPPON MITSUBISHI OIL CORP

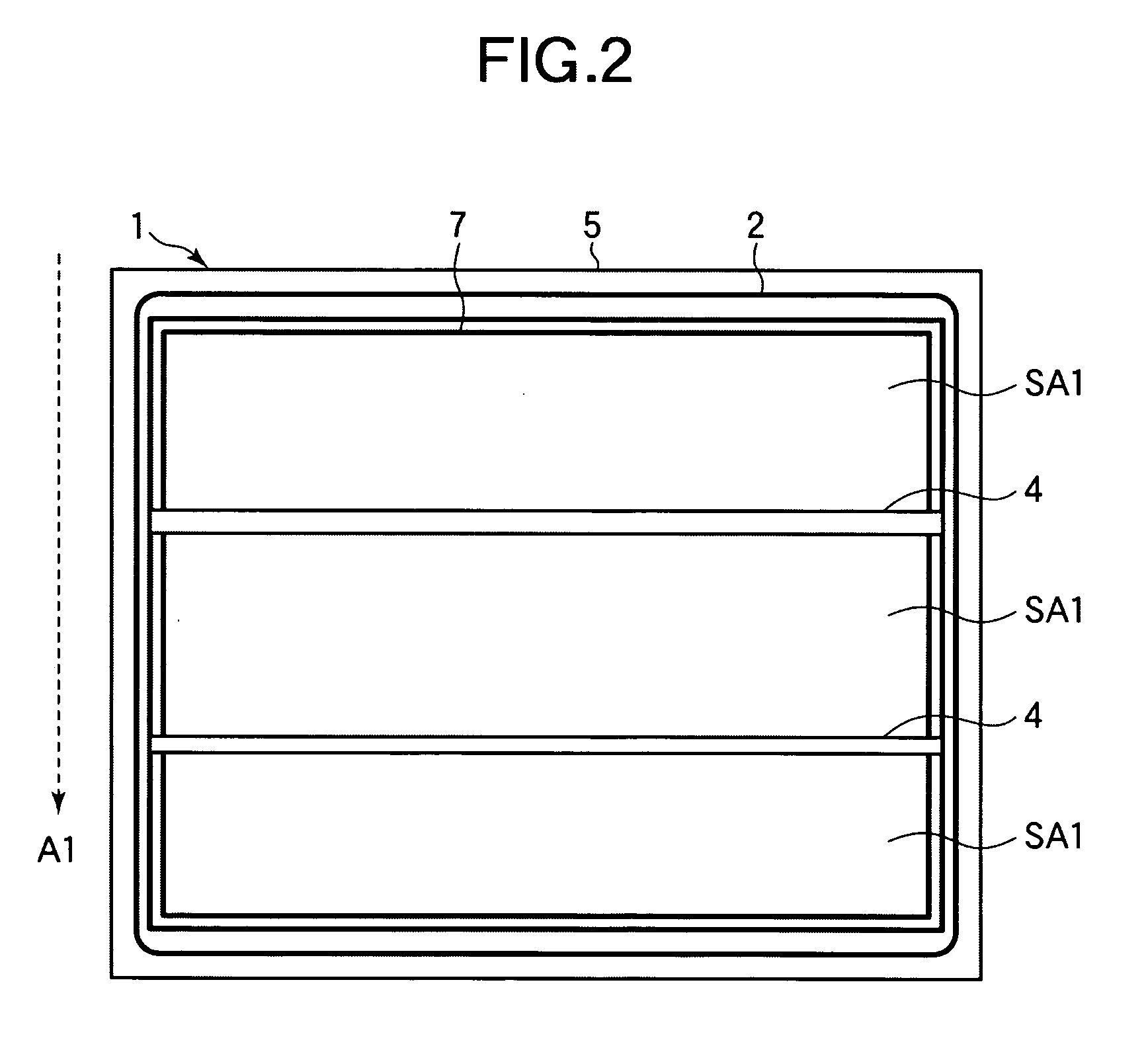

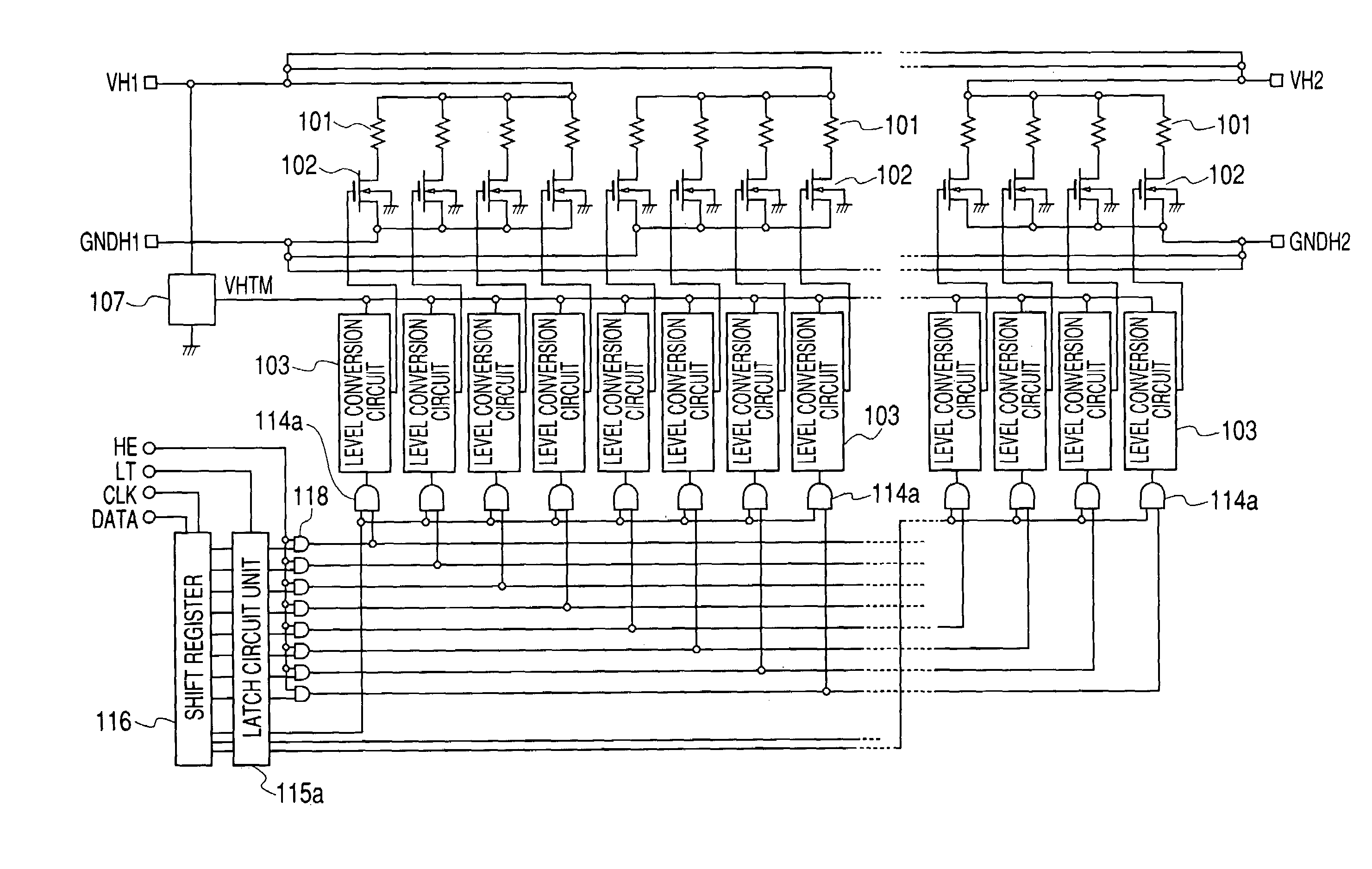

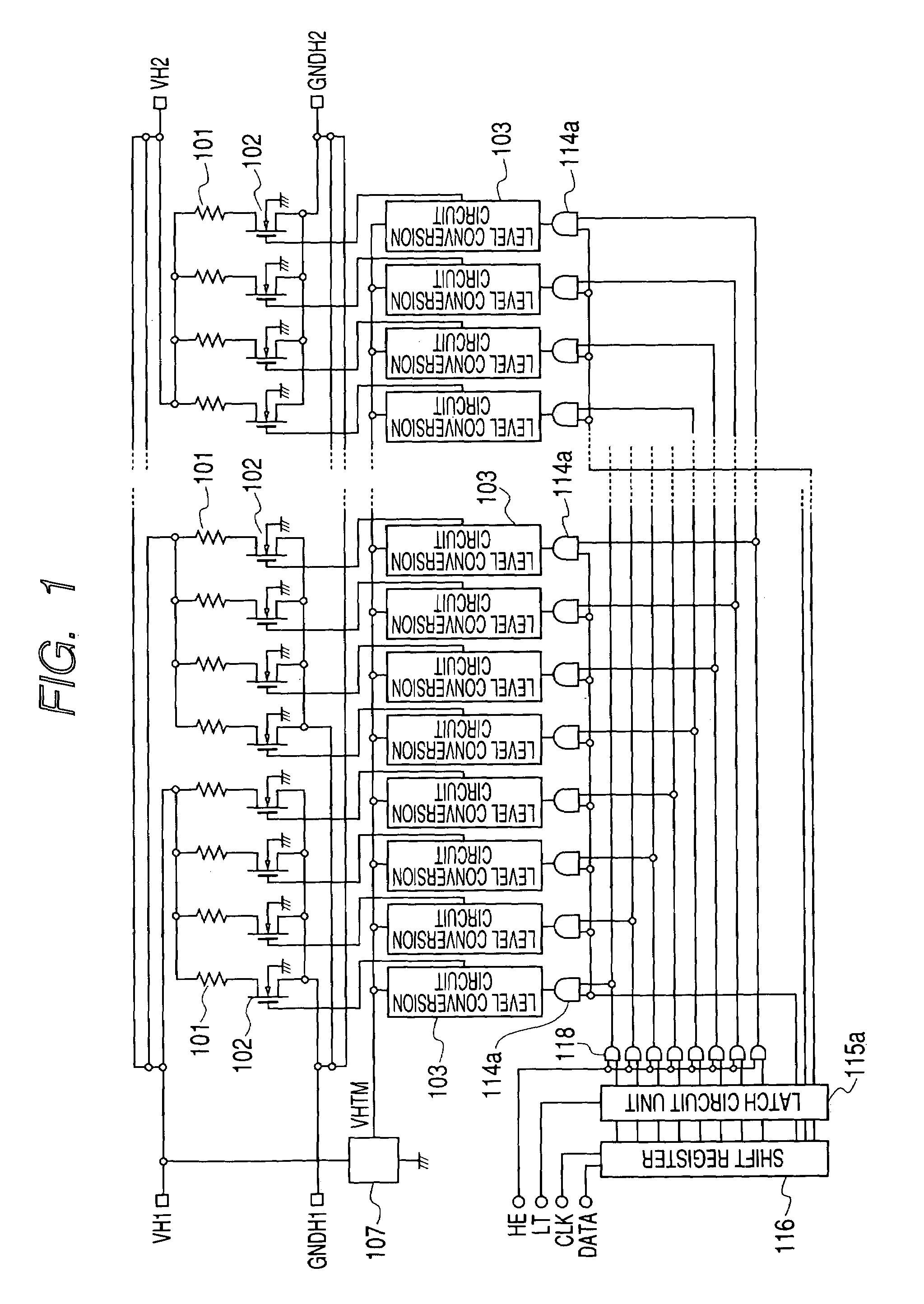

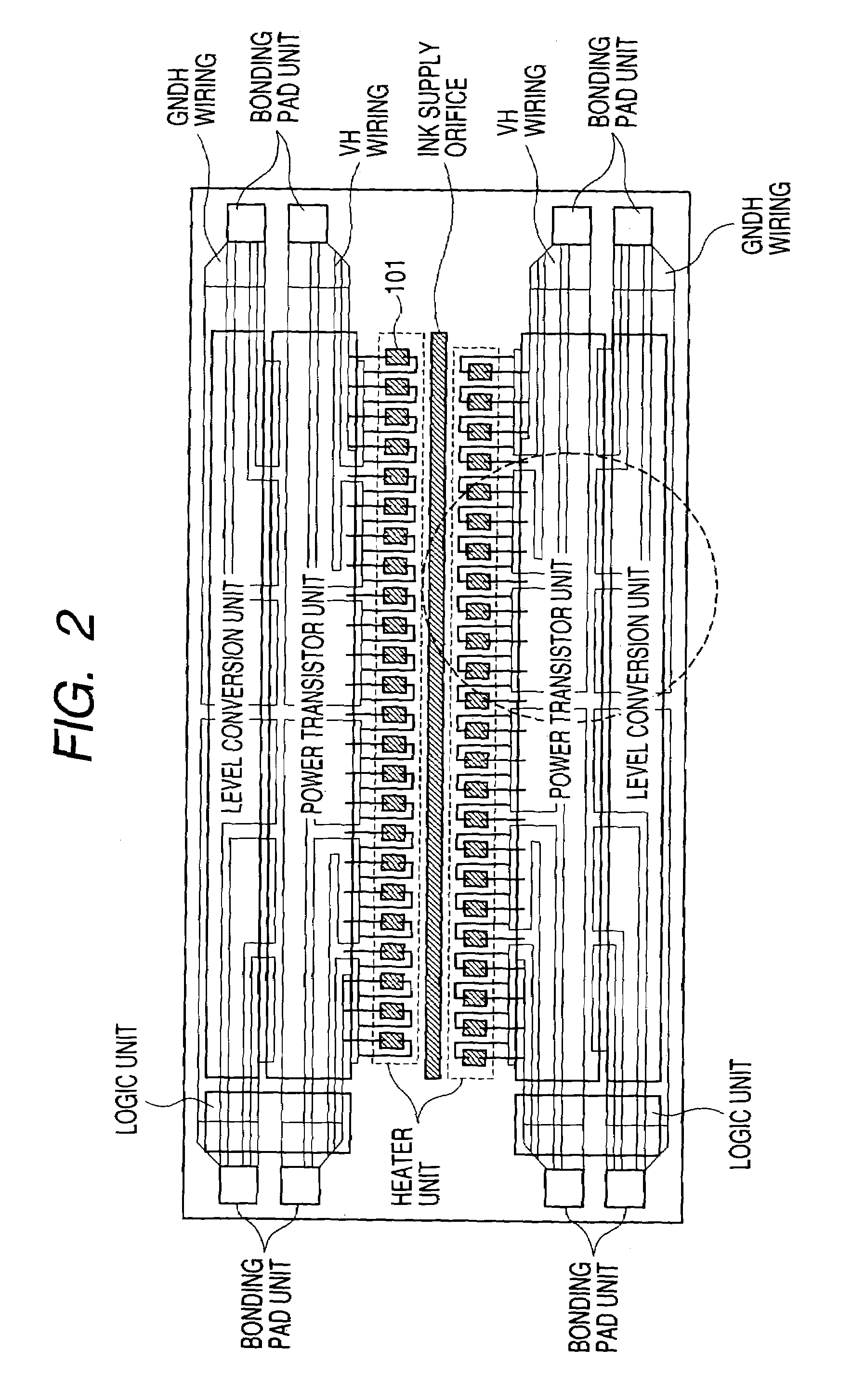

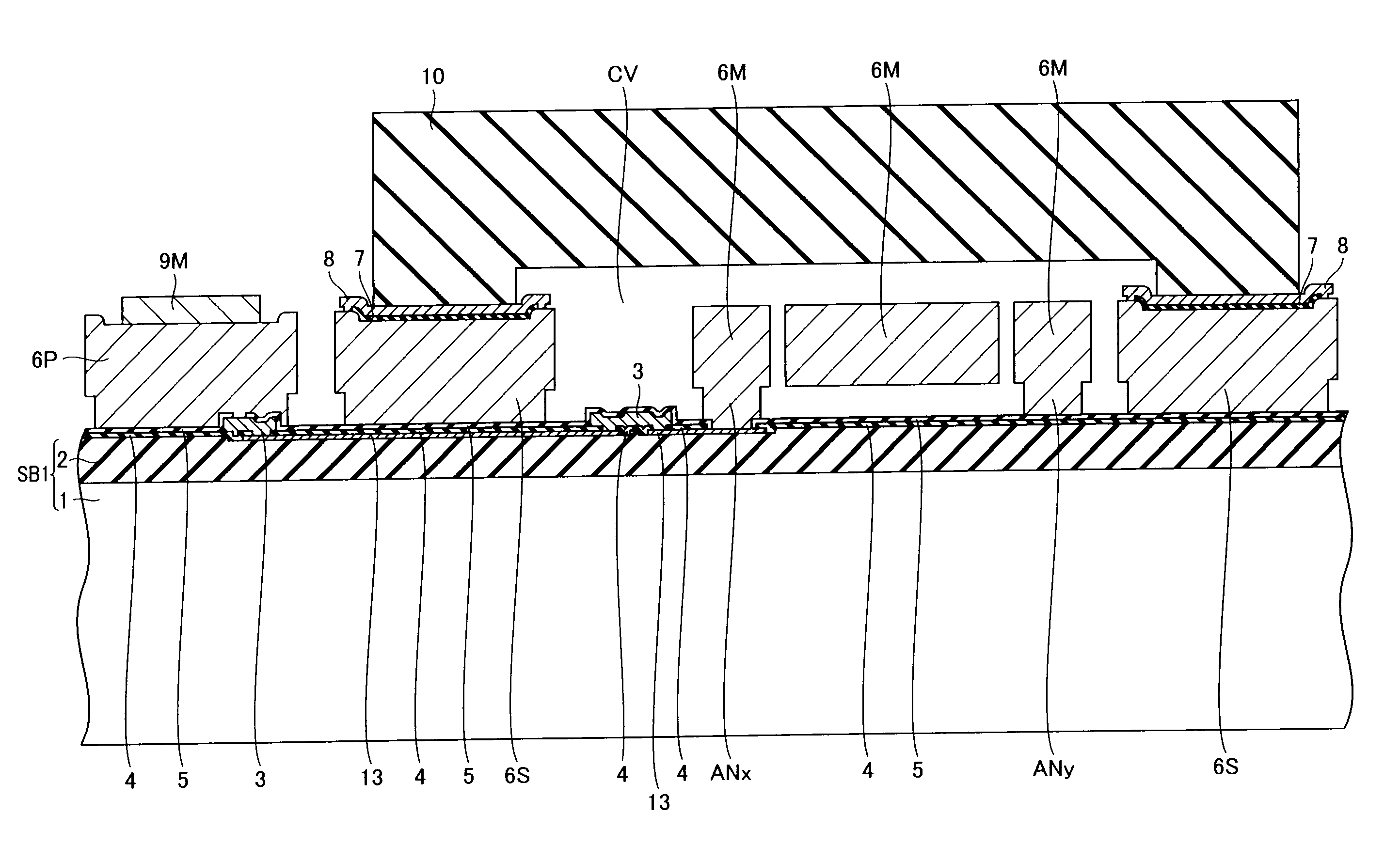

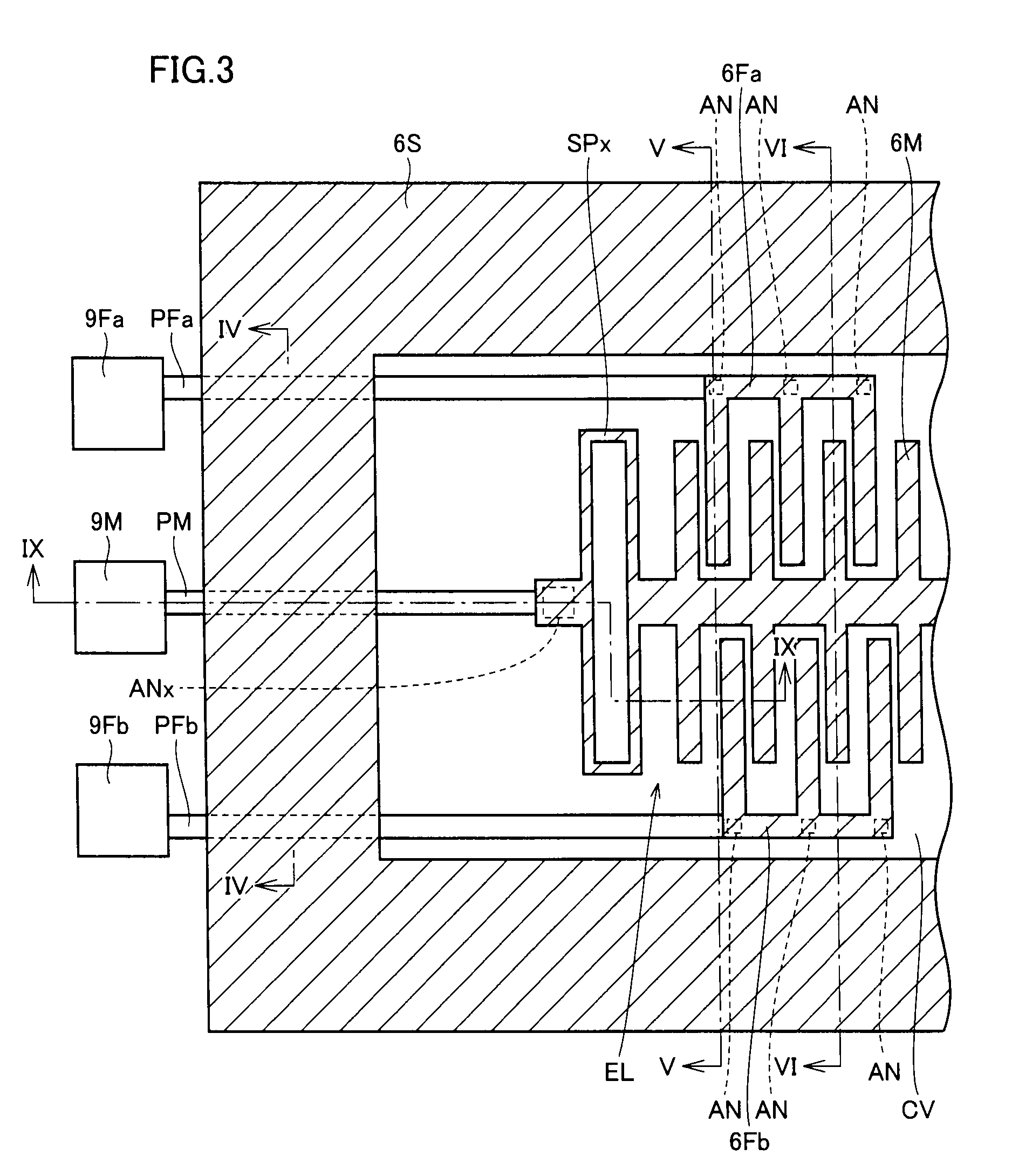

Semiconductor device for liquid ejection head, liquid ejection head, and liquid ejection apparatus

A semiconductor device constituting a liquid ejection head for ejecting a liquid such as an ink, comprising a segment having a plurality of pairs of recording element and driving element, wherein a first wiring for mutually connecting a first terminal of each driving element arranged within the same segment is formed on a first wiring layer on a semiconductor substrate, and a second terminal of the driving element and a first terminal of the recording element are connected on one for one base, and a second terminal of the recording element is connected to a power source wiring formed by the wiring layer different from the first wiring layer, and an auxiliary wiring for mutually connecting the second terminal of the recording element with the same segment is formed by the first wiring layer, thereby eliminating and suitably adjusting the irregularity of wiring resistance values within the segment.

Owner:CANON KK

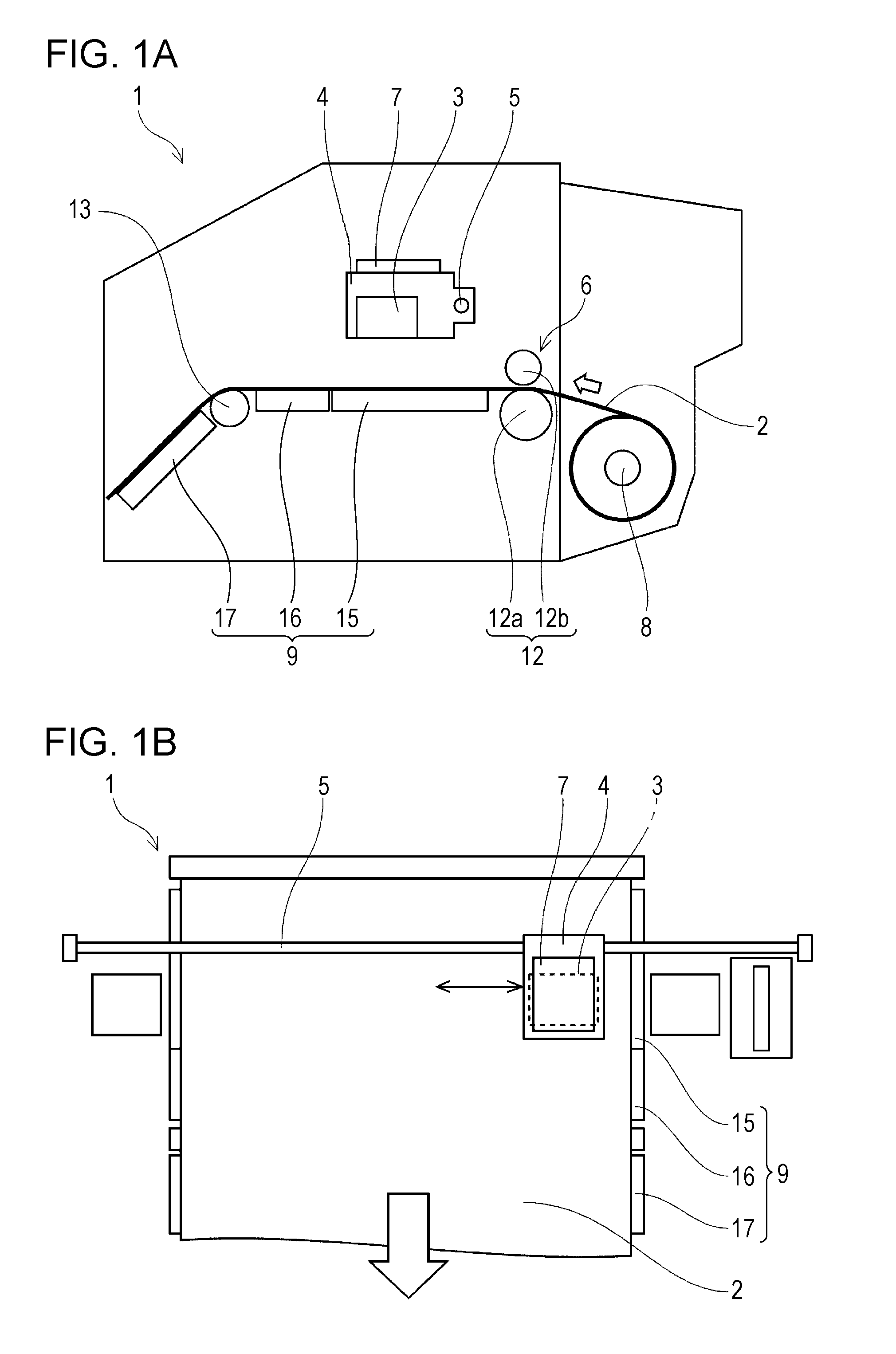

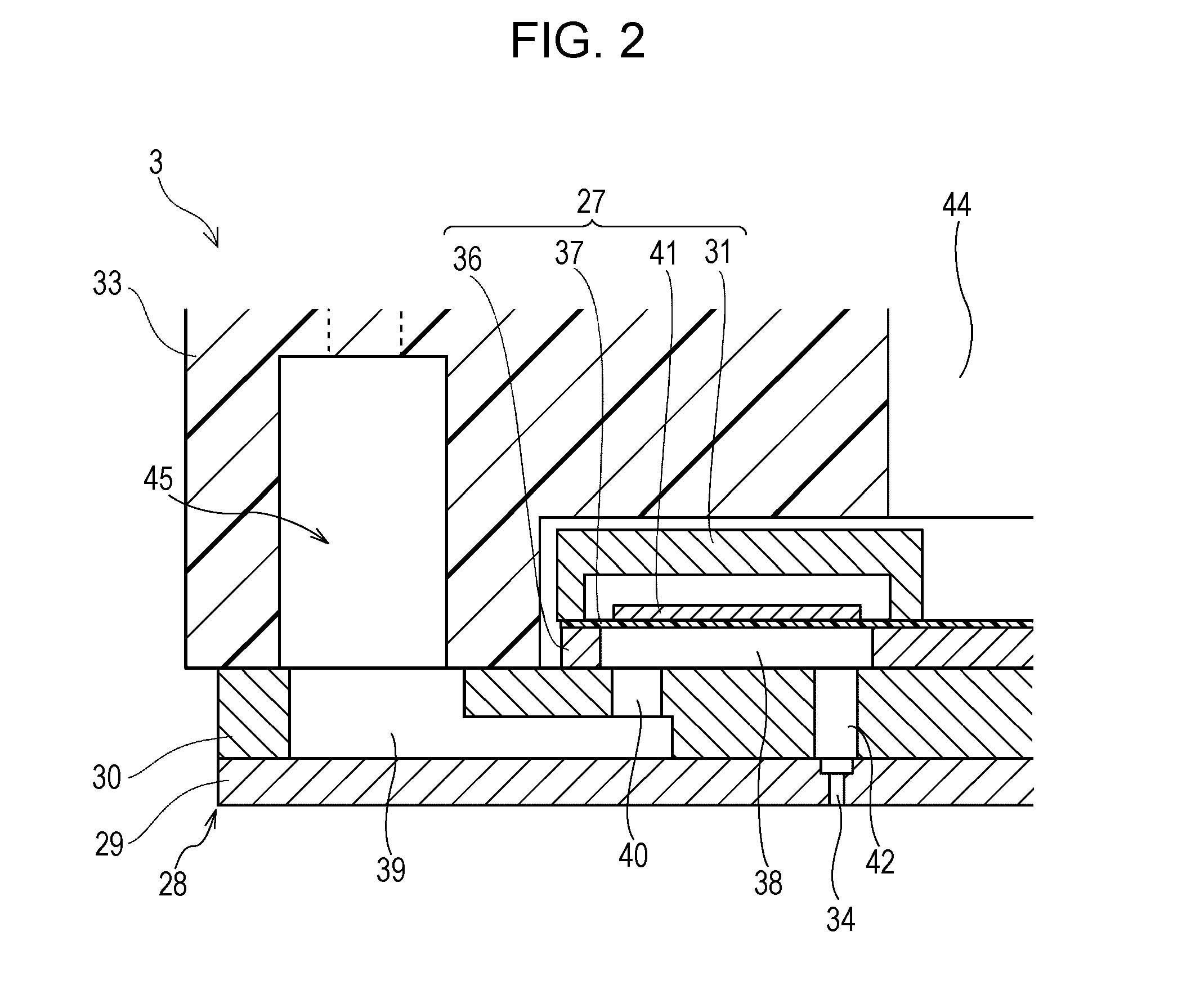

Liquid ejecting apparatus

ActiveUS20140375720A1Reduce in quantitySimple configurationOther printing apparatusLiquid jetSpray nozzle

A liquid ejecting apparatus has a liquid ejecting head capable of ejecting an ink containing thermoplastic resin particles from nozzles to a landing target and a heating unit of heating ink droplets landing on the landing target, in which the heating unit heats the ink droplets at a filming control temperature according to the minimum film forming temperature at which the filming of the surface of the ink droplets starts to thereby control the filming degree of the surface of the ink droplets.

Owner:SEIKO EPSON CORP

Piezoelectric thin-film resonator and filter using the same

ActiveUS7211931B2Little irregularityHigh strengthPiezoelectric/electrostriction/magnetostriction machinesImpedence networksResonatorPiezoelectric thin films

A piezoelectric thin-film resonator includes a substrate, a lower electrode arranged on the substrate, a piezoelectric film arranged on the lower electrode, and an upper electrode arranged on the piezoelectric film. A region in which the upper electrode overlaps with the lower electrode through the piezoelectric film has an elliptical shape, and a condition such that 1<a / b<1.9 is satisfied where a is a main axis of the elliptical shape, and b is a sub axis thereof.

Owner:TAIYO YUDEN KK

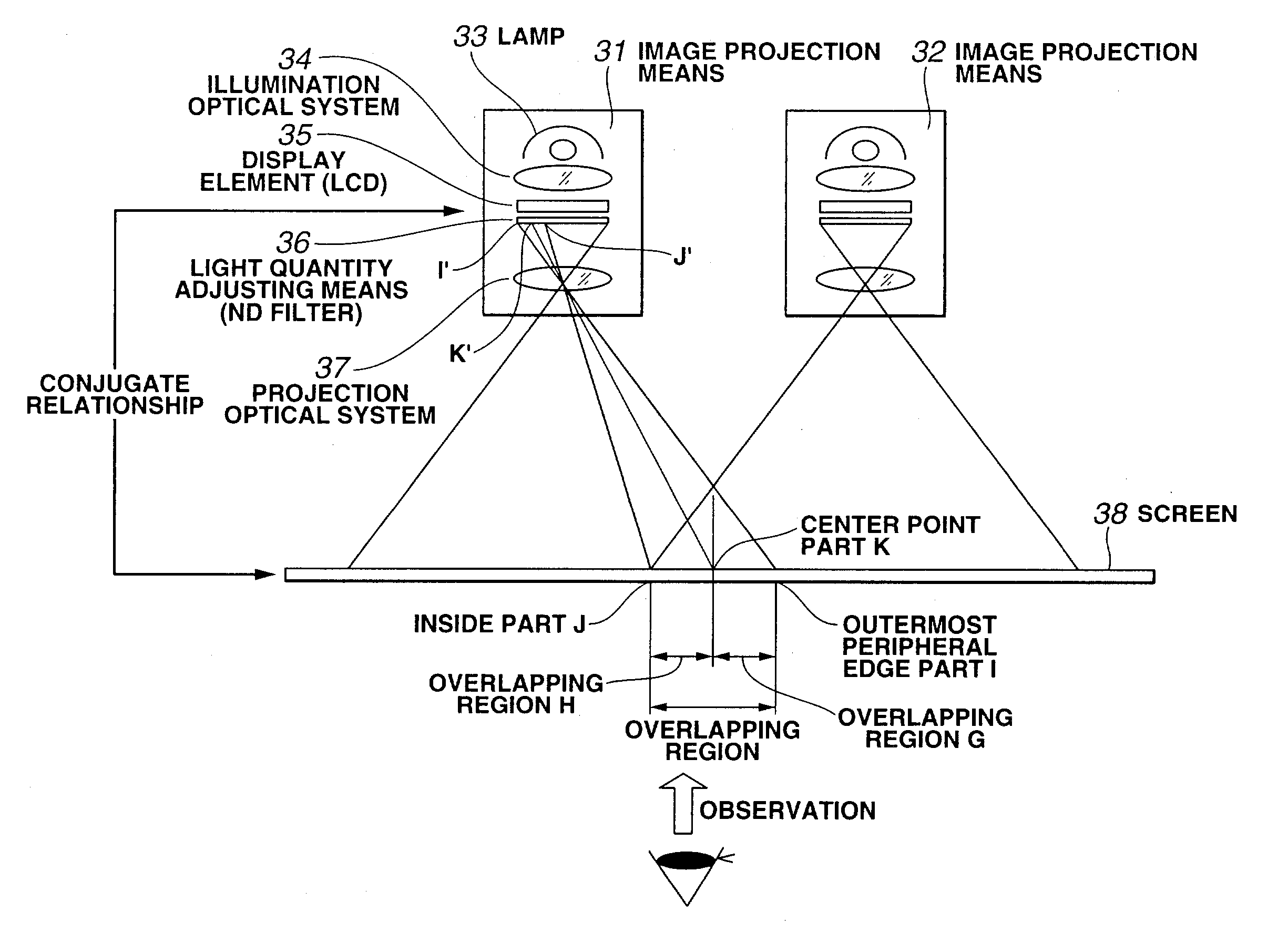

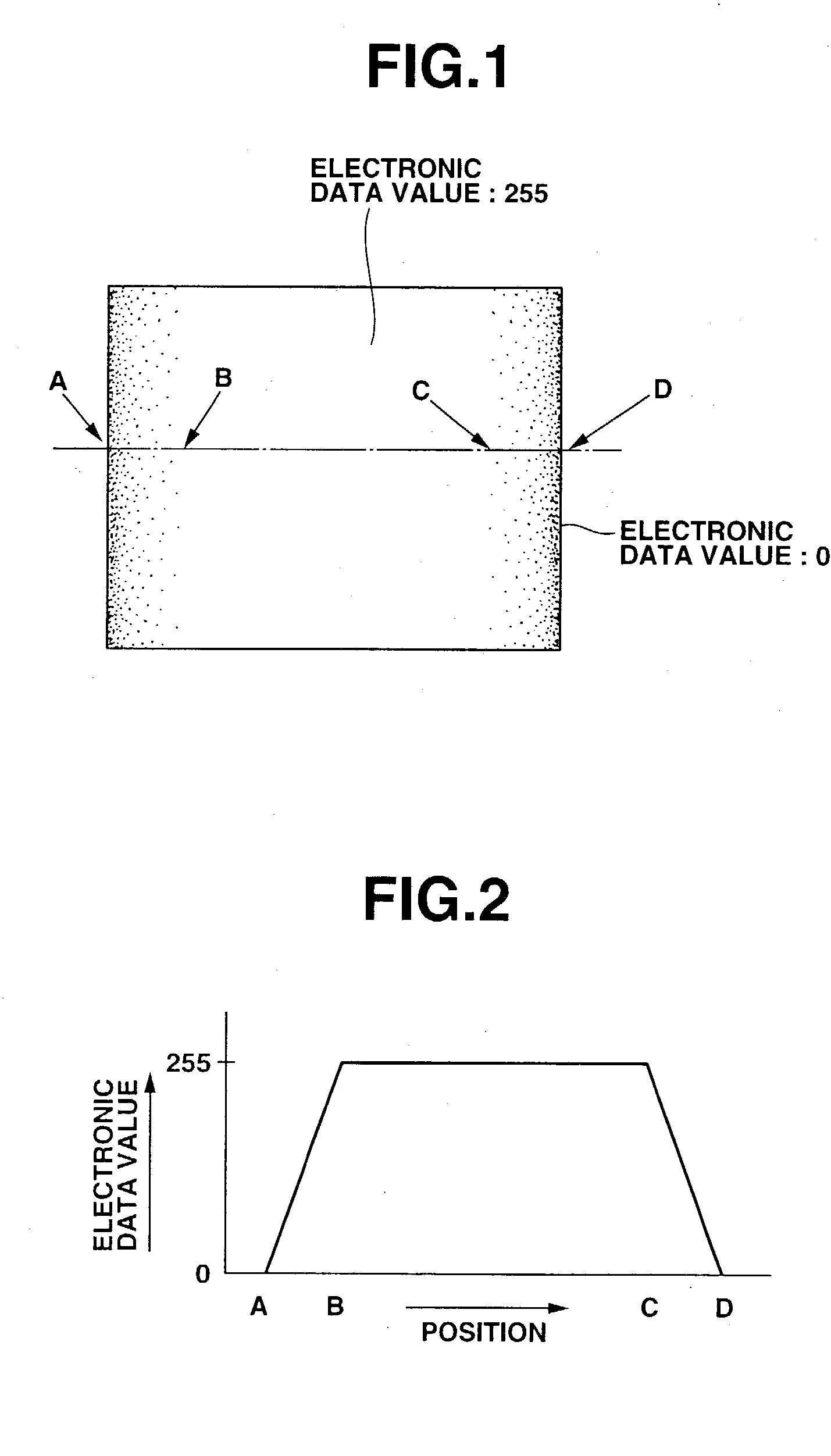

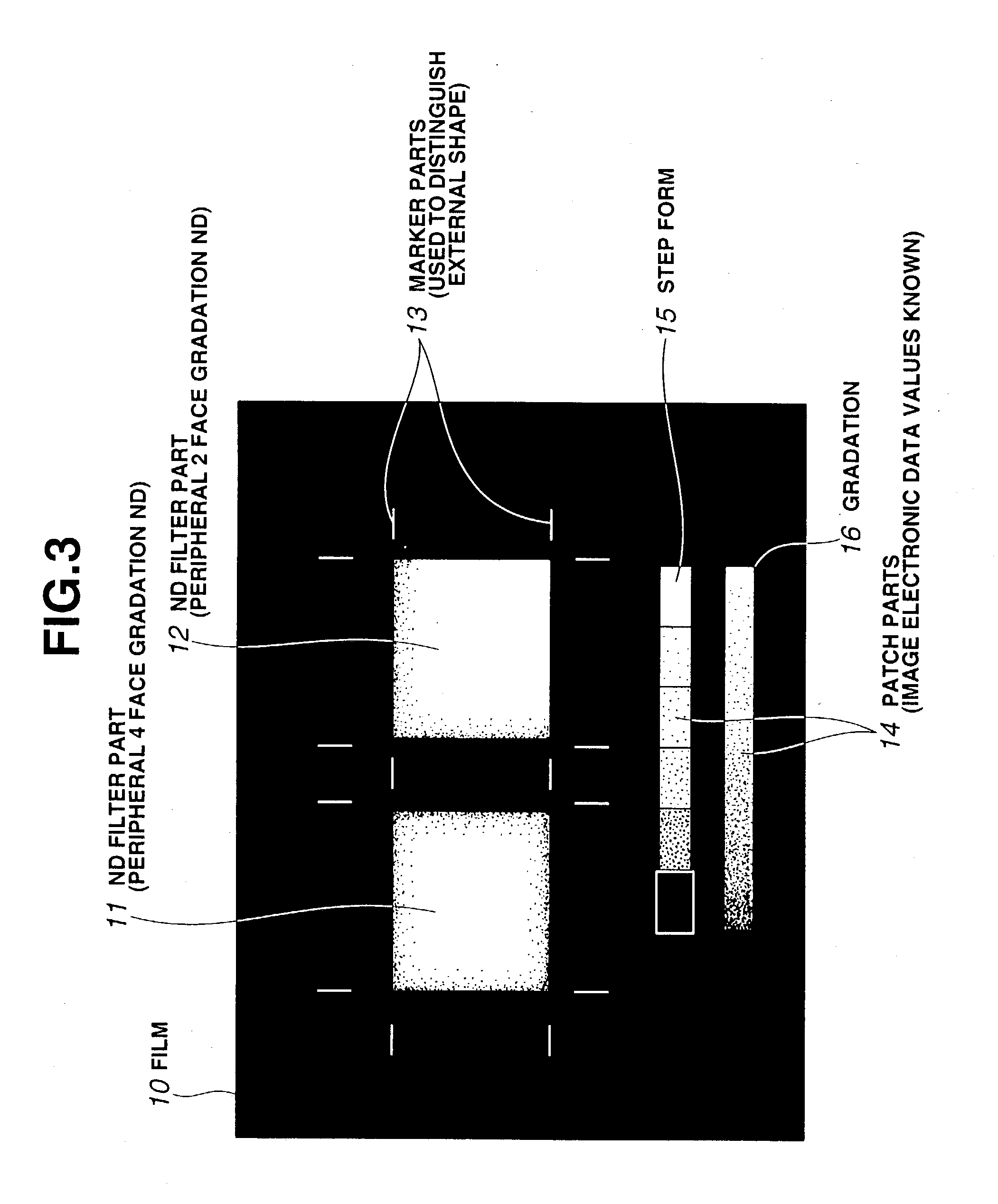

ND filter, method for manufacturing said filter, and multi-display device and image forming device using said filter

InactiveUS20030160946A1Suppress drop in transmittanceSuppress stray lightTelevision system detailsProjectorsOptical transmittanceDisplay device

The present invention provides an ND filter manufacturing method which makes it possible to obtain an ND filter film that has light transmittance information in respective positions by exposing and imaging image electronic data that has light transmittance information for respective positions used to form an ND filter by employing an exposure imaging device that is capable of the direct exposure imaging of the image electronic data, and developing the film. Furthermore, the light transmittance distributions of ND filters disposed in positions corresponding to the overlapping regions in a multi-display device are constructed from curves, so that the overlapping regions are hard to distinguish from the non-overlapping regions.

Owner:OLYMPUS CORP

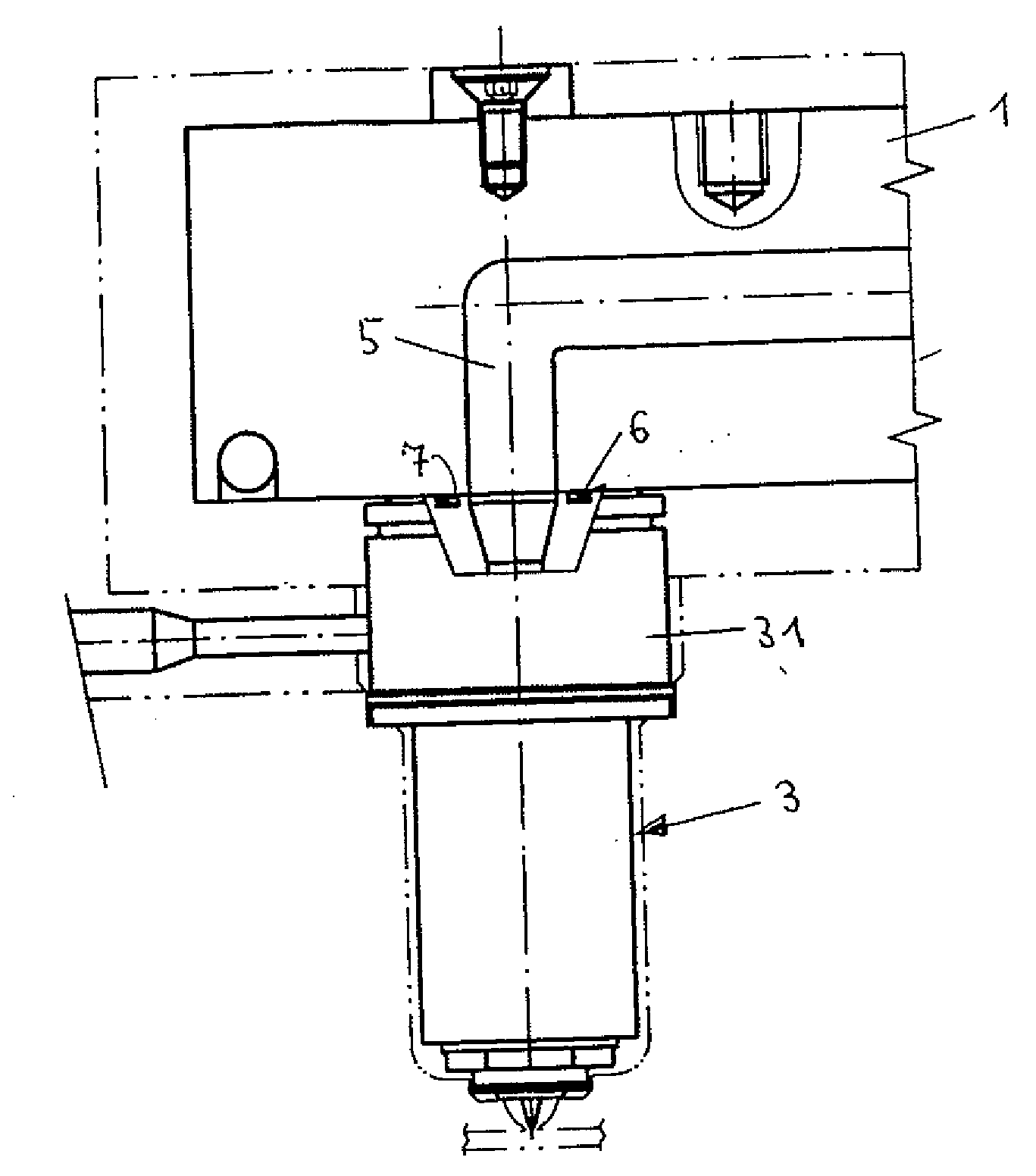

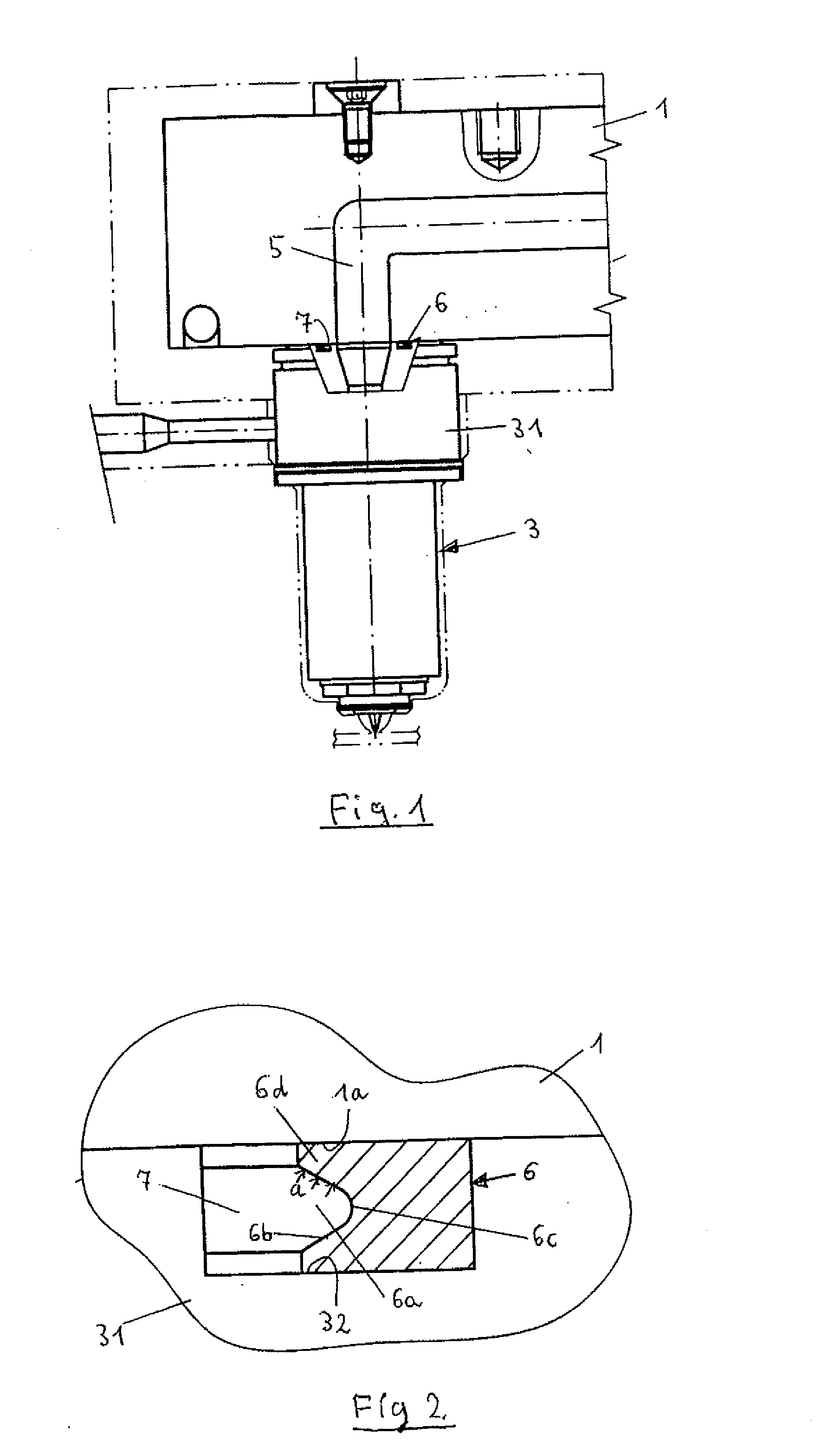

High-Stress Seals for Injection Molding Machines

A high-stress seal for injection molding machines, intended for sealing the gap between the injector nozzle and the injector rail of the tool. The seal in the ingate area is designed in a dome shape with an opening in the top of the dome for flux to enter. Correspondingly, the injector nozzles and the opposing wall of the injector rail of the tool have a dome-shaped design and are spatially adapted to the seal. This construction provides the seal with very dense, firm placement when the injector is pressed into the tool recess, and flux under high pressure cannot dislodge it.

Owner:INCOE CORP

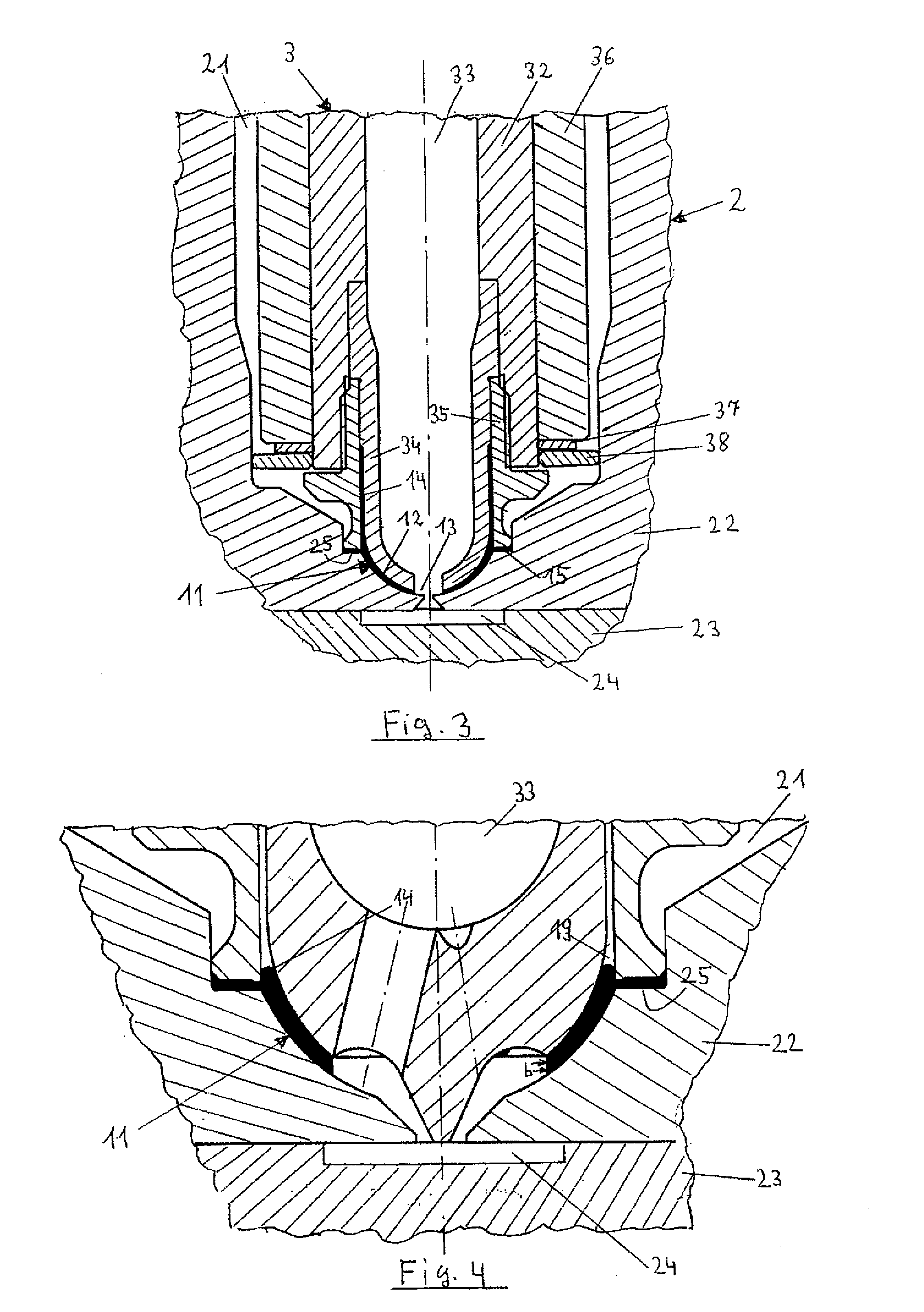

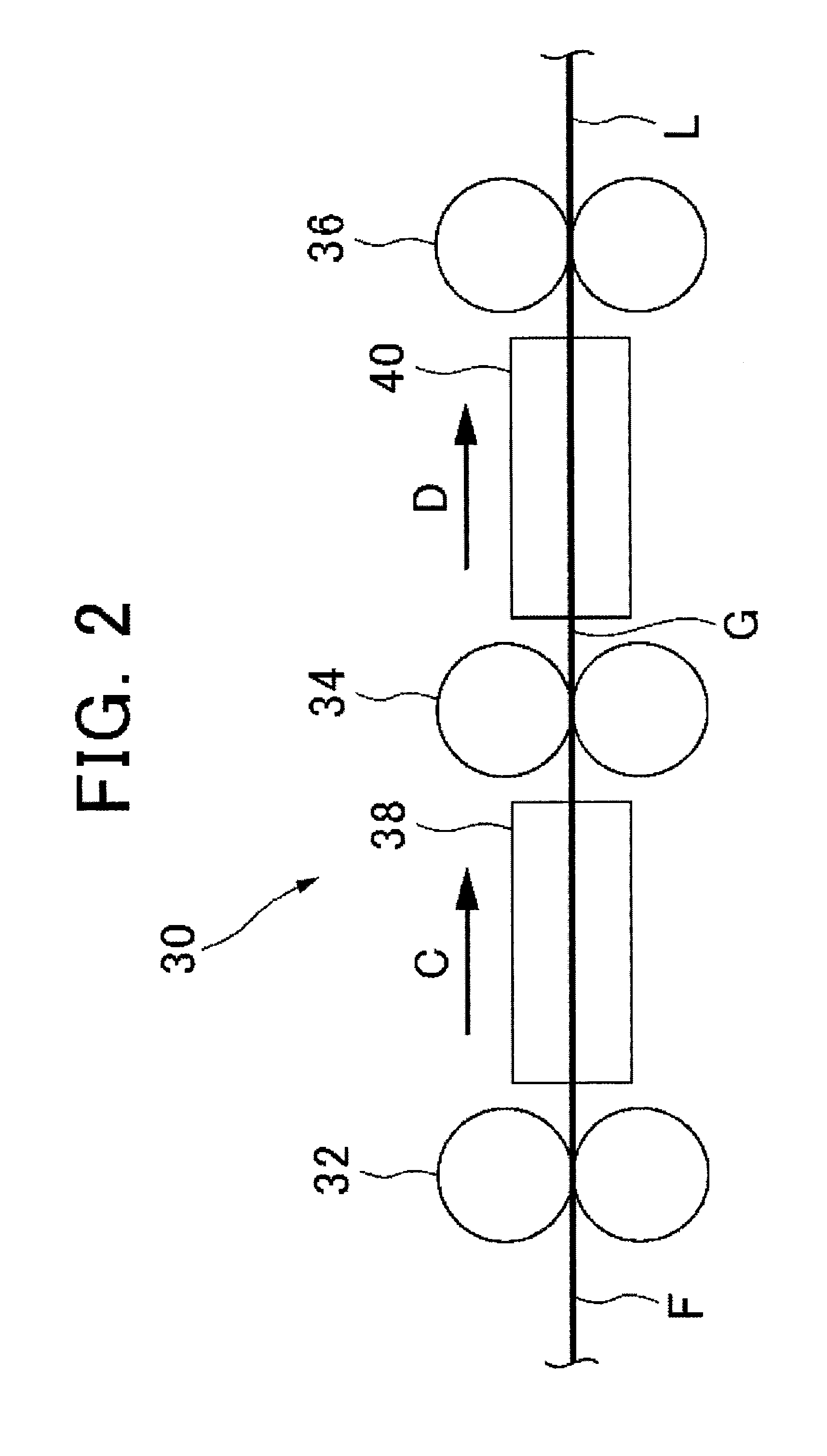

Process for Producing Polyamide Based Resin Laminated Film Roll

A production process of a film roll according to the present invention includes a step of melt-extruding and cooling wherein polyamide based resin is melt-extruded and cooled in a sheet form onto a movable cooling material surface to obtain an unstretched sheet; a step of biaxial stretching wherein an unstretched sheet is stretched biaxially in the longitudinal direction and the transverse direction; and a winding-up step of taking up the biaxially stretched film in a roll form. And in the step of melt-extruding and cooling, corona discharge in a streamer corona state is performed between an electrode applied with high dc voltage and the polyamide based resin sheet in the melted state, and sufficient electric charges that enable the polyamide based resin sheet in the melted state to come in close contact with the movable cooling material surface are imparted.

Owner:TOYO TOYOBO CO LTD

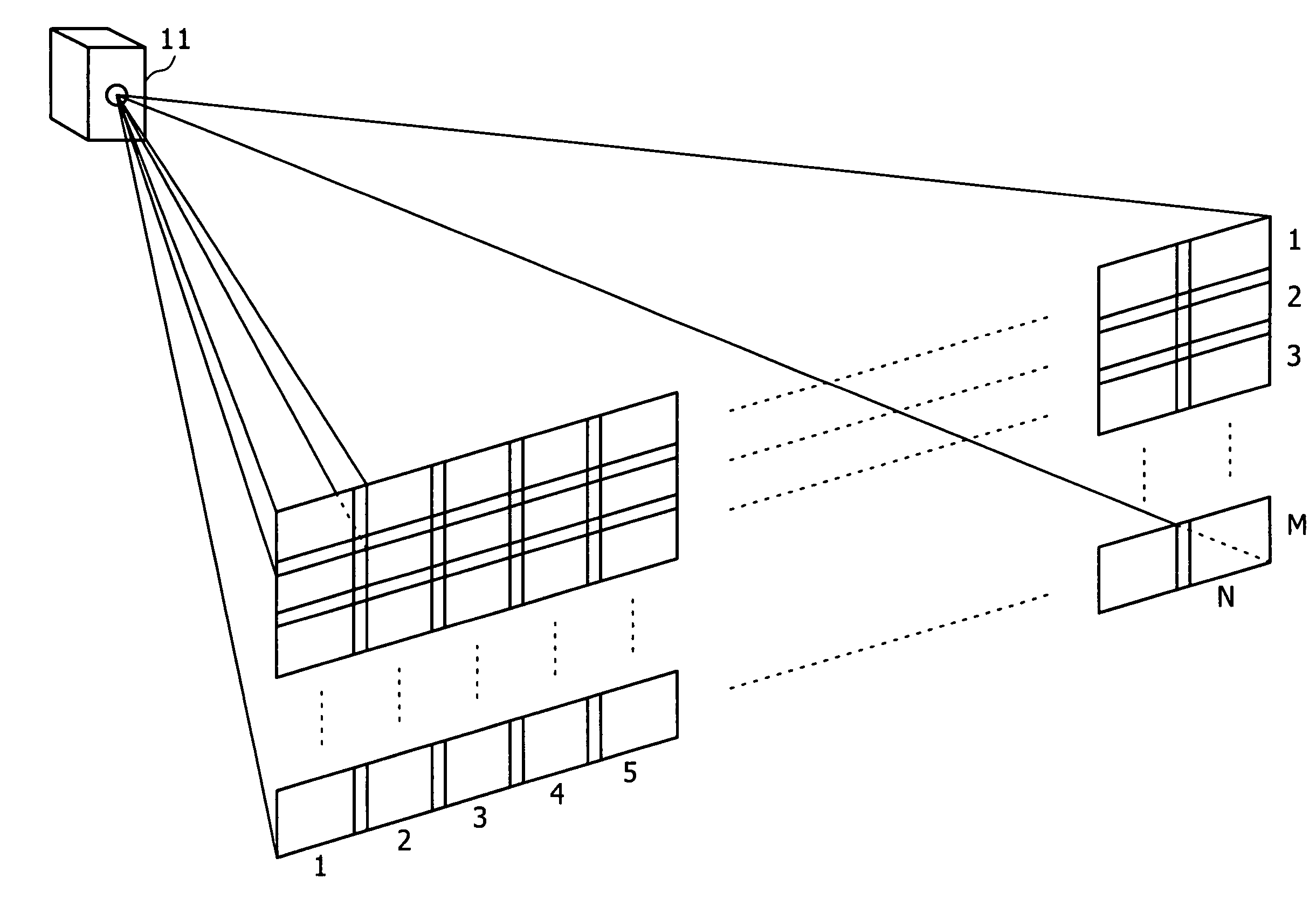

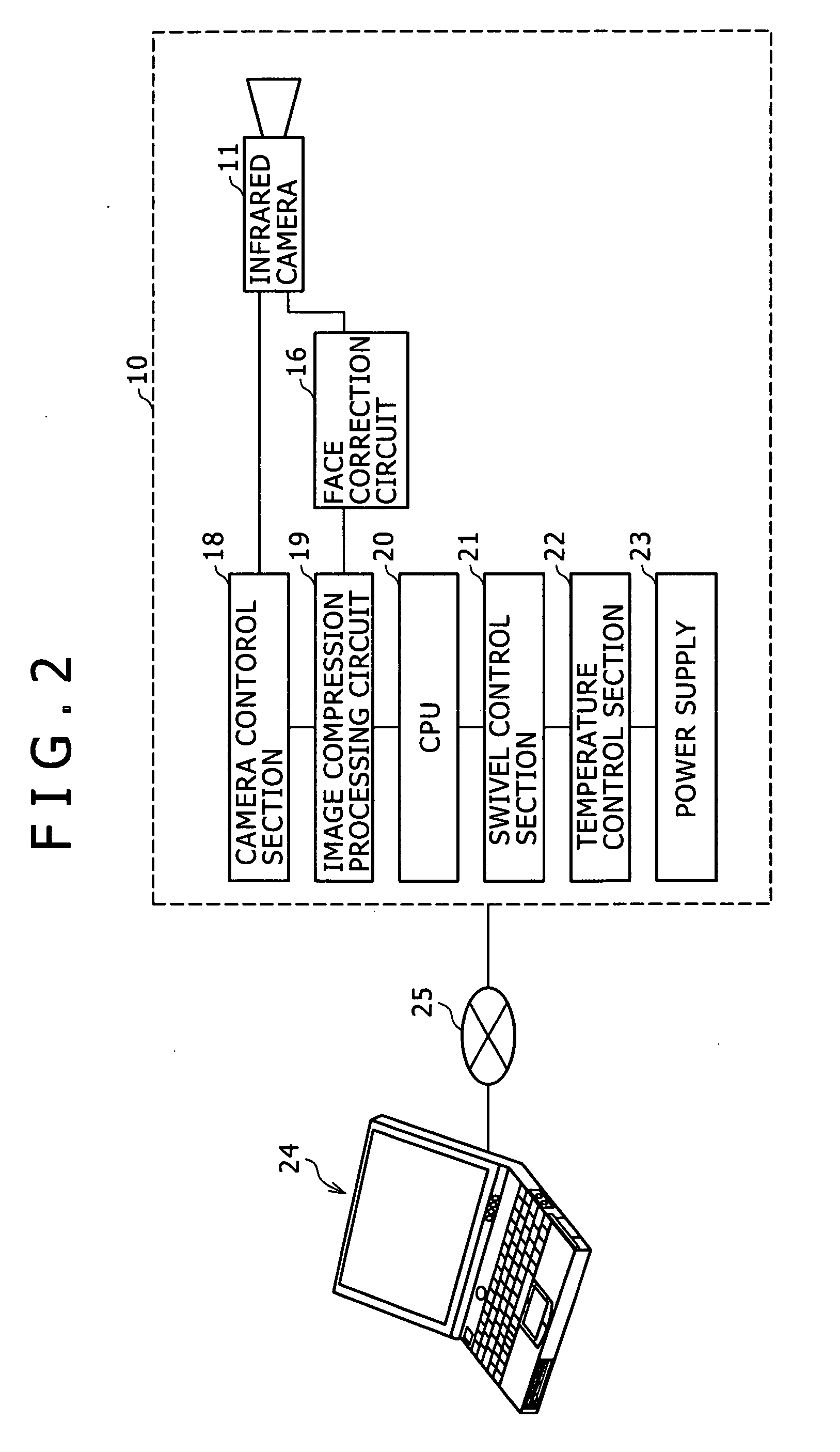

Monitoring system

InactiveUS20090066791A1Quality imageQuality improvementTelevision system detailsColor television detailsBrightness perceptionImaging data

Disclosed herein is a monitoring system, including an infrared camera; an image pickup direction control section configured to vary the image pickup direction of the infrared camera; a correction section configured to correct irregularity in brightness of a screen image of image data picked up in each of the image pickup directions by the infrared camera and output the corrected image data whose irregularity in brightness is corrected; an image processing section configured to connect the corrected image data corresponding to the image data picked upon in the individual image pickup directions by the infrared camera to produce a whole image; and a display section configured to display the whole image.

Owner:SONY CORP

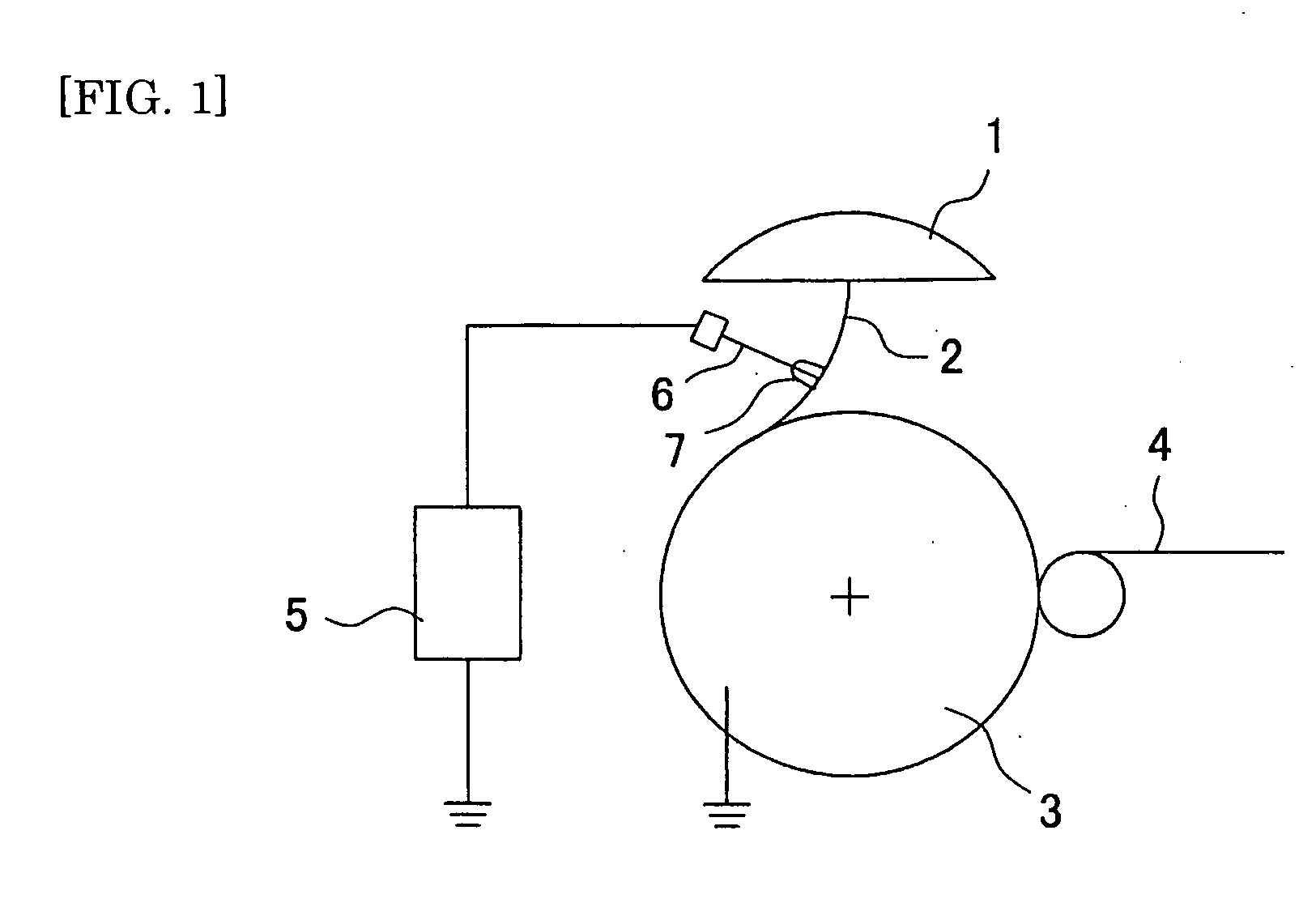

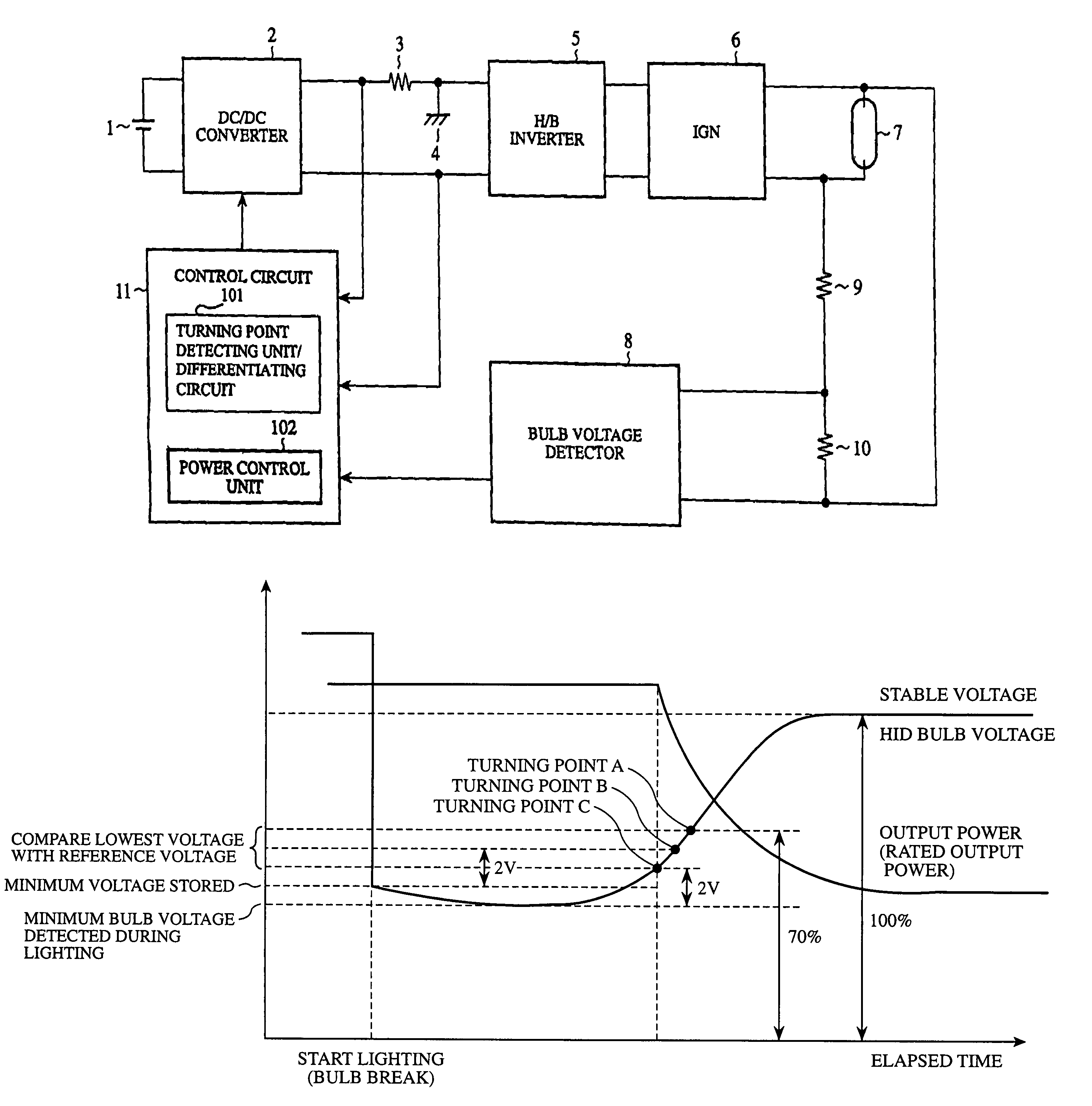

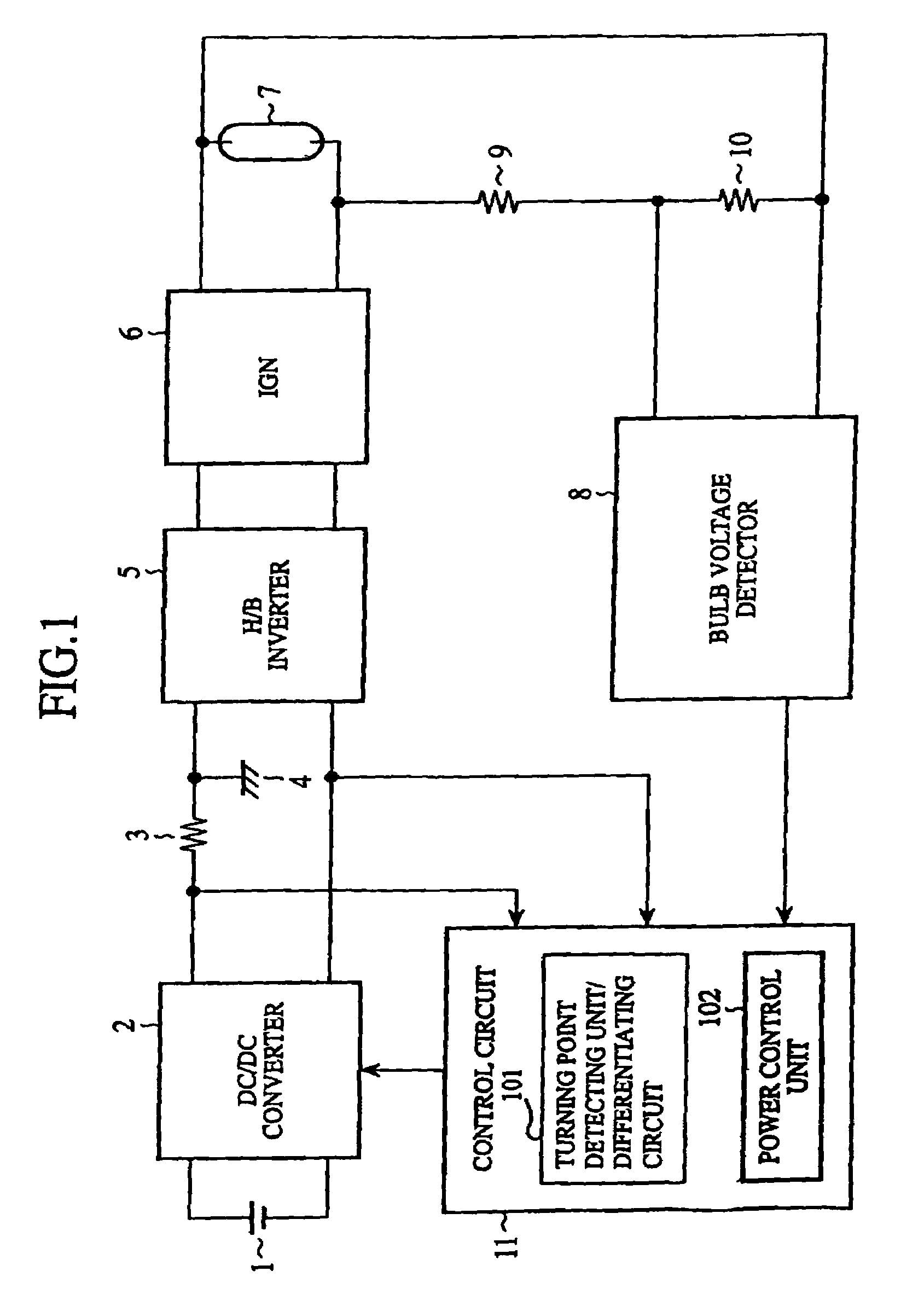

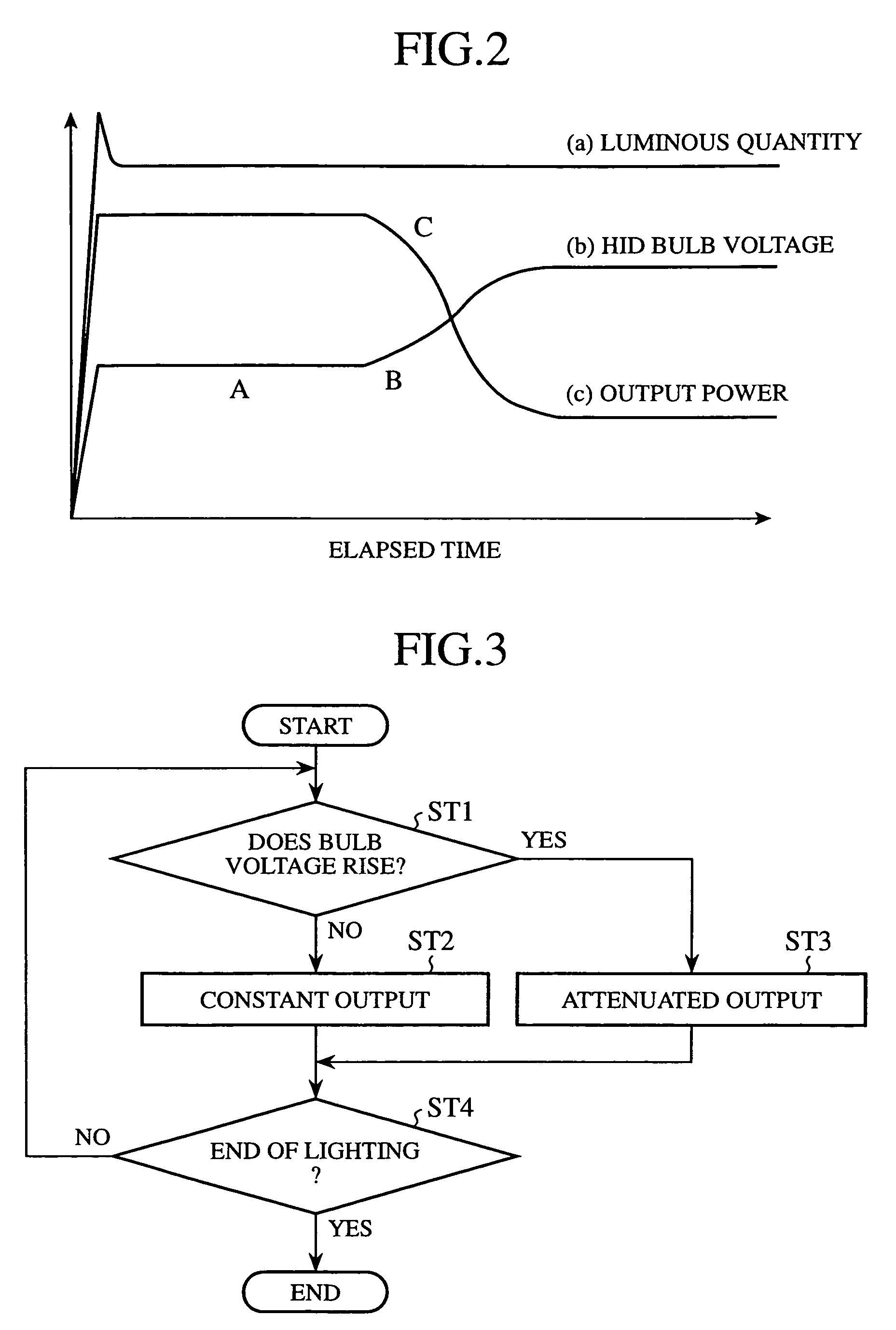

Discharge lamp lighting device

InactiveUS7091673B2Sufficient quantityPrecise attenuation control of output powerElectrical apparatusElectric light circuit arrangementEffect lightControl circuit

A discharge bulb ballast has a control circuit (11) that includes a turning point detecting unit (101) for detecting a turning point at which a bulb voltage starts rising after switching on a discharge bulb (7). Immediately after switching on the discharge bulb (7), a power control unit (102) carries out control in such a manner that the discharge bulb (7) is supplied with first power. When the turning point detecting unit (101) detects that the voltage of the discharge bulb (7) exceeds the turning point, the power control unit (102) supplies the discharge bulb (7) with second power less than the first power.

Owner:MITSUBISHI ELECTRIC CORP

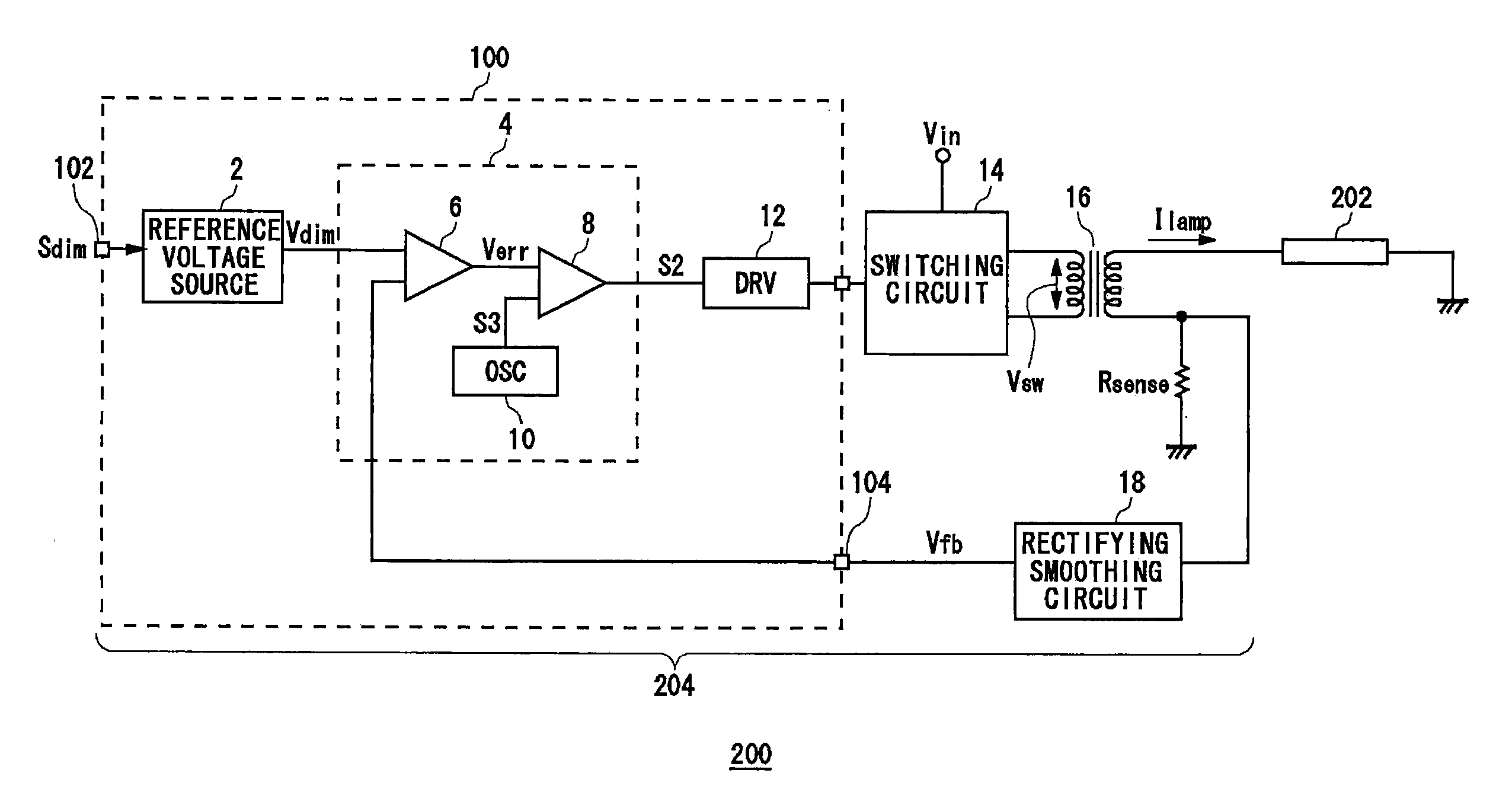

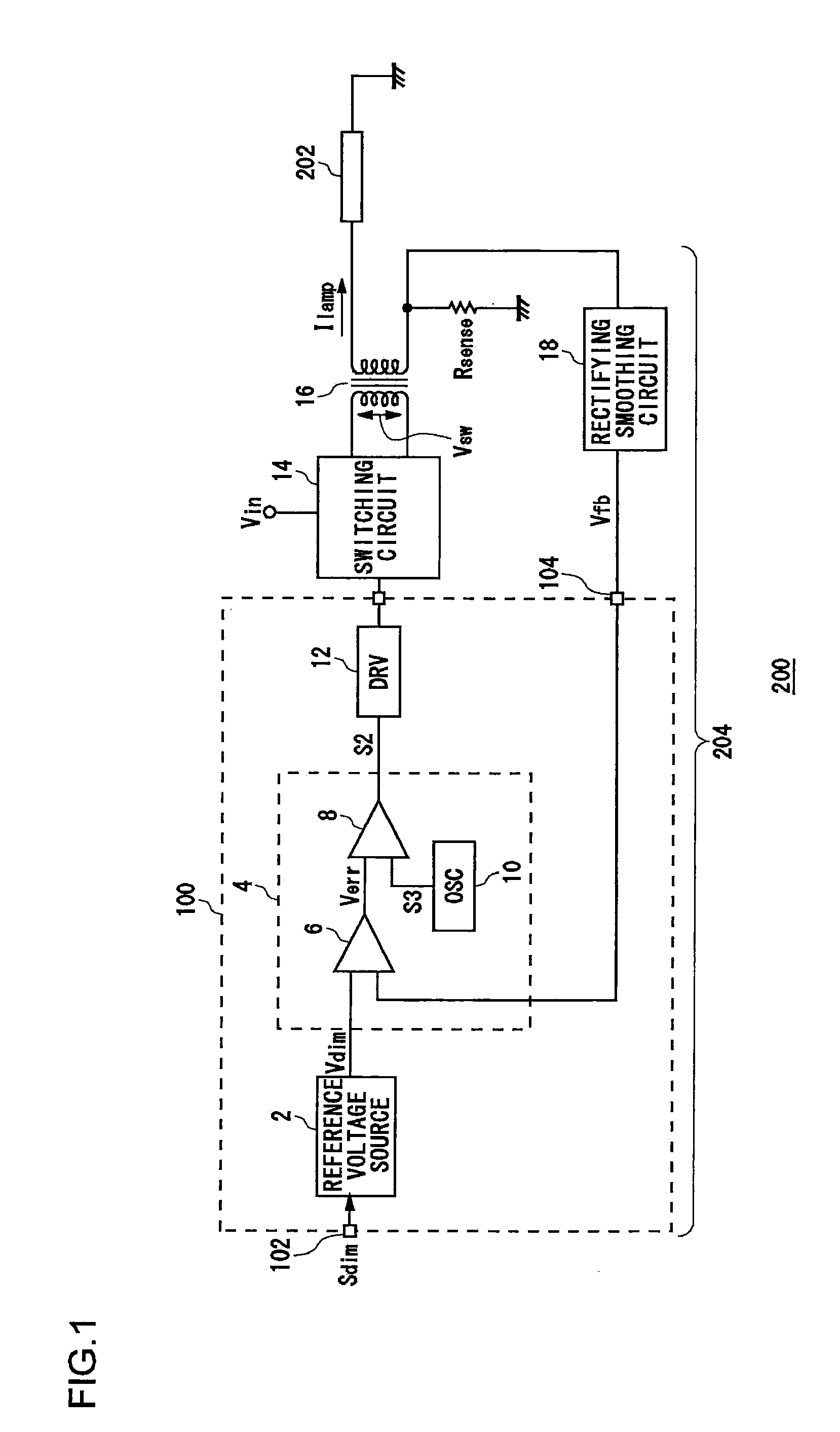

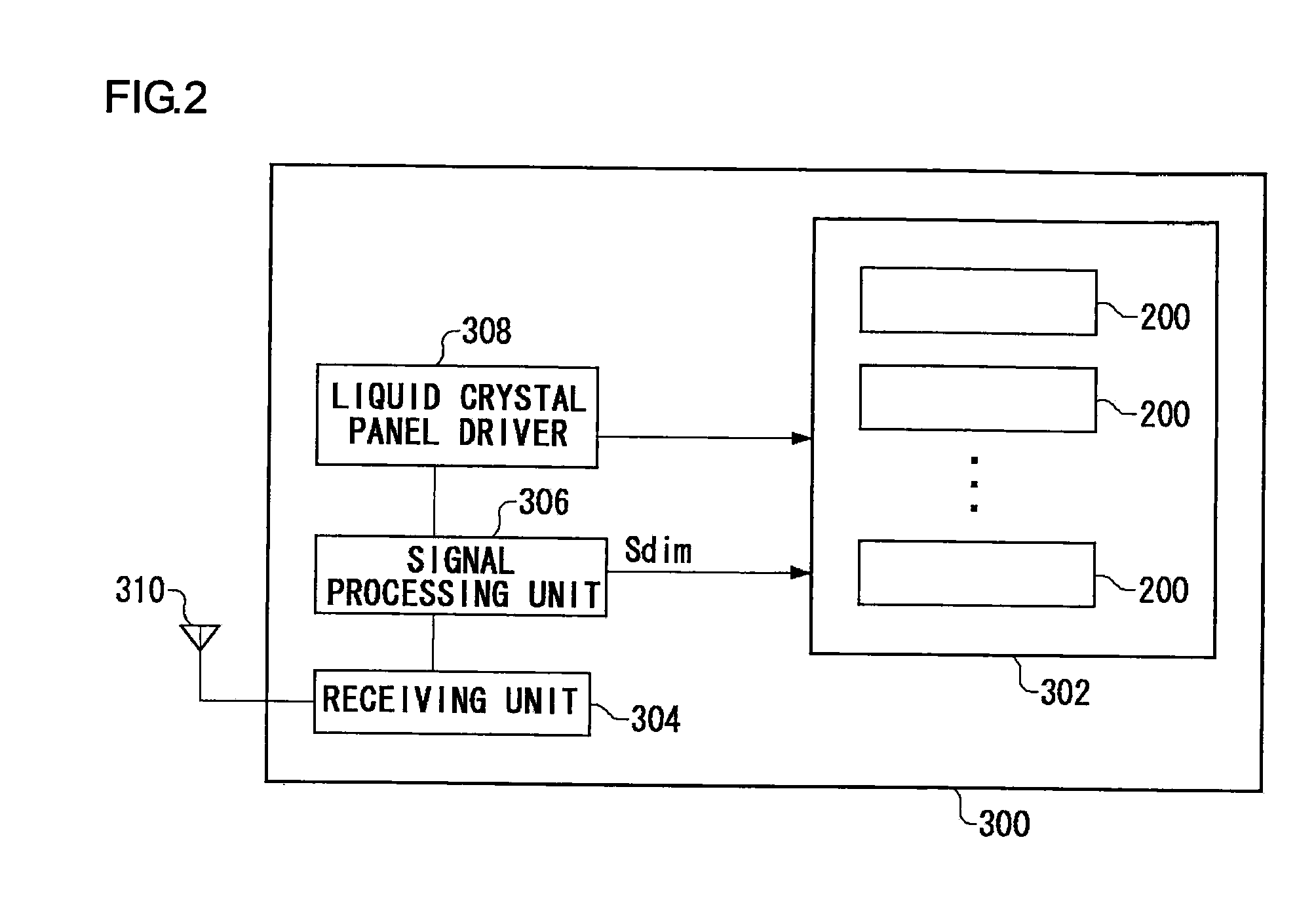

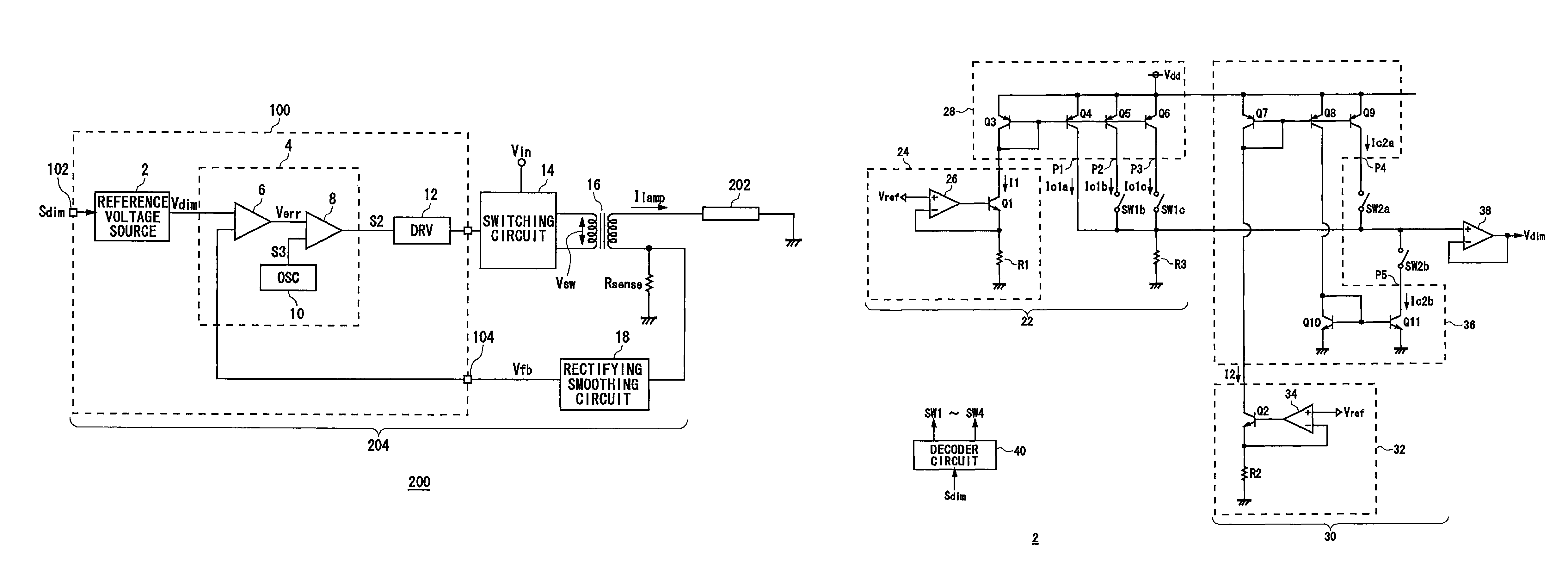

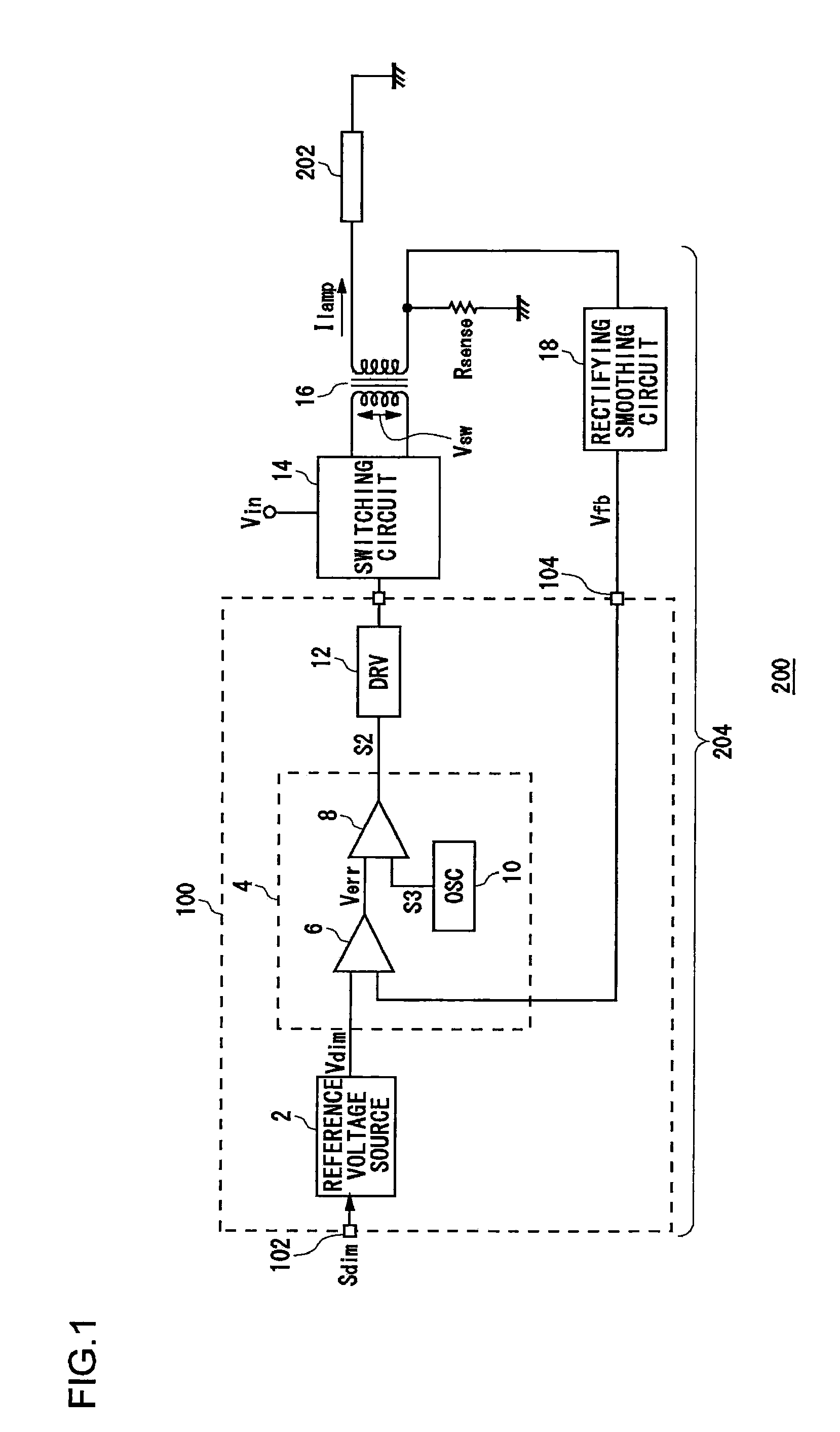

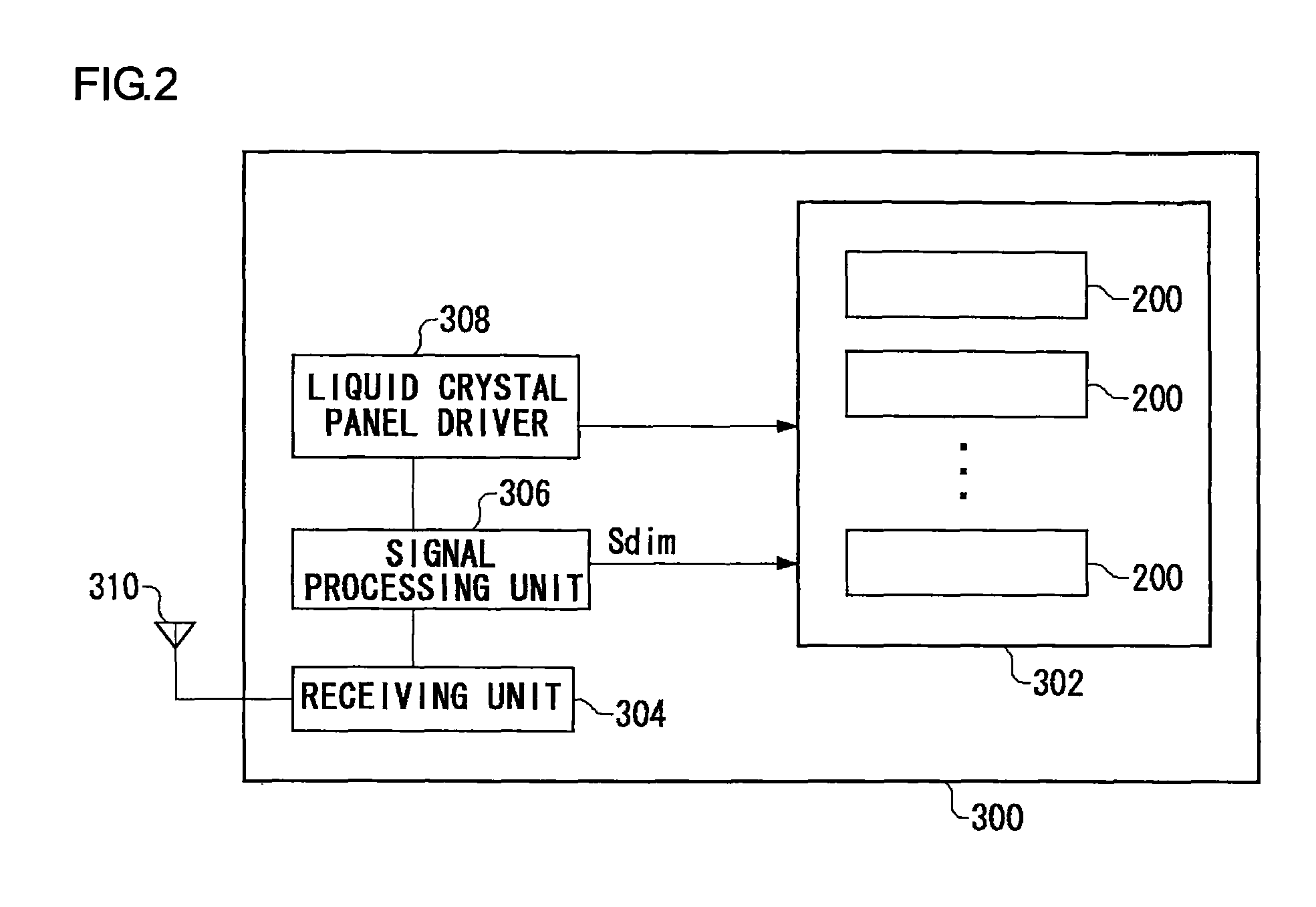

Control circuit for inverter

InactiveUS20100194310A1Improve accuracyHigh precision adjustmentElectric light circuit arrangementElectric discharge lampsControl signalSoftware engineering

A reference voltage source generates a reference voltage for adjusting an electric current for a dimming operation. The first current source generates a first current. A first current mirror circuit includes multiple output terminals, duplicates the first current, and outputs multiple first duplicated currents via the multiple output terminals. Multiple first switches are provided on paths for the respective multiple first duplicated currents. A converting resistor, with one terminal set to a fixed electric potential, is provided on a path for the multiple first duplicated currents output from the first current mirror circuit. A decoder circuit receives a control signal from an external circuit, and controls the ON / OFF operations of the multiple first switches. The reference voltage source outputs, as the reference voltage, a voltage that corresponds to a voltage drop that occurs at a converting resistor.

Owner:ROHM CO LTD

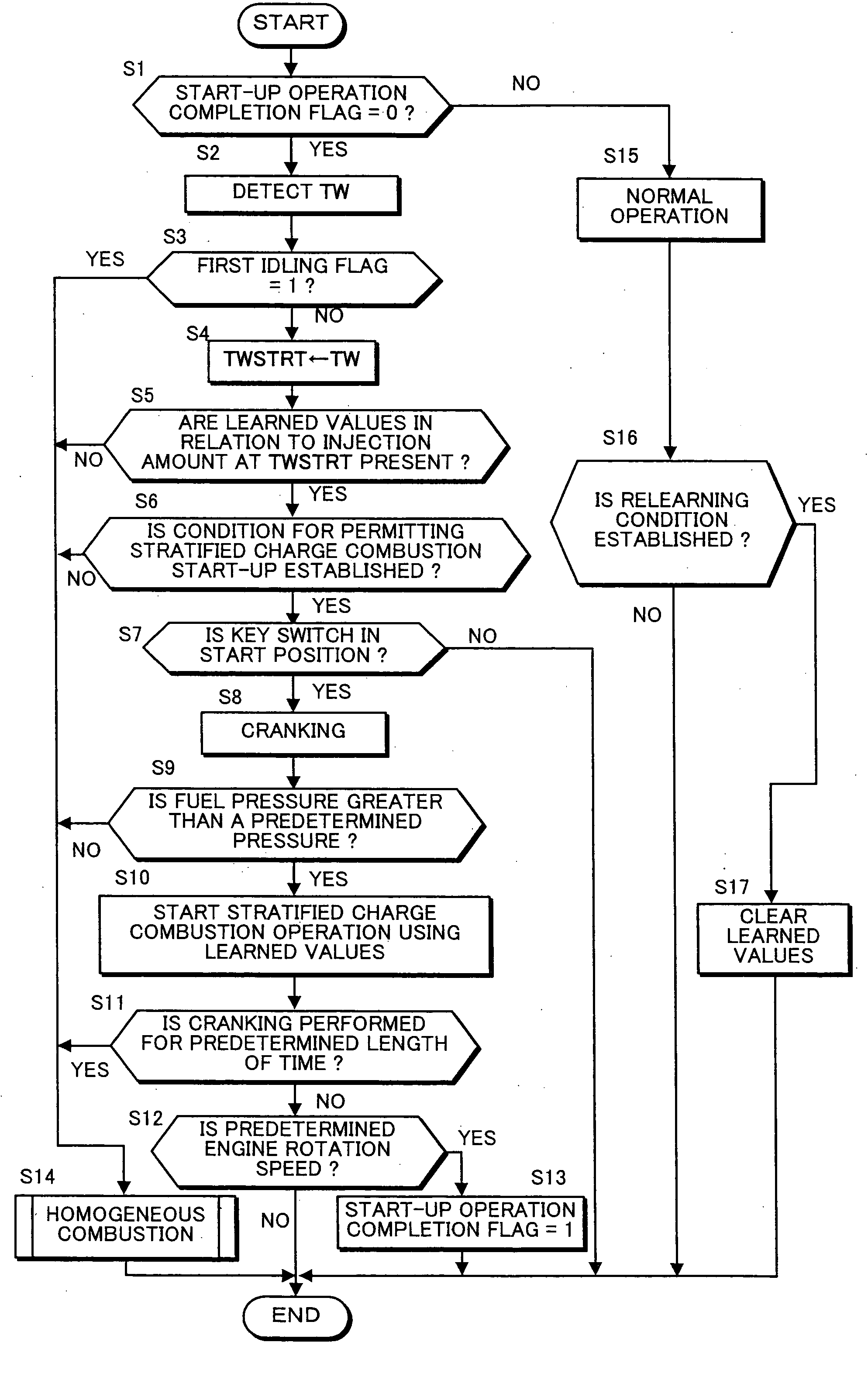

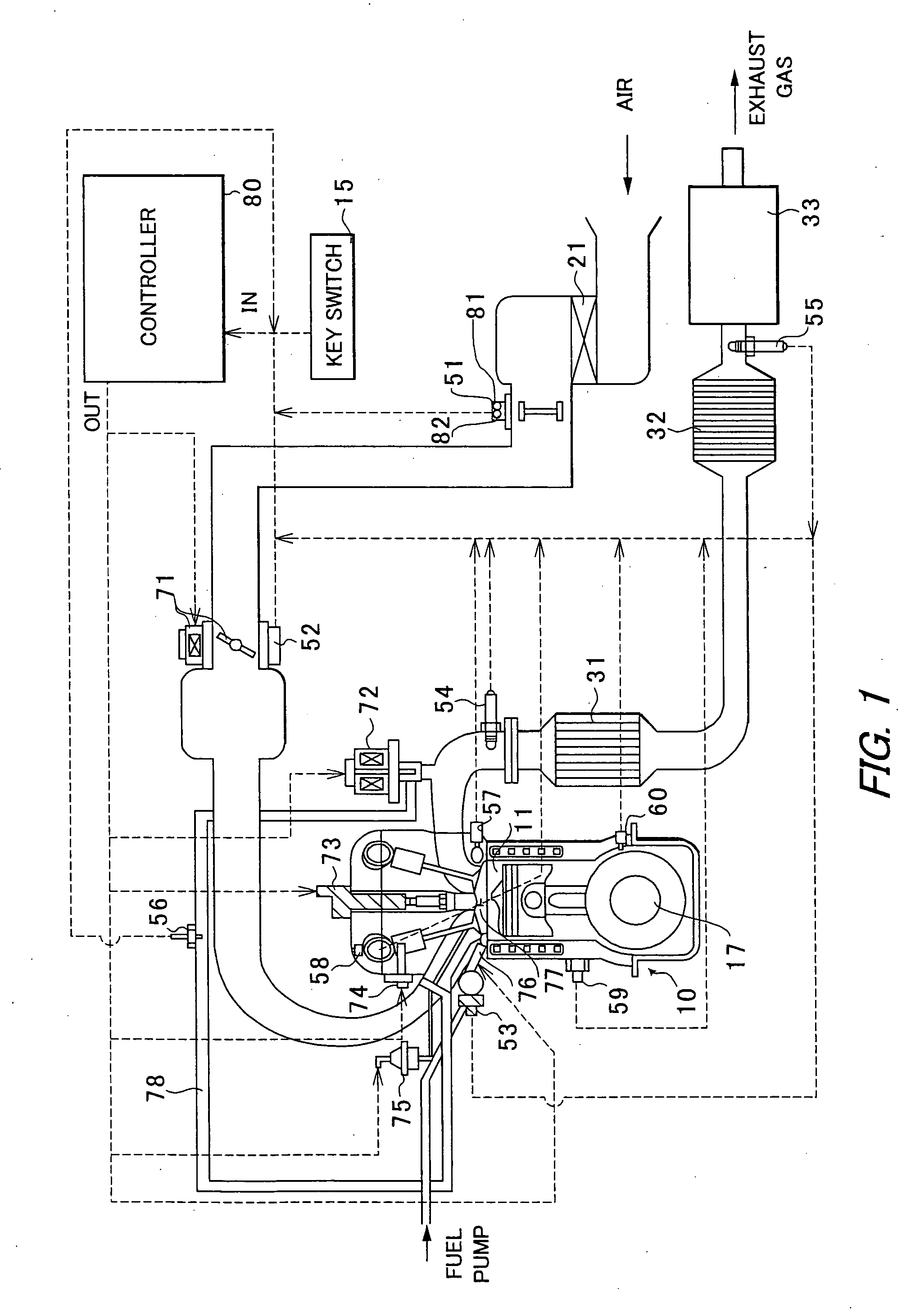

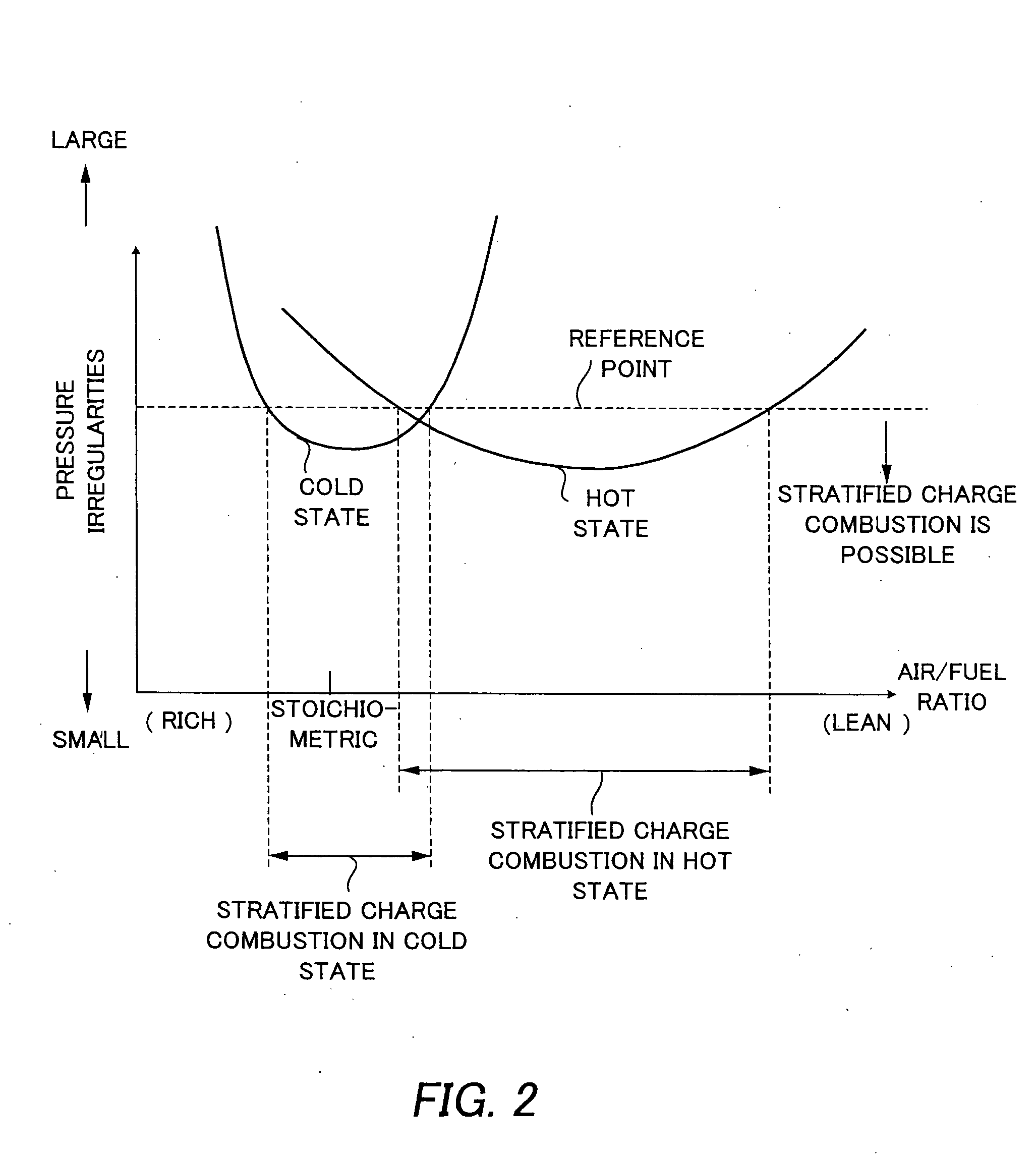

Start-up control of direct injection engine

A start-up control device of a direct injection engine has a fuel injector (76) for injecting fuel into the engine; and a controller. The controller is programmed to determine the presence of a learned value for calculating on the basis thereof a fuel injection amount during start-up of the engine (10) by means of a stratified charge combustion operation; calculate the fuel injection amount on the basis of the learned value when the learned value is present, and control the fuel injector (76) to inject fuel in the compression stroke to start up the engine (10) by means of a stratified charge combustion operation; and control the fuel injector (76) to inject fuel in the intake stroke of the engine to start up the engine by means of a homogeneous combustion operation when the learned value is absent, and obtain and store the learned value during the homogeneous combustion operation of the engine.

Owner:NISSAN MOTOR CO LTD

Control circuit for inverter

InactiveUS8159151B2High precisionLittle irregularityElectric light circuit arrangementElectric discharge lampsFrequency changerControl signal

A reference voltage source generates a reference voltage for adjusting an electric current for a dimming operation. The first current source generates a first current. A first current mirror circuit includes multiple output terminals, duplicates the first current, and outputs multiple first duplicated currents via the multiple output terminals. Multiple first switches are provided on paths for the respective multiple first duplicated currents. A converting resistor, with one terminal set to a fixed electric potential, is provided on a path for the multiple first duplicated currents output from the first current mirror circuit. A decoder circuit receives a control signal from an external circuit, and controls the ON / OFF operations of the multiple first switches. The reference voltage source outputs, as the reference voltage, a voltage that corresponds to a voltage drop that occurs at a converting resistor.

Owner:ROHM CO LTD

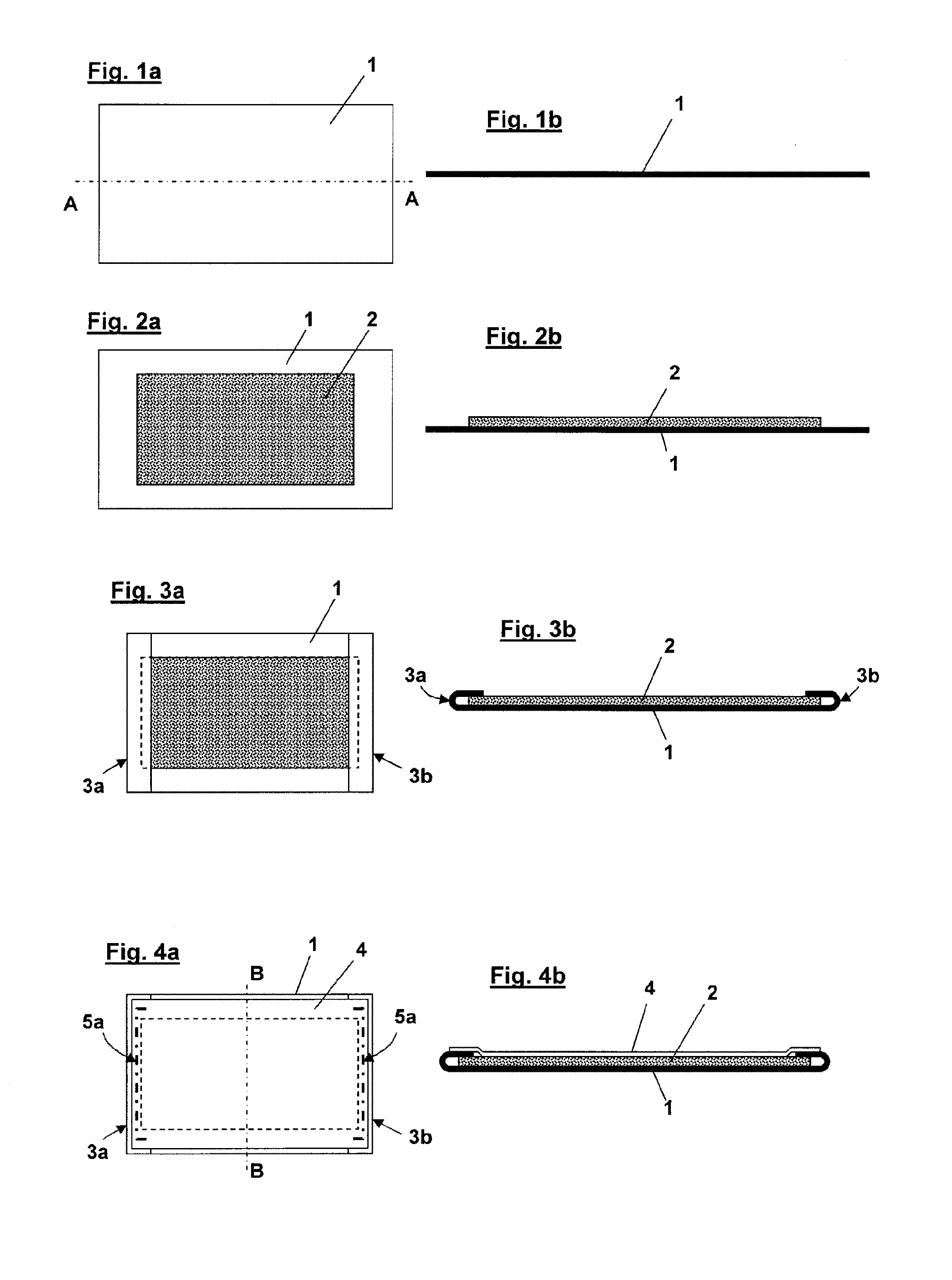

Method for producing a bag-like storage container for cut flowers

InactiveUS20110192747A1Large thicknessLittle irregularityEnvelopes/bags making machineryLiving organism packagingThermoplasticCut flowers

A method for producing a bag-like storage container for cut flowers comprising a flexible cover of a water-impermeable thermoplastic film and an inner coating of an absorbent material is described. The absorbent material thereby forms a soakable water reservoir for the cut flowers. The absorbent material is covered by a water-permeable cover layer of thermoplastic plastic, wherein the water-impermeable thermoplastic film is folded over the inner coating of soakable material towards the inside in the area of a bag opening and is connected to the cover layer at least on one side in the fold-over area. The method includes a method step, in the case of which a welding is carried out along longitudinal edges (6a, b) such that two layers of the water-permeable cover layer are located between two layers of the water-impermeable film in the area of welding seams (7).

Owner:SCHULTER RUTH

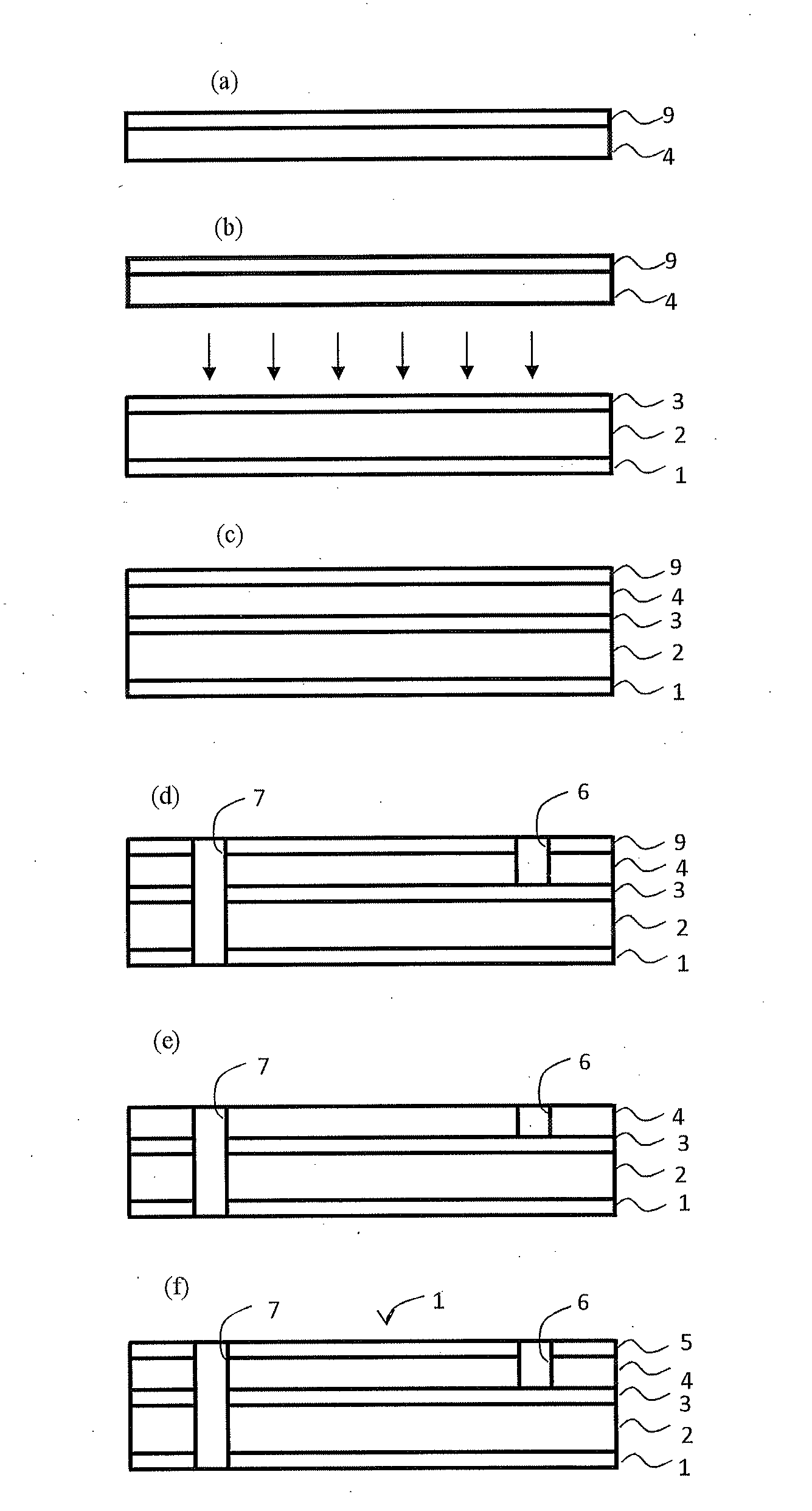

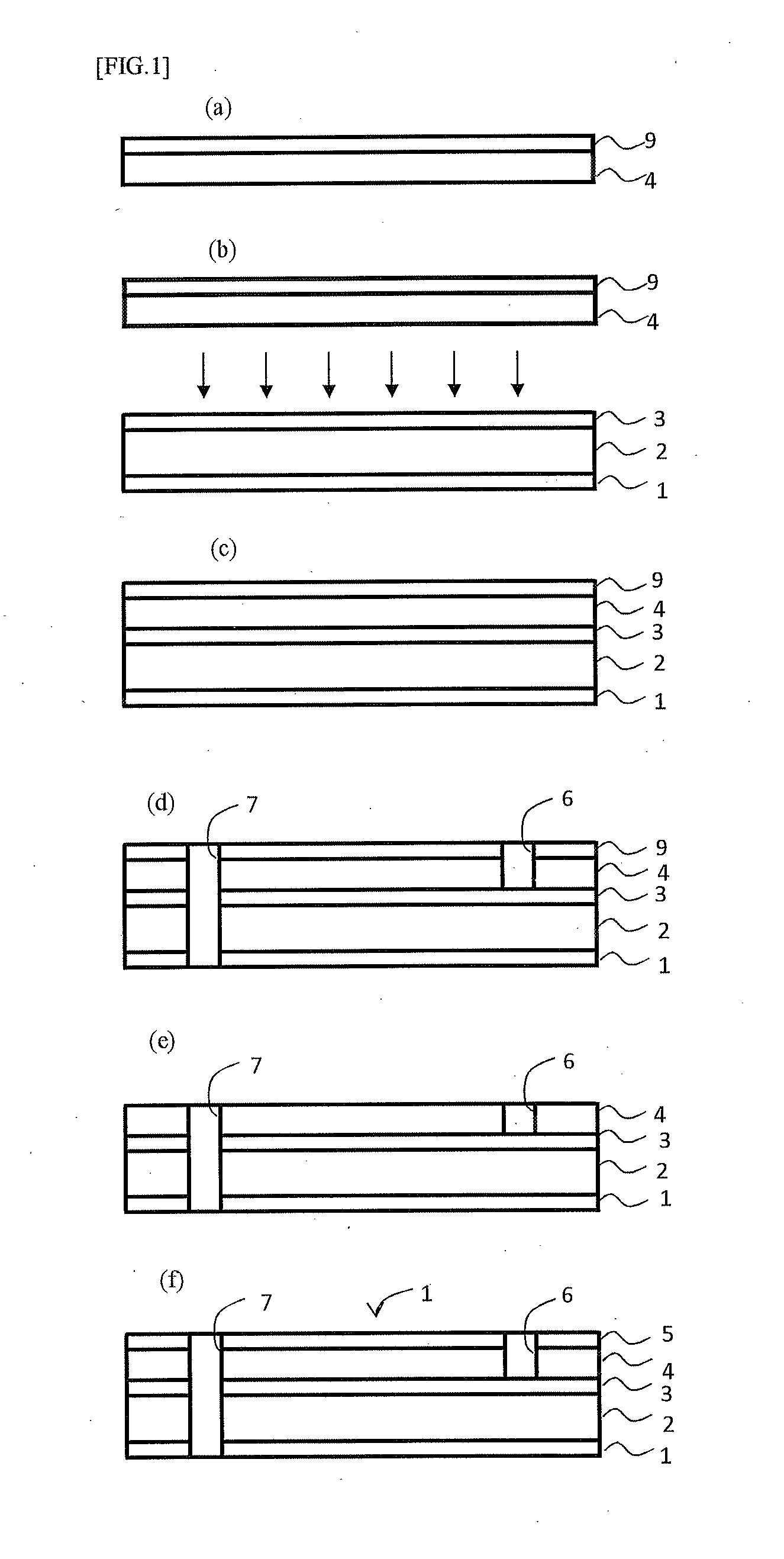

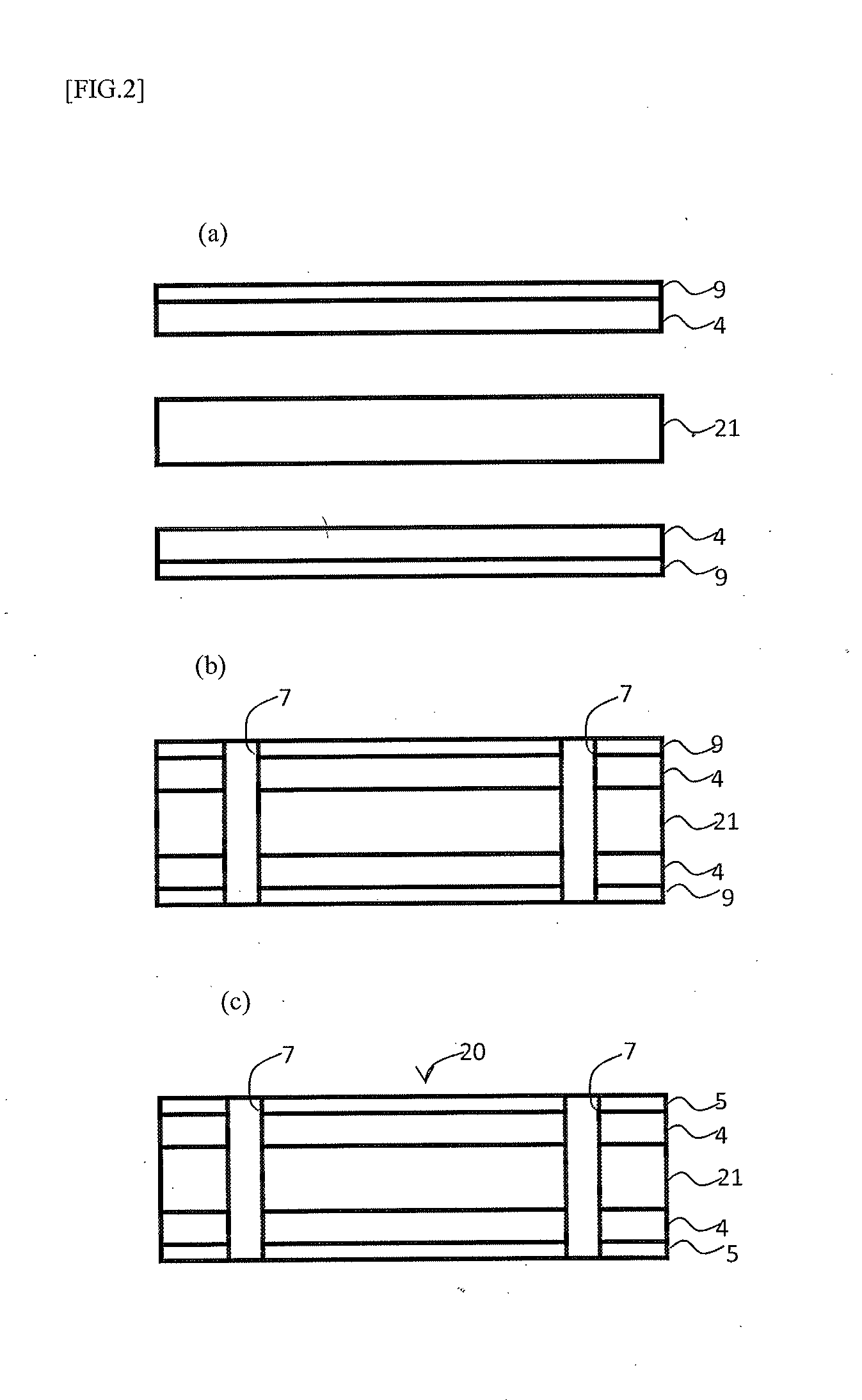

Method of manufacturing liquid ejection head

InactiveUS20060196025A1Reduce warpageLittle irregularityPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusScreen printingBiomedical engineering

The method manufactures a liquid ejection head comprising: a plurality of nozzles which eject liquid; a plurality of pressure chambers which are connected to the nozzles, respectively; a diaphragm which forms wall faces of the pressure chambers; and piezoelectric elements which are disposed on the diaphragm at positions corresponding to the pressure chambers and each are formed of at least a piezoelectric material and electrodes overlapping each other. The method comprises the steps of: forming a lower electrode on a whole surface of a substrate that is to form the diaphragm; then forming piezoelectric material by screen printing onto a whole surface of the lower electrode; then forming an upper electrode on a whole surface of the piezoelectric material; then forming a mask having a prescribed pattern on the upper electrode; then dividing the piezoelectric material and the upper electrode by performing a sandblasting process through the mask; and then calcining the substrate together with the divided piezoelectric material and upper electrode.

Owner:FUJIFILM CORP

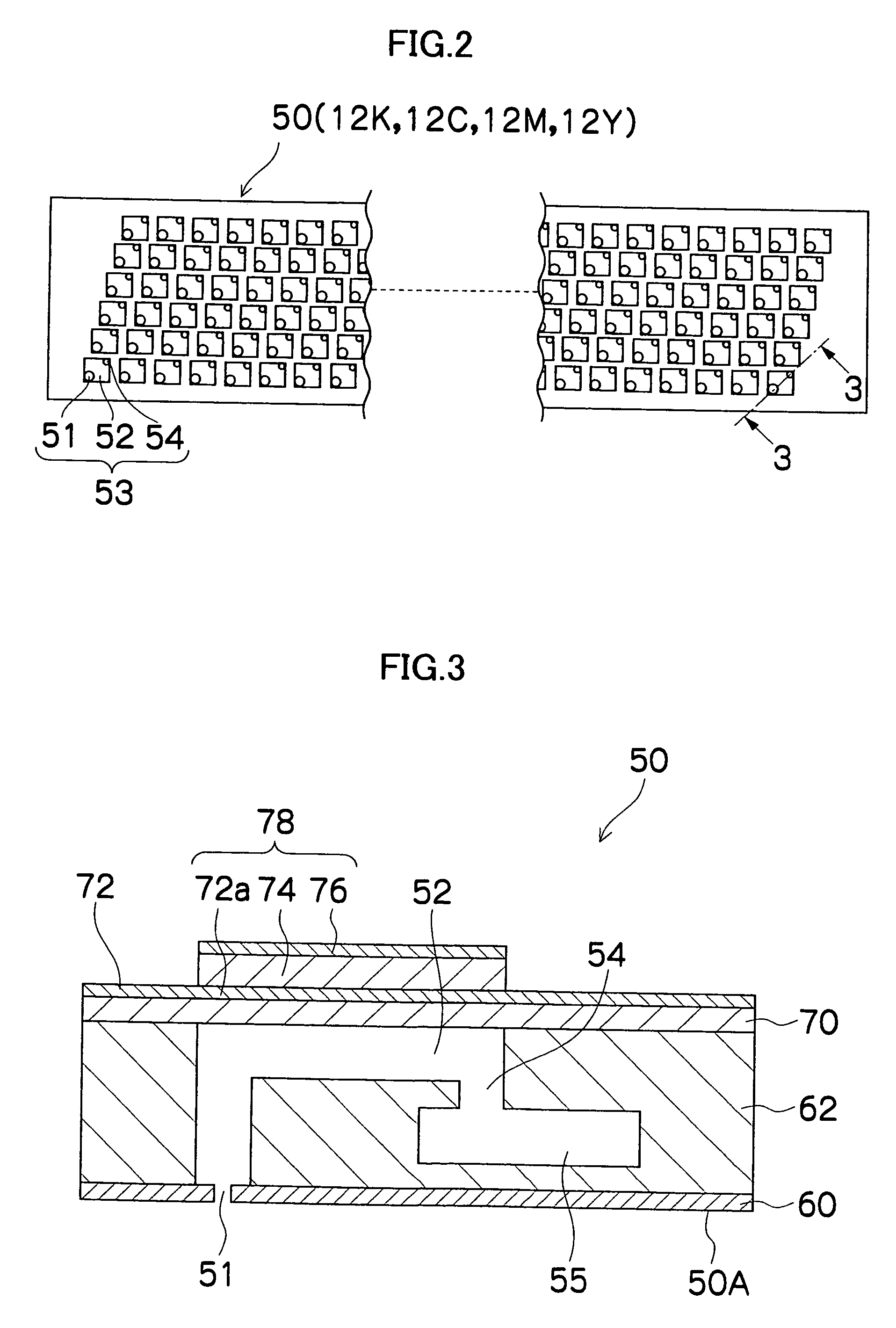

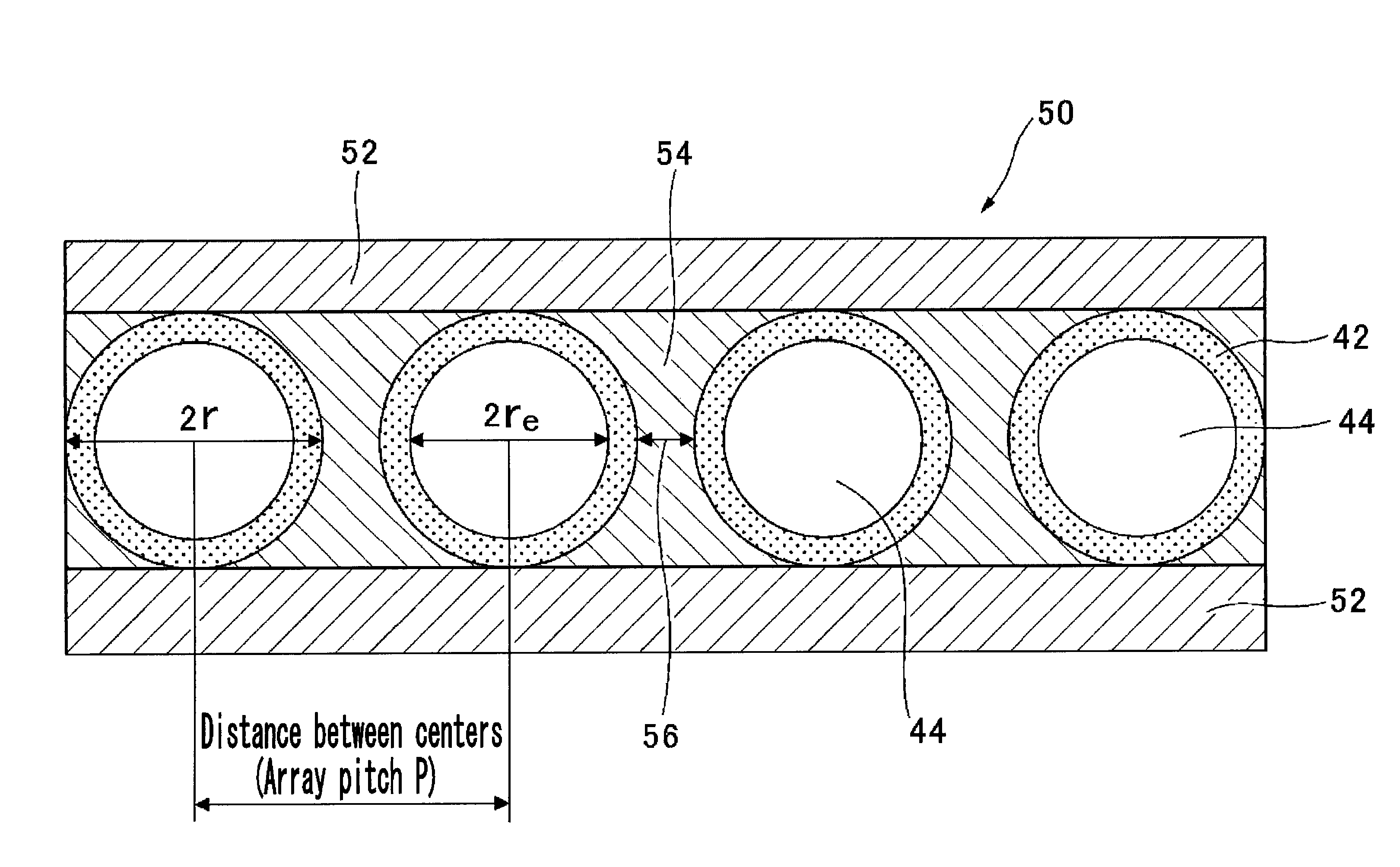

Rod lens array and image sensor head that uses same

ActiveUS9448337B2Shorten the lengthLarge transmitted light amountSolid-state devicesRadiation controlled devicesRefractive indexEngineering

The purpose of the present invention is to provide a rod lens array, which has a deep depth of focus and a small depth of focus spot. The present invention provides a rod lens array that is equipped with at least one line of rod lenses between two substrates, said line of rod lenses having a plurality of columnar rod lenses wherein the refractive index decreases toward the outer periphery from the center, said rod lenses being arranged in such a manner that the center axes of the rod lenses are substantially parallel to each other. The rod lens array is characterized in that the average value (DOFave) of the depth of focus (DOF) is at least 0.9 mm, and the depth of focus spot (DOFcv) in the scanning direction of the line of rod lenses is not more than 12%.

Owner:MITSUBISHI CHEM CORP

Resin composition, cured resin product, wiring board, and manufacturing method for wiring board

ActiveUS20190218415A1Improve adhesionLittle irregularitySynthetic resin layered productsInsulating layers/substrates workingEpoxyPolymer science

By producing a resin composition containing (A) an epoxy resin having two or more epoxy groups in one molecule thereof and containing a hexanediol structure, (B) an ultraviolet ray active ester group-containing compound, and (C) an epoxy resin curing accelerator, even in a state where an irregular shape of the surface of an insulating resin layer is small, a high adhesive force to a wiring conductor can be easily revealed.

Owner:SHOWA DENKO MATERIALS CO LTD

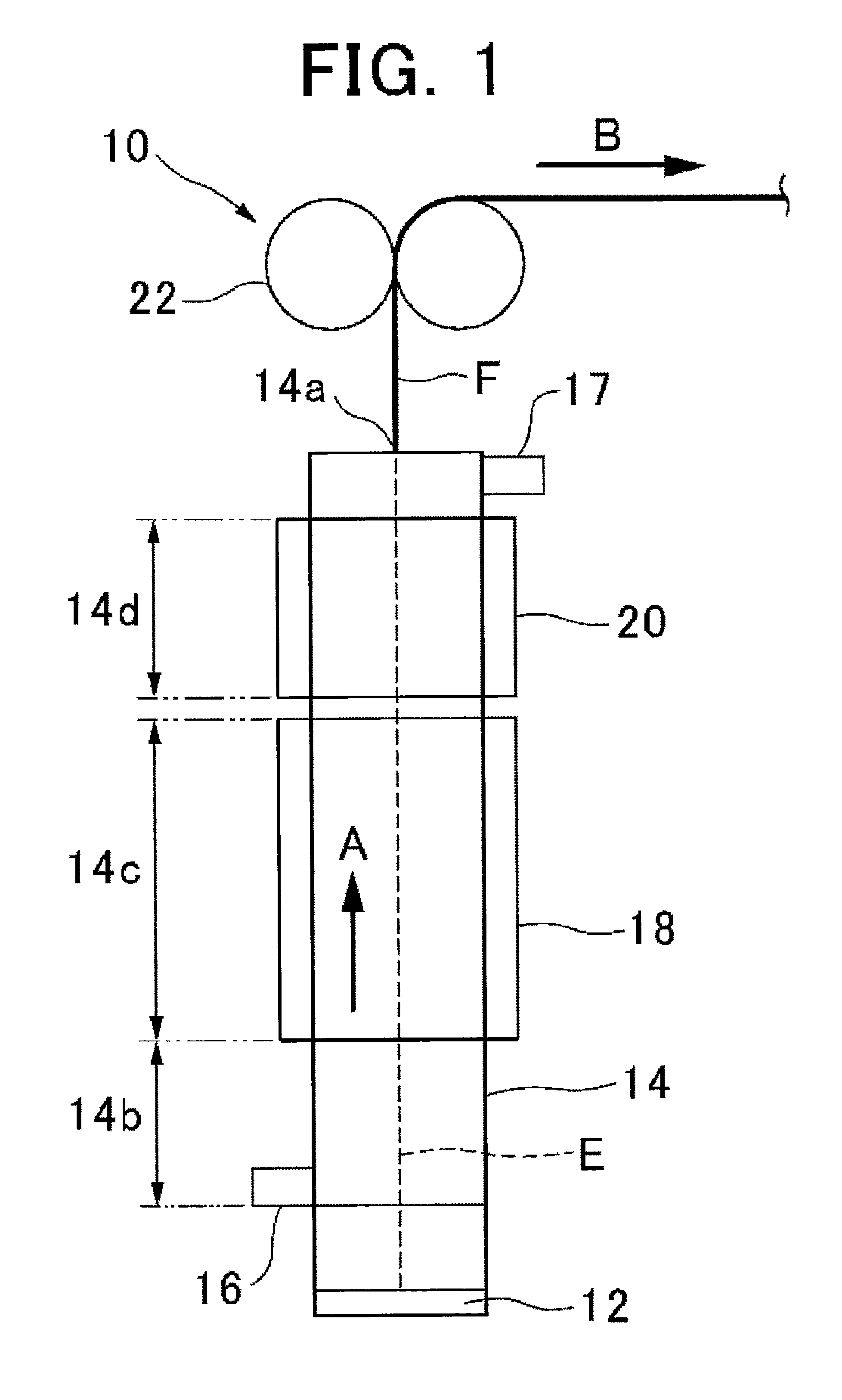

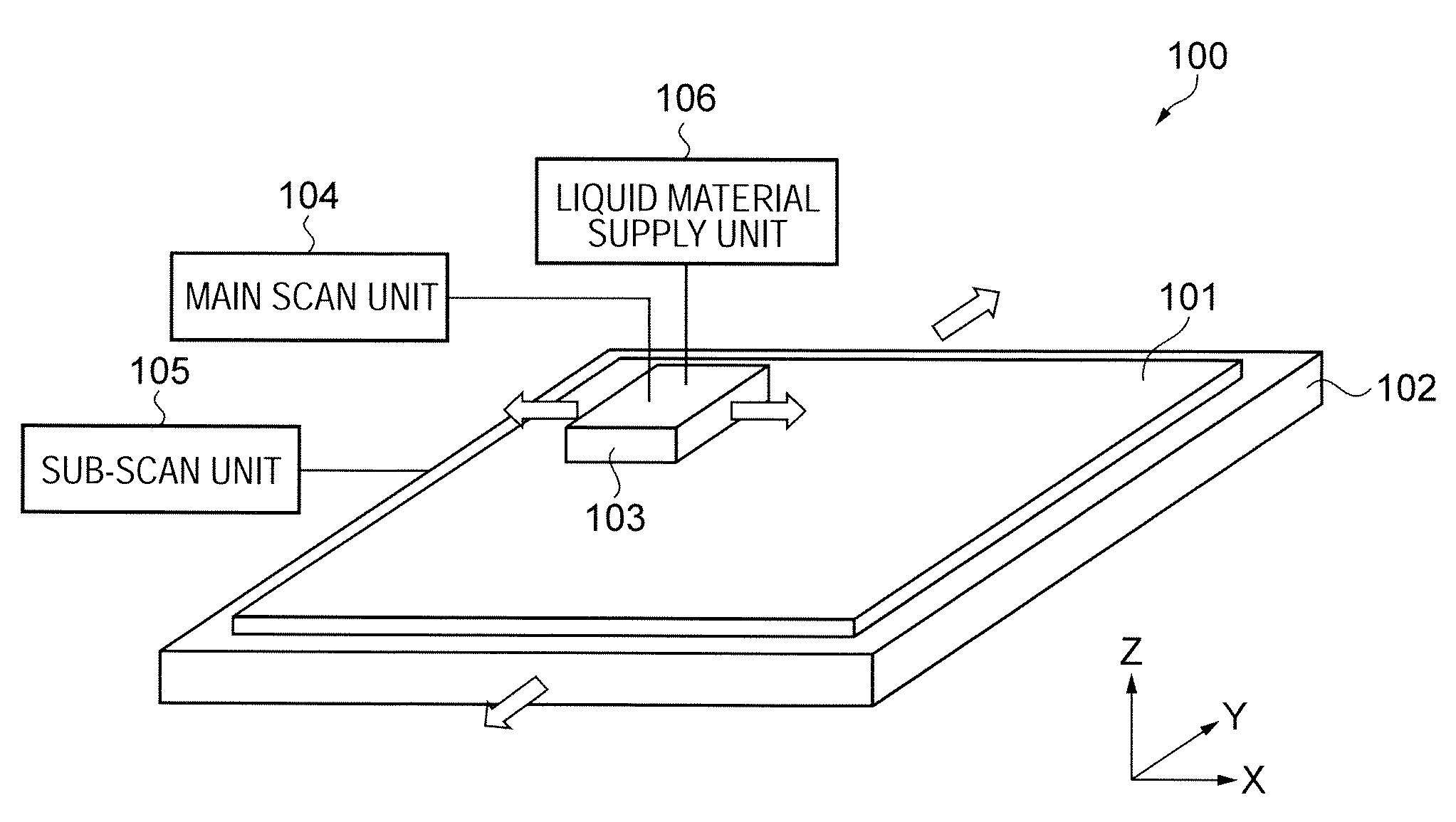

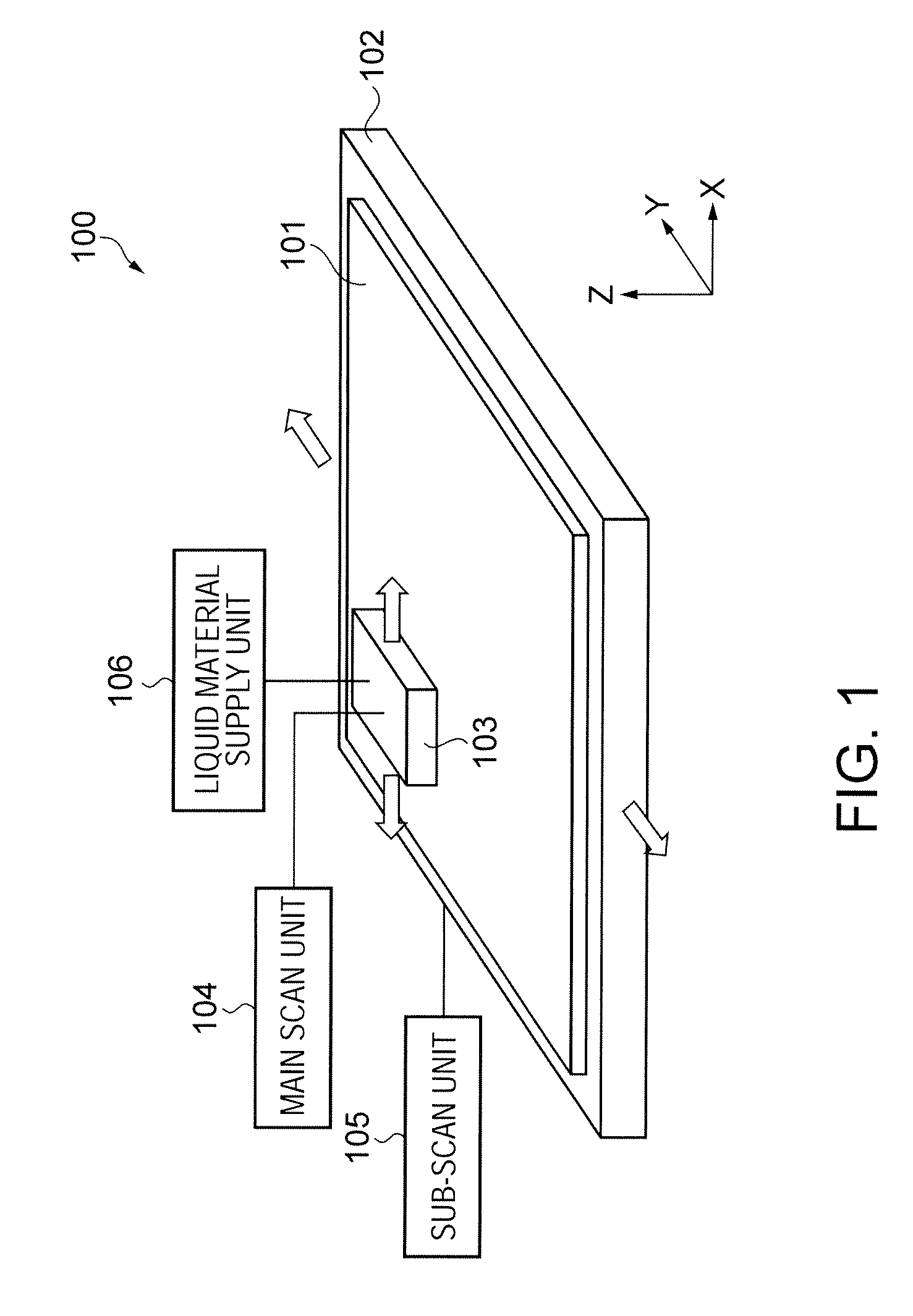

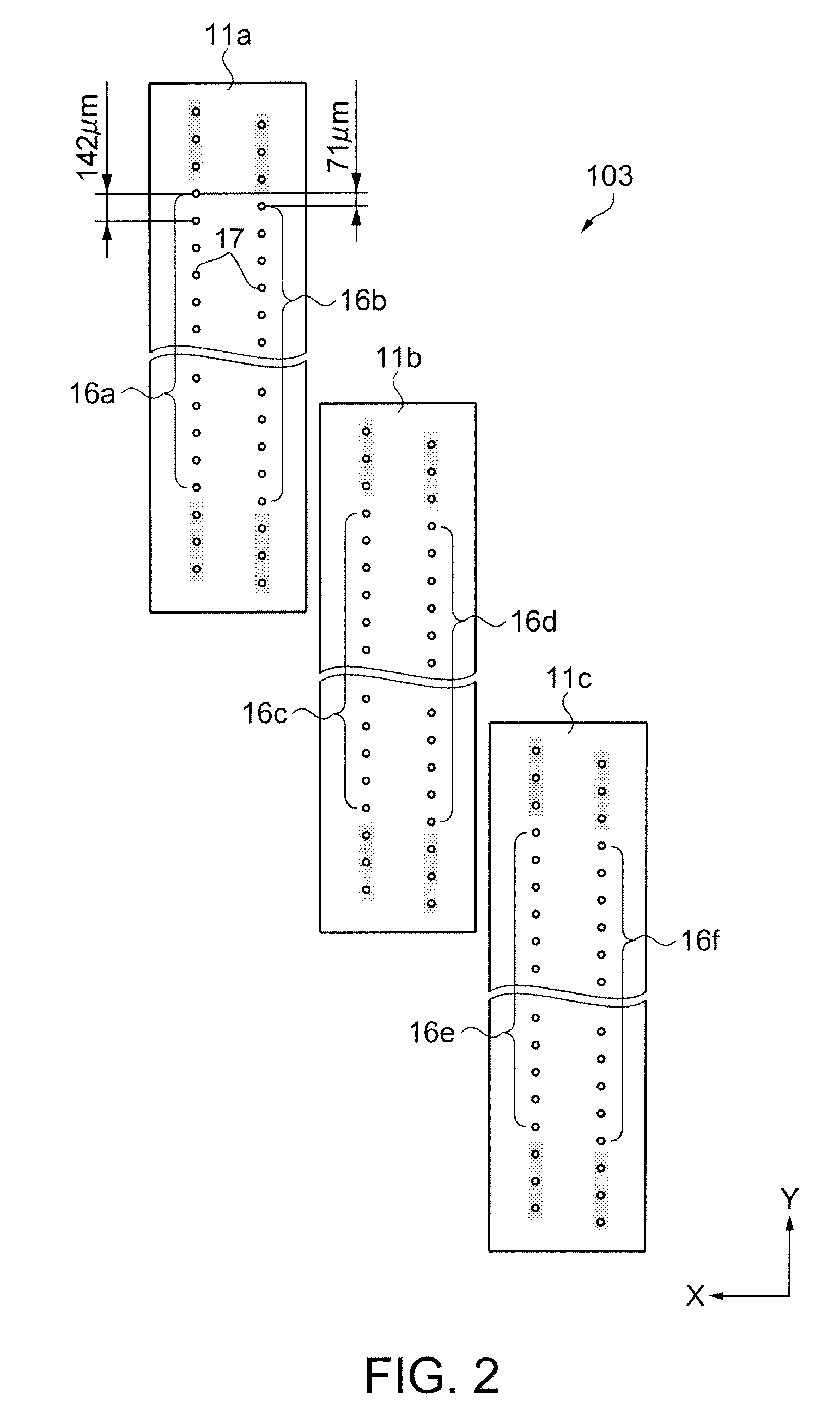

Liquid material placing method, manufacturing method for electro-optical device, electro-optical device and electronic apparatus

InactiveUS20070215713A1Easy to useHigh efficiency of using nozzleWatering devicesDust removalEngineeringElectrical impulse

A method for placing a liquid material includes a) discharging the liquid material from a plurality of nozzles into a single region of a substrate during a scan of the substrate performed by a head having a nozzle group including the plurality of nozzles using a first electric pulse, and b) discharging the liquid material into the single region from the plurality of nozzles during the scan using a second electric pulse. The first and second electric pulses are supplied to a pressure controller to control pressure of a liquid chamber communicated with the plurality of nozzles so as to cause the plurality of nozzles to discharge the liquid material. The first and second discharge steps are performed by using the same plurality of nozzles during the same scan.

Owner:SEIKO EPSON CORP

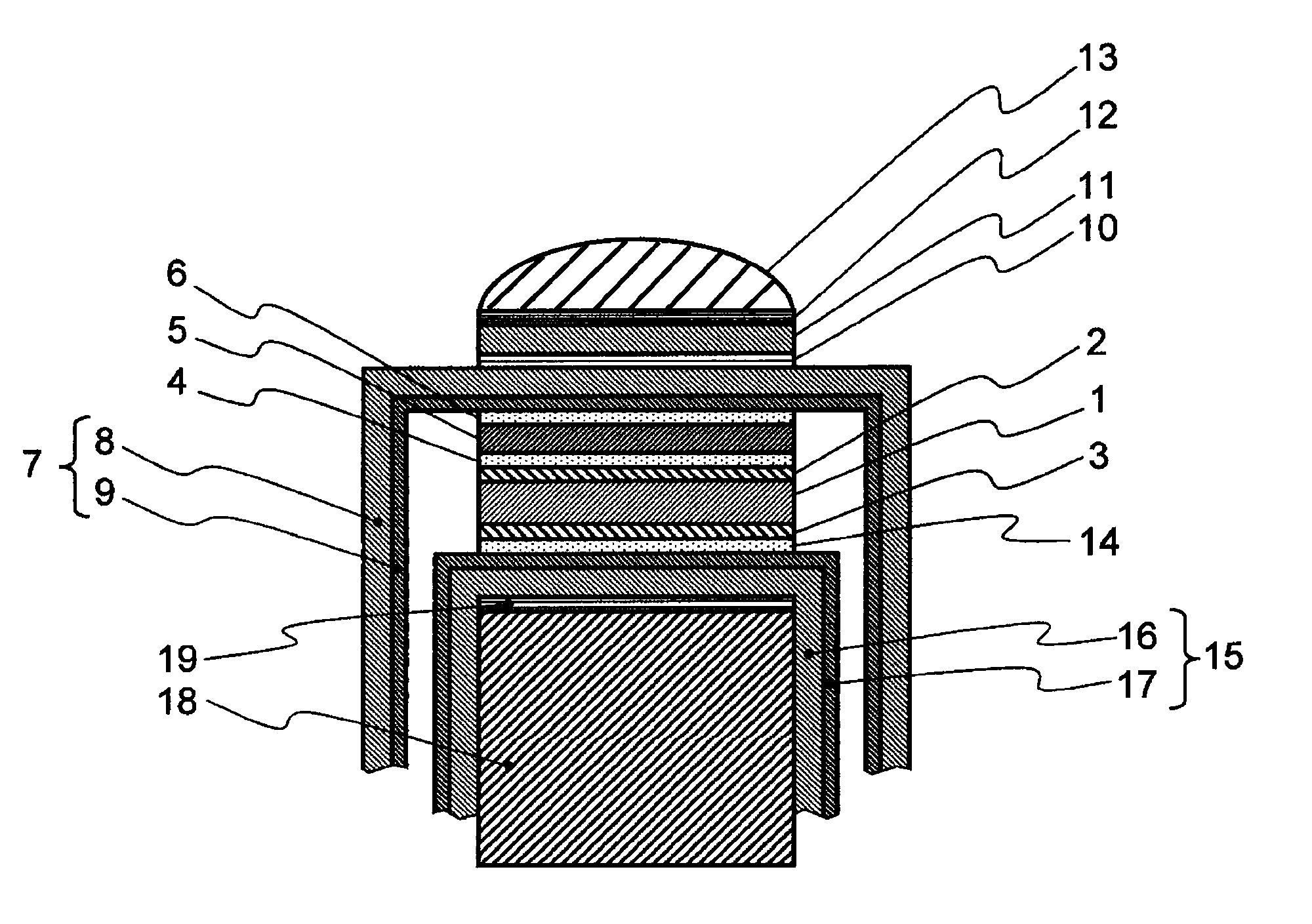

Ultrasonic probe

ActiveUS8834377B2Quality improvementSensibility irregularityOrgan movement/changes detectionMechanical vibrations separationAdhesiveGraphite

An ultrasonic probe that enables the sensibility irregularity between arrays to be reduced is disclosed. This piezoelectric element contains: a piezoelectric element 1; a first electrode layer 2 formed on one side of the piezoelectric element 1; one or more conductive acoustic matching layers 5 layered via an adhesive layer 4 on the first electrode layer 2; a first film 7 which is layered via an adhesive layer 6 on the acoustic matching layer 5 and in which an electrode pattern is formed on the side of the adhesive layer 6; a second electrode layer 3 formed on the other side of the piezoelectric element 1; and a second film 15 which is layered via an adhesive layer 14 on the second electrode layer 3 and in which an electrode pattern is formed on the side of the adhesive layer 14, wherein the adhesive layers 4, 6 and 14 are thermosetting two-component type adhesives in which graphite powder is uniformly distributed therein.

Owner:KONICA MINOLTA INC

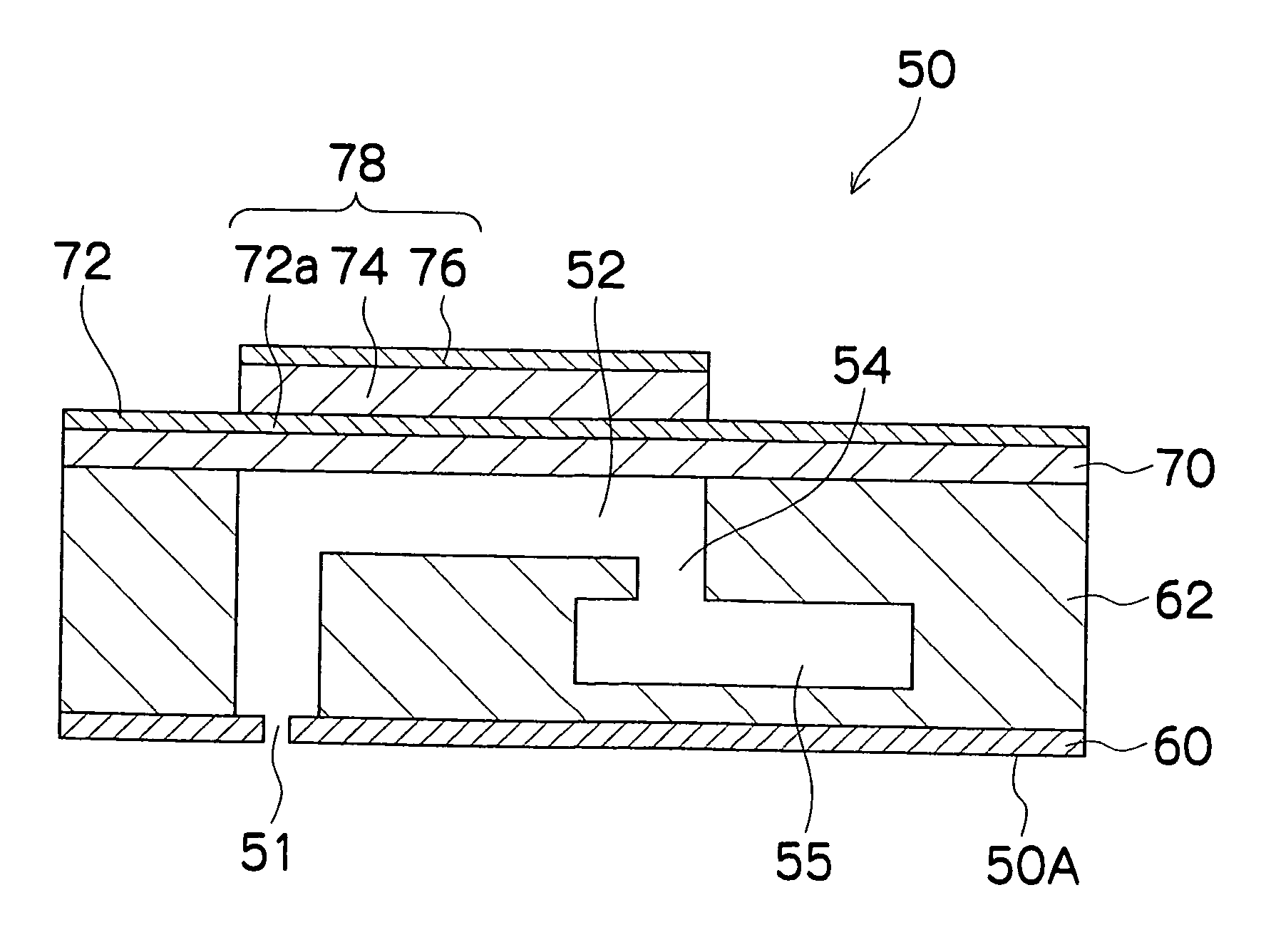

Semiconductor device and method of manufacturing the semiconductor device

ActiveUS8193631B2Ensure overall airtightnessLower resistanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringInterconnection

A first interconnection is formed along a groove of a substrate and on a bottom surface of the groove, and has a first thickness. A second interconnection is electrically connected to the first interconnection and has a second thickness larger than the first thickness. An acceleration sensing unit is electrically connected to the second interconnection. A sealing unit has a portion opposed to the substrate with the first interconnection therebetween, and surrounds the second interconnection and the acceleration sensing unit on the substrate. A cap is arranged on the sealing unit to form a cavity on a region of the substrate surrounded by the sealing unit. Thereby, airtightness of the cavity can be ensured and also an electric resistance of the interconnection connected to the acceleration sensing unit can be reduced.

Owner:MITSUBISHI ELECTRIC CORP

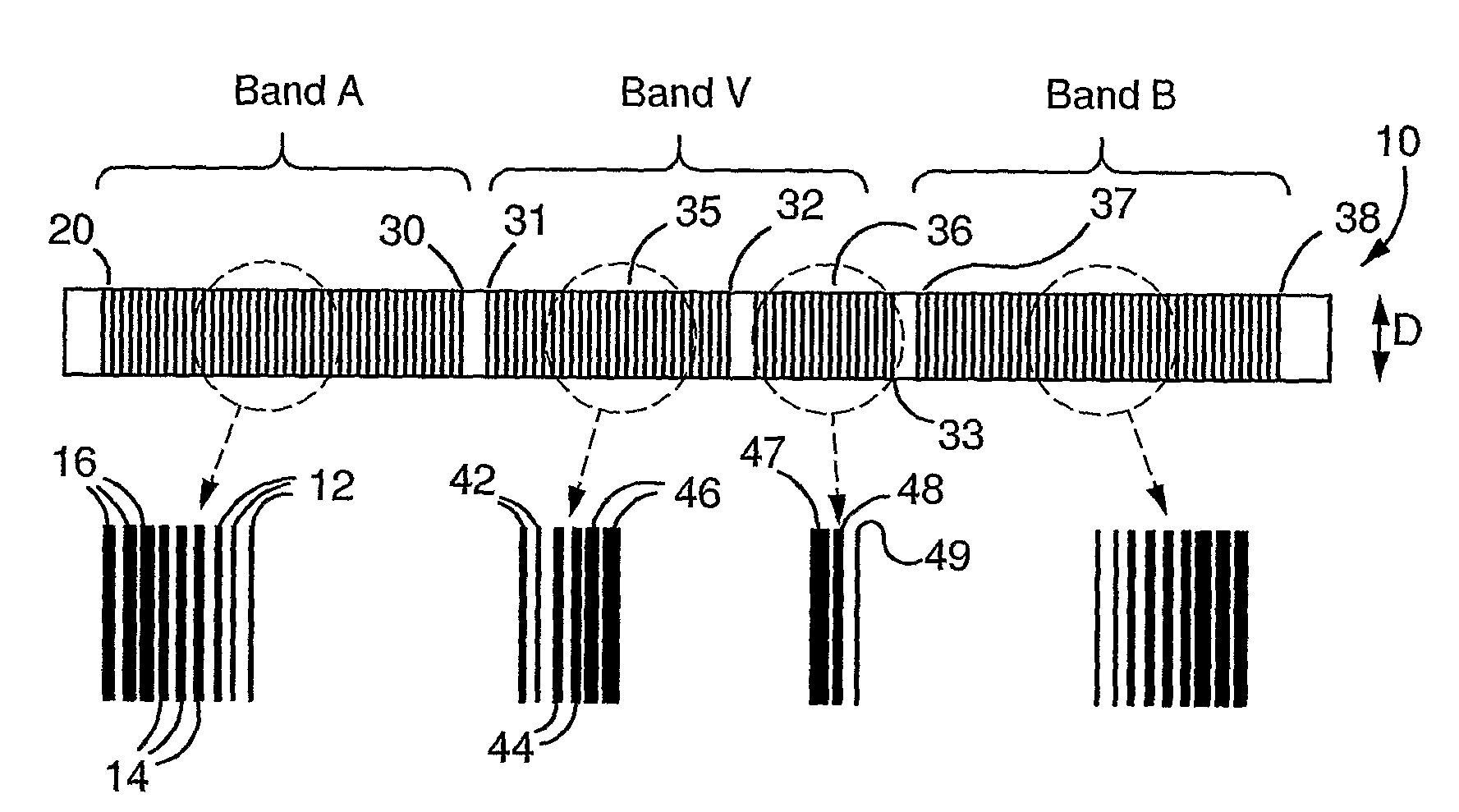

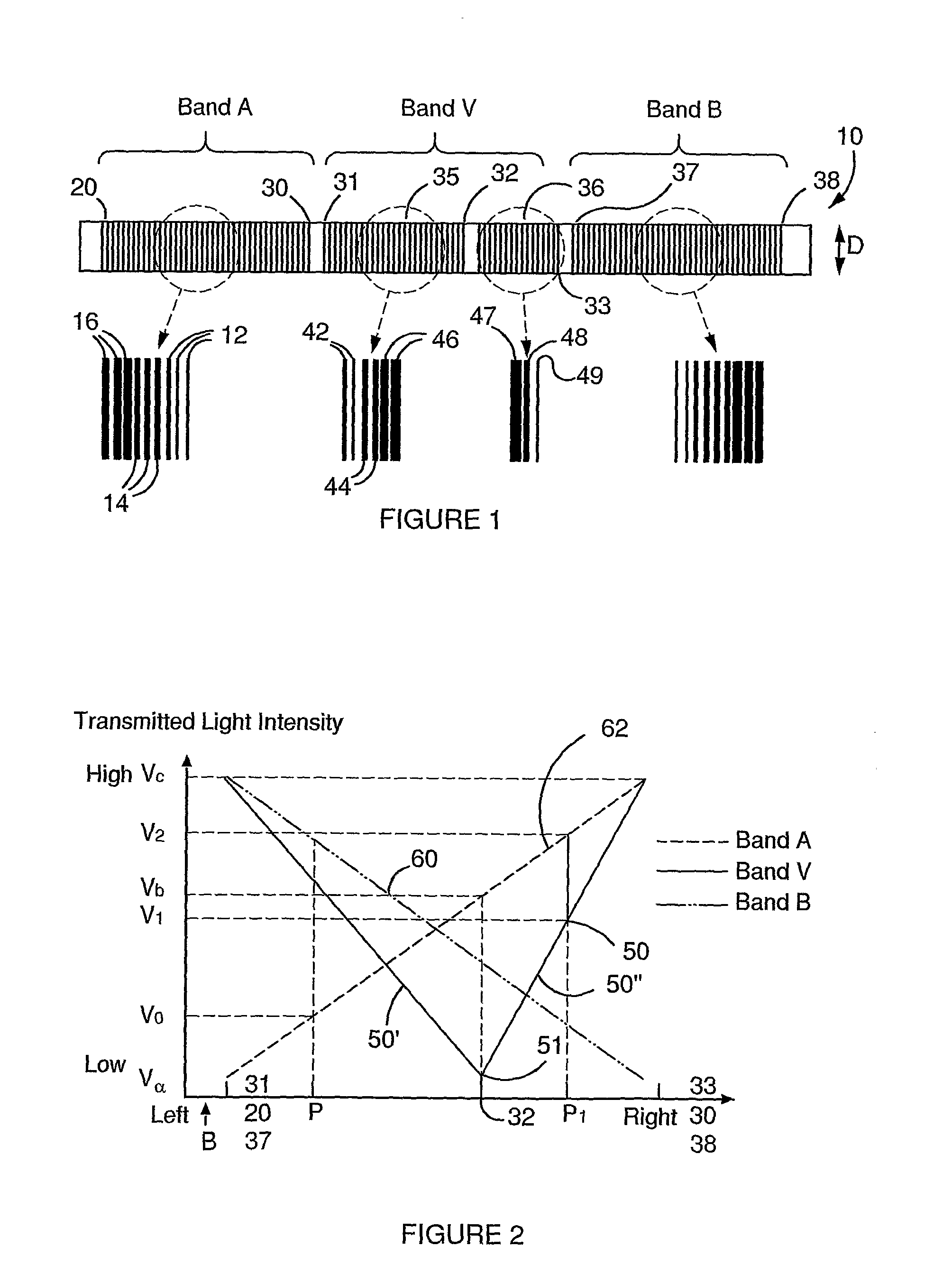

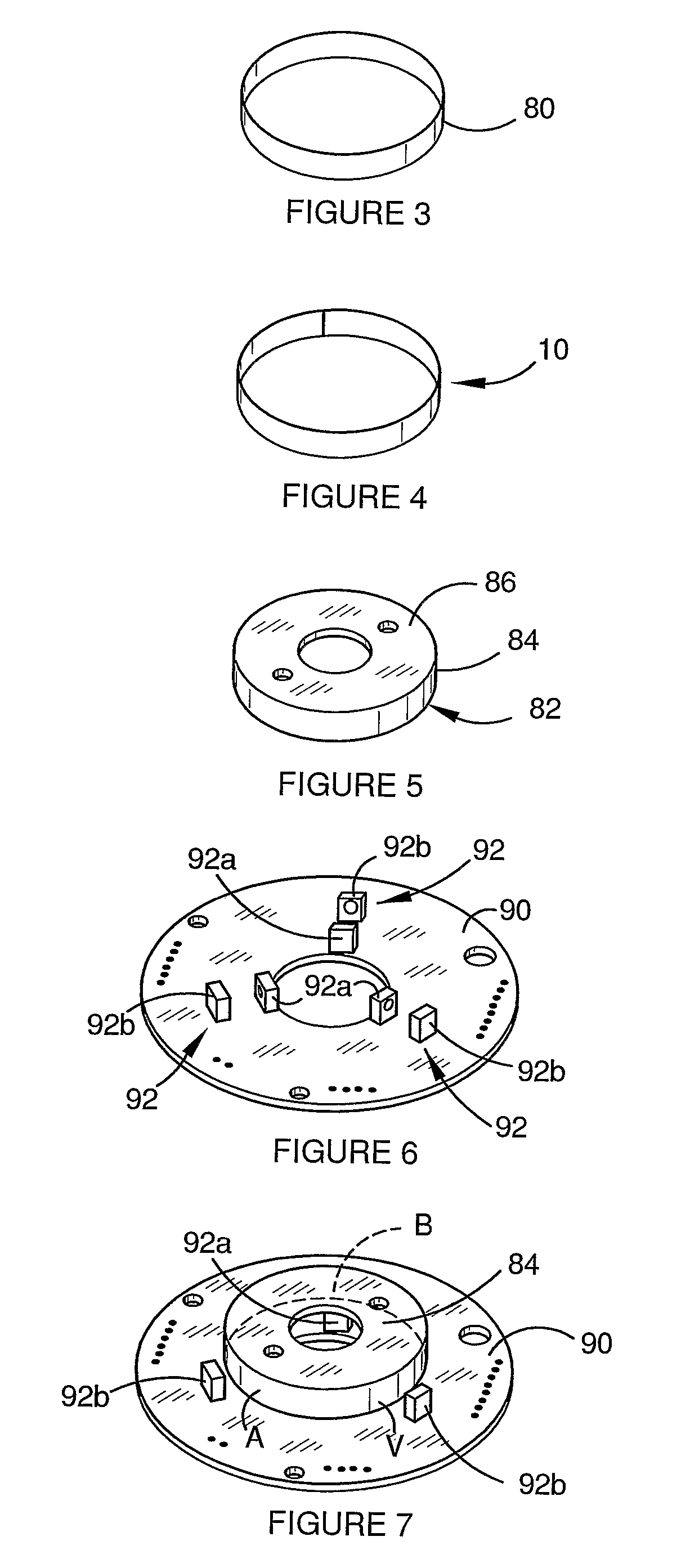

Optical Potentiometer with Temperature Drift Compensation

InactiveUS20080283732A1High sensitivityLong processMaterial analysis by optical meansConverting sensor output opticallyEngineeringUltimate tensile strength

A potentiometer is disclosed which comprises an opaque screen element (10) and light emitters and collectors (92) for transmitting light through the screen and detecting the light transmitted through the screen. The screen has three sections (A, V and B). The sections (A, V and B) have bars which are parallel to one another and extend transverse to the direction of movement of the screen (10). The section (A) has bars which are arranged in groups comprising the same number of bars, but each of a different thickness. The section (V) has two parts (35, 36), the first part has bars which are formed in the same manner as the section (A) except they are a mirror image to the bars in section (A) and each group comprises less bars than are in the groups in section (A). The second part of section (V) has individual bars which increase in thickness. Section (B) is a mirror image of section (A). This configuration allows for any drifting of voltage indicative of a change in light intensity which is detected by the emitter to be identified and compensated for because the intensity of light passing through the sections and plotted against position forms a U or V-shaped profile, with the apex identifying the maximum or minimum light intensity and therefore voltage at the collector.

Owner:AIMBRIDGE

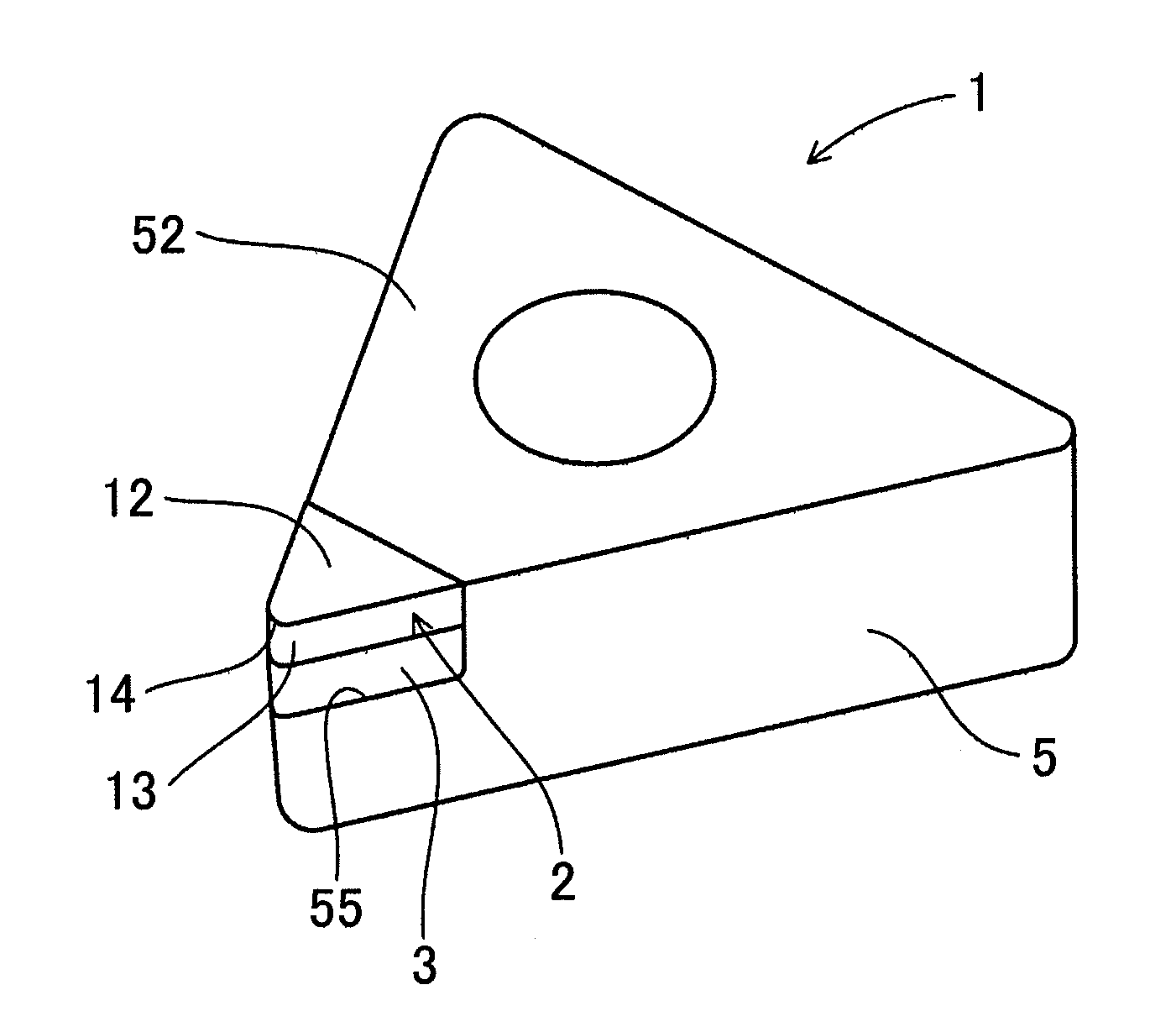

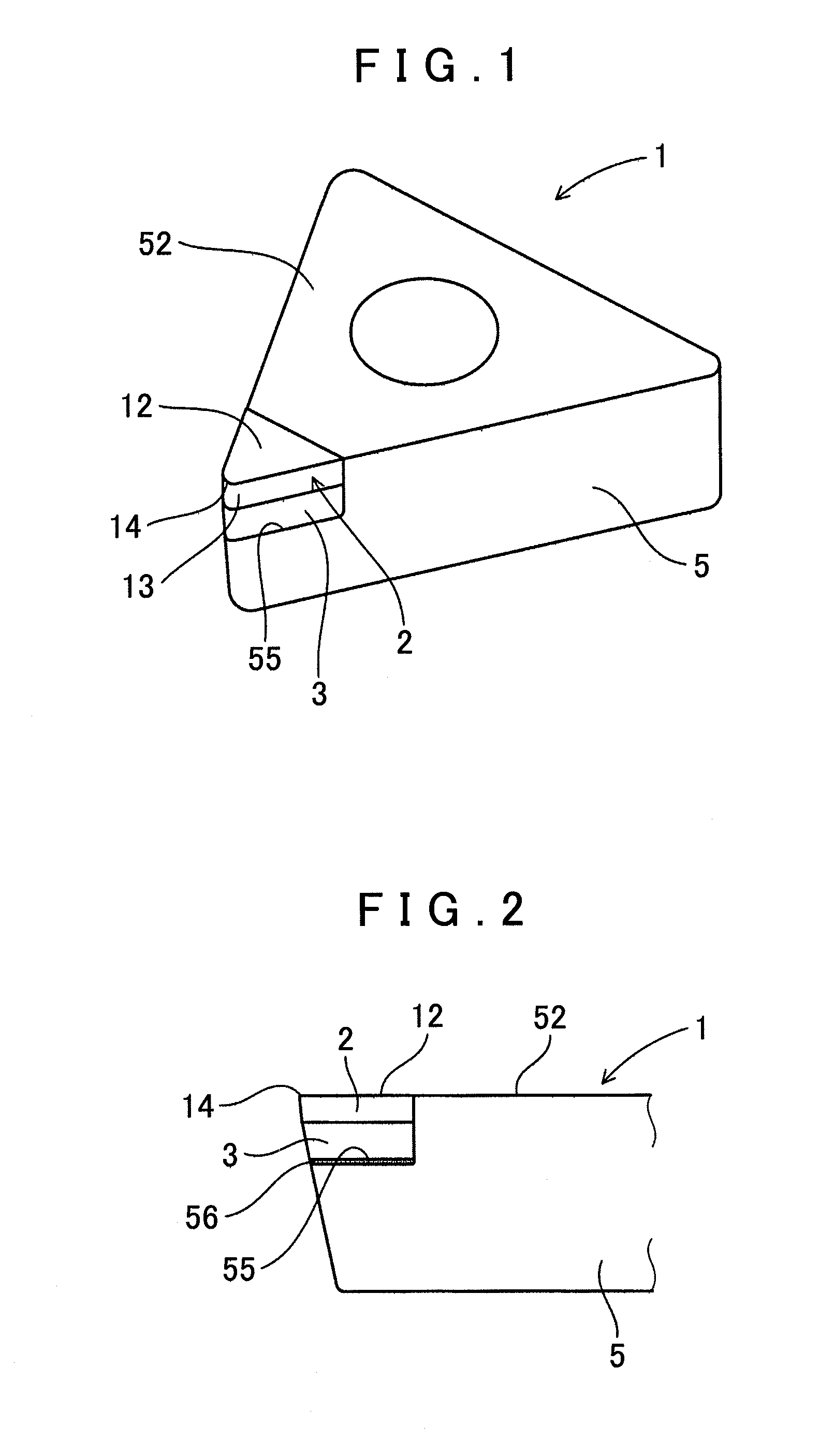

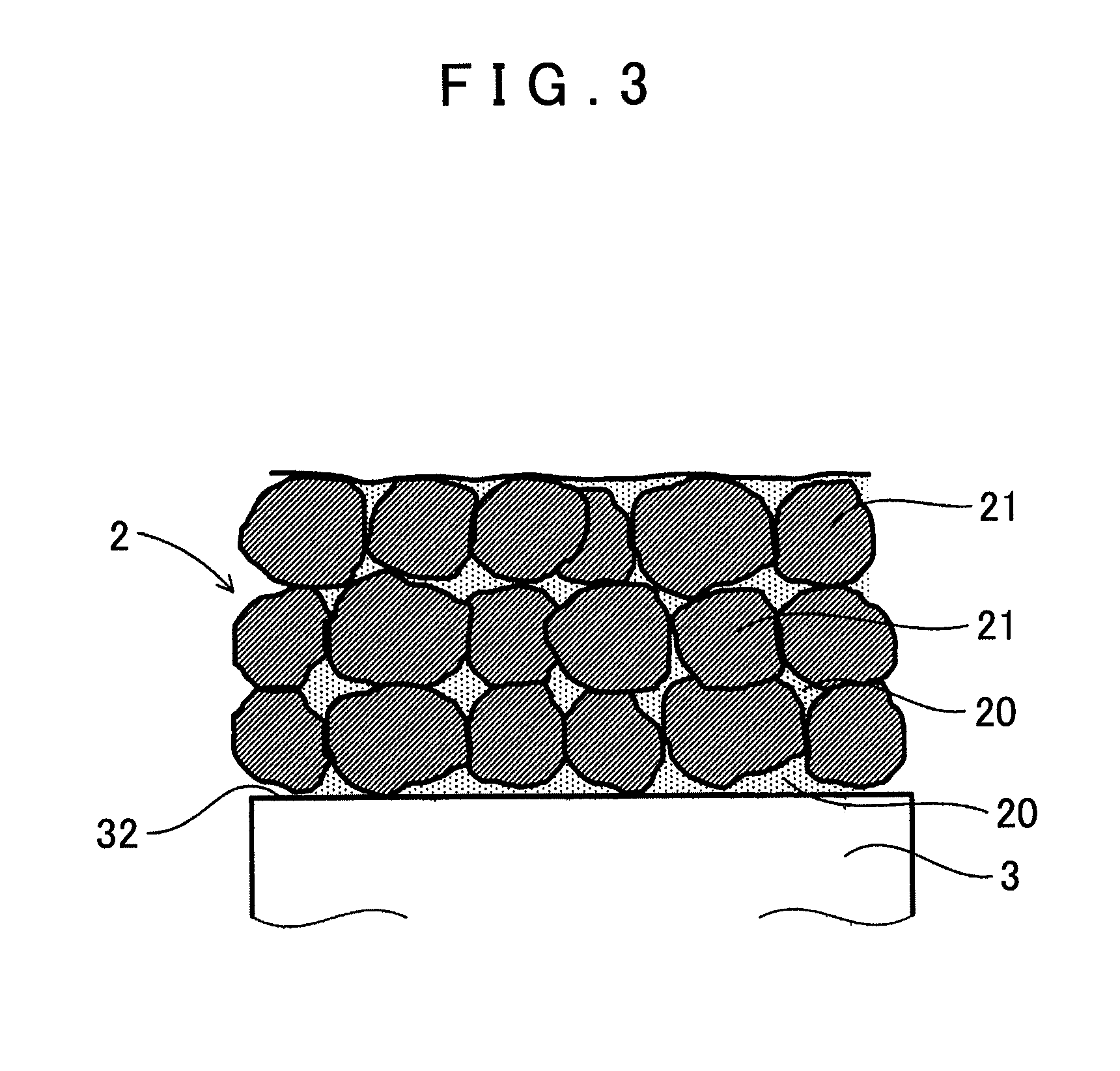

Cutting tool

InactiveUS20090087269A1Increased durabilityImprove cutting performanceCutting insertsWorkpiecesAlloyMetal

A cutting tool for cutting a lead-free copper-based bearing alloy containing 75 to 95% by mass Copper(Cu):, 1 to 15% by mass Bismuth(Bi), and 1 to 10% by mass hard particles comprising metal phosphide, boride, or carbide. The Cutting tool includes a rake surface, a clearance surface, and a cutting edge formed on a line of intersection between the rake surface and the clearance surface. A tip end site including the cutting edge comprises a diamond tip, and the diamond tip comprises a sintered body formed by sintering diamond particles having an average particle diameter (D50) between 0.2 μm and 1.6 μm. The cross section of the cutting edge preferably has a curved surface shape with a radius of curvature between 10 μm and 50 μm.

Owner:AISIN AW CO LTD

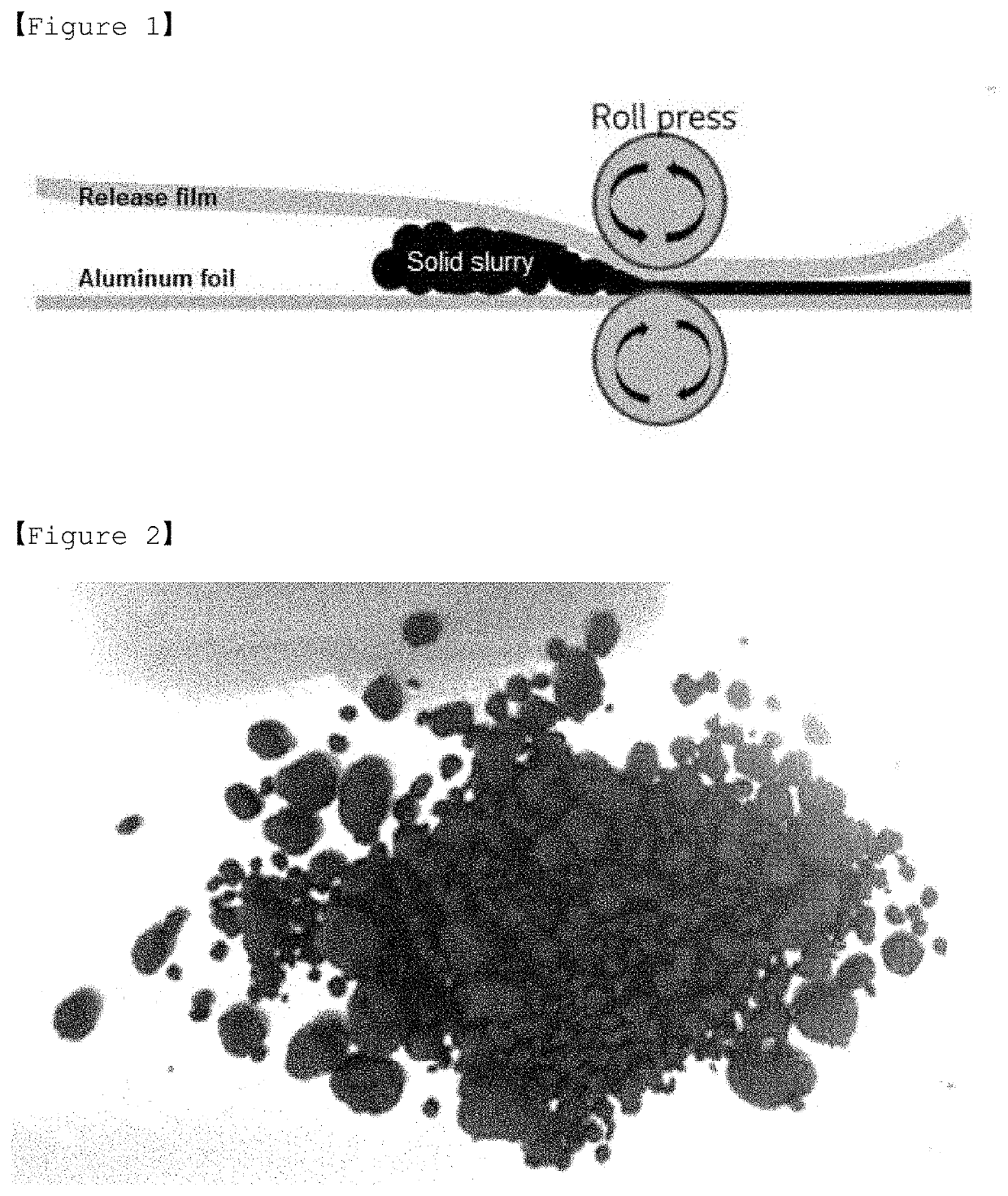

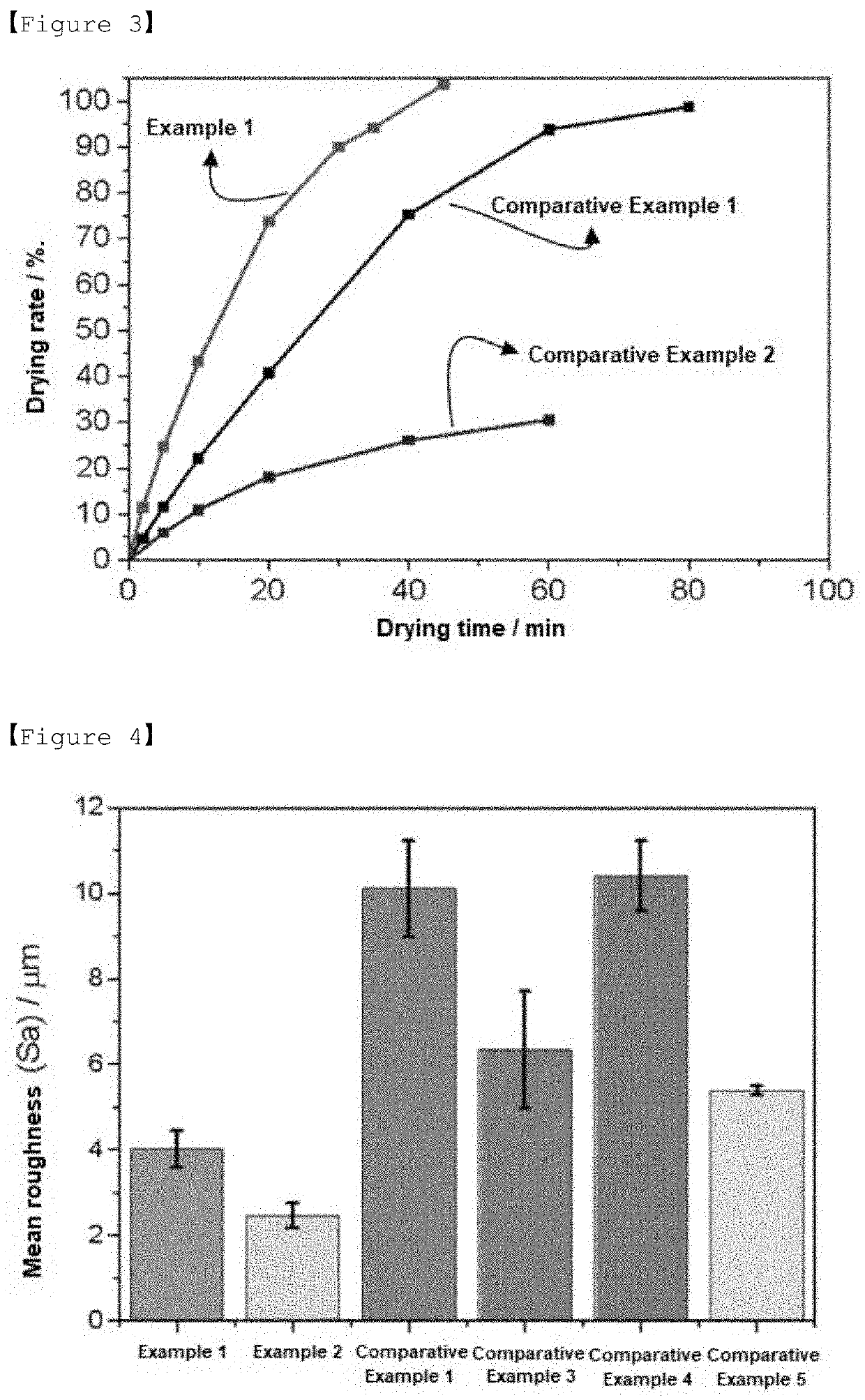

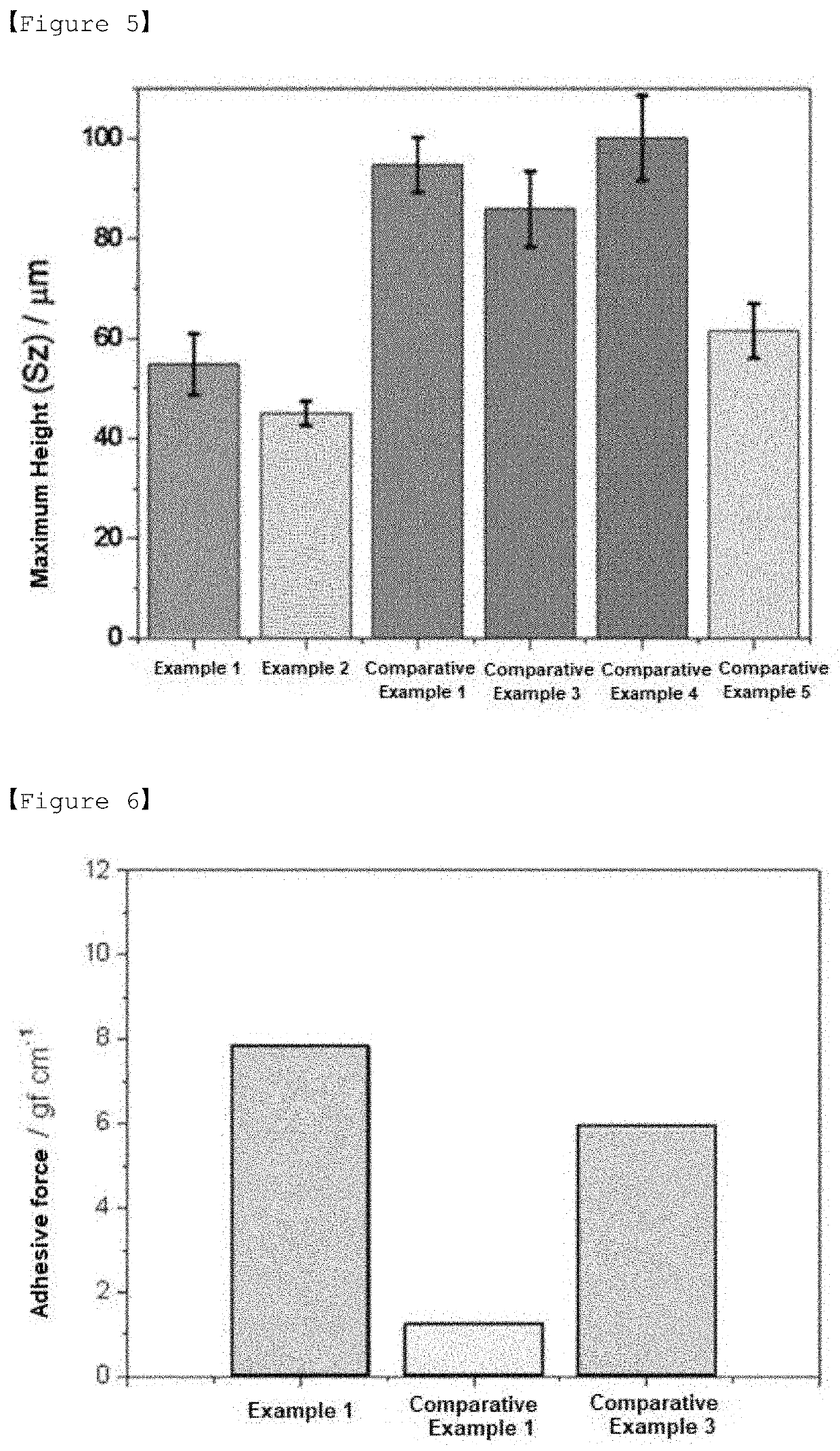

Positive electrode for lithium-sulfur battery and method for manufacturing same

PendingUS20220367873A1Little irregularityImprove adhesionElectrode rolling/calenderingPositive electrodesLithium–sulfur batteryElectrical battery

Disclosed is a positive electrode for a lithium-sulfur battery, including a current collector; and a positive electrode active material layer on the current collector, wherein the positive electrode active material layer includes a positive electrode active material and a binder, and the positive electrode active material layer has surface properties defined by the following Sa (arithmetic mean surface roughness of the positive electrode) and Sz (maximum height roughness of the positive electrode) ((i) 1 μm≤Sa≤5 μm, (ii) 10μm≤Sz≤60 μm (wherein Sa is the average value of the distance from the middle surface of the surface irregularity structure of the positive electrode to the highest point and the lowest point of each irregularity part, and Sz means the distance from the lowest point to the highest point of the positive electrode)) and a method for manufacturing the same.

Owner:LG ENERGY SOLUTION LTD

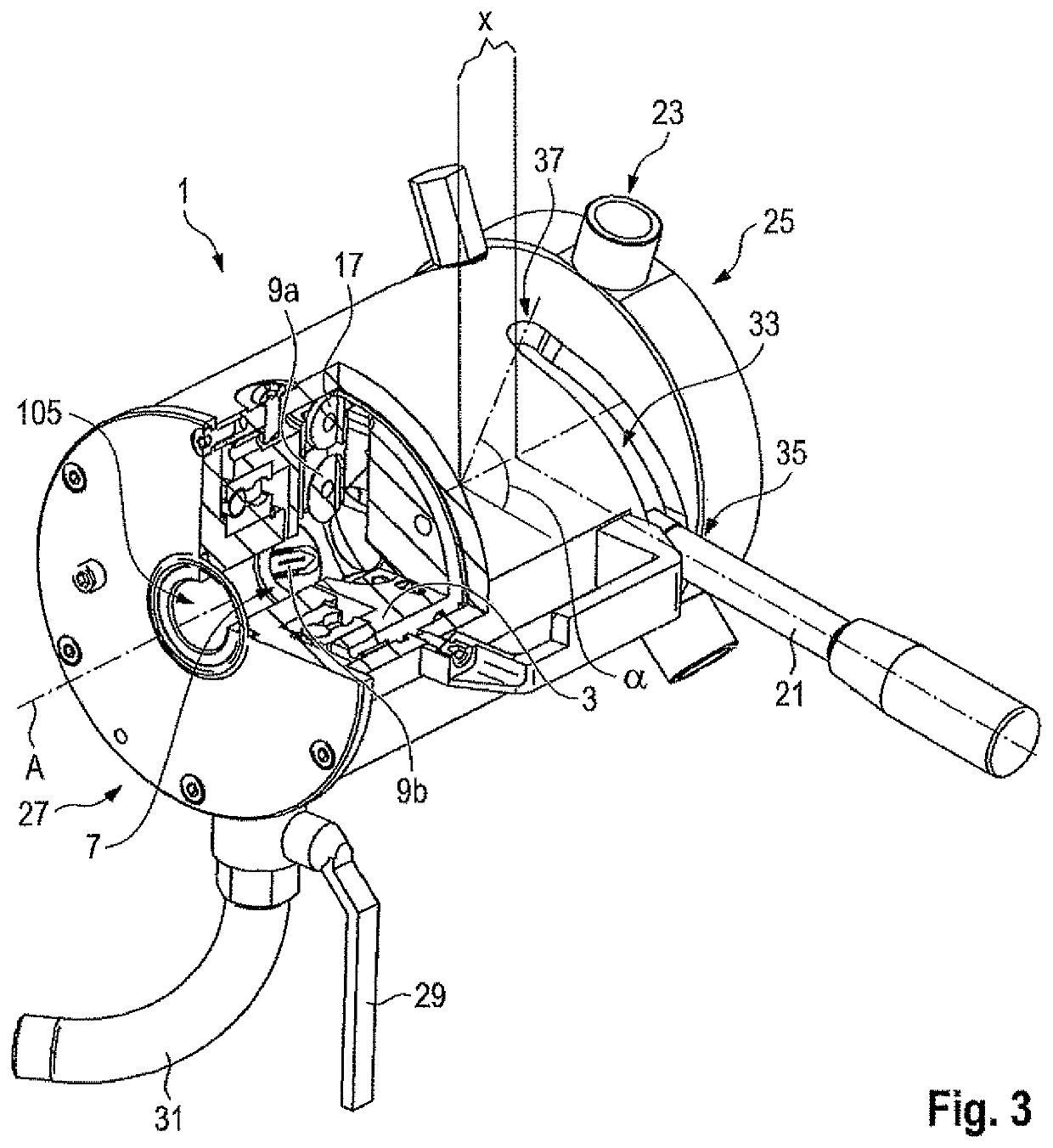

Tensioning cable spreading device and tensioning cable lubrication device and method

ActiveUS11248341B2Promote disseminationReduce sliding frictionRope making machinesClassical mechanicsStructural engineering

A device for spreading a multi-stranded tensioning cable, in particular steel tensioning cables, comprising a main body having a feedthrough opening for the entire tensioning cable, and a number of spreading elements which are arranged radially movably in the main body and each have a contour which is of a configuration tapering inwardly in the radial direction for engaging and producing a gap between respectively adjacent strands of the tensioning cable.

Owner:WOBBEN PROPERTIES GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com