Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Little generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

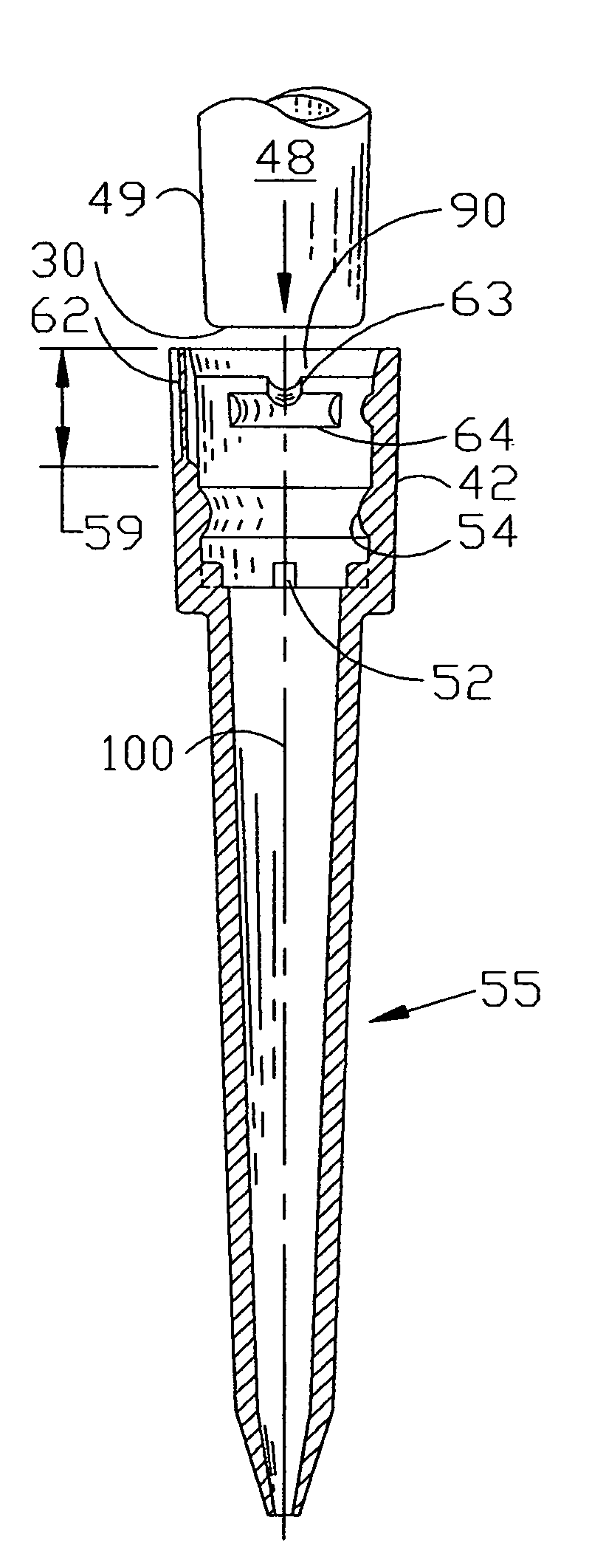

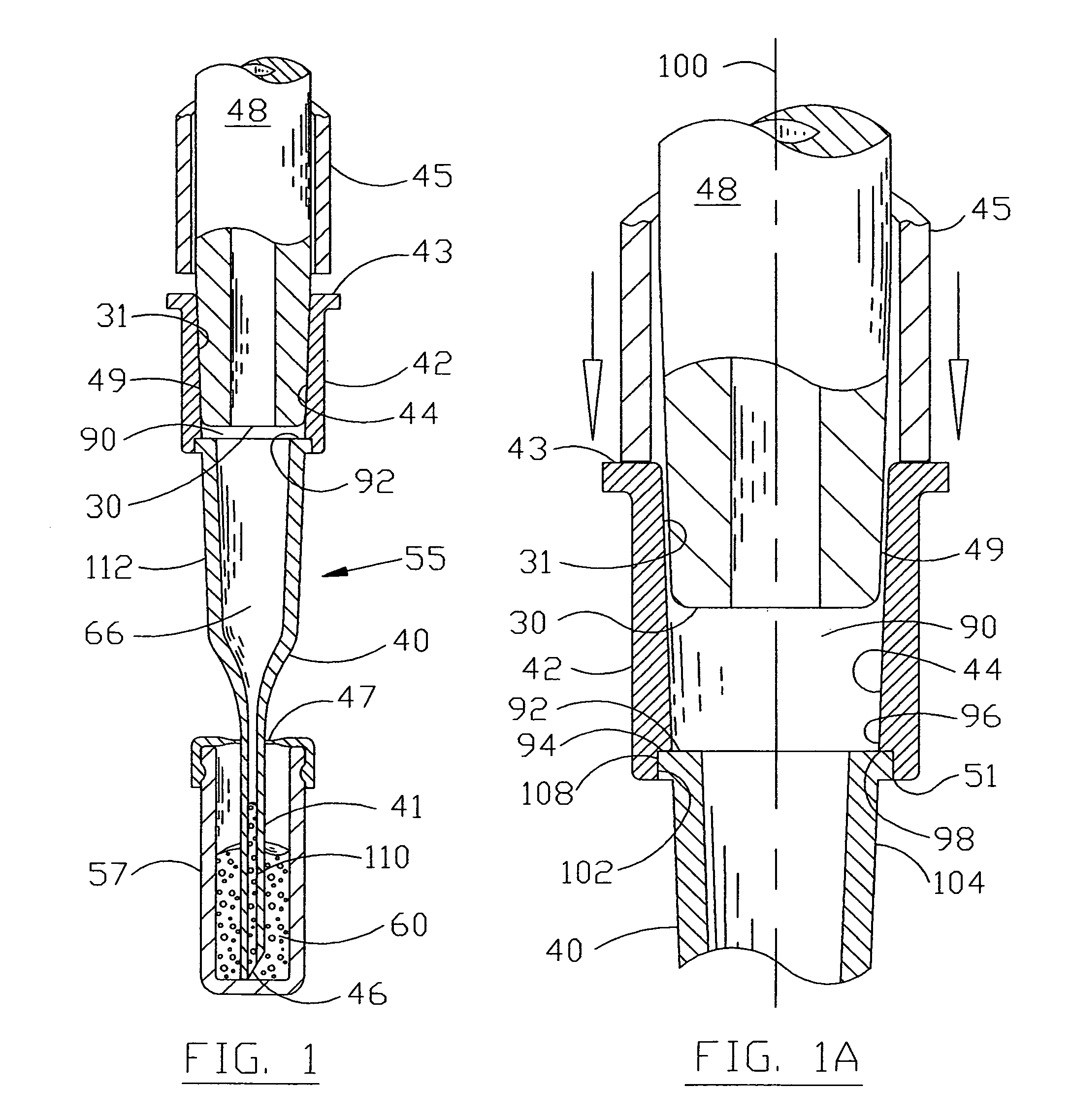

Ergonomic pipette tip and adapters

ActiveUS7335337B1Easily and securely mountedLittle generationWithdrawing sample devicesBurettes/pipettesBiomedical engineeringExpansion joint

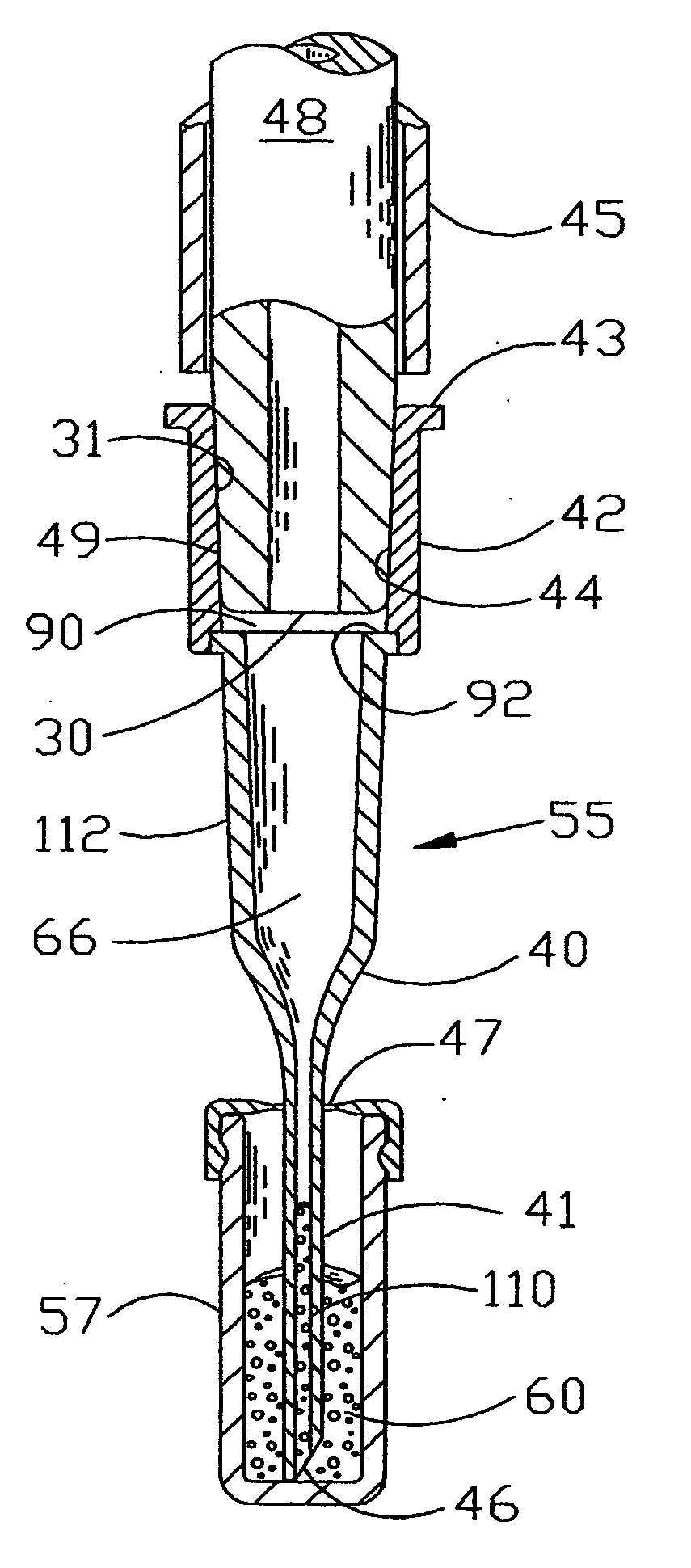

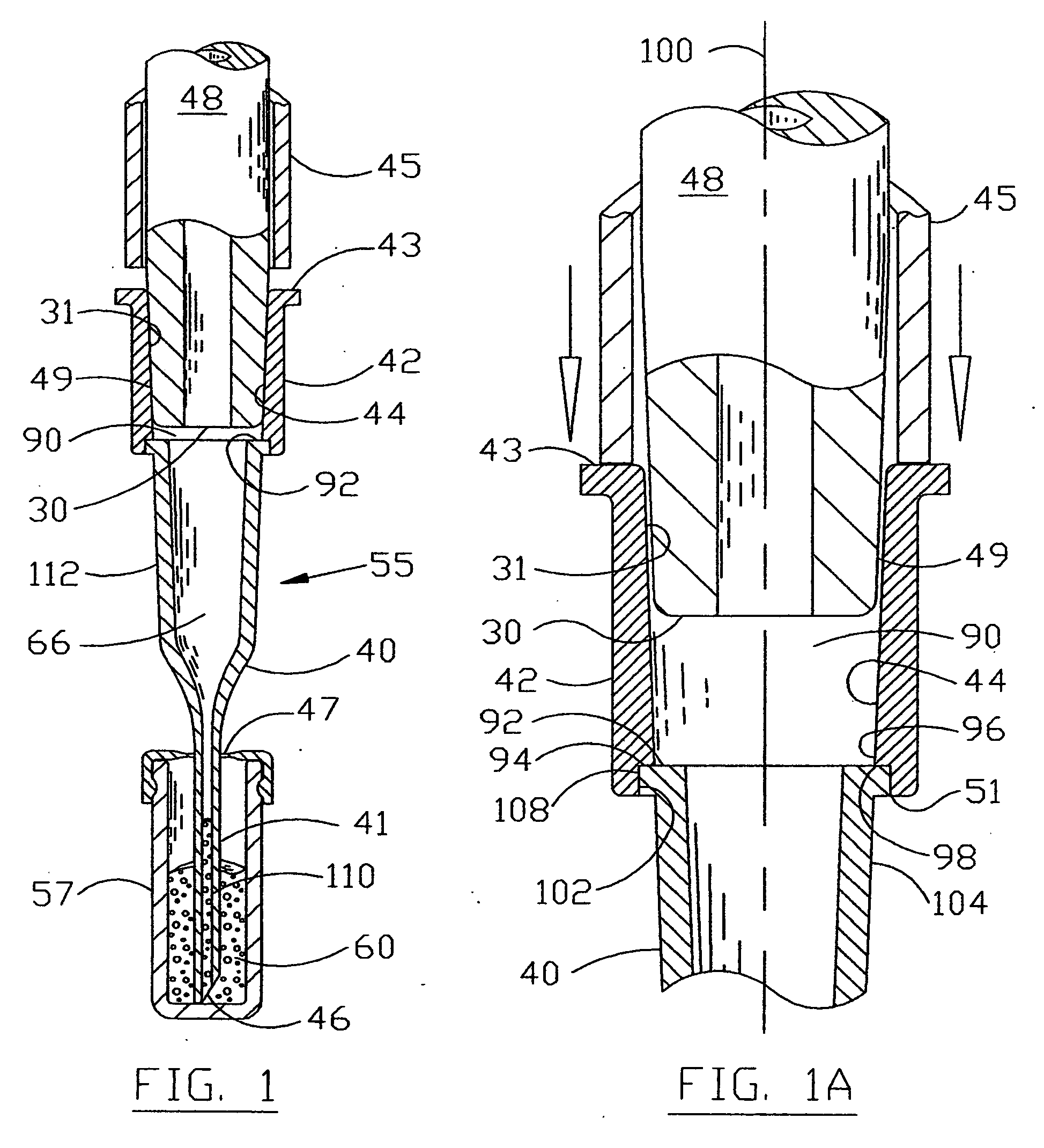

An ergonomically designed pipette tip that can be securely mounted to a barrel of a pipetter yet is designed to substantially reduce the axial force necessary to install and eject the pipette tip from the pipetter. The ergonomic pipette tip includes molded-in expansion joints and / or the addition of a second elastic material to decrease the amount of force necessary to radially expand the entrance to the pipette tip when the pipetter barrel is guided and stability oriented towards the sealing region of the pipette tip. Also disclosed is an ergonomic adapter with similar features as the tip that can also be mounted to the barrel of the pipetter and attached to a standard pipette tip or a combination of tips. Therefore, the relatively small axial forces necessary for mounting and ejecting the new ergonomic tip and adapter can substantially help to reduce the hand and thumb forces, that due to repeated use, will sometimes result in repetitive stress injury.

Owner:SMITH JAMES C

Thermoplastic composites with improved sound absorbing capabilities

InactiveUS20060137799A1Alter its performanceOptimization propertiesWood working apparatusBaby linensGlass fiberPolyethylene terephthalate

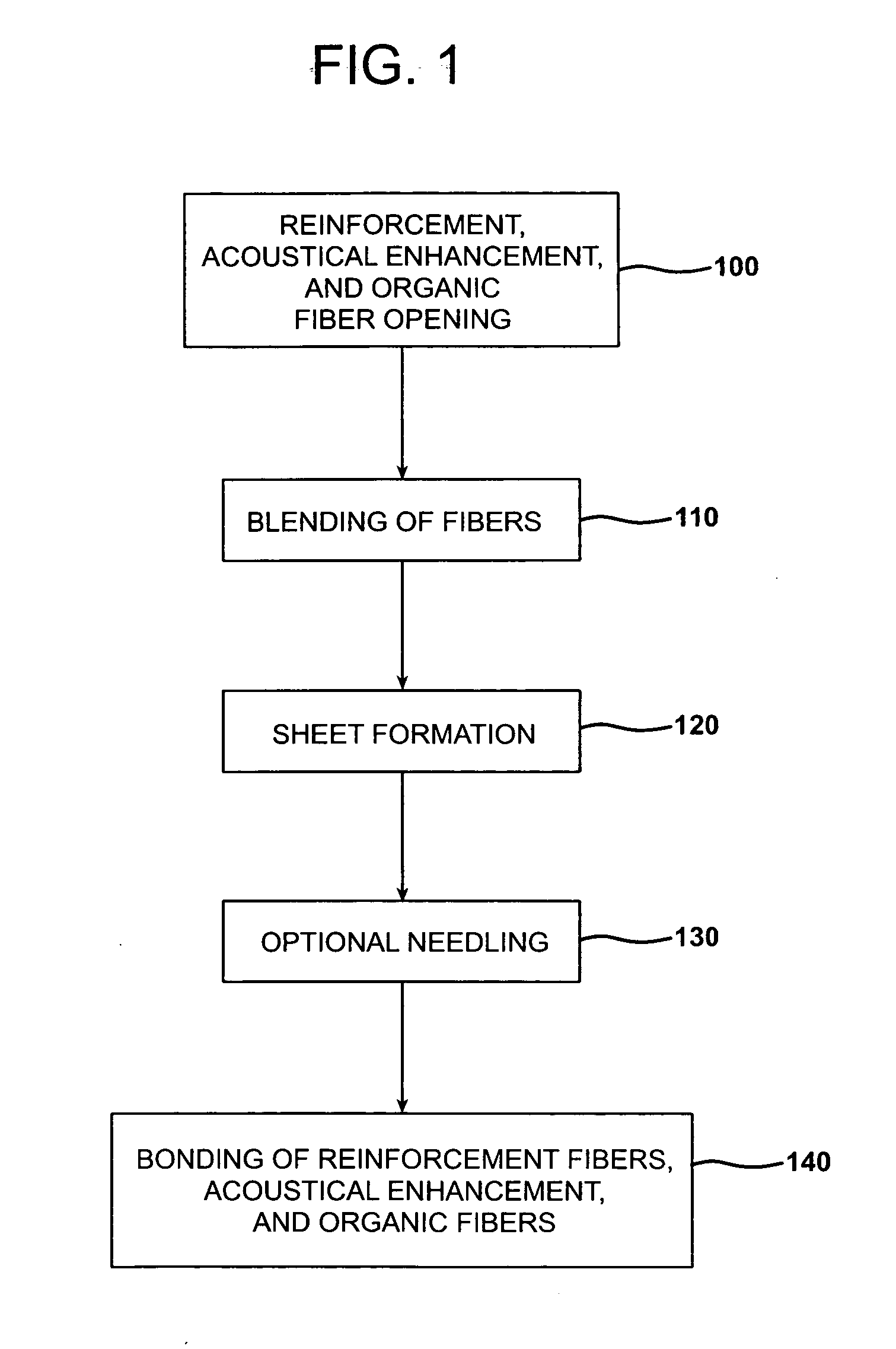

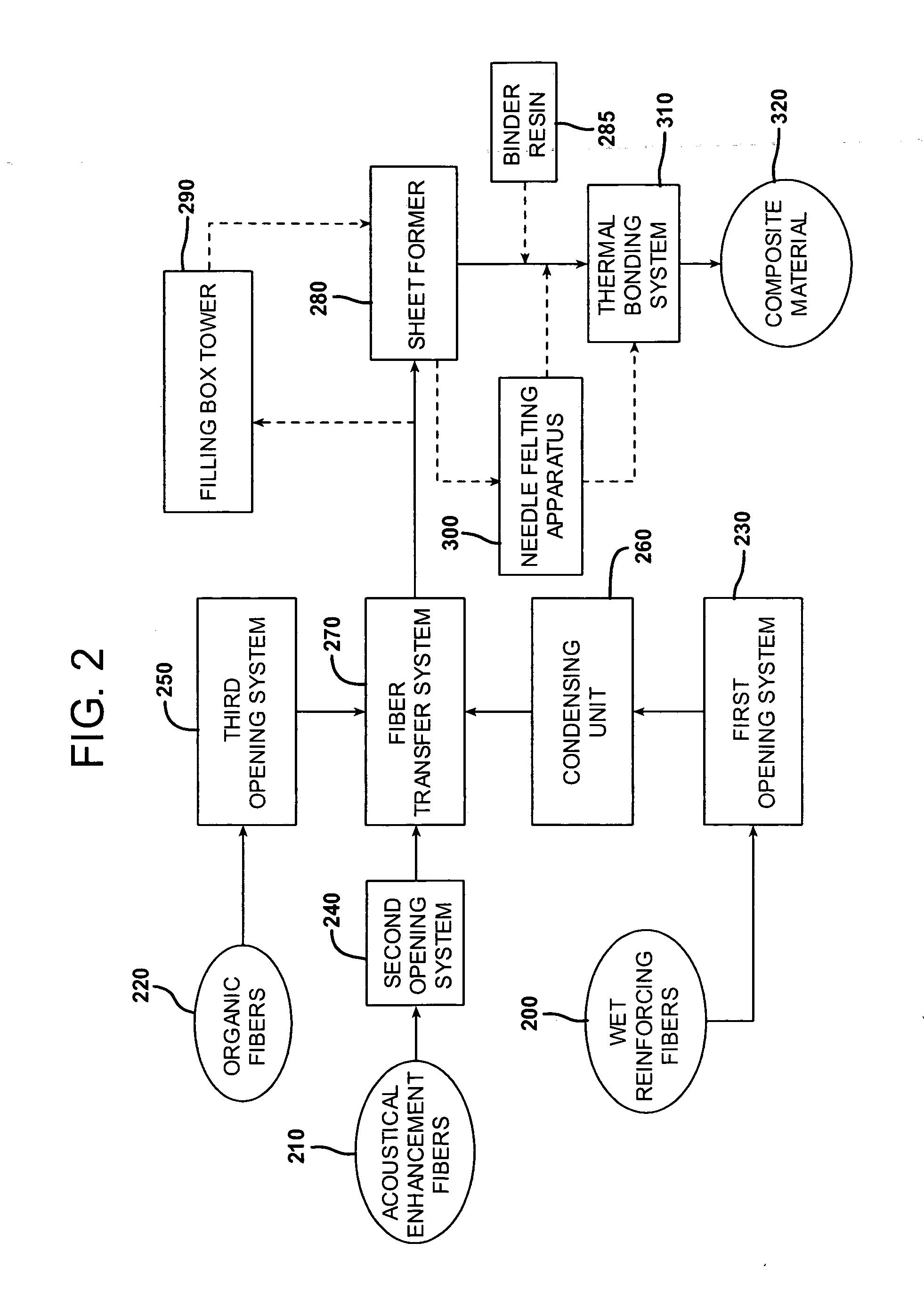

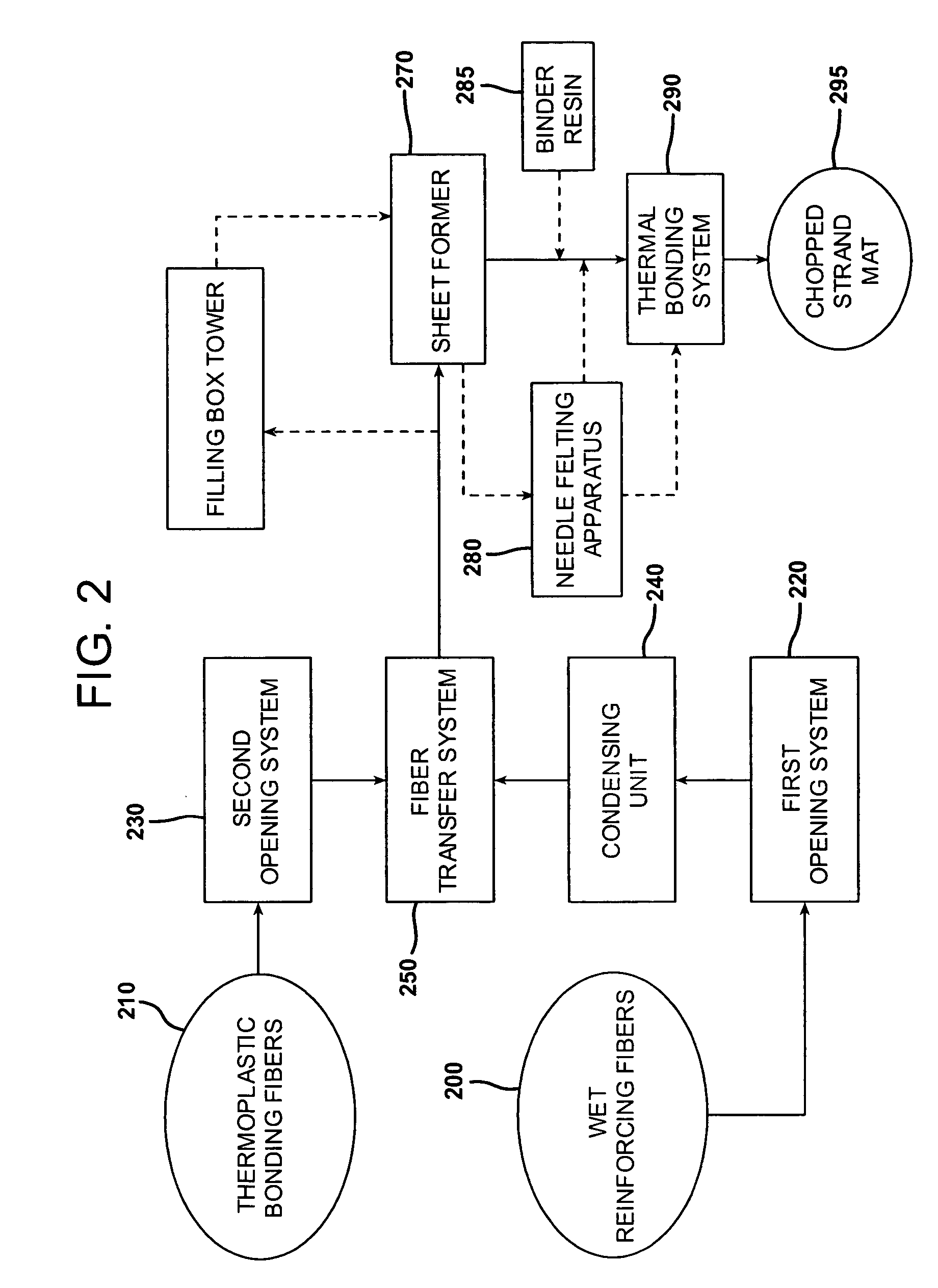

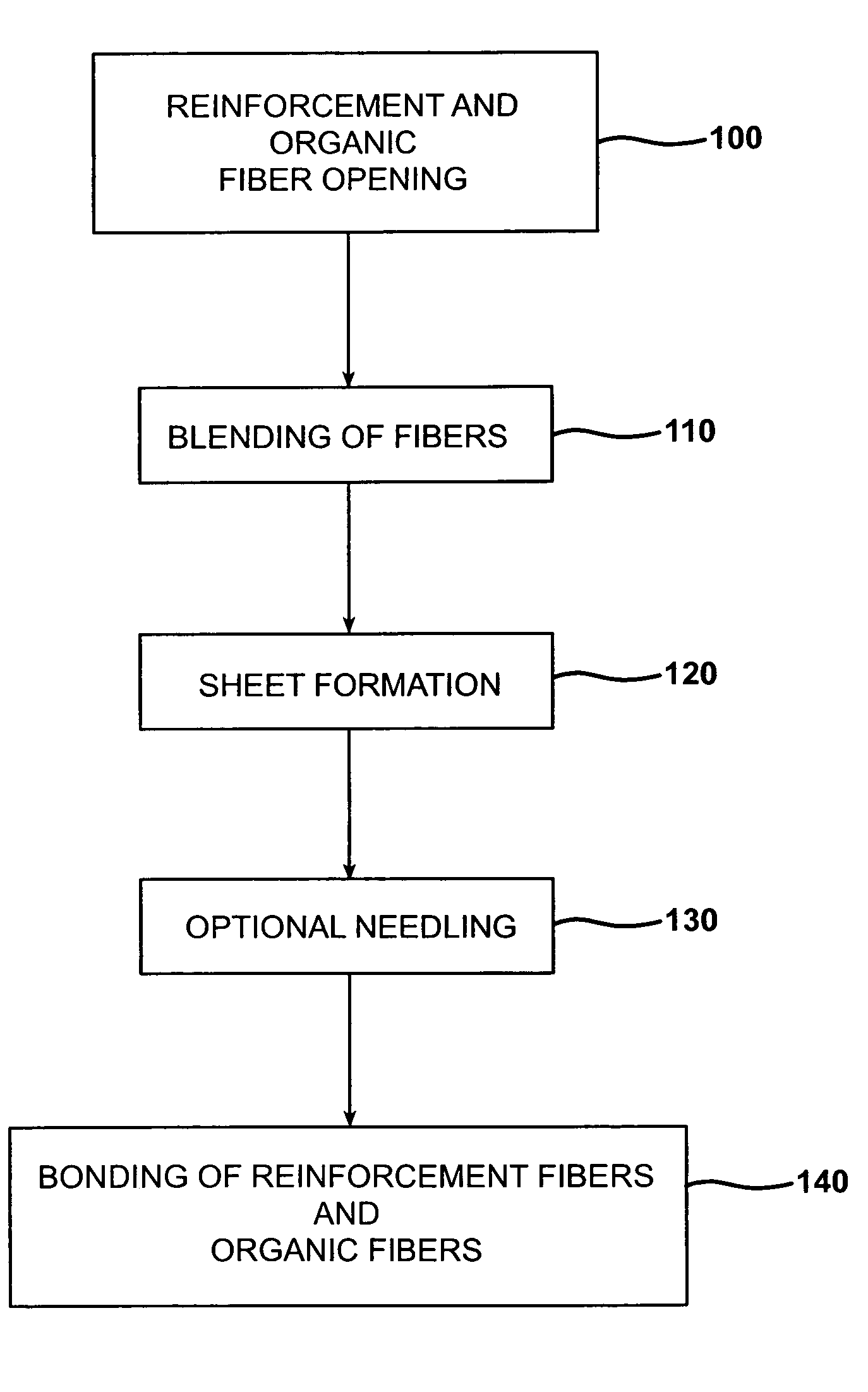

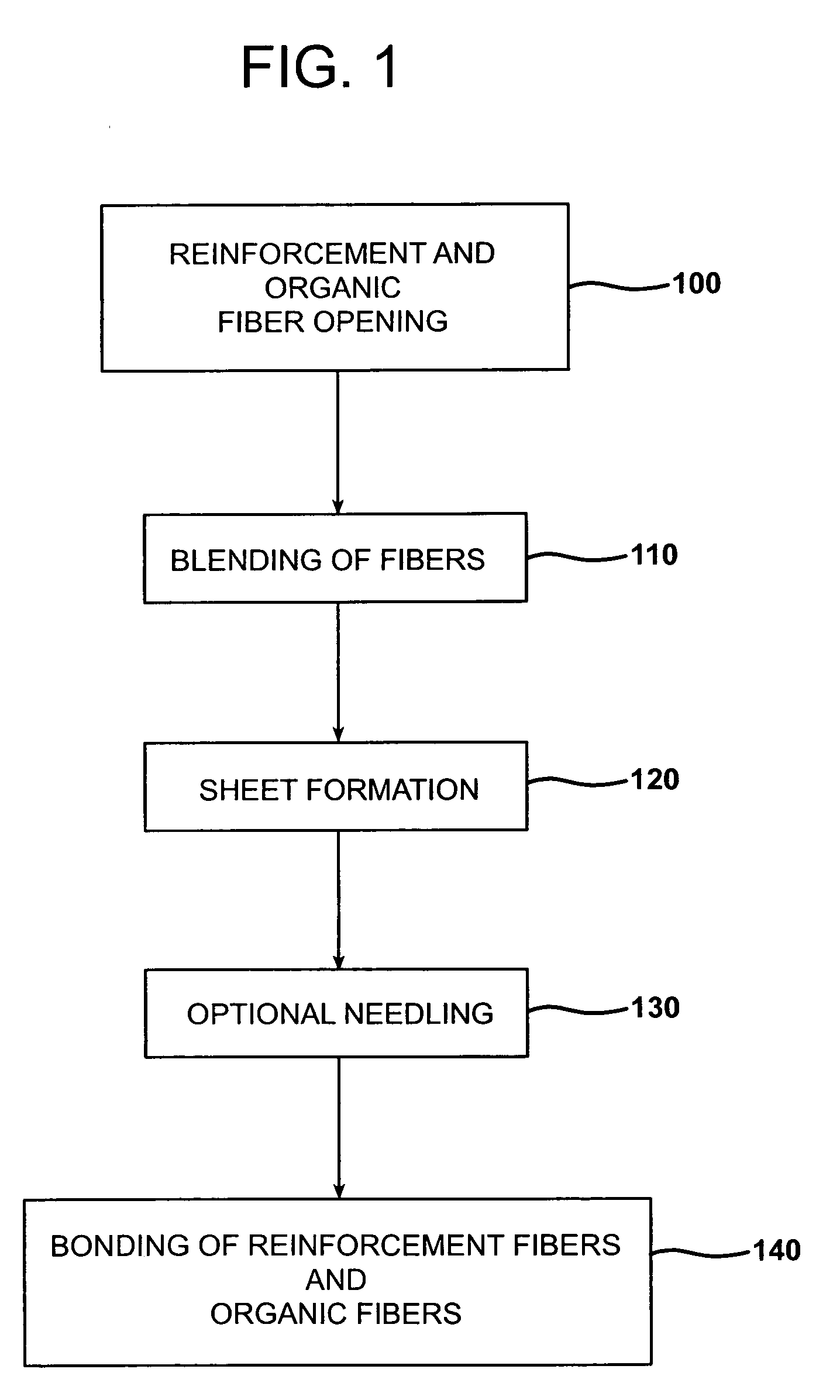

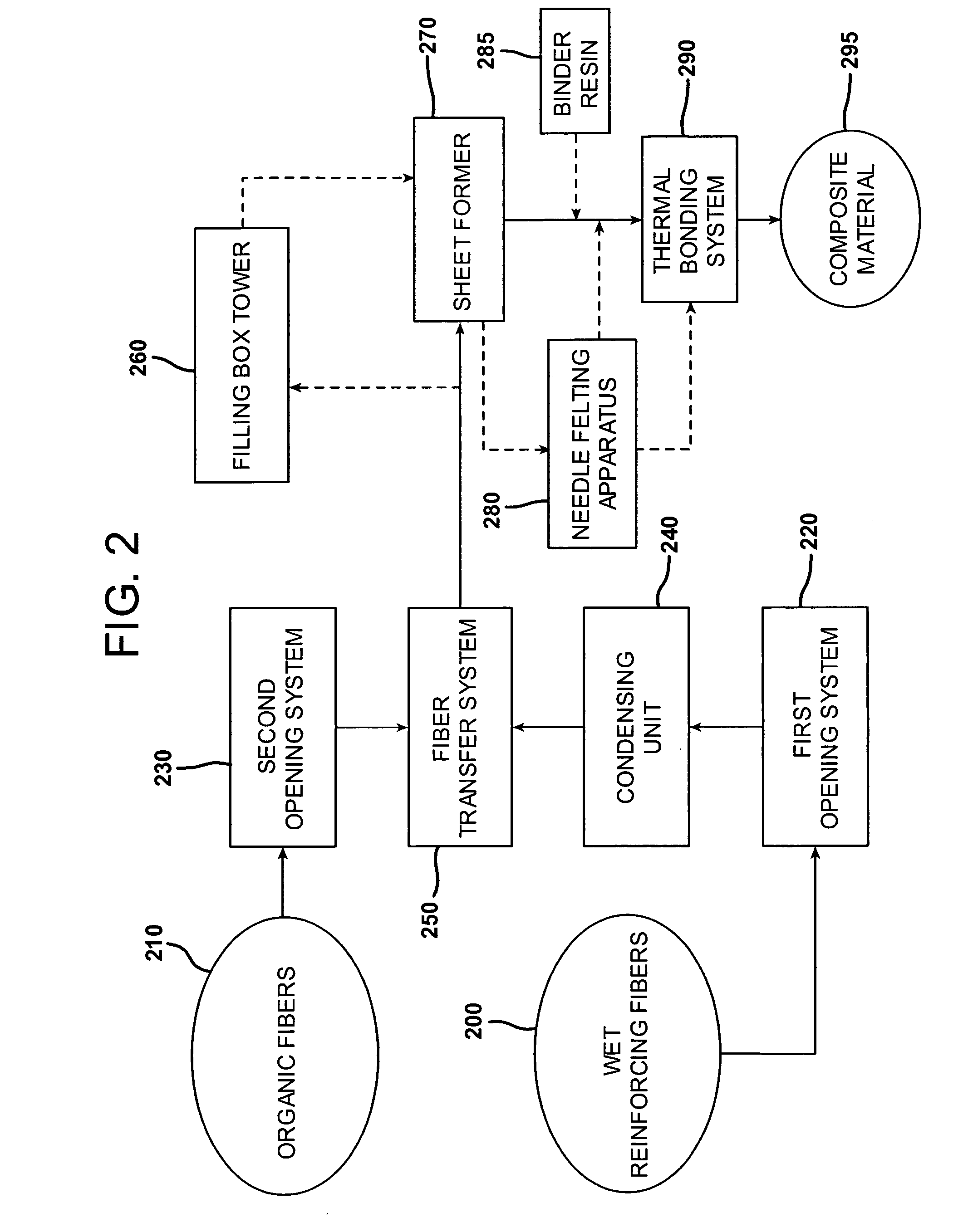

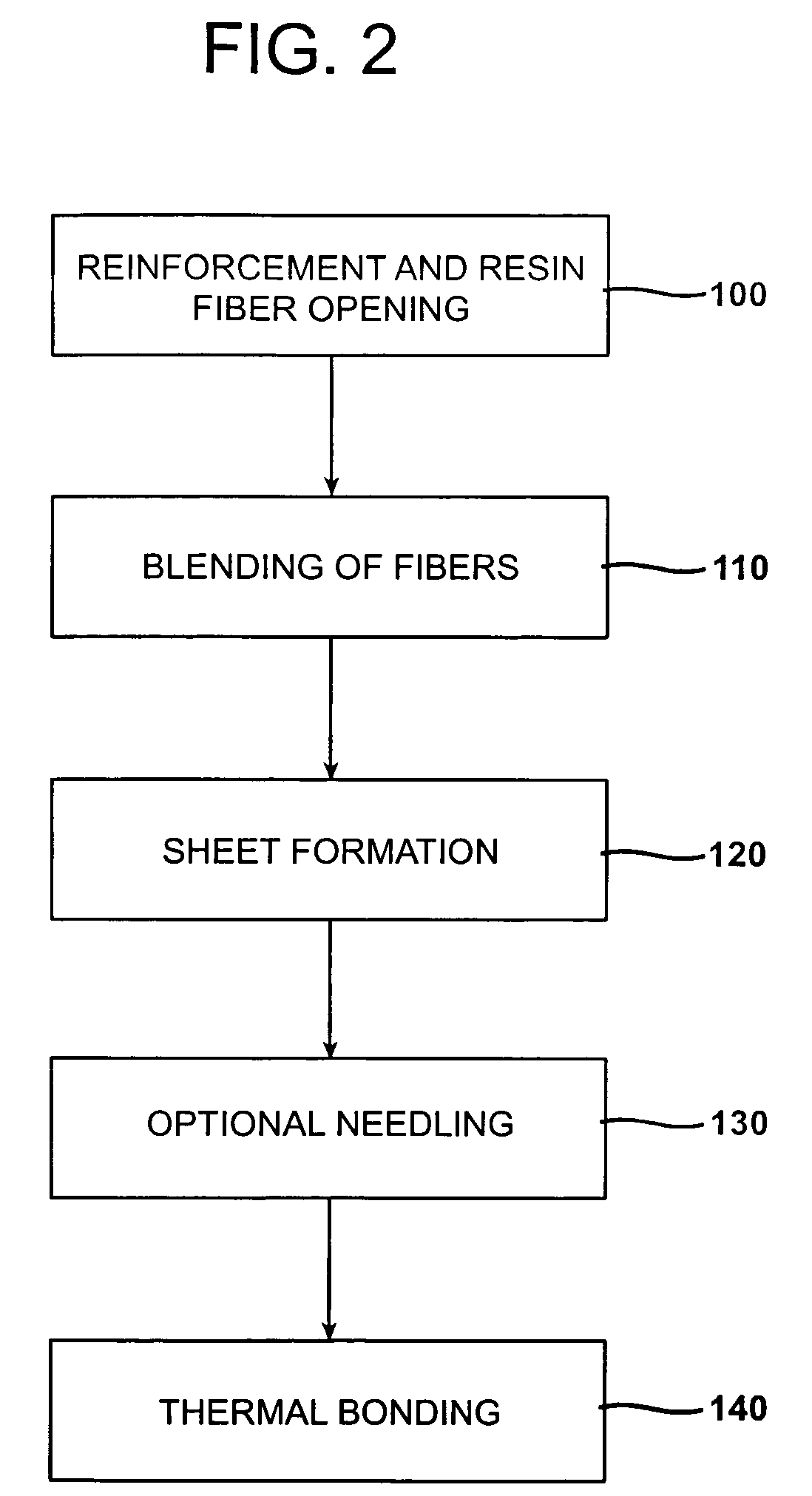

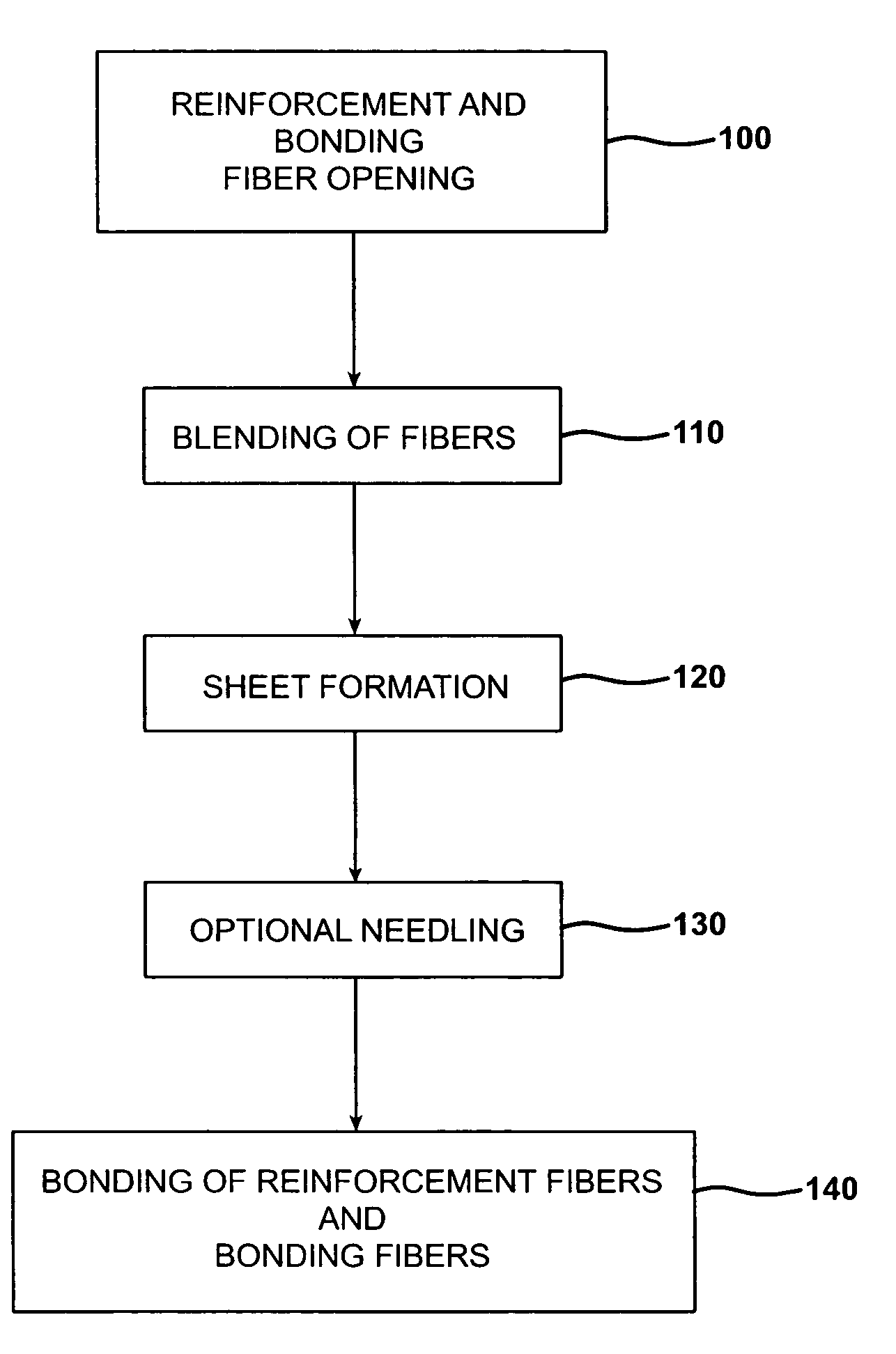

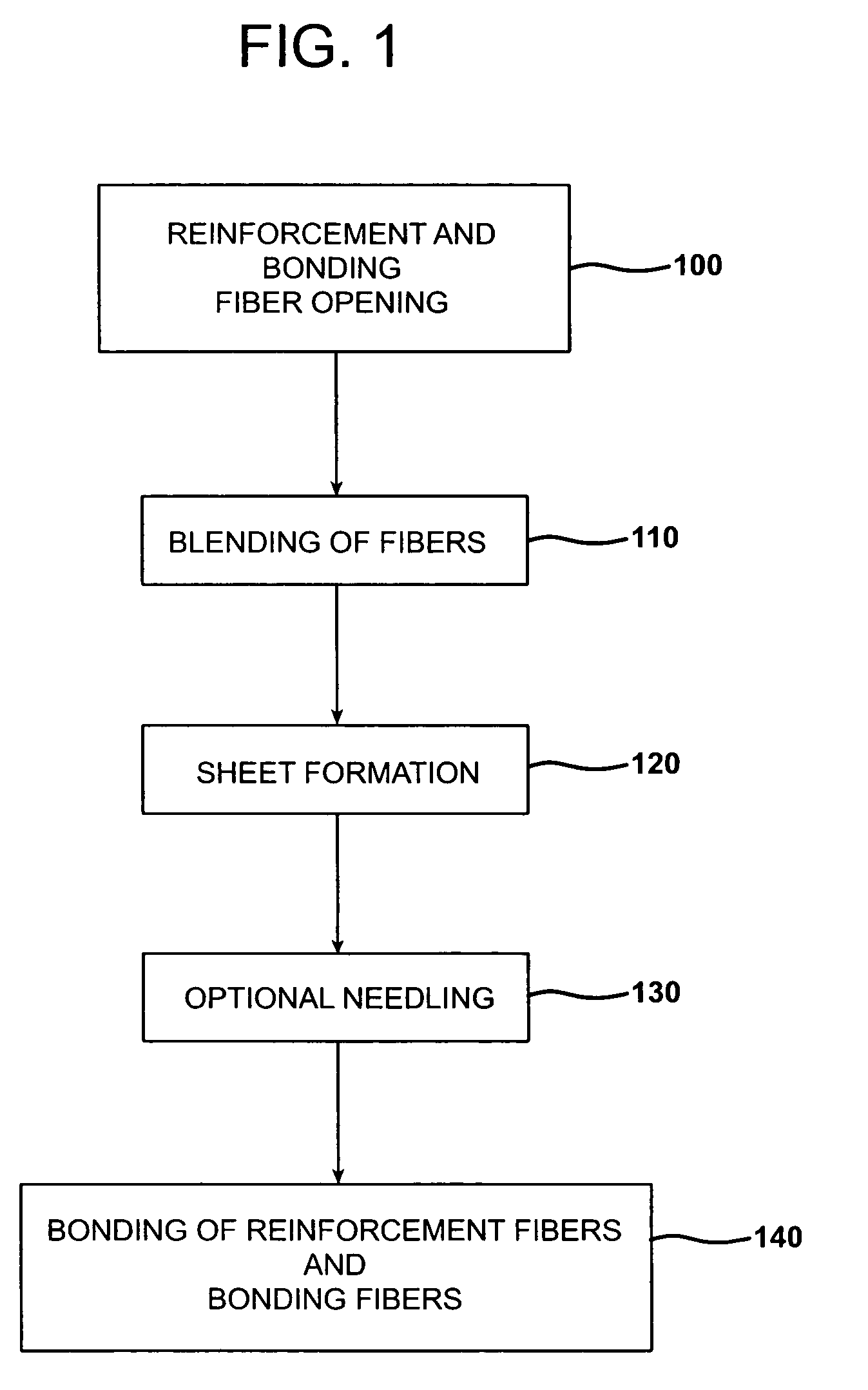

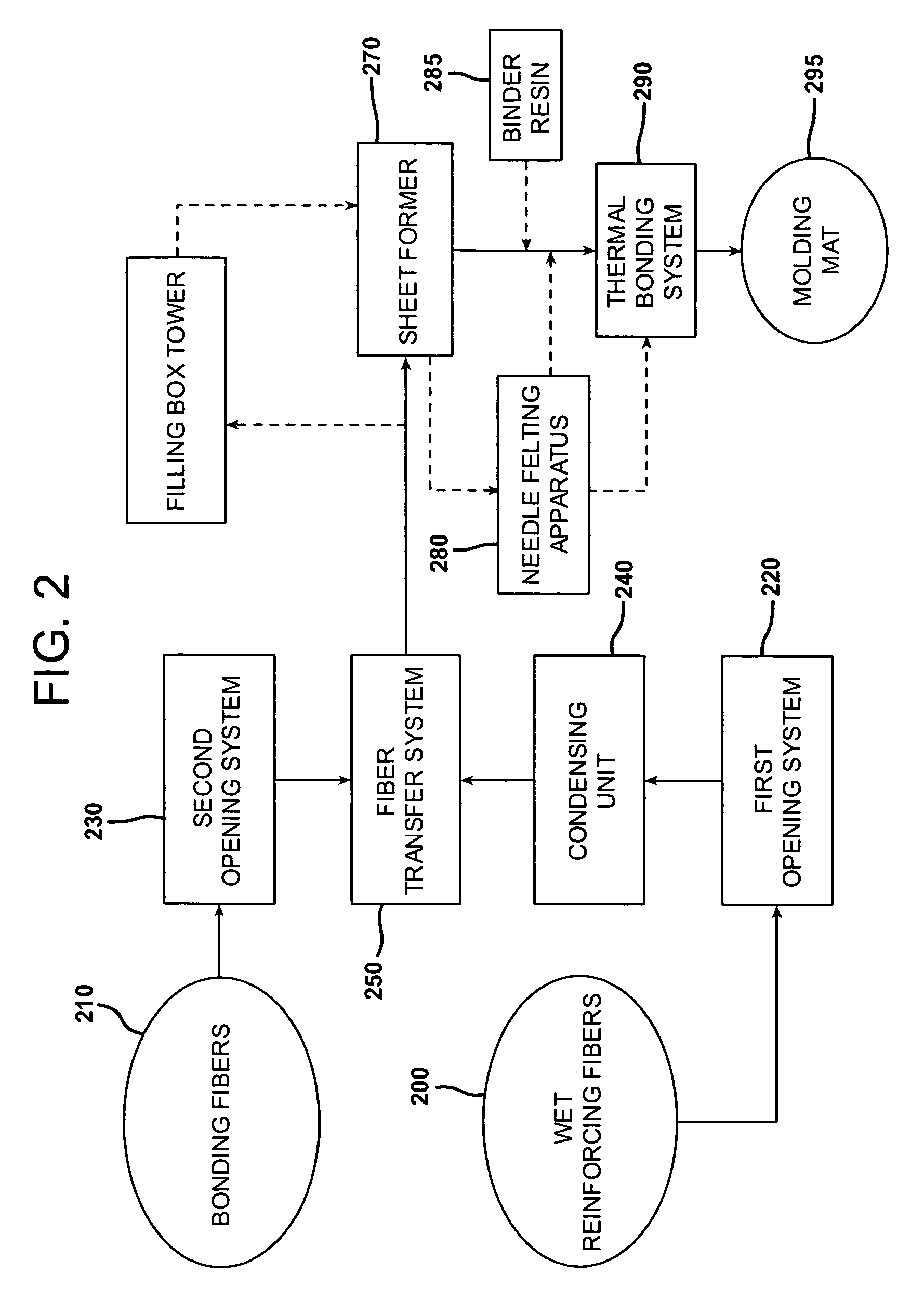

A composite material formed of reinforcement fibers, acoustical enhancing fibers such as polyethylene terephthalate (PET) fibers or modified polyethylene terephthalate fibers, and one or more organic fibers is provided. The acoustical enhancing fiber may be any fiber that provides increased or enhanced acoustical absorbance, particularly at low frequencies. The composite material may be formed by partially opening wet reinforcing fibers, acoustical enhancing fibers, and organic fibers, mixing the reinforcing, acoustical enhancement, and organic fibers, forming the fibers into a sheet, and bonding the fibers in the sheet. Preferably the reinforcing fibers are wet use chopped strand glass fibers. The composite material may be formed of a single layer of reinforcement, acoustical enhancement fibers, and organic fibers. Alternatively, the composite material may be a multi-layered composite in which the acoustical enhancement fibers are located in an acoustical layer laminated to a thermal layer formed of the organic fibers and reinforcement fibers.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

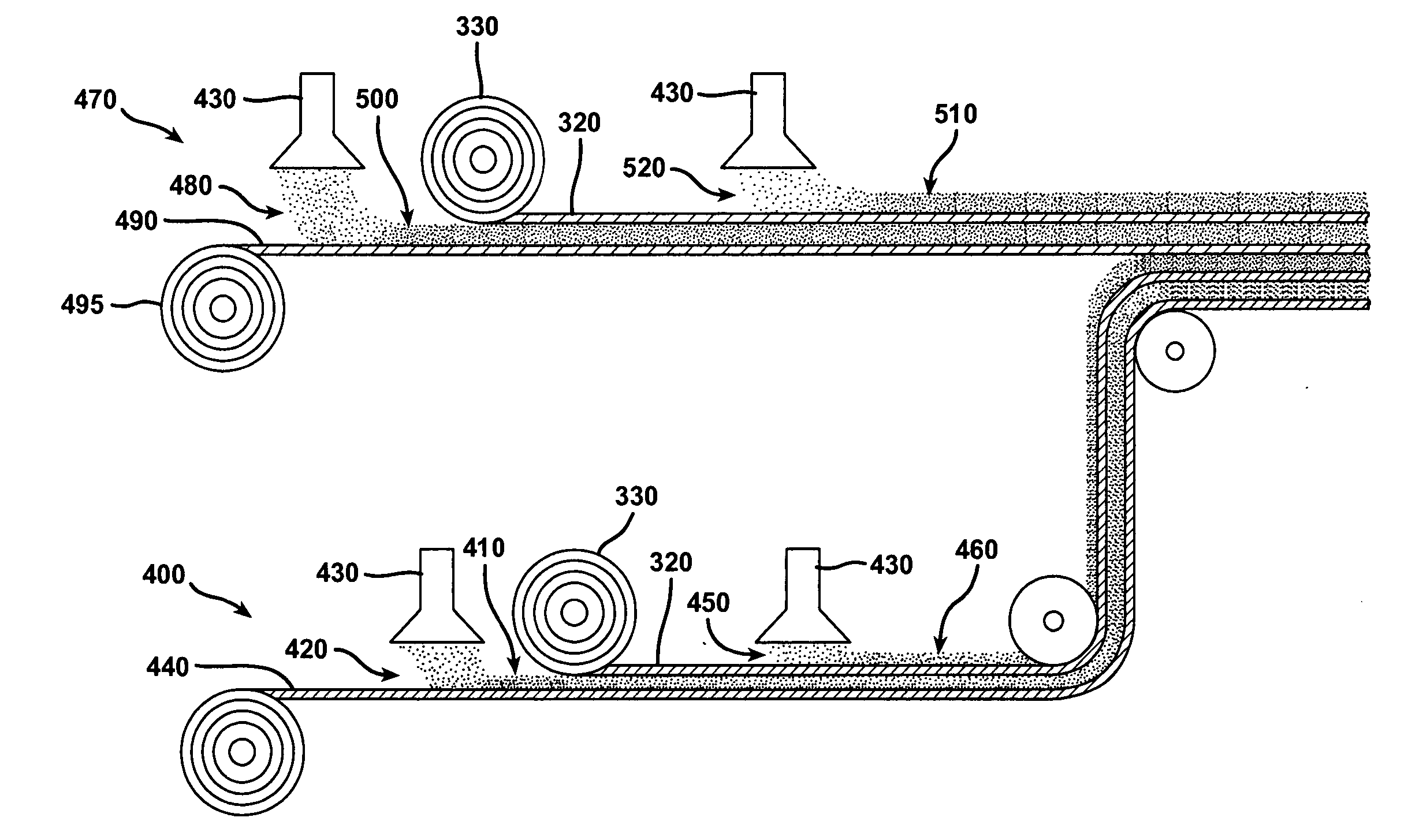

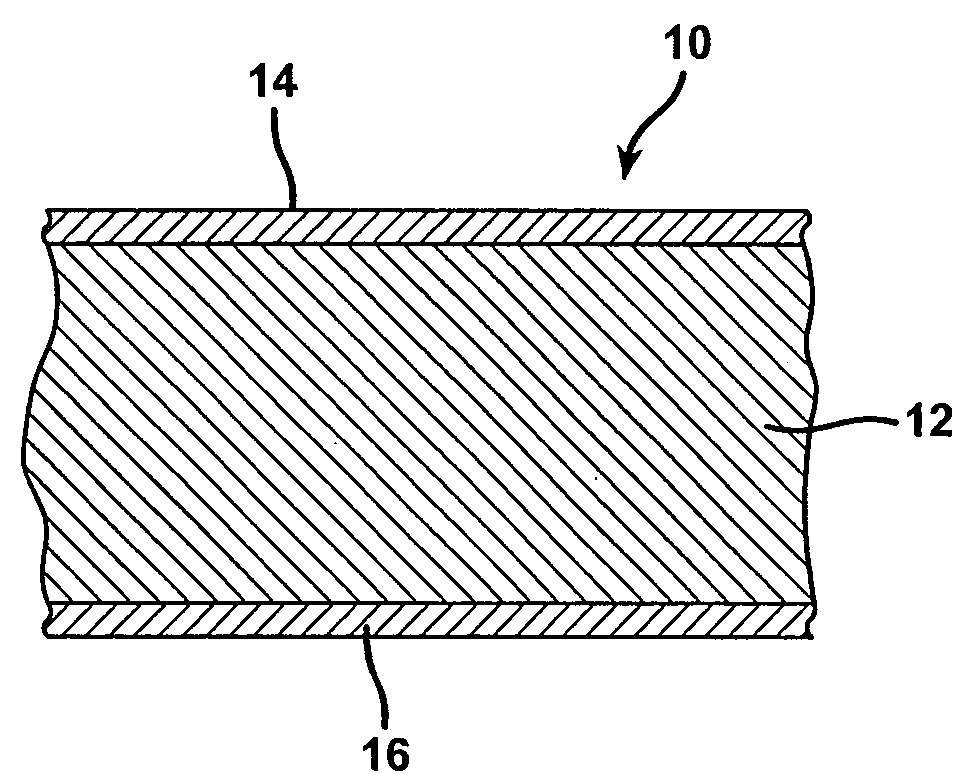

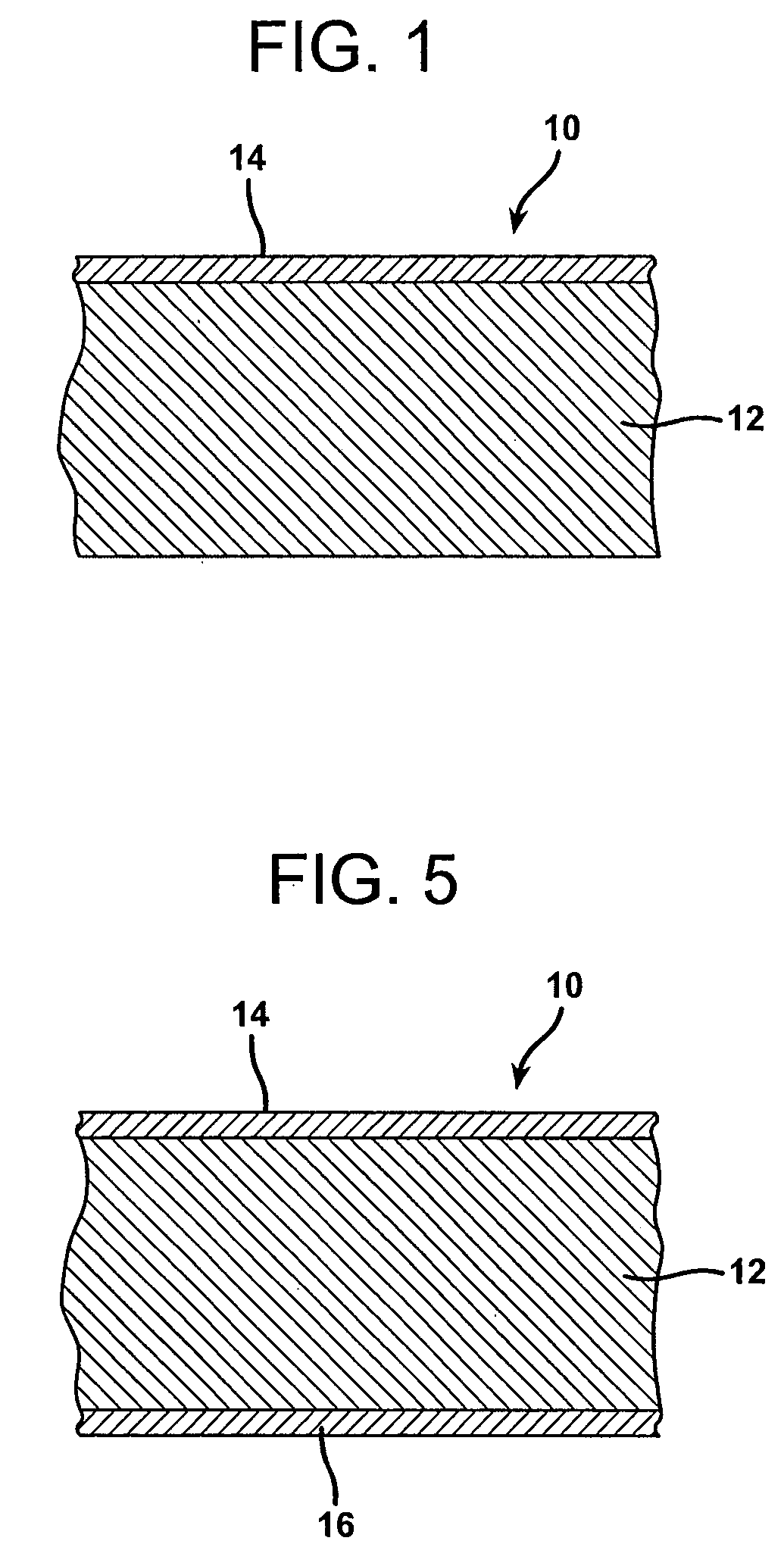

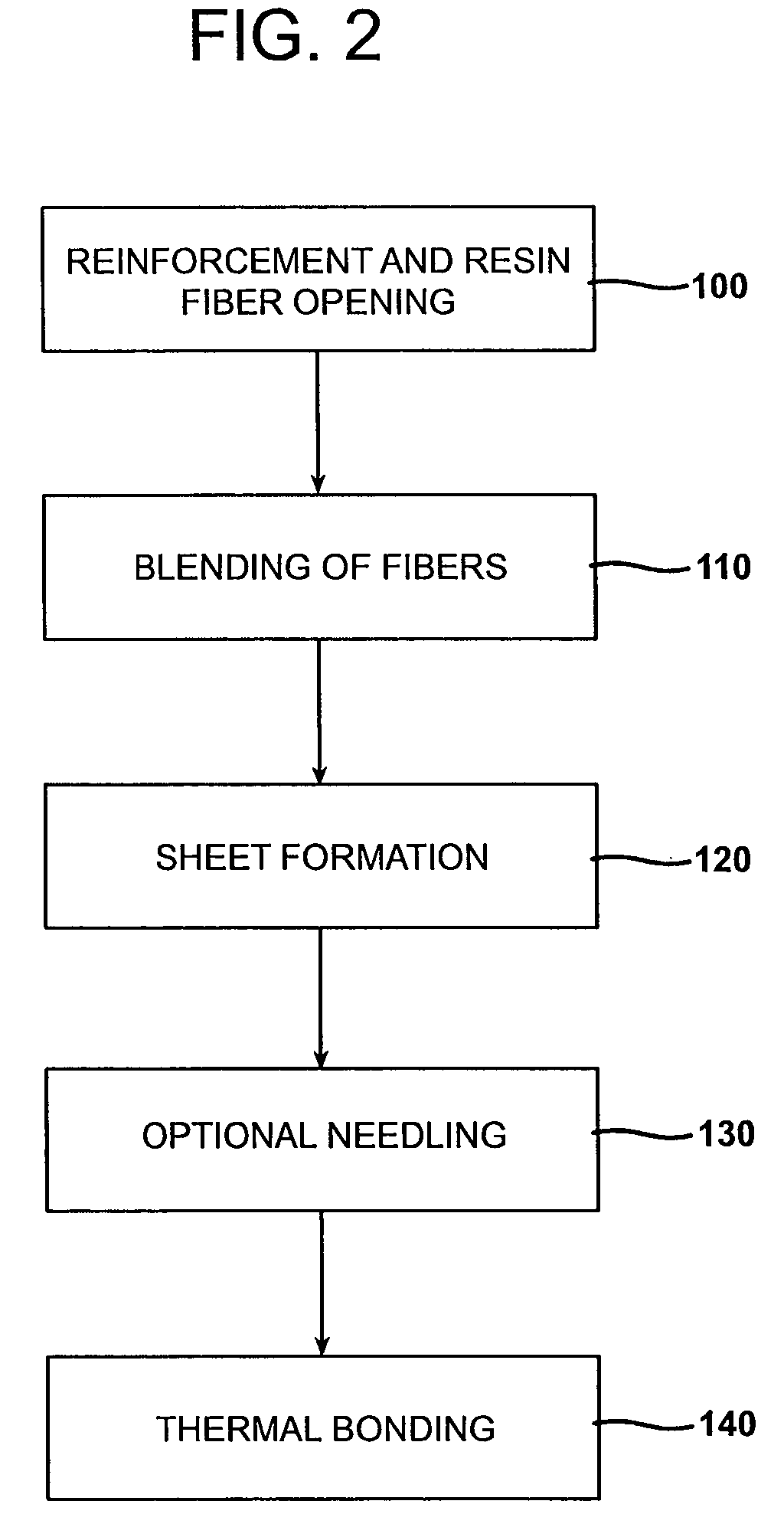

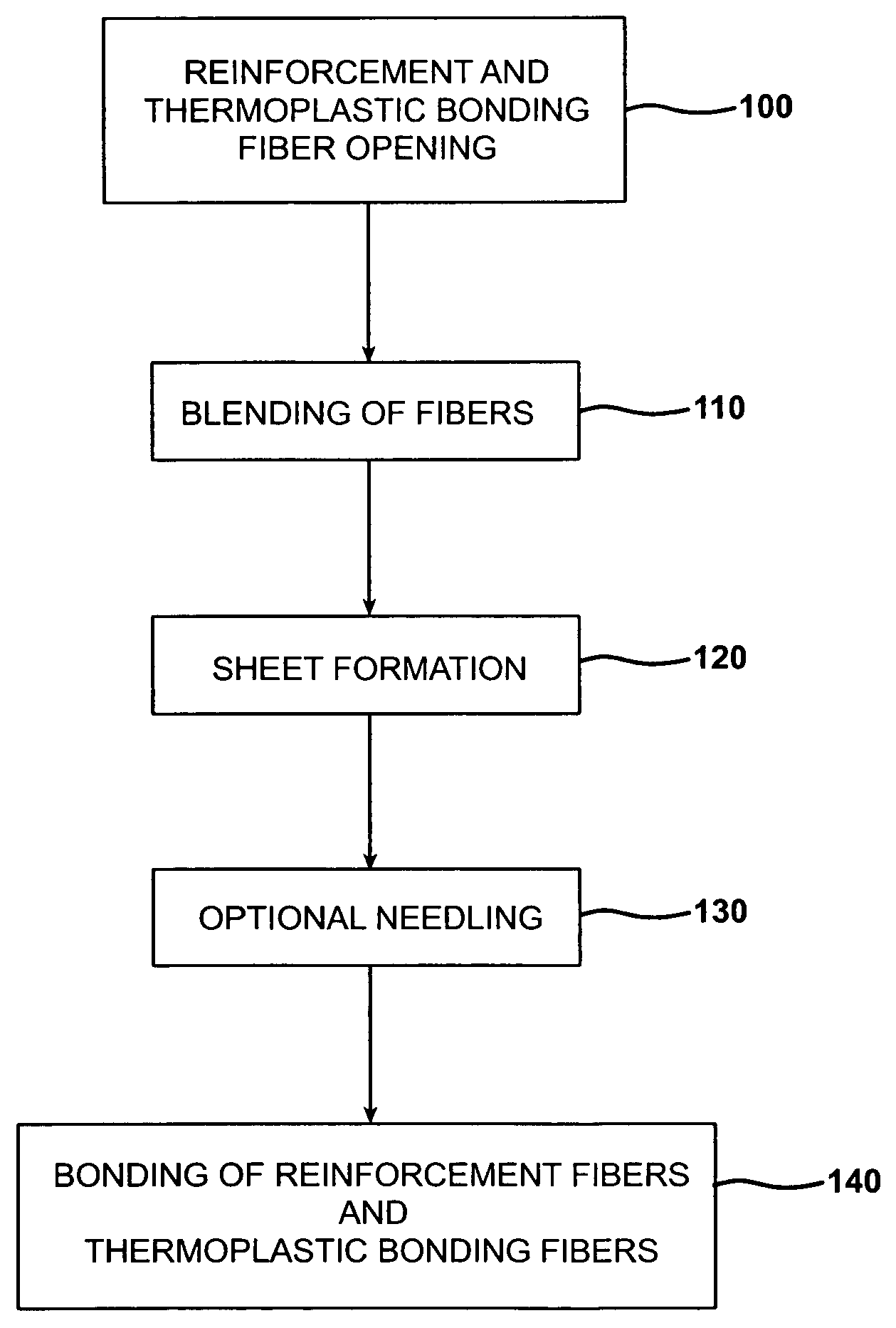

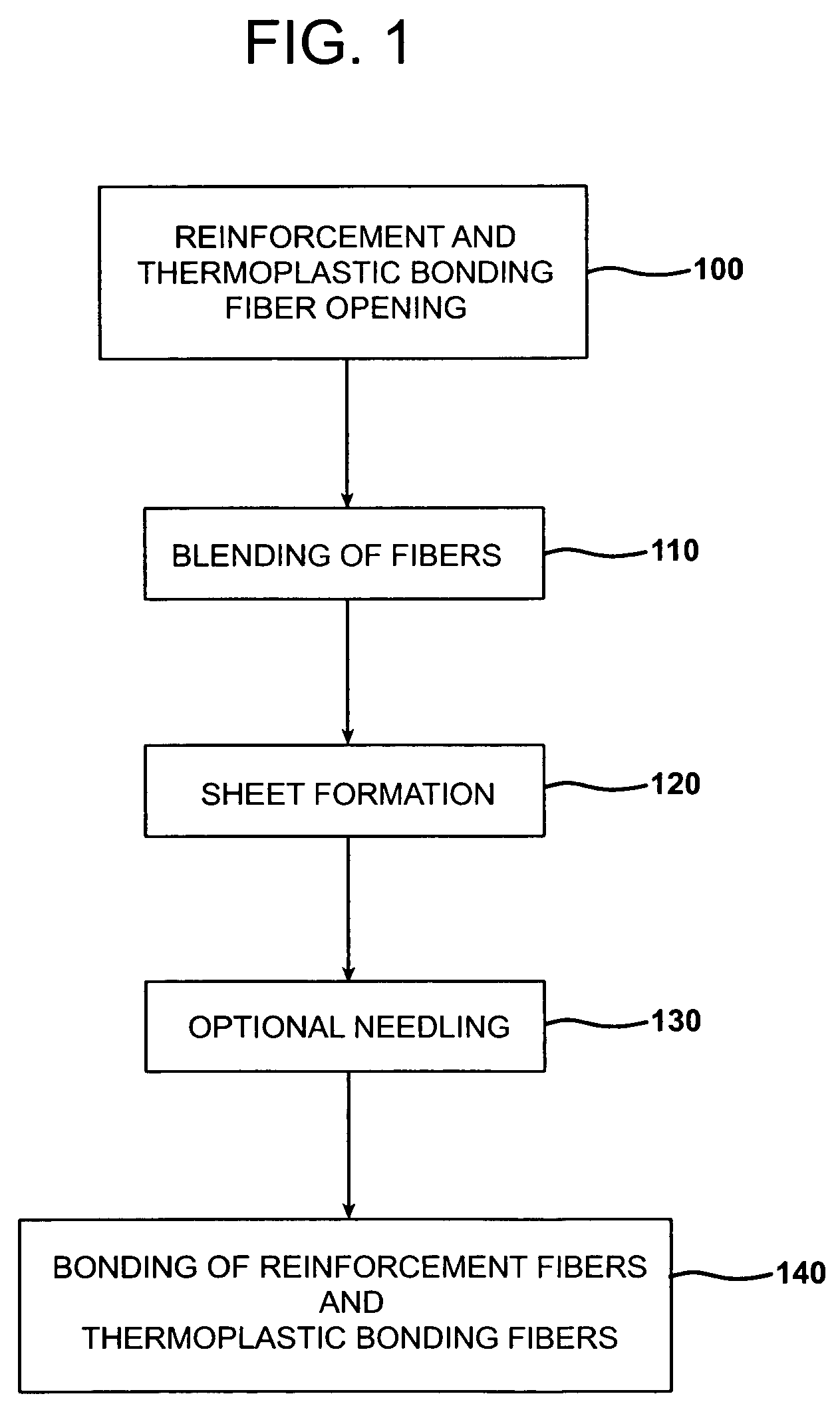

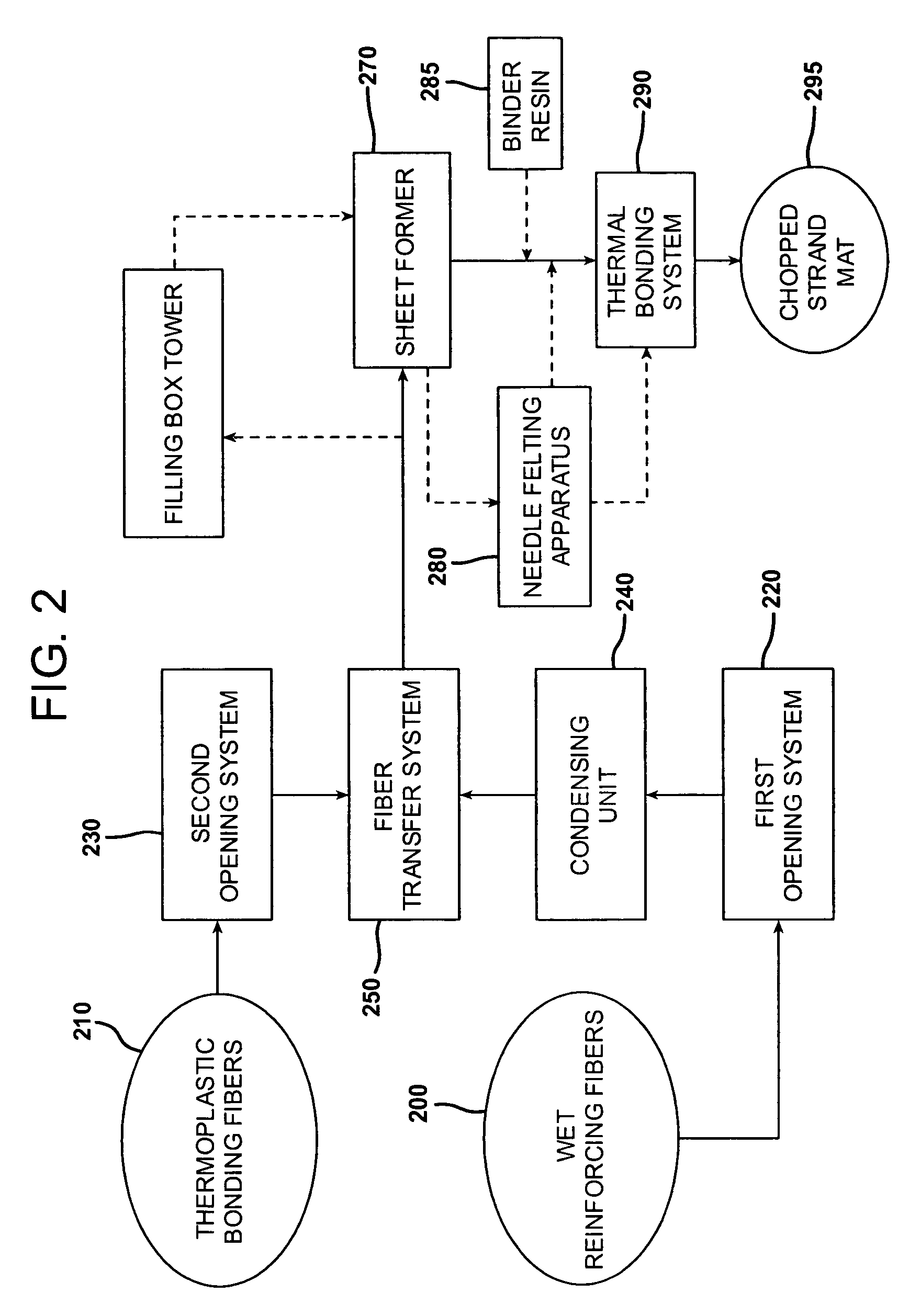

Polymer/wucs mat for use in automotive applications

InactiveUS20060141884A1Optimize and tailor physical property of matUniform consistencyWood working apparatusBaby linensGlass fiberThermoplastic

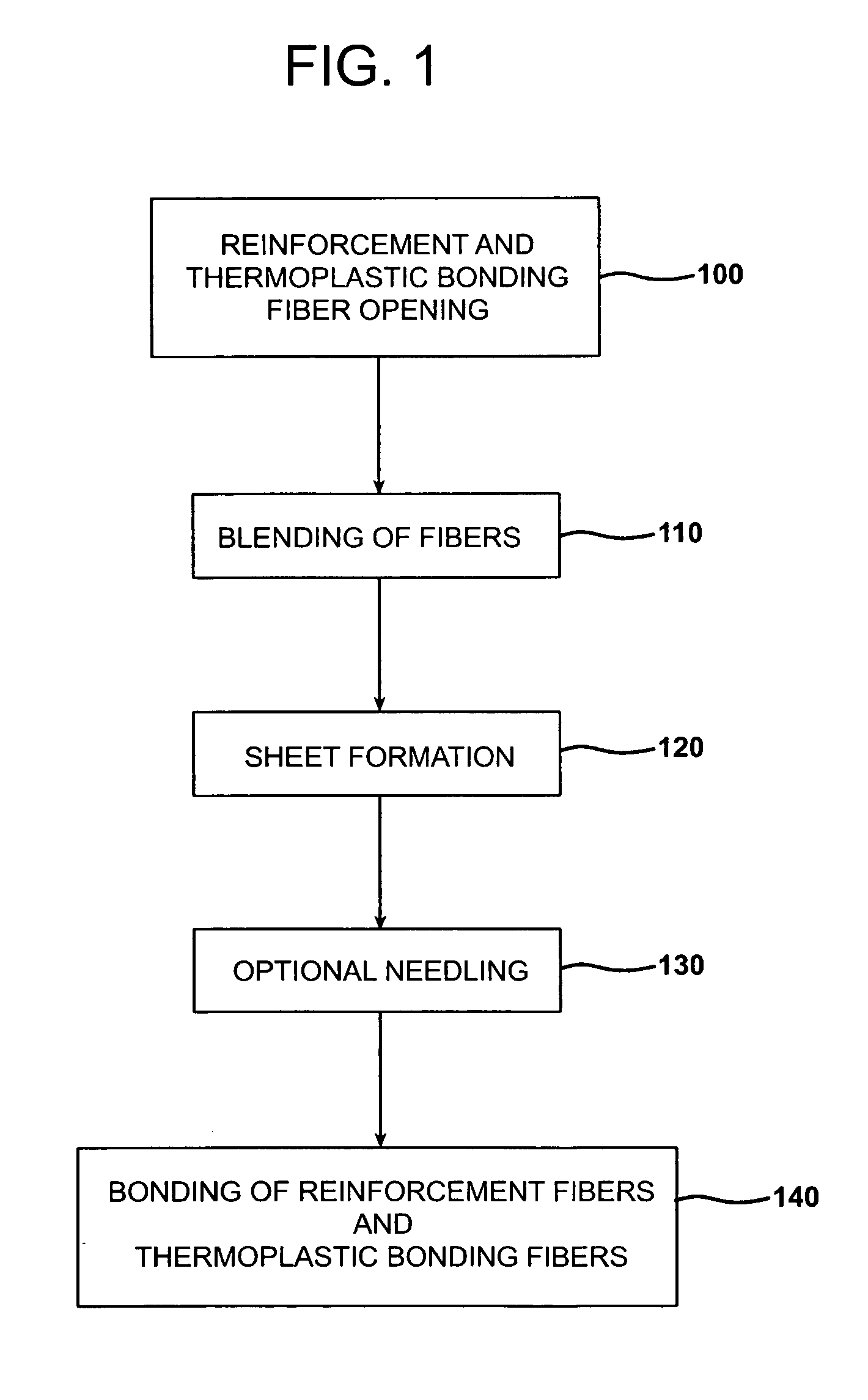

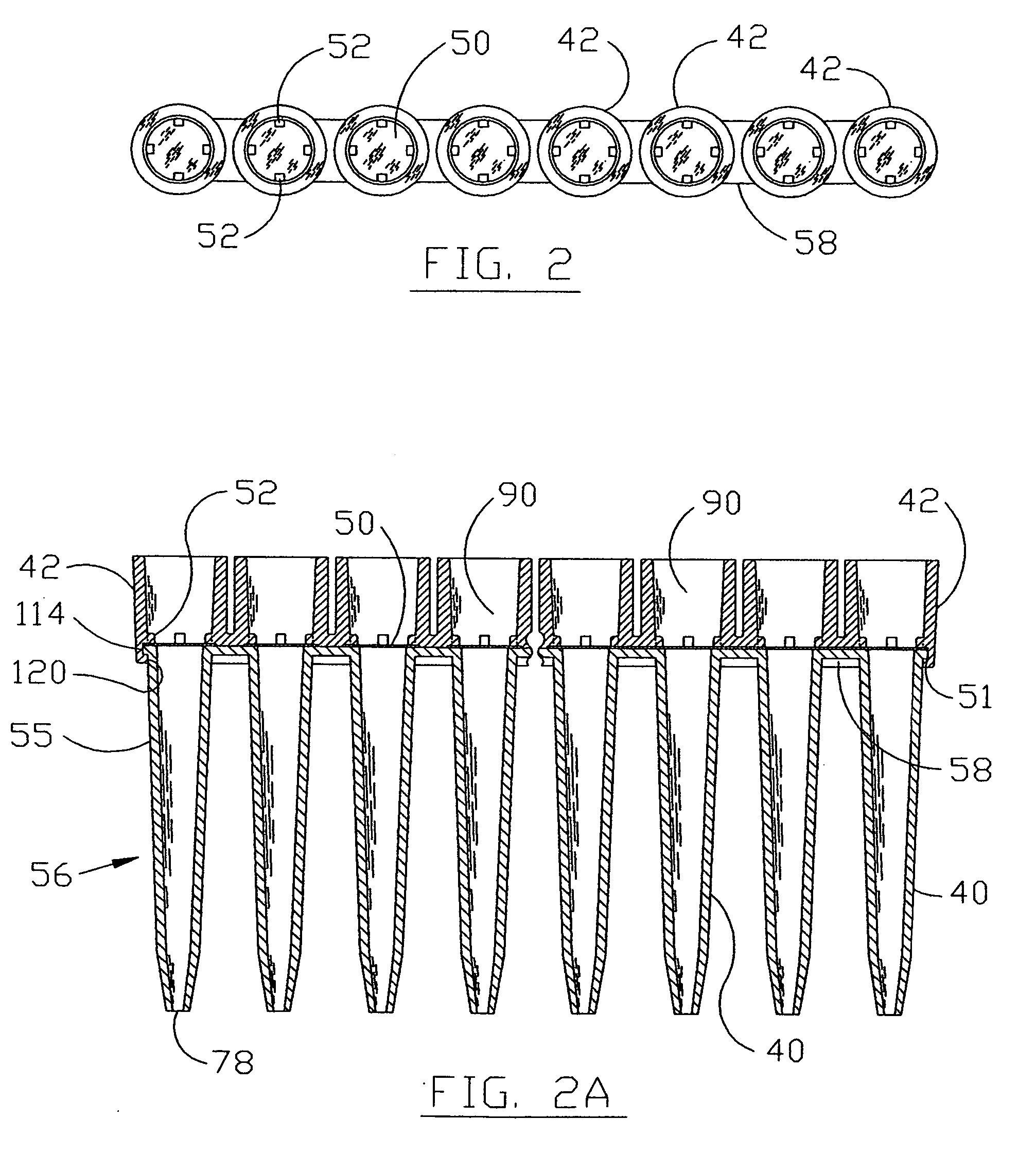

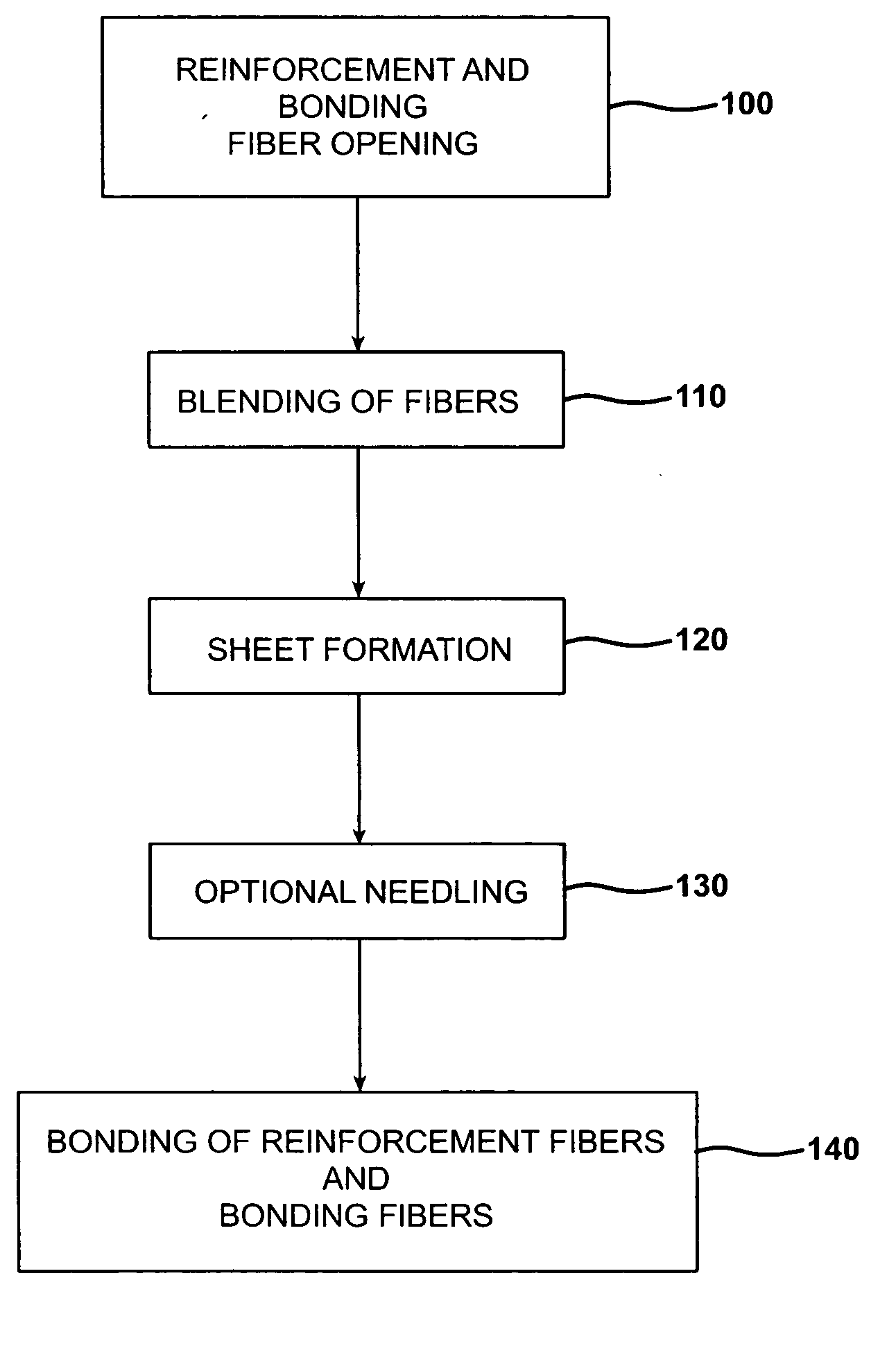

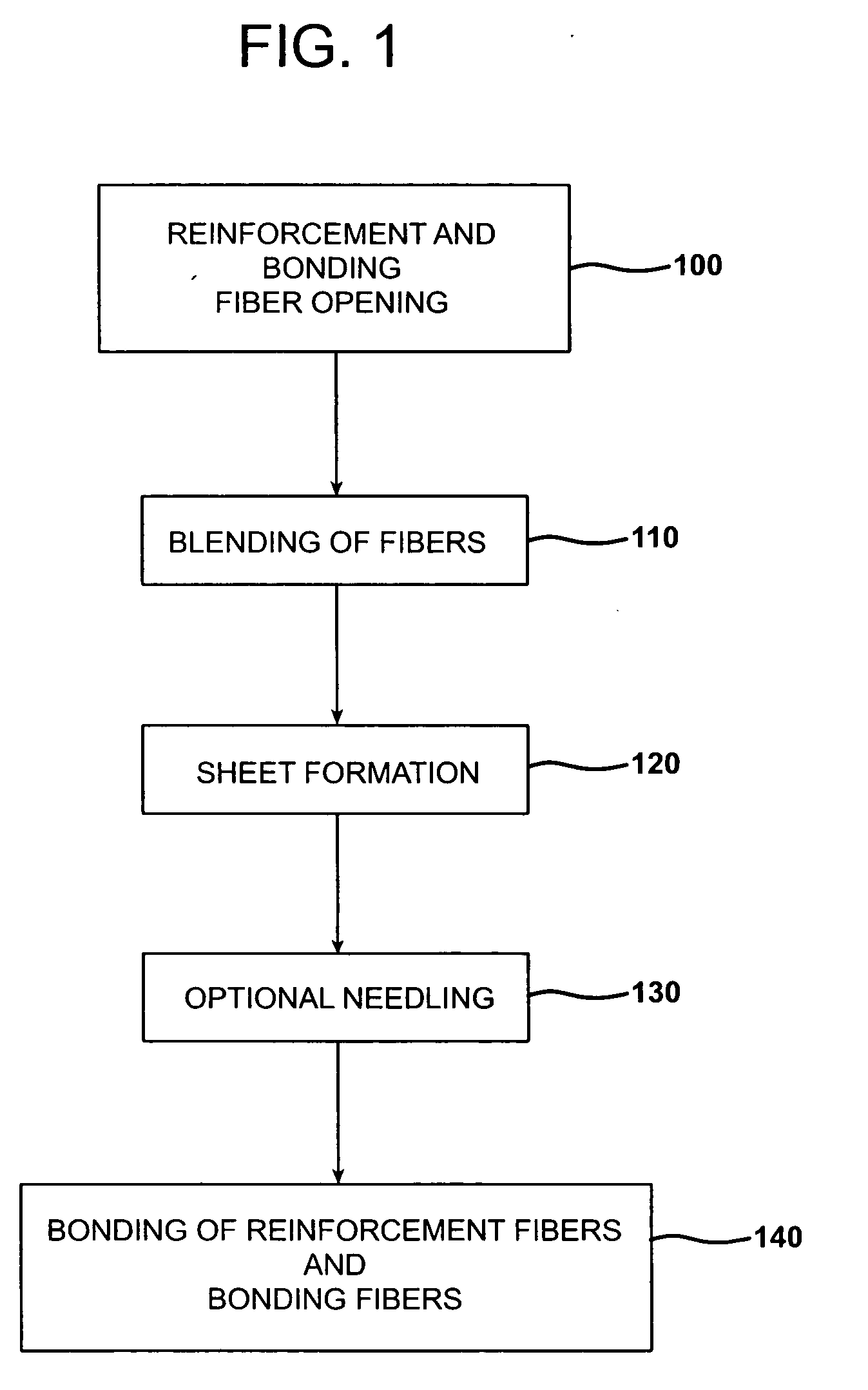

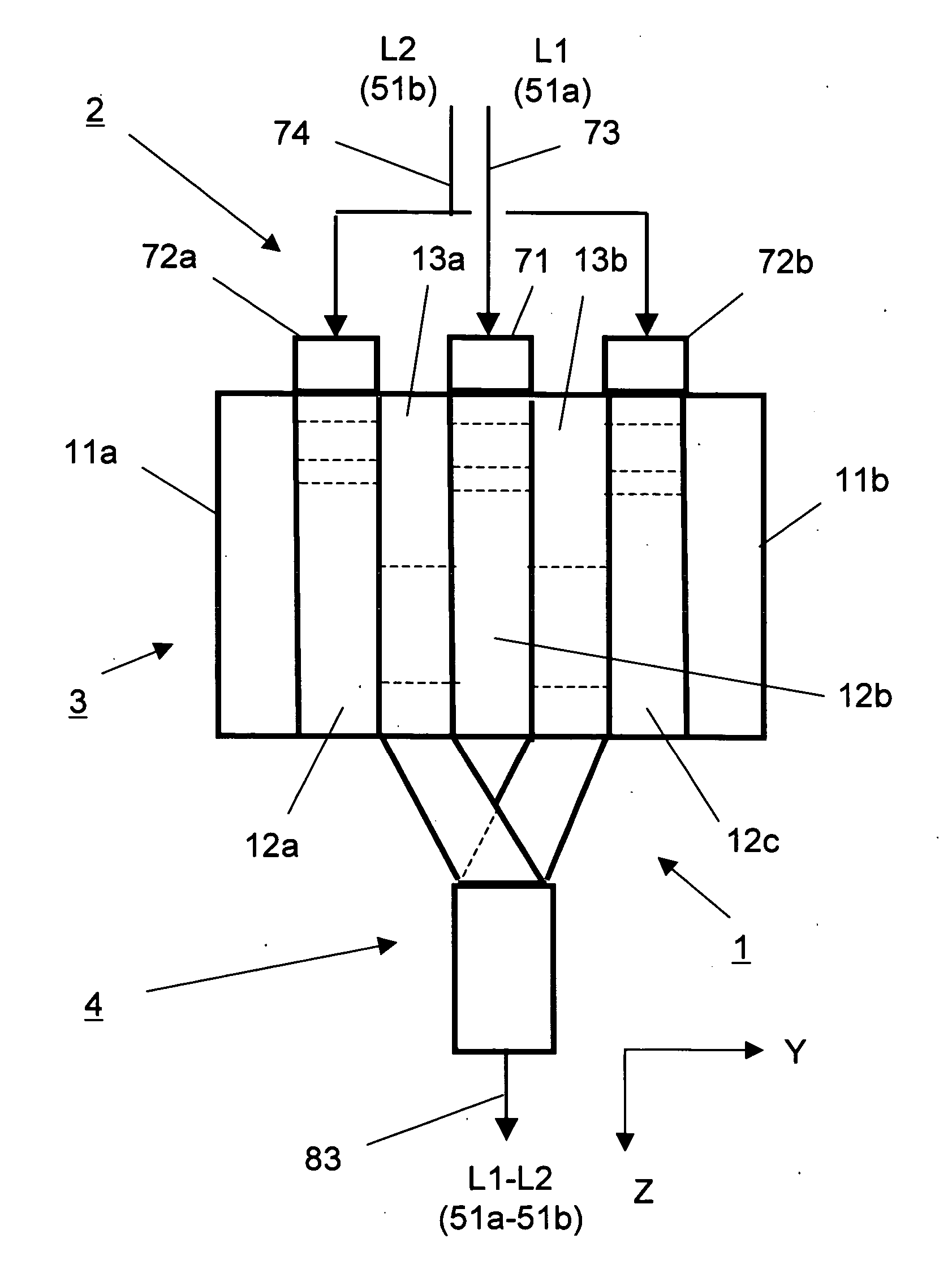

An acoustical and thermally absorbent chopped strand mat formed of thermoplastic bonding materials and bundles of reinforcing fibers is provided. The reinforcing fibers are preferably wet use chopped strand glass fibers (WUCS). The thermoplastic bonding materials may be any thermoplastic or thermosetting material having a melting point less than the reinforcing fiber. The chopped strand mat may be formed by partially opening the WUCS fibers and filamentizing the thermoplastic bonding materials, blending the reinforcement and thermoplastic bonding fibers, forming the reinforcement and thermoplastic bonding fibers into a sheet, and bonding the sheet. During bonding, the sheet is heated to a temperature above the melting point of the thermoplastic bonding fibers but below the temperature of the glass fibers. The melted thermoplastic bonding fibers act as a glue to hold the glass fibers in bundles. The chopped strand mat thus formed may be used as a reinforcement material in automotive applications.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

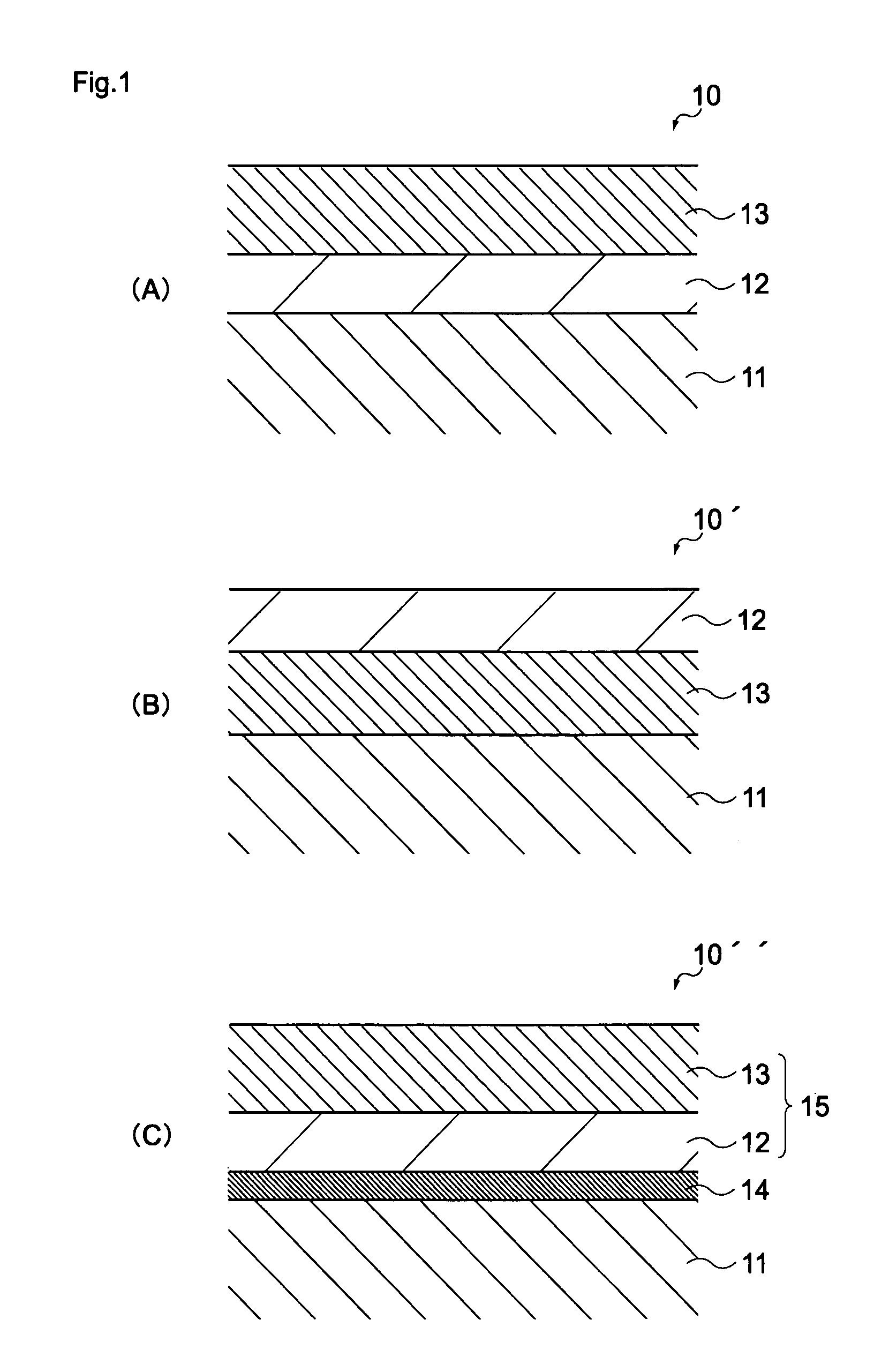

Sandwich composite material using an air-laid process and wet glass

InactiveUS20060141260A1Increase deflectionMeet growth requirementsWood working apparatusFurniture partsGlass fiberFiber

A sandwich composite material formed of a core layer positioned between first and second skin layers is provided. Either the core layer or the first and second skin layers are formed of a composite material that includes reinforcement fibers and organic fibers. Preferably, the reinforcing fibers are wet use chopped strand glass fibers. The composite material may be formed by opening the reinforcement fibers, blending the reinforcement and organic fibers, forming the reinforcement and organic fibers into a sheet, and bonding the sheet. The core layer and first and second skin layers may be attached by adhesives or resin tie layers. The sandwich composite material may include a facing layer affixed to an exposed major surface of one or both of the first and second skin layers. The strength, stiffness, and load deflection of the sandwich composite material may be modified by changing the amount and / or type of fibers present.

Owner:OWENS CORNING FIBERGLAS TECH INC

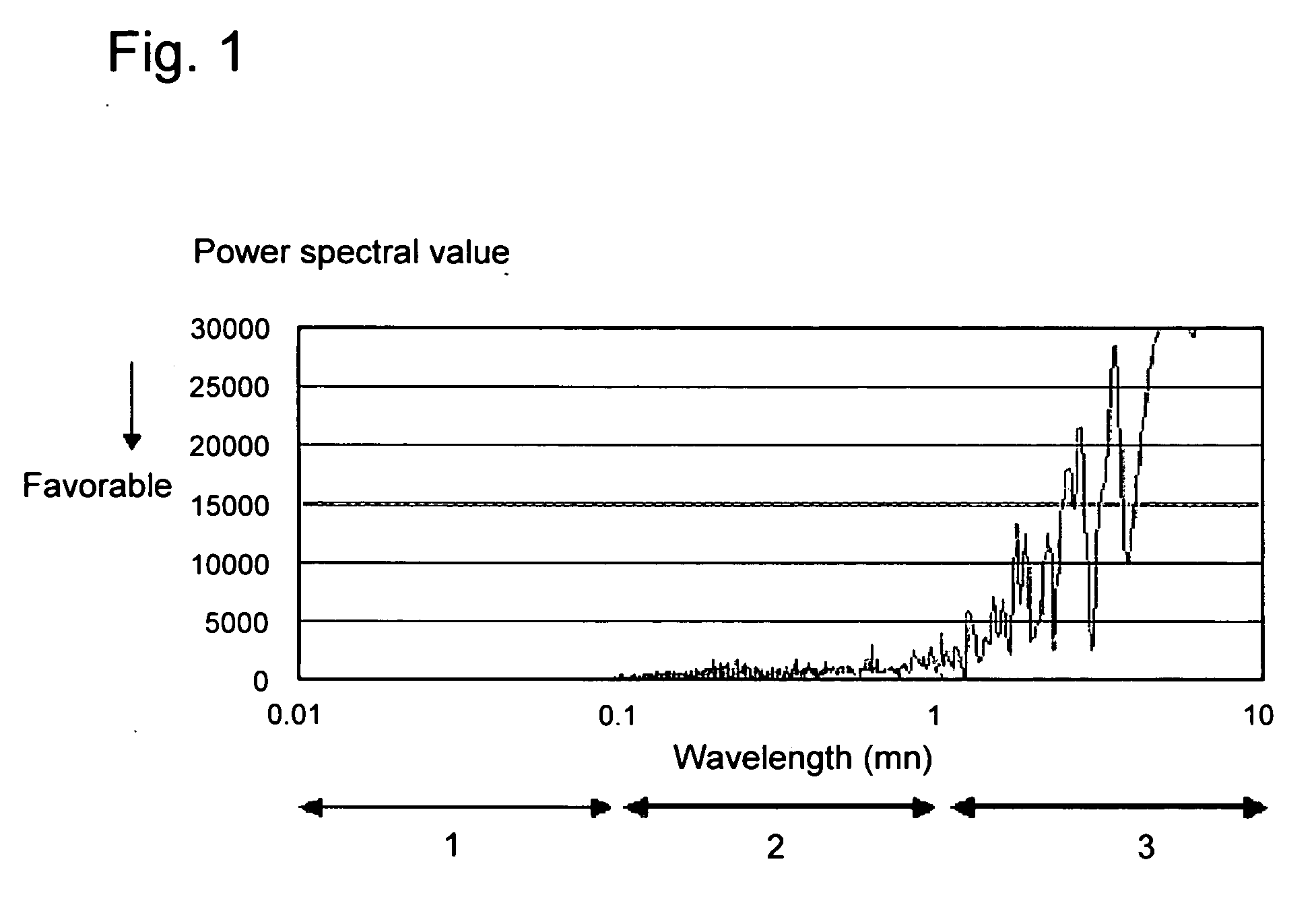

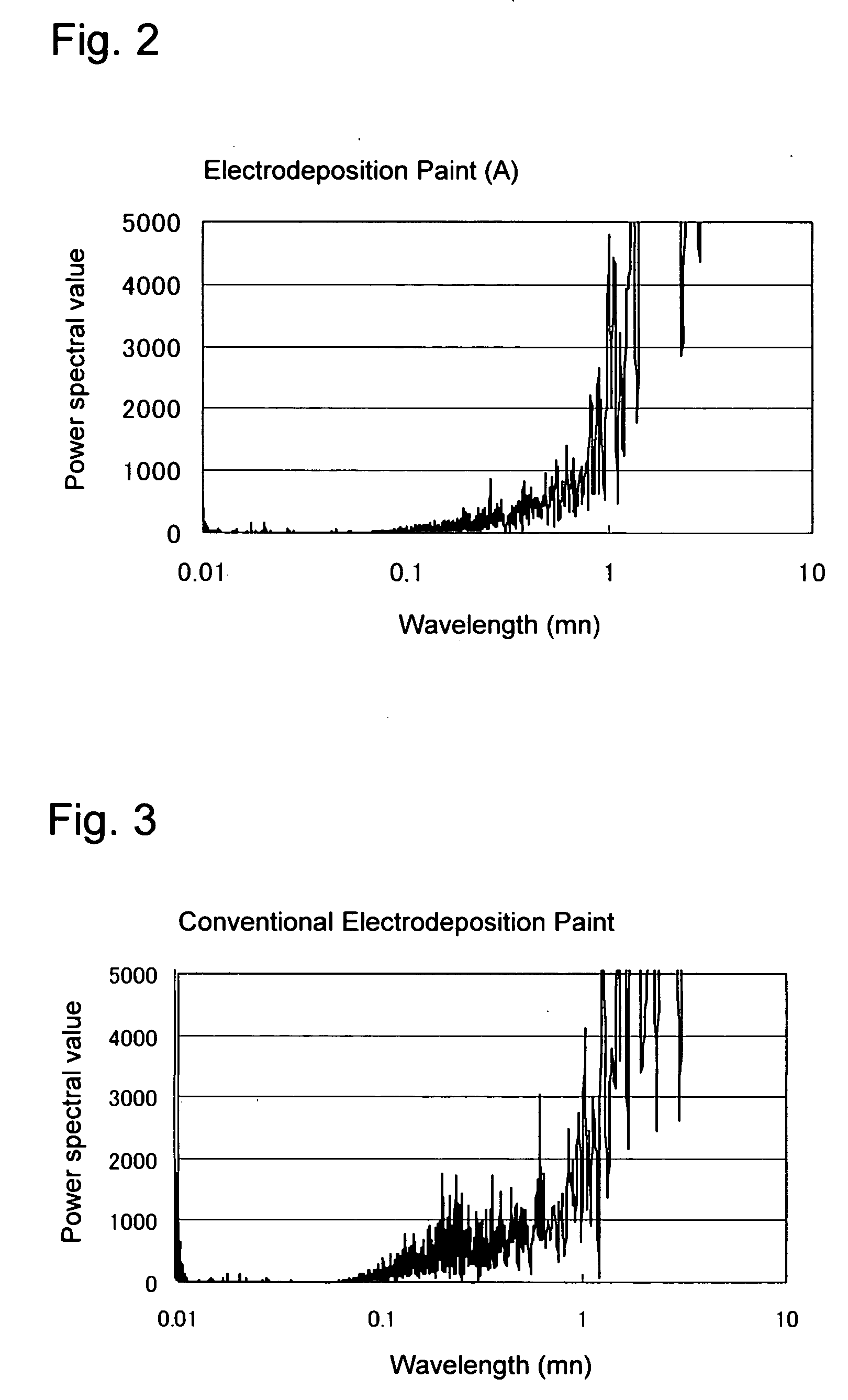

Method of forming multi-layered coating film

InactiveUS20070023288A1Reduce generationSmall weightLiquid surface applicatorsElectrolysis componentsLacquerCorrosion

This invention provides a method for forming multi-layered coating film excelling in appearance, corrosion resistance and chipping resistance, which comprises applying a first coloring paint (B), second coloring paint (C) and clear paint (D) onto cured coating film of a specific electrodeposition paint (A) of low weight loss under heating, wet-on-wet by the order stated; and heat-curing the three-layered coating film simultaneously.

Owner:KANSAI PAINT CO LTD

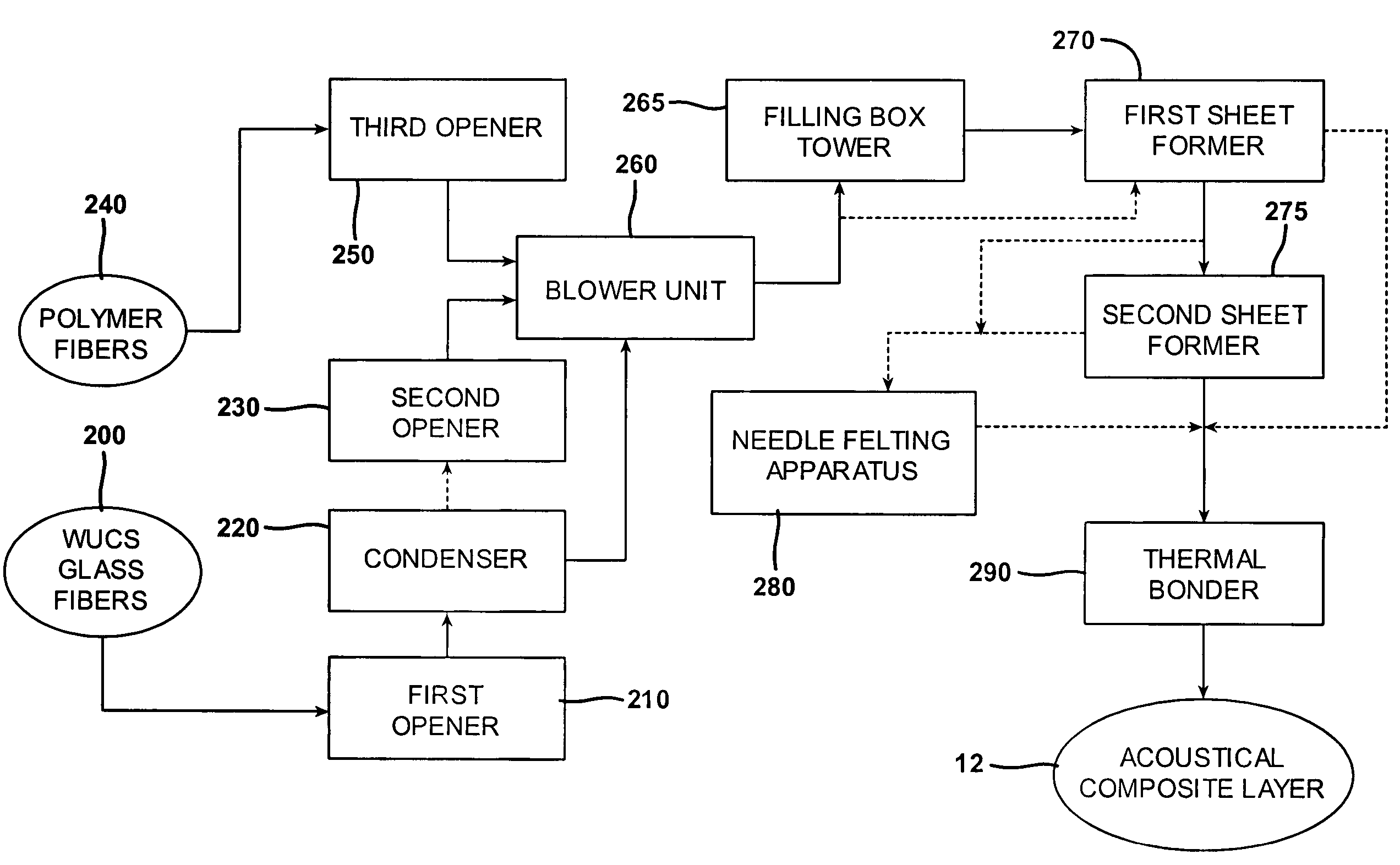

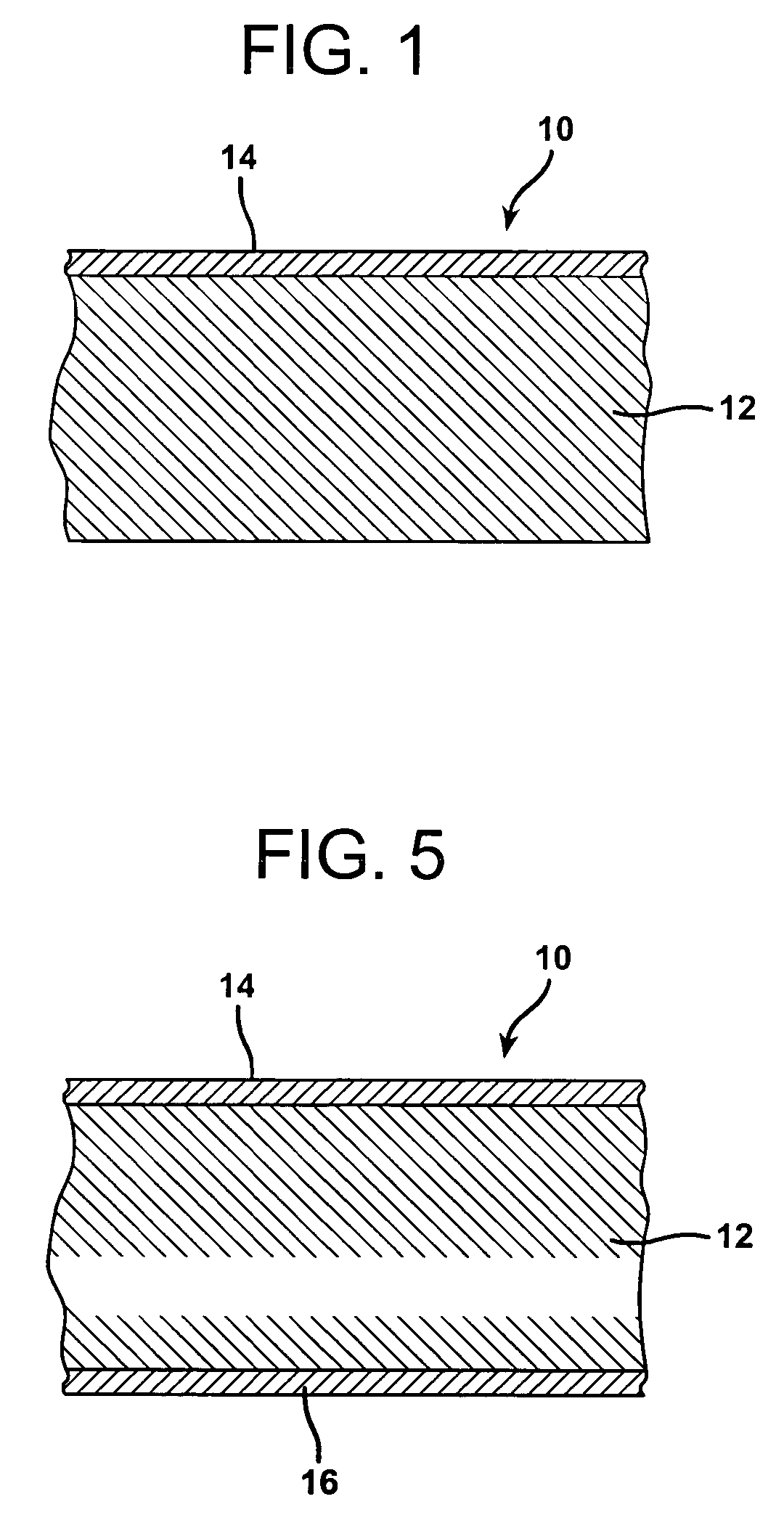

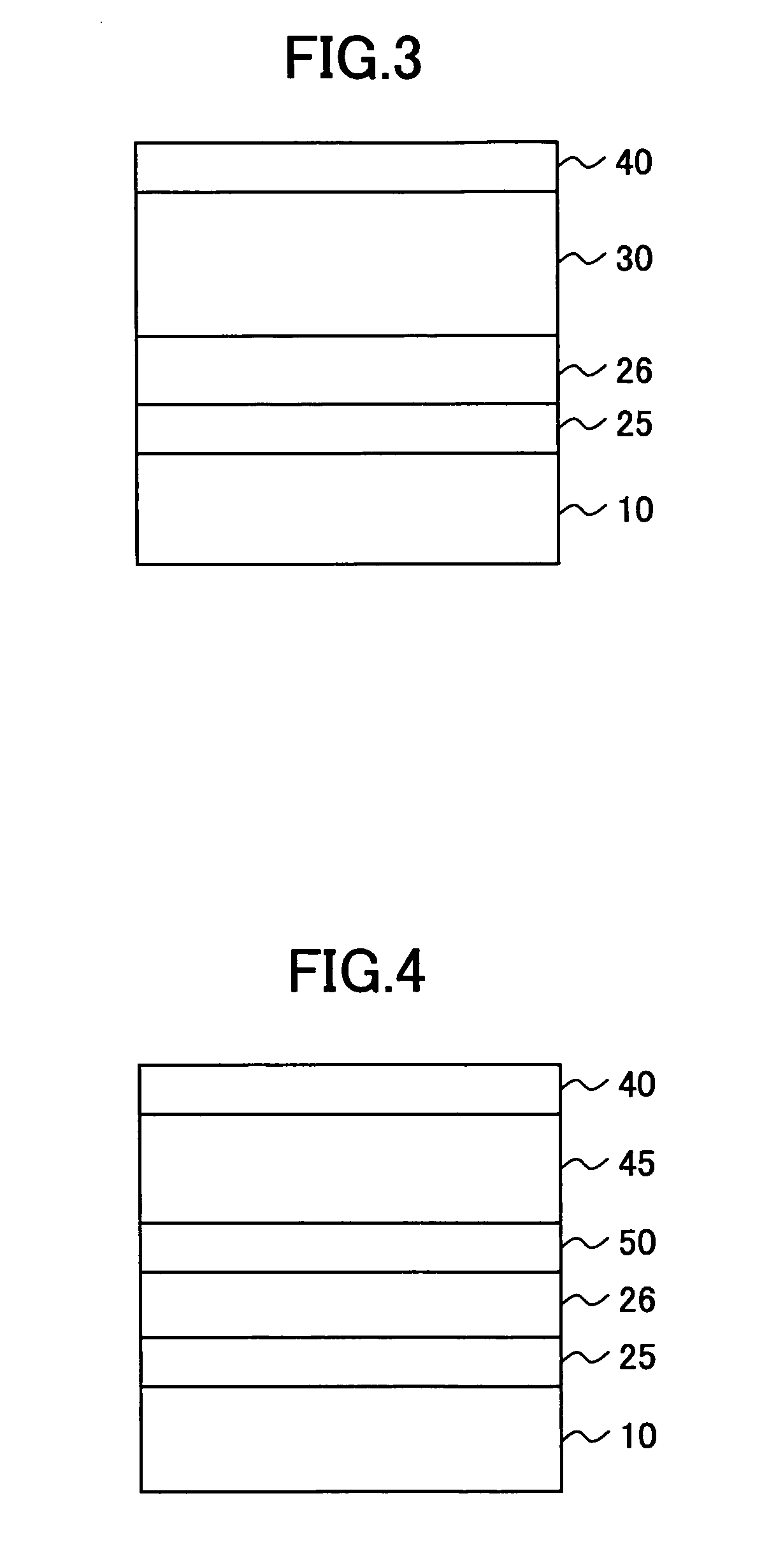

Composite material with improved structural, acoustic and thermal properties

InactiveUS7294218B2Improved structural and thermal propertyReduce the amount requiredWood working apparatusHeat proofingFiberGlass fiber

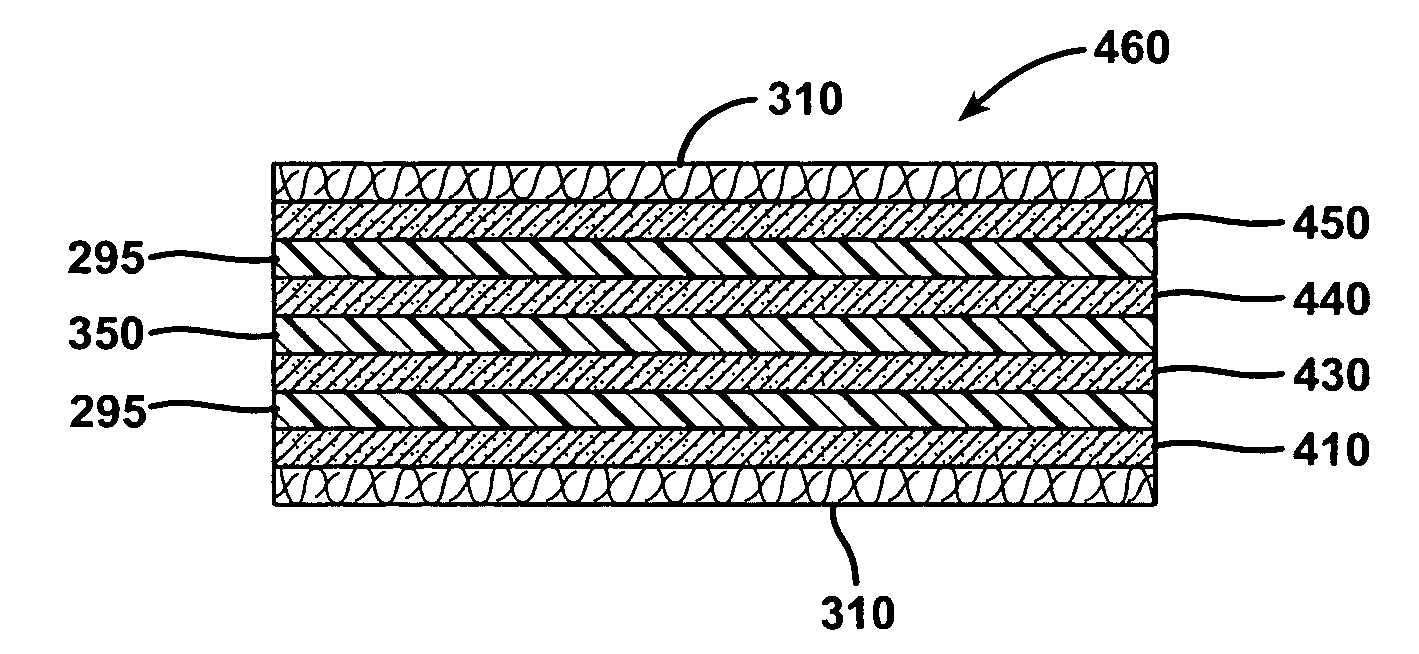

A method of forming a multilayer insulation material formed of an acoustical composite layer and a first thermal layer is provided. The acoustical and insulting layer is formed of a polymer based thermoplastic material and reinforcing fibers. Preferably the reinforcing fibers are wet use chopped strand glass fibers (WUCS). The acoustical composite layer may be formed by opening the WUCS fibers, blending the reinforcement and polymer fibers, forming the reinforcement and polymer fibers into a sheet, and then bonding the sheet. A first thermal layer formed of one or more polymer based thermoplastic organic materials is then positioned on a first major surface of the acoustical composite layer. A second thermal layer of polymeric fibers may be optionally positioned on a second major surface of the acoustical composite layer. The multilayer acoustic material may be utilized in semi-structural and acoustical applications.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

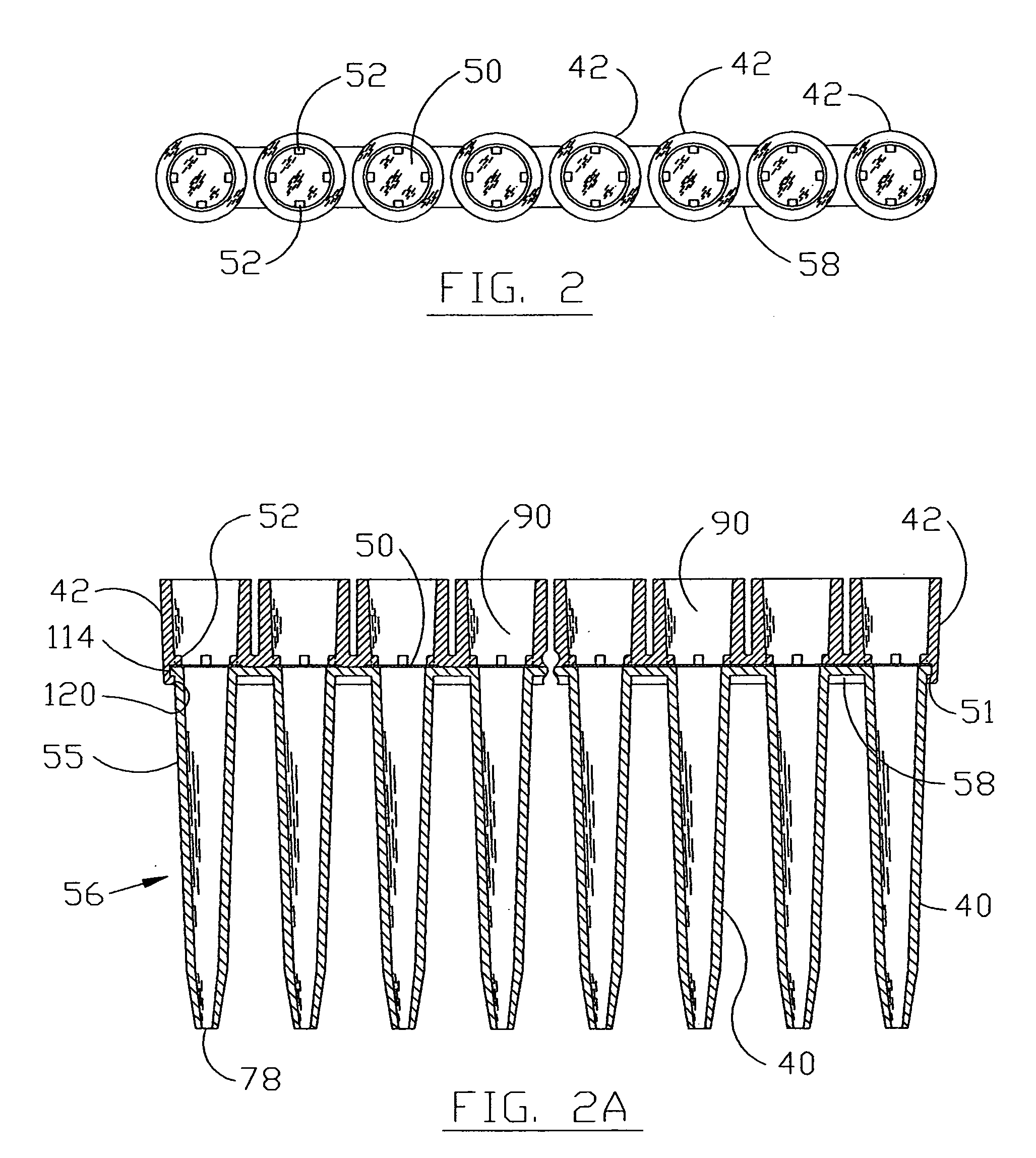

Ergonomic pipette tip and adapters

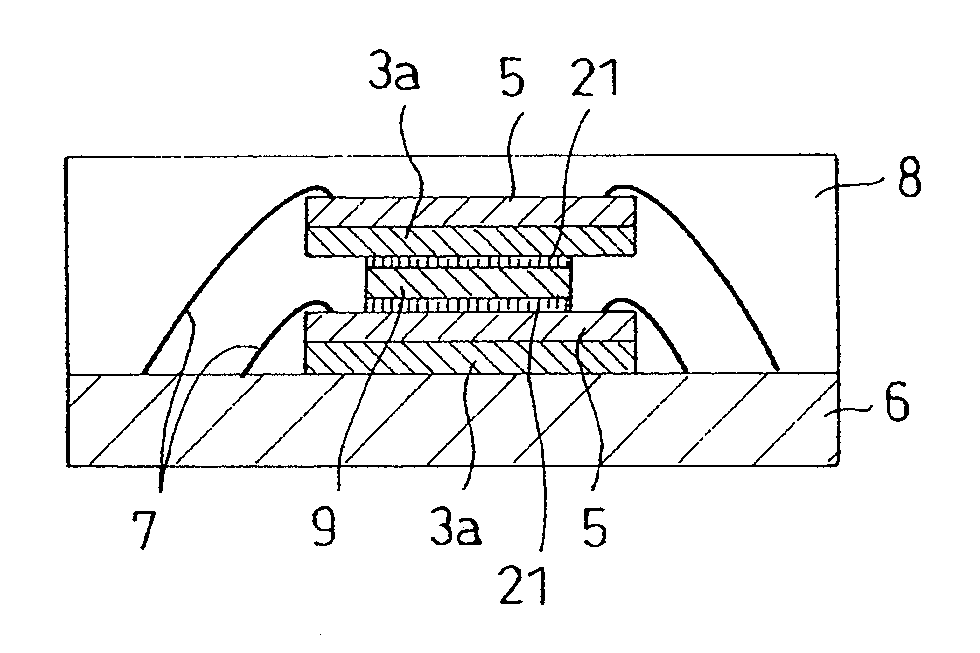

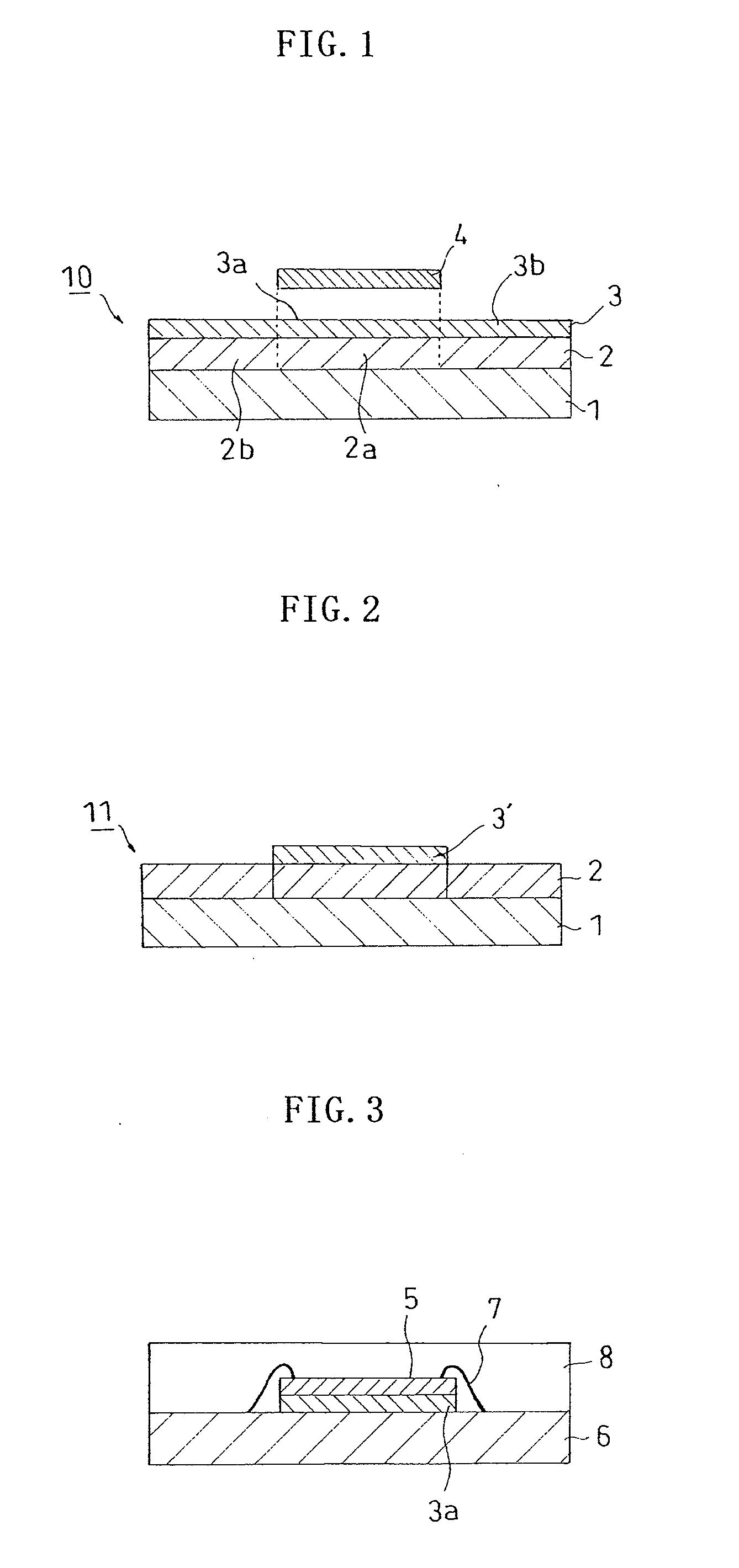

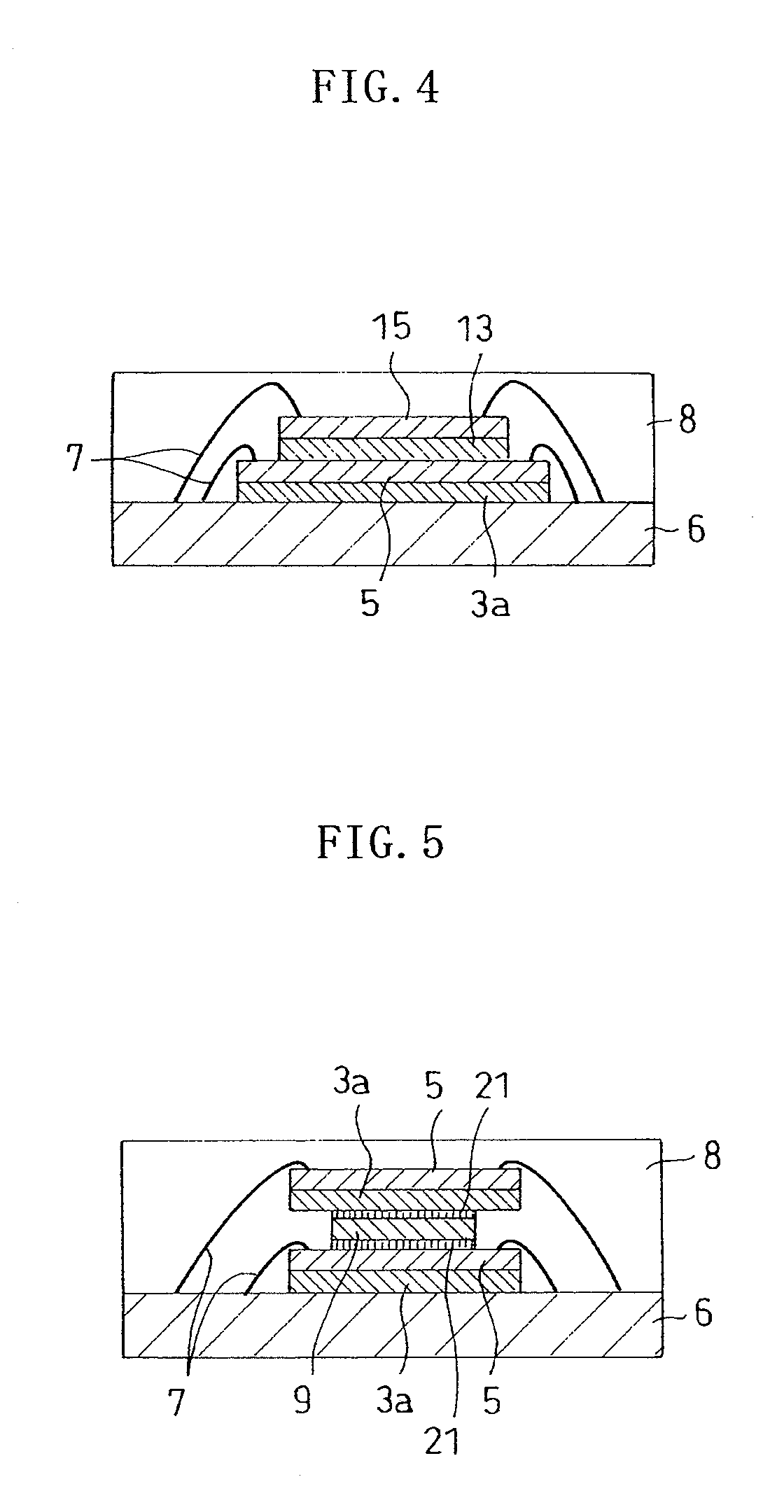

ActiveUS20080095665A1Easily and securely mountedImprove scalabilityAnalysis using chemical indicatorsWithdrawing sample devicesPipetteStress injury

An ergonomically designed pipette tip that can be securely mounted to a barrel of a pipetter yet is designed to substantially reduce the axial force necessary to install and eject the pipette tip from the pipetter. An improved pipette tip that includes the addition of a second elastomeric material and cooperative means for insuring uniform interference and depth of penetration of the pipetter barrel as successive barrels are inserted and ejected. Also disclosed is an improved multiple-tip configuration with similar features as the ergonomic pipette tip that can be mounted to multiple barrels of a multi-pipetter as one tip instead of 8 or 12 individual tips. The secondary elastomeric material allows for better sealing and eliminates alignment issues, high installation and ejection requirements while reducing the hand and thumb forces that due to repeated use will sometimes result in repetitive stress injury.

Owner:SMITH JAMES C

Composite material with improved structural, acoustic and thermal properties

InactiveUS20080251187A1Improved structural and thermal propertyReduce the amount requiredNon-woven fabricsFiberGlass fiber

A method of forming a multilayer insulation material formed of an acoustical composite layer and a first thermal layer is provided. The acoustical and insulting layer is formed of a polymer based thermoplastic material and reinforcing fibers. Preferably the reinforcing fibers are wet use chopped strand glass fibers (WUCS). The acoustical composite layer may be formed by opening the WUCS fibers, blending the reinforcement and polymer fibers, forming the reinforcement and polymer fibers into a sheet, and then bonding the sheet. A first thermal layer formed of one or more polymer based thermoplastic organic materials is then positioned on a first major surface of the acoustical composite layer. A second thermal layer of polymeric fibers may be optionally positioned on a second major surface of the acoustical composite layer. The multilayer acoustic material may be utilized in semi-structural and acoustical applications.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

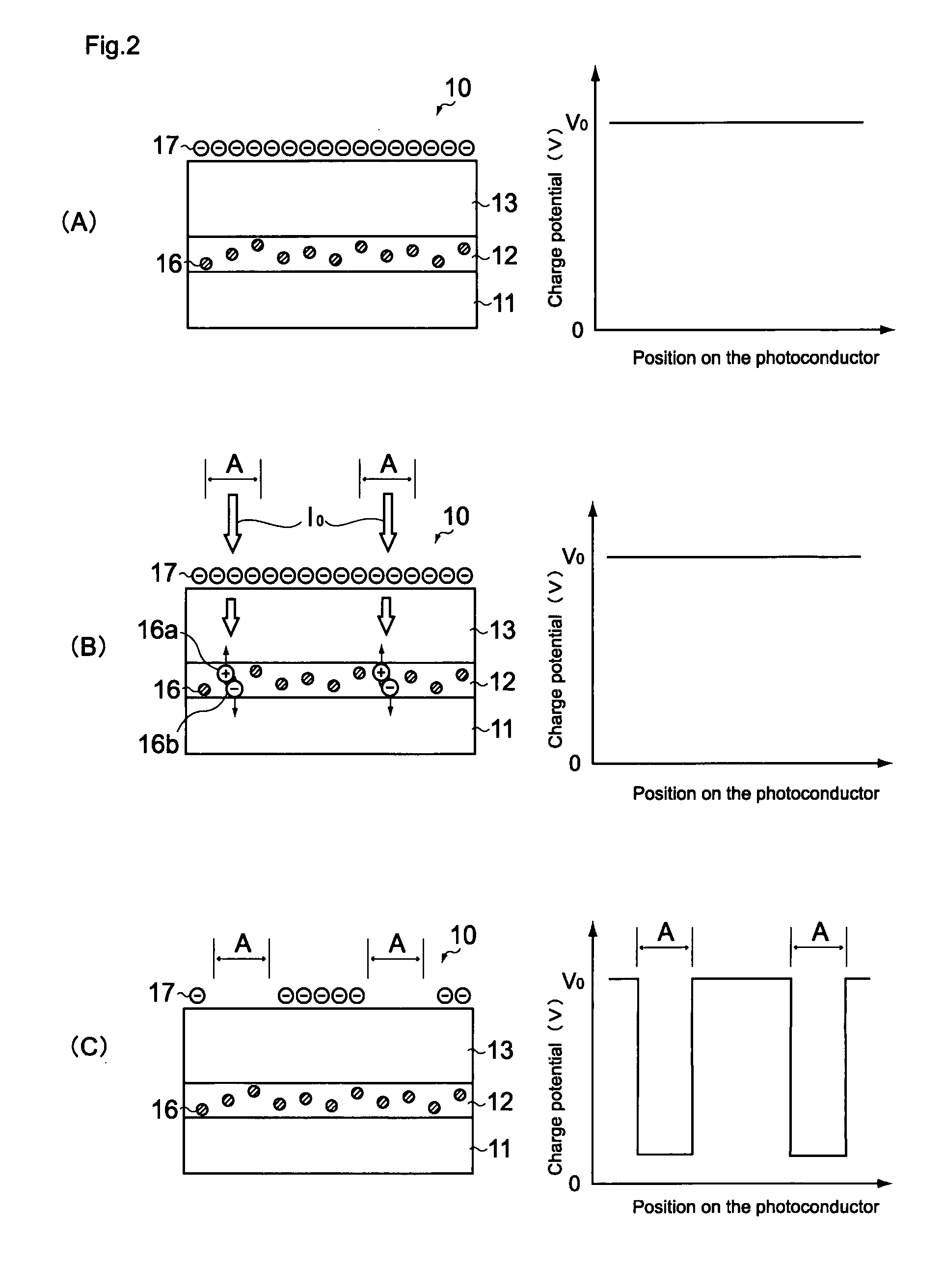

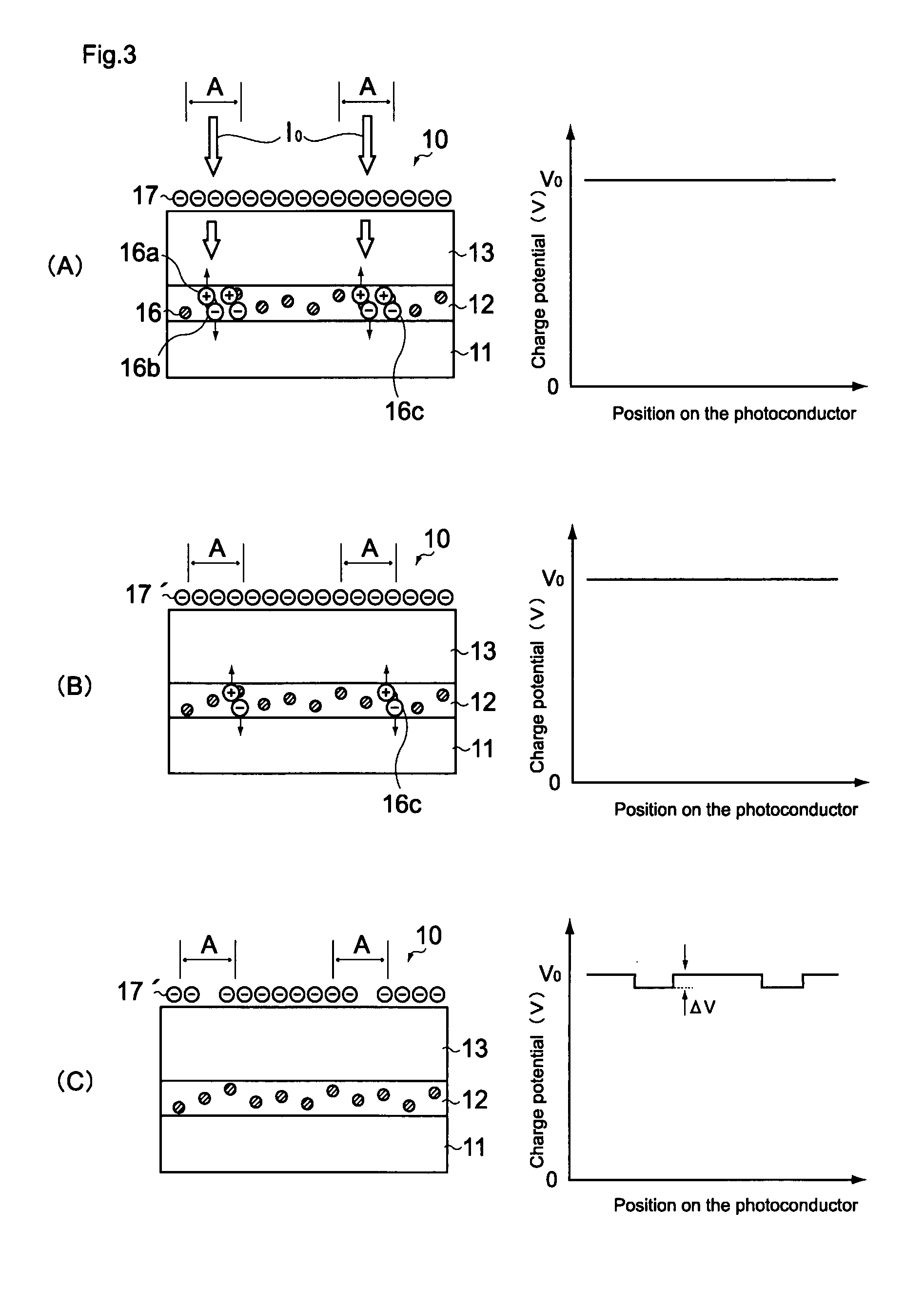

Multilayer type electrophotographic photoconductor and image forming apparatus

ActiveUS20070281227A1Improve image qualityLittle generationElectrographic process apparatusCorona dischargeElectrical conductorInter layer

The present invention is to provide a multilayer type electrophotographic photoconductor capable of stably obtaining a high image quality image over a long term by restraining the exposure memory and the photo memory, and an image forming apparatus comprising such a multilayer type electrophotographic photoconductor. A multilayer type electrophotographic photoconductor comprising a charge generating layer containing at least a charge generating agent on a base member directly or via an intermediate layer, and a charge transporting layer containing at least a charge transporting agent and a binder resin formed successively, wherein the light absorption degree at a 680 nm wavelength light beam in the photoconductive layer of the multilayer type electrophotographic photoconductor is of a value of 0.8 or less, and the light absorption degree at a 450 nm wavelength light beam is of a value of 1.0 or more, and an image forming apparatus comprising such a multilayer type electrophotographic photoconductor are provided.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

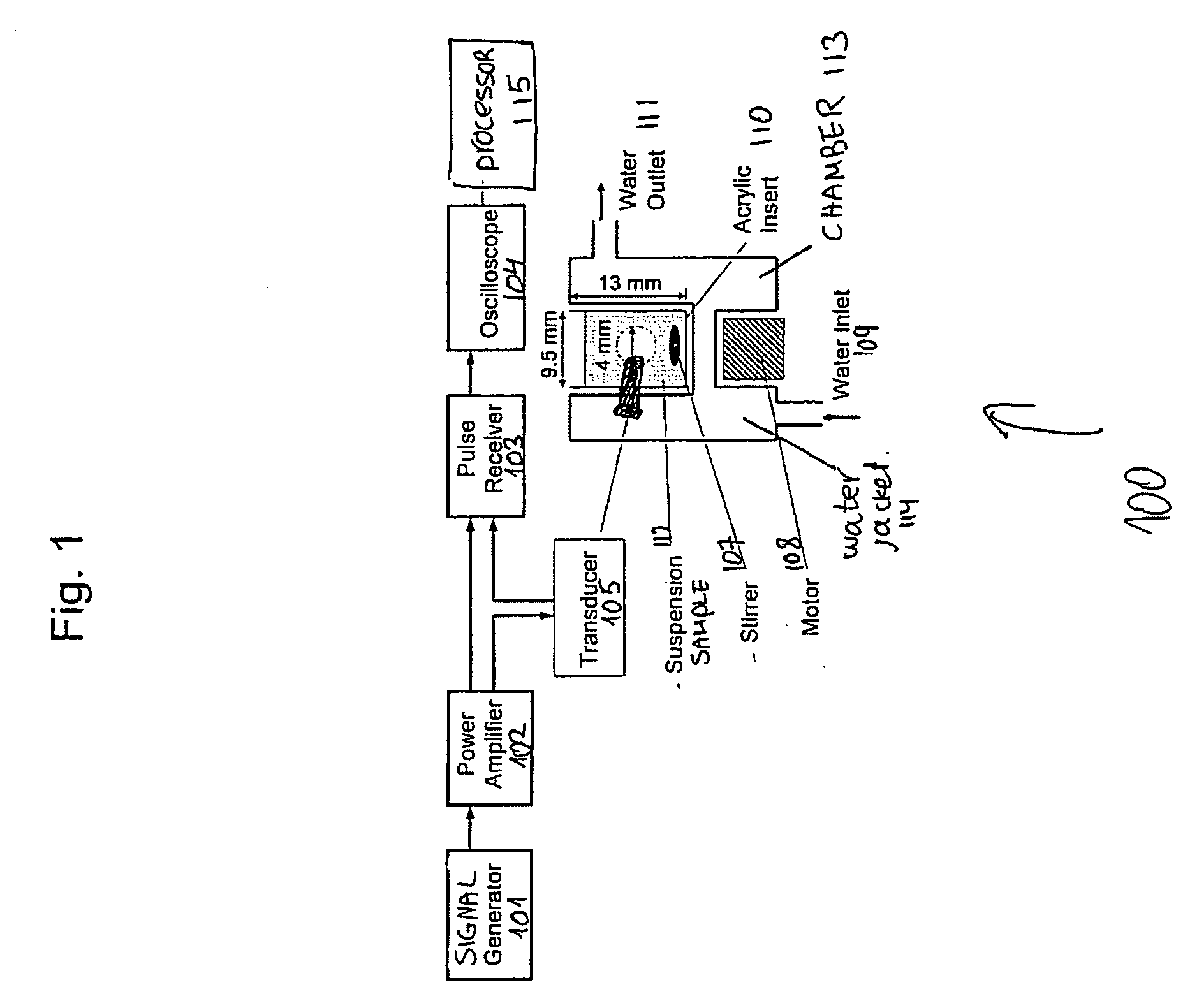

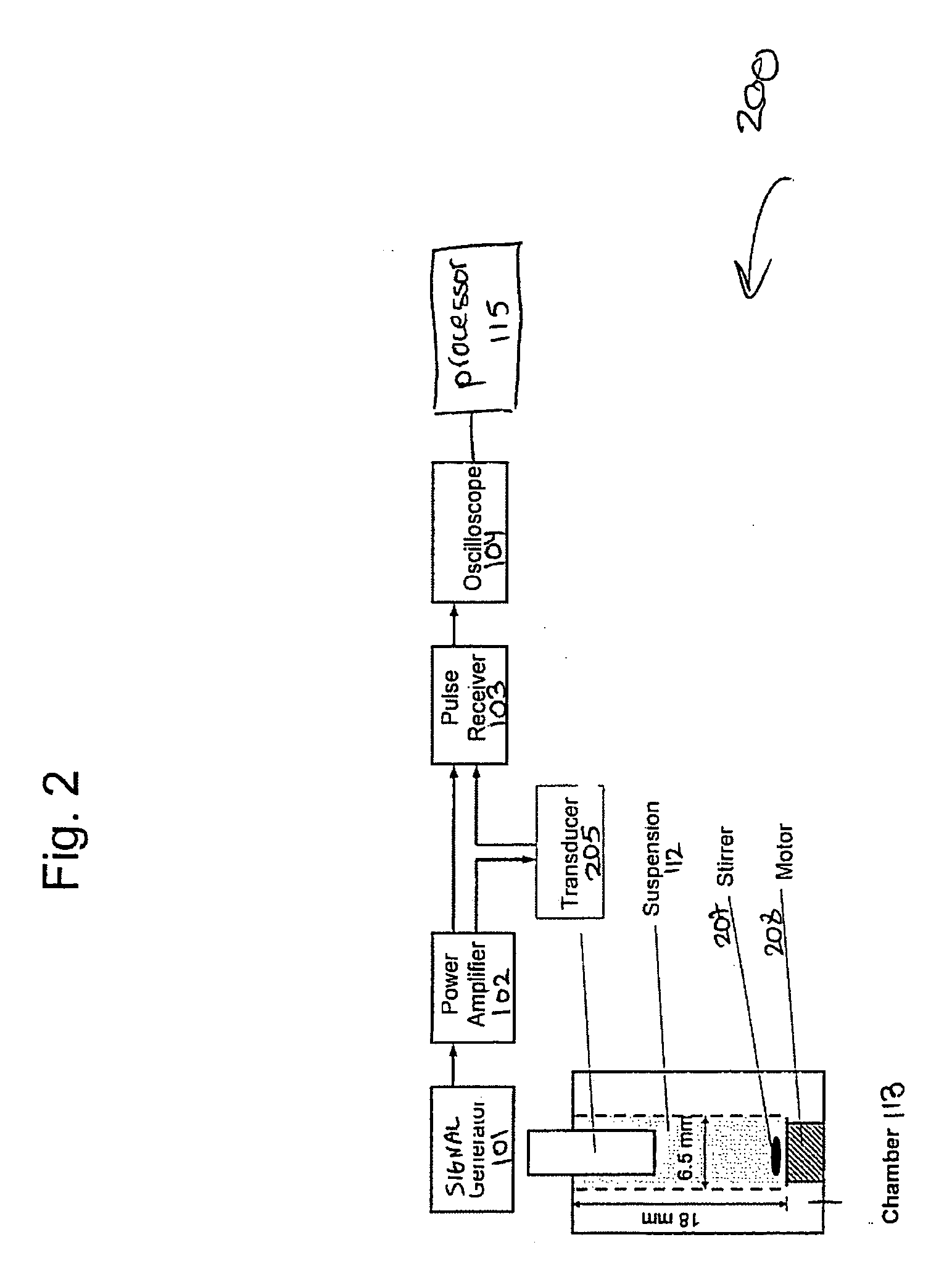

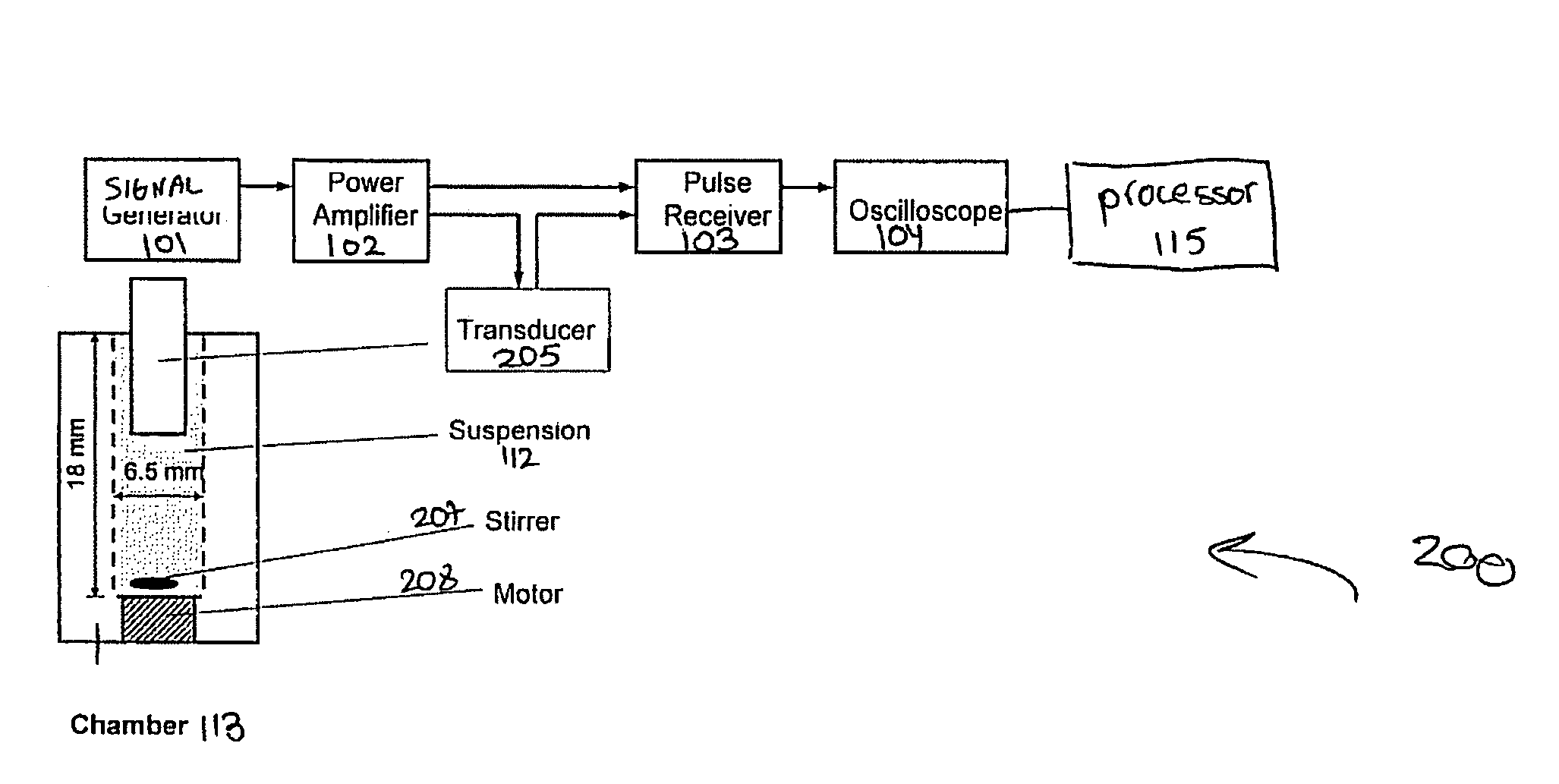

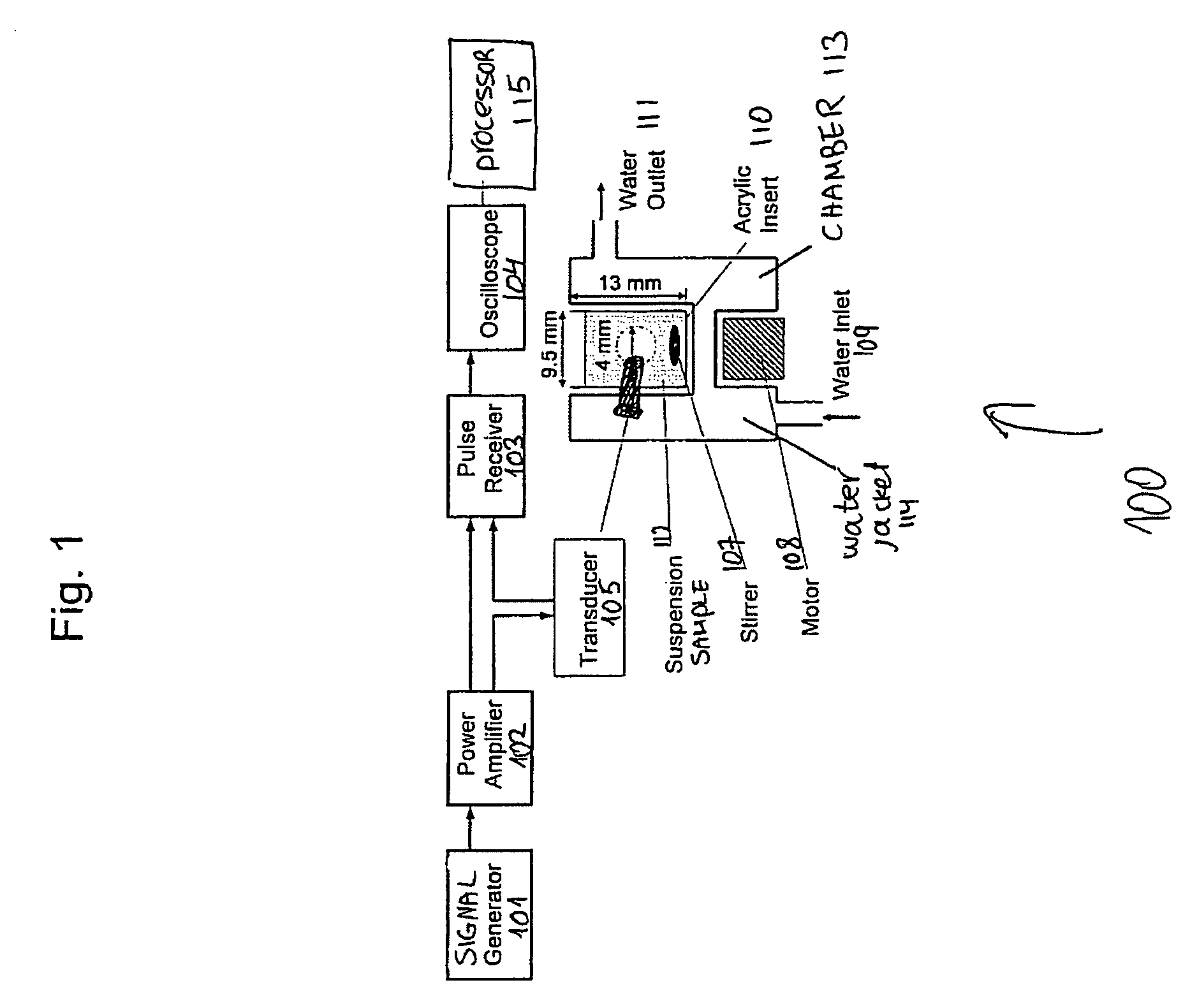

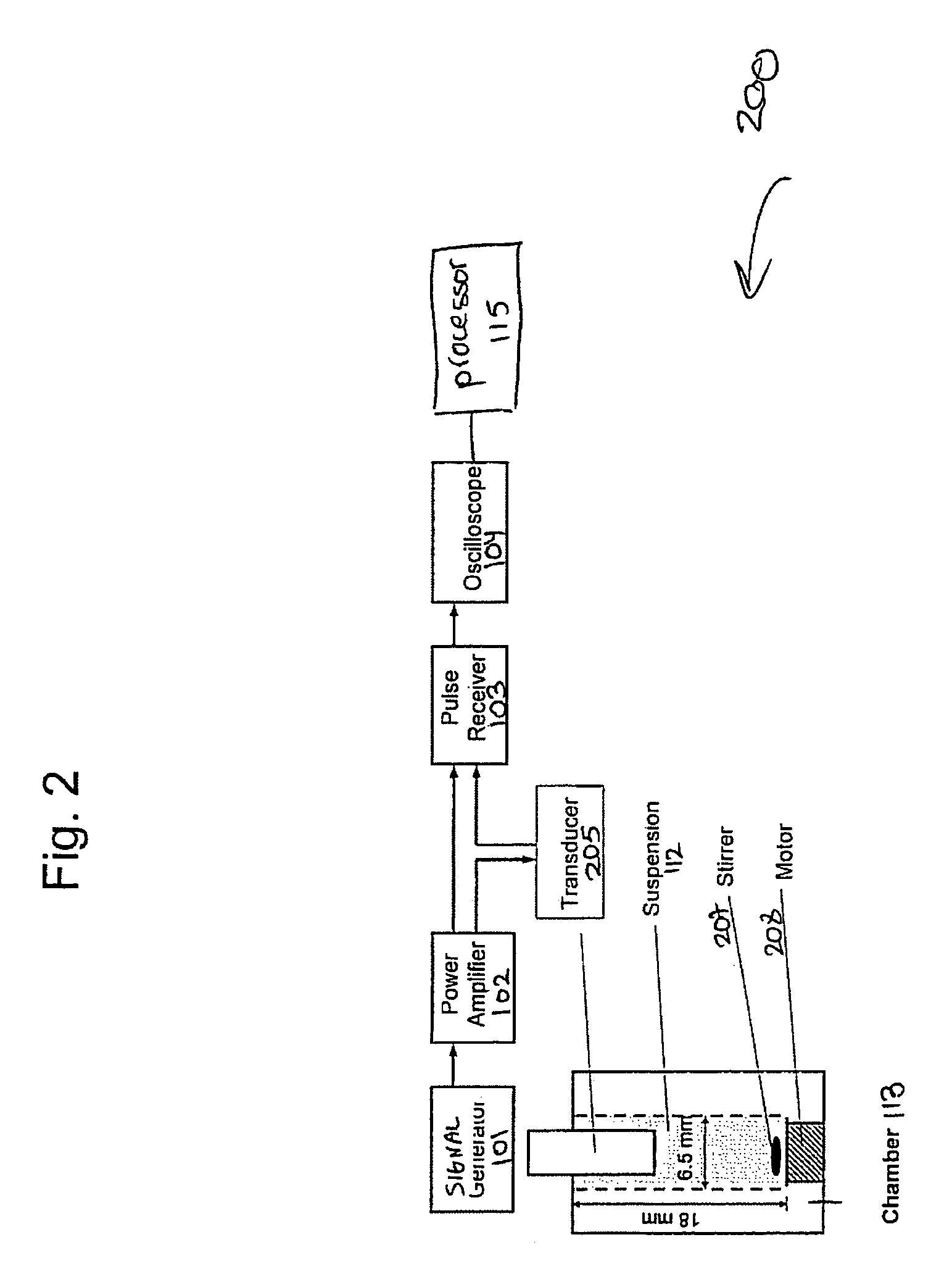

System and method for ultrasonic measuring of particle properties

ActiveUS20060178581A1Improve the level ofSmall volumeUltrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationAcoustic energy

Devices, systems and methods for measuring and detecting properties of a variety of particles or cells in suspension. Properties, such as, for example, velocity of particles, concentration and / or size may be measured according to the methods of the invention. Acoustic energy may be introduced to a focal zone and narrow band interrogating signals may be used. The acoustic energy may cause movement or streaming of the fluid or suspension. The acoustic streaming may allow a Doppler effect measurement without any other source of velocity.

Owner:PRODYNE CORP +1

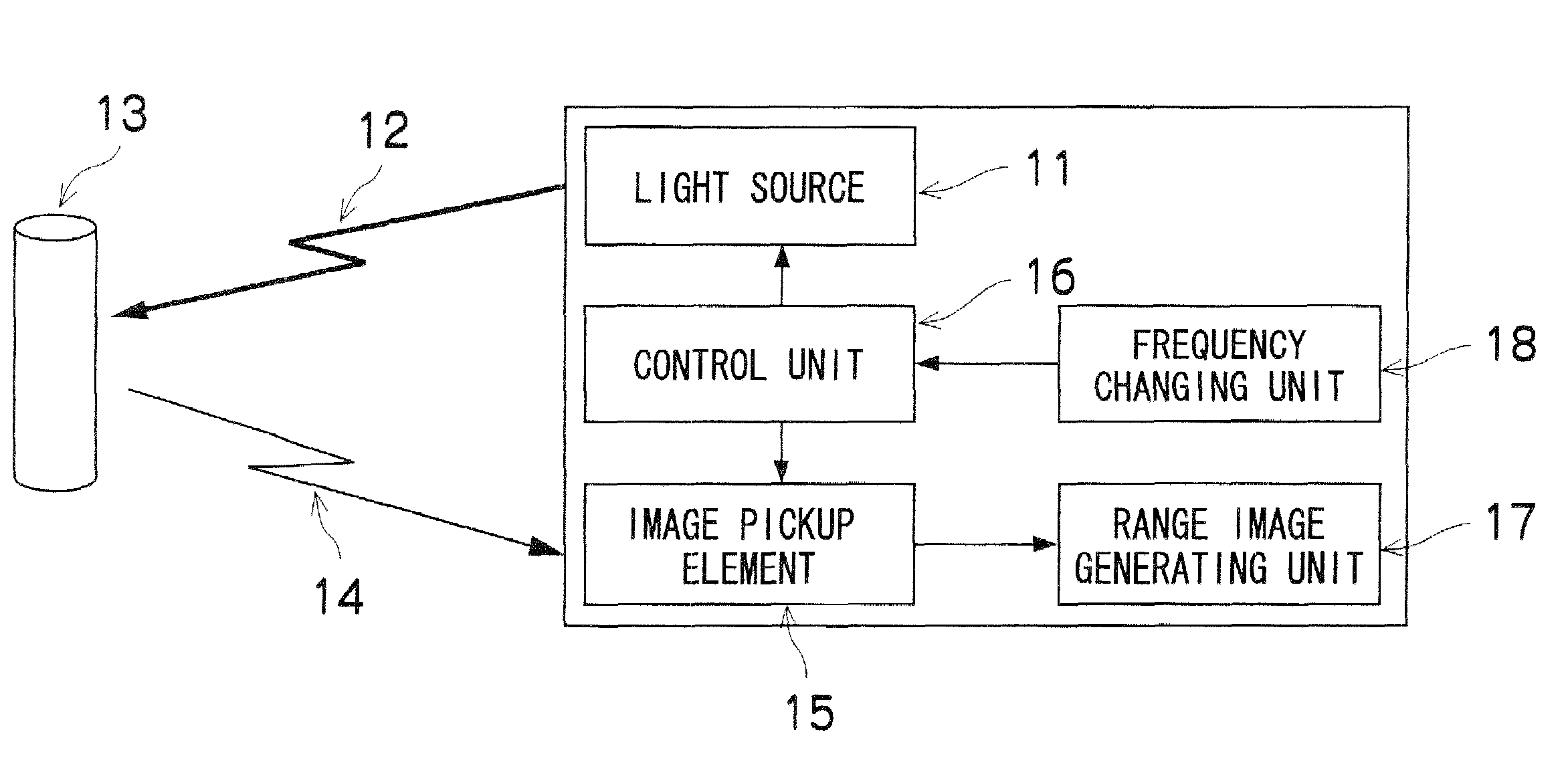

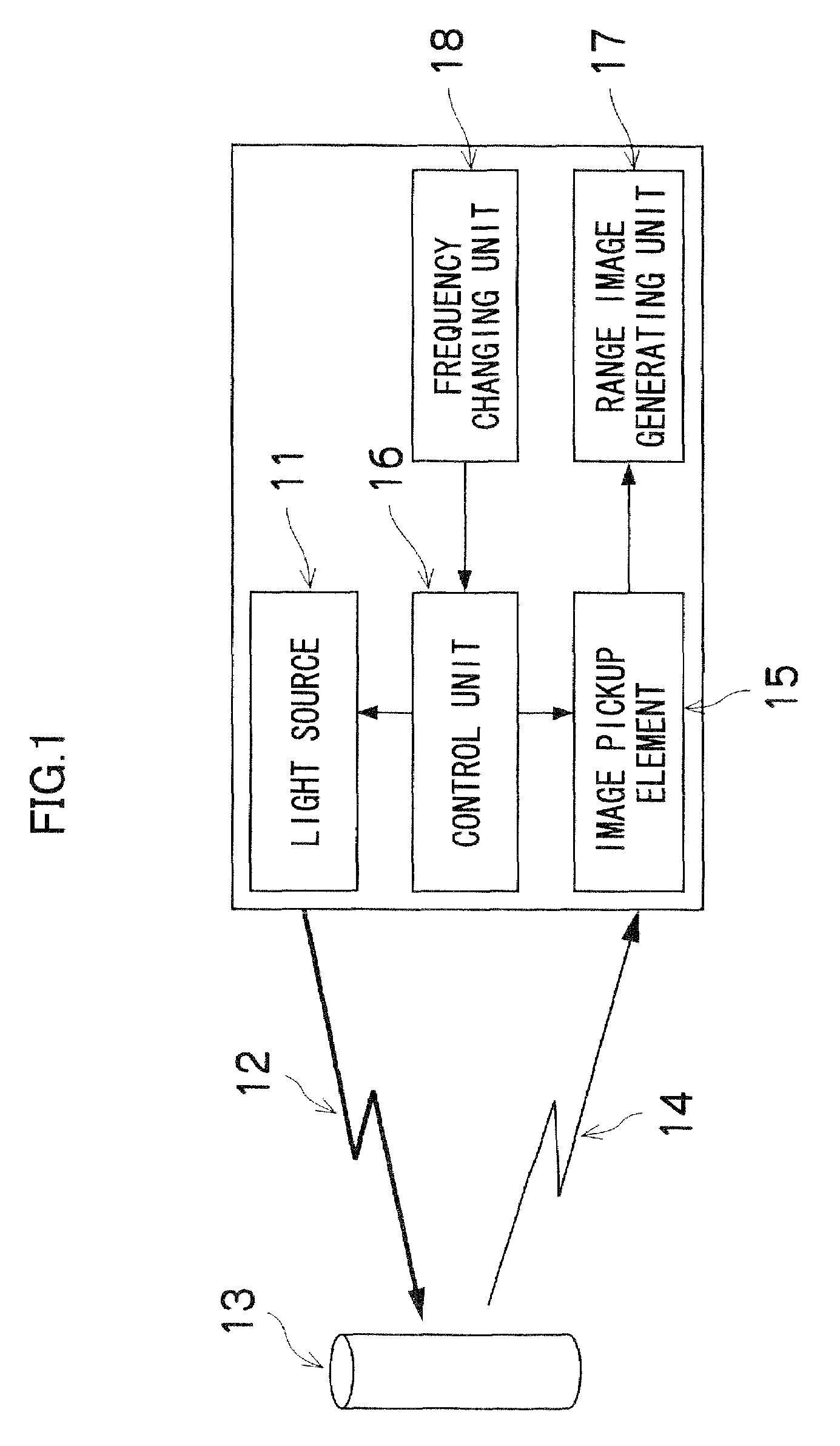

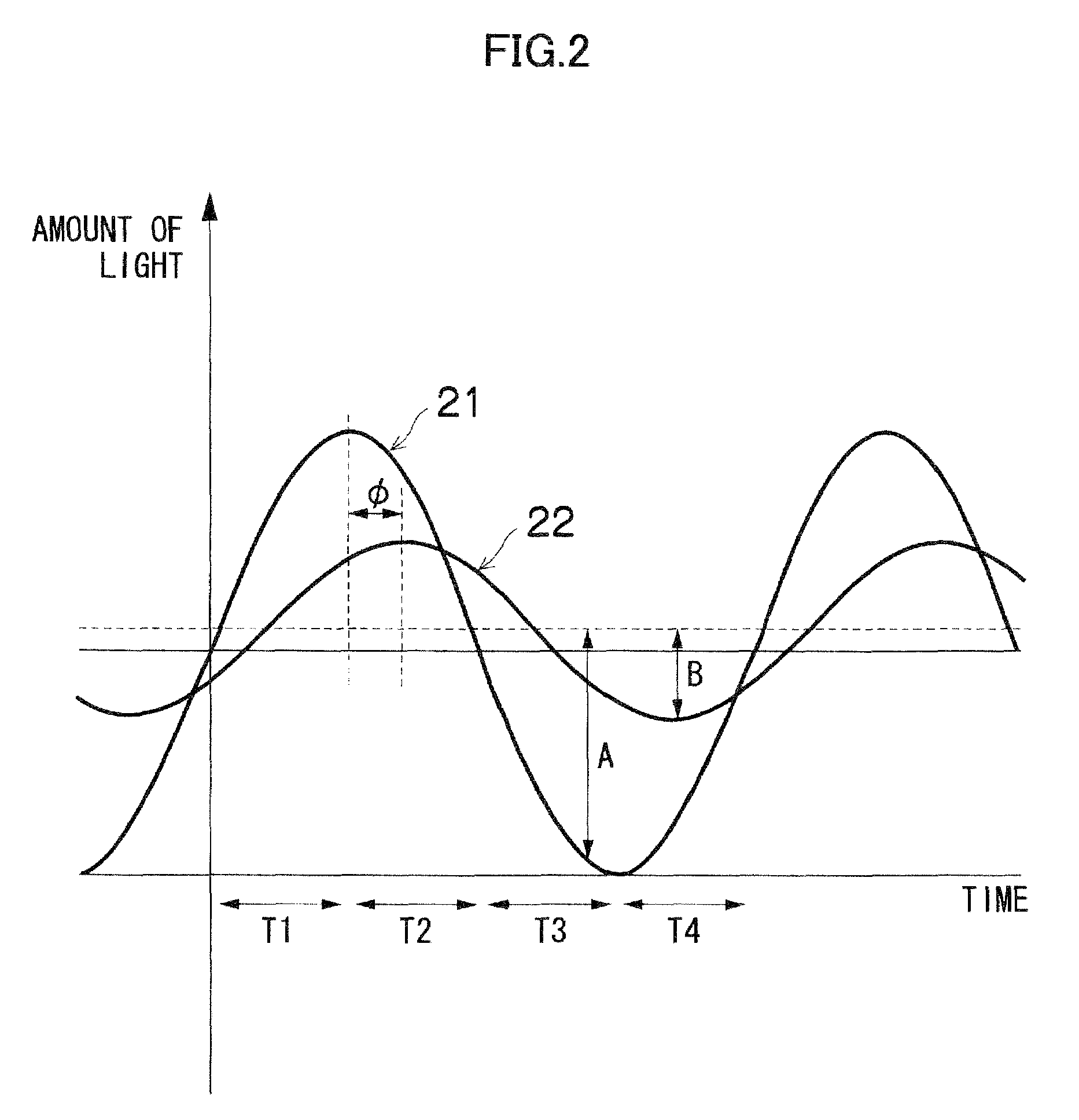

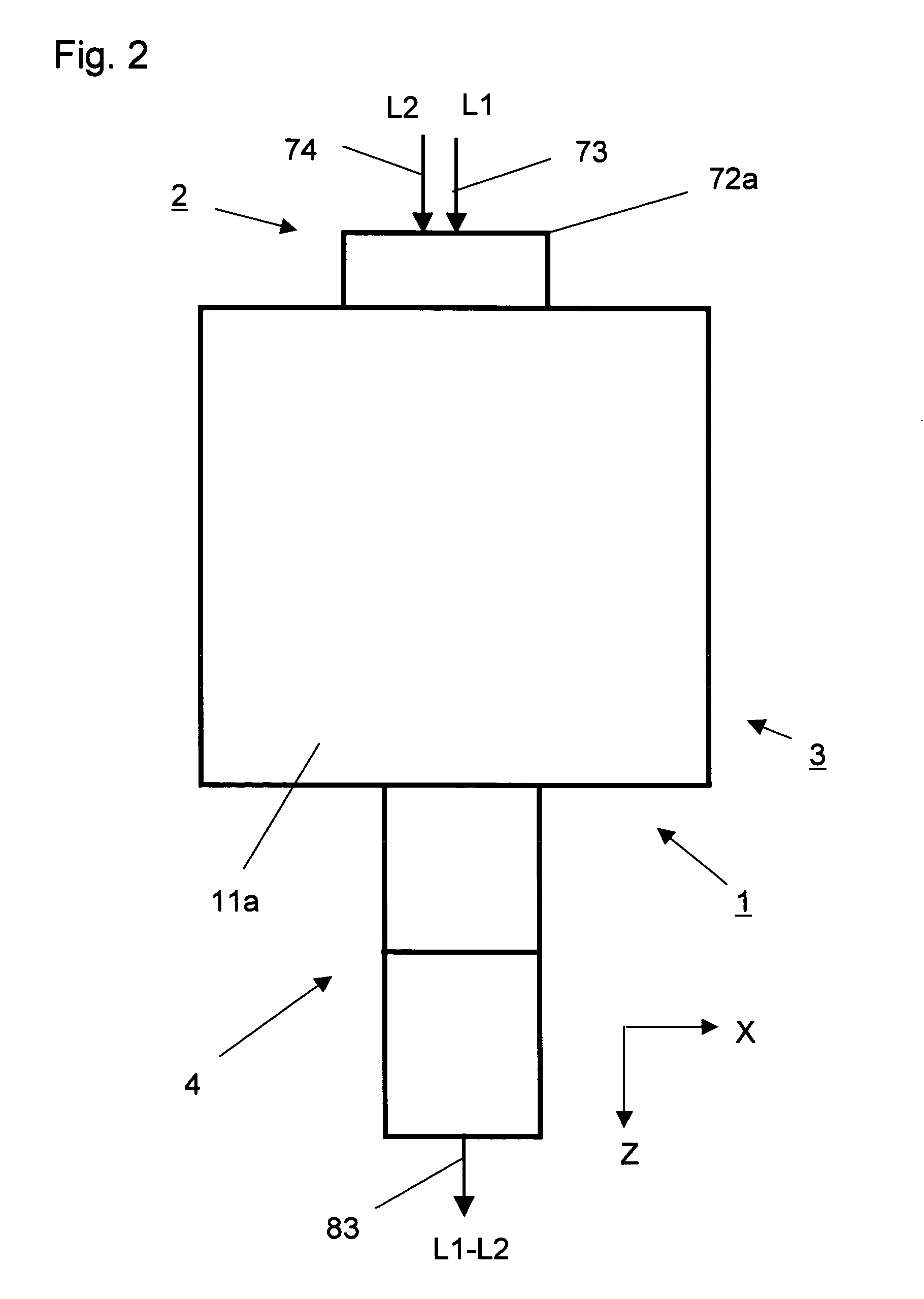

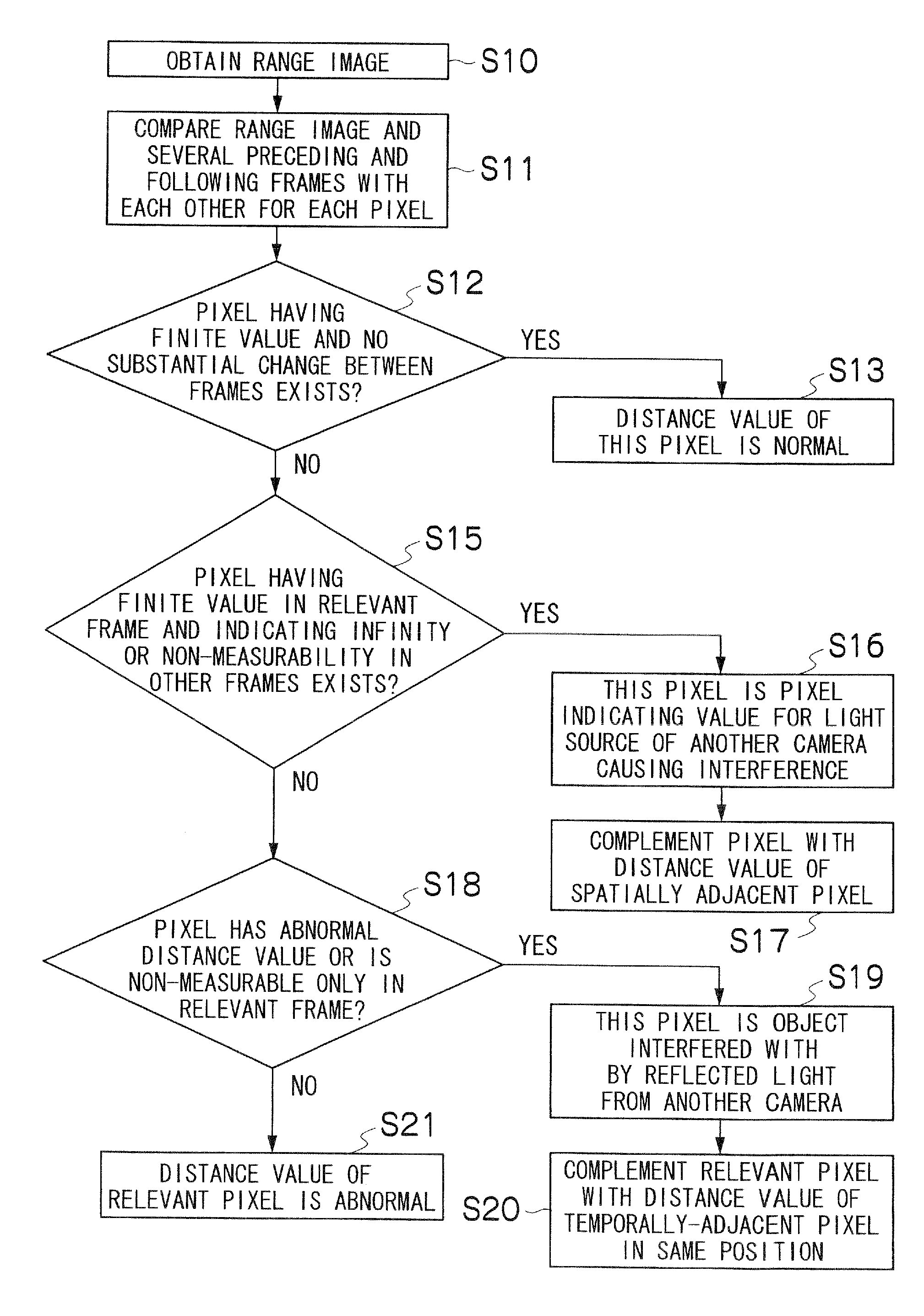

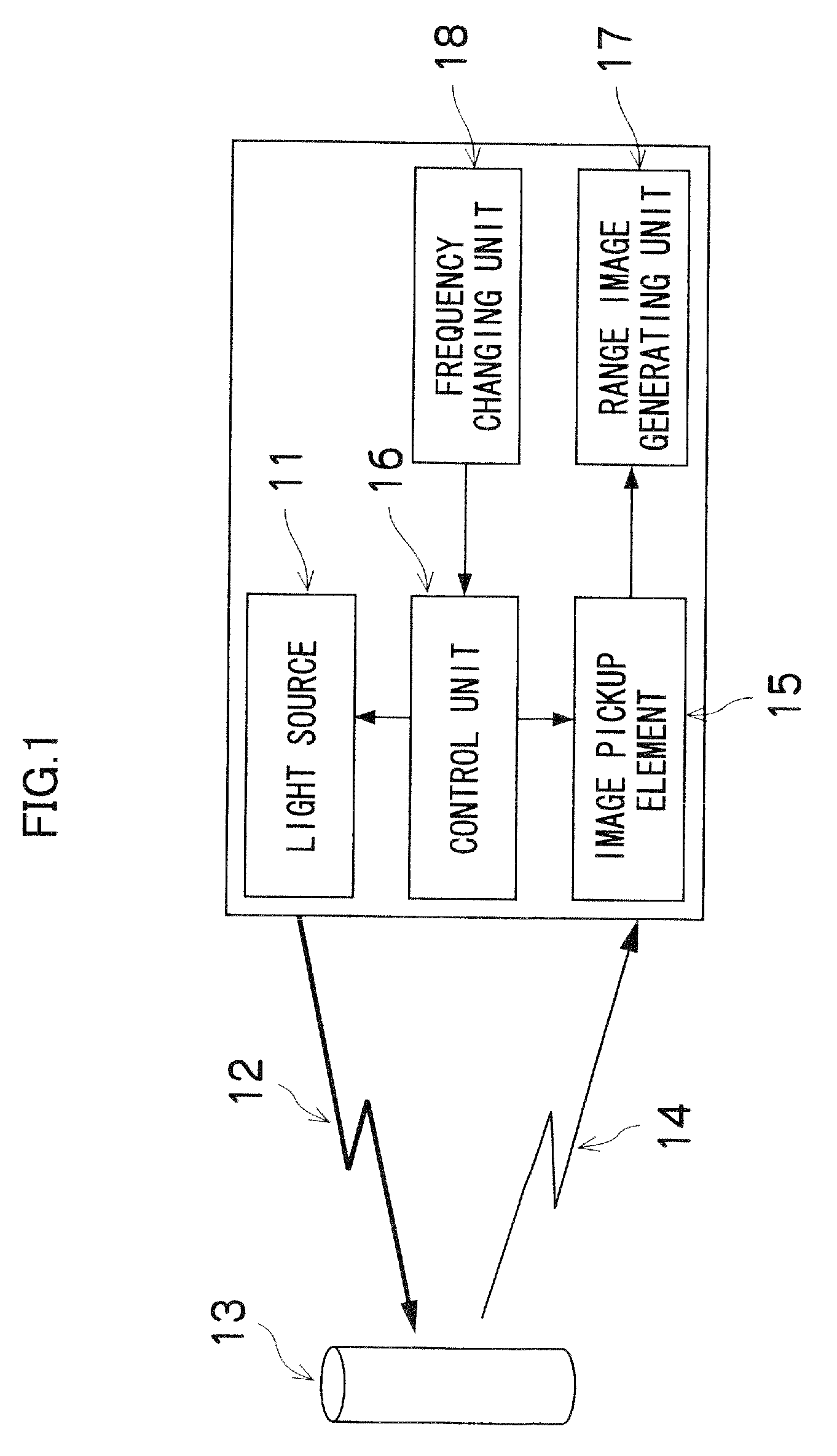

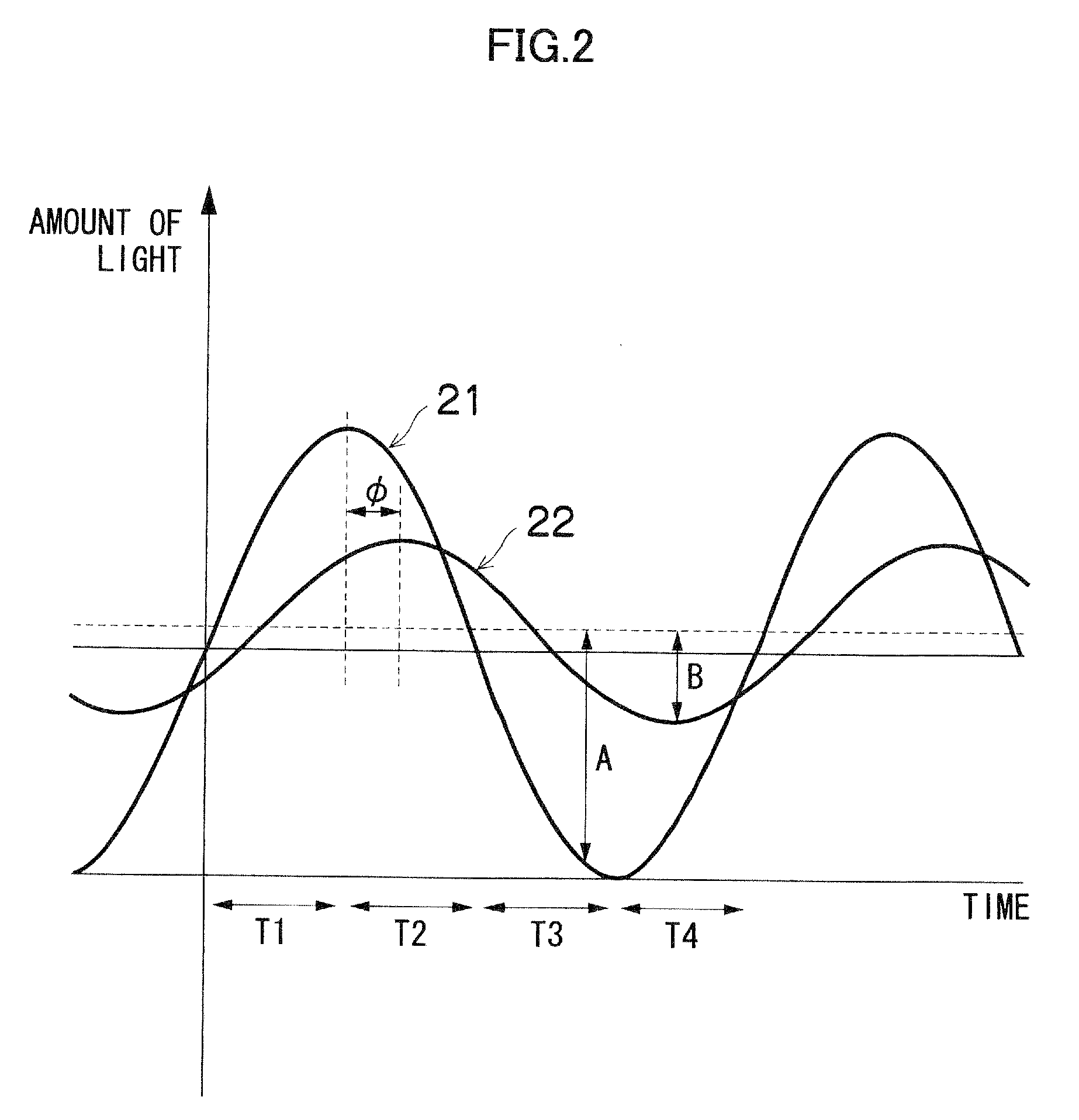

Range image generating apparatus

ActiveUS7697119B2Reduce and prevent generationLittle generationOptical rangefindersCharacter and pattern recognitionFrame rateImage generation

A range image generating apparatus capable of preventing or reducing generation of range images with interference, which contain e.g., pixels with erroneous distance values is provided. The range image generating apparatus includes: a light source radiating a light; an image pickup element; a range image generating unit; a frequency changing unit that changes a modulation frequency for each frame rate or charge storage time; and a control unit that controls the light source and the image pickup element in synchronization with the modulation frequency changed by the frequency changing unit.

Owner:STANLEY ELECTRIC CO LTD

Polymer/WUCS mat for use in sheet molding compounds

InactiveUS20060137798A1Uniform consistencyUniform propertyFibreboardNon-fibrous pulp additionFiberMelting point

A method of forming a molding mat formed bundles of reinforcing fibers and bonding materials is provided. The reinforcing fibers are preferably wet use chopped strand glass fibers (WUCS). The bonding materials may be any thermosetting material having a melting point less than the reinforcing fiber. The molding mat may be formed by partially opening the wet use chopped strand glass fibers and filamentizing the bonding materials, blending the reinforcement and bonding fibers, forming the reinforcement and bonding fibers into a sheet, and bonding the sheet. During bonding, the sheet is heated to a temperature above the melting point of the bonding fibers but below the temperature of the glass fibers. The molding mat thus formed may be used as a reinforcement material in sheet molding compounds.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

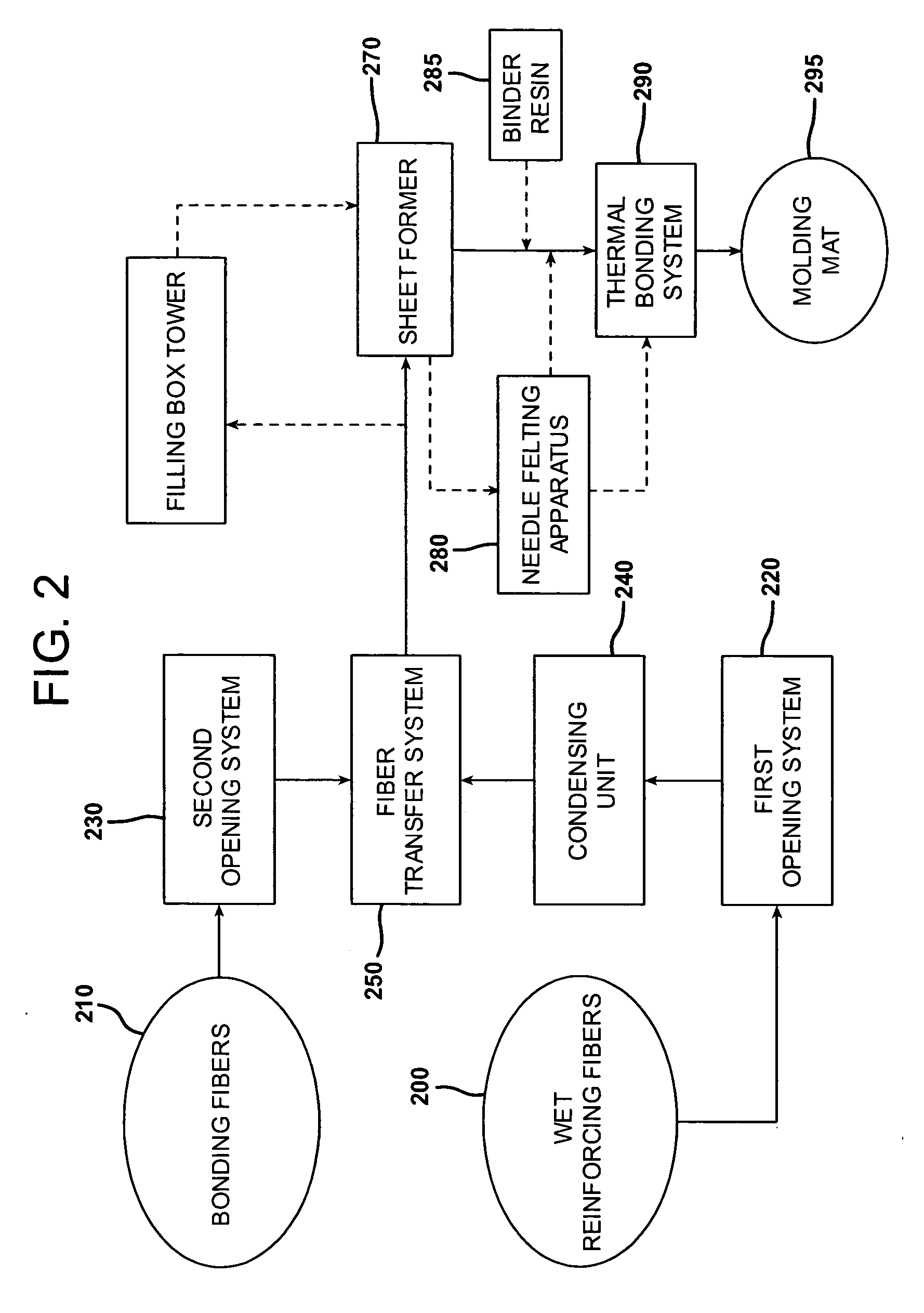

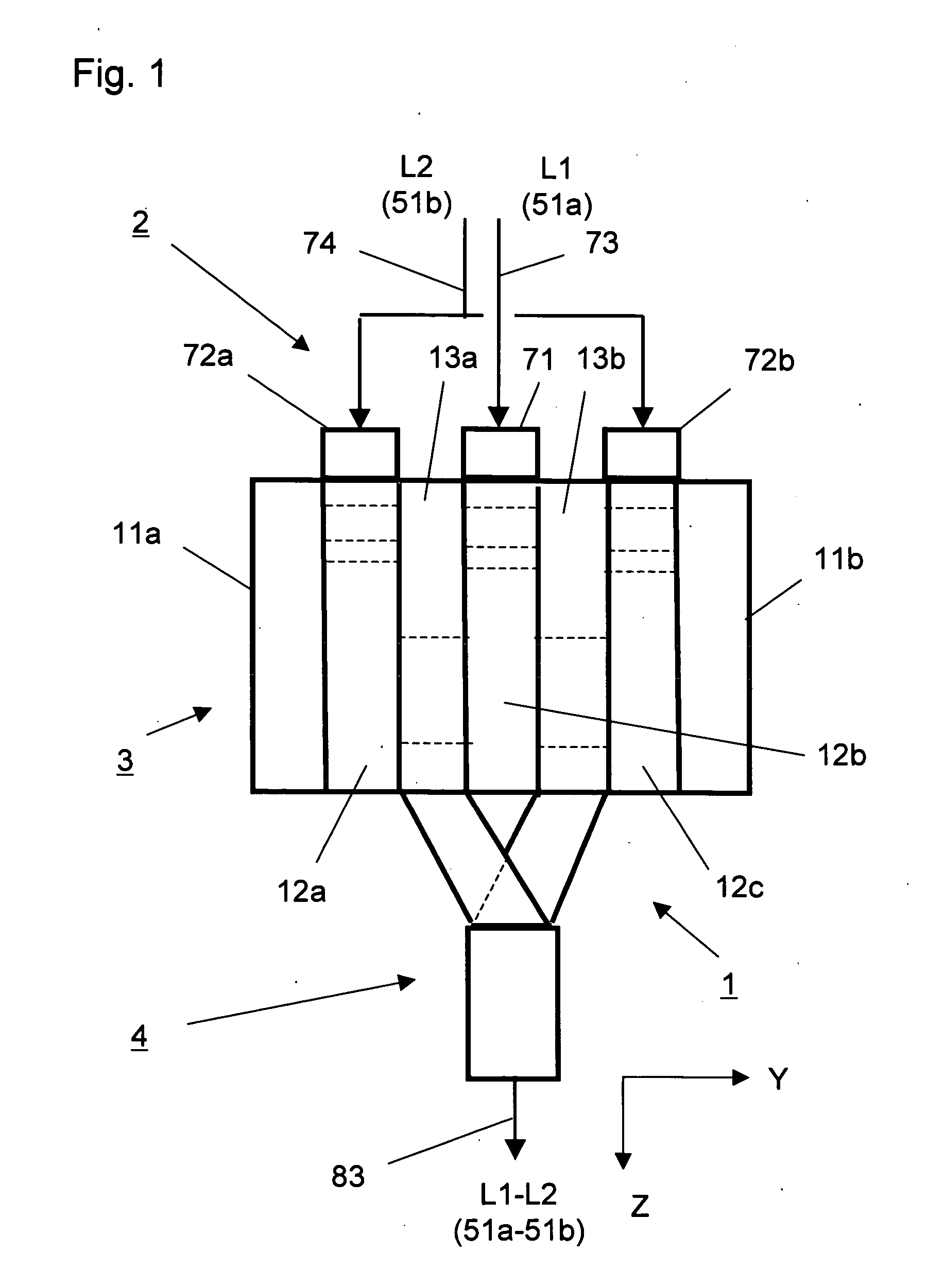

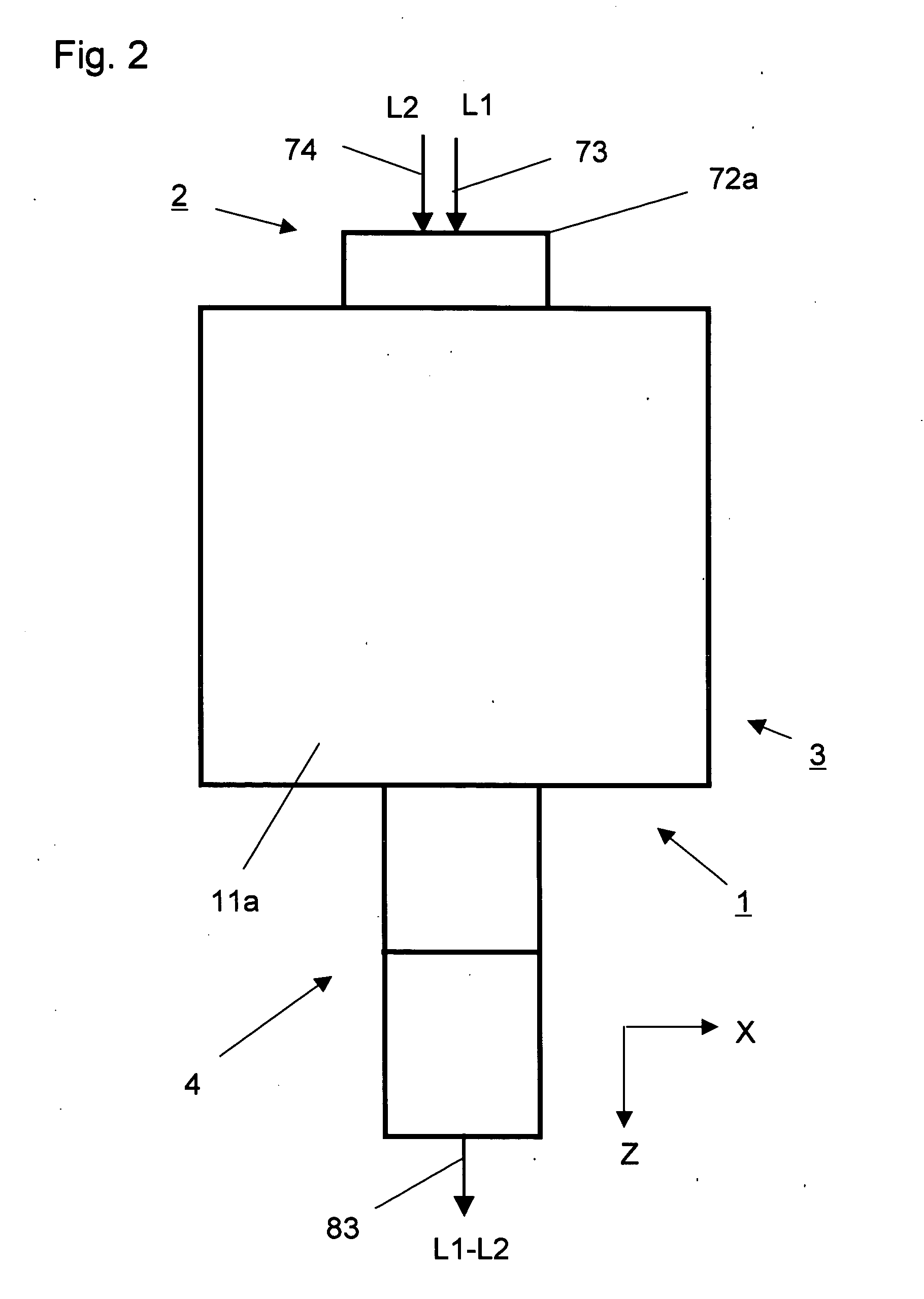

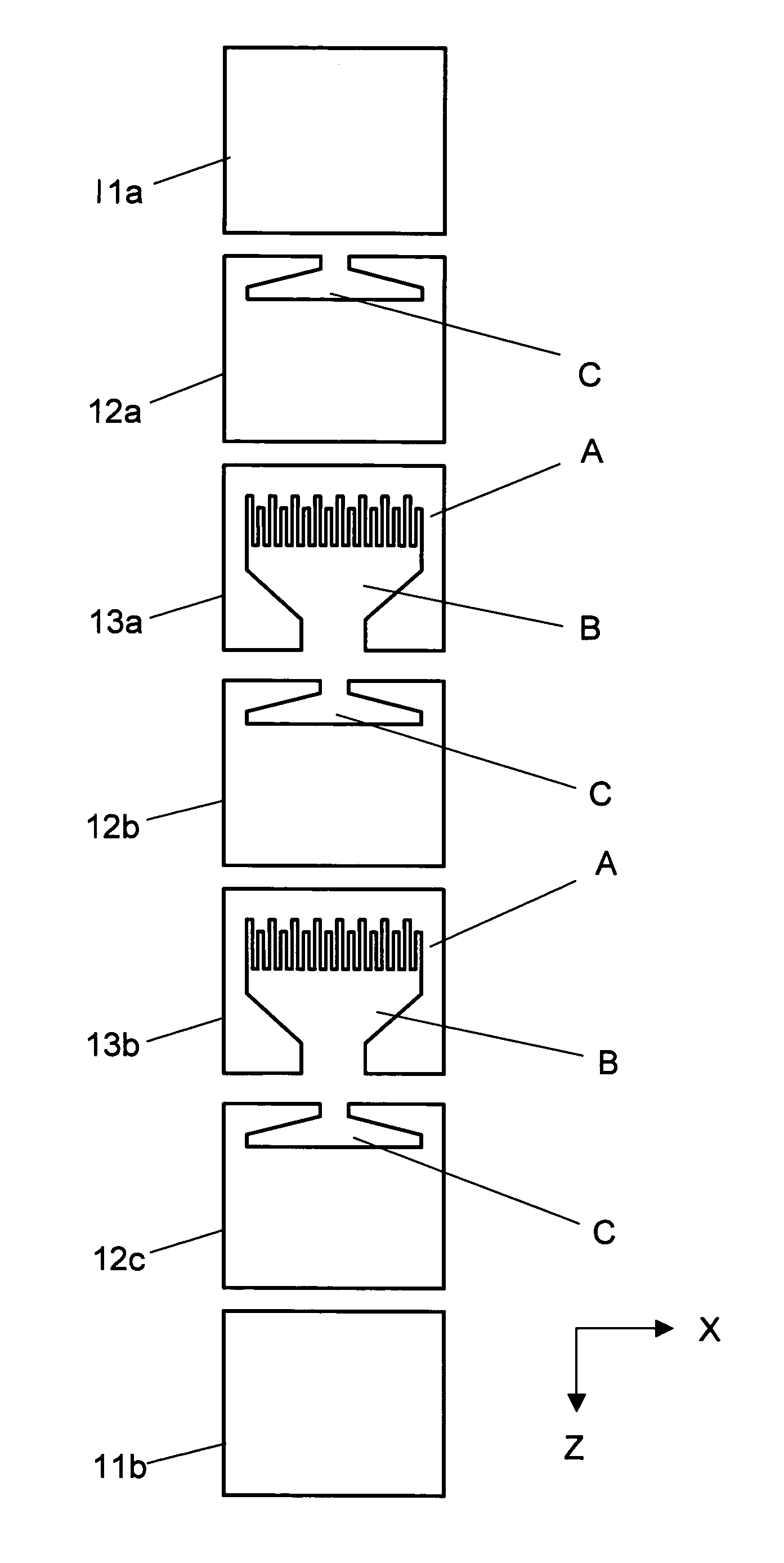

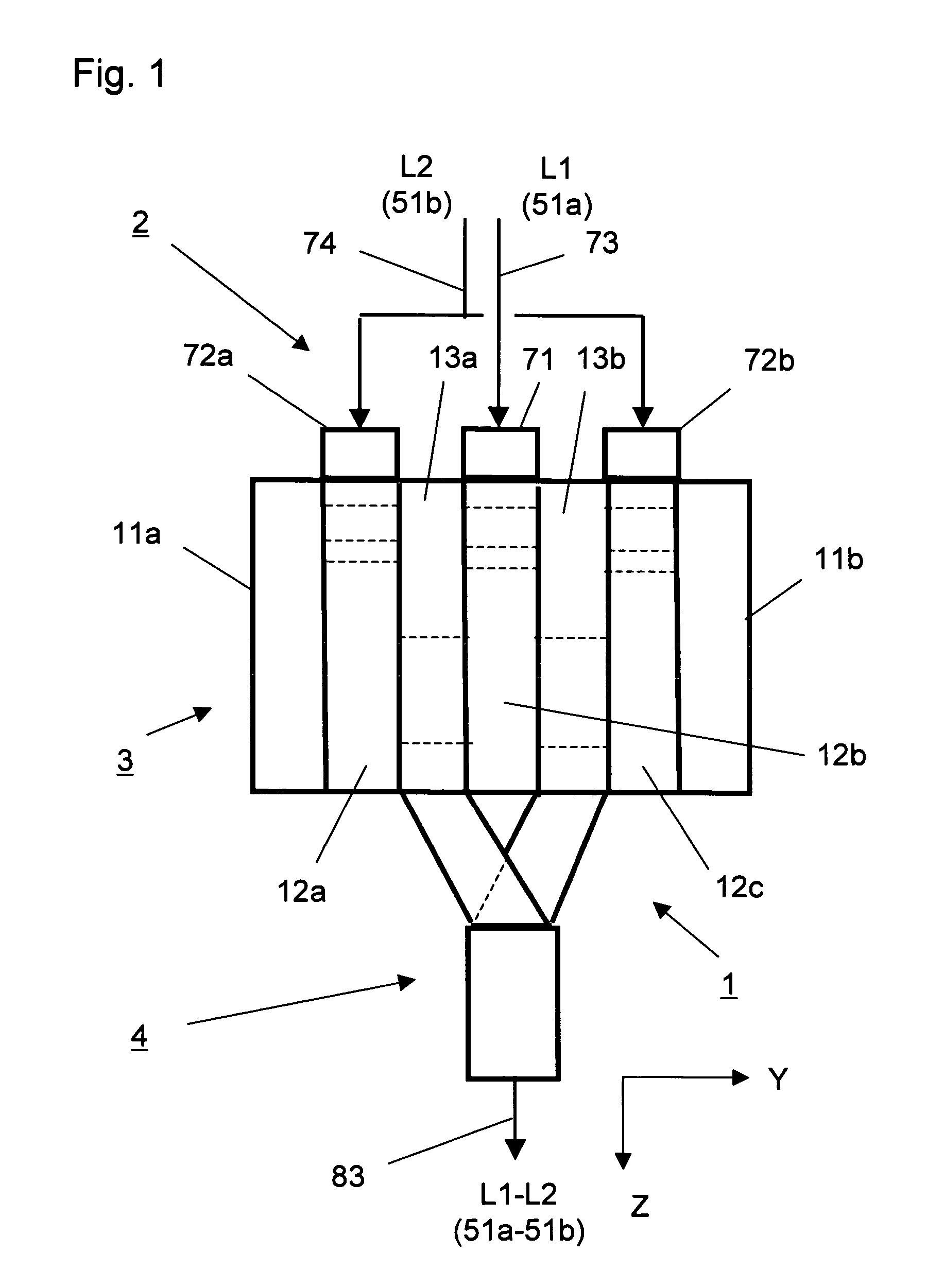

Liquid Flow Converging Device and Method of Manufacturing Multi-Layer Film

ActiveUS20080067712A1High layer accuracyLittle generationConfectioneryLaminationEngineeringElectrical and Electronics engineering

Owner:TORAY IND INC

Liquid flow converging device and method of manufacturing multi-layer film

ActiveUS8388331B2High layer accuracyLittle generationConfectioneryLaminationElectrical and Electronics engineeringEngineering

Owner:TORAY IND INC

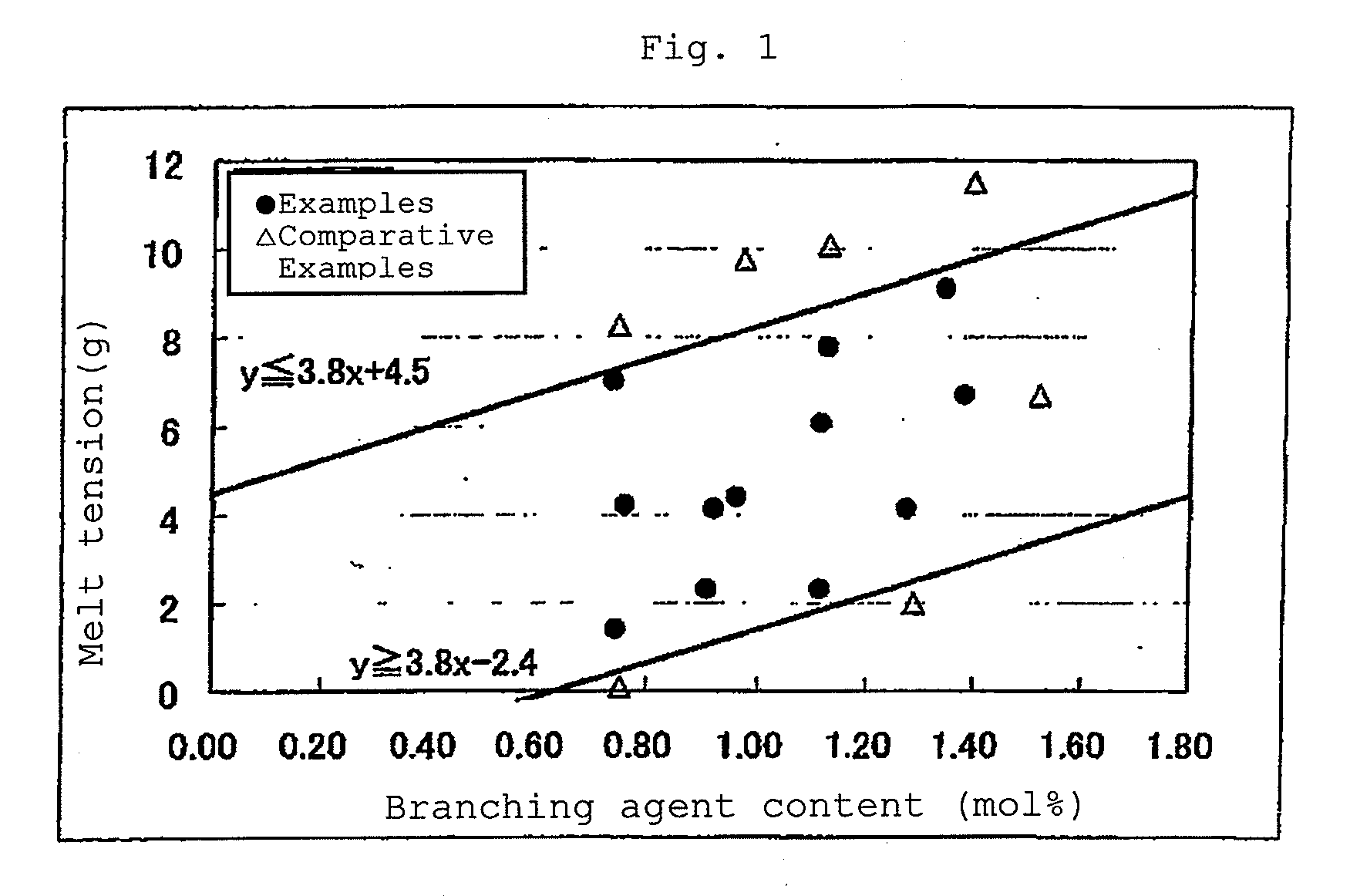

Branched polycarbonate resin and process for producing the same

The invention seeks to provide a branched polycarbonate resin having a high branching agent content, which has a good melt tension, virtually causes no drawdown and permits stable molding when it is molded in extrusion molding, blow molding, injection molding, vacuum molding, etc., and a process for producing the same.This invention provides a branched polycarbonate resin obtained from a dihydric phenol compound, a branching agent, monohydric phenols and phosgene by an interfacial polymerization reaction method in the presence of an alkali aqueous solution and an organic solvent, the branched polycarbonate resin having features that:(i) the branching agent content (X) thereof is over 0.70 mol % but 1.50 mol % or less,(ii) the branching agent content (X) and the melt tension (Y) thereof at 280° C. satisfy the following expression (1),3.8X−2.4≦Y—3.8X+4.5 (1),and(iii) the entire N content in the branched polycarbonate resin is 0 to 7 ppm.

Owner:TEIJIN KASEK KK

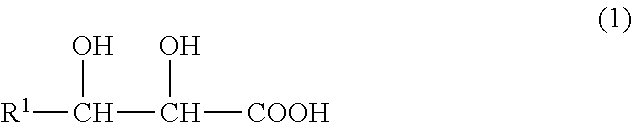

Cleaning agent for semiconductor substrates and method for processing semiconductor substrate surface

ActiveUS20160272924A1Improve removabilityLittle generationCationic surface-active compoundsOrganic detergent compounding agentsDiamineOrganic acid

The present invention relates to a cleaning agent for a semiconductor substrate having a copper wiring film or a copper alloy wiring film, and a cobalt-containing film to be used in a post-process of a chemical mechanical polishing process, comprising (A) an organic acid represented by general formula described in the present specification, (B) amines selected from the group consisting of (B-1) diamines, (B-2) amidines, (B-3) azoles, and (B-4) pyrazines or pyrimidines, represented by general formulae described in the present specification, (C) a hydroxylamine derivative, and (D) an oxygen scavenger represented by general formula described in the present specification, and being an aqueous solution having a pH of 10 or higher; and a processing method for the surface of a semiconductor substrate, having a copper wiring film or a copper alloy wiring film, and a cobalt-containing film, which comprises using the cleaning agent.

Owner:FUJIFILM CORP

Gas-barrier multi-layer structure

ActiveUS7258929B2Easy to processLess discoloration and malodor generationSynthetic resin layered productsFlexible pipesPolymer sciencePolyamide

The gas-barrier multi-layer structure of the present invention comprises at least one gas-barrier layer A and at lease one thermoplastic resin layer B. The gas-barrier layer A comprises a crystallizable polyamide resin which is produced by the polycondensation of a diamine component mainly comprising m-xylylenediamine with a dicarboxylic acid component comprising a C4-C20 α,ω-linear aliphatic dicarboxylic acid and isophthalic acid in a specific proportion so as to have a particular crystallization behavior. The gas-barrier multi-layer structure is excellent in the fabricability such as deep drawing ability and can be fabricated into a highly transparent shaped article with less discoloration and malodor generation.

Owner:MITSUBISHI GAS CHEM CO INC

Range image generating apparatus

ActiveUS20090122297A1Reduce and prevent generationLittle generationOptical rangefindersCharacter and pattern recognitionComputer scienceFrame rate

A range image generating apparatus capable of preventing or reducing generation of range images with interference which contain e.g., pixels with erroneous distance values is provided. The range image generating apparatus includes: a light source radiating a light; an image pickup element; a range image generating unit; a frequency changing unit that changes a modulation frequency for each frame rate or charge storage time; and a control unit that controls the light source and the image pickup element in synchronization with the modulation frequency changed by the frequency changing unit.

Owner:STANLEY ELECTRIC CO LTD

System and method for ultrasonic measuring of particle properties

ActiveUS7543480B2Improve the level ofLittle generationUltrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationAcoustic energy

Devices, systems and methods for measuring and detecting properties of a variety of particles or cells in suspension. Properties, such as, for example, velocity of particles, concentration and / or size may be measured according to the methods of the invention. Acoustic energy may be introduced to a focal zone and narrow band interrogating signals may be used. The acoustic energy may cause movement or streaming of the fluid or suspension. The acoustic streaming may allow a Doppler effect measurement without any other source of velocity.

Owner:PRODYNE CORP +1

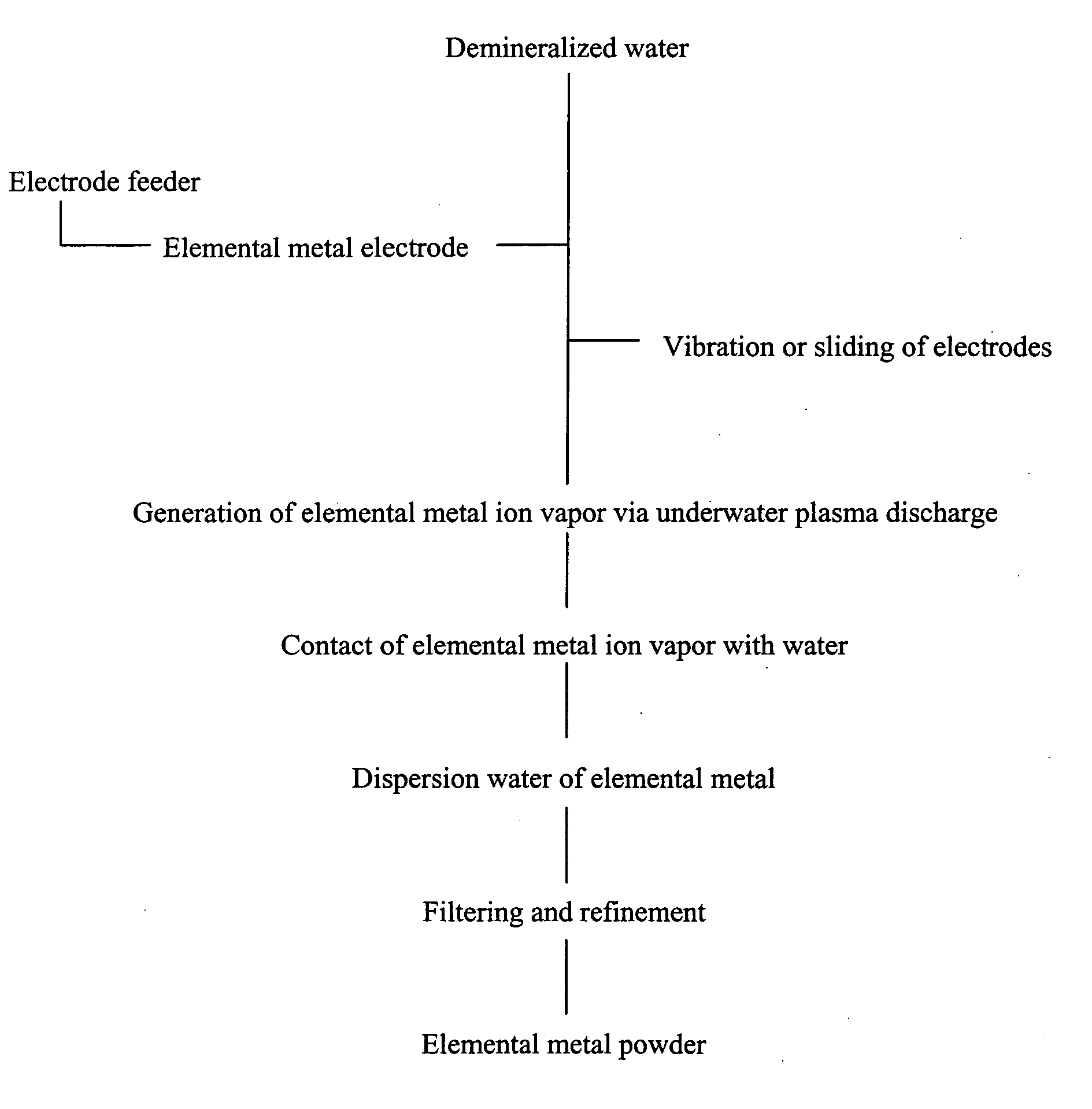

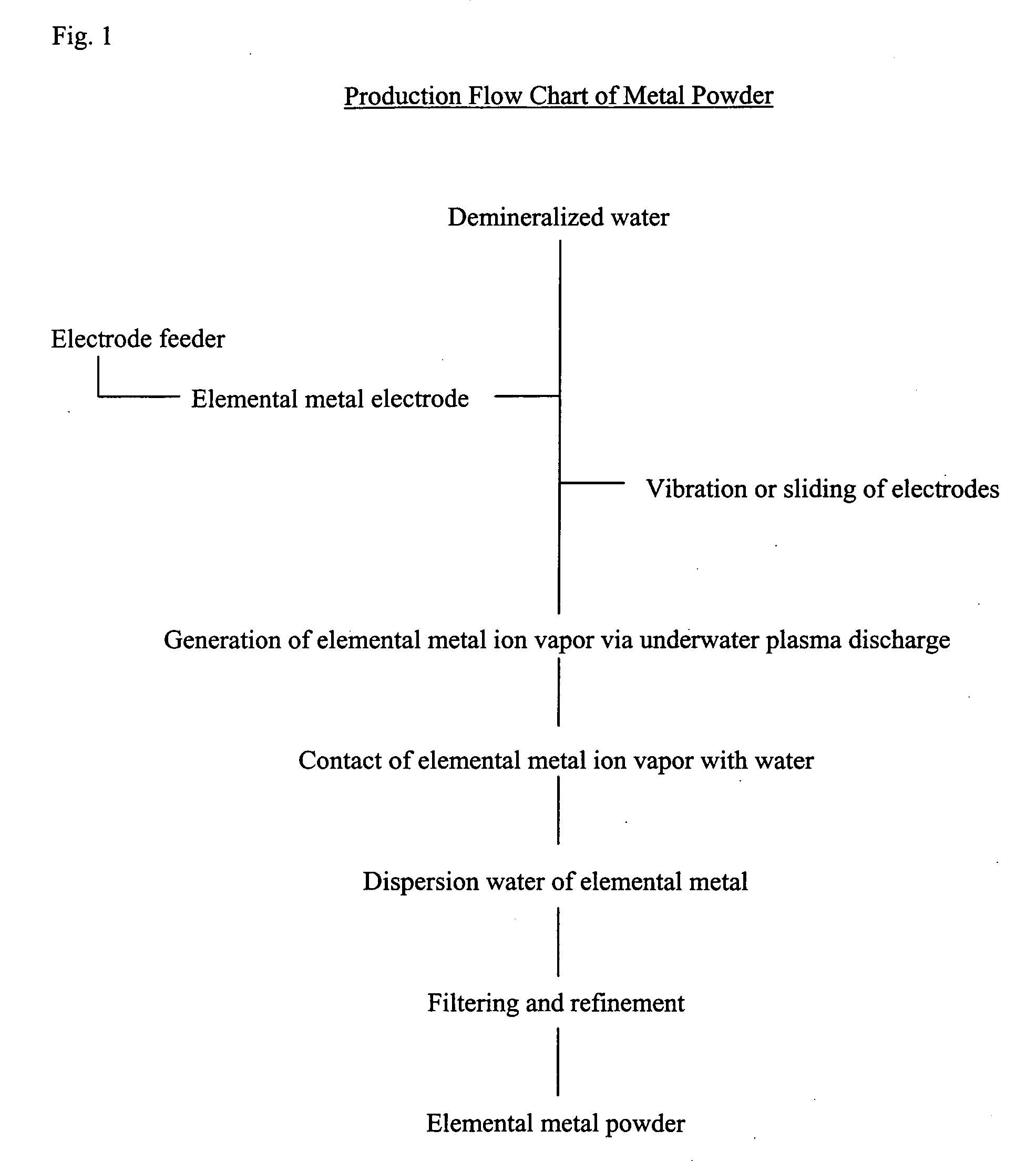

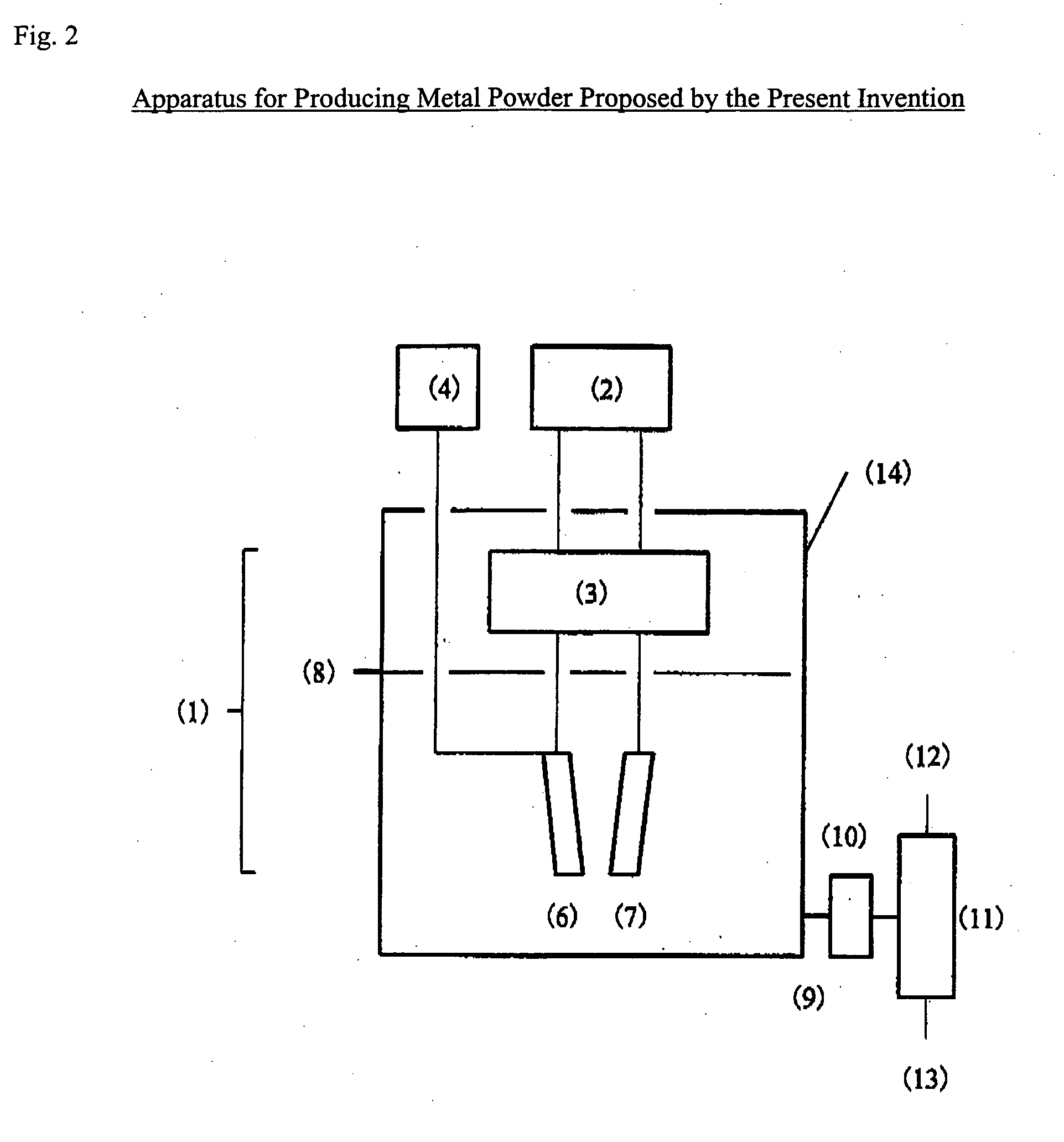

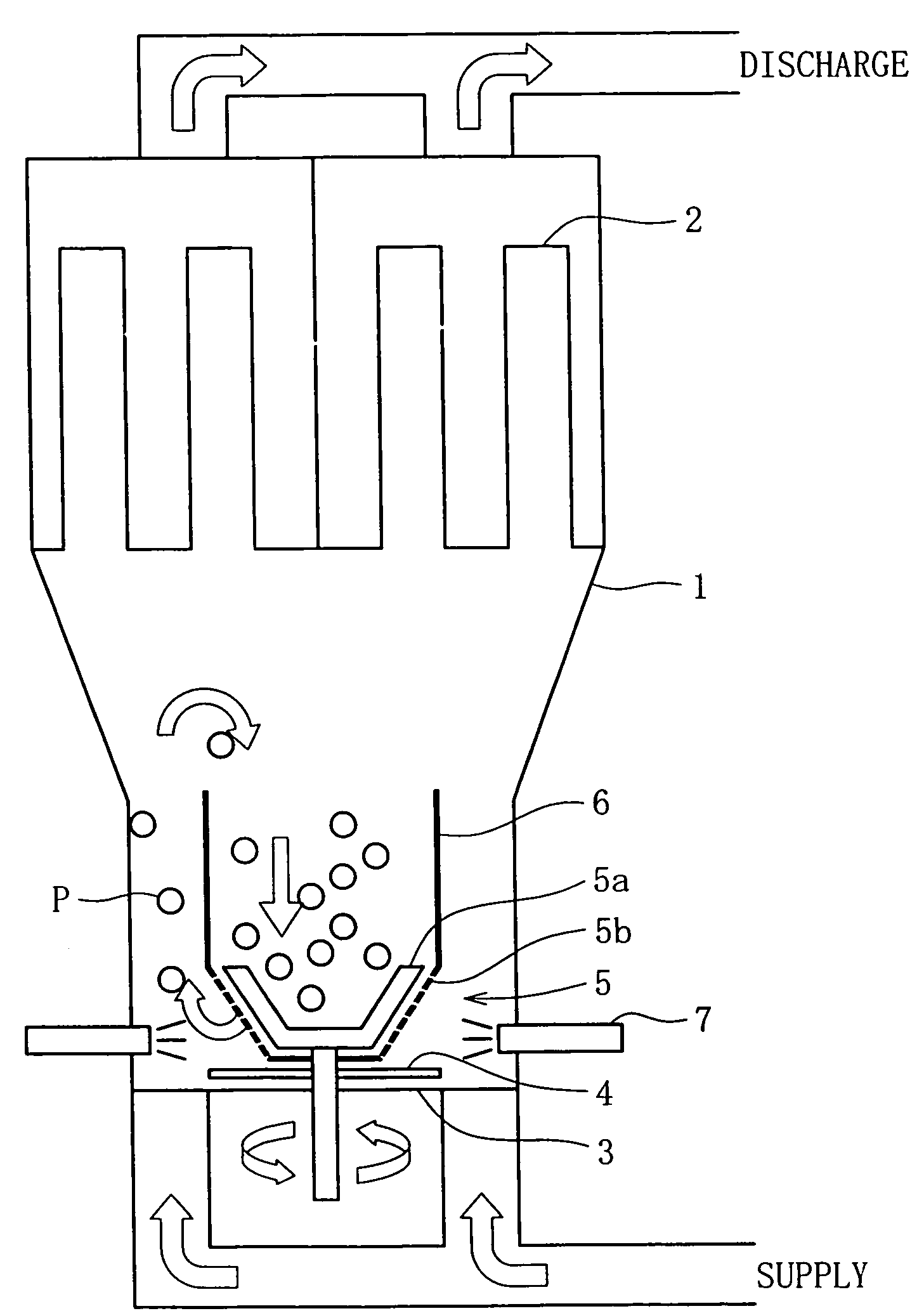

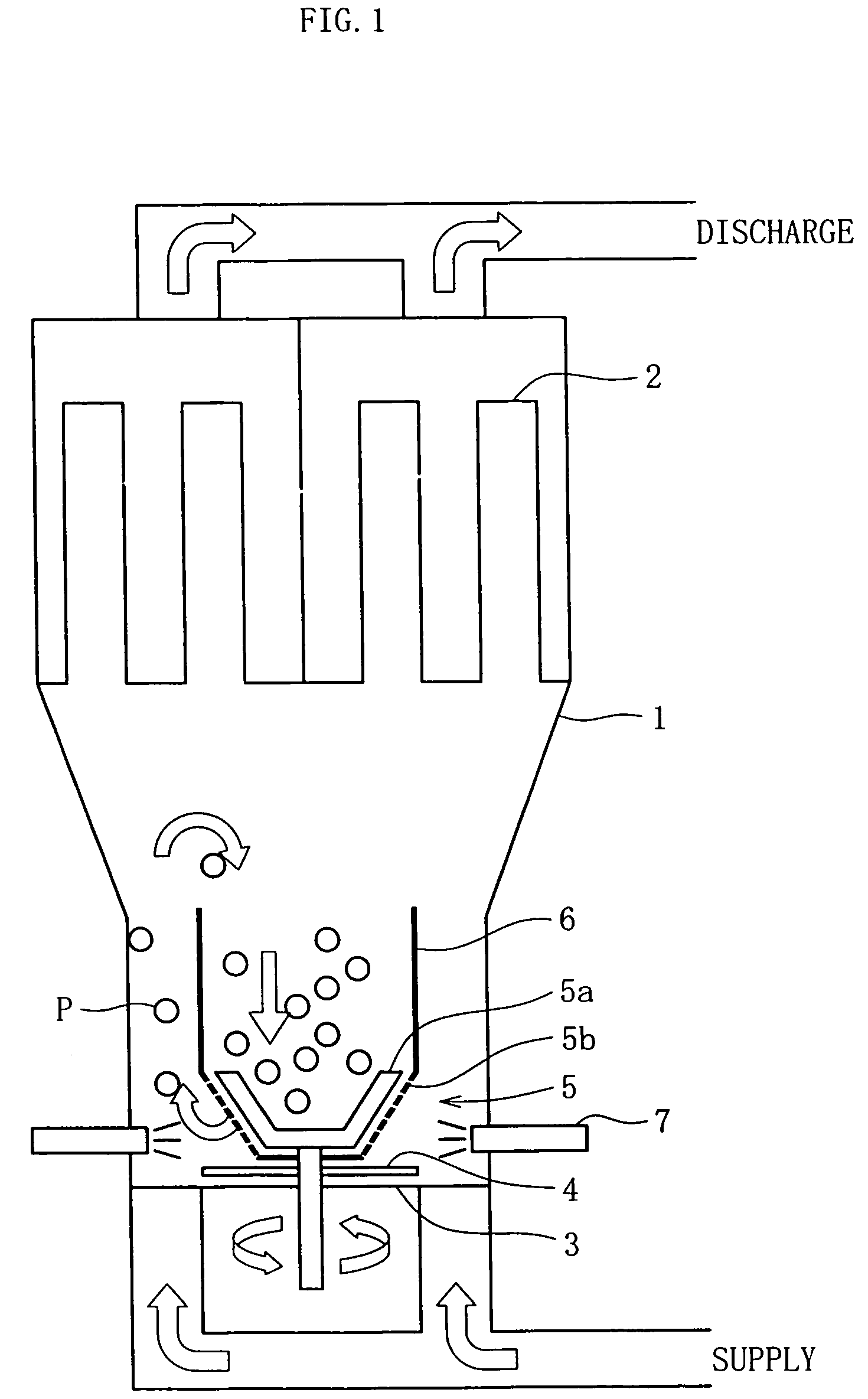

Method and apparatus for the production of metal powder

InactiveUS20050092132A1Easy to adjustImprove uniformityFurnace typesHeat treatment furnacesTitanium metalTitanium

Provide a method and apparatus for producing, in an economical manner, metal powder offering high purity and comprising uniform particle shape and size. Produce metal powder of titanium metal, etc., using an apparatus that comprises a power supply for high-voltage / current discharge, a feeder of metal electrode made of titanium metal, etc., a high-voltage discharge generator equipped with a metal electrode made of titanium, etc., and its counter electrode, a water tank, a water inlet, an outlet for produced metal dispersion solution containing titanium metal, etc., a discharge pump, and an adjunct device for separating / recovering metal powder of titanium metal, etc., from the metal dispersion solution containing titanium metal, etc.

Owner:PHITEN

Cleaning solution for removing residue

InactiveUS6949495B2Improve abilitiesImprove solubilityOrganic detergent compounding agentsSurface-active detergent compositionsWater solubleFluoride

A solution for washing away residue, comprising an aqueous solution of a water-soluble high molecular compound in which is dissolved at least one kind of dissolving agent selected from an amine and a fluoride. The washing solution is capable of effectively washing away the residue formed during the production of electronic circuits, is very lowly corrosive to the insulating films, low-dielectric interlayer insulating films and wirings, and offers an advantage of little generating foam.

Owner:TOKUYAMA CORP

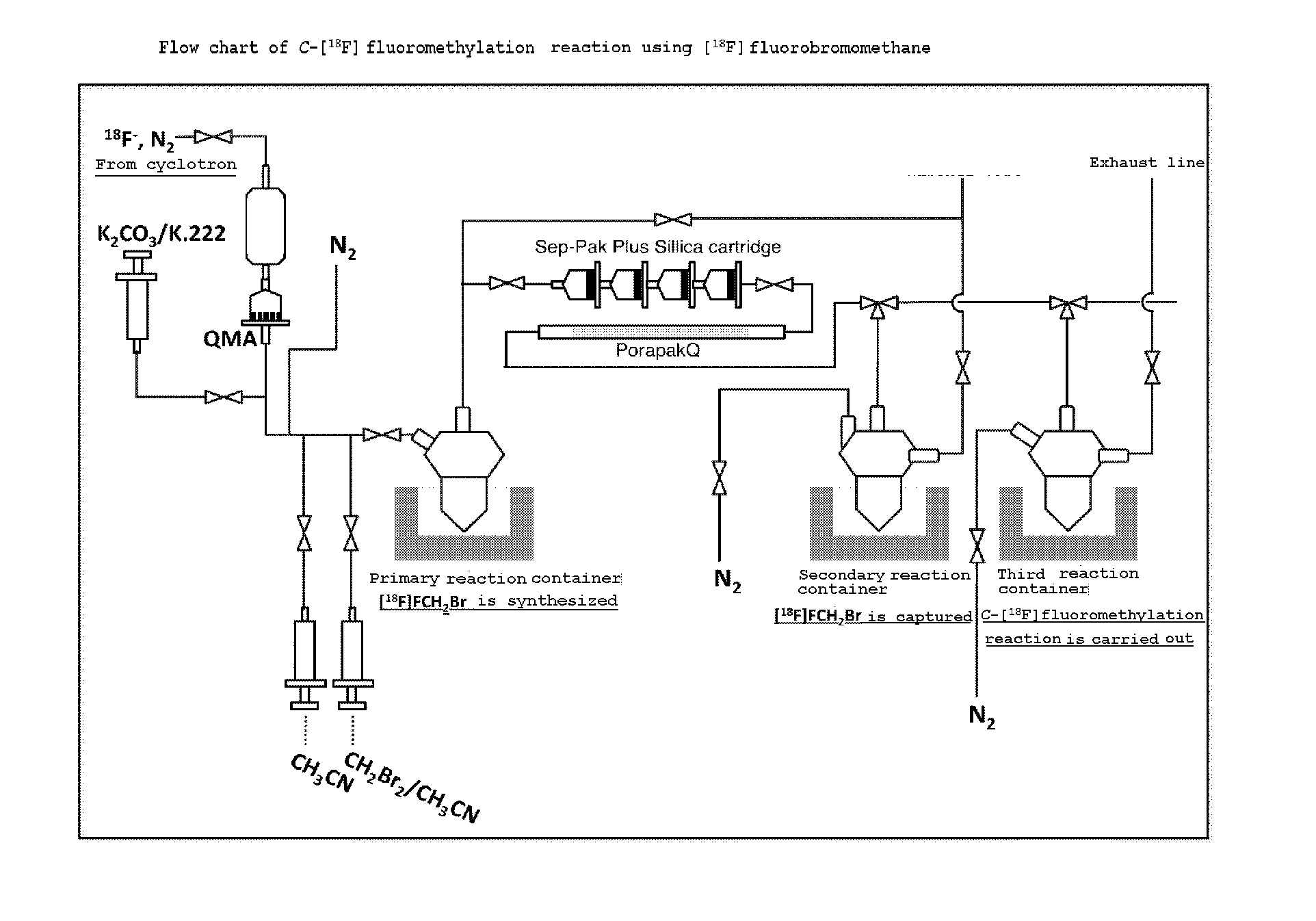

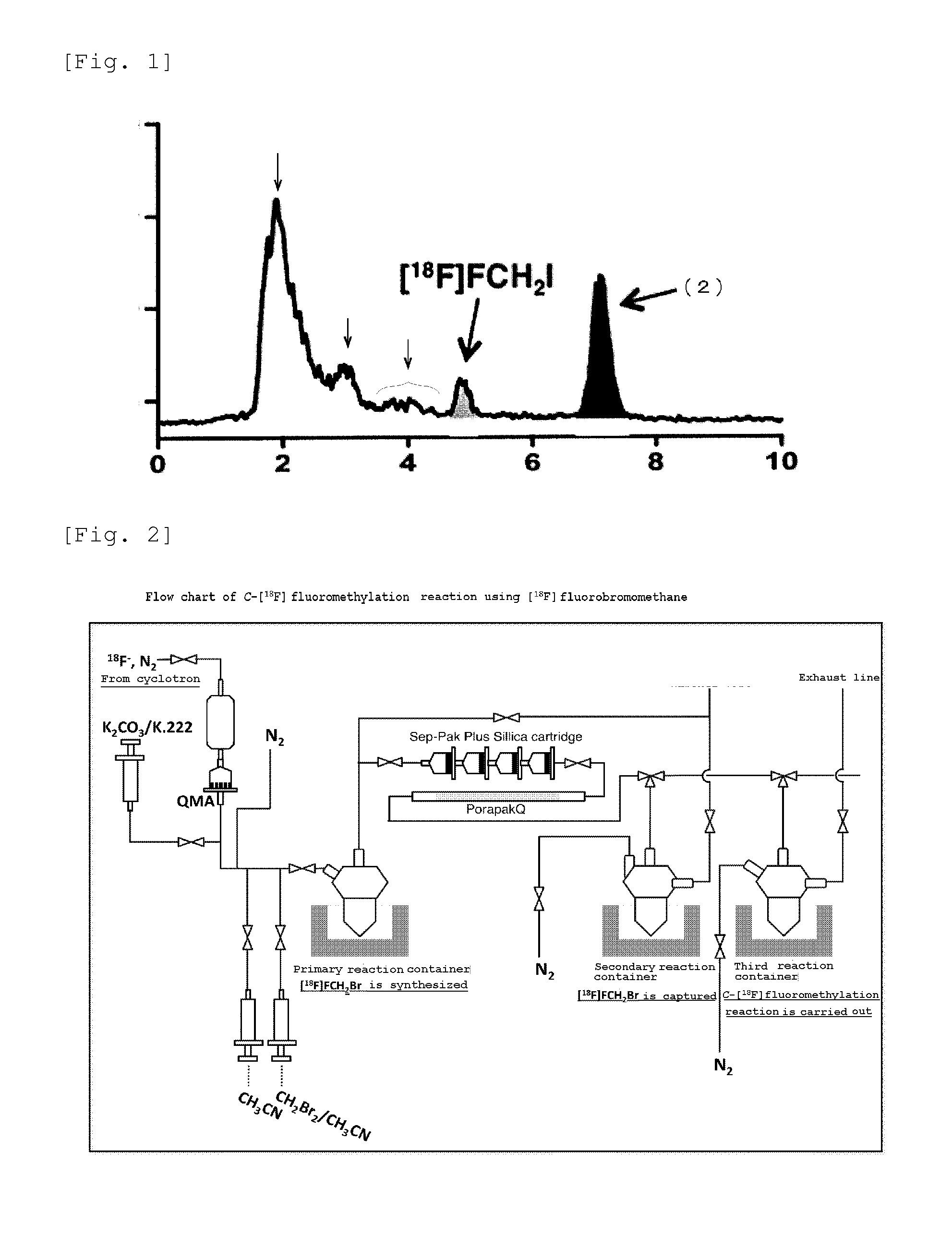

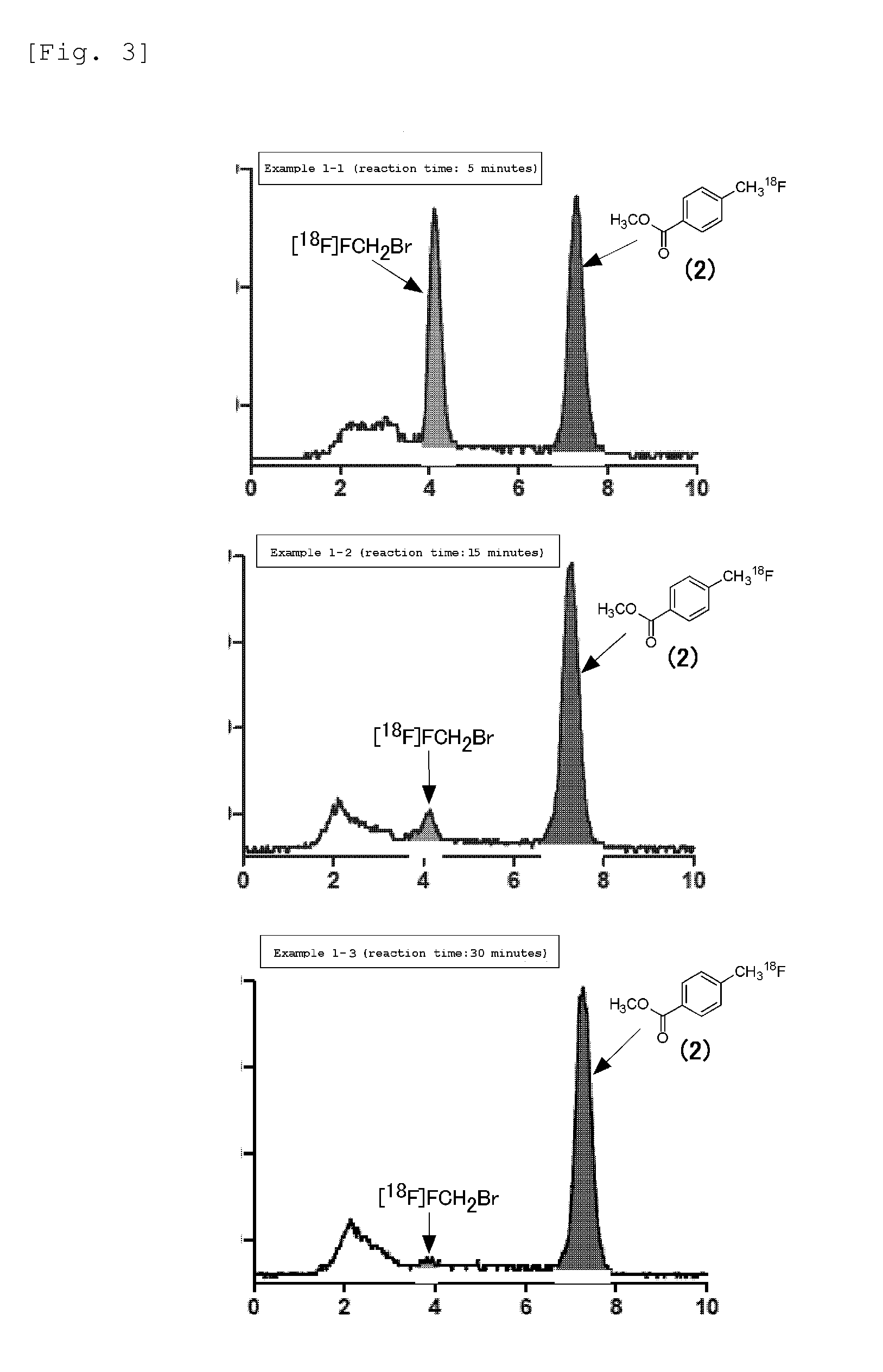

Method for high-speed fluoromethylation and process for preparation of pet tracer using same

ActiveUS20120289716A1Little generationImprove adhesionOrganic compound preparationCarboxylic acid esters preparationHydrogenChemical compound

Provided are: a method for rapid fluoromethylation, by which a fluoromethyl group can be easily bonded to an aromatic-ring carbon of an aromatic compound with little generation of by-products; and a process for preparation of a PET tracer using the same. The method is characterized by cross-coupling an organoboron compound in which an aromatic ring is bonded to a boron atom with FCX2Br (wherein X is ordinary hydrogen or heavy hydrogen) in a solvent obtained by adding water to an aprotic polar solvent, in the presence of a palladium complex, a phosphine ligand, and a base.

Owner:RIKEN

Electrophotographic photoreceptor, method of image formation, image formation apparatus and process cartridge for image formation apparatus

ActiveUS7560203B2Improve image qualityIncreased durabilityElectrographic process apparatusCorona dischargeElectrical conductorImaging quality

Owner:RICOH KK

Polymer/WUCS mat for use in automotive applications

InactiveUS7279059B2Optimize and tailor physical property of matImprove propertiesWood working apparatusBaby linensGlass fiberFiber

An acoustical and thermally absorbent chopped strand mat formed of thermoplastic bonding materials and bundles of reinforcing fibers is provided. The reinforcing fibers are preferably wet use chopped strand glass fibers (WUCS). The thermoplastic bonding materials may be any thermoplastic or thermosetting material having a melting point less than the reinforcing fiber. The chopped strand mat may be formed by partially opening the WUCS fibers and filamentizing the thermoplastic bonding materials, blending the reinforcement and thermoplastic bonding fibers, forming the reinforcement and thermoplastic bonding fibers into a sheet, and bonding the sheet. During bonding, the sheet is heated to a temperature above the melting point of the thermoplastic bonding fibers but below the temperature of the glass fibers. The melted thermoplastic bonding fibers act as a glue to hold the glass fibers in bundles. The chopped strand mat thus formed may be used as a reinforcement material in automotive applications.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Method for manufacturing glass substrate for data storage medium and glass substrate

InactiveUS20110151282A1High sensitivityLittle generationMagnetic materials for record carriersBase layers for recording layersPotassium nitrateMolten salt

The present invention relates to a method for manufacturing a glass substrate for data storage mediums, the method including a chemical strengthening treatment step of dipping a glass for a substrate in a mixed molten salt to form a compressive layer on front and back surfaces of the glass for a substrate, in which the glass for a substrate contains a lithium ion as an alkali component, the mixed molten salt contains sodium nitrate, potassium nitrate and lithium nitrate, an amount of lithium nitrate being from 1 to 6% by mass, and the glass for a substrate is dipped in the mixed molten salt at a treatment temperature of 325° C. or more and 475° C. or less for a treatment time of 30 minutes or less, under the requirement satisfying the following formula: 1900≦T×log(t2)≦2900, in which T is a treatment temperature (unit: K) and t is a treatment time (unit: second).

Owner:ASAHI GLASS CO LTD

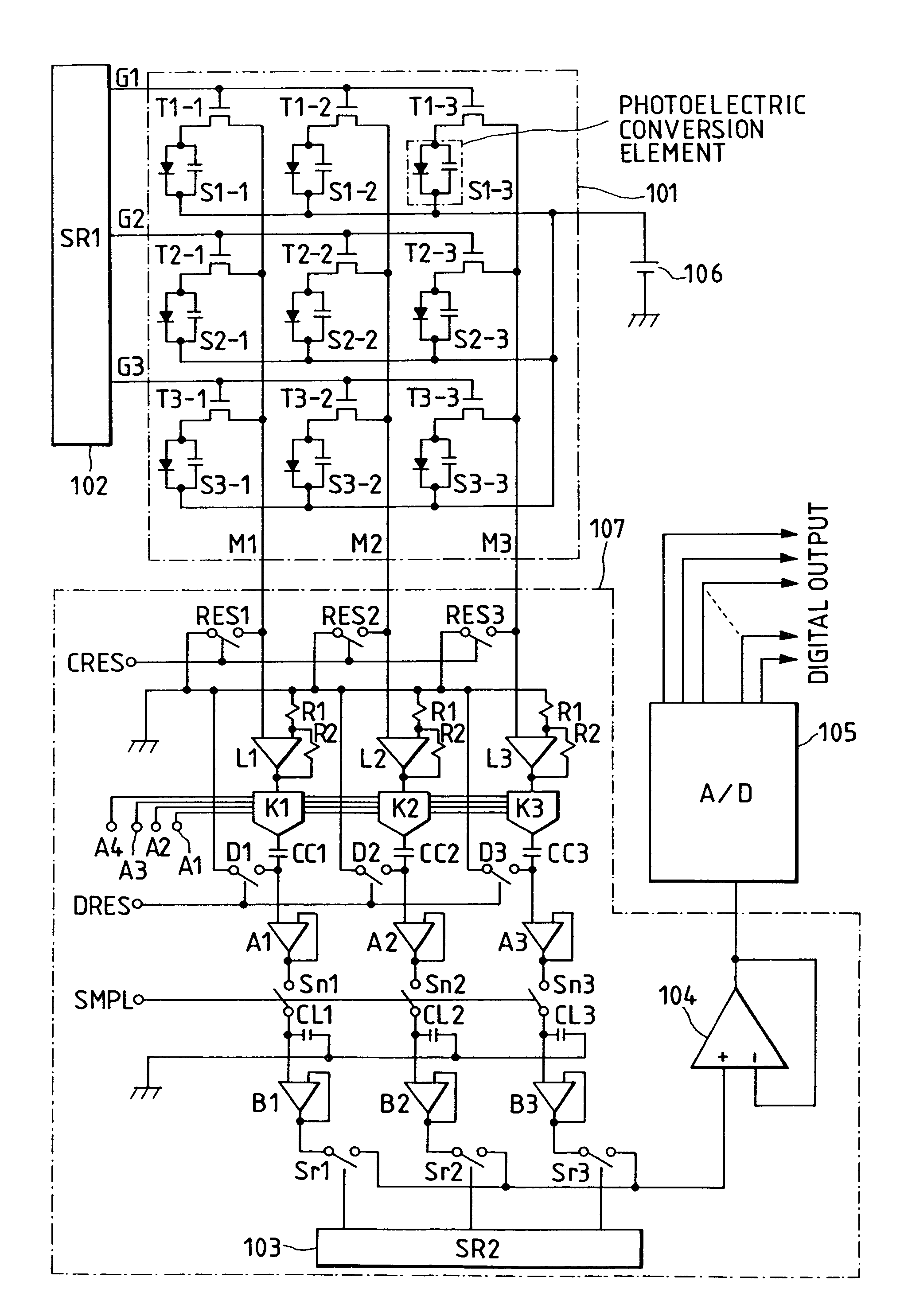

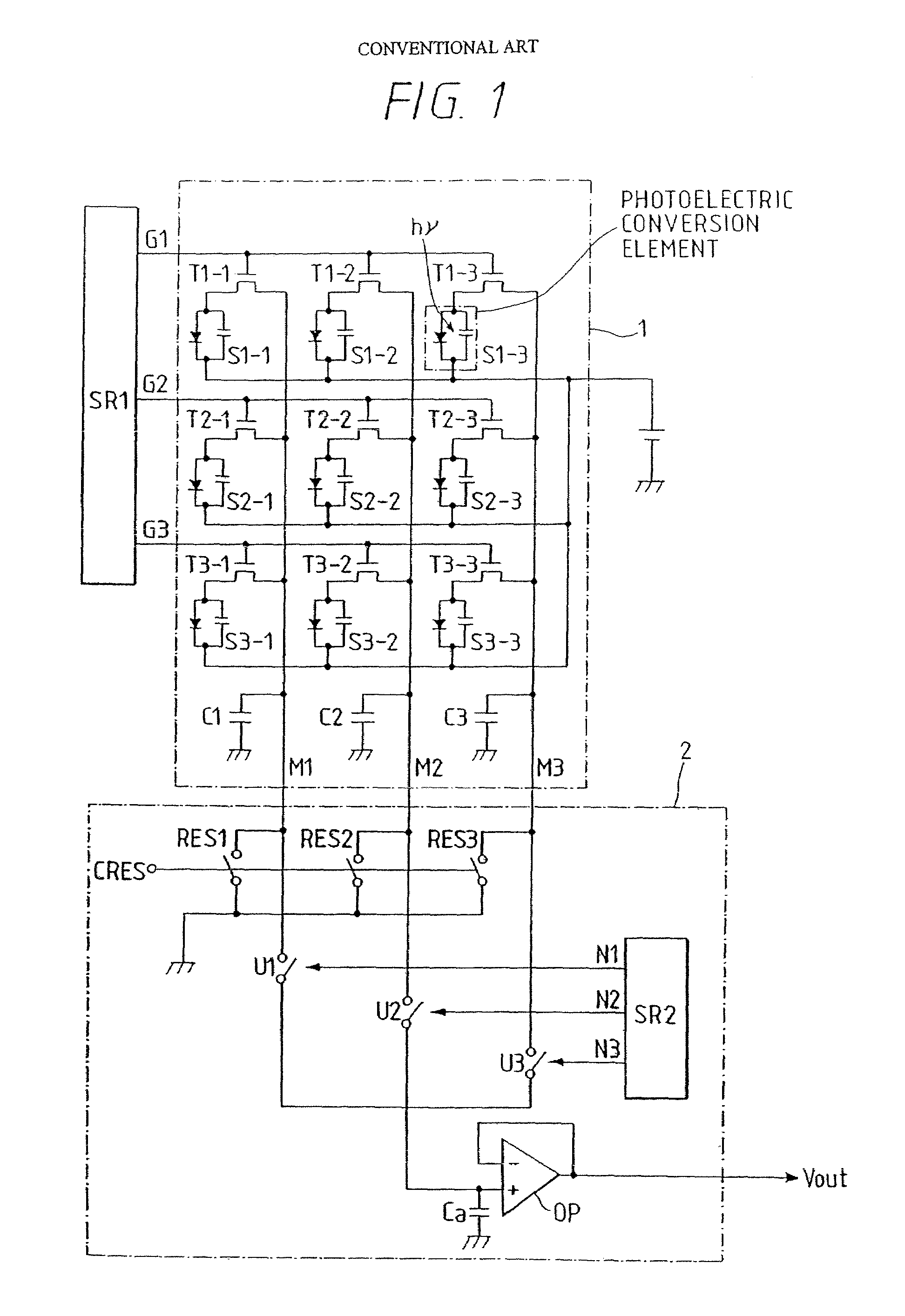

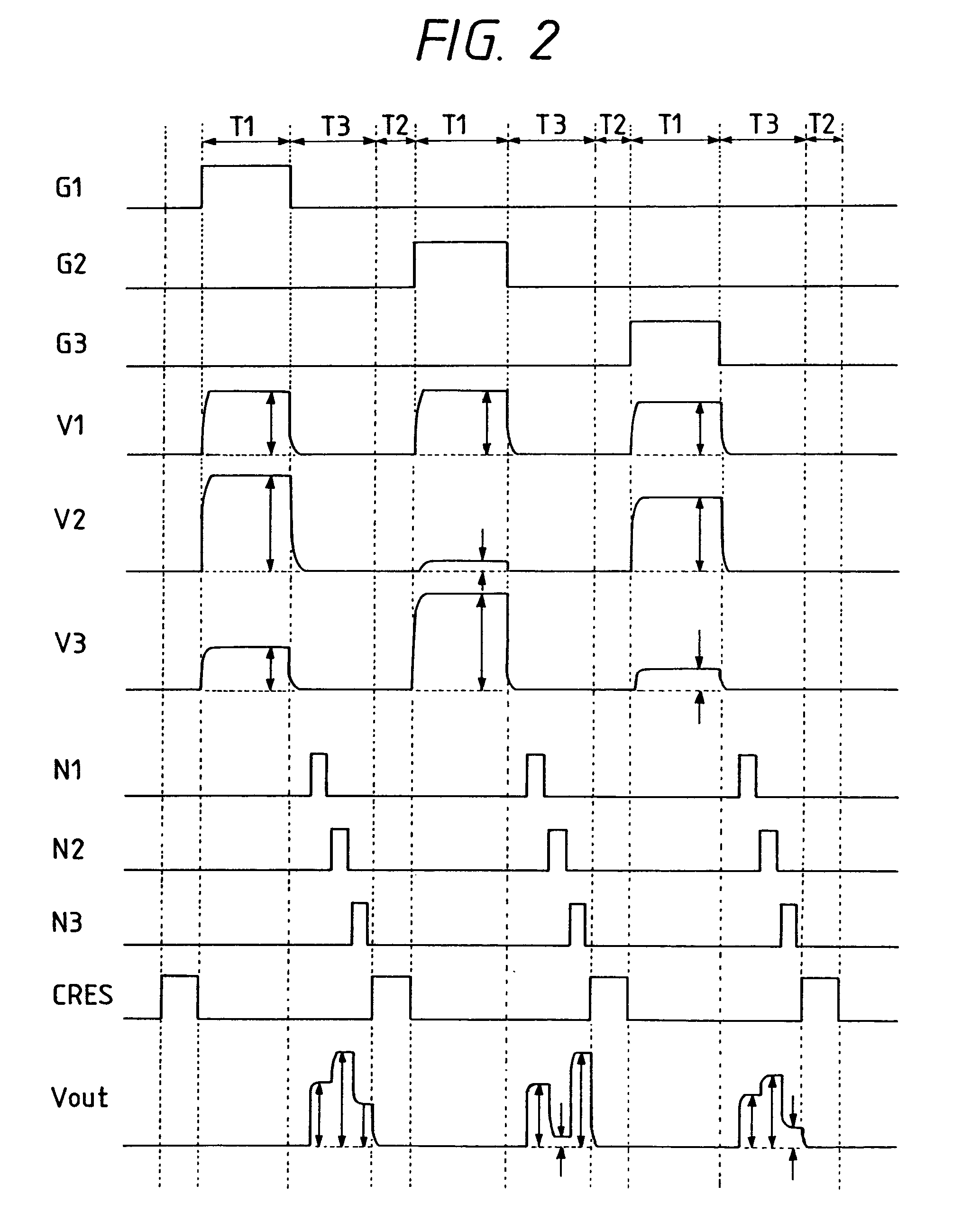

Photoelectric conversion apparatus and photoelectric conversion system having the apparatus

InactiveUS7440017B2Shorten the timeHigh speed readTelevision system detailsTelevision system scanning detailsAudio power amplifierTransfer switch

In order to provide a photoelectric conversion apparatus, which is an apparatus excellent in reading speed, high S / N, high tone level, and low cost, the photoelectric conversion apparatus has a photoelectric conversion circuit section comprising a plurality of photoelectric conversion elements, switching elements, matrix signal wires, and gate drive wires arranged on a same substrate in order to output parallel signals, a driving circuit section for applying a driving signal to the gate drive wire, and a reading circuit section for converting the parallel signals transferred through the matrix signal wires to serial signals to output them, wherein the reading circuit section comprises at least one analog operational amplifier connected with each of the matrix signal wires, transfer switches for transferring output signals from the respective matrix signal wires, output through each amplifier, reading capacitors, and reading switches for successively reading the signals out of the reading capacitors in the form of serial signals.

Owner:CANON KK

Thermosetting die-bonding film

InactiveUS20100055842A1Prevent be damageImprove throughputSynthetic resin layered productsSolid-state devicesChemistryPhenols

The thermosetting die-bonding film of the present invention is used in manufacturing a semiconductor device, has at least an epoxy resin, a phenol resin, and an acrylic copolymer, and the ratio X / Y is 0.7 to 5 when X represents a total weight of the epoxy resin and the phenol resin and Y represents a weight of the acrylic copolymer.

Owner:NITTO DENKO CORP

Polymer/WUCS mat for use in sheet molding compounds

InactiveUS7252729B2Quality improvementIncrease resistanceFibreboardNon-fibrous pulp additionFiberGlass fiber

A method of forming a molding mat formed bundles of reinforcing fibers and bonding materials is provided. The reinforcing fibers are preferably wet use chopped strand glass fibers (WUCS). The bonding materials may be any thermosetting material having a melting point less than the reinforcing fiber. The molding mat may be formed by partially opening the wet use chopped strand glass fibers and filamentizing the bonding materials, blending the reinforcement and bonding fibers, forming the reinforcement and bonding fibers into a sheet, and bonding the sheet. During bonding, the sheet is heated to a temperature above the melting point of the bonding fibers but below the temperature of the glass fibers. The molding mat thus formed may be used as a reinforcement material in sheet molding compounds.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

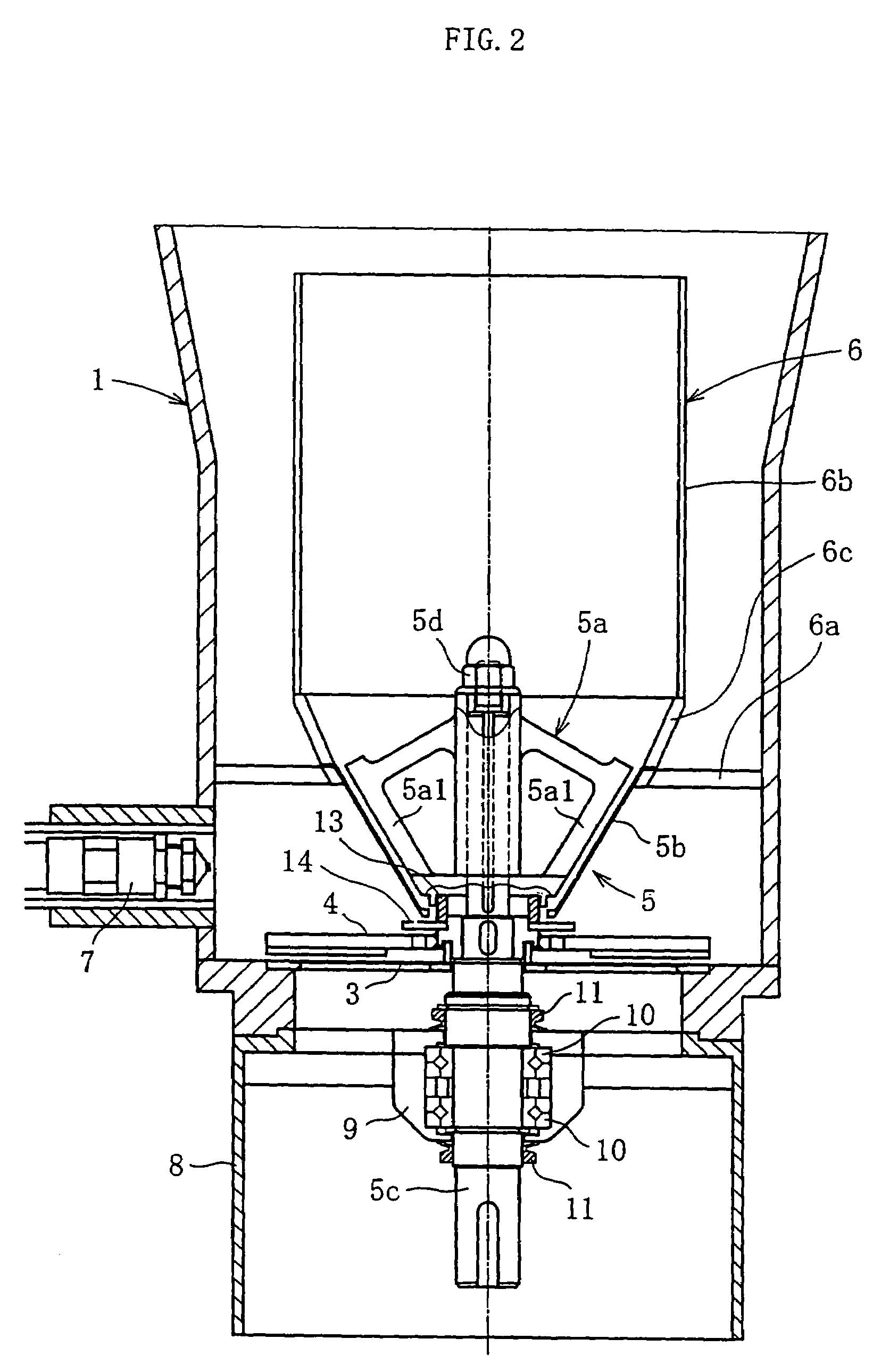

Fluidized bed device

InactiveUS7297314B2High yieldImprove efficiencyGranule coatingDrying solid materials with heatFluidized bedEngineering

Owner:POWREX

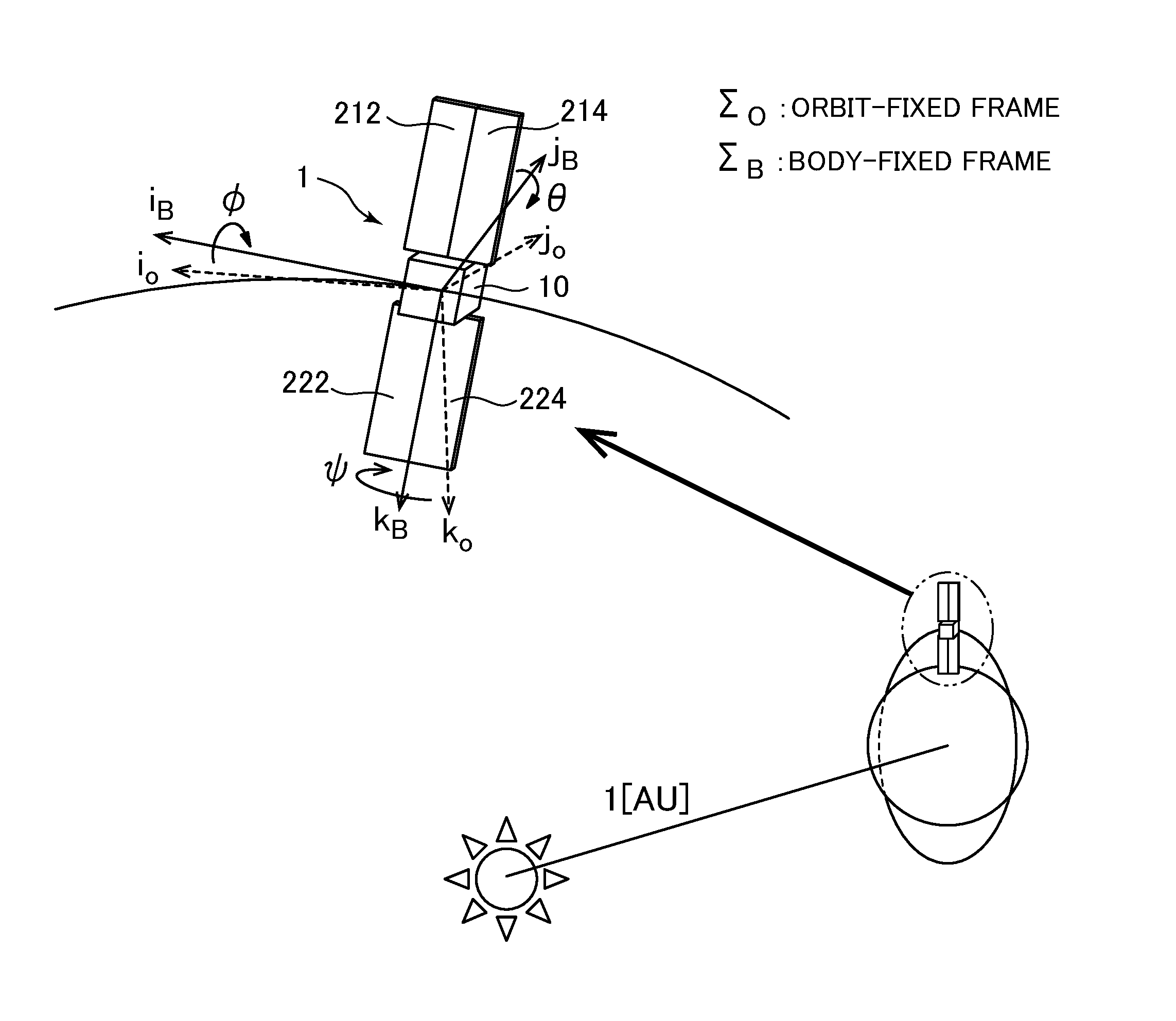

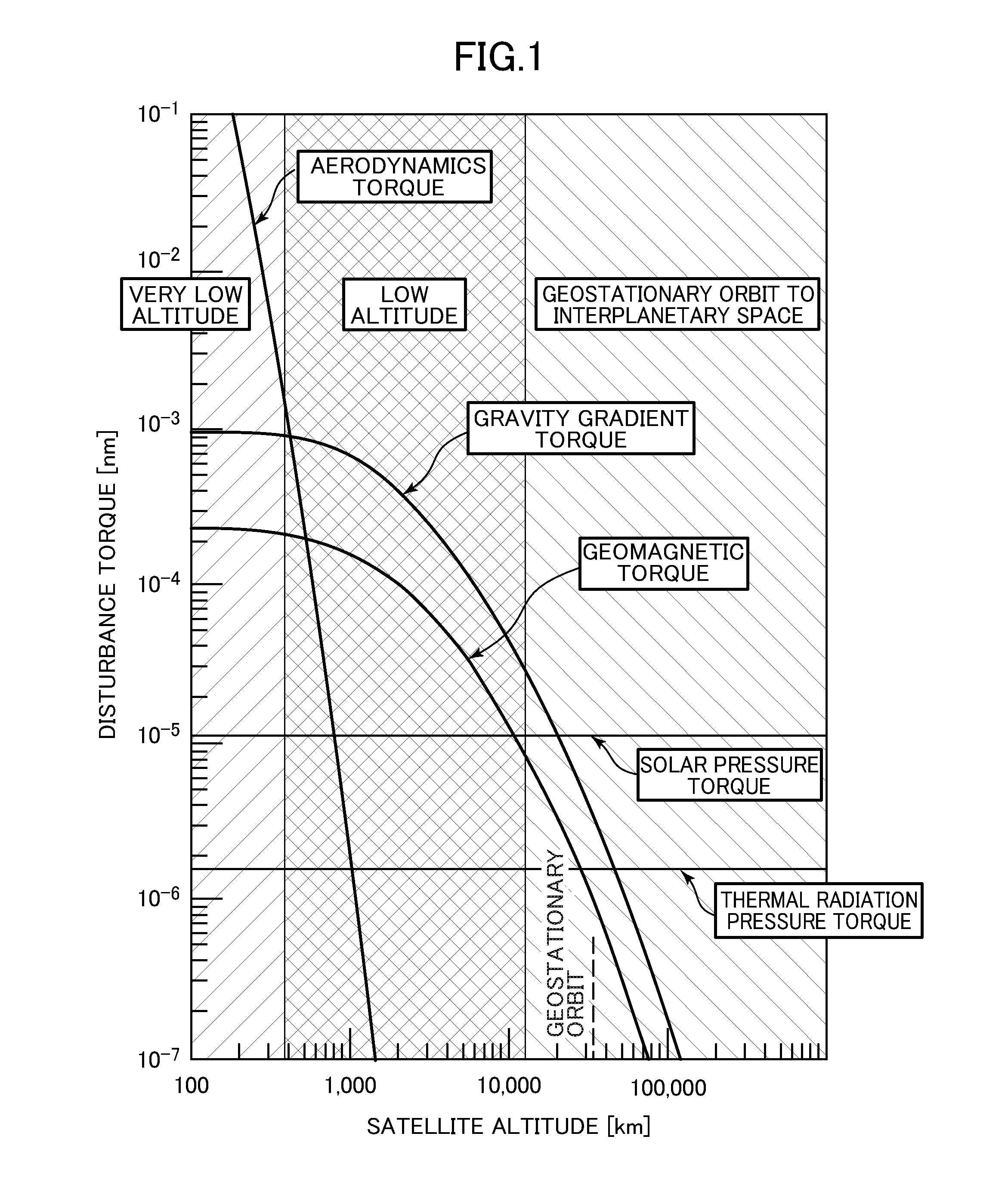

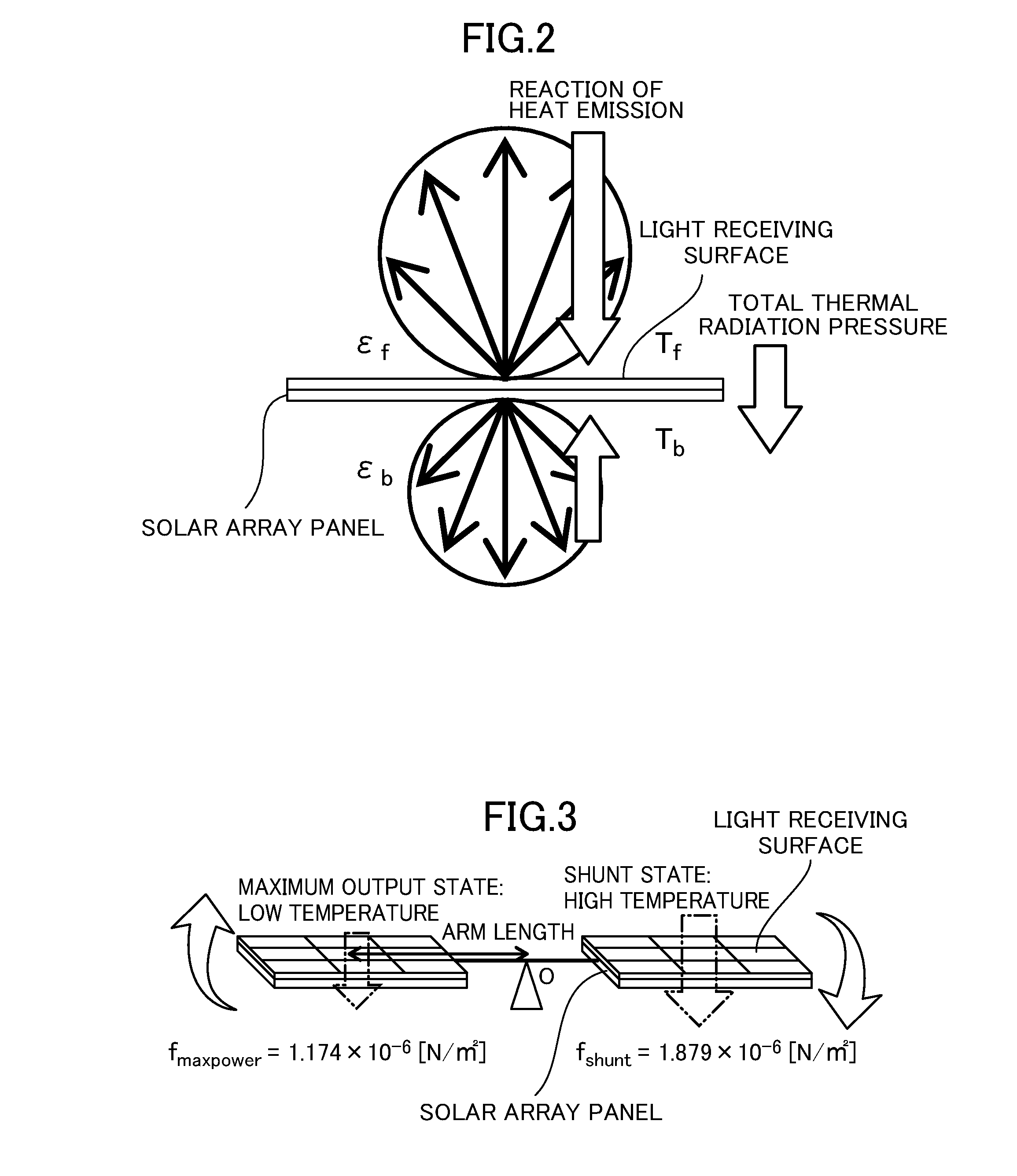

Torque generation system, attitude control system for spacecraft, and relative position and velocity control system for spacecraft

InactiveUS20160376032A1Reduce the differenceLittle generationCosmonautic power supply systemsPhotovoltaicsSpacecraft attitude controlSpeed control system

A torque generation system includes: a plurality of solar array panels and / or solar array panel divisions; and a torque controller configured to control an electricity generation ratio of each of the plurality of solar array panels and / or solar array panel divisions to generate torque.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com