Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Large tightening torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

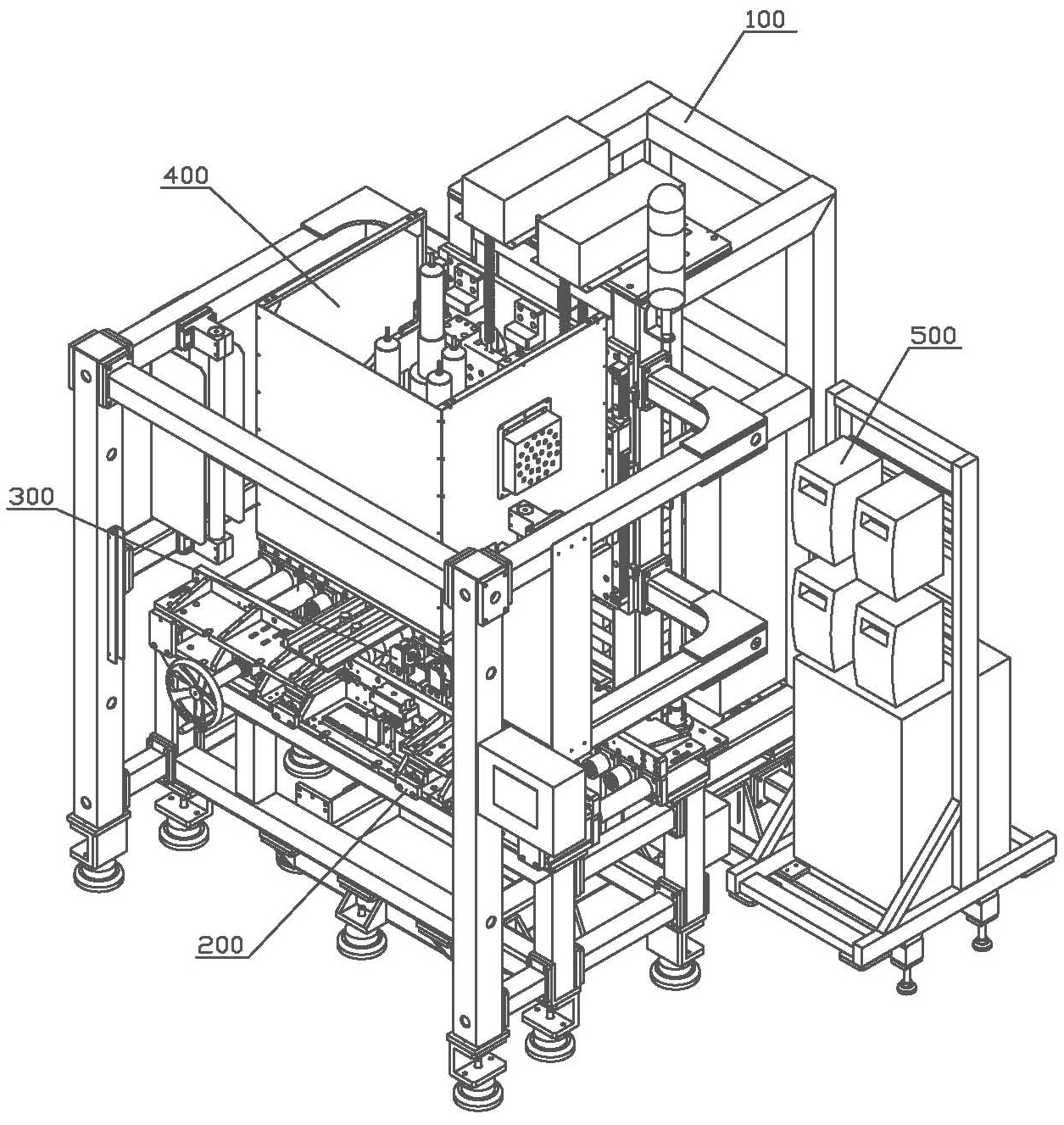

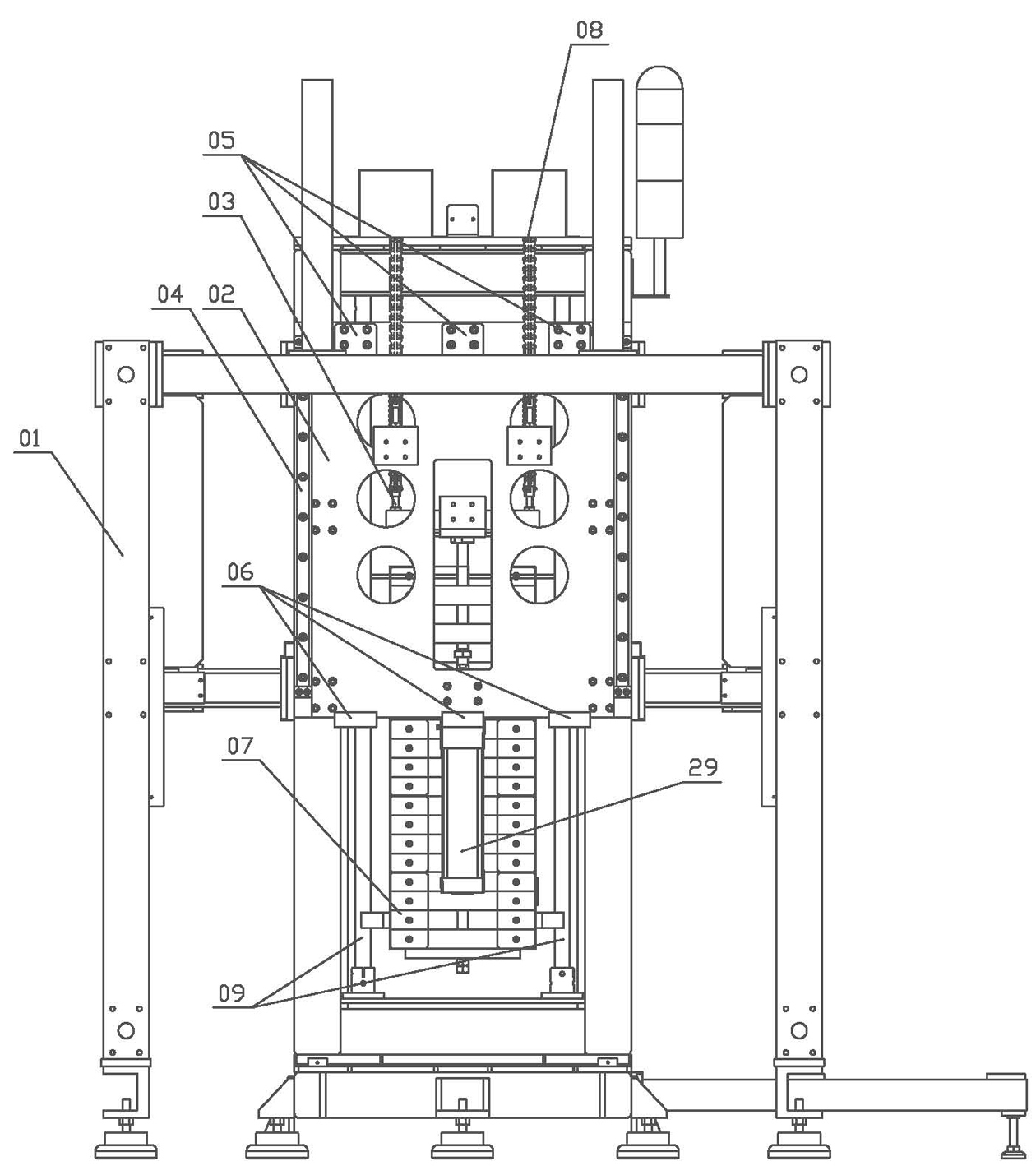

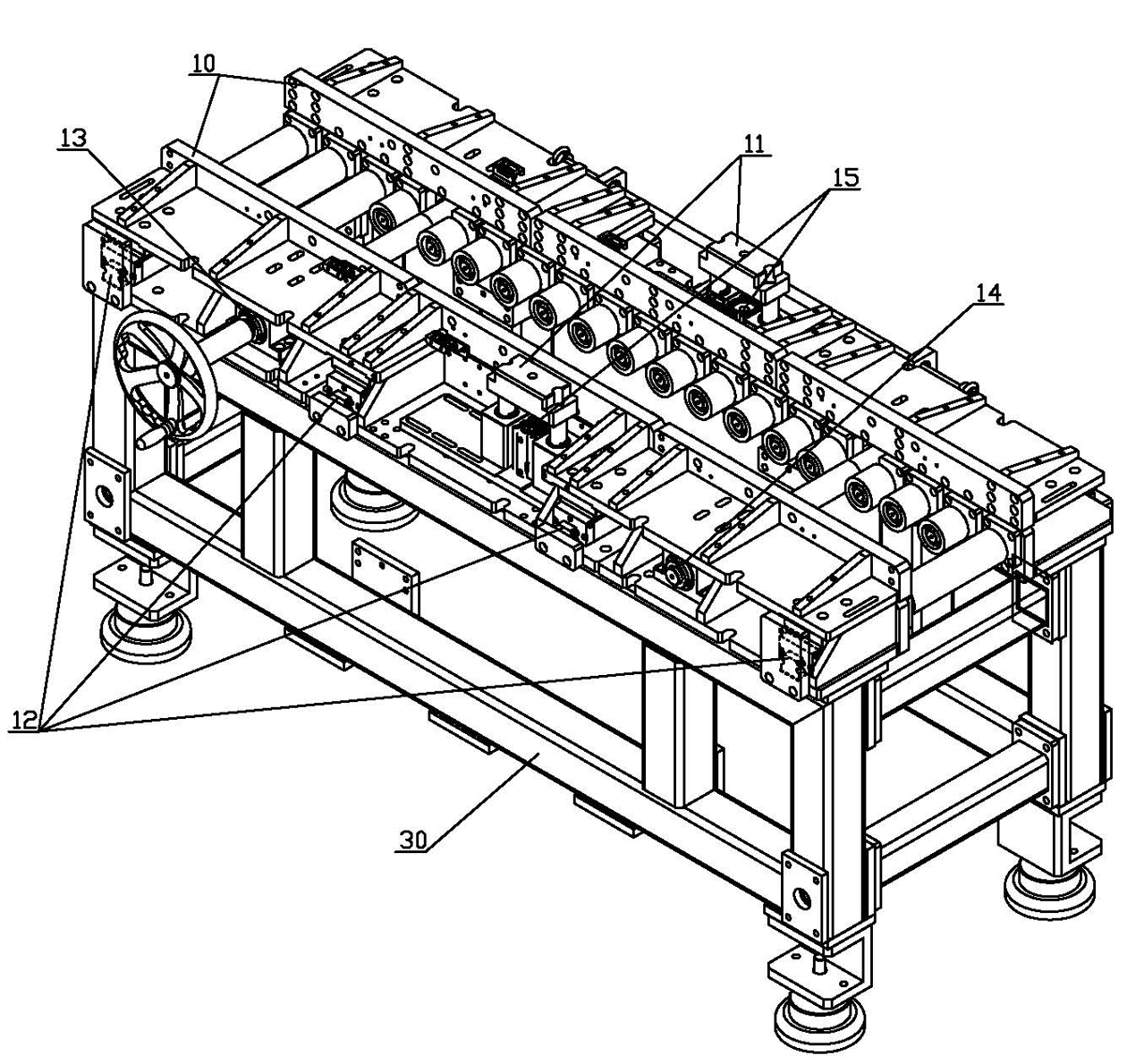

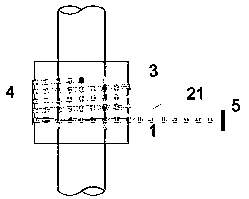

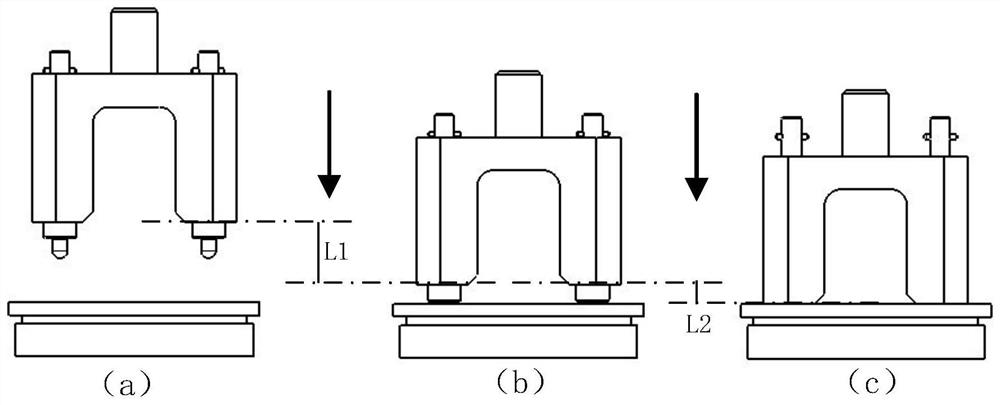

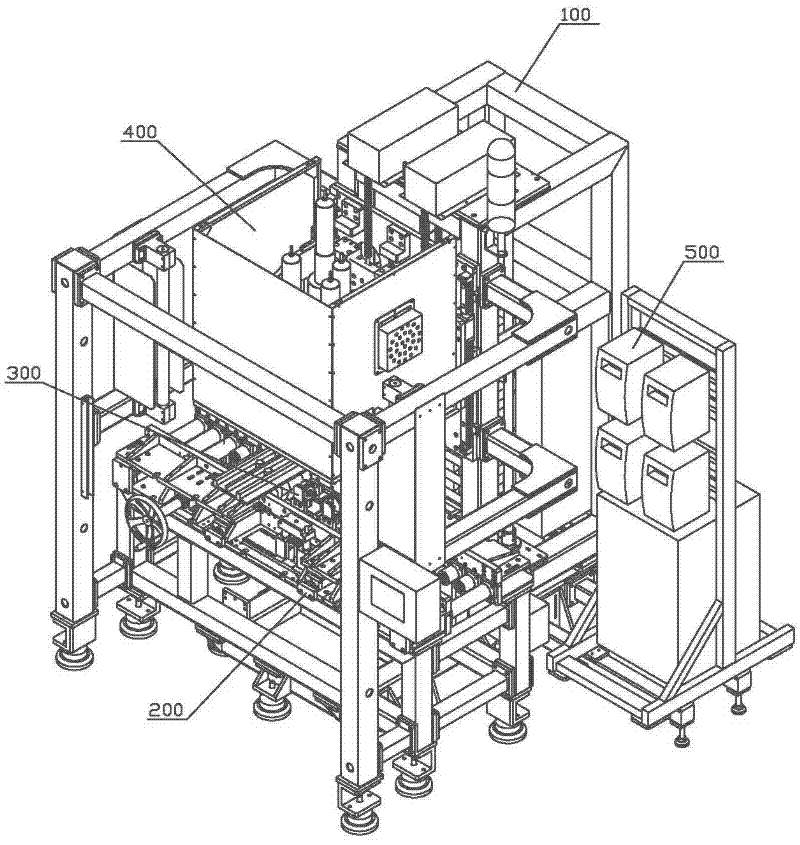

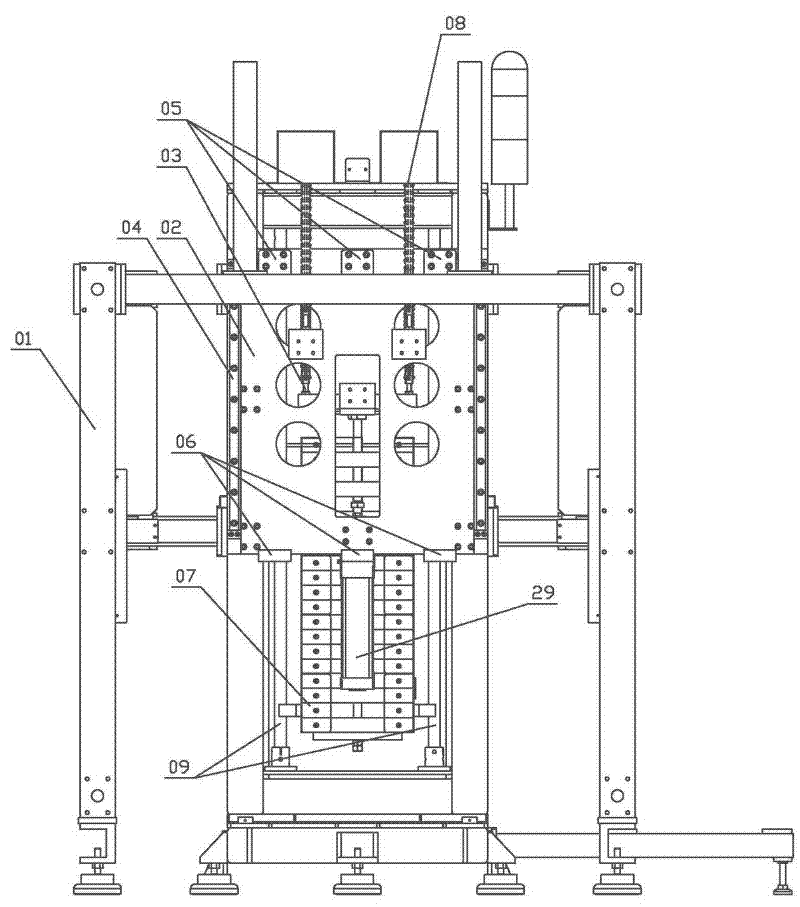

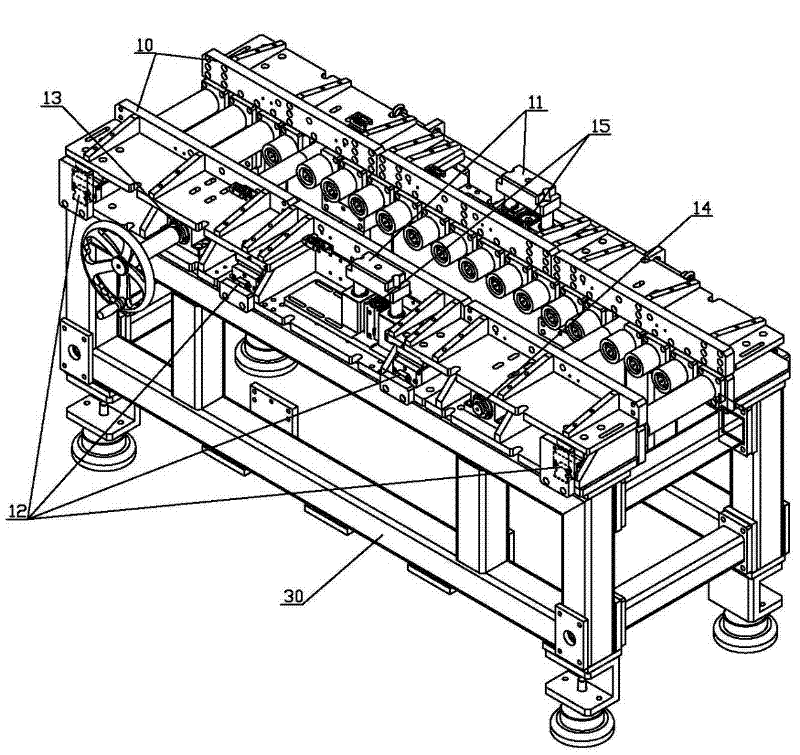

Caterpillar track four-axis automatic screwing machine

ActiveCN101941149AGuaranteed tightening qualityLarge tightening torqueMetal working apparatusElectrical controlEngineering

The invention discloses a caterpillar track four-axis automatic screwing machine, comprising a frame part, a linear body part, a stepping mechanism, a screwing mechanism and an electrical control part, wherein the linear body part is mounted in a lower space inside a frame body of the frame part, the stepping mechanism is mounted on an underframe of the linear body part, the screwing mechanism is mounted a screwing head ascending / descending structure of the frame part; the linear body part, the stepping mechanism, the screwing mechanism and the frame part are subjected to corresponding electrical control to automatically complete conveyance, guidance, positioning, clamping and screwing of a whole caterpillar track. The caterpillar track four-axis automatic screwing machine can be suitable for the automatic screwing of the caterpillar tracks in six specifications or more and can accurately screw four bolts simultaneously with large screwing torque, thereby ensuring the screwing quality of the connection between caterpillar track and bolts, realizing automatic operation and bringing high production efficiency.

Owner:SHANGHAI INGERSOLL RAND COMPRESSOR CO LTD

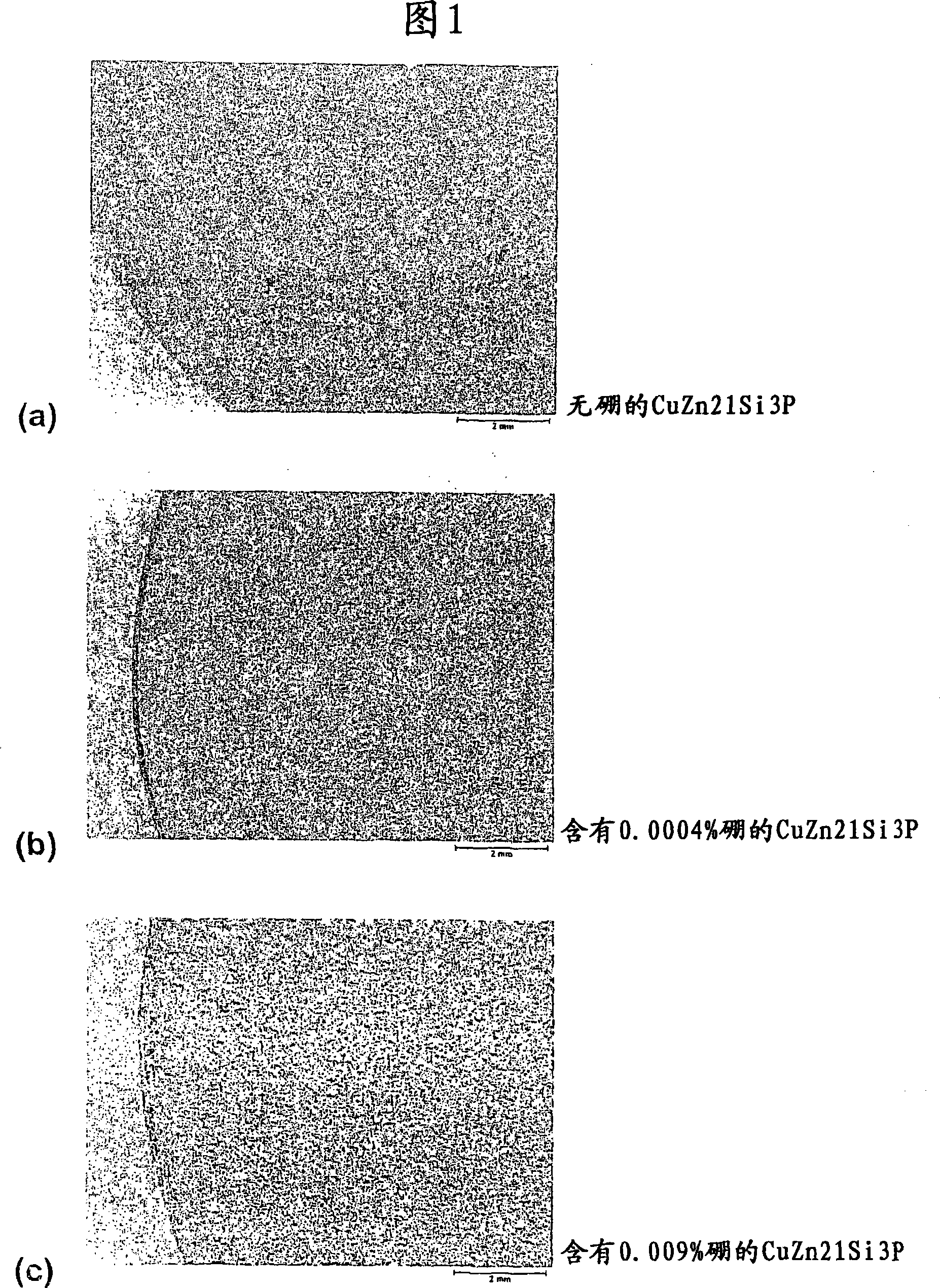

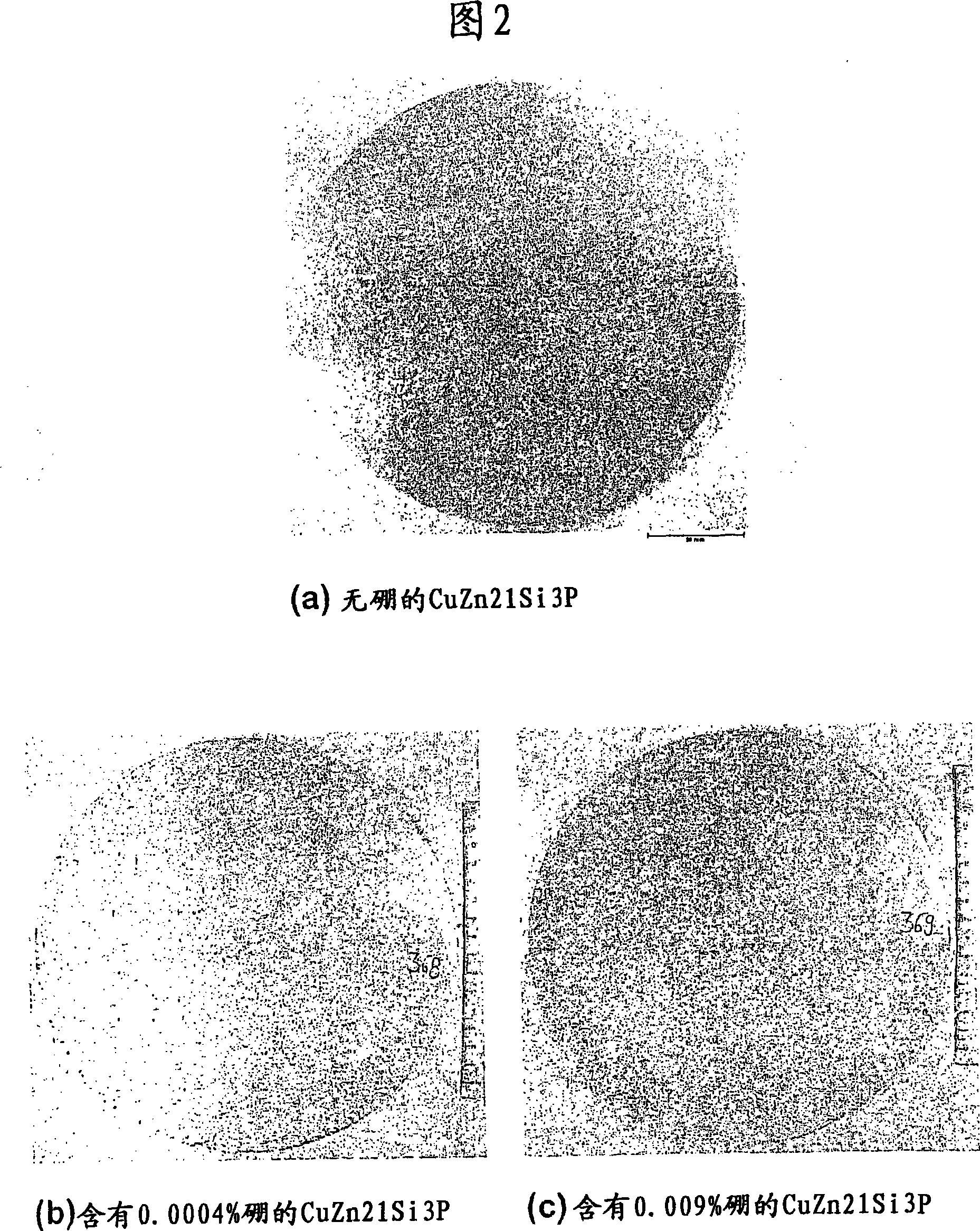

Copper/zinc/silicon alloy, use and production thereof

A Cu-Zn-Si alloy includes, in % by weight, 70 to 80% of copper, 1 to 5% of silicon, 0.0001 to 0.5% of boron, up to 0.2% of phosphorus and / or up to 0.2% of arsenic, a remainder of zinc, plus inevitable impurities. Products using the alloy and processes for producing the alloy are also provided. The alloy is distinguished by an improved resistance to oxidation and by uniform mechanical properties.

Owner:DIEHL METAL STIFTUNG & CO KG

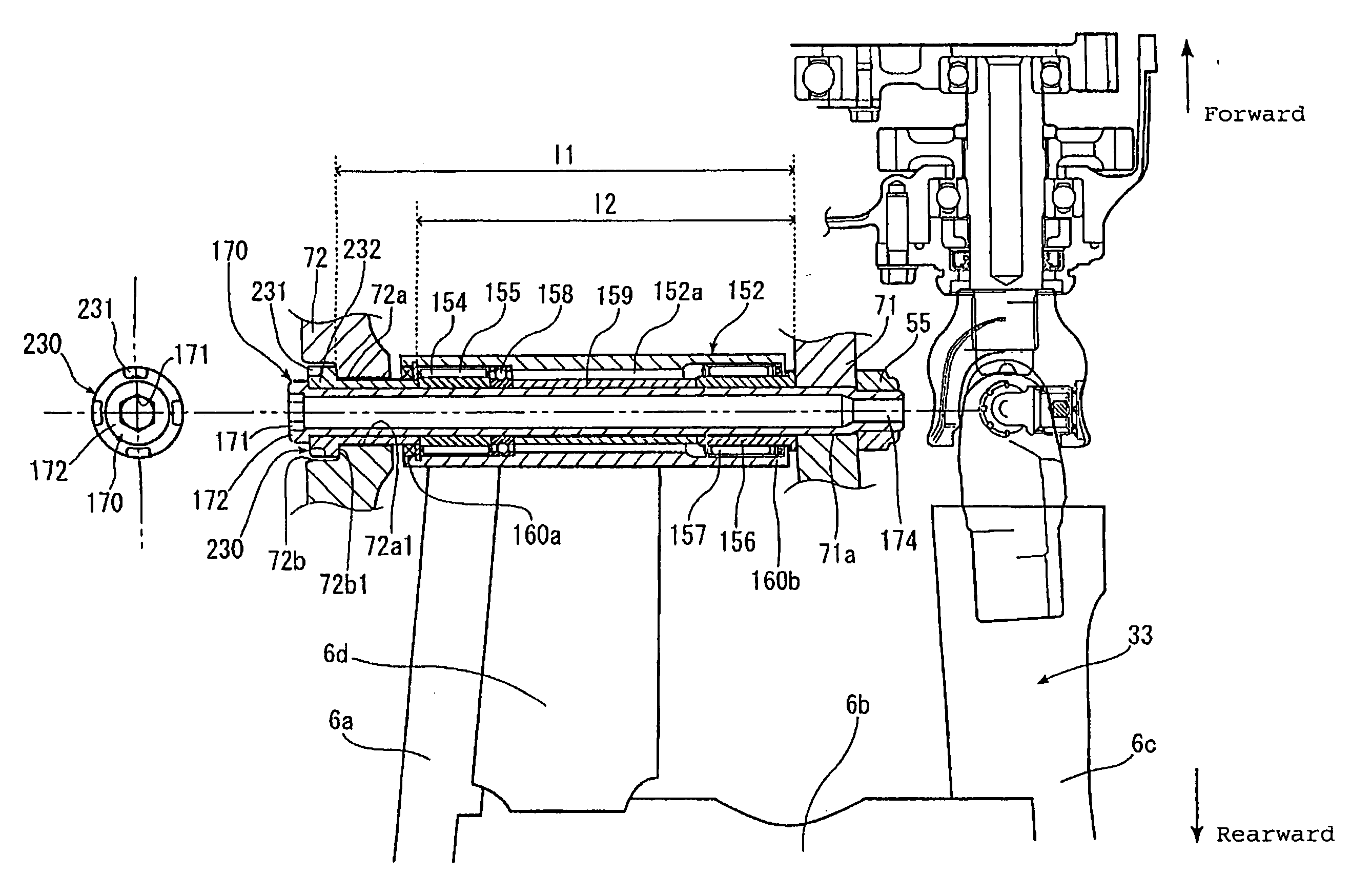

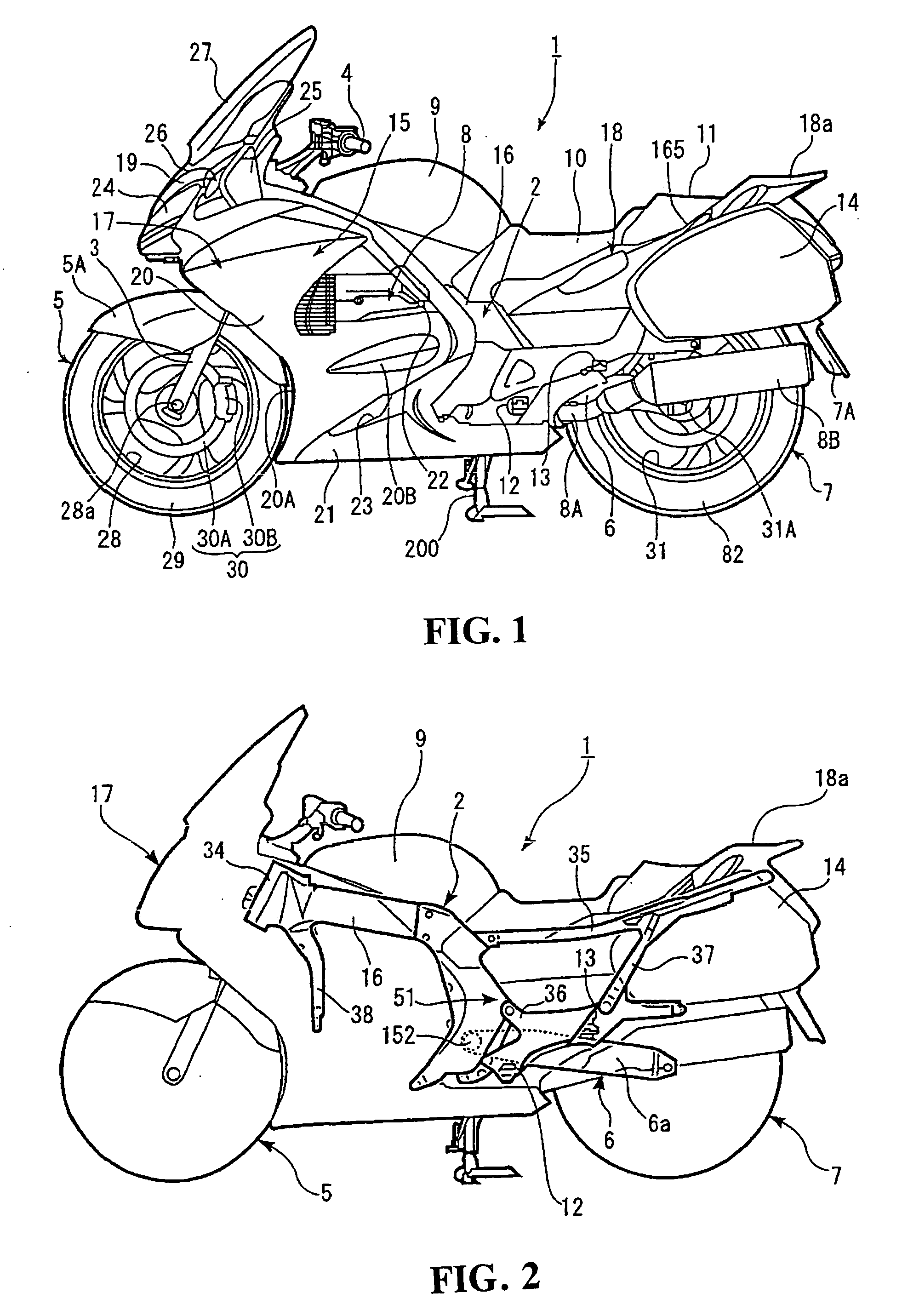

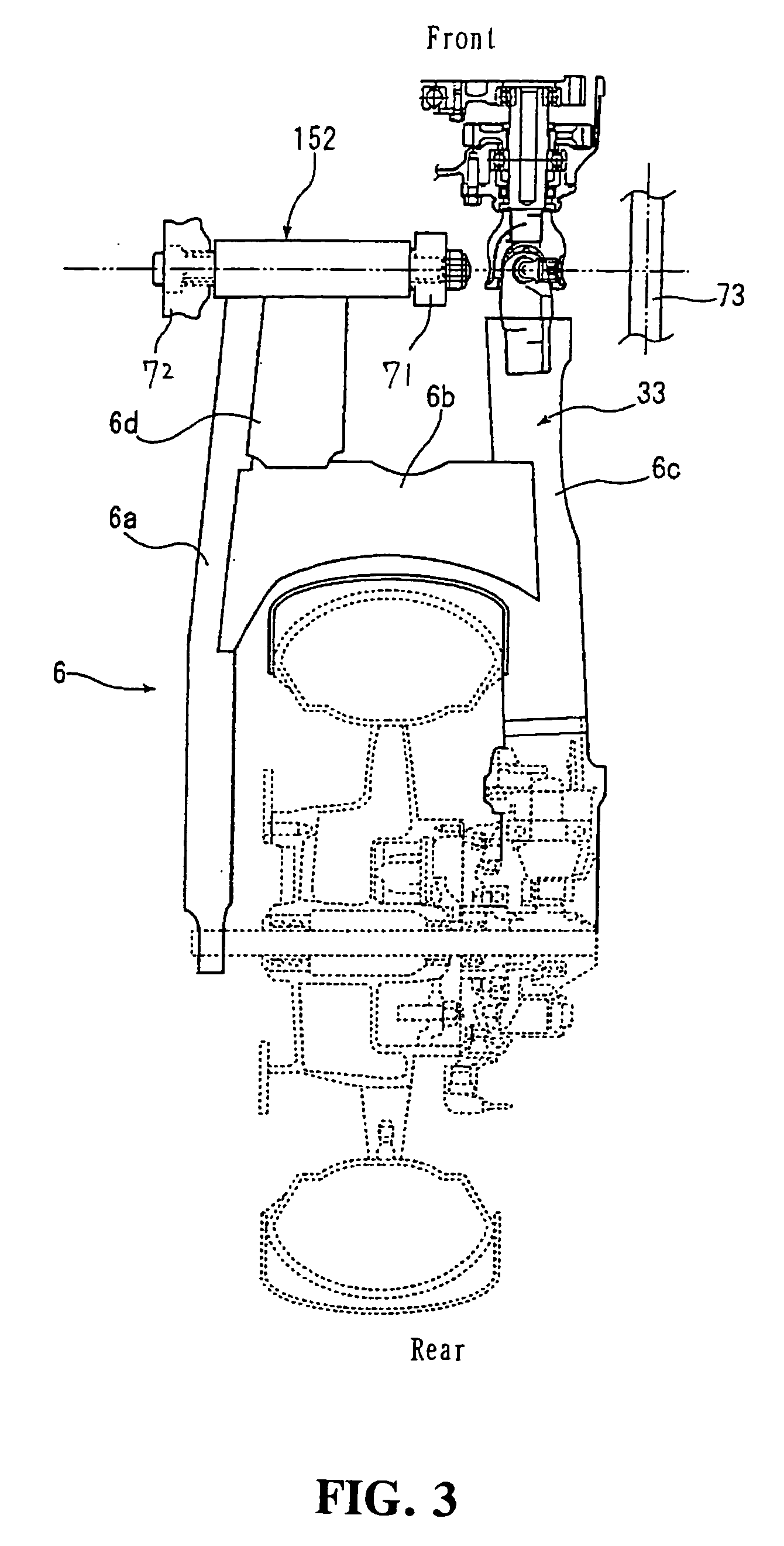

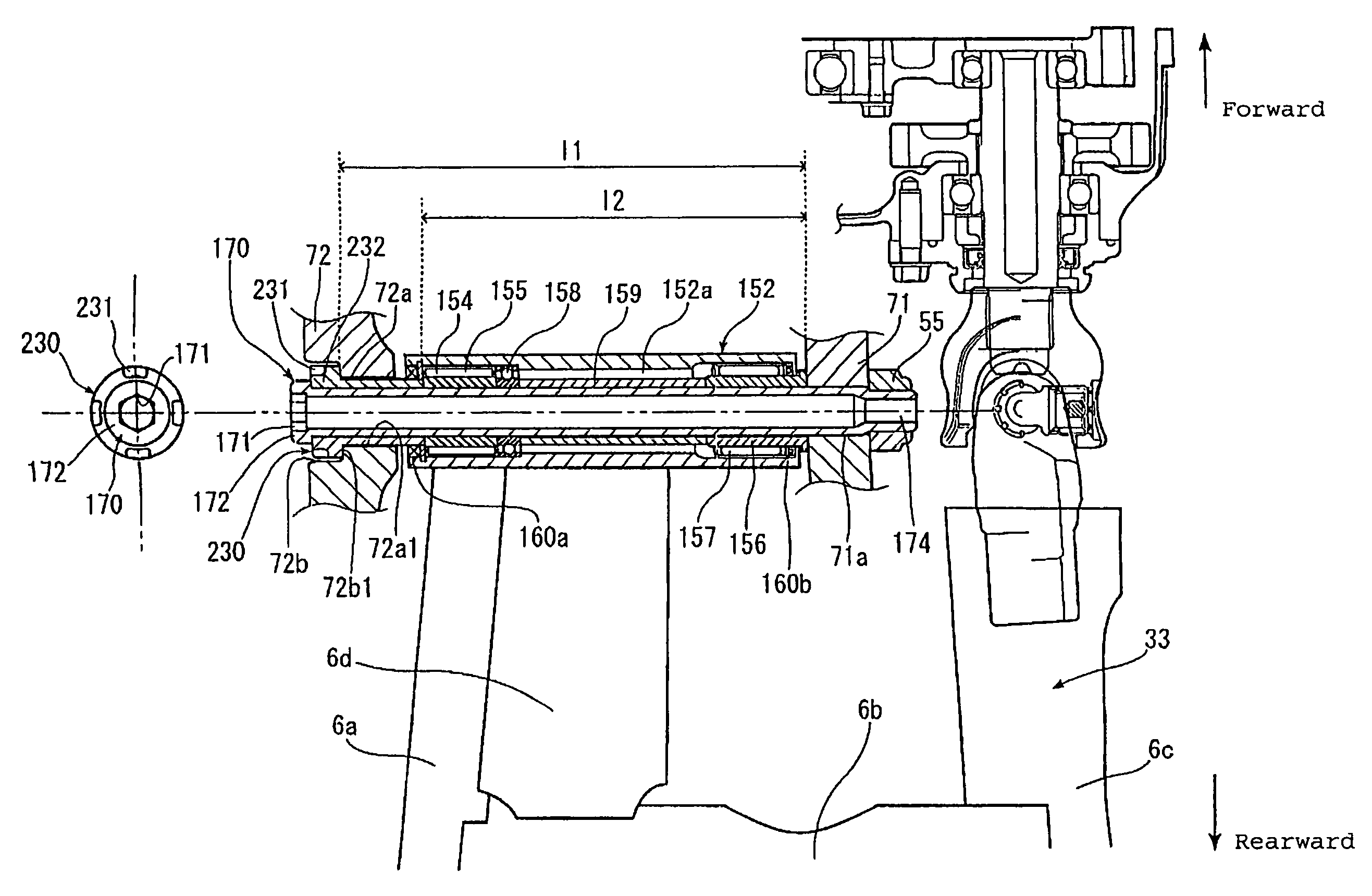

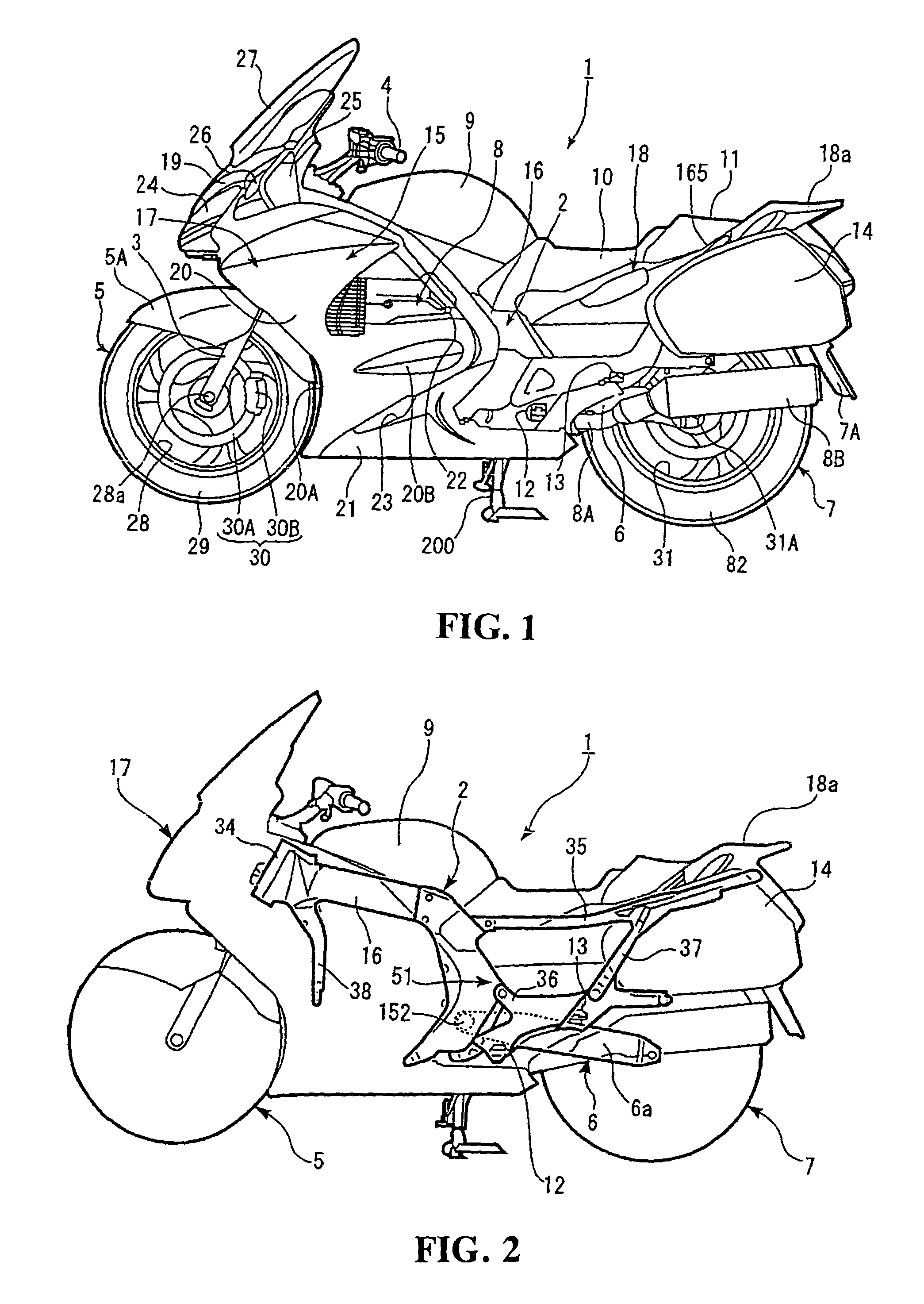

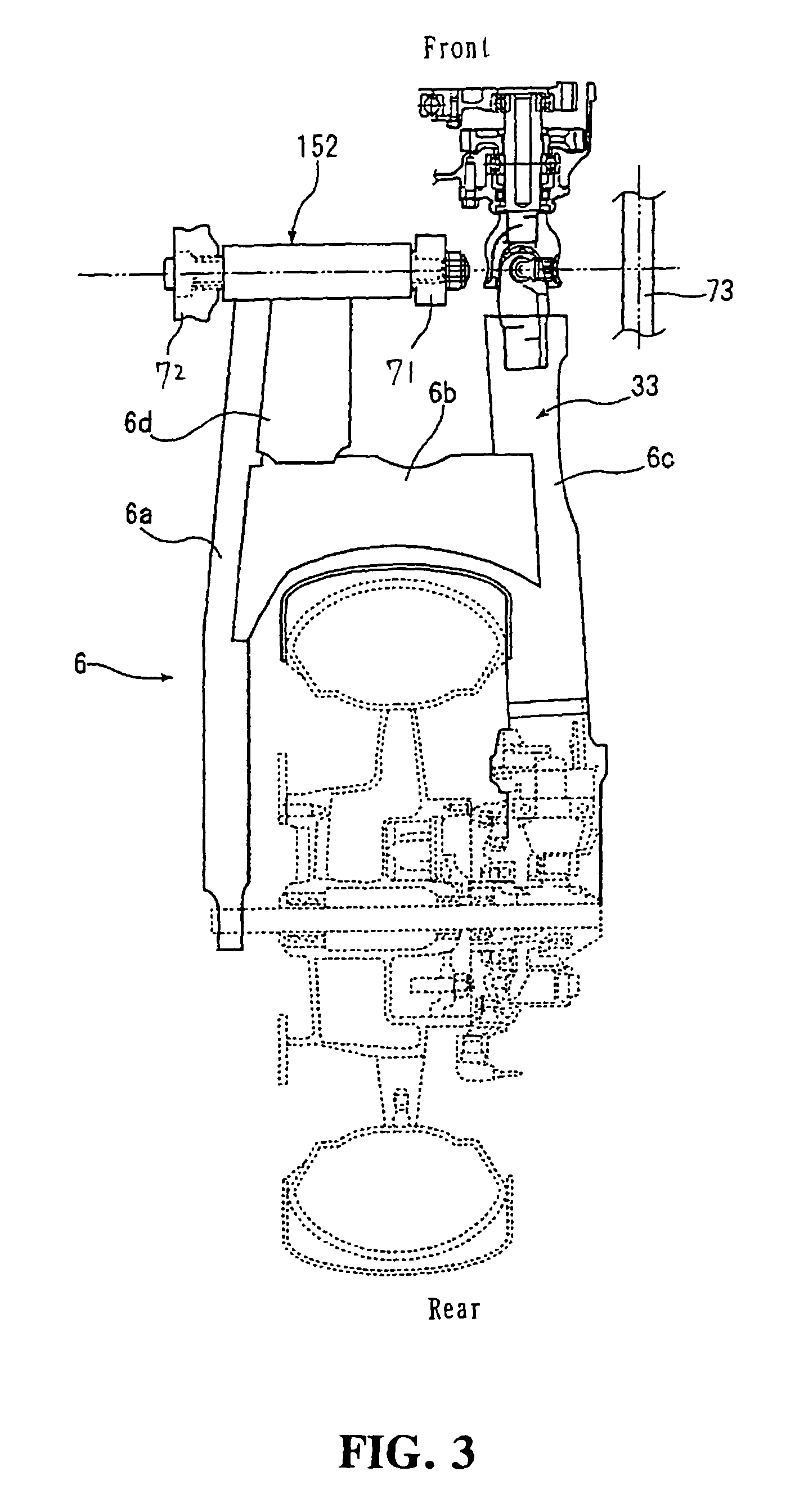

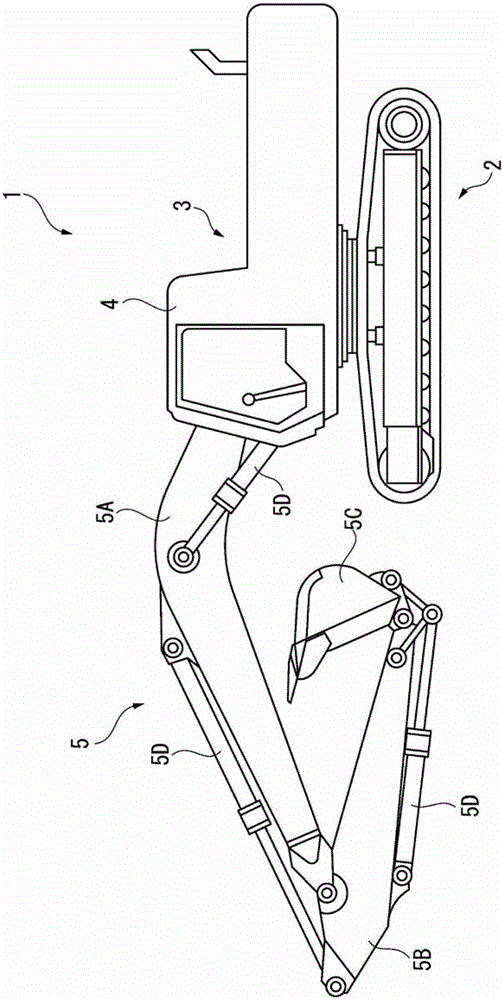

Rear swing arm installation structure

InactiveUS20060278458A1Easy to adjustIncrease the number ofRotary transmissionsCrankshaft transmissionEngineeringScrew thread

To provide a rear swing arm installation structure that does not require large tightening force and upsizing and can avoid backlash of a rear swing arm. In a rear swing arm installation structure, a cylindrical spacer into which a pivot shaft is inserted is screwed into the pivot bearing holes of a pair of vehicle body frames. The spacer includes a head section of a large diameter and a screw section having a smaller diameter than the head section. The head section touches an end face of the pivot bearing hole of the vehicle body frame and the tip of the screw section touches an end face of a rear swing arm.

Owner:HONDA MOTOR CO LTD

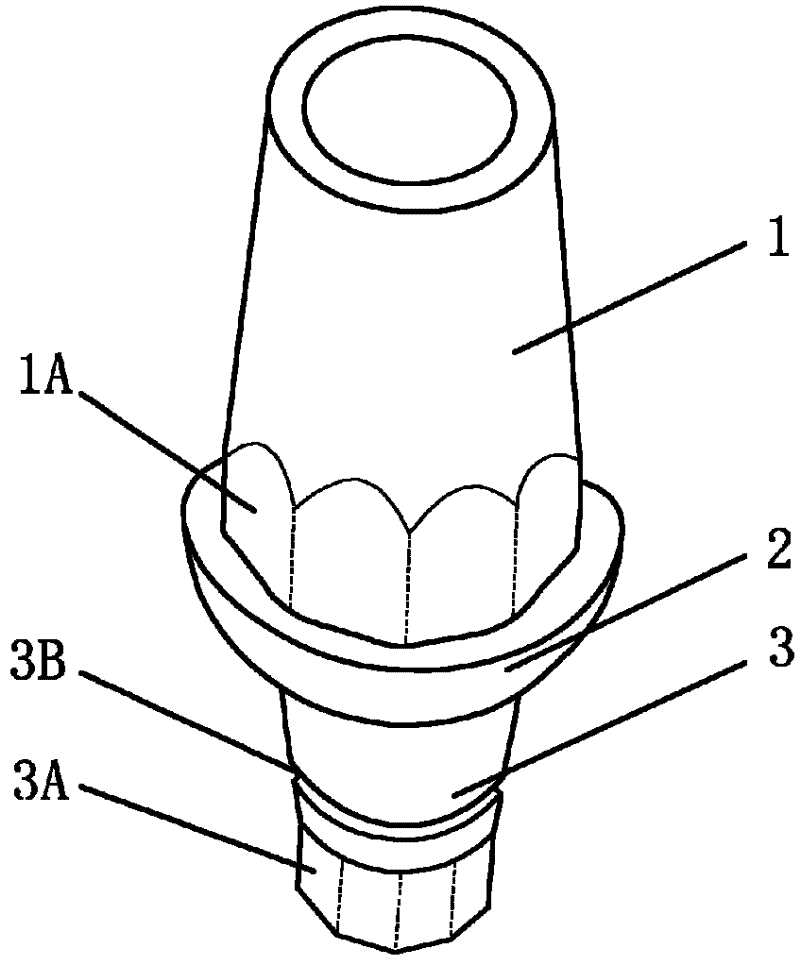

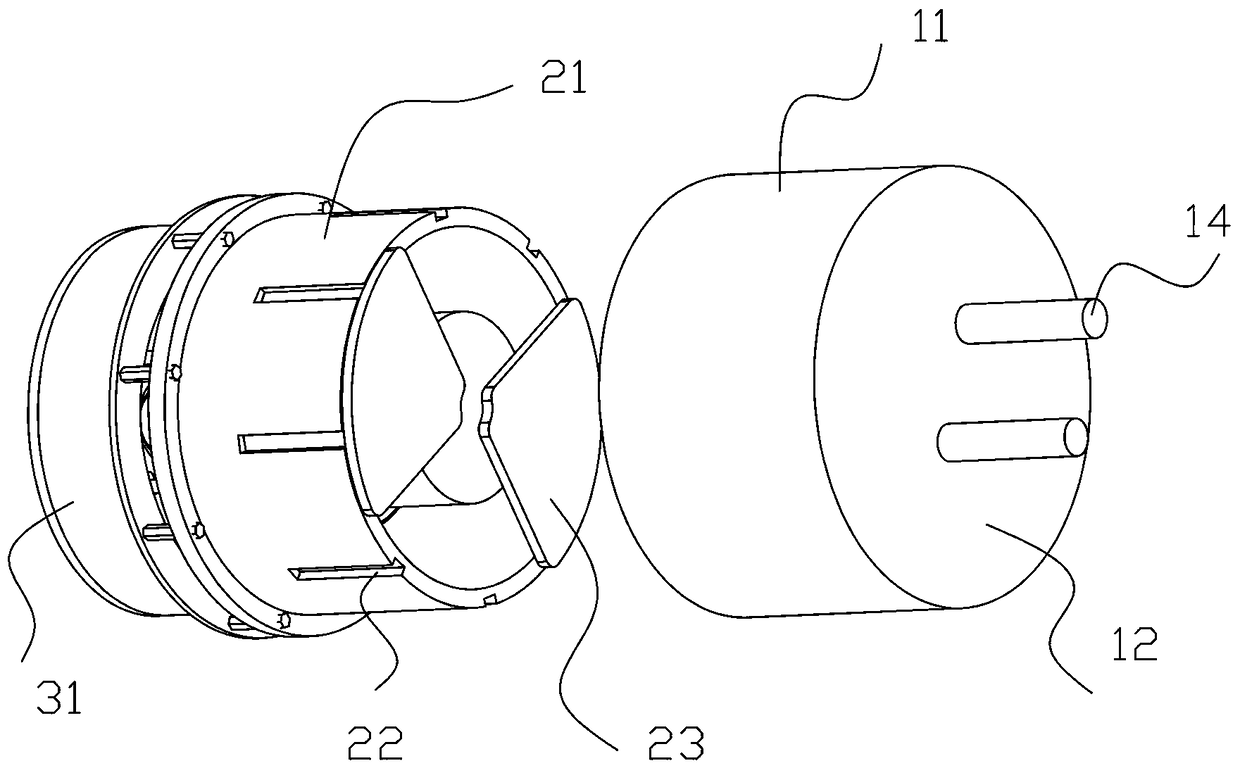

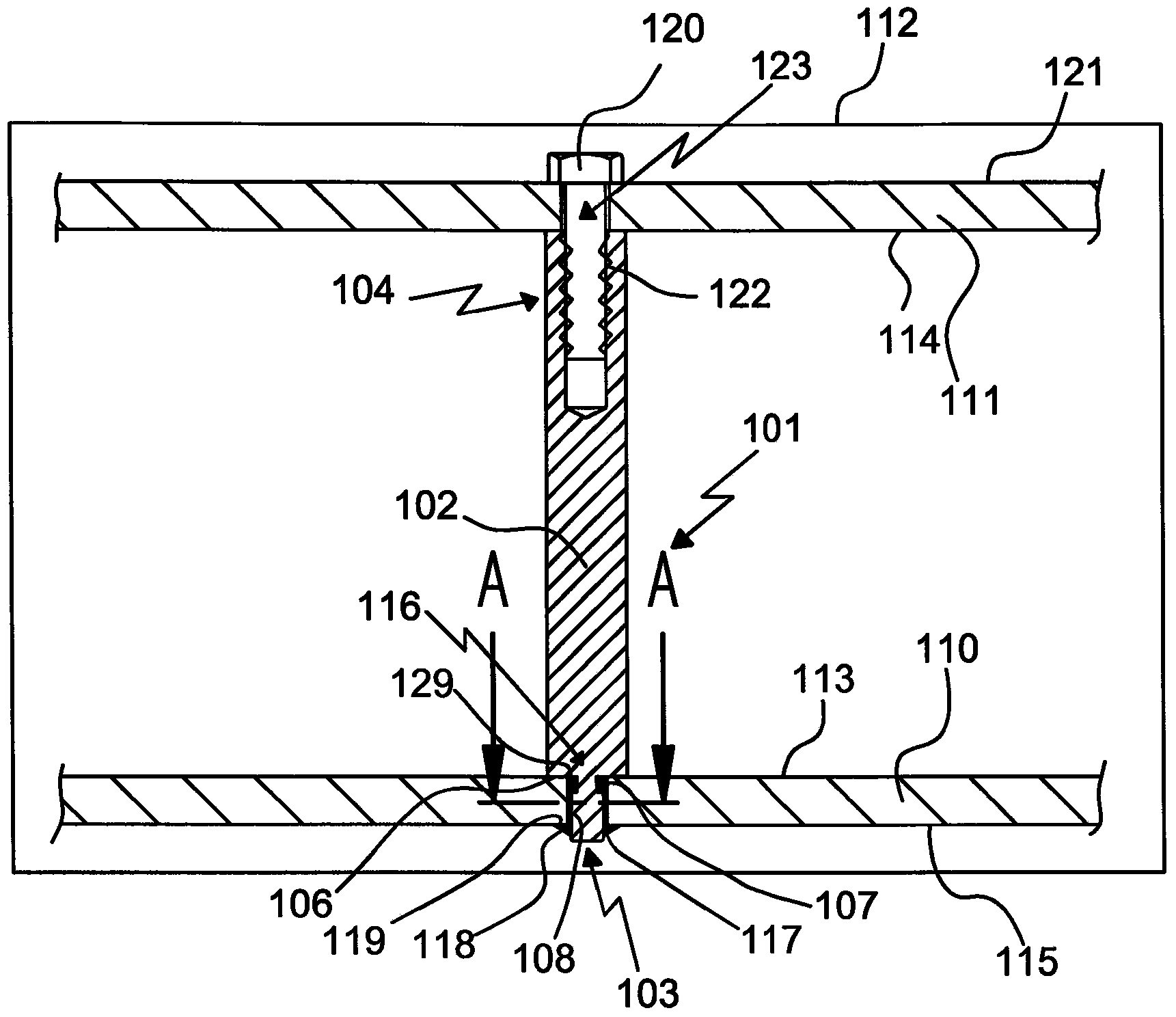

Hollow abutment capable of connecting with interior of dental implant

The invention discloses a hollow abutment capable of connecting with the interior of a dental implant. The hollow abutment is characterized in that an upper part of a repair part section (1) of the hollow abutment is a circular truncated cone of which sectional areas are increased from top to bottom; a lower part of the repair part section (1) is a regular eight-edge prism (1A) of which corners are cambered; the middle transition section (2) is a projecting circular truncated cone of which a side surface is cambered and sectional areas are decreased from top to bottom and is coated with a silver carrying TiO2 antibacterial coating; an upper part of an implant insertion section (3) is a circular truncated cone of which sectional areas are decreased from top to bottom and inclination is in a range of 10 to 12 degrees and an annular groove (3B) is arranged in the surface of the circular truncated cone of the implant insertion section (3); a silicone rubber gasket (3C) is embed into the annular groove (3B); and a lower part of the implant insertion section (3) is regular eight-edge prism (3A) of which corners are cambered. The hollow abutment has the advantages of good fretting damageresistance, good closure, strong corrosion resistance, good antibacterial property, good gum forming function and long service life.

Owner:SICHUAN UNIV

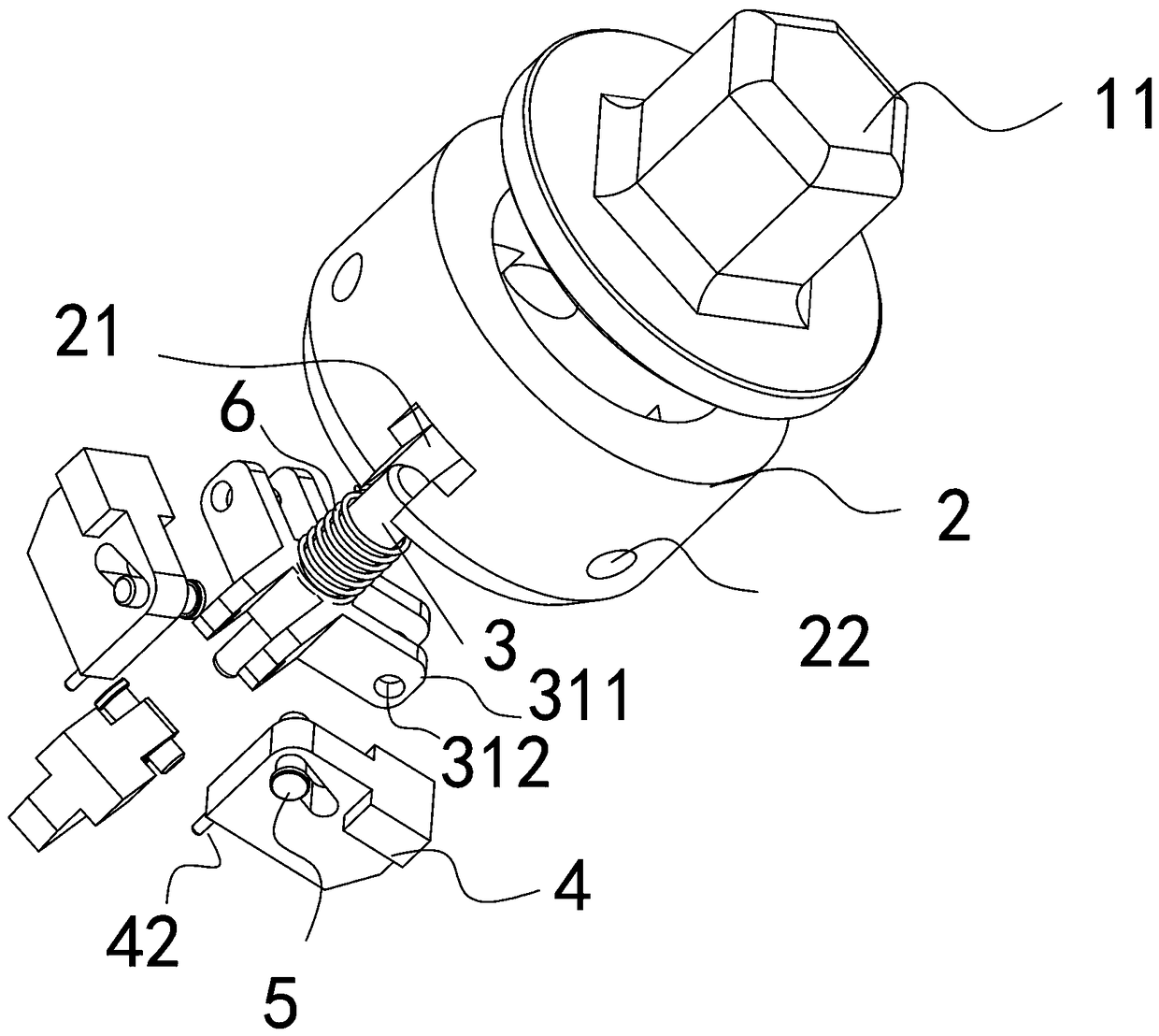

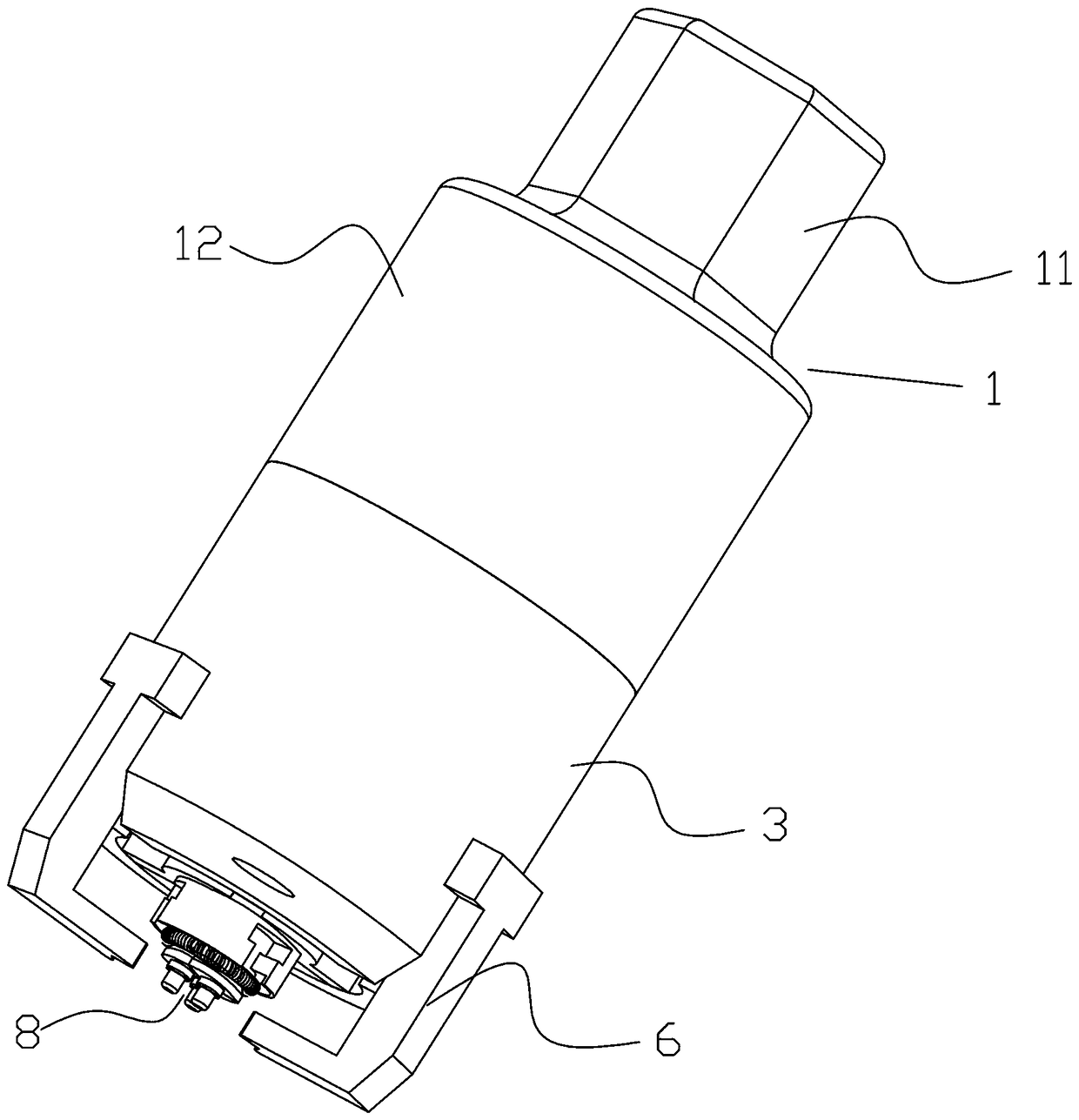

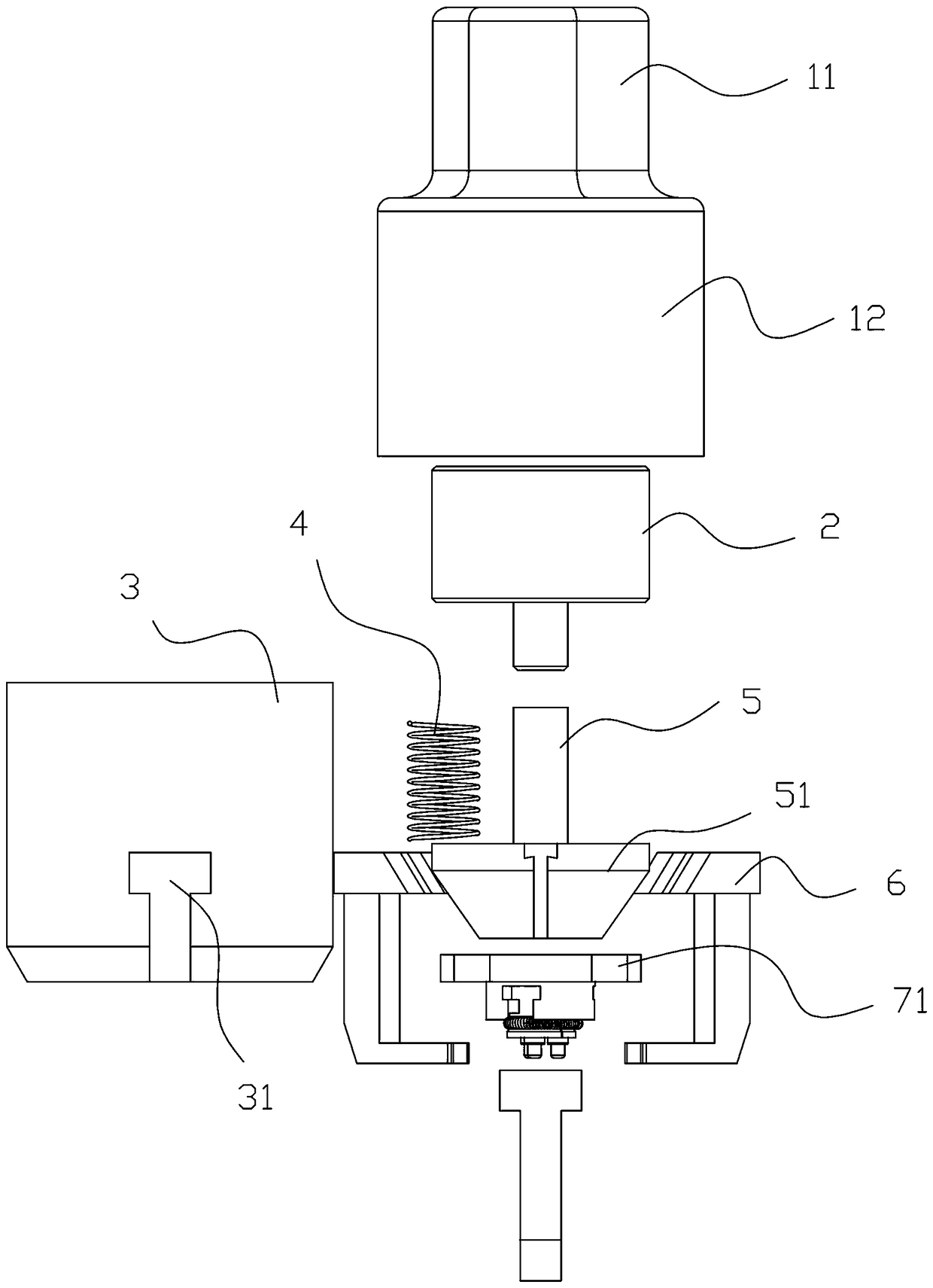

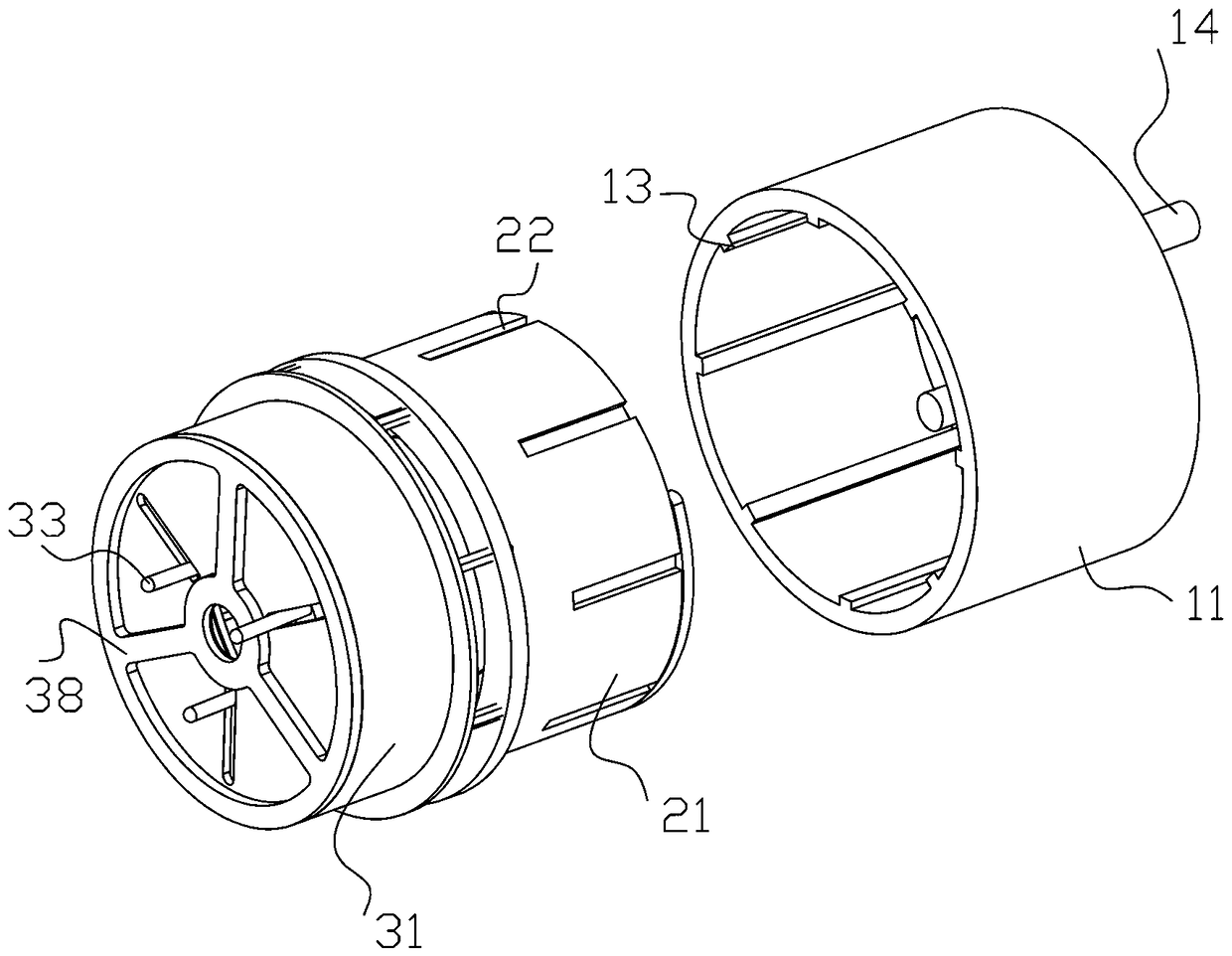

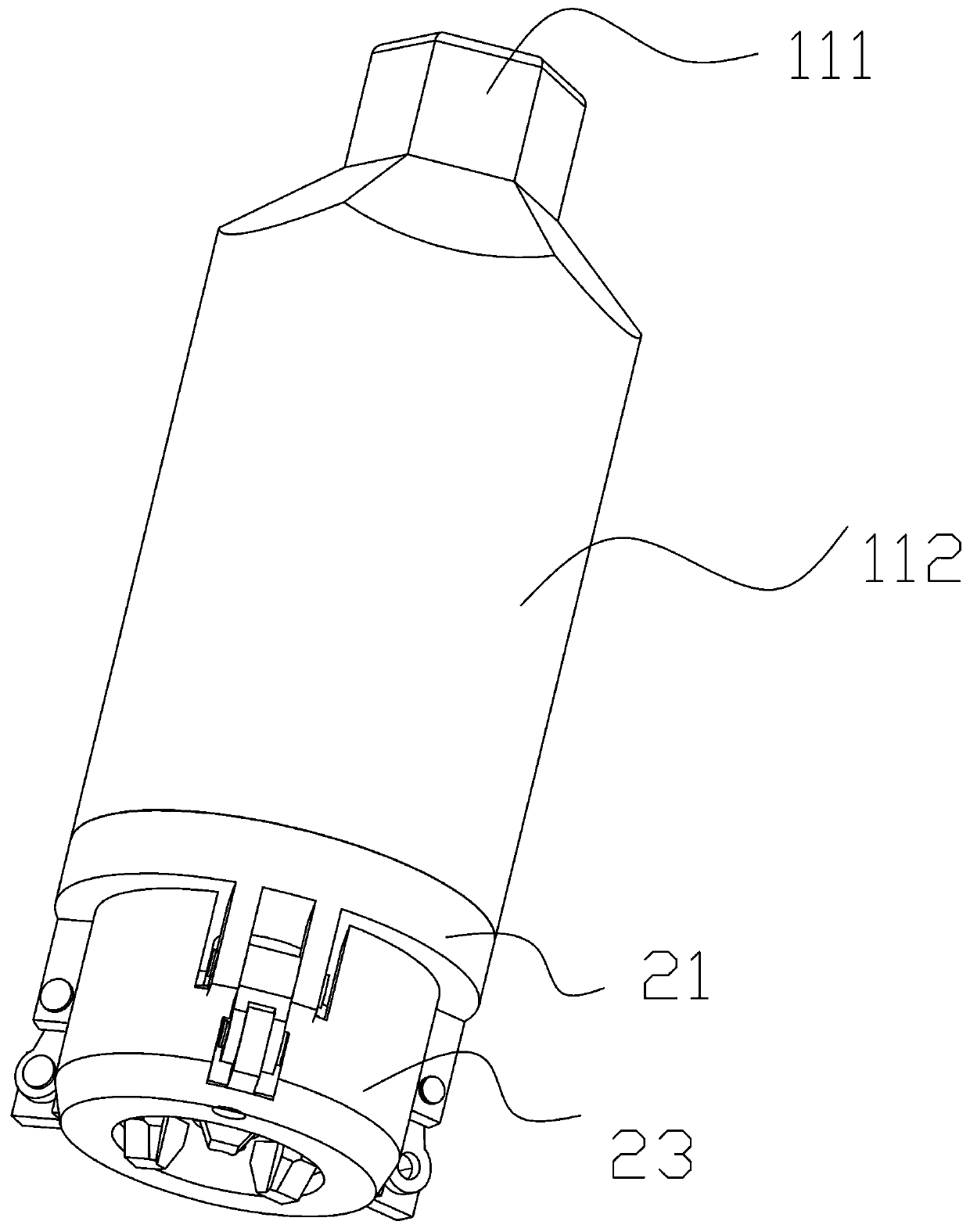

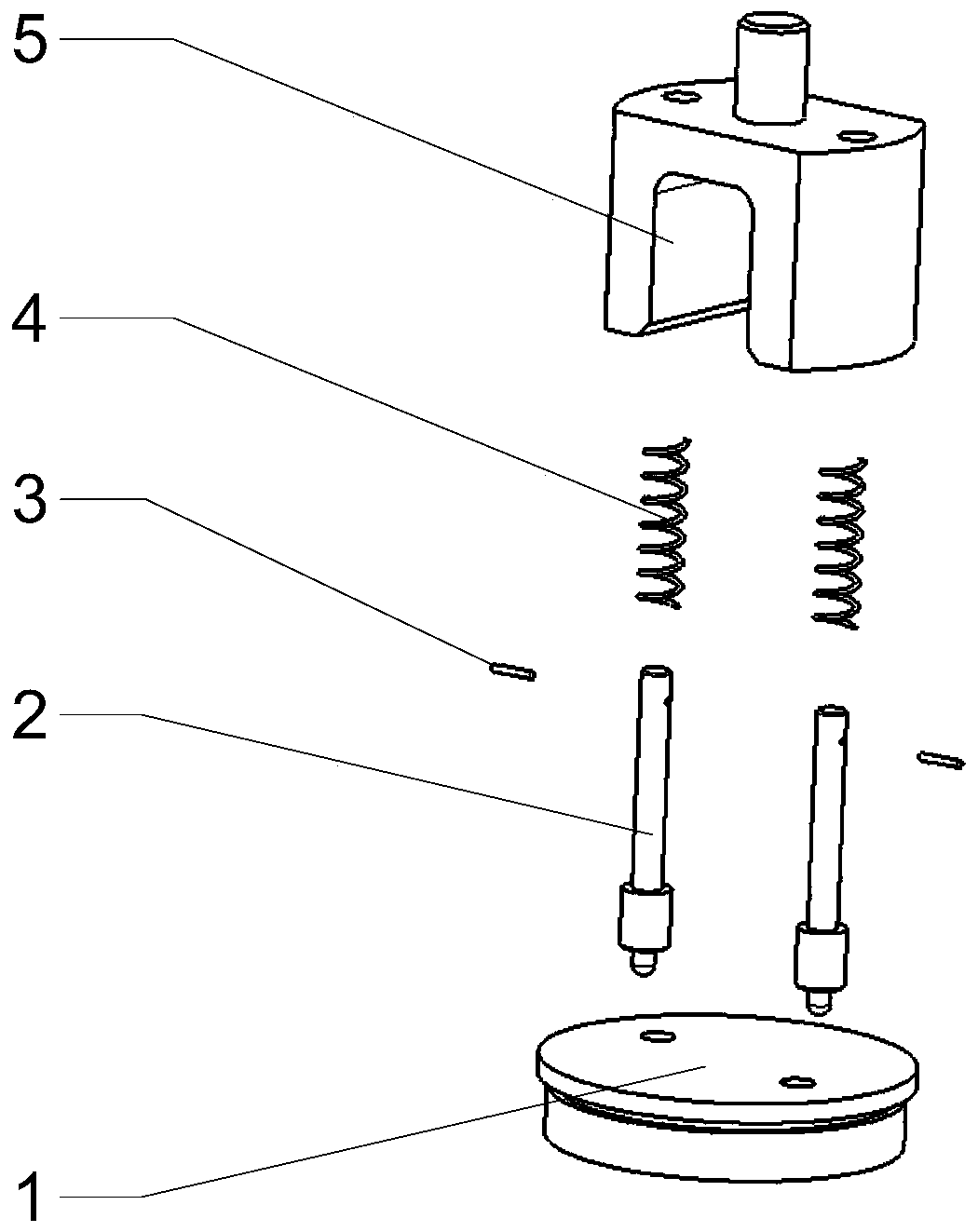

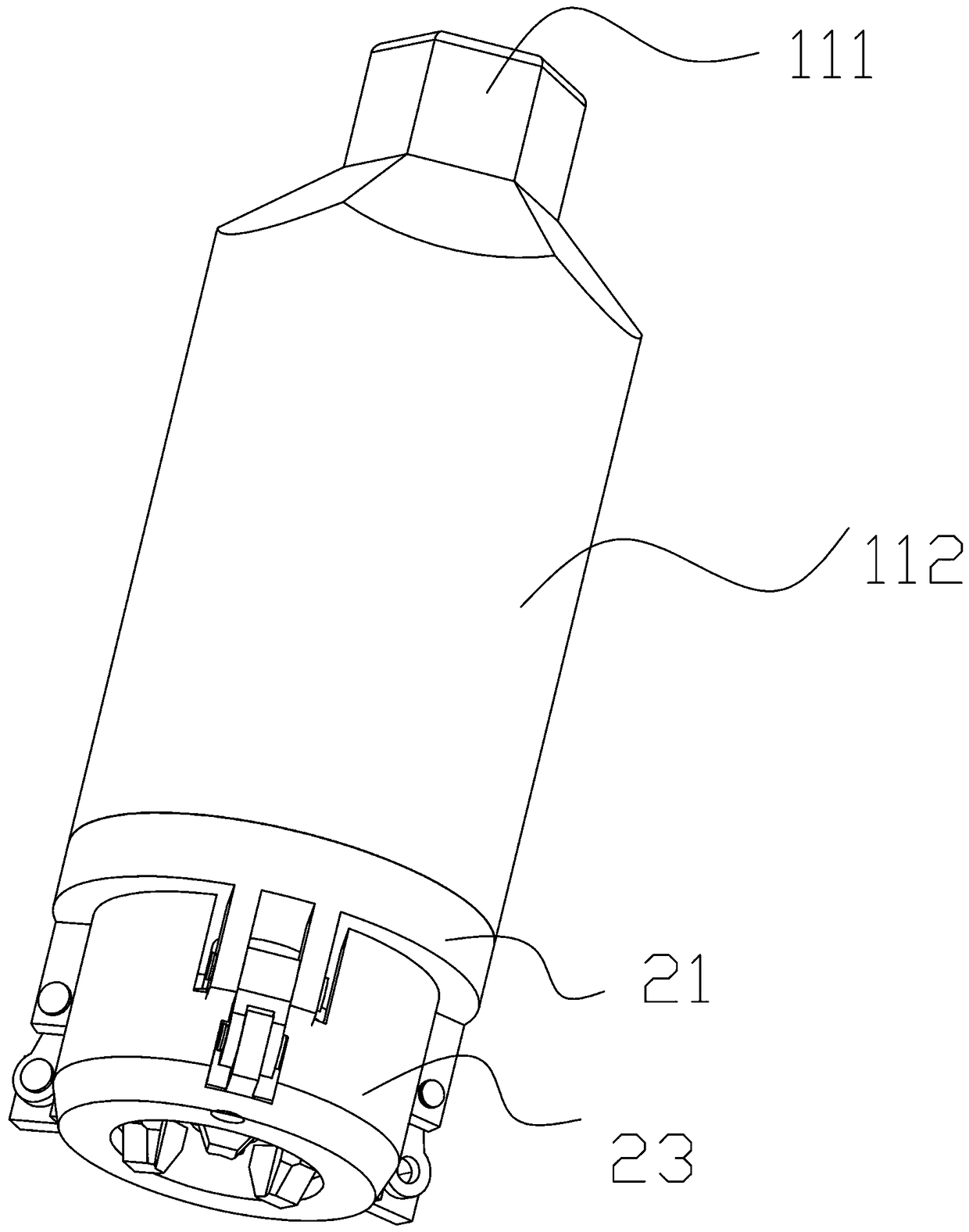

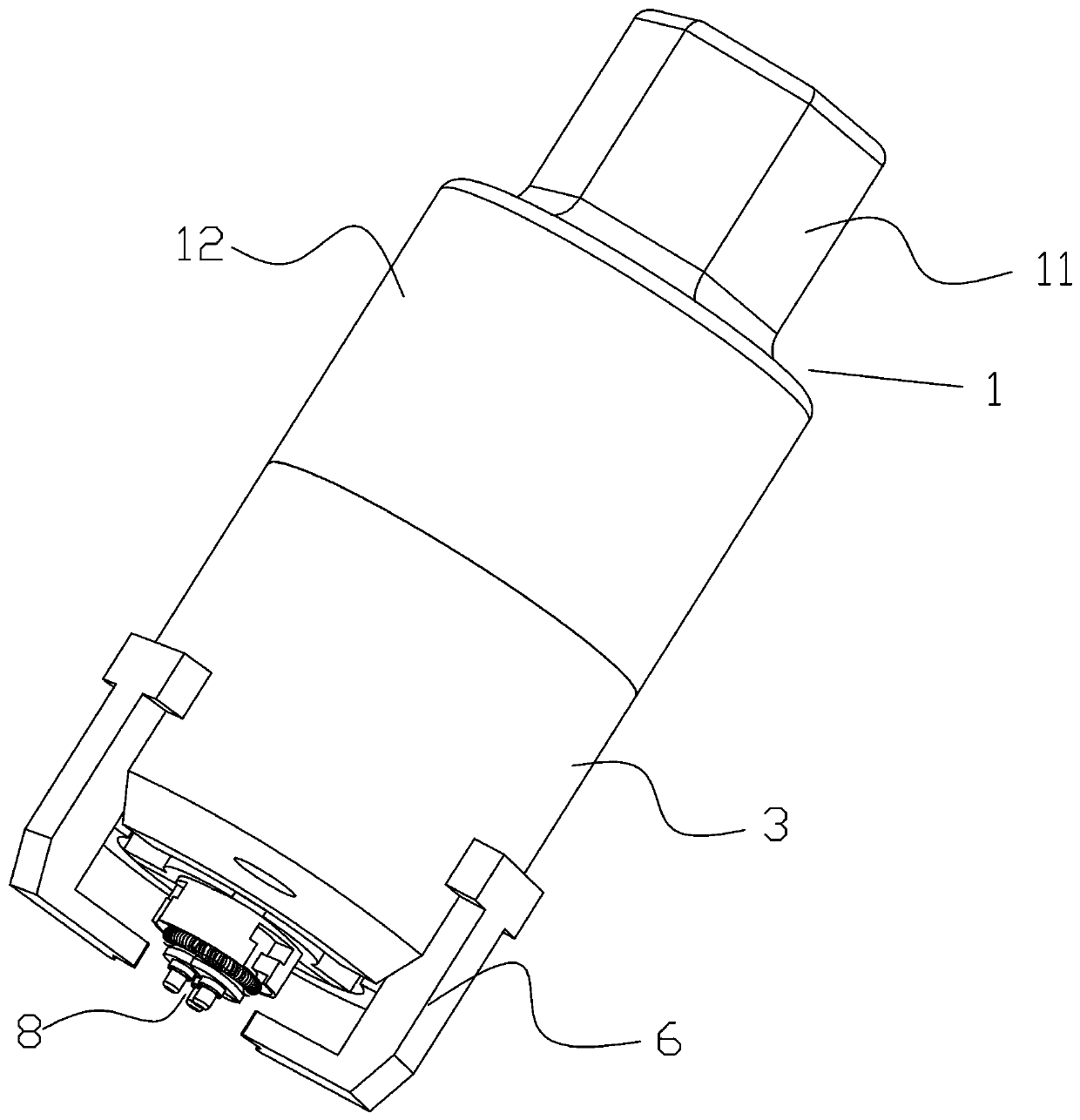

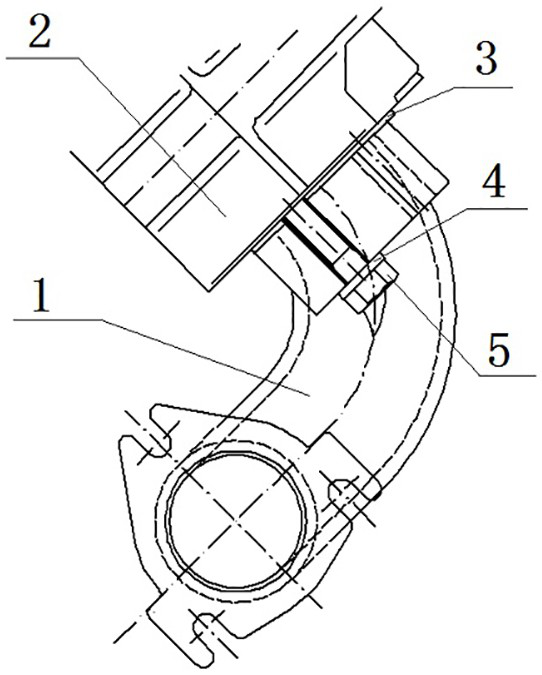

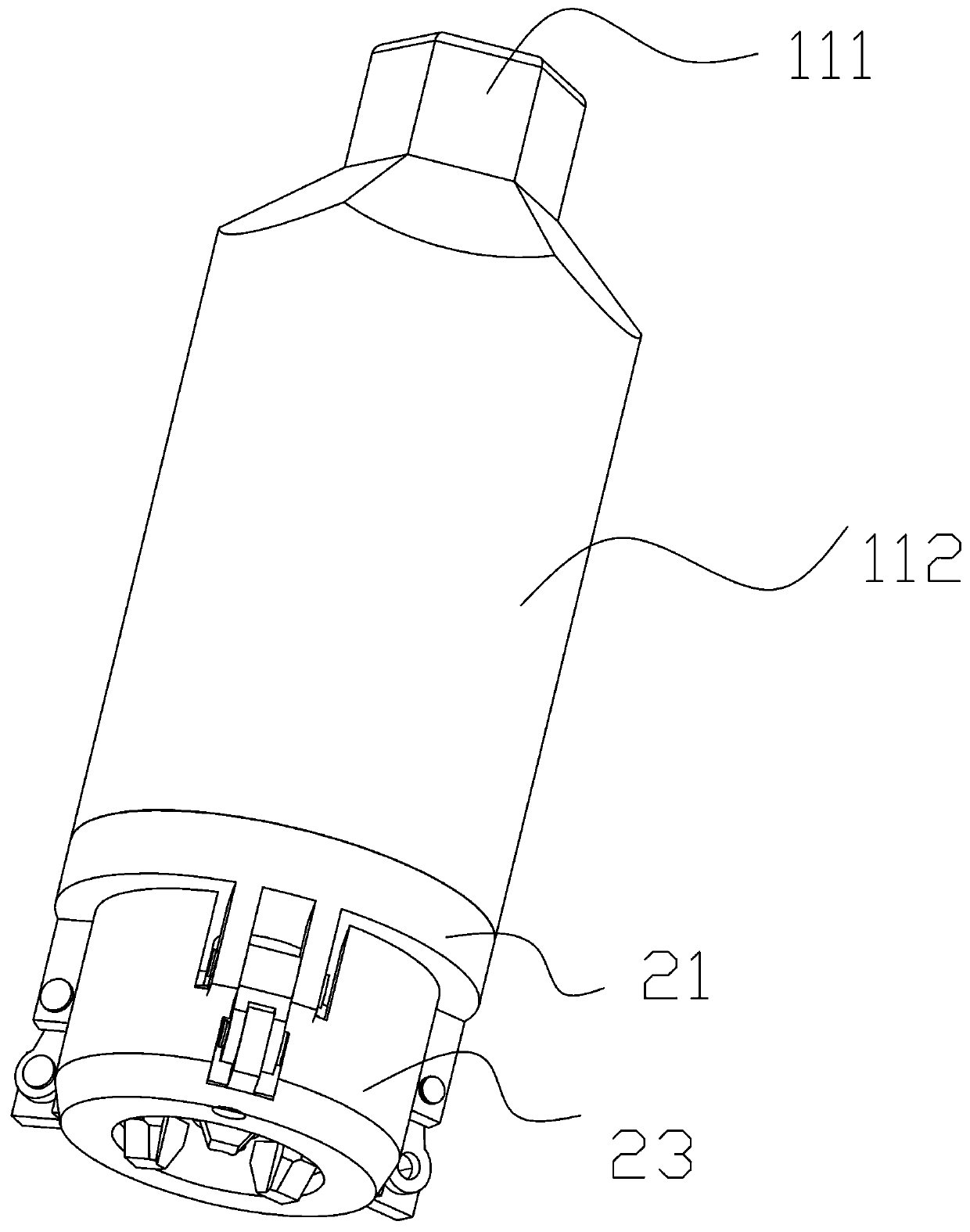

Tightening clamp for hinge screw tightening robot

ActiveCN108555580ALarge tightening torqueCompact structureGripping headsMetal working apparatusEngineeringMachining

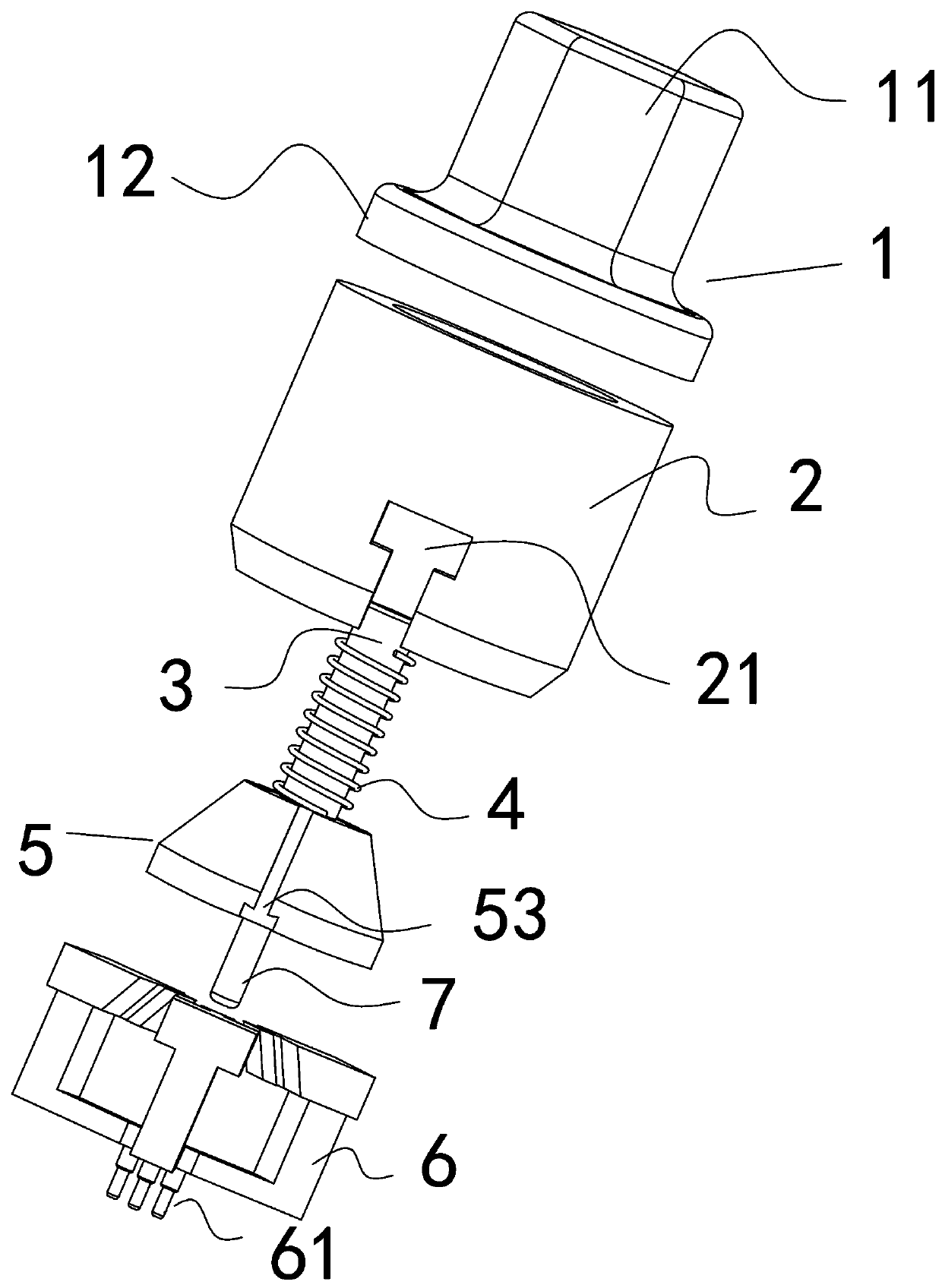

The invention relates to the technical field of machining screw tightening, in particular to a tightening clamp for a hinge screw tightening robot. The tightening clamp comprises a top cap, and a circular hole is formed in one end of the top cap. A center shaft and a first spring are further included, and an ejector rod and a support are arranged at the other end of the center shaft. The support comprises three U-shaped blocks with openings back onto the center shaft, and the bottoms of the three U-shaped blocks are connected in pairs to be located on the same horizontal plane, the bottoms ofthe three U-shaped blocks are all connected with the center shaft, the ejector rod downwards stretches out, and the center shaft is sleeved with the first spring. Three sliding blocks are further included, the upper surfaces and the front end faces of the sliding blocks are in a T shape. Each sliding block is provided with an oblique first sliding groove, and clamping and sleeving pieces are arranged on the bottom faces of the sliding blocks. A guiding barrel is further included and provided with three T-shaped second sliding grooves. The tightening clamp has the beneficial effects that the large tightening torque is transmitted, reducing through additional power is not needed, the structure is compact, and reliability is high.

Owner:SHANDONG WANGCHAOTIANRUN MACHINERY MFG CO LTD

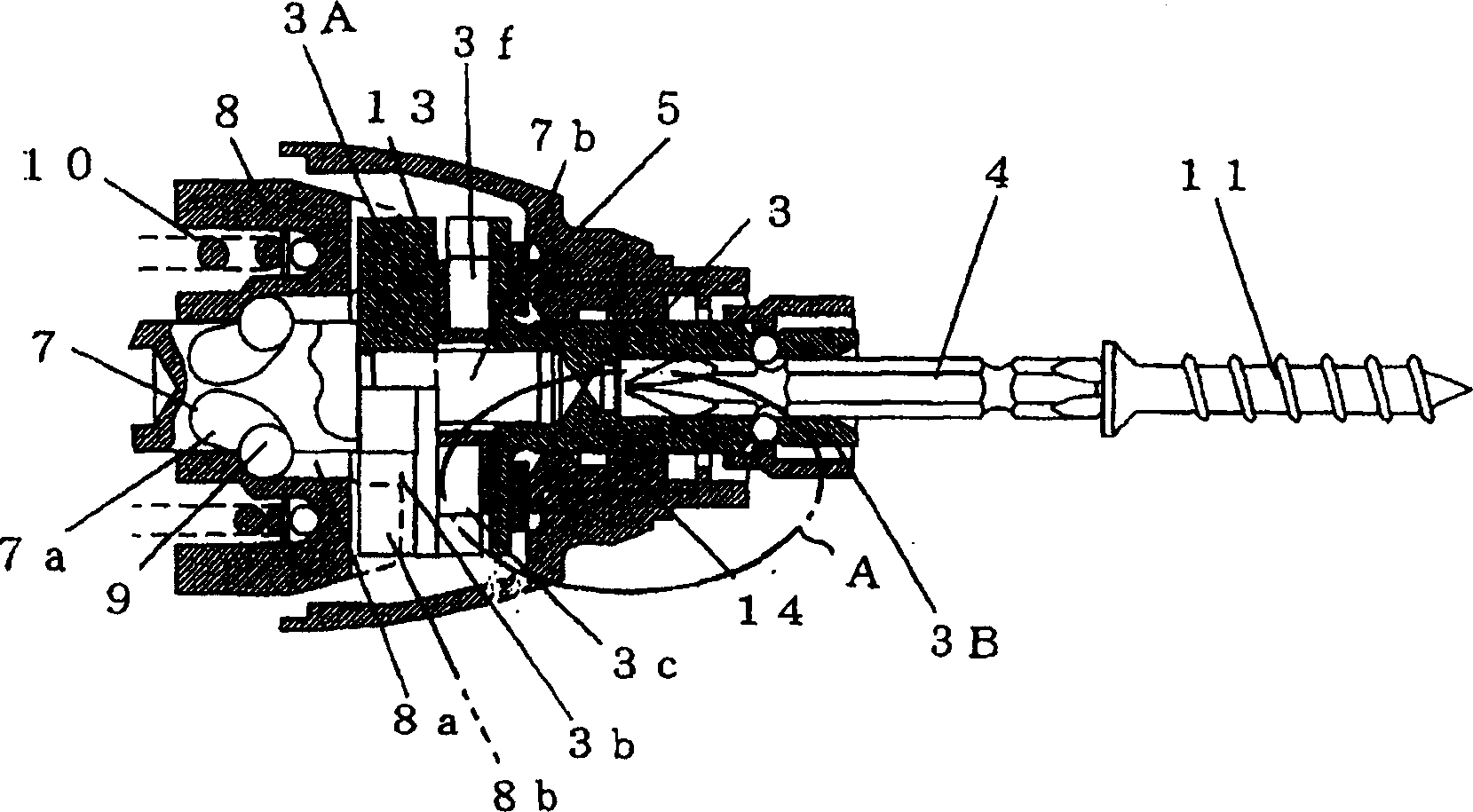

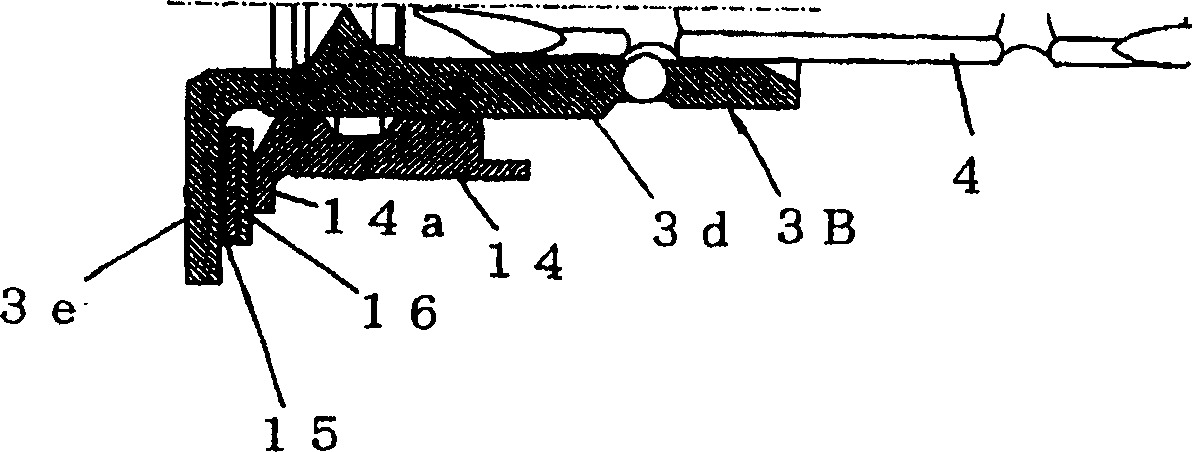

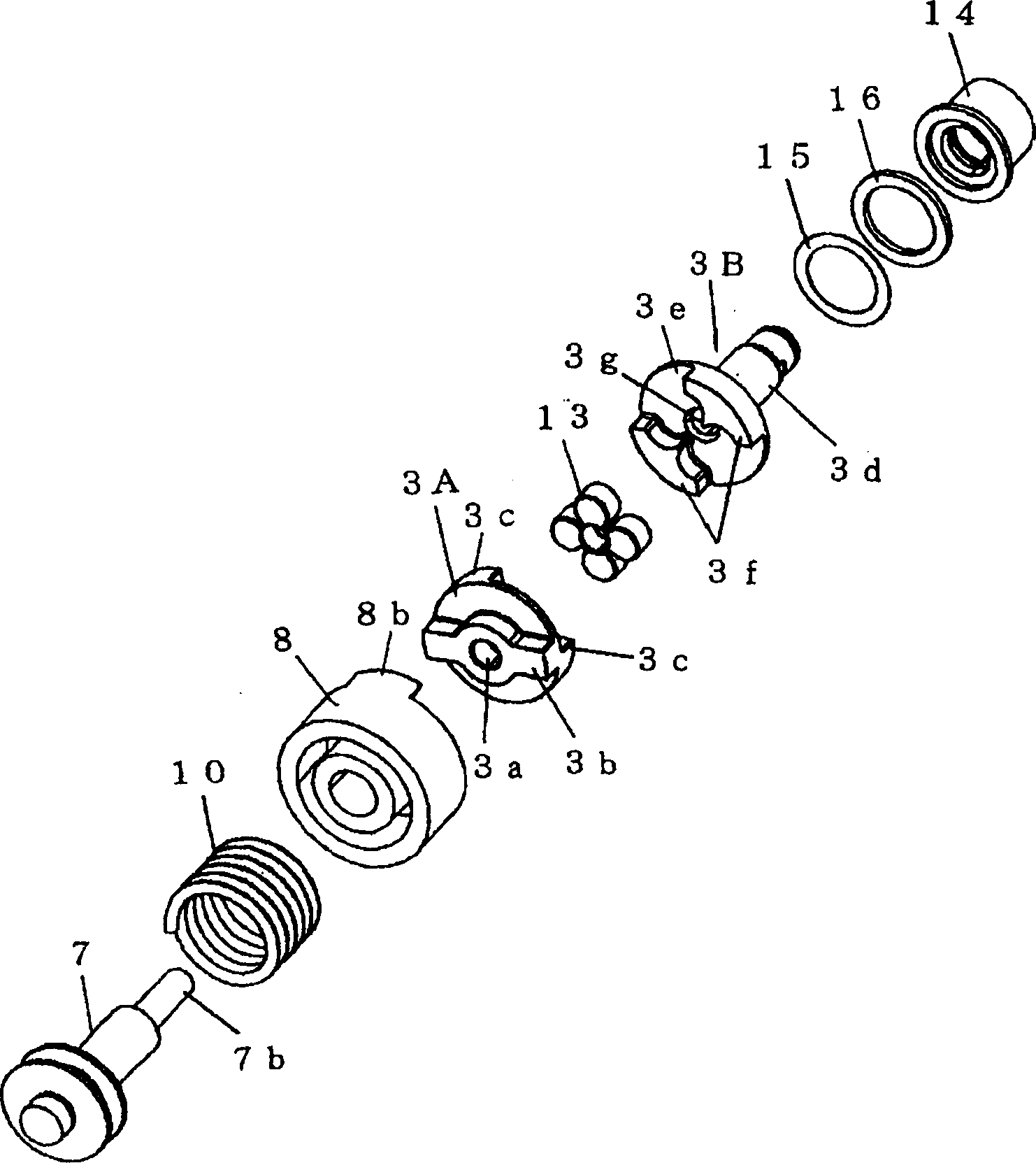

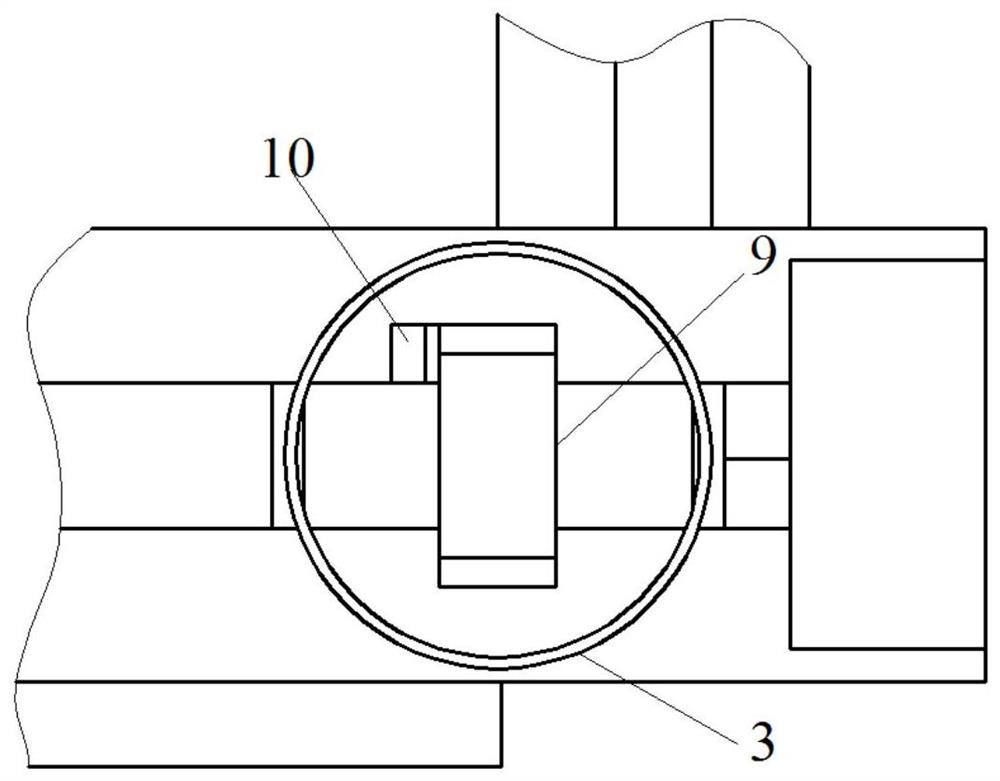

Impact tool

InactiveCN1846946ANo decrease in fastening abilitySuppression of axial vibration transmissionPortable percussive toolsPortable power-driven toolsElastomerTipped tool

An impact tool comprising a motor, a hammer 8 that is rotated and axially moved by a drive force of the motor, an anvil 3 that repeats engagement / disengagement from the hammer 8 accompanying rotation and axial movements of the hammer 8, and a tip tool 4 mounted to the anvil 3, the anvil 3 comprising a first split piece 3 A, which includes pawls 3 c (first concave-convex part) on an opposite side to the hammer and repeats engagement / disengagement from the hammer 8, a second split piece 3 B, which includes pawls 3 f (second concave-convex part) engageable with the pawls (first concave-convex part) 3 c of the first split piece 3 A in a direction of rotation, and to which the tip tool 4 is mounted, and a rubber damper (elastic body) 13 interposed between the first and second split pieces 3 A, 3 B to prevent direct contact between the pawls (first concave-convex part) 3 c and the pawls (second concave-convex part) 3 f in the direction of rotation and in an axial direction.

Owner:HITACHI KOKI CO LTD

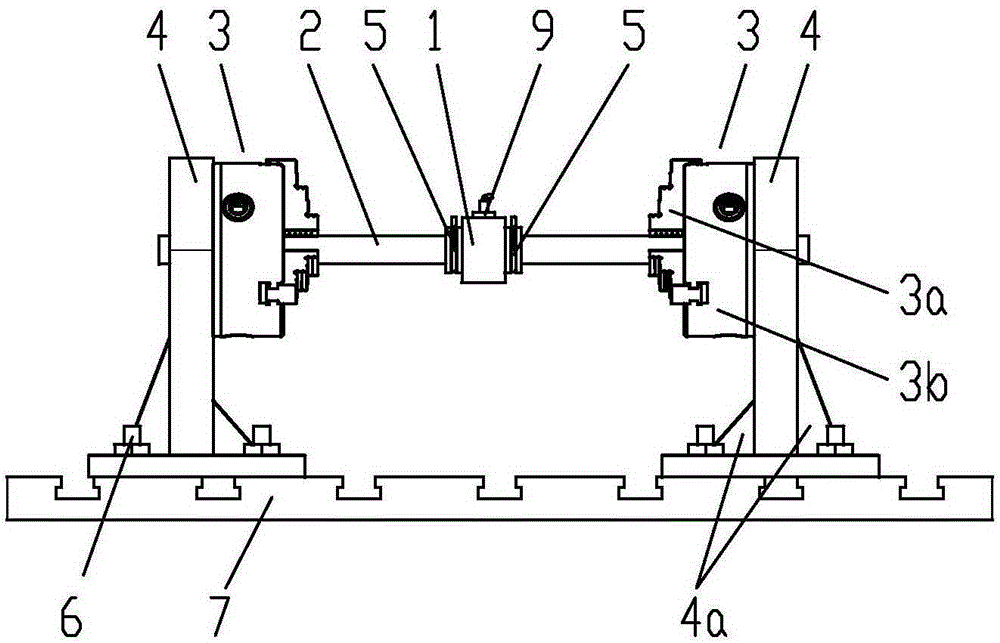

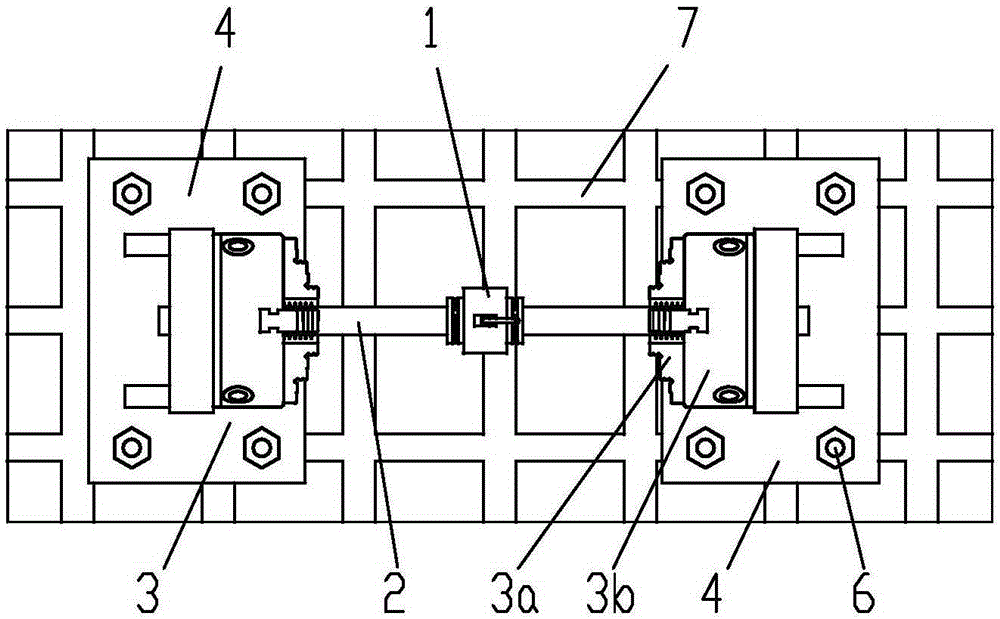

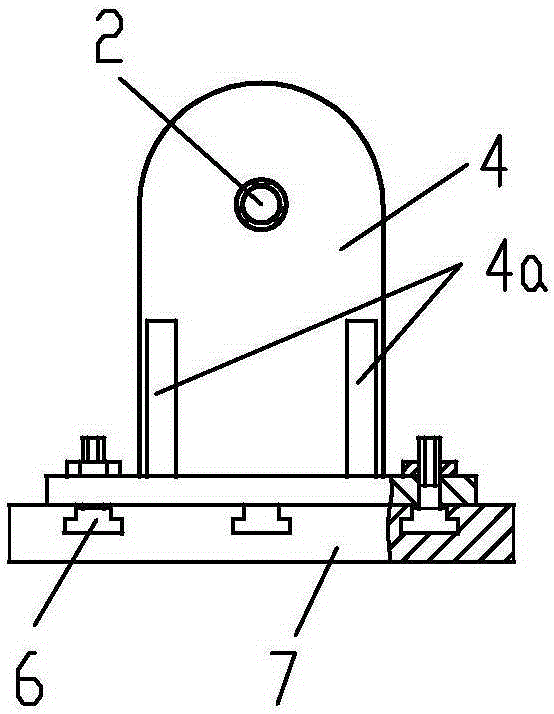

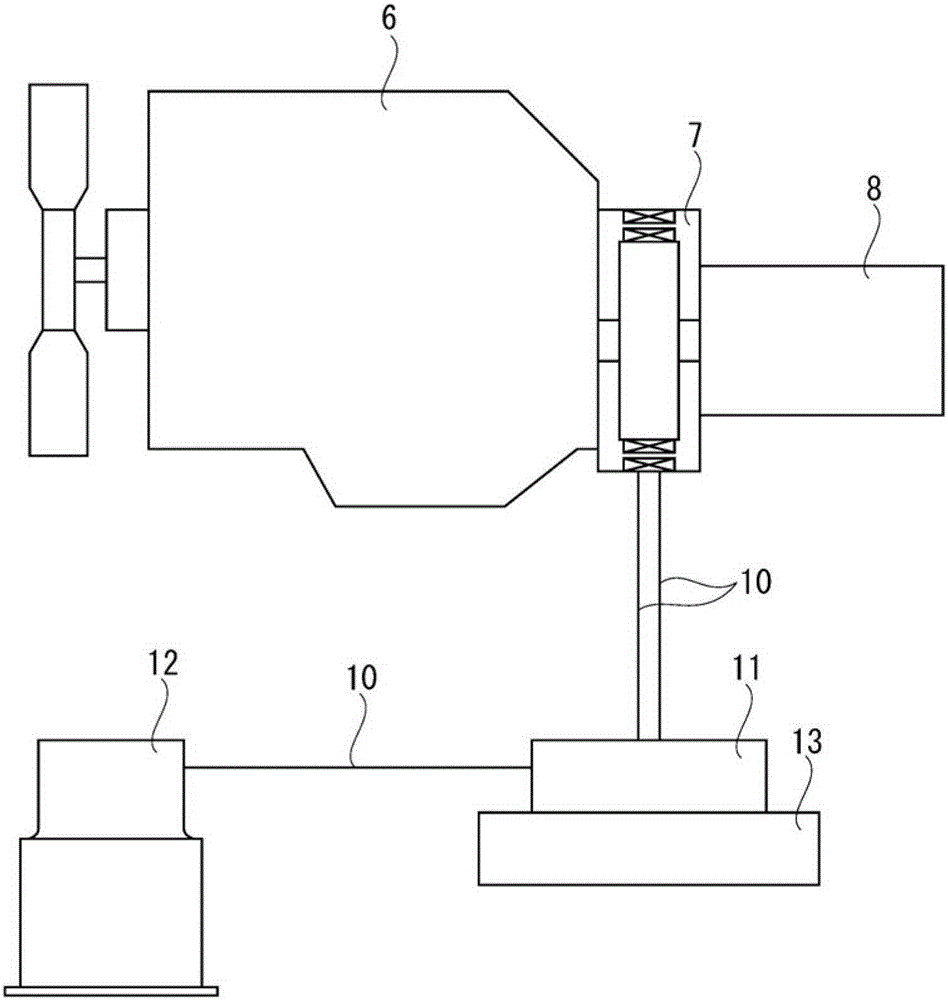

Dynamic characteristic testing device and method for vehicle transmission system dynamic vibration absorber

ActiveCN105203337AEliminate the effects ofAvoid influenceVehicle suspension/damping testingVertical edgeData acquisition

The invention discloses a dynamic characteristic testing device and method for a vehicle transmission system dynamic vibration absorber. The testing device comprises a circular rod type or circular tube type circular mandrel for installation of the hydraulic vibration absorber. The circular mandrel is fixed to be in the horizontal state through three jaws of three-jaw chucks at the two ends in a clamping or expansion holding mode. The two three-jaw chucks are fixedly connected to vertical edges of the two supporting bases respectively. The horizontal edges of the two supporting bases are fixedly connected to a workbench through bolts. Testing is performed by means of the testing device, and the method comprises the steps of hydraulic vibration absorber installation, data collection and analysis system connection, signal calibration and testing, data processing and analysis and the like, wherein the dynamic vibration absorber is installed on the circular mandrel, and the circular mandrel is clamped and fixed through the two three-jaw chucks. The dynamic characteristic testing device has the advantages of being simple in structure, convenient to adjust and wide in application range, and the testing method has the advantages of being easy to implement, high in testing accuracy and capable of effectively shortening the vehicle development period.

Owner:CHINA AUTOMOTIVE ENG RES INST

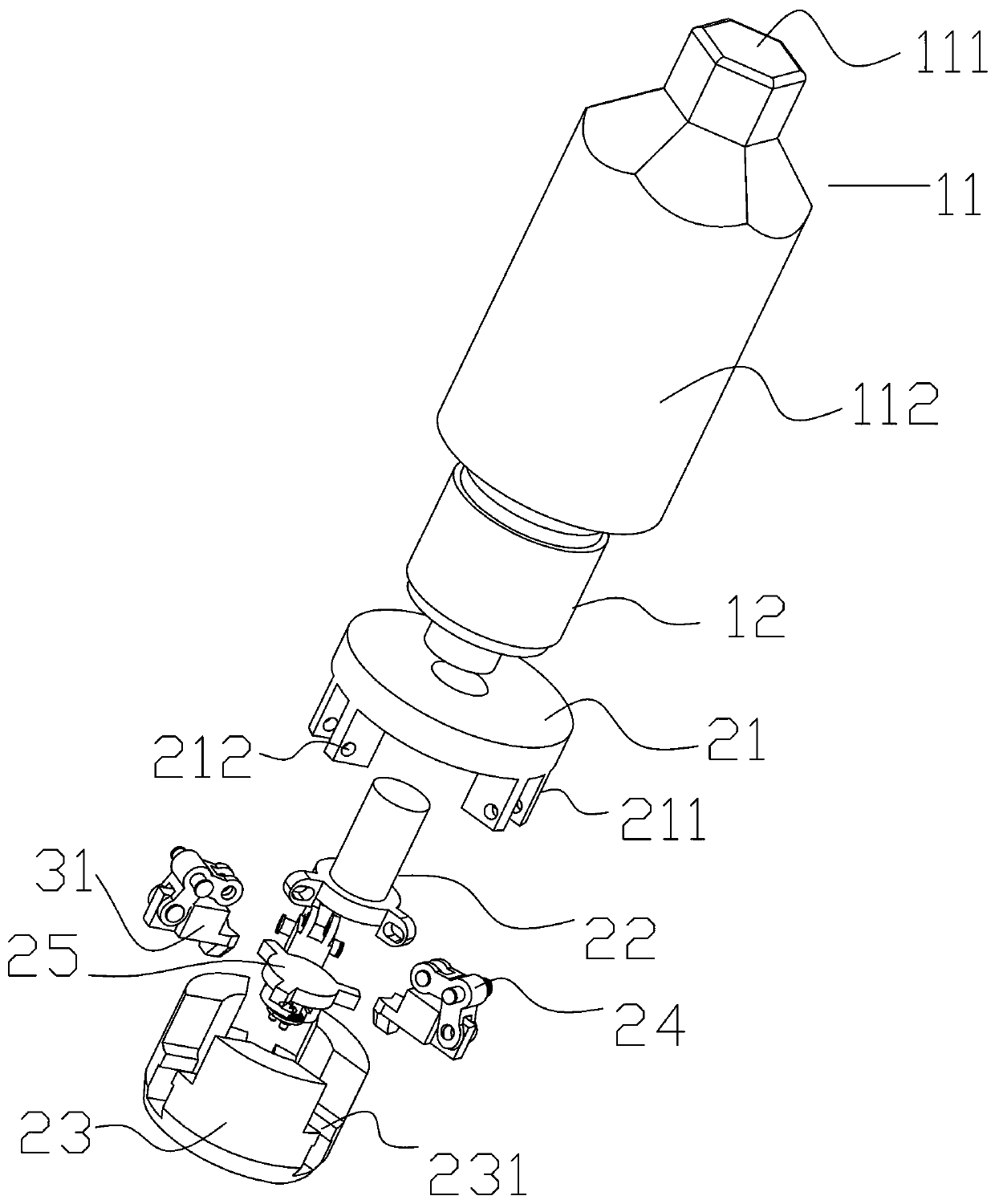

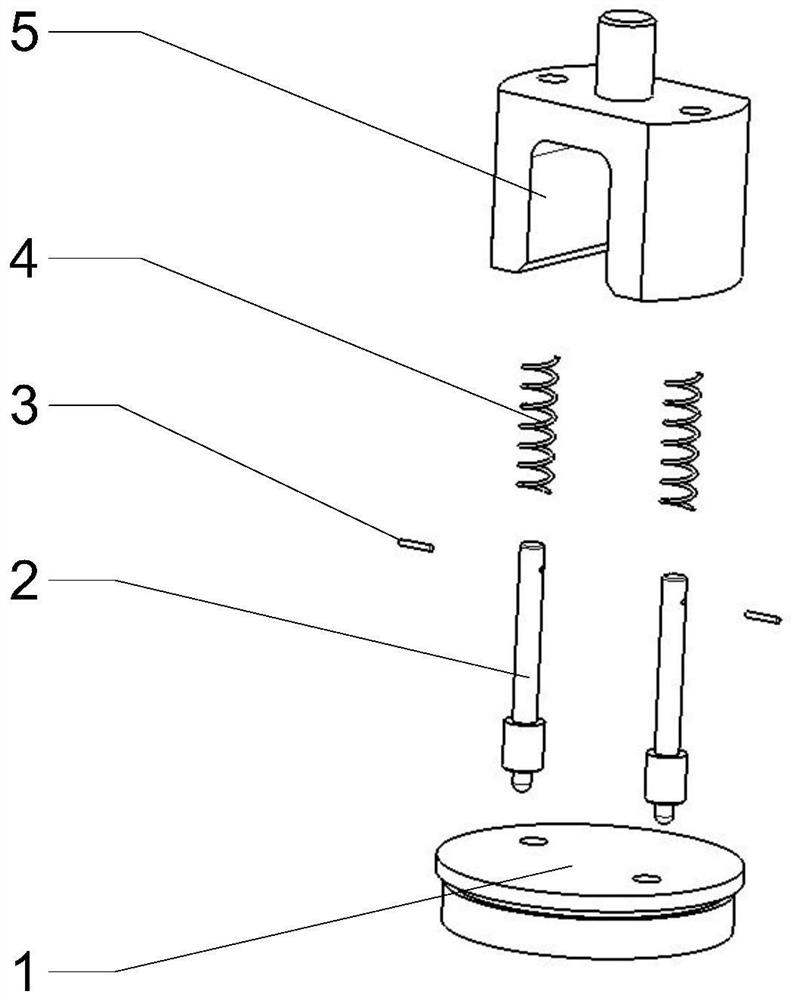

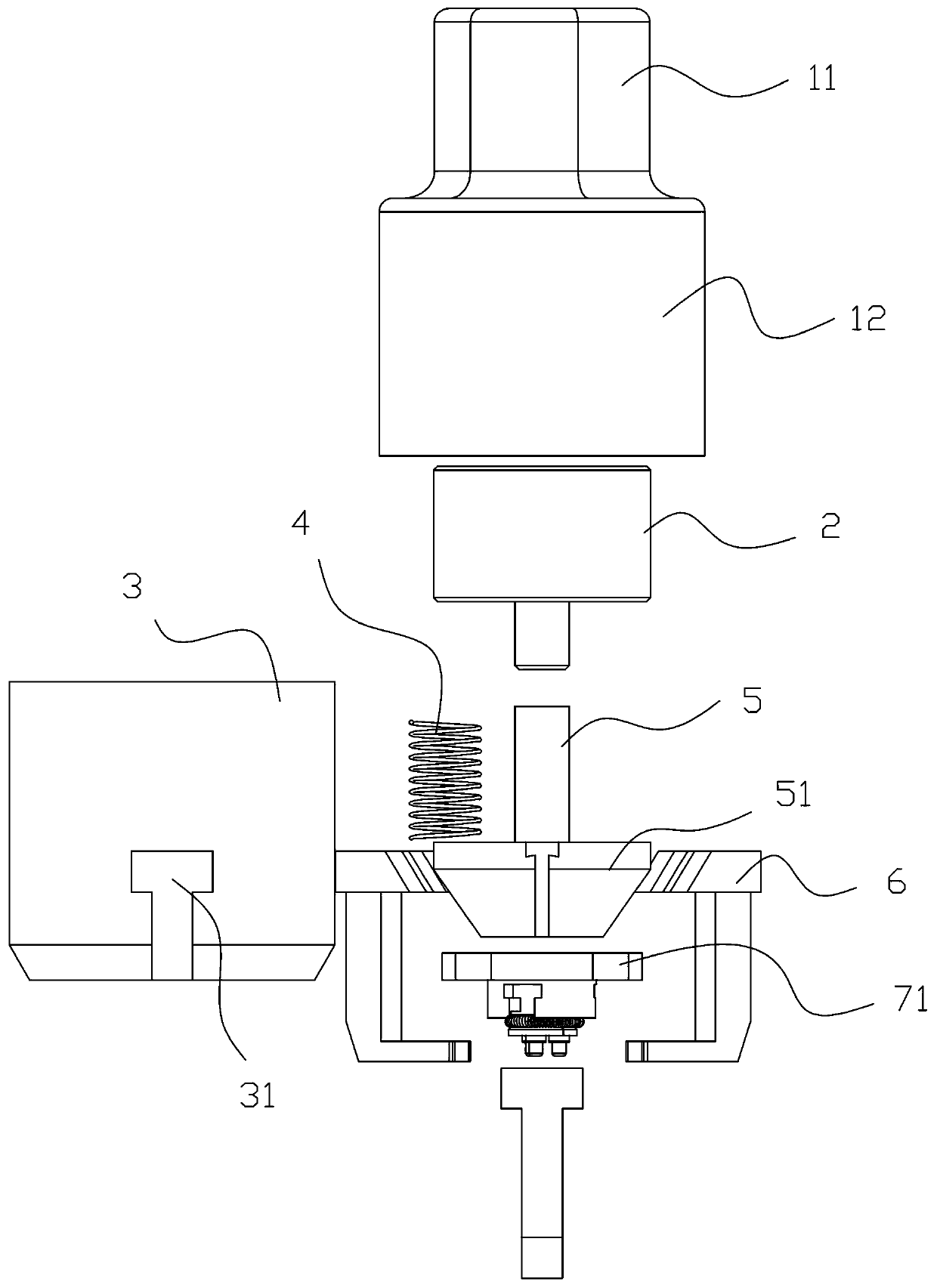

Self-resetting non-standard precise screw screwing-up robot

ActiveCN108453497ALarge tightening torquePrevent slippingMetal working apparatusIsoetes triquetraEngineering

The invention relates to a self-resetting non-standard precise screw screwing-up robot comprising a force supply mechanism and a centrifugal clamping mechanism. The other end of a center shaft is provided with a round sliding table, the round sliding table is provided with three H-shaped second sliding slots, and the second sliding slots are formed along the oblique plane of the round sliding table. One ends of chuck sliding blocks are embedded into first sliding slots and are provided with inclined first protruding blocks with the cross sections being in T shapes, and the first protruding blocks are embedded into the second sliding slots. A variable-diameter device comprises a disc-shaped installation block with the opening facing downwards, a round guide block, three centrifugal blocks and a round second spring. The guide block is provided with three T-shaped third sliding slots, a first pit in an equilateral triangle shape is formed in the center of the three attached centrifugal blocks, the lower ends of the three centrifugal blocks are attached to one another to form a cylinder, and the bottom faces of the centrifugal blocks are downwards provided with torsion needles. The self-resetting non-standard precise screw screwing-up robot has the characteristics that large tightening torque is transferred, and the slip phenomenon can be effectively prevented.

Owner:江苏中鲲智能装备有限公司

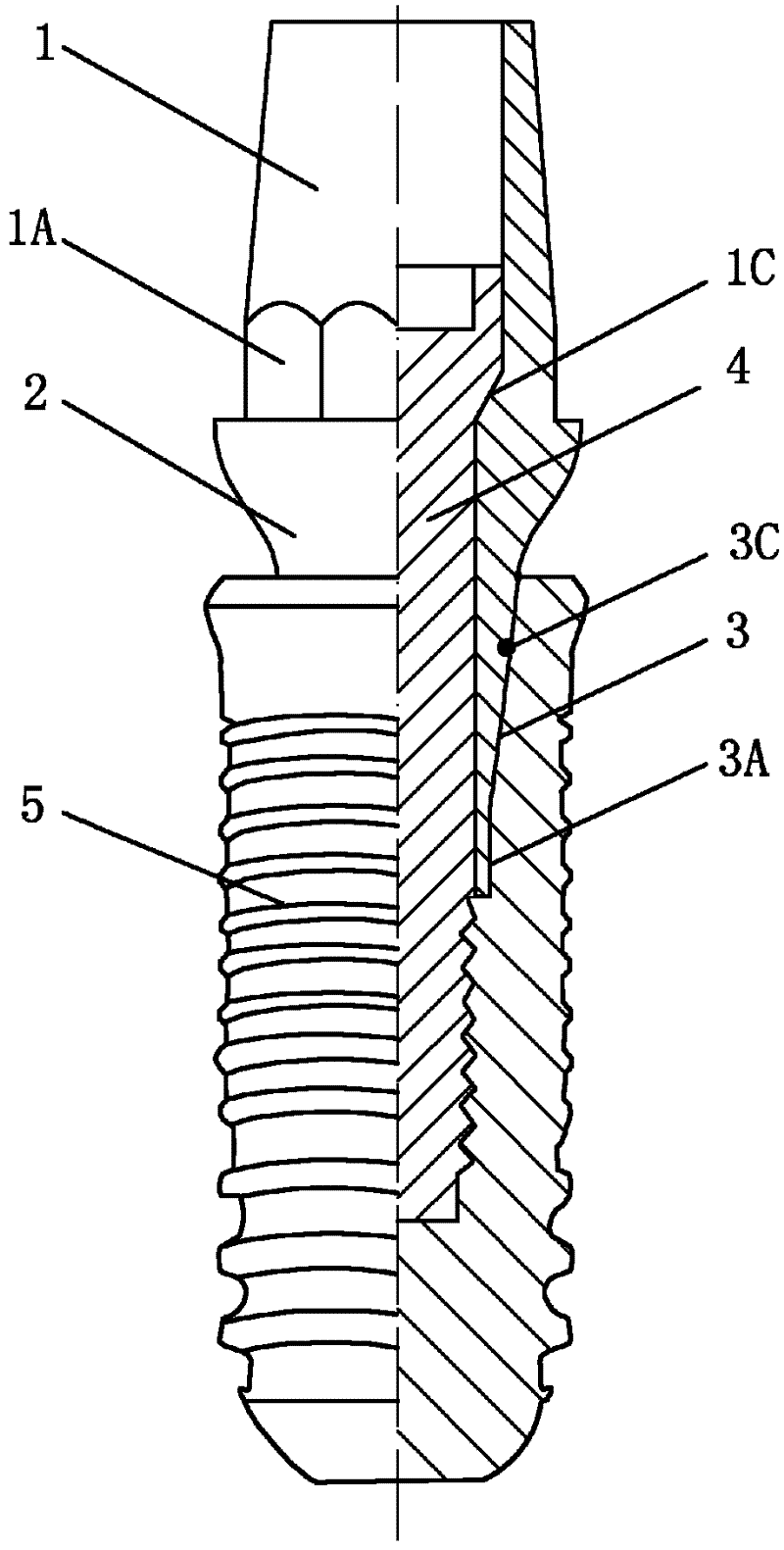

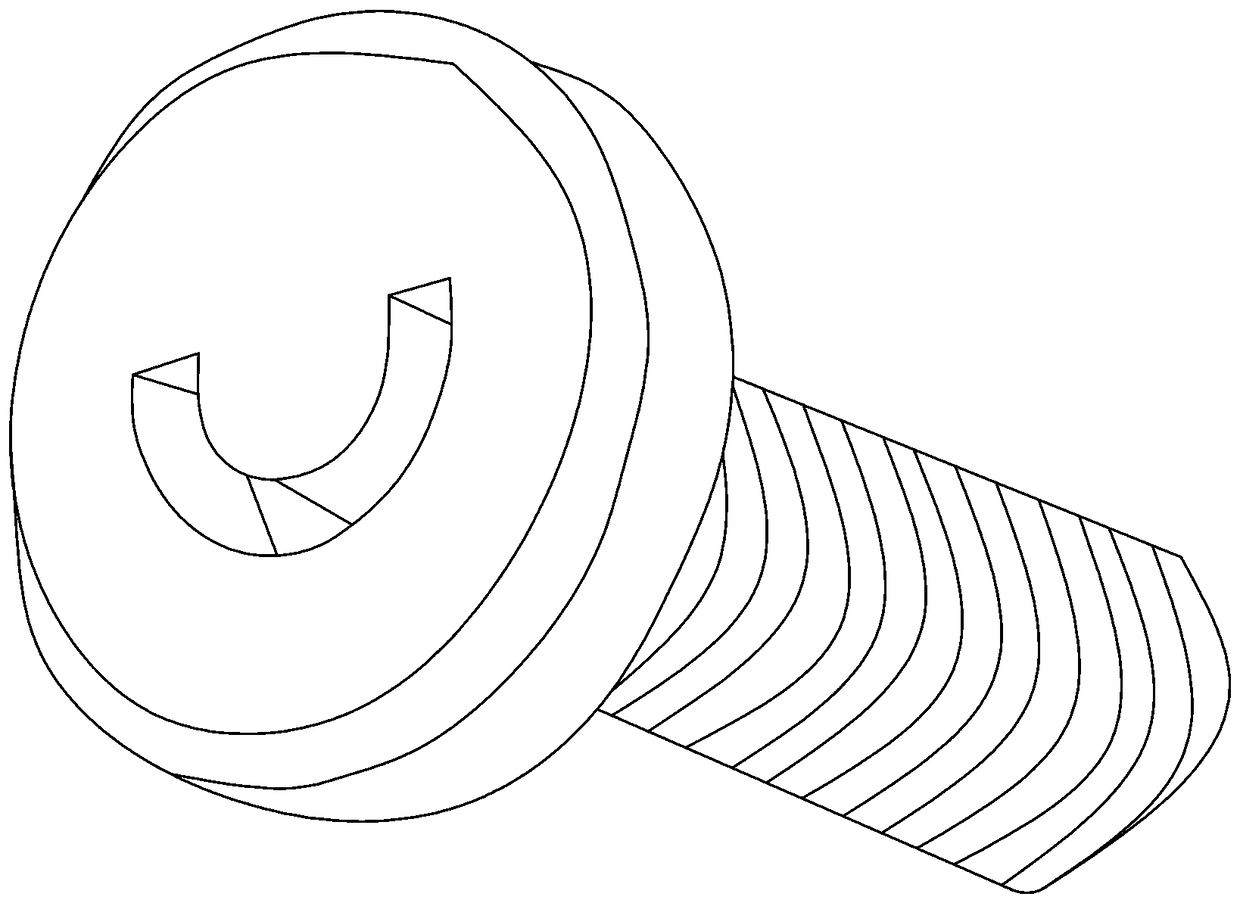

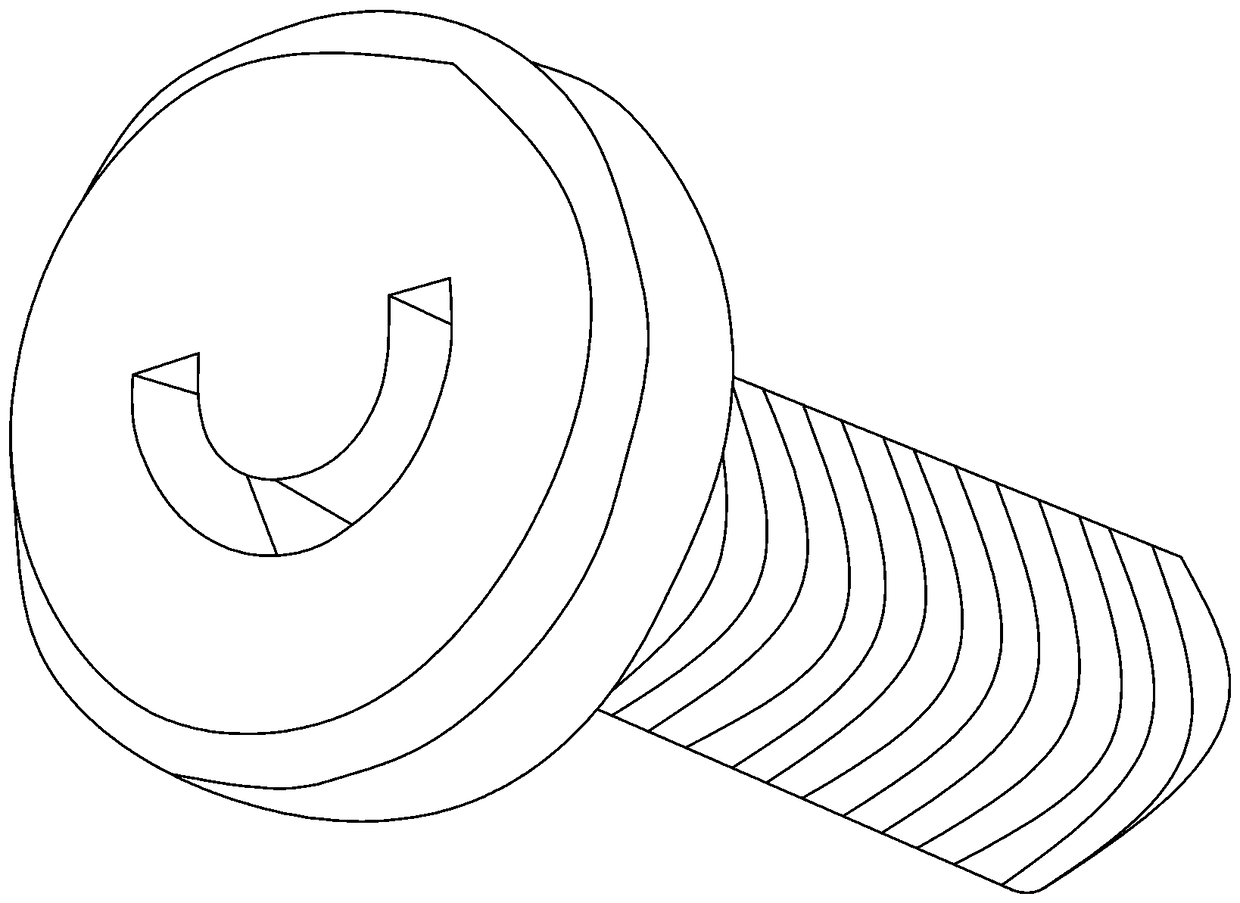

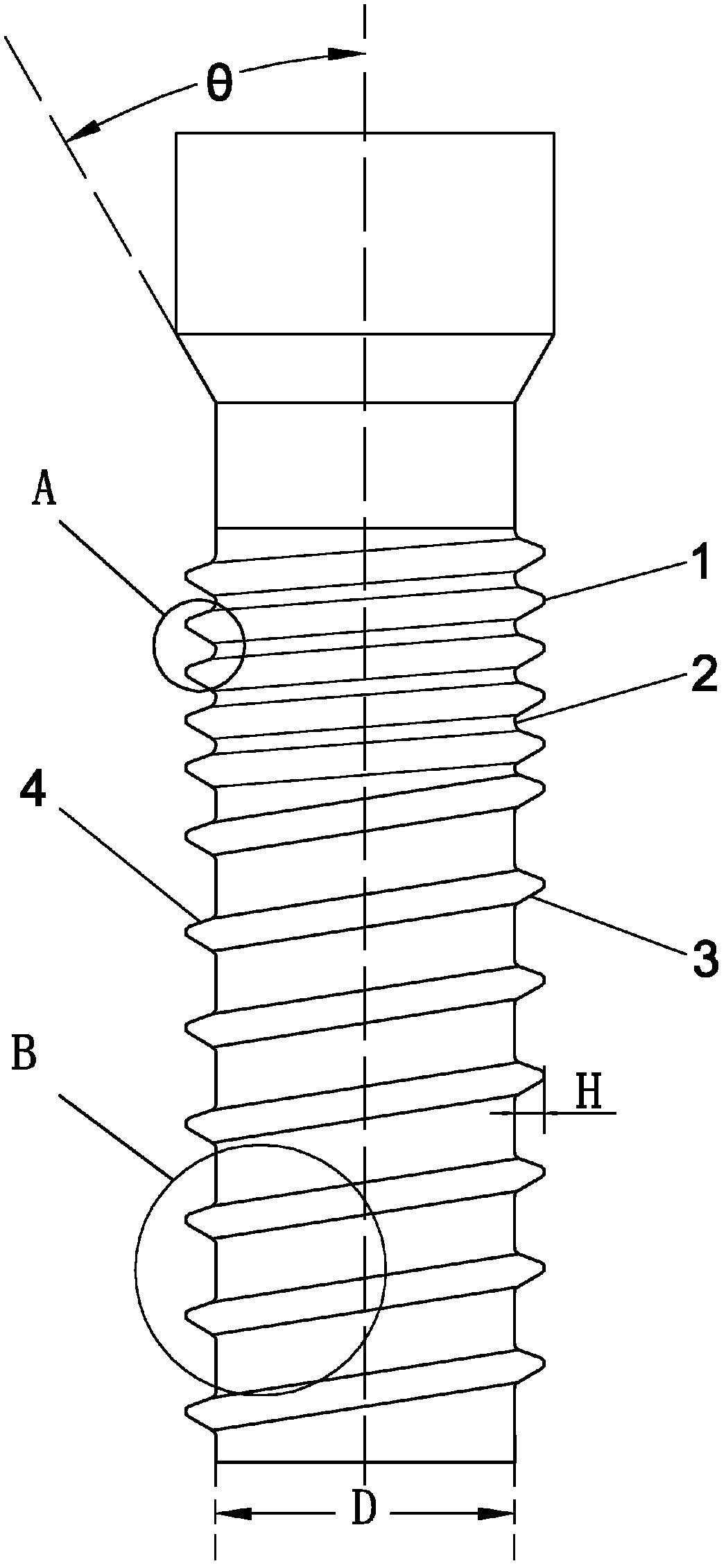

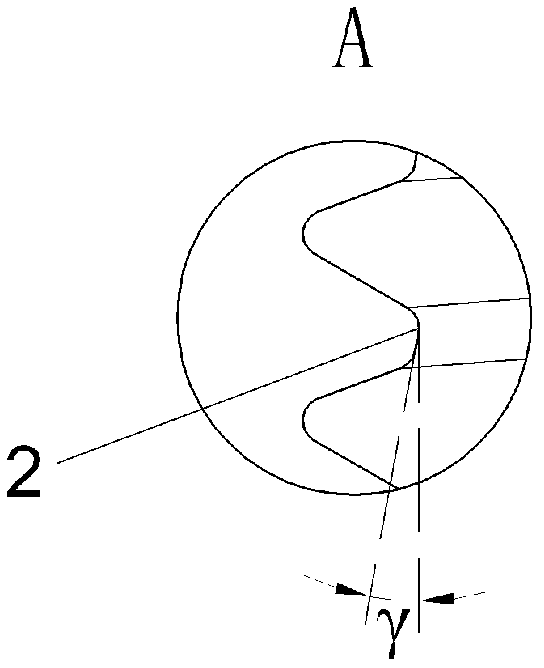

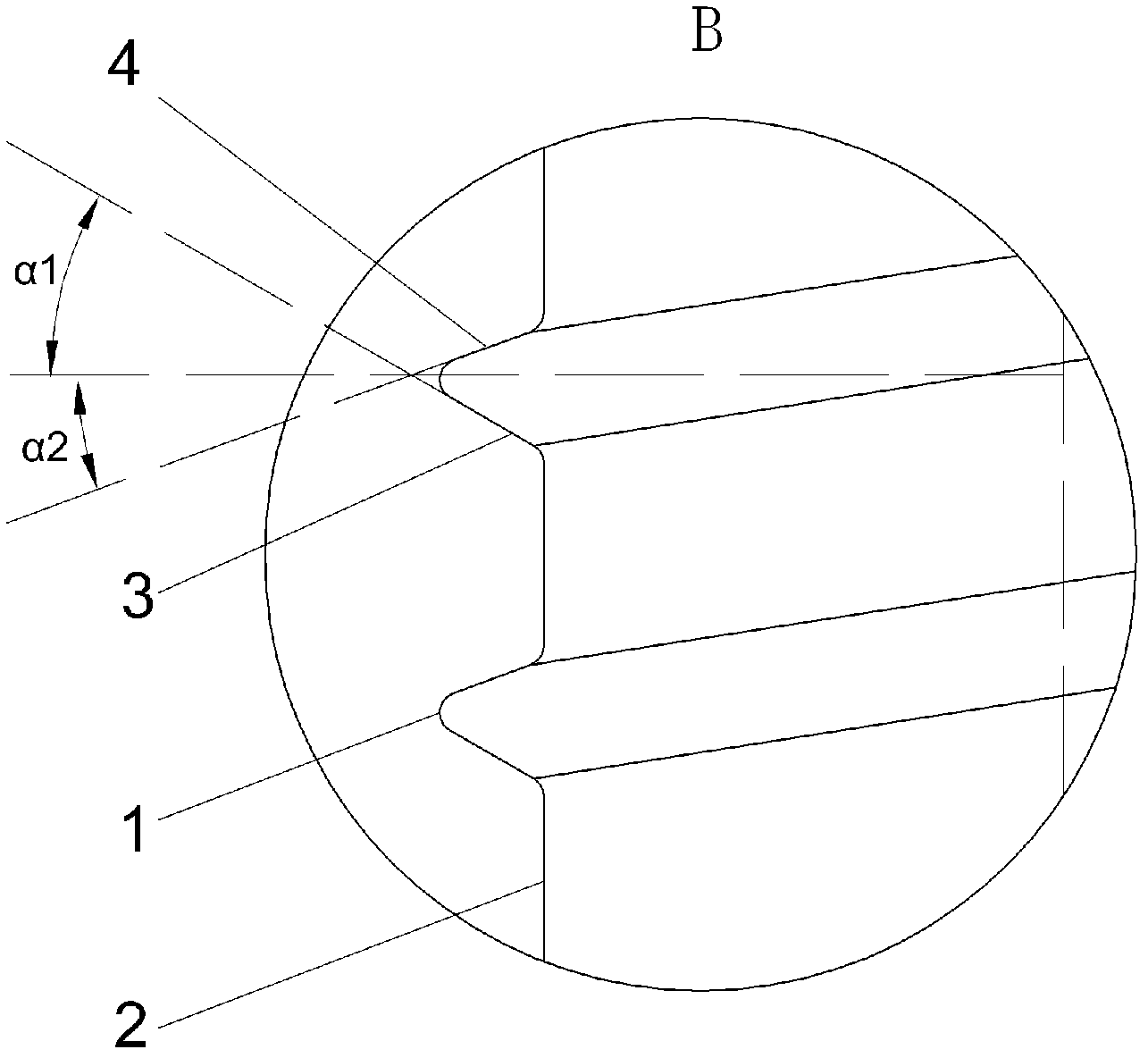

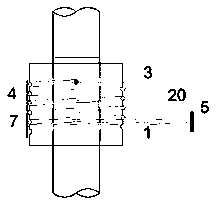

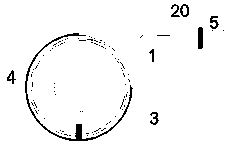

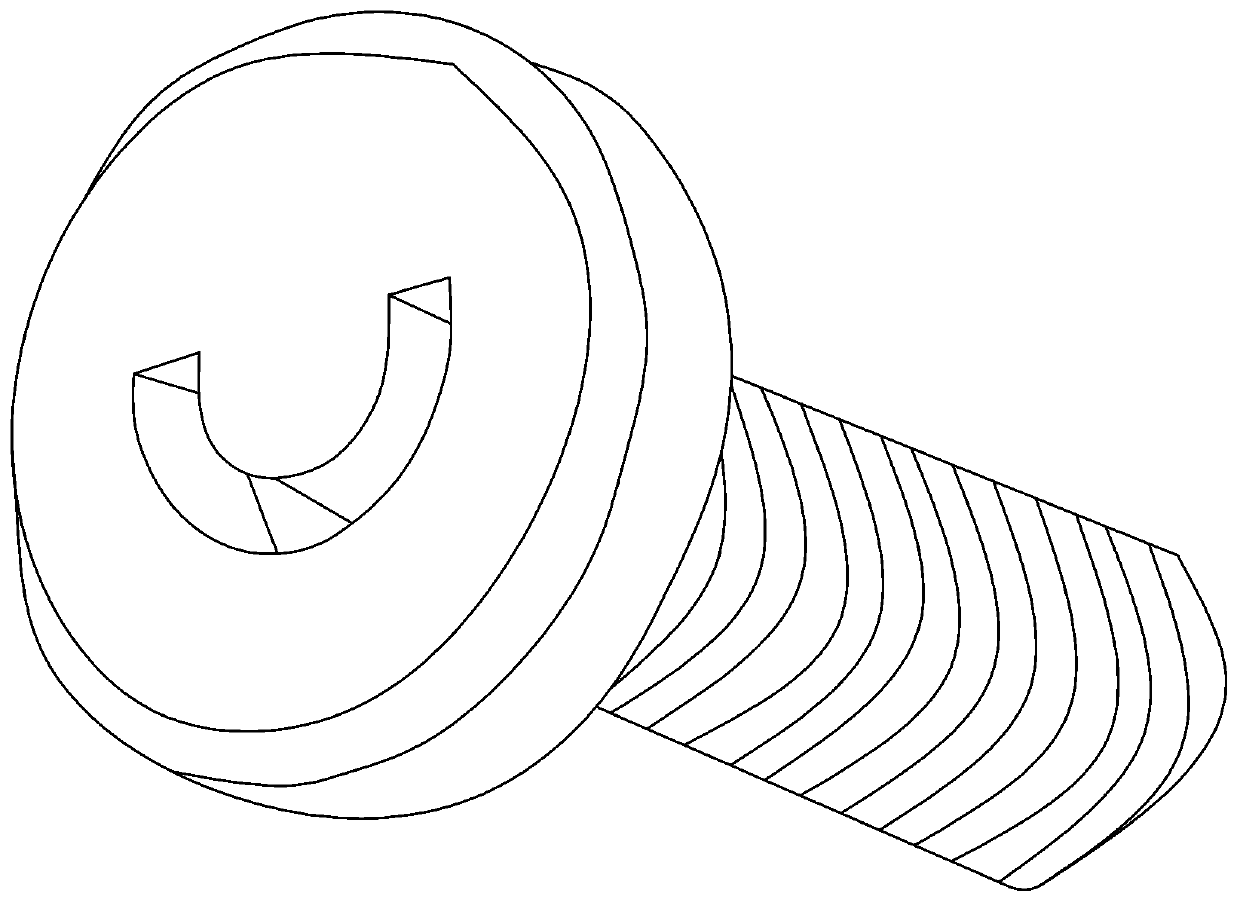

Anti-loosing and corrosion-proof dental-implant central screw

ActiveCN102319125AStrong resistanceImprove corrosion resistanceDental implantsEngineeringScrew thread

The invention discloses an anti-loosing and corrosion-proof dental-implant central screw, which is characterized in that the minor thread diameter of the screw is 1.5-2.5 mm, the height of a thread form of the screw is 1 / 10 of the minor thread diameter, and the surface of the screw is coated with a phosphorus-containing TiO2 membrane by using a sol-gel method; the thread form of the central screwis triangular, the flank angle of a leading flank is 30 degrees, and the flank angle of a following flank is 20 degrees; the thread crest is arc-shaped, junctions between a thread root and the leading flank as well as the following flank are also arc-shaped, and the curvature radiuses of the arc-shaped parts are all 1 / 50 of the minor thread diameter; the pitches between five channels of screw threads (close to a screw cap) of the central screw are 0.4-0.5 mm, the thread root inclines inwards along the screw cap, and a 10-degree included angle is formed between the thread root and a thread axis; and the pitches between the other screw threads are 0.8-1.0 mm, and the thread root is parallel to the thread axis. The central screw disclosed by the invention is uneasy to loose, difficult to corrode, reliable in performance and long in service life, therefore, the central screw can be used for improving the long-term success rate of dental implants.

Owner:SICHUAN UNIV

Rear swing arm installation structure

InactiveUS7757801B2Easy to adjustIncrease the number ofRotary transmissionsCrankshaft transmissionEngineeringScrew thread

To provide a rear swing arm installation structure that does not require large tightening force and upsizing and can avoid backlash of a rear swing arm. In a rear swing arm installation structure, a cylindrical spacer into which a pivot shaft is inserted is screwed into the pivot bearing holes of a pair of vehicle body frames. The spacer includes a head section of a large diameter and a screw section having a smaller diameter than the head section. The head section touches an end face of the pivot bearing hole of the vehicle body frame and the tip of the screw section touches an end face of a rear swing arm.

Owner:HONDA MOTOR CO LTD

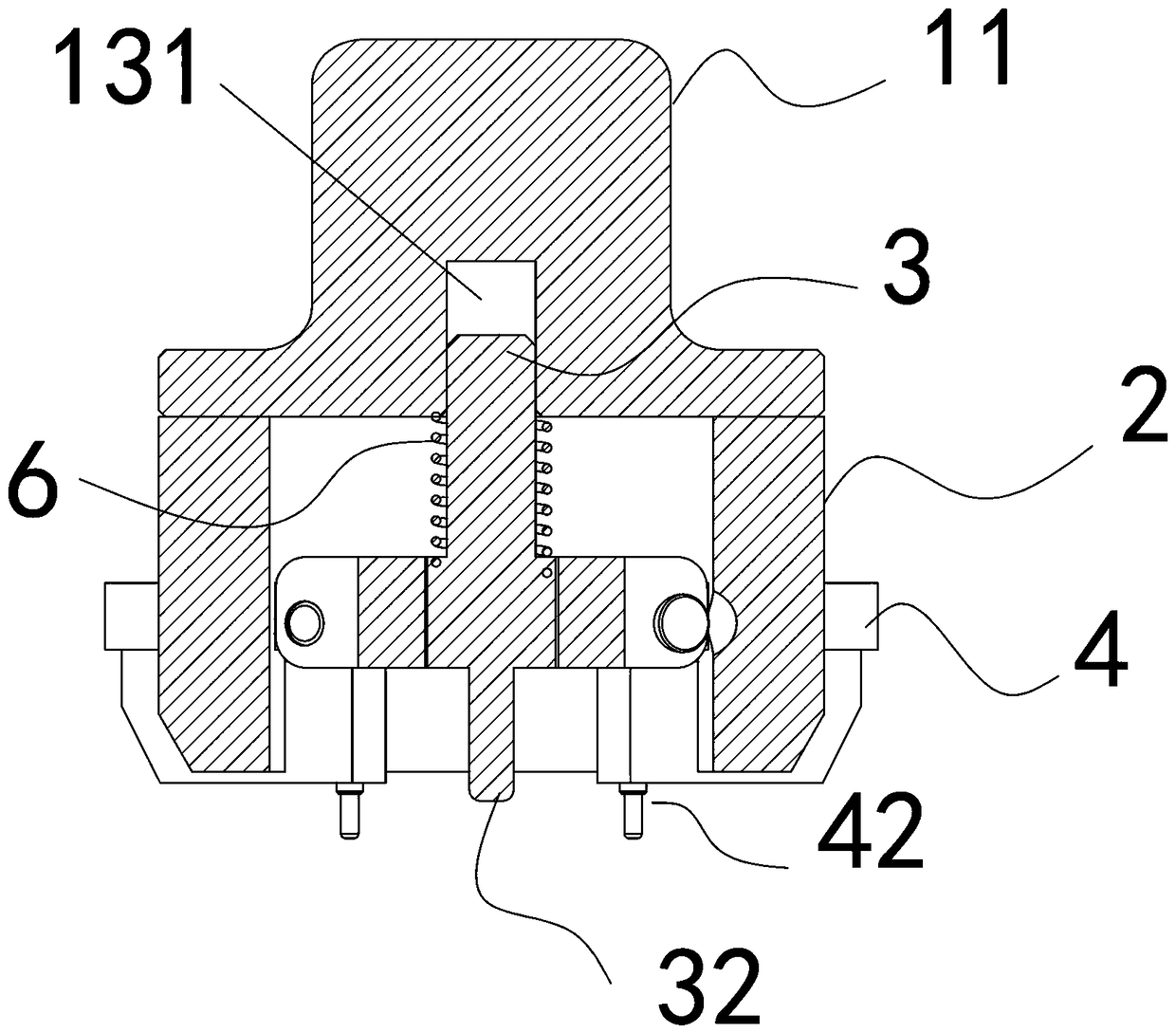

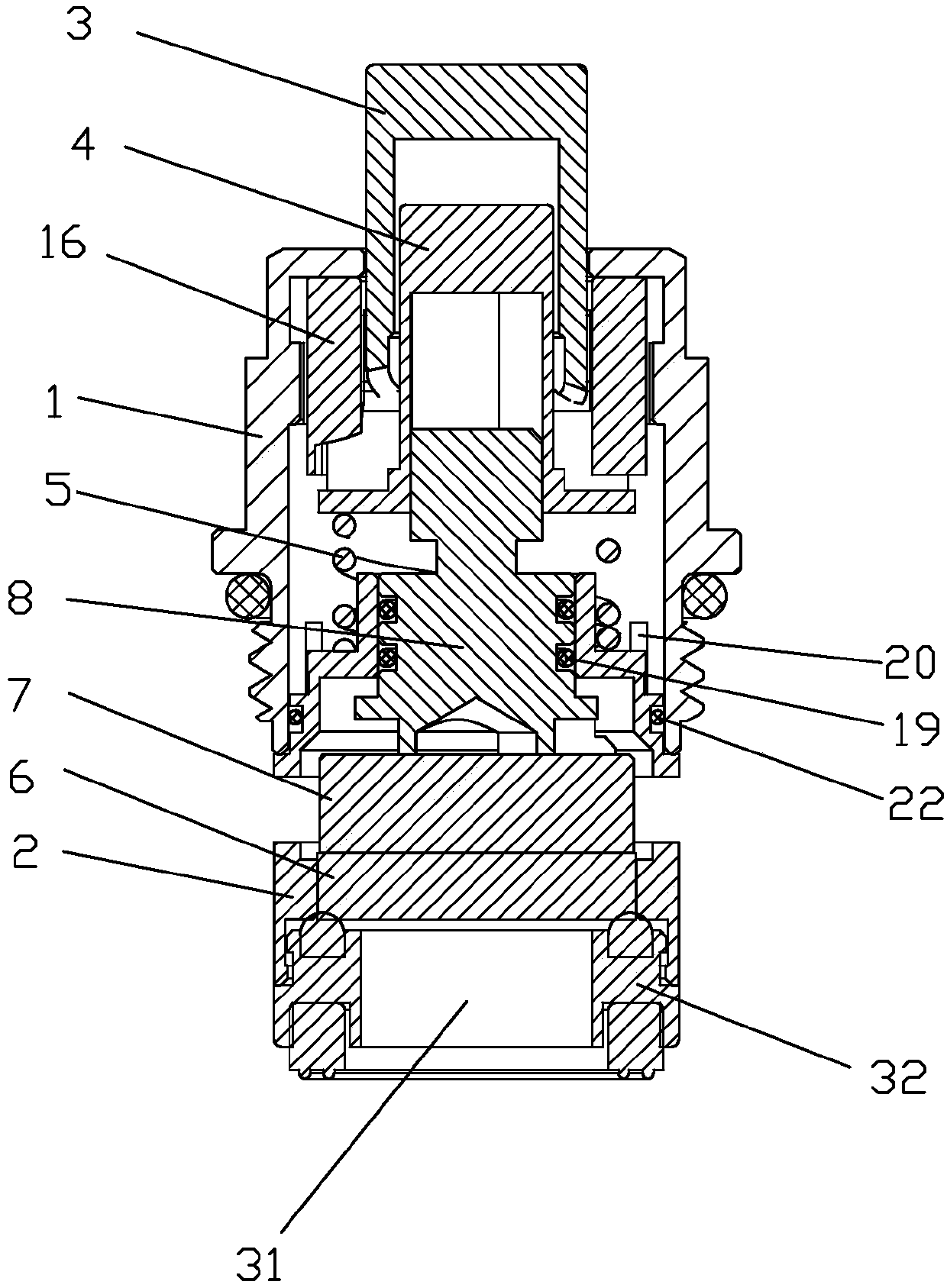

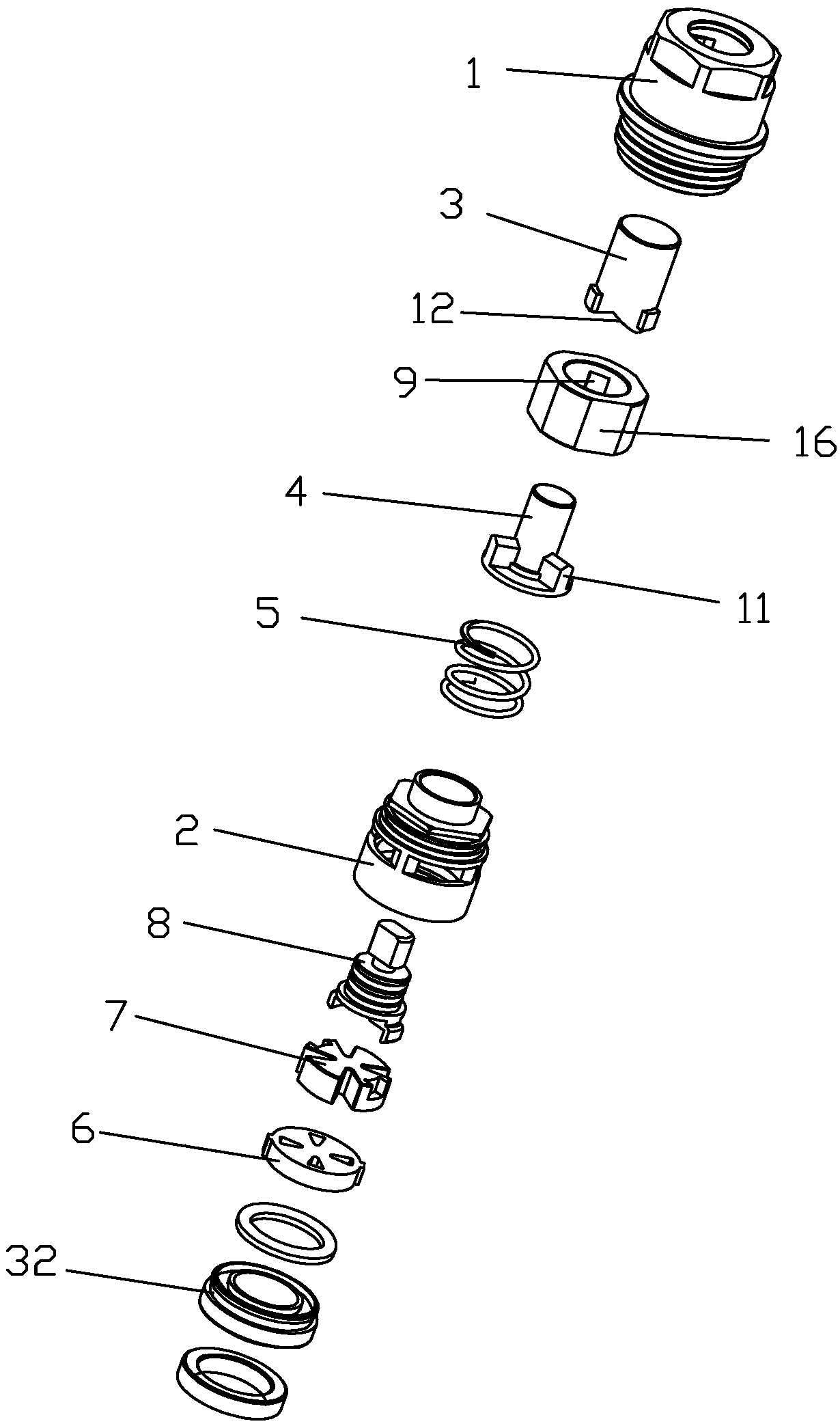

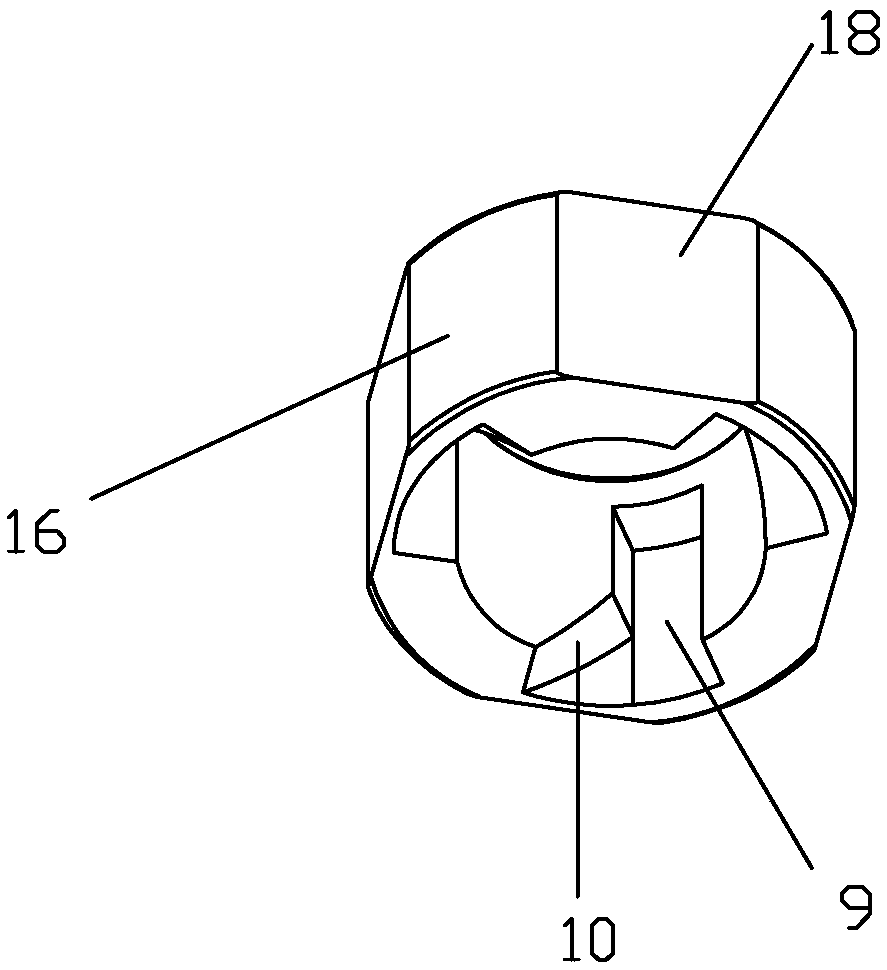

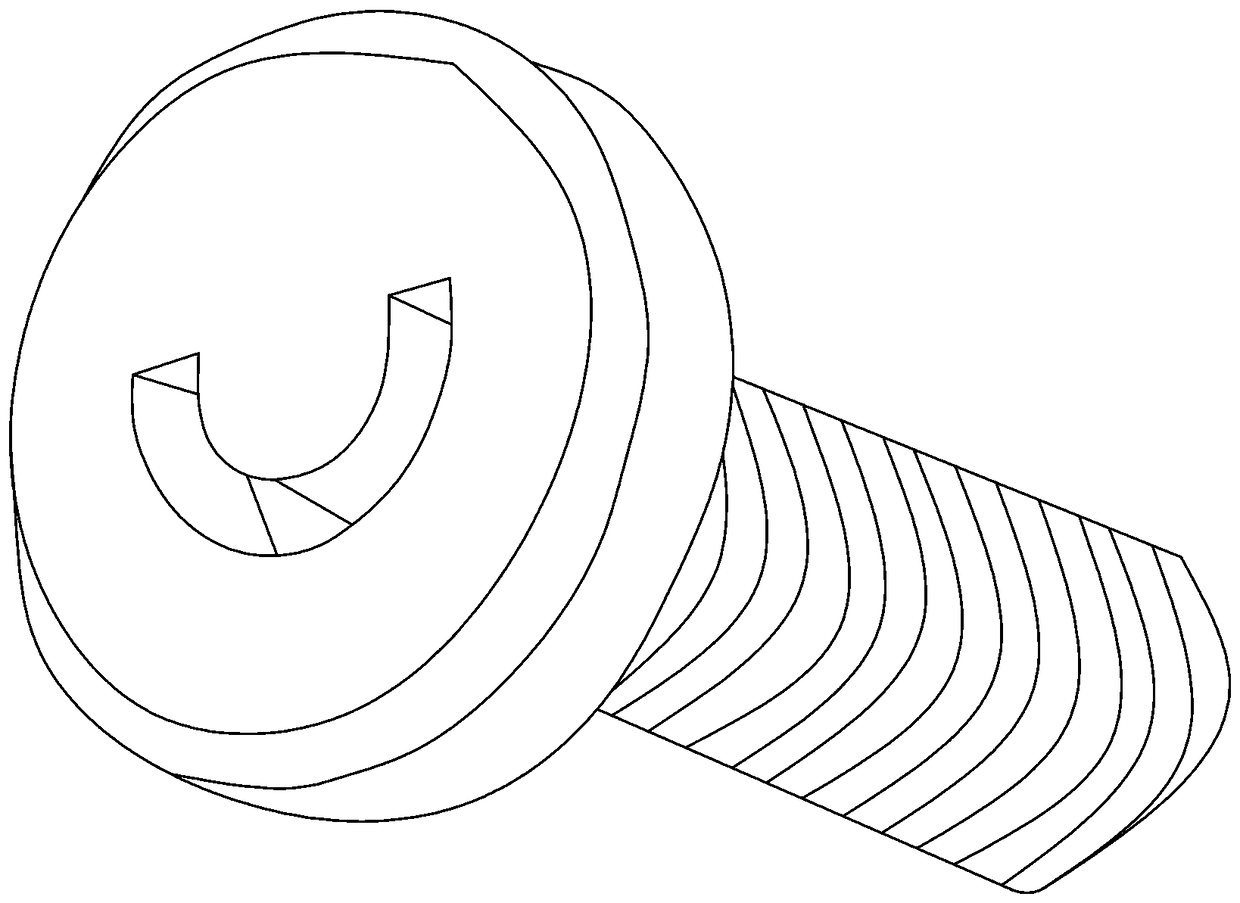

Automatic reset pressing valve element

PendingCN109681672AImprove sealingReduce resistanceOperating means/releasing devices for valvesMultiple way valvesRotational axisAutomatic testing

Owner:浙江赤心实业股份有限公司

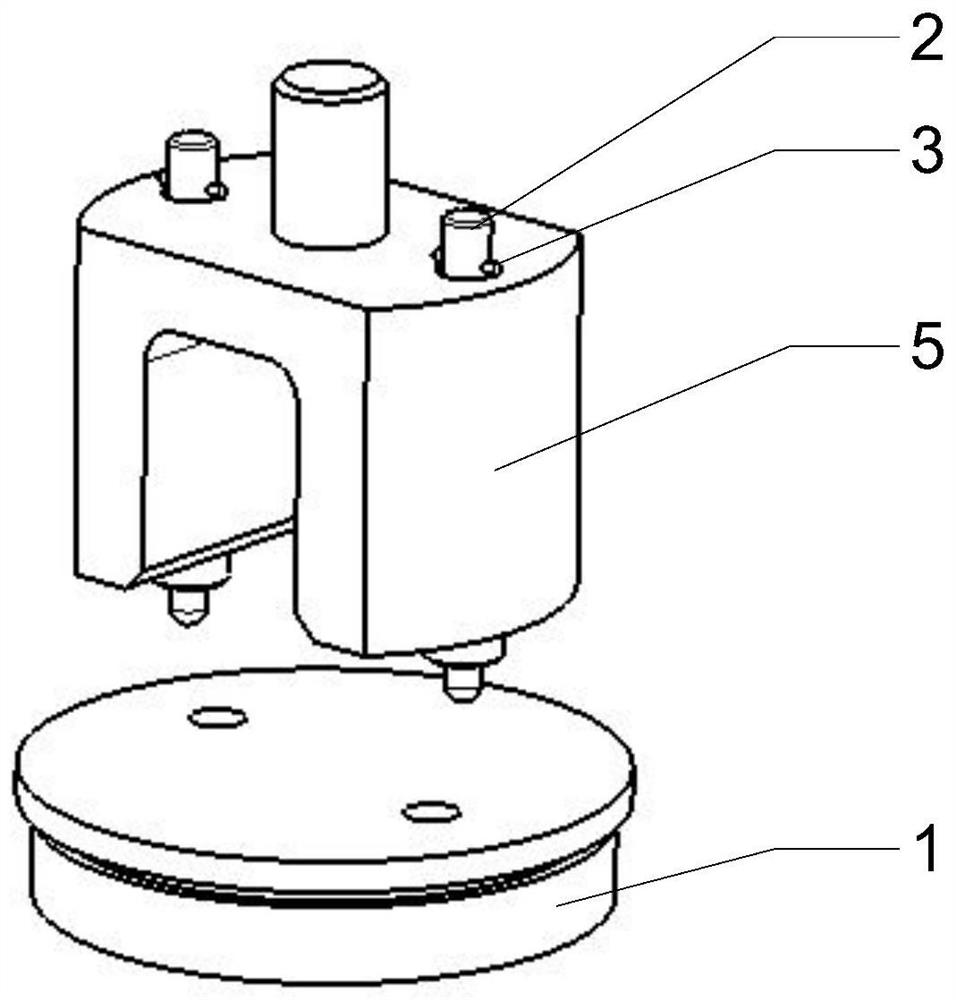

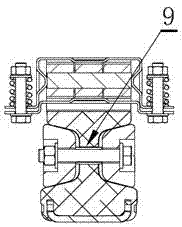

Non-standard precise screw tightening robot

The invention relates to the technical field of machining screw tightening, in particular to a non-standard precise screw tightening robot. One end of a second cylinder is fixedly connected with the other end of a first cylinder; the other end of the second cylinder is fixed to a circular surface of a cone; one end of a first spring is fixed onto an inner circumference of a second support; a strip-shaped hole is formed along a radial direction of the bottom surface of the second support; one end of a staple bolt penetrates through the strip-shaped hole; one end of one side surface of a slidingblock is fixedly connected with the other end of the first spring; a circular bead is arranged on the other side surface of the sliding block; a hole is formed in the sliding block; one end of the staple bolt is located in the hole; the staple bolt is movably connected with the sliding block; a second spring is located in the hole; and one end of the second spring abuts against the other end of the staple bolt. The non-standard precise screw tightening robot provided by the invention has the characteristics of capabilities of transferring a larger tightening torque and realizing reducing without the help of extra power.

Owner:江苏南京国家农业高新技术产业示范区发展集团有限公司

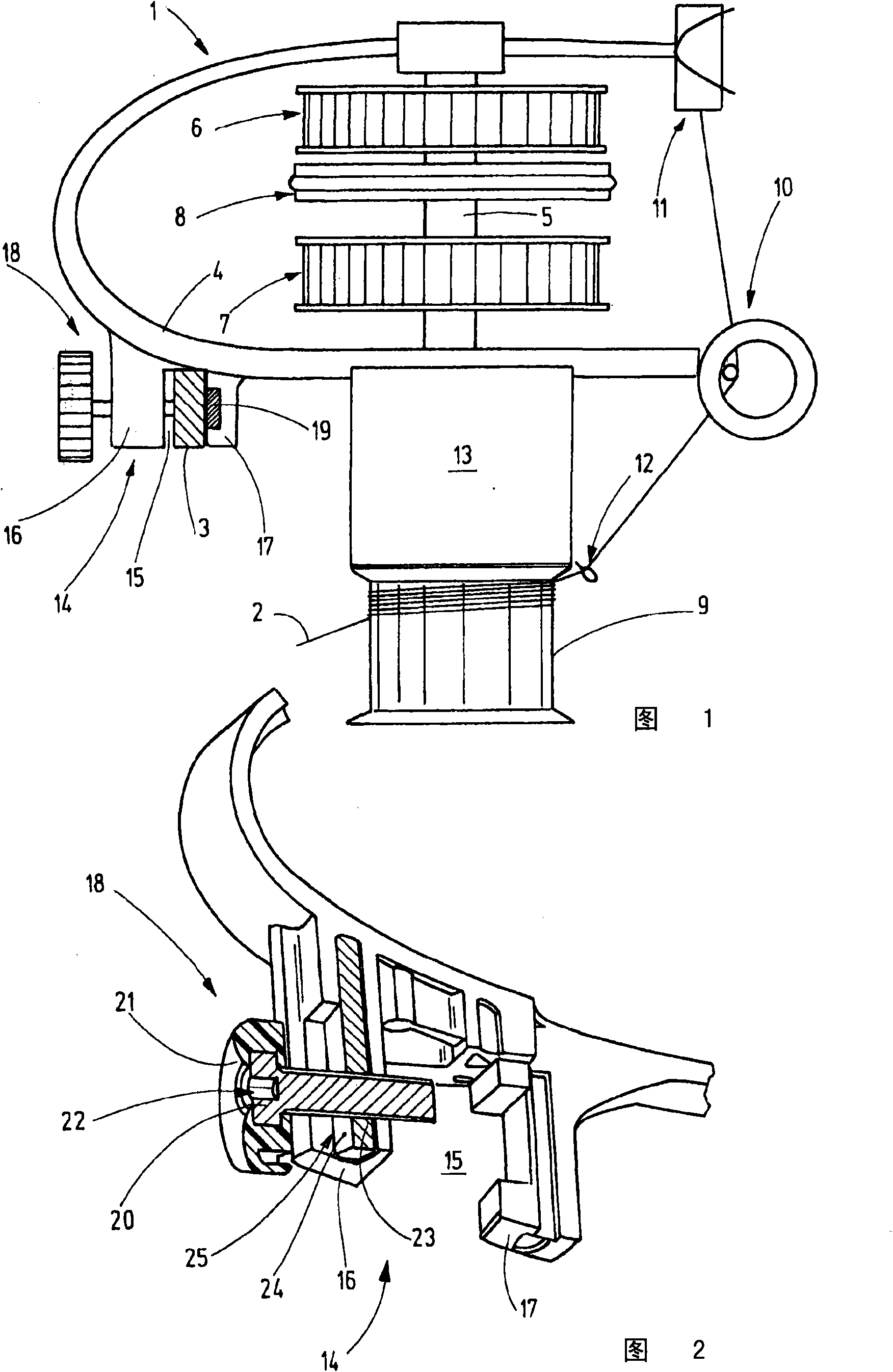

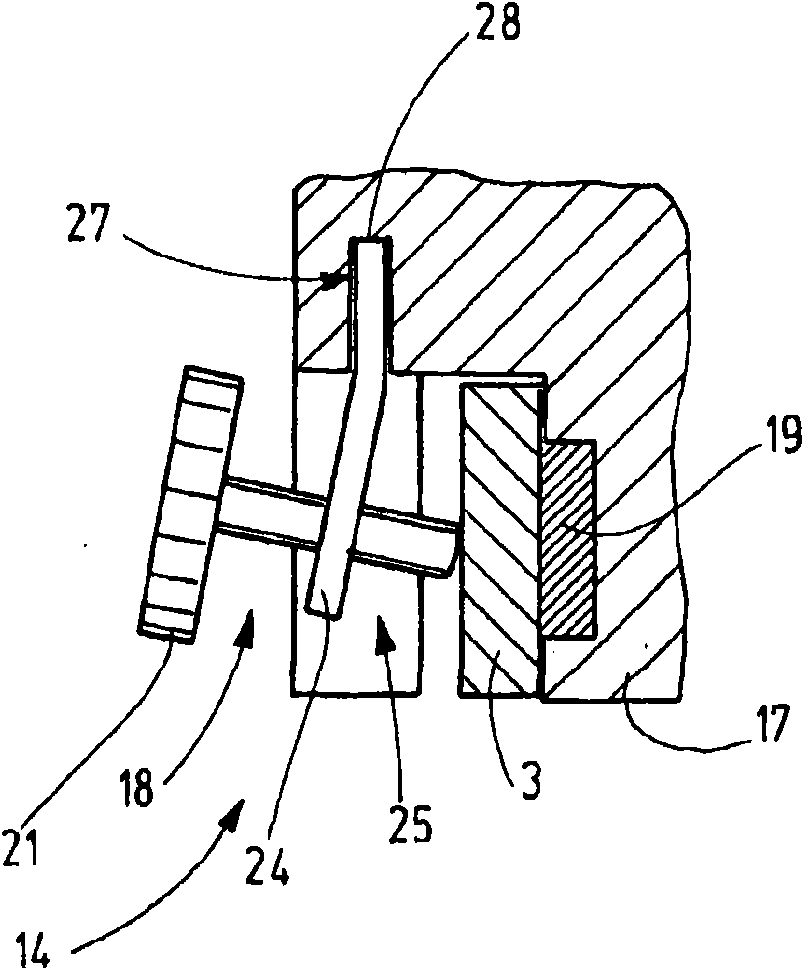

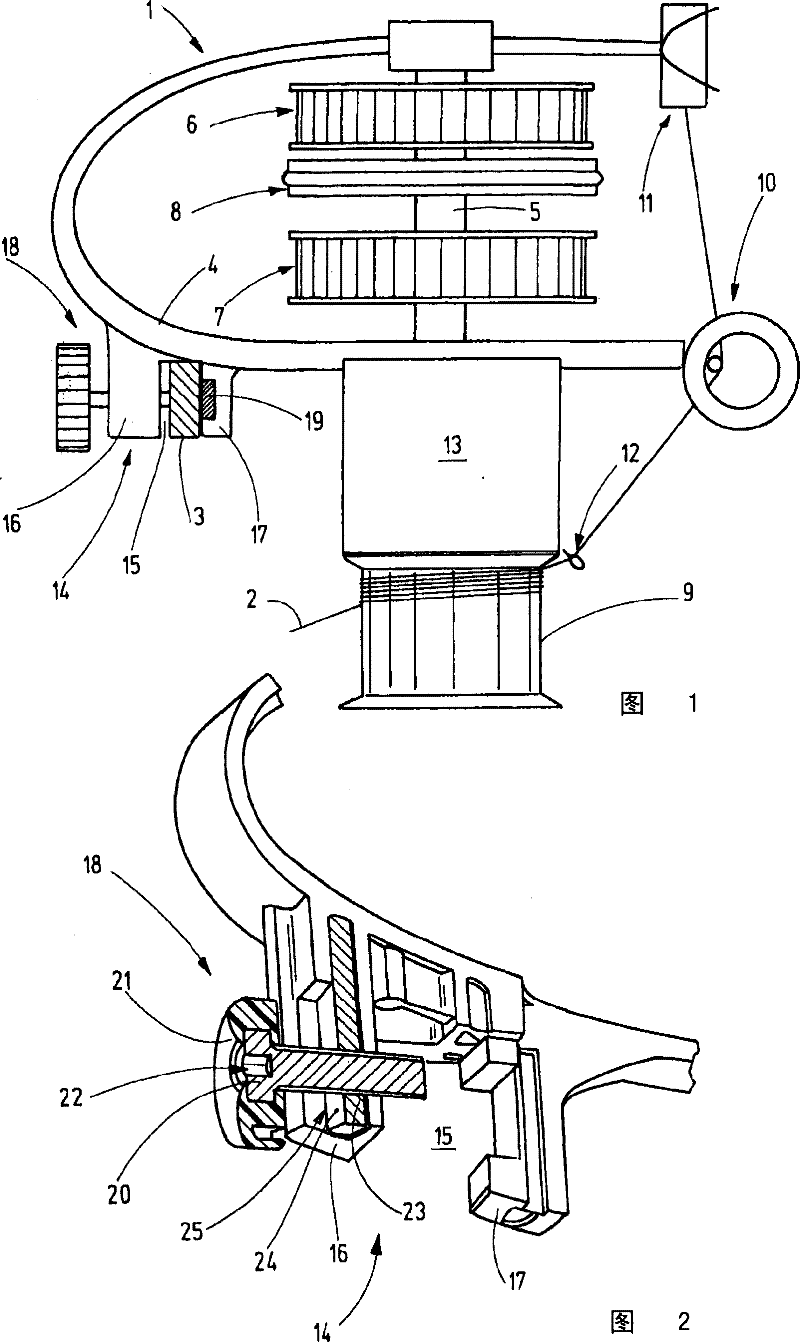

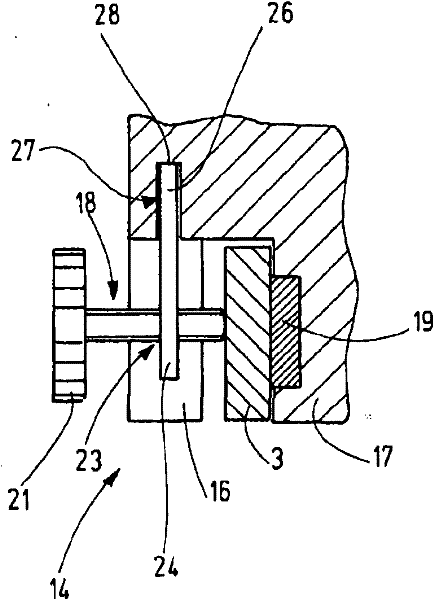

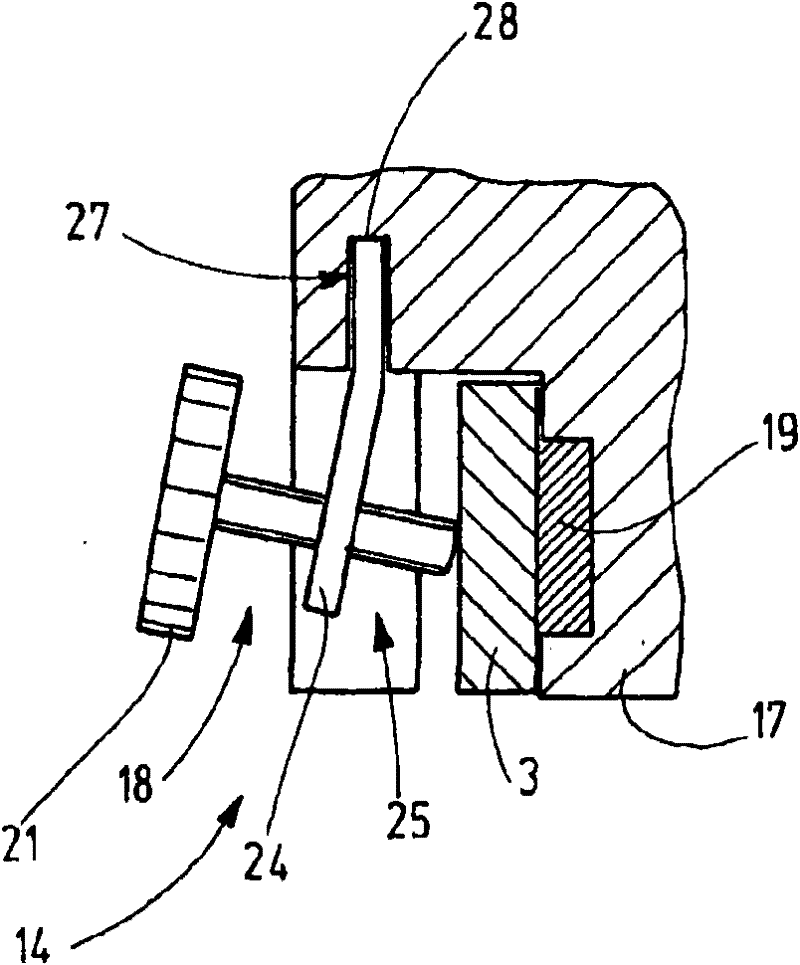

Yarn feeder with an overload-protected anchoring clip

ActiveCN101688338ANo risk of damageStable supportWeft knittingLoad modified fastenersYarnFlexural strength

A yarn feeder according to the invention or other device has a clip (14) with overload protection in the form of a force-limiting means (25). The latter is preferably formed by a deformable wearing part, for example in the form of a sheet-metal piece (24), which bears the attachment screw (18). The sheet-metal piece (24) is dimensioned with respect to its flexural strength in such a manner that itfirstly permits reliable tightening of the clip (14), but secondly prevents damage to the clip (14), in particular the expansion thereof.

Owner:MEMMINGER IRO GMBH

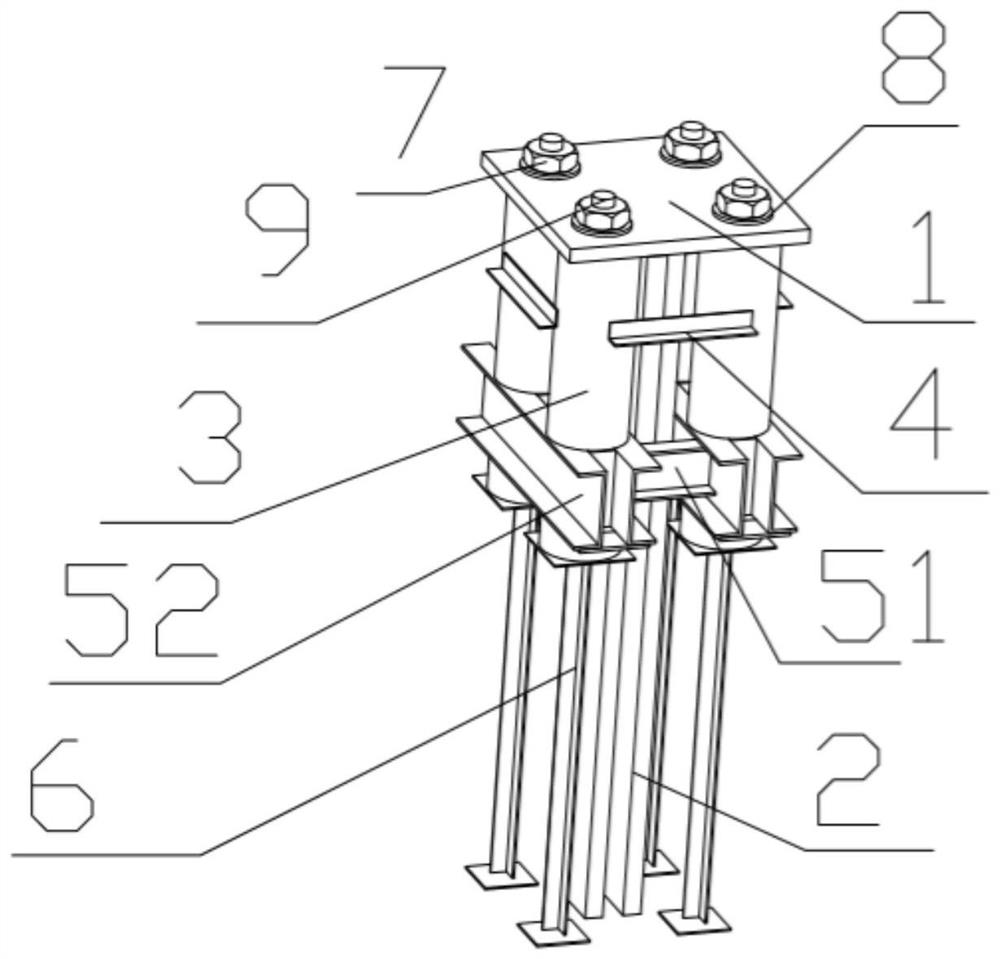

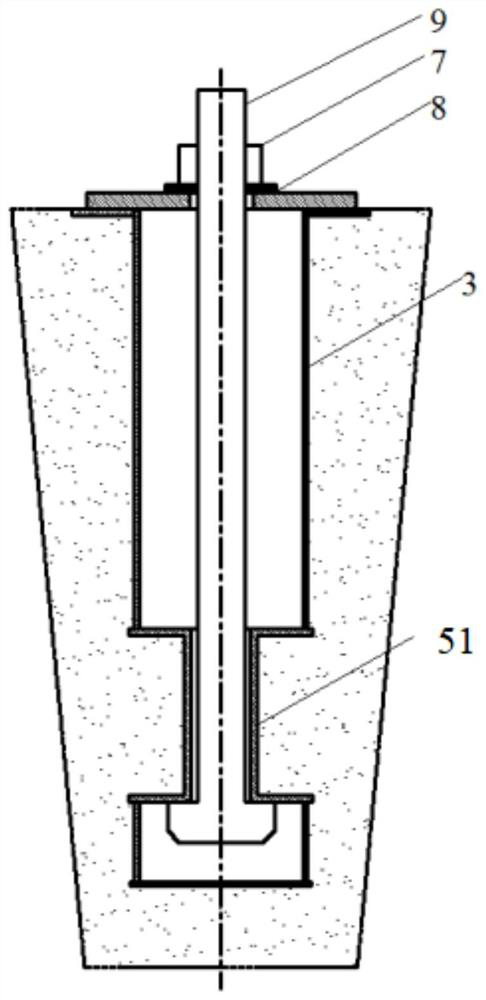

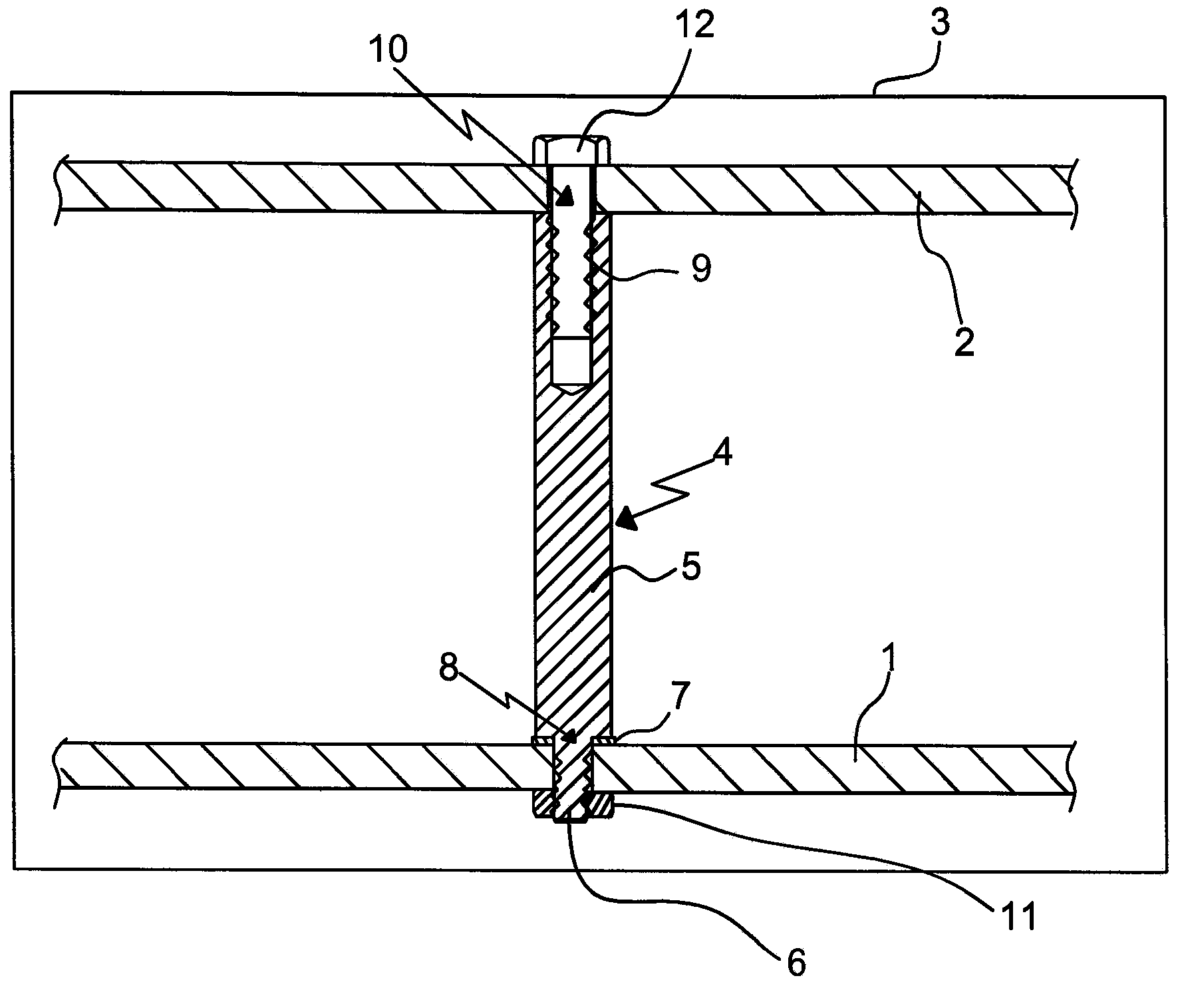

Gas turbine base fixing device and fixing device installing method

ActiveCN113062804AImprove installation accuracyEasy to controlGas turbine plantsFoundation engineeringClassical mechanicsEngineering

The invention relates to a gas turbine base fixing device and a fixing device installing method. The gas turbine base fixing device comprises a bearing part structure, an embedded part structure and a tightening structure, wherein the bearing part structure comprises a pre-embedded plate and a pre-embedded plate supporting base, the pre-embedded plate supporting base is connected to the pre-embedded plate, the embedded plate is used for fixing a gas turbine base, the embedded part structure comprises a sleeve, channel steel I and a bottom bracket, the tightening structure comprises a foundation bolt and a nut, the method comprises the following steps that after the embedded part is welded, delivered to a site and positioned, it is ensured that the levelness of the channel steel is within the tolerance range through a gradienter, primary grouting is conducted, and after concrete is solidified, the T-shaped foundation bolt can be placed in and screwed to the limiting baffle, and the nut is tightened. By means of the gas turbine base fixing device and the fixing device installing method, the embedded part structure is used, control over the position deviation of the whole embedded part in the concrete pouring process can be improved, and therefore it is guaranteed that the installation precision of the embedded part is high.

Owner:HANGZHOU TURBINE POWER GRP +1

A tightening manipulator for a self-returning c-groove precision screw tightening robot

ActiveCN108555583BLarge tightening torquePrevent slippingMetal working apparatusRobot handControl engineering

The invention relates to a self-deboosting tightening manipulator for a C type groove precise screw tightening robot. A connecting cylinder is used for fixing an electromagnet; one end of a central shaft penetrates through a central hole to be corresponding to an iron core; the interior angle of an L-shaped connecting rod is towards the central shaft; a guiding block is provided with three first sliding chutes, and the opening of each of the first sliding chutes is T-shaped; the first sliding chutes are arranged in the radial direction of the guiding block and communicate with each other; centrifugal blocks are positioned in the first sliding chutes; the upper end of each of the centrifugal blocks is T-shaped; the upper ends of the three centrifugal blocks fit the center to form a triangular first concave pit; the lower surface of each of the three centrifugal blocks is fan-shaped; the lower surfaces of the three centrifugal blocks fit to form a complete circle; an arc-shaped second concave pit is arranged on the outer surface of the lower end of each of the three centrifugal blocks; first springs are arranged in the second concave pits; and a clamping claw is arranged in a secondsliding chute. The self-deboosting tightening manipulator has the characteristics of transmitting larger tightening torque and effectively preventing the slippage phenomenon.

Owner:江苏二五七特显科技集团有限公司

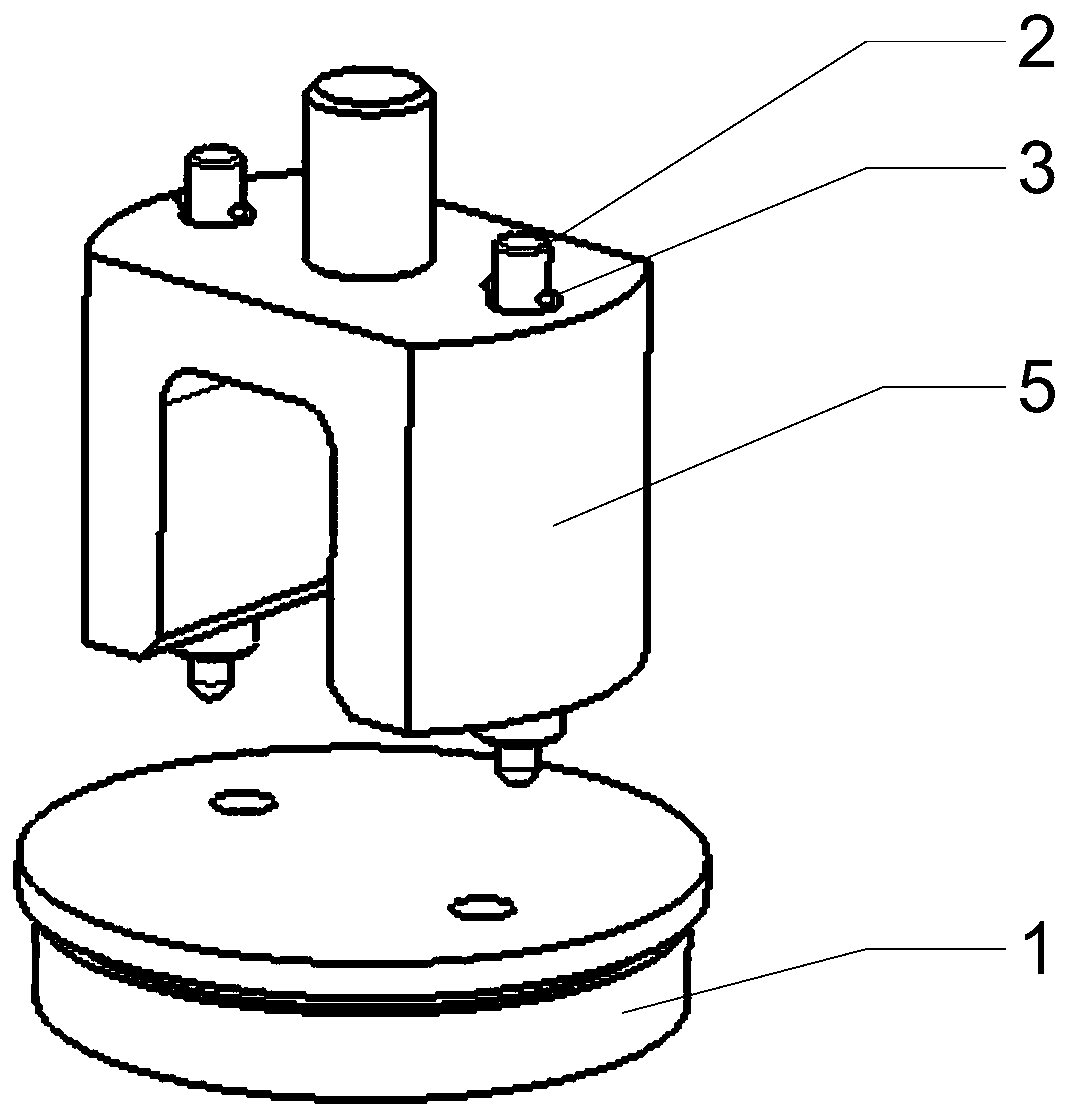

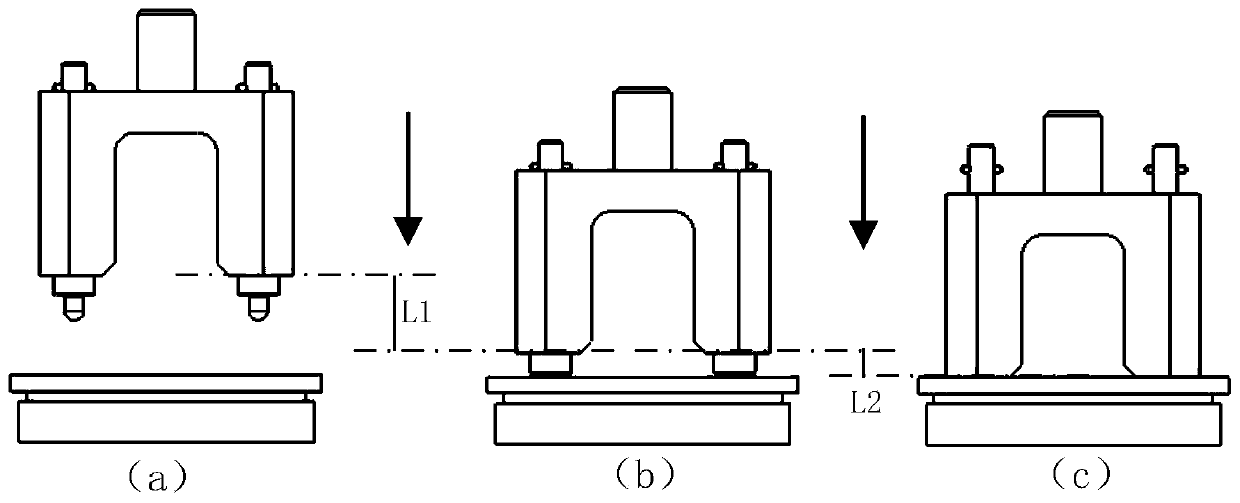

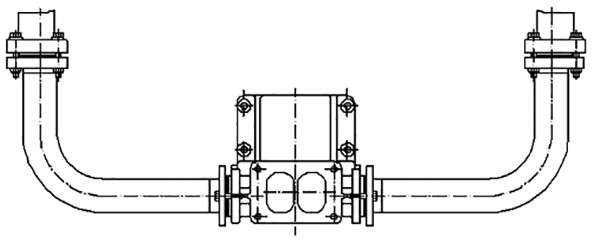

Flexible tightening head and tightening method

ActiveCN109928345ASolve the problem of small static friction torqueLarge tightening torqueRotating screw stopper insertionEngineeringBottle

The invention relates to a flexible tightening head and a tightening method, and belongs to the technical field of packaging machines. The problem that by means of an existing tightening device, metalexternally-threaded bottle covers, large in mass, poor in elastoplasticity, small in thread pitch and large in circle number, and internal threads of bottle bodies cannot be tightened is solved. Theflexible tightening head comprises an installation base body, telescopic rods and springs arranged on the telescopic rods in a sleeving manner. Reducing through holes used for upward and downward movement of the telescopic rods are formed in the installation base body. The longitudinal section of each reducing through hole is in a reversed-T shape. A working part matched with groove holes in the tops of the bottle covers is coaxially arranged at one end of each telescopic rod, and a limiting part used for limiting downward sliding of the telescopic rod is arranged at the other end of each telescopic rod. Each working part comprises a tip and a working cylinder. The diameter of the tips is smaller than or equal to the hole diameter of the groove holes. The diameter of the working cylindersis larger than the hole diameter of the groove holes and is smaller than or equal to the hole diameter of the lower portions of the reducing through holes. The flexible tightening head can provide large enough tightening torque to be suitable for automatic tightening of products with external threads, a tightening method is easy to operate, and cost is remarkably reduced.

Owner:BEIJING MECHANICAL EQUIP INST

External screwing combined thread piece for fabricated structure

PendingCN109853861ASolve the tightening problemExpand connectivityBuilding reinforcementsPull forceEngineering

Owner:SHANGHAI YIPINLILIAN CONSTR TECH CO LTD

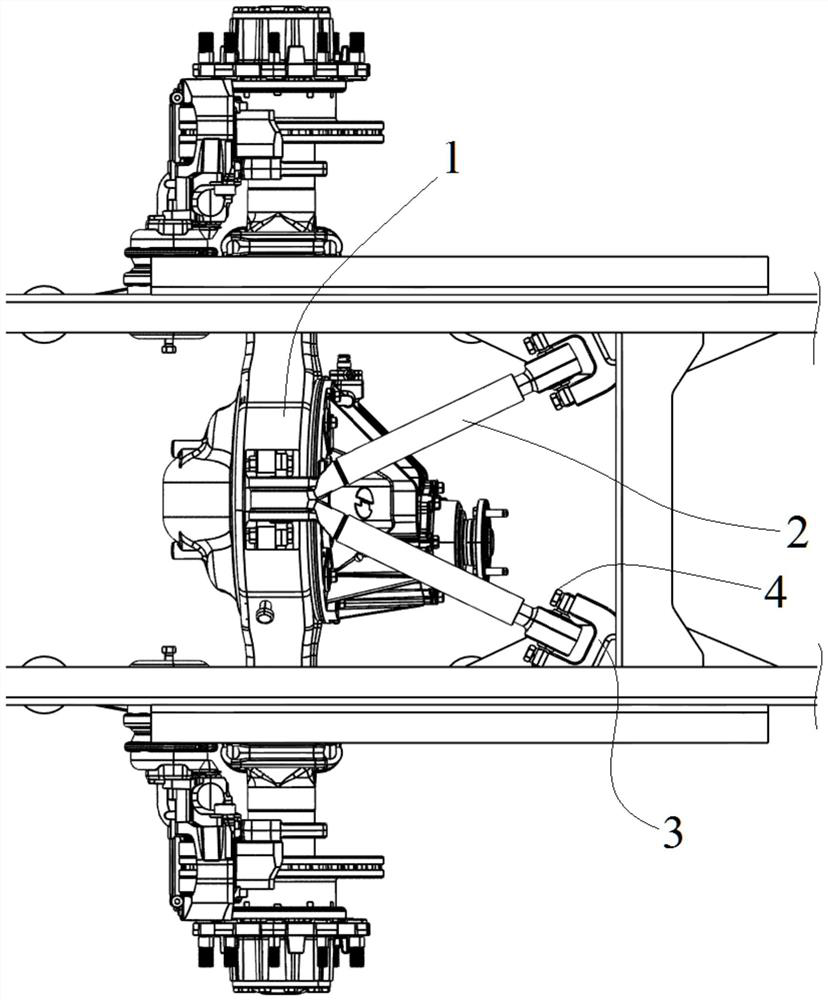

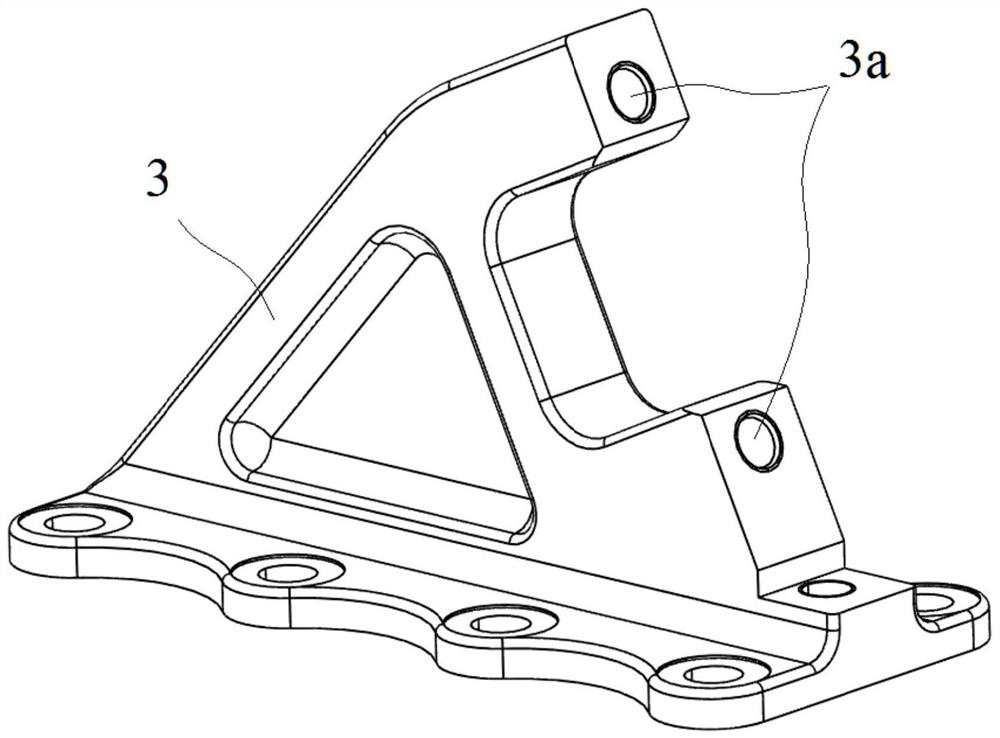

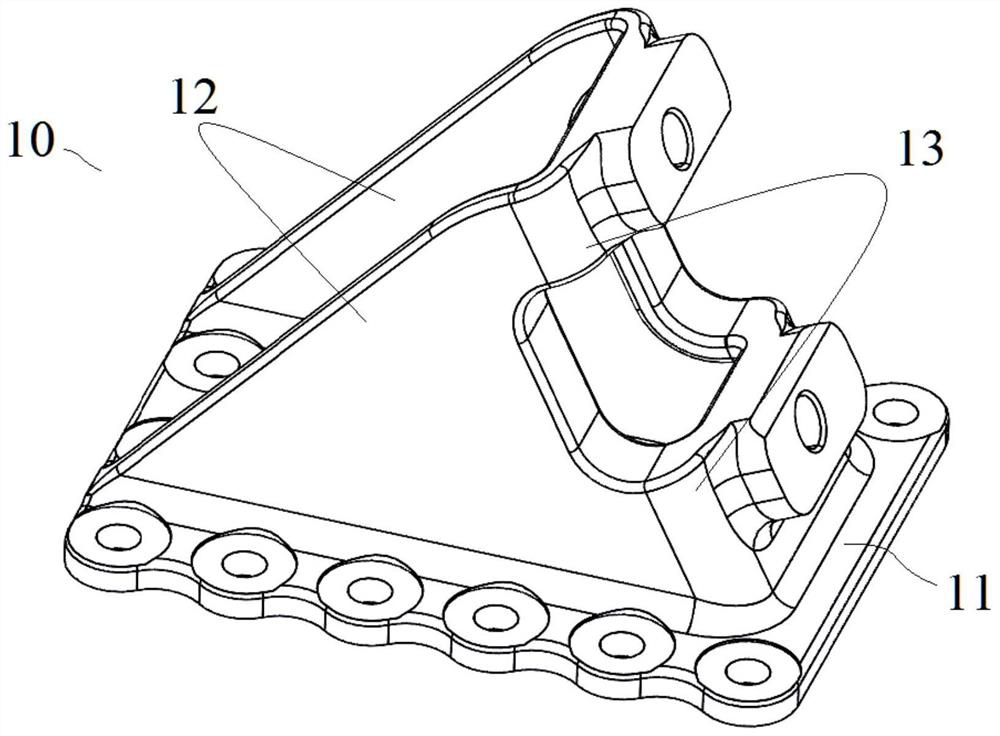

V-shaped thrust rod support and V-shaped thrust rod connecting structure

PendingCN114103575AEasy to assembleRealize structural hollowing outPivoted suspension armsEngineeringStructural engineering

The invention relates to a V-shaped thrust rod support and a V-shaped thrust rod connecting structure. The V-shaped thrust rod support comprises a bottom plate, a side plate and a mounting part, the number of the side plates is two, and the two side plates are vertically connected to the bottom plate and are oppositely arranged at intervals; the mounting part is connected between the two side plates and located at one ends of the side plates, two mounting holes used for mounting the V-shaped thrust rod are formed in the mounting part in a penetrating mode, on the premise that the strength is guaranteed, compared with an original support, light weight can be achieved, machining is convenient, it is guaranteed that the V-shaped thrust rod is easy and convenient to assemble, and the service life of the V-shaped thrust rod is prolonged. The tightening torque can be increased in a bolt and nut combined fastening mode, the anti-loosening effect is good, and loosening is not prone to occurring.

Owner:东风汽车底盘系统有限公司

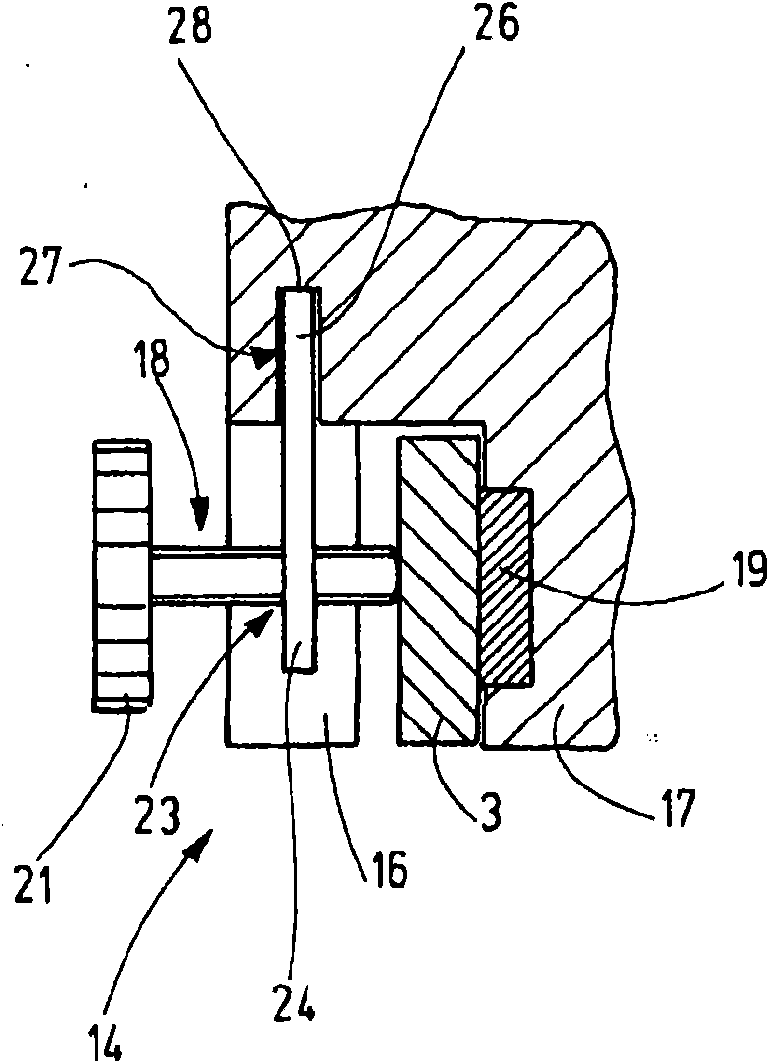

Connectors and Construction Machinery

InactiveCN103733441BReduce the numberEasy to assembleVehicle connectorsIncorrect coupling preventionElectric power transmissionPower cable

The present invention provides a connector and a construction machine. The connector (20) is used to connect a power cable for power transmission to an electrical device mounted on a vehicle, and includes: a device-side socket; a cable-side plug (22 ), which is plugged and unplugged relative to the socket on the equipment side; the detection switch (30), which is electrically connected and disconnected by using the mechanical contacts on the socket on the equipment side and the plug (22) on the cable side; on the equipment side The contact terminal of the detection switch (30) is provided on the socket, and the plug (22) on the cable side is provided with: a plug shell (41) electrically grounded by connecting with the socket on the equipment side; covering the plug shell (41) ), the cover plate (43) has: an insulating plate body (51); the contact conductor (52) of the detection switch (30) in contact with the contact terminal, the plate body (51) and the contact conductor (52) are integrally formed.

Owner:KOMATSU LTD

Yarn delivery device with overload-protected fastening gripper

ActiveCN101688338BNo risk of damageStable supportWeft knittingLoad modified fastenersYarnFlexural strength

The yarn delivery device or another device according to the invention comprises a gripper (14) having an overload protection in the form of a force limiting device (25). The means preferably represent a deformable wear part, for example in the form of a sheet metal part ( 24 ) bearing the clamping screw ( 18 ). With regard to its bending strength, the sheet metal part (24) is designed so that it can tighten the clamp (14) securely on the one hand, but prevents the clamp (14) on the other hand. damage, and in particular prevent the holder from unraveling.

Owner:MEMMINGER IRO GMBH

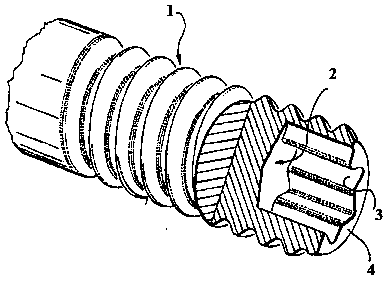

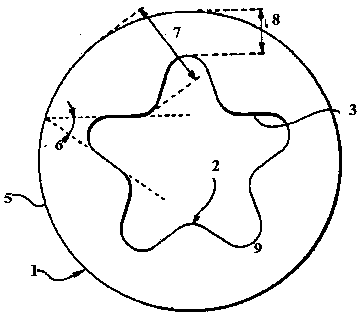

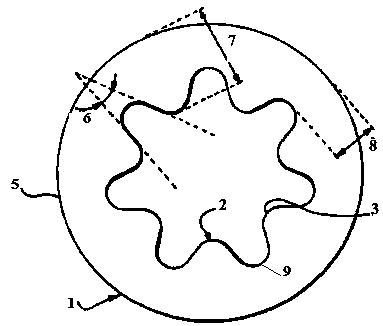

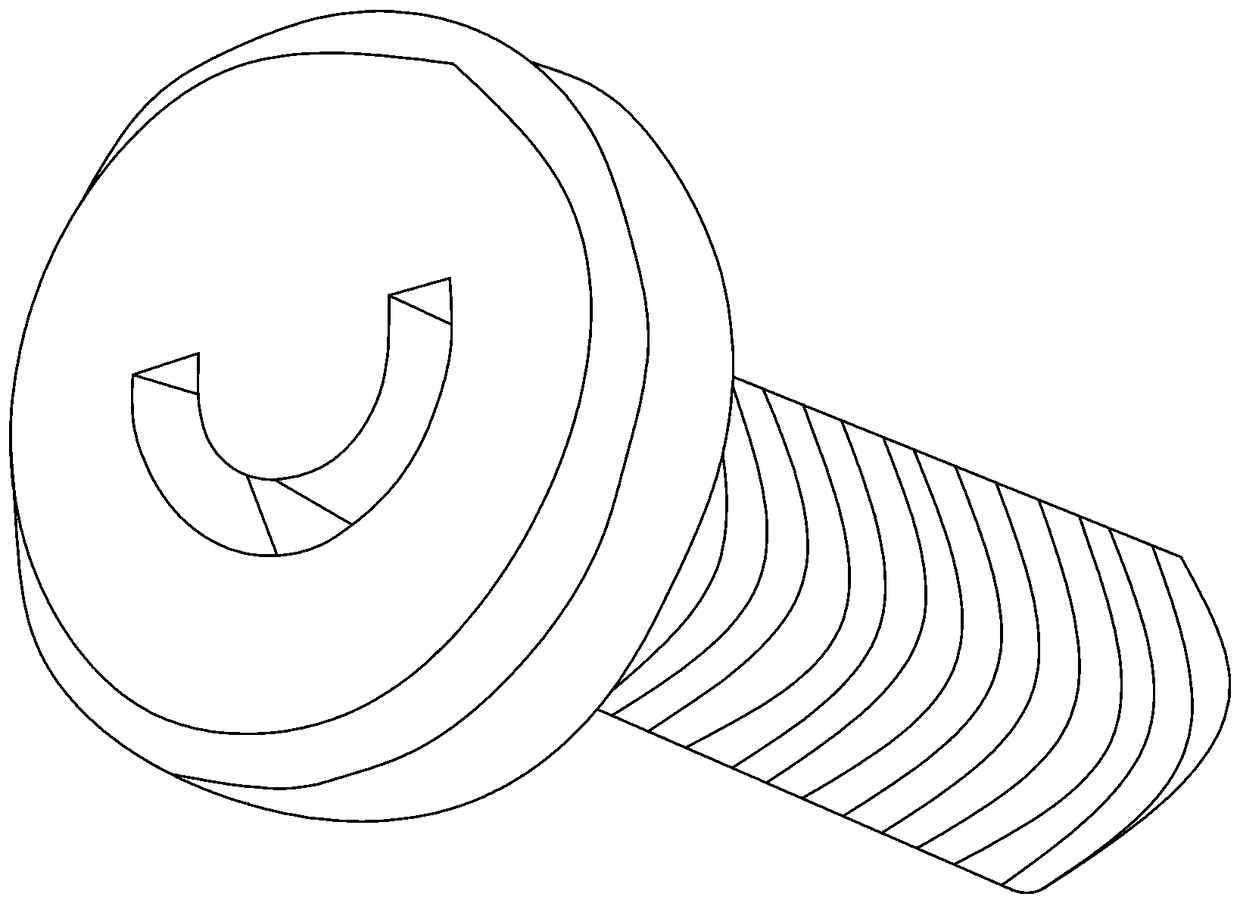

Outer thread tail end pulling twisting coining part

The invention discloses an outer thread tail end pulling twisting coining part. The outer thread tail end pulling twisting coining part comprises a hollow coining part (2) at the tail end of an outerthread (1) and a continuous curve (3) on an end (4), the continuous curve (3) is composed of evenly-distributed four to ten same or different petals (9), the adjacent petals (9) are connected througharcs tangent with side faces, and the ratio of the maximum distance (7) between the hollow coining part (2) and the thread outer circumference surface (5) to the minimum distance (8) is 1.25 to 1.75.The coining part has the beneficial effects that punching forming is easily achieved, cracking is not prone to happening, and the twisting torque is large.

Owner:AVIC STANDARD PARTS MFG

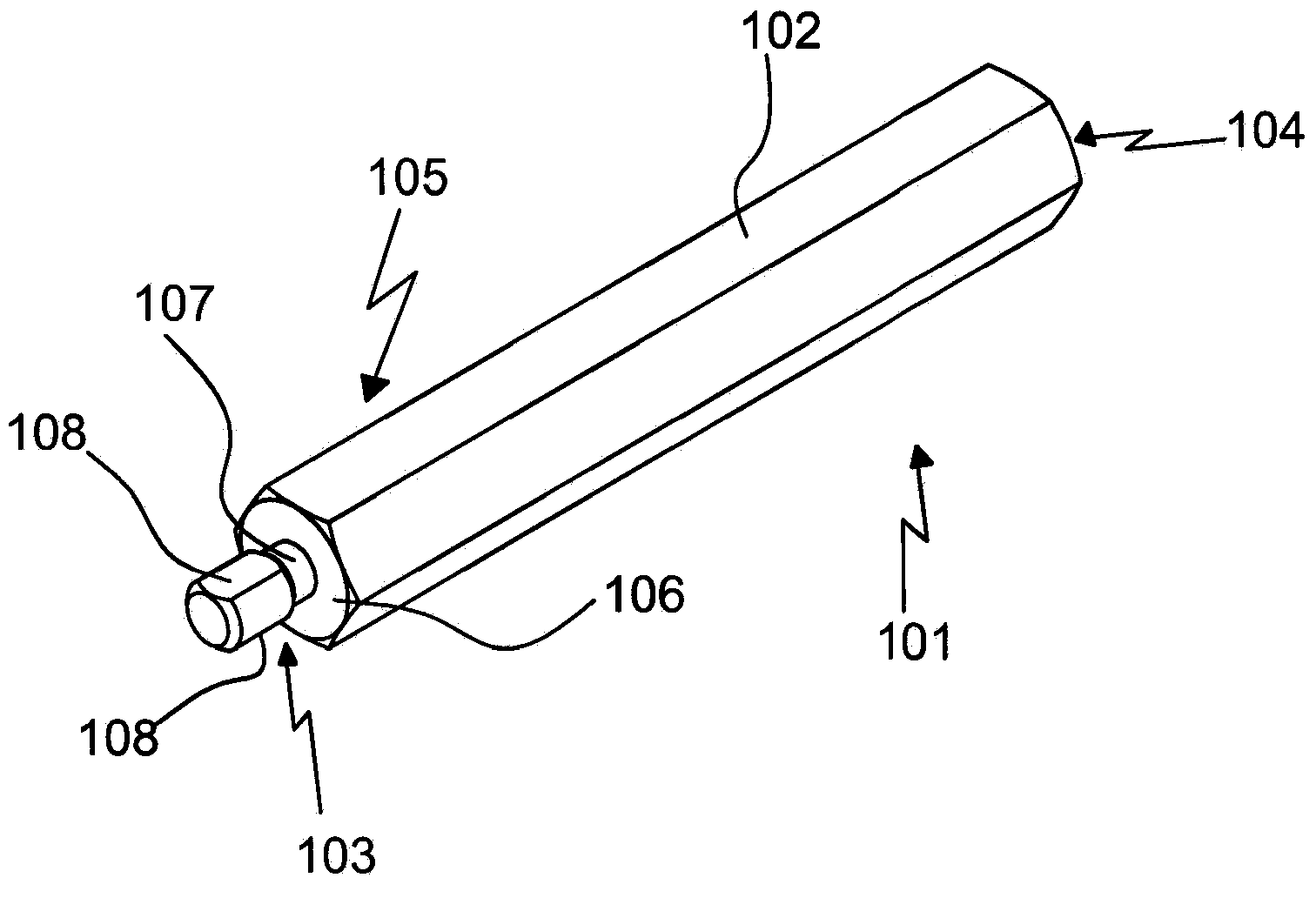

A non-standard screw tightening robot

The invention relates to the technical field of nonstandard screw tightening in machining, in particular to a nonstandard screw tightening robot comprising an ejector cap. One end of the ejector cap is provided with a round hole. The nonstandard screw tightening robot further comprises a center shaft. One end of the center shaft extends into a cavity. The other end of the center shaft is providedwith a sliding platform and an ejector rod. The sliding platform, the ejector rod and the center shaft are integrally formed. The outer surface of the center shaft is provided with an elastic piece. The sliding platform is provided with three I-shaped first guide grooves. The nonstandard screw tightening robot further comprises three U-shaped sliding blocks with the openings facing the sliding platform. One end of each U-shaped sliding block is further provided with an inclined convex block with a T-shaped cross section. The other end of each U-shaped sliding block is provided with a clampingand sleeving piece extending out. The nonstandard screw tightening robot further comprises a guide cylinder. The guide cylinder is provided with second guide grooves. The nonstandard screw tighteningrobot has the advantages of transmitting a large tightening torque, achieving reducing without the need for extra power force and being compact in structure and high in reliability.

Owner:上海帝升实业有限公司

Self-force return C type groove precision screw tightening robot

ActiveCN108526864AAvoid slippingLarge tightening torqueMetal working apparatusEngineeringMechanical engineering

Owner:点栈(绍兴)智能科技有限公司

A flexible tightening head and tightening method

ActiveCN109928345BSolve the problem of small static friction torqueLarge tightening torqueRotating screw stopper insertionEngineeringBottle cap

The invention relates to a flexible tightening head and a tightening method, belonging to the technical field of packaging machinery, which solves the problem that the existing tightening device cannot meet the requirements of tightening the metal external threaded bottle cap and the inner thread of the bottle with large quality, poor elastic-plasticity, small pitch and many turns. The problem. The flexible tightening head includes a mounting base, a telescopic rod, and a spring sleeved on the telescopic rod. The mounting base is provided with a variable-diameter through hole for the telescopic rod to move up and down. The longitudinal section of the variable-diameter through hole is convex; one end of the telescopic rod There is a working part coaxial with the slot on the top of the bottle cap, and the other end is provided with a limiting part for limiting the downward sliding of the telescopic rod; the working part includes a terminal and a working cylinder, and the diameter of the terminal is smaller than or equal to the diameter of the slot. The diameter of the working cylinder is larger than the aperture of the slot hole and smaller than or equal to the lower aperture of the variable diameter through hole. The flexible tightening head of the invention can provide sufficient tightening torque to adapt to the automatic tightening of products with external threads, and the tightening method is easy to operate and significantly reduces the cost.

Owner:BEIJING MECHANICAL EQUIP INST

A self-returning non-standard precision screw tightening robot

ActiveCN108453497BLarge tightening torquePrevent slippingMetal working apparatusCircular discClassical mechanics

The invention relates to a self-resetting non-standard precise screw screwing-up robot comprising a force supply mechanism and a centrifugal clamping mechanism. The other end of a center shaft is provided with a round sliding table, the round sliding table is provided with three H-shaped second sliding slots, and the second sliding slots are formed along the oblique plane of the round sliding table. One ends of chuck sliding blocks are embedded into first sliding slots and are provided with inclined first protruding blocks with the cross sections being in T shapes, and the first protruding blocks are embedded into the second sliding slots. A variable-diameter device comprises a disc-shaped installation block with the opening facing downwards, a round guide block, three centrifugal blocks and a round second spring. The guide block is provided with three T-shaped third sliding slots, a first pit in an equilateral triangle shape is formed in the center of the three attached centrifugal blocks, the lower ends of the three centrifugal blocks are attached to one another to form a cylinder, and the bottom faces of the centrifugal blocks are downwards provided with torsion needles. The self-resetting non-standard precise screw screwing-up robot has the characteristics that large tightening torque is transferred, and the slip phenomenon can be effectively prevented.

Owner:江苏中鲲智能装备有限公司

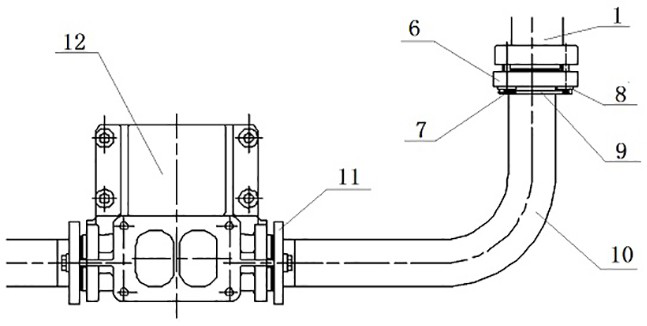

Exhaust system structure capable of improving reliability

PendingCN113202608AIncrease residual preloadImprove high temperature strengthExhaust apparatusNutsConvertersDiesel engine

The invention discloses an exhaust system structure capable of improving reliability, and belongs to the field of diesel engine exhaust systems. The exhaust system structure comprises a metal wave-shaped exhaust pipe gasket arranged between an exhaust pipe and a cylinder cover of a diesel engine, a plurality of exhaust pipe bolts fixedly connected with the exhaust pipe and the cylinder cover, first anti-loosening pads arranged on the exhaust pipe bolts, a first elbow flange arranged between the exhaust pipe and an exhaust elbow, a plurality of bolts with holes for fixedly connecting the exhaust pipe and the exhaust elbow, a second anti-loosening pad arranged between a first elbow flange and the bolts with holes, and a second elbow flange arranged between the exhaust elbow and a pulse converter, wherein the exhaust elbow is fixedly connected with the pulse converter through a plurality of second bolts with holes, and meanwhile third anti-loosening pads are arranged between the second bolts with holes and the second elbow flange. The problems that bolts of a diesel engine exhaust system are loosened, and smoke leaks from a junction surface are solved, and the use requirement is met; and the structure is simple, and installation and maintenance are simple and easy.

Owner:HEBEI HUABEI DIESEL ENGINE

A self-returning C-groove precision screw tightening robot

ActiveCN108526864BLarge tightening torquePrevent slippingMetal working apparatusStructural engineeringMechanical engineering

The invention relates to a self-force return C type groove precision screw tightening robot. A connecting barrel is used for fixing an electromagnet, one end of a center shaft penetrates a center holeto correspond to an iron core, an inner corner of an L-shaped connecting rod faces a center shaft, a guide block is provided with three first sliding grooves with T-shaped openings, the first slidinggrooves are arranged in the radial direction of the guide block, the first sliding grooves are communicated, centrifugal blocks are located in the first sliding grooves, the upper ends of the centrifugal blocks are in T shapes, the upper ends of the three centrifugal blocks are attached to the center to form first pits of triangles, the lower surfaces of the three centrifugal blocks are in fan shapes, the lower surfaces of the centrifugal blocks are attached to form a complete round, arc-shaped second pits are formed in the outer surfaces of the lower ends of the centrifugal blocks, first springs are arranged in the second pits, and clamping claws are located in the second sliding grooves. The self-force return C type groove precision screw tightening robot has the beneficial effects thatlarge tightening moment is transmitted, and the slipping phenomenon is effectively prevented.

Owner:点栈(绍兴)智能科技有限公司

Solder spacer and electronic module comprising such a spacer

ActiveCN104412725AFastening strength achievedLarge tightening torquePrinted circuit assemblingStacked spaced PCBsEngineeringSolder paste

Owner:SAGEMCOM BROADBAND

Caterpillar track four-axis automatic screwing machine

ActiveCN101941149BGuaranteed tightening qualityLarge tightening torqueMetal working apparatusElectrical controlEngineering

The invention discloses a caterpillar track four-axis automatic screwing machine, comprising a frame part, a linear body part, a stepping mechanism, a screwing mechanism and an electrical control part, wherein the linear body part is mounted in a lower space inside a frame body of the frame part, the stepping mechanism is mounted on an underframe of the linear body part, the screwing mechanism is mounted a screwing head ascending / descending structure of the frame part; the linear body part, the stepping mechanism, the screwing mechanism and the frame part are subjected to corresponding electrical control to automatically complete conveyance, guidance, positioning, clamping and screwing of a whole caterpillar track. The caterpillar track four-axis automatic screwing machine can be suitable for the automatic screwing of the caterpillar tracks in six specifications or more and can accurately screw four bolts simultaneously with large screwing torque, thereby ensuring the screwing quality of the connection between caterpillar track and bolts, realizing automatic operation and bringing high production efficiency.

Owner:SHANGHAI INGERSOLL RAND COMPRESSOR CO LTD

Rail transmit conductor rail compensation device

InactiveCN107878260AGood electrical conductivityFlexible left and rightPower railsEngineeringChangeover

The invention relates to a rail transmit conductor rail compensation device which includes a left sliding rail, a middle sliding rail, a right sliding rail, anchoring clamping plates, a current connector main slice, a current connector auxiliary slice and a changeover backing plate. The right end face of the left sliding rail is provided with an insertion connection mechanism A, the two end facesof the middle sliding rail are provided with insertion connection mechanisms B, the left end face of the right sliding rail is provided with an insertion connection mechanism C, the insertion connection mechanism is in insertion connection with the insertion connection mechanism B through a gear shaping structure, and the insertion connection mechanism C is in insertion connection with the insertion connection mechanism B through a gear shaping structure. The left sliding rail and the right sliding rail are provided with long holes, the middle sliding rail is provided with fixing holes, the anchoring clamping plates are mounted on the two sides of the left sliding rail, the middle sliding rail and the right sliding rail through connecting pieces, the long holes and the fixing holes, and the anchoring clamping plates are fixedly connected with the middle sliding rail and slidably connected with the left sliding rail and the right sliding rail. The current connector main slice is fixedlyconnected to the upper end face of the left sliding rail through a conductive part, the current connector auxiliary slice is connected to the upper end face of the right sliding rail through a conductive part, and the main slice is slidably connected with the auxiliary slice.

Owner:ZHENJIANG DAQO SECHERON TRACTION POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com