Exhaust system structure capable of improving reliability

An exhaust system and reliability technology, applied in exhaust devices, connecting components, engine sealing devices, etc., can solve problems such as failure to meet exhaust temperature requirements, lack of anti-loosening measures for bolts, and ablation of non-metallic liners , to achieve the effect of strengthening fastness, preventing flange deformation and eliminating installation stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

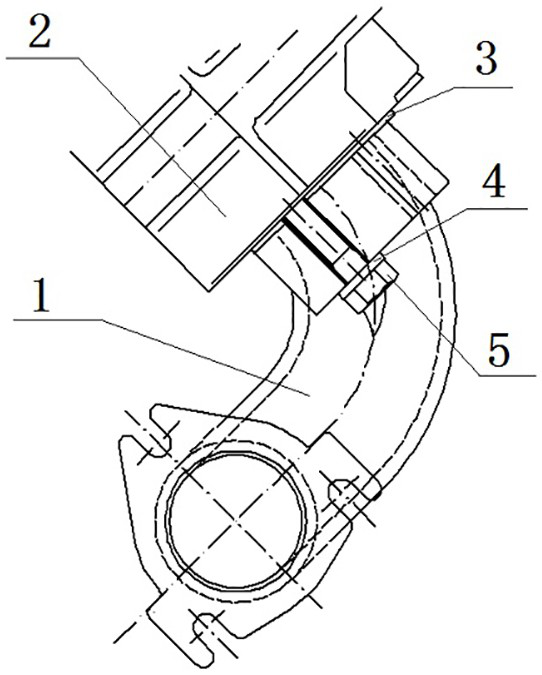

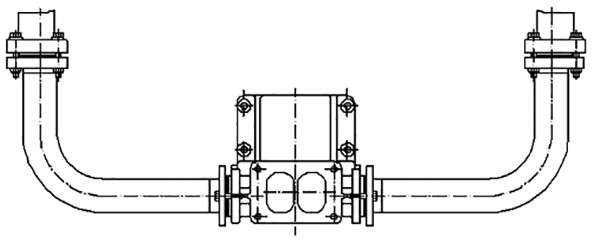

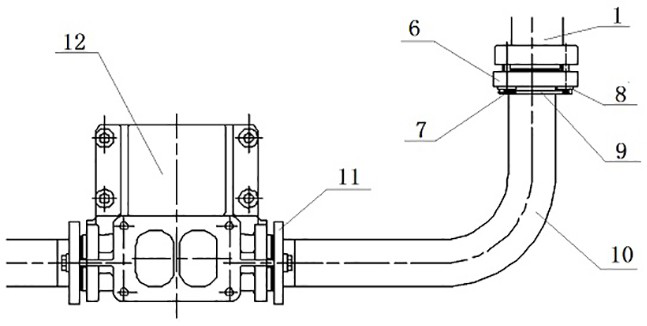

[0040] Such as figure 1 As shown, an exhaust system structure to improve reliability, the structure includes a metal corrugated exhaust pipe liner 3 arranged between the exhaust pipe 1 and the cylinder head 2 of the diesel engine, and a fixed connection between the exhaust pipe 1 and the cylinder head 2, a number of exhaust pipe bolts 5, anti-loosening pads arranged on the exhaust pipe bolts 5-4, elbow flanges arranged between the exhaust pipe 1 and the exhaust elbow pipe 10-6, fixed connection row Several holed bolts 7 of the air pipe 1 and the exhaust elbow 10, anti-loosening pads 2 arranged between the elbow flange one 6 and the holed bolts 7, and the anti-loosening pad two 8 arranged between the exhaust elbow 10 and the pulse converter Elbow flange 2 11 between 12; said exhaust elbow 10 and pulse converter 12 are also fixedly connected by several ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com