Flexible tightening head and tightening method

A tightening head and flexible technology, applied in the direction of screw plugs, etc., can solve the problems of unsatisfactory quality, poor elastic-plasticity, and small pitch, and achieve the effect of strong scalability, poor elastic-plasticity, and small pitch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

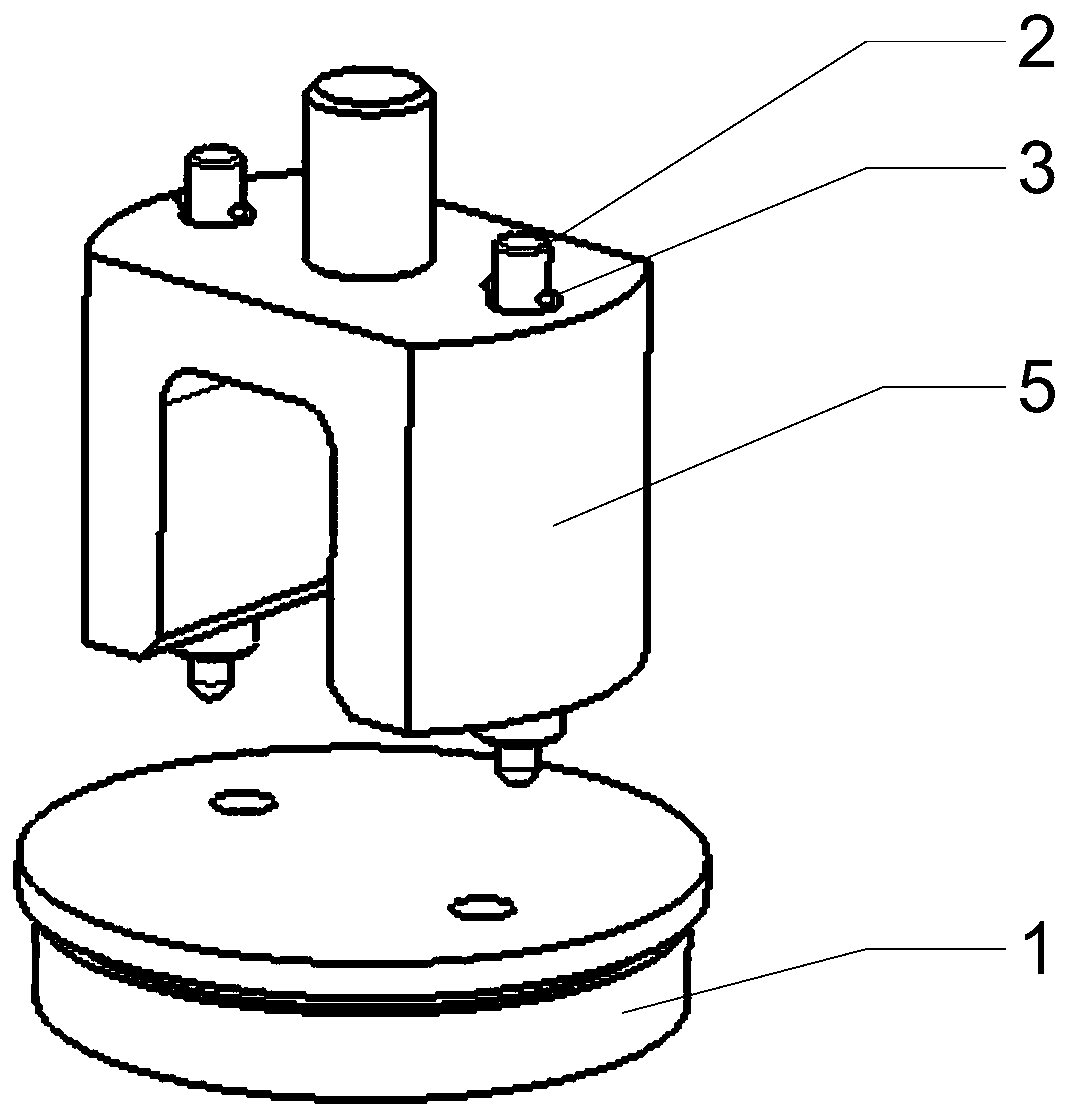

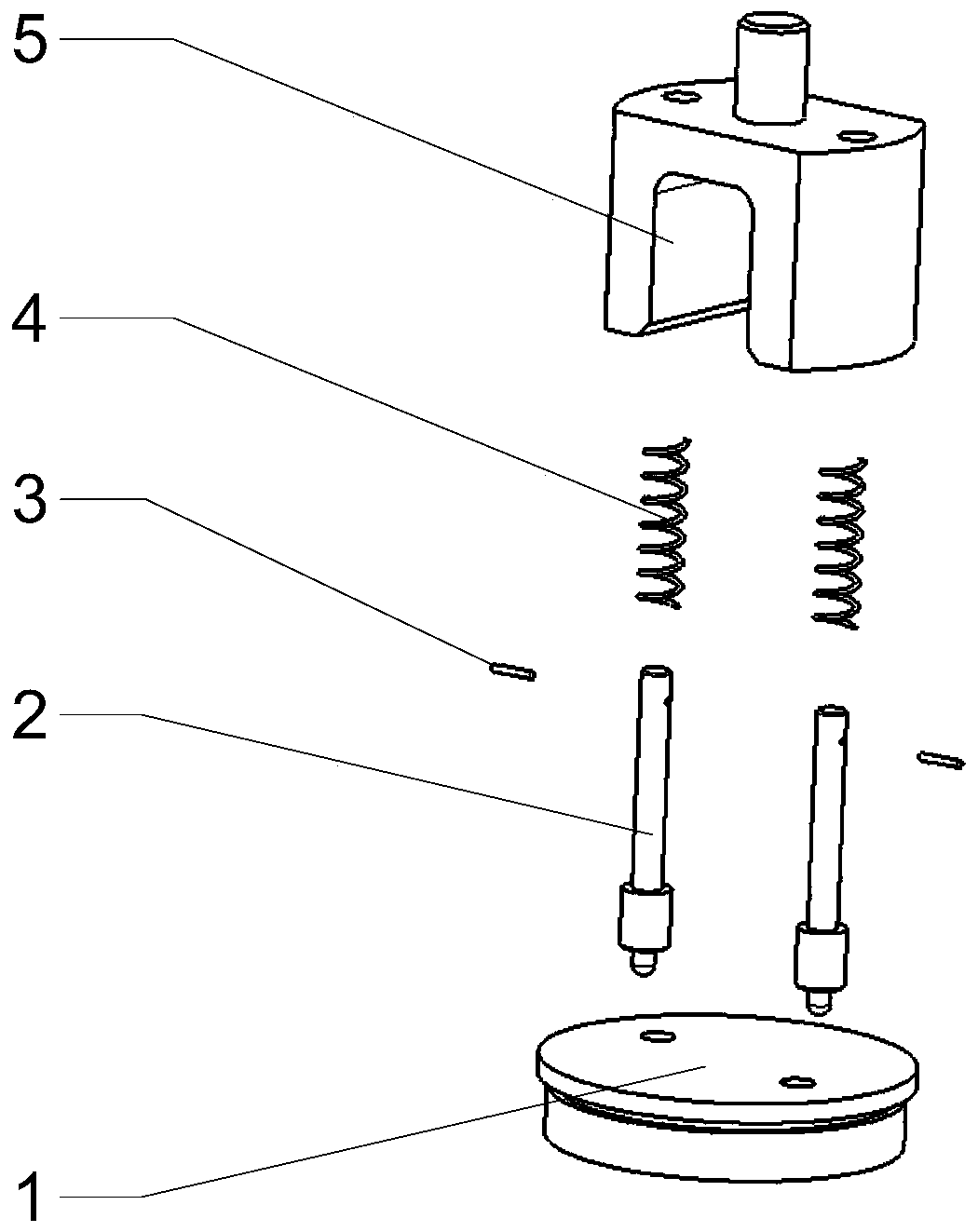

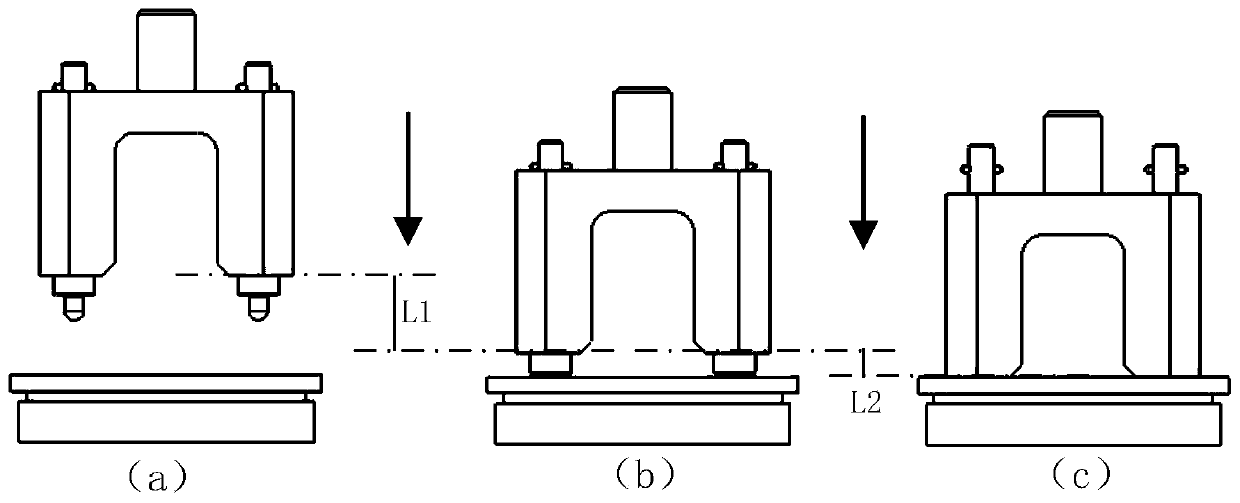

[0037] A specific embodiment of the present invention discloses a flexible tightening head for the case where a metal externally threaded bottle cap with large mass, poor elastoplasticity (high rigidity), small pitch, and many turns cooperates with the internal thread of the bottle, such as Figures 1 to 2 As shown, it includes an installation base 5, a telescopic rod 2 and a spring 4 sleeved on the telescopic rod 2. The installation base 5 is provided with a variable-diameter through hole for the telescopic rod 2 to move up and down, and the longitudinal section of the variable-diameter throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com