Outer thread tail end pulling twisting coining part

A technology of external thread and thread, which is applied in the direction of threaded fasteners, screws, connecting components, etc., and can solve the problem of small tightening torque of polygonal embossing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

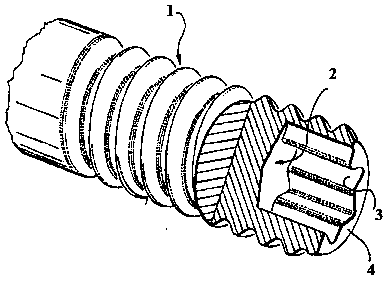

[0014] In the following, with reference to the accompanying drawings and preferred embodiments, the specific implementation, structure, features and functions of the external thread end wrenching stamping according to the present invention will be described in detail as follows.

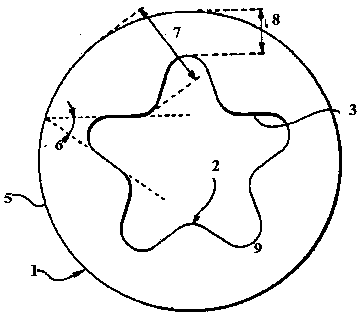

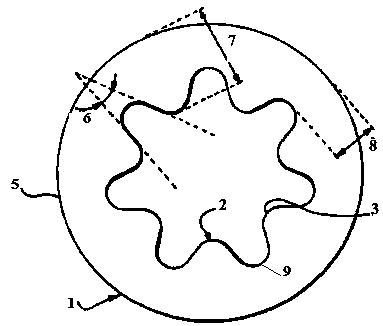

[0015] see Figure 1-4 , a wrenching impression at the end of an external thread of the present invention, including a hollow impression 2 on the thread 1, a continuous curve 3 on the end face 4, the continuous curve 3 is composed of five petals 9 of the same size, and the adjacent petals 9 are connected by circular arcs tangent to the sides. The hollow imprint 2 on the end of the external thread 1, the continuous curve 3 on the end face 4, wherein the continuous curve 3 is composed of 4-10 petals 9 of the same or different sizes evenly distributed, and the adjacent petals 9 pass through The arc is tangent to the side to achieve the connection.

[0016] The ratio of the maximum distance 7 and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com