A self-returning C-groove precision screw tightening robot

A C-shaped groove and robot technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of easy slippage and small torque, and achieve the effect of preventing slippage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the invention is not limited thereto.

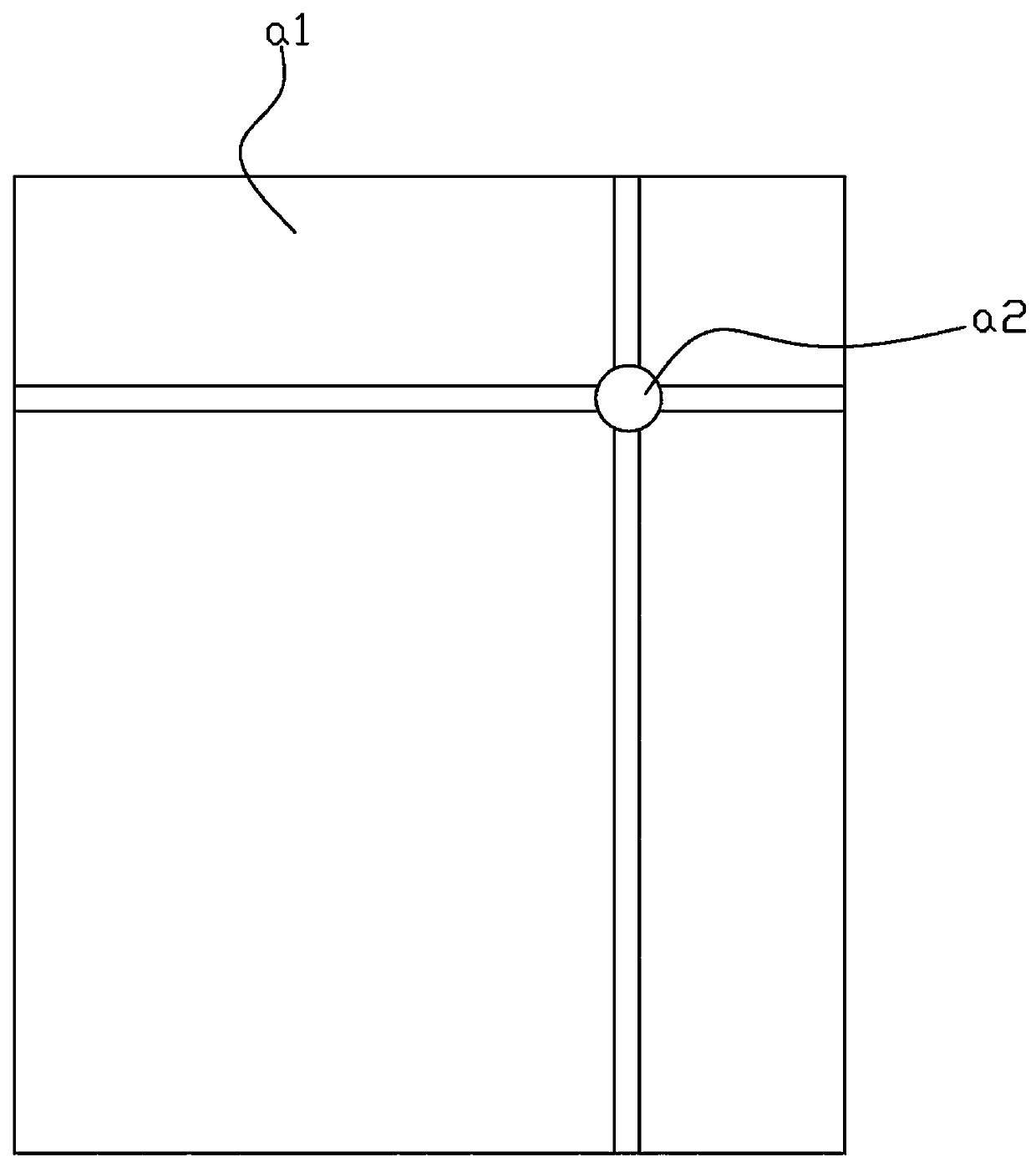

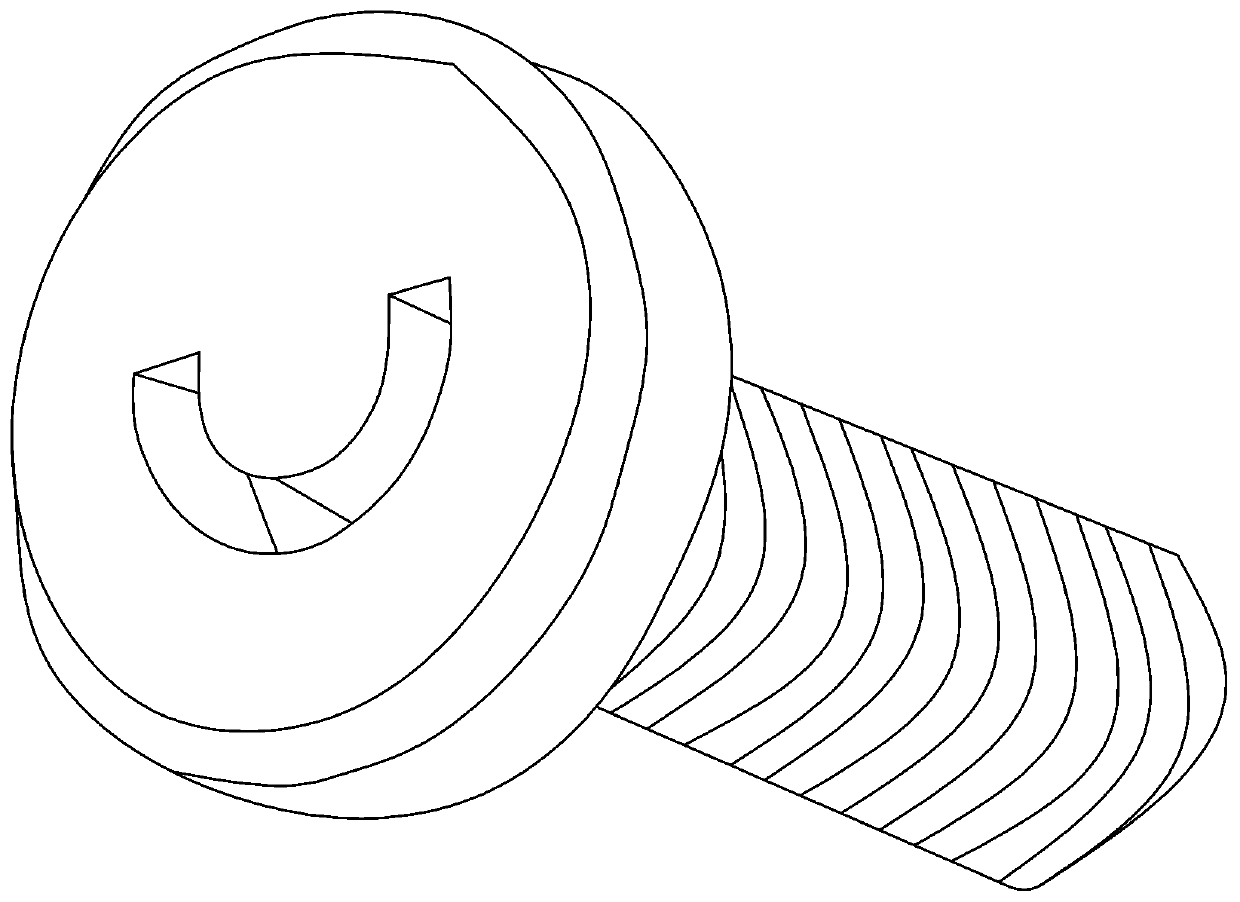

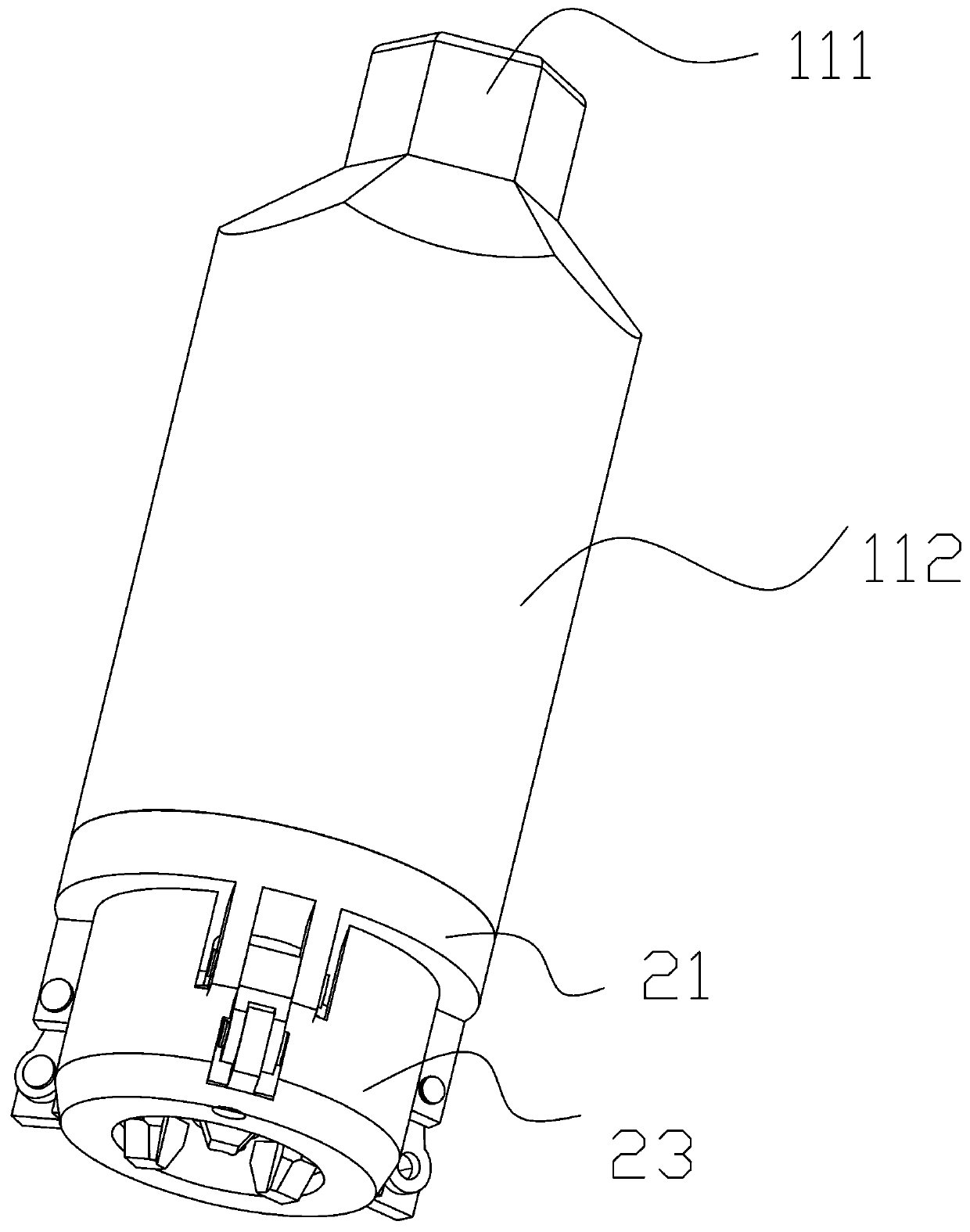

[0027] Such as Figure 1 to Figure 11 As shown, a self-returning force C-groove precision screw tightening robot described in this embodiment includes a base plate a1, and a moving frame that can move along the X-axis and Y-axis is arranged on the base plate. The installation part is used to install the mechanical tightening head a2. The mechanical tightening head includes a power supply device and a centrifugal clamping mechanism;

[0028] The power supply device includes a connecting cylinder 11 and an electromagnet 12, the connecting cylinder 11 is used to fix the electromagnet 12, the electromagnet 12 is located in the connecting cylinder 11, and the electromagnet 12 includes a silicon steel frame in the form of an I-shaped wheel, a winding and an iron core, the iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com