A non-standard screw tightening robot

A non-standard screw and robot technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem of small transmitted torque and achieve high reliability and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

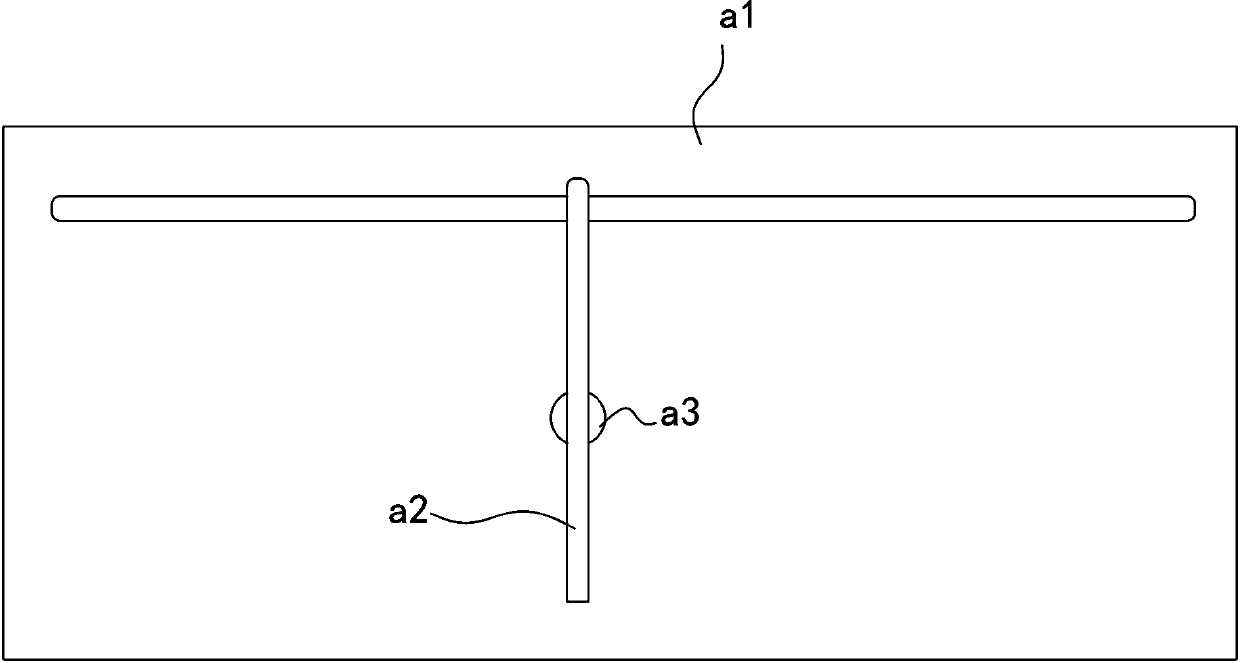

[0032] like Figures 3 to 11 As shown, a non-standard screw tightening robot described in this embodiment includes a main frame a1, and the main frame is provided with a mounting head a3 that can move along the X-axis and Y-axis; the movement of the X-axis and the Y-axis passes through The mobile frame is controlled by a2, and the screw head is installed on the installation head;

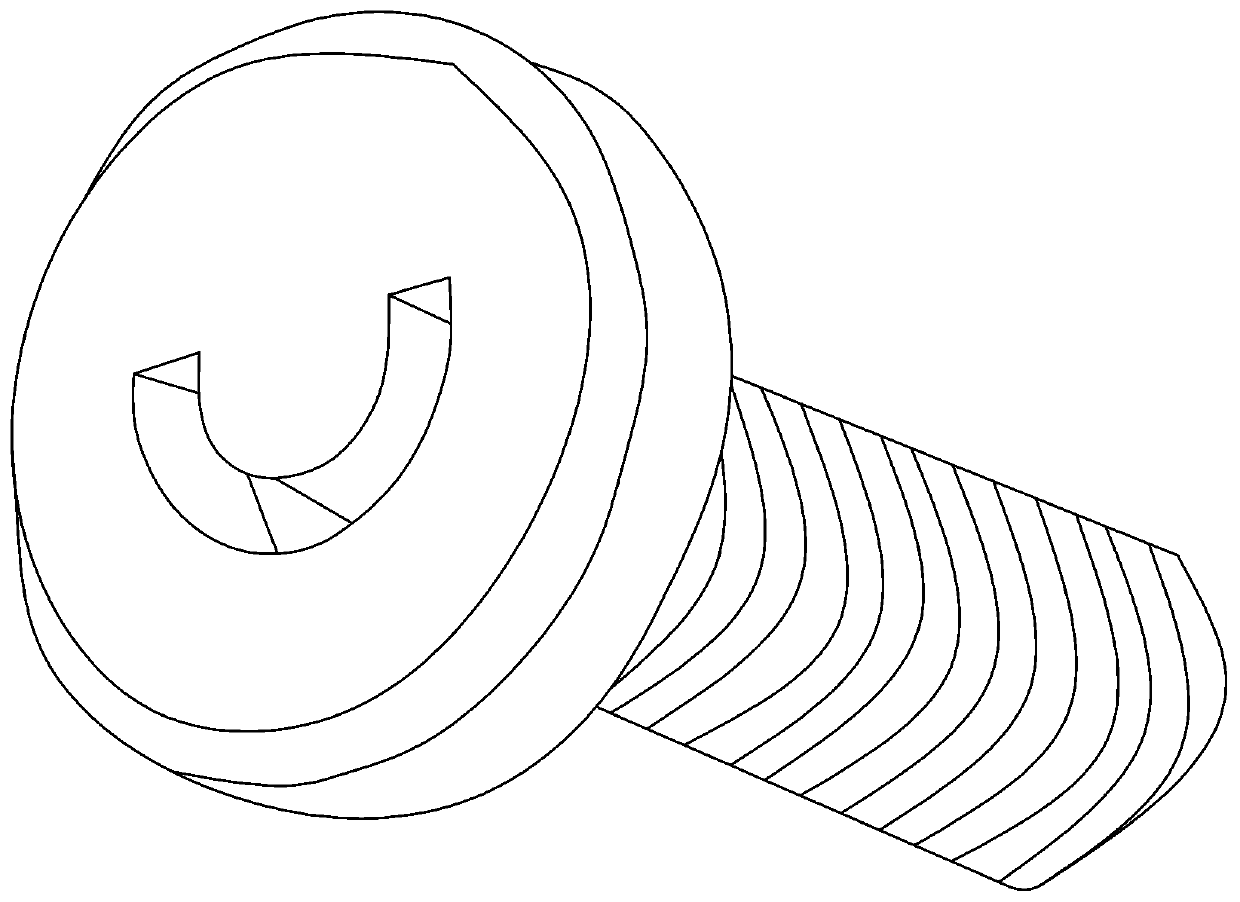

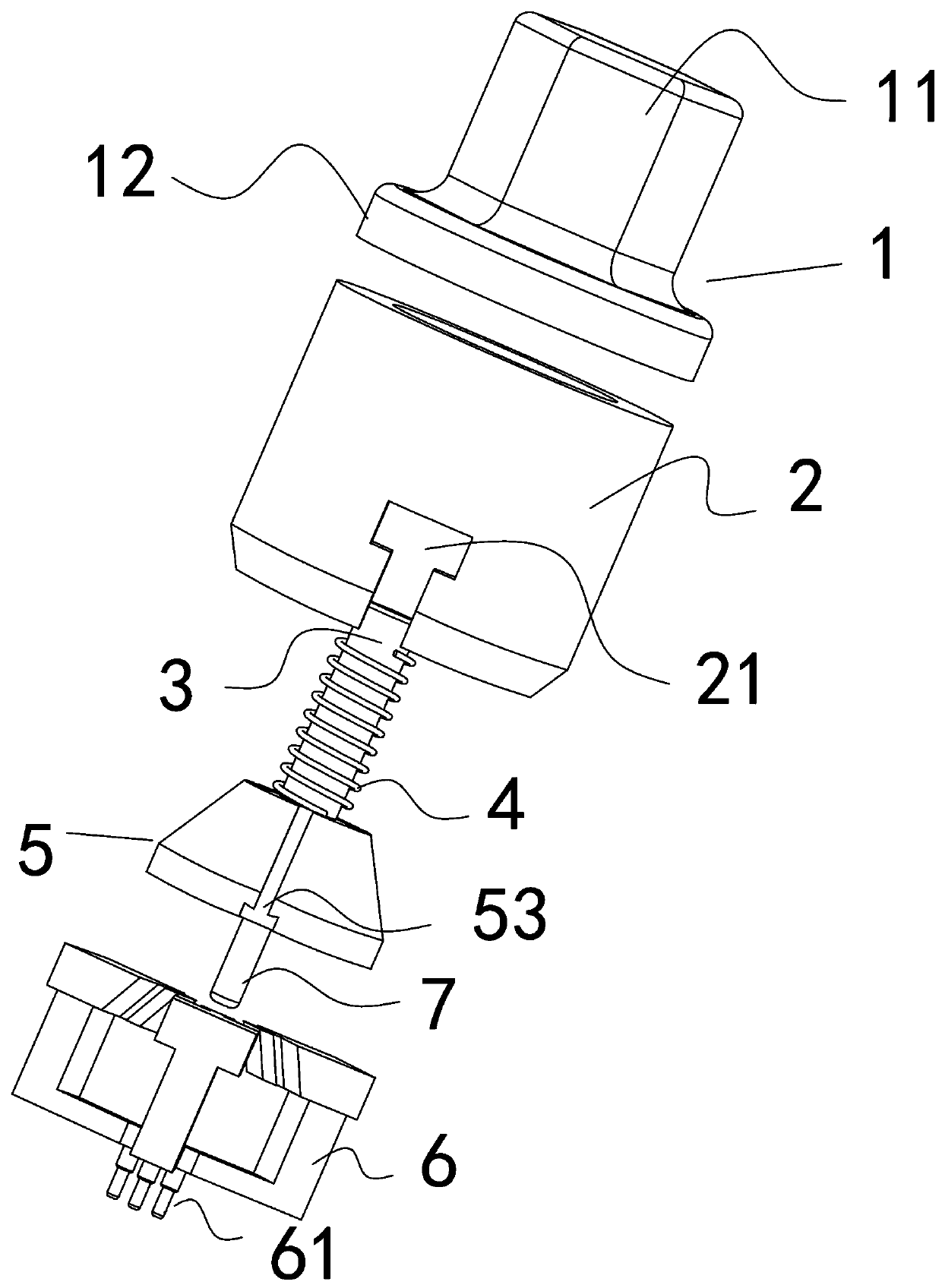

[0033] The screw head includes a top cap 1, one end of the top cap 1 is provided with a round hole 13, and the round hole (13) extends into the top cap (1) to form a cavity (131);

[0034] Also includes a central shaft 3, one end of the central shaft 3 extends into the cavity 131, the other end of the central shaft 3 is provided with a slide table 5 and a push rod 7, and the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com