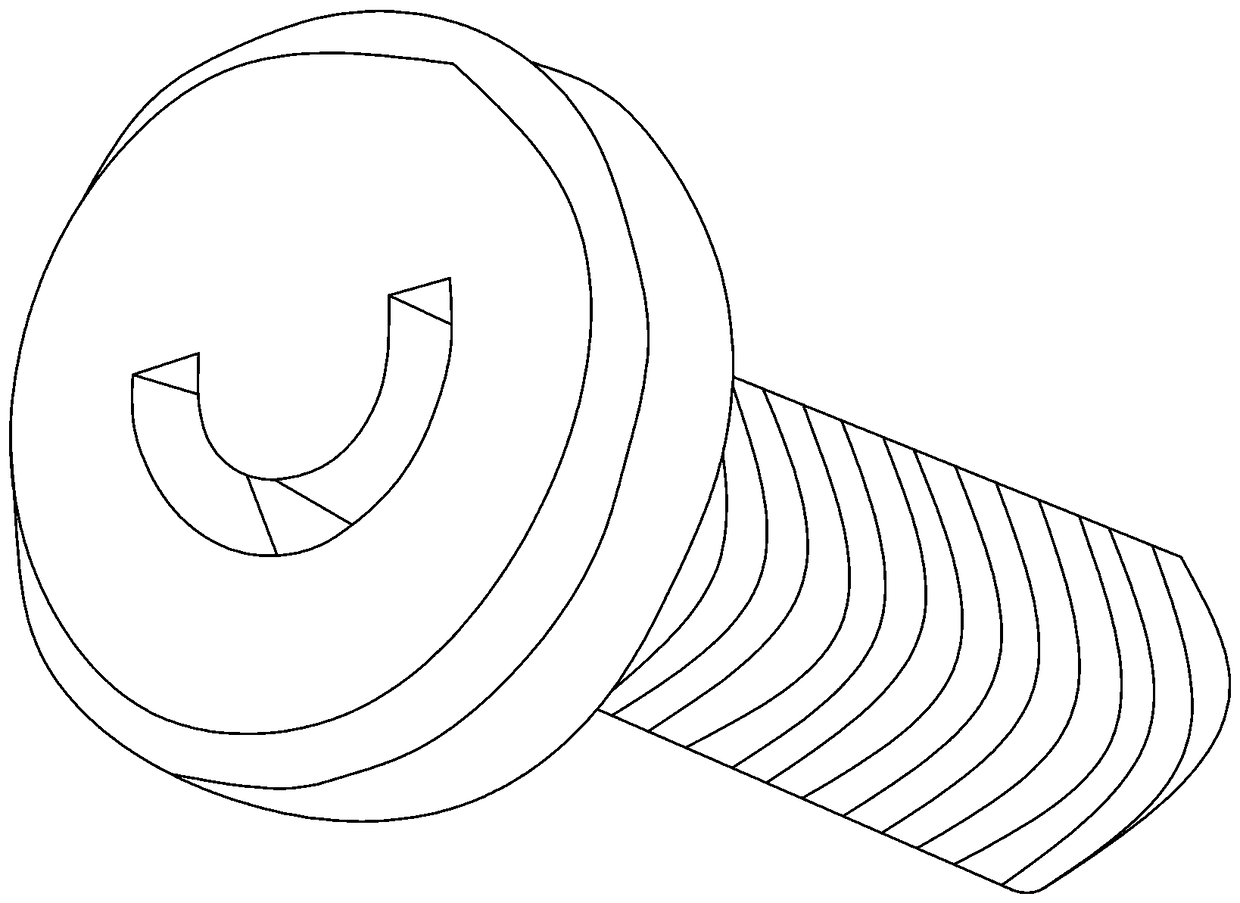

Self-resetting non-standard precise screw screwing-up robot

A robot and screw technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of easy slippage and small torque, and achieve the effect of preventing slippage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

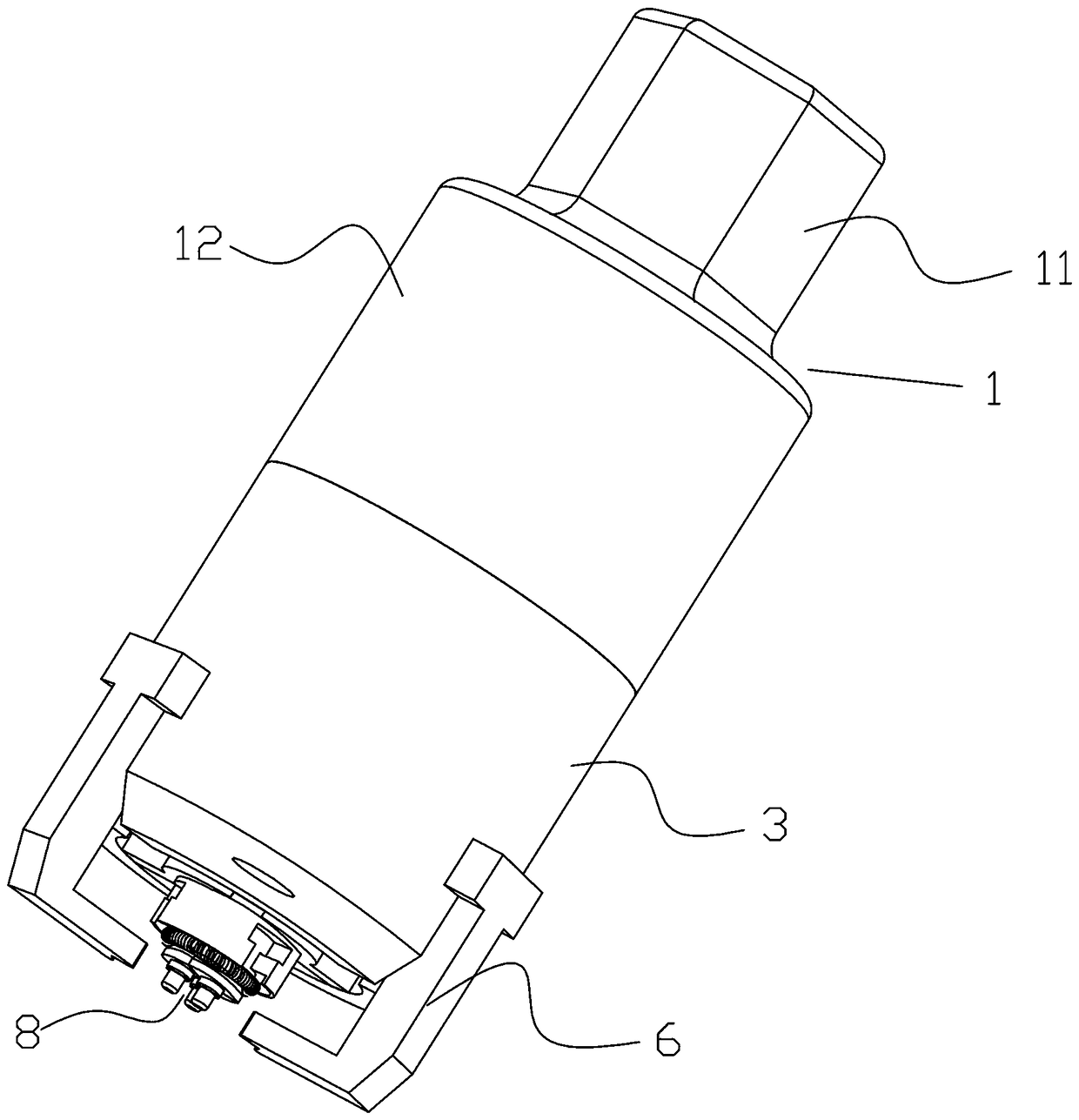

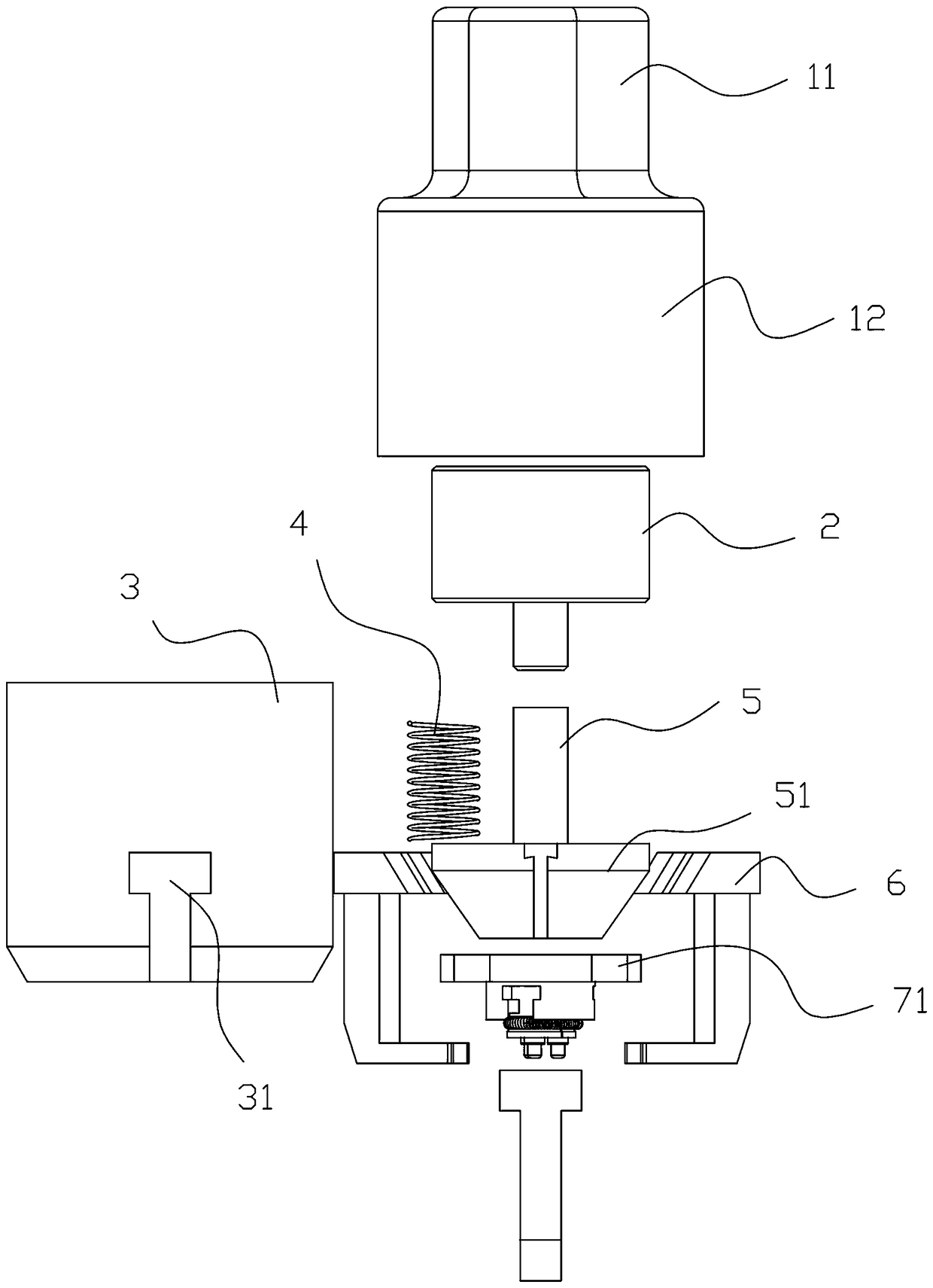

[0025] Such as Figure 2 to Figure 12 As shown, a self-returning non-standard precision screw tightening robot described in this embodiment includes a frame a1, and a movable moving mechanism a2 arranged on the frame, and a replaceable screw head is installed on the moving structure .

[0026] The screw head includes a force supply mechanism and a centrifugal clamping mechanism; the force supply mechanism includes a connecting cylinder 1 and an electromagnet 2 for generating a magnetic field, and the electromagnet 2 is fixed in the connecting cylinder 1, and the The electromagnet 2 includes an iron core and a coil winding;

[0027] The centrifugal clamping mechanism includes a barrel-shaped guide cylinder 3 with the opening facing downward, a first spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com