Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Large expansion volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

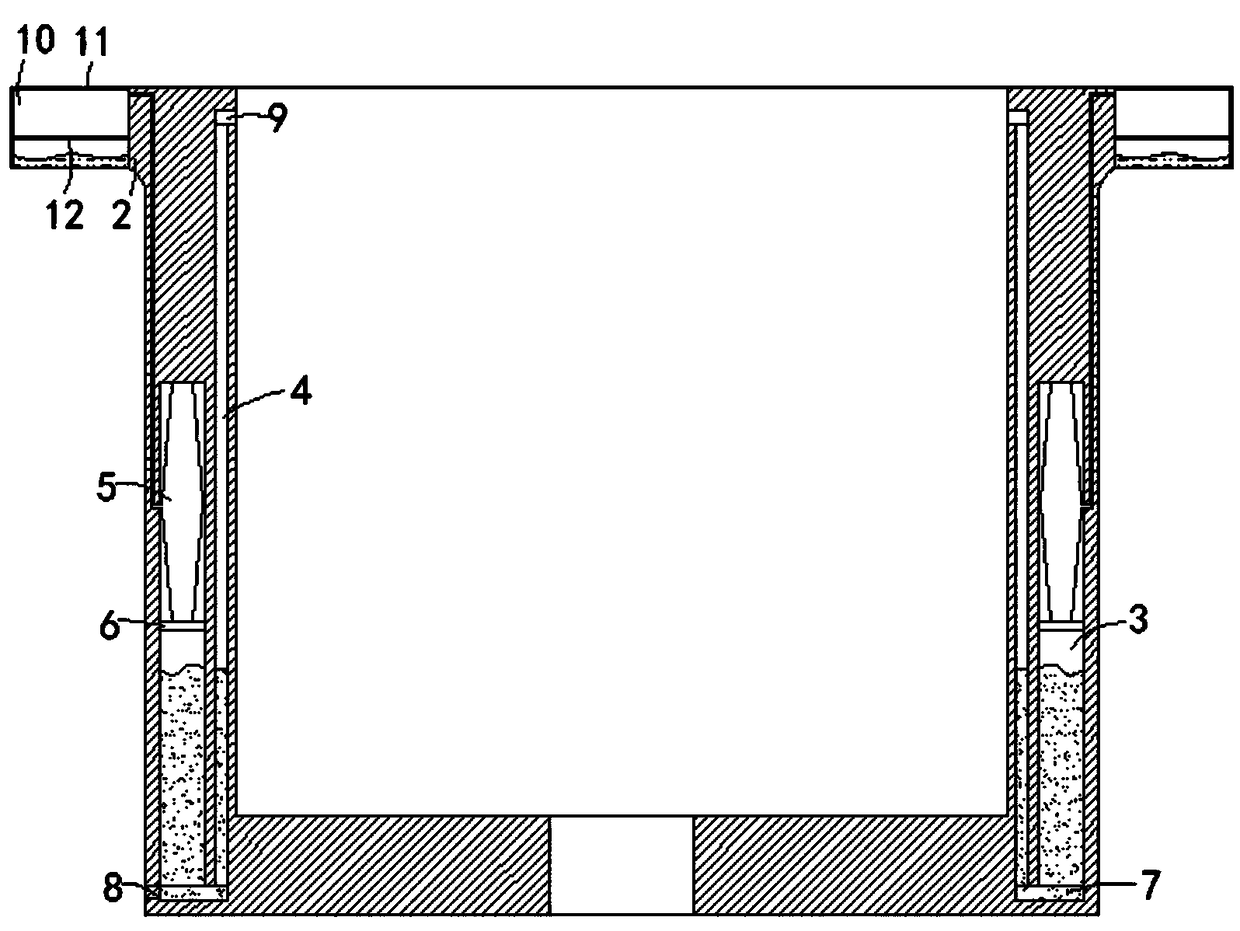

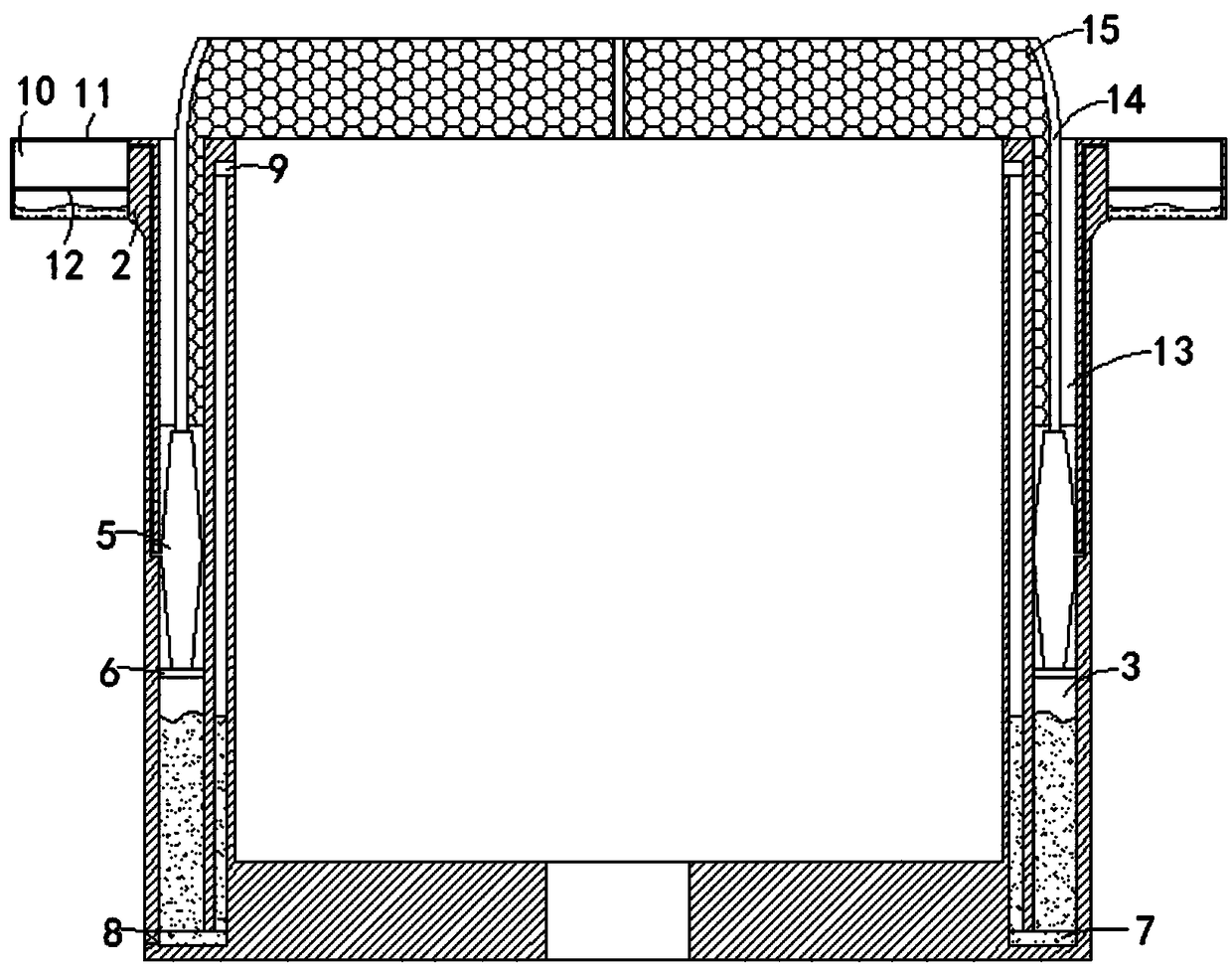

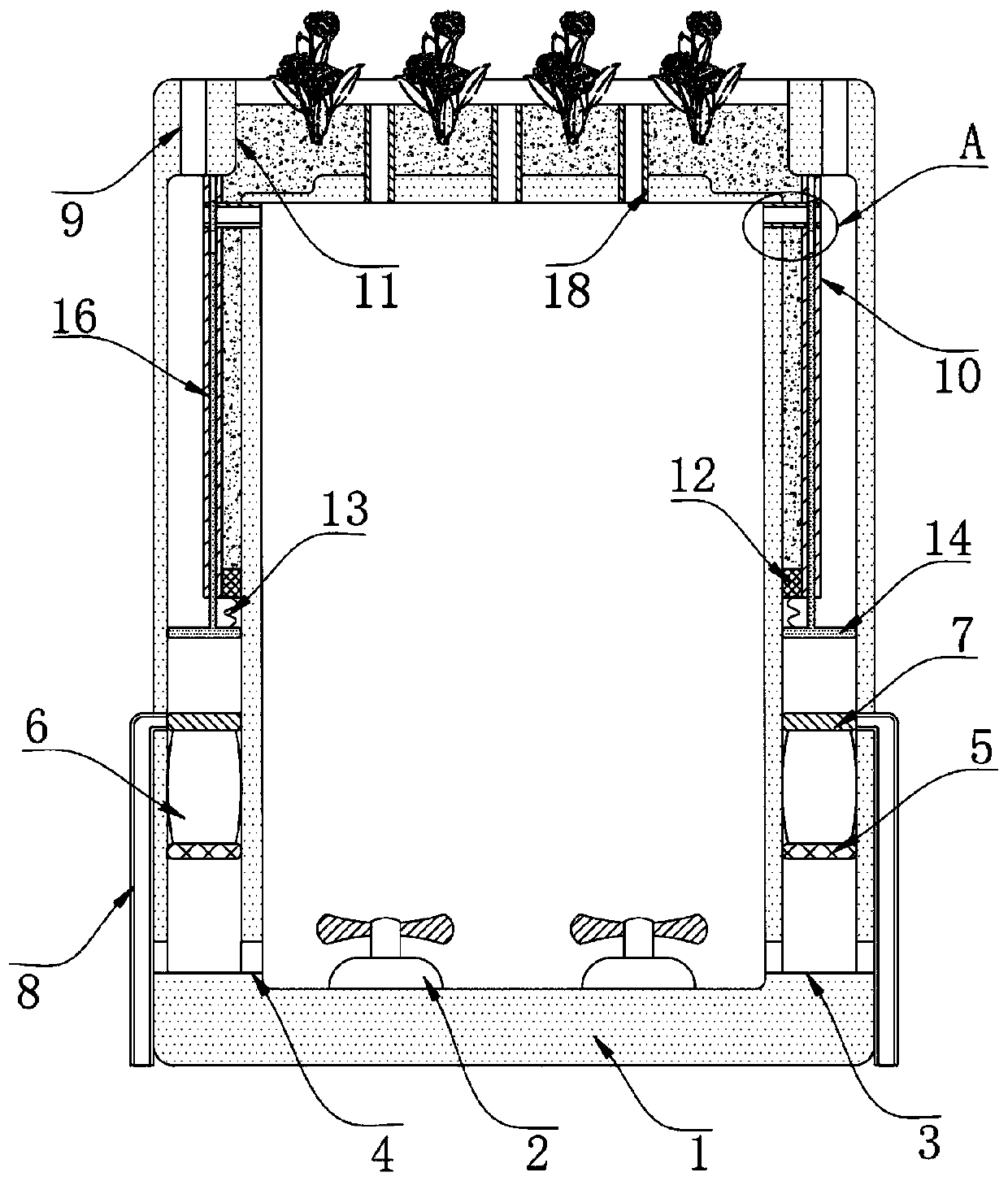

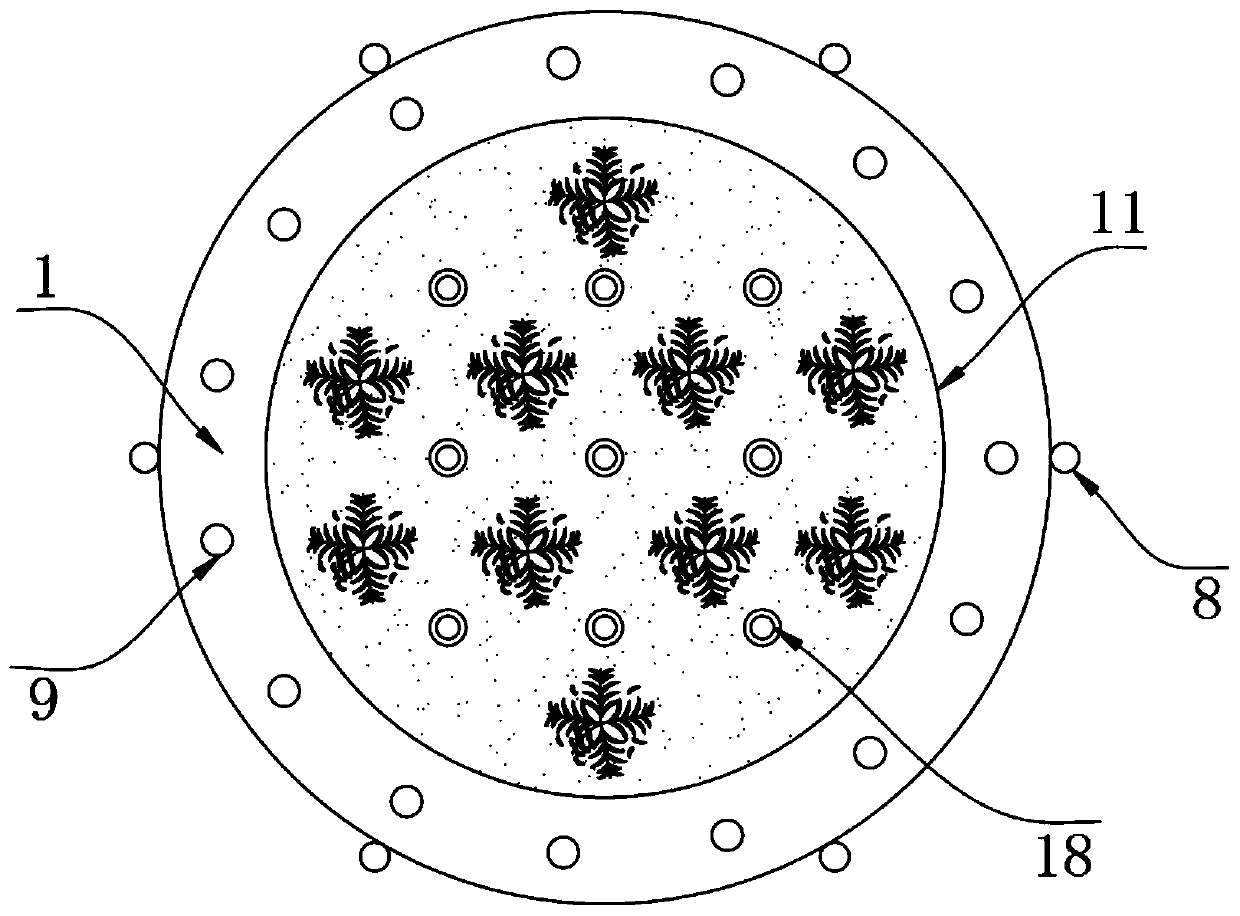

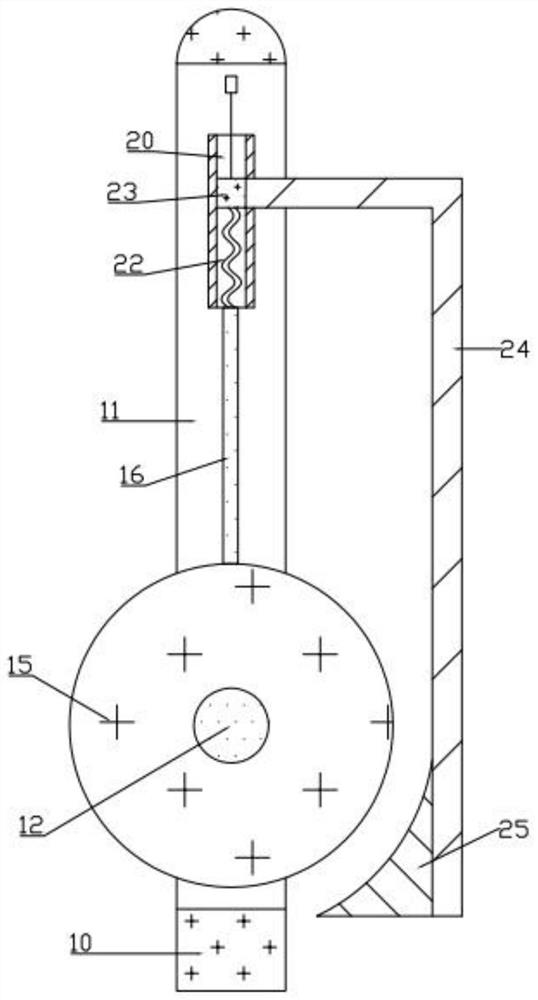

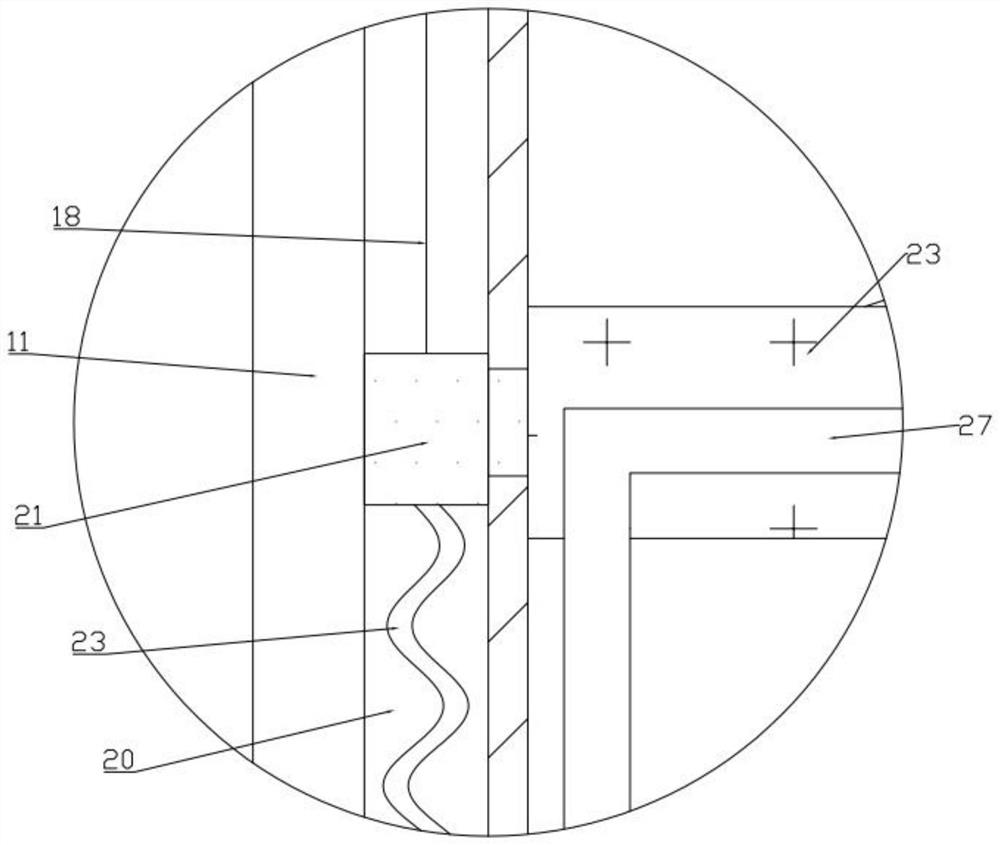

Flowerpot with water supplement function

InactiveCN109258190AAvoid damageAvoid too dark a growing environmentSelf-acting watering devicesReceptacle cultivationPistonEngineering

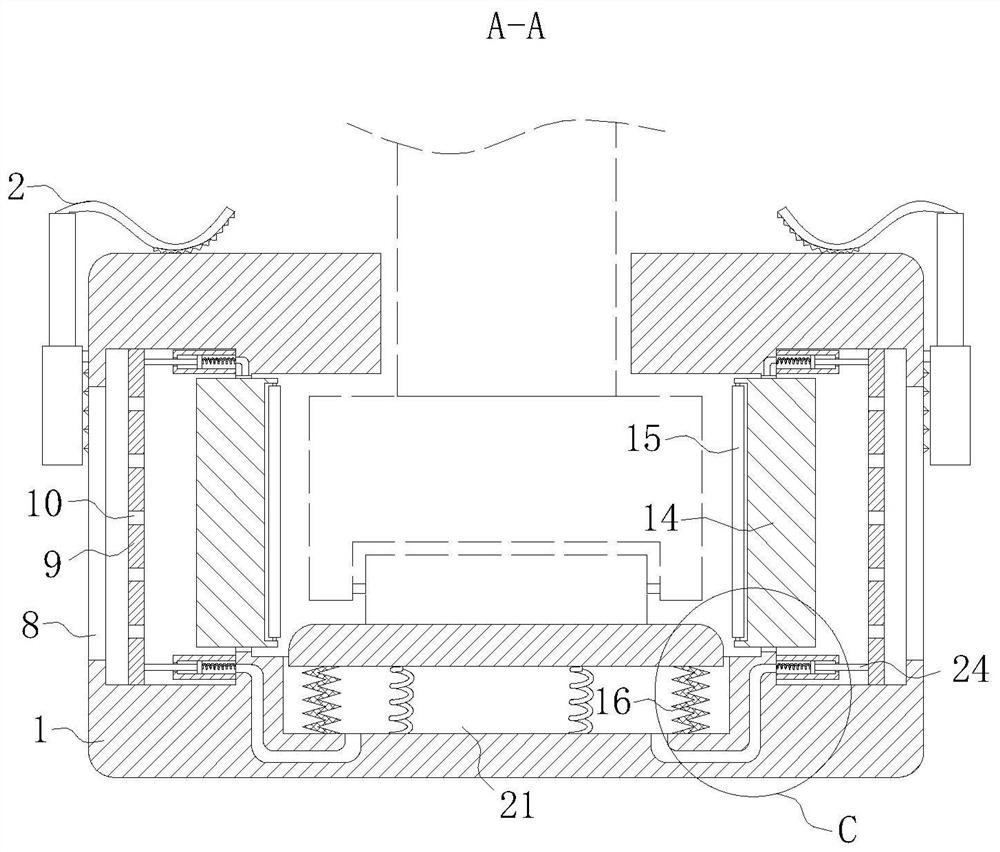

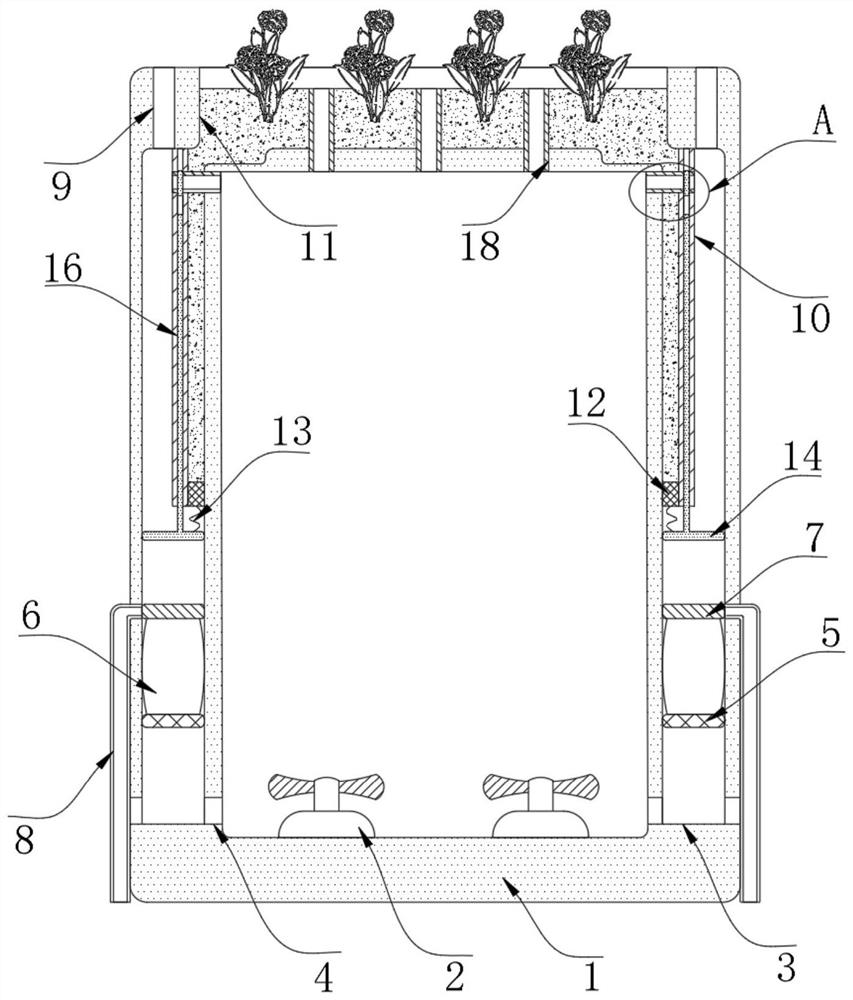

The invention belongs to the technical field of flowerpots, in particular to a flowerpot with a water supplement function. The flowerpot comprises a pot body, a pot edge is arranged on the circular side wall of the pot body, a plurality of first chambers and a plurality of second chambers are arranged on the inner wall of the pot body, the first chambers are in one-to-one corresponding to the second chambers, the first chambers are arranged in the pot body among the second chambers and the pot edge, air bags arranged on the top surfaces of the first chambers and can only vertically expand andcontract, the middle side walls of the air bags are fixedly connected with the inner walls of the first chambers, first arc-shaped piston plates are slidably and hermetically connected in the first chambers, the upper ends of the first arc-shaped piston plates are fixedly connected with the lower ends of the air bags, a water spraying opening is formed in the inner wall of one end, far away from the pot edge, of each second chamber, the water spraying openings approach to top surfaces of the second chambers, and third chambers are arranged on the inner wall of the pot body. The flowerpot can automatically supplement water for upper soil in high temperature weather of sun shine and has a sunscreen effect on planted young seedlings.

Owner:何静雅

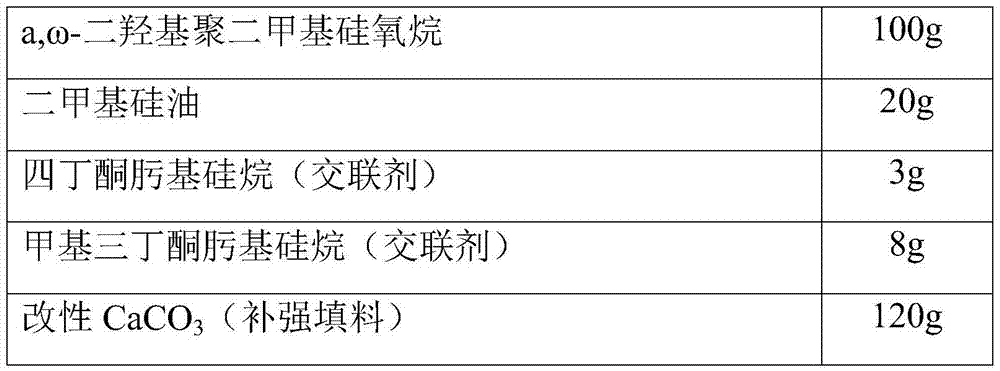

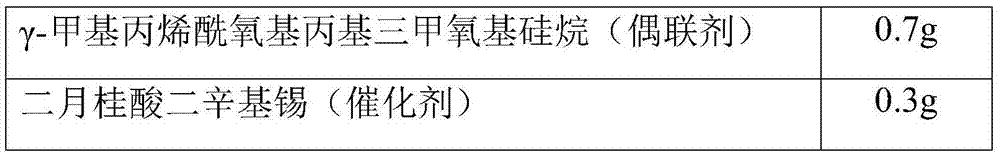

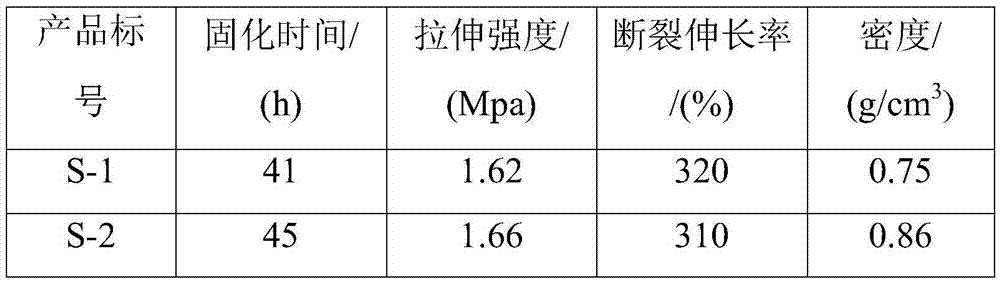

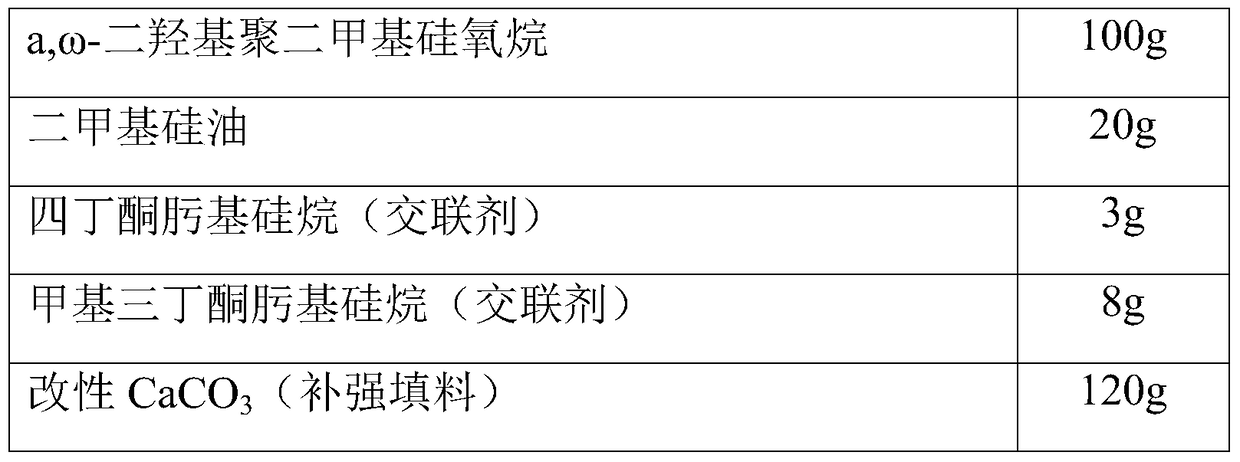

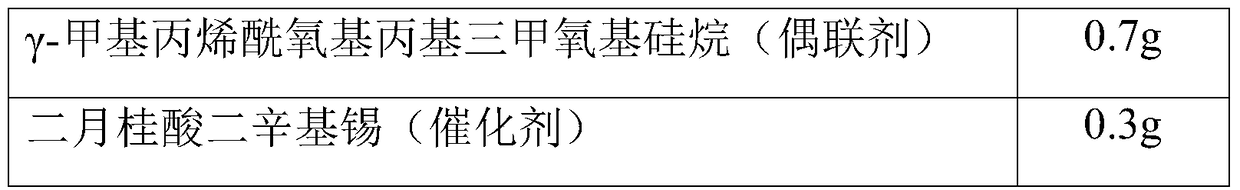

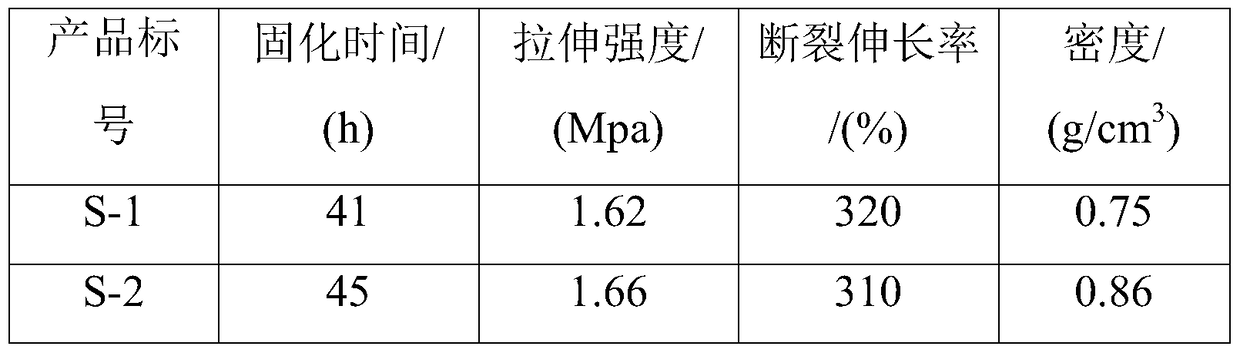

Low-density deketoxime type silicone sealant and preparation method thereof

ActiveCN105441019ALow densityImprove stabilityNon-macromolecular adhesive additivesThermal expansionLow density

The invention discloses a low-density deketoxime type silicone sealant. The sealant comprises components in parts by weight as follows: 100 parts of alpha, omega-dyhydroxyl polydimethylsiloxane, 1-40 parts of dimethyl silicone oil, 0.1-4 parts of thermal expansion microcapsules, 1-25 parts of a cross-linking agent, 20-180 parts of reinforcing filler, 0.01-5 parts of a coupling agent and 0.005-1 part of a catalyst. The invention further discloses a preparation method of the low-density deketoxime type silicone sealant. The low-density deketoxime type silicone sealant has excellent mechanical property and adhesive property, the density of the sealant is remarkably reduced, the foaming effect is excellent, and the stability is high. According to the preparation method, a process is simple and easy to implement, equipment is conventional, operation is facilitated, and industrial large-scale production is facilitated.

Owner:浙江中天东方氟硅材料股份有限公司

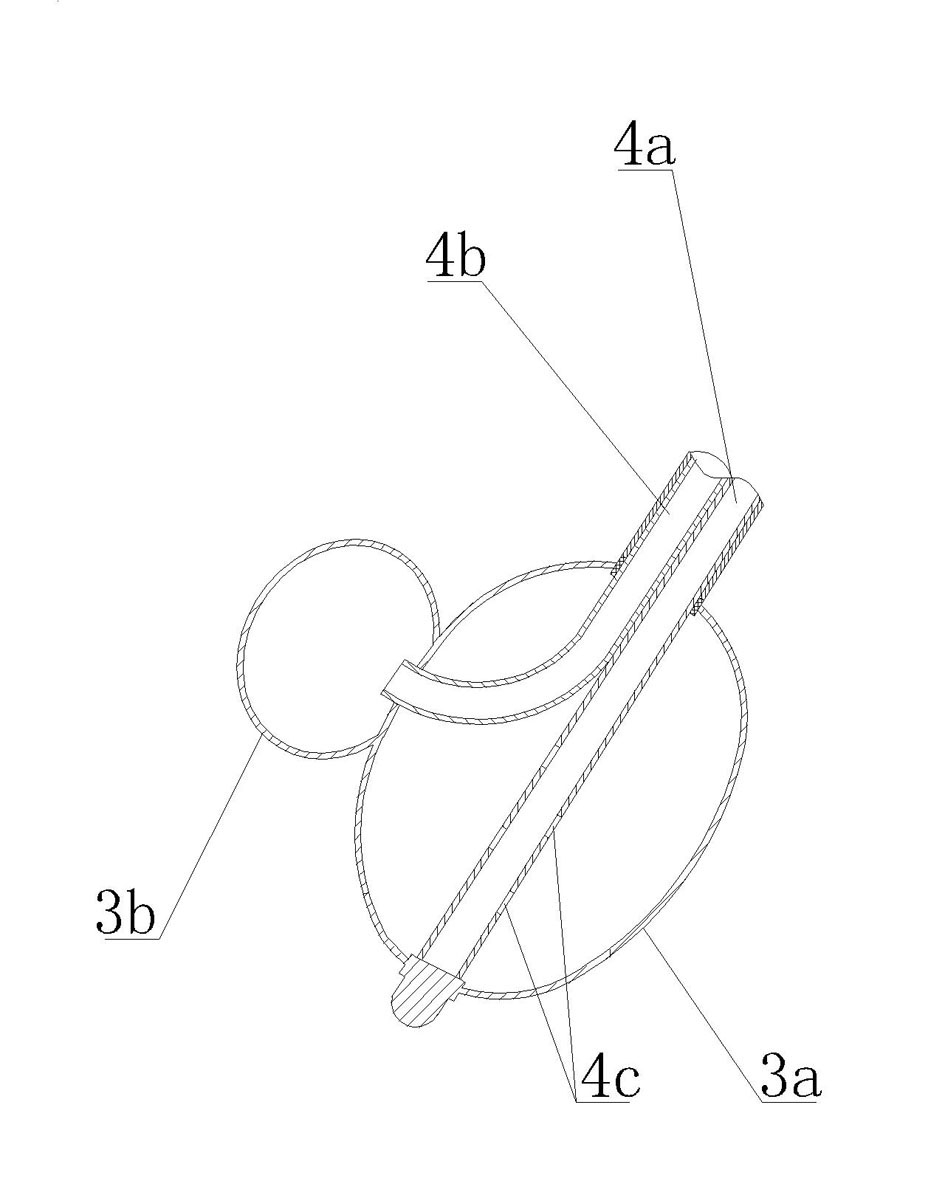

Double-balloon dilator for bone surgery

InactiveCN101954146ALarge expansion volumeAchieve expansion effectInternal osteosythesisDilatorsDilatorVertebral pedicle

The invention discloses a double-balloon dilator for a bone surgery, which belongs to the technical field of medical apparatuses. The double-balloon dilator for the bone surgery is mainly characterized by comprising a pressurizing injection device, a developer syringe and a dilating balloon, wherein the pressurizing injection device is communicated with an inner cavity of the dilating balloon by a conduit; the developer syringe is arranged on the conduit between the pressurizing injection device and the dilating balloon; the dilating balloon comprises a main balloon and an auxiliary balloon; the auxiliary balloon is arranged at the side of the main balloon; the conduit comprises a main conduit and an auxiliary conduit; one ends of the main conduit and the auxiliary conduit are respectively communicated with the main balloon and the auxiliary balloon, and the other ends of the main conduit and the auxiliary conduit are respectively connected with the pressurizing injection device; a hydraulic flow dividing valve is connected to a pipeline among the main conduit, the auxiliary conduit and the pressurizing injection device; and the developer syringe is respectively communicated with the main conduit and the auxiliary conduit by the flow dividing valve. The invention aims to provide the double-balloon dilator for the bone surgery, which can be used for single-side vertebral pedicle puncture so as to achieve the bone cement filling effect with same double-side puncture and is used for treating osteoporotic vertebral compression fracture.

Owner:陈柏龄

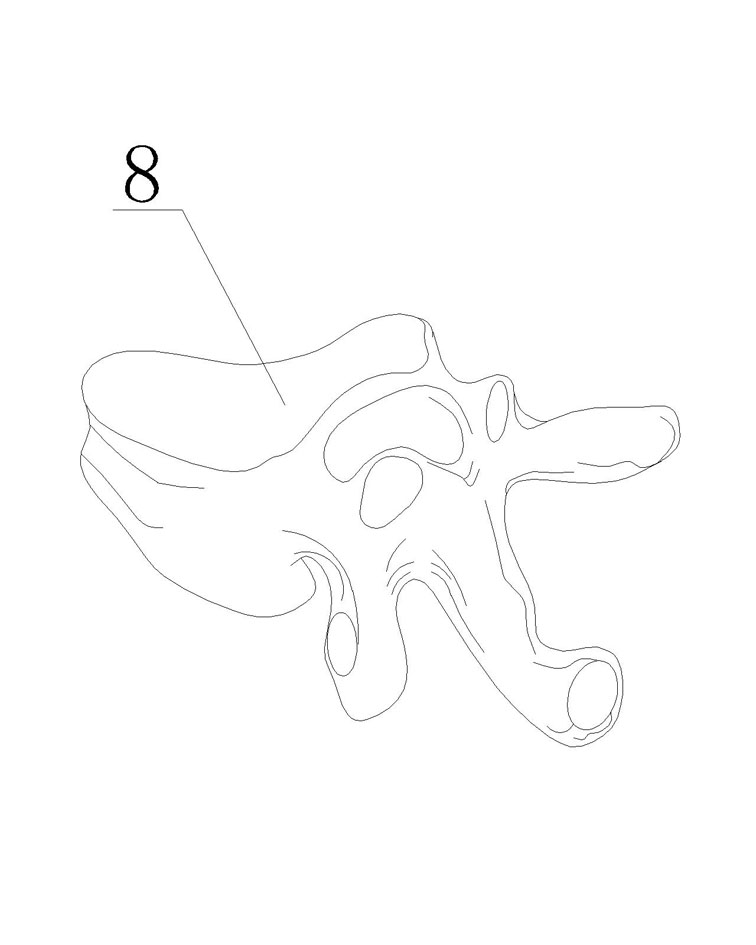

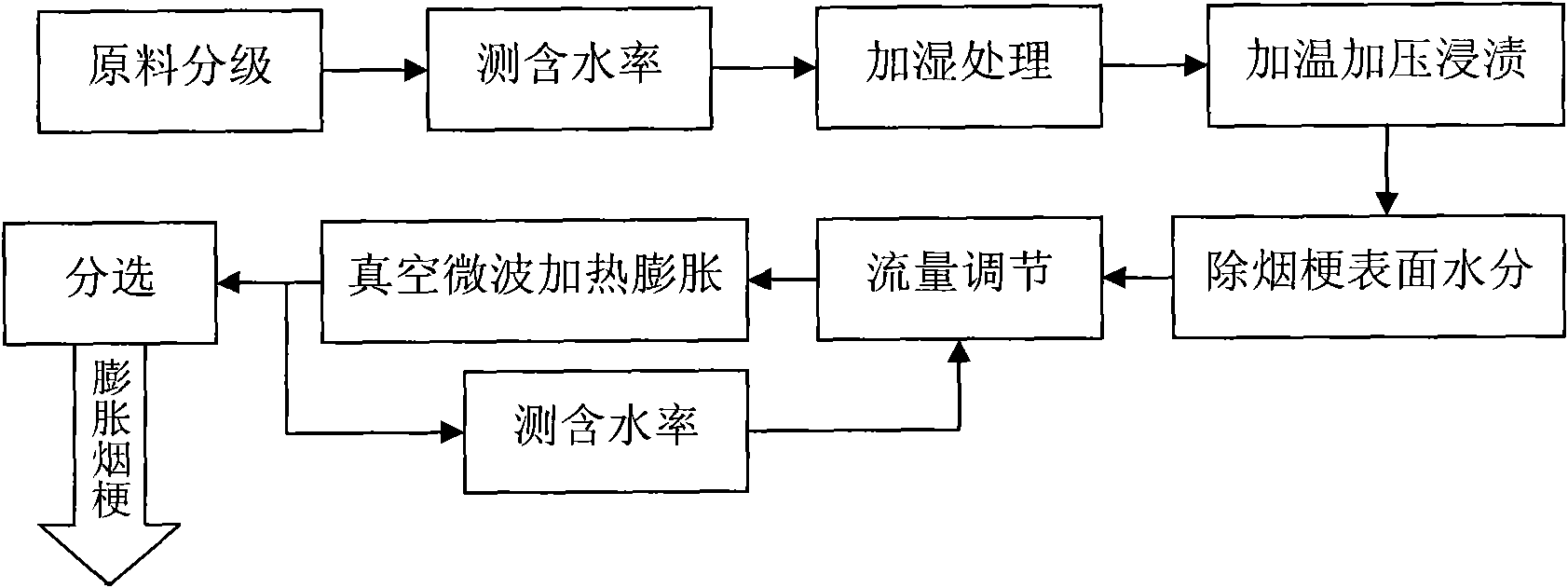

Tobacco stalk expansion method

InactiveCN101862023AUniform moistureUniform expansionTobacco preparationTobacco treatmentMicrowaveEngineering

The invention provides a tobacco stalk expansion method, which comprises the following steps of: grading tobacco stalks, performing impregnation remoistening on the graded tobacco stalks and expanding the tobacco stalks, wherein a microwave heating expansion method is adopted in the expansion of the tobacco stalks; preferably, the microwave heating expansion is performed on the tobacco stalks under a vacuum condition; more preferably, the microwave heating expansion is performed on the tobacco stalks by adopting more than two different kinds of continuous microwave output power under the vacuum condition, wherein the former two kinds of continuous microwave output power are 4.0 to 8.0 kw and 1.5 to 2.5 kw respectively for every kilogram of remoistened tobacco stalks; and the impregnation remoistening comprises the steps of: spraying water onto the tobacco stalks, and performing the impregnation remoistening under the pressure of 0.112 to 0.203 MPa and at the temperature of 50 to 100 DEG C. The expanded tobacco stalk has the characteristics of greater volume that is 1 to 3 times that of the conventional tobacco stalk, uniform expansion, remarkable fragrance, less wood smell, high resilience, the water content of 0.5 to 3 percent, high combustibility, improved intrinsic quality and relatively better smoke characteristic maintenance.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

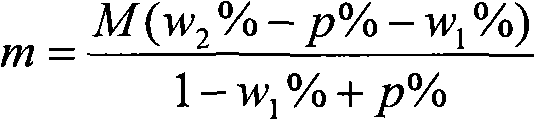

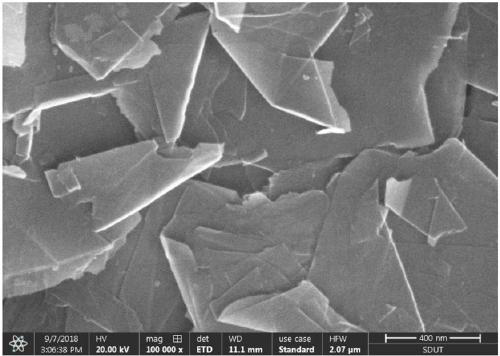

Method for preparing biological expanded graphite with visible light catalytic activity

InactiveCN102533715ALarge expansion volumeImprove hydrophobicityPhysical/chemical process catalystsMicroorganism based processesHydrolysisContaminated water

The invention relates to a method for preparing biological expanded graphite with visible light catalytic activity. Natural flake graphite is taken as a raw material, and the method comprises the following steps of: allowing tetrabutyl orthotitanate to enter gaps of a graphite layer by using an oxidation-intercalation method, hydrolyzing the intercalated graphite in an alcoholic solution of ammonia water to fulfill the aim of doping nitrogen by using a sol-gel method, drying and expanding at high temperature to obtain N-TiO2 expanded graphite, and culturing and breeding mixed bacteria by taking the N-TiO2 expanded graphite as a carrier under the conditions of aerobic and constant temperature culture to obtain the biological expanded graphite with the visible light catalytic activity. The biological expanded graphite with the visible light catalytic activity has the characteristics of high hydrophobicity, high visible light catalytic activity, proper porosity, high adsorptivity, high biodegradation property and the like. During use, the biological expanded graphite with the visible light catalytic activity can be directly applied to the surface of petroleum contaminated water, the biological expanded graphite can be floated on an oil-water interface for a long term to efficiently remove floating oil on the water surface, and the biological expanded graphite is convenient to recycle and avoids secondary pollution.

Owner:TONGJI UNIV

Preparation method of graphene

InactiveCN109319771AIncrease layer spacingLess peeling layersGrapheneBulk chemical productionGraphiteGraphene

The invention discloses a preparation method of graphene. The preparation method comprises the following steps that S1, hydrogen peroxide with the mass fraction being 35-40% is added into a reaction kettle, and the amount of the added hydrogen peroxide accounts for 55-60% of the volume of the reaction kettle; S2, expanded graphite is added into the reaction kettle, the mass ratio of the expanded graphite to the hydrogen peroxide is 1:(0.01-0.02), the temperature is raised to 200-280 DEG C under the normal pressure, and a reaction is conducted at the temperature of 200-280 DEG C for 10-20 minutes; S3, supercritical carbon dioxide is introduced into the reaction kettle for pressurizing, thus the pressure is increased to 8-15 MPa, and the pressure is maintained for 5-8 hours; S4, objects obtained in the reaction kettle is discharged and put into a homogenizer to be homogenized; and S5, the homogenized objects are dried, and then the graphene is prepared after drying. The preparation method has the advantages that stripping of graphene sheet layers is more thorough, the stripping layer number is less and more even, and environmental protection is achieved.

Owner:青岛岩海碳材料有限公司

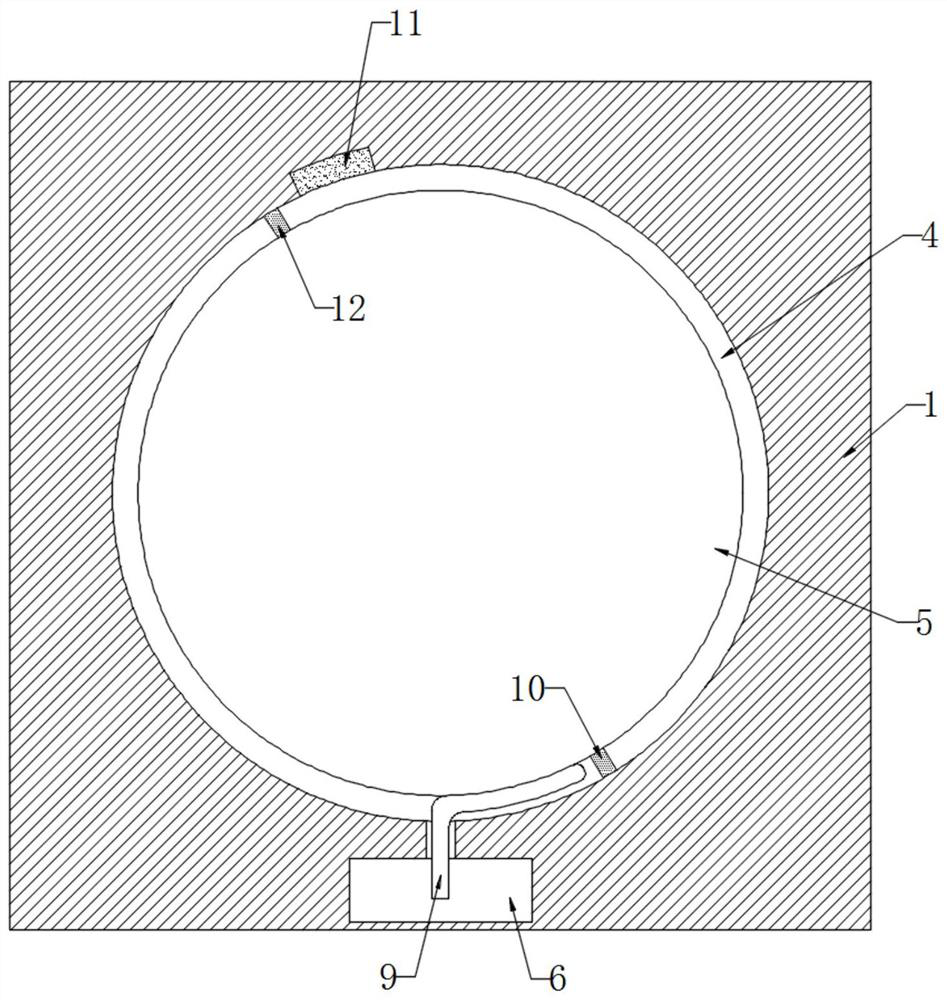

Environment-friendly power distribution cabinet for sponge city

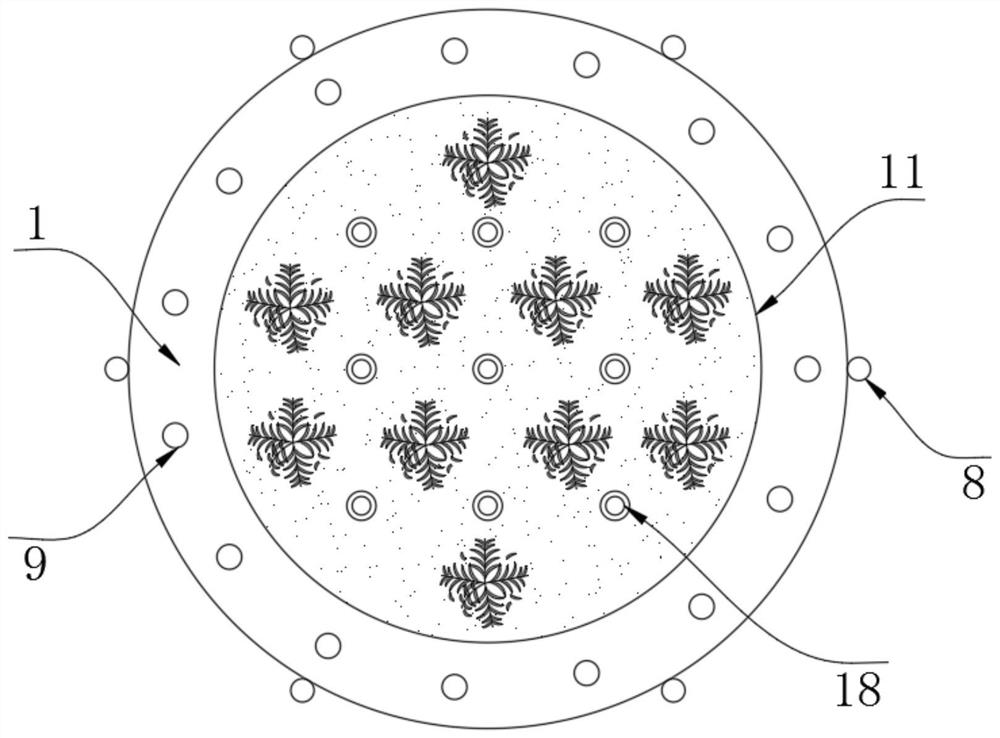

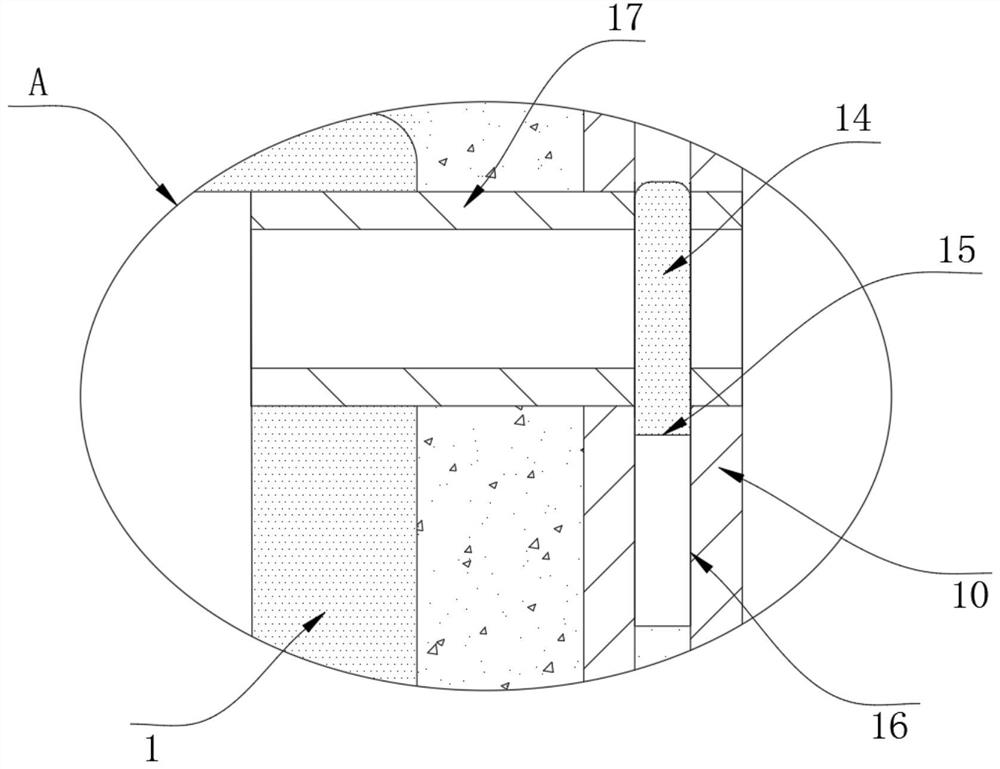

ActiveCN110739624AHeat dissipation fastImprove cooling efficiencySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsWater storageThermodynamics

The invention discloses an environment-friendly power distribution cabinet for a sponge city. The power distribution cabinet comprises a cylindrical power distribution box body and is characterized inthat a plurality of cooling fans are fixed at the inner bottom of the power distribution box body, an annular water storage cavity is formed on a side wall of the power distribution box body, a plurality of drainage pipes communicating with the interior of the water storage cavity are inserted into an outer wall of the power distribution box body in a penetrating mode, a plurality of vent holes communicating with the water storage cavity are formed on a circumferential side wall of the power distribution box body in a penetrating mode, a supporting plate is welded to an inner wall of the water storage cavity, and an air bag is glued to an upper end of the supporting plate. The power distribution cabinet is advantaged in that the air bag absorbs the heat of the distribution box body and the outside to heat and evaporate the hot evaporation liquid in the air bag, the air bag is expanded, so the expansion volume of the air bag is increased, the stored rainwater can move upwards to be closer to the evaporation holes, the rainwater is affected by the external temperature to be increased, the rainwater can be evaporated more quickly to supplement into the air, the comfort of the external air is kept, and dryness caused by the high temperature is avoided.

Owner:PANJIN GUANGLIDA ELECTRIC

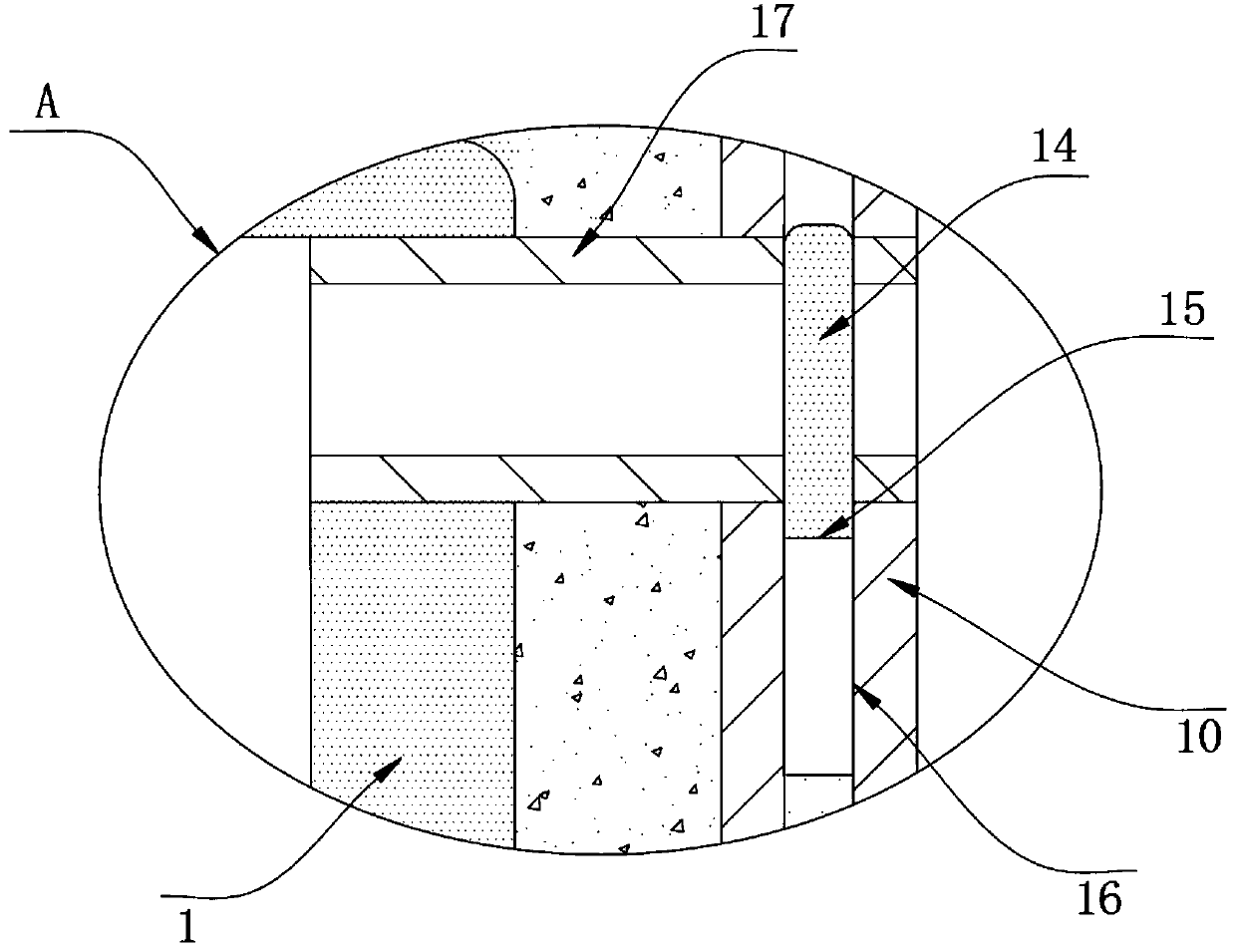

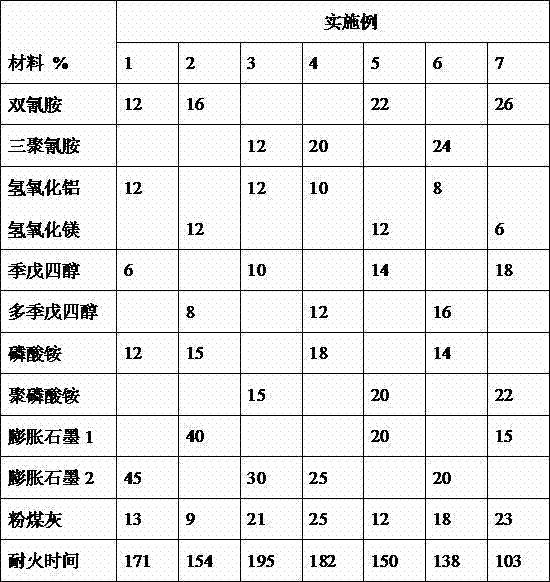

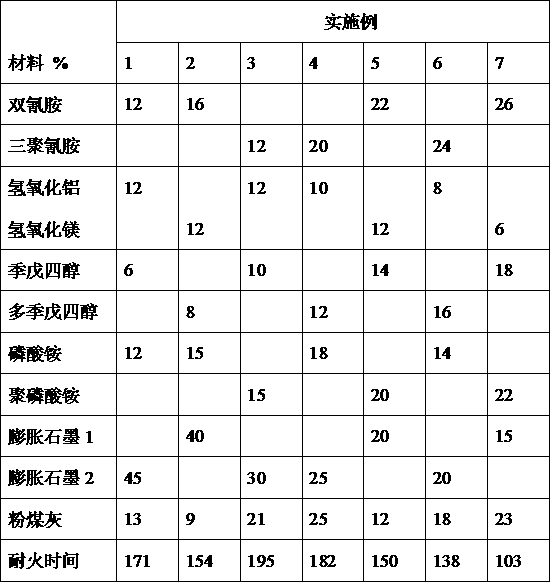

Prescription of intumescent filler for fireproof package

The invention discloses a prescription of an intumescent filler for a fireproof package. The prescription disclosed by the invention is obtained by mixing the following components in parts by weight: 6-20 parts of char-forming agent, 6-20 parts of char-forming catalyst, 10-30 parts of foaming agent, 10-30 parts of inorganic reinforcement, 6-15 parts of inorganic filling agent and 15-45 parts of intumescent material. The prescription disclosed by the invention combines with inorganic filler and organic filler and uses the advantages thereof; fire-resistant barrier with a certain thickness and a certain strength can be intumesced and rapidly charred in a short time in fire, and heat is absorbed and non-flammable gases are released during intumescing and charring processes, so as to achieve the purposes of resisting fire, isolating head and isolating smoke. The prescription has high application value.

Owner:GUANGDONG LIANSU TECH INDAL

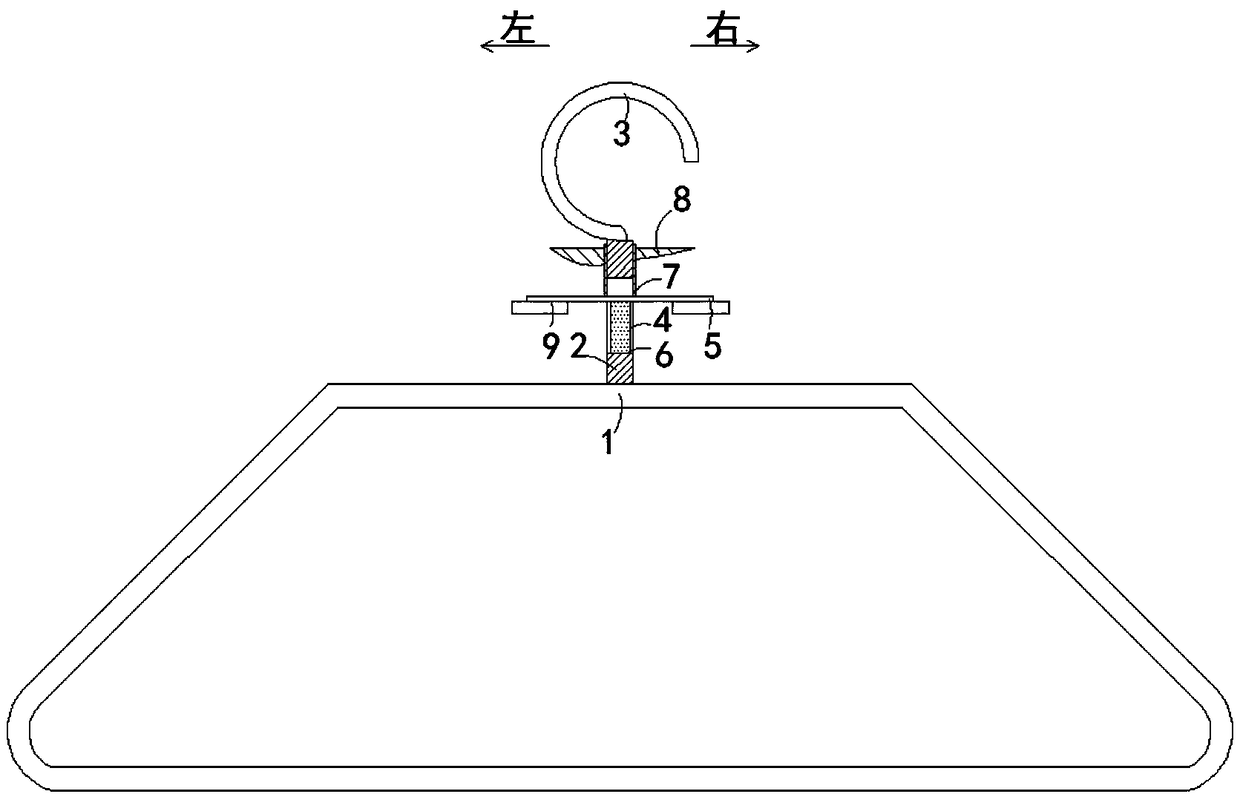

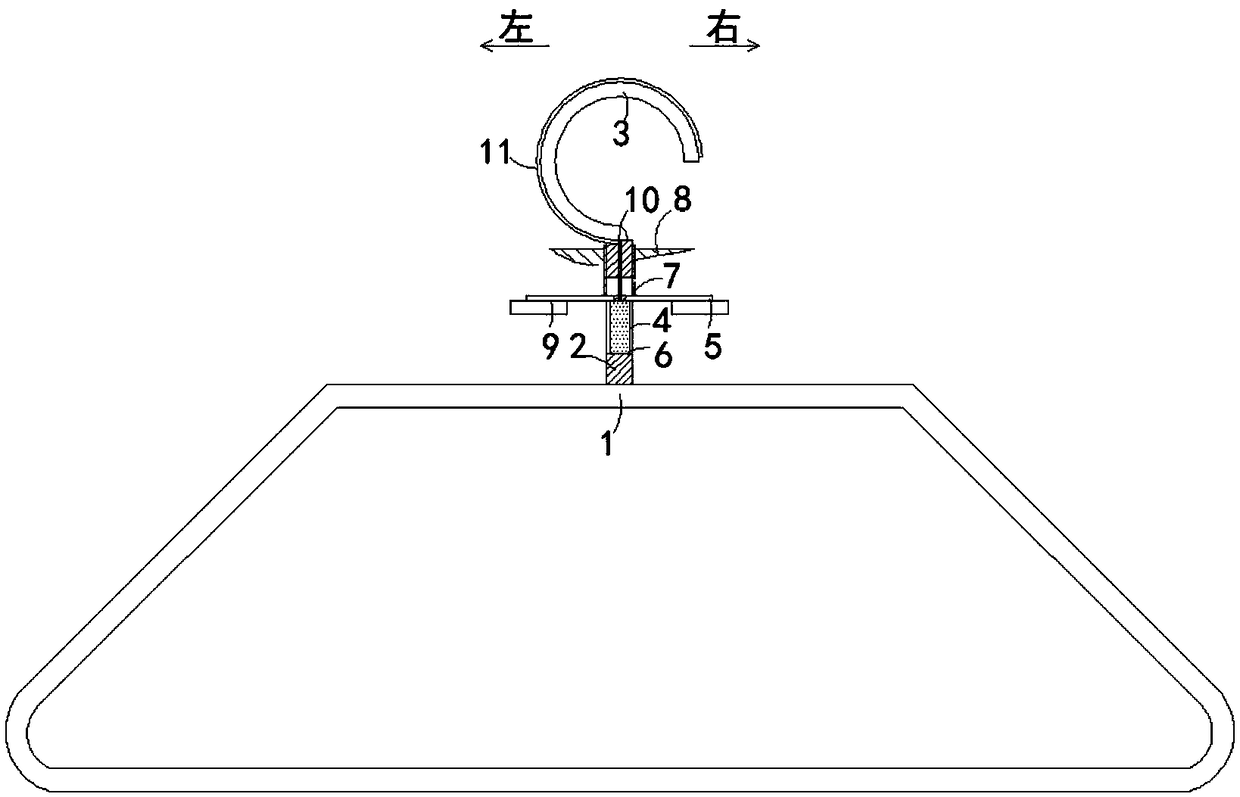

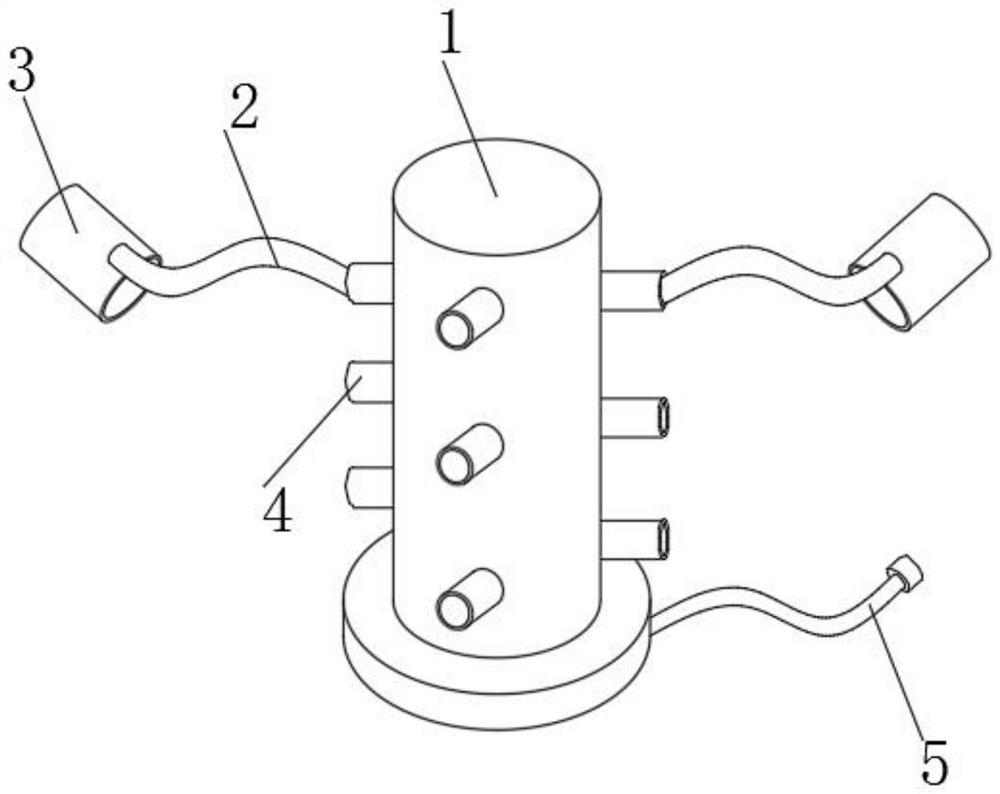

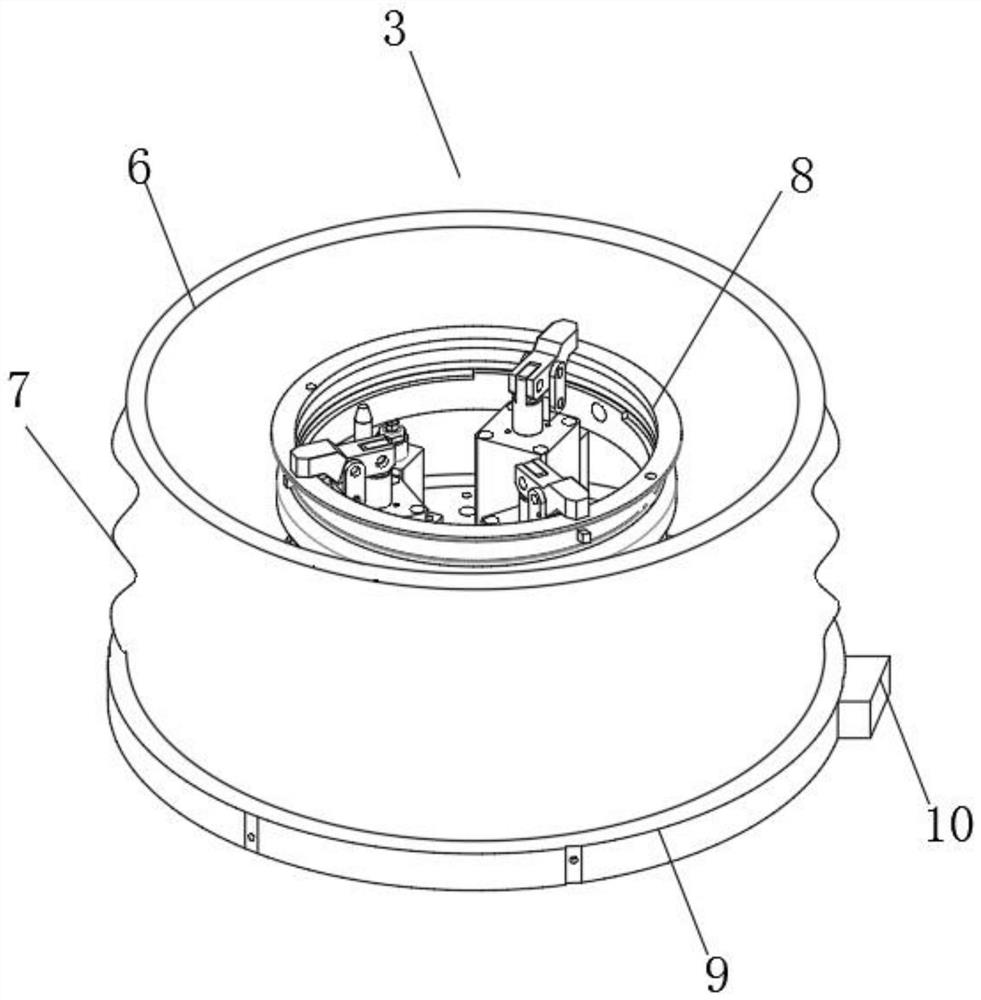

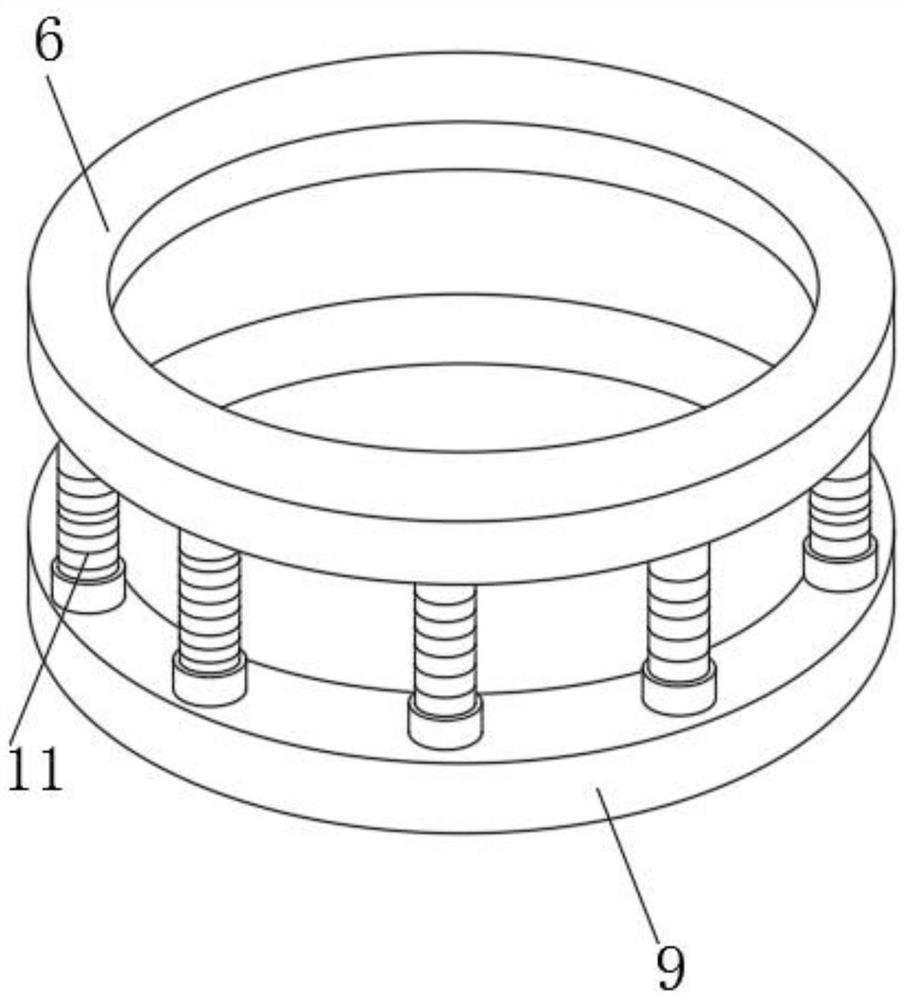

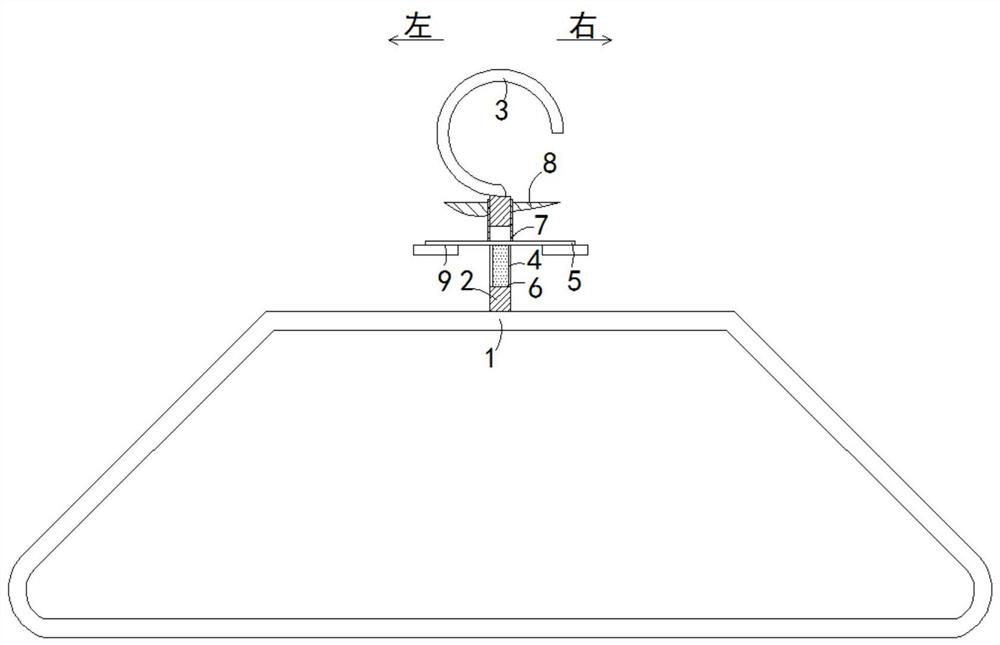

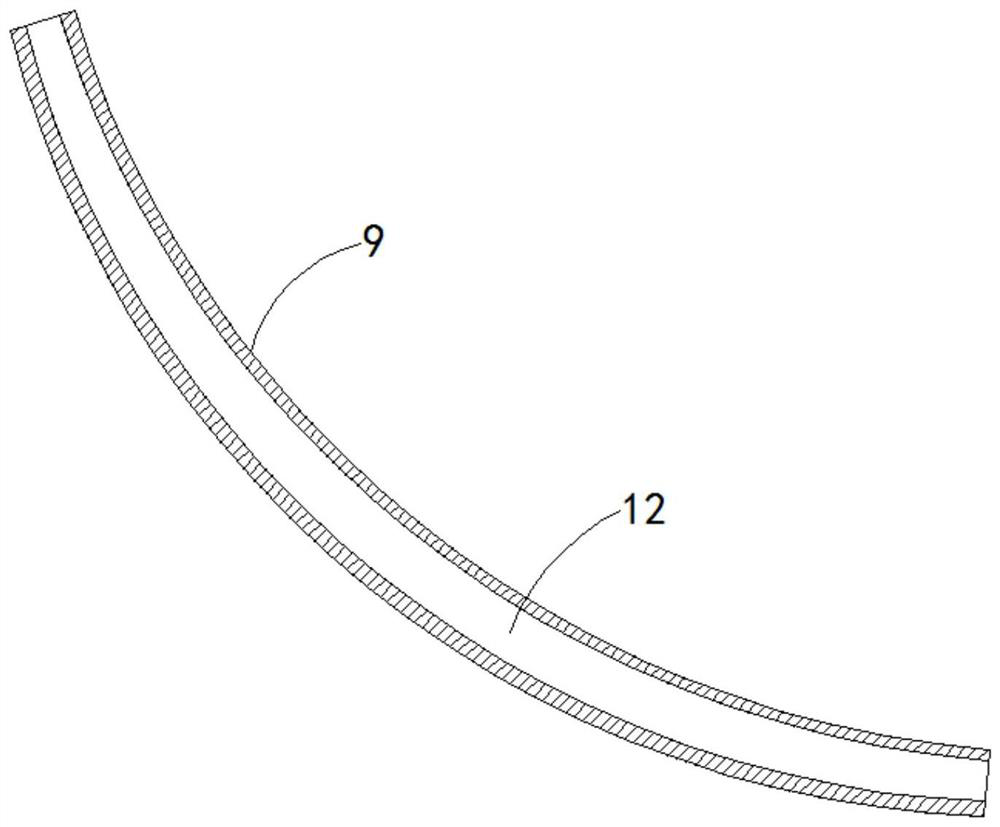

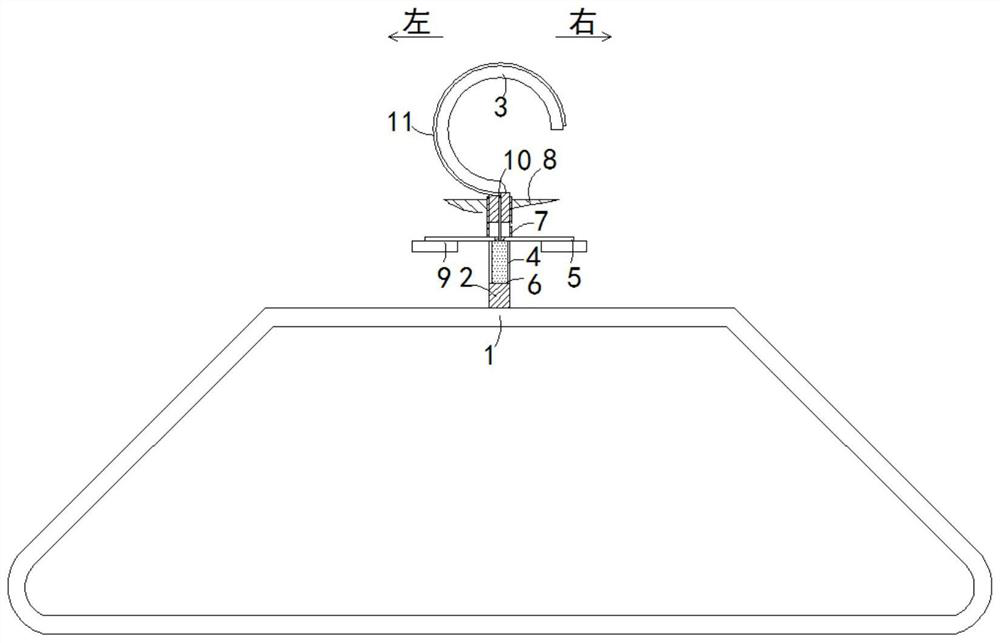

Clothes hanger preventing clothes from being blown off by wind

The invention belongs to the technical field of clothes hangers and particularly relates to a clothes hanger preventing clothes from being blown off by wind. The clothes hanger comprises a clothes hanger body, wherein the upper end of the clothes hanger body is fixedly connected with a vertical rod, the upper end of the vertical rod is fixedly connected with a hook, the side wall of the vertical rod is vertically provided with a strip-shaped opening communicated in a left-right way, horizontal rods are arranged in the strip-shaped opening through movable penetration, the lower ends of the horizontal rods are fixedly connected with arc-shaped plates, two arc-shaped plates are arranged on the horizontal rods at the left and right ends of the vertical rod, the bottom of the strip-shaped opening is fixedly connected with an elastic air bag, the upper end of the elastic air bag is fixedly connected with the lower ends of the horizontal rods, the vertical rod is sleeved with a lifting tube,the lower end of the lifting tube is slidingly connected with the lower ends of the horizontal rods, and the lifting tube is coaxially and fixedly connected with an inversely arranged wing plate. Theclothes hanger has the advantages that the arc-shaped plates can be matched with the clothes hanger body through downward movement of the wing plate in strong wind weather to effectively fix a shirt and prevent the shirt from being blown off by wind.

Owner:嘉兴市万荣电器股份有限公司

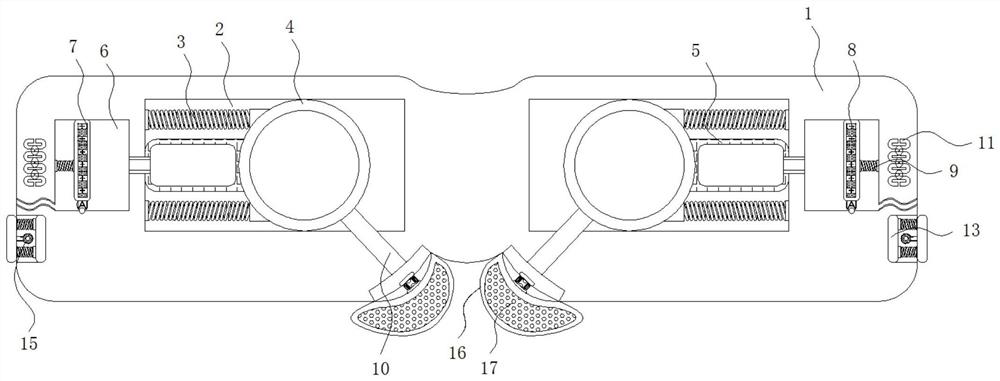

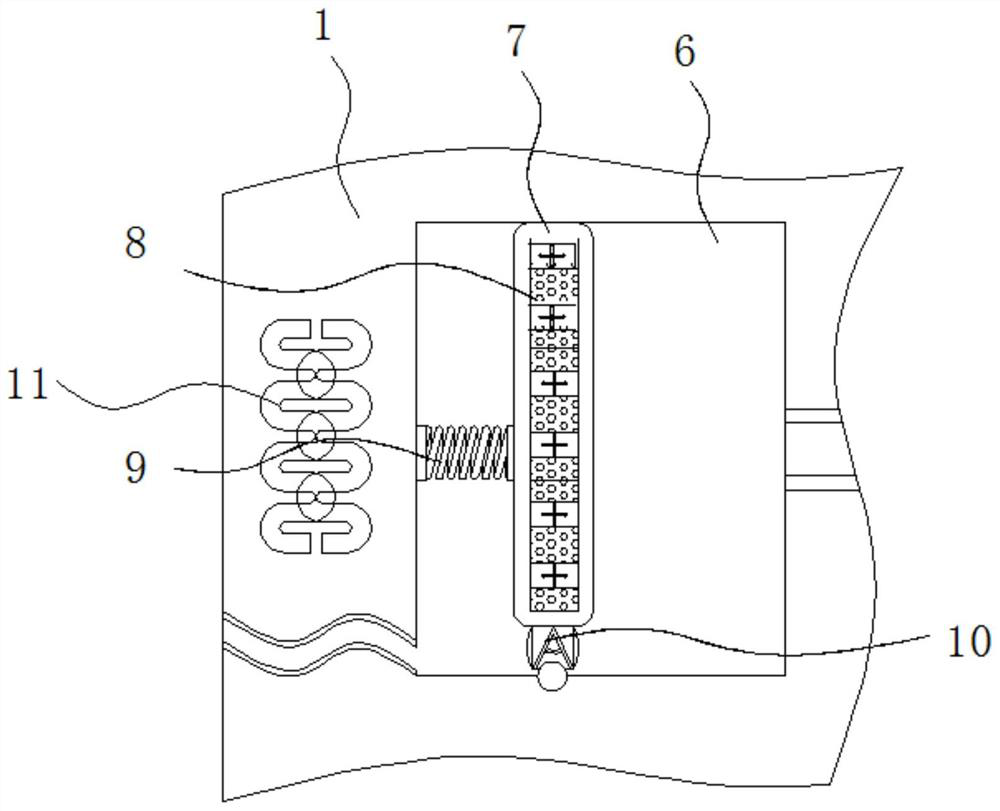

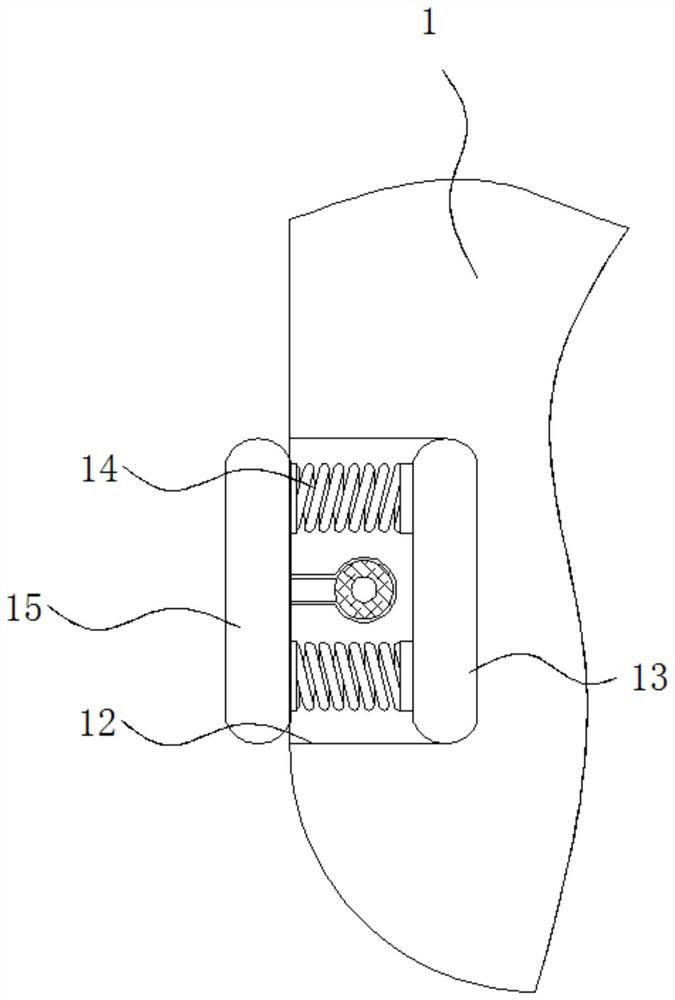

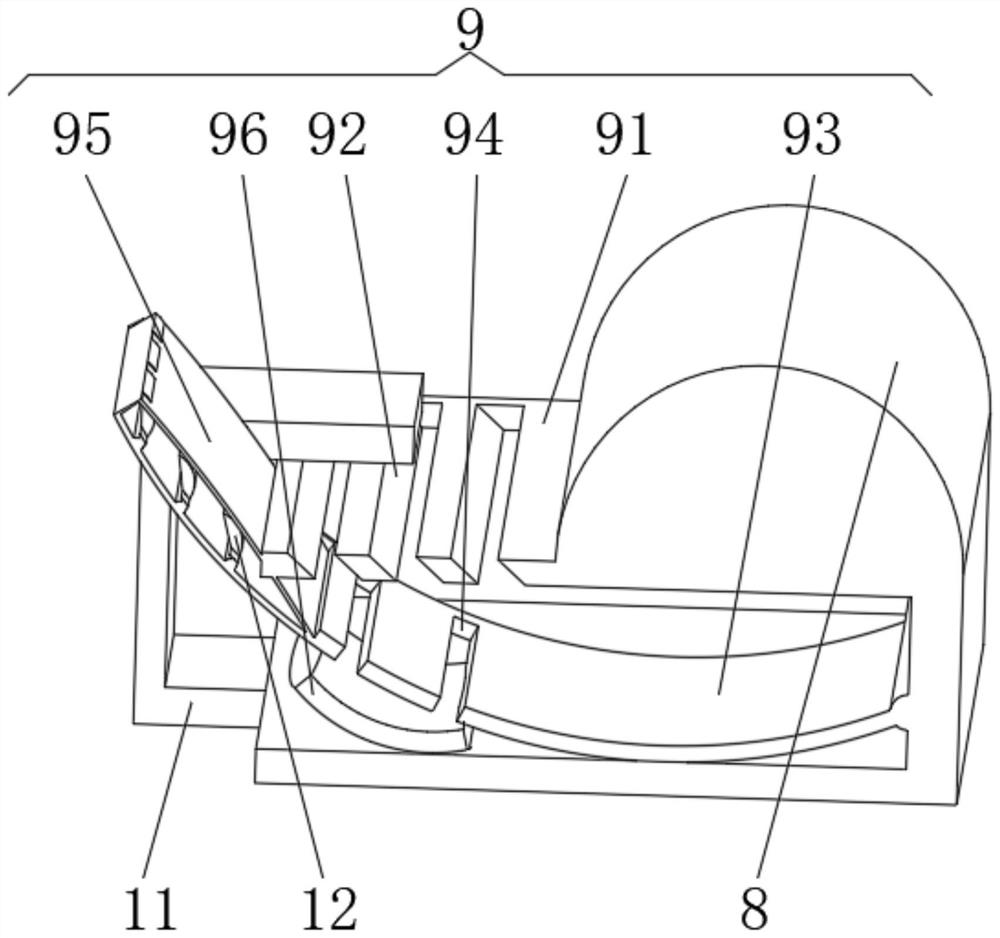

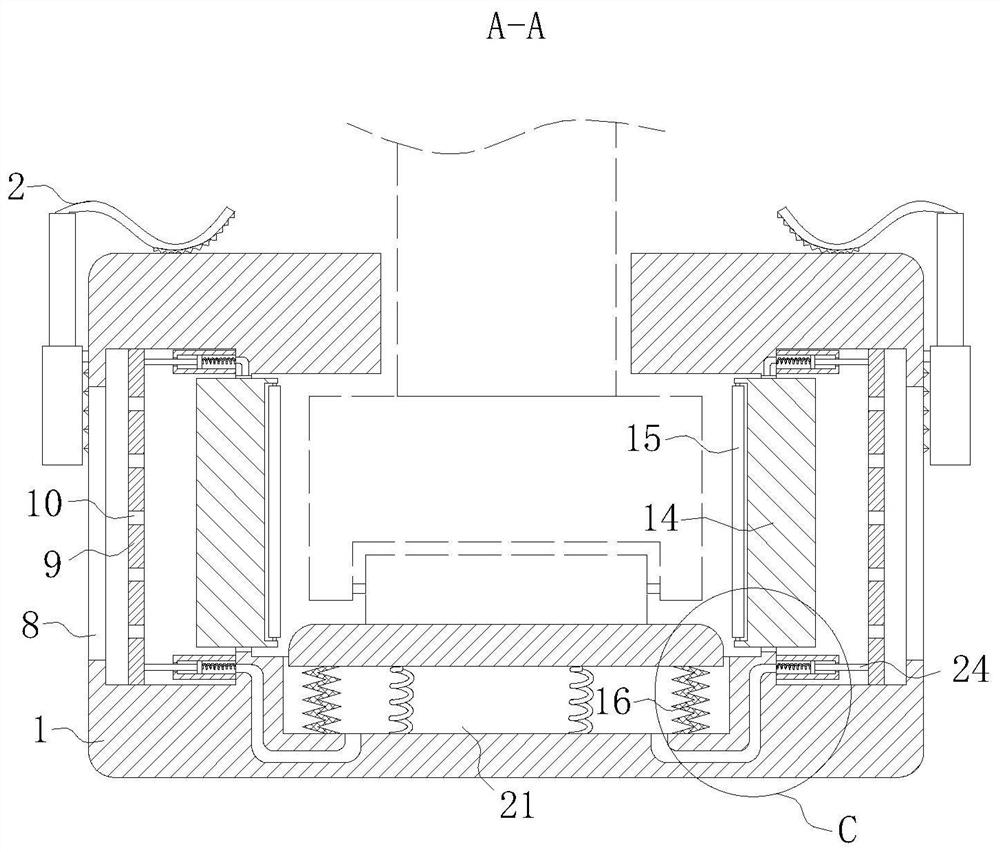

VR head-mounted display equipment capable of adjusting distance between lenses

InactiveCN112526753AAdjustable spacingLarge expansion volumeOptical elementsDisplay deviceEngineering

The invention relates to the technical field of game making auxiliary equipment, and discloses VR head-mounted display equipment capable of adjusting lens spacing, the equipment comprises an equipmentshell and lens fixing frames, adjusting grooves is formed in the equipment shell, first springs are fixedly connected to the inner walls of the adjusting grooves, and the inner sides of the first springs are fixedly connected with the lens fixing frames; the inner walls of the adjusting grooves are fixedly connected with expansion air bags, and air exhaust cavities are formed in the equipment shell. According to the VR head-mounted display device capable of adjusting the distance between lenses, pressing impact blocks are continuously pressed into containing grooves by thumbs, piezoelectric crystals deform to generate current, electromagnets are powered on and have magnetism, the electromagnets pushes magnet filling blocks to the inner sides of the air exhaust cavities, and piston blockspress air in the air exhaust cavities into the expansion air bags; the expansion volume of the expansion air bags is increased, and the lens fixing frames are are pushed along the inner sides of the adjusting grooves, so that the distance between the lens fixing frames is matched with the eye distance of a user, and the use comfort is higher.

Owner:义乌超德贸易有限公司

Industrial aluminum sectional material

ActiveCN111810531ARealize card connectionQuick snap-onLinear bearingsRod connectionsStructural engineeringMechanical engineering

The invention belongs to the technical field of aluminum sectional materials, and particularly relates to an industrial aluminum sectional material. The industrial aluminum sectional material comprises aluminum sectional material bodies. The aluminum sectional material bodies are U-shaped sliding groove aluminum sectional materials which are used as sliding rails. Clamping connection columns are fixedly arranged on the front end faces of the aluminum sectional material bodies. Clamping connection plates which are parallel to the aluminum sectional material bodies are arranged on the outer edges of the clamping connection columns. Clamping connection grooves which are matched with the clamping connection columns are formed in the rear end faces of the aluminum sectional material bodies. When the aluminum sectional material bodies are actually spliced, the clamping connection columns on one aluminum sectional material body can be directly inserted into the clamping connection grooves formed in the other aluminum sectional material body, then barrier strips are rotated so that the barrier strips can be separated from the upper surfaces of the aluminum sectional material bodies, springs which are fixedly connected with rectangular sliding blocks can push the rectangular sliding blocks to downwards move under the action of the elastic force of the springs, movable insertion rods which are fixedly connected with the rectangular sliding blocks are downwards pushed, the movable insertion rods can be inserted into insertion holes, and therefore the clamping connection between the two aluminum sectional material bodies is achieved. In addition, the clamping connection is quick, and compared with a conventional screw connection mode, the clamping connection mode has the advantagesof more saving the labor and being more efficient.

Owner:佛山市凤盈铝制品有限公司

Refrigerating and firefighting dual-purpose system

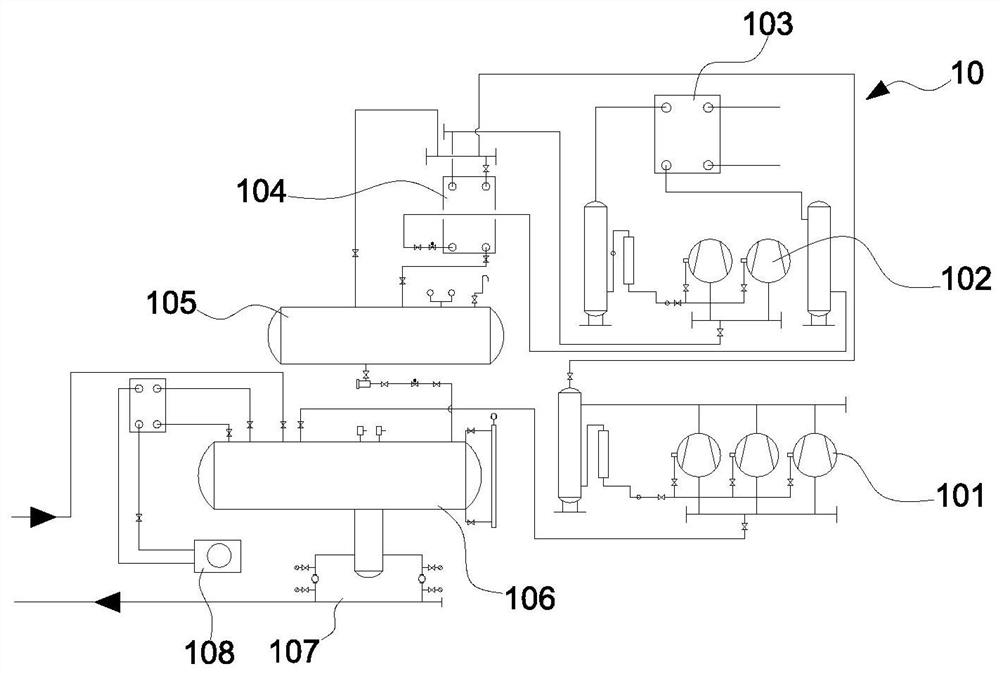

InactiveCN112902485AReduce in quantityReduce setup costsCompression machinesFire rescueCold airSpray nozzle

The invention relates to a refrigerating and firefighting dual-purpose system which comprises a refrigerating assembly, a conveying pipeline, a cold air blower, a spray nozzle, a first valve and a second valve, wherein the refrigerating assembly communicates with the conveying pipeline for outputting a refrigerant to the conveying pipeline; the conveying pipeline separately communicates with the cold air blower and the spray nozzle; the first valve is arranged at the front end of the cold air blower; and the second valve is arranged at the front end of the spray nozzle. The function of the refrigerating system is expanded, the cost can be effectively reduced, occupied space is reduced, and therefore, the refrigerating and firefighting dual-purpose system is suitable for scenes with narrow spaces such as a fishing boat.

Owner:浙江英诺绿能科技有限公司

An environment-friendly power distribution cabinet for sponge city

ActiveCN110739624BHeat dissipation fastImprove cooling efficiencySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsWater storageThermodynamics

Owner:PANJIN GUANGLIDA ELECTRIC

Solar heat collection type seawater desalination device

PendingCN113753995ALarge expansion volumeAdjust reflection angleGeneral water supply conservationSeawater treatmentThermodynamicsLight reflection

The invention discloses a solar heat collection type seawater desalination device which comprises a shell, a heat collection water tank is installed in the shell, one side of the heat collection water tank communicates with a water inlet pipe, the end, away from the heat collection water tank, of the water inlet pipe penetrates through the shell, and the side, close to the water inlet pipe, of the heat collection water tank communicates with a steam pipe. The end, away from the heat collection water tank, of the steam pipe penetrates through the shell to communicate with a condensation pipe, one side of the heat collection water tank communicates with a connecting pipe, a water suction pump is installed on one side of the connecting pipe, the end, away from the heat collection water tank, of the connecting pipe communicates with a water conveying pipe, and one side of the water conveying pipe communicates with a solar heat collecting pipe. A light reflecting device is mounted on one side of the solar heat collecting pipe. The invention relates to the technical field of seawater desalination. According to the solar heat collection type seawater desalination device, the purpose of adjusting the light reflection angle is achieved, the solar heat collection pipe absorbs sunlight to the maximum extent, and the absorption capacity is improved.

Owner:陈云鹏

Printer ink cartridge capable of improving printing effect

InactiveCN113085379AWell mixedLarge expansion volumeRotary stirring mixersTransportation and packagingThermal dilatationCircular disc

The invention provides a printer ink cartridge capable of improving a printing effect. The printer ink cartridge comprises a cartridge body, wherein a heating plate is embedded in the bottom in the cartridge body, a rotating shaft is rotationally connected to the inner wall of the cartridge body, a circular cavity is formed in the side wall of the cartridge body, and one end of the rotating shaft penetrates through the side wall of the cartridge body and extends into the circular cavity. A disc is fixedly connected to the end, located in the circular cavity, of the rotating shaft, a first driving mechanism for driving the disc to rotate is installed on the cartridge body, and a plurality of stirring plates are symmetrically and fixedly connected to the side wall of the rotating shaft in the horizontal direction of the rotating shaft. Printing ink in the cartridge body can be heated through a heating plate, so that thermal expansion liquid absorbs heat through a heat conducting rod, the expansion volume of the thermal expansion liquid is increased, a sliding plate is pushed to slide, a driving strip slides in a circular cavity, the disc is driven to rotate, and a plurality of stirring plates coaxially and fixedly connected with the disc are driven to rotate, and ink in the cartridge body is uniformly mixed, so that the printing effect of the printer is improved.

Owner:杨道会

An electrocardiogram pulse pressure synthesis acquisition device

ActiveCN110251090BLarge expansion volumeNot easy to fall offCatheterDiagnostic recording/measuringPulse pressureEngineering

The invention discloses an electrocardiogram pulse pressure synthesis acquisition device, which comprises a mounting rod and a fixing cylinder. A plurality of connecting heads are arranged on the outside of the installing rod, and the ends of the connecting heads are connected with the fixing cylinder through wires. The fixing cylinder includes a top ring, a fixing ring and a bottom ring, a base is installed horizontally at the top middle end of the bottom ring, a perforation is provided through the inner middle end of the base, and the top of the base is vertically connected at the peripheral edge of the perforation There are several side plates, the outer side of the side plate is connected with a stabilizing plate, the inner side of the side plate is connected with an abutment plate in parallel, and a plurality of measuring probes are installed on the side of the abutment plate away from the side plate. The fixed ring rotates on the outside of the wrist, ankle and neck to adjust the position so that the measuring probe can fully contact the wrist, ankle and neck, measure different positions, and can measure multiple sets of waveforms and multiple sets of data. more fully. And the position adjustment is convenient and fast during measurement, which can adapt to different work requirements.

Owner:徐州市宝兴医疗设备有限公司

A wind-proof clothes hanger

The invention belongs to the technical field of clothes hangers, and in particular relates to a wind-proof clothes hanger, which includes a clothes hanger body. The wall is vertically provided with a strip-shaped opening connected to the left and right, and a horizontal rod is movable through the strip-shaped opening. The lower end of the horizontal rod is fixedly connected with an arc-shaped plate. On the horizontal rods at the left and right ends of the rod, the bottom of the strip-shaped opening is fixedly connected with an elastic airbag, the upper end of the elastic airbag is fixedly connected with the lower end of the horizontal rod, and a lifting tube is set on the vertical rod, and the lifting tube The lower end of the lower end is slidingly connected with the lower end of the horizontal bar, and an inverted wing plate is coaxially fixedly connected to the lifting tube. The advantage is that the present invention can effectively fix the inch shirts by the arc-shaped plate cooperating with the clothes hanger body through the downward movement of the wing plate in a windy day, preventing it from being blown off by the strong wind.

Owner:嘉兴市万荣电器股份有限公司

An industrial aluminum profile

ActiveCN111810531BRealize card connectionQuick snap-onLinear bearingsRod connectionsEngineeringMechanical engineering

The invention belongs to the technical field of aluminum profiles, specifically an industrial aluminum profile, including an aluminum profile body; the aluminum profile body is a U-shaped chute aluminum profile used as a slide rail; column; the outer edge of the clamping column is provided with a clamping plate parallel to the aluminum profile body; the rear end surface of the aluminum profile body is provided with a clamping groove that matches the clamping column; The clamping posts on one group of aluminum profile bodies are inserted into the clamping slots on the other group of aluminum profile bodies, and then the retaining bar is rotated to separate from the upper surface of the aluminum profile body. The spring will push the rectangular slider down under the action of its own elastic force, and push down the movable insertion rod fixedly connected with the rectangular slider, so that the movable insertion rod can be inserted into the socket, so as to realize the gap between the two sets of aluminum profile bodies. The card connection is fast, and it is more labor-saving and efficient than the traditional screw connection method.

Owner:佛山市凤盈铝制品有限公司

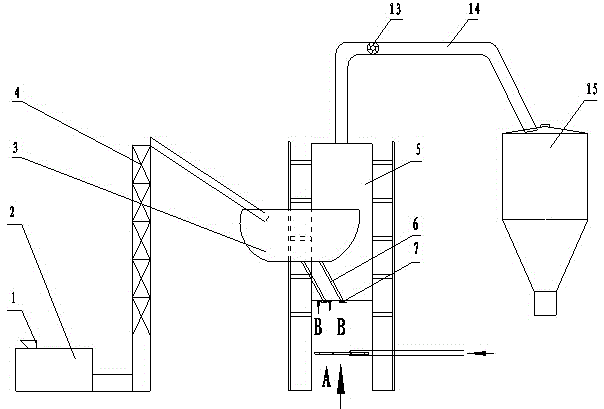

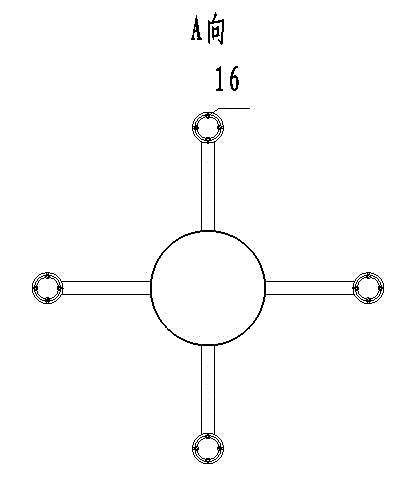

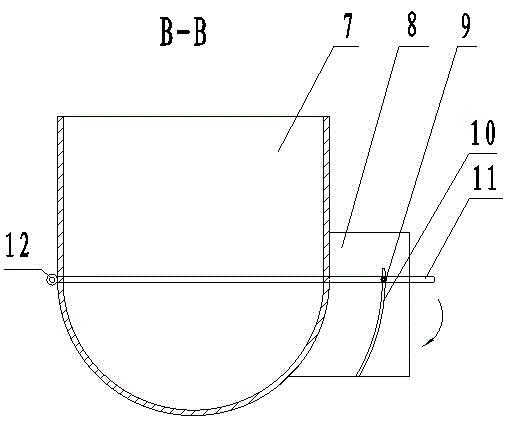

Gas sucking type perforated microsphere expanding equipment

InactiveCN103278006BLarge expansion volumeImprove thermal efficiencyVertical furnacesThermodynamicsMicrosphere

The invention provides gas sucking type perforated microsphere expanding equipment. The gas sucking type perforated microsphere expanding equipment comprises a preheating furnace, an elevator, an expanding furnace, an induced draft fan and a product bin, and a feeding port and the elevator are positioned at one end of the expanding furnace. Materials enter the preheating furnace via the feeding port, then are stirred up and down in the preheating furnace and are pushed ahead along the spiral direction. The heated materials enter a storage bin through the elevator, a plurality of guide pipes are arranged on the circumferential face of the bottom face of the storage bin, the materials in the storage bin are fed into corresponding hoppers through the guide pipes, each hopper is provided with a manual flow regulating handle used for controlling the quantity of the materials fed into the expanding furnace, the materials in the hoppers fall along the inner wall of the expanding furnace, the materials in high-temperature areas nearby burners expand rapidly, the expanding size of the expanded materials is 8-15 times of the original size of the materials, microspheres subjected to expansion sintering move from the bottom to the top of the expanding furnace under the action of sucking force of the induced draft fan and are conveyed to the product bin via a conveying pipe, and the hoppers and the burners are the same in number and corresponding in position. The gas sucking type perforated microsphere expanding equipment is high in working efficiency.

Owner:SHANDONG UNIV OF TECH

Tobacco stalk expansion method

InactiveCN101862023BUniform moistureUniform expansionTobacco preparationTobacco treatmentMicrowaveEngineering

The invention provides a tobacco stalk expansion method, which comprises the following steps of: grading tobacco stalks, performing impregnation remoistening on the graded tobacco stalks and expanding the tobacco stalks, wherein a microwave heating expansion method is adopted in the expansion of the tobacco stalks; preferably, the microwave heating expansion is performed on the tobacco stalks under a vacuum condition; more preferably, the microwave heating expansion is performed on the tobacco stalks by adopting more than two different kinds of continuous microwave output power under the vacuum condition, wherein the former two kinds of continuous microwave output power are 4.0 to 8.0 kw and 1.5 to 2.5 kw respectively for every kilogram of remoistened tobacco stalks; and the impregnation remoistening comprises the steps of: spraying water onto the tobacco stalks, and performing the impregnation remoistening under the pressure of 0.112 to 0.203 MPa and at the temperature of 50 to 100 DEG C. The expanded tobacco stalk has the characteristics of greater volume that is 1 to 3 times that of the conventional tobacco stalk, uniform expansion, remarkable fragrance, less wood smell, high resilience, the water content of 0.5 to 3 percent, high combustibility, improved intrinsic quality and relatively better smoke characteristic maintenance.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

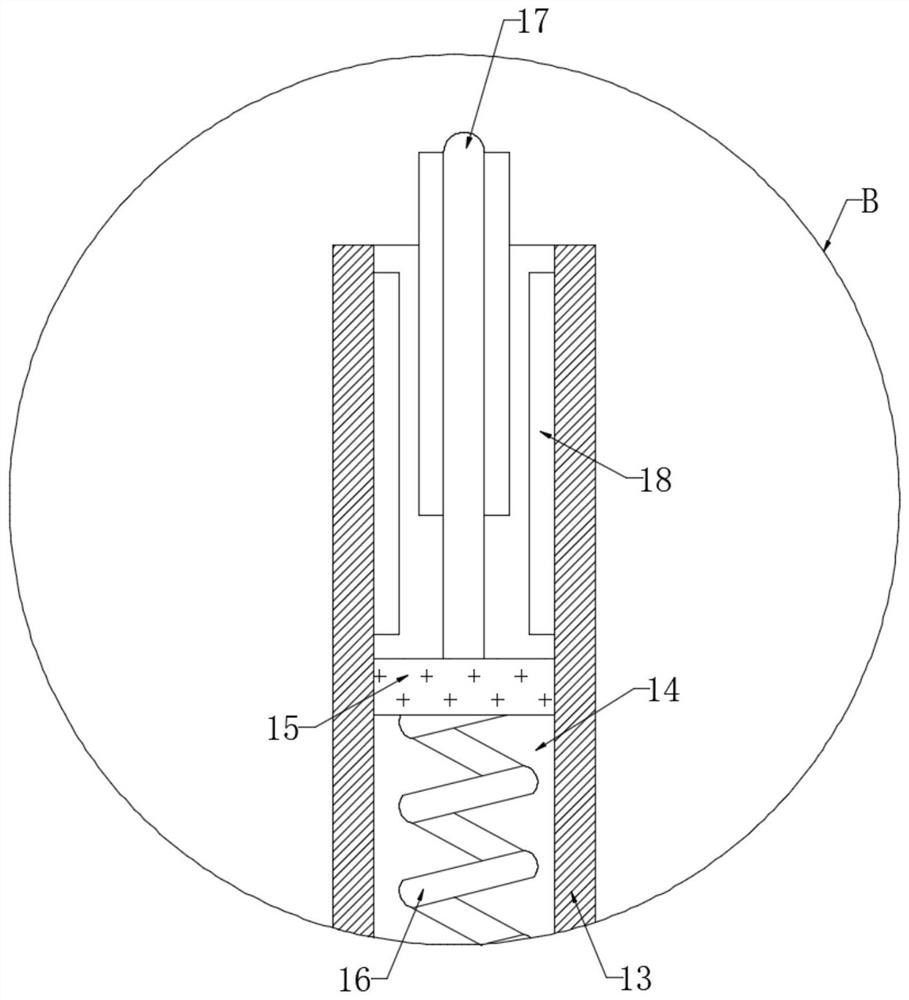

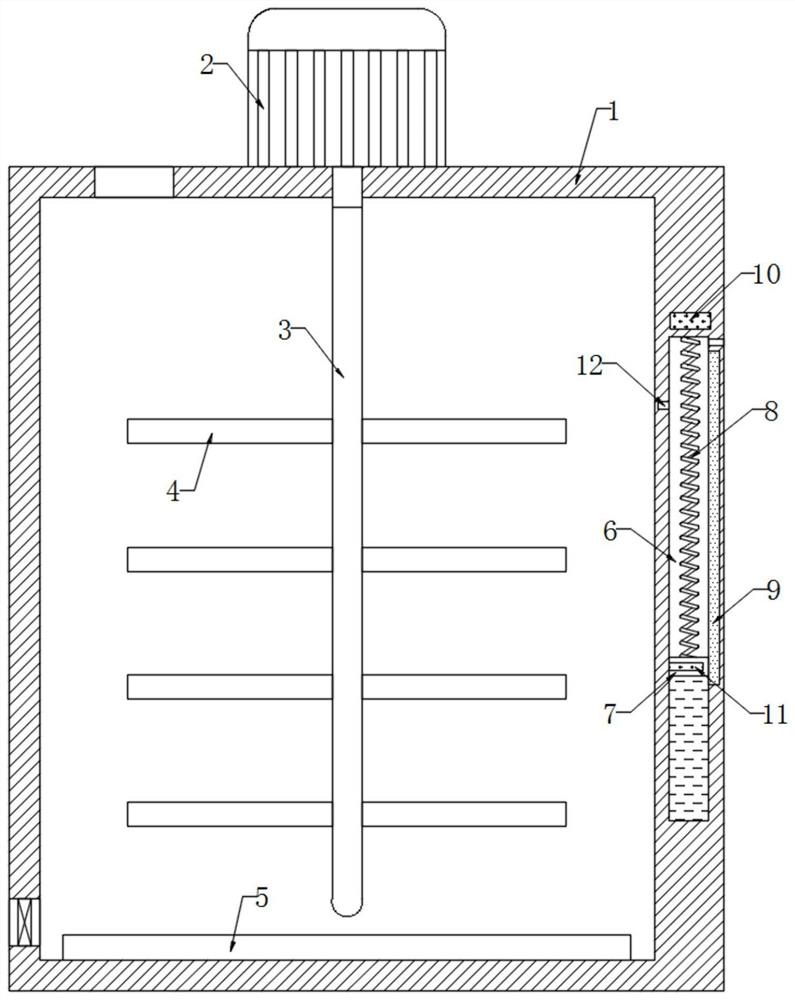

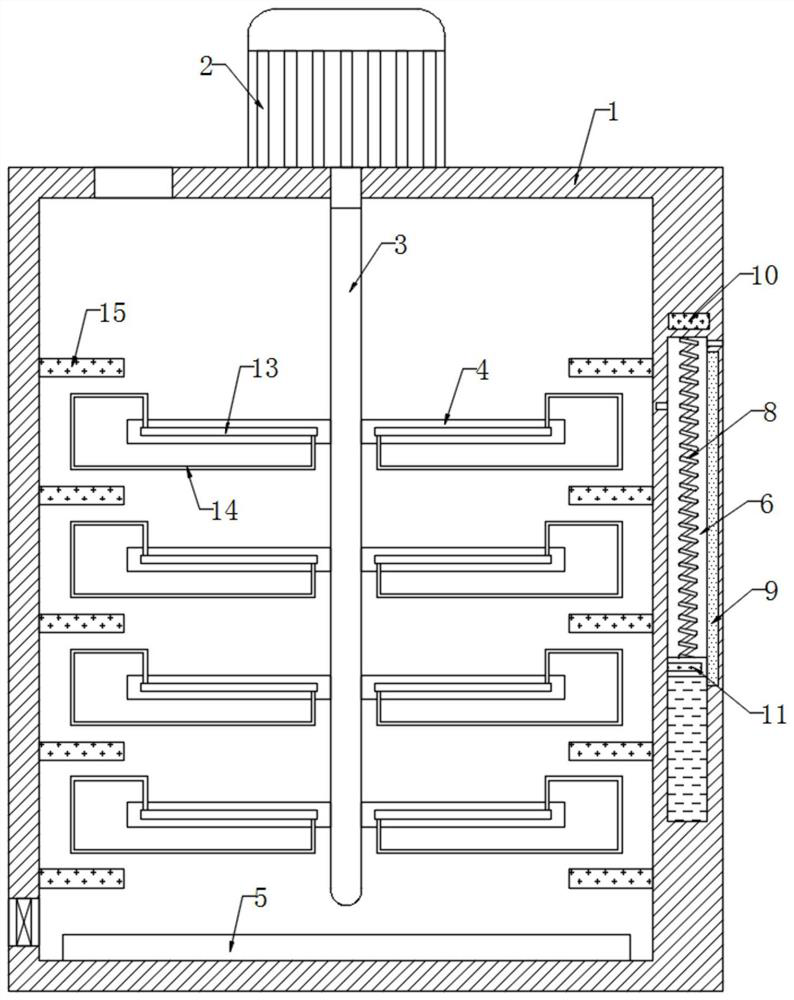

Rotating speed self-adjusting type lithium battery cell slurry fluctuation type stirring equipment

InactiveCN112316837ALarge expansion volumeIncrease pressureFinal product manufactureRotary stirring mixersElectrical resistance and conductanceElectric machine

The invention discloses rotating speed self-adjusting type lithium battery cell slurry fluctuation type stirring equipment which comprises a stirring box, a motor is fixedly connected to the upper endof the stirring box, a movable end of the motor penetrates through the upper end of the stirring box and is fixedly connected with a rotating shaft, and a plurality of stirring rods are fixedly connected to the side wall of the rotating shaft. A heating plate is fixedly connected to the bottom in the stirring box, a sliding plug cavity is formed in the side wall of the stirring box, and a conductive plate is slidably connected to the inner wall of the sliding plug cavity in a sealed mode. The conductive plate continuously slides up and down on the inner wall of the sliding plug cavity under the action of expansion force of expansion liquid and magnetic repulsion of a permanent magnet plate to an electromagnet, so that resistance of a resistance plate connected into a circuit is continuously changed, then current flowing through the motor is continuously changed, the motor drives the rotating speed of the stirring rods to be continuously changed, and further cell slurry is subjected tofluctuation type stirring; and moreover, manual intervention is not needed, heat generated at the heating plate is reasonably utilized, energy is saved, and the environment is protected.

Owner:王慧慧

A kind of low-density deketoxime type silicone sealant and preparation method thereof

ActiveCN105441019BLow densityImprove stabilityNon-macromolecular adhesive additivesThermal expansionVolumetric Mass Density

The invention discloses a low-density deketoxime type silicone sealant. The sealant comprises components in parts by weight as follows: 100 parts of alpha, omega-dyhydroxyl polydimethylsiloxane, 1-40 parts of dimethyl silicone oil, 0.1-4 parts of thermal expansion microcapsules, 1-25 parts of a cross-linking agent, 20-180 parts of reinforcing filler, 0.01-5 parts of a coupling agent and 0.005-1 part of a catalyst. The invention further discloses a preparation method of the low-density deketoxime type silicone sealant. The low-density deketoxime type silicone sealant has excellent mechanical property and adhesive property, the density of the sealant is remarkably reduced, the foaming effect is excellent, and the stability is high. According to the preparation method, a process is simple and easy to implement, equipment is conventional, operation is facilitated, and industrial large-scale production is facilitated.

Owner:浙江中天东方氟硅材料股份有限公司

Prescription of intumescent filler for fireproof package

Owner:GUANGDONG LIANSU TECH INDAL

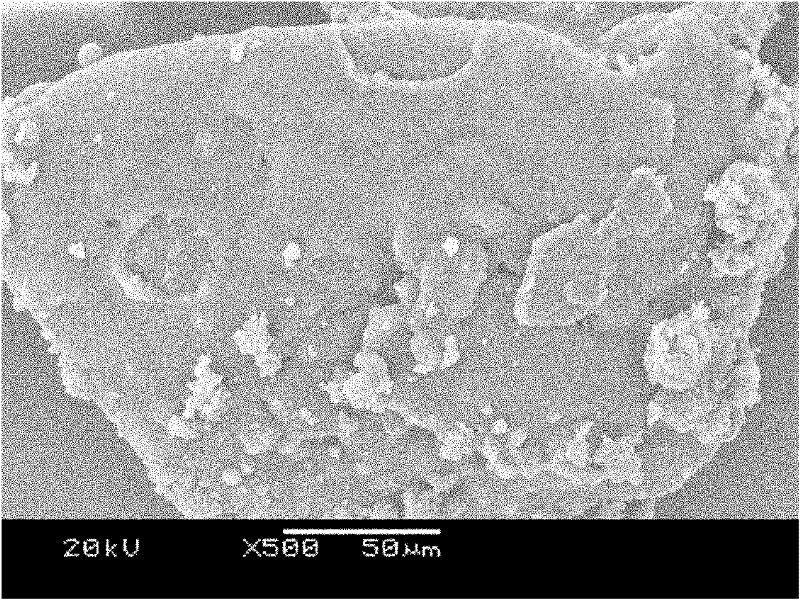

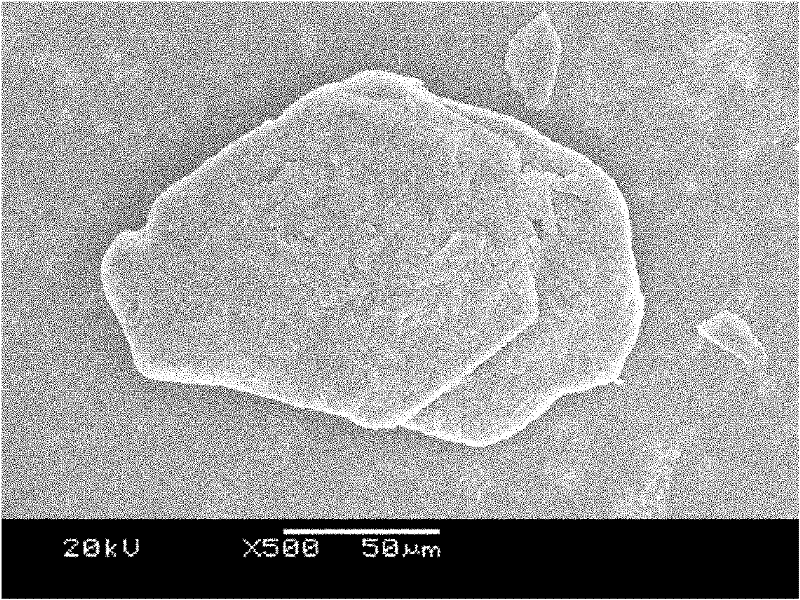

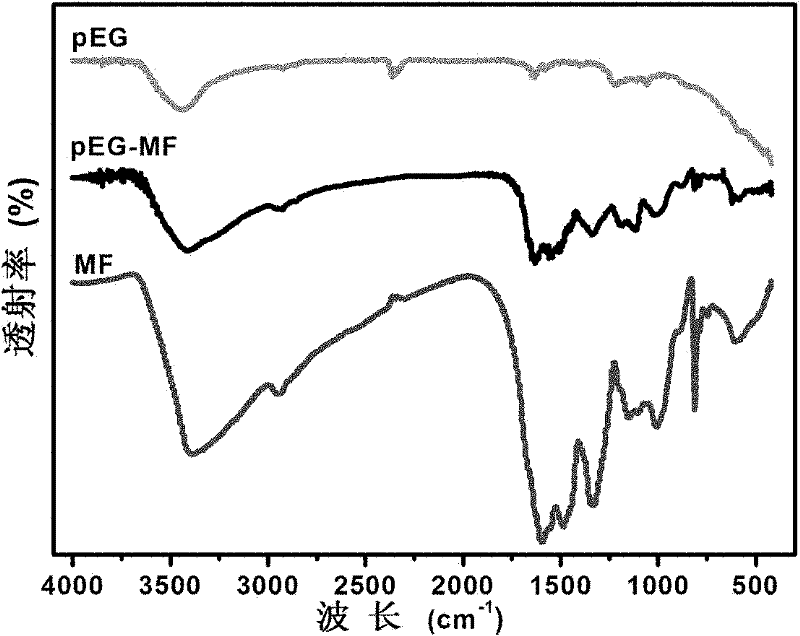

Composite flame retardant with core-shell structure and preparation method thereof

The invention discloses a composite flame retardant with a core-shell structure, which is formed into dark gray solid particles. The cores of the particles are expansible graphite with an average particle size of 100 to 200 mu m, and the shells of the particles are melamine formaldehyde resin. After the composite flame retardant is subjected to heat treatment at a high temperature of 900 DEG C for 15 seconds, the volume expansibility of the composite flame retardant is 58 to 74ml / g according to measurement. The invention also discloses a preparation method of the composite flame retardant with the core-shell structure. As the flame retardant provided by the invention is formed by coating the expansible graphite particles with a layer of very thin melamine formaldehyde resin, when the particles of the flame retardant with the core-shell structure is heated, the gas generated by the expansible graphite particles cannot escape to the outside immediately due to the protection of the shelllayer formed by polymer on outer layer, instead the gas is released after the graphite sheet layer is opened completely; and thus, the expanded volume of the expansible graphite is increased, and theflame retarding performance is improved greatly. The method provided by the invention adopts simple process, is high in operability and makes the realization of large scale production easy.

Owner:SICHUAN UNIV

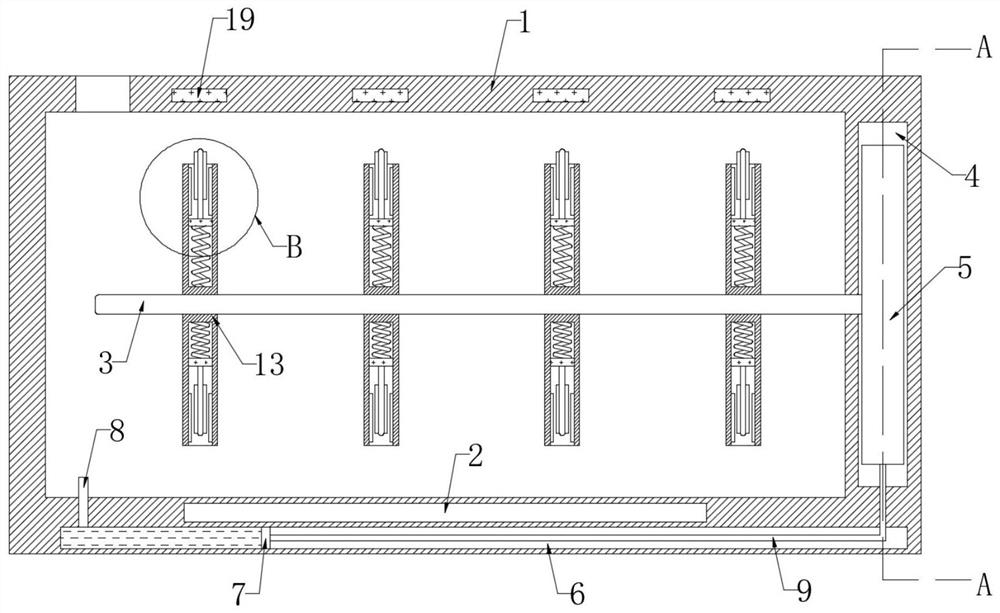

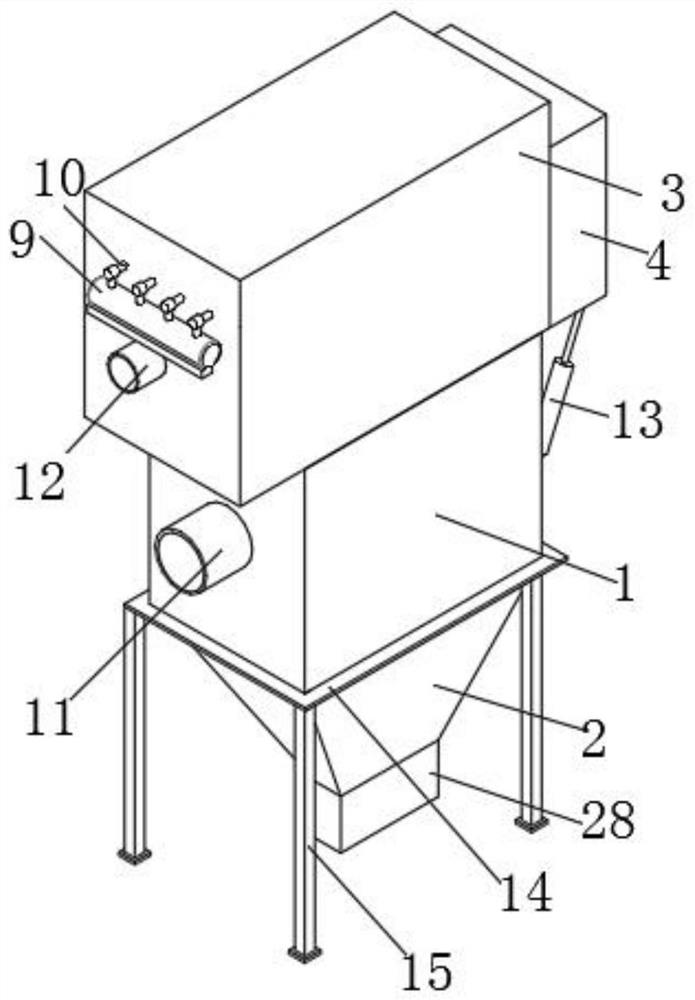

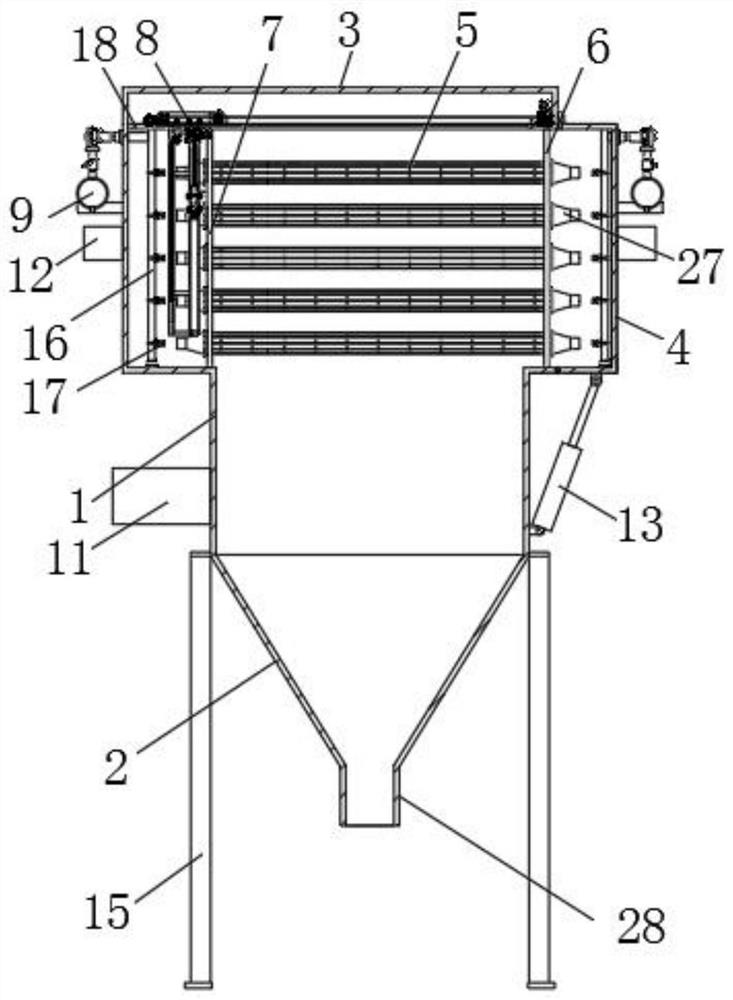

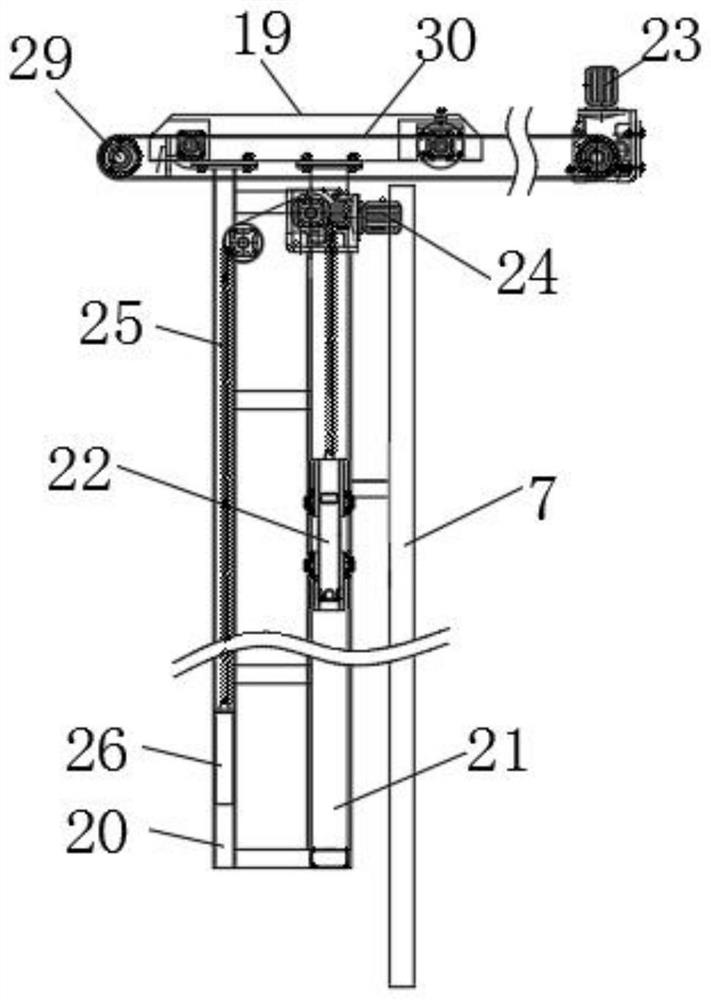

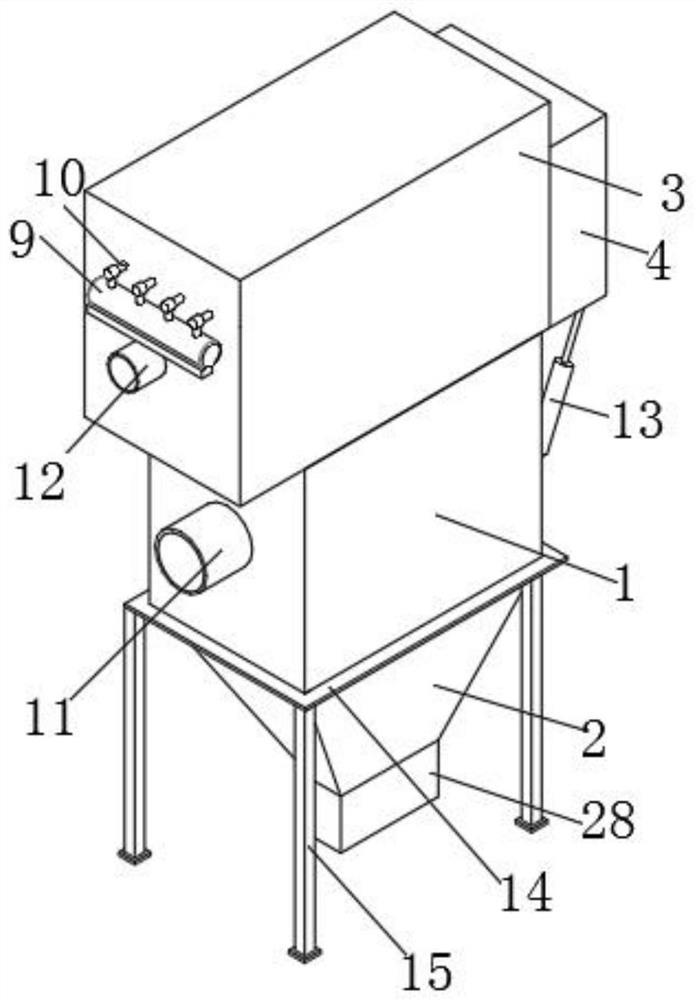

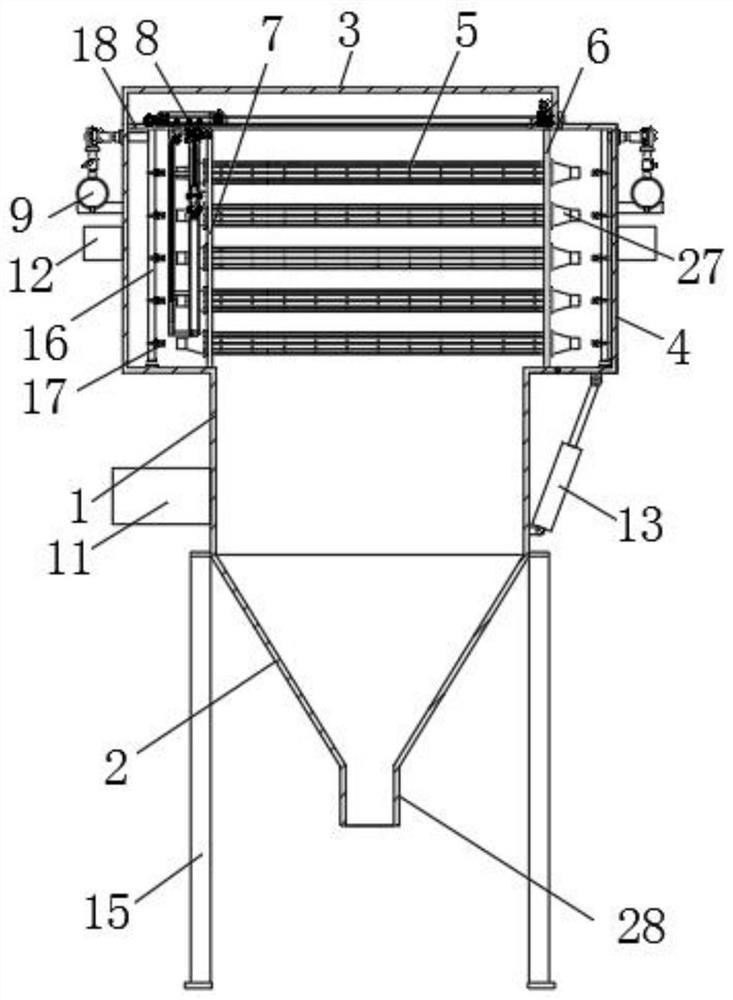

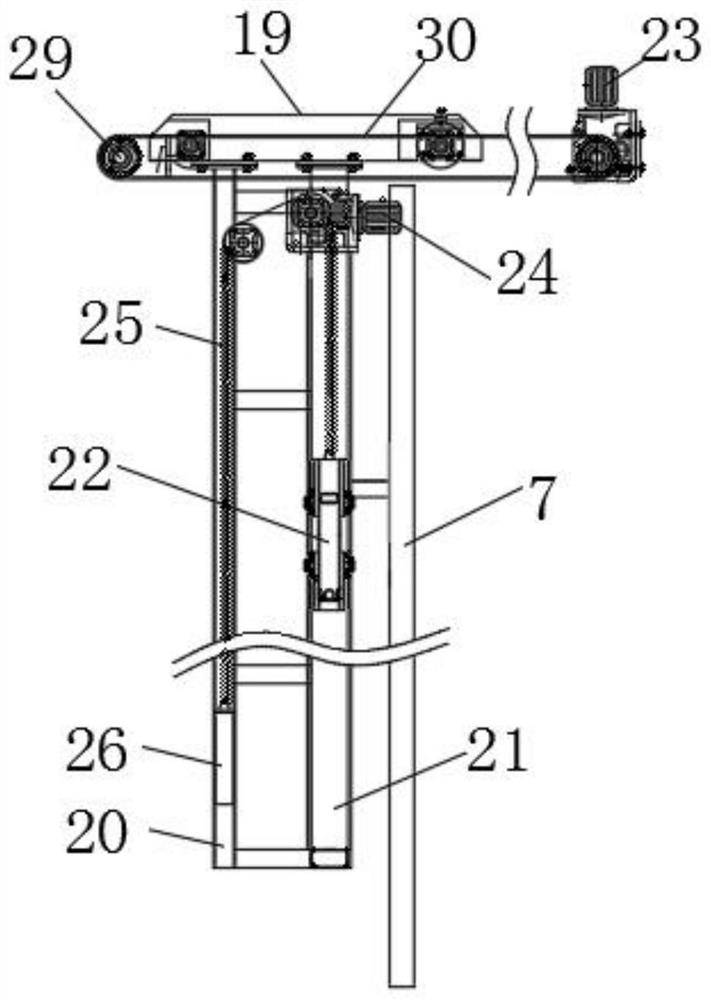

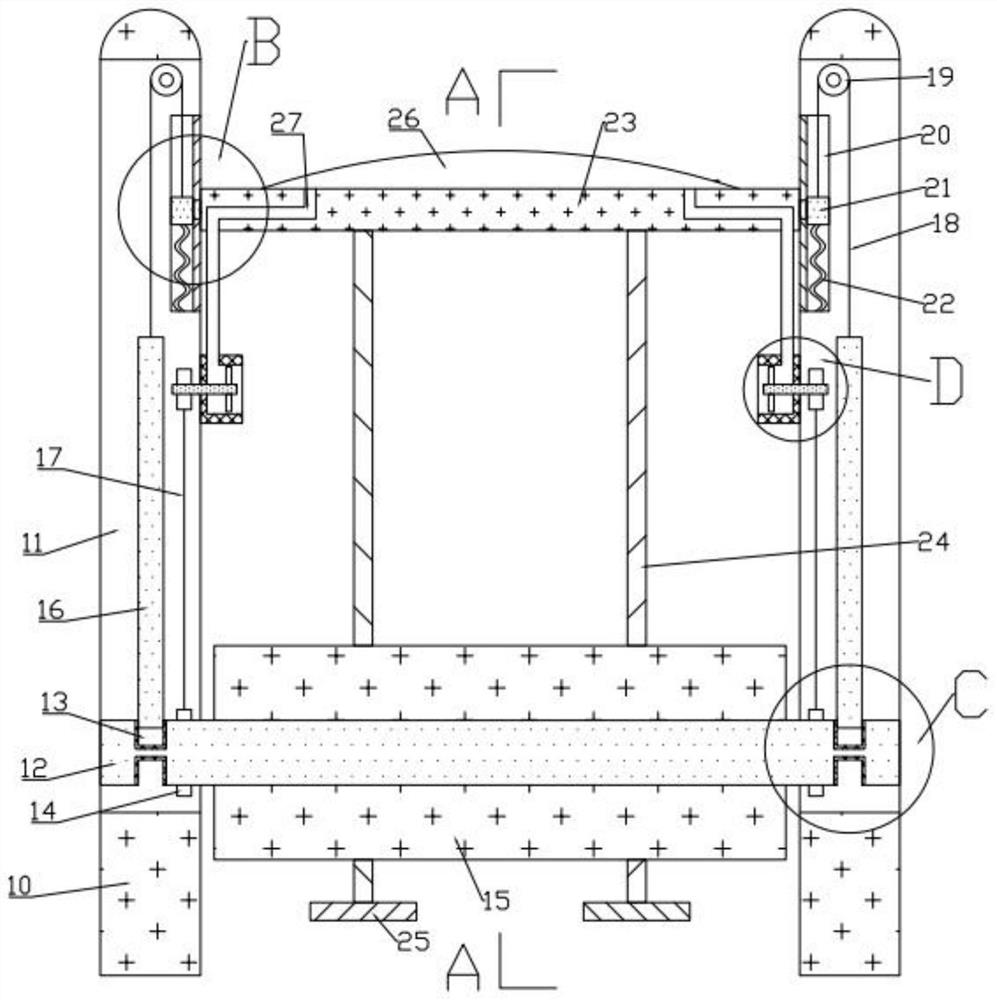

A high-efficiency pulse dust collector and its working method

ActiveCN112023547BSpeed up filteringImprove dust removal efficiencyDispersed particle filtrationAir filtrationDust control

The invention discloses a high-efficiency pulse dust remover and its working method. The dust remover comprises a lower box body. A flip cover is provided, and several groups of filter bags are arranged between the fixed mounting plate and the movable mounting plate. A high-pressure gas tank is installed on the outer wall of one side of the flip cover and the outer wall of the upper box away from the flip cover, and the high-pressure gas tank passes through The connecting pipe is connected with the air spray pipe, and the moving assembly is installed on the supporting frame, and the moving assembly is fixedly connected with the movable mounting plate; the filter bag in the present invention is placed horizontally, so that the contact area between the air and the filter bag is larger, thereby accelerating Air filtration improves dust removal efficiency, and at the same time, compressed gas is fed into both ends of the filter bag, which shortens the time for compressed gas to fill the filter bag. The filter bag of the present invention is easy to install and disassemble, and can quickly maintain the filter bag.

Owner:临泉县由基食品股份有限公司

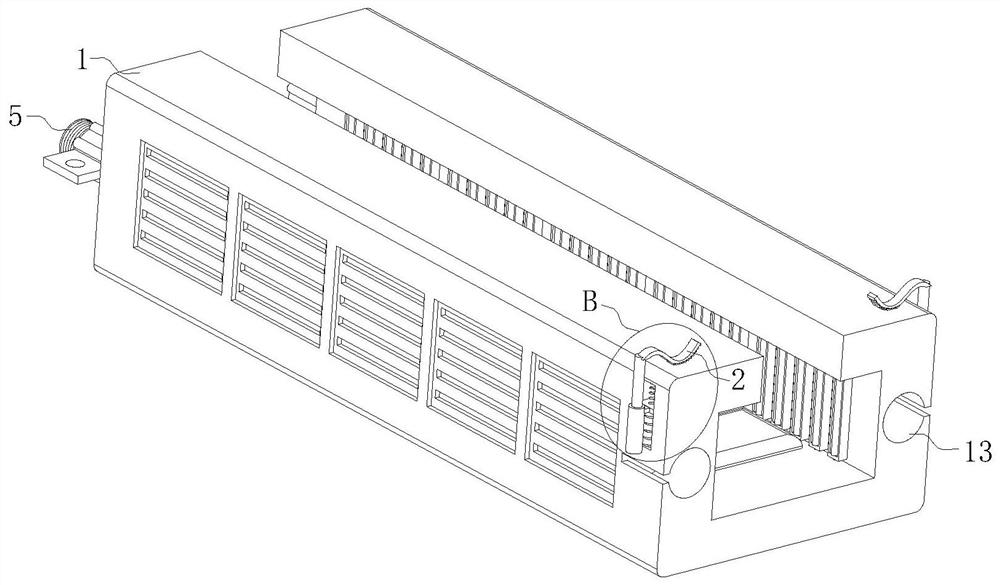

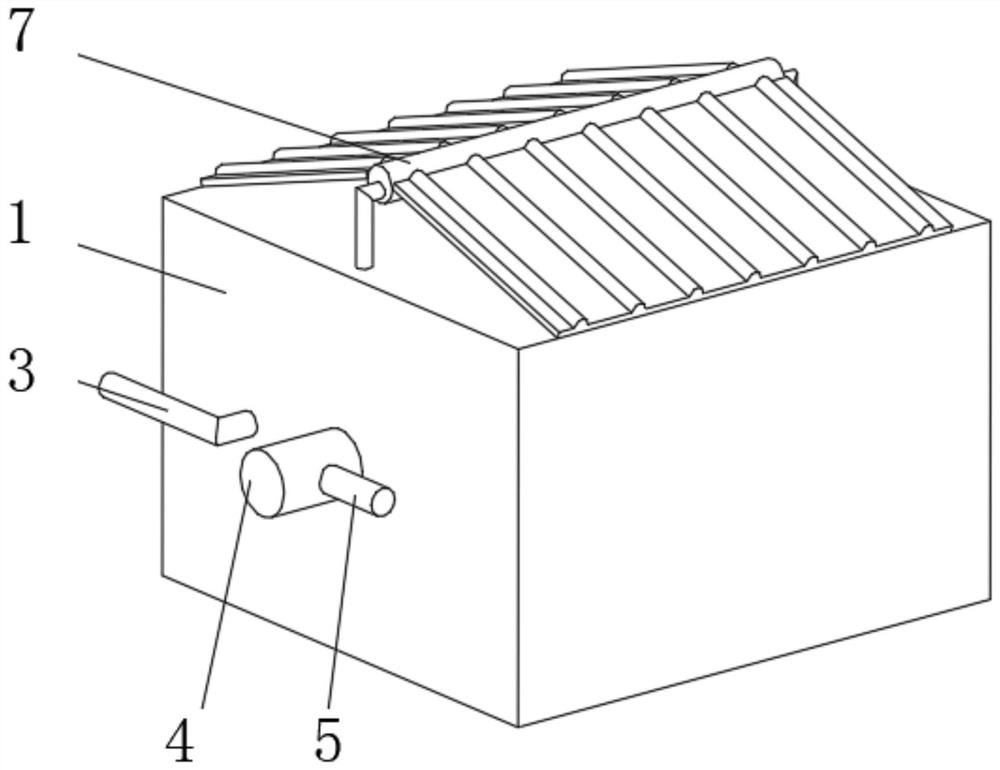

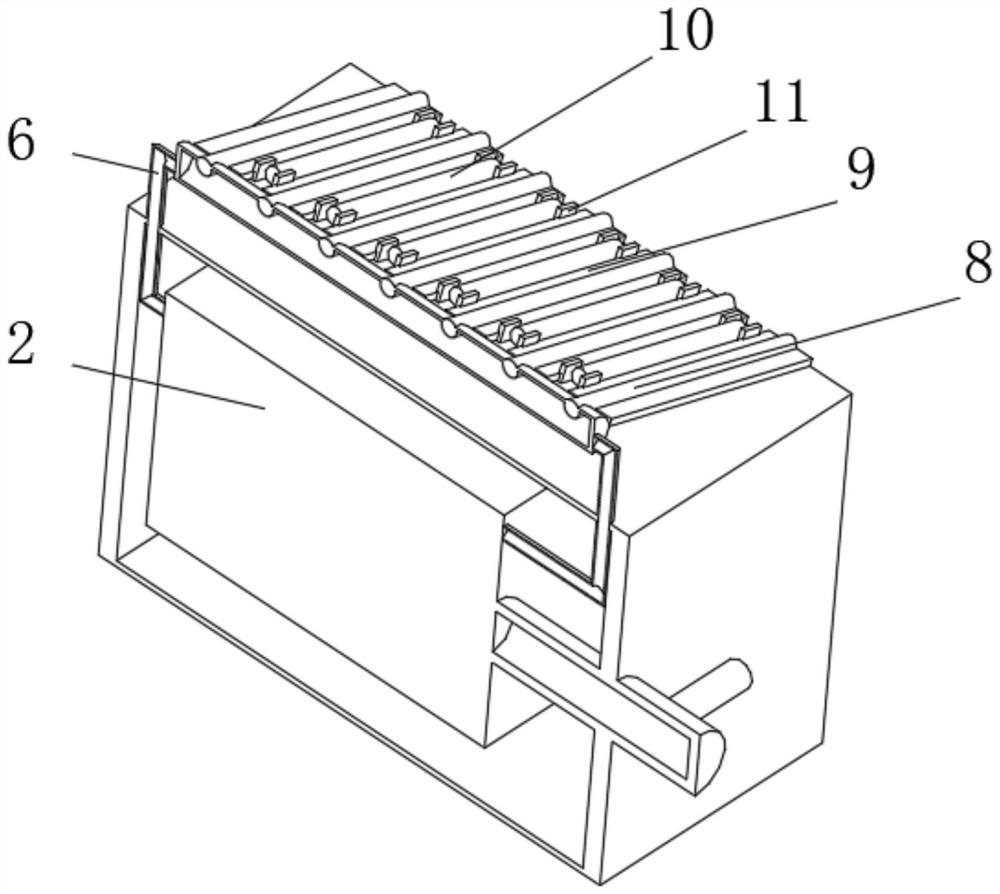

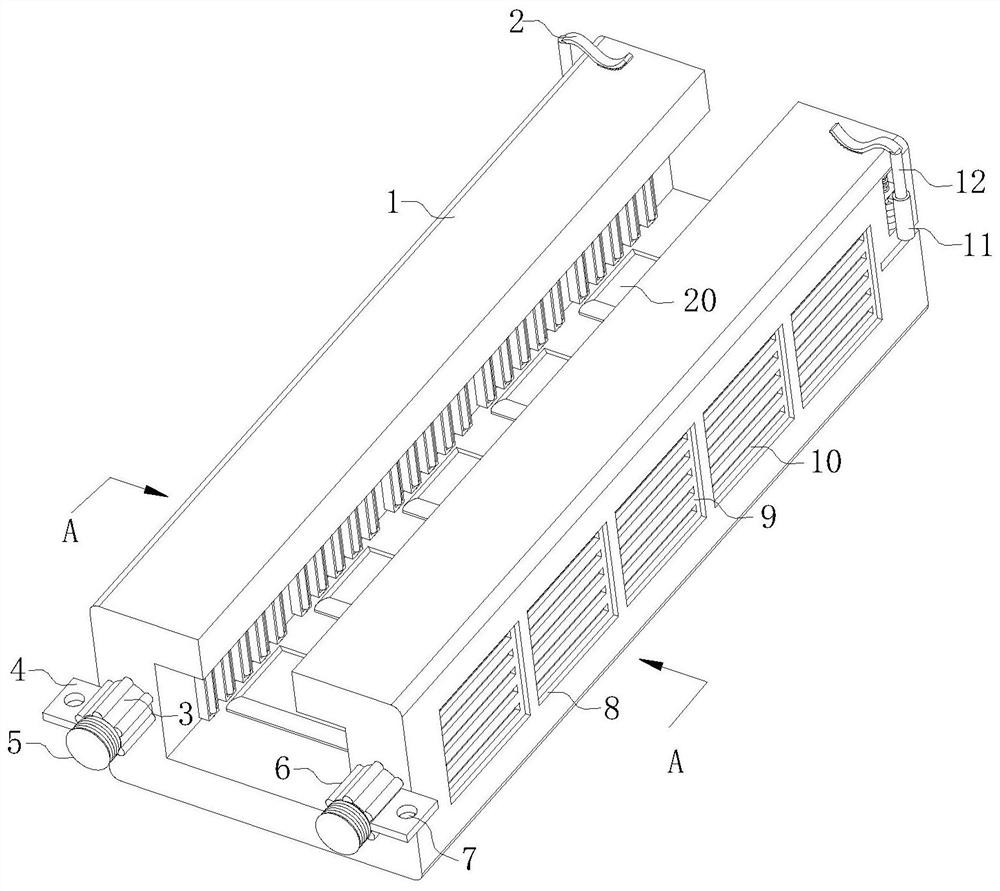

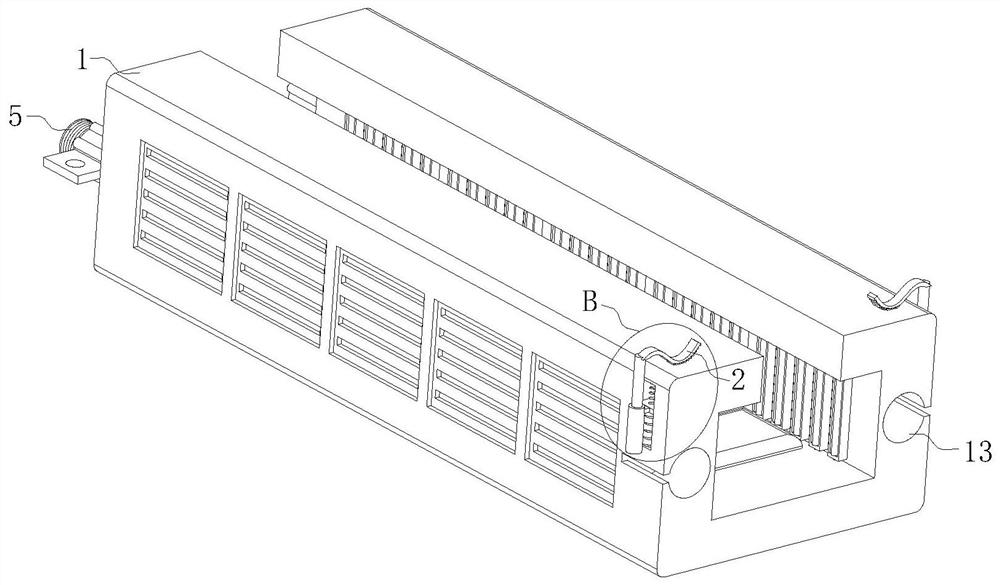

Efficient pulse dust collector and working method thereof

ActiveCN112023547ASpeed up filteringImprove dust removal efficiencyDispersed particle filtrationAir filtrationDust control

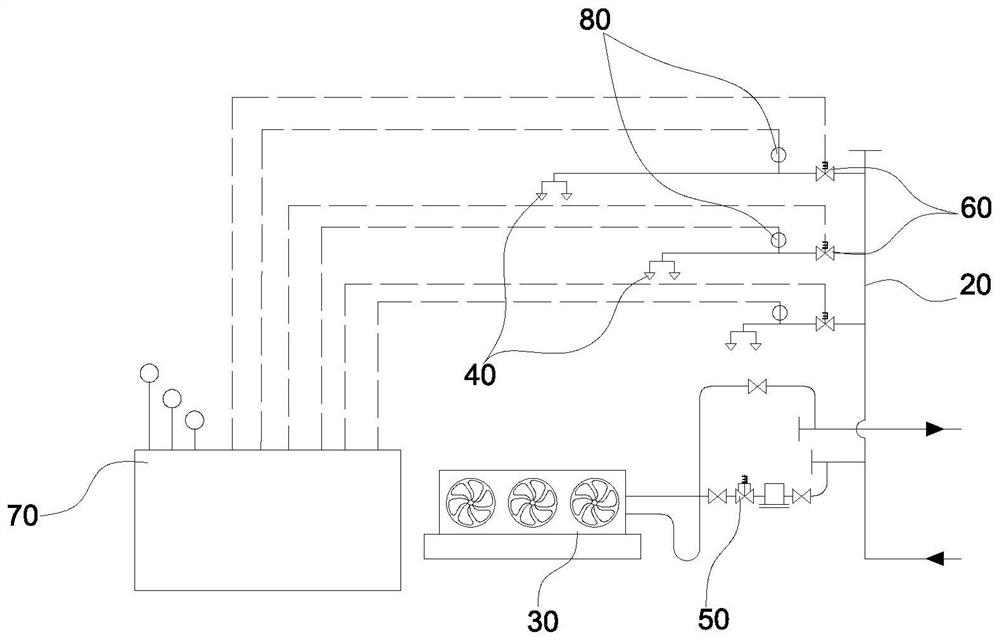

The invention discloses an efficient pulse dust collector and a working method thereof. The dust collector comprises a lower box body, a dust collecting hopper is arranged at the bottom of the lower box body, an upper box body is arranged at the top of the lower box body, an overturning cover is arranged at one end of the upper box body, and a plurality of sets of filter bags are arranged betweena fixed mounting plate and a movable mounting plate; and high-pressure air tanks are installed on the outer wall of one side of the overturning cover and the outer wall of the side, away from the overturning cover, of the upper box body, the high-pressure air tanks are connected with air spraying pipes through connecting pipes, and a moving assembly is movably installed on a supporting frame and fixedly connected with the movable mounting plate. The filter bags are transversely placed, so that the contact area of air and the filter bags is large, air filtration is accelerated, and the dust removal efficiency is improved; and meanwhile, compressed gas is introduced into the two ends of each filter bag, the time for filling the filter bags with the compressed gas is shortened, and the filterbags are convenient to mount and dismount and high in practicability, and can be quickly maintained.

Owner:临泉县由基食品股份有限公司

A gravity sensing limit roller

The invention provides a gravity induction limit roller, which belongs to the technical field of sports equipment. It solves the problem that the speed of the existing roller equipment is uncontrollable, and the upper and lower rollers are prone to danger caused by pulleys. The gravity sensing limit roller includes two support rods, each of which is provided with a placement cavity, and a rotating shaft is rotatably connected between the two support rods, and the left and right ends of the rotating shaft extend through the support rods to In the placement cavity, the rotating shaft is covered with rollers for leg exercise, and a supporting mechanism capable of supporting the human body is also provided between the two support rods. The first position-limiting mechanism is provided, and the second position-limiting mechanism for position-limiting the rotating shaft is respectively provided in the two arranging cavities. The use of the gravity sensing limit roller is more stable and safe.

Owner:苏州普诺兹电子有限公司

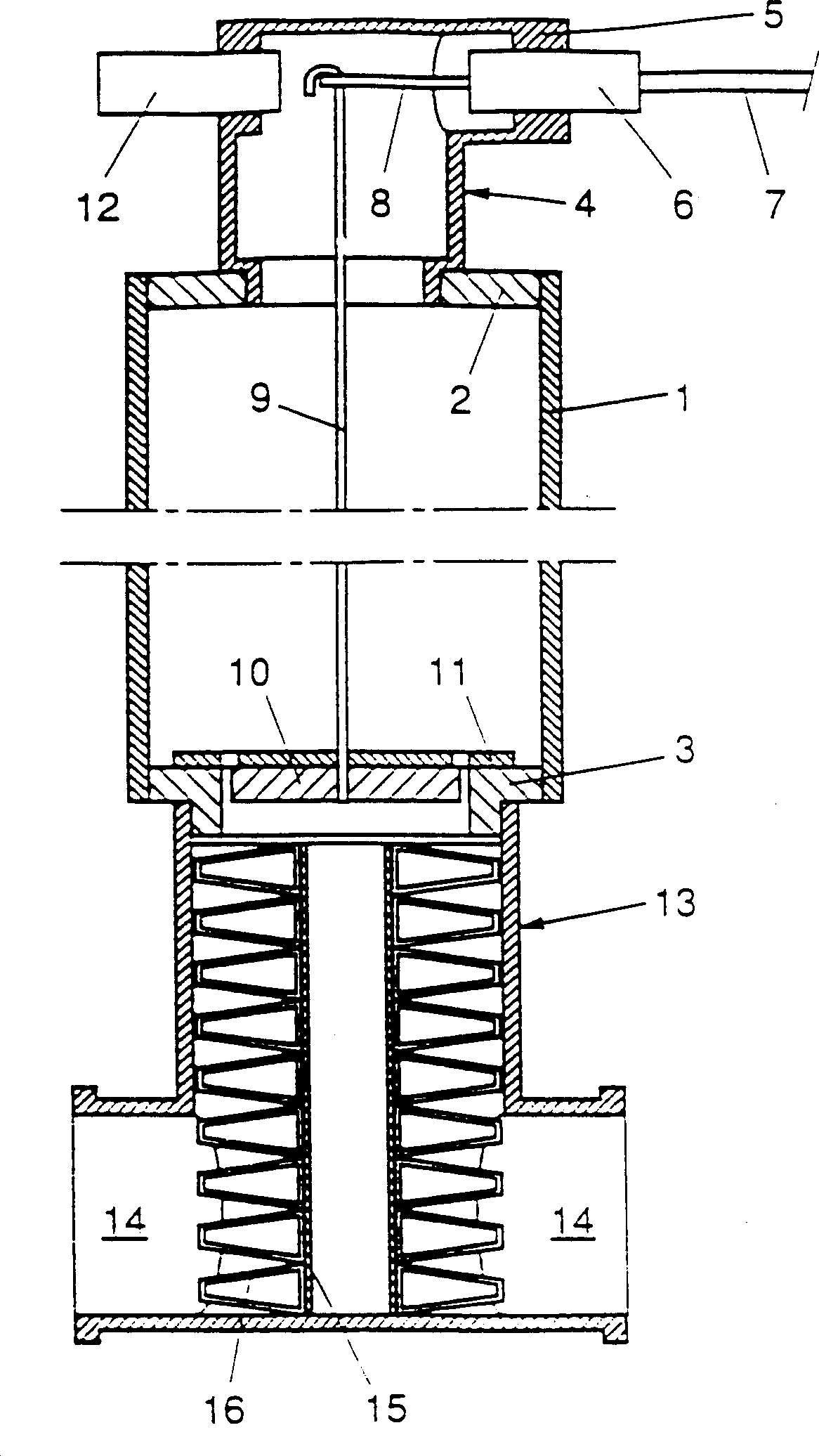

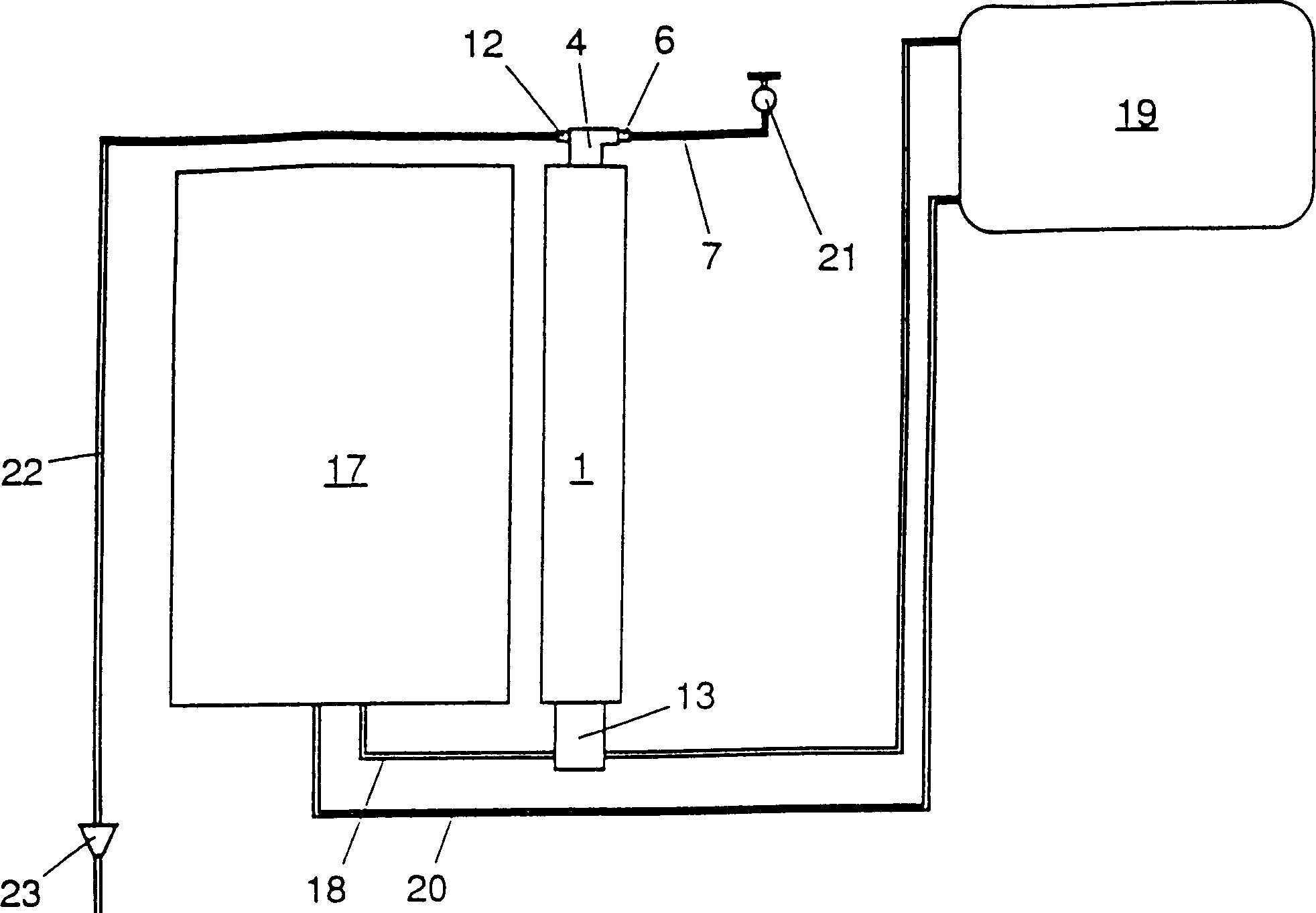

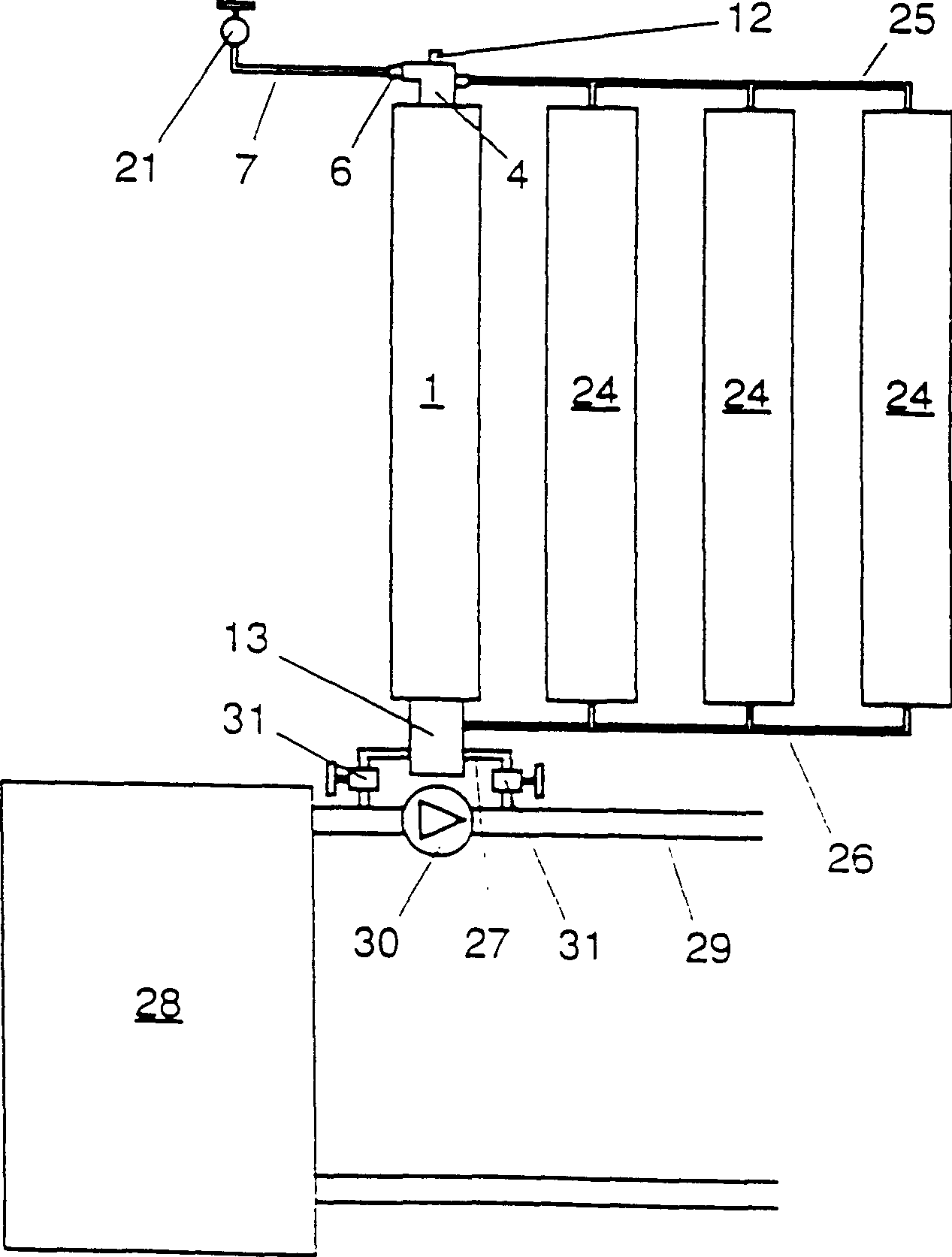

Closed fluid circulation system and its expansion control method

InactiveCN1121580CConvenient supplementDoes not affect the closed stateLighting and heating apparatusSpace heating and ventilation detailsEngineeringLiquid circulation

PCT No. PCT / NL96 / 00219 Sec. 371 Date Oct. 13, 1998 Sec. 102(e) Date Oct. 13, 1998 PCT Filed Jun. 3, 1996 PCT Pub. No. WO96 / 38694 PCT Pub. Date Dec. 5, 1996A method for expansion control in a closed fluid circulation system with varying temperature, in which system air is drawn from the circulating fluid through the formation of an air head wherein air to be withdrawn is collected and from which air can be blown off, controlled by a valve, to the environment or a receiving space, while further off, measures are taken for taking up, when the temperature varies, an attendant expansion and shrinking of the fluid within the closed system, and measures for enabling adding fluid to the system, which fluid is withdrawn from an external stock of fluid under pressure, and the air head volume is measured and when a predetermined value is exceeded, a fluid valve is opened through which fluid is introduced into the air head until the volume of the air head is substantially equal to the predetermined value and the fluid valve is closed.

Owner:SPIRO RES BV

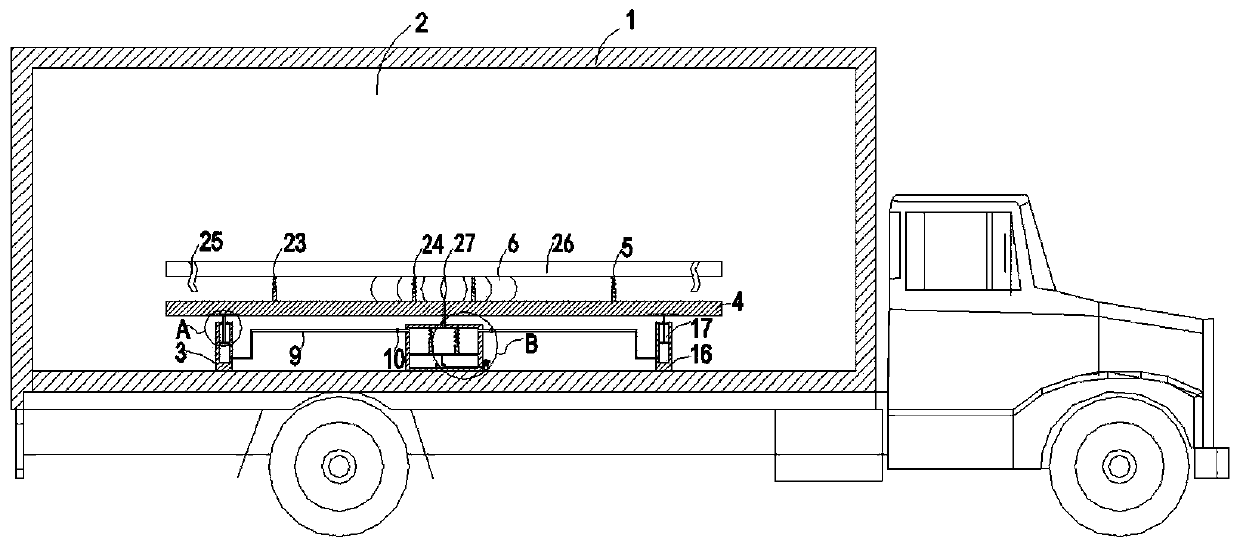

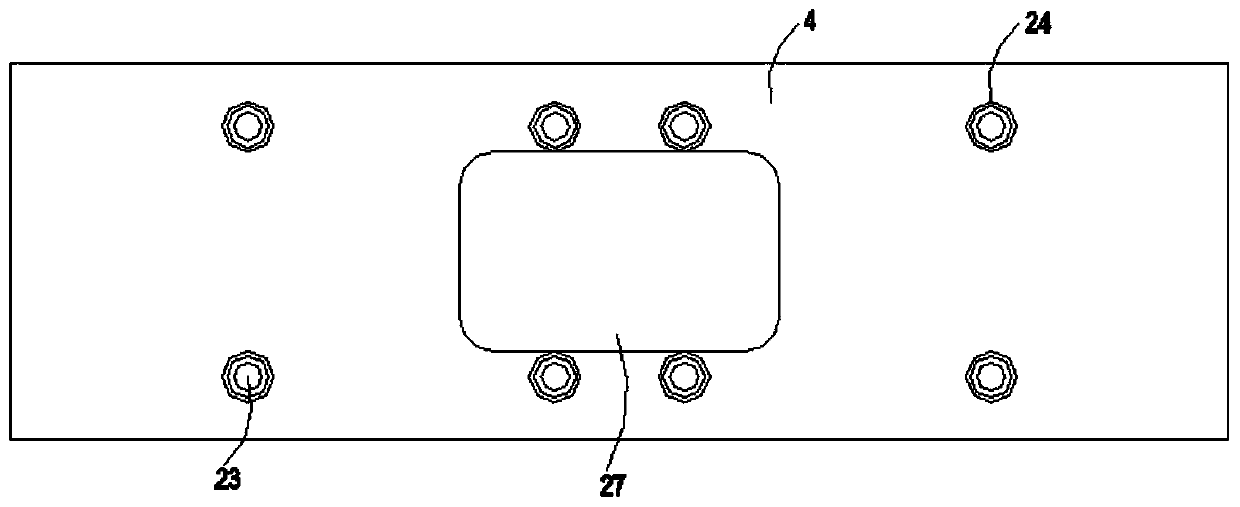

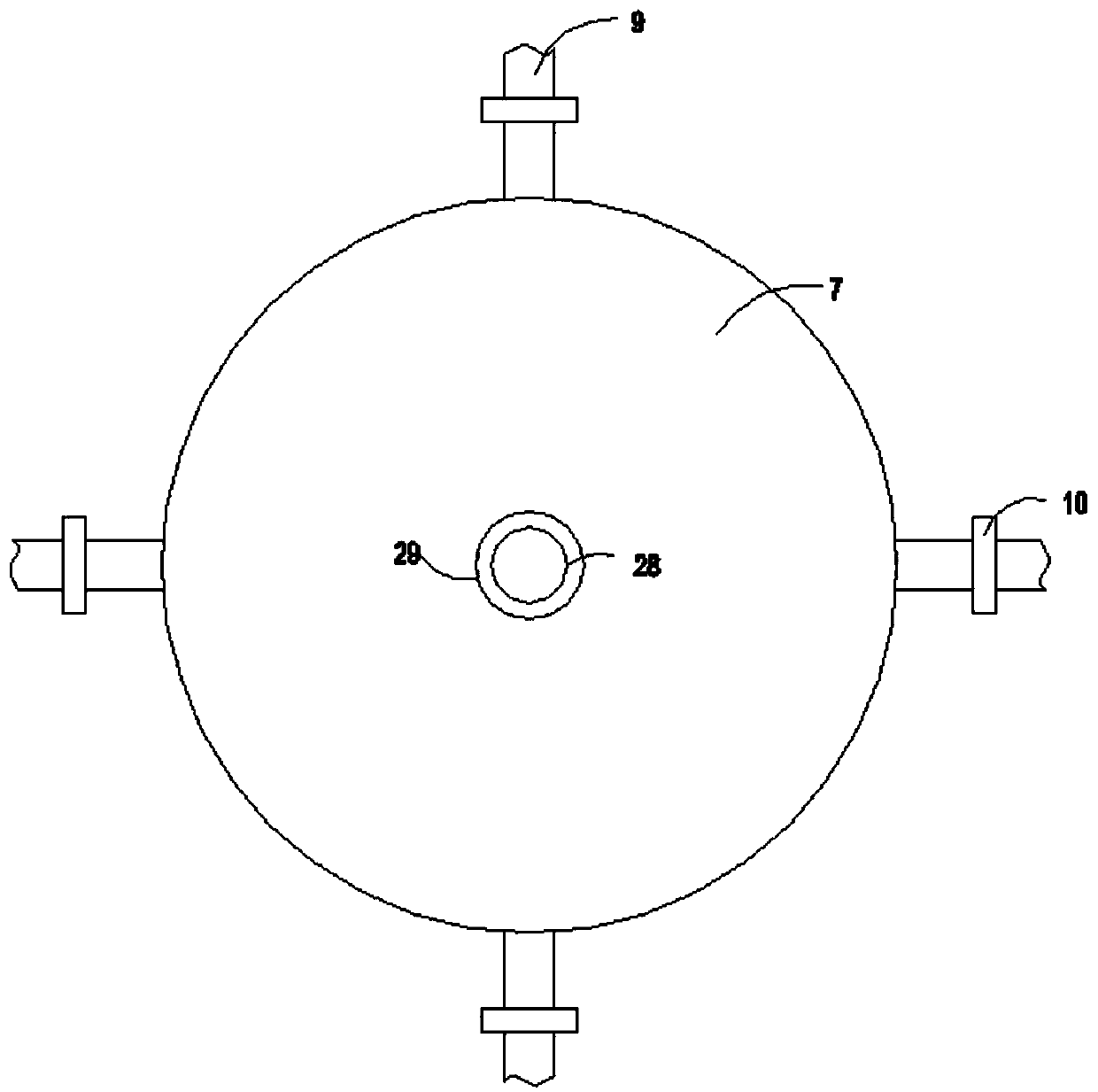

An automatic adjustment mechanism for the level of the medical cabin of an operating cart

InactiveCN108814822BEasy to placeEasy to operateOperating tablesAmbulance serviceMedical equipmentEngineering

The invention belongs to the technical field of medical equipment, and particularly relates to a horizontal automatic adjusting mechanism of an operation van medical chamber. The mechanism comprises avan body, a medical chamber is arranged in the van body, and a plurality of supporting mechanisms are fixedly connected to the bottom of the medical chamber; first horizontal plates are arranged on the upper ends of the supporting mechanisms, the lower ends of the first horizontal plates are rotatably connected to the upper ends of the supporting mechanisms, and a plurality of first damping mechanisms are fixedly connected to the upper ends of the first horizontal plates; second horizontal plates are fixedly connected to the upper ends of the damping mechanisms, the upper ends of the second horizontal plates are fixedly connected with a plurality of binding bands, and the upper ends of the first horizontal plates are fixedly connected with second damping mechanisms; the lower ends of thesecond damping mechanisms penetrate through and extend below the first horizontal plates, an adjusting block is fixedly connected to the bottom of the medical chamber and located below the first horizontal plates, and a first cavity chamber is formed in the adjusting block. The mechanism has the advantages that not only can the stationarity of an operation bed be improved conveniently, but also the dampness performance of the operation bed can be effectively improved.

Owner:王大巍

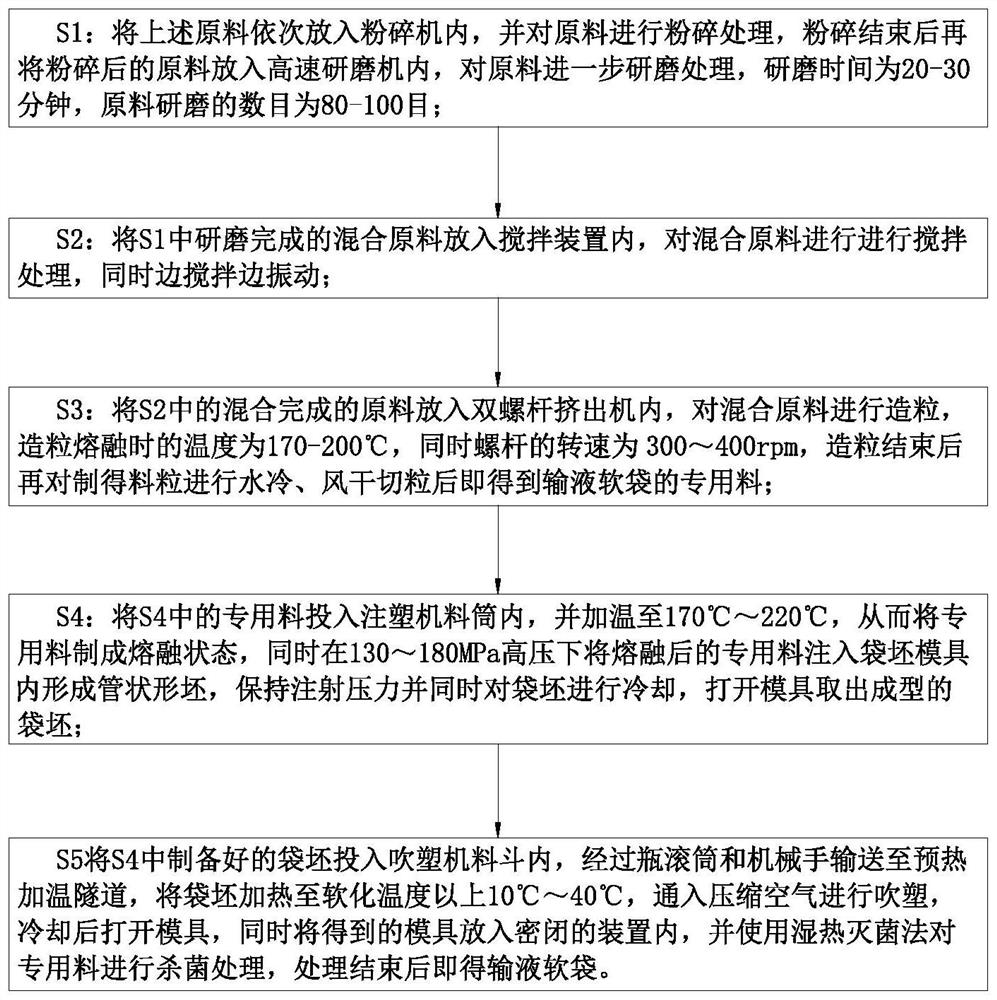

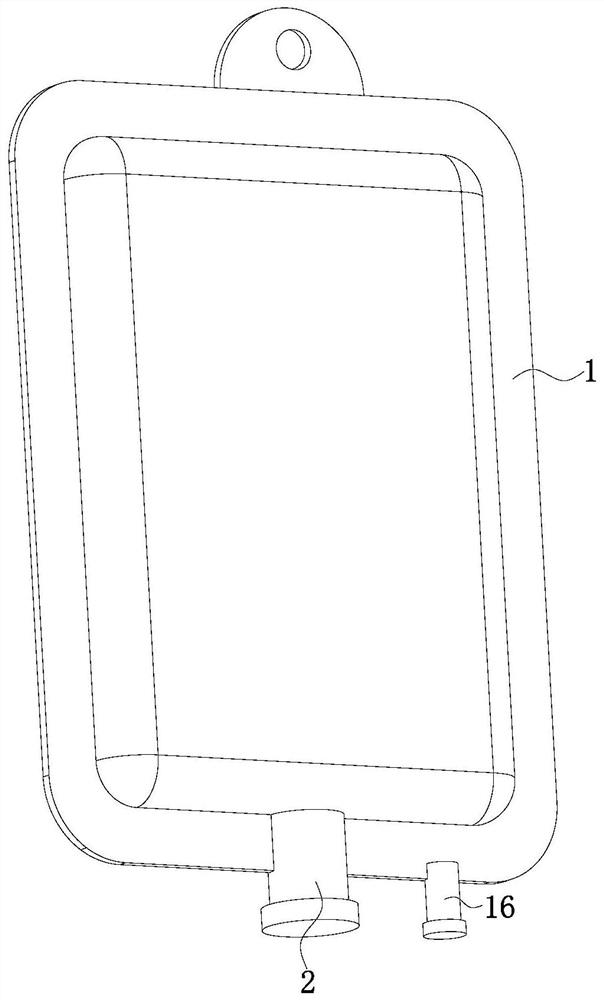

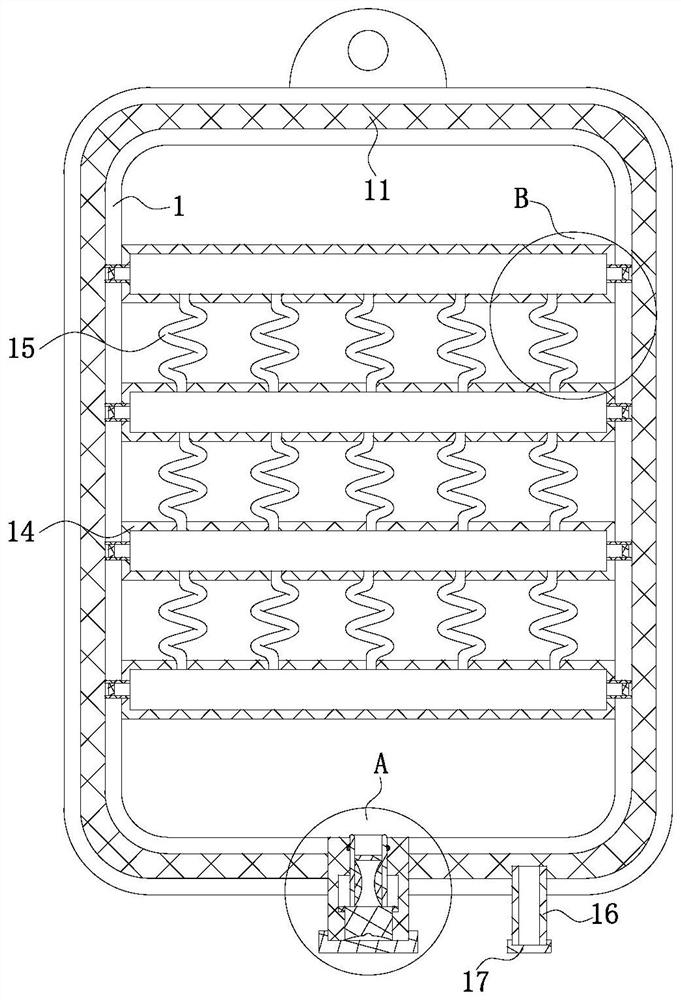

A kind of preparation method of transfusion soft bag

ActiveCN111171445BNo pollution in the processImprove stabilityProductsReagentsPharmaceutical drugAnti bacteria

Owner:HUAXIASHENGSHENG PHARMA BEIJING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com