Preparation method of graphene

A graphene and expanded graphite technology, which is applied in the field of graphene preparation, can solve the problems of graphene sheet thickness, direct exhaust emission, and inability to recycle, and achieves the effects of uniform thickness, environmental protection in the production process, and sufficient peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

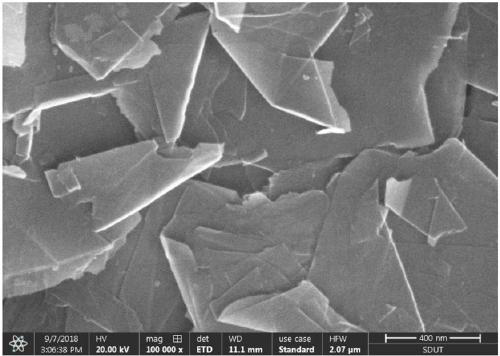

Image

Examples

preparation example 1-3

[0043] Phosphoric acid, glacial acetic acid, and potassium permanganate in Preparation Examples 1-3 were all analytically pure, and the flake graphite was selected from ZX-S flake graphite sold by Zhengxu Mineral Products Processing Factory in Lingshou County.

preparation example 1

[0044]Preparation Example 1: According to the ratio in Table 1, 1 kg of potassium permanganate was added to 5 kg of flake graphite with a particle size of 150 μm and a carbon content of 95%, and 1 kg of phosphoric acid with a mass fraction of 80% and 5 kg of The glacial acetic acid with a mass fraction of 70% is mixed evenly, heated in a water bath at 30°C, stirred continuously, taken out after reacting for 50 minutes, washed with distilled water until neutral, and dried at 60°C after suction filtration. Put it into a muffle furnace for high-temperature expansion at 900°C to obtain expanded graphite.

[0045] The raw material ratio of expanded graphite in table 1 preparation example 1-3

[0046]

preparation example 2

[0047] Preparation Example 2: According to the proportioning in Table 1, 2 kg of potassium permanganate was added to 8 kg of flake graphite with a particle size of 165 μm and a carbon content of 97%, and 3 kg of phosphoric acid with a mass fraction of 83% and 15 kg of The glacial acetic acid with a mass fraction of 73% was mixed evenly, heated in a water bath at 33°C, stirred continuously, taken out after 55 minutes of reaction, washed with distilled water until neutral, and dried at 65°C after suction filtration. Put it into a muffle furnace for high-temperature expansion at 940°C to obtain expanded graphite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com