A kind of low-density deketoxime type silicone sealant and preparation method thereof

A technology of silicone sealant and deketoxime, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the limitation of sealant density reduction, can not achieve improved mechanical properties, hollow glass microspheres High brittleness and other problems, to achieve the effect of reducing the density of the sealant, good foaming performance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

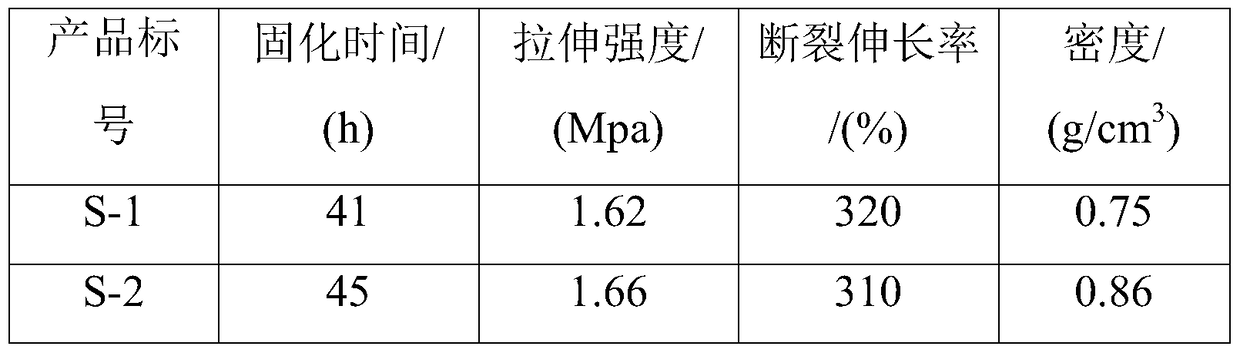

Examples

Embodiment 1

[0029] A low-density deketoxime type silicone sealant, consisting of the following components in parts by weight:

[0030] α,ω-Dihydroxypolydimethylsiloxane

100g

25g

Thermally expandable microcapsules F-48

0.3g

Vinyl tributylketoxime silane (crosslinking agent)

2g

Methyltributylketoximosilane (crosslinking agent)

15g

Modified CaCO 3 (reinforcing filler)

80g

γ-aminopropyltriethoxysilane (coupling agent)

2g

Dibutyltin dilaurate (catalyst)

0.2g

[0031] The preparation method of the low-density deketoxime type silicone sealant is as follows:

[0032] A. Mix 100g of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 30mpa·s, 25g of simethicone oil with a viscosity of 400pa·s, 0.3g of thermally expandable microcapsules F-48, and 80g of modified CaCO 3 After mixing, put it into a planetary stirring tank for stirring, control the temperature at 120°C, and mix for 3 hours under the ...

Embodiment 2

[0036] A low-density deketoxime type silicone sealant, which consists of the following components:

[0037] a,ω-Dihydroxypolydimethylsiloxane

100g

10g

Thermally expandable microcapsules F-50

0.5g

Methyltributylketoximosilane (crosslinking agent)

12g

Modified CaCO 3 (reinforcing filler)

100g

γ-(2,3-Epoxypropyl)propyltrimethoxysilane (coupling agent)

1.6g

Dibutyltin dilaurate (catalyst)

0.3g

[0038]The preparation method of the low-density deketoxime type silicone sealant is as follows:

[0039] A. Mix 100g of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 40mpa·s, 10g of simethicone oil with a viscosity of 500pa·s, 0.5g of thermally expandable microcapsules F-50, and 100g of modified CaCO 3 After mixing, put it into a planetary stirring tank for stirring, control the temperature at 130°C, and mix for 3 hours under the condition of vacuum degree -0.098MPa, and then pass N 2 , rem...

Embodiment 3

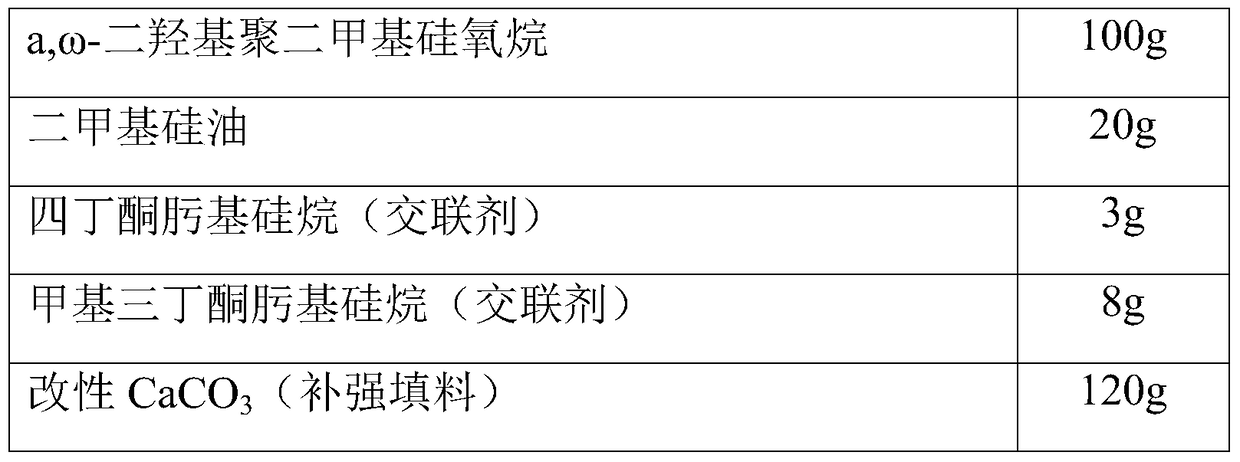

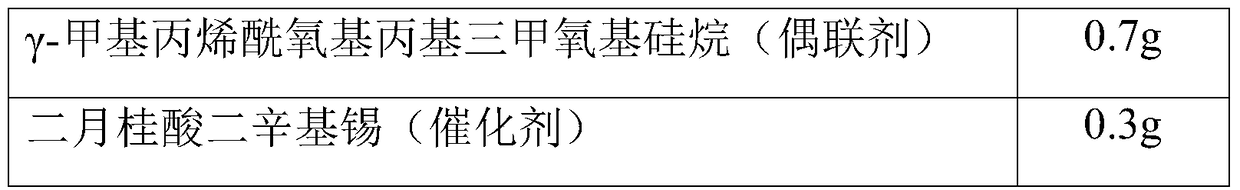

[0043] A low-density deketoxime type silicone sealant, which consists of the following components:

[0044] a,ω-Dihydroxypolydimethylsiloxane

100g

20g

Thermally expandable microcapsules F-78K

0.4g

Vinyl tributylketoxime silane (crosslinking agent)

2g

Methyltributylketoximosilane (crosslinking agent)

8g

Modified CaCO 3 (reinforcing filler)

120g

γ-aminopropyltriethoxysilane (coupling agent)

2.4g

Dioctyltin dilaurate (catalyst)

0.4g

[0045] The preparation method of the low-density deketoxime type silicone sealant is as follows:

[0046] A. 100 parts of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 20mpa·s, 20g of simethicone oil with a viscosity of 450pa·s, 0.4g of thermally expandable microcapsules F-78K, and 120g of modified CaCO 3 After mixing, put it into a planetary stirring tank for stirring, control the temperature at 140°C, and mix for 3 hours under the conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com