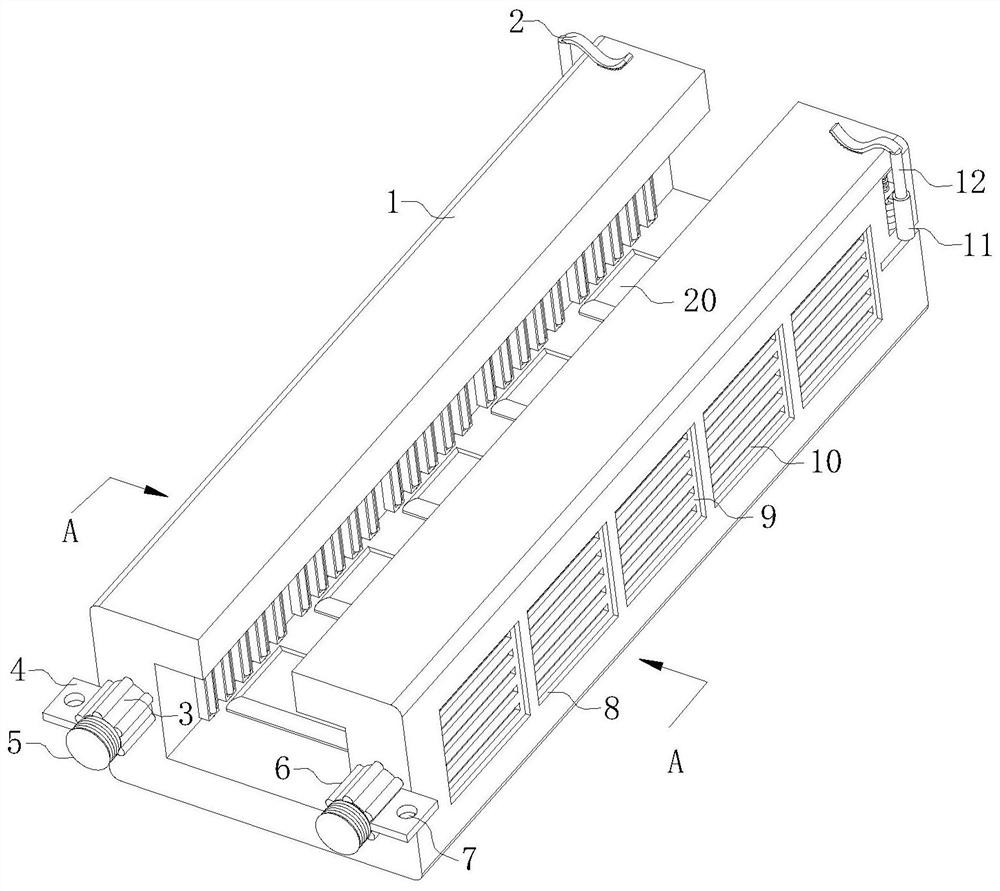

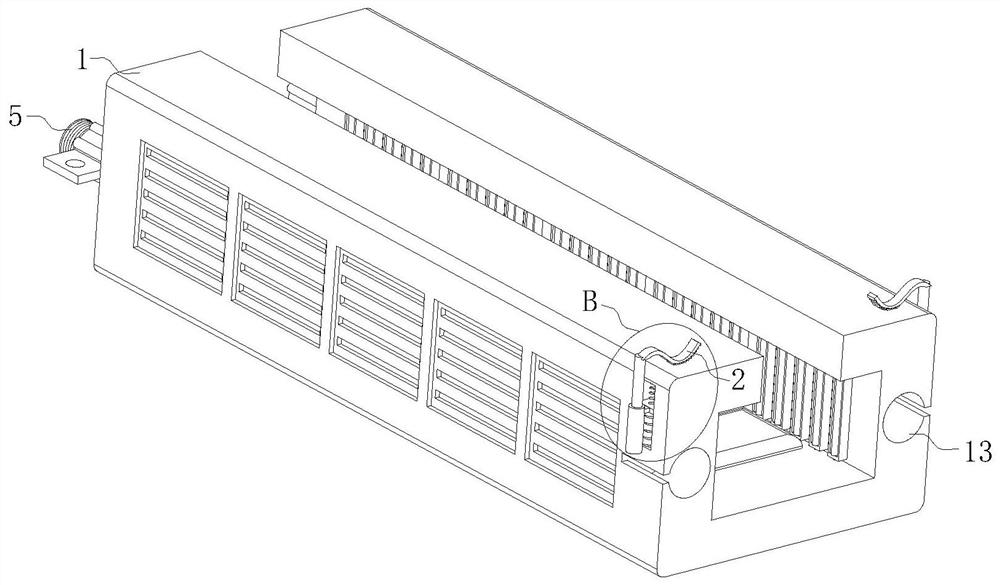

An industrial aluminum profile

An aluminum profile and industrial technology, applied in the field of industrial aluminum profiles, can solve the problems of screw splicing waste, heat can not be discharged, time and labor, etc., to achieve the effect of improving service life, good heat dissipation, and fast clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

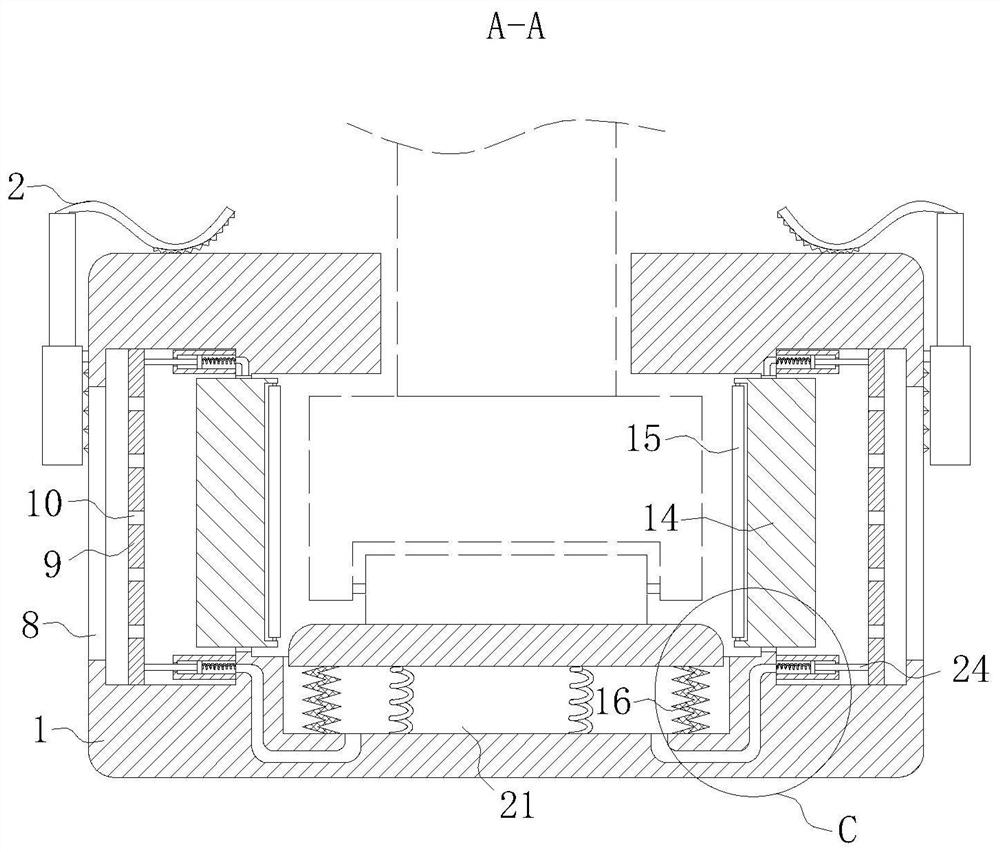

[0029] As an embodiment of the present invention, grooves are provided on the inner end surface of the heat dissipation fins 14, and a roller 15 is movable inside the groove; during operation, the roller 15 can greatly reduce the friction between the slider and the aluminum profile body. 1, the frictional resistance between the inner sidewalls, thereby reducing the generation of frictional heat, can also delay the service life of the aluminum profile body 1.

[0030] As an embodiment of the present invention, the inner surface of the support plate 9 is fixedly connected with one end of the push rod 24; the other end of the push rod 24 passes through the sealing end of the cylindrical groove 23 and is fixedly connected with the piston plate 22 The piston plate 22 is fixedly connected to the inner side wall of the heat dissipation cavity by a spring; the inner open end of the columnar groove body 23 is fixedly connected to the inner wall of the heat dissipation cavity, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com